Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Assembly does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

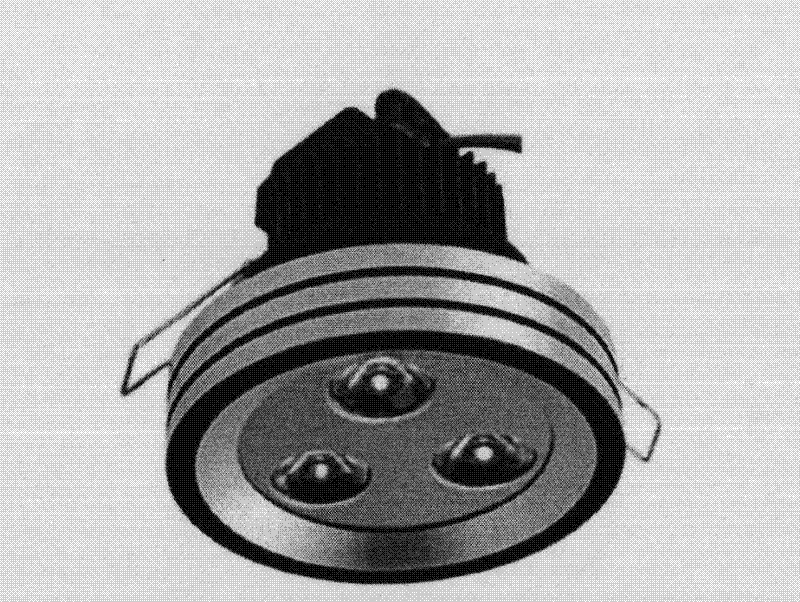

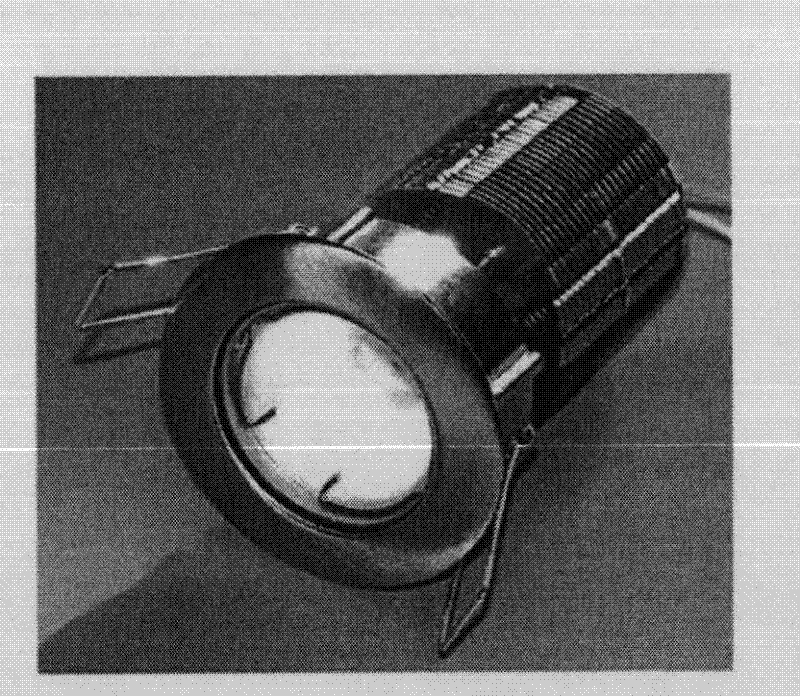

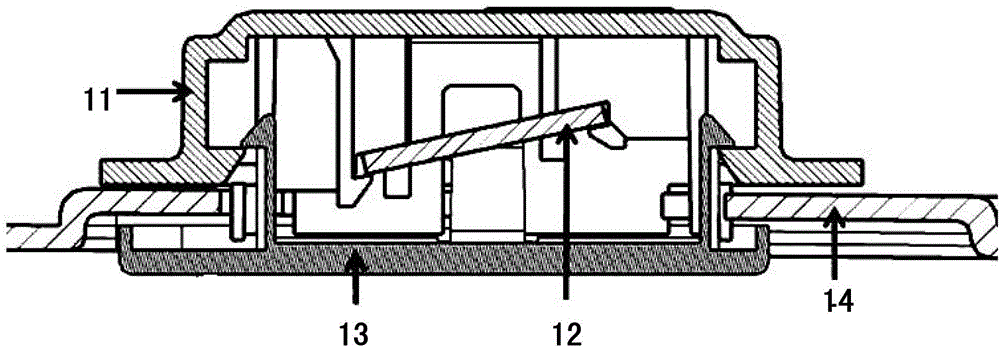

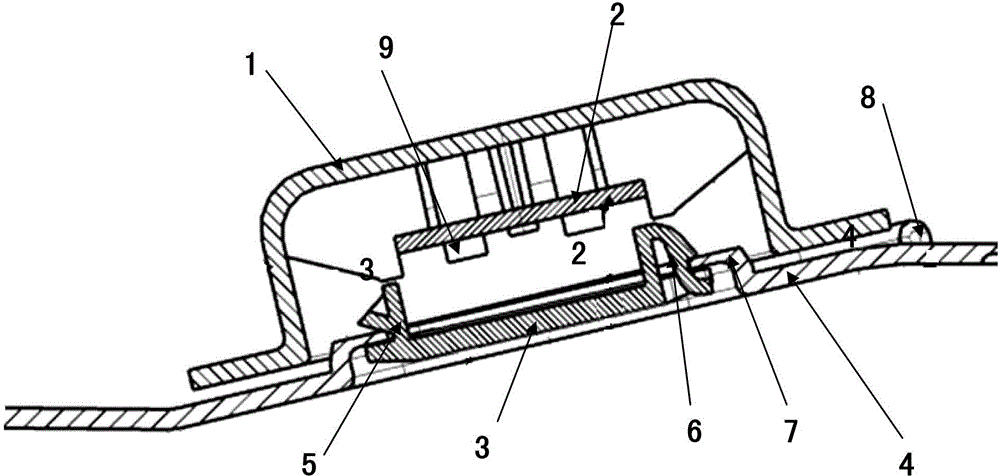

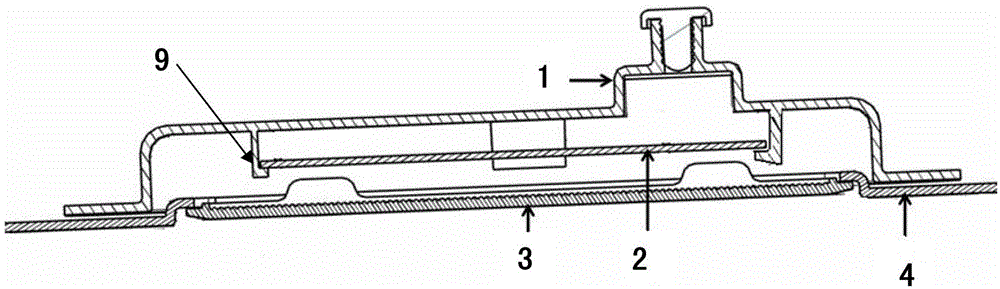

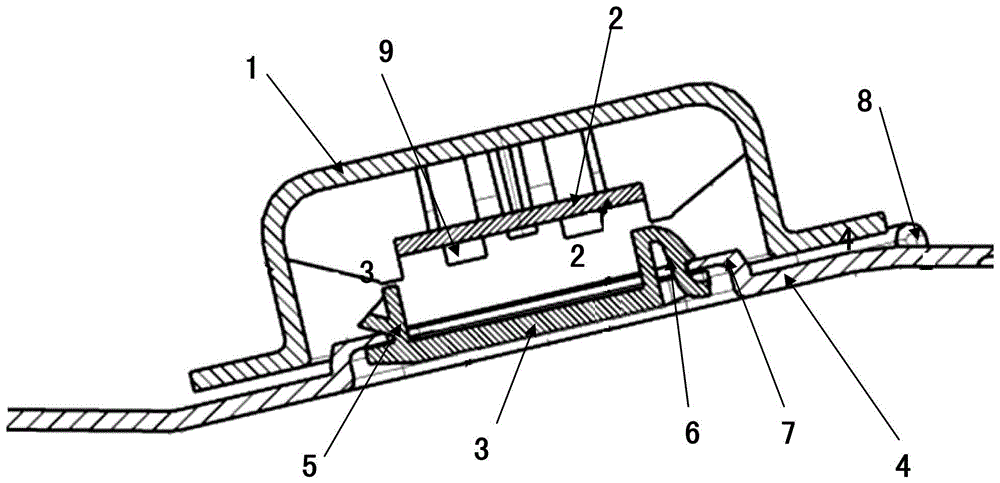

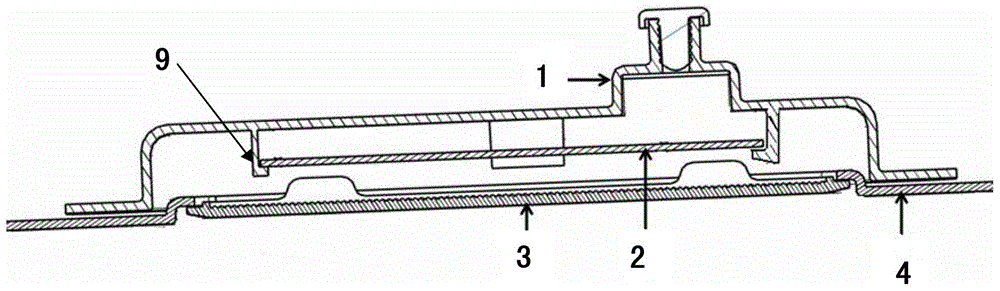

Radiating structure and spotlight with radiating structure

InactiveCN102410514AAssembly does not affectImprove cooling effectLighting heating/cooling arrangementsLight fasteningsHeat conductingHeat sink

