Length variable connecting rod

A connecting rod and variable technology, applied in the connecting rod, machine/engine, shaft and bearing, etc., can solve the problems of the invariable compression ratio of the engine combustion chamber, the inability to solve the contradiction between fuel consumption and knocking, and the difficulty in implementing the scheme. The effect of improving reliability and economy, simple and reliable structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

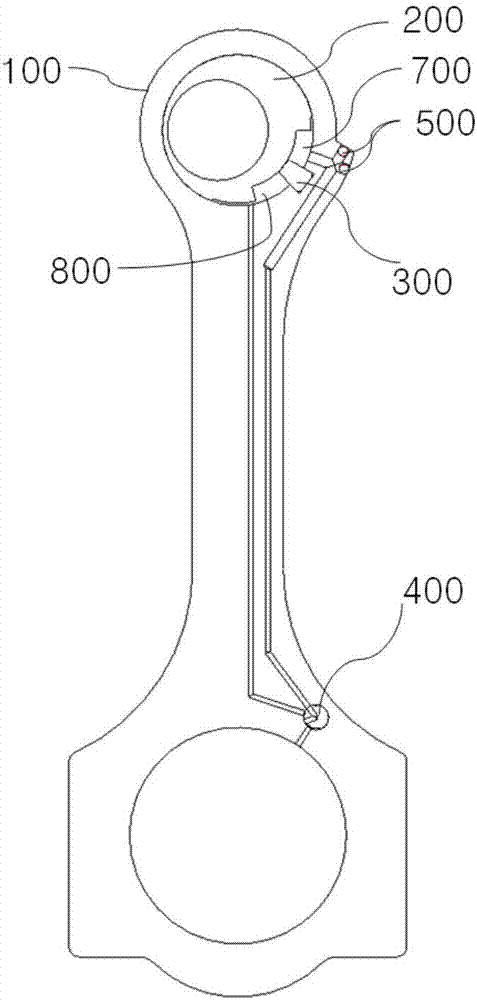

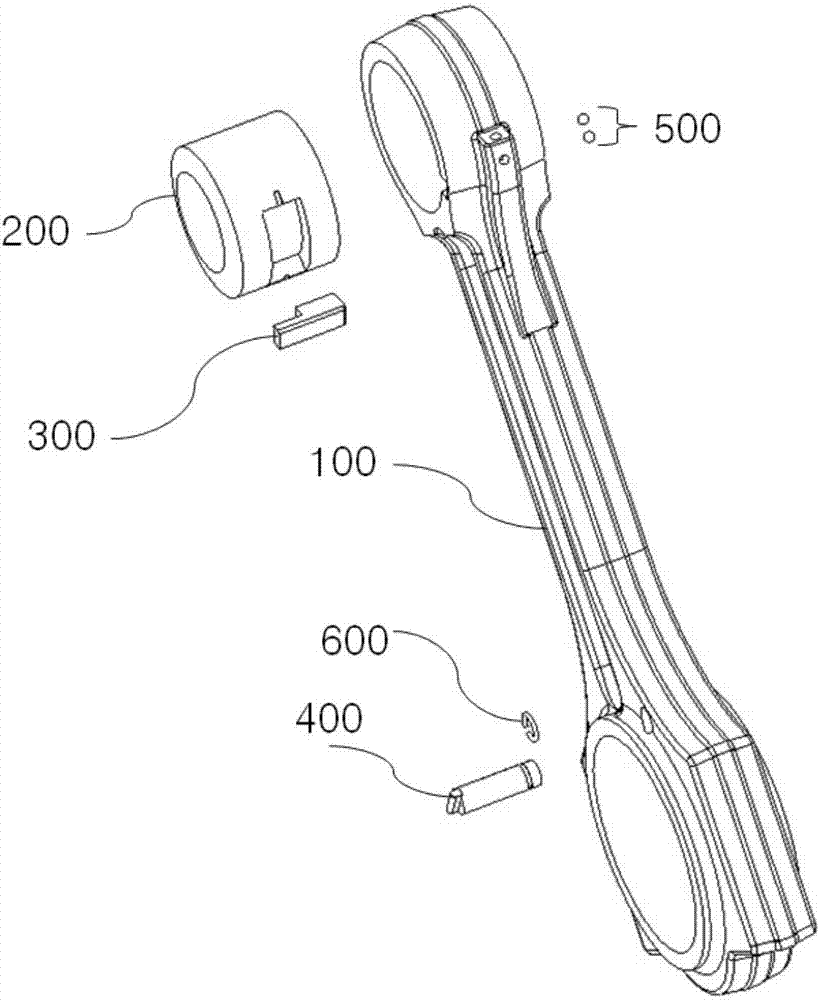

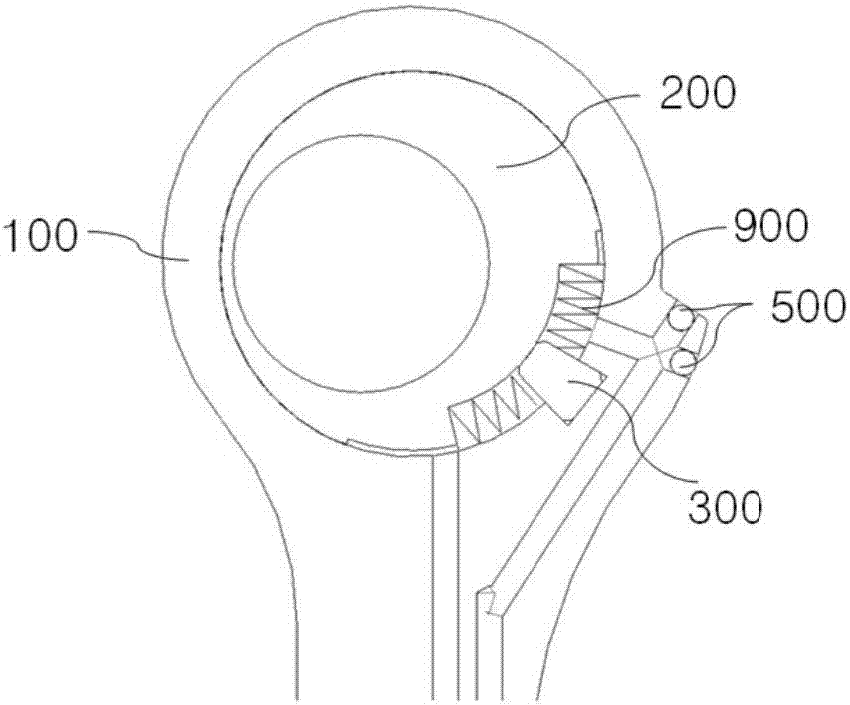

[0045] Connecting rod 100 as Figure 4 As shown, it includes a small-diameter round hole 101, a large-diameter round hole 102, a high compression ratio oil passage 103, a low compression ratio oil passage 106 and a first oil inlet oil passage 111, a hole 108 for placing the spool, and a place for placing the limit member. the first groove 110 .

[0046] The high compression ratio oil passage 103 communicates with the small-diameter round hole 101 of the connecting rod and the hole 108 for placing the spool; the low compression ratio oil passage 106 communicates with the small-diameter round hole 101 of the connecting rod and the hole 108 for placing the spool; the low compression ratio oil passage and the There is no communication between the high compression ratio oil passages.

[0047] The first oil inlet passage 111 communicates with the large-diameter circular hole 102 of the connecting rod and the hole 108 for placing the valve core. On the inner wall of the small-diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com