Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Avoid idle work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

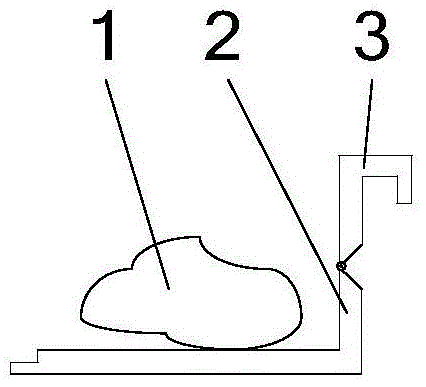

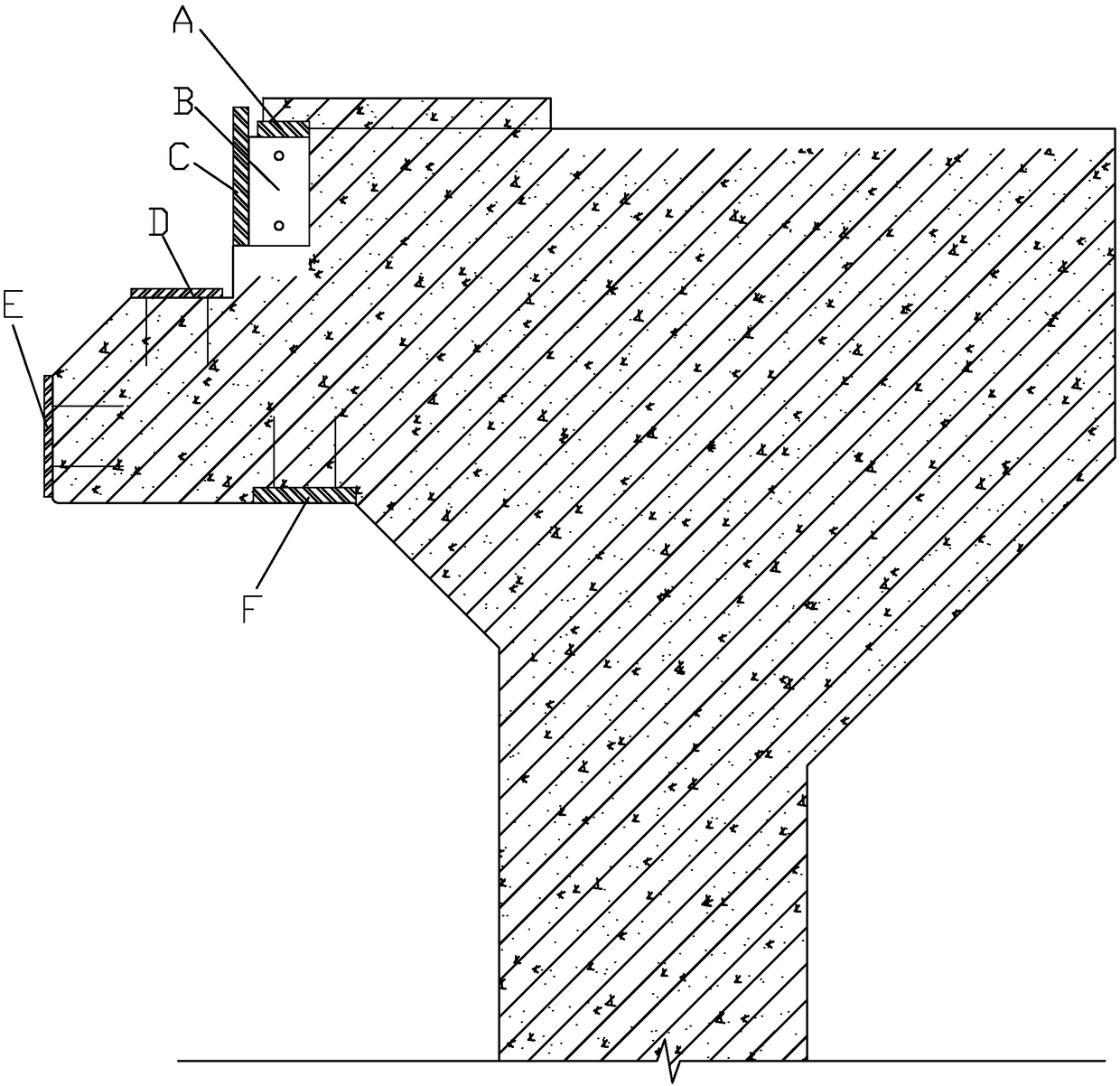

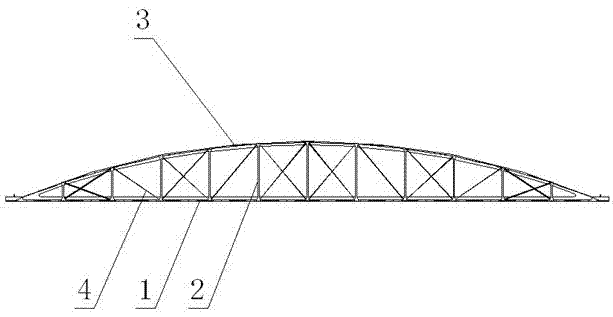

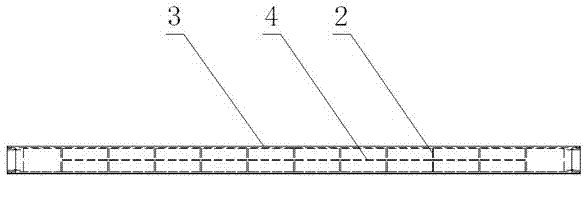

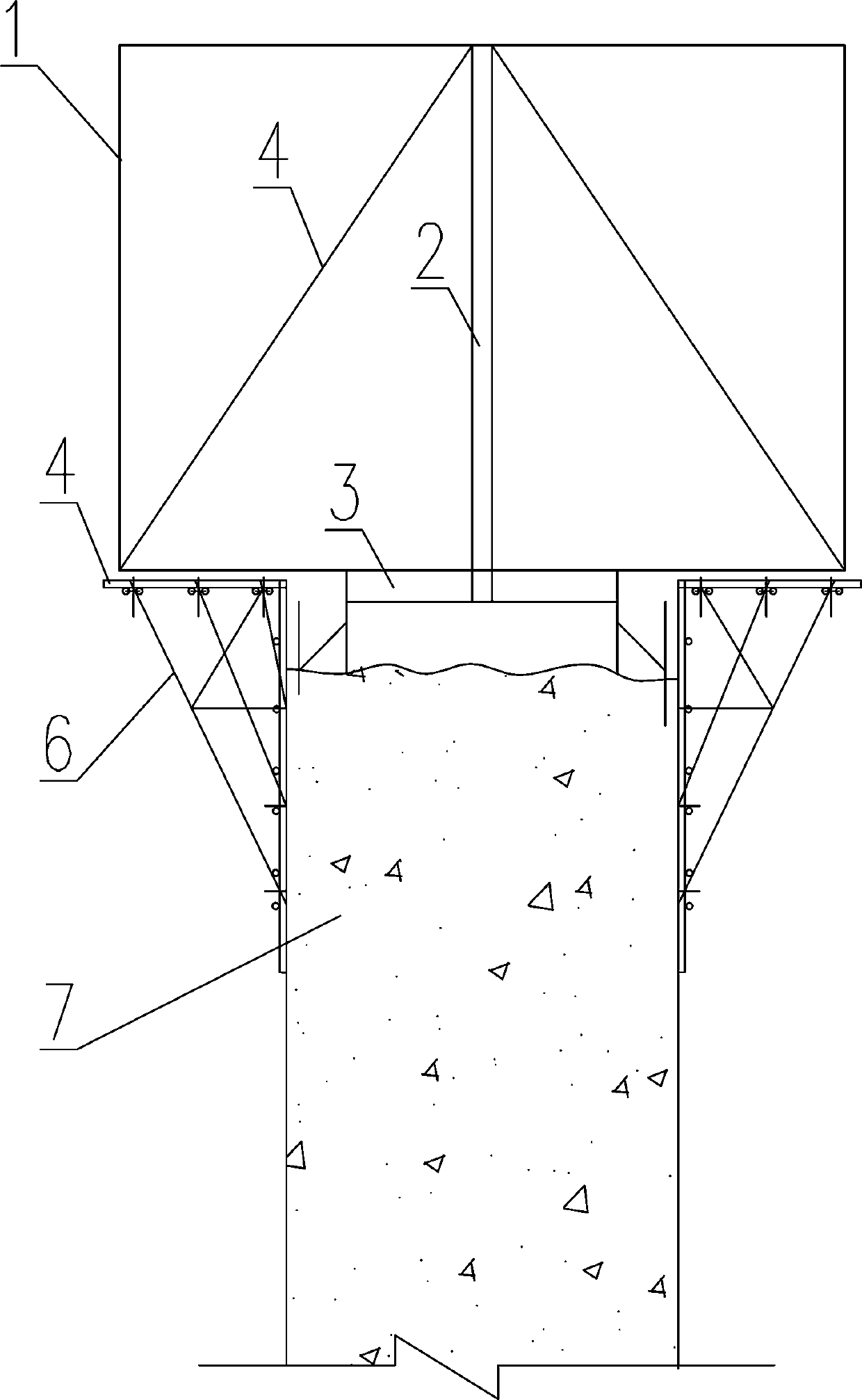

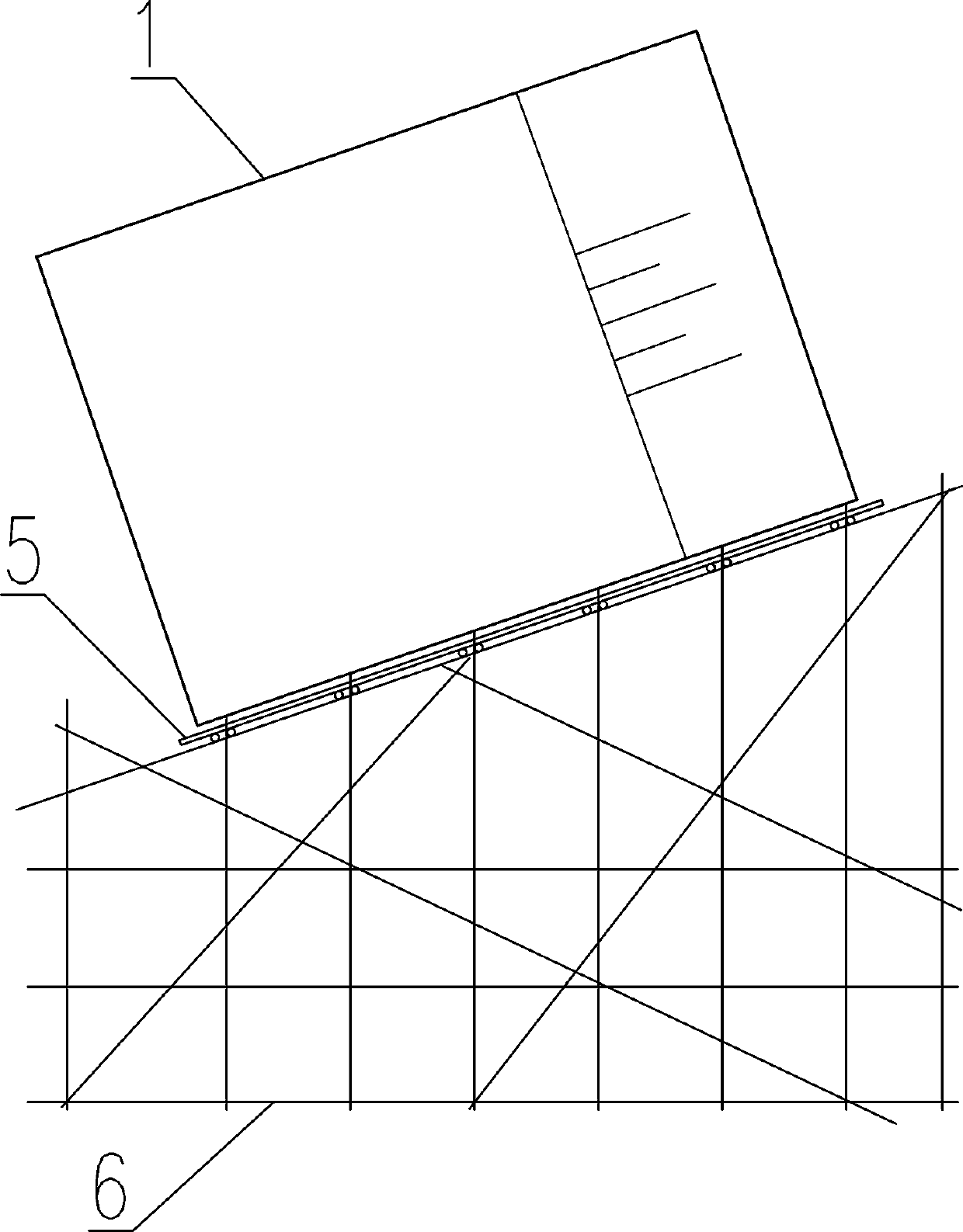

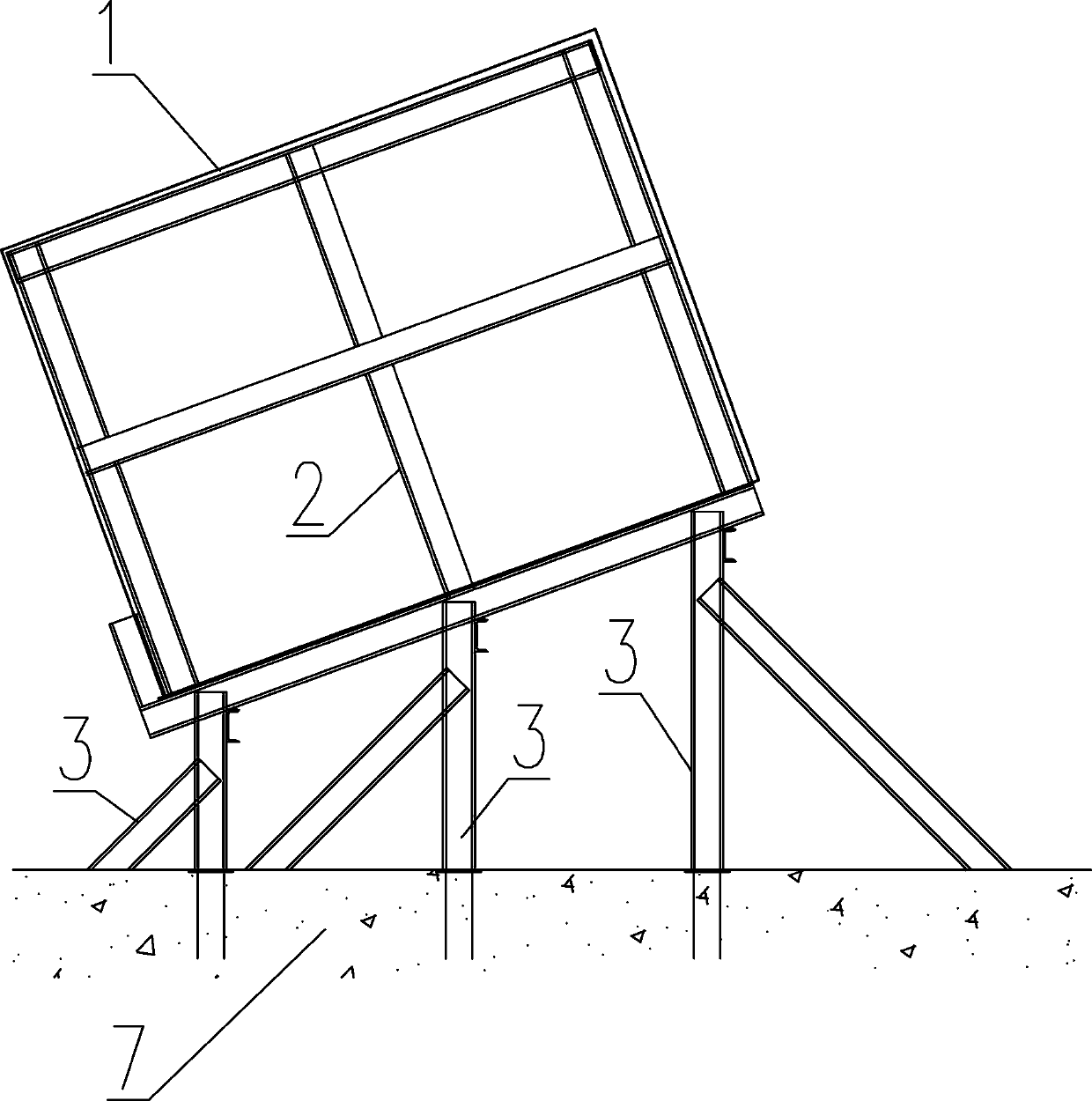

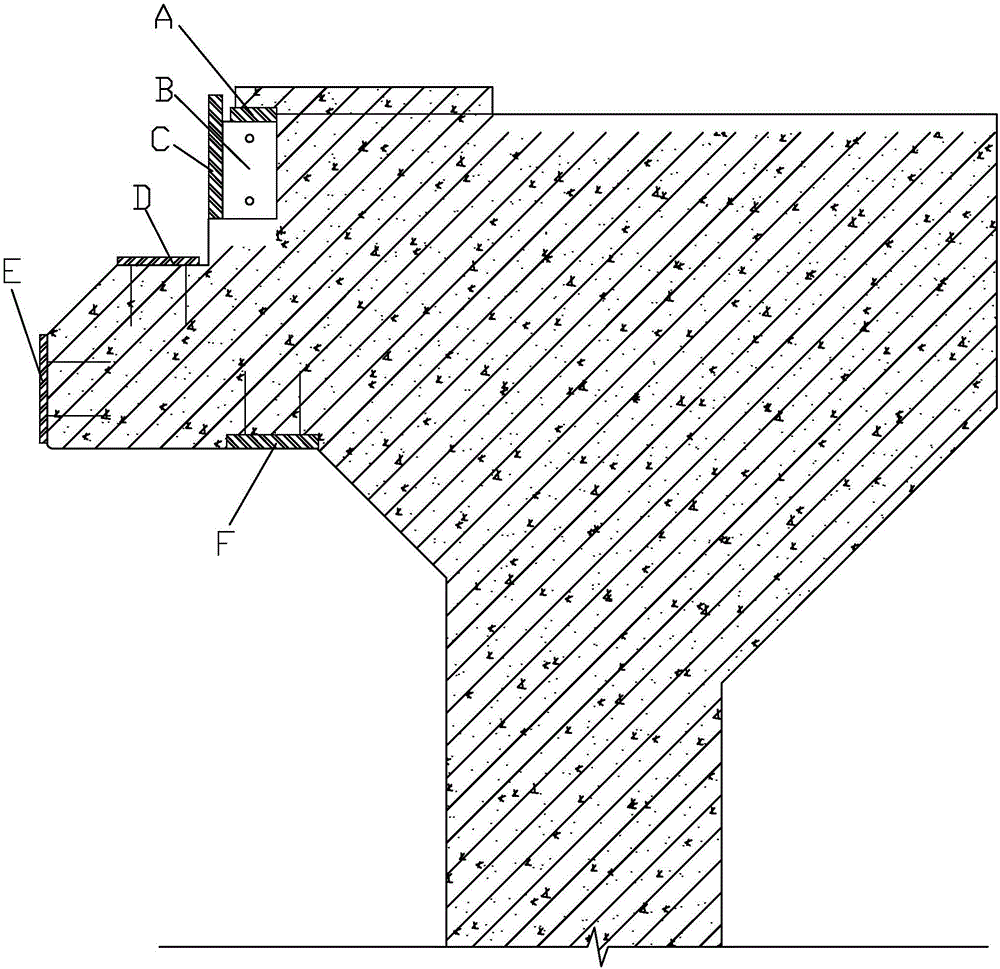

Construction method for reinforced concrete arched roof of grain store

InactiveCN102251667AReduce investmentReduce temporary land useBuilding material handlingFalseworkReinforced concrete

The invention discloses a construction method for a reinforced concrete arched roof of a grain store. The method comprises the following steps of: erecting a scaffold at the middle longitudinal part of a ring beam, and making a pedestal; paving lower chord prestressed steel bars, and performing prestressed tensioning; erecting a lower chord bottom die and a side die, installing a partition plate,and installing an upper chord arched bottom die and an upper chord arched side die at the top of the partition plate; paving upper chord steel bars; pouring concrete; stretching the prestressed steelbars when the strength of the concrete reaches over 85 percent, welding diagonal braces, and obtaining an arched plate after the diagonal braces are welded; and translating the arched plate, and welding and fixing the arched plate with an embedded steel plate. Because the construction mode of overhead prefabrication and integral translation is adopted, a large machine for hoisting is avoided, theconstruction progress is quickened, the safety risk is reduced, the cost is saved, the temporary site is reduced, and the construction efficiency is improved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