Owner:OSRAM GMBH

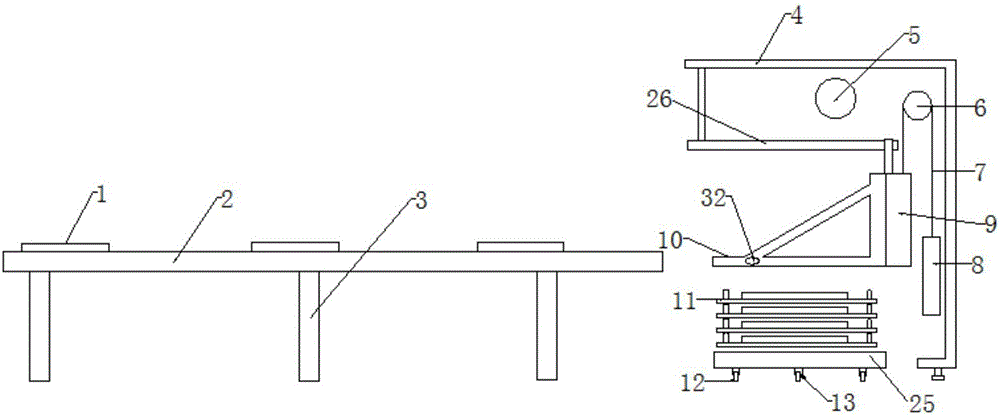

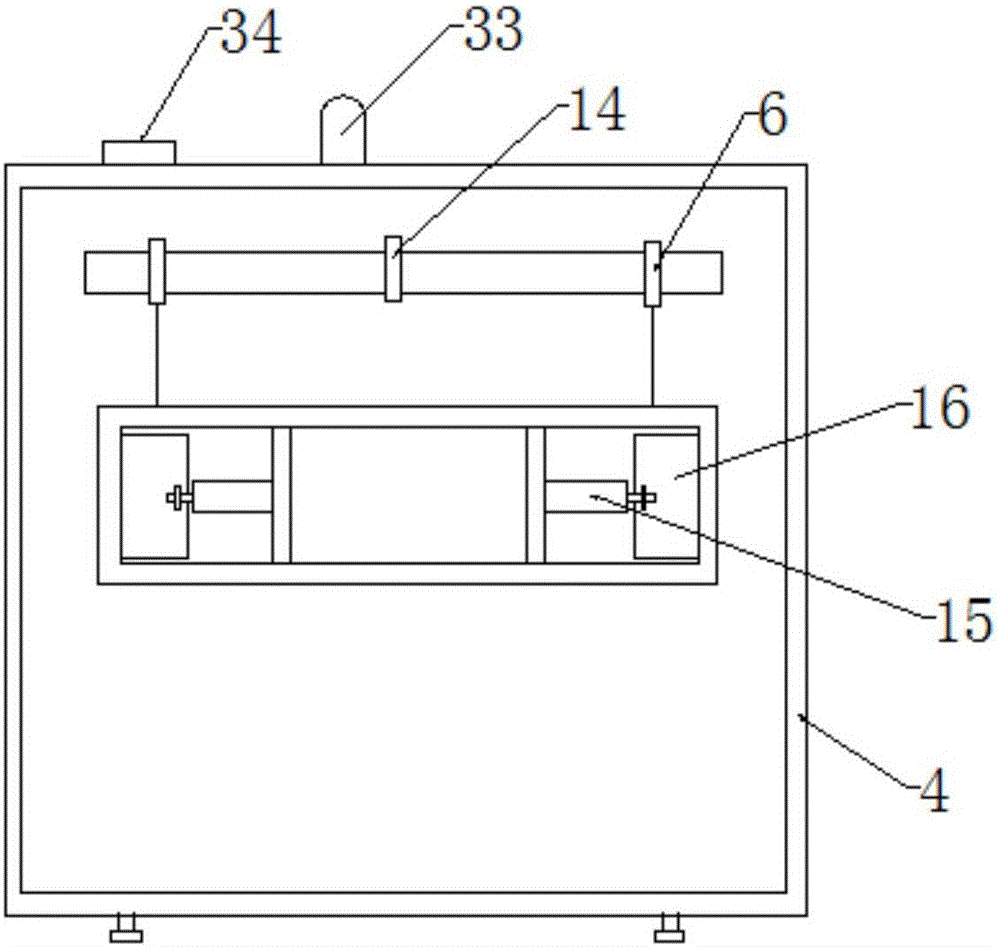

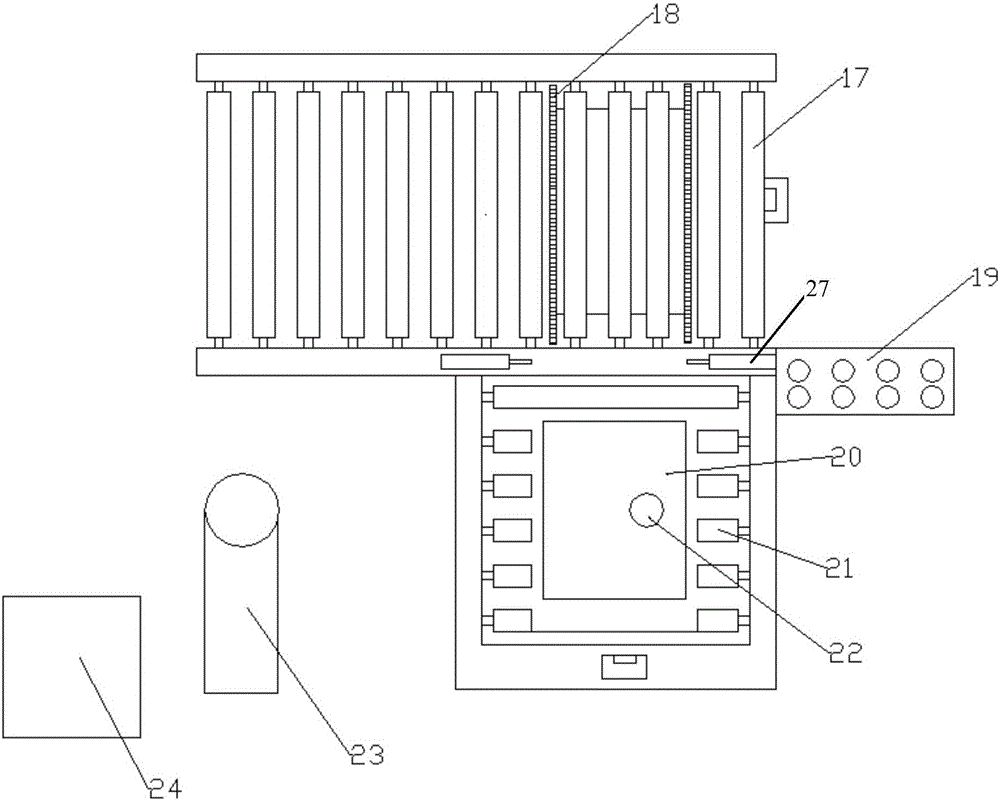

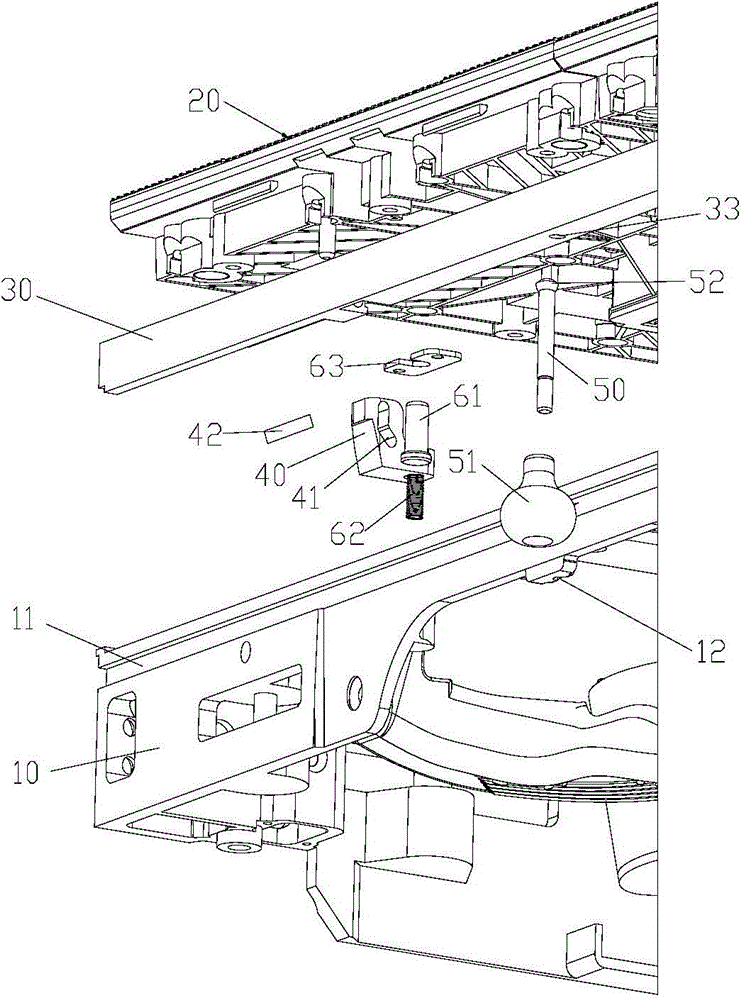

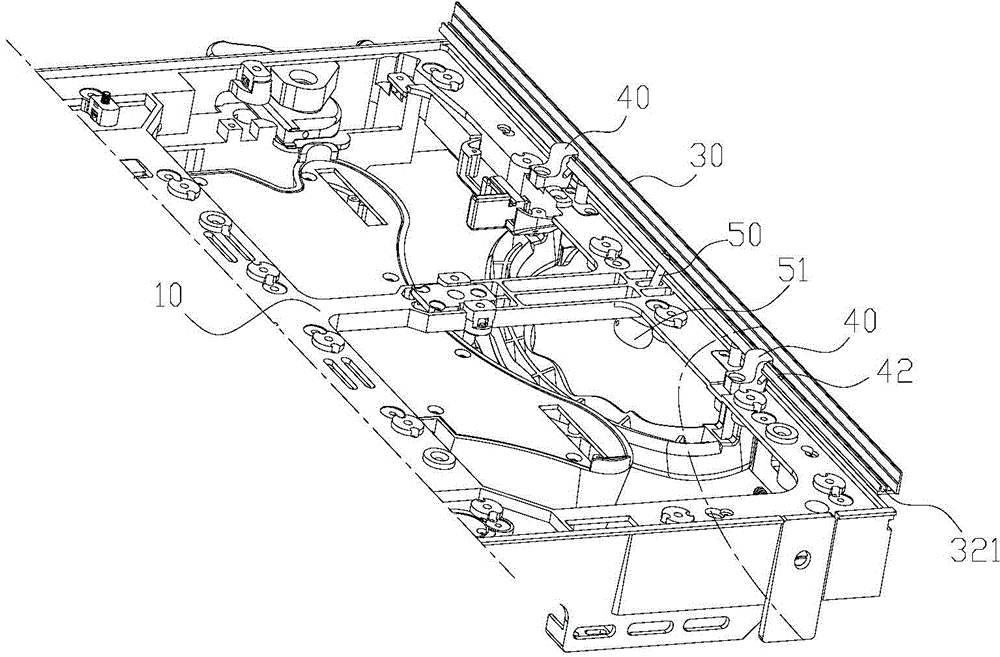

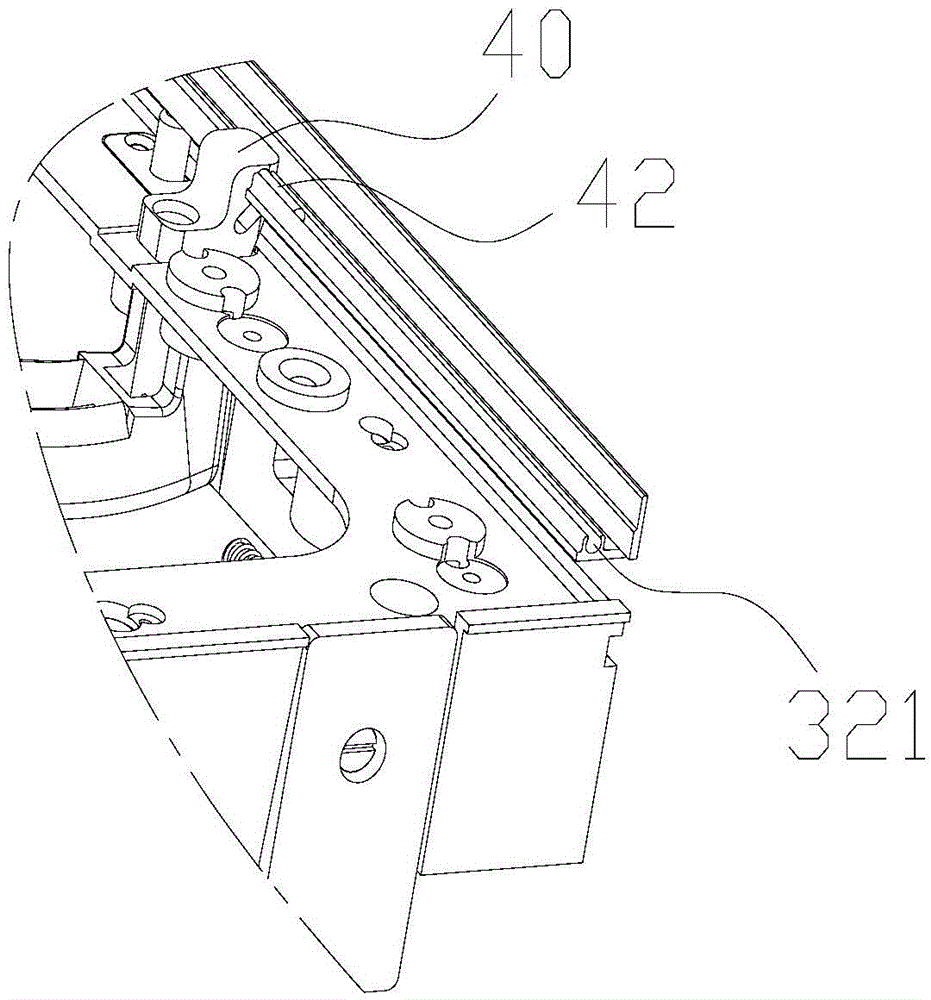

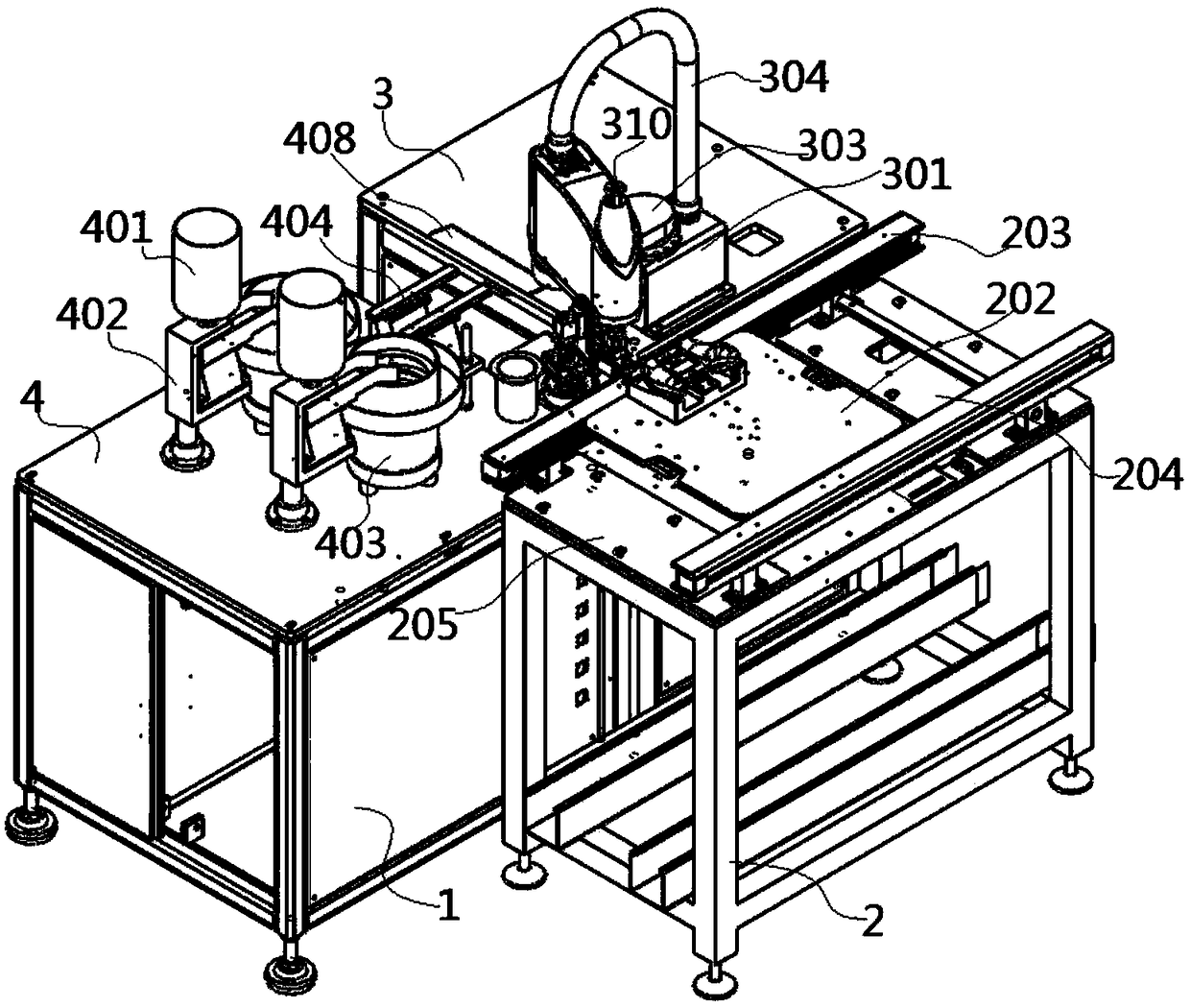

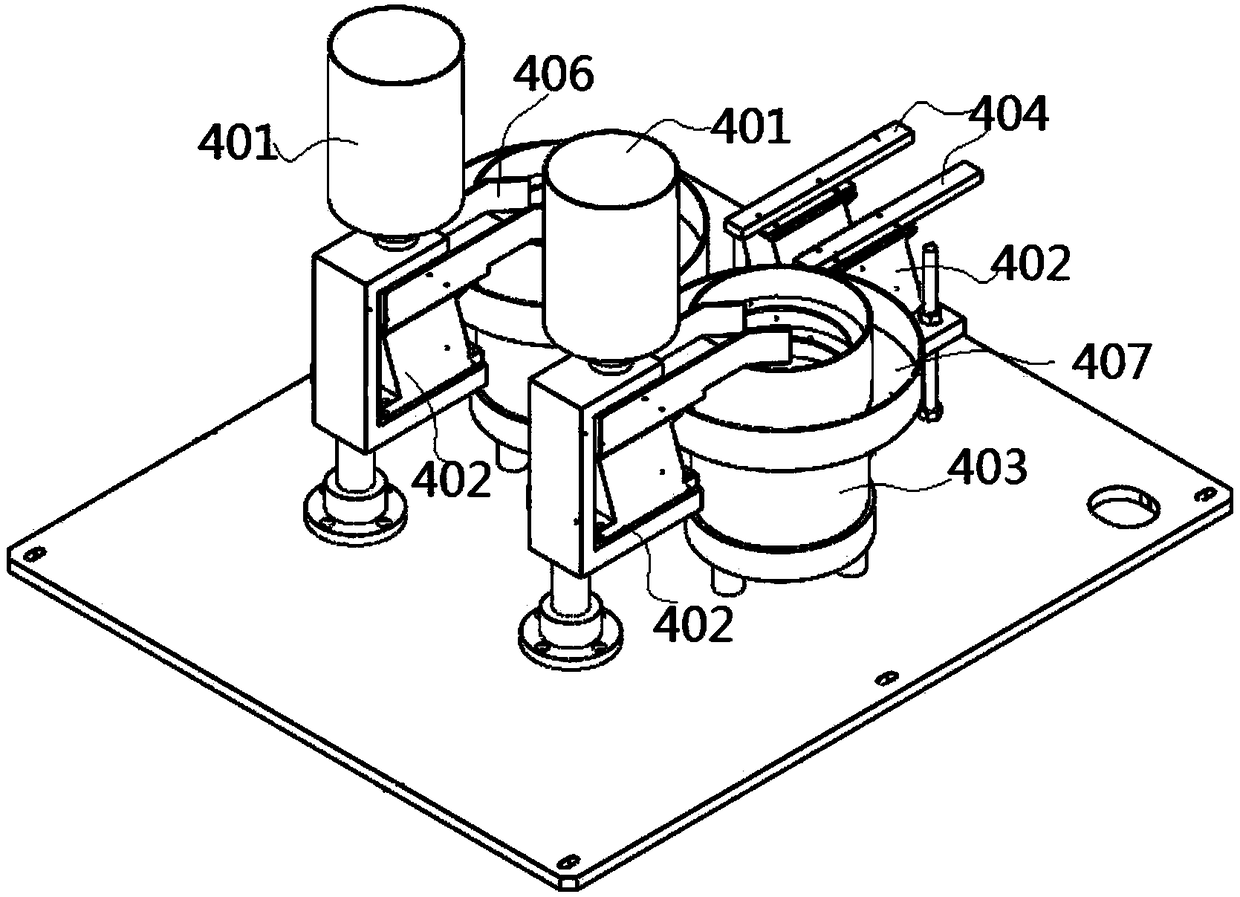

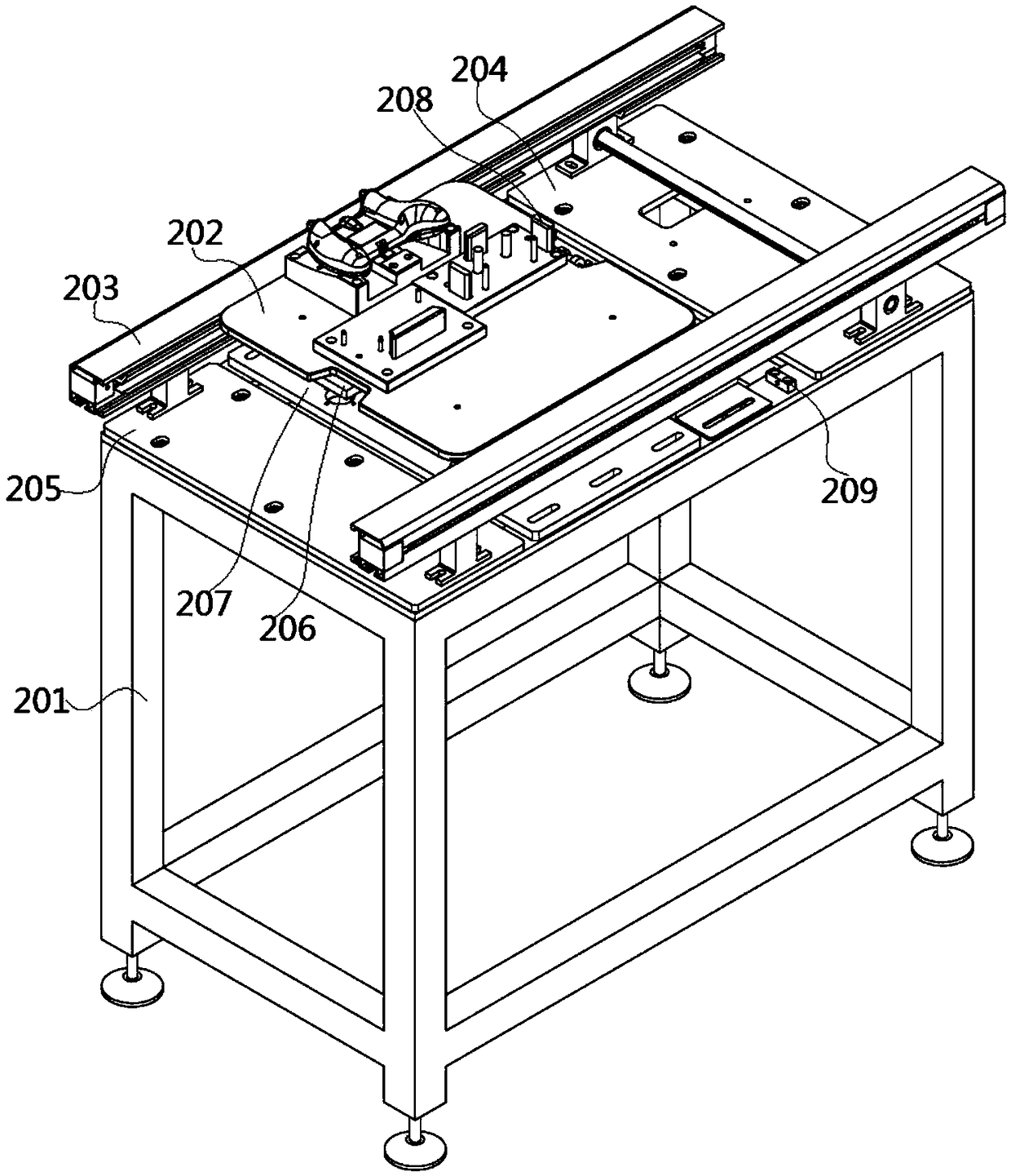

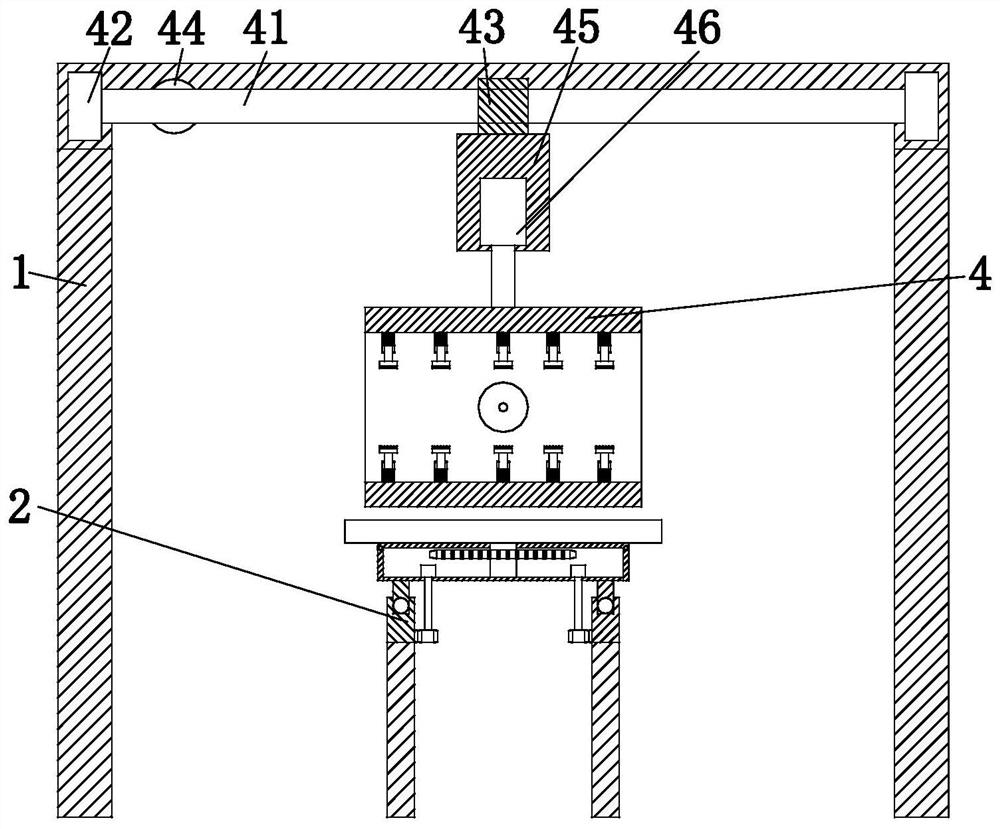

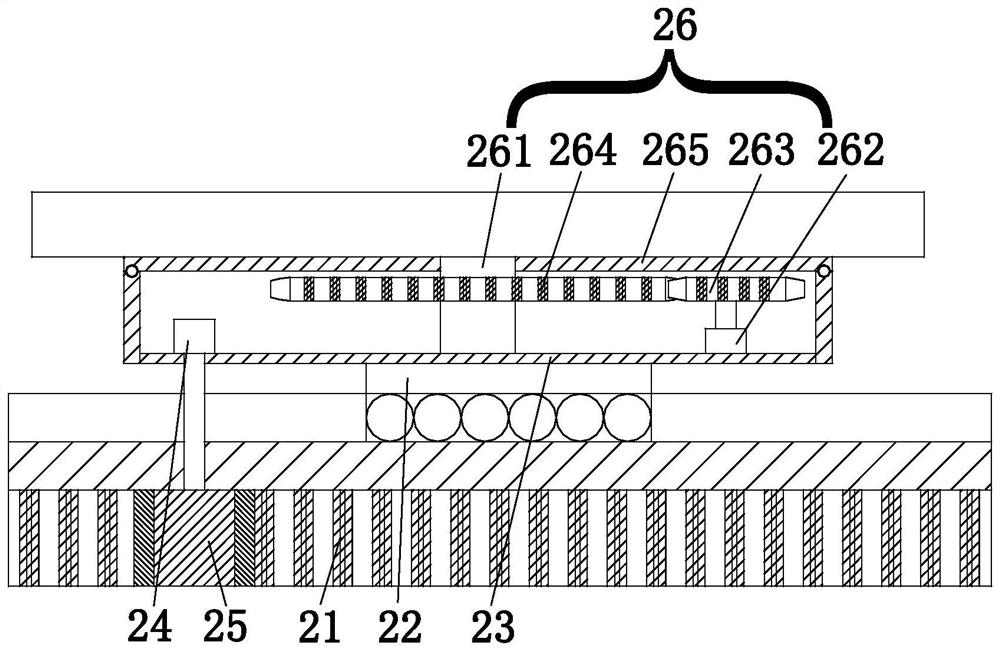

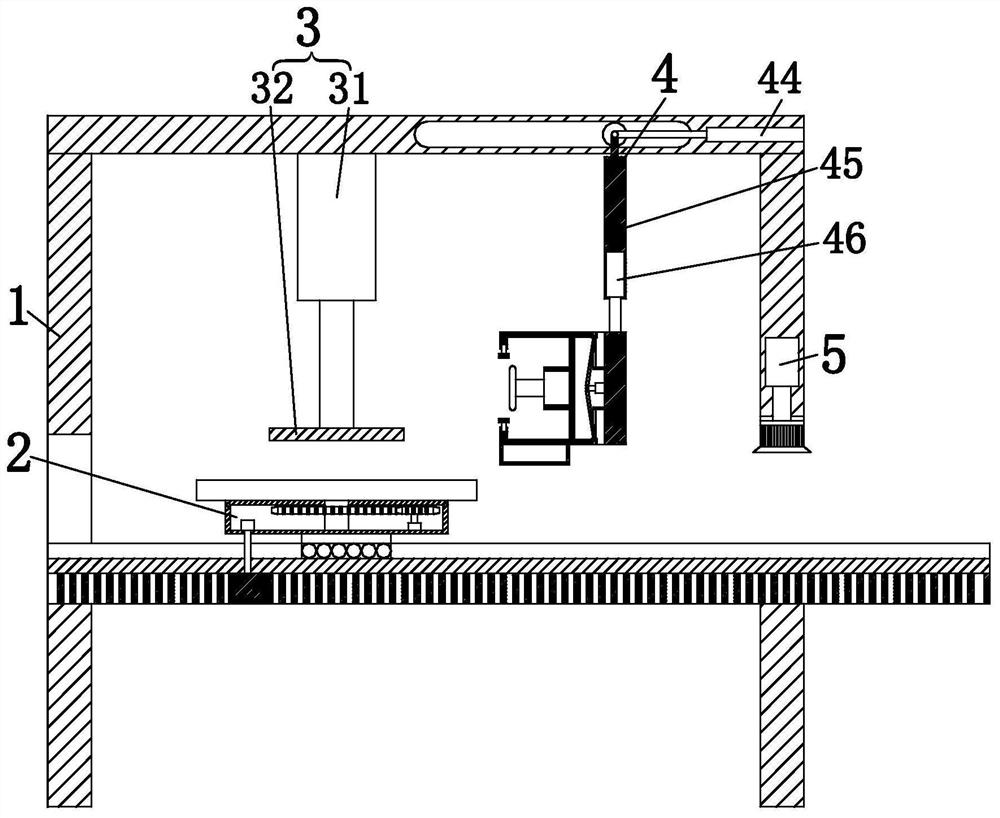

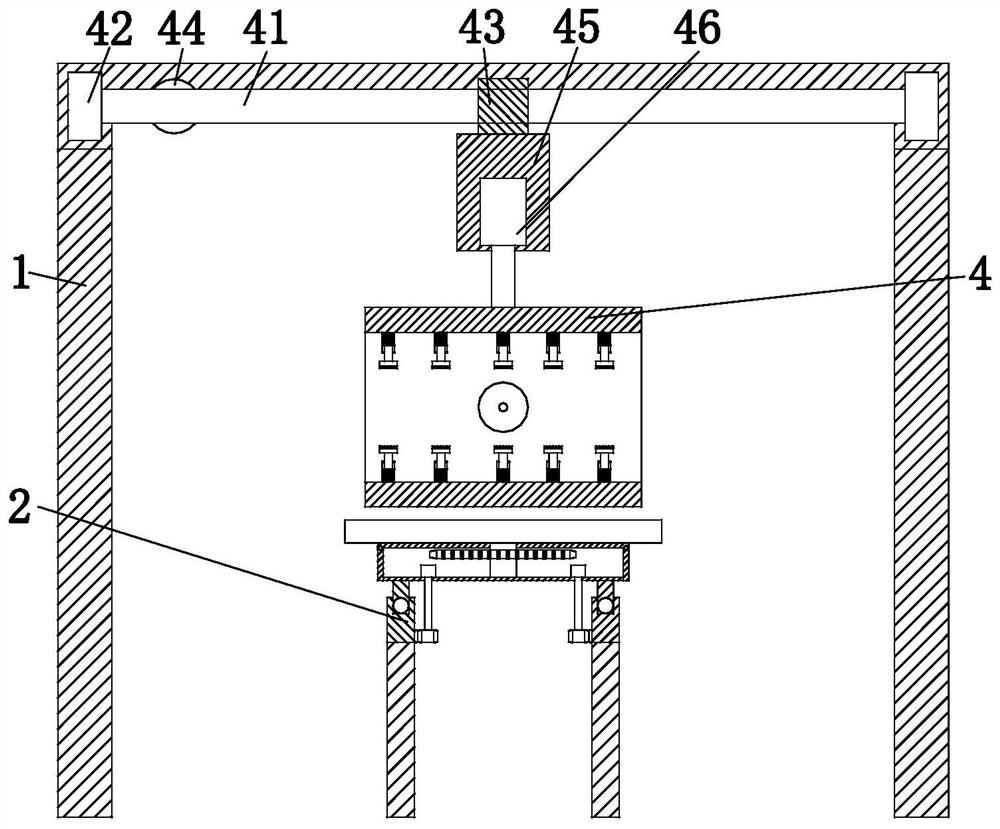

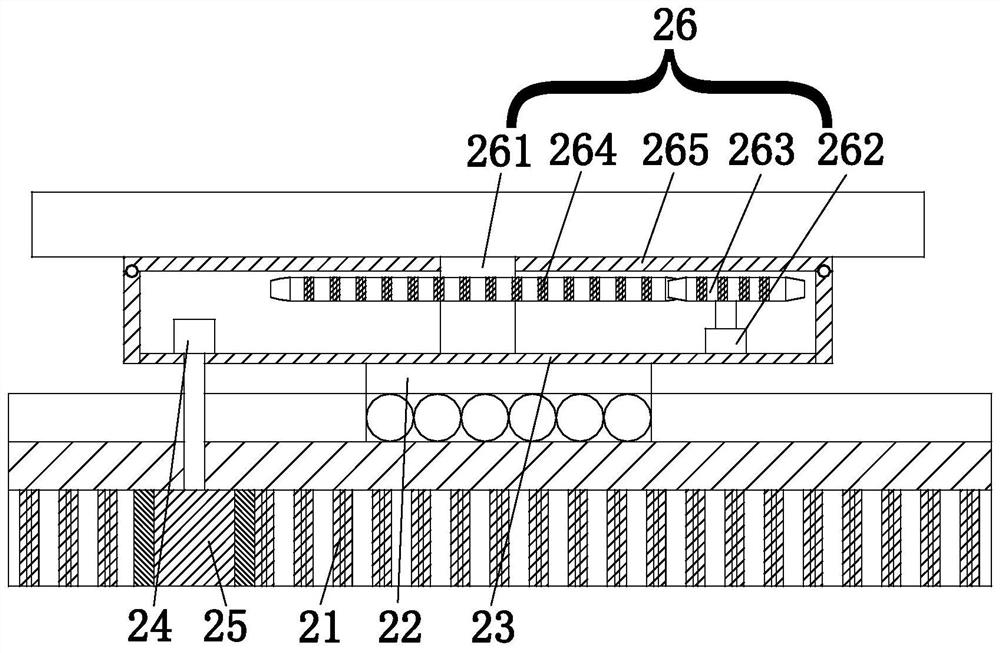

Circuit breaker assembly line and controlling method thereof

ActiveCN105109996AImprove production capacity and production efficiencyGuarantee product qualityControl devices for conveyorsMetal working apparatusMachine pressEngineering

The invention discloses a circuit breaker assembly line and a controlling method thereof. The assembly line comprises a lifting and sending device used for lifting and sending assembling jigs, a conveying device used for conveying the assembling jigs, a loading device used for placing circuit breaker shells on an assembly table and a control device, wherein the lifting and sending device is arranged at the start end of the conveying device; a plurality of working tables are arranged at the side edge of the conveying device; the loading device is arranged at the side edges of the working tables; the control device is separately connected with the lifting and sending device, the conveying device, the loading device and each working table. The circuit breaker assembly line has the following benefits that the assembly line production mode is adopted, so that the production efficiency and production capacity are greatly improved; the application of a press machine is avoided, so that damage to the workpieces is avoided, and the quality of the product is effectively guaranteed; a plurality of working tables are adopted, and a plurality of circuit breakers can be assembled at the same time, so that the assembly line is large in conveying capacity, high in speed and capable of achieving same-line divided transportation of products of multiple types; and through the loading device, the lifting of the circuit breaker shells is realized, so that the general assembly efficiency is further improved.

