Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Change the compression ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engine with variable compression ratio

InactiveCN101403342AChange volumeChange the compression ratioEngine controllersMachines/enginesEffective lengthHydraulic pump

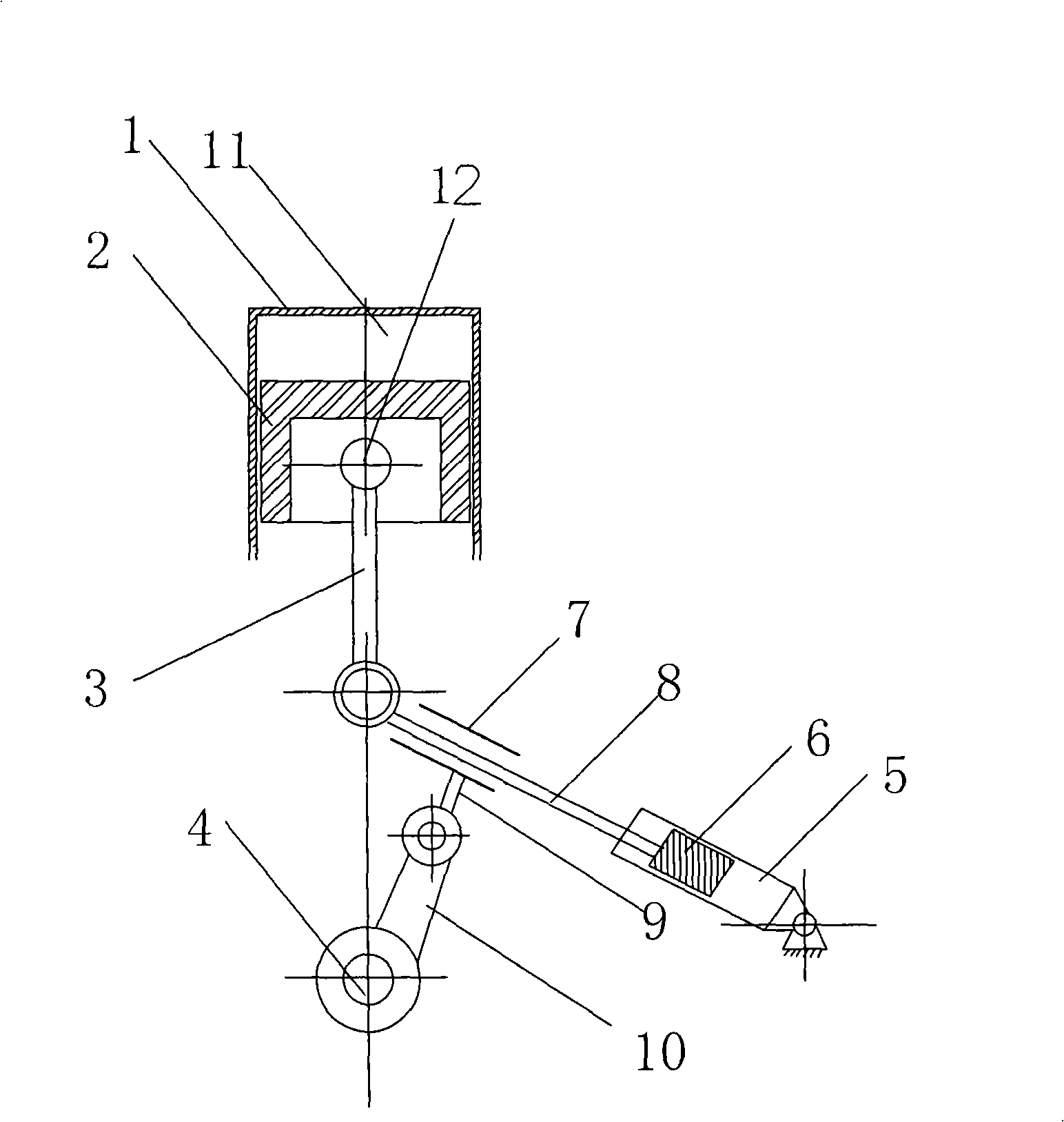

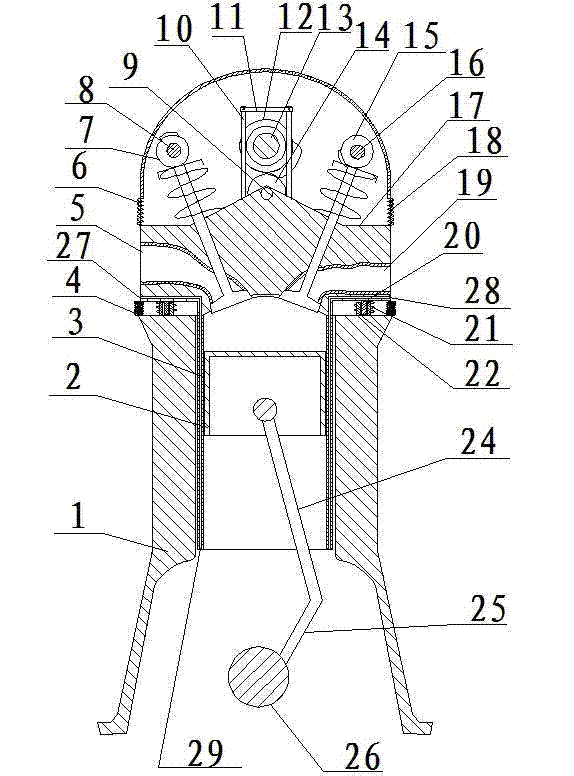

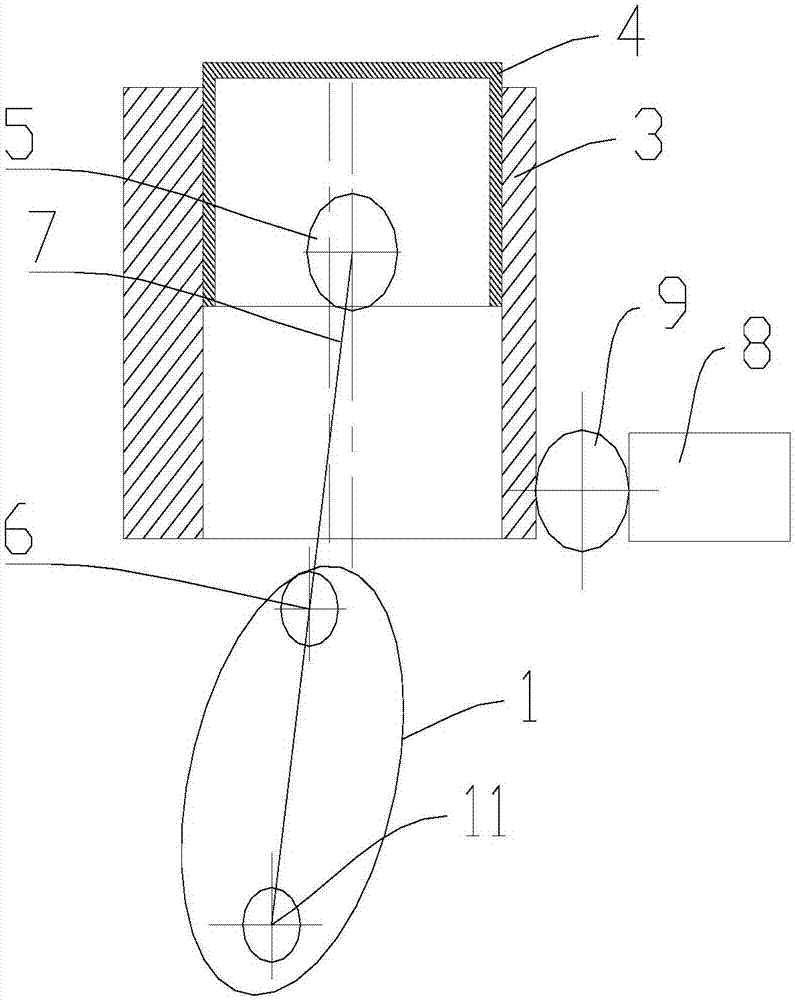

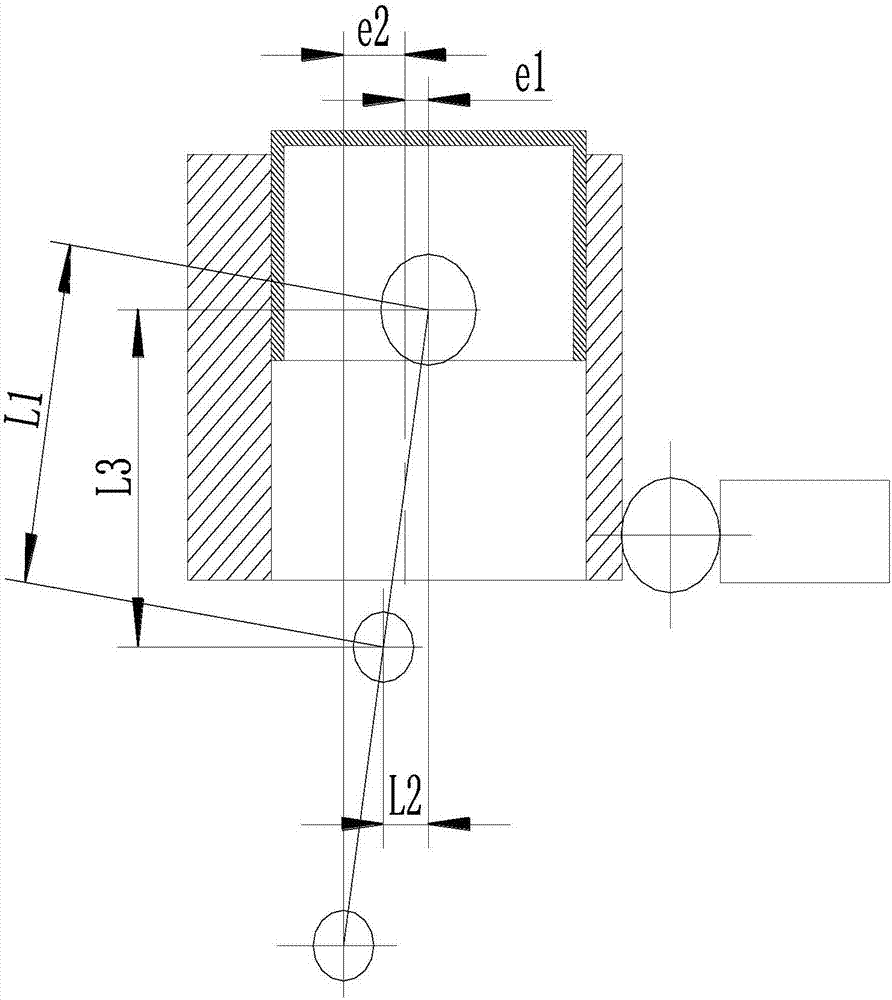

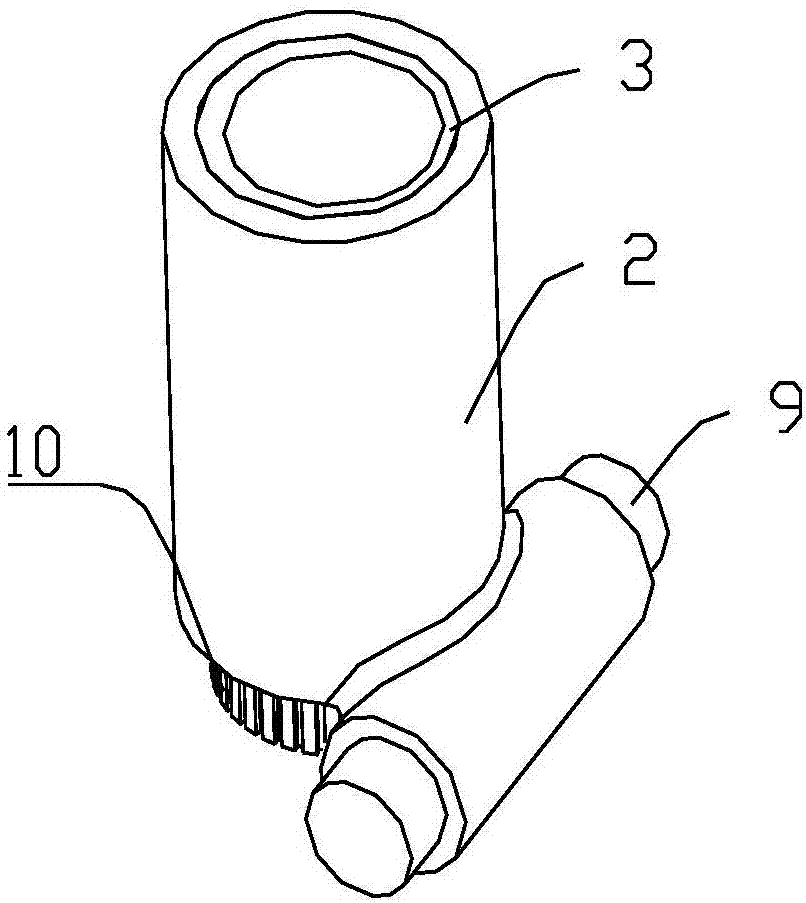

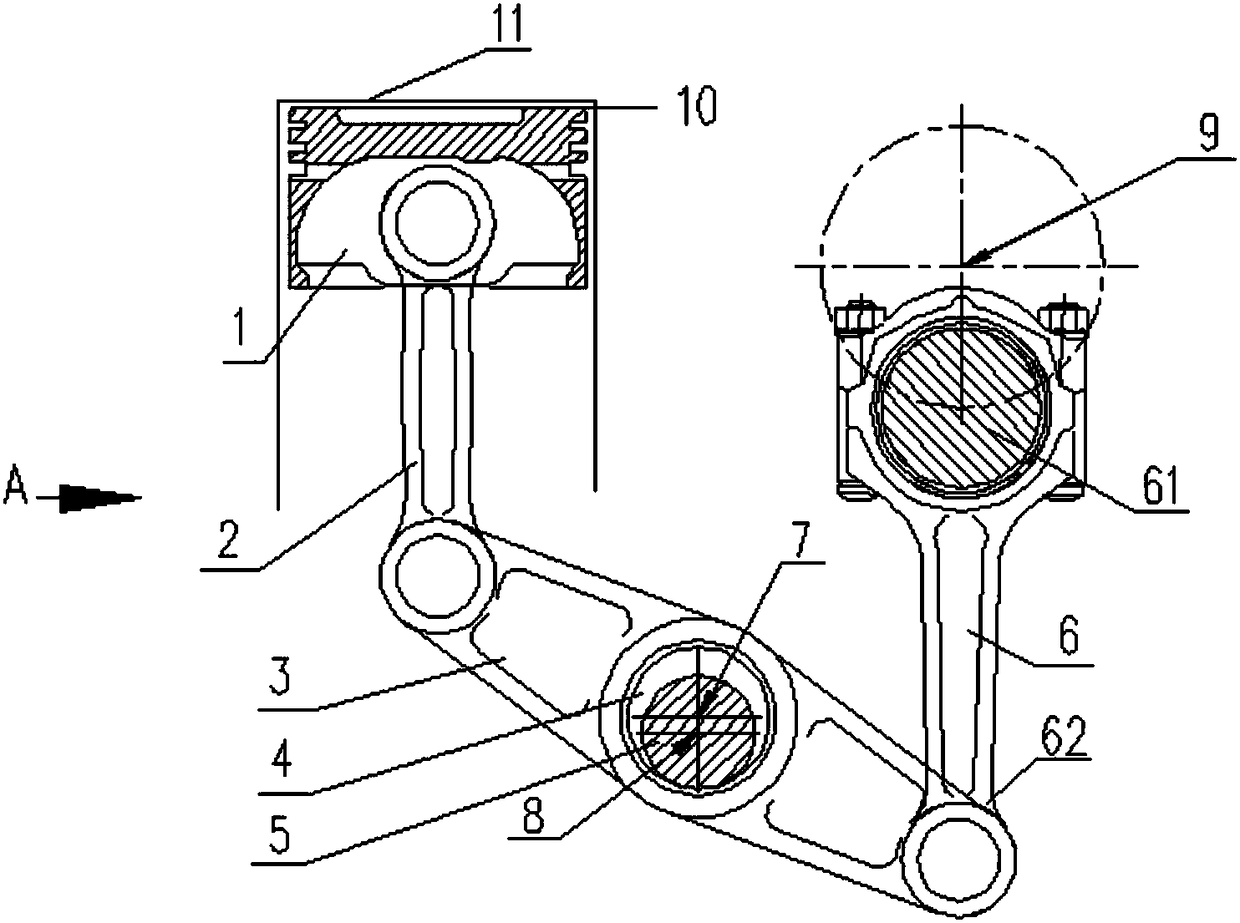

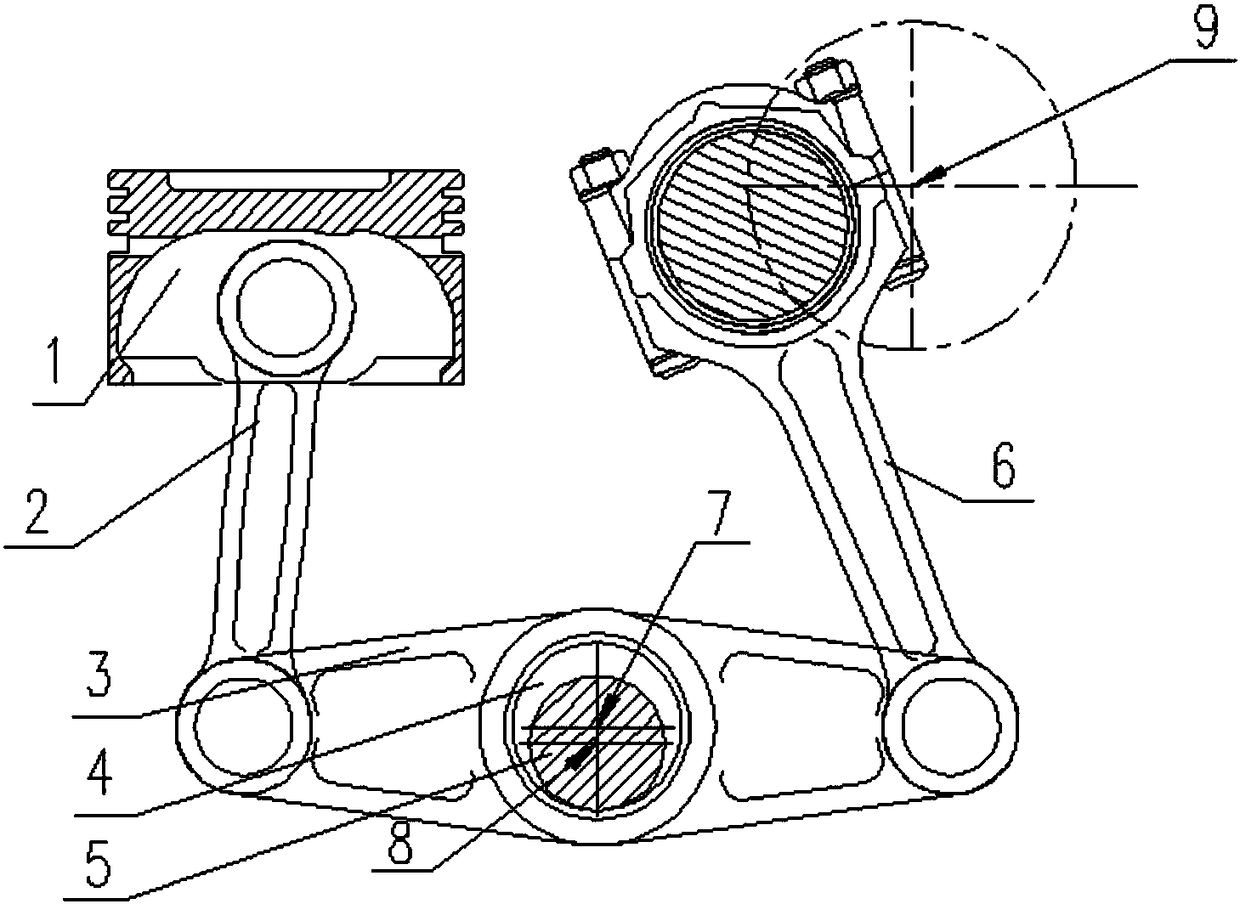

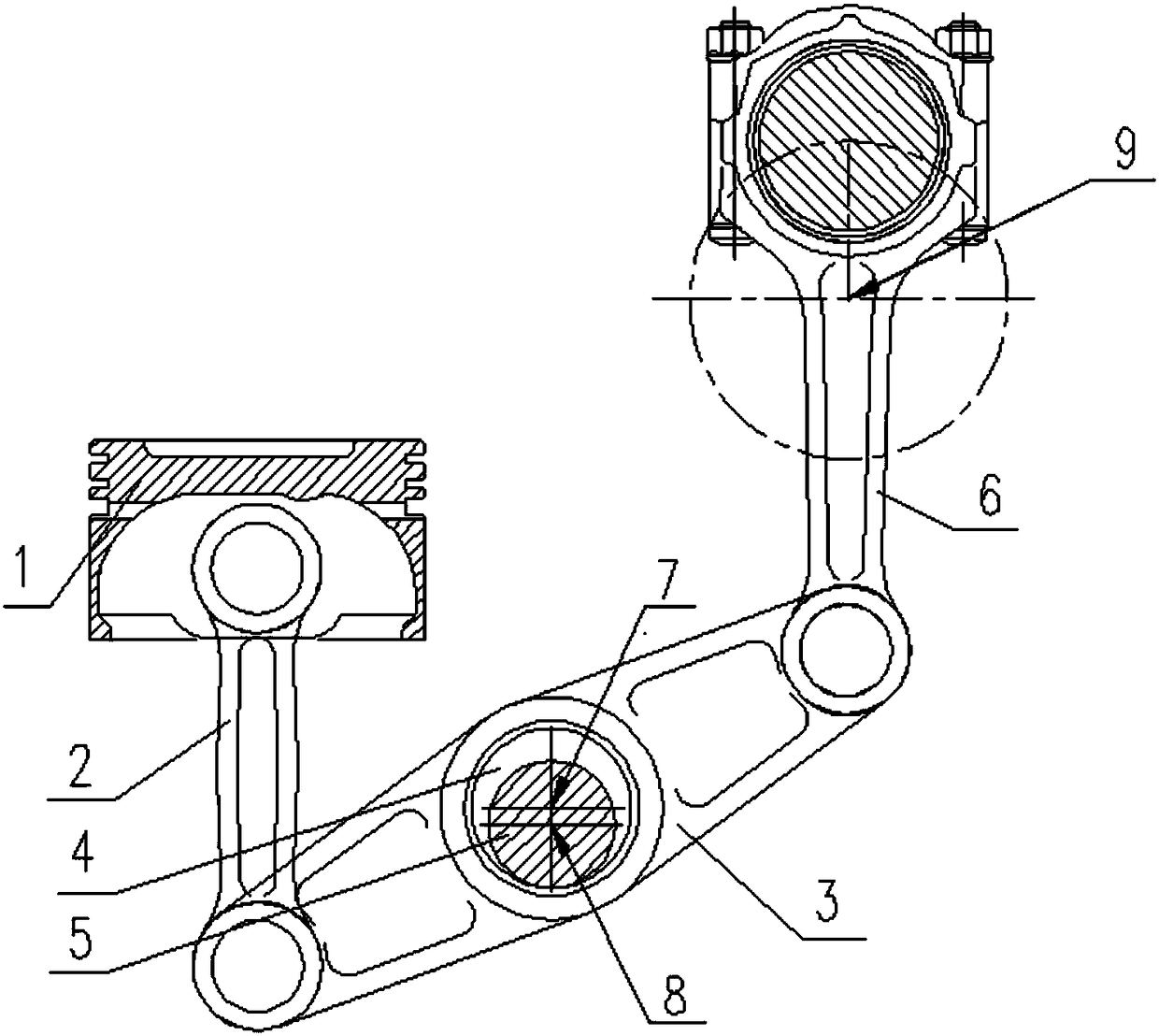

The invention discloses a variable compression ratio engine, including a cylinder body (1) internally provided with a cylinder, a piston (2), a connecting rod (3) and a crankshaft (4), wherein, the piston (2) is arranged in the cylinder, the connecting rod (3) is linked with the crankshaft (4) and the piston (2), the cylinder body (1) is also provided with a mechanism which can change the effective length of the connecting rod (3), and two ends of the mechanism are respectively linked with the connecting rod (3) and the crankshaft (4). The mechanism which can change the effective length of the connecting rod is a retractable hydraulic lever mechanism and controlled by a hydraulic pump controlled by ECU and a triple valve. The variable compression ratio engine has the following advantages that the compression ratio can be continuously changed and the change is controllable; the structure is simple; the control strategy is relatively simple; and the dynamic property and the fuel economy of the engine can be effectively improved.

Owner:CHERY AUTOMOBILE CO LTD

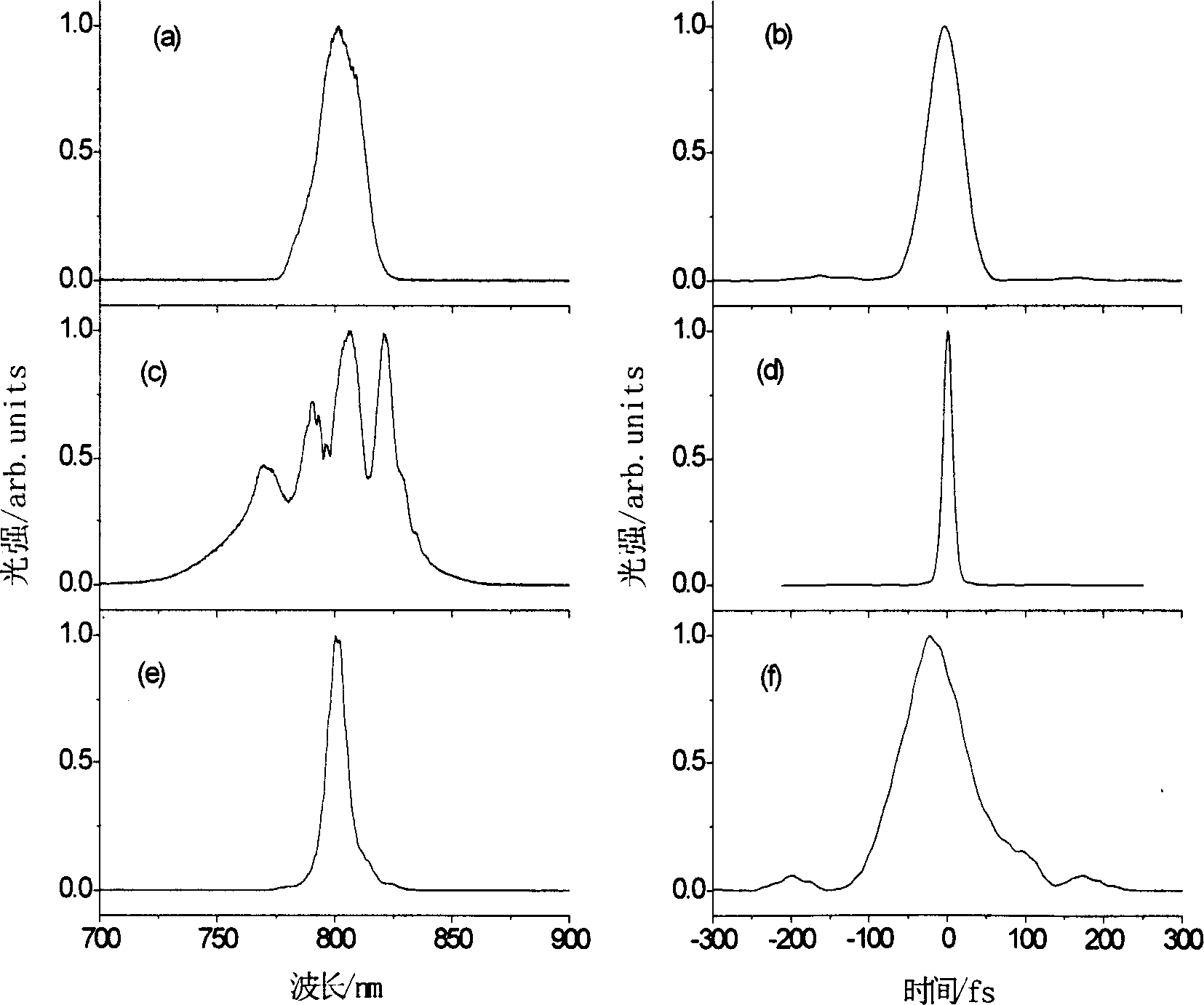

Laser pulse stretching and compression device

InactiveCN1870359ASolve the problems of low conversion efficiency and complex structureSolve the limitation of low incident pulse energyLaser detailsNon-linear opticsControl systemEnergy control

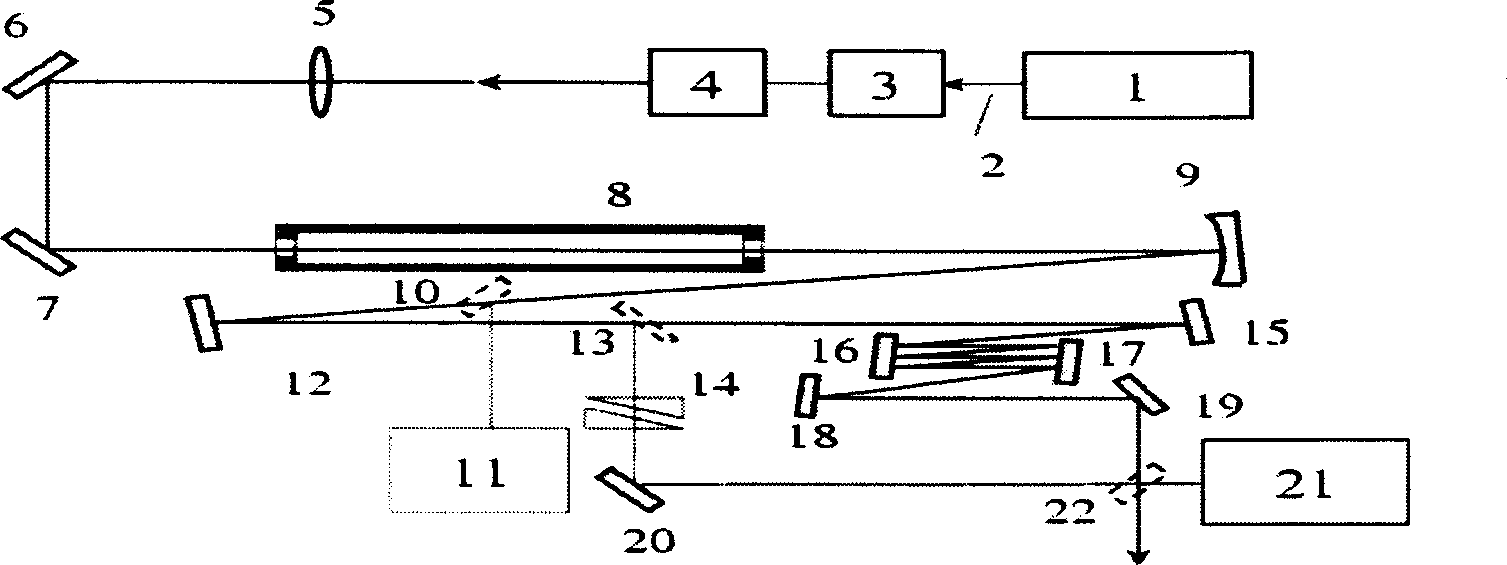

This invention relates to a laser pulse expansion and compression device charactering that it is composed of a super-short pulse laser, a chirp control system, an energy control system, a non-linear action system, a dispersion compensation system and a test system, which can either expand spectrums and compress pulses or compress spectrums and expand pulses.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