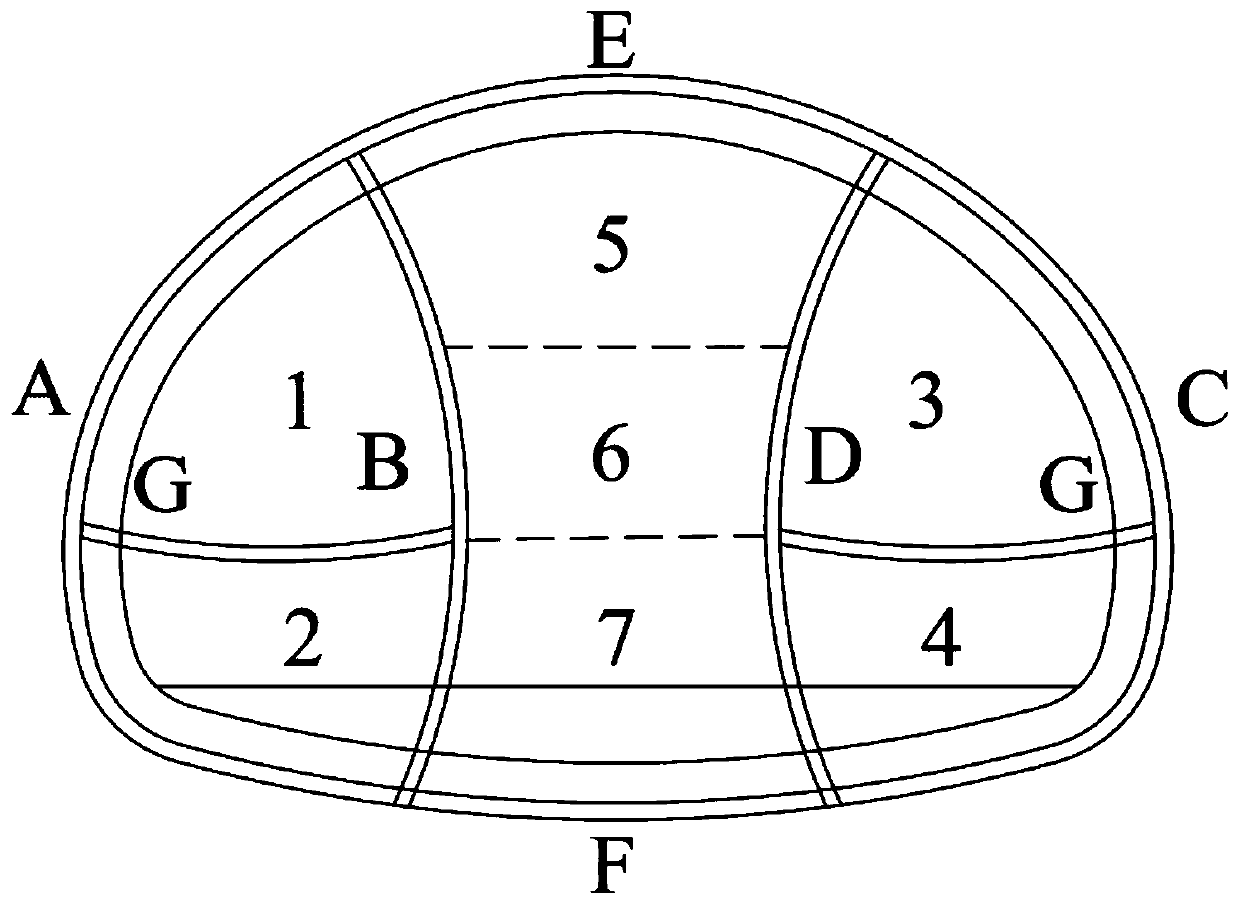

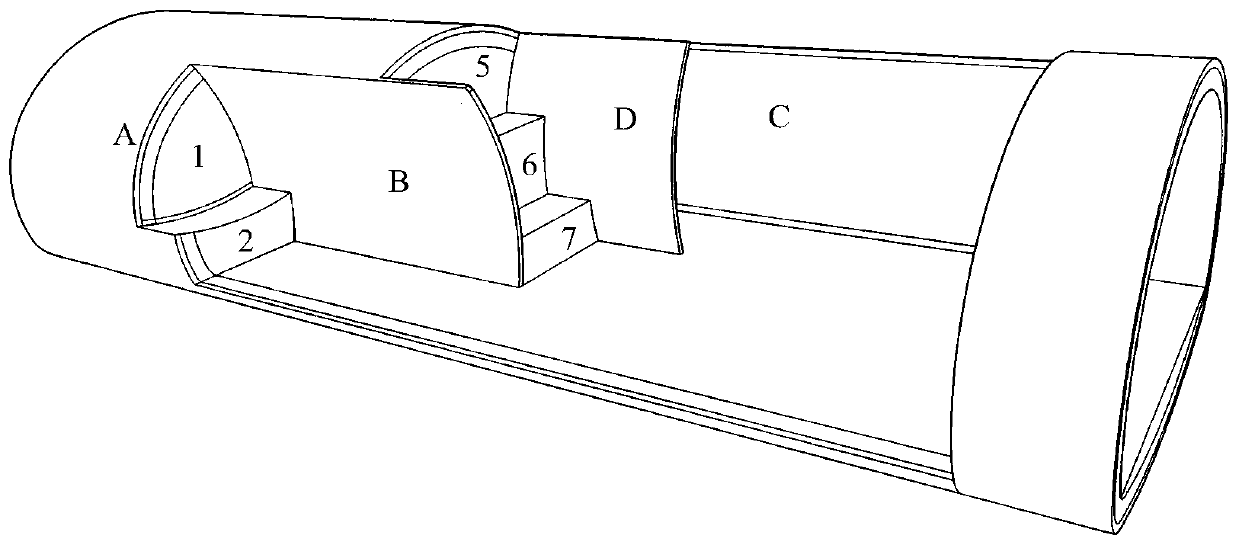

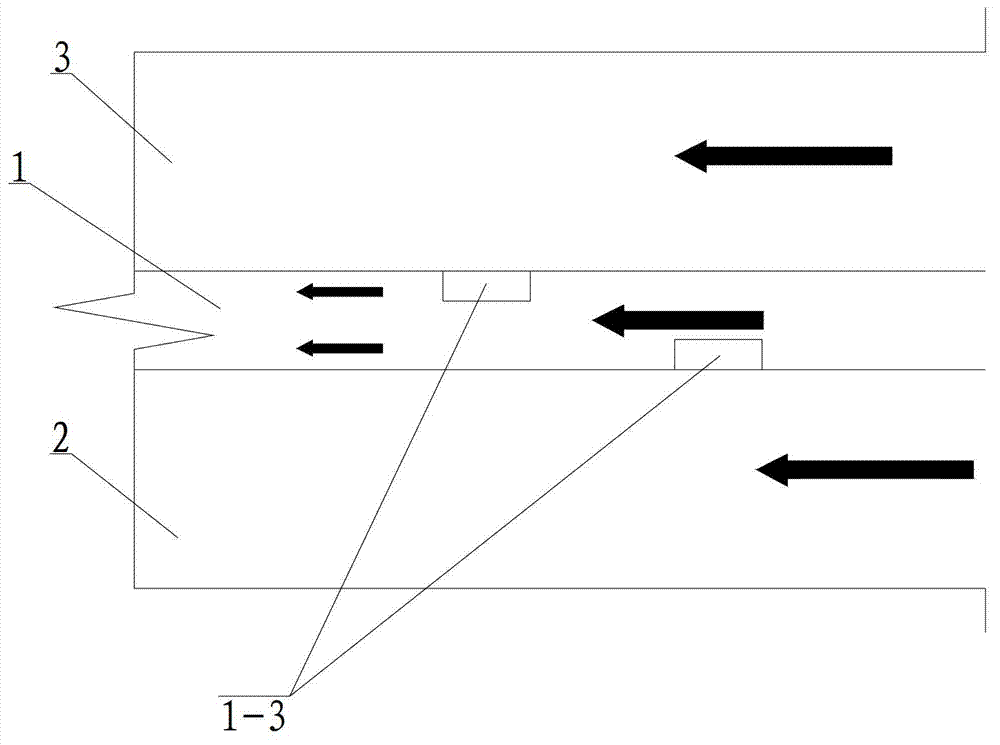

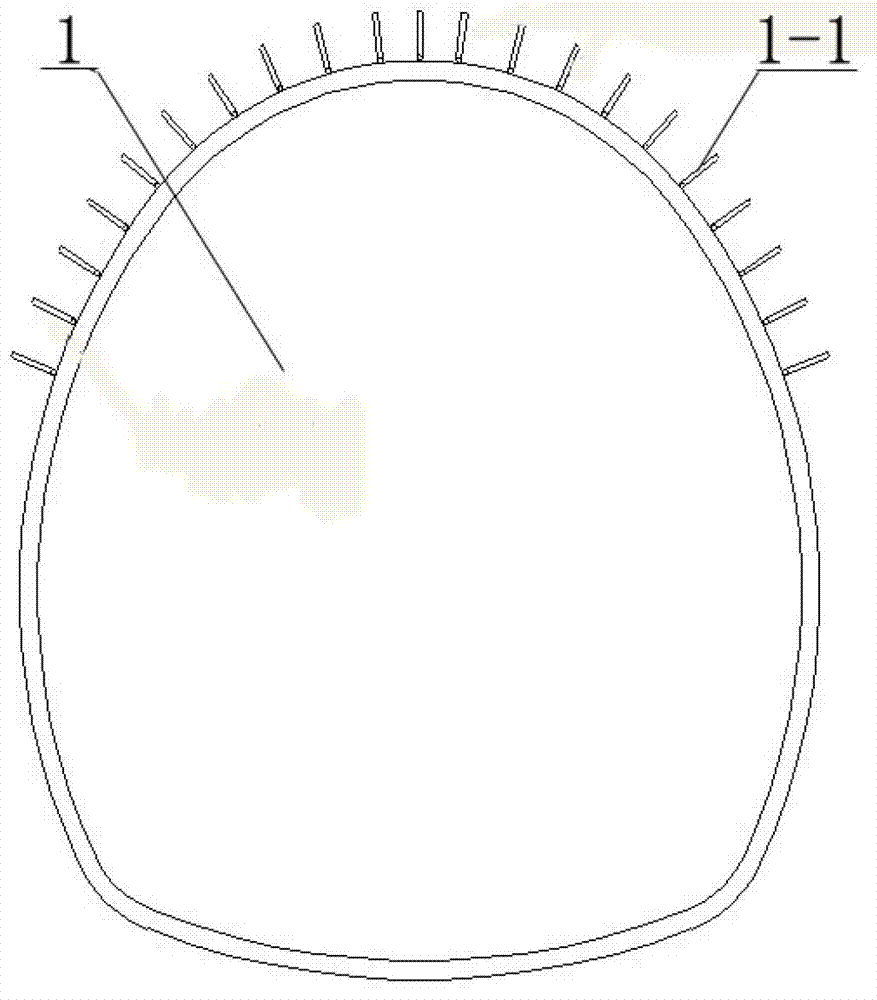

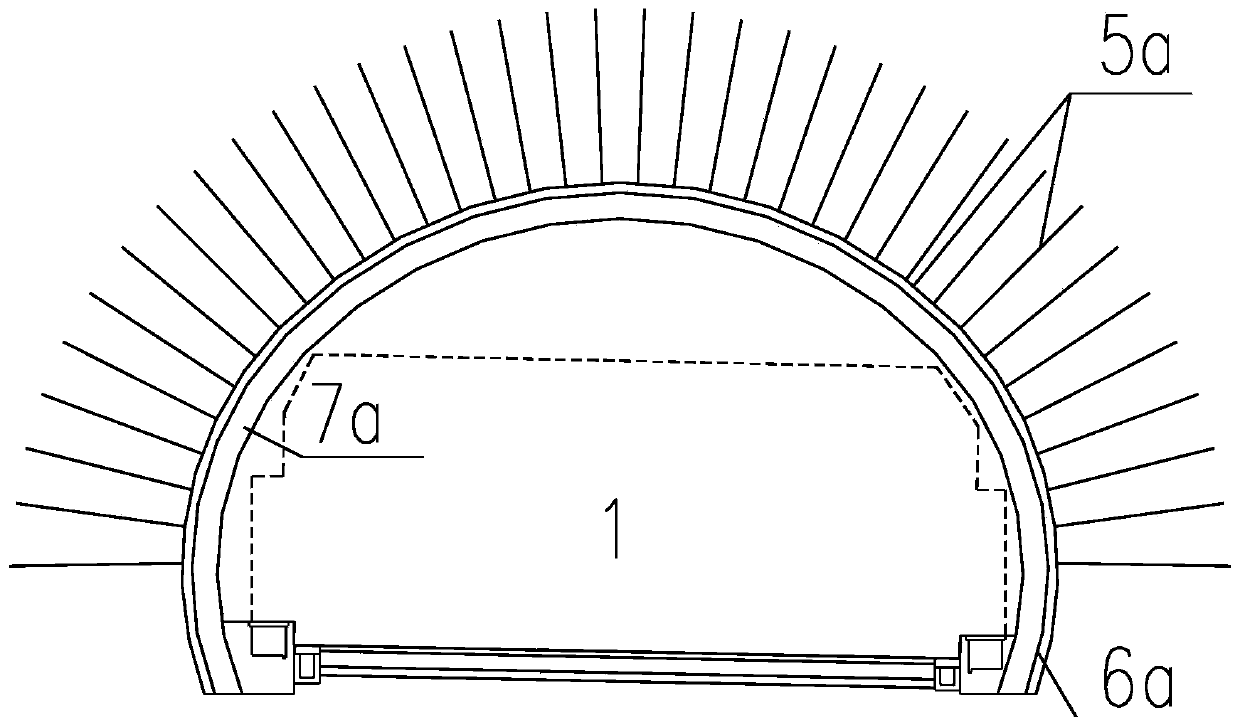

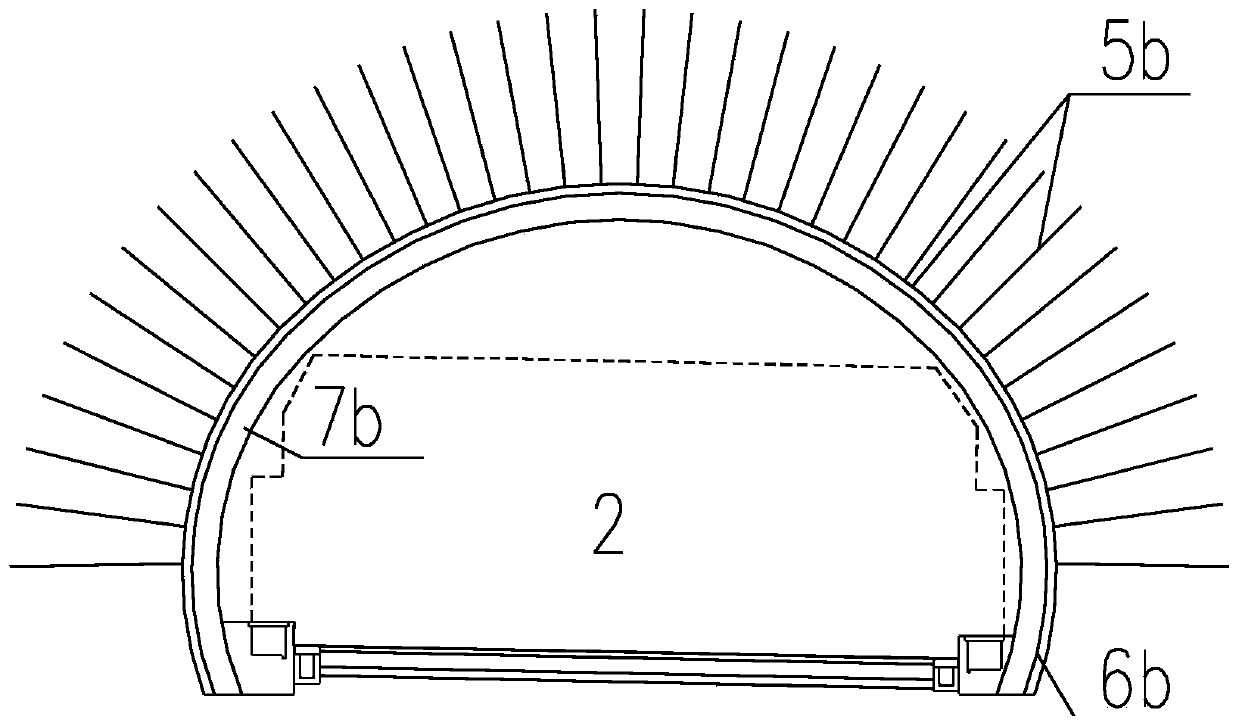

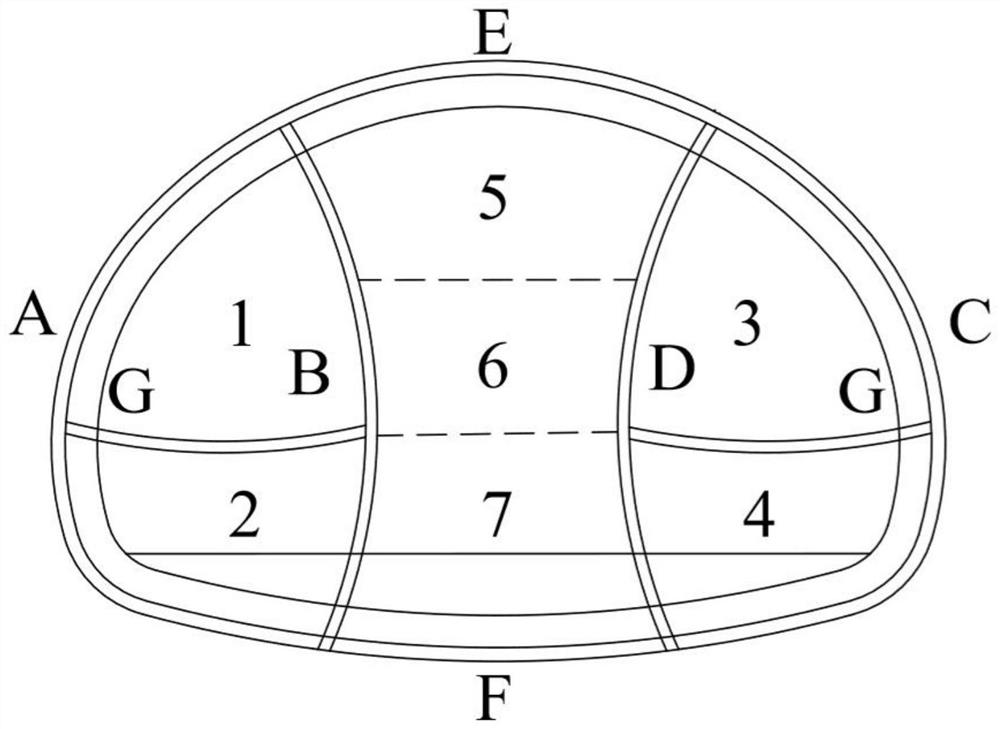

Construction method conversion construction method of super-large-span tunnel in V-level to IV-level surrounding rock section

ActiveCN109989757AReduce disturbanceAvoid intervalsUnderground chambersTunnel liningTunnel constructionBuilding construction

The invention discloses a construction method conversion construction method of a super-large-span tunnel in a V-level to IV-level surrounding rock section. The elevation of an excavation arching lineis controlled to be consistent; in transition section construction, a left pilot tunnel temporary middle wall and a right pilot tunnel temporary middle wall on the two sides of a pilot and a rear pilot in a surrounding rock double-side-wall pilot tunnel method simultaneously move towards the middle of the tunnel until the left pilot tunnel temporary middle wall is in contact with the right pilottunnel temporary middle wall, and foot locking anchor rods are applied to the two sides of a temporary inverted arch; and then the right pilot tunnel temporary middle wall is removed, and the left pilot tunnel temporary middle wall is reserved as a middle temporary middle wall of a CRD method. According to the method, a double-side-wall pilot tunnel method is transversely transited to the CRD method through a gradual change method, the time interval between construction method conversion is avoided, and disturbance of later removal of temporary supports of the double-side-wall pilot tunnel method to surrounding rock is reduced; and therefore the construction speed is increased, the construction period is shortened, enforced idleness due to poor organization of work is avoided, and economicbenefits of tunnel construction are improved.

Owner:CHANGAN UNIV

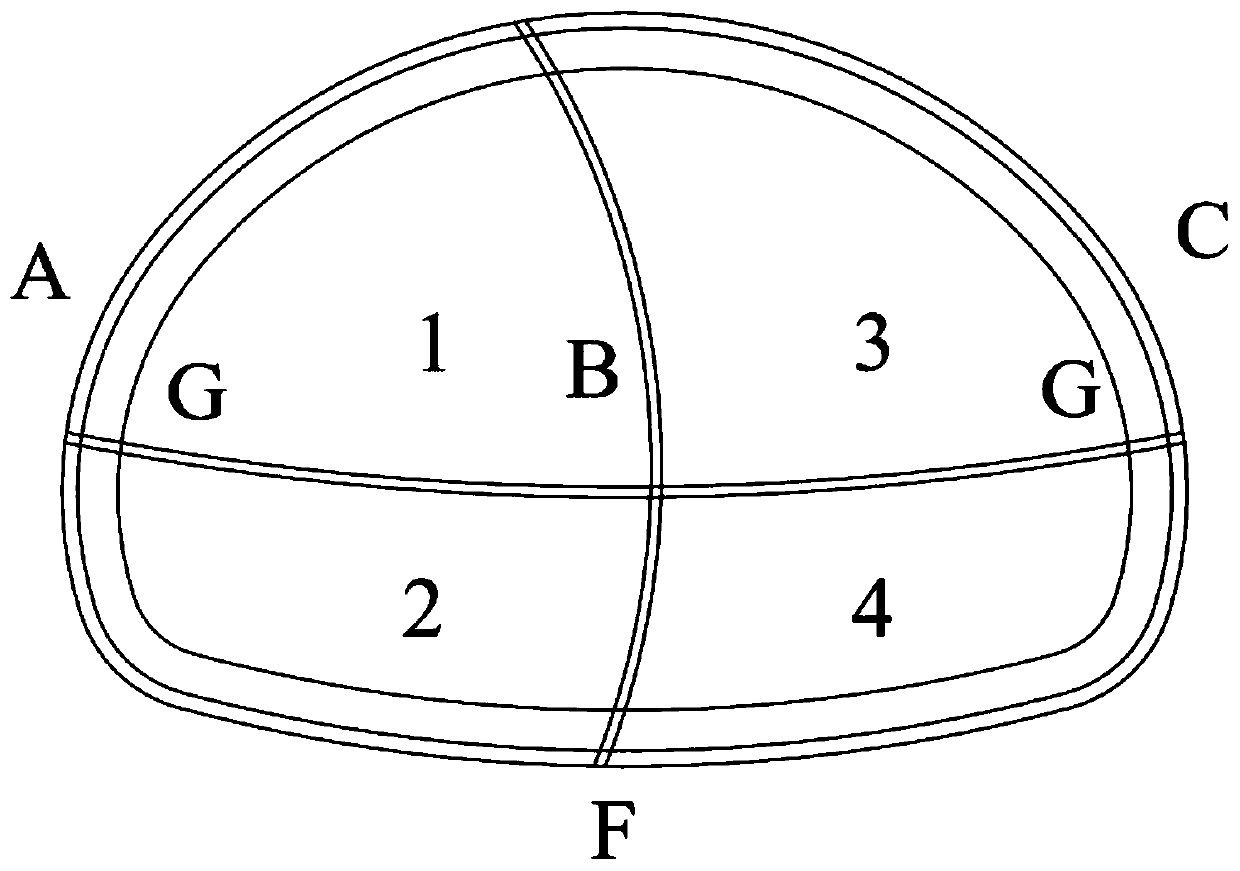

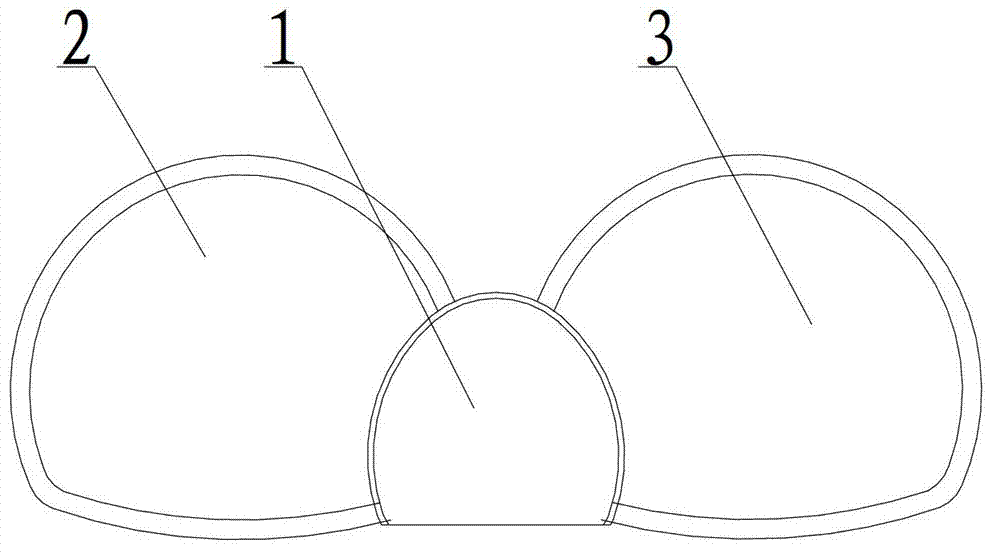

Method for quickening construction of multiple-arch tunnel

ActiveCN103244127ASave the construction period of entering the holeShorten the construction periodTunnelsDischarge efficiencyBuilding construction

The invention relates to a method for quickening construction of a multiple-arch tunnel. The method includes: firstly, pre-supporting a middle pilot tunnel; and secondly, excavating the middle pilot tunnel, constructing a left main tunnel, a right main tunnel, and a cover arch and a long pipe roof of the middle pilot tunnel, setting a widened segment allowing a loader to turn around in the middle of the middle pilot tunnel, and after the middle pilot tunnel is through, constructing a middle partition wall from an entrance of the middle pilot tunnel to an exit of the middle pilot tunnel. The method has the advantages that construction entering is assisted by advanced small pilot pipes so that entering construction period of the middle pilot tunnel is reduced; the section of the middle pilot tunnel is locally enlarged, the loader is used with a dumper for construction, and accordingly residue discharging efficiency is improved greatly; the construction method of the middle partition wall is modified, so that the main tunnels can be constructed in advance; and the middle partition wall and the main tunnels are constructed in parallel, time and space are more reasonable, and accordingly personnel idleness and machine idleness are avoided and construction speed is increased.