Owner:YIHE ELECTRIC GRP

Box lateral side protecting device of LED curtain wall screen

ActiveCN103606339AAssembly does not affectDoes not interfere with flatnessCasings/cabinets/drawers detailsIdentification meansEngineeringLED lamp

The invention discloses a box lateral side protecting device of an LED curtain wall screen. The box lateral side protecting device comprises a box, LED lamp beads mounted on the surface of the box, a retaining plate and a pull rod, a containing groove is formed in the side wall of the box, the retaining plate is movably mounted in the containing groove, an elastic element is arranged between the retaining plate and the containing groove and used for providing a force pushing the retaining plate to a direction away from the box, the pull rod is provided with a handle portion, one end, away from the handle portion, of the pull rod penetrates the box to be hinged on the retaining plate, and a limiting face matched with the handle portion of the pull rod is arranged on the box and used for preventing the pull rod from retracting into the box. The retaining plate capable of being movably mounted on the lateral side of the box is arranged on the lateral side of the box, so that when the box is demounted from the curtain wall screen, the retaining plate slides out of the containing groove and retains on the lateral side of the box, and effect of protecting the LED lamp beads is realized; when the curtain wall screen is assembled, the retaining plate is hidden in the containing groove and does not affect flatness of the lateral side of the box, so that assembling of the curtain wall screen is not affected.

Owner:SHENZHEN INFILED ELECTRONICS

Automatic four-axis manipulator assembly system

PendingCN108237400AAccurate and efficient transmissionGuaranteed accuracyAssembly machinesMetal working apparatusComputer moduleMultiple sensor

The invention discloses an automatic four-axis manipulator assembly system. The system comprises a rack, wherein an assembly module and a manipulator module are arranged on one side of the rack, and afeeding module is arranged on the rack; the feeding module is ensured to efficiently and accurately delivering materials and parts and grabbing materials on the correct position by utilizing electromagnetic vibration of a round vibration disc and an output rail, vision detection devices are arranged on the manipulator module, and whether a material is complete and direction and position are positioned or not can be conveniently determined; and the assembly module is positioned by adopting multiple sensors to ensure the accuracy of a tooling plate, and the tooling plate is jacked up by adopting a cylinder to fix the tooling plate and improve the assembly stability. According to the automatic assembly system, two vision detection devices for accurate positioning and direction discriminatingare used to automatically identify in a certain deviation area, the whole assembly is not influenced, cost increased generated by the client product accuracy requirement required by the assembly requirement can be reduced. The system can be suitable for large-batch production.

Owner:SHENZHEN GRANDSEED TECH DEV

Refrigerator illumination structure and assembly positioning method of refrigerator illumination structure

InactiveCN104101174AImprove assembly efficiencyReduce manufacturing costLighting and heating apparatusLighting arrangementEmbedded systemEngineering

The invention discloses a refrigerator illumination structure and an assembly positioning method of the refrigerator illumination structure. The refrigerator illumination structure comprises an embedded box, an LED (light emitting diode) lamp board and a lampshade, wherein the LED lamp board is arranged on the embedded box, the lampshade is arranged on the outer side of the LED lamp board in a covering way, the embedded box is fixedly arranged on an inner liner, and the lampshade is fixedly connected with the inner liner. Through fixedly connecting the lampshade and the inner liner, the lampshade and the embedded box do not have the direct assembling relationship, so the forming thickness of the inner liner does not influence the assembling of the lampshade, the assembling efficiency is improved, the problem of box body rejection as the lampshade cannot be assembled is avoided, and the production cost is reduced. Meanwhile, through installing positioning ribs, the position of the embedded box is effectively positioned, so the relative accuracy of the position of the LED lamp board is guaranteed for realizing the correct illumination of the LED lamp board.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

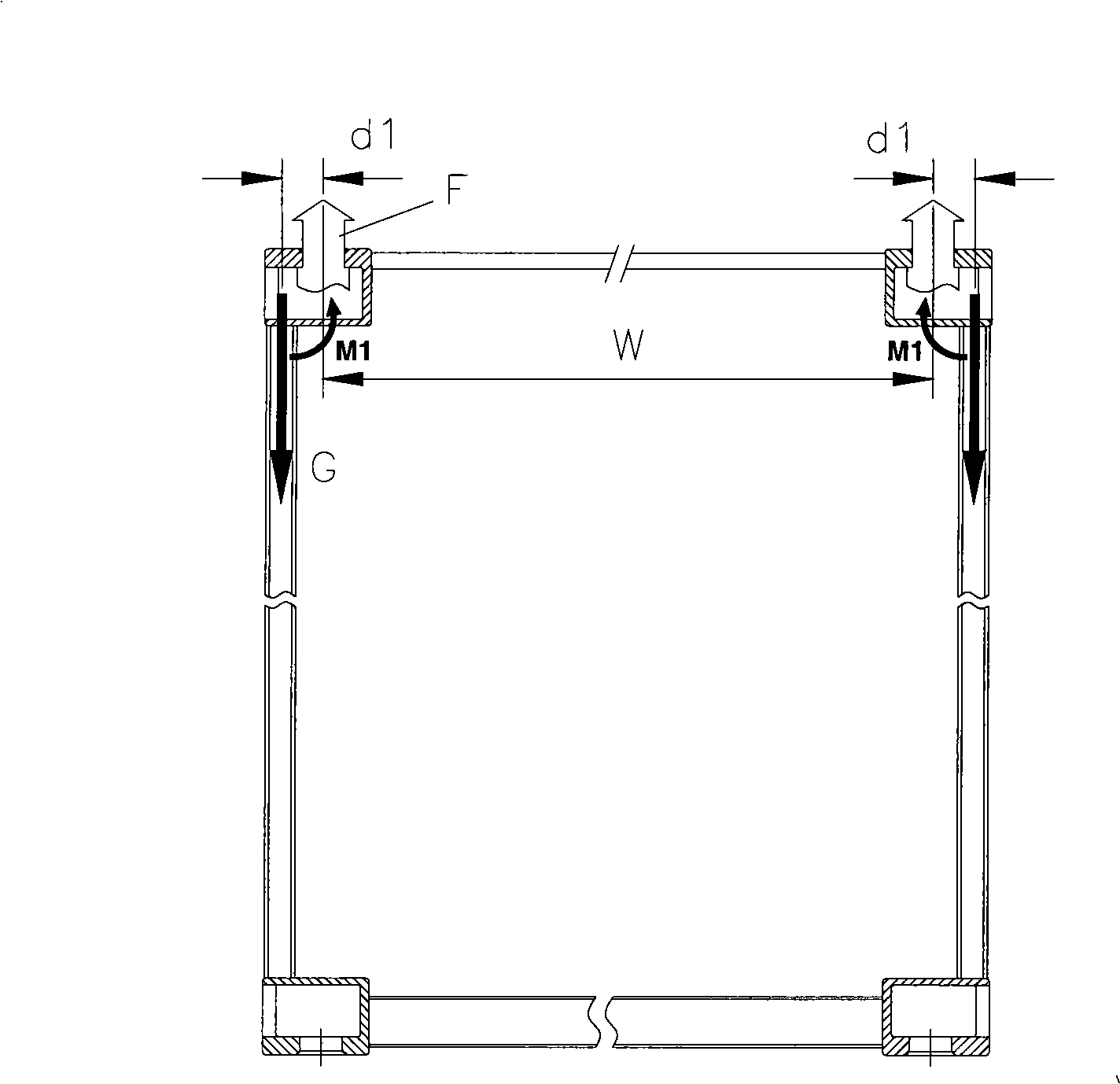

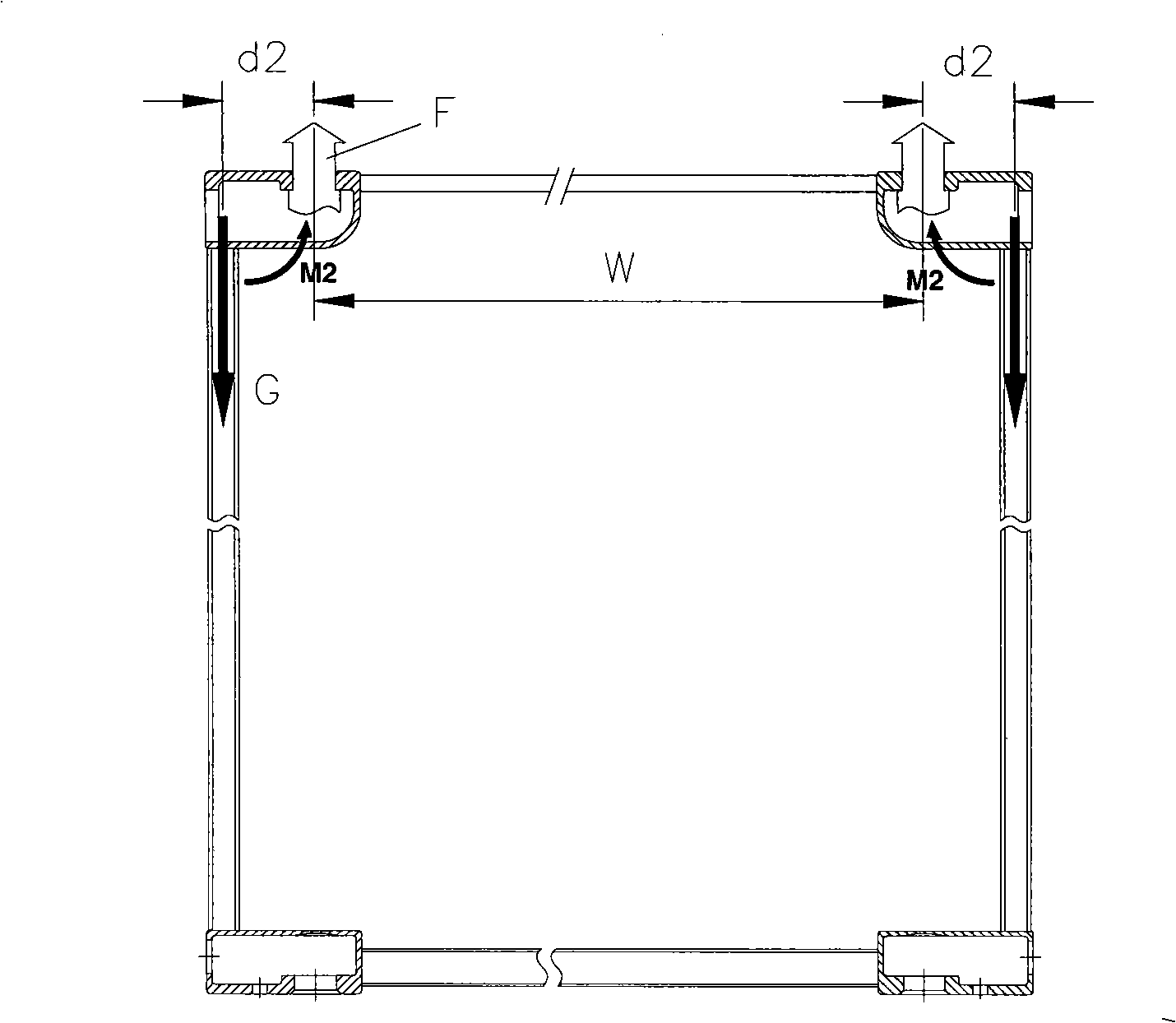

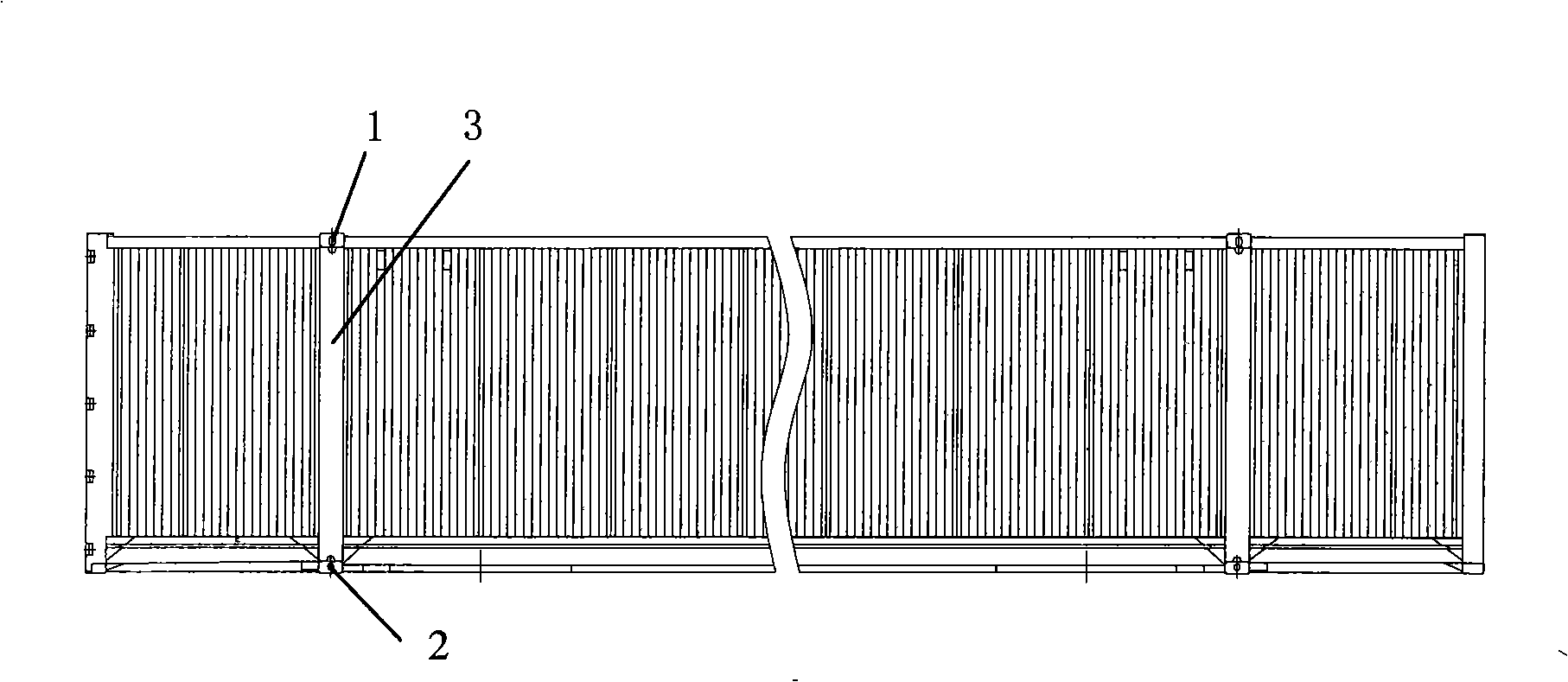

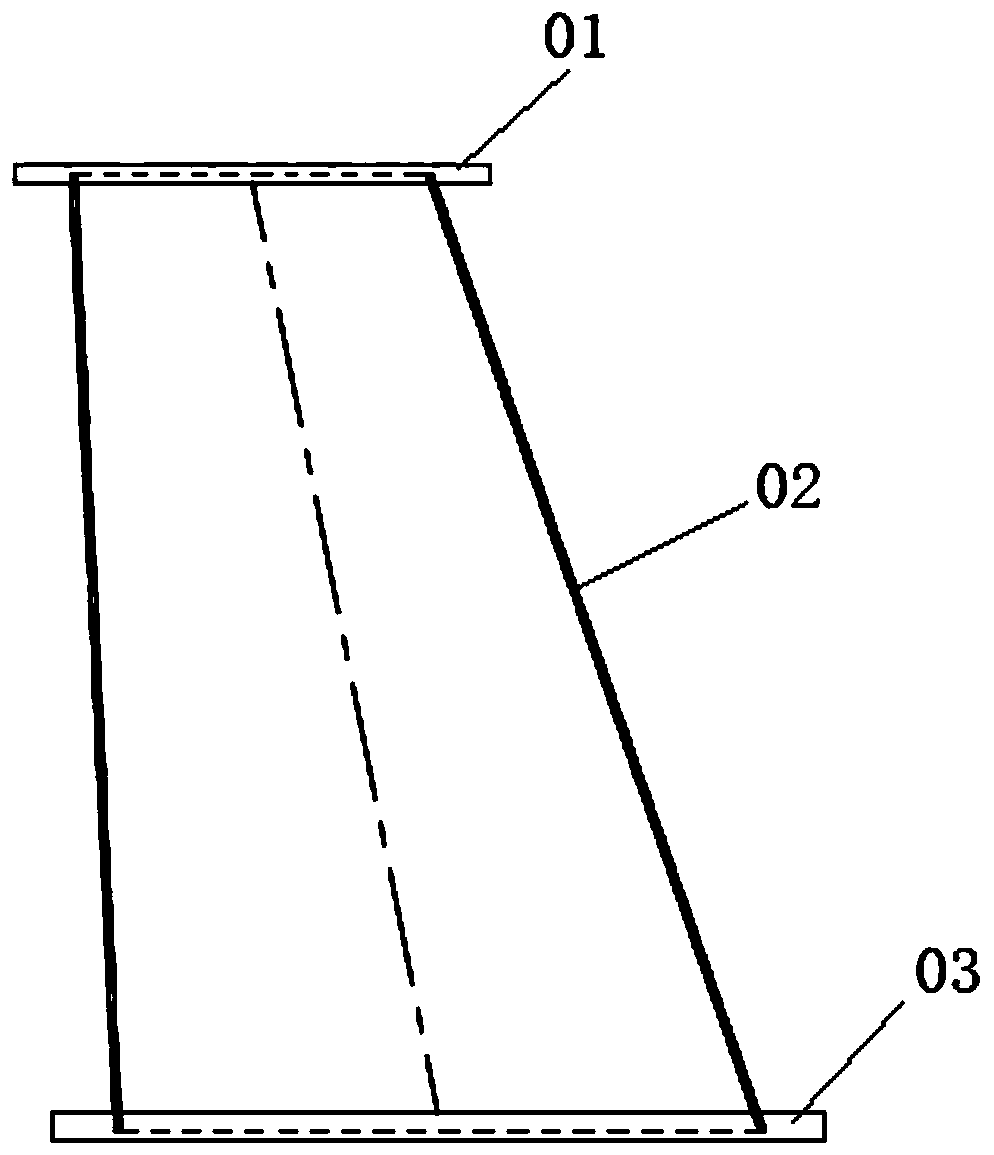

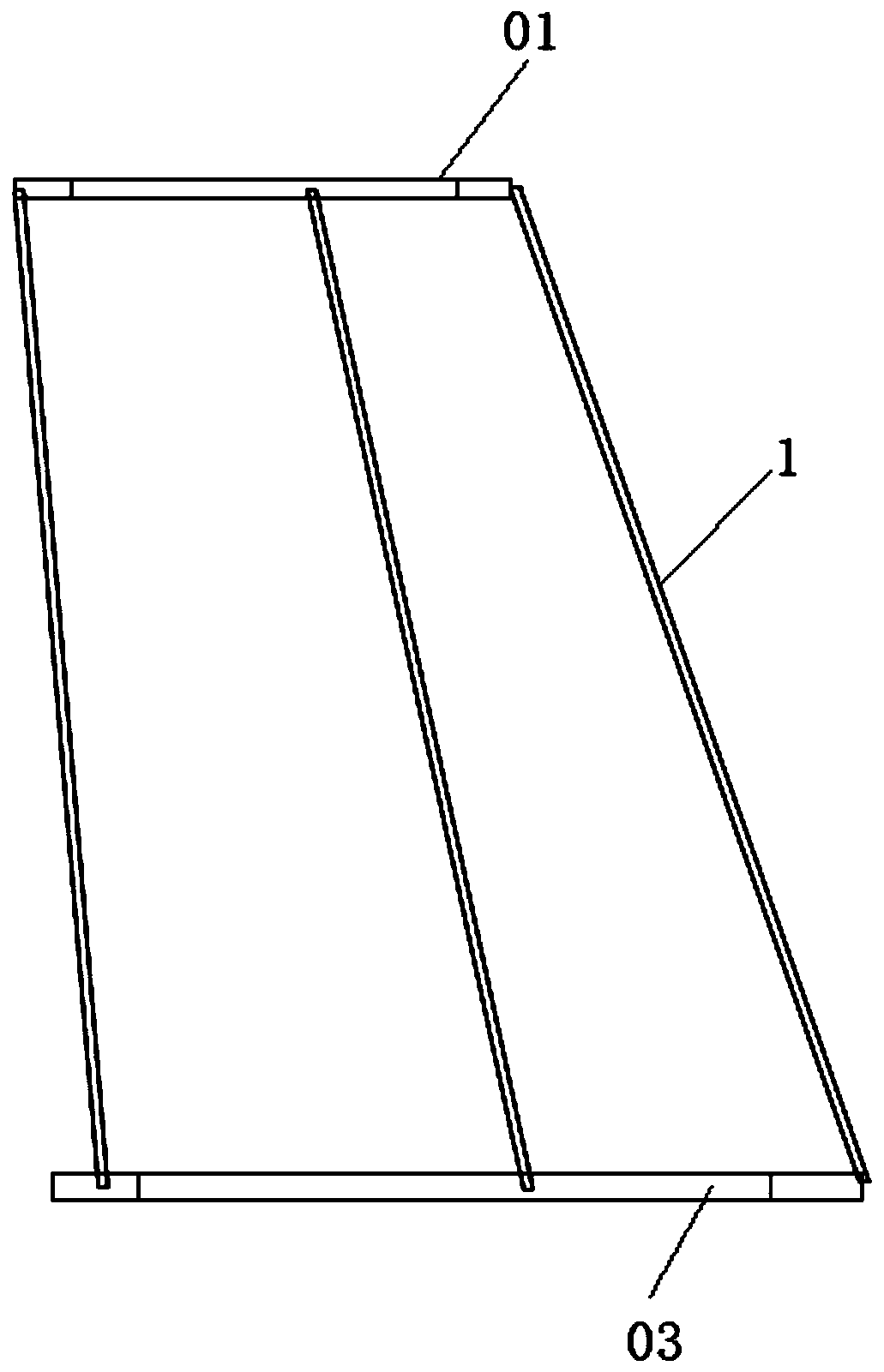

Hoisting and piling structure of container

ActiveCN101402414AStrengthen connectionAvoid assembly process problemsLarge containersEngineeringMechanical engineering