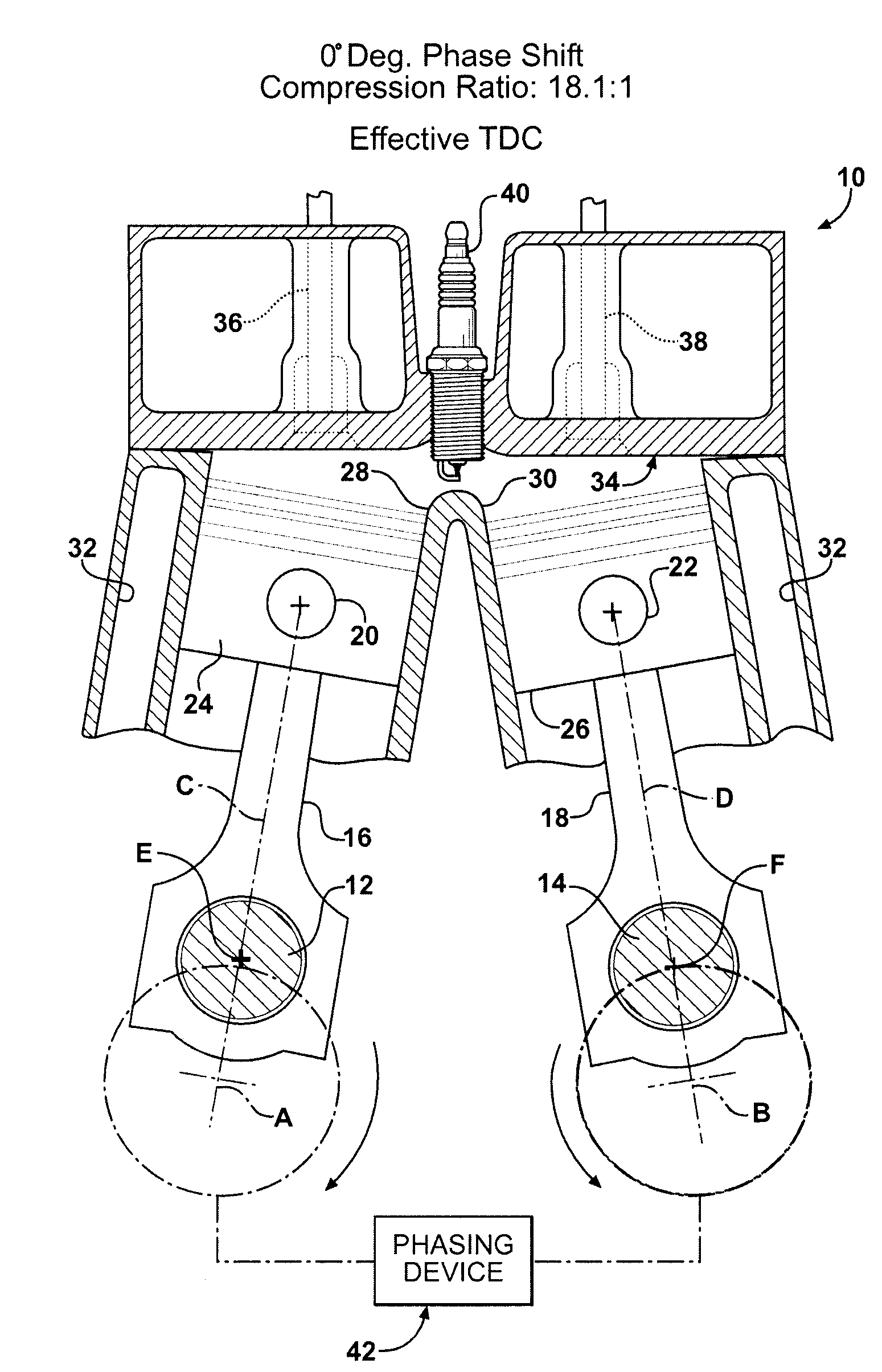

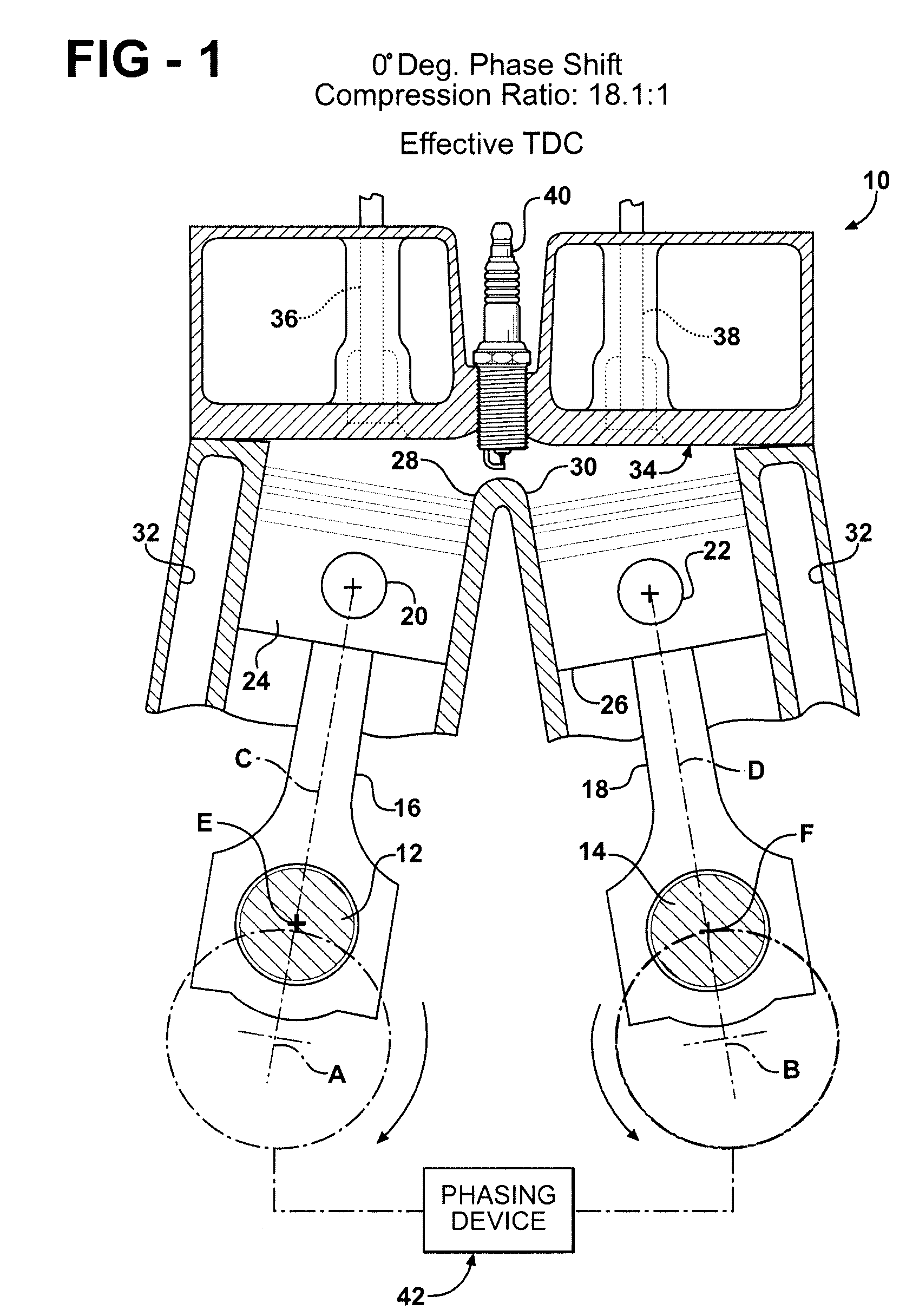

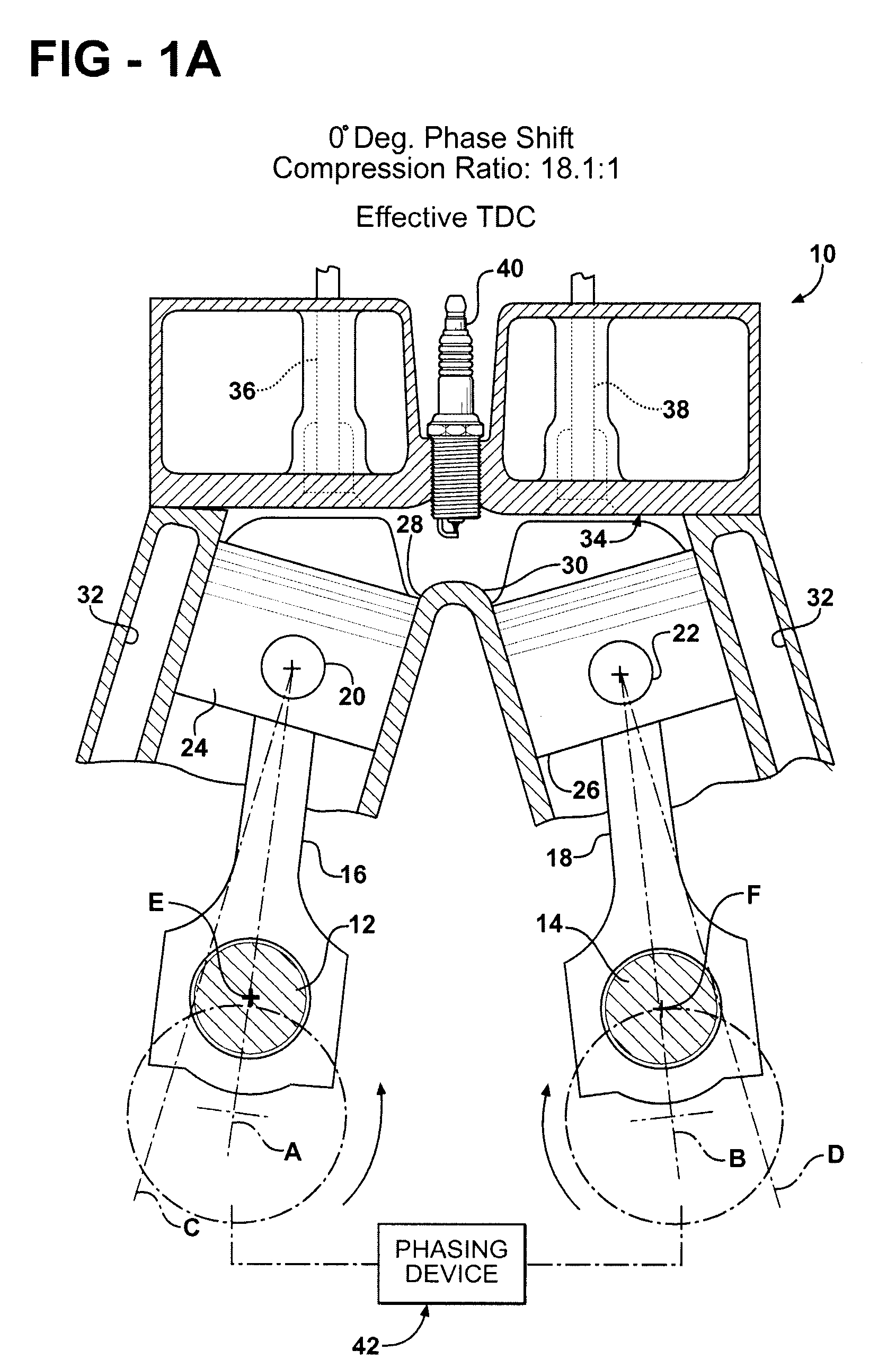

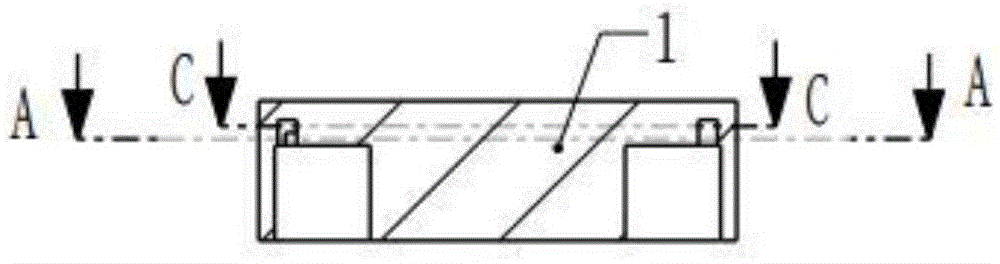

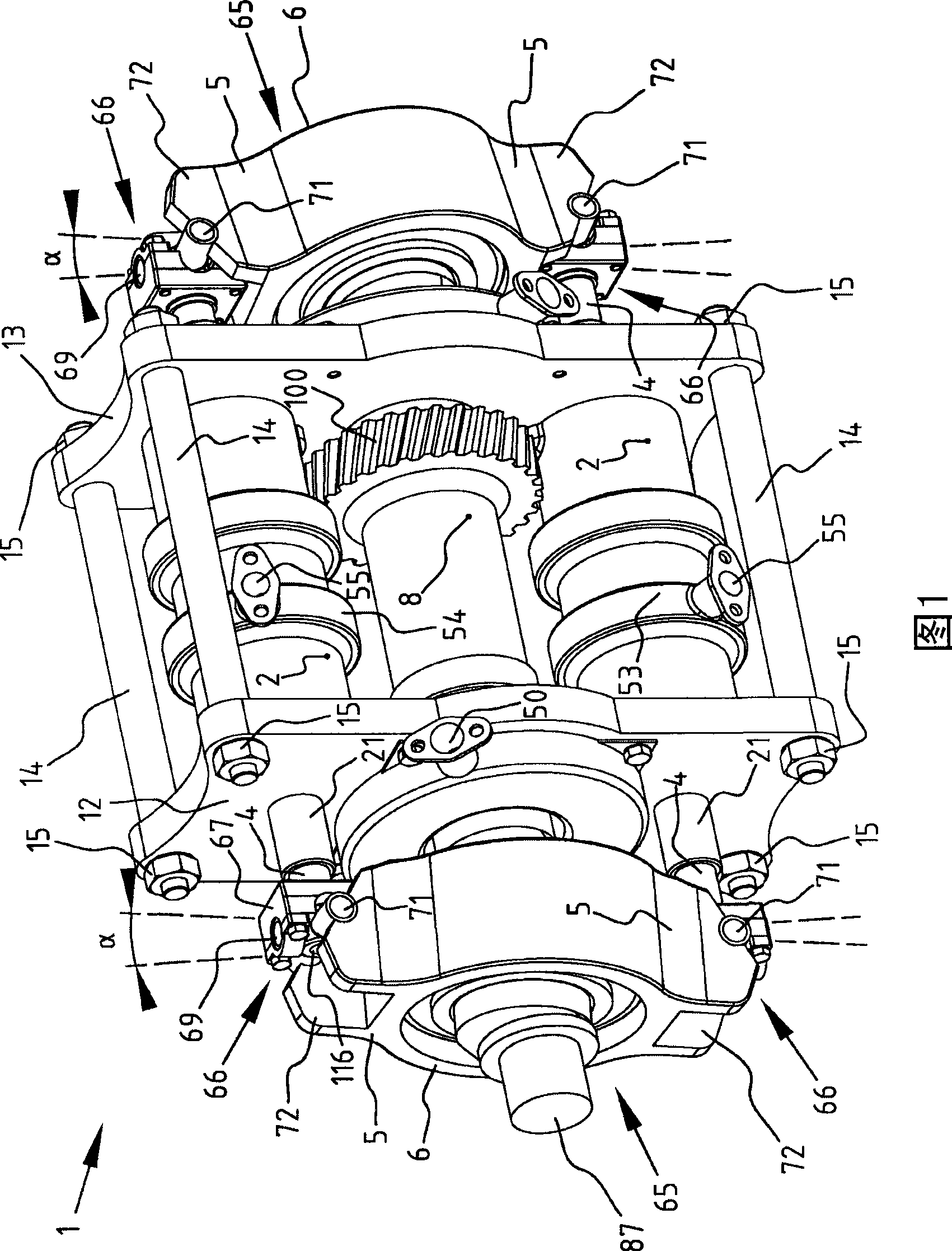

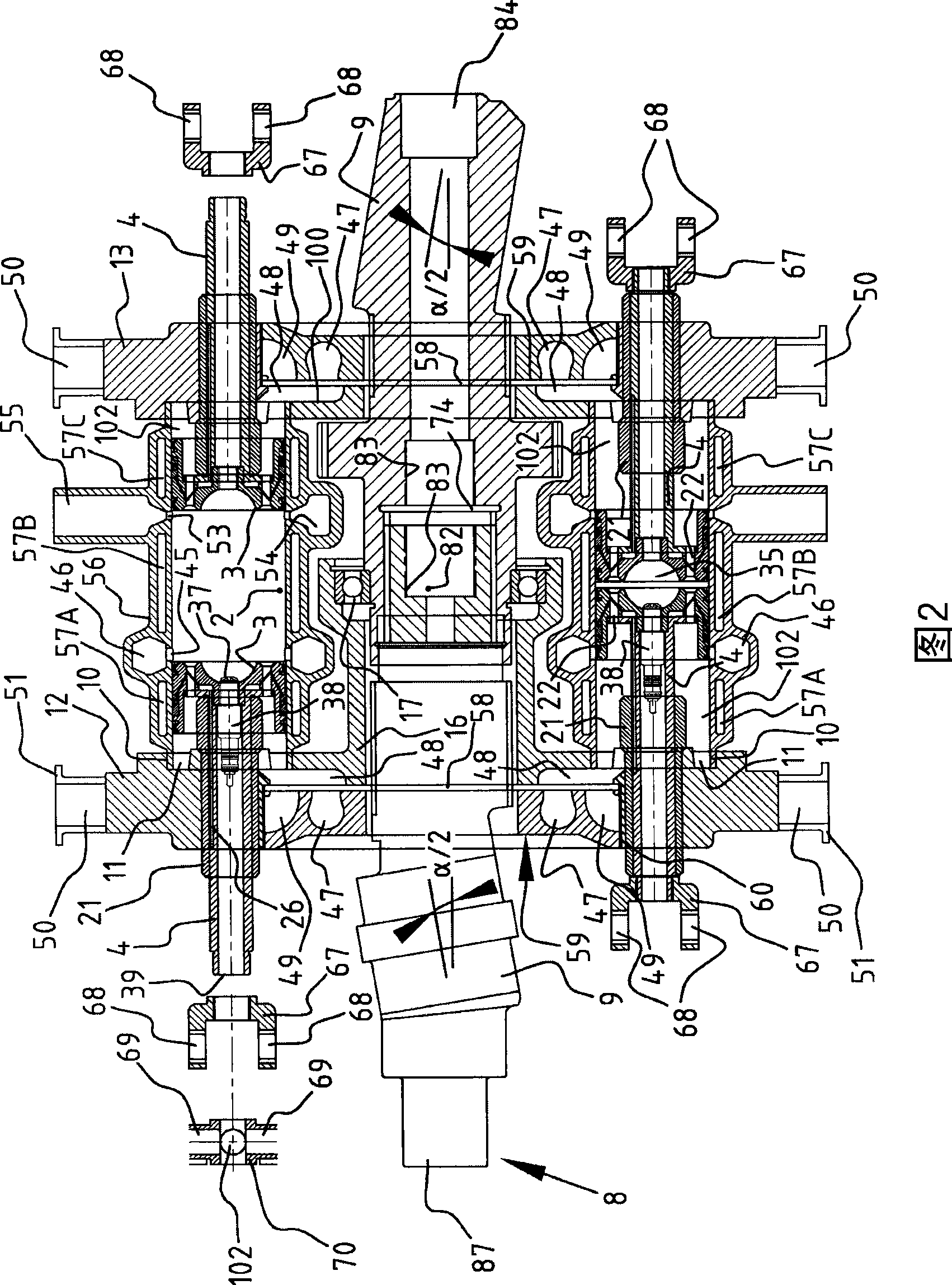

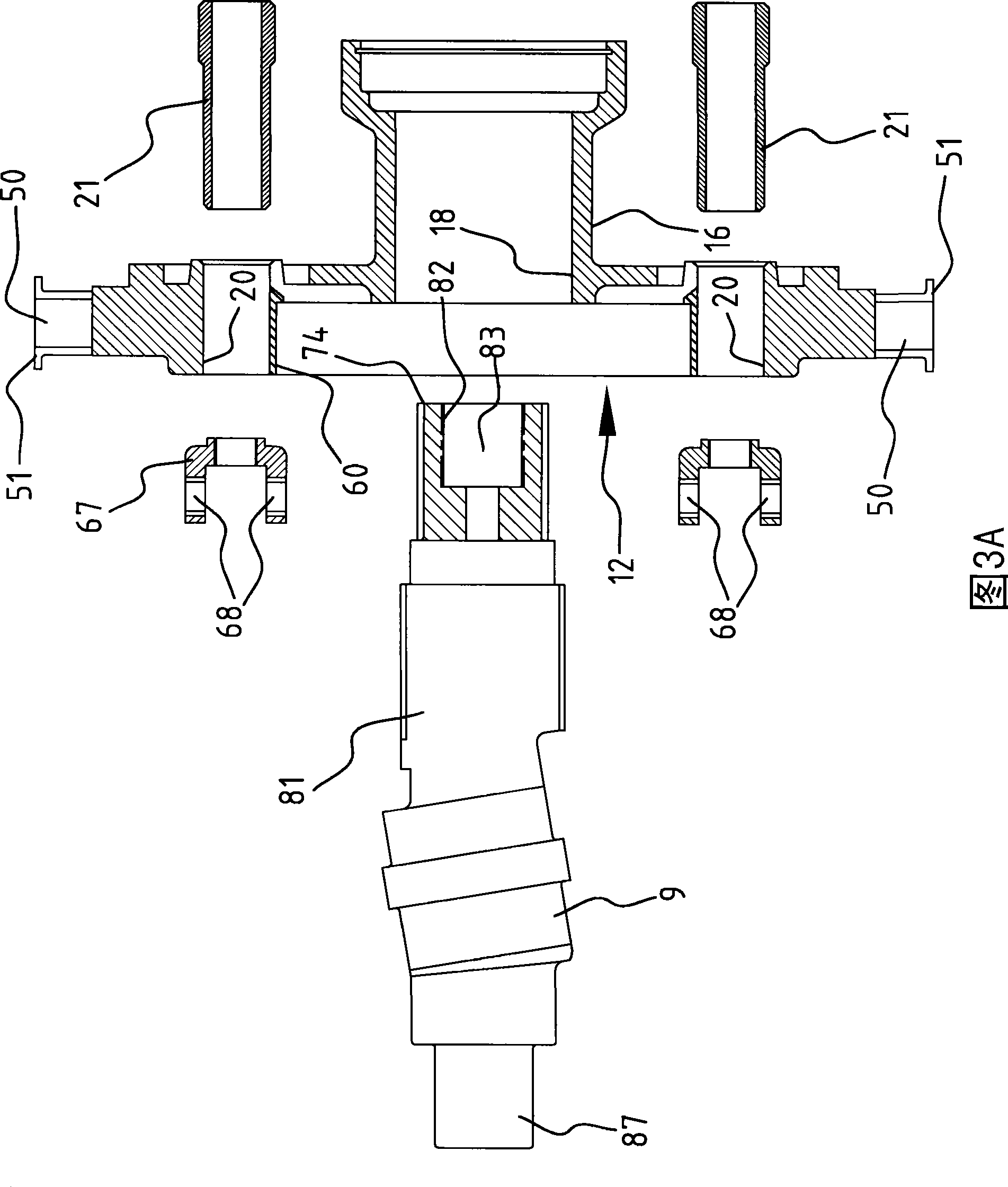

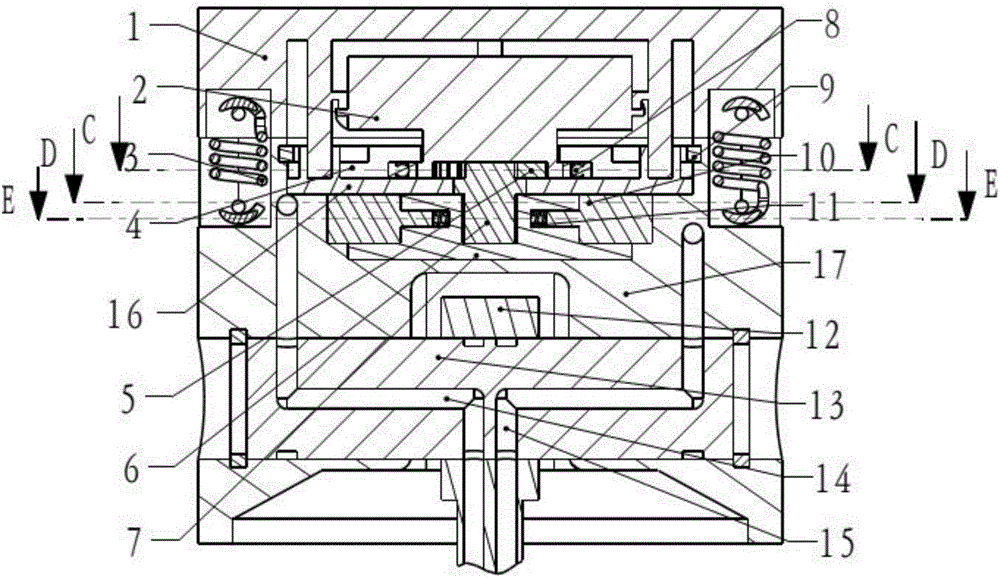

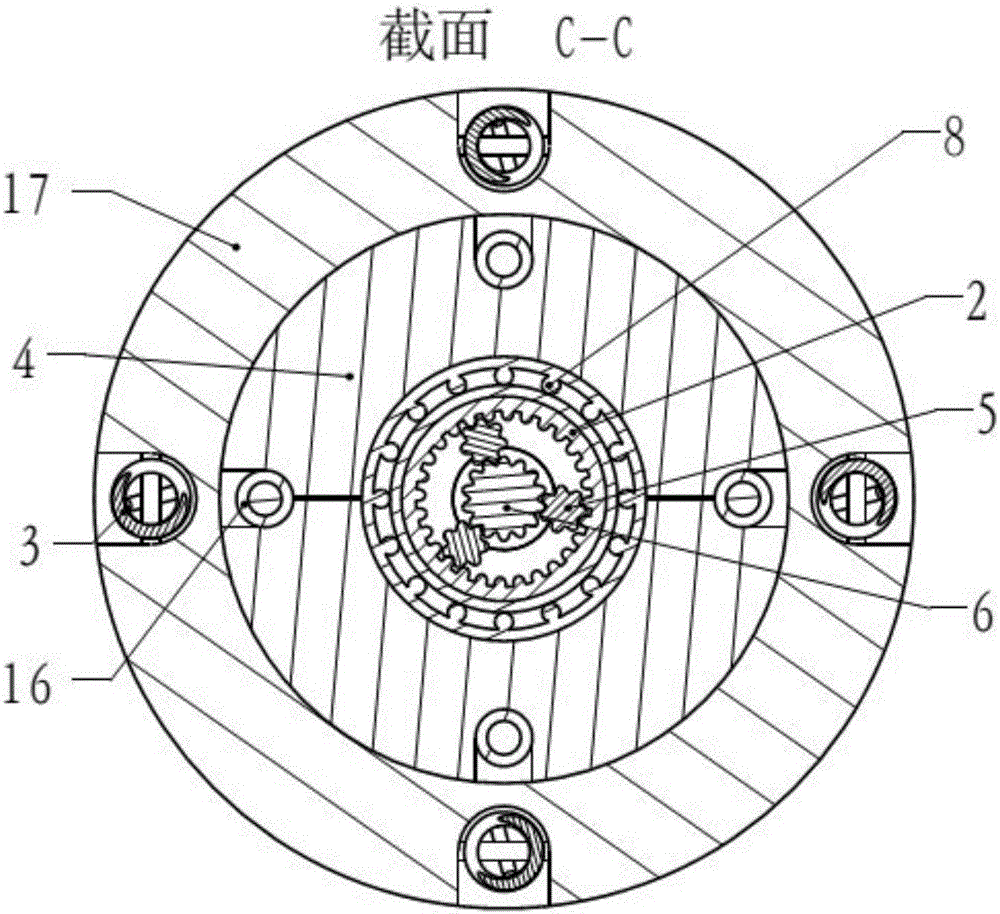

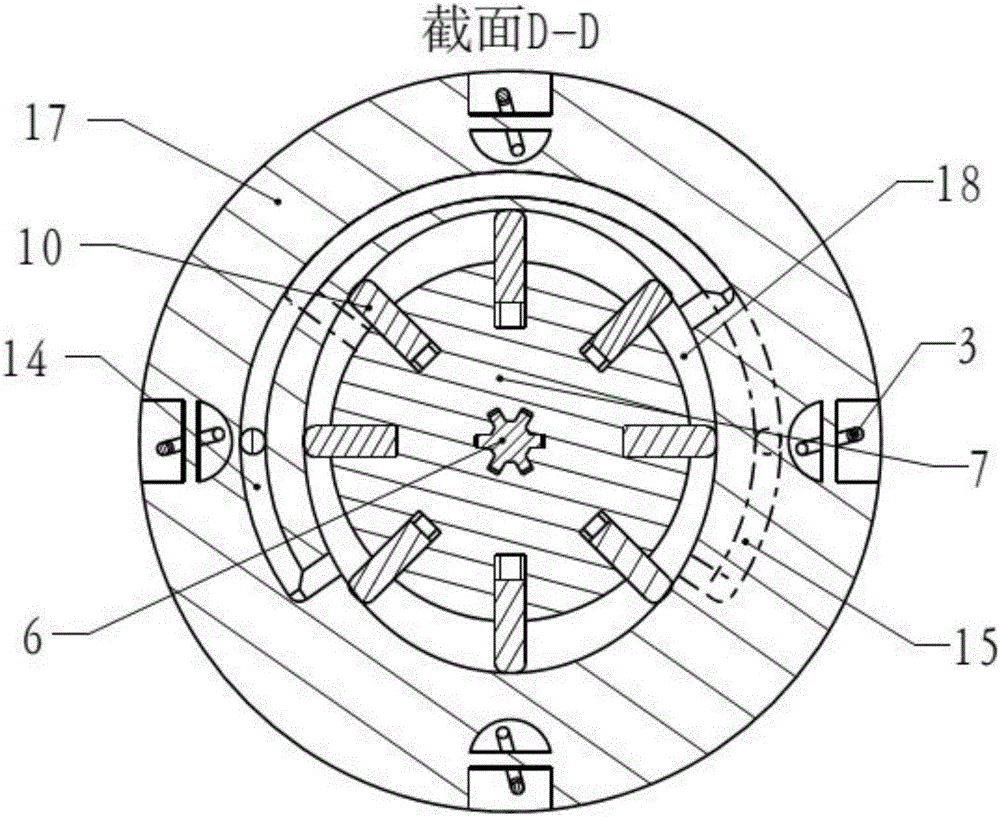

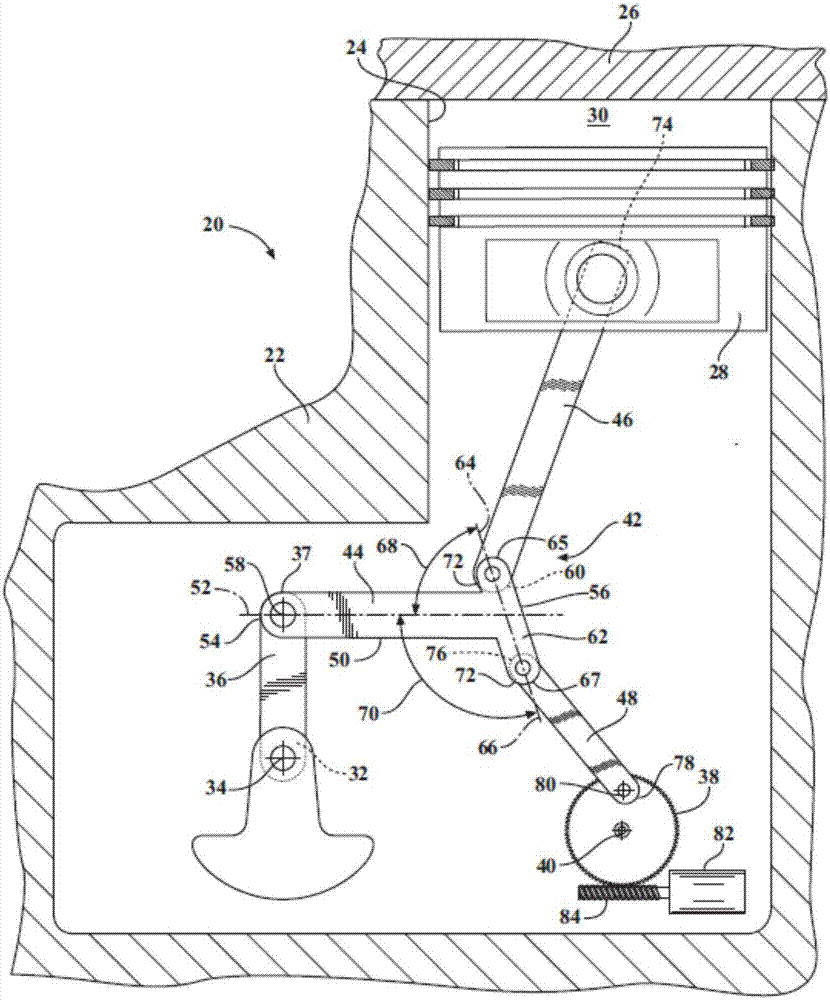

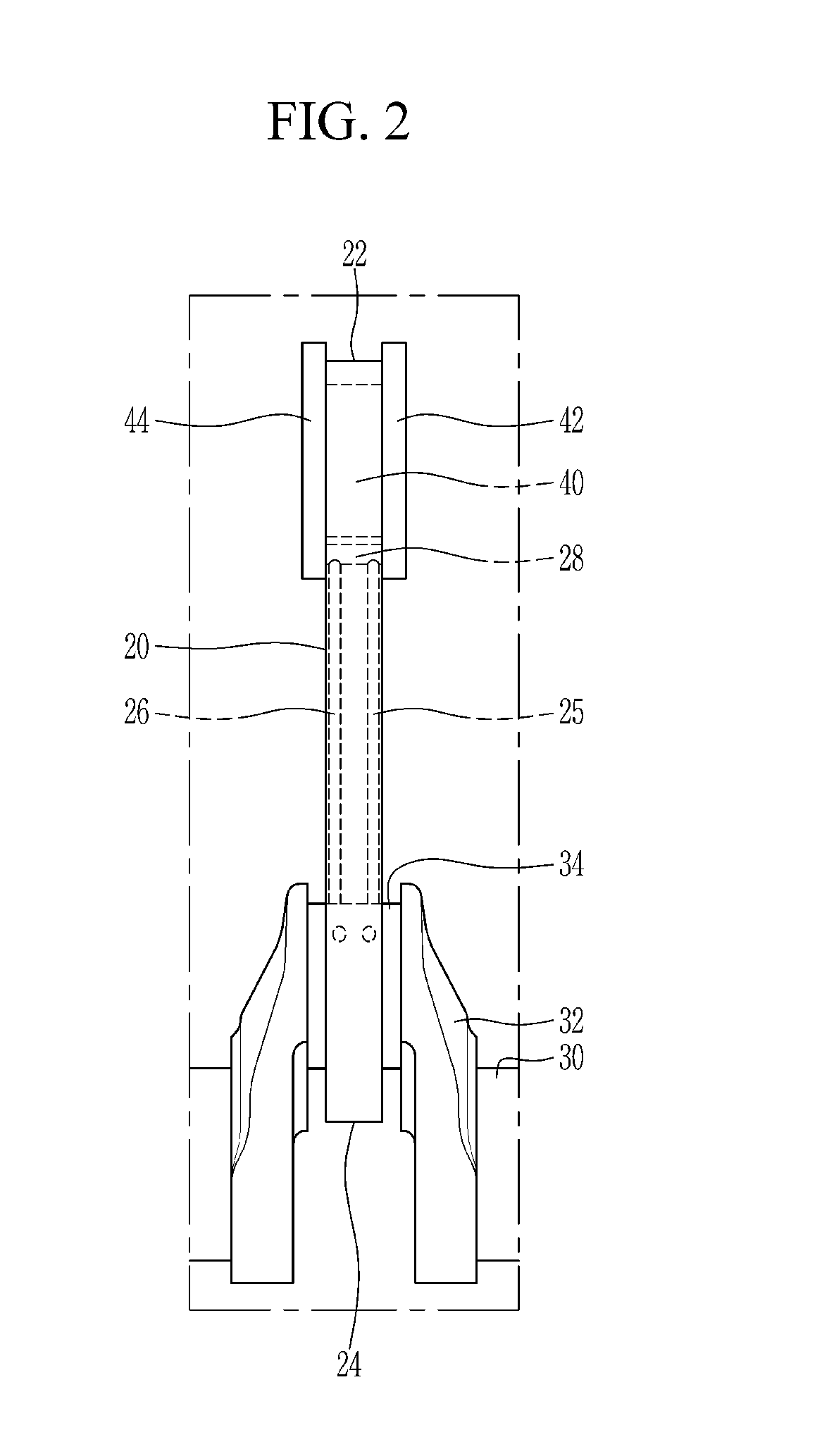

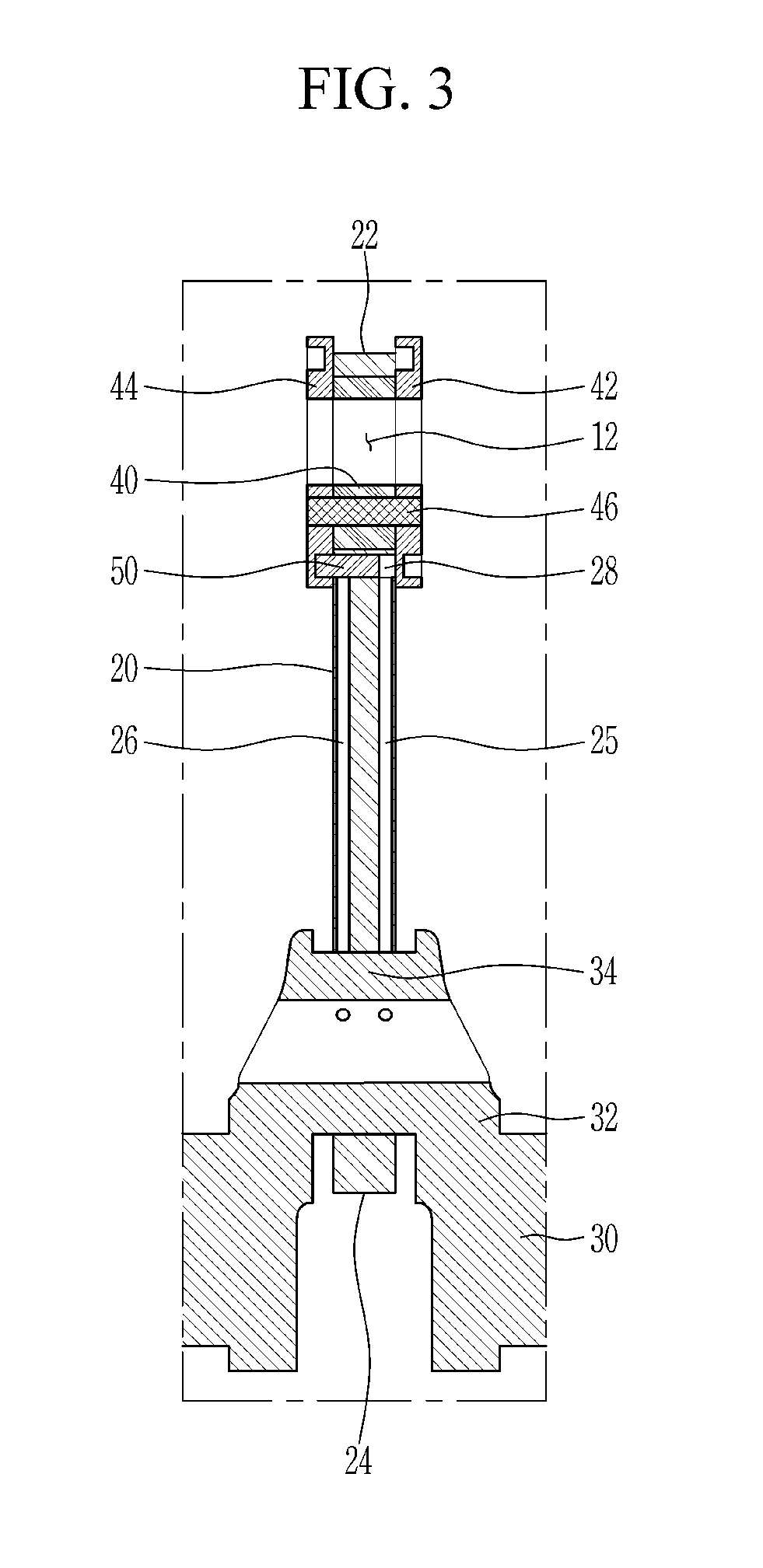

Variable compression ratio dual crankshaft engine

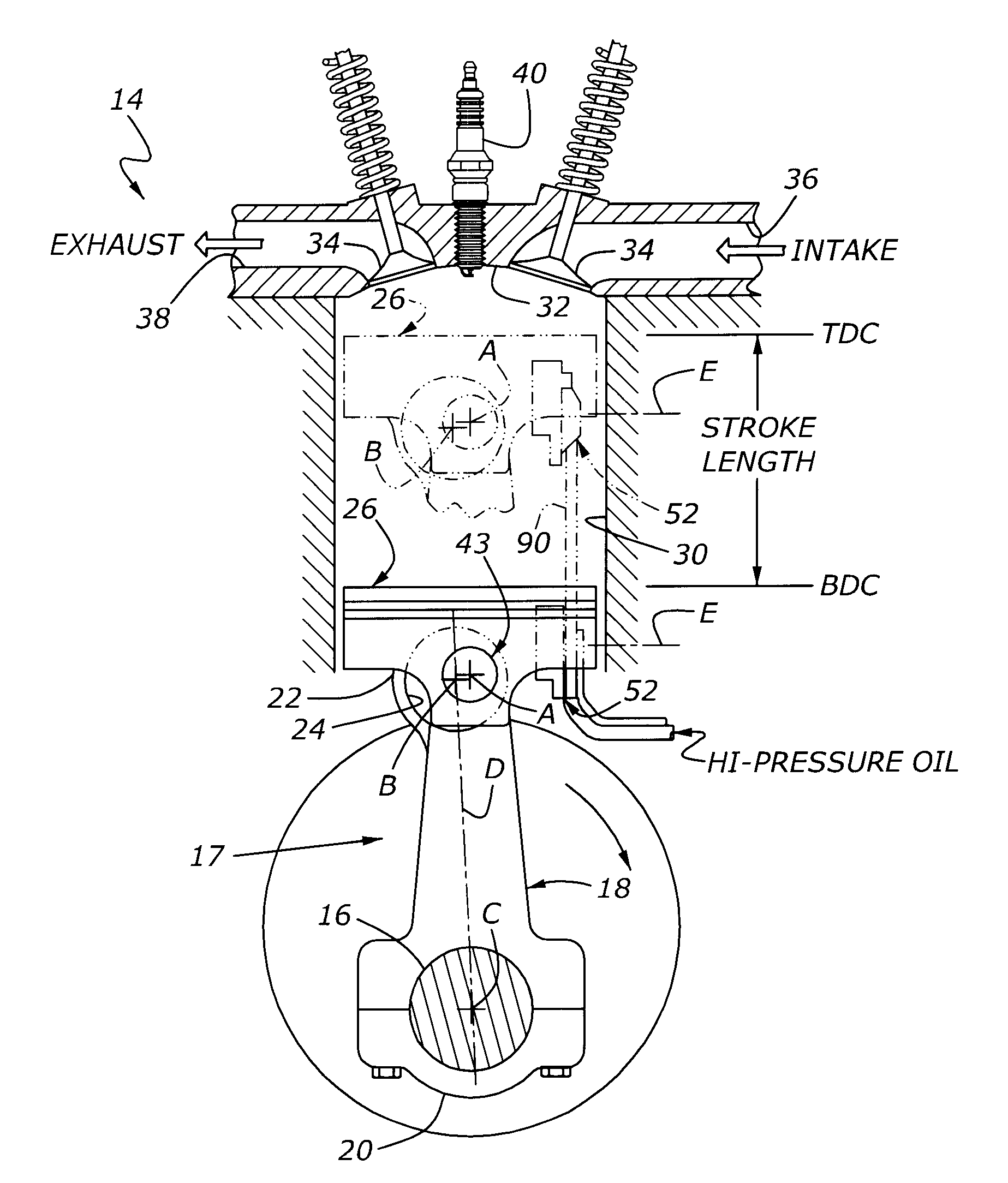

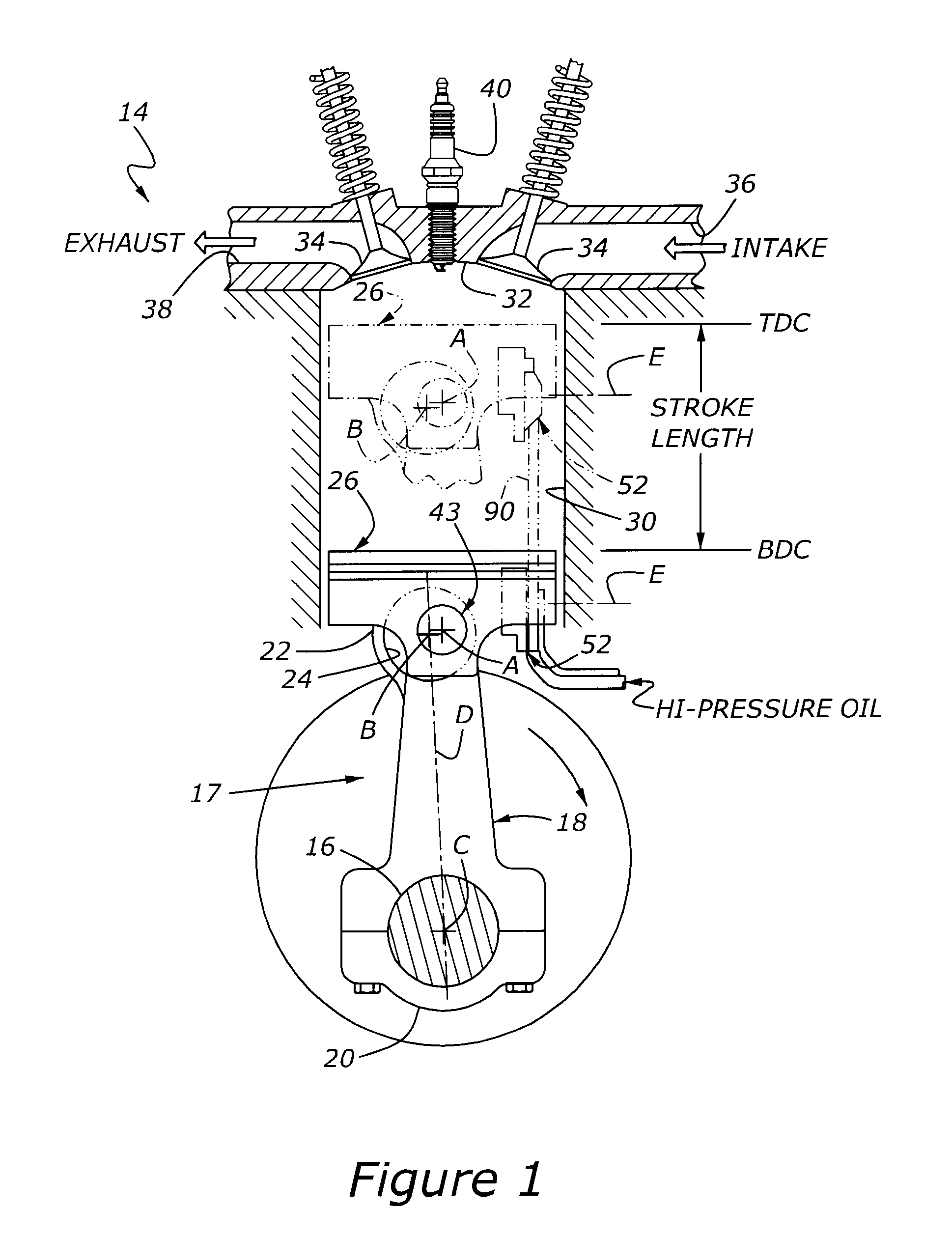

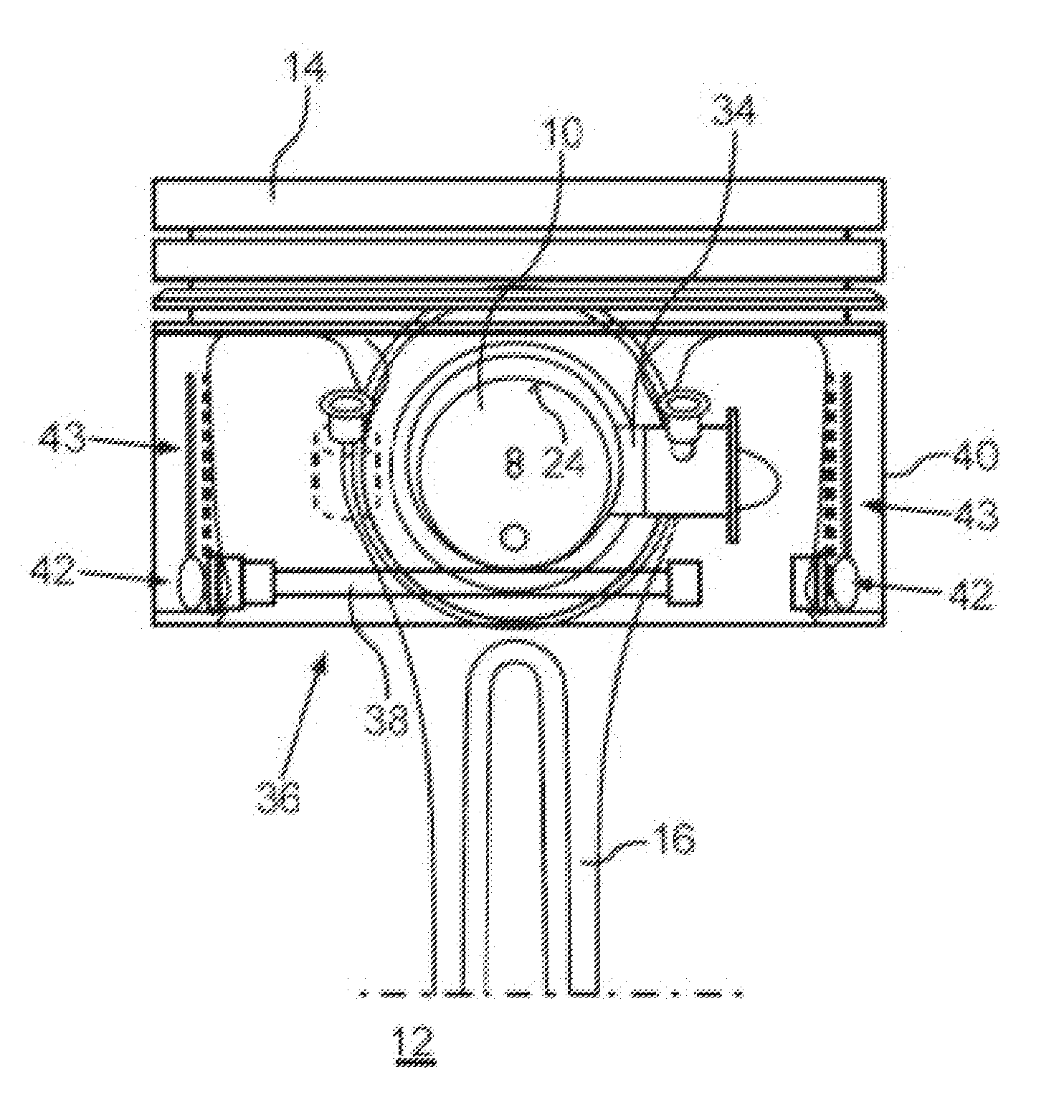

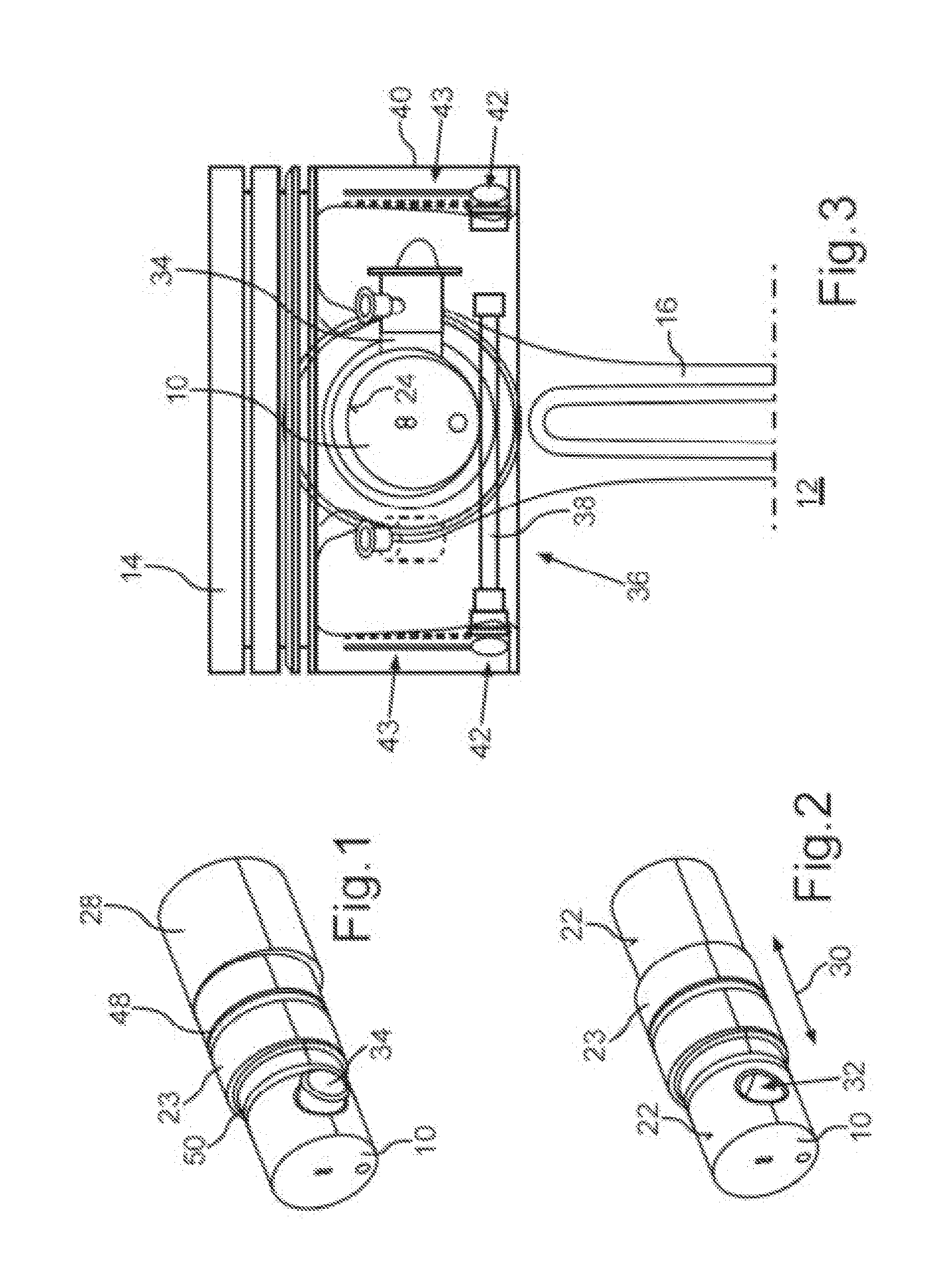

ActiveUS7584724B2Change the compression ratioEnhanced couplingInternal combustion piston enginesEngine controllersExhaust valveCombustion chamber

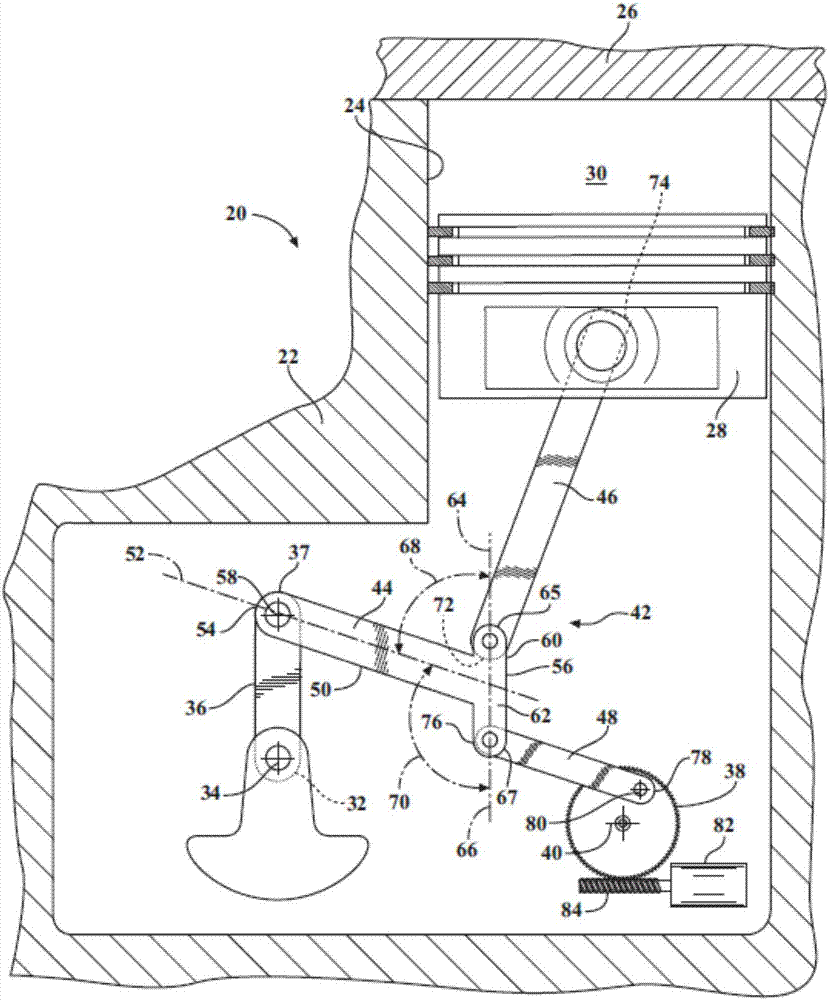

