Internal combustion engine with variable compression ratio

A technology of internal combustion engine and compression ratio, applied in the direction of variable capacity engine, mechanical equipment, engine control, etc., can solve the problems of insufficient robustness, extra load, complex structure and operability of intake valve and exhaust valve, and achieve Large engine power, uniform transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

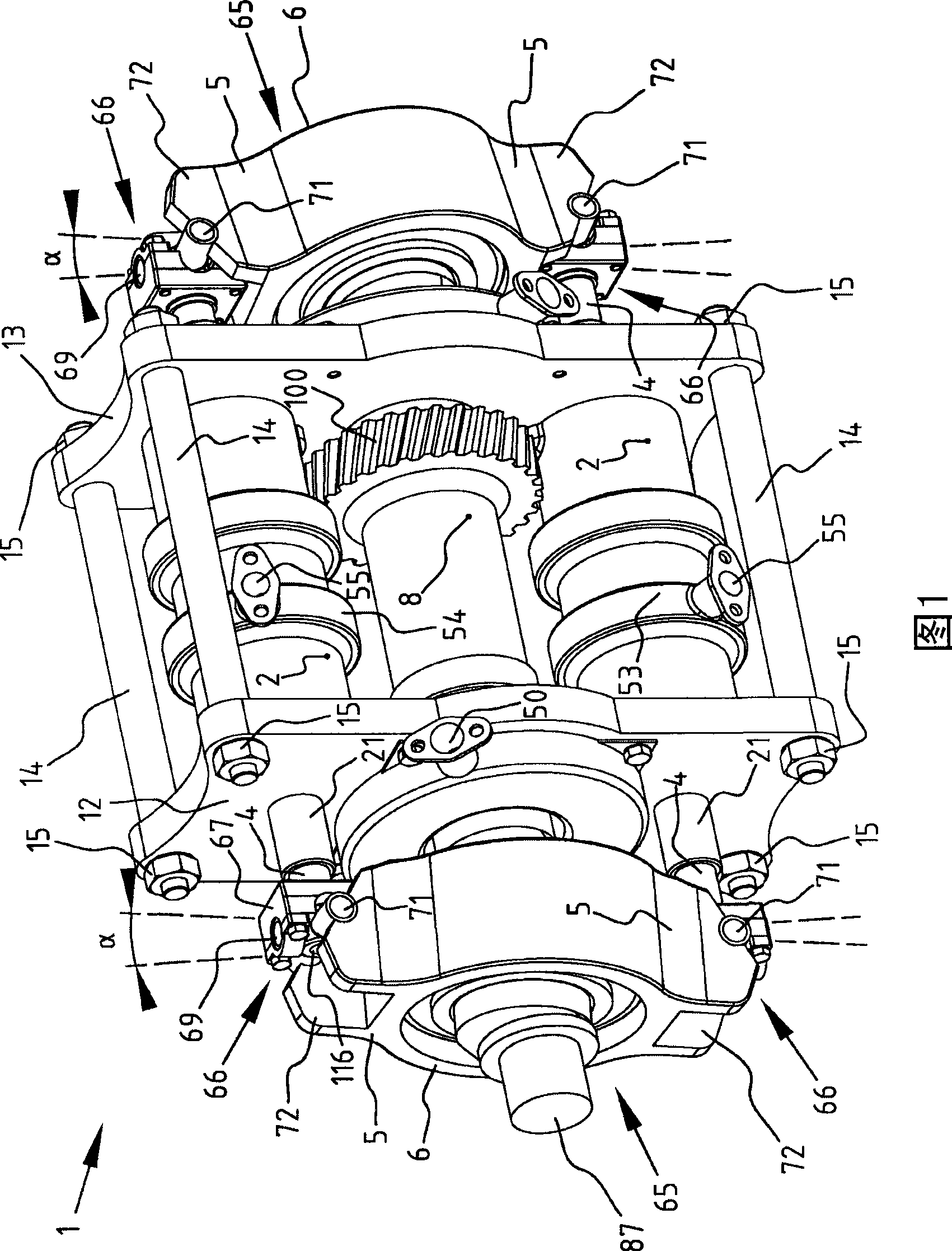

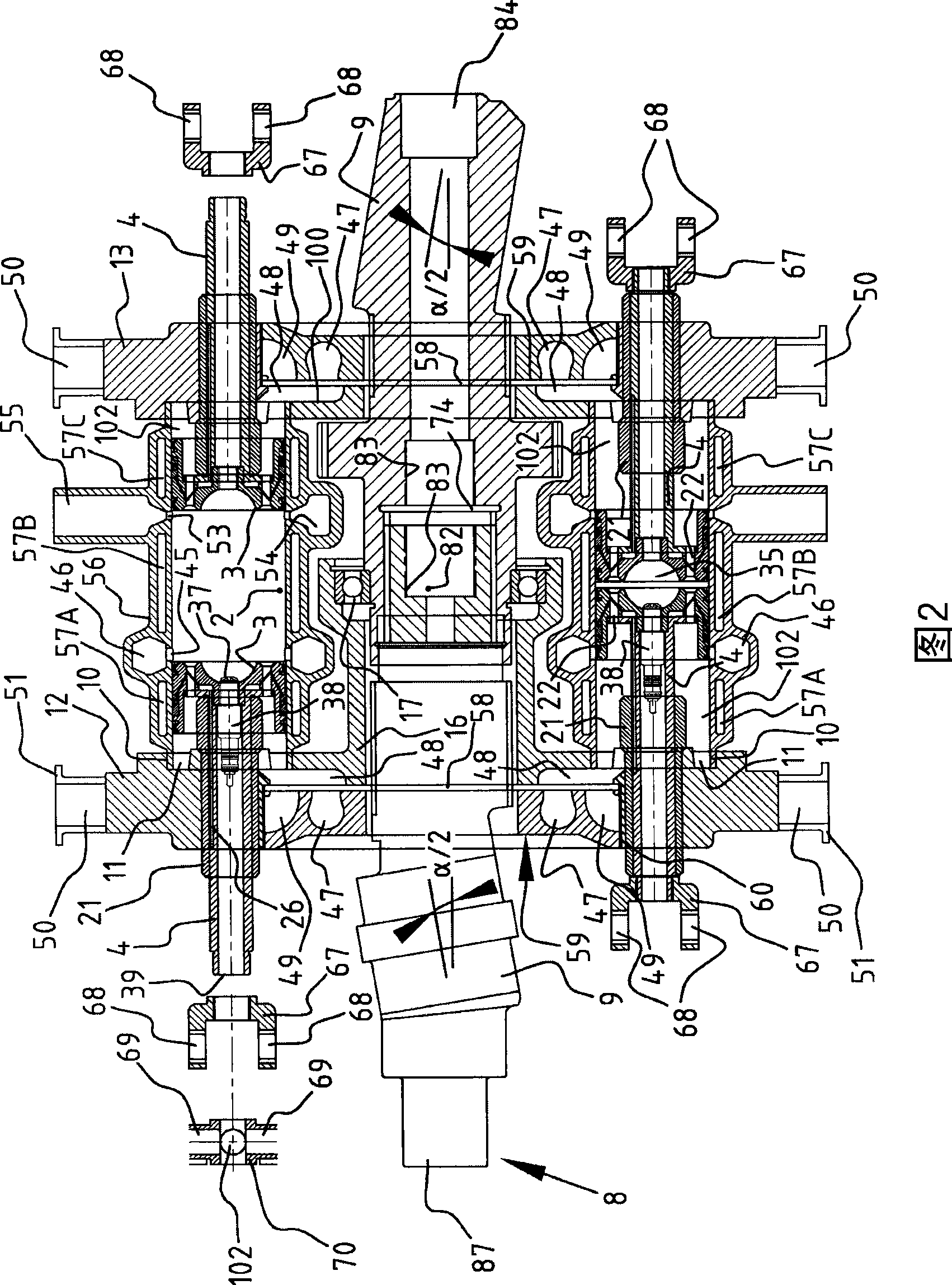

[0044] An internal combustion engine 1 ( FIG. 1 ) comprises a plurality (two in the illustrated example) of cylinders 2 within each cylinder 2 or within which two pistons 3 reciprocate in opposite directions to each other ( FIG. 2 ). A combustion chamber 35 is formed between two pistons 3 in each cylinder, while a space 102 behind each piston 3 is used as a scavenging chamber (discussed later). The internal combustion engine 1 illustrated in the illustrated example is a two-stroke engine, so that the piston 3 forms a scavenging pump.