The invention relates to a hoisting and stacking structure of a container, which comprises a corner post, a top angle piece and a bottom angle piece arranged on the top and the bottom of the corner post respectively, wherein a first ear is arranged on the top angle piece extending downwardly; a second ear is arranged on the bottom angle piece extending upwardly; and the first ear and the second ear both extend into the corner post and are welded with the inner surface of the corner post. The hoisting and stacking structure of the container increases the weld length between the corner post and the top angle piece, as well as the bottom angle piece, so as to strength the connecting between among the corner post and the top angle piece as well as the bottom angle piece. Because of the simple plane fit between the first ear together with the second ear and the corner post, the problem of imprecise assembly can not happen; moreover, even if the precisions of the top angle piece and bottom angle piece are reduced, the assembly of the corner post can not be affected, thereby avoiding the problem of the assembly process caused by the difference of casting the angle piece, and ensuring the convenient and simply assembly of the angle piece with ears and the corner post.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

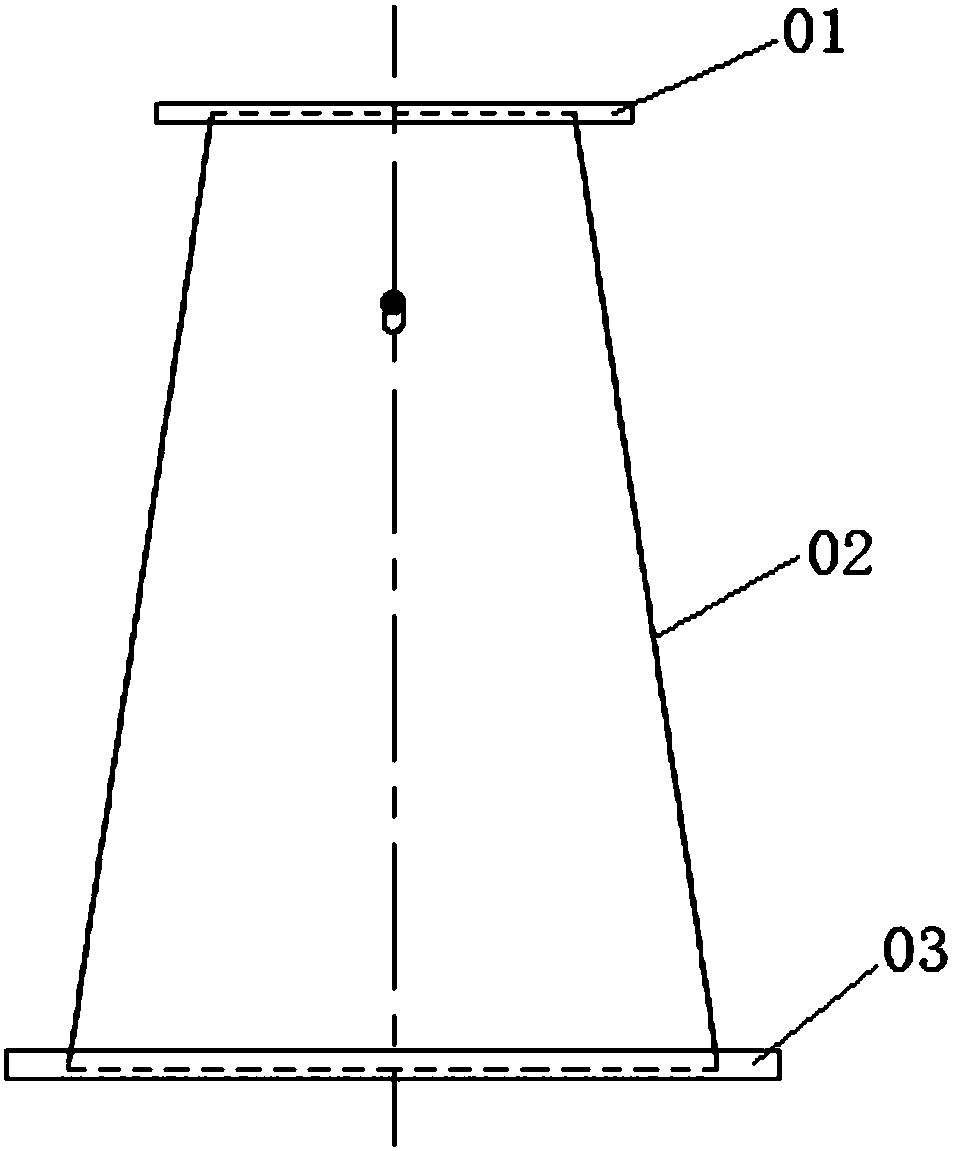

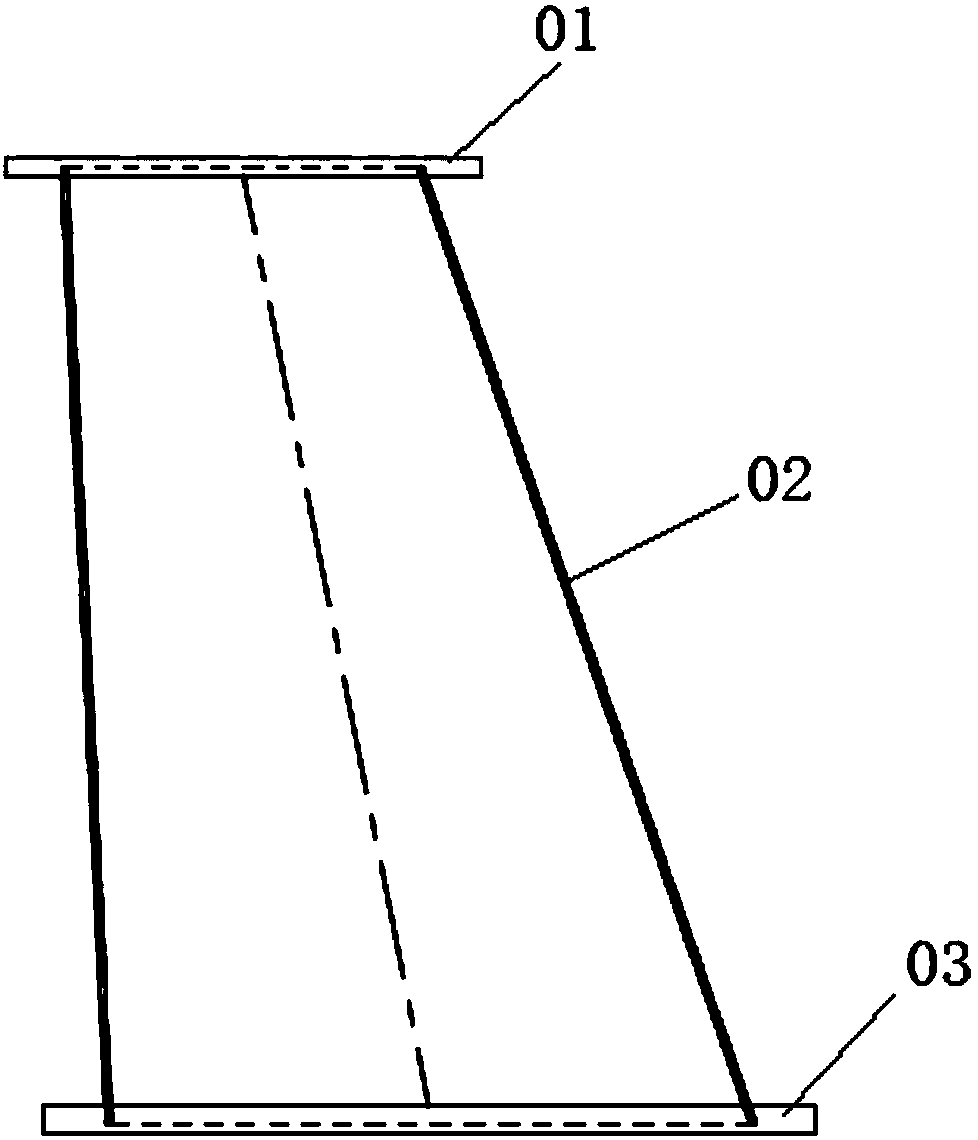

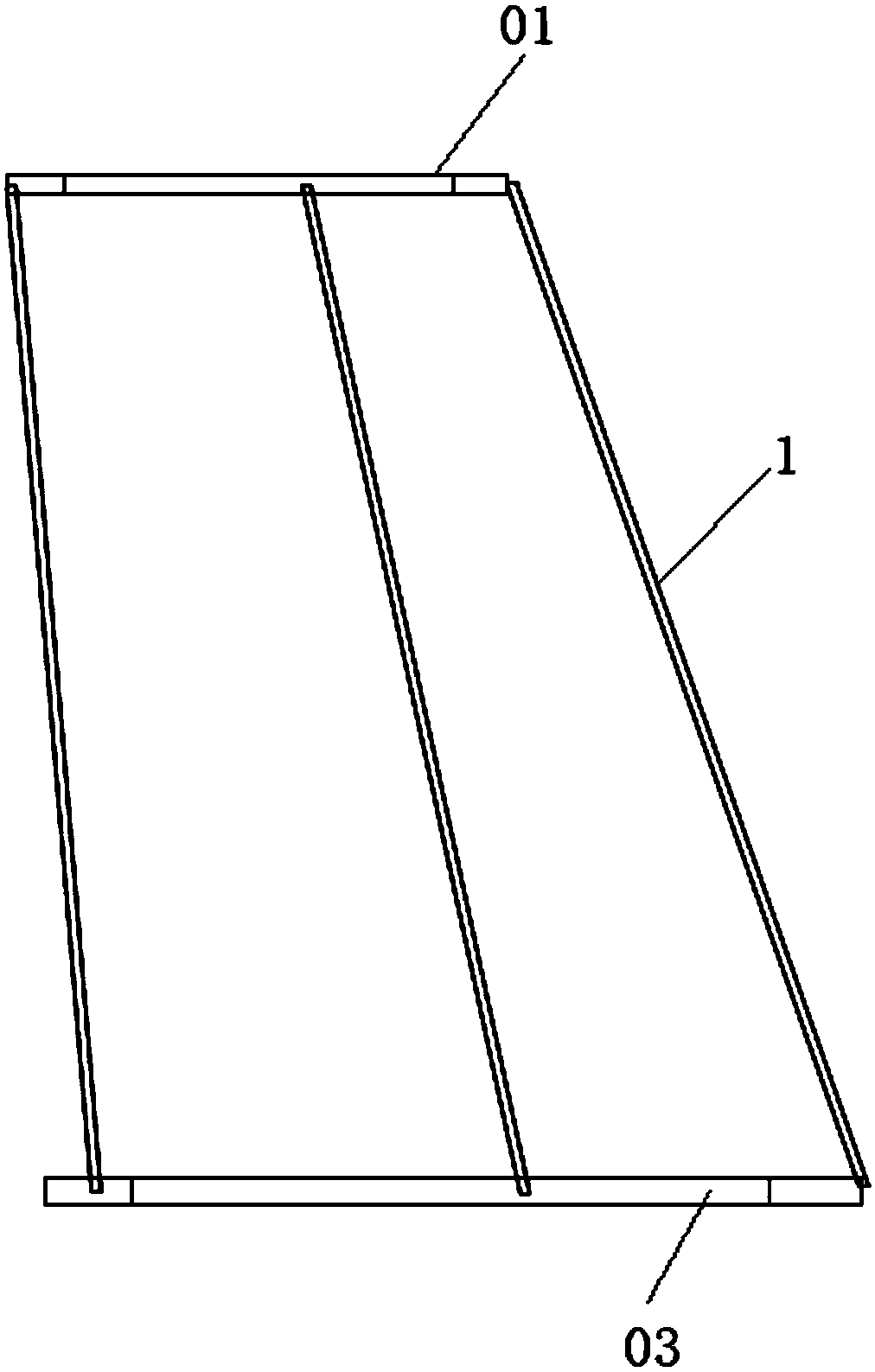

Technological method for assembly and welding of diffuser tube in marine diesel engine

The invention discloses a technological method for assembly and welding of a diffuser tube in a marine diesel engine. According to the technological method, the adaptation to the relative position between a top flange and a bottom flange can be achieved by replacing a tapered tube in the diffuser tube with a plurality of positioning ribs; on the one hand, the problem that the tapered tube is slowly delivered during the pre-assembly process can be solved and the normal assembly of a main machine can be guaranteed; on the other hand, the onsite assembly and welding of the diffuser tube can be changed into welding in a steel structure workshop through the use of the positioning ribs, the restrictions to the operation space and the operation position during the welding of the diffuser tube canbe changed, and the problem about large assembly and welding deformation can be solved; meanwhile, the process of flatness detection after welding is added in the technological method and the millingprocessing is achieved, so that the problem about assembly flatness errors can be solved; and an expansion joint is arranged on a turbocharger as well as the expansion and contraction quantity of theexpansion joint reaches 3 mm, so that the proper milling operation can be prevented from influencing the assembly.

Owner:中船发动机有限公司

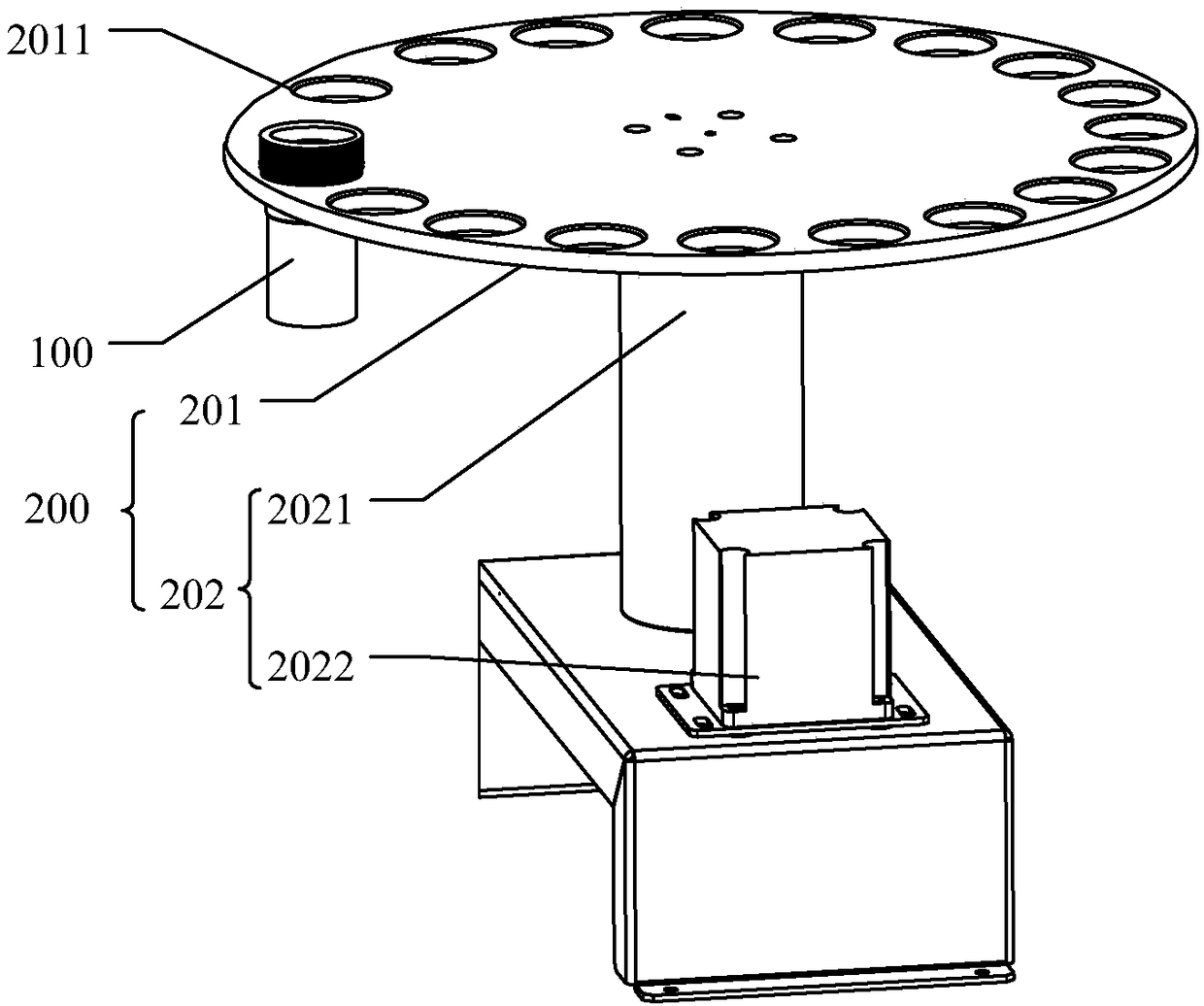

Cell enriching system and method

ActiveCN108303309AImprove concentrationReduce overlayPreparing sample for investigationBiochemical engineeringCell concentration

The invention discloses a cell enriching system and a cell enriching method. The cell enriching system comprises a sample bottle, a loading mechanism, a uniformly mixing mechanism, a concentrating anduniformly mixing mechanism and a controller, wherein the loading mechanism can convey the sample bottle; the uniformly mixing mechanism can perform a first uniformly mixing operation on the sample bottle; the concentrating and uniformly mixing mechanism can pierce the bottom of the bottle, and perform sucking and reverse blowing operations on the sample bottle; the controller controls the loadingmechanism to convey the sample bottle to a uniformly mixing position, and then the uniformly mixing mechanism performs the first uniformly mixing operation; after the controller controls the loadingmechanism to convey the sample bottle to a concentrating position, the controller controls the concentrating and uniformly mixing mechanism to pierce the bottom of the bottle to enter a second cavityand repeatedly perform the sucking and reverse blowing operations. The cell enriching system provided by the invention achieves cell concentration by performing the sucking and reverse blowing operations, so that a filter device of the sample bottle and a concentrating needle can be effectively prevented from being blocked, cell superposition can be effectively reduced while cell concentration isaccelerated, and thus the cell enriching quality is improved.

Owner:MACCURA MEDICAL INSTR CO LTD

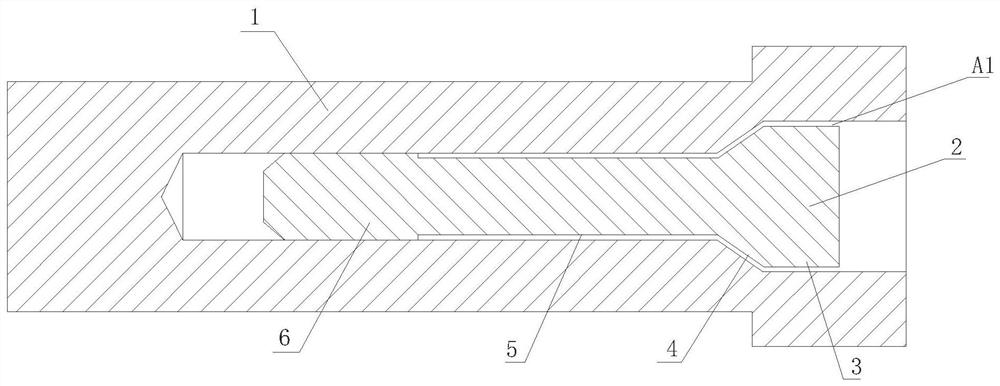

Vacuum brazing method for slender weld joint of hole-shaft matched part

The invention discloses a vacuum brazing method for a slender weld joint of a hole-shaft matched part. The method comprises the following steps of assembling the part, and spraying brazing filler metal, specifically, spot-welding a sheared nickel sheet to a conical surface part of a shaft-shaped part, and uniformly distributing the nickel sheet at 3-5 parts along the circumferential direction of the conical surface part; assembling, specifically, putting the shaft-shaped part in a hole-shaped part and assembling to the bottom, and enabling a clamping part to be in close fit with the inner wall of the hole-shaped part; coating and injecting the brazing filler metal, specifically, uniformly coating and injecting the prepared paste brazing filler metal on the edge of a gap formed by the shaft-shaped part and the hole-shaped part for a circle by using an injector; drying, specifically, cleaning the part, putting the part into a drying oven at (80+ / -10) DEG C, and keeping the temperature for (40+ / -10) minutes; and conducting brazing in a furnace. According to the vacuum brazing method, the front end of the hole-shaft matched part is in close fit, and the nickel sheets with the same thickness are uniformly distributed on the conical surface along the circumference for spot welding, so that the welding clearance is doubly ensured, the conical surface is prevented from being stuck in the assembling process, and the brazing quality of the slender weld joint is better ensured; and the process is easy to operate, parts are easy to assemble, and part assembly is not affected after the nickel sheets are preset on the conical surface.