Owner:CHINA COMM NORTH ROAD & BRIDGE +1

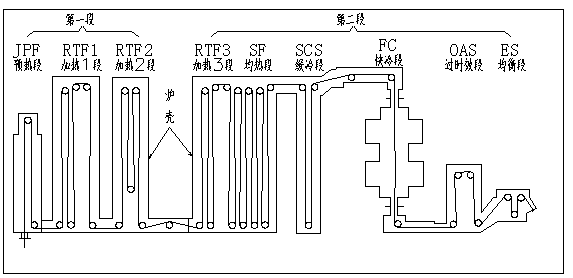

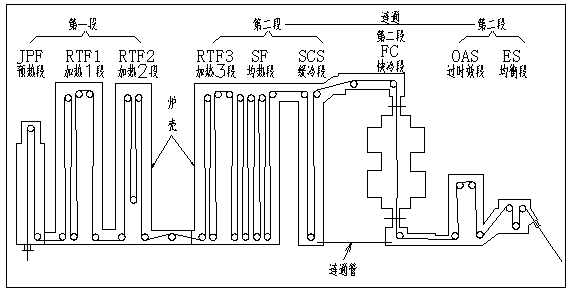

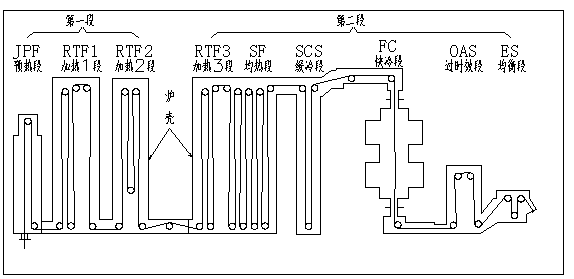

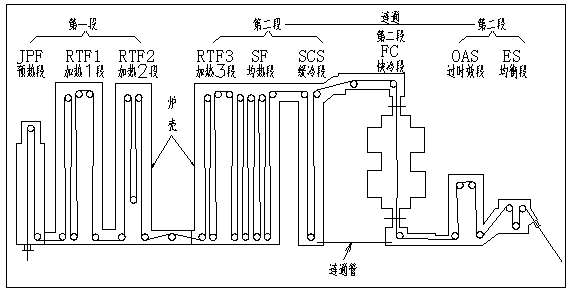

Jumping type air tightness test construction method for continuous annealing furnace

ActiveCN107560793AAvoid idle workShorten the durationFluid-tightness measurementFurnace typesSlow coolingContinuous annealing

Owner:CHINA MCC20 GRP CORP

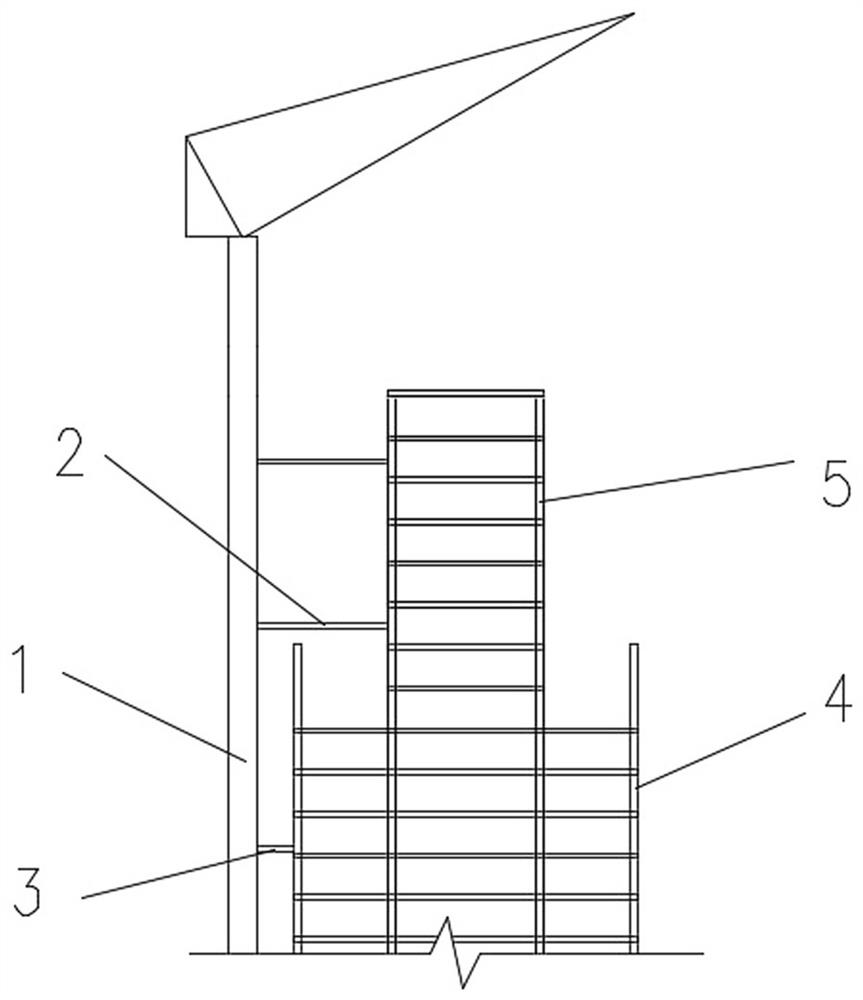

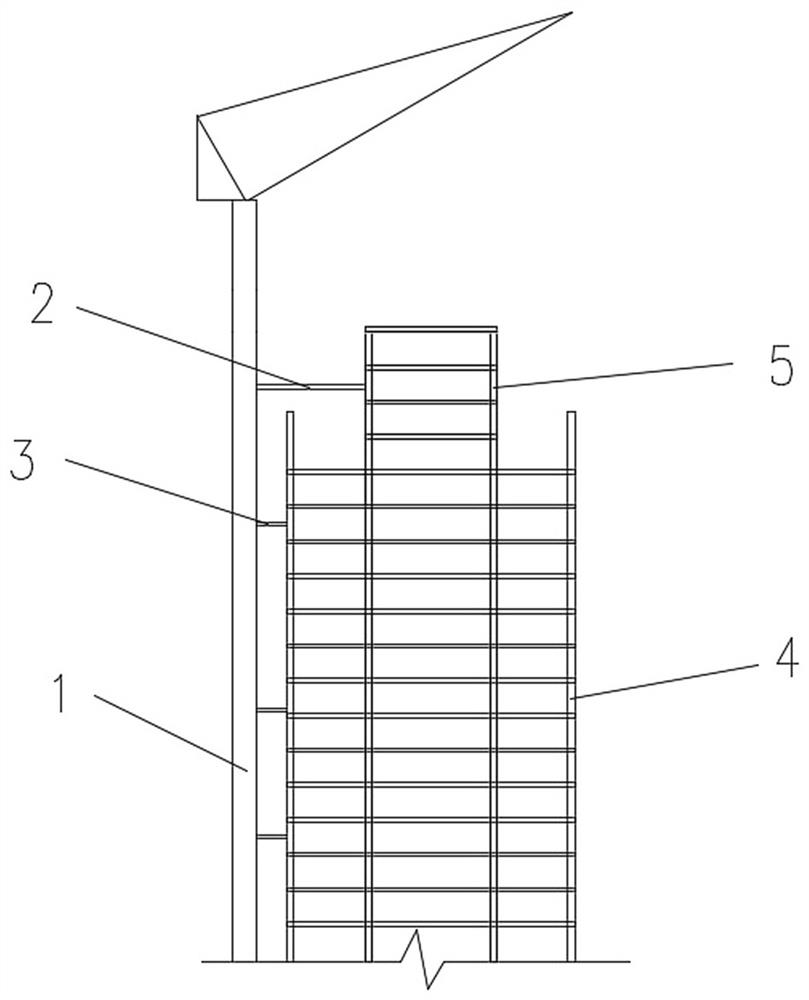

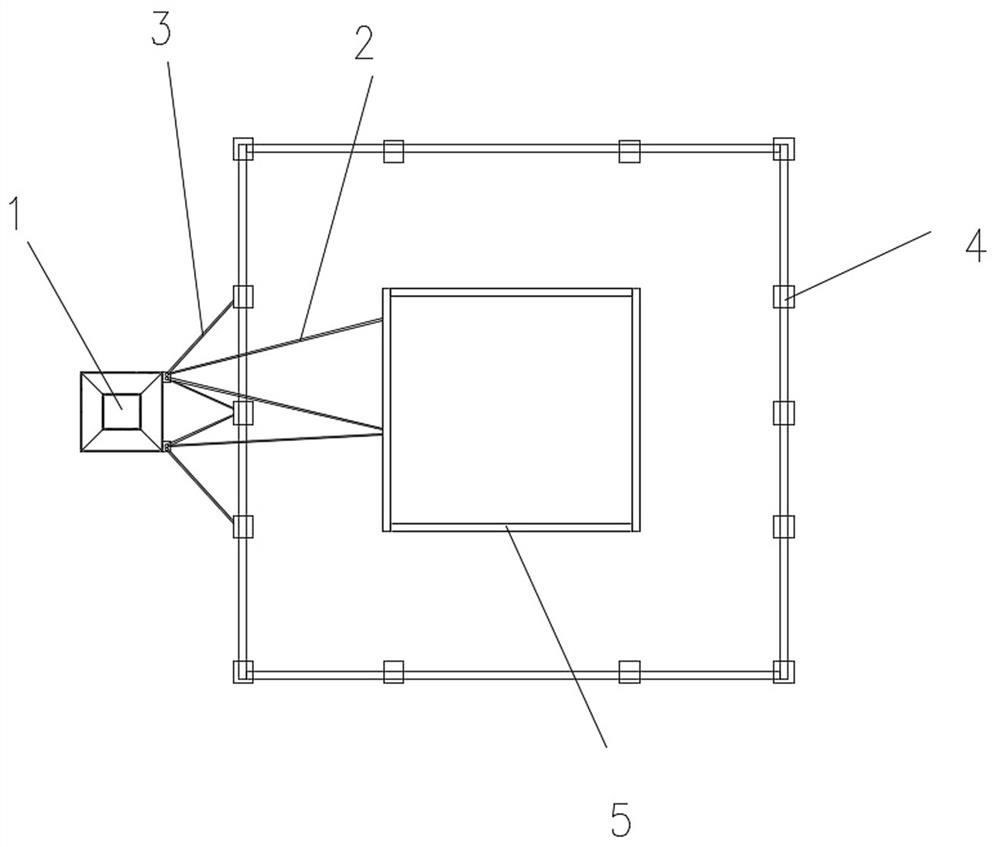

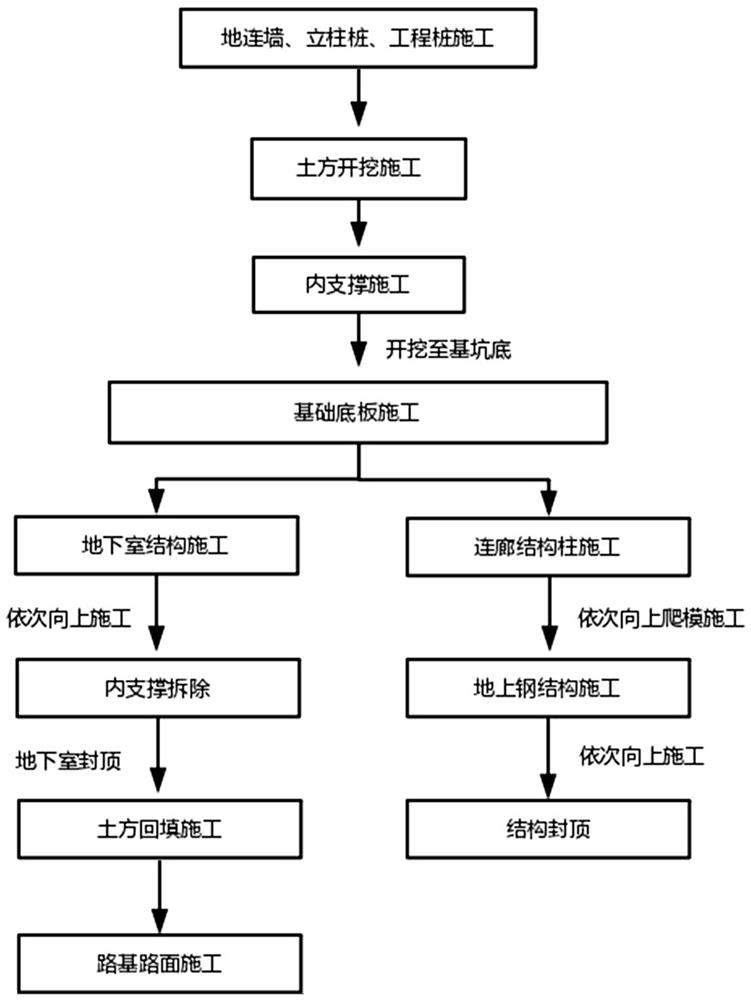

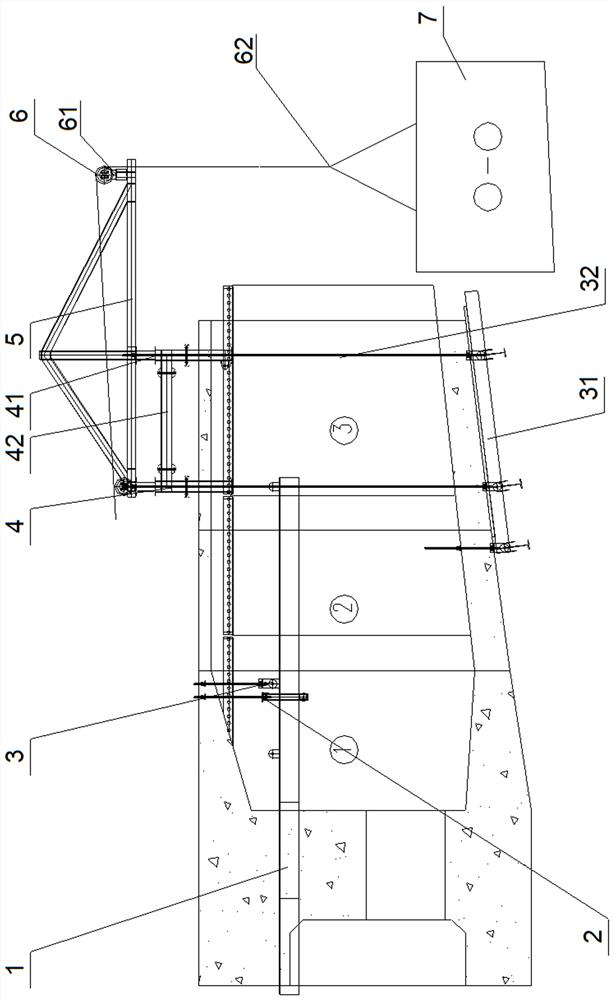

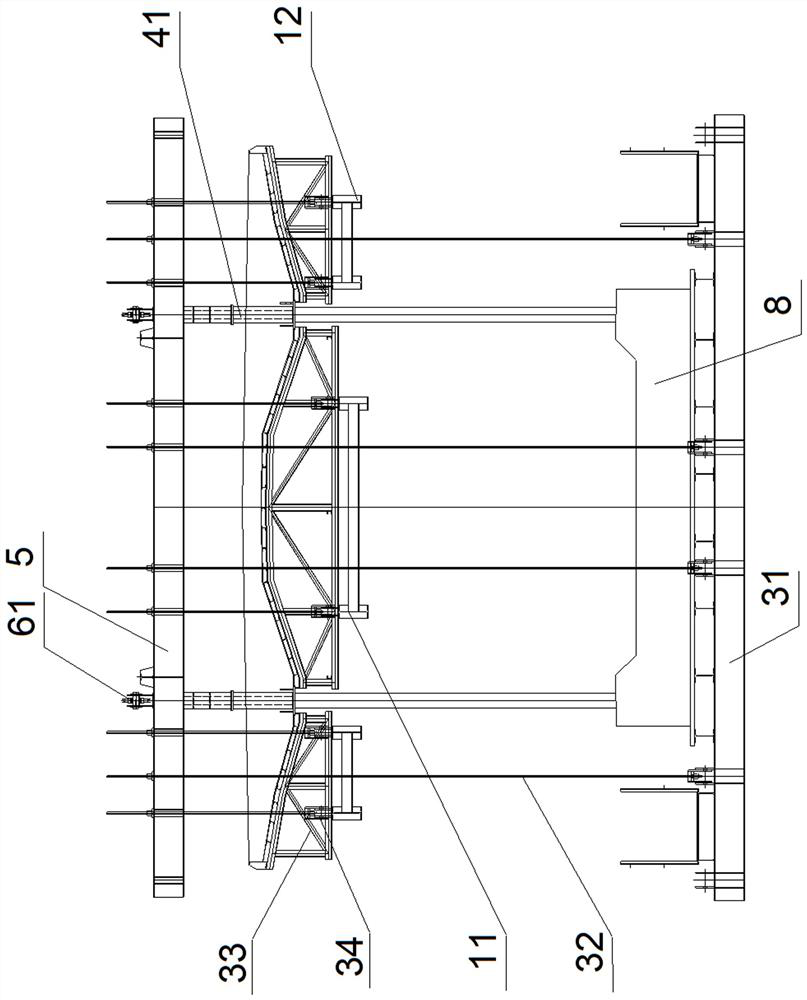

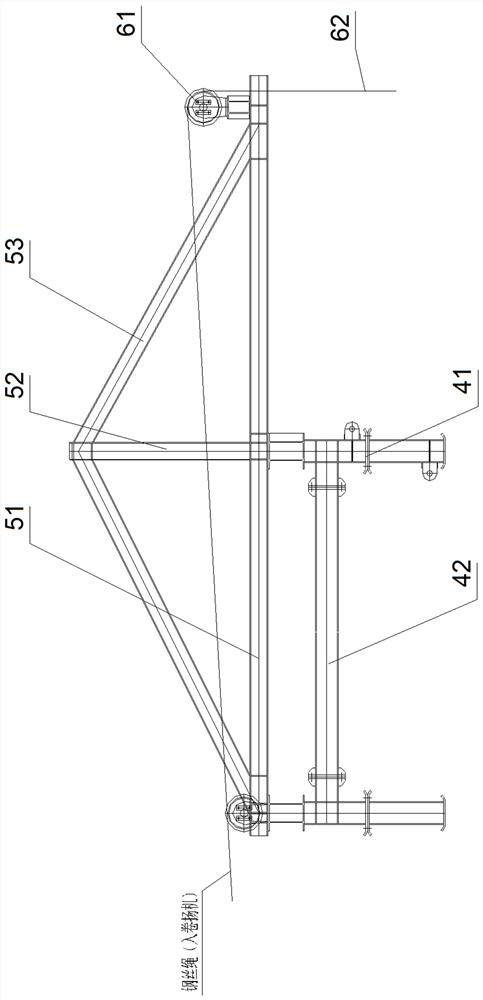

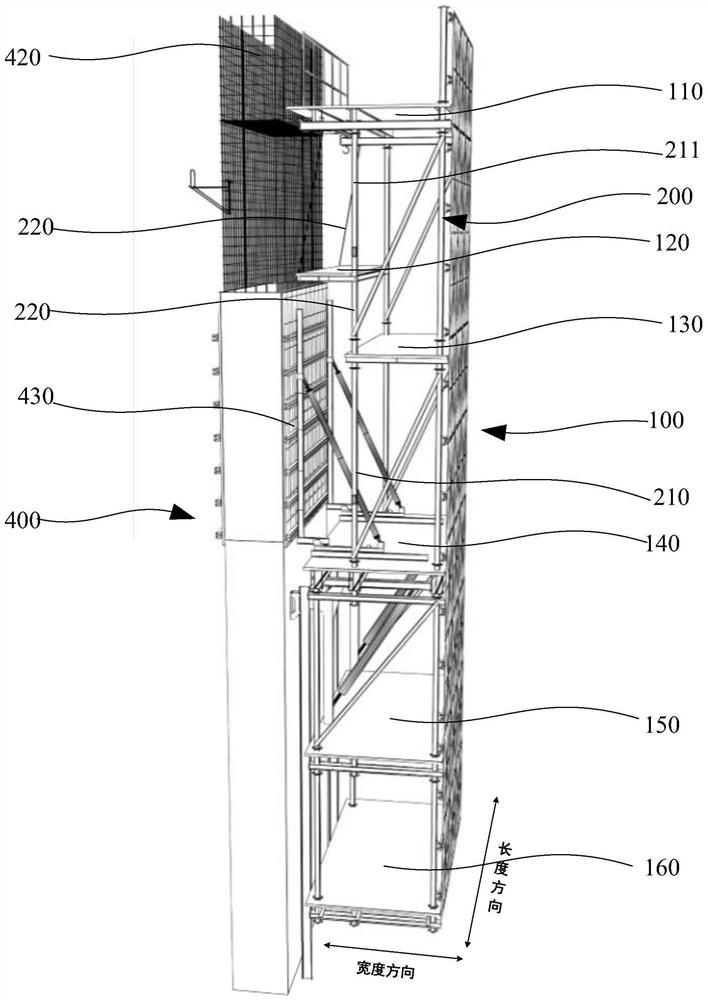

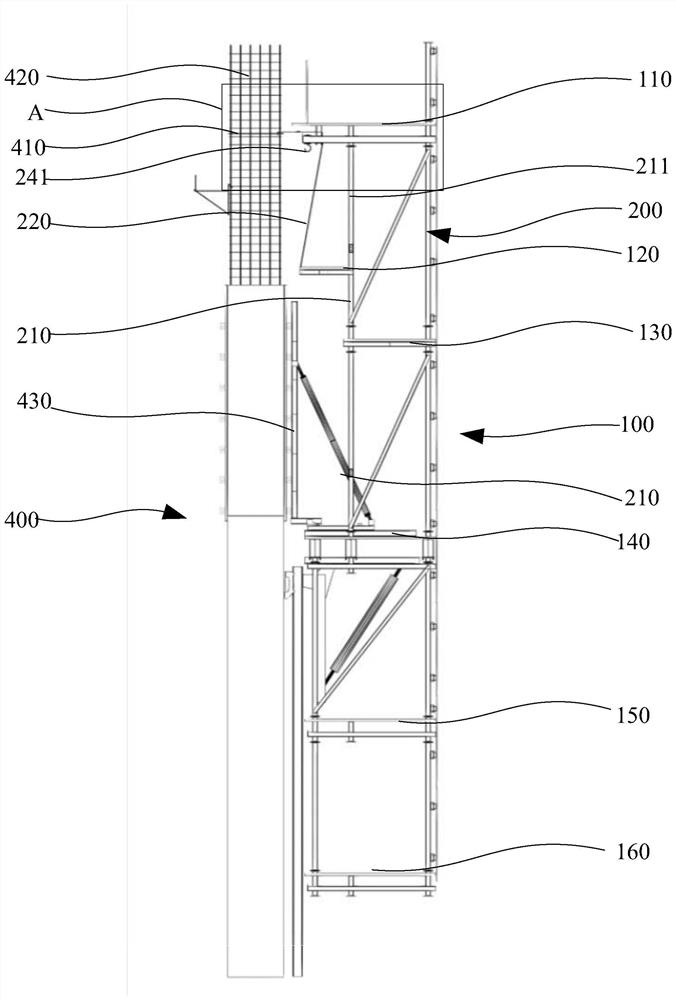

External tower crane alternate conversion attachment system and construction method

ActiveCN113387281AAvoid idle workEase of construction progressExtraordinary structuresBuilding material handlingArchitectural engineeringTower crane

The invention discloses an external tower crane alternate conversion attachment system and a construction method. A tower crane structure comprises a tower crane, a temporary attachment system and a formal attachment system; the temporary attachment system and the formal attachment system are both arranged on the tower crane; the formal attachment system is located below the temporary attachment system; the two ends of the temporary attachment system are connected to the tower crane and a core tube correspondingly; and the two ends of the formal attachment system are connected to the tower crane and an outer frame column correspondingly. For a super high-rise building constructed by adopting a core tube first-moving and outer frame following method, when the height difference between the working surfaces of the core tube and the outer frame is too large, a temporary attachment system is adopted firstly, so that the phenomenon that the tower crane cannot be effectively attached to cause idleness of the tower crane due to the too large height difference between the working surfaces; and when the outer frame column is constructed above the temporary attachment position, temporary attachment is converted into formal attachment, so that the influence of a tower crane attachment rod piece on subsequent decoration and curtain wall construction of a building is avoided, and the overall construction progress of a project is facilitated.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

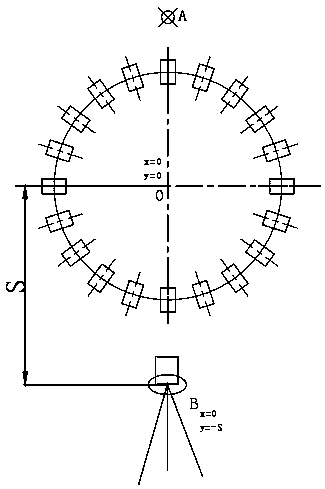

Rotary hearth furnace support carrier roller platform-free installation and adjustment method

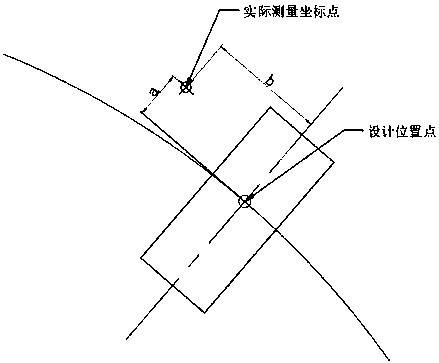

InactiveCN108627143AReduce dependenceEasy and fast measurementSurveying instrumentsComputer Aided DesignHearth

The invention relates to a rotary hearth furnace support carrier roller installation method, in particular to a rotary hearth furnace support carrier roller platform-free installation and adjustment method. The method comprises the steps of preliminarily installing all support rollers in place; determining a pre-buried point A as a 0-degree rear view point for stationing of a total station on a zero line of the design position; determining the position of the center O of a circle of a rotary hearth furnace after the preliminary installation of rotary hearth equipment is completed, and erectingthe total station outside of the circle at which the support rollers are located, and on a point B on an extension line of AO; stationing in the total station, setting the azimuth as 0, establishinga rectangular plane coordinate system with a point O as the origin, and measuring the actual position coordinates of the support rollers one by one; inputting the measured actual coordinates of all the rollers into computer aided design (CAD) by taking the point O in the design drawing of the rotary hearth furnace in the CAD as the coordinate origin, and resolving the difference between the actualmeasured coordinates and design values into a radial direction deviation a and a tangential direction deviation b; giving the result an operator, carrying out fine adjustment on the support rollers one by one, and then fixing the support rollers. The rotary hearth furnace support roller platform-free installation and adjustment method can shorten the construction period and reduce the cost.