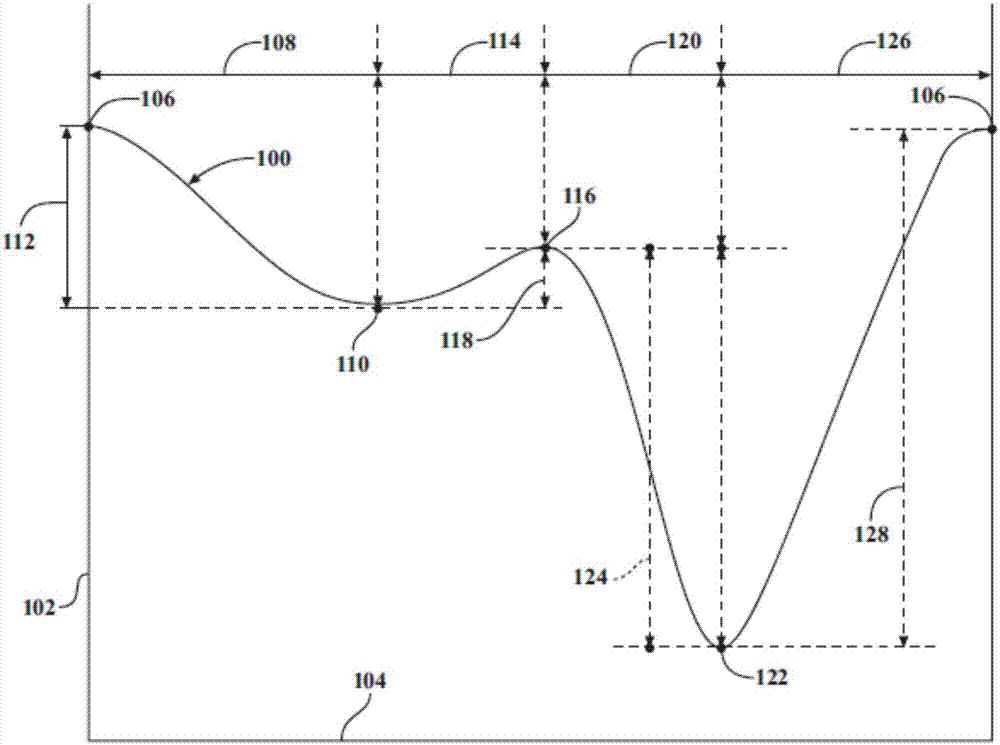

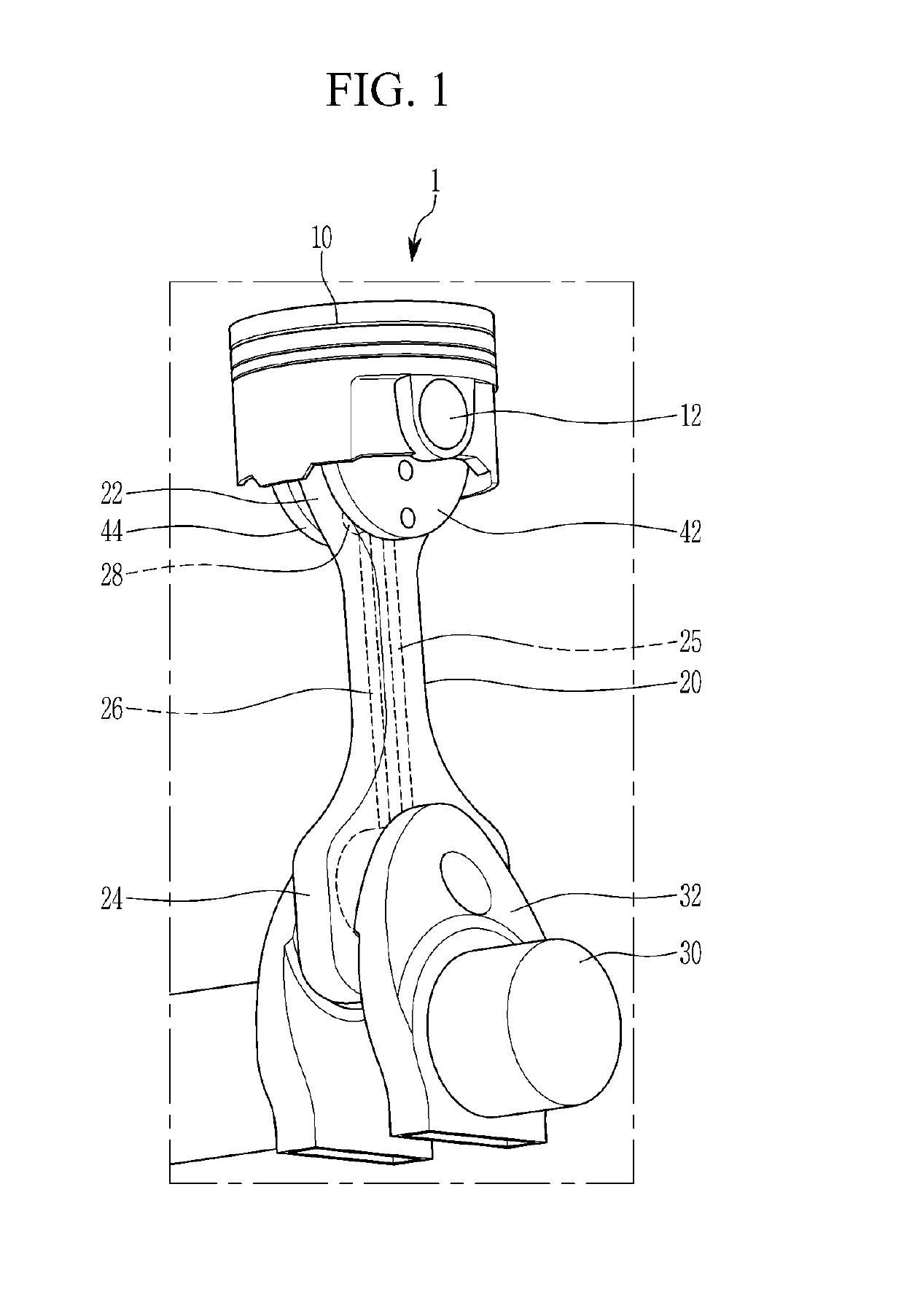

A synchronized, dual crankshaft engine (10) uses a phase-shifting device (42) to alter the angular position of one crankshaft (12) relative to the other crankshaft (14) for dynamically varying the engine's developed compression ratio. Each crankshaft (12, 14) drives a respective connecting rod (16, 18) which, in turn, reciprocates a piston (24, 26) in a cylinder (28, 30). The center lines (C, D) of each cylinder (28, 30) are skewed relative to each other so that the pistons (24, 26) converge toward a common combustion chamber formed under a common cylinder head (34). Movable exhaust valves (36) are located above the piston (24) whose phase shifted orientation is retarded or lagging dead center conditions, whereas movable intake valves (38) are located above the piston (26) that is leading or advanced in its phase displacement relative to dead center conditions.