Owner:西安成立航空制造有限公司

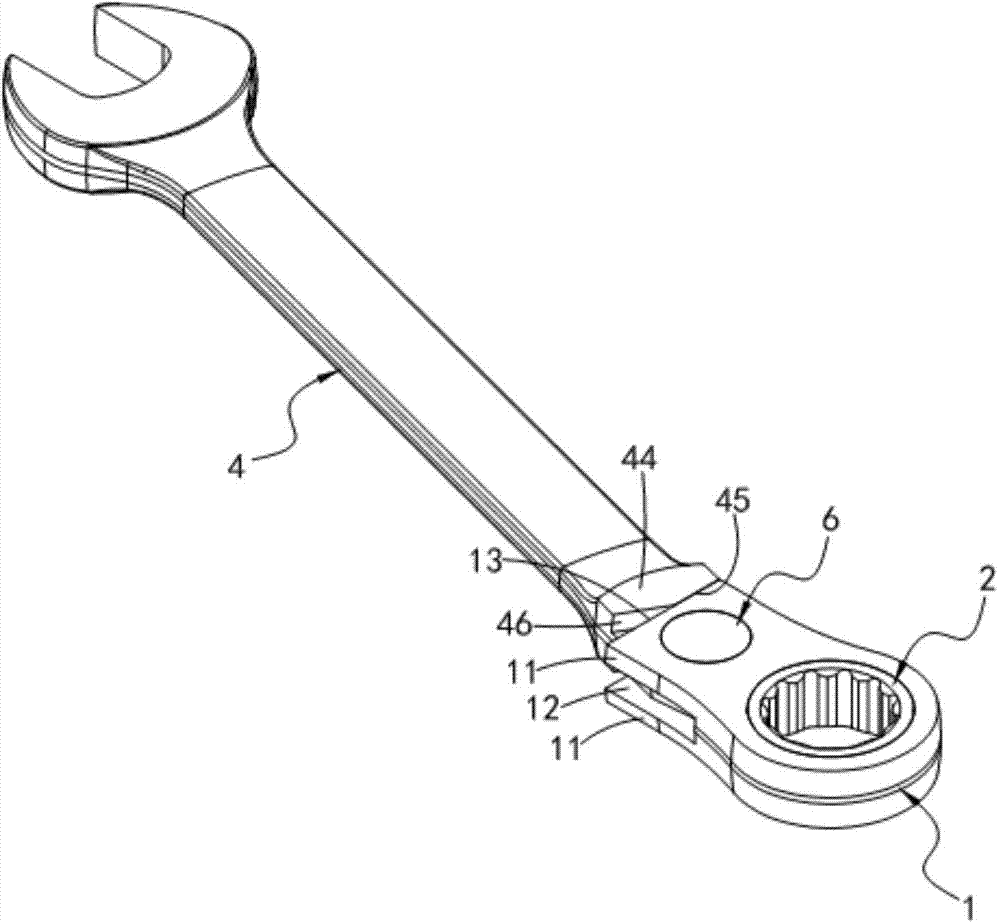

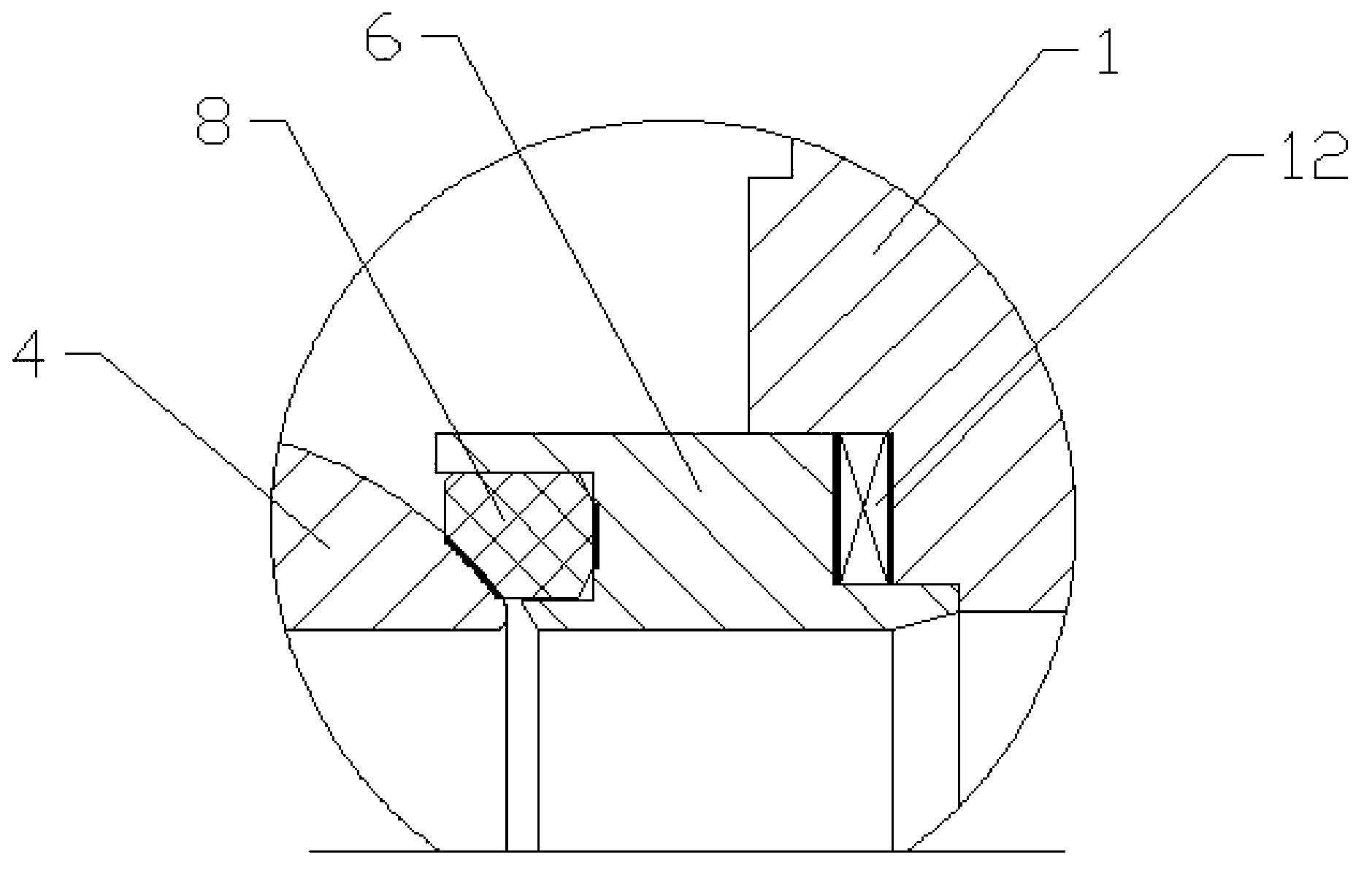

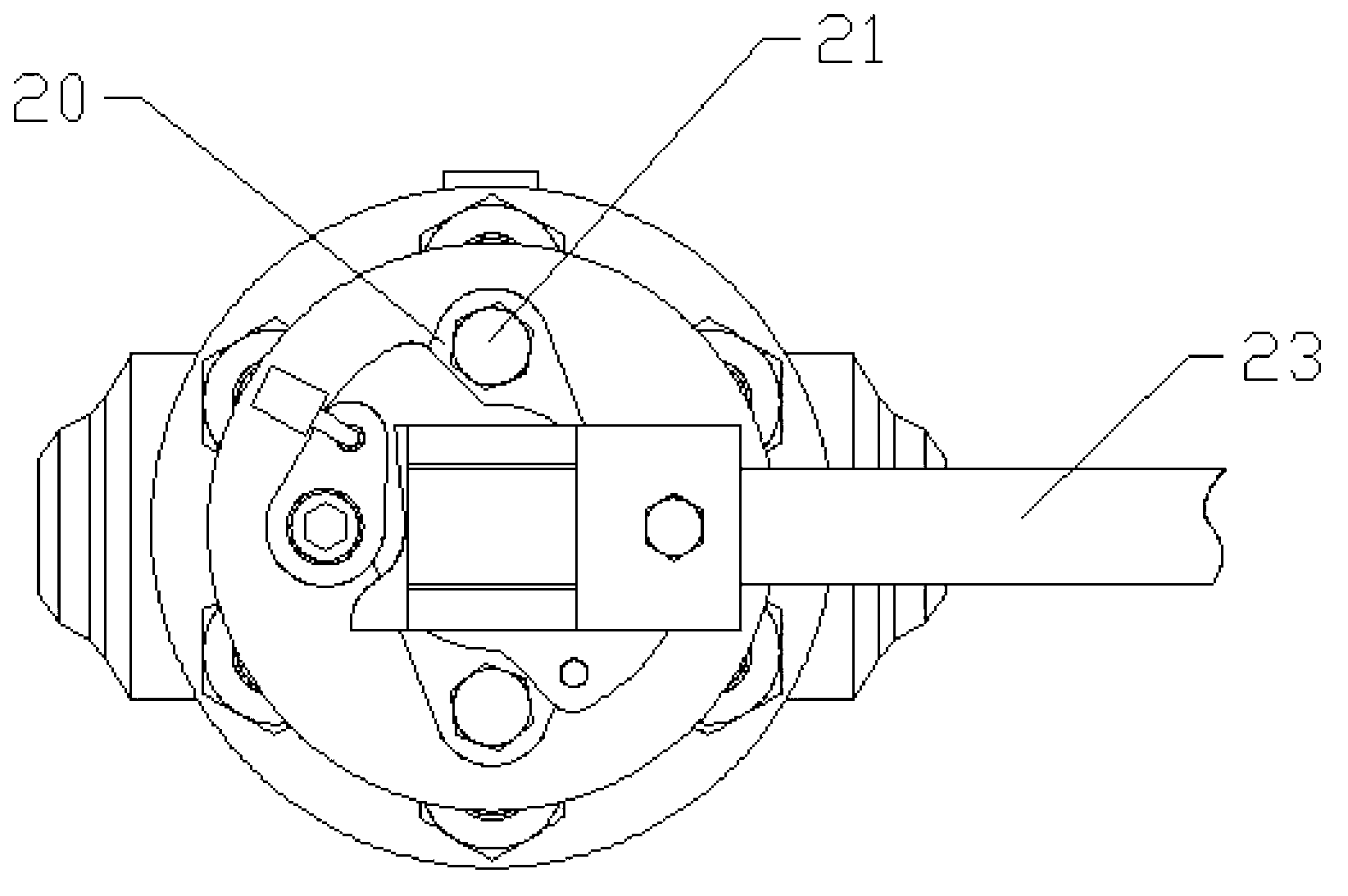

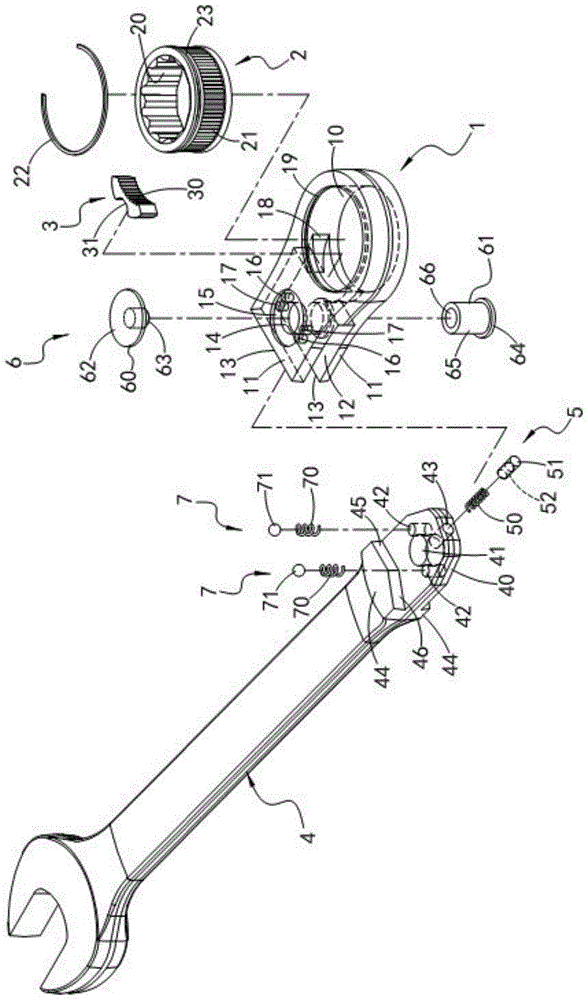

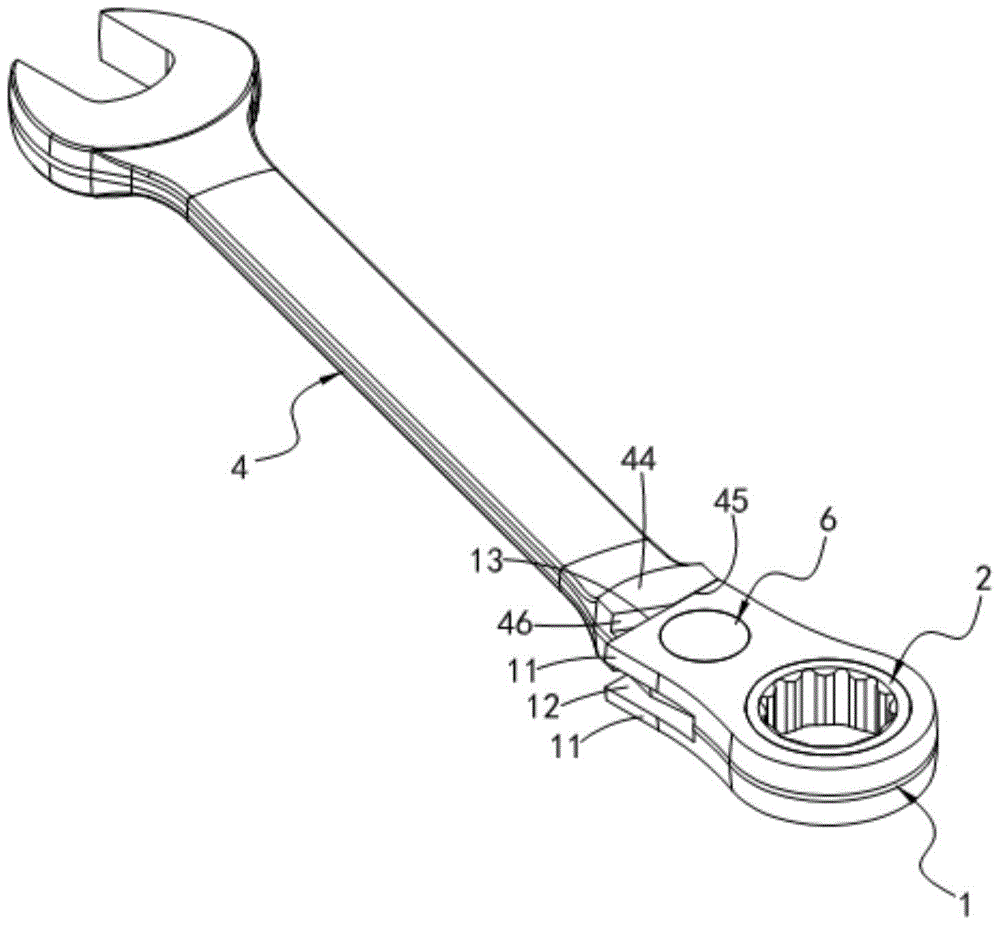

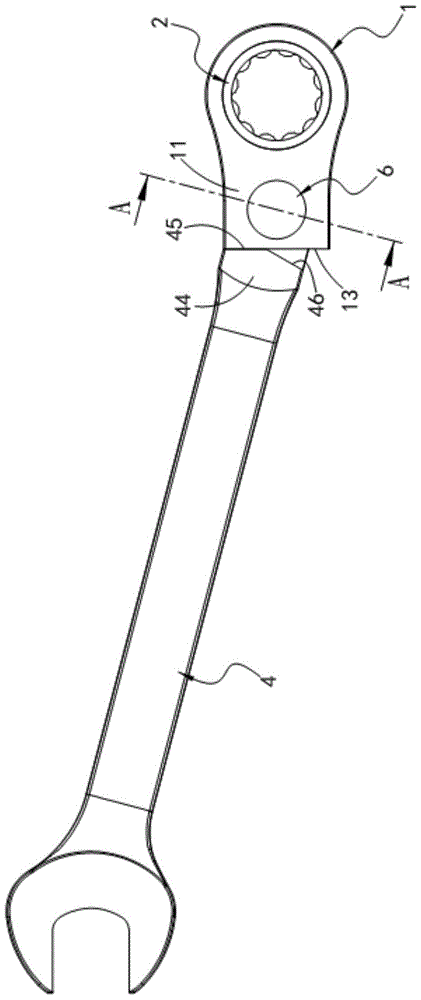

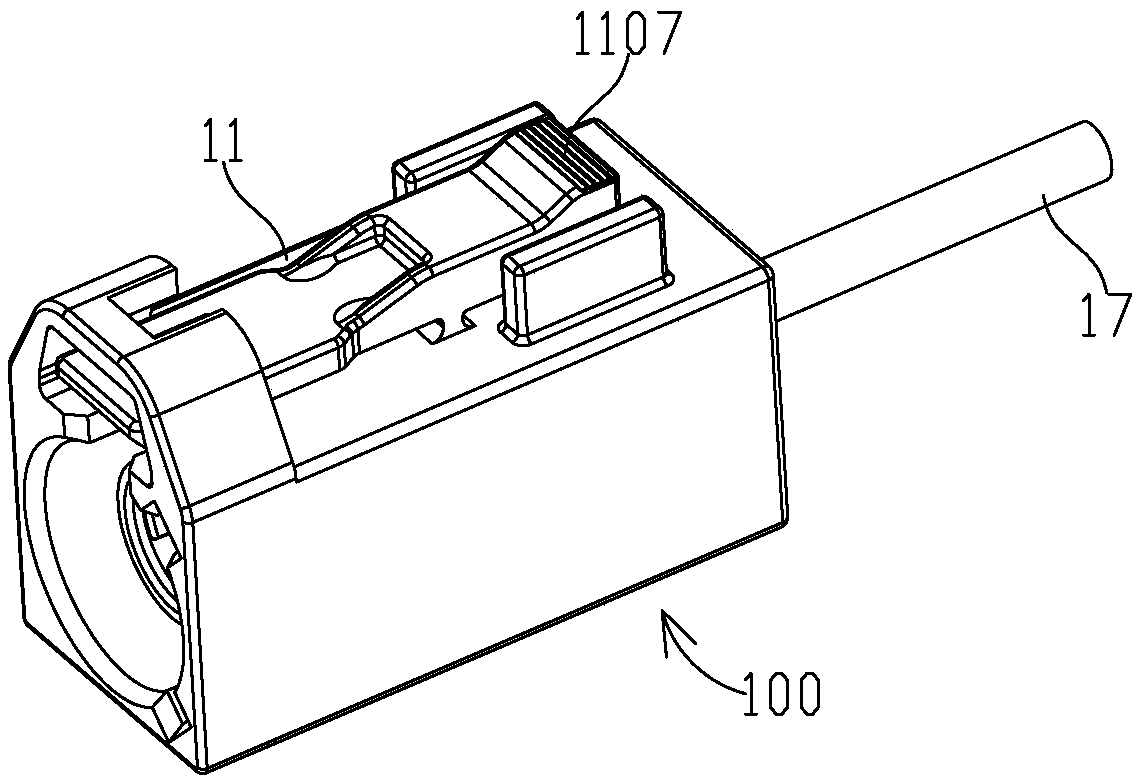

Ratchet wrench reversing structure

ActiveCN104760013ANot easy to break and damageImprove structural strengthSpannersWrenchesHead holderUltimate tensile strength

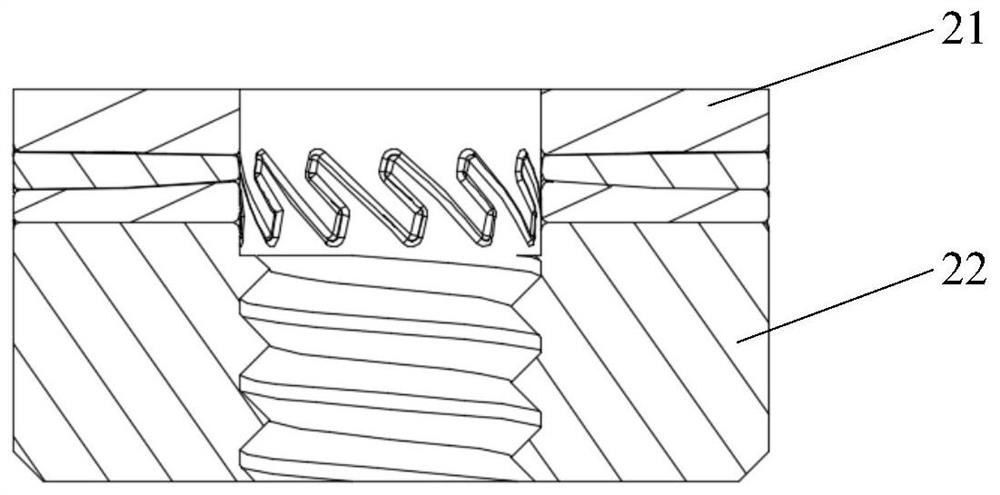

The invention relates to a ratchet wheel and discloses a ratchet wrench reversing structure. The ratchet wrench reversing structure comprises a head holder (1), a ratchet (2), a clamping part (3), a handle (4), an elastic linkage component (5), a pivot (6) and two elastic positioning components (7), wherein an accommodating hole (10) for penetrating through the upper and lower surfaces of the head holder (1) is formed in the head holder (1); two parallel lugs (11) and a pivot groove (12) formed between two lugs (11) are arranged on the head holder (1); a clamping groove (18) penetrating through the pivot groove (12) is formed in the lateral side of the accommodating hole (10); the racket (2) is rotationally combined in the accommodating hole (10) of the head holder (1); the racket (2) comprises a drive part (20) and an external toothed part (21) at the periphery of the racket (2). The ratchet wrench reversing structure has good structural strength, increasing of service life, is easy in manufacturing and assembling and low in cost and the like.

Owner:ZHEJIANG YIYANG TOOL MFG

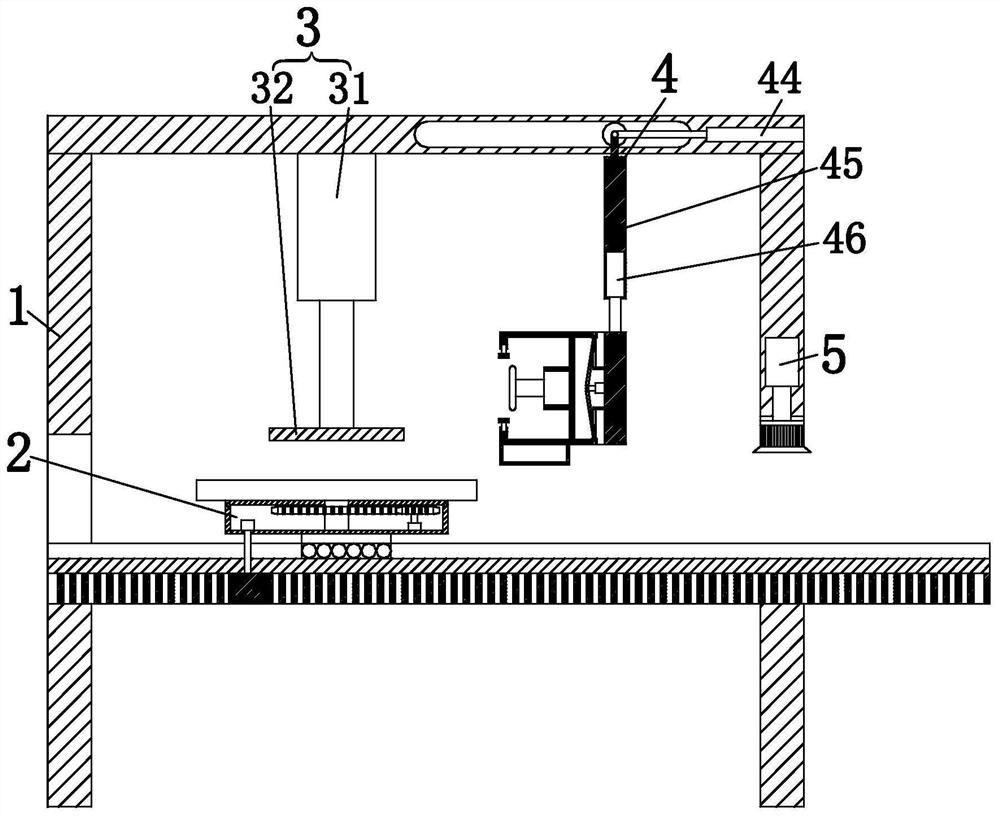

Fabricated concrete prefabricated wall manufacturing and machining machine and machining process

ActiveCN111844400ALabor intensiveAssembly does not affectEdge grinding machinesCeramic shaping apparatusPolishingMachining process

The invention relates to a fabricated concrete prefabricated wall manufacturing and machining machine and machining process. The fabricated concrete prefabricated wall manufacturing and machining machine comprises a frame body, a conveying device, a fixing device, a polishing device and a scrap blowing device, wherein the conveying device is arranged at the lower end inside the frame body, the fixing device is installed at the upper end inside the frame body, the polishing device is arranged on the right side of the upper end inside the frame body, and the scrap blowing device is installed inthe middle of the right side wall of the frame body. According to the fabricated concrete prefabricated wall manufacturing and machining machine and the machining process, the problems that a traditional prefabricated wall rough material polishing method adopts a manual polishing method, namely before the prefabricated wall is assembled and used, the surface of the prefabricated wall is manually polished and then is directly used for assembling, the labor intensity of assembling workers can be increased and the polishing effect cannot be guaranteed by adopting the manual polishing, cooperationamong walls can be further influenced, and the assembly efficiency is influenced and the like can be solved

Owner:江西建工集团新型材料科技有限公司

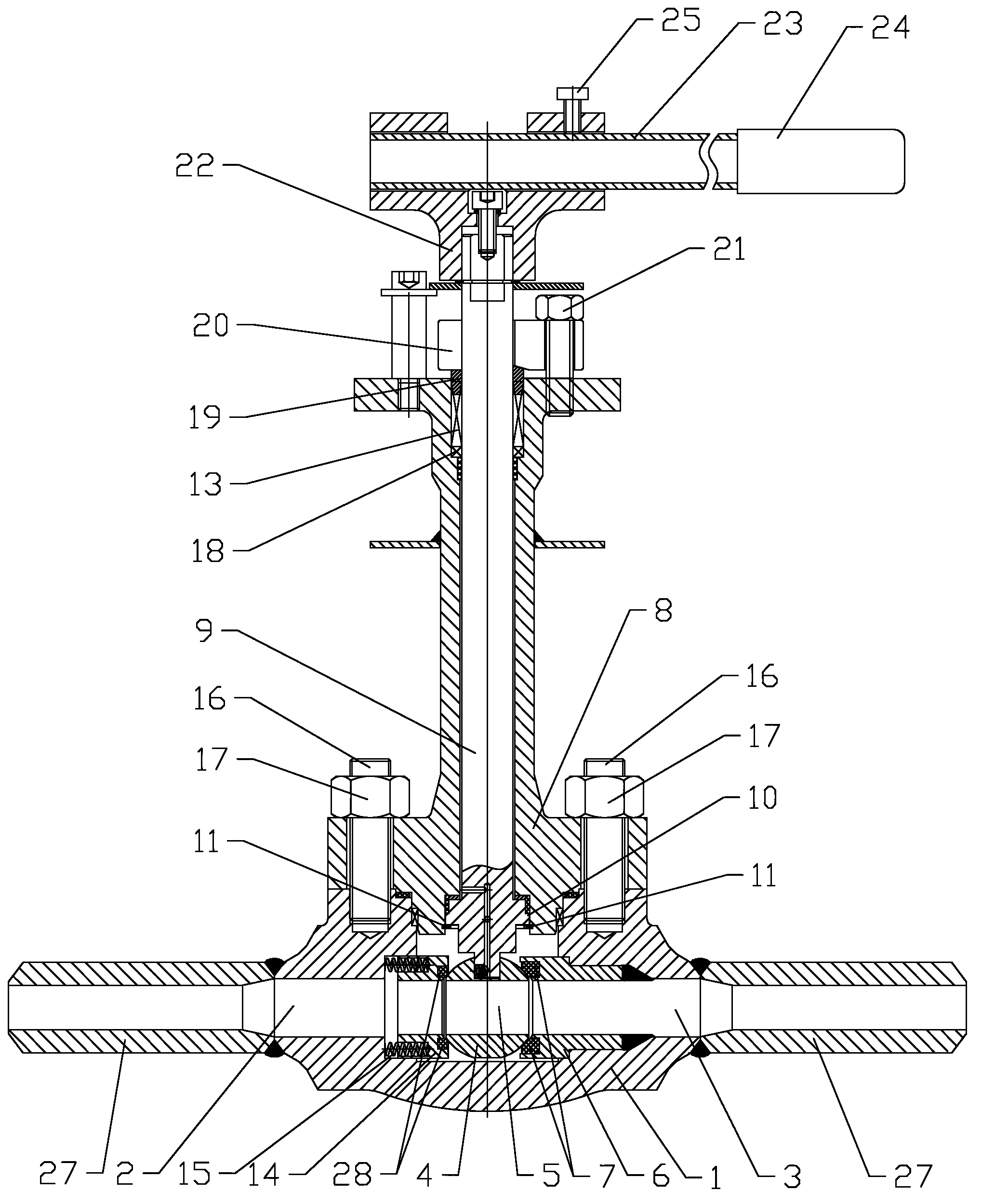

Top-mounted low temperature floating ball valve

The invention relates to a top-mounted low temperature floating ball valve which comprises a valve body (1), a spherical valve core (4) and a fixator (6). The valve body (1) is provided with an inlet (2) and an outlet (3); a cavity is formed inside the valve body (1); the spherical valve core (4) is arranged in the cavity; the spherical valve core (4) is provided with a through passage (5) in the horizontal direction; the spherical valve core (4) can rotate around the vertical axis of the spherical valve core; the fixator (6) is arranged in the cavity and is positioned on the side of the spherical valve core (4), which is close to the outlet (3); a ring-shaped groove of the fixator (6) is provided with an outlet side valve seat (7); the outlet side valve seat (7) is in sealed contact with the spherical valve core (4); the outer wall of the fixator (6) is directly and fixedly connected with the valve body (1) in a gapless manner. According to the top-mounted low temperature floating ball valve disclosed by the invention, no leakage point exists between the fixator and the valve body, the valve has good sealing performance and the top-mounted low temperature floating ball valve is safe and reliable.