Owner:CHINA MCC20 GRP CORP +1

Construction method of onsite supply operation for micro surfacing

InactiveCN102561144ARealize continuous paving operationReduce distractionsIn situ pavingsRoads maintainenceBatch machineSewage

The invention discloses a construction method of onsite supply operation for micro surfacing. The method is characterized by comprising the following steps: firstly, using a batching machine to load mineral aggregate into bulk bags in specific proportion in accordance with the performance requirement, and tieing the ropes of the bulk bags; secondly, using one crane truck to stack the mineral aggregate in bulk bags along the line, and using another crane truck to lift the mineral aggregate in bulk bags onto seal equipment for unloading; thirdly, using an integrated liquid supply vehicle with a liquefied asphalt tank and a water tank to transfer the modified emulsified asphalt and the water respectively into the seal equipment through waste water and a water pump or onsite supply; fourthly, using a jubilee truck to carry the cement to the construction site, carrying out onsite cement supply to the seal equipment with manpower; fifthly, performing paving in accordance with the normal construction procedure, after the paving is finished, supplying the material, and then performing the paving again; carrying out the operation repeatedly until the paving is finished. By adopting the construction method, the construction efficiency can be remarkably improved, the construction quality is ensured, materials and fuels are saved; in addition, the operation is convenient, and the construction is environmental protection.

Owner:广东能达公路养护股份有限公司

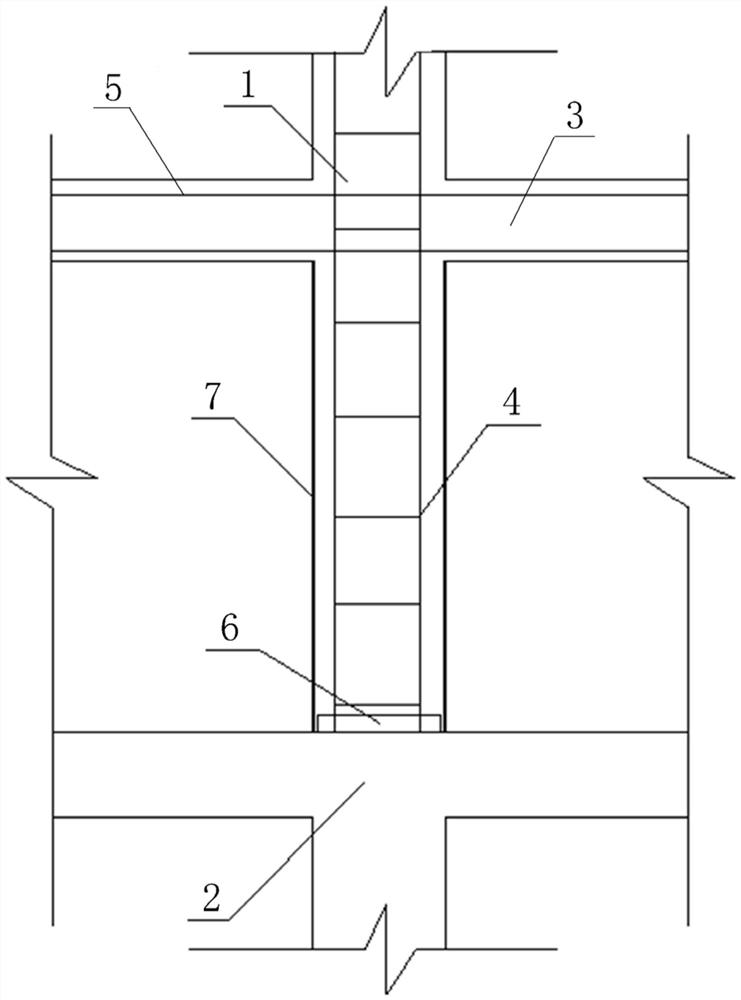

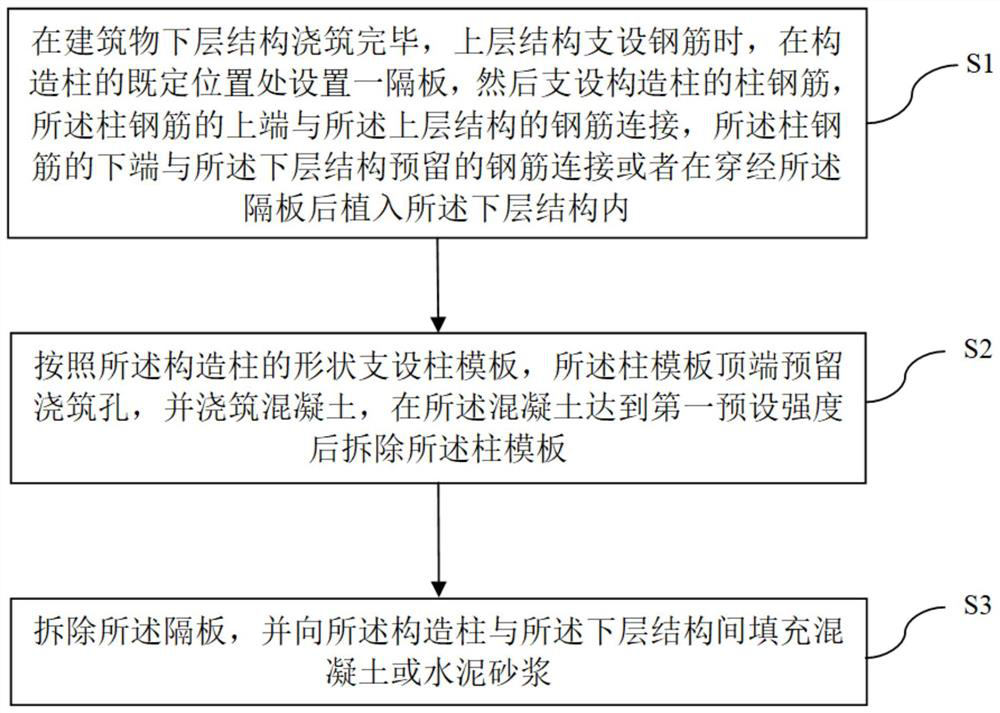

Constructional column construction method

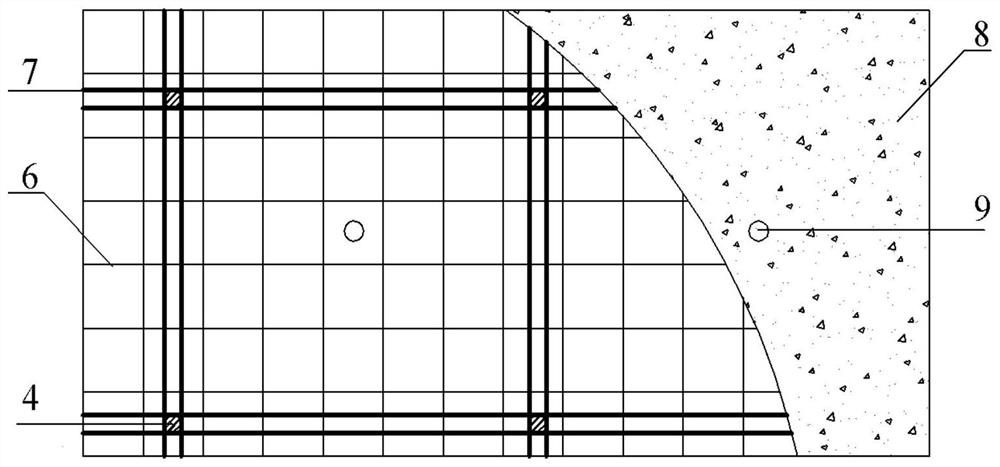

PendingCN113565263AEven by forceAvoid formingStrutsForms/shuttering/falseworksArchitectural engineeringRebar

The invention relates to the technical field of building construction, and provides a constructional column construction method. The constructional column construction method comprises the following steps that when pouring of a lower-layer structure of a building is completed and steel bars are erected on an upper-layer structure, a partition plate is arranged at a set position of a constructional column, then column steel bars of a constructional column are erected, the upper ends of the column steel bars are connected with the steel bars of the upper-layer structure, the lower ends of the column steel bars are connected with steel bars reserved in the lower layer structure or penetrate through the partition plate to be implanted into the lower layer structure; a column formwork is erected according to the shape of the constructional column, a pouring hole is reserved in the top end of the column formwork, concrete is poured, and the column formwork is dismantled after the concrete reaches the first preset strength; the partition plates are dismantled, and the space between the constructional column and the lower layer structure is filled with the concrete or cement mortar. According to the constructional column construction method, a main body part of the constructional column and a main body structure of the building are constructed synchronously, the construction efficiency is improved, it is guaranteed that stress of the constructional column is uniform, and the problem of secondary construction is avoided.

Owner:NORTH CHINA METALLURGICAL CONSTR ENG CONSTR +1

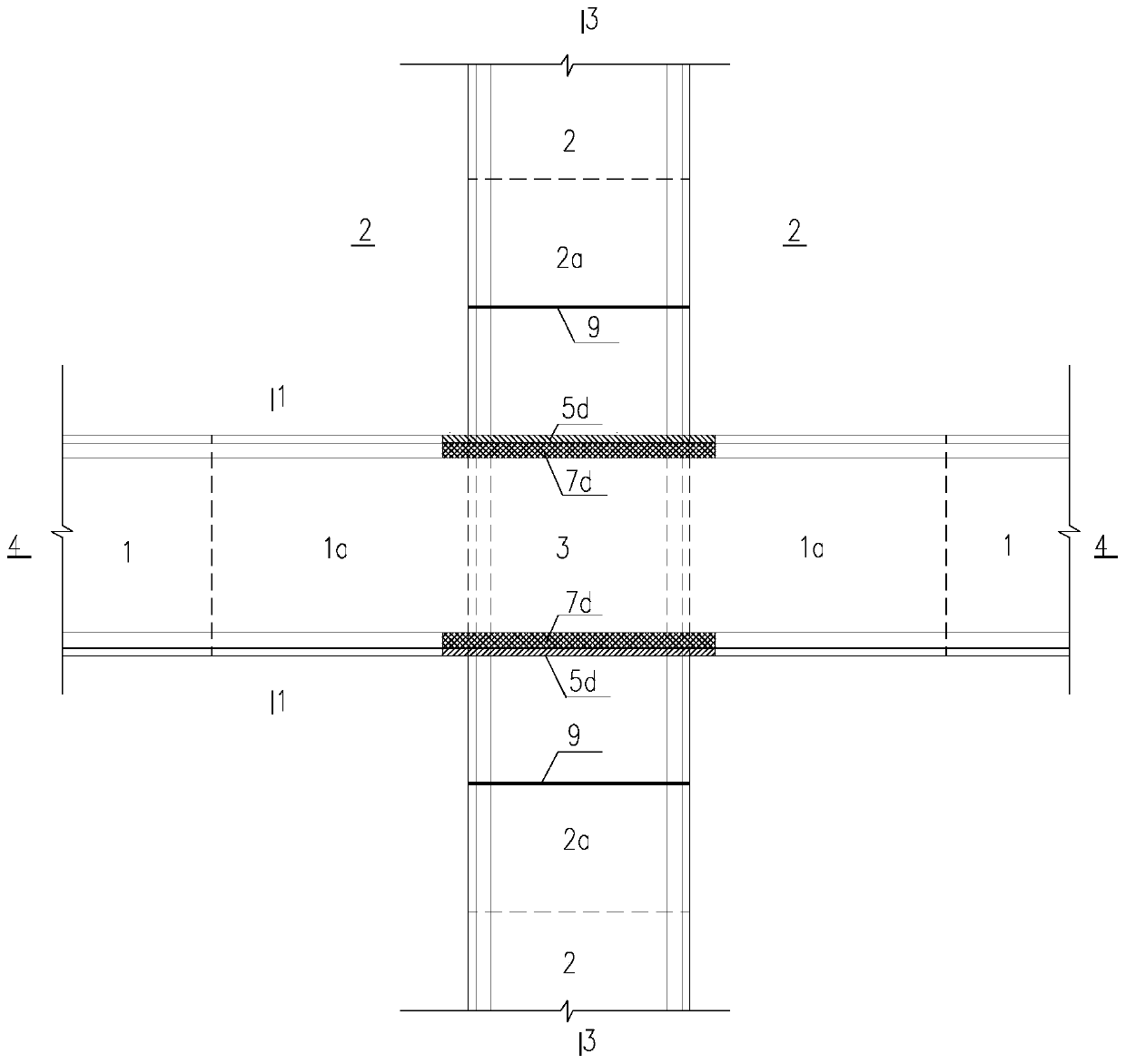

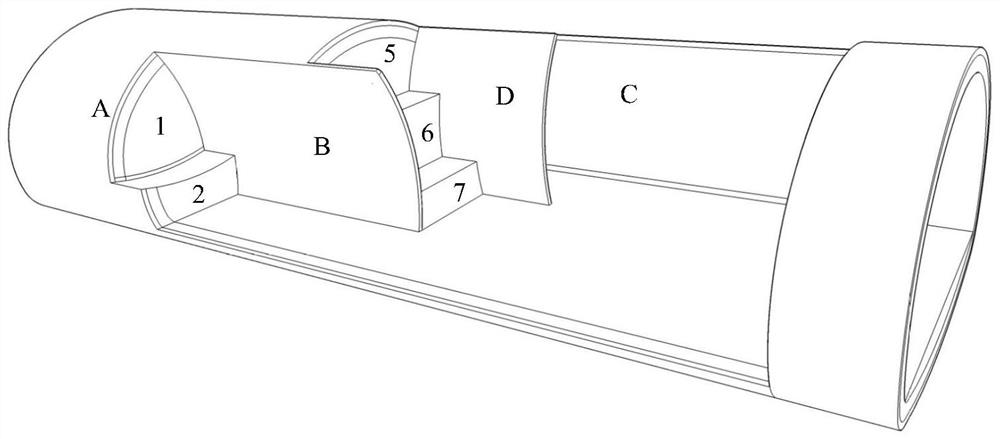

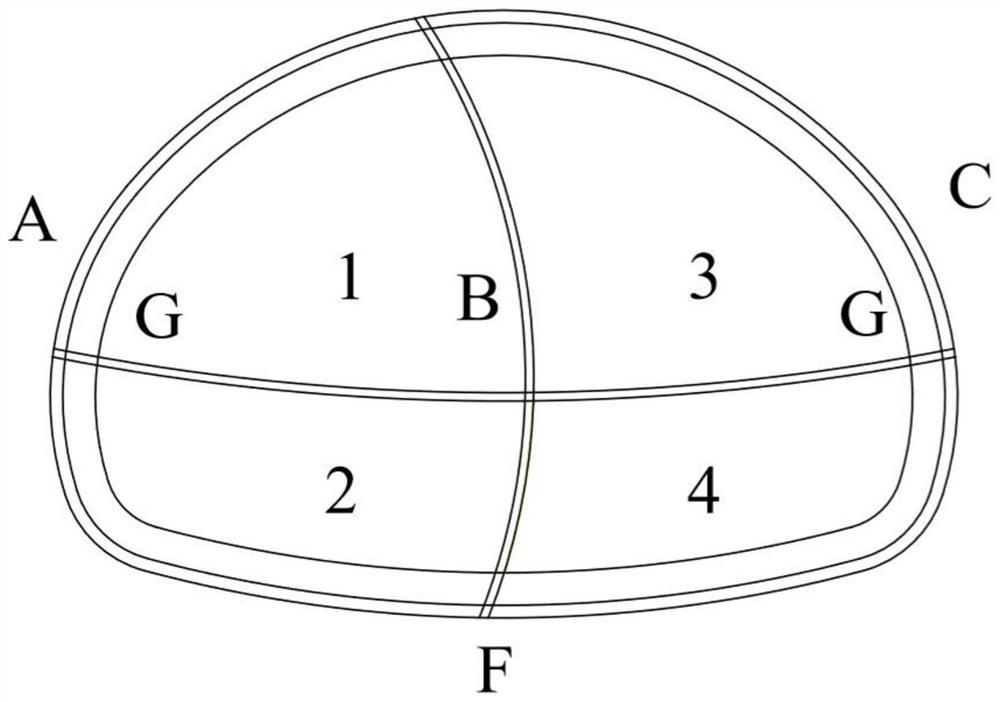

Intersection tunnel joint building structure and construction method thereof

PendingCN111075473AAvoid idle workShorten the construction periodUnderground chambersTunnel liningArchitectural engineeringConstruction scheduling

The invention is applicable to the technical field of municipal engineering, and provides an intersection tunnel joint building structure and a construction method thereof. The intersection tunnel joint building structure is provided with an upper-layer tunnel, a lower-layer tunnel and a single-hole double-layer joint building section structure, wherein the upper-layer tunnel and the lower-layer tunnel are crossed in a plane, and the joint building section structure is located at a crossed position between the upper-layer tunnel and the lower-layer tunnel; the middle position of the joint building section structure in the vertical direction is separated by a middle plate, and a space above the middle plate is used for allowing vehicles at the upper-layer tunnel to pass; and a space below the middle plate is used for allowing vehicles at the lower-layer tunnel to pass. Through the structure, the vertical height difference between the upper-layer tunnel and the lower-layer tunnel can becompressed to limitation, and the road line type is optimized; and meanwhile, the construction method can start construction from any tunnel face arriving at a crossed node in advance, the down time problem caused by the fact that the construction progress of the upper-layer tunnel and the lower-layer tunnel are different is avoided, the construction period is effectively shortened, the implementation performance is high, the construction cost is low, and the intersection tunnel joint building structure is worthy of wide popularization.