Owner:FORD GLOBAL TECH LLC

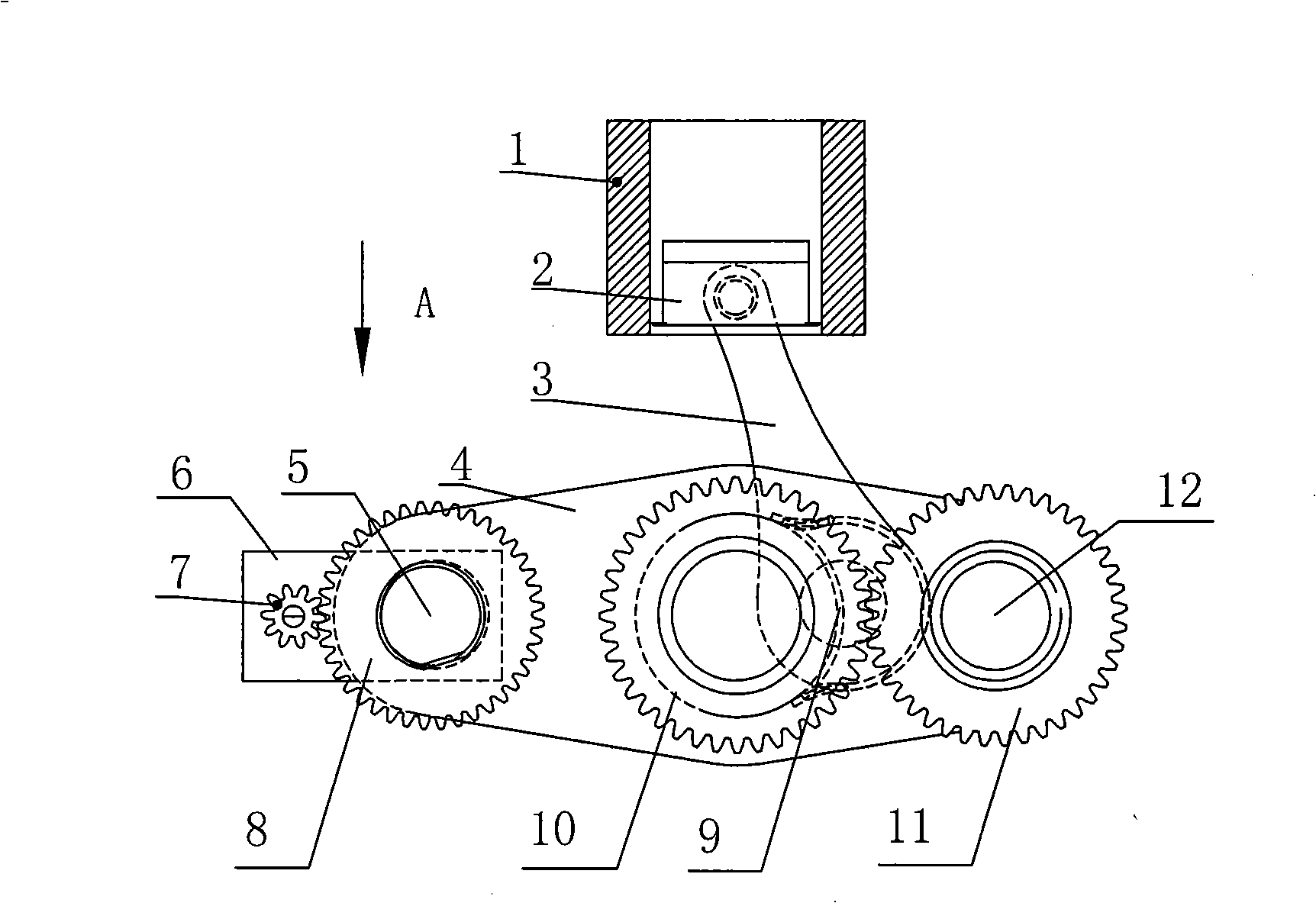

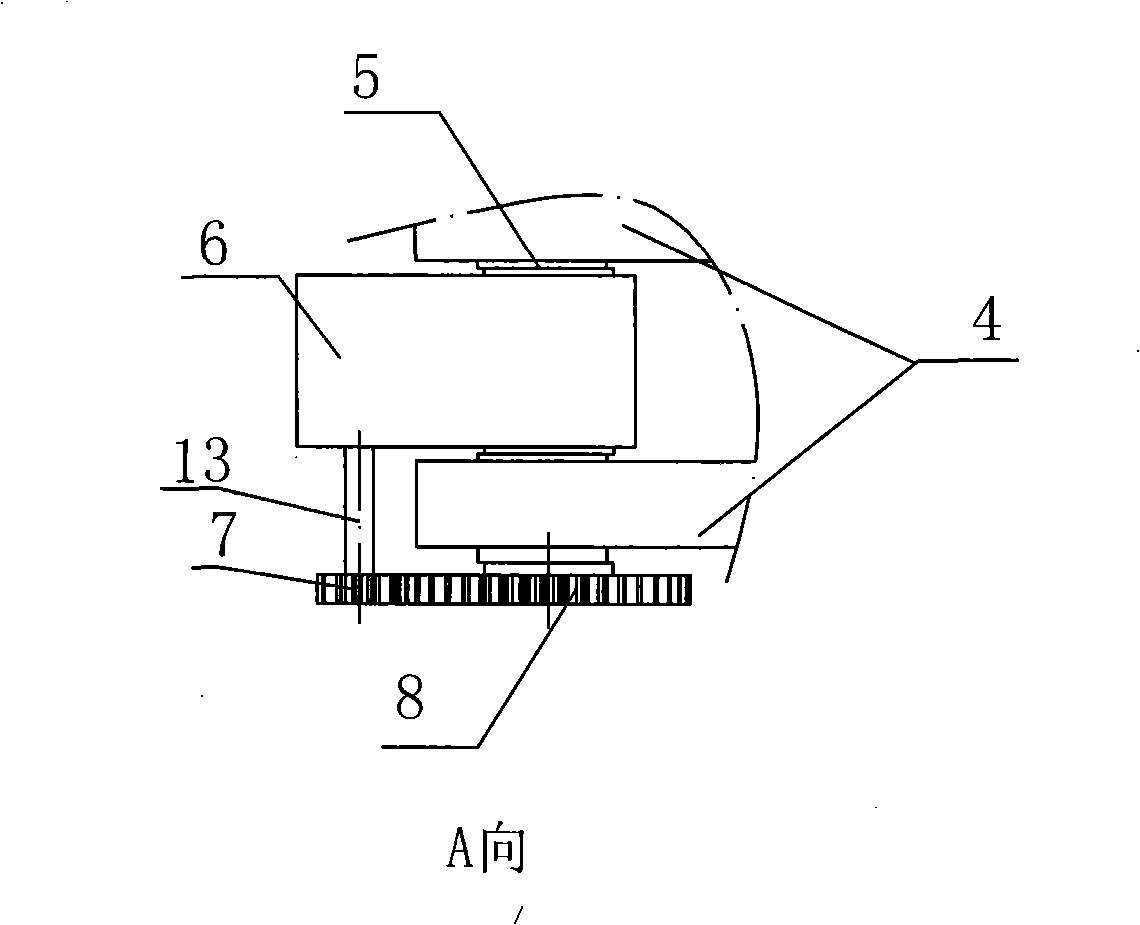

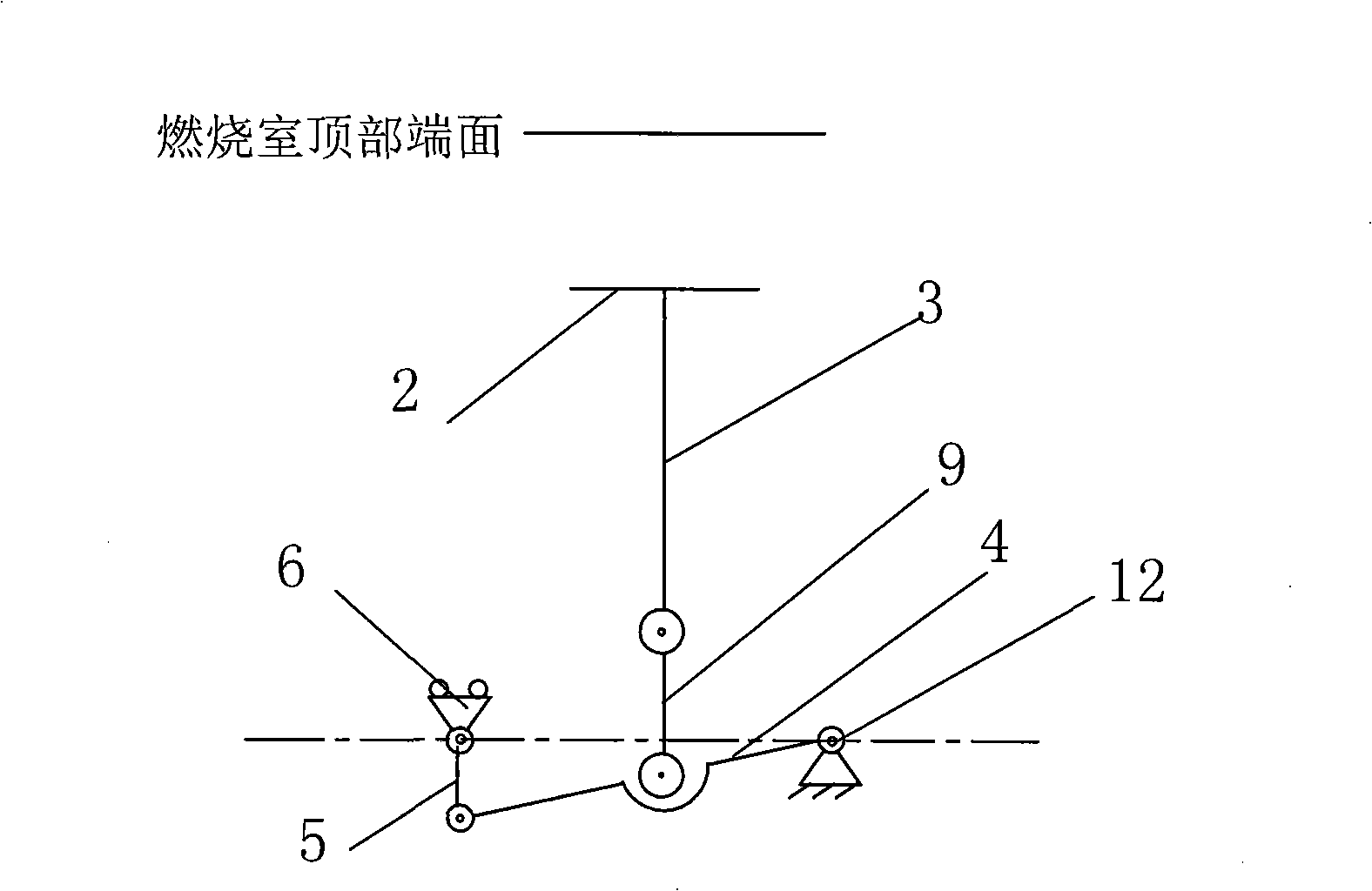

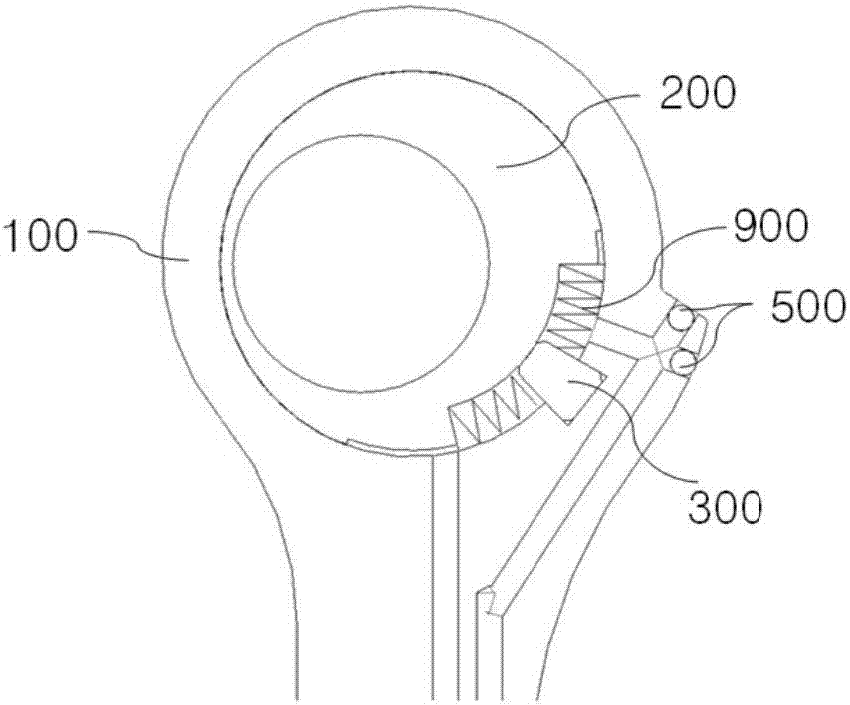

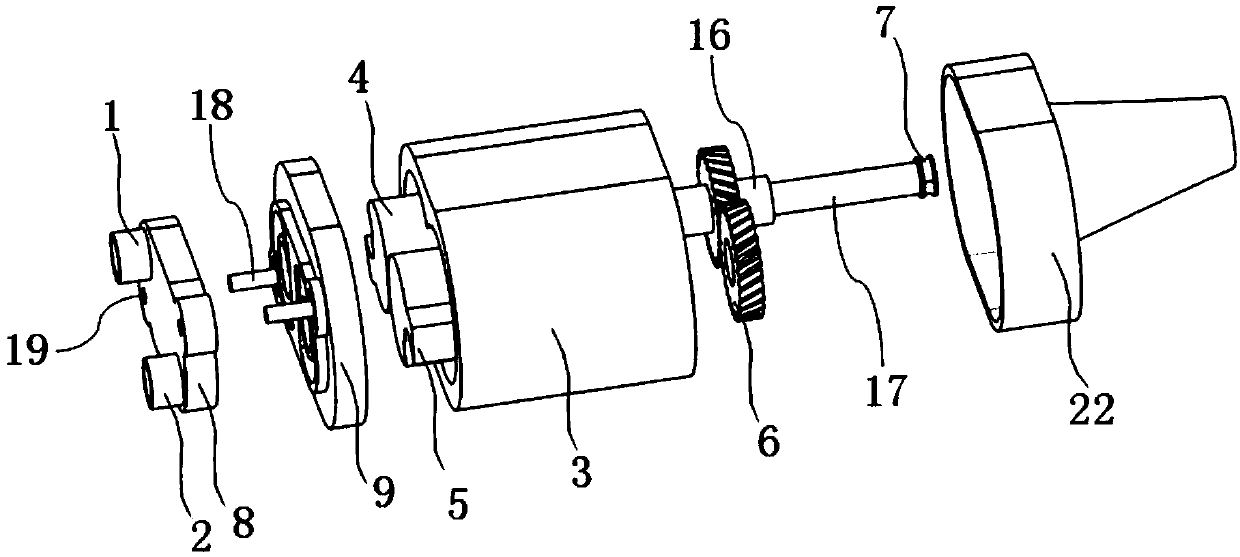

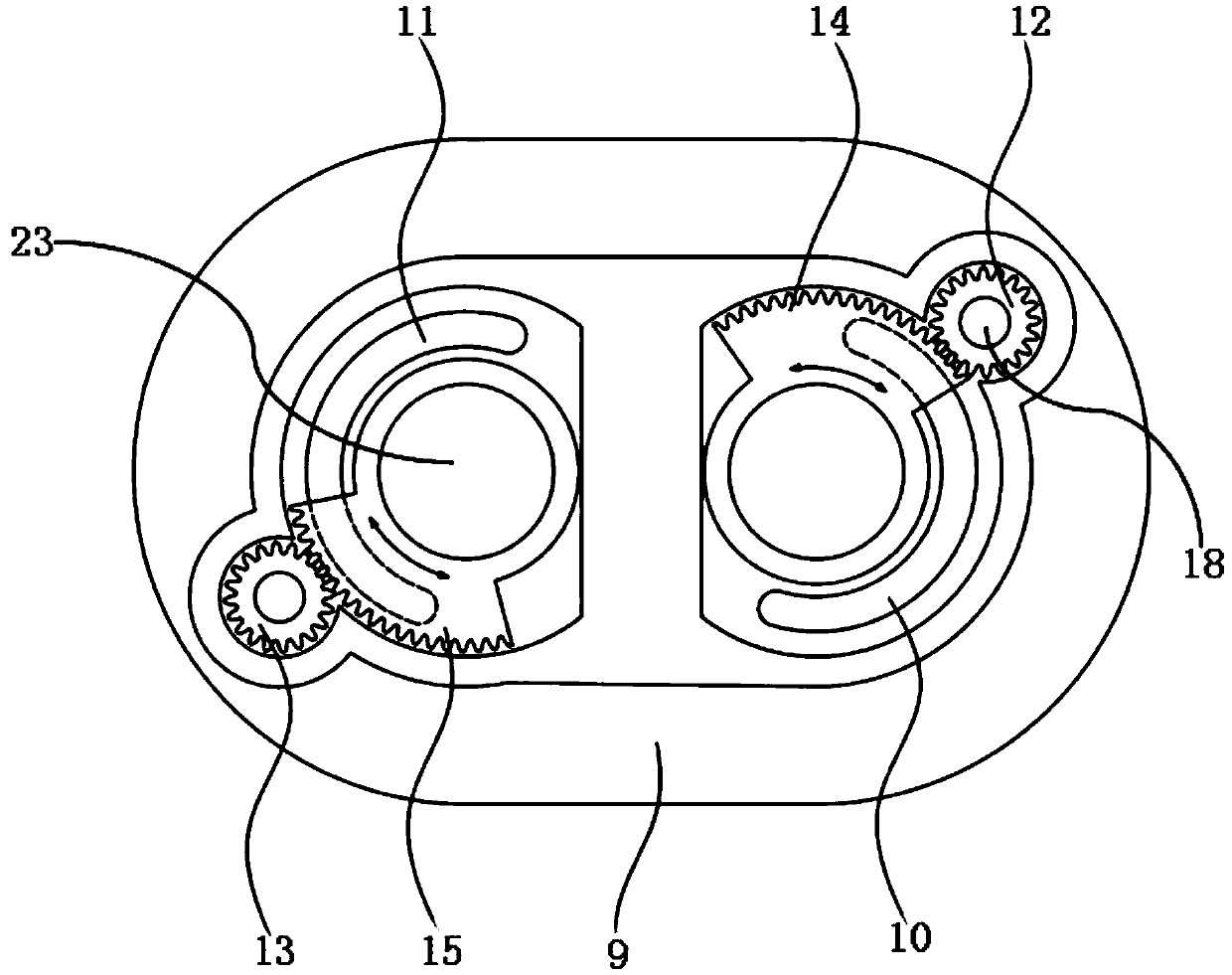

Variable compression ratio engines

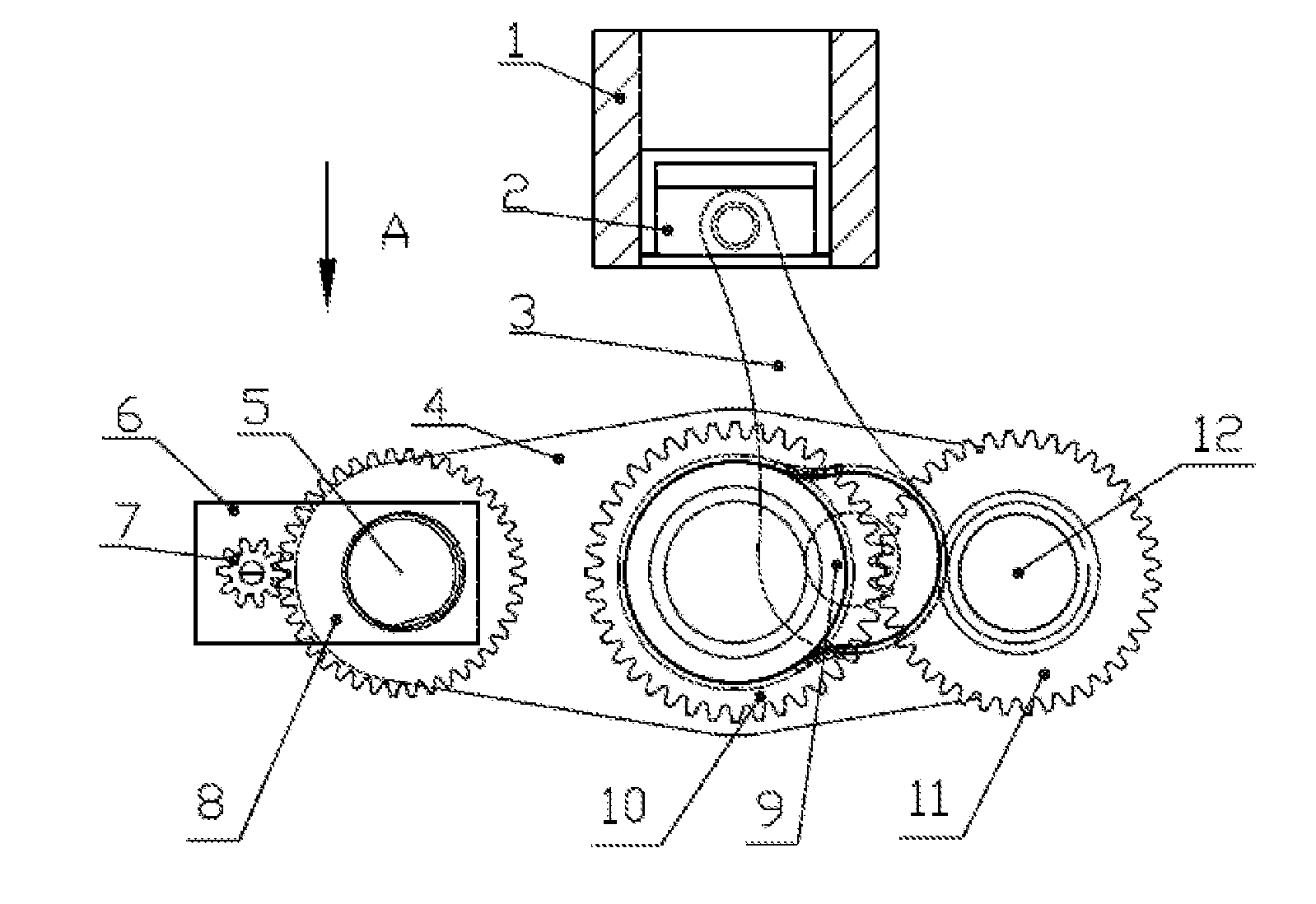

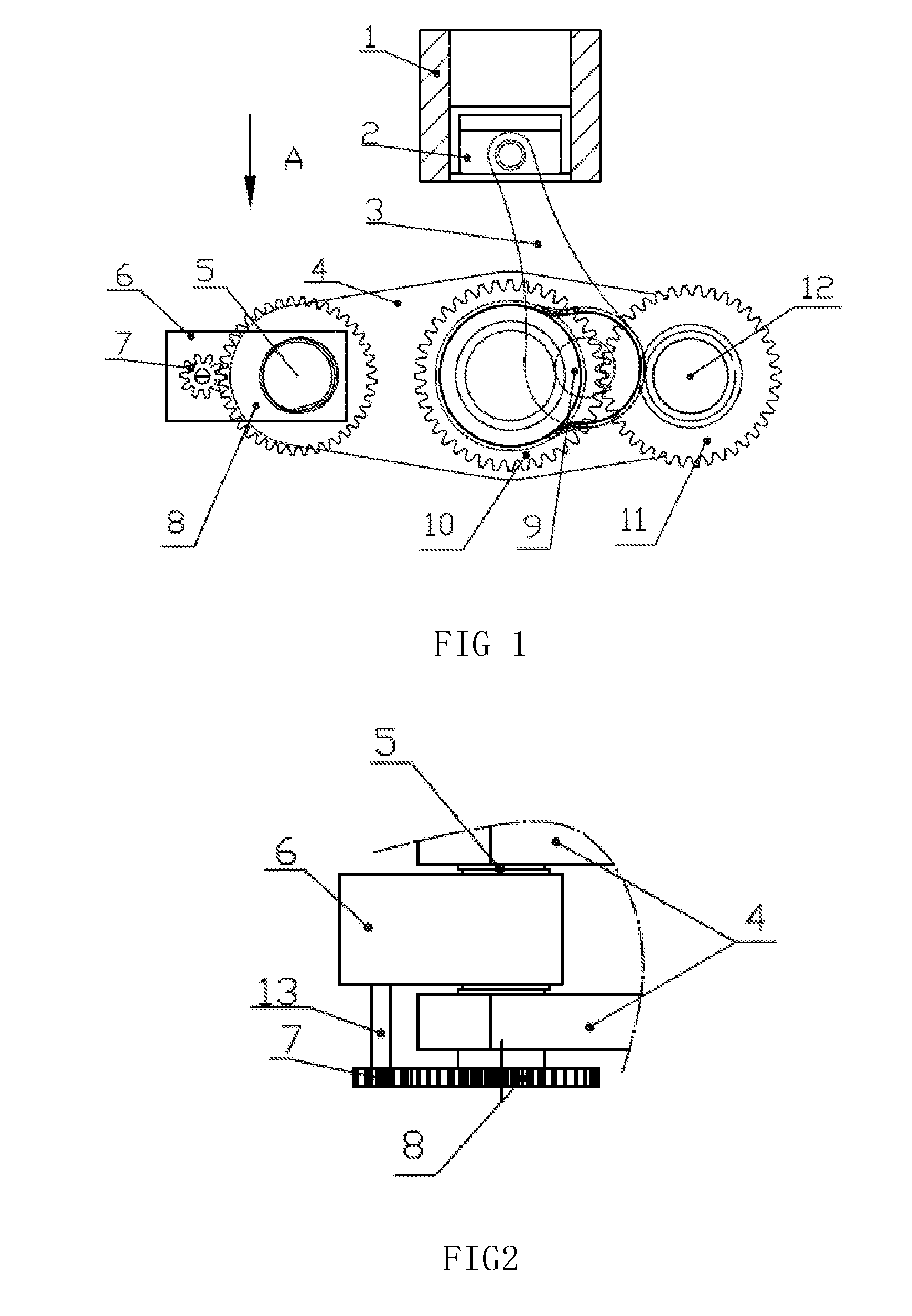

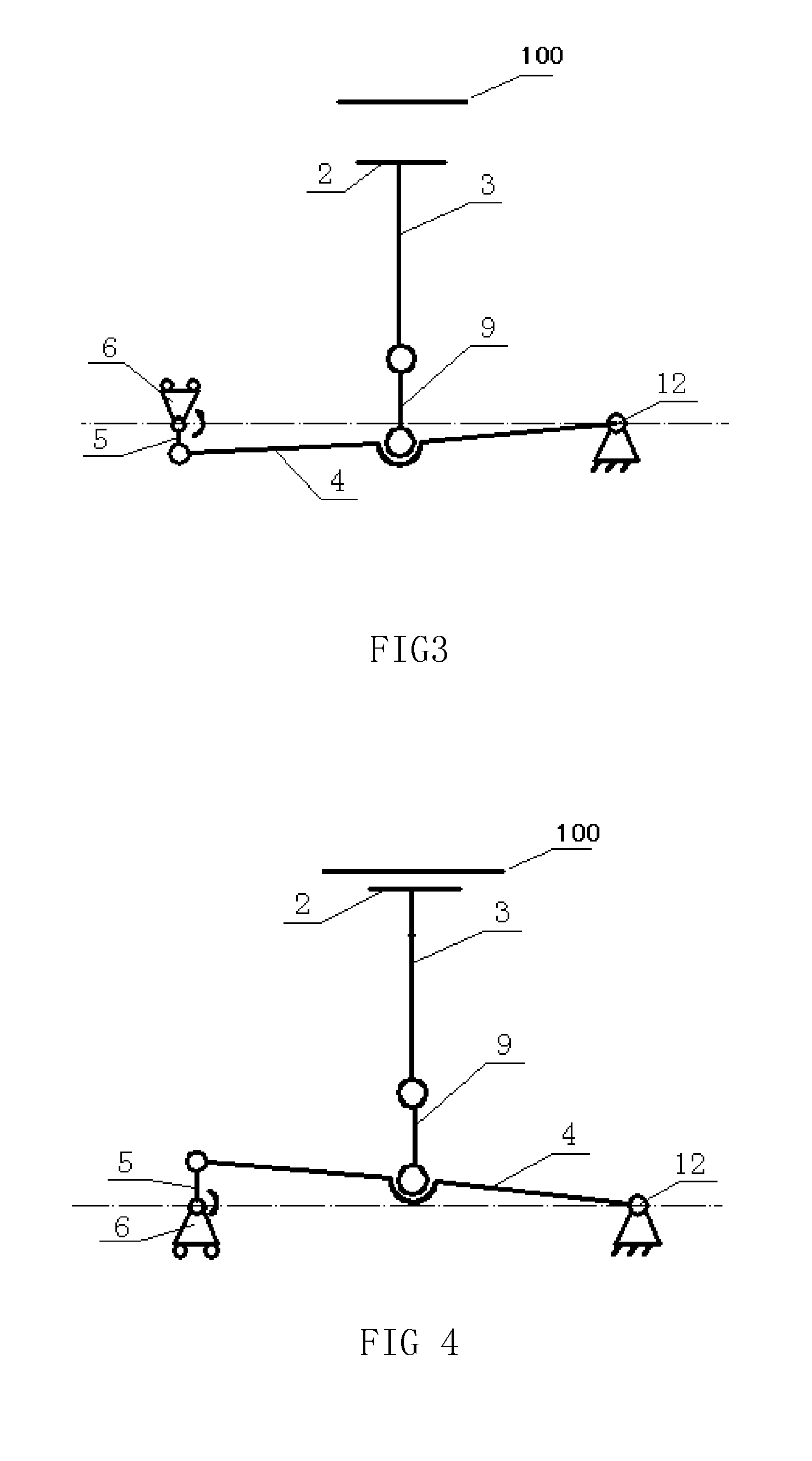

InactiveCN101333970AChange the compression ratioInternal combustion piston enginesEngine controllersGear wheelCrankcase

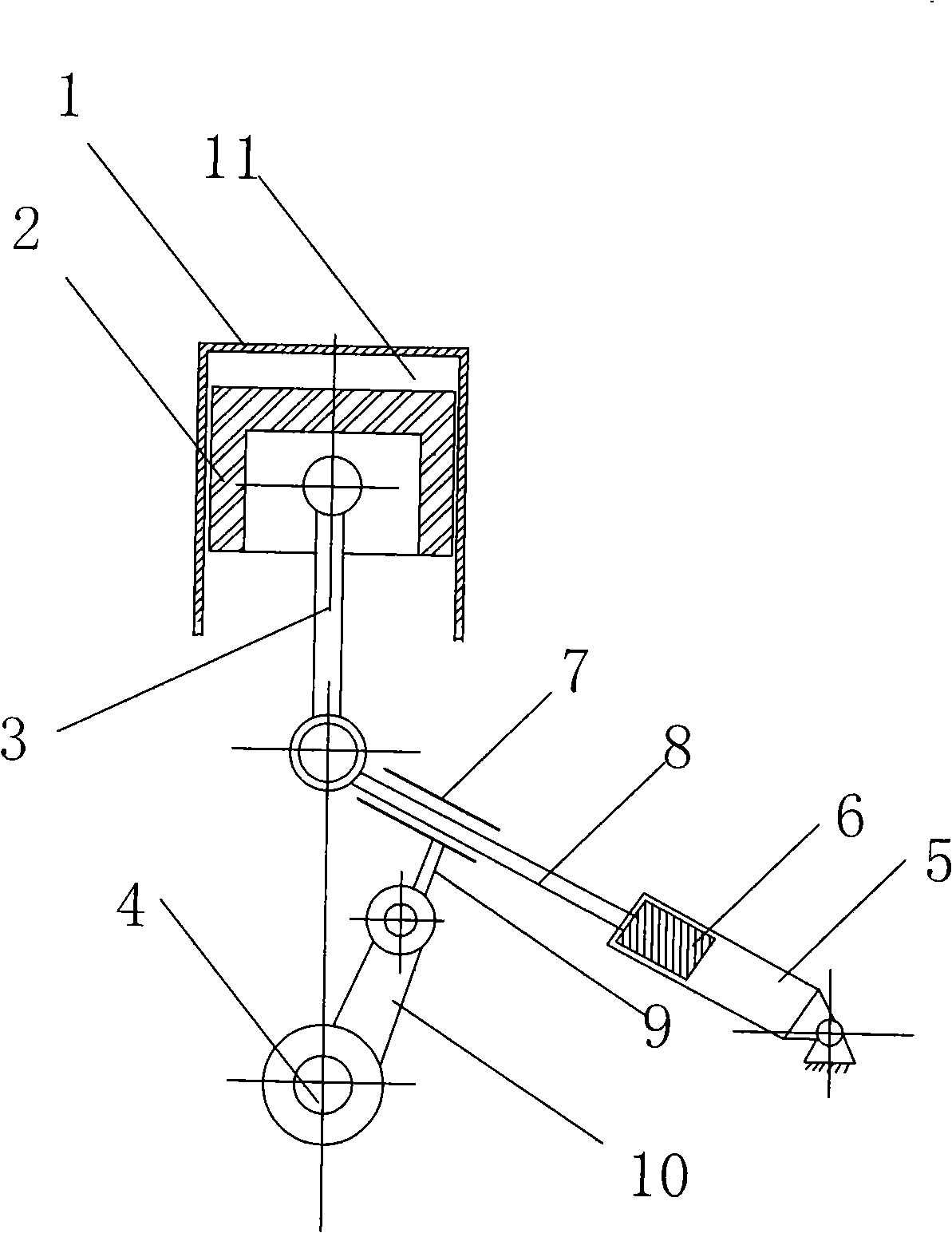

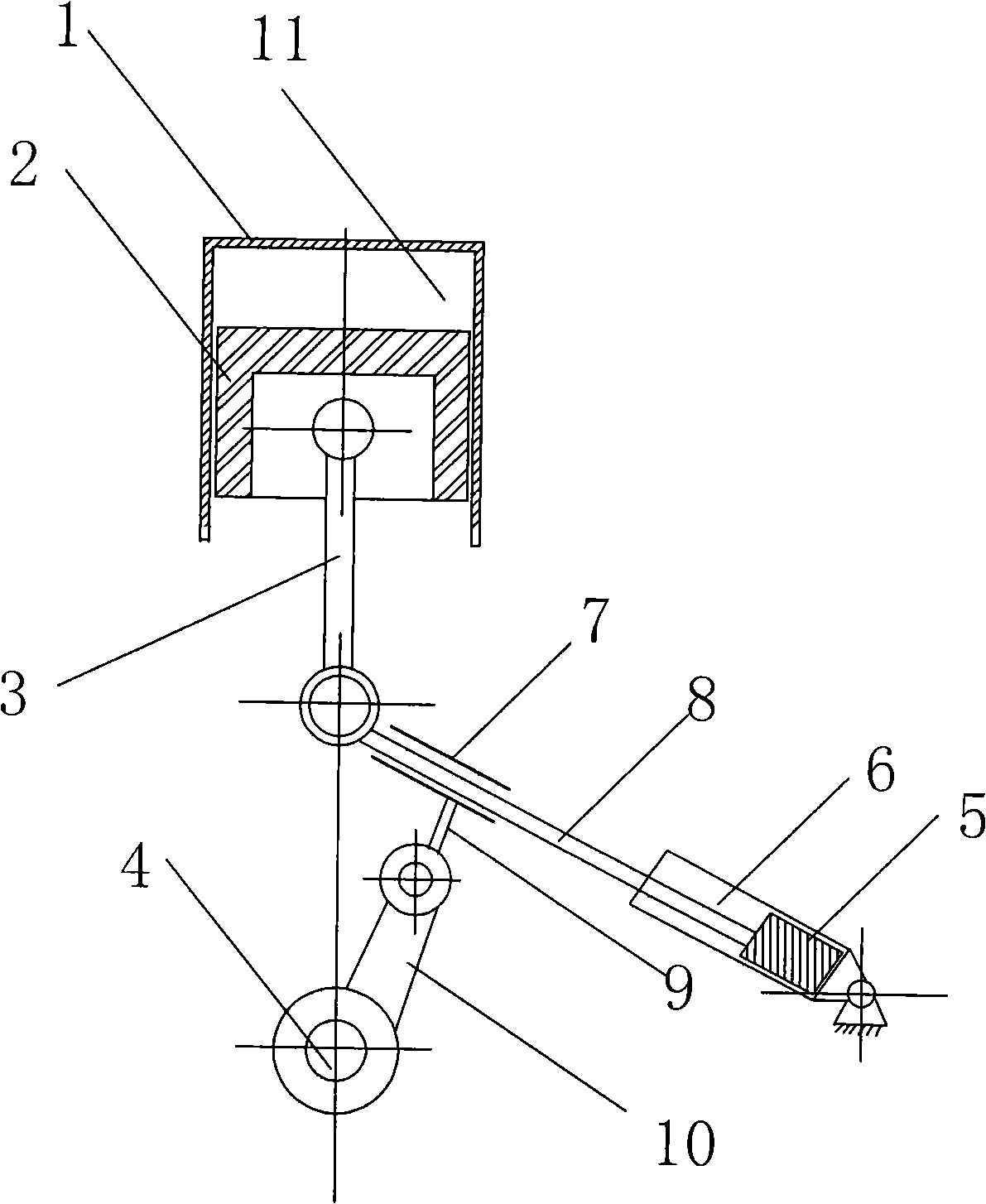

The invention discloses a variable compression-ratio engine which comprises a cylinder cover, a cylinder body, a power output shaft and a crankcase. The cylinder cover is fixed on the upper surface of the cylinder body; the crankcase and the cylinder body are formed integrally. In the cylinder body, a piston is connected with the crankcase through a connecting rod. The power output shaft is mounted on the crankshaft; the power output shaft and the crank neck of the crank are respectively provided with a power output gear and an input gear; the power output gear is meshed with the input gear. A support arm is arranged in the crankcase; the crank is hinged with the support arm. One end of the support arm is hinged with the crankcase and the hinged shaft is the power output shaft. The other end of the support arm is the control end; the control end is connected with a control mechanism which drives the support arm to rotate around the power output shaft. Because the control mechanism is adopted for controlling the displacement of the control end of the support arm, the compression-ratio of the engine is ensured to be consistent with the operating condition of the engine, so as to improve the efficiency and reduce the exhaust.