Owner:NEWAY VALVE SUZHOU

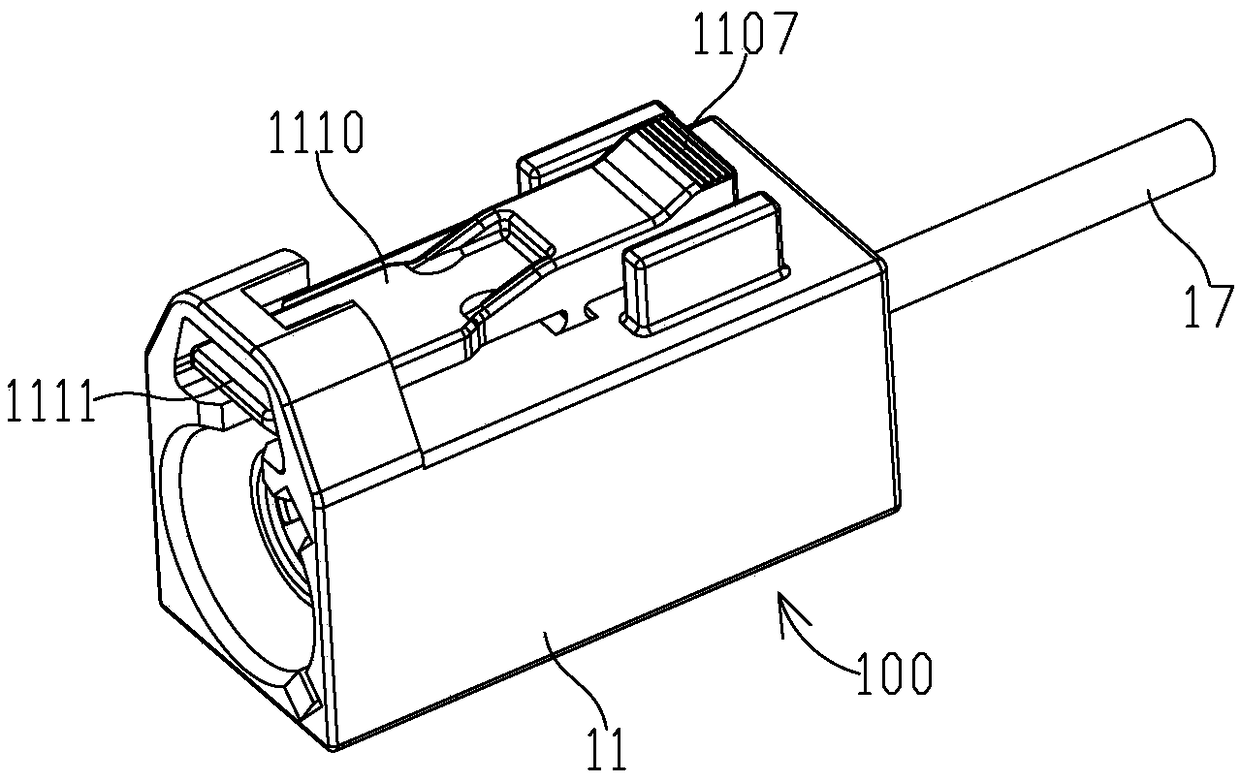

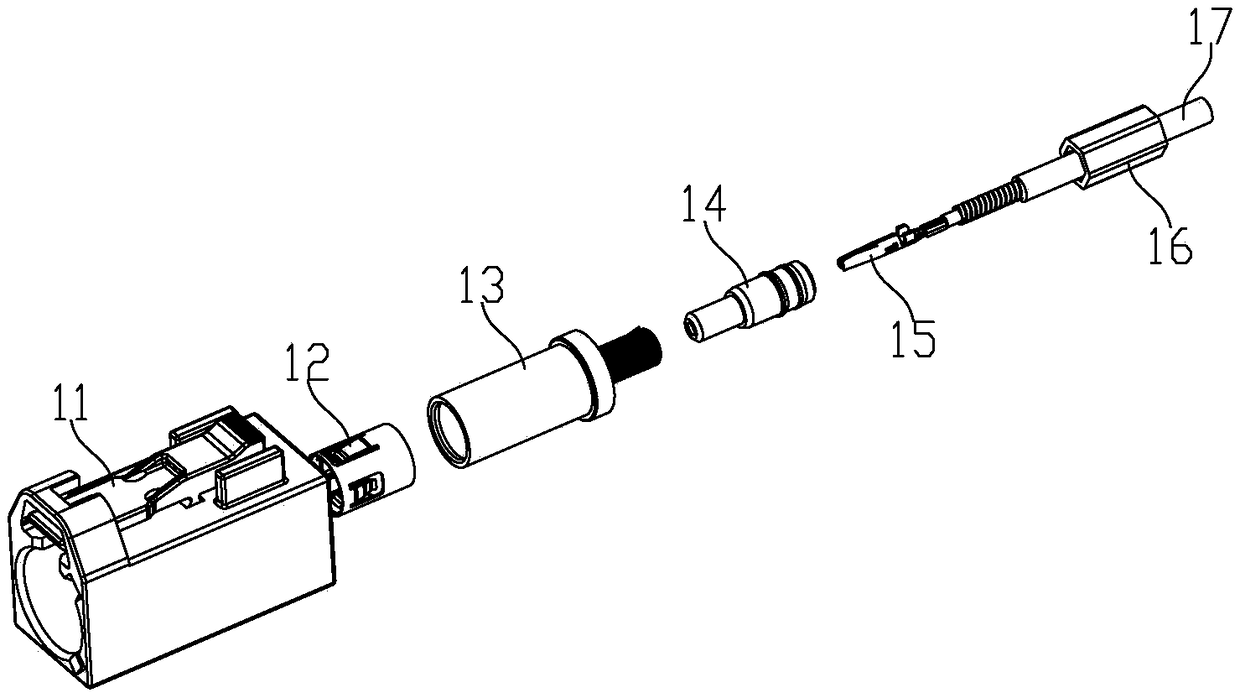

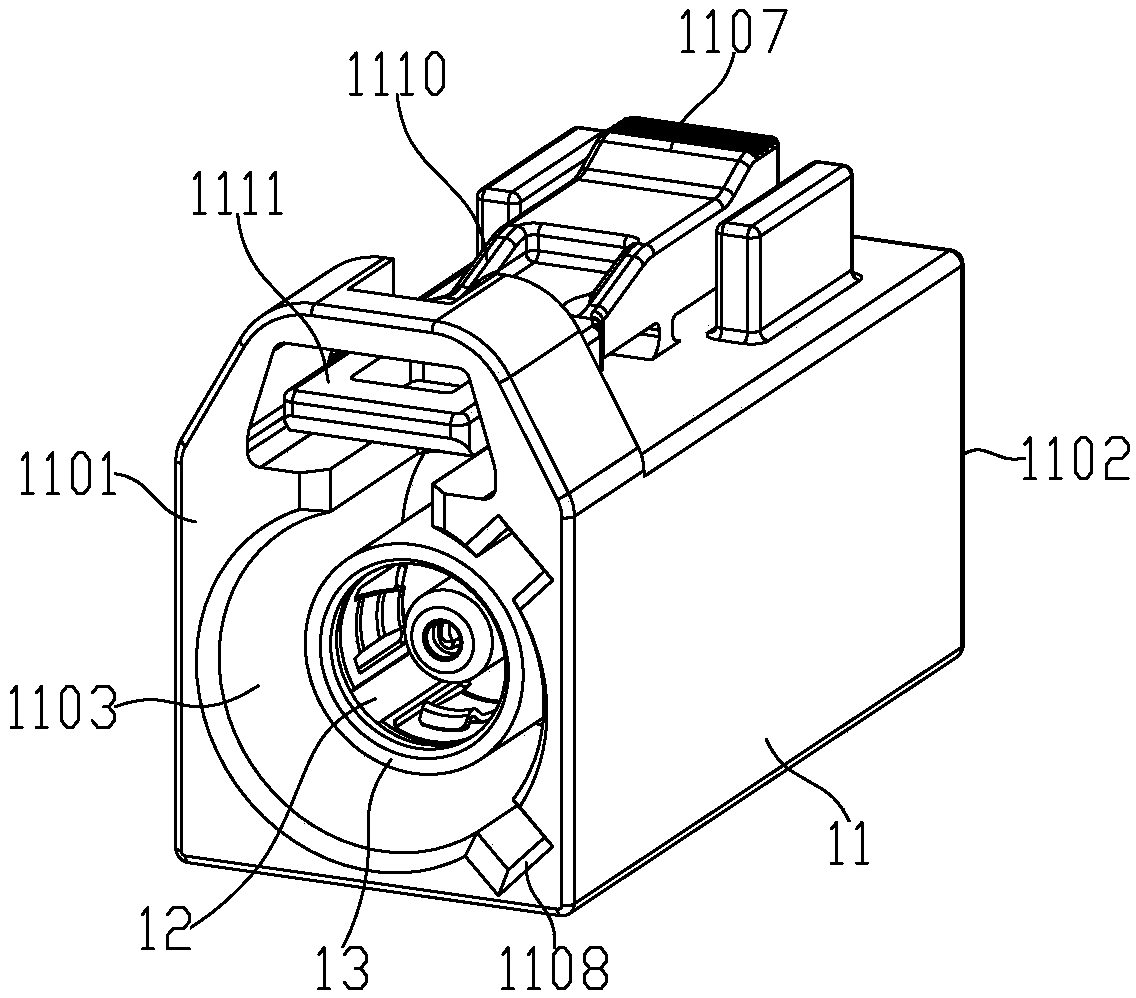

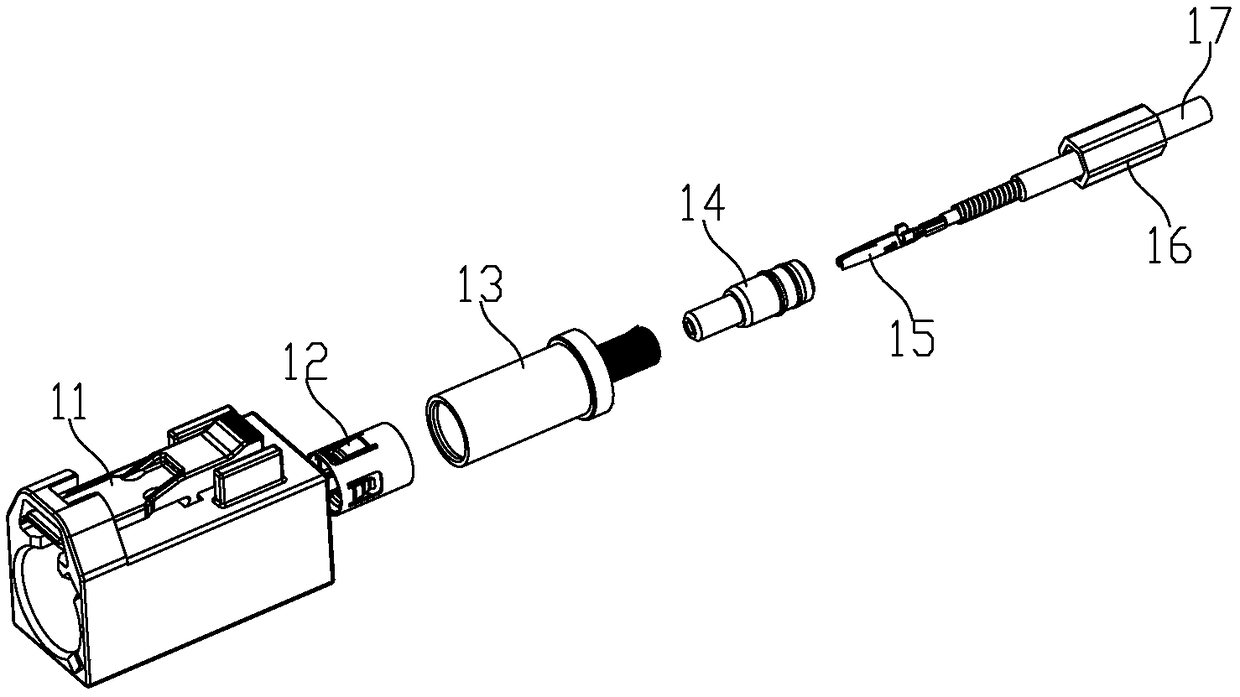

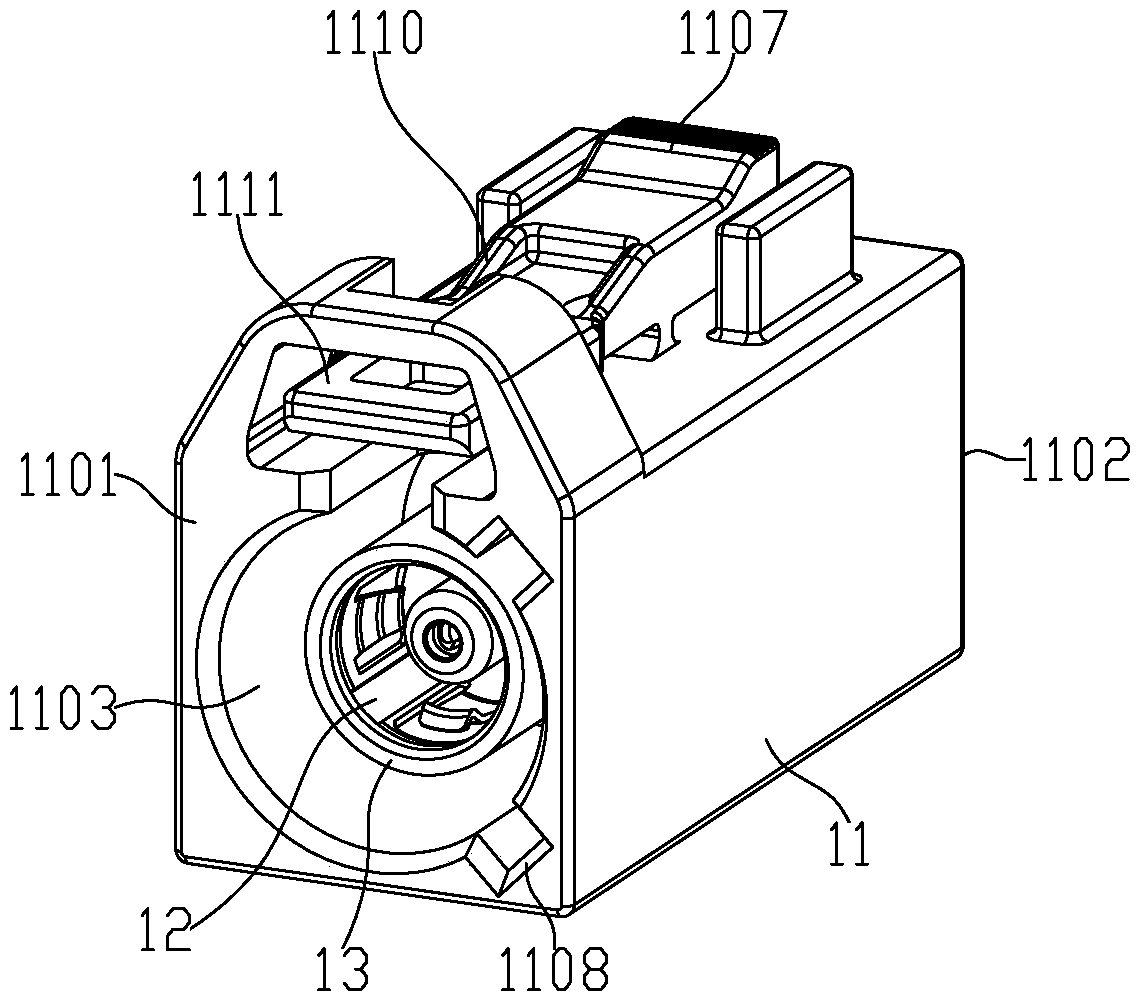

Female end connector capable of improving connection reliability and male end connector

PendingCN109462087AIncreased durabilityImprove connection reliabilityVehicle connectorsCoupling device detailsAnatomyStructural engineering

The invention discloses a female end connector capable of improving connection reliability and a male end connector. The female end connector comprises a clamping sleeve, wherein the clamping sleeve is arranged in a female plug and is provided with a plurality of positive elastic clamping parts and a plurality of negative elastic clamping parts, the plurality of positive elastic clamping parts andthe plurality of negative elastic clamping parts oppositely extend in an axial direction and are movable, and protruding parts inwards protruding are arranged at end parts of the positive elastic clamping parts and the negative elastic clamping parts. The male end connector comprises an outer shell, a male plug, an insulation body and a central contact which are axially connected, and a pluralityof sunken parts are arranged at a peripheral surface of an abutting end of the male plug. By effective matching of the positive elastic clamping parts and the negative elastic clamping parts of the clamping sleeve and the male plug of the male end connector, the plugging durability is improved, and the function failure caused by deformation of the female end connector during the plugging processis prevented; and with the adoption of positive and negative alternative distribution, the positive elastic clamping parts are used for providing a main acting force, the negative elastic clamping parts are used for providing a balancing acting force in the process, and the deformation of the female end connector caused by connection of different shafts is prevented.

Owner:COCENTRA PRECISION TECH (JIANGSU) CO LTD

A prefabricated concrete wall manufacturing and processing machine and processing technology

ActiveCN111844400BAssembly does not affectGuaranteed to be polishedEdge grinding machinesCeramic shaping apparatusStructural engineeringMachining process

The invention relates to an assembled concrete prefabricated wall manufacturing and processing machine and processing technology, including a frame body, a conveying device, a fixing device, a grinding device and a chip blowing device. The inner lower end of the frame body is provided with a conveying device, and the frame body A fixing device is installed on the inner upper end of the frame body, a grinding device is installed on the right side of the inner upper end of the frame body, and a chip blowing device is installed on the middle part of the right side wall of the frame body. The present invention can solve the problem that the traditional prefabricated wall grinding method adopts the manual grinding method, that is, the surface of the prefabricated wall is directly used for assembly after being manually polished before assembly, and manual grinding will not only increase the number of assembly workers The labor intensity is high, and the grinding effect cannot be guaranteed, and it will also affect the cooperation between the walls, thereby affecting the assembly efficiency and other problems.