Owner:深圳市综合交通与市政工程设计研究总院有限公司

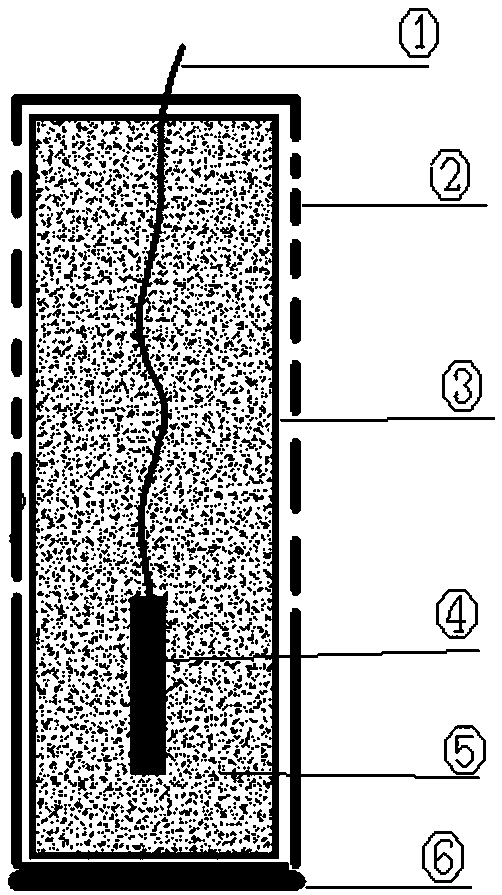

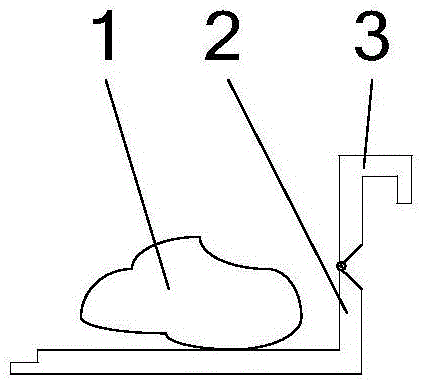

Quick installing and embedding device of concrete dam osmometer

PendingCN109507083AQuick installation and embeddingImprove installation and embedding efficiencyPermeability/surface area analysisRoller-compacted concreteSteel tube

The invention provides a quick installing and embedding device of a concrete dam osmometer. The quick installing and embedding device comprises a galvanized steel pipe, wherein holes are uniformly formed in the surface of the galvanized steel pipe; a bottom cover is arranged on one end of the galvanized steel pipe, and one surface of the bottom cover is embedded in the galvanized steel pipe and istightly connected with the galvanized steel pipe; geotechnical cloth is arranged on the inner wall of the galvanized steel pipe, and the galvanized steel pipe is internally filled with dense medium-coarse sand; an observation osmometer is embedded in the dense medium-coarse sand, an observation cable is arranged on one end of the observation osmometer, and one end of the observation cable is exposed outside the galvanized steel pipe. According to the quick installing and embedding device disclosed by the invention, quick installing and embedding of the dam osmometer can be realized, the interference of installing and embedding construction of the dam osmometer to dam construction, particularly the interference to dam roller compacted concrete construction, can be avoided, the effective utilization time of a compacting machine is increased, and unnecessary idling of labor force is avoided; meanwhile, the installing and embedding efficiency of the osmometer is increased, and the safetyrisk brought by cross operation is reduced.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

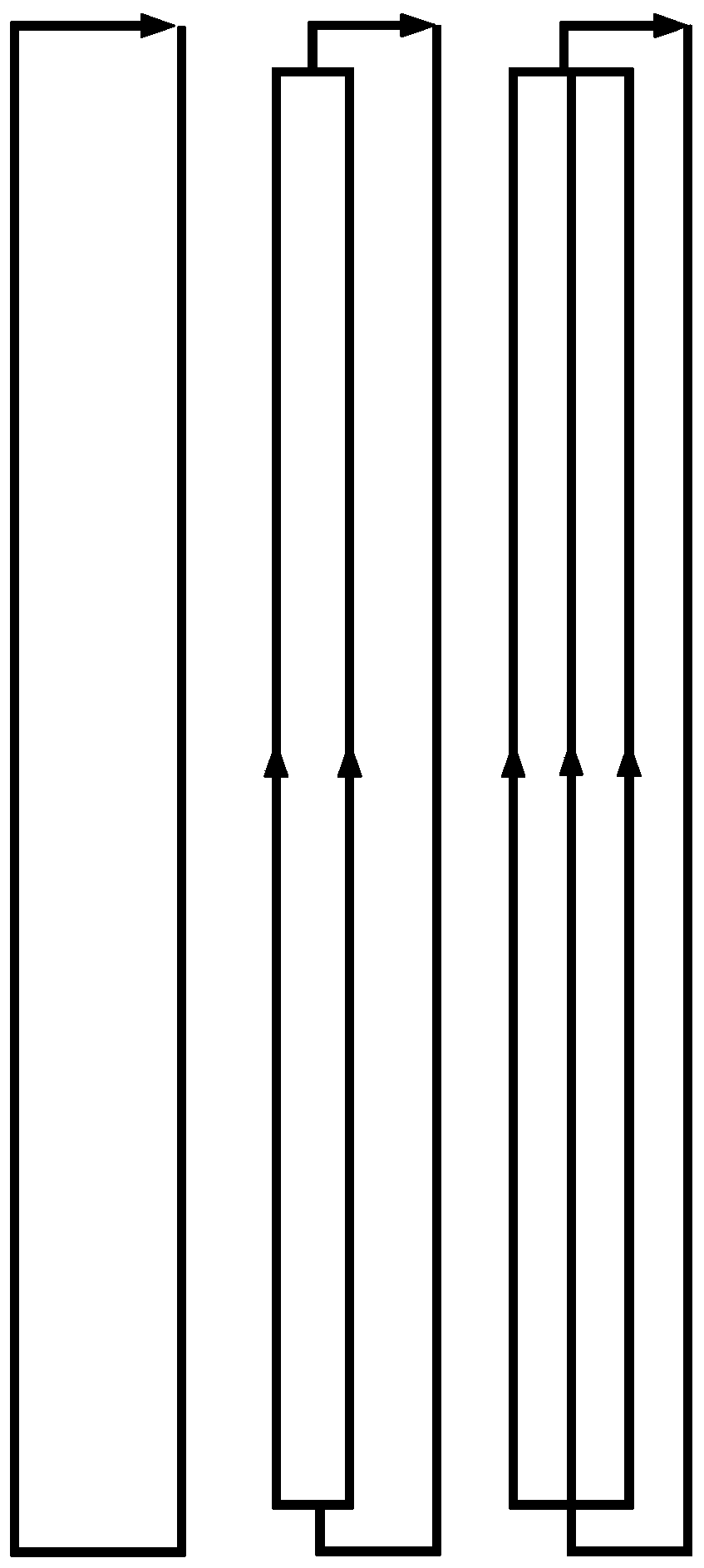

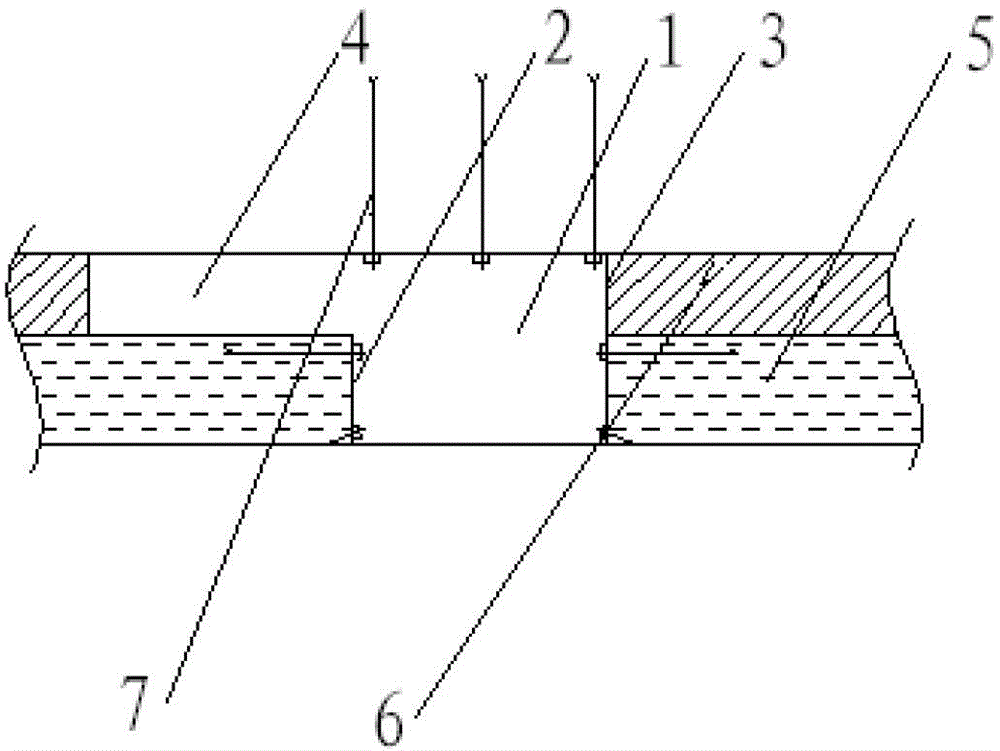

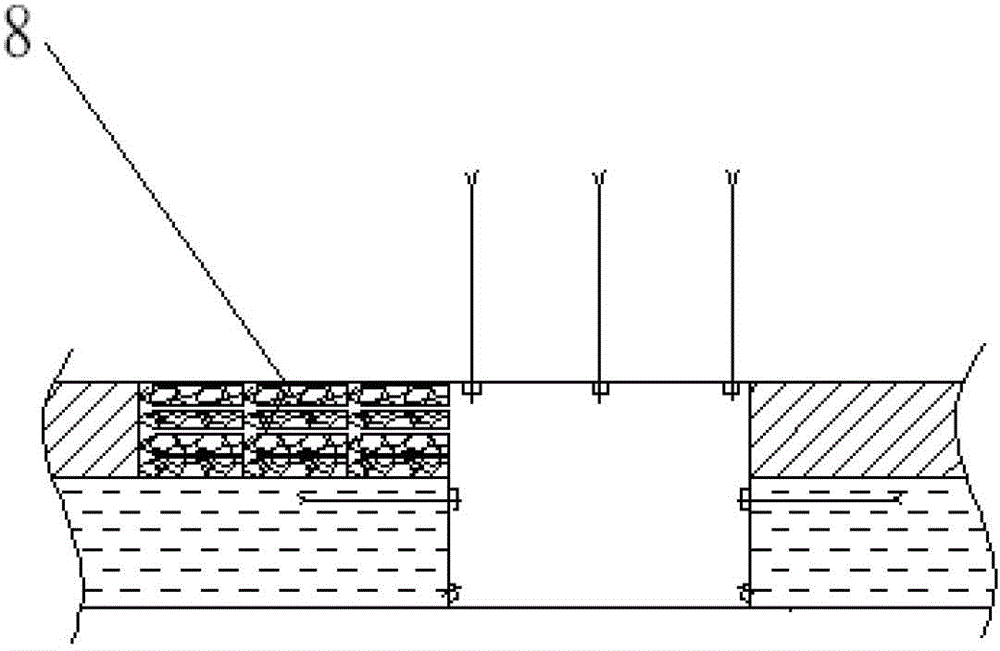

Arrangement method for double circulation process of interior wallboard member production line

The invention relates to an arrangement method for a double circulation process of an interior wallboard member production line. An assembly line comprises the following steps: mold cleaning; releaseagent spraying; side form lineating; side form mounting; reinforcing steel bar mounting; embedded part mounting; pouring and vibrating; striking off; leaving to stand and procuring; plastering and press polishing; steam curing; mold disassembling; rough surface treatment; and putting in storage. The assembly line performs construction by adopting two independent circulating assembly lines: an inner circulating assembly line and an outer circulating assembly line. The arrangement method for the double circulation process of the interior wallboard member production line avoids stagnation of theassembly line and idling of the labor force of staff as a result of single circulation of a conventional process. By adopting the inner and outer independent double circulation assembly line circulation method, fields and resources are utilized fully, so that the production efficiency is increased to two times of that of a conventional assembly line.

Owner:CHINA 22MCC GROUP CORP

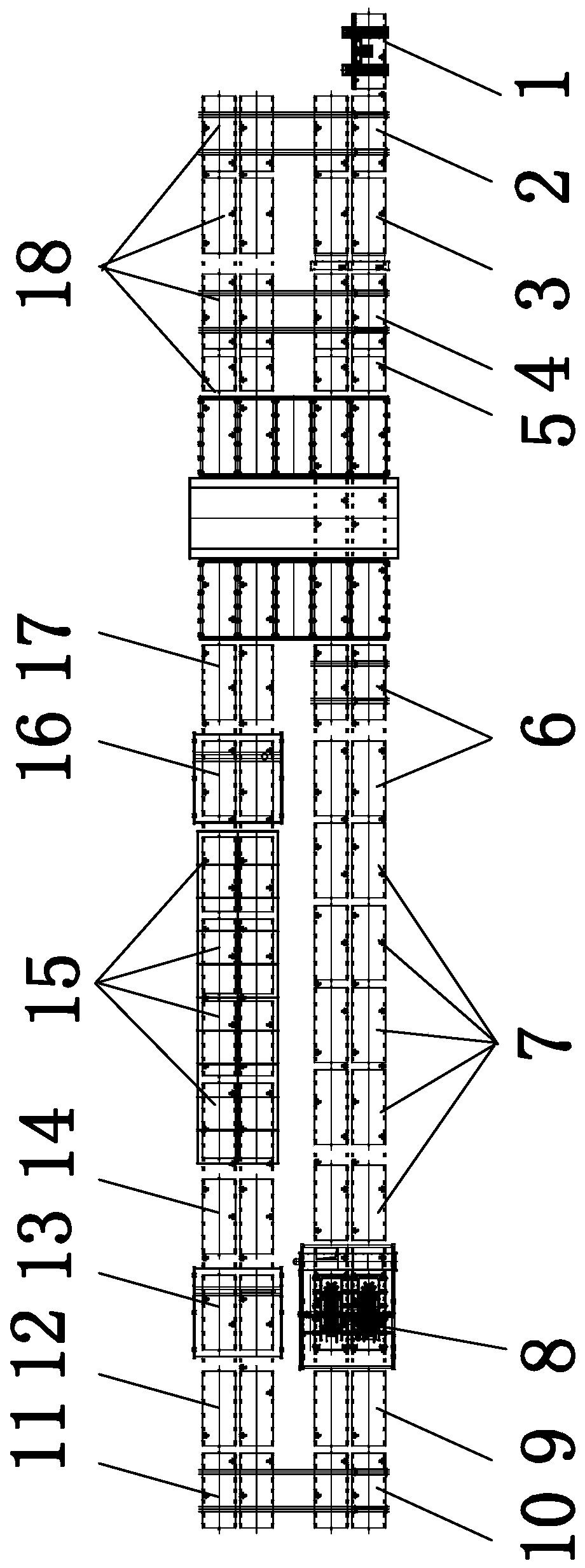

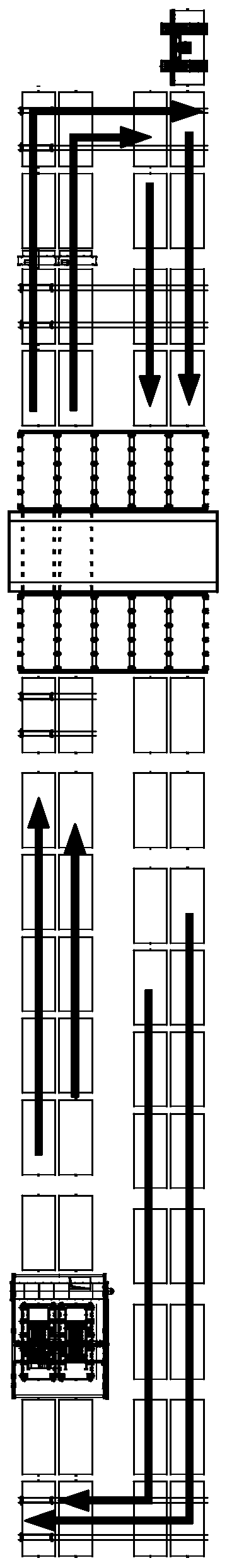

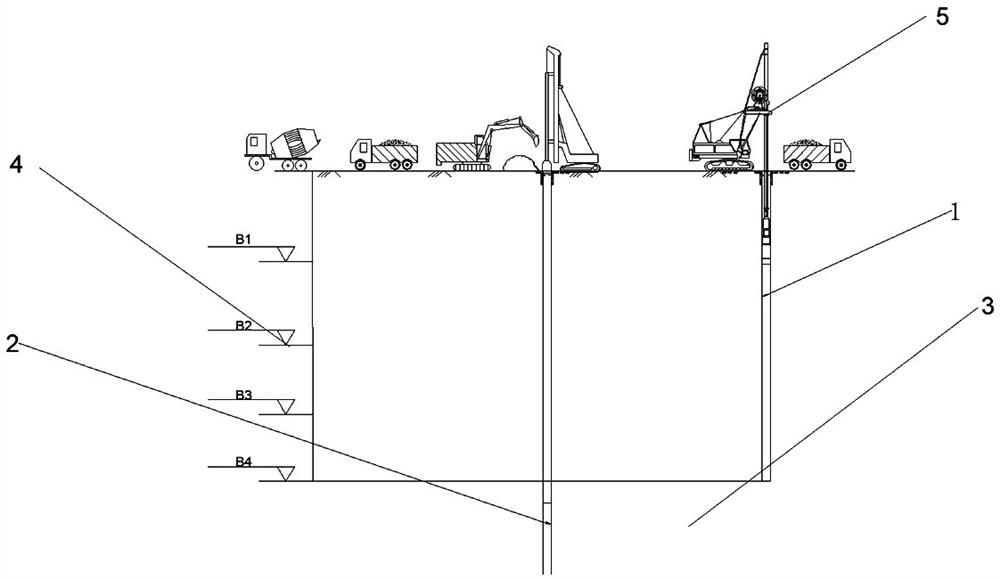

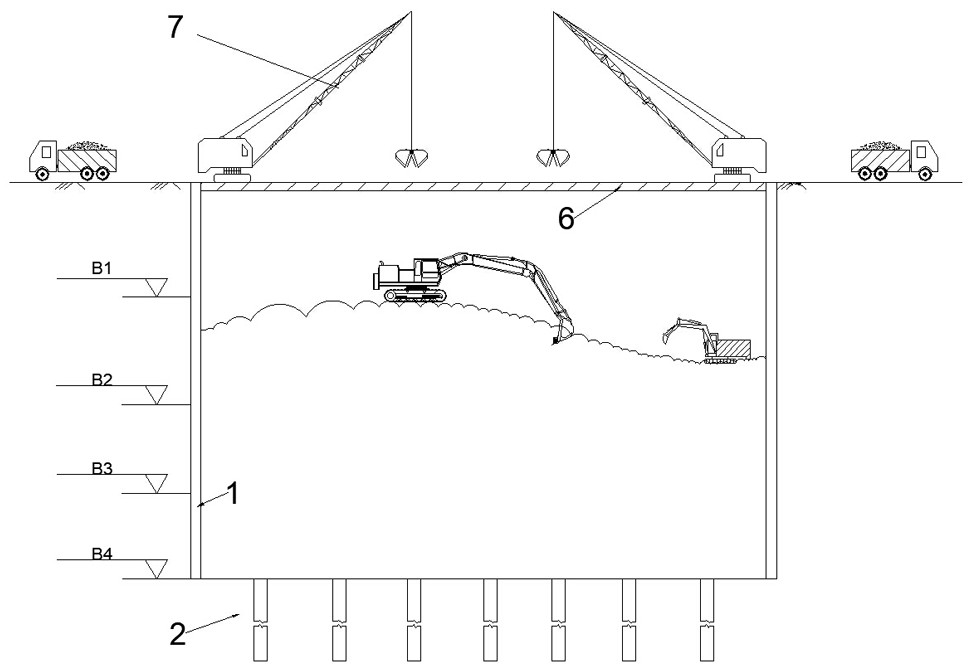

Semi-reverse construction method for large-span corridor structure along street

ActiveCN113898007AImprove construction efficiencyLow costArtificial islandsUnderwater structuresArchitectural engineeringEngineering

The invention discloses a semi-reverse construction method for a large-span corridor structure along a street. During construction, a foundation pit support and a basement structure are constructed in sequence, an overground structure is constructed by adopting a semi-reverse construction method, the construction efficiency can be effectively improved and the cost can be saved by combining cross construction of the foundation pit support and the basement structure and the overground structure, more operation time is provided for other professional insertion construction, and the project delay risk is reduced. According to the construction method, construction of an underground diaphragm wall maintenance structure and supporting columns is completed on the ground firstly, then earthwork excavation, inner support construction and bottom plate construction are sequentially conducted, then a creeping formwork is adopted for constructing corridor structure columns to a corridor structure layer on the ground, a corridor steel structure is installed, and other structure floors are sequentially and upwards constructed; and in this way, the overground and underground structures are convenient to operate, mutual assistance is achieved, the influence of a construction working face is avoided, the construction period can be greatly shortened, and construction quality is guaranteed. According to the method, the traffic influence on a commercial core area is reduced, the road occupation of a project is reduced, and more construction working surfaces are provided.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

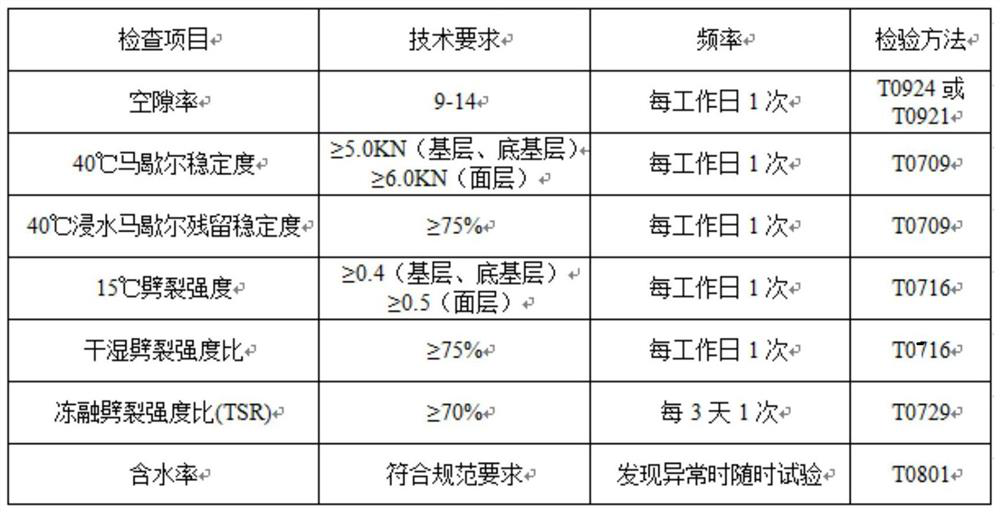

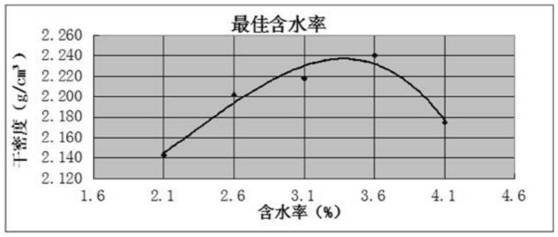

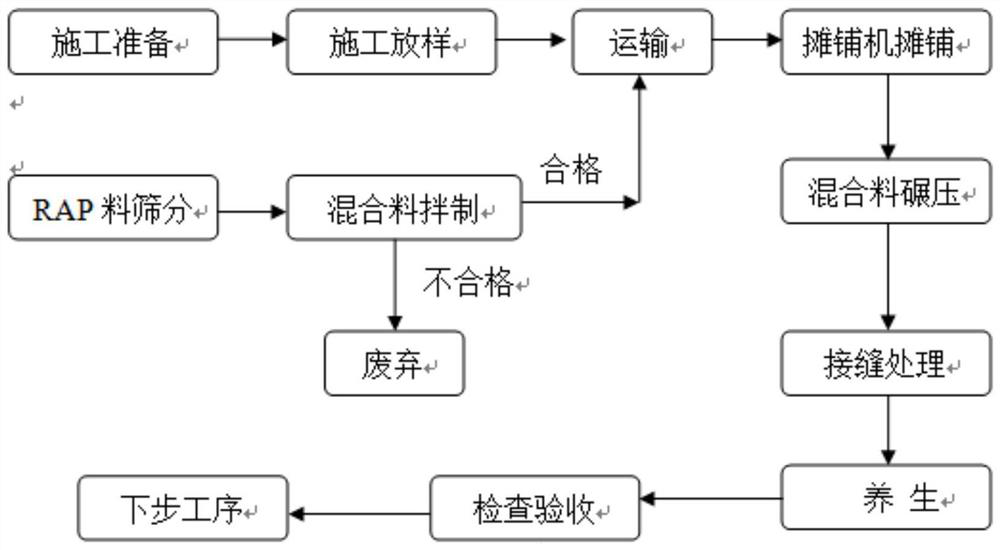

Emulsified asphalt plant-mixed cold-recycled mixture and construction process thereof

InactiveCN114163187ATake advantage ofReduce maintenance construction timeIn situ pavingsSolid waste managementFiberLand resources

The invention relates to an emulsified asphalt plant-mixed cold-recycled mixture and a construction process thereof. The emulsified asphalt plant-mixed cold-recycled mixture comprises a cold-recycled mixture mineral aggregate, emulsified asphalt and cement, the ratio of the components is as follows: RAP (0-5mm): RAP (5-10mm): RAP (10-30mm): aggregate with the particle size of 10-30mm: mineral powder: emulsified asphalt: cement = 30: 23: 35: 10: 2: 3.3: 1.5; the proportion of water is 3.6%; the construction technology of the mixture comprises the eight steps of original pavement milling and screening, construction lofting, fiber cloth laying, mixing, mixture transportation, paving, compaction and maintenance. The invention has the following beneficial effects: from the perspective of resource saving, 100% of original pavement old materials are fully utilized, no waste material is used, and mineral and land resources are saved; and the regeneration unit performs continuous construction, regeneration, paving and additional paving synchronously. The pavement maintenance construction time is greatly shortened through emulsified asphalt cold regeneration, and time, materials, resources and the like are greatly saved.