Owner:CHERY AUTOMOBILE CO LTD

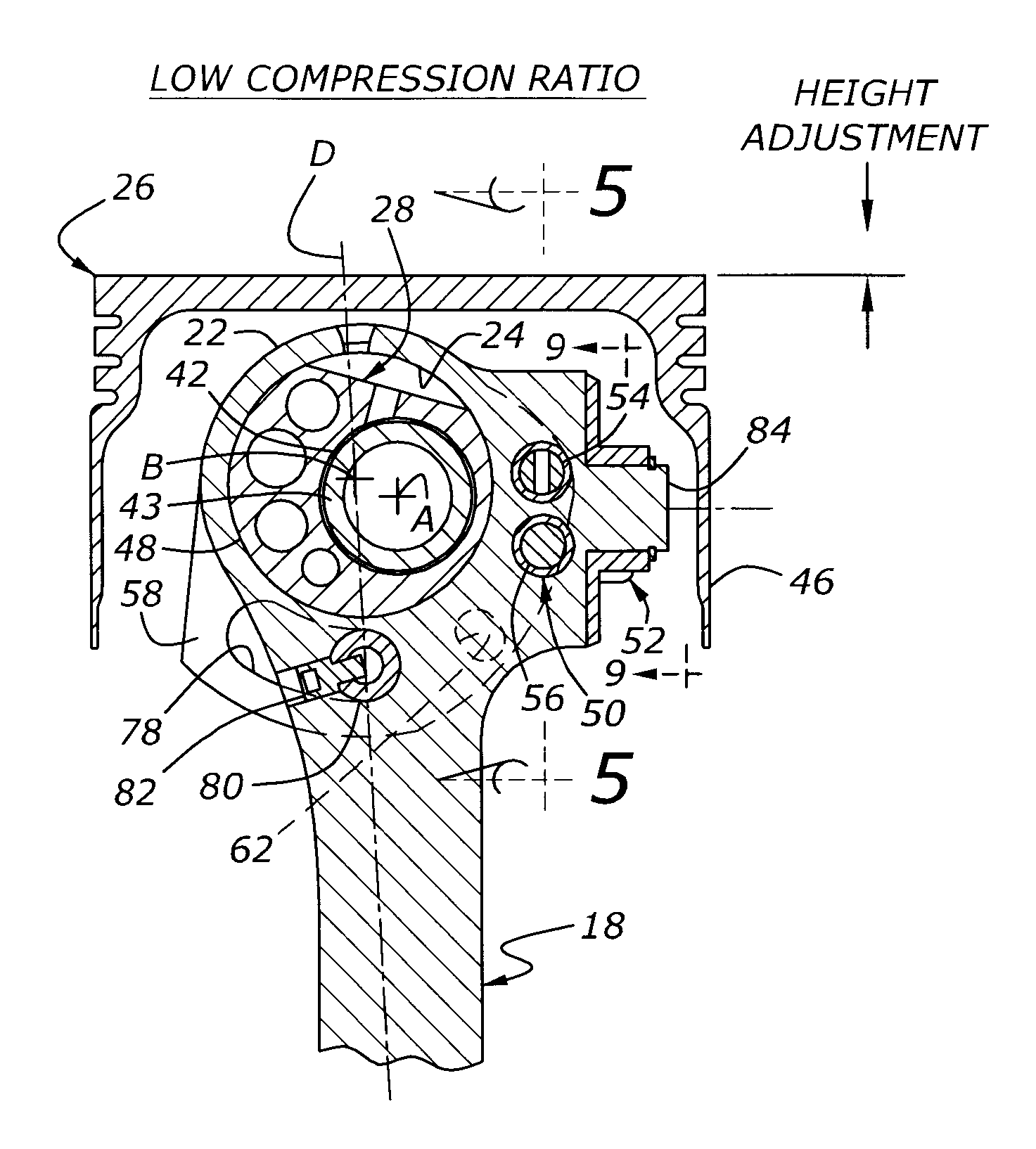

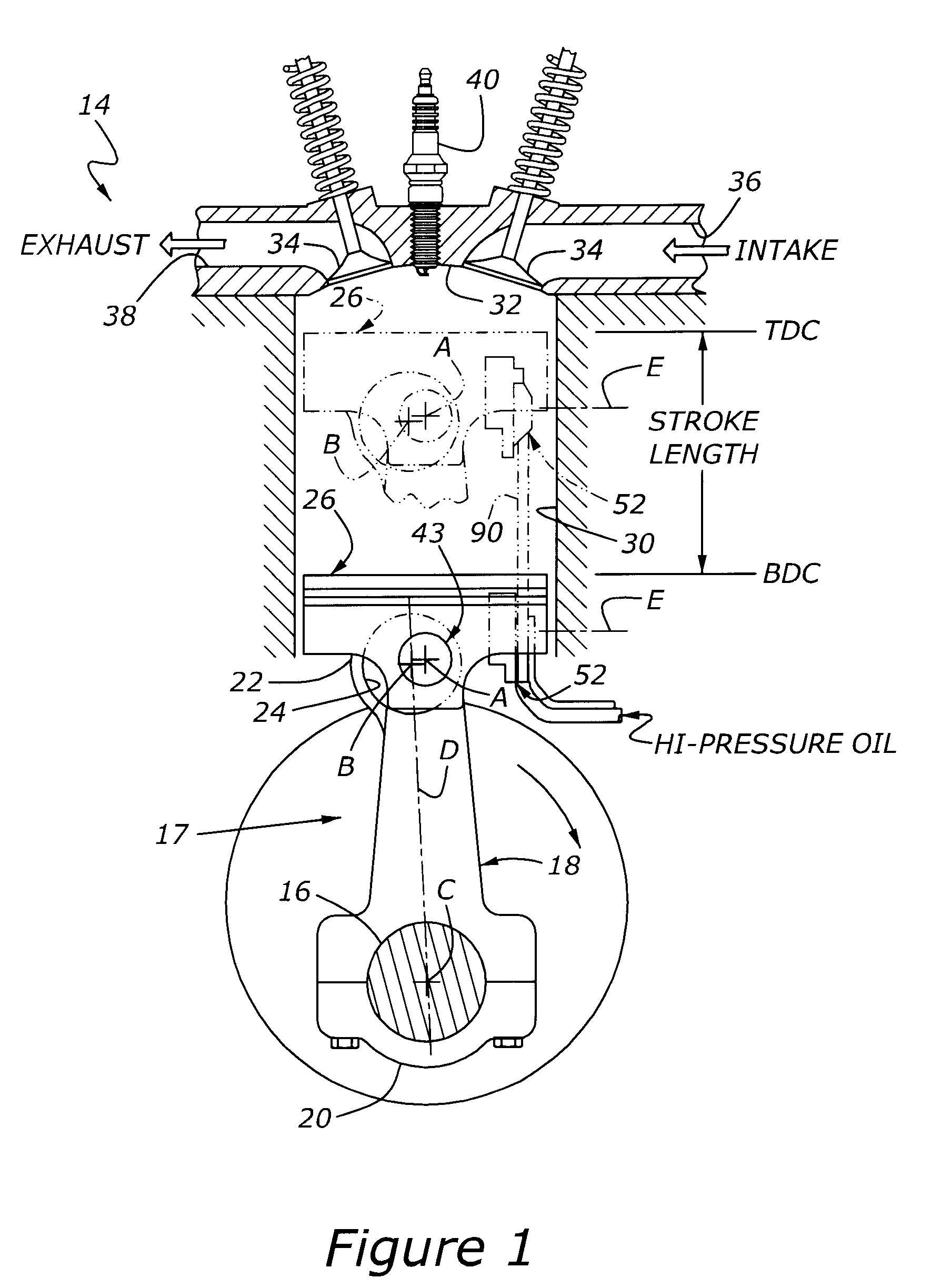

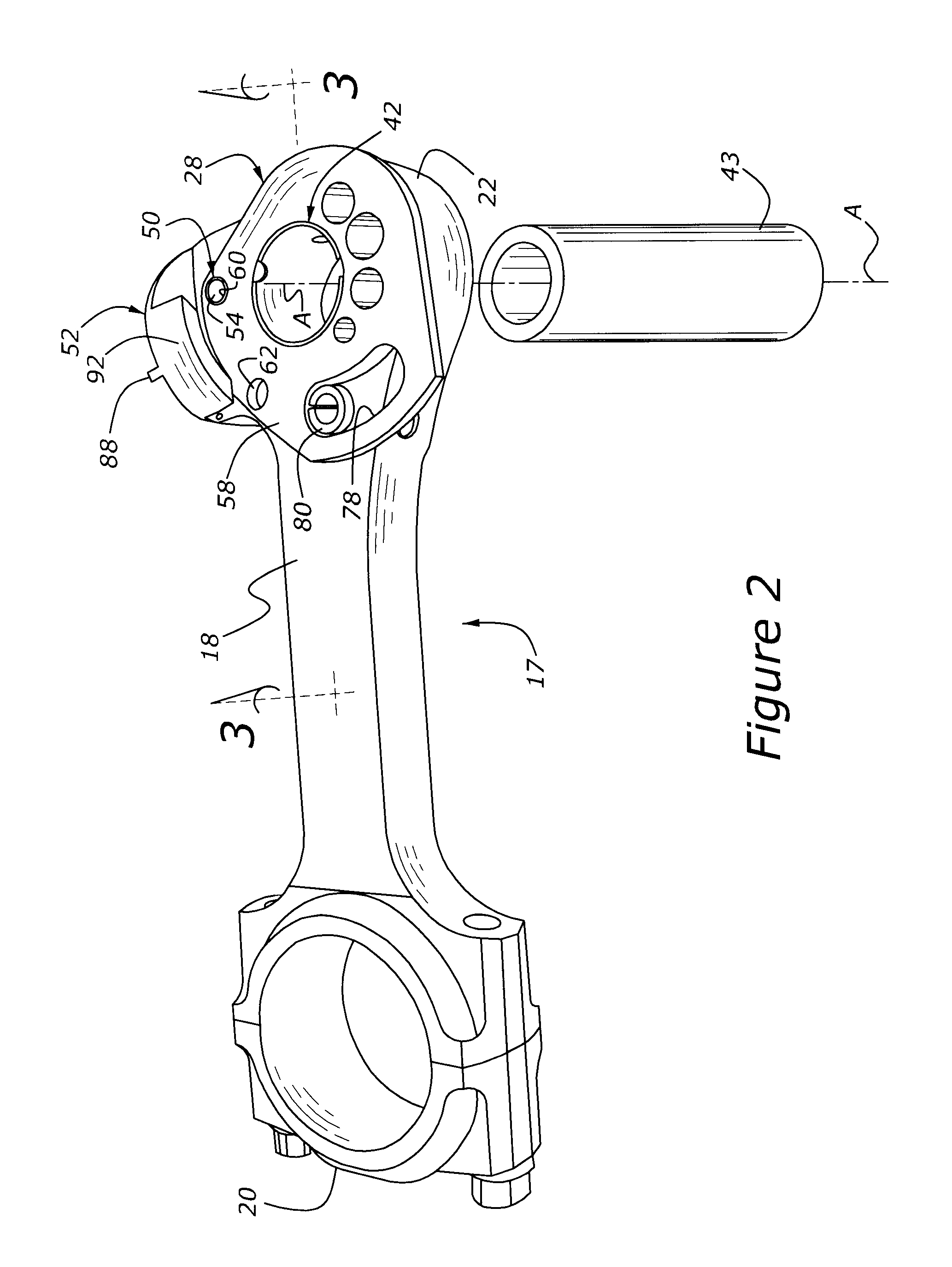

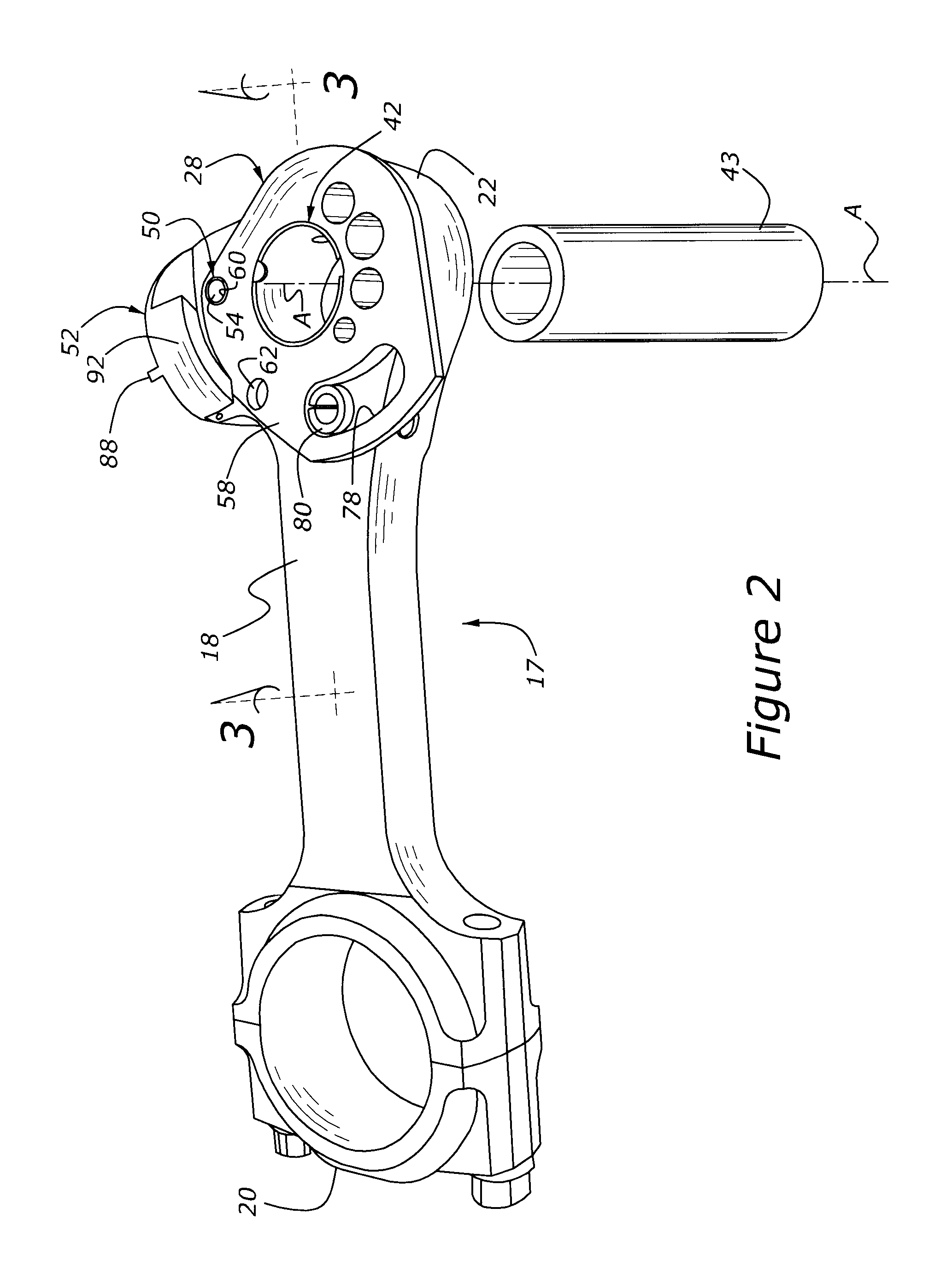

Variable compression ratio engine with isolated actuator

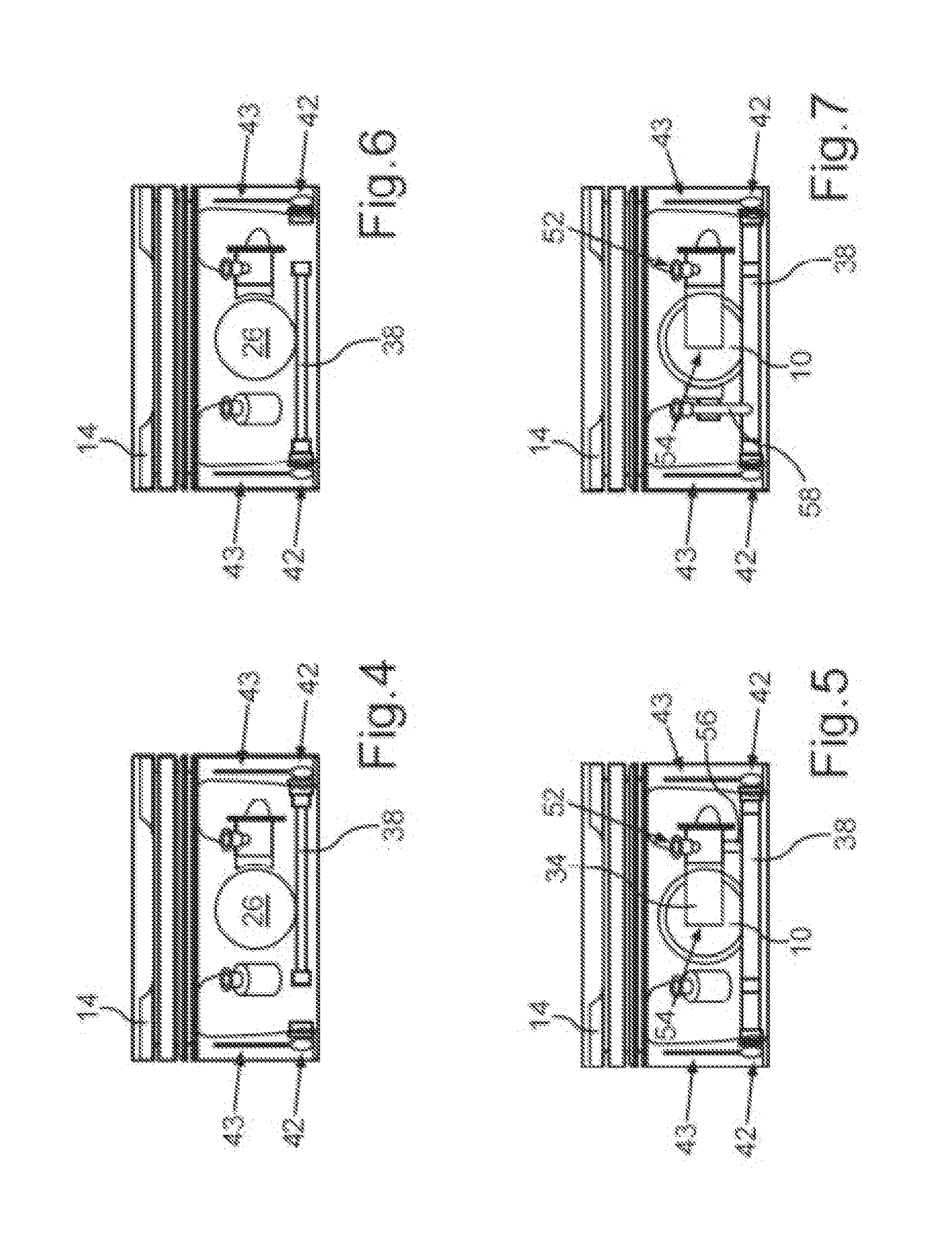

InactiveUS7685974B2Prevents unintended spatial displacementEffective compression ratioEngine controllersMachines/enginesEngineeringActuator

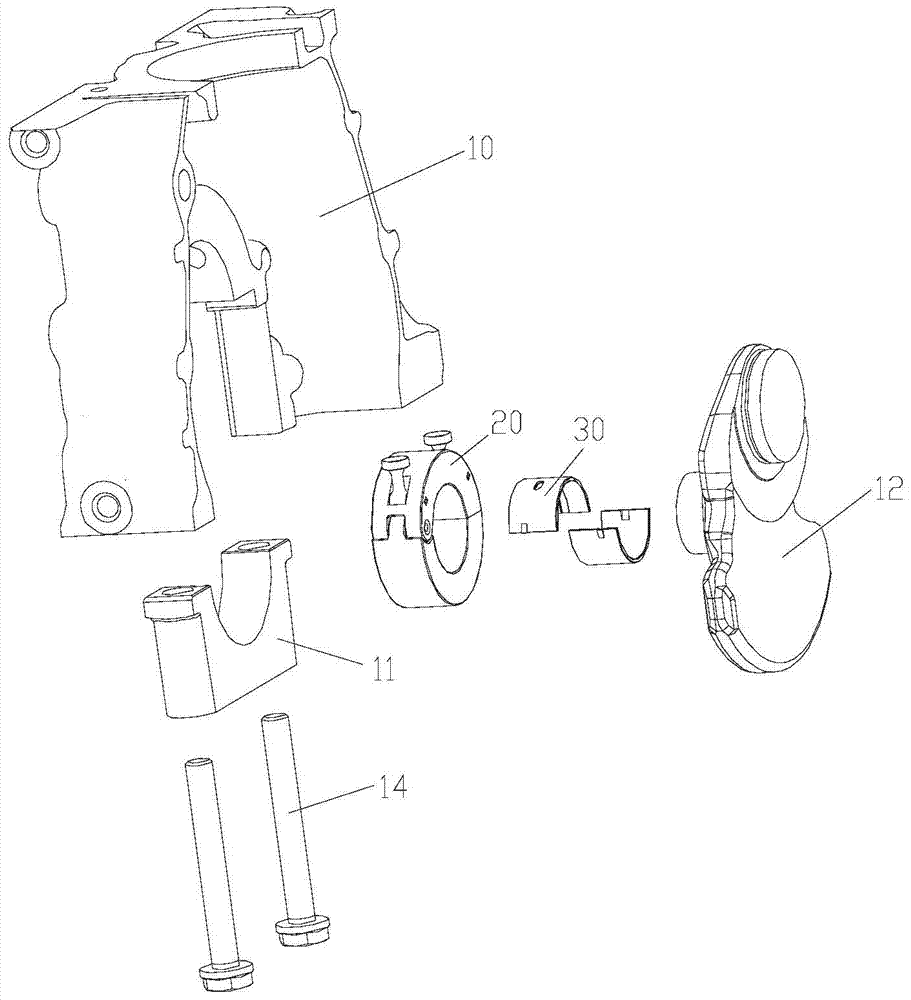

A variable compression ratio piston (26) and connecting rod (18) assembly for an internal combustion engine (14) includes an eccentric bushing (28) that carries a piston pin bushing (42) and contains a journaled portion (48) held in the rod bore (24) of the connecting rod (18). The eccentric bushing (28) can be selectively rotated between either of two angle adjusted positions to effect a change in the height of the piston (26) relative to the connecting rod (18), and thus change the compression ratio of the assembly. A latch (50) mechanism is actuated by oil jets (90, 91) external to the connecting rod (18). The latch (50) includes bolts (54, 56) with tapered tips that seat in oblong holes (60, 62) in a flange plate (58) to reduce destructive lash. A resilient stop post (80) bears the brunt of stresses associated with stopping the flange plate (58) during switching events to protect the latching bolts (54, 56).

Owner:FORD GLOBAL TECH LLC

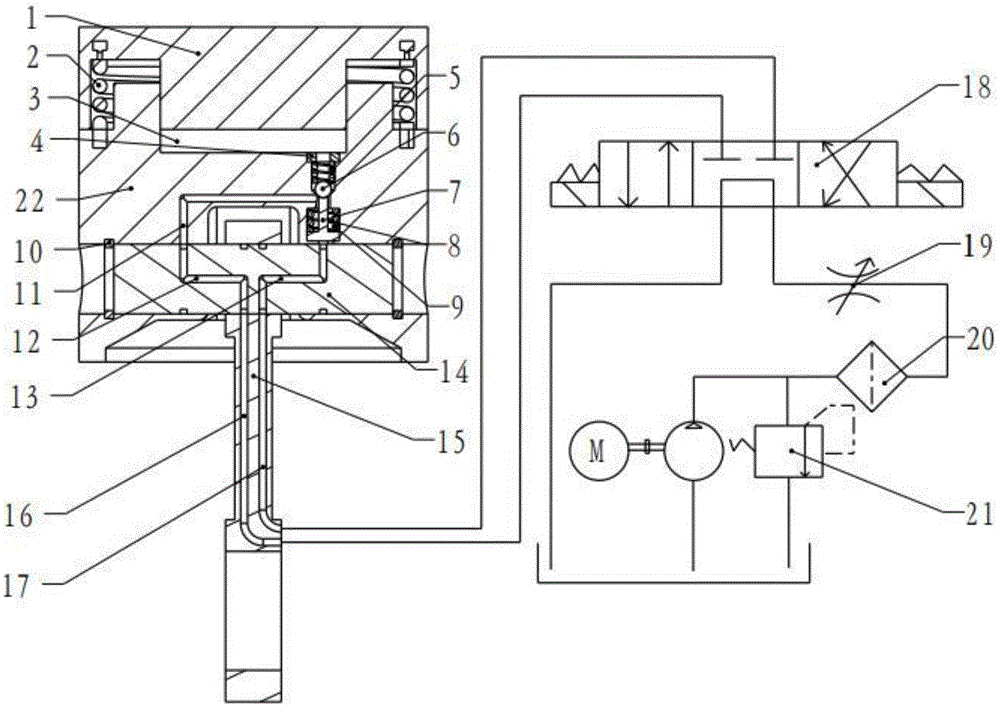

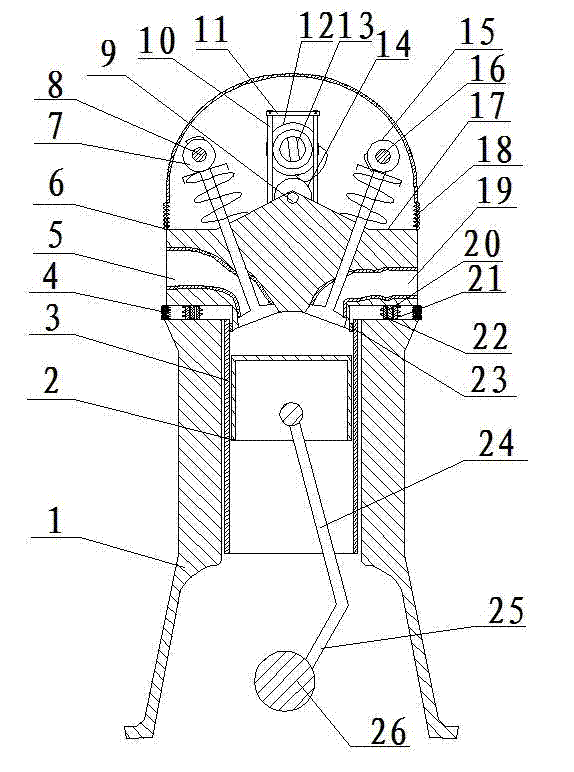

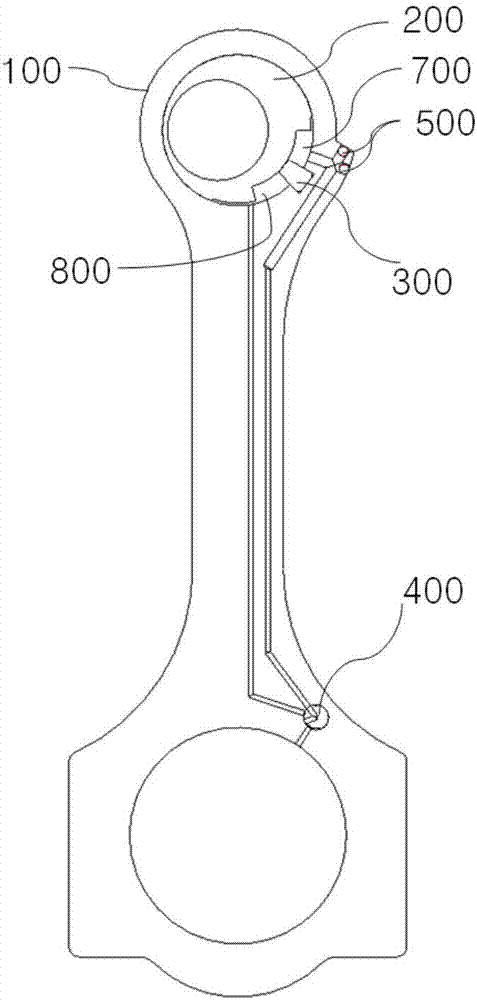

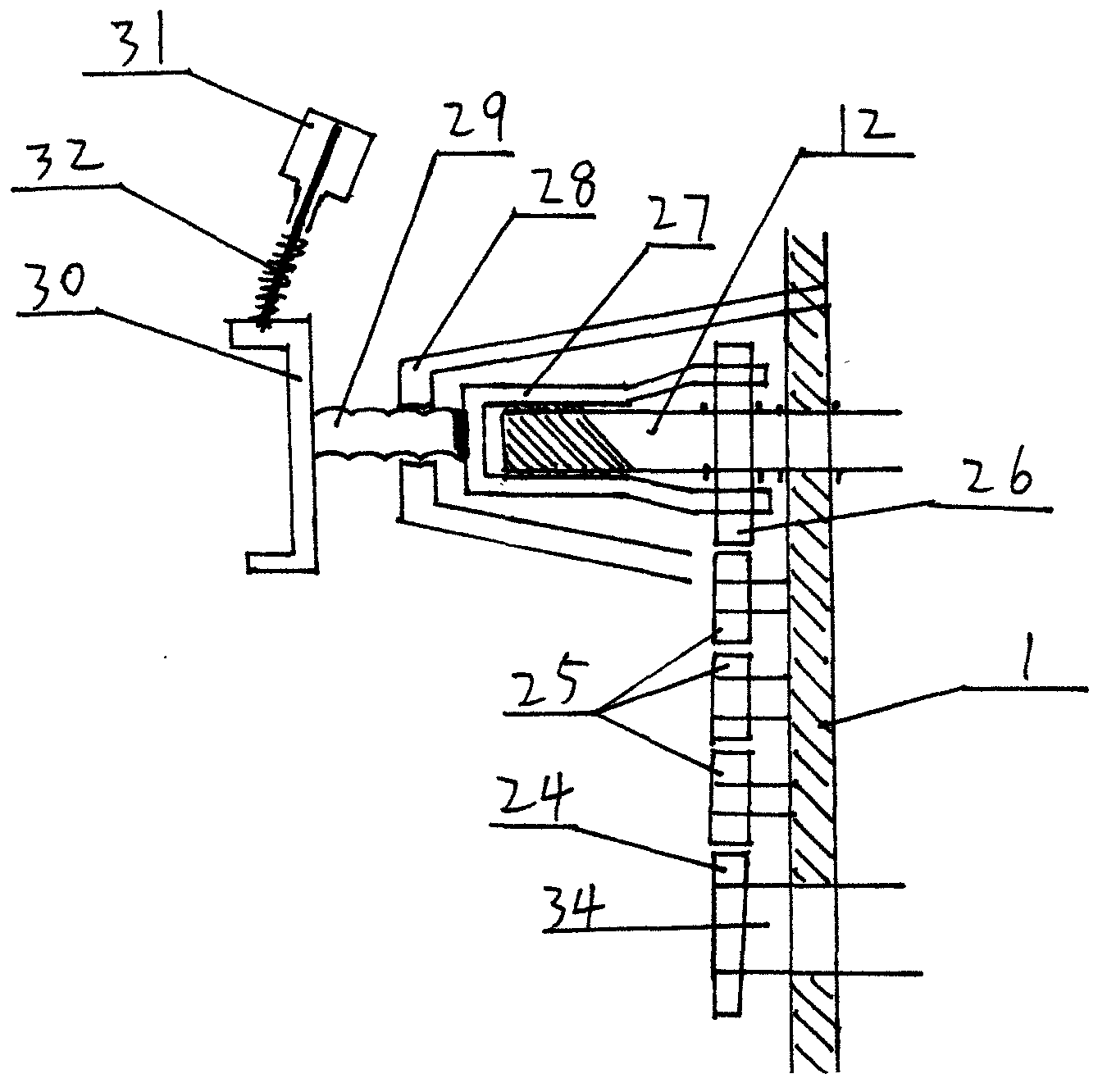

Hydraulic-drive type variable-compression-ratio piston connection rod assembly

InactiveCN105626258AChange the compression ratioWork reliablyMechanical controlConnecting rodsHydraulic pumpEngineering

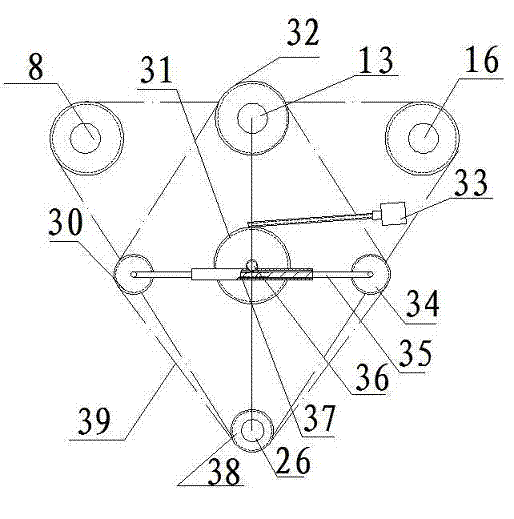

The invention discloses a hydraulic-drive type variable-compression-ratio piston connection rod assembly in order to solve the problems that in the prior art, a mechanism is complex, abrasion is large and control precision is low. The hydraulic-drive type variable-compression-ratio piston connection rod assembly comprises a piston, an extension spring, a piston pin, a connection rod, a three-position four-way electromagnetic valve, a hydraulic pump, a one-way valve and other hydraulic elements. Engine oil is pumped out by the hydraulic pump, after the direction of the engine oil is changed through the three-position four-way electromagnetic valve, the engine oil sequentially flows in an oil way of the connection rod and an oil way of the piston pin, and finally a push rod ejects a small ball in the one-way valve so that the size of a main oil cavity is reduced and the compression ratio of an engine is reduced. By means of the mode that the pressure of the engine oil in the oil way on the lower portion of the piston is increased and the small ball of the one-way valve is ejected, the size of the main oil cavity is increased, and accordingly the compression ratio of the engine is increased. The compression ratio piston uses a hydraulic mechanism mode, is quick in response, high in precision and high in reliability, and meets requirements of the engine for dynamic performance and fuel economy under various working conditions.