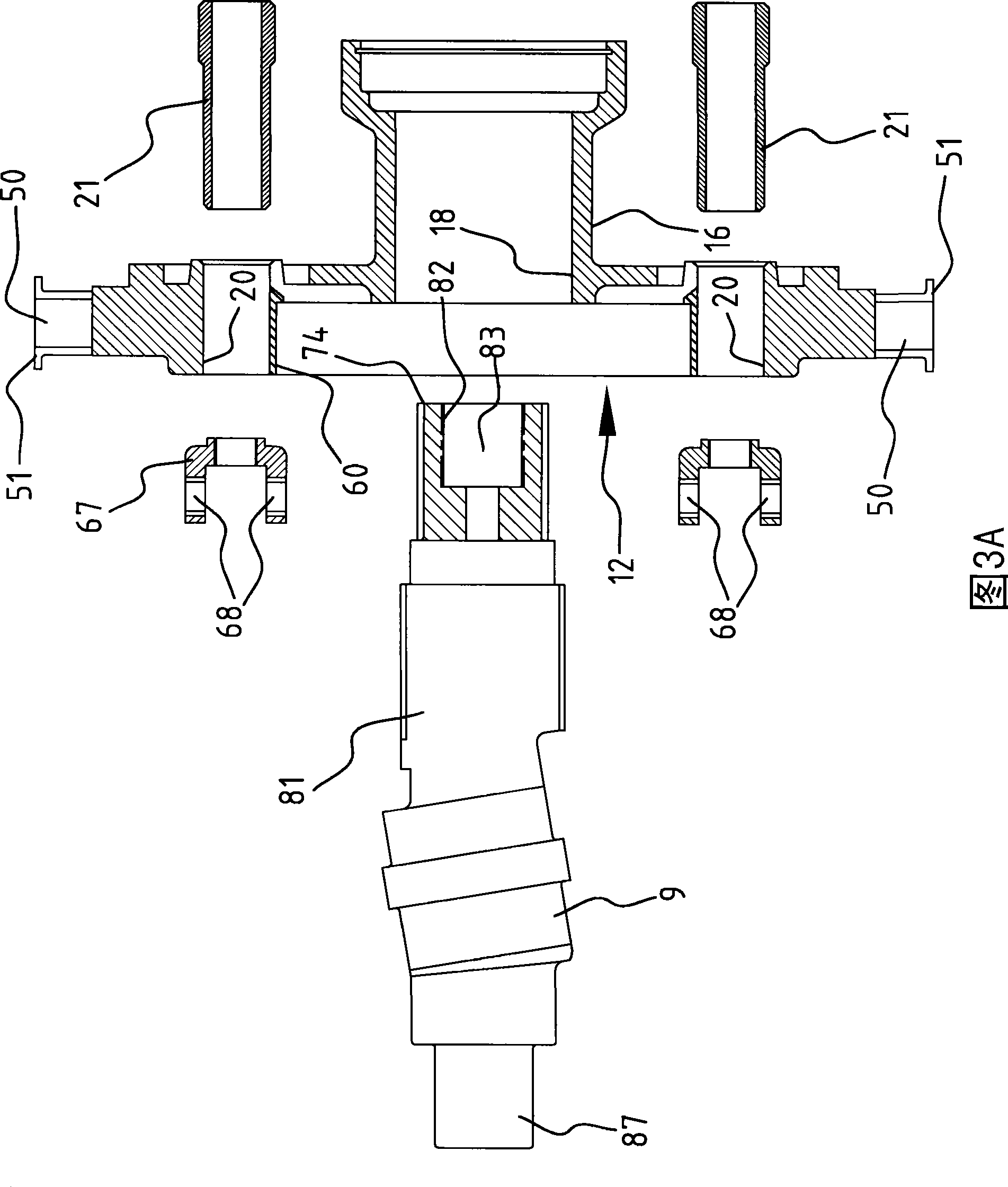

[0045] Each piston 3 is connected to a corresponding arm 5 via a piston rod 4 . The arms 5 of the individual pistons 3 are fixed on a common bearing ring 6 which defines an opening 7 . The two bearing rings 6 on both sides of the engine 1 are connected by a main shaft 8 , which is rotatably supported by two ball bearings 76 in bearings in the opening 7 . The spindle 8 and the centerline C of each opening 7 L An angle α is included and for thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com