Hydraulic-drive type variable-compression-ratio piston connection rod assembly

A technology of piston connecting rod and piston assembly, applied in the direction of connecting rod, piston, cylindrical piston, etc., can solve the problems of no benefit to the engine, decrease of compression ratio stability, and shortened engine life, so as to improve fuel economy and displacement Reduced, responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below according to the accompanying drawings, and the present invention is a preferred embodiment among many embodiments.

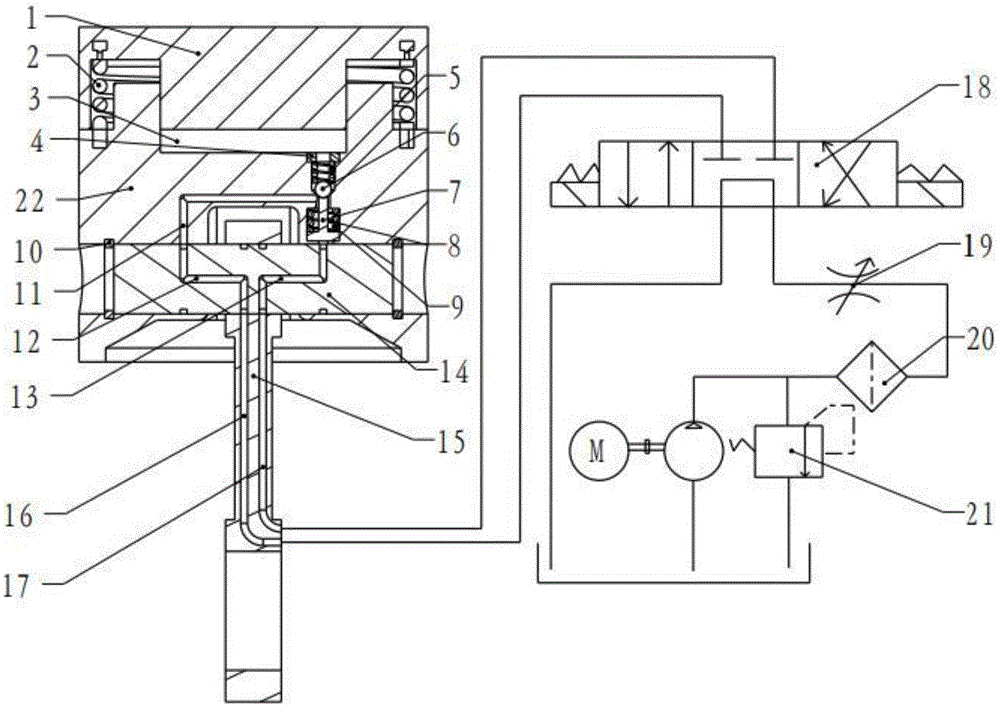

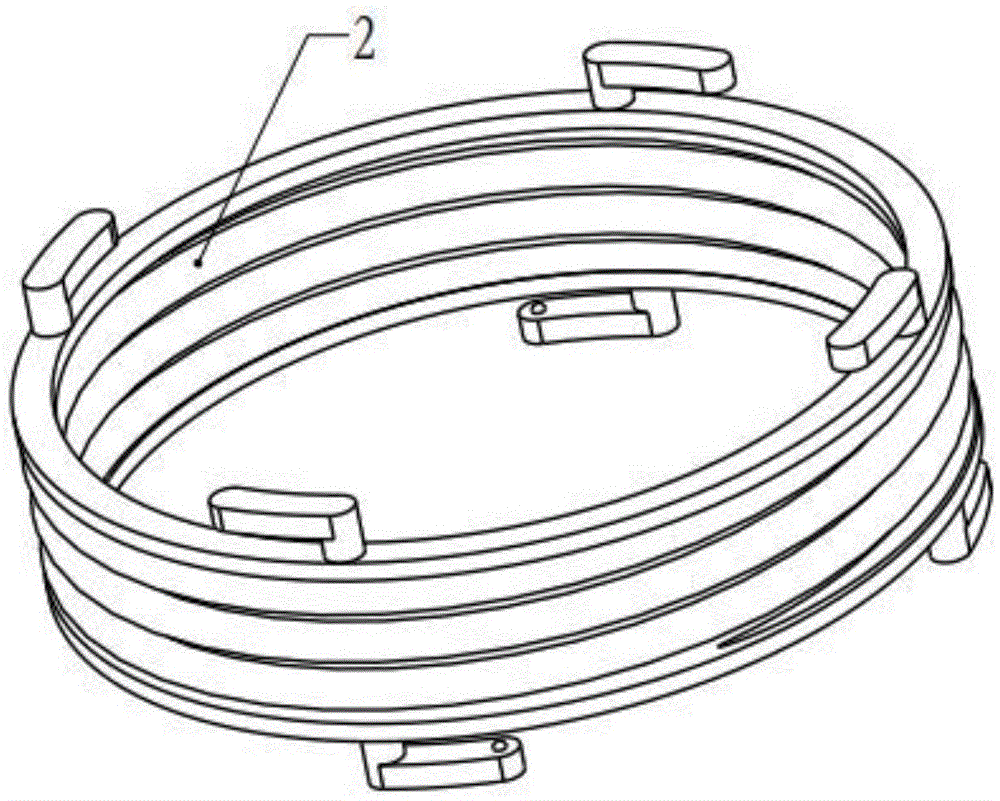

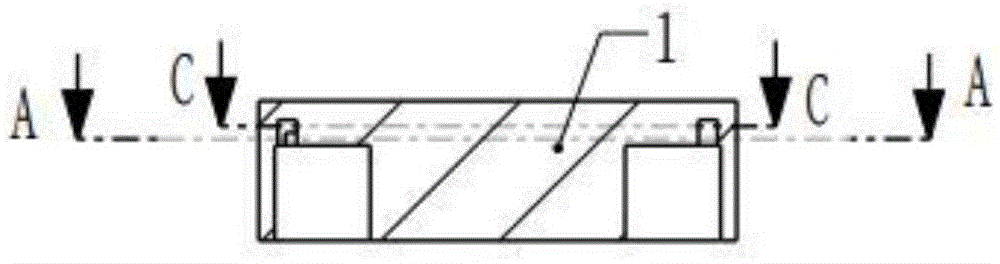

[0041] refer to figure 1 , the piston is divided into two parts, the upper piston body 1 and the lower piston body 22, which are connected together by the tension spring 2, the one-way valve is installed on the lower surface of the main oil chamber 3, and the bottom of the one-way valve ball 6 is connected to the push rod chamber 8 , the side of the one-way valve ball 6 is connected to the piston lower body oil passage 11, the piston lower body oil passage 11 corresponds to the upper oil hole of the piston pin left oil passage 12, and the oil hole at the lower end of the push rod chamber 8 is connected to the upper oil passage 13 of the piston pin Corresponding to the oil hole, the piston pin 14 is restrained on the piston lower body 22 by the snap ring 10, which prevents the axial movement of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com