Owner:JILIN UNIV

Variable-compression-ratio mechanism of engine

InactiveCN102937052AGuaranteed safe operationVolume changeEngine controllersMachines/enginesHydraulic cylinderCombustion chamber

The invention relates to an engine assembly, and in particular relates to a variable-compression-ratio mechanism of an engine. The variable-compression-ratio mechanism comprises a cylinder cover, wherein a hydraulic cylinder communicated with a combustion chamber of the cylinder is arranged on the cylinder cover; and a variable-pressure piston which can slide in the hydraulic cylinder under drive of a hydraulic device is arranged in the hydraulic cylinder. The variable-pressure piston is driven to move in the hydraulic cylinder through the hydraulic device, and the volume of a part at which the hydraulic cylinder is communicated with the combustion chamber can be changed, so that the total size of the combustion chamber is changed, the aim of changing the compression ratio of the engine is fulfilled, and the structures of a crankshaft and a connecting rod are not required to be changed.

Owner:GREAT WALL MOTOR CO LTD

Engine with compression ratios variable

ActiveCN103114908AChange the compression ratioIncrease motivationInternal combustion piston enginesEngine controllersGear wheelCylinder head

Owner:范伟俊

Mechanical auxiliary homogeneous charge compression ignition control system for combustion engine

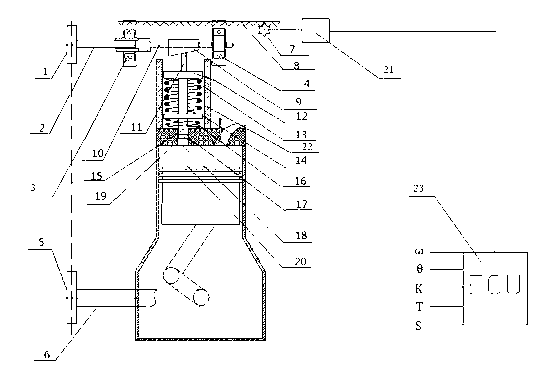

InactiveCN103256126AImprove reliabilityImprove efficiencyEngine controllersMachines/enginesCamControl system

The invention discloses a mechanical auxiliary homogeneous charge compression ignition control system for a combustion engine. The mechanical auxiliary homogeneous charge compression ignition control system for the combustion engine comprises a driven chain wheel, a driven chain wheel shaft, a first sliding bearing, a second sliding bearing, a driving chain wheel, a driving chain wheel shaft, a gear, a rack, a gradually-changed cam, a cam shaft, a transmission rod, a first disc, an energy storage spring, a second disc, a pressure rod, a return spring, an auxiliary cylinder piston, an auxiliary cylinder, a sensor used for measuring the displacement of the auxiliary cylinder piston, a motor and an electronic control unit. The mechanical auxiliary homogeneous charge compression ignition control system for the combustion engine achieves accurate control over ignition moments, can collect redundant energy, improves efficiency and facilitates saving energy.

Owner:ZHEJIANG UNIV

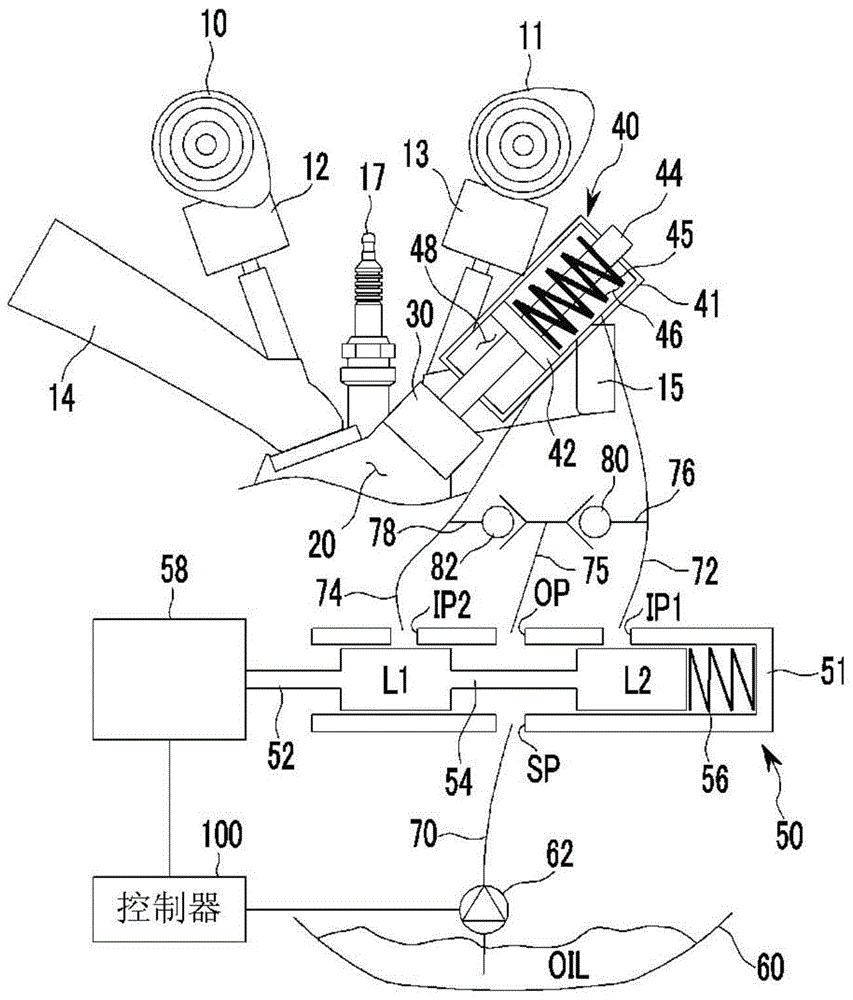

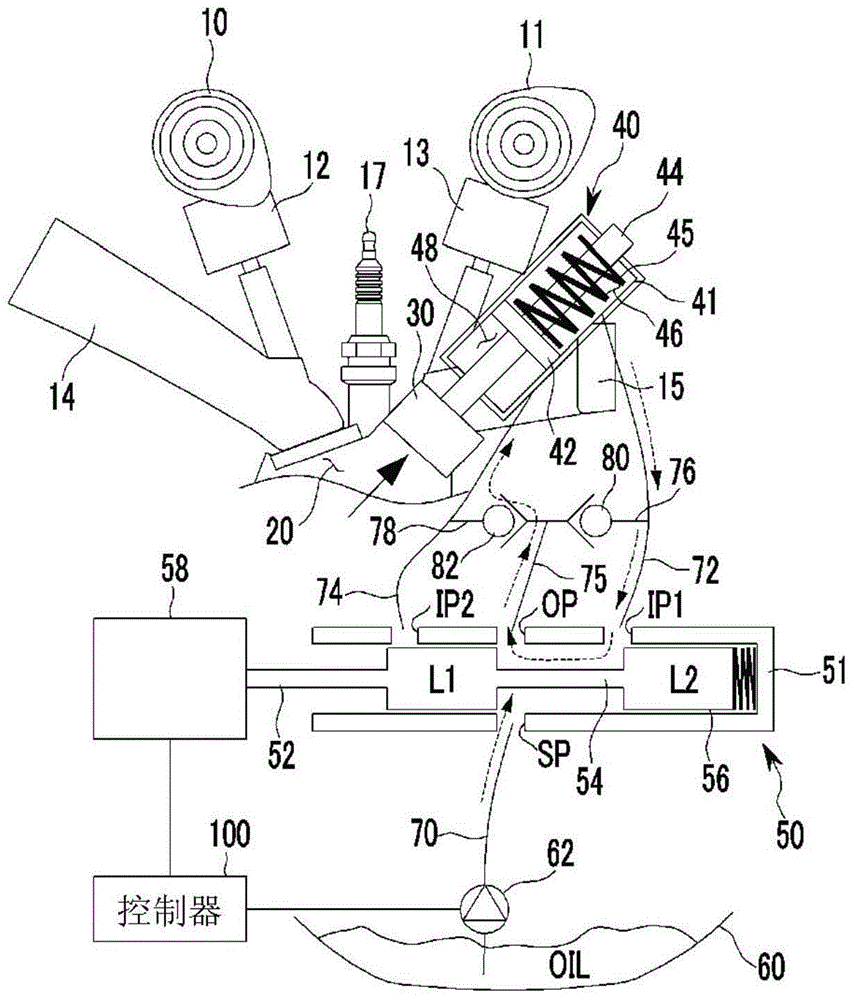

Engine With Variable Compression Ratio

InactiveUS20110107998A1Improve dynamic performanceImprove fuel economy performanceConnecting rodsInternal combustion piston enginesDisplacement controlEngineering

The present invention provides an engine with variable compression ration comprising a cylinder cover, a cylinder body, a power output shaft and a crankshaft box, the cylinder cover is fixed on the cylinder body, the crankshaft box is formed with the cylinder body integrally; In the cylinder body, an piston is connected with a crankshaft via a connecting rod; the power output shaft is mounted on the crankshaft box; a power output gear is placed on the power output shaft, an input gear is placed on a crank journal of the crankshaft, the power output gear engages with the input gear; A supporting arm is placed in the crankshaft box, the crankshaft is hinged on the supporting arm; one end of the supporting arm is hinged on the crankshaft box, and the hinging shaft is the power output shaft; the other end of the supporting arm is a control end, the control end is connected with a rotation control mechanism, which can make the supporting arm rotate around the power output shaft. Since the rotation control mechanism is used to make displacement control over the control end of the supporting arm, the compression ratio of engine matches the engine behavior, so that the efficiency is improved while the emission is reduced.

Owner:XIONG ZHIJIANG +1

Variable Compression Ratio Device

InactiveCN106870128AChange the compression ratioReduce consumptionRotary bearingsConnecting rod bearingsCombustionEngineering

A variable compression ratio device mounted to an engine, the engine rotating a crankshaft using a combustion force of a gas mixture and a piston, the variable compression ratio device changing a compression ratio of the mixture and including a connecting rod including a small end rotatably connected to the piston and a big end formed with a circular hole to be eccentrically rotatably connected to the crankshaft, a crank pin provided in the crankshaft, an eccentric cam provided to be concentrically rotatable in the hole of the big end and having a crank pin mounting hole eccentrically inserted with the crank pin to be rotatably connected, and a cam rotation unit provided inside the eccentric cam and rotating the eccentric cam in a clockwise or counterclockwise direction in a hole of the big end by a selectively supplied hydraulic pressure.

Owner:HYUNDAI MOTOR CO LTD

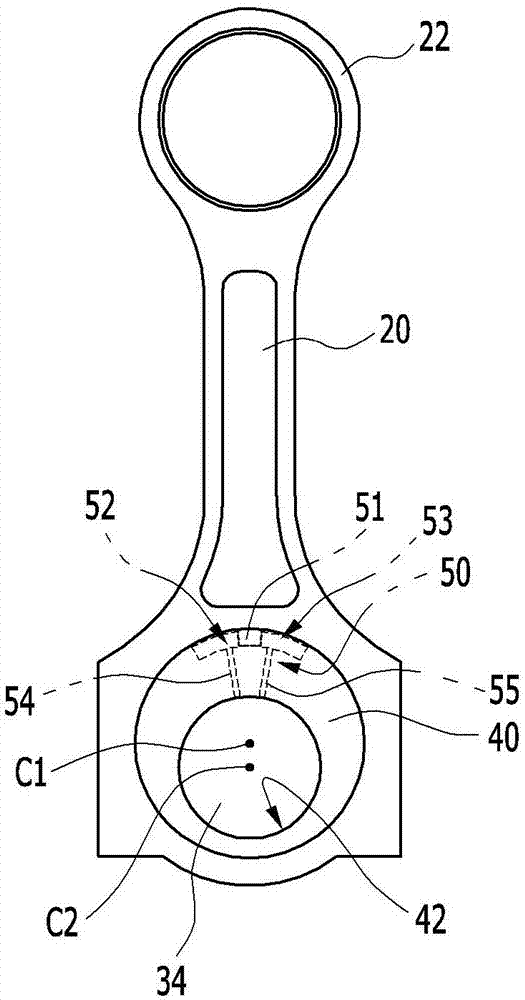

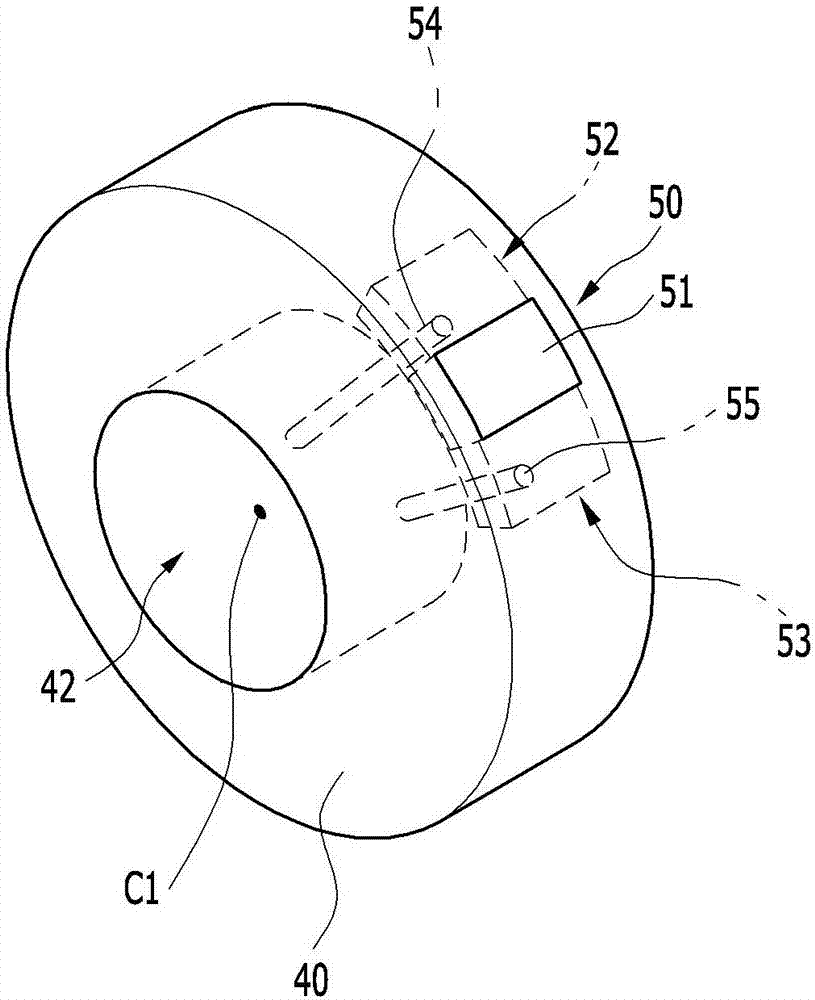

Variable compression ratio engine with isolated actuator

InactiveUS20090107464A1Effective compression ratioPrevents unintended spatial displacementEngine controllersMachines/enginesEngineeringActuator

A variable compression ratio piston (26) and connecting rod (18) assembly for an internal combustion engine (14) includes an eccentric bushing (28) that carries a piston pin bushing (42) and contains a journaled portion (48) held in the rod bore (24) of the connecting rod (18). The eccentric bushing (28) can be selectively rotated between either of two angle adjusted positions to effect a change in the height of the piston (26) relative to the connecting rod (18), and thus change the compression ratio of the assembly. A latch (50) mechanism is actuated by oil jets (90, 91) external to the connecting rod (18). The latch (50) includes bolts (54, 56) with tapered tips that seat in oblong holes (60, 62) in a flange plate (58) to reduce destructive lash. A resilient stop post (80) bears the brunt of stresses associated with stopping the flange plate (58) during switching events to protect the latching bolts (54, 56).

Owner:FORD GLOBAL TECH LLC

Internal combustion engine with variable compression ratio

InactiveCN101421498AGuaranteed positioningImprove cooling effectEngine controllersReciprocating piston enginesCombustionReciprocating motion

The invention concerns a combustion engine, comprising at least one cylinder with in it two oppositely directed reciprocating pistons, which are each connected via a piston rod with a corresponding arm, whereby each arm shows an opening in which a main shaft that connects the two arms is rotatably supported in bearings, which main shaft includes an angle with a centre line of each opening, and means for varying the compression ratio in the cylinder, which compression ratio variation means comprise a division in the main shaft, as well as drive means in order to move the parts formed by it of the main shaft apart from each other. The combustion engine can be provided with at least one spark plug, which protrudes through the bottom of one of the pistons. The combustion engine can also be provided with means for the metering to the cylinder of a supply of air or a fuel / air mixture, which supply means comprise a rotatable metering device along at least one supply opening, connected with the main shaft, which shows at least one metering opening, which can be brought into governing with the supply opening via rotation of the metering device.

Owner:VALCON MOTOR COMPANY

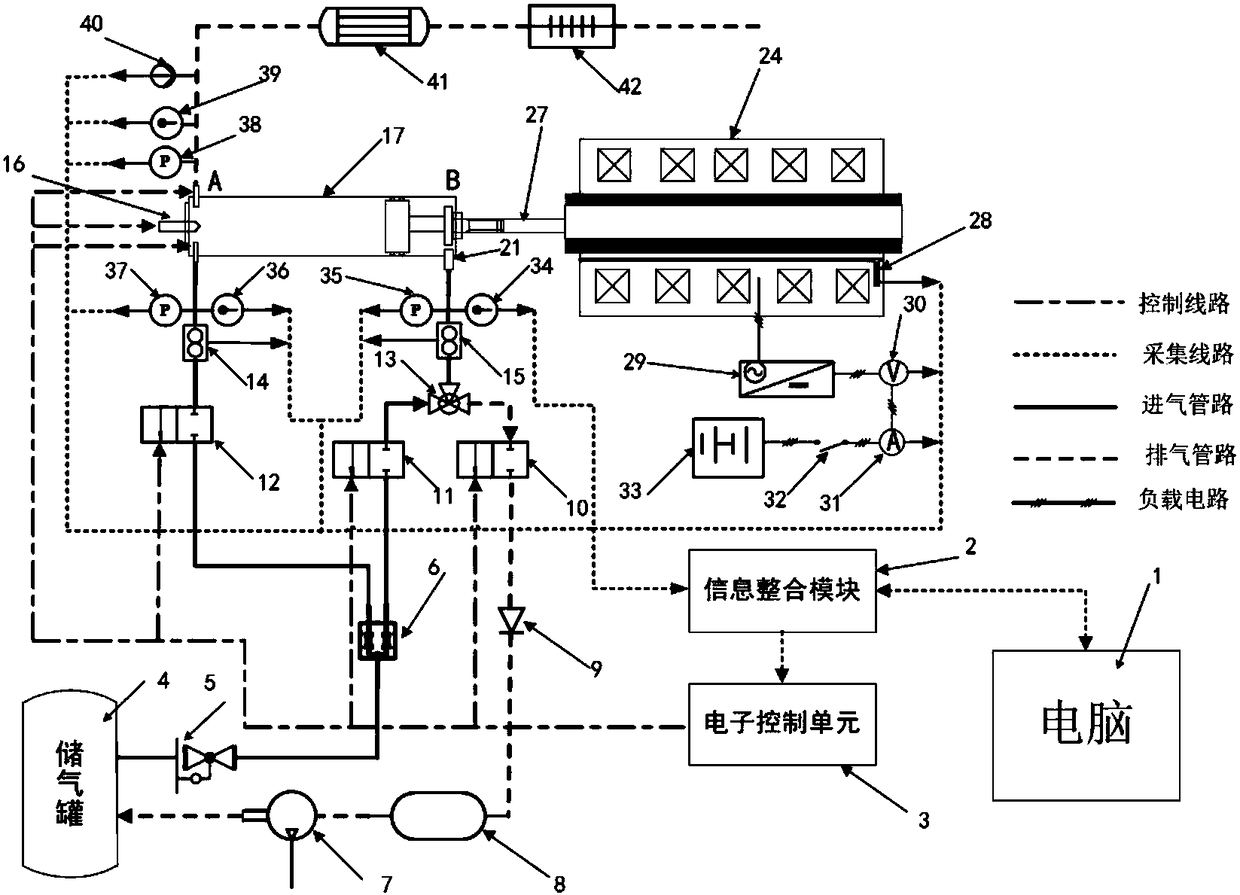

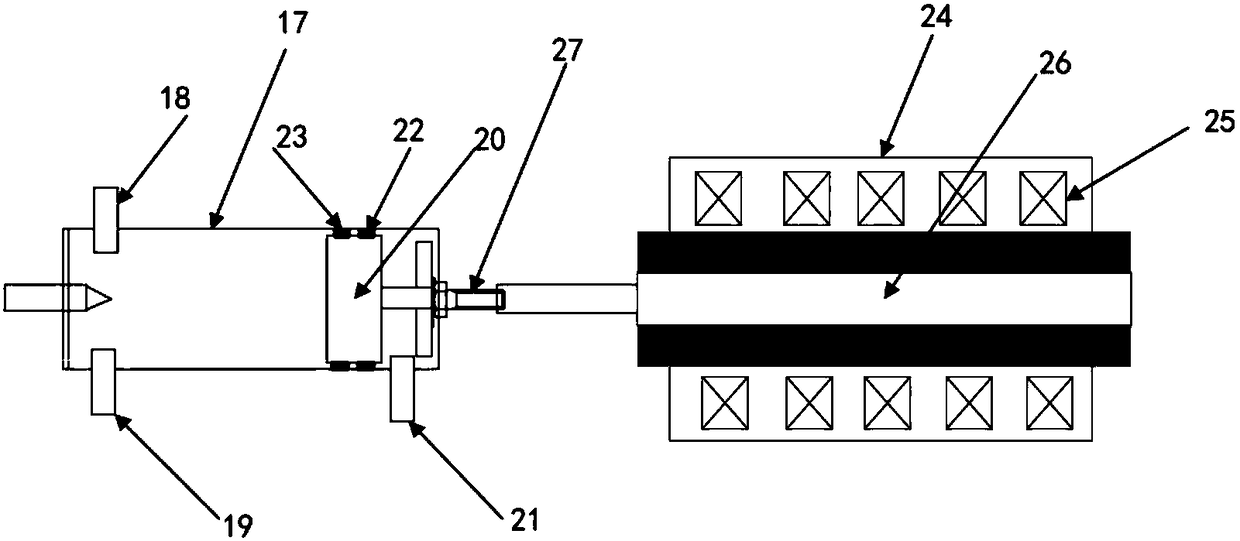

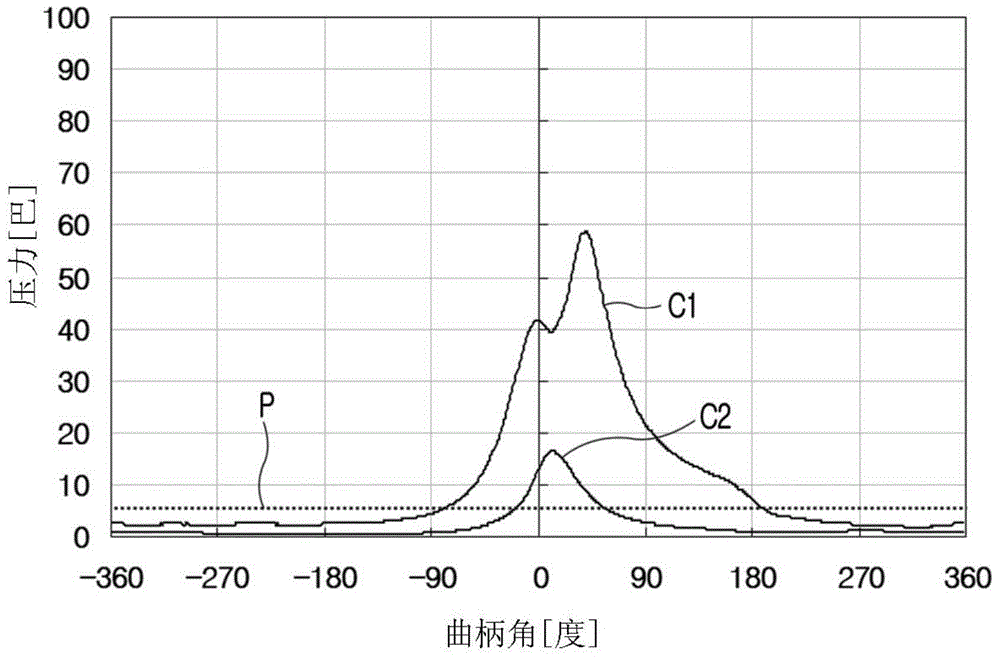

Integrated testing and control system of internal combustion type free piston linear power generator with piston travel-controllable effect

ActiveCN108374718AReduce lossesImprove conversion efficiencyInternal combustion piston enginesEngine controllersCombustionControl system

The invention relates to an integrated testing and control system of an internal combustion type free piston linear power generator with piston travel-controllable effect, and belongs to the field ofenergy power machinery. The integrated testing and control system is characterized in that a single piston, a free piston air cylinder with double functions, and a permanent magnet type linear power generator are coupled; the piston is pushed to do reciprocating movement by the energy released by combustion of combustible mixed gas at the left side of an air cylinder, and the high-pressure mixed gas inputted at the right side of the air cylinder, a rotor of the linear power generator is driven to repeatedly cut magnetic induction lines, and then the energy carried by the combustible mixed gasis converted into electric energy to be outputted; under different running working conditions, the air intake time t at the side A of the air cylinder, and the special displacement points A1 and B1 and preset combustion ratio displacement point X at both ends can be freely changed by a collection control system, so as to change the air intake amount, piston travel and compression ratio of the device, thereby meeting the requirements under different working conditions.

Owner:BEIJING UNIV OF TECH

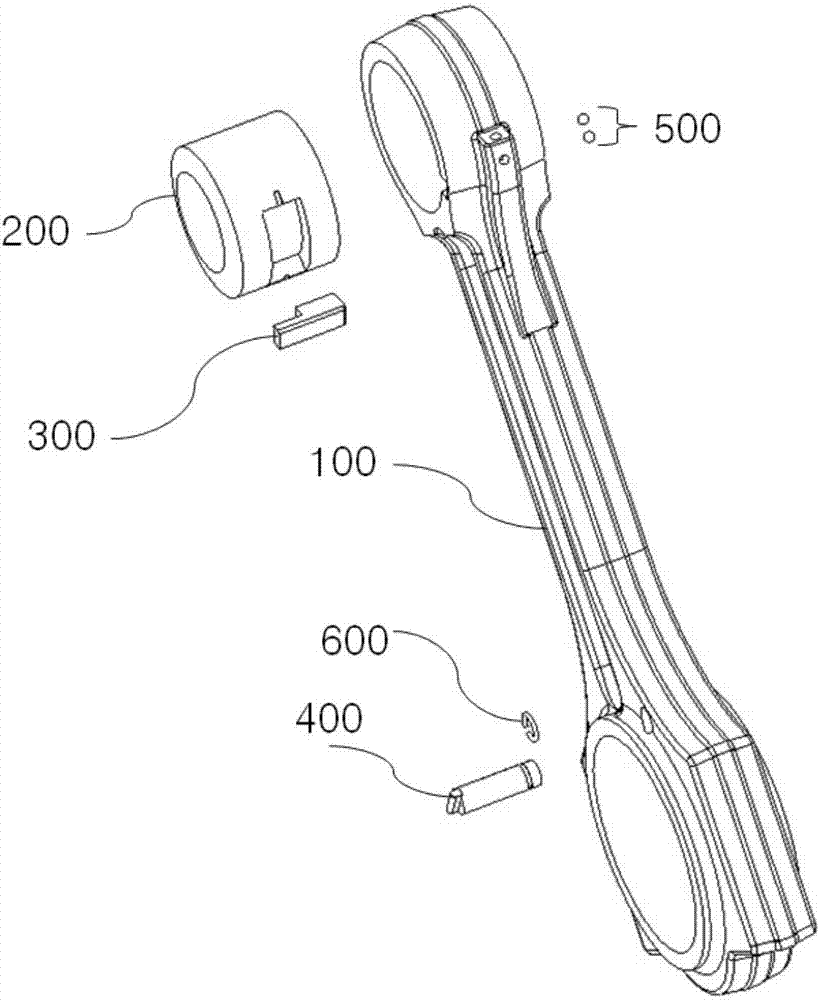

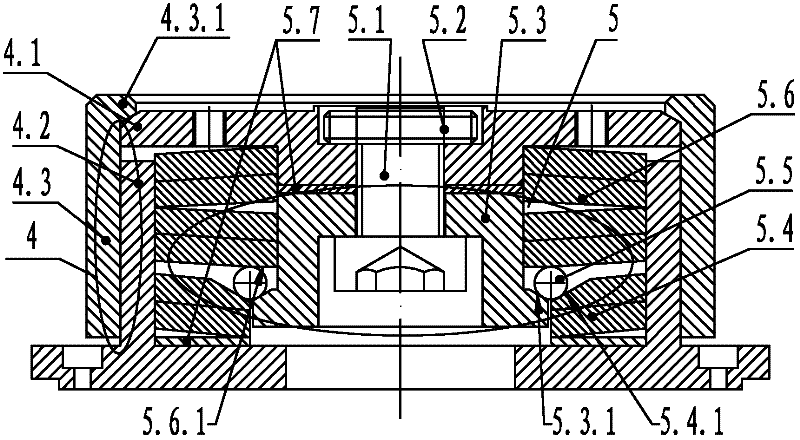

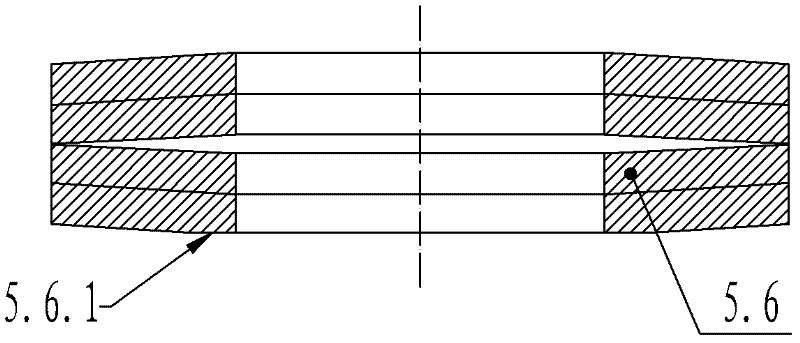

Length variable connecting rod

ActiveCN107529584AChange the compression ratioImprove reliabilityConnecting rodsMachines/enginesProduction modelEffective length

The invention discloses a length variable connecting rod which comprises a connecting rod main body, an eccentric part, a limiting component and a valve core. According to the connecting rod disclosedby the invention, an effective length of the connecting rod can be controllable and variable, so that the compression ratio of a gasoline engine is changed, the thermal efficiency of partial load ofthe gasoline engine can be improved, engine knocking during full load can be avoided, and the reliability and economical efficiency of the engine are effectively improved. The length variable connecting rod disclosed by the invention is simple and reliable in structure, small in size, low in cost and excellent in applicability of the existing volume production models. The length variable connecting rod disclosed by the invention is also applicable to a diesel engine.