Owner:HUITONG ROAD & BRIDGE CONSTR GROUP

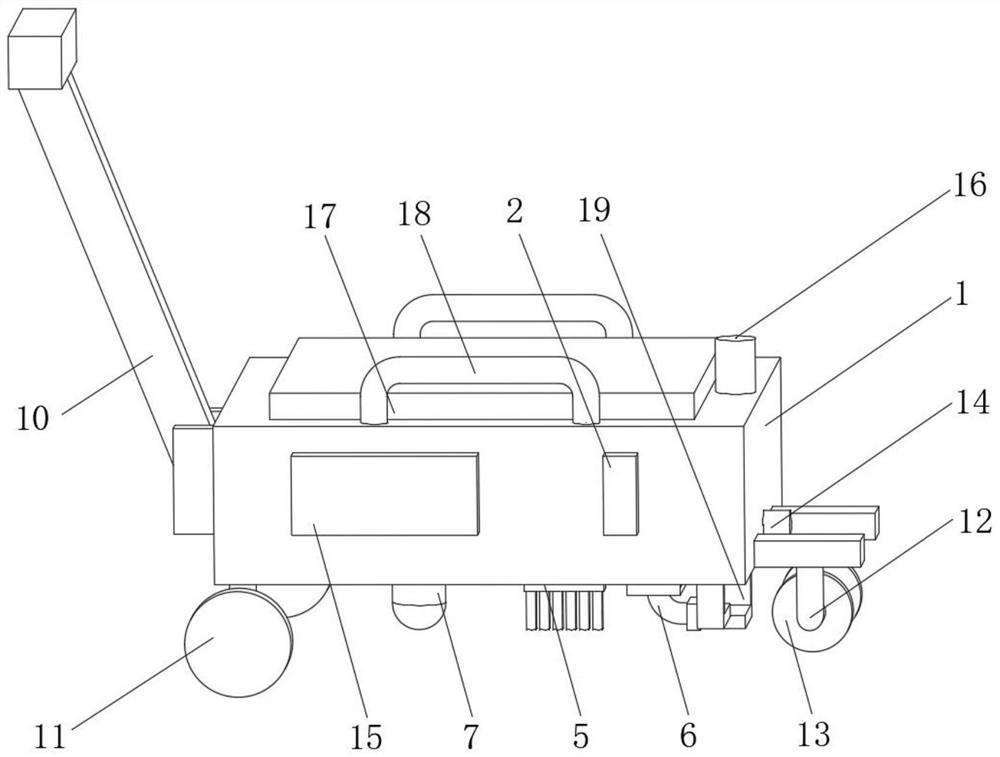

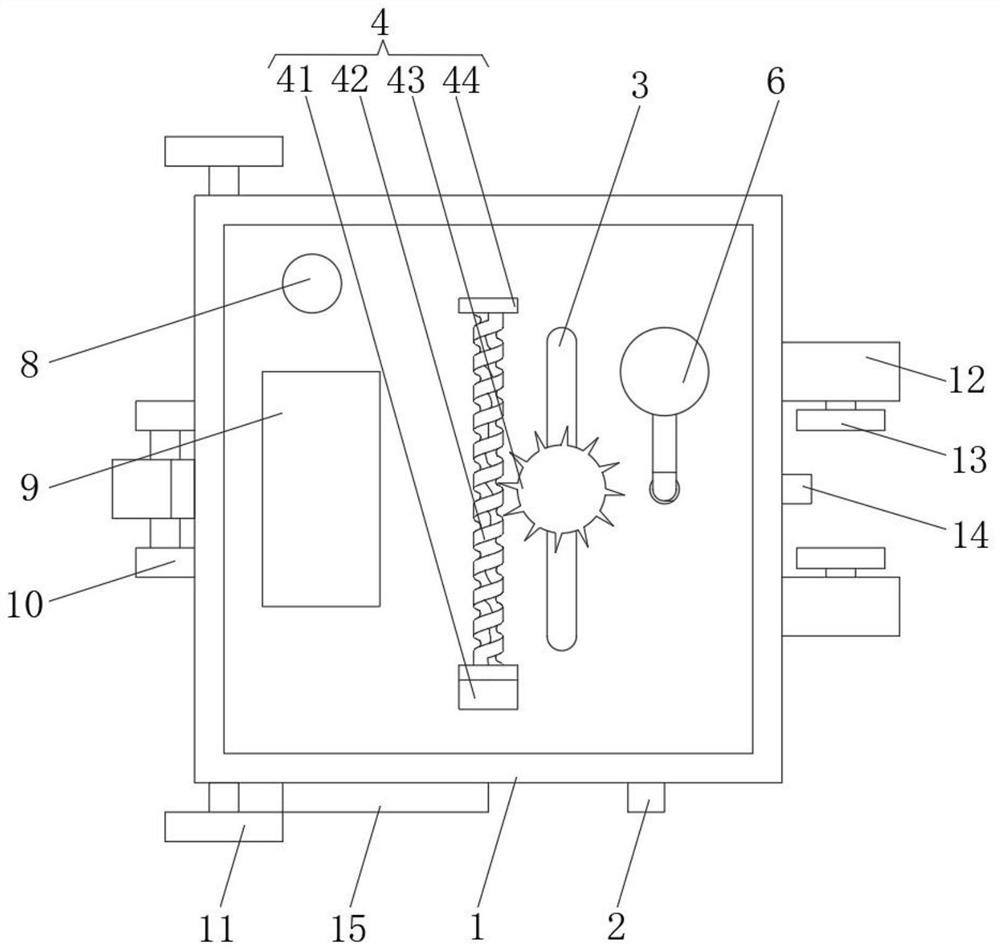

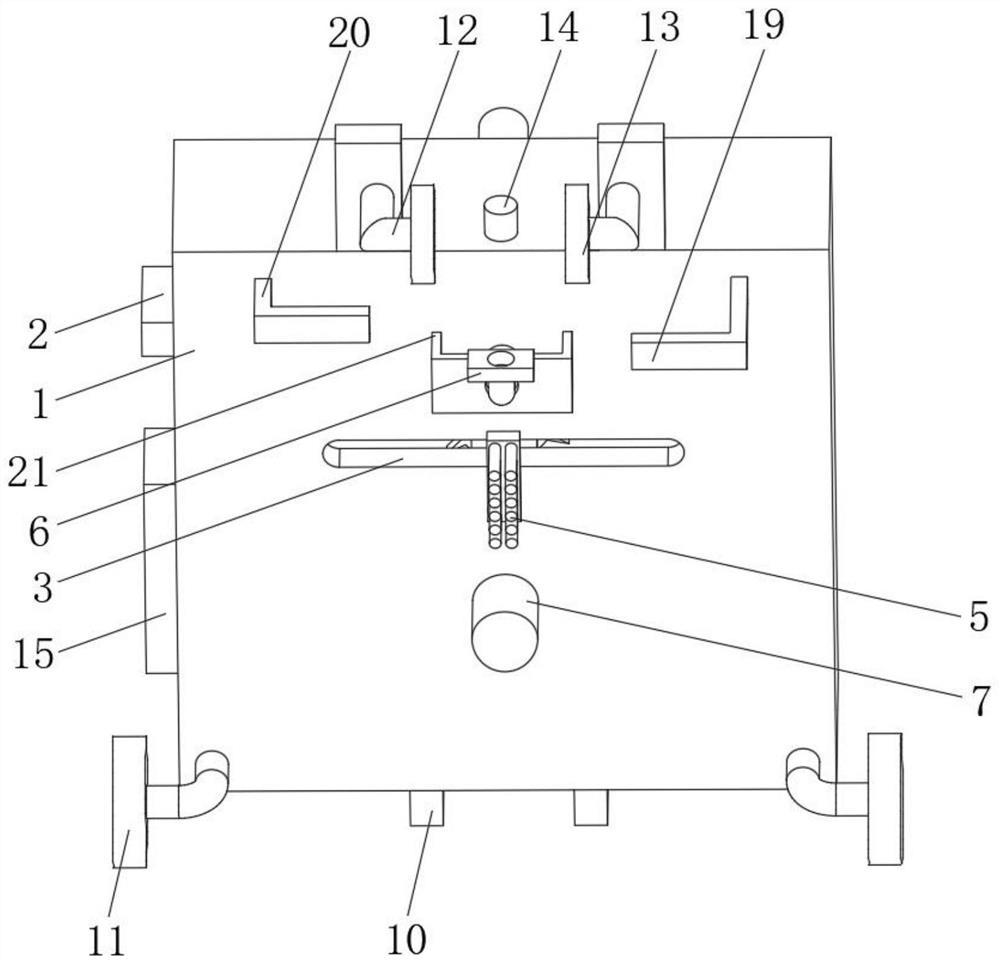

Efficient geomembrane welding equipment

InactiveCN112356444AImprove welding efficiencyAvoid affecting the welding effectCleaning using toolsCleaning using gasesGeomembraneEngineering

The invention discloses efficient geomembrane welding equipment which comprises a working box and an adjusting unit. An inverter and a storage battery are sequentially arranged at the left end of thelower surface of an inner cavity of the working box, an air injection unit is arranged at the right end of the lower surface of the inner cavity of the working box, an adjusting groove is formed in the middle of the lower surface of the inner cavity of the working box, and a welding piece is arranged at the left end of the lower surface of the working box. According to the efficient geomembrane welding equipment, the welding position in front of two geomembranes is cleaned through high-pressure air in the air injection unit, and therefore the situation that the welding effect is affected by dust and impurities left at the welding position is avoided, the geomembranes cleaned by the air injection unit can be cleaned through a cleaning unit, and therefore the welding effect between the geomembranes can be achieved; and the cleaning unit can circularly move through the adjusting unit, then the cleaning range of the cleaning unit can be widened, and therefore the cleaning effect to the welding position of the geomembranes is improved.

Owner:朱爱成

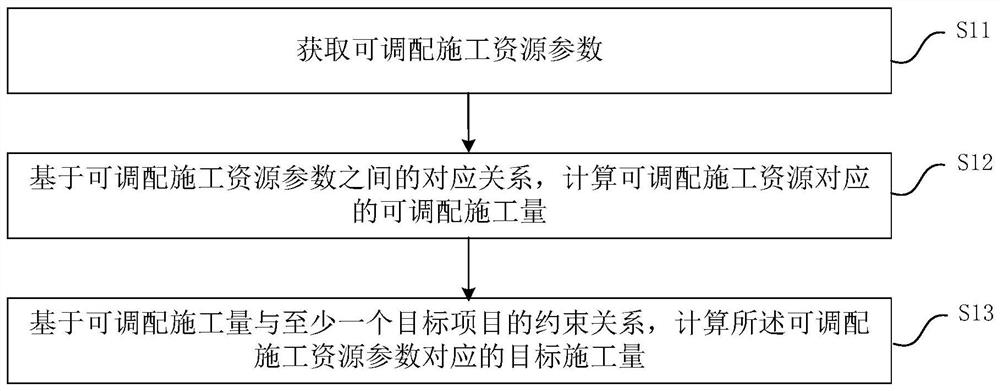

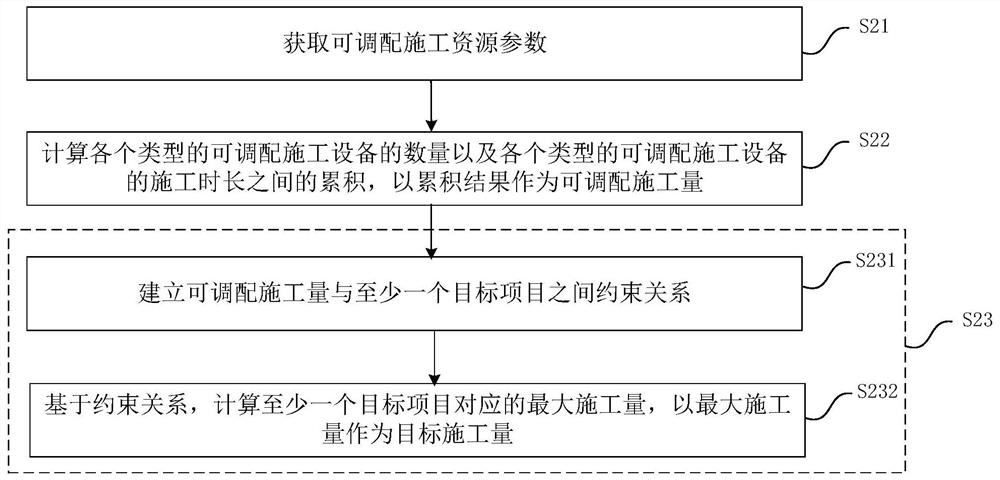

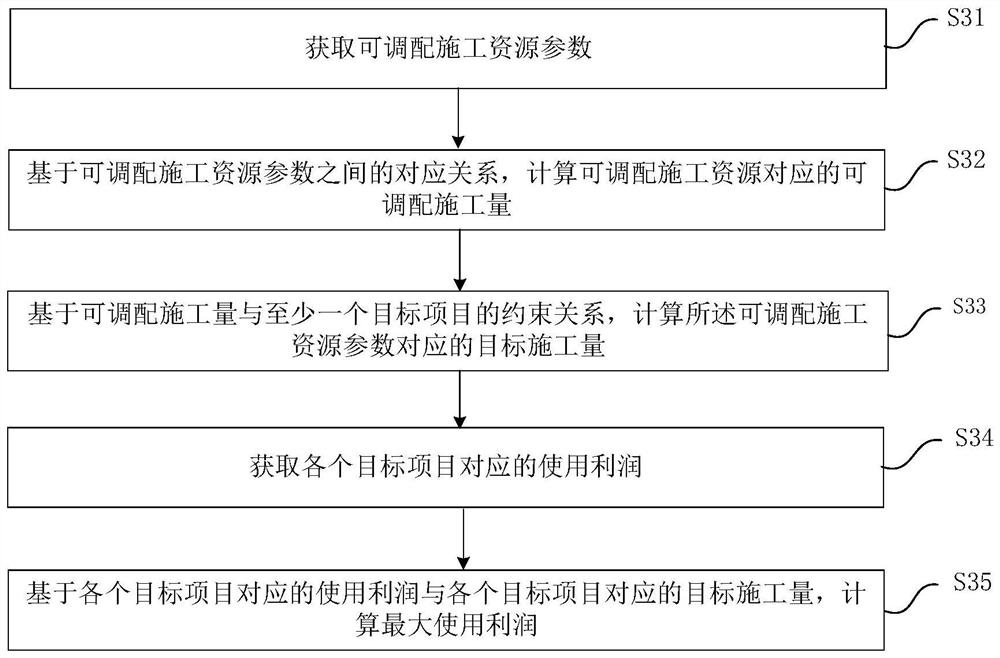

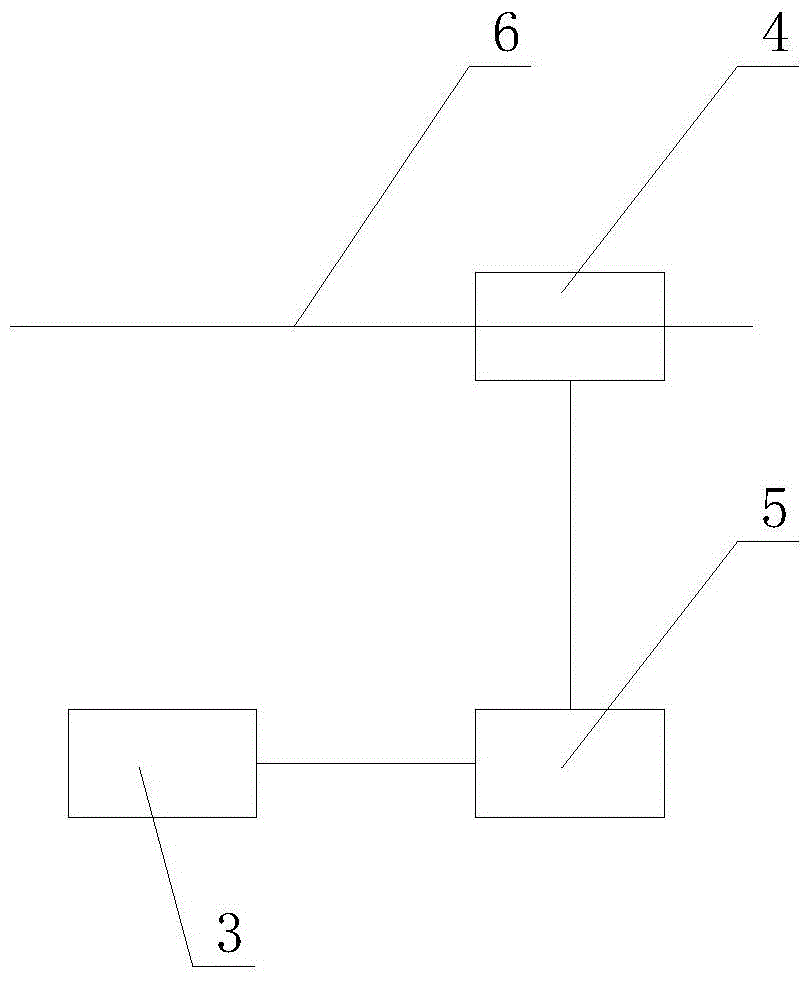

Construction quantity determination method and device, electronic equipment and readable storage medium

PendingCN113283879AAvoid idle workImprove the utilization rate of construction resourcesOffice automationResourcesProcess engineeringEnvironmental geology

The invention relates to the technical field of construction resource optimization, and discloses a construction quantity determination method and device, electronic equipment and a readable storage medium. The method comprises the following steps: obtaining deployable construction resource parameters; calculating an adjustable construction amount corresponding to the adjustable construction resources based on a corresponding relationship among the adjustable construction resource parameters; and calculating a target construction amount corresponding to the deployable construction resource parameters based on a constraint relationship between the deployable construction amount and the at least one target project. Through the implementation of the method, it is guaranteed that the adjustable construction resources can be utilized to the maximum degree so as to achieve reasonable distribution, waste of the construction resources is avoided, the utilization rate of the construction resources is increased, then environmental pollution aggravation caused by waste of the construction resources is avoided, and environmental pressure is relieved.

Owner:HUADIAN HEAVY IND CO LTD

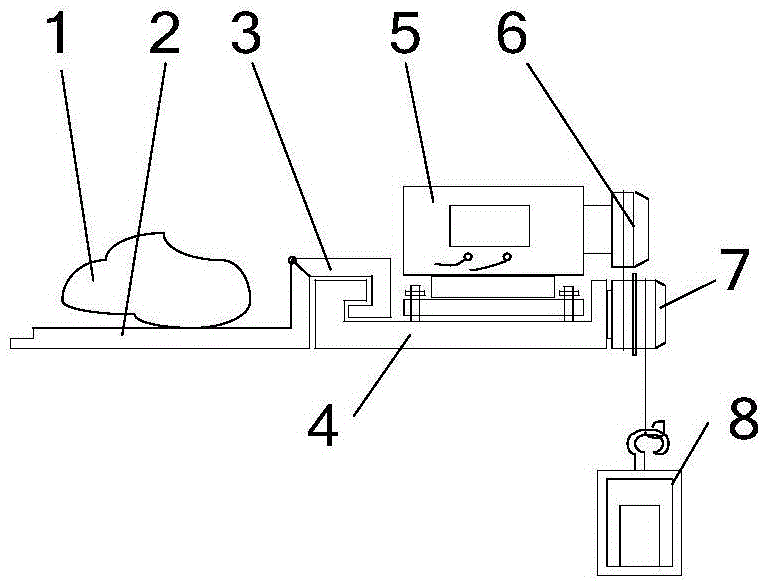

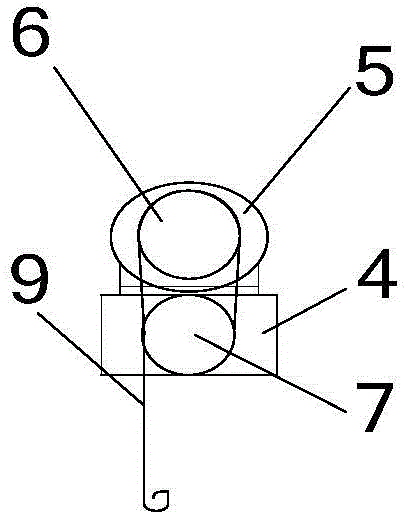

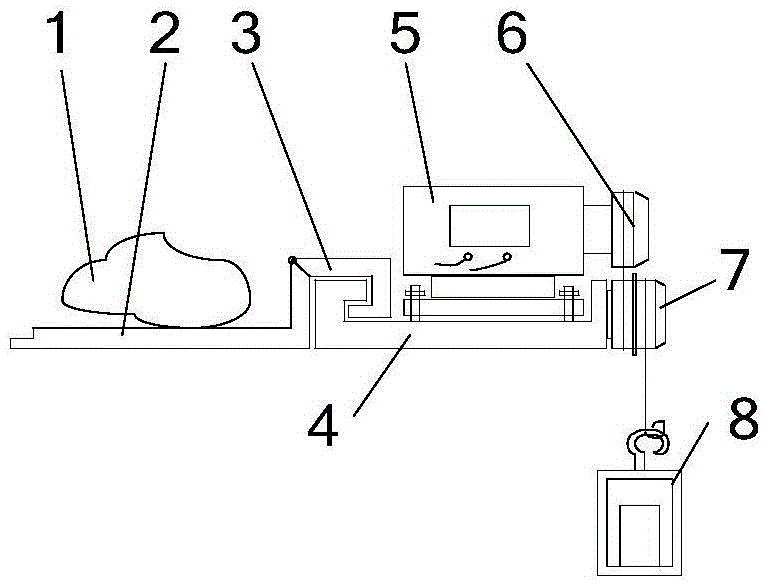

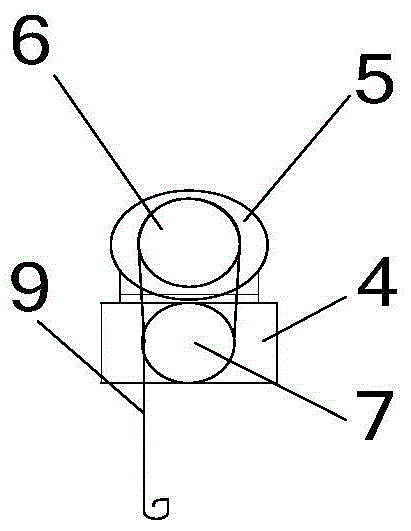

Special crane for vertically transporting explosive

InactiveCN104649177AEasy to makeGood sound and vibration insulationPortable liftingSelf lockingEngineering

The invention relates to a special crane for vertically transporting an explosive. The special crane comprises a main base, a motor, an explosive containing box and a plurality of auxiliary bases, wherein the auxiliary bases are arranged at the side edge of the main base; the auxiliary bases are connected with the main base through detachable self-locking structures; the motor is arranged on the main base, a driving wheel is arranged on an output shaft of the motor, the main base is provided with a rope winding fixed pulley, and the driving wheel and the fixed pulley are in transmission connection through a crawler belt; the explosive containing box is connected with the fixed pulley through a rope. Compared with the prior art, the special crane has the advantages that the safety of hoisting of the explosive is improved, the requirements on that the explosive is hoisted to various locations are met, the manning is reduced, working conditions are improved, meanwhile, construction progress is guaranteed, the safety of construction is guaranteed, the idling of labor force is greatly avoided, the blasting cost is reduced, and a better economic benefit is obtained.

Owner:WUHAN UNIV OF SCI & TECH

Paper tension detection and processing device for printing equipment

ActiveCN104309326BAvoid idle workExtend your lifeOther printing apparatusPower apparatusIndustrial engineering

The invention discloses a printing device paper tension detecting and processing device. A first board and a second board are arranged in parallel with a preset gap. Paper penetrates the preset gap. A power device is installed on the second board, and a groove, a groove perpendicular to the moving direction of the paper and a slot are formed in the second board. A cutter is composed of a cutter handle fixedly connected with the front end of a driving rod and a plurality of cutter units fixed at one end of the cutter handle far away from the driving rod, and the cutter units are evenly distributed along one end of the cutter handle far away from the driving rod. A plurality of slot units matched with the cutter units are arranged on the second board. A tension detection device for detecting real-time tension value of the paper transmits the real-time tension value to a control device, and the control device compares the real-time tension value and the preset first threshold. When the real-time tension value is larger than the first threshold, the control unit controls the power device to drive the cutter units to enter the slot units matched with the cutter units to cut off the paper. The service life is prolonged.