Owner:江西建工集团新型材料科技有限公司

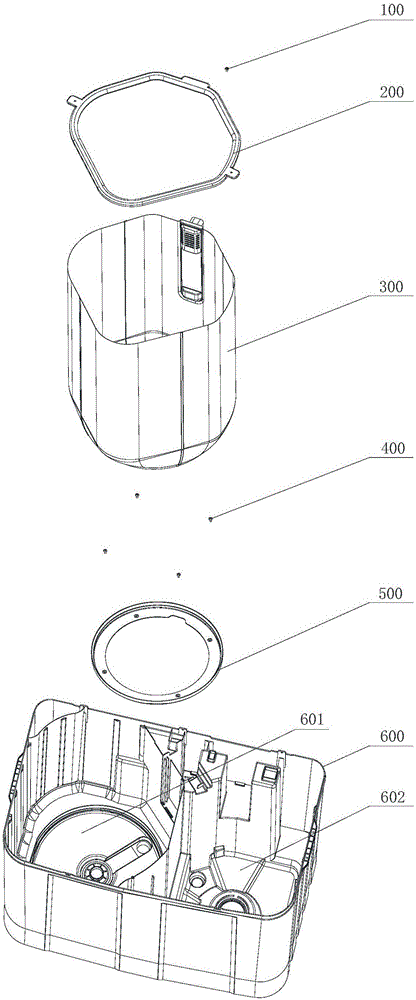

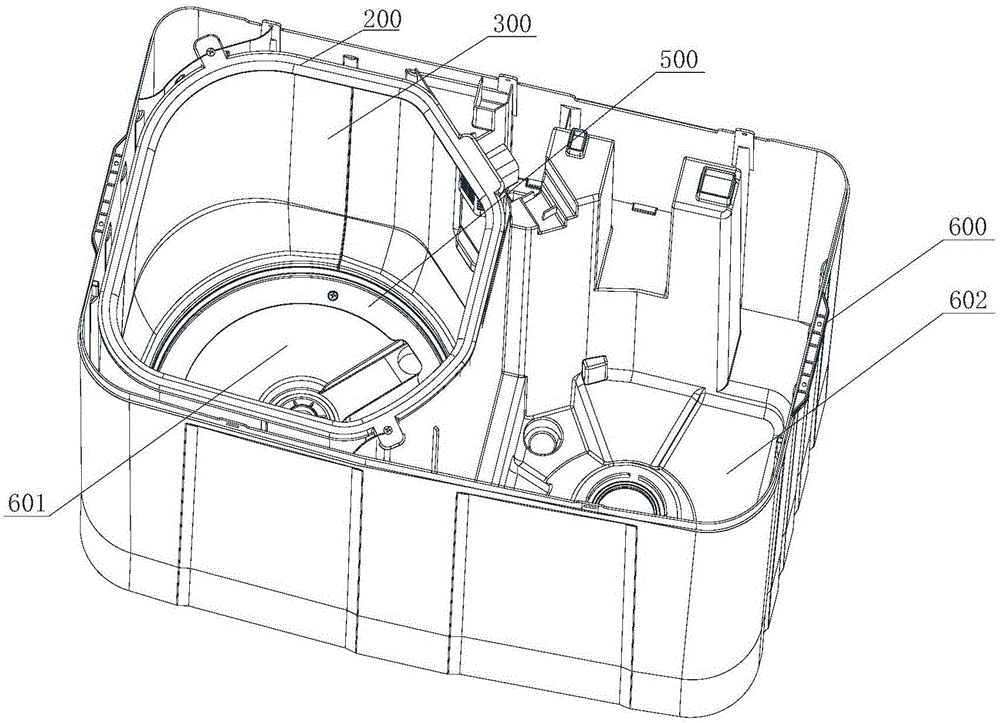

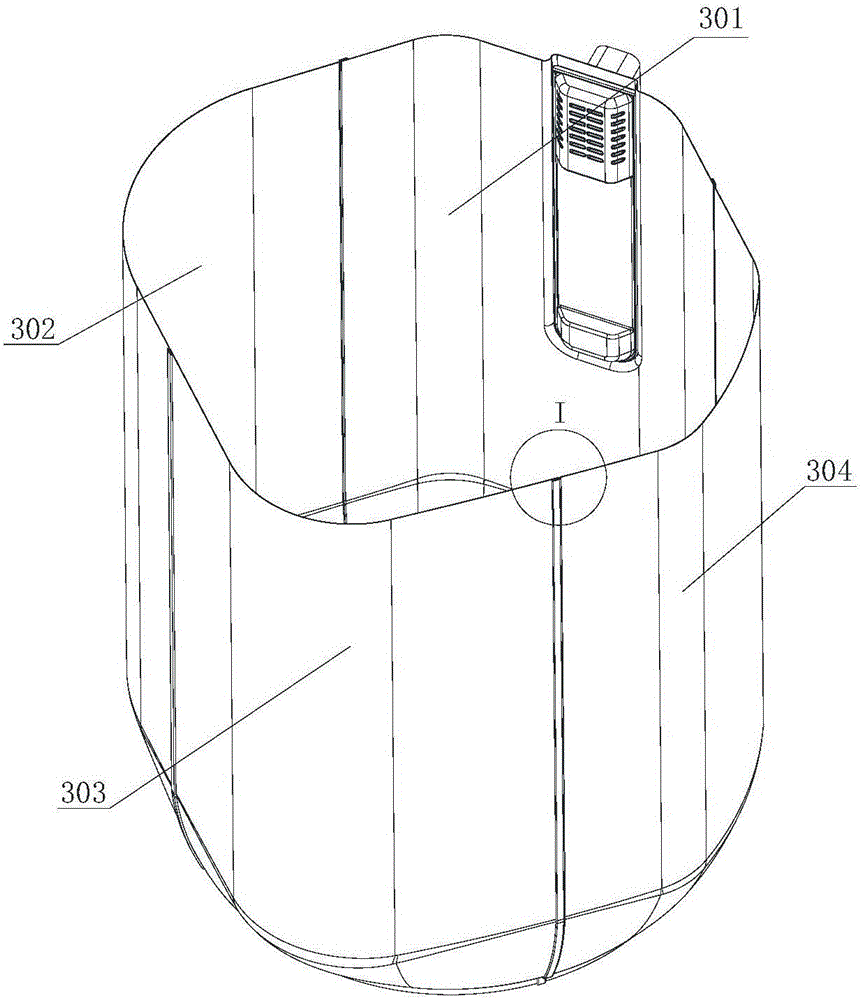

Washing barrel and washing machine

ActiveCN106436144AMake the most of the interior spaceIncrease washing capacityOther washing machinesTextiles and paperInterior spaceEngineering

The invention provides a washing barrel and a washing machine. The washing barrel is provided with a barrel body accommodating washings. The barrel body is in a cylindrical structure with a sealed peripheral wall and formed by a plurality of barrel body assembling sheets in a splicing way. Two ends of the cylindrical structure are opened and the peripheral wall is sealed; and the barrel body assembling sheets are fixedly connected. The washing barrel is spliced via the plurality of barrel body assembling sheets, so internal space of the washing machine can be fully utilized and washing machine washing capacity can be improved.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

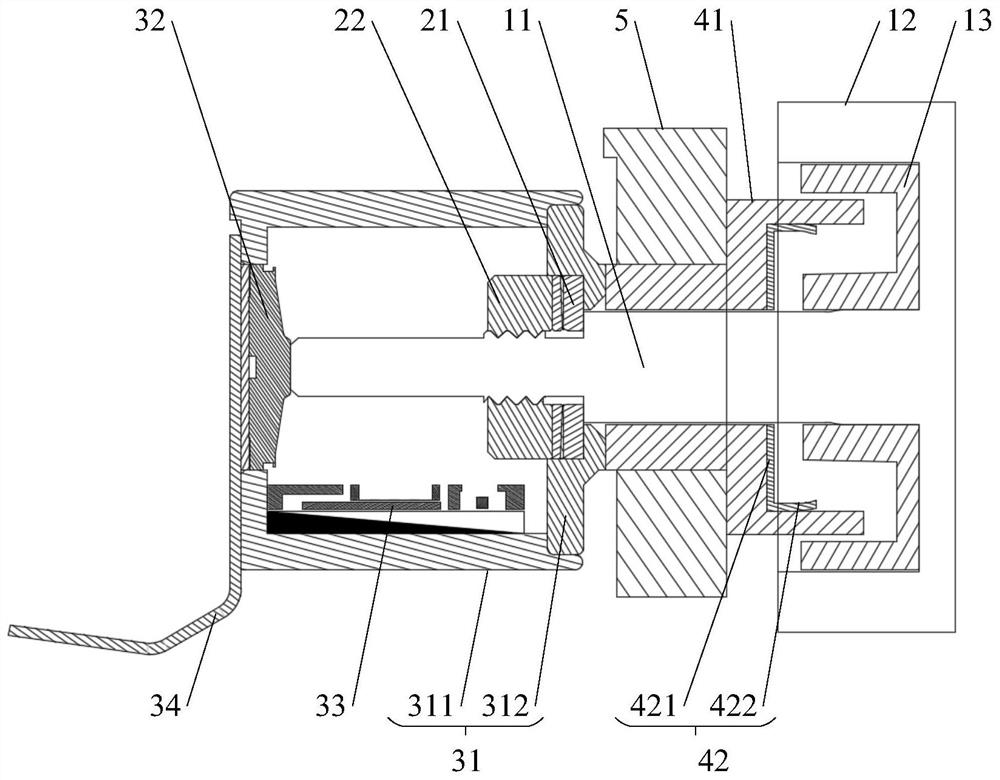

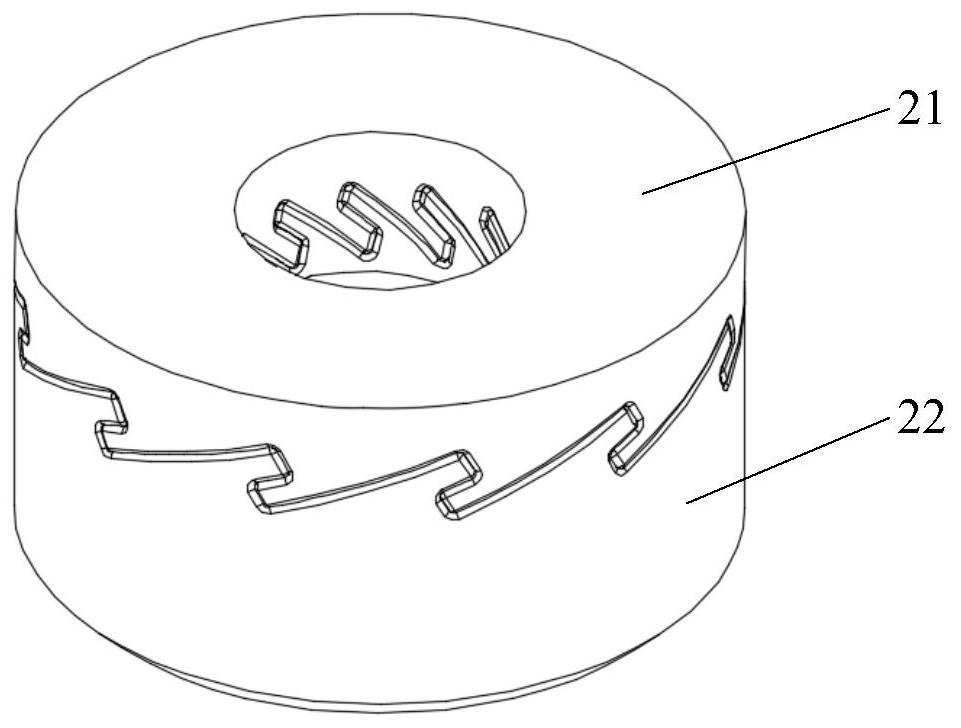

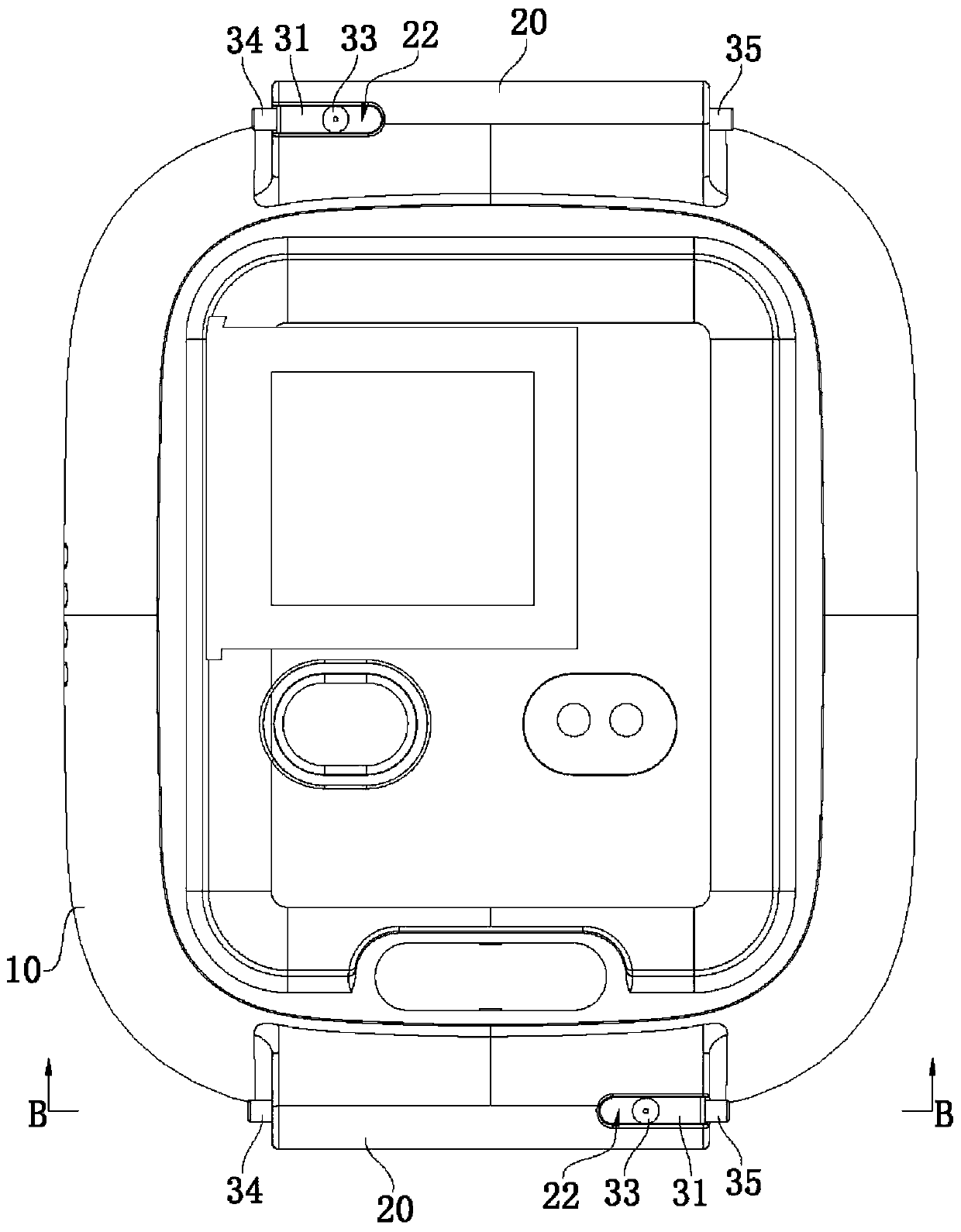

Watch crown and wrist-wearing equipment with watch crown

ActiveCN112433460AEasy to assembleReduce complexityMechanical devices for setting timeMechanical engineeringEngineering

The invention discloses a watch crown and wrist-wearing equipment with the watch crown. The watch crown comprises a key rod provided with an external thread, a body, a non-loosening nut and a second non-loosening nut, wherein the body is used for being fixedly connected with the inner side of the watchcase, and the body is provided with a first insertion hole for allowing the key rod to be inserted; the first non-loosening nut is fixedly arranged on the body; the second non-loosening nut and the first non-loosening nut are locked in a one-way mode, the second non-loosening nut is provided withan internal thread used for being connected with the external thread in a matched mode, and the screwing direction of the external thread and the internal thread is the same as the locking directionof the first non-loosening nut and the second non-loosening nut; and the second non-loosening nut can be assembled on the body in advance through the first non-loosening nut, then the key rod is installed, the second non-loosening nut does not affect assembly of the key rod, axial limiting of the key rod can be achieved, and the effect of blind installation of the key rod is achieved. And comparedwith the prior art, by using the watch crown and the wrist-wearing equipment of the invention, assembling is convenient, and the assembling complexity is reduced. The wrist-wearing equipment comprises the watch crown and has the above beneficial effects.

Owner:西安歌尔泰克电子科技有限公司

Lock device for seat cushion of motorcycle

ActiveCN102864998AAssembly is smooth and quickAvoid assembly errorsBicycle locksVehicle frameCushion

The invention discloses a lock device for a seat cushion of a motorcycle. The lock device comprises a lock body portion structure and a locking portion structure which are opposite to each other, the lock body portion structure is fixed on a covering part, and the locking portion structure is fixed on a frame. The lock device is characterized in that a straightened flexible pull rope is arranged between the lock body portion structure and the locking portion structure, and when a lock cylinder of the lock body portion structure is driven to rotate by a key, a lock rod of the locking portion structure can be pulled through the flexible pull rope. A force transmitting action mode of the lock device for the seat cushion of the motorcycle is changed during locking and unlocking, the flexible pull rope is connected between the lock body portion structure and the locking portion structure to transmit force, influence on assembly and service due to mounting errors is avoided, assembly difficulty is reduced, assembly quality is improved, assembly time is shortened, and reliability of final products is guaranteed.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

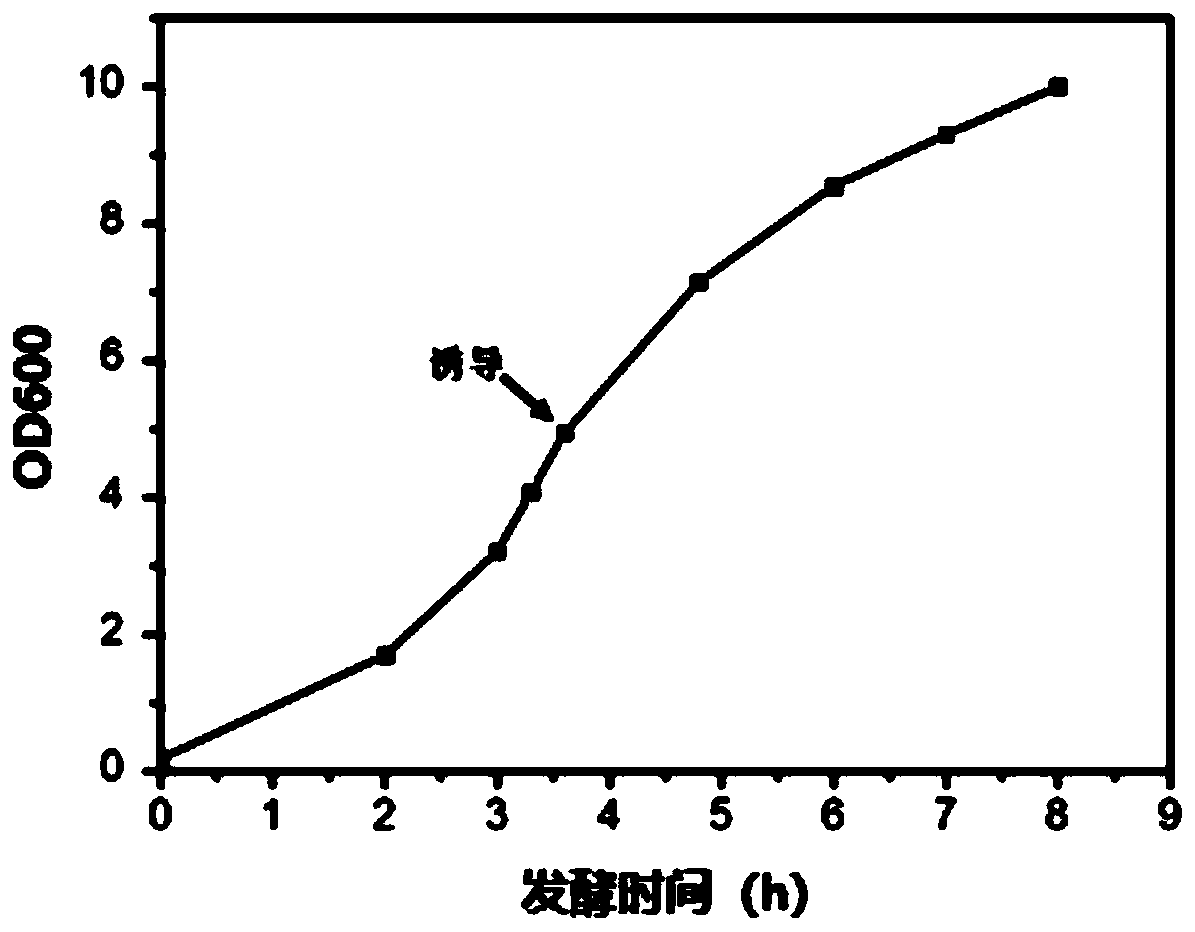

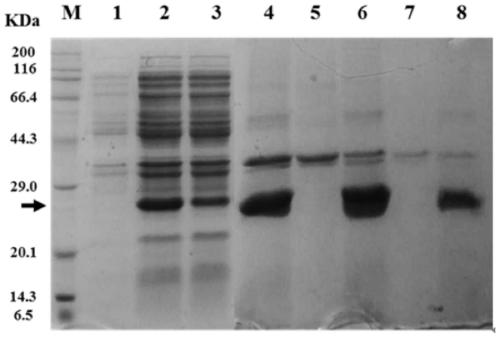

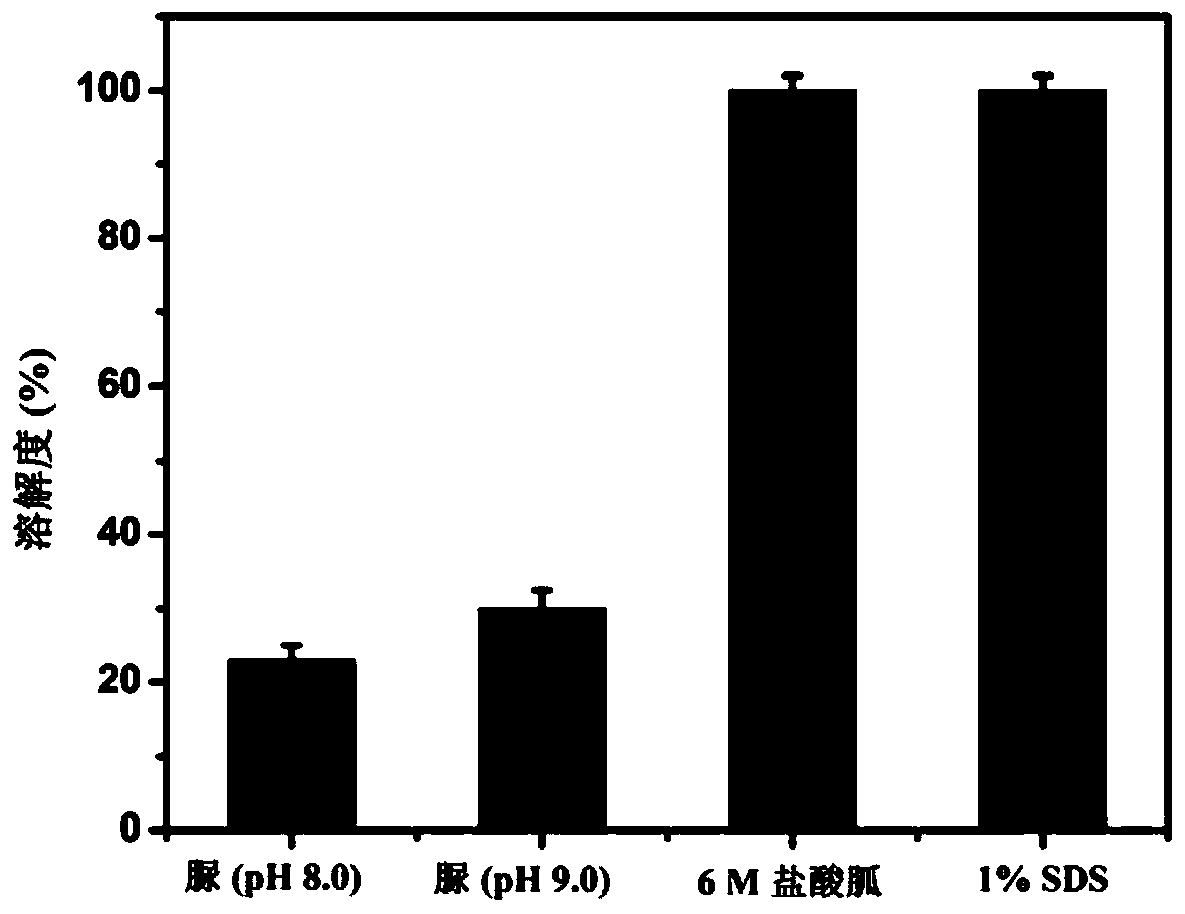

Recombinant virus-like particle expressed based on inclusion body form, preparation method and application thereof

ActiveCN110092841AEasy to prepareEasy to operateSsRNA viruses positive-senseAntibody mimetics/scaffoldsInclusion bodiesVirus-like particle