Owner:CHINA FIRST AUTOMOBILE

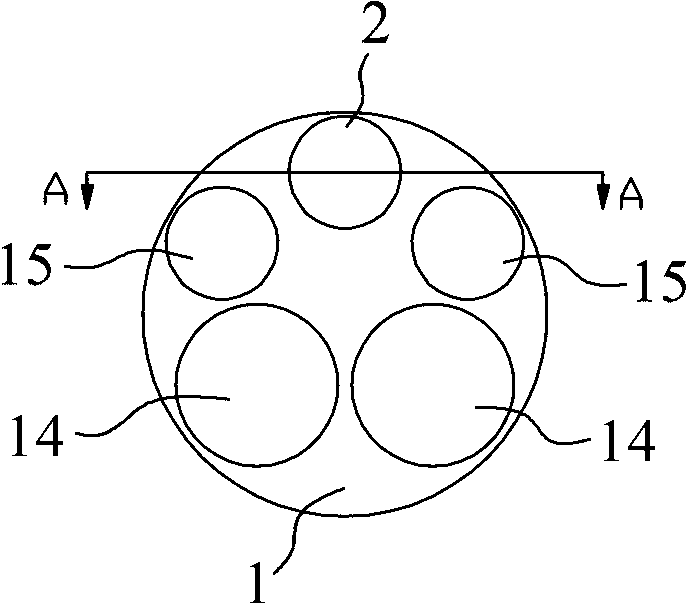

Hydraulic motor driving variable compression ratio piston

InactiveCN106481477ASimple structureCompact structureMechanical controlMachines/enginesHydraulic motorControl theory

The invention discloses a hydraulic motor driving variable compression ratio piston. The hydraulic motor driving variable compression ratio piston comprises a piston top, a piston skirt, a hydraulic motor mechanism, a rotating wheel, a speed reducing mechanism and an access port oil way; the piston top and the piston skirt respectively have cavities; the hydraulic motor mechanism is put in the cavity of the piston skirt; the rotating wheel is positioned in the piston top; four laps of spiral plates on the rotating wheel are matched with four spiral projections of the piston top; the contact part between the hydraulic motor and the rotating wheel is the speed reducing mechanism consisting of a driving gear, a planet gear and an inner gear; the hydraulic motor mainly consists of a hydraulic base, a hydraulic blade, a hydraulic baffle plate, a sealing spring and an elliptic cavity of the piston skirt; pressure oil enters the elliptic oil cavity from an oil inlet way, so that the hydraulic blade rotates to drive rotation of the rotating wheel; and under the effect of a guide rod, the piston top moves corresponding to the piston skirt to change an engine compression ratio.

Owner:JILIN UNIV

Variable compression ratio apparatus

ActiveCN104595042AChange the compression ratioEngine controllersMachines/enginesEngineeringControl valves

Owner:HYUNDAI MOTOR CO LTD

Independent compression and expansion ratio engine with variable compression ratio

InactiveCN107237690AVary the compression stroke lengthCompression stroke length change or adjustmentEngine controllersMachines/enginesInternal combustion engineControl theory

An internal combustion engine includes a crankshaft rotatably supported by an engine block, and rotatable about a crank axis. A control shaft is rotatably supported by the engine block, and rotatable about a control axis. A link rod is rotatably connected to the crankshaft. A lower connecting rod includes a first end rotatably connected to the link rod, and a second end rotatably connected to the control shaft. An upper connecting rod is rotatably connected to the link rod and a piston. The second end of the lower connecting rod and the control shaft are rotatably connected at a location offset from the control axis to define an eccentric connection relative to the control axis. Rotation of the control shaft about the control axis rotates the second end of the lower connecting rod about the control axis to adjust a compression stroke length of the piston.

Owner:GM GLOBAL TECH OPERATIONS LLC

Variable-compression-ratio structure of engine and engine

InactiveCN104847506AChange positionChange the compression ratioEngine controllersMachines/enginesTop dead centerCrankcase

The invention discloses a variable-compression-ratio structure of an engine. The variable-compression-ratio structure of the engine comprises a crank shaft case, a crank shaft installed in the crank shaft case through a main bearing seat, an eccentric adjustment ring and a driving mechanism, wherein the eccentric adjustment ring is installed on a spindle neck of the crank shaft in a sleeving mode and installed in the main bearing seat, the driving mechanism is used for driving the eccentric adjustment ring to rotate in the main bearing seat so as to change the position of the crank shaft in the crank shaft case. The invention further discloses the engine. The engine comprises the variable-compression-ratio structure. In the variable-compression-ratio structure, the position of the crank shaft in the crank shaft case is changed through the eccentric adjustment ring, accordingly the position of a top dead center of a piston and the compression ratio of the engine can be changed, and the variable-compression-ratio structure is simple and easy to achieve.

Owner:BEIQI FOTON MOTOR CO LTD

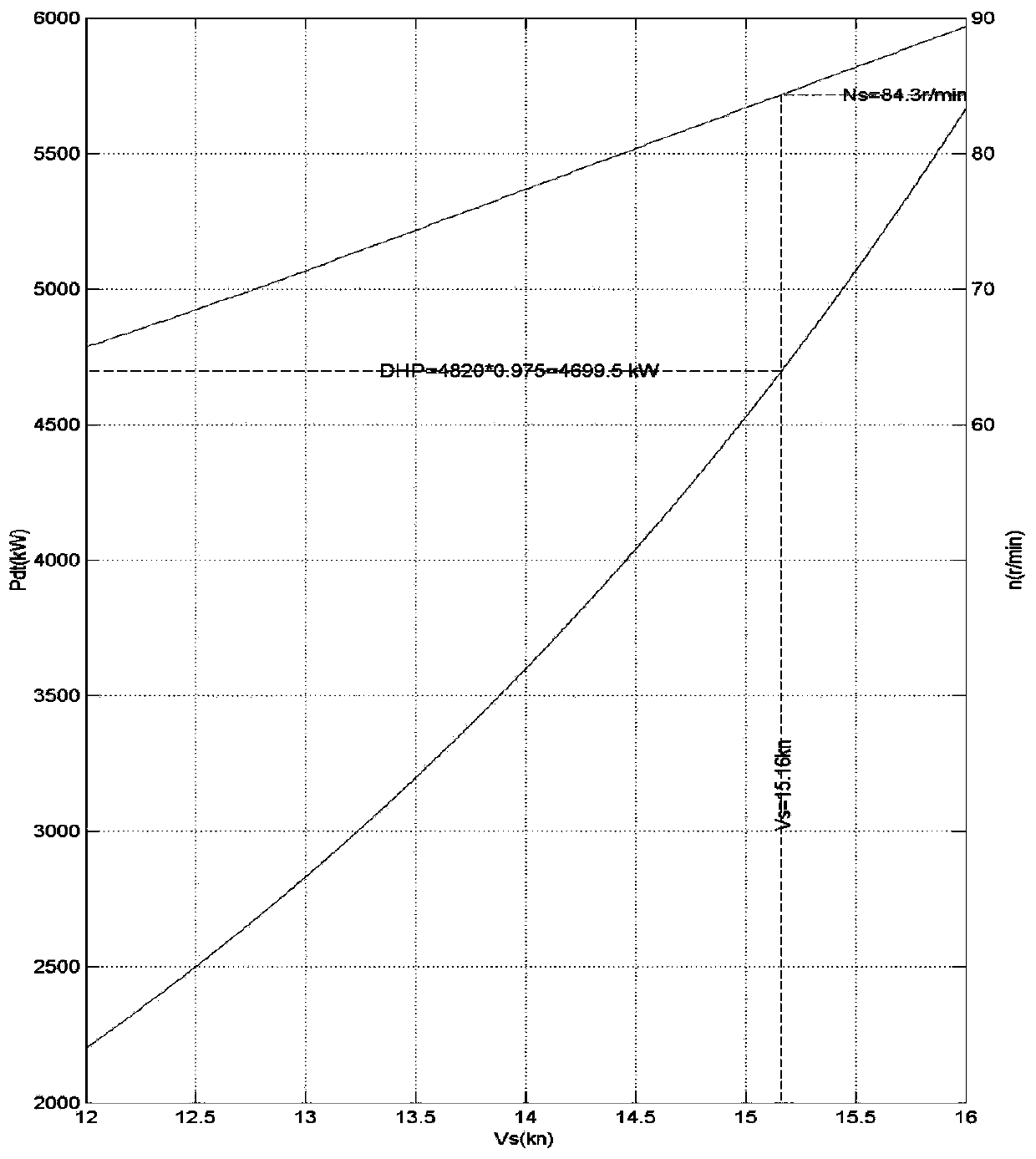

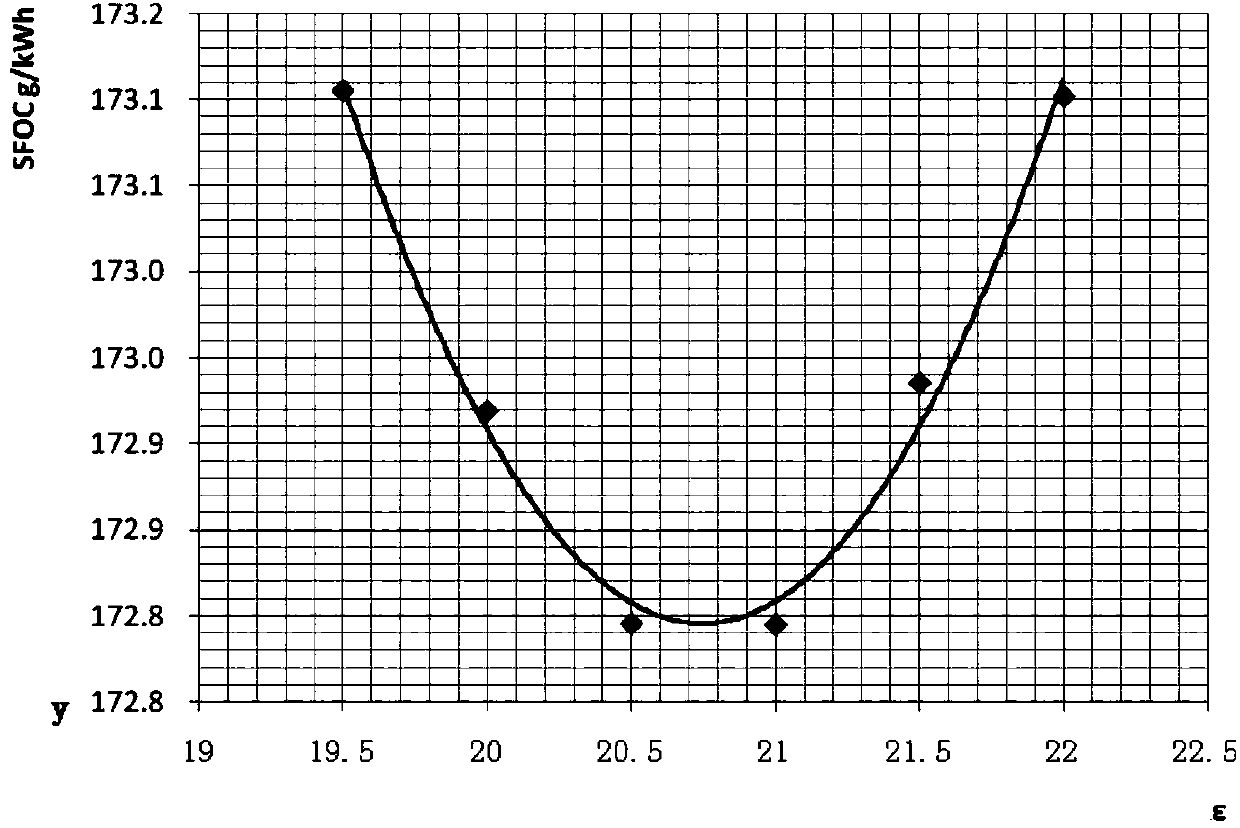

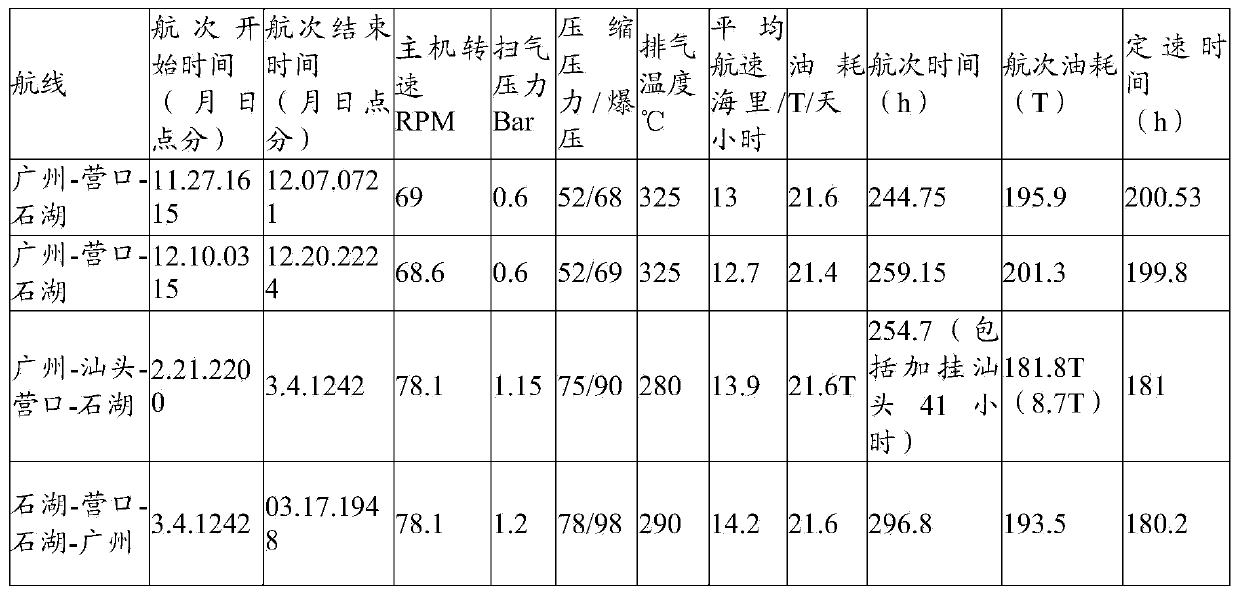

Compression ratio adjustment method for diesel main engine of ship propulsion system

ActiveCN104260867AChange the compression ratioIncreasing the thicknessPower plants being motor-drivenCombustionDiesel engine

The invention discloses a compression ratio adjustment method for a diesel main engine of a ship propulsion system. The thickness of an adjusting washer between a piston rod of a cylinder and a cross head of the diesel main engine is adjusted, and the compression ratio of the diesel main engine can be changed. According to the compression ratio adjustment method for the diesel main engine of the ship propulsion system, the thickness of the adjusting washer between the piston rod and the cross head is changed, related movement traces are not changed or affected as compared with change of the washer at a large head end of a connecting rod, complicated movement traces do not need to be checked, the compression ratio of the diesel main engine can be changed at low cost and matched with a supercharger of a ship, the combustion condition of diesel is improved, and unit oil consumption of the diesel main engine is reduced, so that energy is saved and emission is reduced.

Owner:QUANZHOU AN SHENG SHIPPING

Radial extruding machine

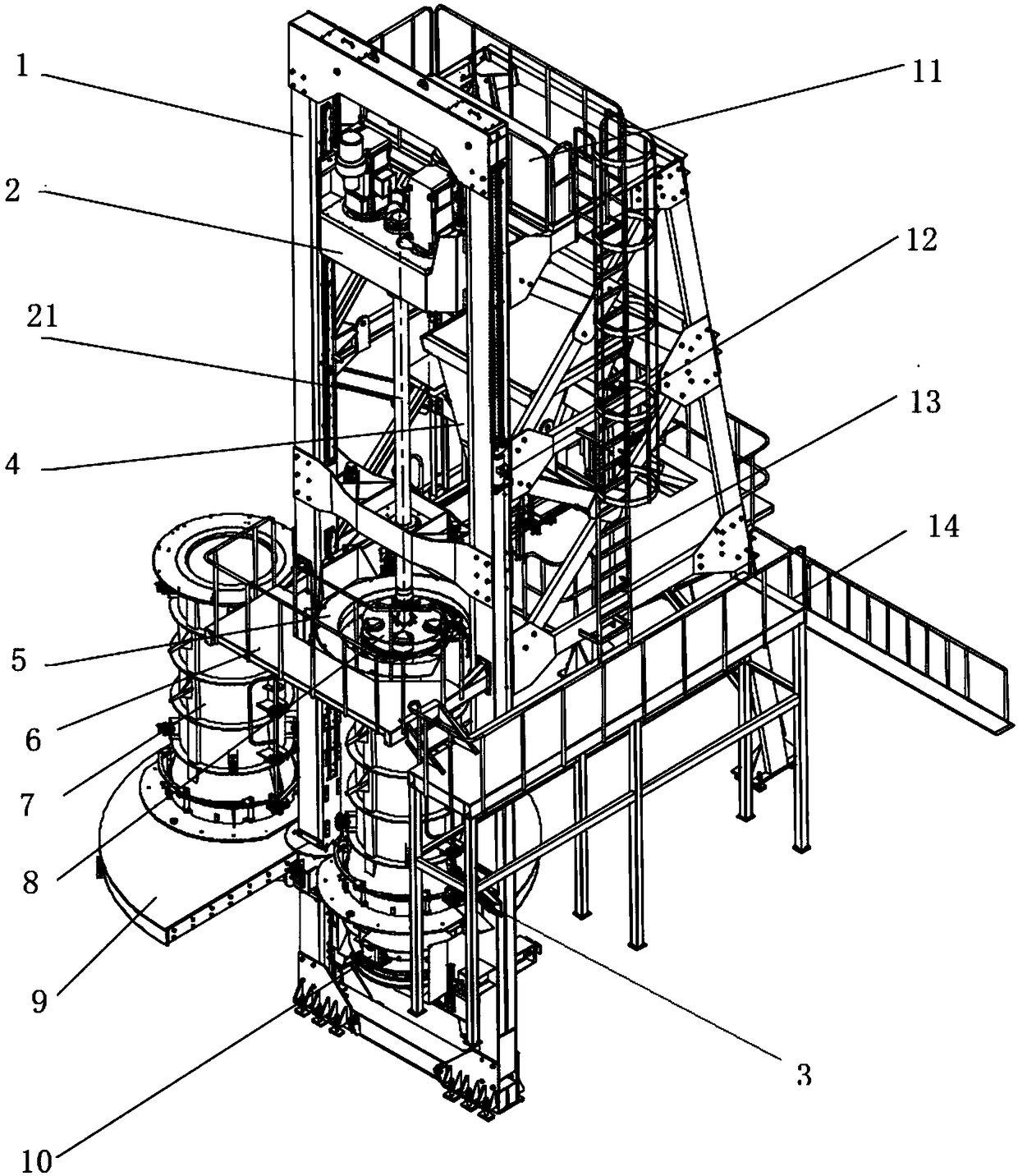

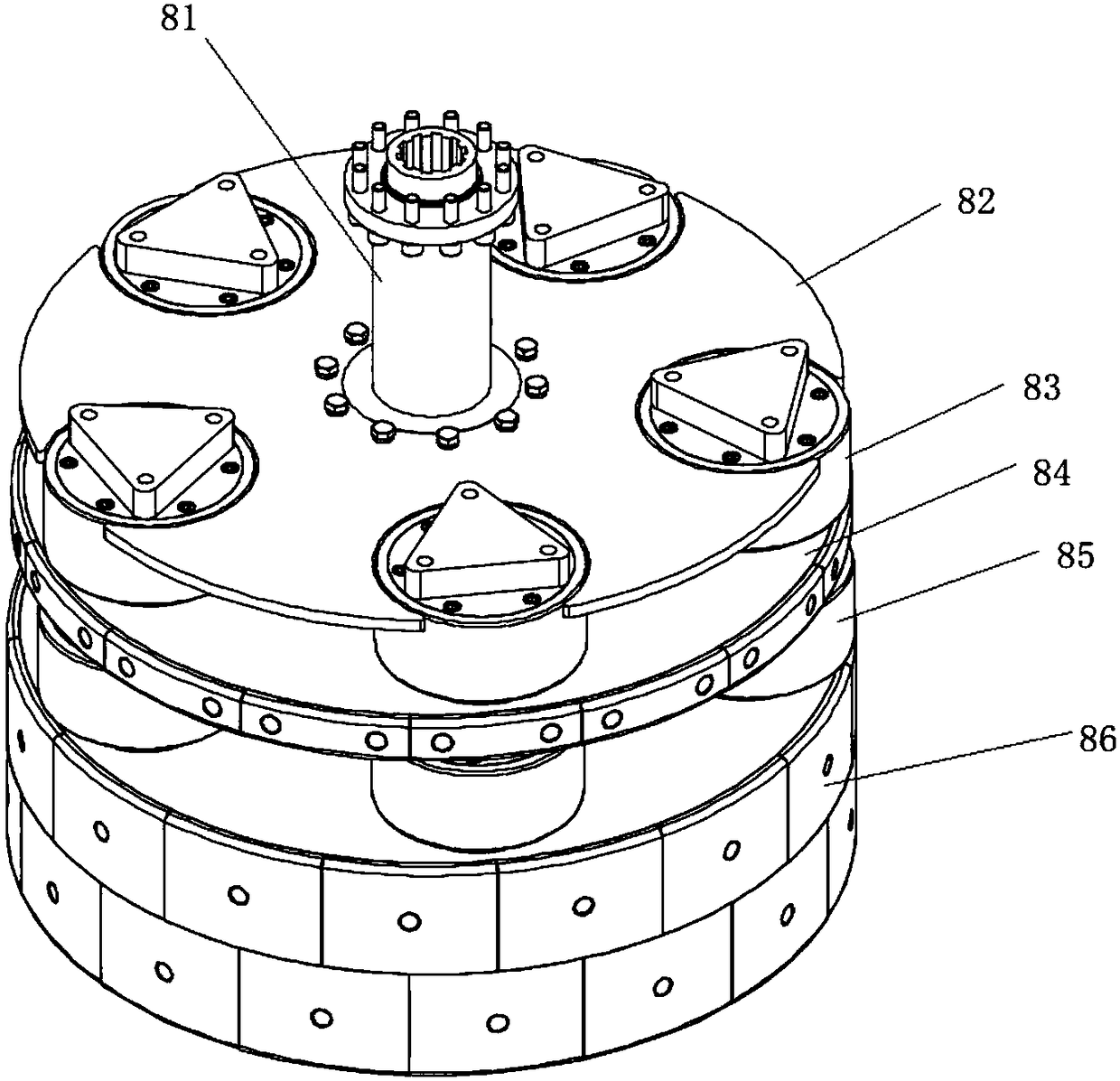

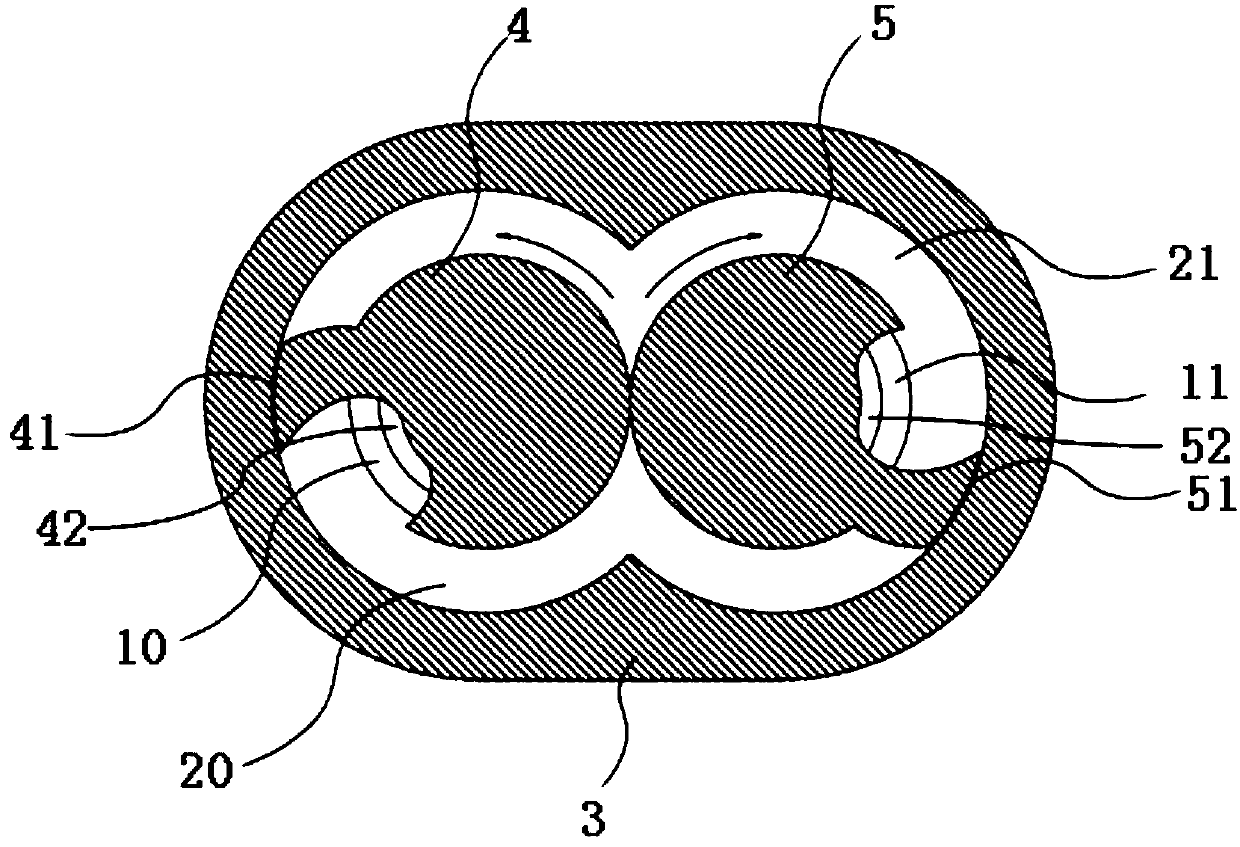

PendingCN108189216AUniform extrusionChange the compression ratioCeramic shaping apparatusEngineeringMechanical engineering

The invention relates to a radial extruding machine. The radial extruding machine comprises a frame (1), a power box (2), an air supply device (3), a feeding device (4), an insertion port forming device (5), a mold (7), an extruding head (8), a rotary chassis (9), a vibration device (10) and an oil cylinder (12). The extruding head (8) is internally provided with a plurality of upper extruding head bodies and lower extruding head bodies, wherein the upper extruding head bodies rotate coaxially, and the lower extruding head bodies do not rotate coaxially; and thus, by adjusting the eccentricity, the compression rate of pipe making concrete can be changed, so that the better extruding effect is achieved.