Owner:安徽汇川管理咨询有限公司

Asynchronous hanging basket with triangular truss type hoisting equipment and use method of asynchronous hanging basket

PendingCN114873491ASolve the problem of insufficient lifting capacityImprove stabilityPortable liftingBridge erection/assemblyArchitectural engineeringEconomic benefits

The invention provides an asynchronous hanging basket with triangular truss type hoisting equipment and a using method thereof, and the asynchronous hanging basket comprises a sliding beam mechanism which is fixedly connected with the upper surface of top plate concrete; the suspension mechanism is connected with the right side of the sliding beam mechanism and comprises a hanging bracket connected with the right side of the sliding beam mechanism through a connector, a bottom basket longitudinal beam fixedly connected with the bottom plate concrete through a connector, and a hanging belt with the bottom connected with the connector; the hanging basket mechanism is connected with the right side of the suspension mechanism through a supporting mechanism; and the walking mechanism is fixedly connected with top plate concrete, the right end of the walking mechanism is connected with the sliding beam mechanism, the sliding beam mechanism, the suspension mechanism, the supporting mechanism, the hanging basket mechanism and the lifting mechanism are pushed to synchronously move on the horizontal plane, and hoisting of the corrugated steel web is completed. The tower crane has high stability, the problems that in existing construction, a tower crane is insufficient in hoisting capacity and insufficient in hoisting range are solved, and the problem that use of a large tower crane or hoisting machinery contradicts with economic benefits and construction efficiency is further solved.

Owner:河南新昱鑫桥梁钢构有限责任公司

A special crane for vertically carrying explosives

InactiveCN104649177BEasy to makeGood sound and vibration insulationPortable liftingDrive wheelEconomic benefits

Owner:WUHAN UNIV OF SCI & TECH

Construction method conversion construction method for ultra-long-span tunnels in ⅳ-level to ⅳ-level surrounding rock sections

ActiveCN109989757BReduce disturbanceAvoid intervalsUnderground chambersTunnel liningArchitectural engineeringEconomic benefits

The invention discloses a construction method conversion construction method for super-long-span tunnels in the surrounding rock section of level V to level IV. Controlled excavation is adopted to keep the same elevation of the arching line, and the double side wall pilot pit method of the surrounding rock is used as the leading and leading method in the construction of the transition section. The temporary middle wall of the left pilot pit and the temporary middle wall of the right pilot pit on both sides of the rear guide move to the middle of the tunnel at the same time, until the temporary middle wall of the left pilot pit and the temporary middle wall of the right pilot pit touch, and the temporary inverted arch Lock-foot anchors are applied on both sides; then the temporary middle wall of the right pilot pit is removed, and the temporary middle wall of the left pilot pit is retained as the middle temporary middle wall of the CRD method. This method transitions from the double-side-wall pilot-pit method to the CRD method in the horizontal direction, avoiding the time interval between construction method conversions, and reducing the disturbance of the surrounding rock caused by the removal of the temporary support of the double-side-wall pilot-pit method in the later stage, thus speeding up the construction. , save the construction period, avoid idle work, and improve the economic benefits of tunnel construction.

Owner:CHANGAN UNIV

Simultaneous Construction Method of Shield Crossing Piston Air Duct and Upper Structure of Piston Air Duct

ActiveCN109162741BProtection securityReduce the amount of backfillUnderground chambersFoundation engineeringSupporting systemClassical mechanics

The invention relates to the technical field of subway construction and particularly relates to a method for synchronously constructing a shield crossing piston air duct and a piston air dust upper structure. The segmented flow construction is employed by a second floor underground, the conversion of an inner support force system is reasonably completed, and a reliable reaction support system is provided for the passing of a shield. During the construction of a soil mold, a pit precipitation well is introduced out, and the stability of a piston air duct bottom plate structure in construction is ensured. After the construction of a middle plate, a middle plate hole is blocked by using a hole blocking plate, therefore, piston structure upper and lower structures are completely isolated, a closed space is provided for the shield crossing piston air duct, an effective reaction support is formed, an end reinforcement process is avoided, and the construction of the piston air dust upper structure is carried out simultaneously. According to the method, the problem that the shield crossing piston air duct and the piston air dust upper structure cannot be synchronously constructed is effectively solved, and the method has the advantages of reasonable operation, high safety and reliability, the effective avoidance of slow work, and the effective shortening of a construction period.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

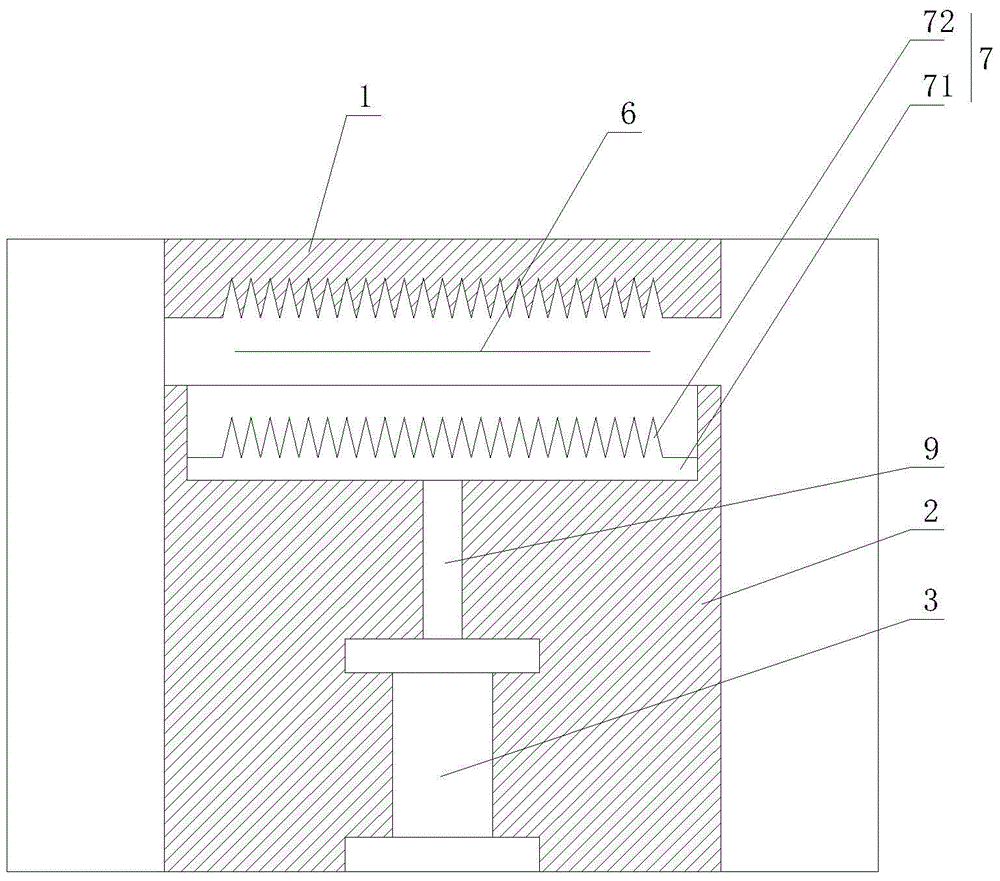

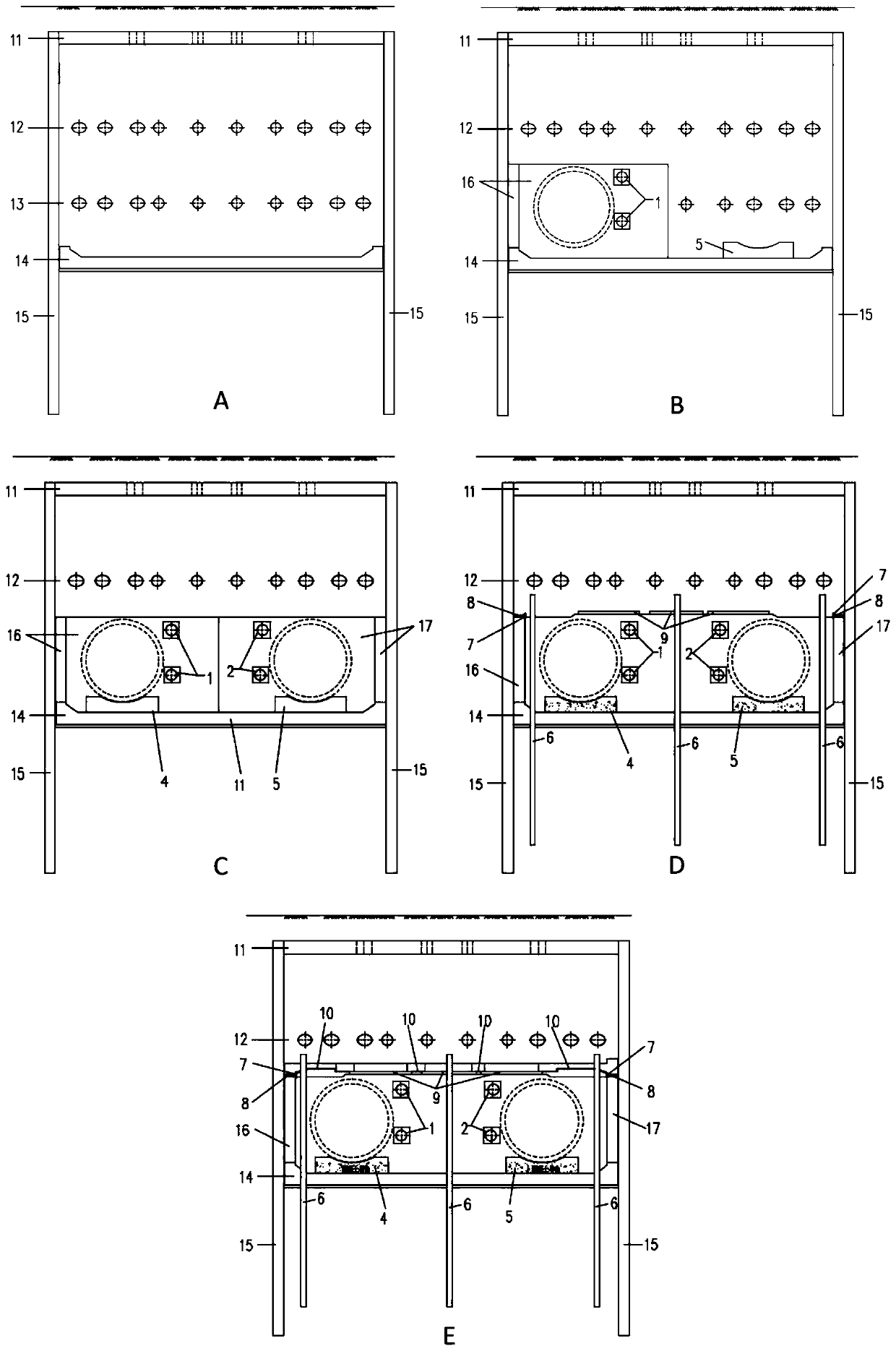

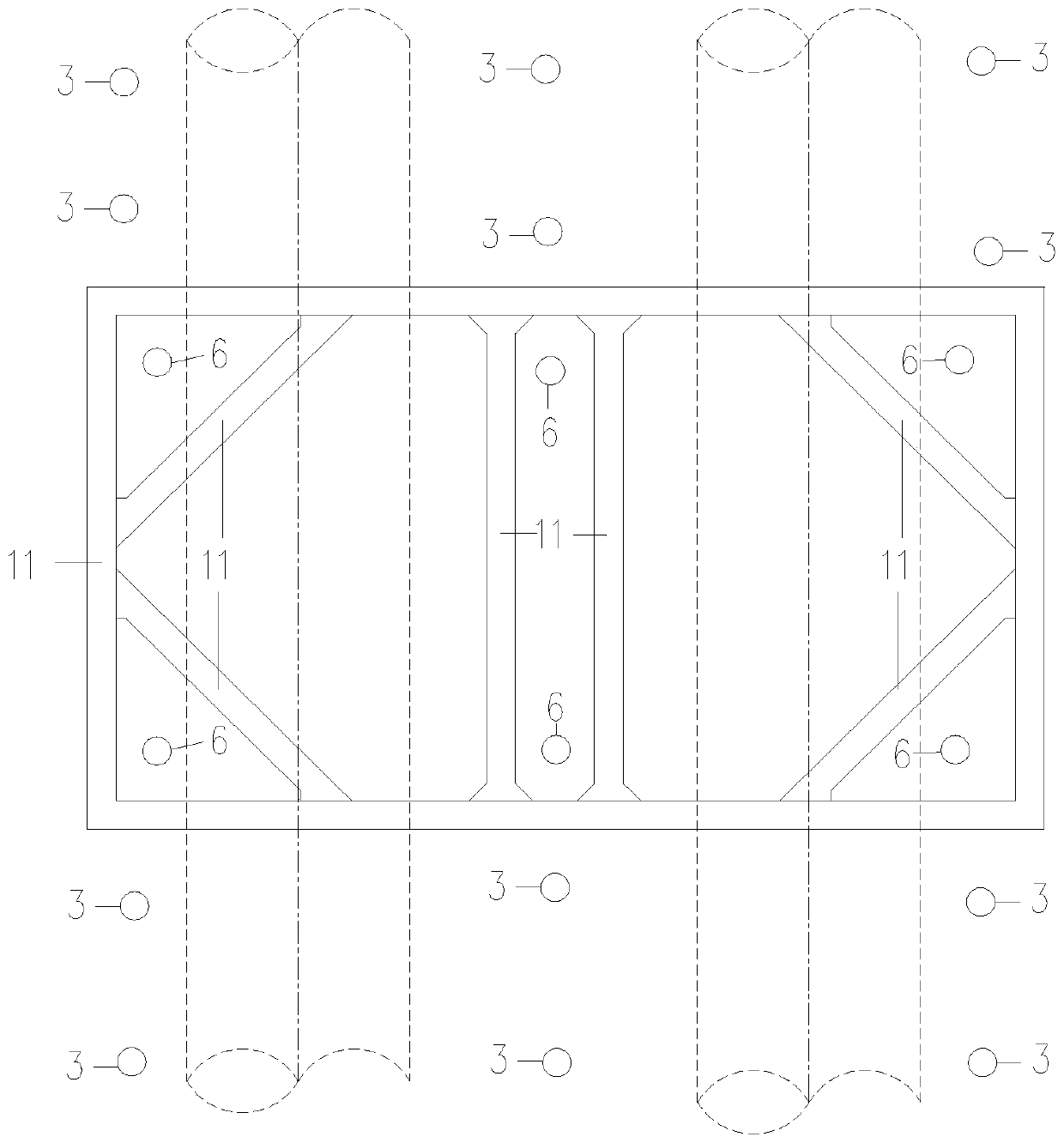

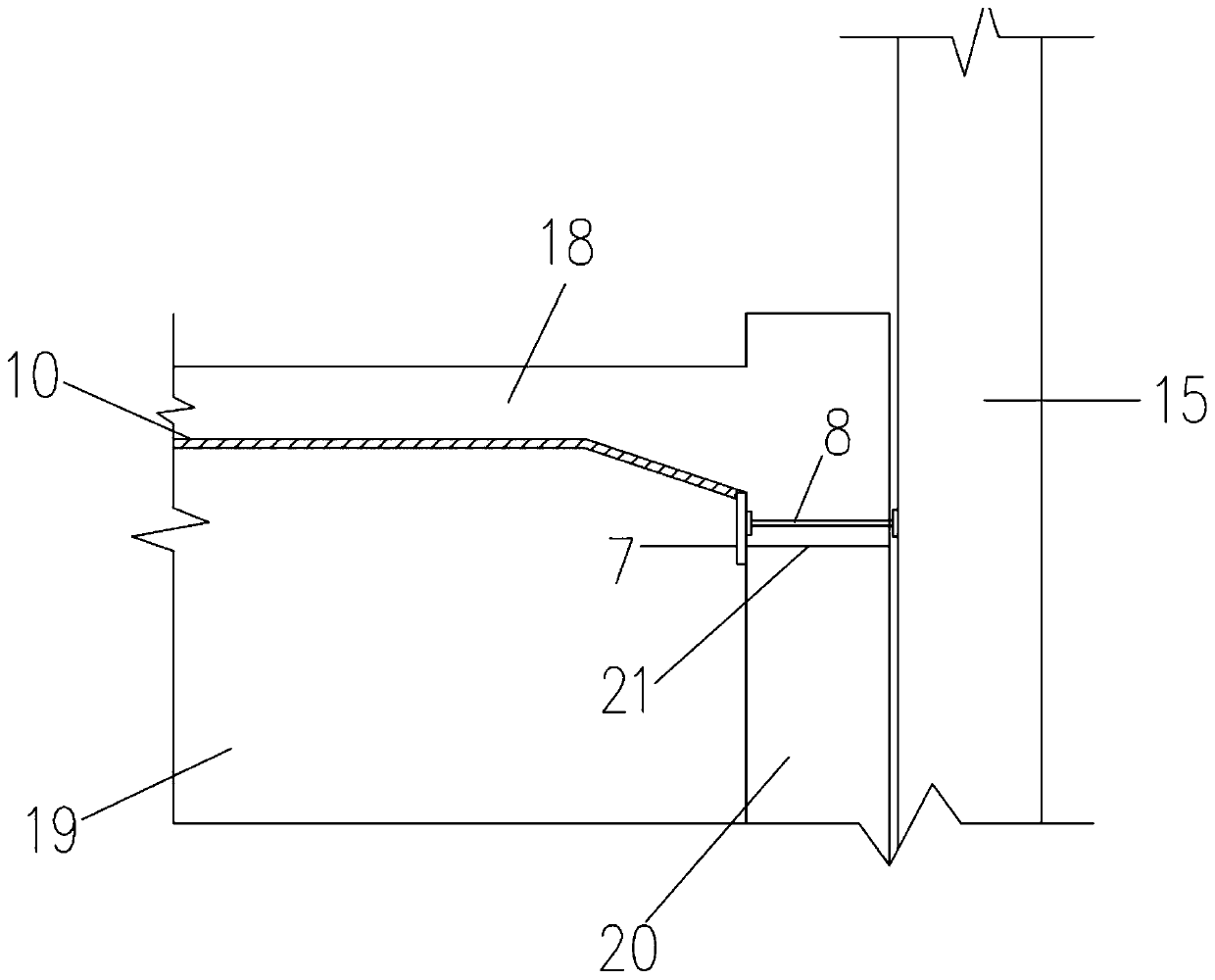

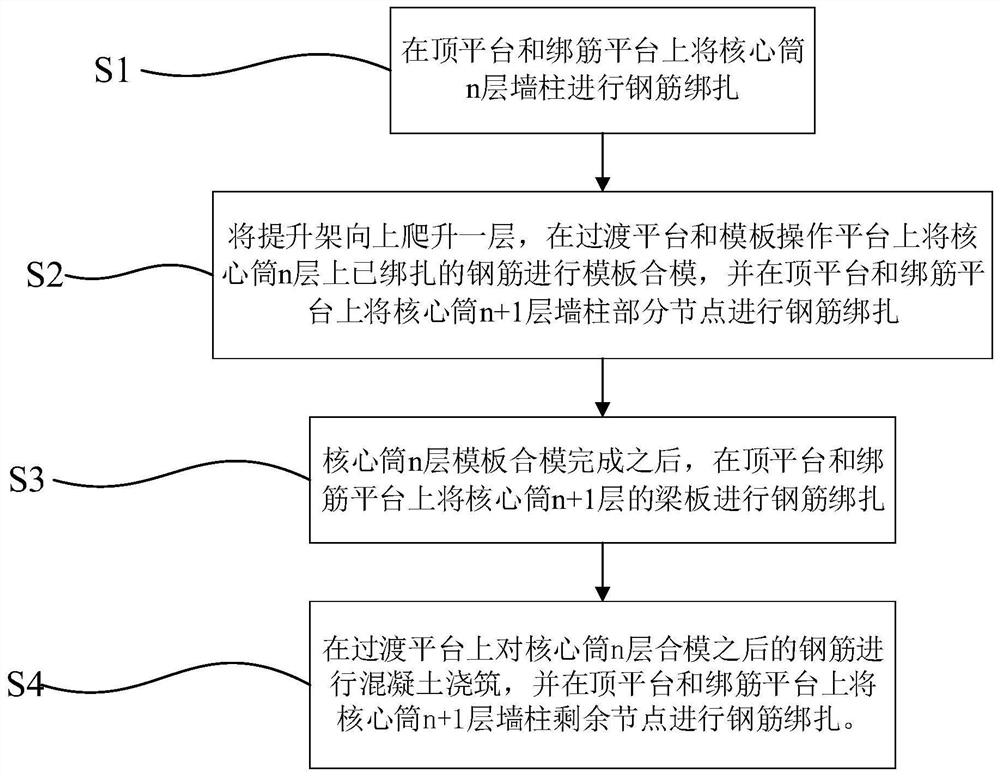

Self-climbing formwork and core tube binding construction method

PendingCN114016610AAvoid idle workImprove efficiencyForms/shuttering/falseworksExtraordinary structuresArchitectural engineeringRebar

The invention discloses a self-climbing formwork and a core tube binding construction method, and is applied to the field of core tube construction. The self-climbing formwork comprises a lifting frame. The lifting frame is installed on the side face of the core tube and can climb upwards. The lifting frame comprises a top platform, a bar binding platform, a transition platform and a formwork operation platform which are sequentially arranged at intervals from top to bottom. The top platform is used for storing steel bars and binding the steel bars, the bar binding platform is used for binding the steel bars, and the transition platform and the formwork operation platform are used for formwork construction. When the self-climbing formwork is constructed, the top platform and the bar binding platform provide working faces for reinforcement workers to bind super-layer steel bars, the phenomenon that the reinforcement workers have no working faces in the mold closing stage and the concrete pouring stage, and consequently work idling is caused can be avoided, and the comprehensive efficiency of core tube construction is improved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

A gangue bag filling method for wide roadway excavation in thin coal seam under hard roof

InactiveCN102943674BImprove stabilityPlay a role in relieving pressureUnderground miningSurface miningMining engineeringRock bolt

The invention discloses a gangue bag filling method in thin coal seam wide roadway tunneling under a tight roof. A roadway is tunneled along a coal seam in the roadway tunneling process, and the initial cross section of the roadway is 3.4m wide and 2.5m high; while tunneling the roadway, rock bolting is conducted in a manner that rock bolts are stroke into the roof, the floor and the two sides of the roadway and diamond metal nets are hung for bolting; when the roadway is tunneled for 6m on the basis of the dimension of the initial cross section, the roadway is expanded at the two outer sides of the roadway along the coal seam to form a stowboard; after that, the roadway and the stowboard are alternately tunneled and advance circularly; the coal extracted from the roadway is transported to the ground while the dug-out gangue is transported to the stowboard to be bagged off, thereby forming gangue bags; and the gangue bags are piled up and built in the stowboard in a manner that the gangue bags are firmly connected with the roof of the coal seam and are flush with the wall of the stowboard.

Owner:SHANDONG UNIV OF SCI & TECH

The construction method of jumping warehouse type air tightness test of continuous annealing furnace

ActiveCN107560793BAvoid idle workShorten the durationFluid-tightness measurementFurnace typesSlow coolingContinuous annealing

The invention specifically relates to a jumping type air tightness test construction method for a continuous annealing furnace. The method is characterized in that a heating furnace is divided into afirst furnace section and a second furnace section; the first furnace section includes a preheating section, a first heating section and a second heating section; the second furnace section includes athird heating section, a soaking section, a slow cooling section, a fast cooling section, an over-aging section and a balancing section; air tightness test is carried out on the first furnace section; and the fast cooling section in the second furnace section is isolated, the slow cooling section and the over-aging section are connected by a connecting pipe, air tightness test is carried out simultaneously on the slow cooling section and the over-aging section, and air tightness test is carried out separately on the fast cooling section. When the construction progress of the fast cooling section lags behind the other furnace areas and air tightness test cannot be carried out simultaneously on all sections from the third heating section to the balancing section, through air tightness testusing the construction method of the invention, idleness of construction personnel can be avoided, the total duration of initial air tightness test on the second section of the furnace area can be shortened, and the total duration of furnace drying, threading and trail production can be guaranteed.

