Engine

An engine and driving mechanism technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of complex engine structure and poor reliability, and achieve the effect of simple structure, low cost, and enlarged adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

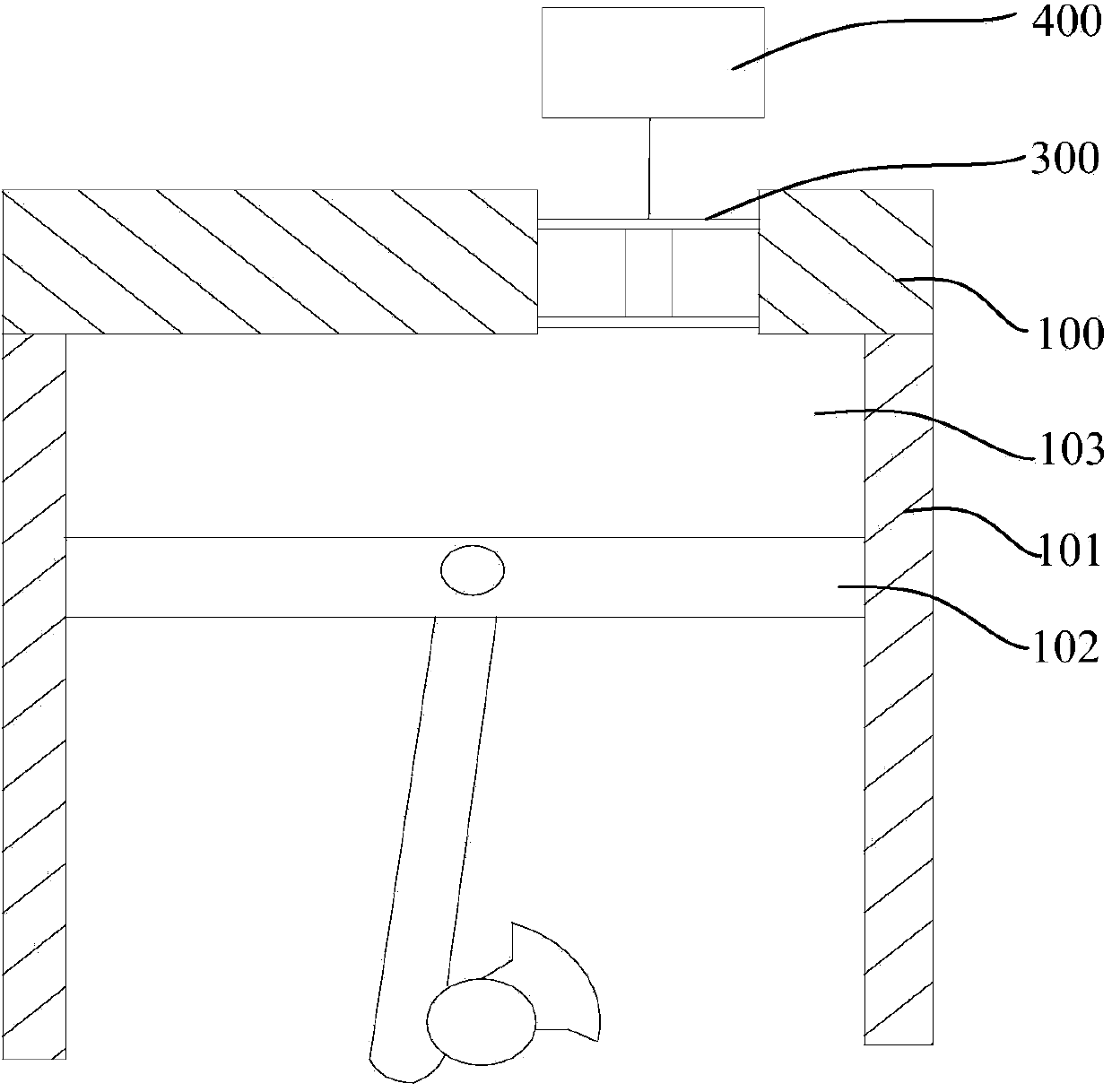

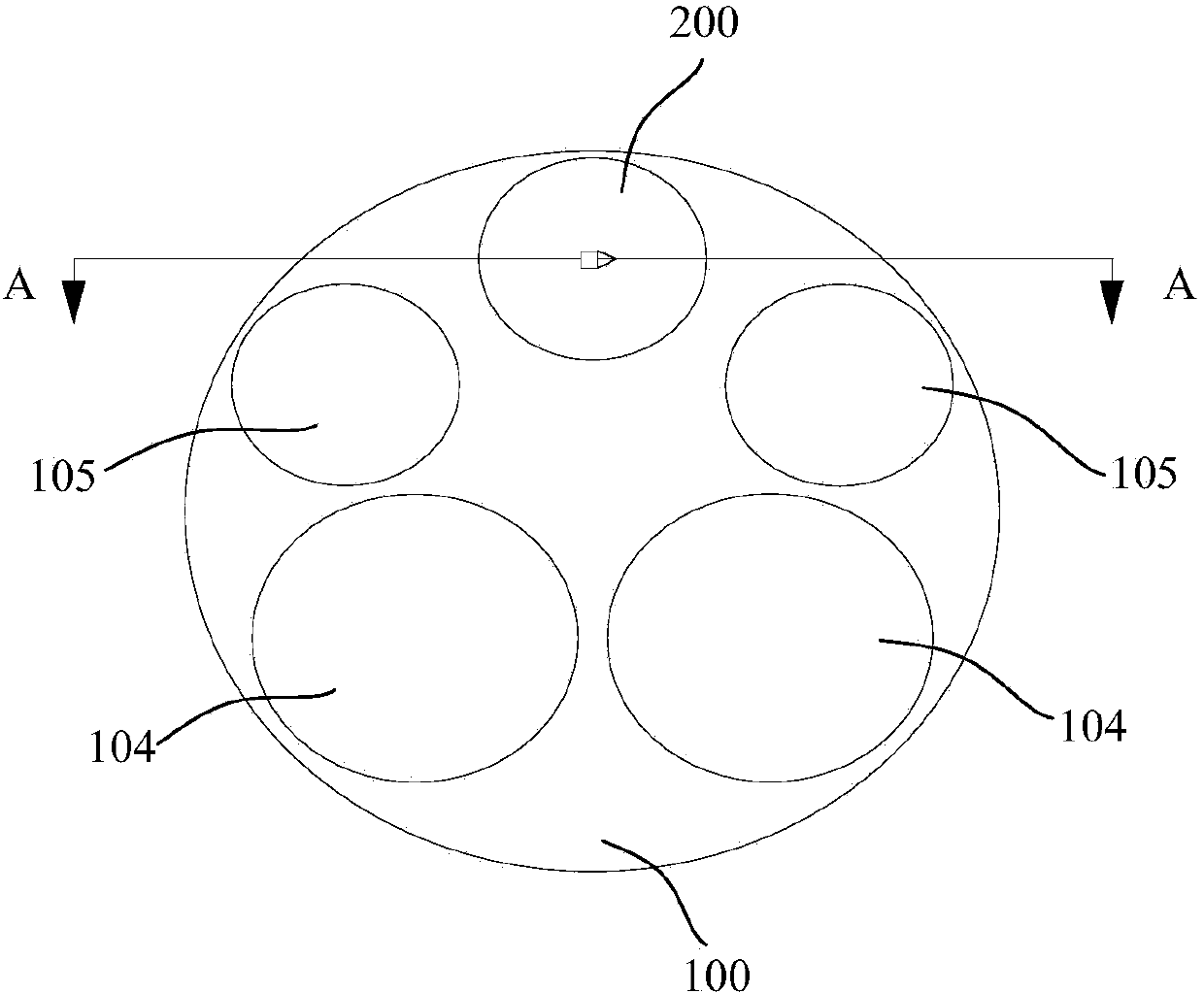

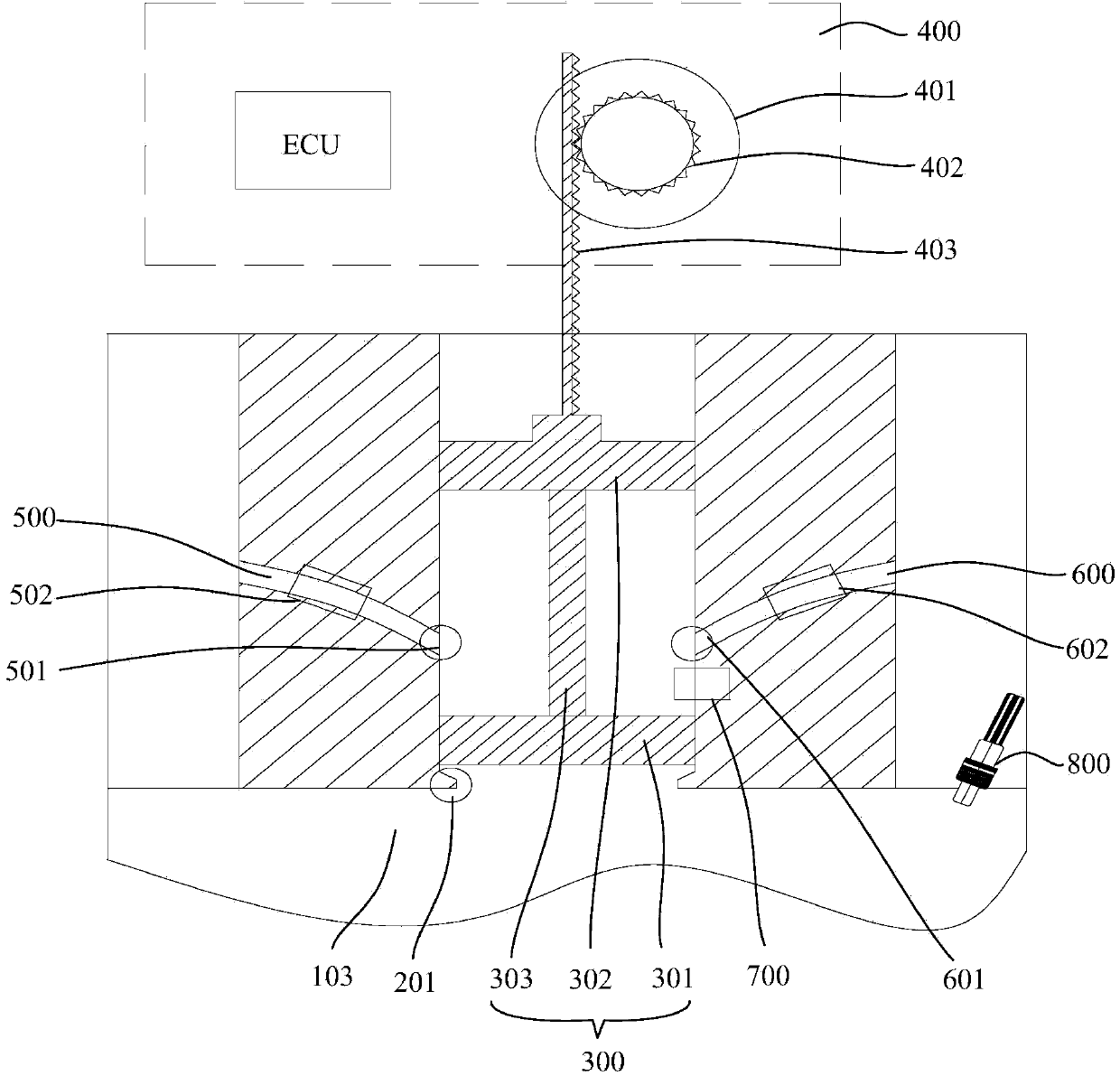

[0039] In order to solve the problems of complex structure and poor reliability of the current variable compression ratio engine, the invention provides an engine. On the cylinder head 100 of the engine, there is a piston mechanism independently arranged and communicated with the combustion chamber to realize the control of the engine compression ratio, so that the structure is simple, the cost is low, the compression ratio can be adjusted in a wider range, and the engine compression ratio can be changed at the same time. The controls are simpler. Moreover, the reliability of the engine is improved because there is no need to modify parts that need to withstand huge impacts, such as connecting rods and crankshafts inside the engine.

[0040] The engine of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] figure 1 It is a schematic structural diagram of an engine according to an embodiment of the present invention;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com