Owner:江苏威姿曼机械有限公司

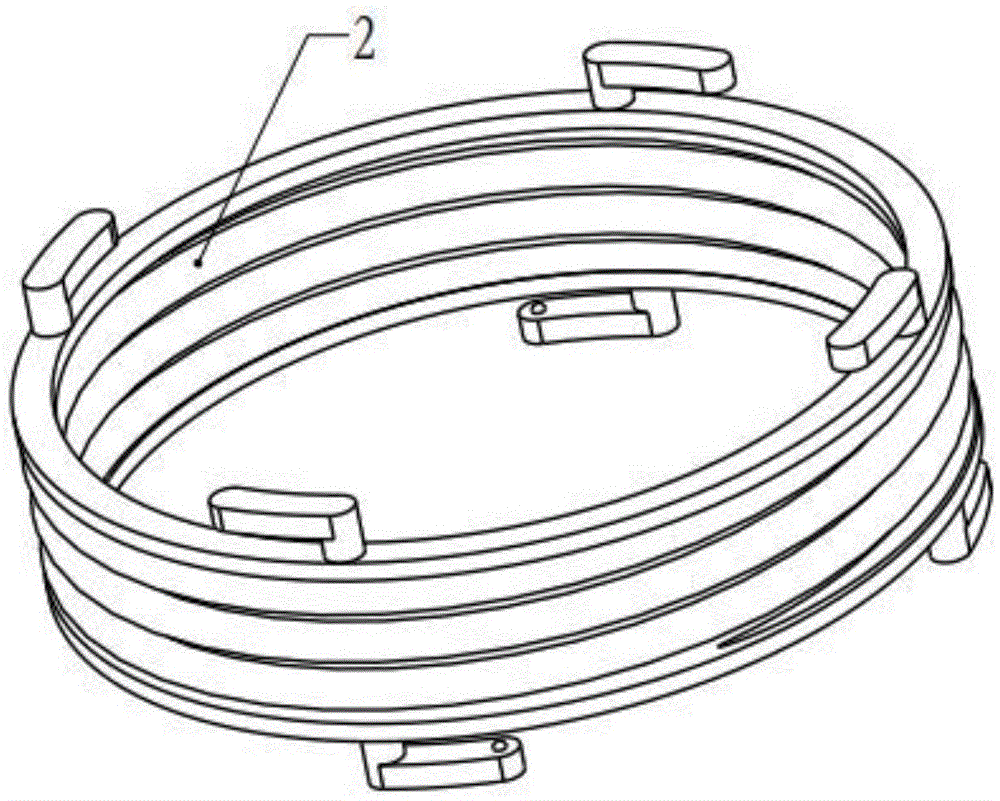

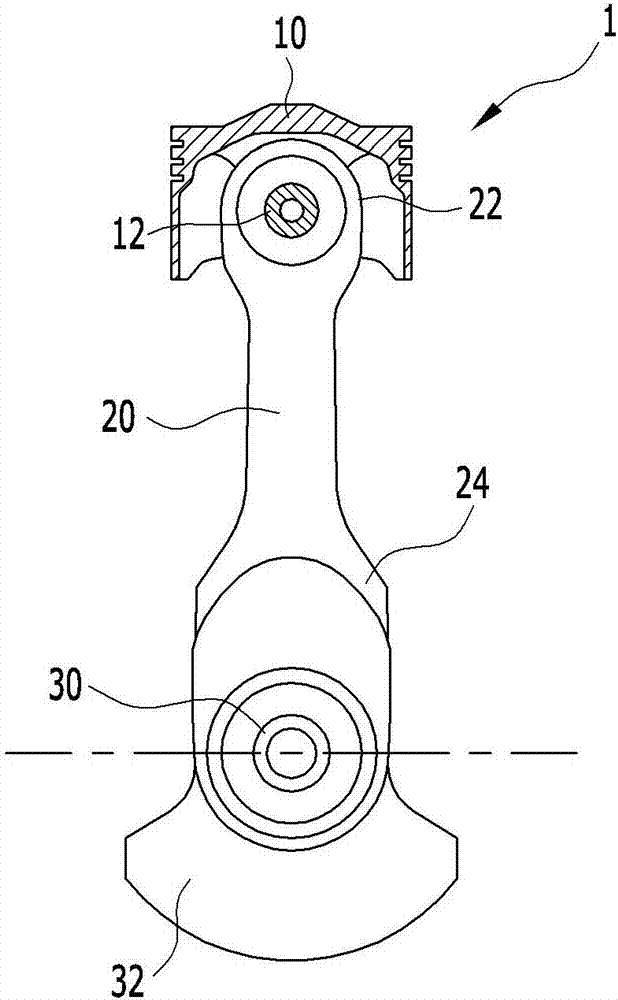

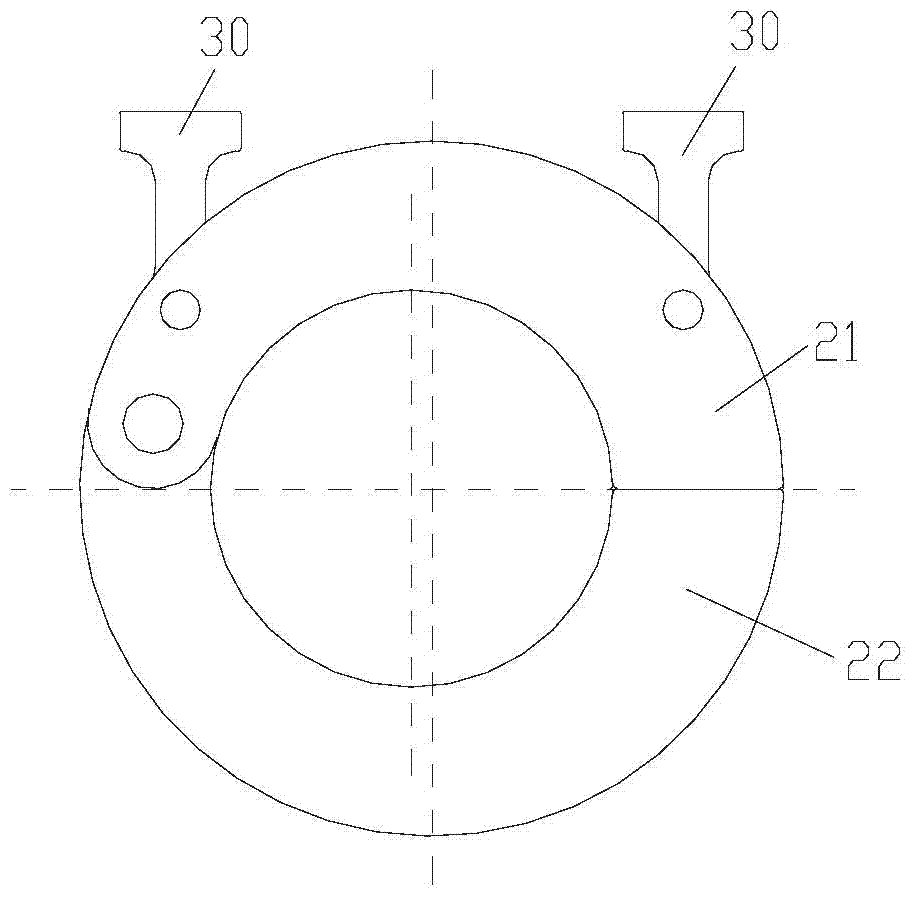

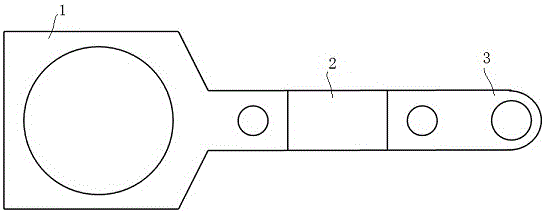

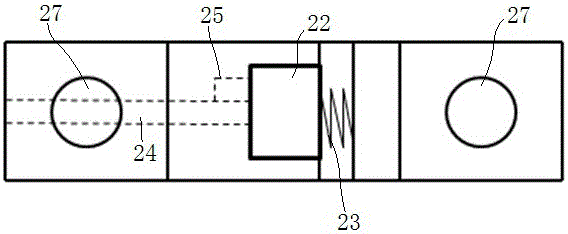

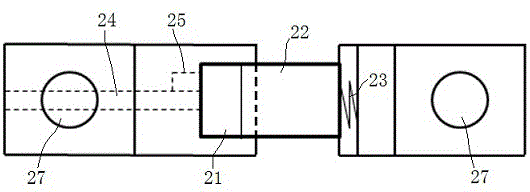

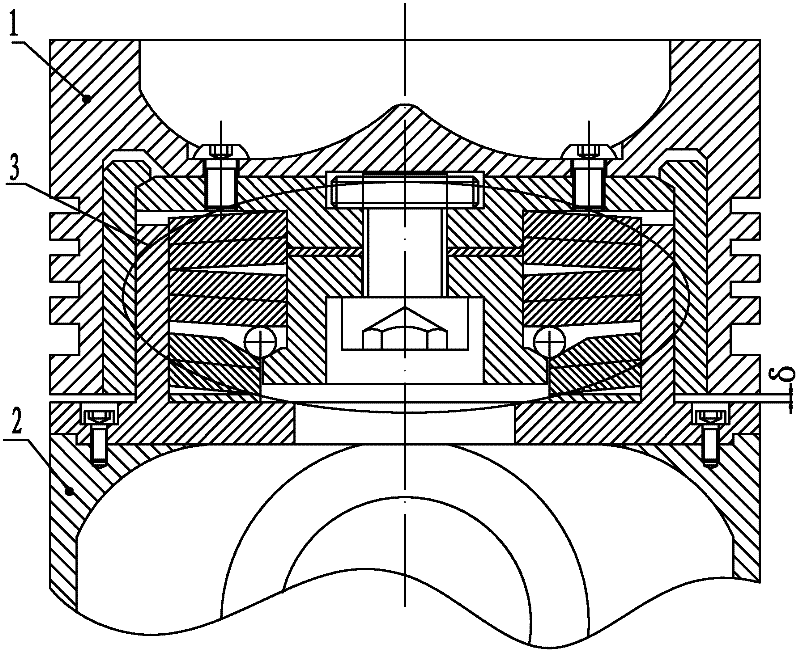

Connecting rod with two-stage-adjustable length

ActiveCN106089978AAdjustable lengthEasy to produceConnecting rodsEngine controllersLocking mechanismSelf locking

The invention relates to a connecting rod with the two-stage-adjustable length. The connecting rod comprises a large connecting rod head (1) and a small connecting rod head (3) and is characterized by further comprising a variable-length rod body (2), wherein one end of the variable-length rod body (2) is connected with the large connecting rod head (1), and the other end of the variable-length rod body (2) is connected with the small connecting rod head (3); the variable-length rod body (2) comprises a cavity (21) and a valve rod (22) which are connected with each other in an inserted manner, a connecting head at the bottom end of the cavity (21) is connected with one end of the large connecting rod head (1), and the bottom of the cavity (21) communicates with an oil duct hole at a crankshaft connecting hole in the large connecting rod head (1) by the aid of a main oil duct (24); and a connecting head at the other end of the valve rod (22) is connected with the small connecting rod head (3), and a spring (23) is arranged between the valve rod (22) and the connecting head of the valve rod (22). A self-locking mechanism (26) is further arranged between the cavity wall of the cavity (21) and the valve rod (22). Engine oil pressure control is adopted, and two-stage length adjustment of the connecting rod is realized by the aid of different oil pressures.

Owner:CHERY AUTOMOBILE CO LTD

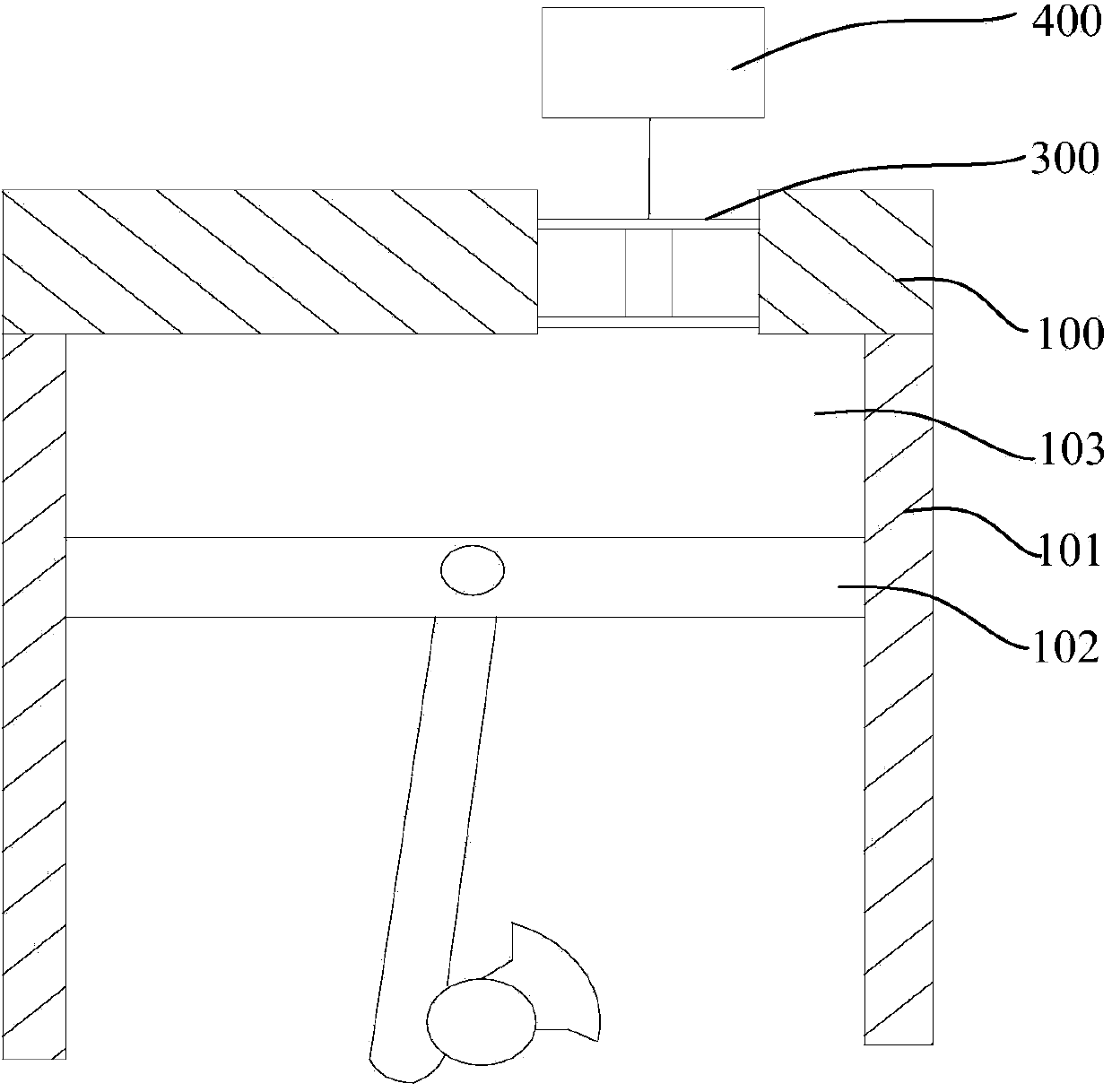

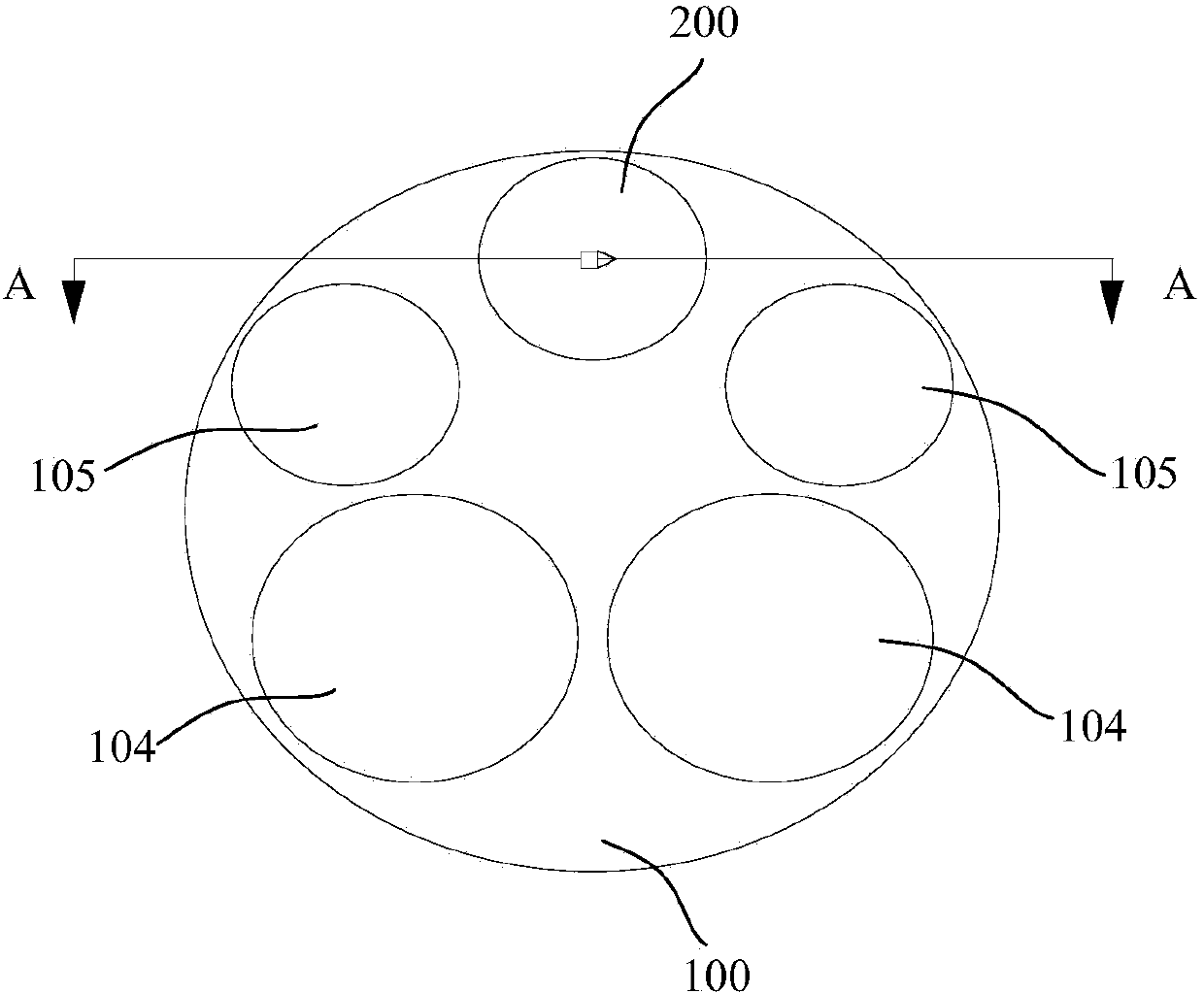

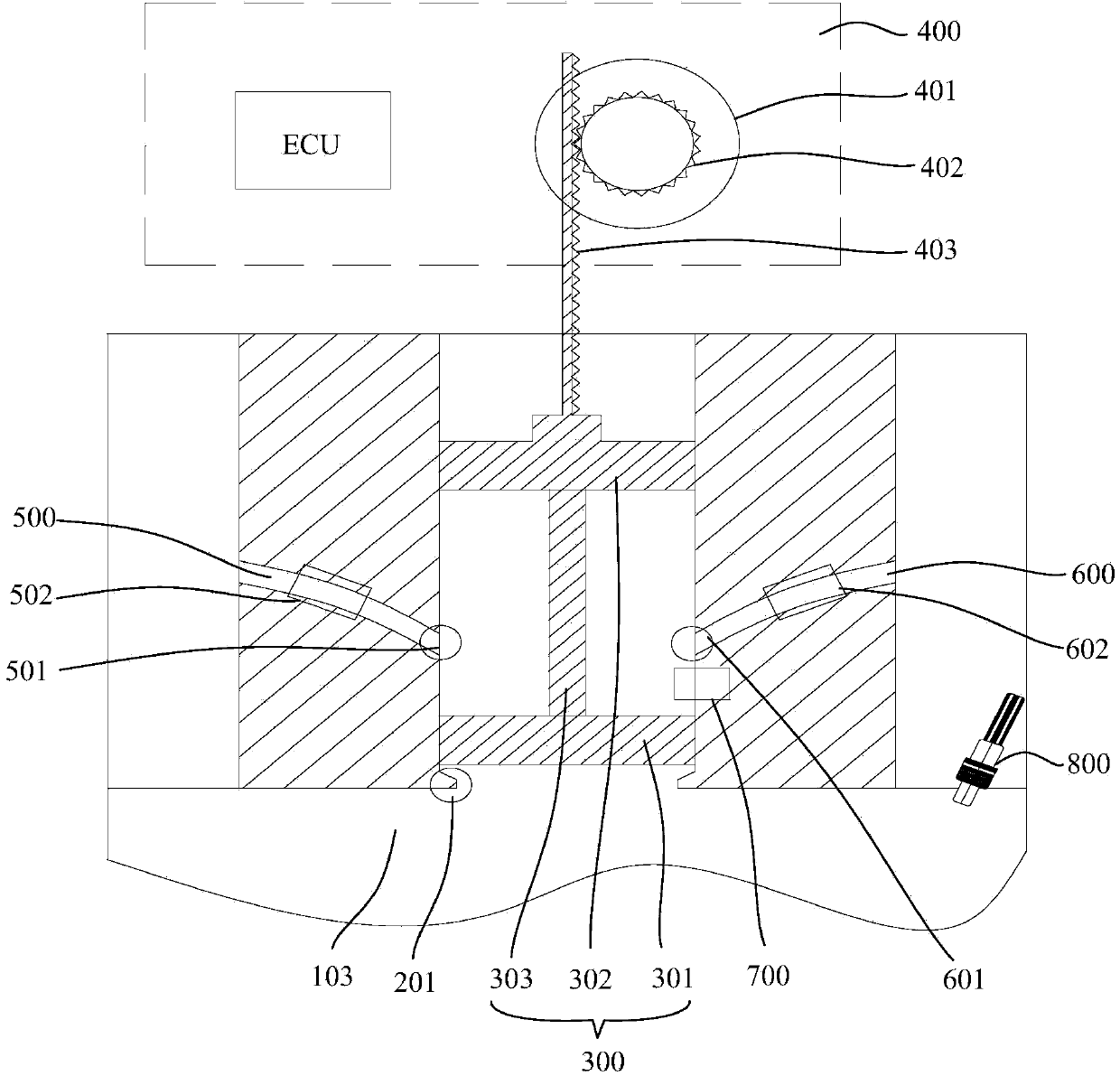

Engine

InactiveCN104265467AChange the compression ratioImprove reliabilityEngine controllersMachines/enginesCombustion chamberReciprocating motion

The invention discloses an engine, relates to the technical field of engines, and can solve the problems of complex structure and weaker reliability of a traditional variable compression engine. The engine comprises a cylinder cover, a cylinder body, and a piston arranged in the cylinder body, wherein a combustion chamber is formed between the piston and the cylinder cover. The engine further comprises an auxiliary cylinder barrel, an auxiliary piston and a driving mechanism, wherein the auxiliary cylinder barrel is arranged on the cylinder cover in a penetrating manner, and is communicated with the combustion chamber; the auxiliary piston is sealed in the auxiliary cylinder barrel; the axis of the auxiliary piston is overlapped with the axis of the auxiliary cylinder barrel; the auxiliary piston can reciprocate in the auxiliary cylinder barrel in the axis direction; and the driving mechanism is arranged at one side, far from the combustion chamber, of the cylinder cover, is connected with the auxiliary piston, and provides power for the reciprocating motion of the auxiliary piston. The engine can be used for an automobile power system.

Owner:GREAT WALL MOTOR CO LTD

Engine and vehicle

ActiveCN107489526AChange the compression ratioMechanical controlCylinder headsReciprocating motionEngineering

The invention relates to an engine and a vehicle. The engine comprises a cylinder body and a crankshaft. The cylinder body comprises an air cylinder (2), a cylinder sleeve (3) arranged in the air cylinder (2) in a sleeved mode and a piston (4) making reciprocating motion in the inner wall of the cylinder sleeve (3). A connecting rod is connected between the piston (4) and the crankshaft. The inner wall and the outer wall of the cylinder sleeve form an eccentric structure so that the relative position of the piston (4) and the air cylinder (2) can be adjusted when the cylinder sleeve (3) rotates. When the cylinder sleeve of the engine rotates in the air cylinder, the piston can make axial motion in the cylinder sleeve as the position of the connecting rod is basically kept unchanged, so that the relative position of the piston and the cylinder sleeve can be adjusted, and the compression ratio of the engine is changed.

Owner:BEIQI FOTON MOTOR CO LTD

Engine with variable compression ratio

InactiveCN104141537AChange the compression ratioIncrease motivationMachines/enginesCylinder headEngineering

The invention discloses an energy-saving engine. The engine comprises a cylinder body, a cylinder cover, a cylinder head cover, a cylinder barrel, a crankshaft, a connecting rod and a piston, and is characterized in that a flat bar is arranged at the top end of the cylinder cover; a cam is arranged above the flat bar and fixedly connected onto a cam shaft; oblique insection and a sliding wheel matched with the oblique insection are arranged at one end of the cam shaft; the sliding wheel is driven by a crankshaft gear at one end of the crankshaft through a transmission mechanism, and a relative angle between the cam and the crankshaft can be changed by the transmission mechanism; the upper edge periphery of the cylinder cover and the lower edge periphery of the cylinder head cover are connected through an upper rubber sleeve, and the lower edge periphery of the cylinder cover and the upper edge periphery of the cylinder body are connected through a lower rubber sleeve; and two pins are symmetrically arranged on the left lower surface and the right lower surface of the cylinder cover, sleeves glidingly matched with the pins are arranged on the left upper surface and the right upper surface of the cylinder body, and springs are arranged on the outer sides of the pins and the sleeves in a sleeving manner. According to the energy-saving engine, the compression ratio of the engine can be changed, the structure is simple, the control is facilitated, engine power can be effectively improved, and fuel economy is improved.

Owner:范伟俊

Improved variable compression ratio piston for internal combustion engine

InactiveCN102269076AThe initial telescopic gap δ decreasesTelescopic gap δ decreasesEngine controllersMachines/enginesSteel ballEngineering

Owner:WUHAN UNIV OF TECH

Piston type internal combustion engine variable compression ratio adjusting device

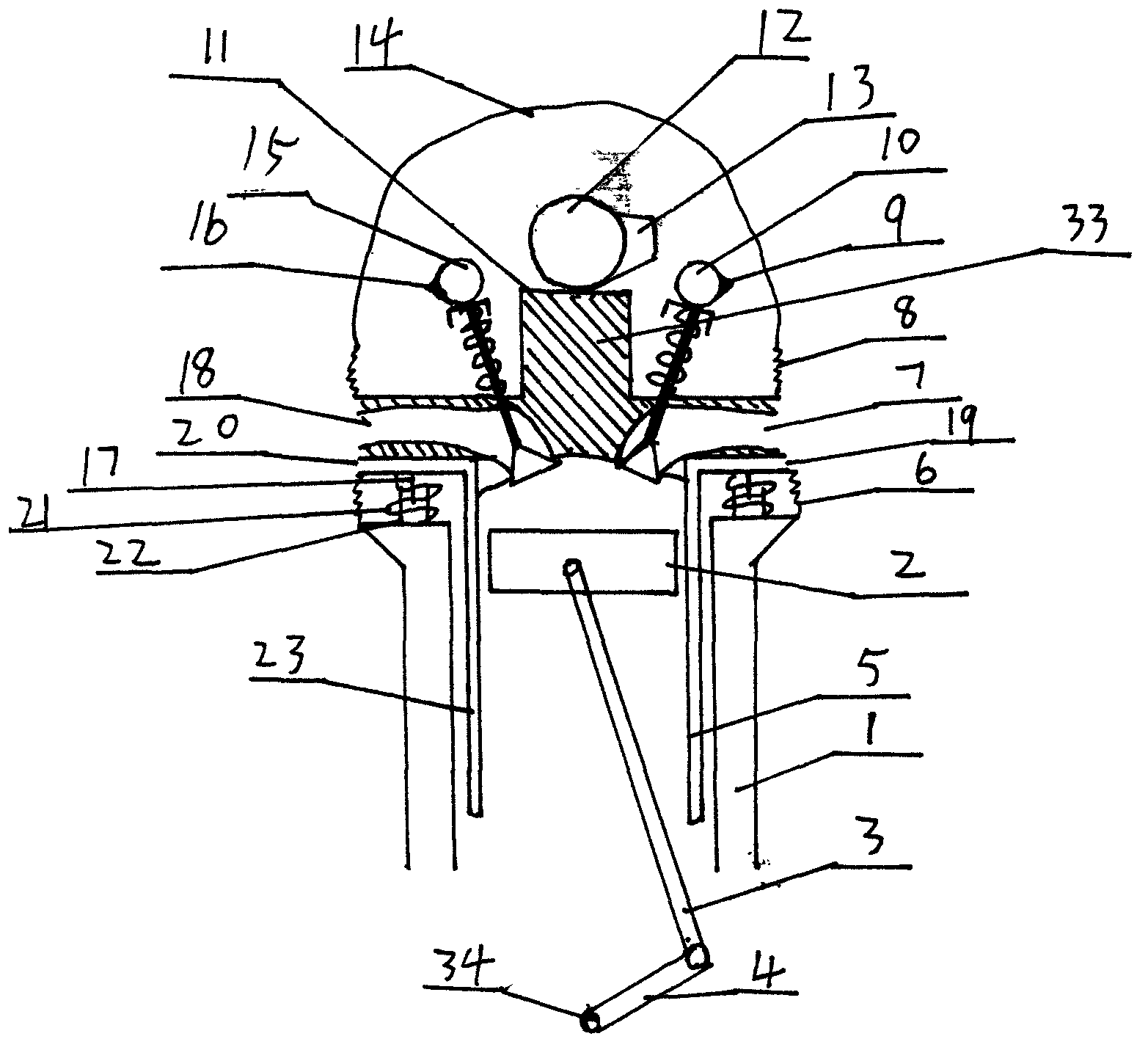

The invention discloses a a piston type internal combustion engine variable compression ratio adjusting device. The device comprises a force transmission rod for being connected with a piston, a connecting rod, a swing rod and a cam, and the force transmission rod is used for transmitting the explosive force of a piston to the swing rod; the connecting rod is provided with a large head end and a small head end, and the large head end of the connecting rod is connected with a crankshaft for transmitting power to the crankshaft to drive the crankshaft to conduct rotation output; the left end ofthe swinging rod is rotatably connected with the force transmitting rod through a swinging rod pin, and the right end of the swinging rod is rotatably connected to the small head end of the connectingrod through a swing rod; the cam is provided with a cam shaft, the cam is an eccentric circular structure, the center of rotation of the cam shaft deviates a certain distance from the center of the cam, the cam shaft is mounted on a bearing hole of a body, the middle of the swing rod is mounted on the cam, and the swing rod is rotated around the cam shaft through the cam to change the center of the rotating and swing of the swing rod, thereby changing a top dead center of the piston. The device changes the compression ratio by changing the top dead center of the piston, and the compression ratio is continuously adjustable.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

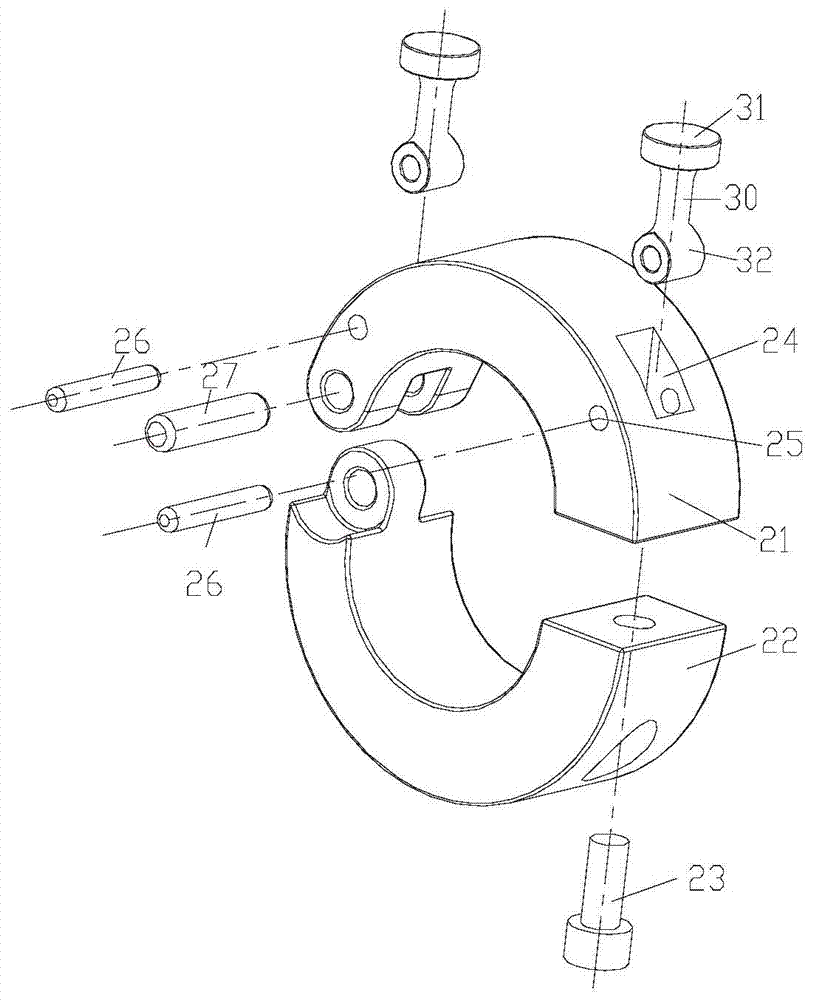

Variable compression ratio apparatus

A variable compression ratio apparatus is provided and is installed within an engine rotating a crankshaft upon receiving combustion power of a mixture from a piston and changes a mixture compression ratio based on an engine driving condition. The apparatus includes a connecting rod at which a small end forming a circular aperture to be rotatably connected with a piston pin moving together with the piston, a larger end rotatably connected with a crankpin eccentrically arranged with respect to the crankshaft, and an acting oil passage formed to supply hydraulic pressure from the larger end to the small end, are formed. An eccentric cam is concentrically arranged and rotatably disposed in the small end aperture and the piston pin is eccentrically inserted thereinto and is rotatably connected therewith. A latching pin selectively latches the small end with the cam by supply of hydraulic pressure through the acting oil passage.

Owner:HYUNDAI MOTOR CO LTD +1

Supercharger capable of changing compression ratio, application of supercharger and engine regulation technology

ActiveCN109630411AImprove efficiencySolve the problem of serious backflow leakageInternal combustion piston enginesRotary piston pumpsPre compressionEngineering

The invention discloses a supercharger capable of changing the compression ratio. The supercharger comprises a gas inlet pipe, an exhaust pipe, a shell, a first rotor, a second rotor, a gear set and abelt pulley; and meanwhile, the invention discloses an engine compression ratio regulation technology, and the engine compression ratio regulation technology comprises the following specific regulation steps that S1, an exhaust port of the exhaust pipe is connected to an engine gas inlet in series; S2, a gas inlet baffle or / and a gas outlet baffle is / are adjusted to pre-compress gas entering an engine air cylinder; and S3, the gas inlet baffle or / and the gas outlet baffle is / are readjusted, and thus the pressure of the gas entering the engine air cylinder is different from the pressure of thegas entering the engine air cylinder in the step S2 so as to regulate the engine compression ratio. According to the supercharger capable of changing the compression ratio, application of the supercharger to an engine and a regulation method, the engine compression ratio is changed by adjusting the gas inlet pre-compression ratio under the situation of not changing the engine structure, and engine performance is improved in a low-cost mode.

Owner:莱州市增峰石业有限公司

Piston Arrangement for a Combustion Chamber of an Internal Combustion Engine, Having a Variable Compression Ratio

InactiveUS20140311439A1Simple variable adjustment of compression ratioChange the compression ratioEngine controllersMachines/enginesExternal combustion enginePiston ring

A piston arrangement for a combustion chamber of an internal combustion engine having a variable compression ratio. A piston includes a device for the variable adjustment of the compression ratio associated with the combustion chamber, and a piston pin is coupled to the piston via respective connecting regions, via which piston pin the piston can be coupled to a connecting rod of the internal combustion engine. The device includes the piston pin having at least one eccentric element, which is eccentrically arranged with respect to the connecting regions of the piston pin and via which the piston pin can be coupled to the connecting rod.

Owner:DAIMLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com