Owner:CHINA MCC20 GRP CORP

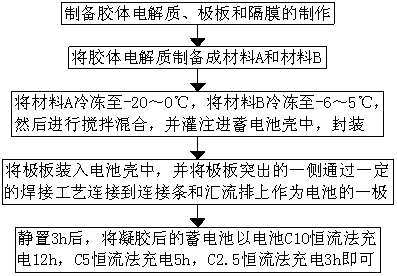

Manufacturing method for automobile storage battery

InactiveCN110858667AIncrease productivityReduce manufacturing costsFinal product manufactureLead-acid accumulators constructionElectrical batteryProcess engineering

The invention discloses a manufacturing method for an automobile storage battery. The manufacturing method comprises the following steps of: A, preparing colloidal electrolyte, a polar plate and a diaphragm, B, preparing the colloidal electrolyte into a material A and a material B, C, freezing the material A to -20 DEG C to 0 DEG C, freezing the material B to -6 DEG C to 5 DEG C, then conducting stirring and mixing, pouring the mixture to a storage battery shell, and conducting packaging; and D, putting the polar plate into a battery shell. By adopting the method, the production of the automobile storage battery can be continuously carried out, the phenomenon of idling is avoided, the production efficiency of the automobile storage battery is effectively improved, so that the production and manufacturing cost of the automobile storage battery is reduced, the market competitiveness is expanded, the benefits of enterprises are met, meanwhile, the raw materials for preparing the colloidalelectrolyte are easy to obtain, the processing method is simple, large-scale production can be realized, and the production efficiency of the automobile storage battery is further guaranteed.

Owner:广东理标信息科技有限公司

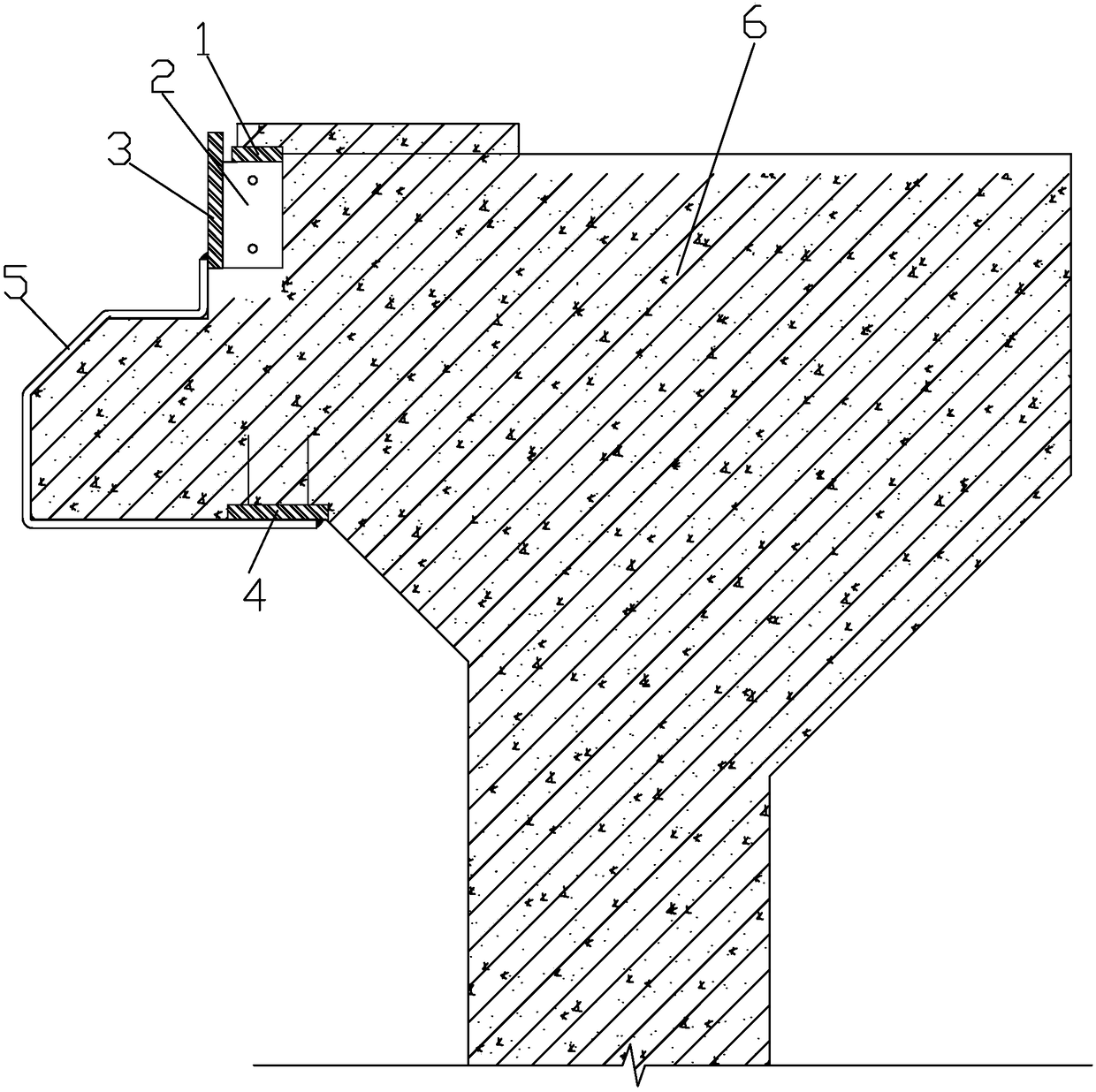

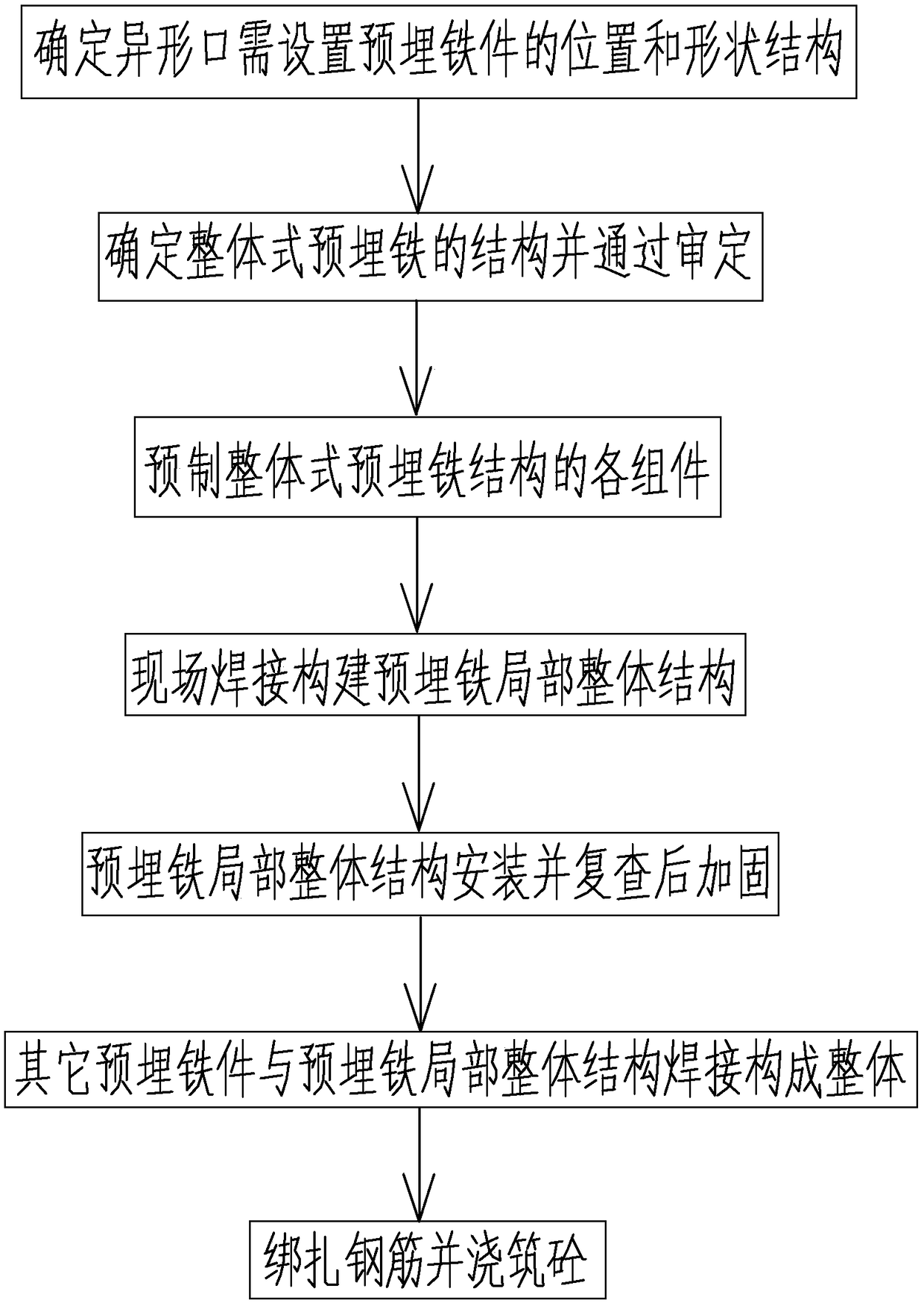

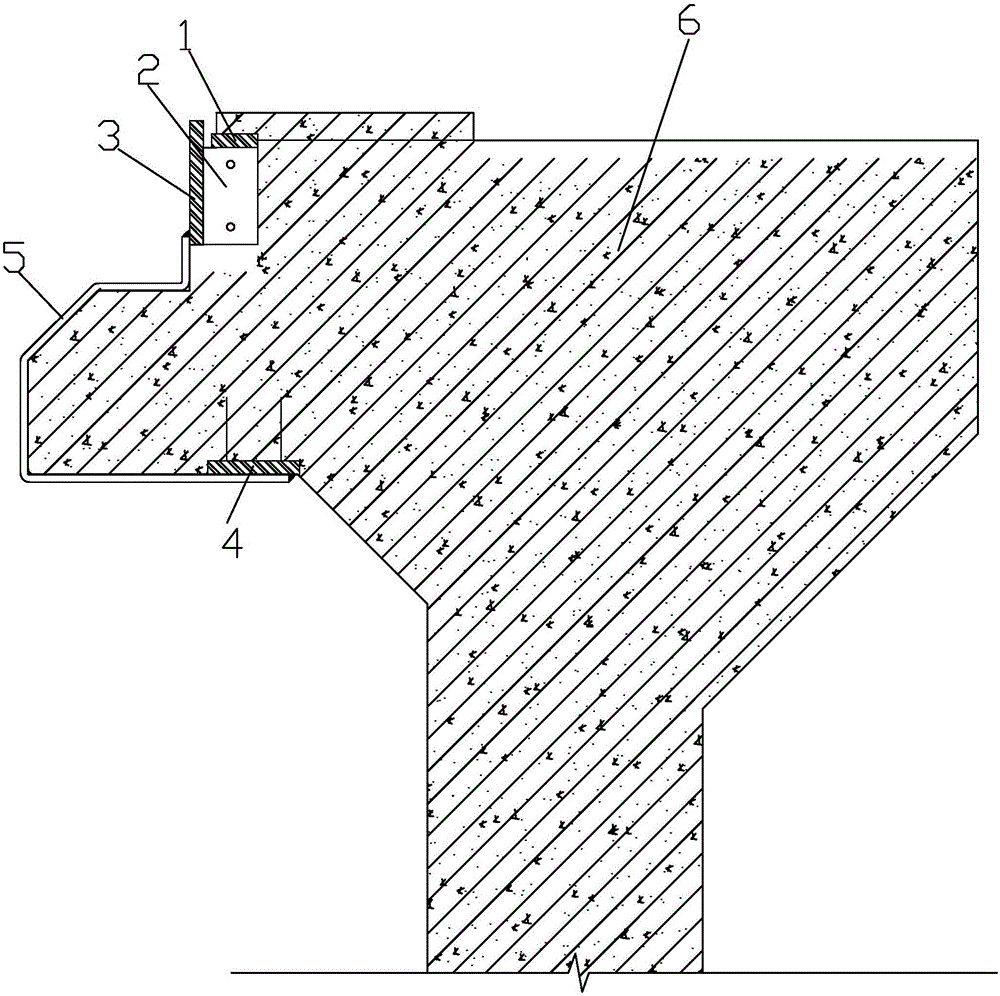

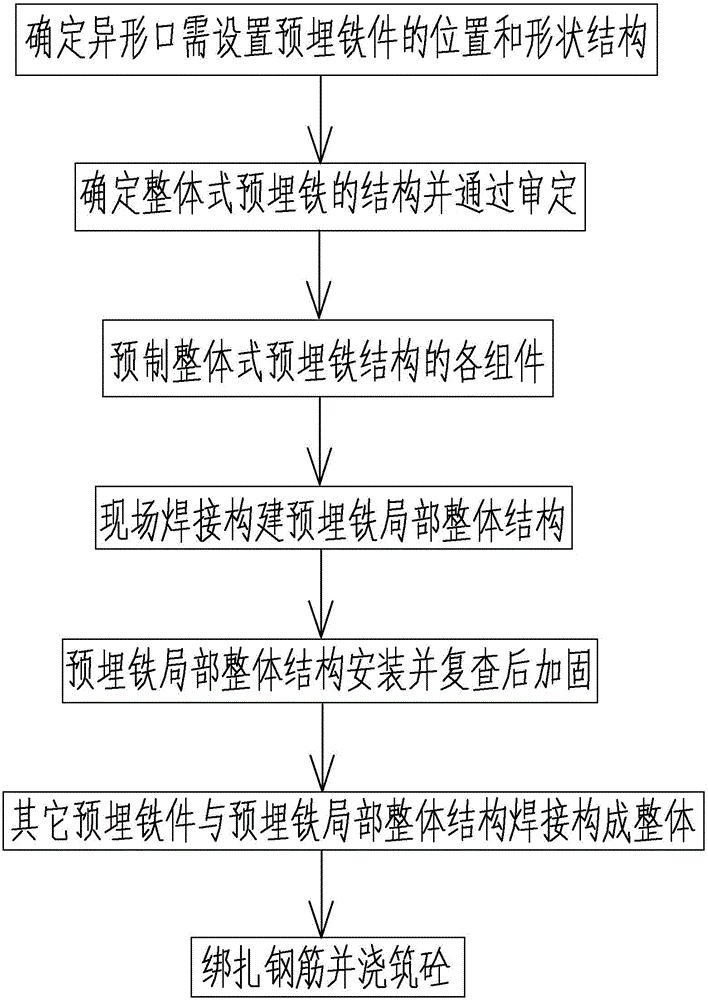

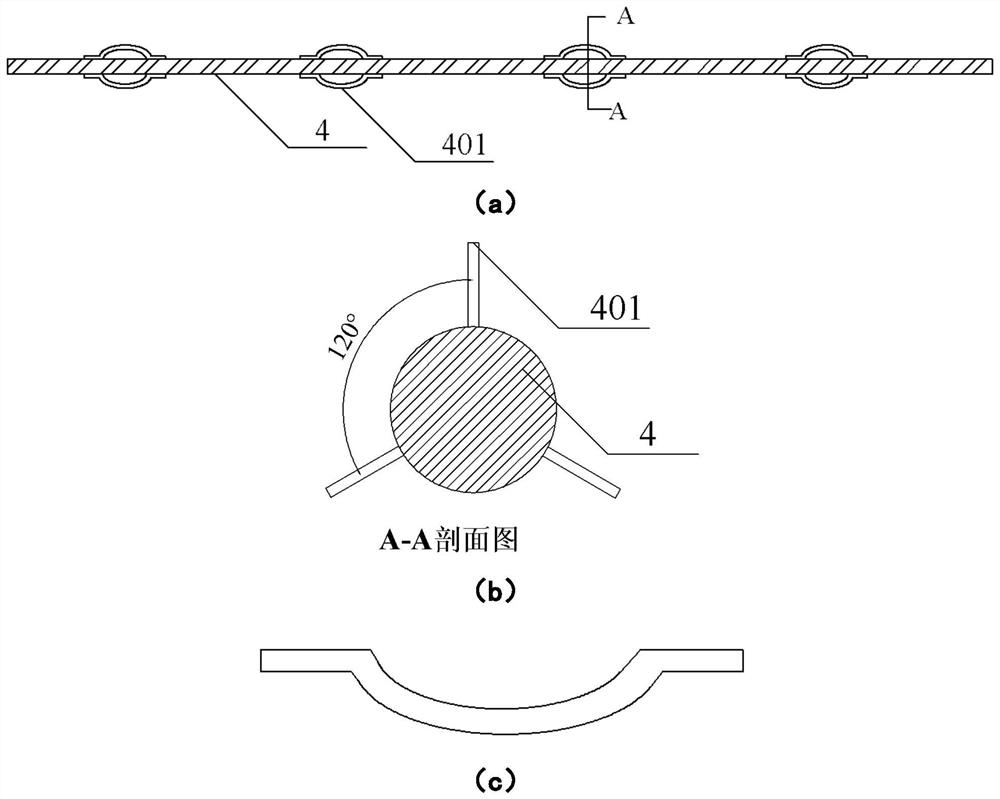

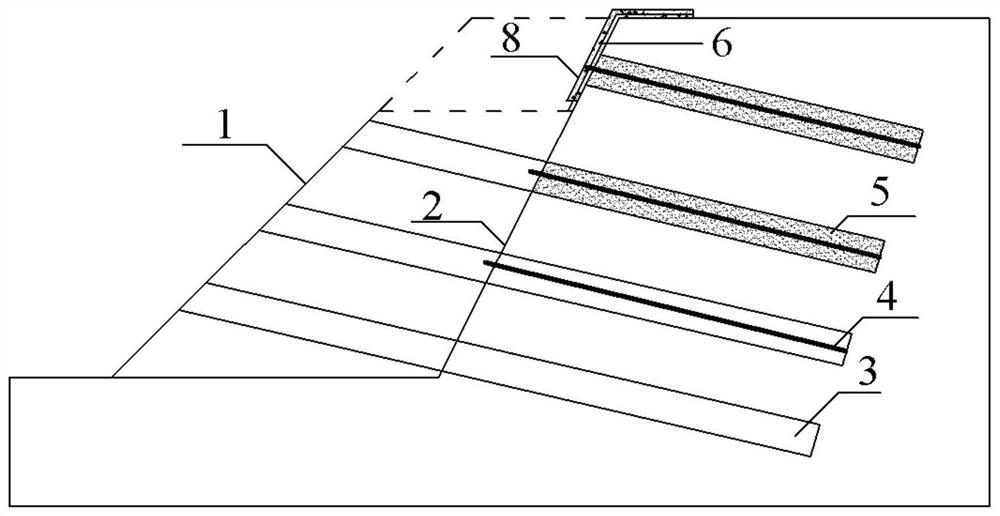

Construction method of pre-embedded iron for special-shaped branches of trenches

ActiveCN106760707BImprove project qualityReduce workloadIndustrial buildingsWhole bodyMaterial consumption

The invention provides a construction method for embedding iron into a special-shaped trench support opening. The construction method comprises the steps that 1, the positions and the shape structures of embedded iron pieces needing to be arranged in the special-shaped trench support opening are determined; 2, an integrated embedded iron structure is designed, determined and subjected to compliance approval; 3, all components of the integrated embedded iron structure are prefabricated; 4, all the related components in the integrated embedded iron structure are welded in advance on site to form a locally integrated embedded iron structure; 5, the locally integrated embedded iron structure is installed and reinforced after rechecking; 6, the other embedded iron pieces and the locally integrated embedded iron structure are welded to form a whole body; 7, steel bar binding and concrete pouring are conducted. According to the construction method, the project quality can be improved, the construction period can be shortened, and the labor cost and building material consumption can be reduced.

Owner:CHANGZHOU NO 1 CONSTR GRP

Construction method for reinforced concrete arched roof of grain store

InactiveCN102251667BReduce investmentReduce temporary land useBuilding material handlingFalseworkReinforced concrete

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Construction method of corbel reinforcement for gate pier

The invention provides a construction method of gate pier corbel reinforcement, which comprises the following steps: 1. Fabricate a reinforcement cage body on a site other than the gate pier, and weld an inner bracket inside the reinforcement cage; 2. Install the poured gate pier concrete for support The outer bracket of the steel cage; 3. Set up the cantilevered scaffolding support device for supporting the bottom mold of the corbel on the poured gate pier concrete; 4. Lift the steel cage as a whole and position it accurately; 5. The steel cage and the gate The other steel structures of the pier body are connected and formed; 6. Remove the inner bracket and outer bracket, and wait for the concrete pouring of the corbel warehouse; through the above steps, the one-time overall prefabrication and hoisting construction of the left and right corbel steel bars of the hydraulic gate pier will be realized. Through the above steps, the hoisting and positioning of the steel cage body can be realized at one time, without the need for secondary welding construction of the steel cage body with the rise of the pier body, avoiding construction interference, improving work efficiency, greatly reducing the workload of high-altitude operations, reducing safety risks, and good economy .

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

Construction method for embedding iron into special-shaped trench support opening

ActiveCN106760707AImprove project qualityReduce workloadIndustrial buildingsWhole bodyMaterial consumption

The invention provides a construction method for embedding iron into a special-shaped trench support opening. The construction method comprises the steps that 1, the positions and the shape structures of embedded iron pieces needing to be arranged in the special-shaped trench support opening are determined; 2, an integrated embedded iron structure is designed, determined and subjected to compliance approval; 3, all components of the integrated embedded iron structure are prefabricated; 4, all the related components in the integrated embedded iron structure are welded in advance on site to form a locally integrated embedded iron structure; 5, the locally integrated embedded iron structure is installed and reinforced after rechecking; 6, the other embedded iron pieces and the locally integrated embedded iron structure are welded to form a whole body; 7, steel bar binding and concrete pouring are conducted. According to the construction method, the project quality can be improved, the construction period can be shortened, and the labor cost and building material consumption can be reduced.

Owner:CHANGZHOU NO 1 CONSTR GRP

Soil nailing wall construction method for pre-reinforcing side slope rock-soil body

ActiveCN114032928AAvoid the disadvantages of segmental excavationGuaranteed stabilityClimate change adaptationExcavationsSoil nailingShotcrete

The invention discloses a soil nailing wall construction method for pre-reinforcing a side slope rock-soil body, which comprises the following steps of: firstly, vertical layered horizontal running water construction is performed on a current side slope surface, holes are drilled in the side slope rock-soil body according to a certain angle, and the drilled holes penetrate through the to be excavated rock-soil body and enter a preset depth in the designed side slope rock-soil body through the designed side slope surface of the side slope; then, soil nails are inserted into the drilling section in the designed side slope rock-soil body from a current side slope surface hole opening following the drilling, and the drilling section provided with the soil nails is grouted and maintained to be strong; and finally, the rock-soil body to be excavated is excavated through layered horizontal running water construction according to the sequence from top to bottom, the designed slope surface of the slope is exposed in a layered mode, slope surface net hanging and concrete spraying operation is completed, and the process is repeatedly circulated to achieve vertical running water construction till the soil nailing wall supporting construction is completed after the first-stage slope is excavated in a layered mode. The temporary stability of the designed slope surface after layered excavation can be guaranteed, vertical flow construction and horizontal flow construction can be conveniently carried out at the same time, the construction efficiency is improved, and the phenomenon of idling of the construction site is avoided.

Owner:NANHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com