The invention relates to a recombinant virus-like particle expressed based on an inclusion body form, a preparation method and an application thereof. The preparation method comprises: expressing a recombinant plasmid containing a recombinant viral capsid protein gene or the recombinant viral capsid protein gene fused with another antigen genes in an exogenous expression system, and obtaining therecombinant viral capsid protein in the form of inclusion bodies or the recombinant viral capsid protein fused with the other antigens; dissolving the inclusion body with a surfactant, diluting the material, adding an amphiphilic cosolvent, and performing desalination to realize assembly of the virus-like particles to obtain the recombinant virus-like particles. The method is applicable to all recombinant virus-like particles expressed in the form of the inclusion bodies, and is simple and easy to operate, and the prepared recombinant virus-like particles have a morphology similar to that of natural viruses, and the method provides a strategy for the development of preventive vaccines and therapeutic vaccines.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

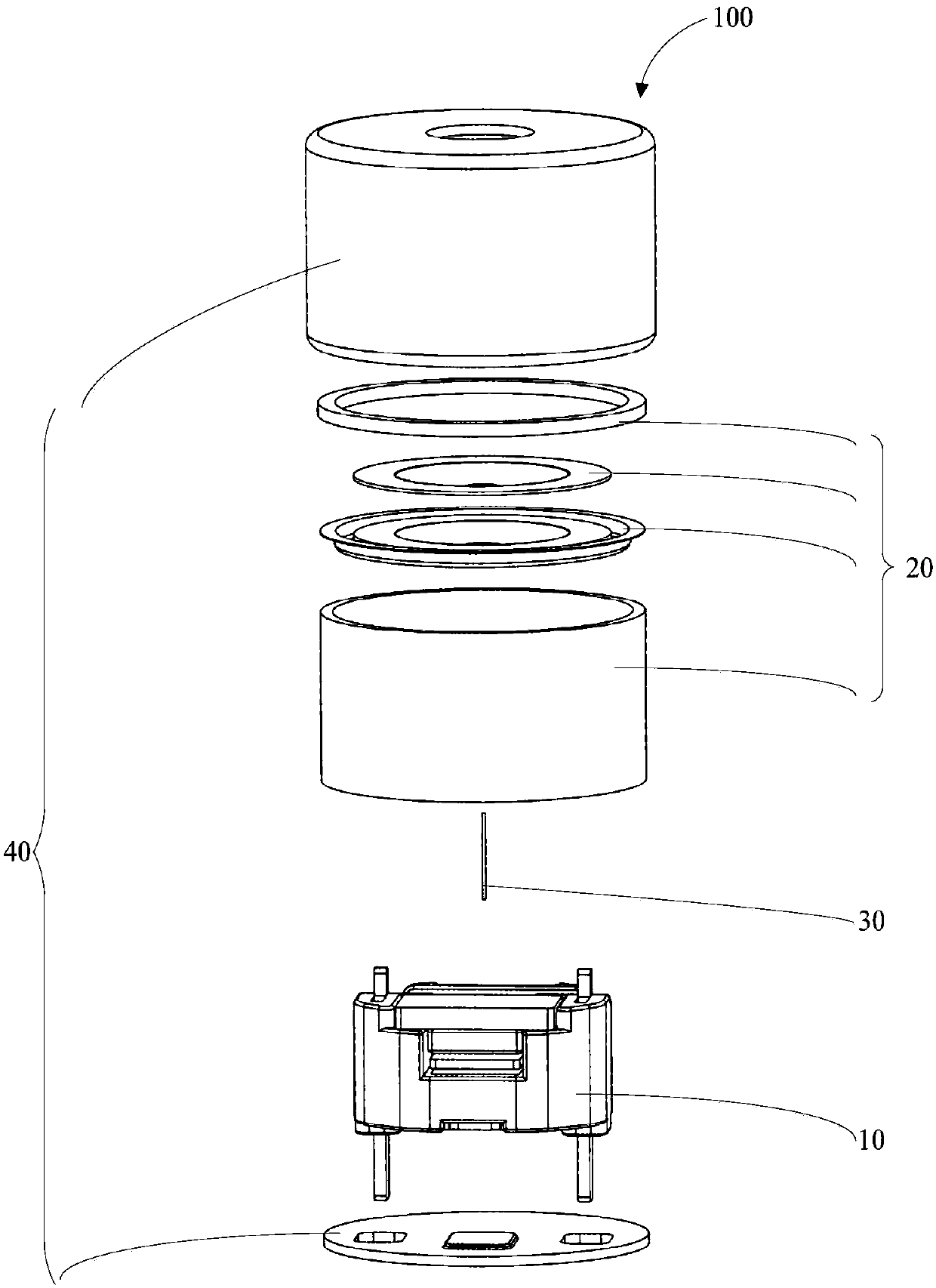

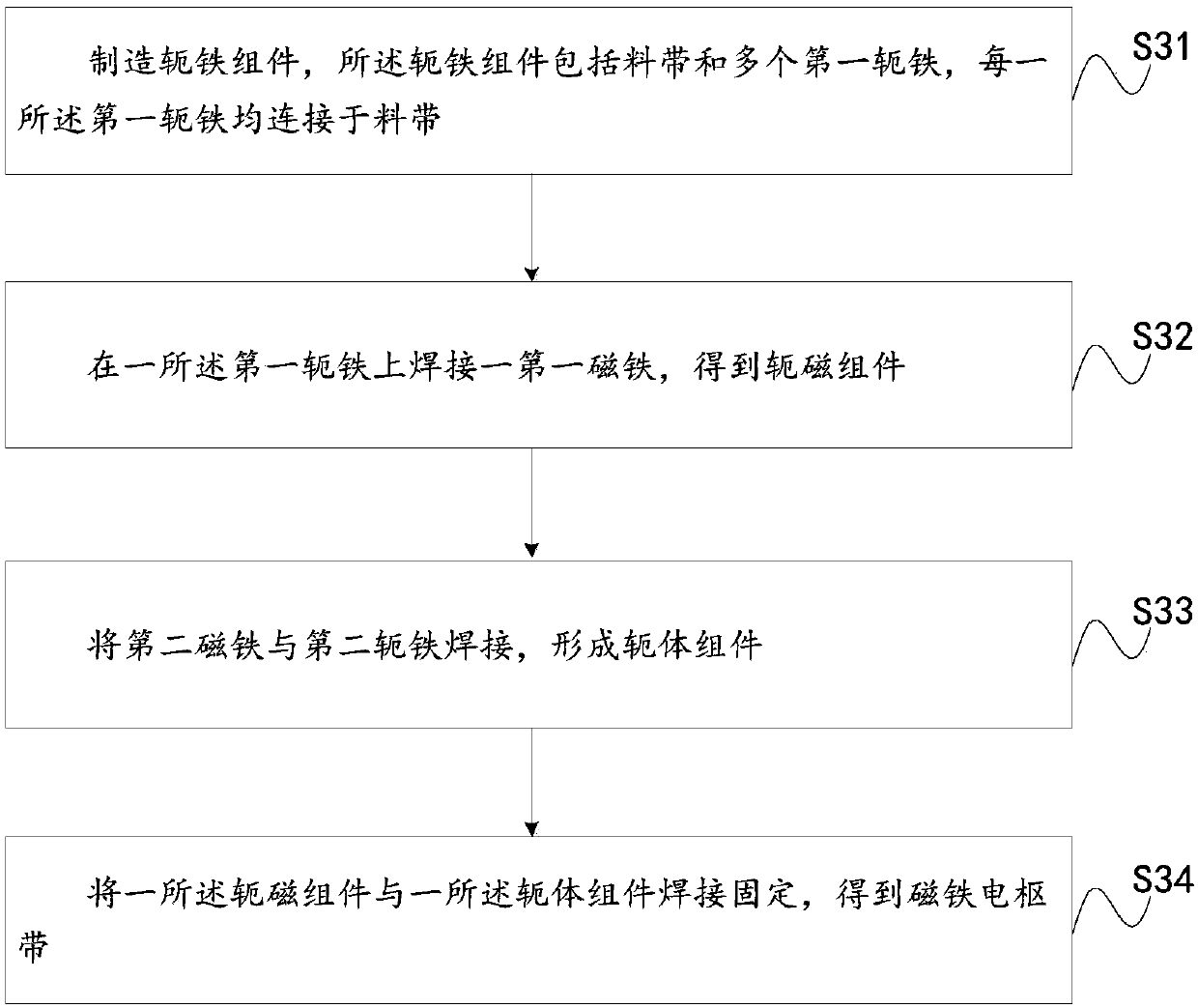

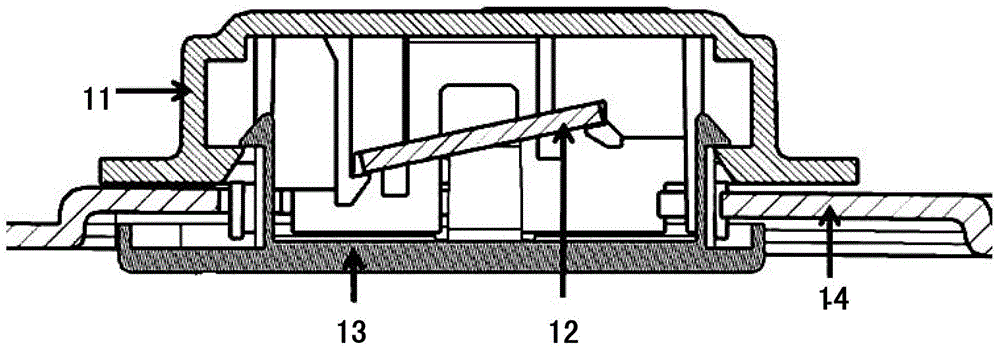

Magnet armature band and preparation method therefor

PendingCN107731504AAvoid inaccurate positioningImprove yieldInductances/transformers/magnets manufactureElectromagnets with armaturesMagnetPhysics

Embodiments relate to the design field of moving iron, and particularly relate to a magnet armature band and a preparation method therefor. The preparation method for the magnet armature band comprises the steps of manufacturing a yoke iron assembly, wherein the yoke iron assembly comprises a material band and multiple pieces of first yoke iron; each first yoke iron is connected to the material band separately; welding a first magnet with each first yoke iron to obtain a yoke magnetic assembly; performing welding and fixing on a second magnet and a second yoke iron to obtain a yoke body assembly; and performing welding and fixing on the yoke magnetic assembly and the yoke body assembly to obtain the magnet armature band, wherein one yoke magnetic assembly and the corresponding yoke body assembly welded therewith form a magnet armature unit. By virtue of the technical scheme, the yield of the magnet armature unit can be realized.

Owner:SHENZHEN BELLSING ACOUSTIC TECH CO LTD

A refrigerator lighting structure and its assembly and positioning method

InactiveCN104101174BAssembly does not affectAvoid scrappingLighting and heating apparatusLighting arrangementForm linerEngineering

The invention discloses a refrigerator lighting structure and an assembly and positioning method thereof. The structure comprises a pre-embedded box, an LED lamp board arranged on the pre-embedded box, and a lampshade arranged on the outside of the LED lamp board. The pre-embedded box is fixedly arranged on the On the inner tank, the lampshade is connected and fixed with the inner tank. By connecting and fixing the lampshade and the inner container, there is no direct assembly relationship between the lampshade and the pre-embedded box, so the molding thickness of the inner container does not affect the assembly of the lampshade, which improves the assembly efficiency and avoids the failure of the lampshade to fit and cause the box to be scrapped. problems and reduce production costs; at the same time, the position of the pre-embedded box is effectively positioned by setting positioning ribs to ensure the relative accuracy of the position of the LED light board to achieve correct lighting of the LED light board.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

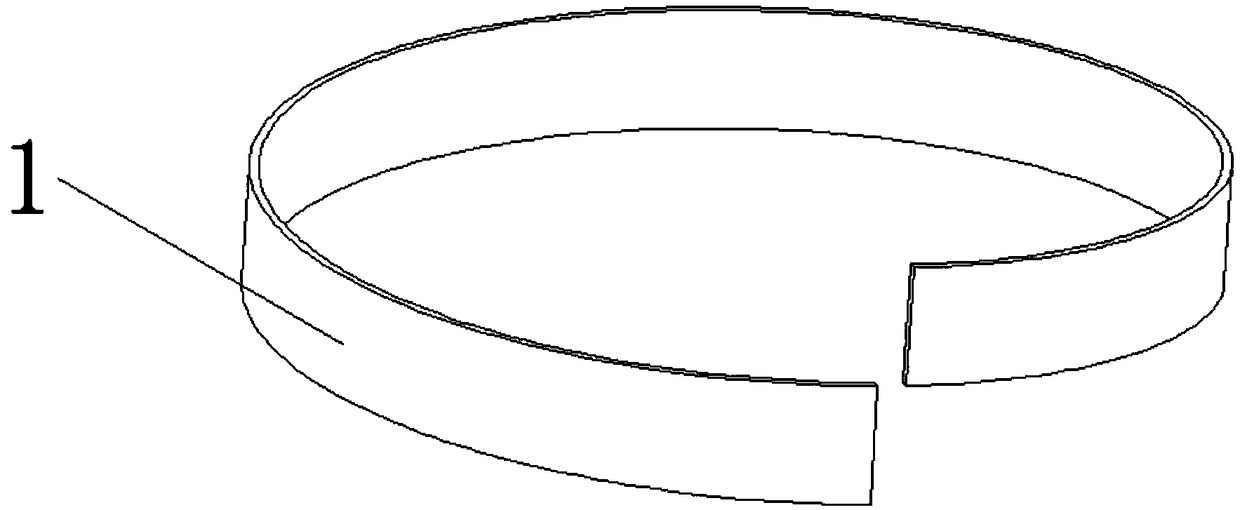

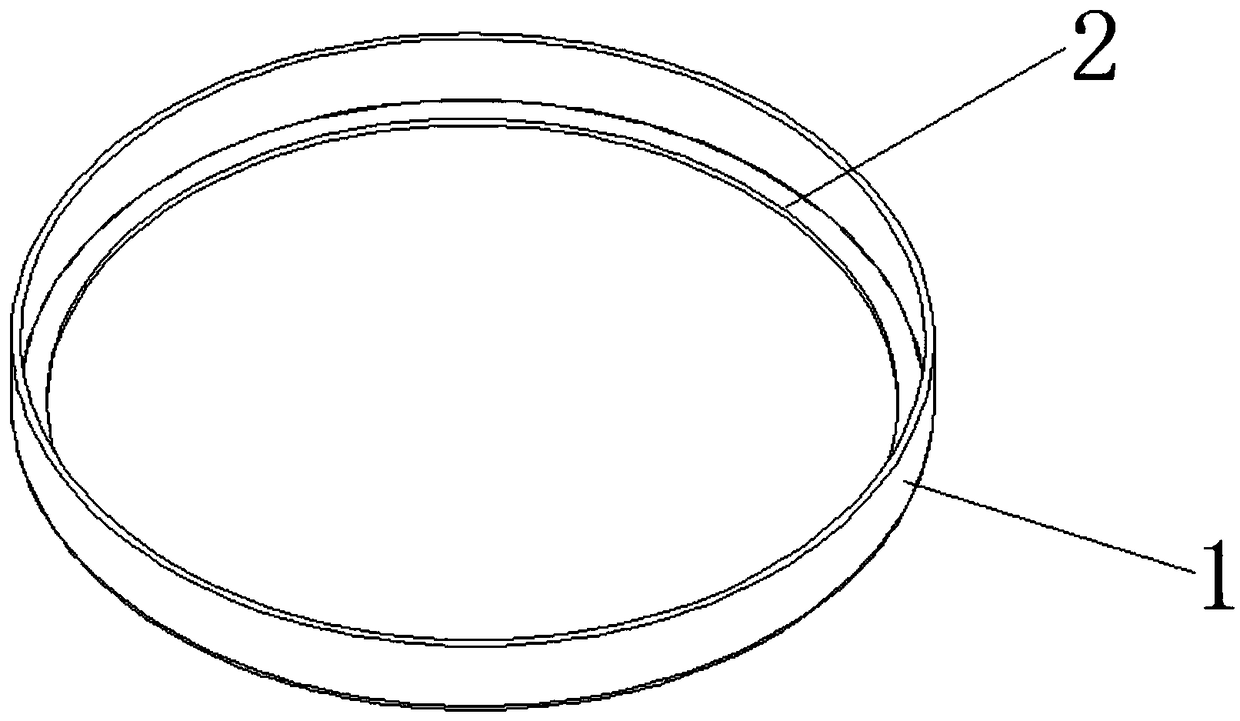

New energy automobile braking air cylinder spinning hoop machining method and spinning hoop

InactiveCN109014776AImprove efficiencyImprove stabilityFriction grip releasable fasteningsReservoir arrangementsNew energyEngineering

The invention discloses a new energy automobile braking air cylinder spinning hoop machining method and a spinning hoop. A hoop body machined through the method is in a circular ring shape, and the top end or the bottom end of the hoop body is provided with a bending part. According to the method, the material utilization rate is high, and cost is greatly reduced. The spinning hoop is easy to assemble, high in efficiency, good in stability and attractive in appearance, and assembly assembling cannot be influenced.

Owner:台山嘉富达五金塑胶制品厂有限公司

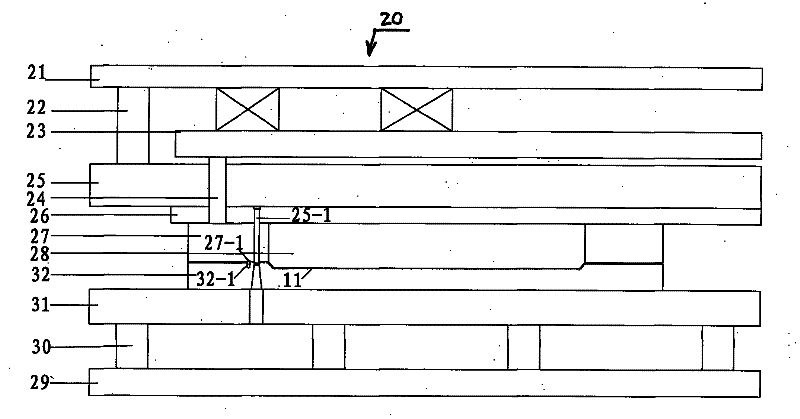

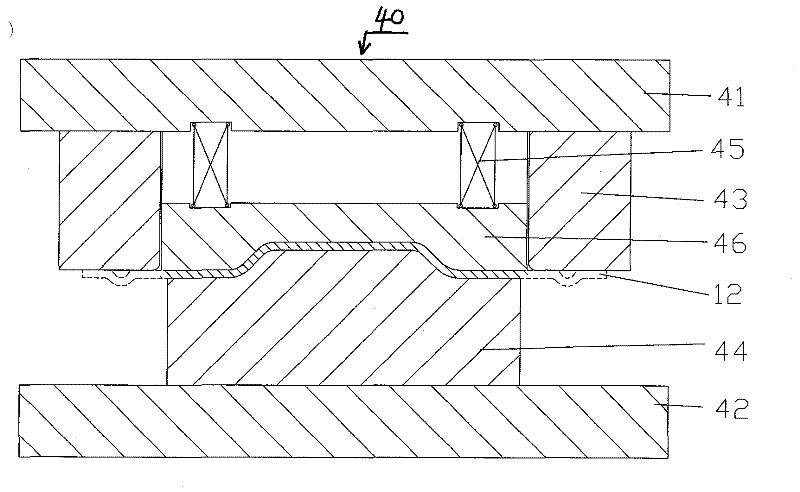

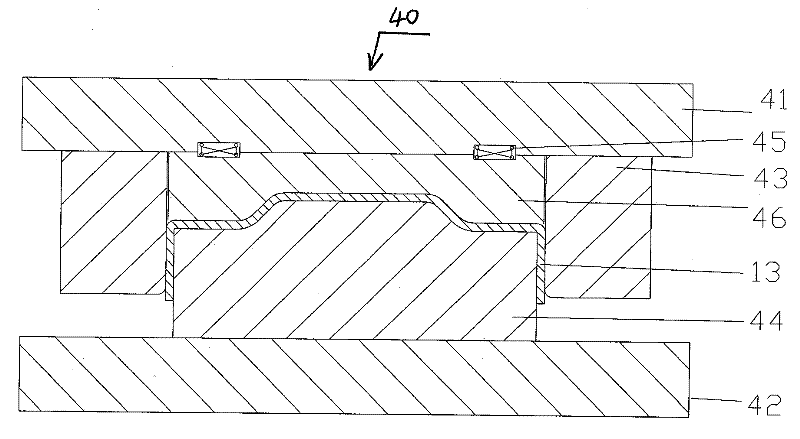

Drawing and bending molding process and die of refrigerator backboard

Owner:QINGDAO HAIER MOLDS

Preparation method of graphene insulating heat-conducting sheet for electric vehicle power supply

InactiveCN113321928ASimple stepsLow production line requirementsConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsFiberEngineering

The invention discloses a preparation method of a graphene insulating heat-conducting sheet for an electric vehicle power supply. The preparation method comprises the following steps of: (1) well mixing matrix resin, graphene fibers and heat-conducting powder by using a stirring device to obtain a mixture; (2) pouring the mixture into an annular groove of a forming device, and starting the forming device to enable the annular groove to rotate around the center of the forming device; orienting the graphene fibers in the mixture along the flowing direction; and meanwhile, heating the mixture to obtain an annular solid; (3) putting the annular solid in an oven for heating and curing; and (4) slicing the heated and cured annular solid in the radius direction of the circular ring by adopting a slicing device to obtain the heat-conducting sheet with the graphene fibers in oriented arrangement in the thickness direction. According to the preparation method of the graphene insulating heat-conducting sheet for the electric vehicle power supply, the heat-conducting sheet with graphene fibers in oriented arrangement in the thickness direction is prepared, so that the prepared heat-conducting sheet has better heat-conducting property.

Owner:深圳市黑金工业制造有限公司

Ratchet wrench reversing structure

ActiveCN104760013BNot easy to break and damageImprove structural strengthSpannersWrenchesEngineeringHead holder

The invention relates to a ratchet wheel and discloses a ratchet wrench reversing structure. The ratchet wrench reversing structure comprises a head holder (1), a ratchet (2), a clamping part (3), a handle (4), an elastic linkage component (5), a pivot (6) and two elastic positioning components (7), wherein an accommodating hole (10) for penetrating through the upper and lower surfaces of the head holder (1) is formed in the head holder (1); two parallel lugs (11) and a pivot groove (12) formed between two lugs (11) are arranged on the head holder (1); a clamping groove (18) penetrating through the pivot groove (12) is formed in the lateral side of the accommodating hole (10); the racket (2) is rotationally combined in the accommodating hole (10) of the head holder (1); the racket (2) comprises a drive part (20) and an external toothed part (21) at the periphery of the racket (2). The ratchet wrench reversing structure has good structural strength, increasing of service life, is easy in manufacturing and assembling and low in cost and the like.

Owner:ZHEJIANG YIYANG TOOL MFG

Self-limiting assembly type female connector

PendingCN109361121AIngenious designAssembly does not affectVehicle connectorsIncorrect coupling preventionSelf limitingEngineering

The invention discloses a self-limiting assembly type female connector. A female end outer shell of the female connector is provided with a port end, a non-port end and a holding cavity, the non-portend is arranged at a rear position relative to the port end, and the holding cavity is communicated with the port end and the non-port end and internally provided with a front positioning portion anda rear positioning portion. The front positioning portion and the rear positioning portion are integrally connected with the female end outer shell; the front positioning portion comprises a front positioning face extending inwards, and the rear positioning portion is provided with a rear positioning face extending inwards; a portion, with the rear positioning face, of the rear positioning portionis capable of moving towards the center axis of the holding cavity. The outer wall of a female plug is provided with a positioning boss which is provided with a front end face and a rear end face, and when the front end face is positioned in rear of the front positioning face and the rear end face is positioned in front of the rear positioning face, the female plug can be axially limited in the holding cavity. By arrangement of a limiting structure in the outer shell, axial fixing can be realized on the premise that no extra part is added, so that unnecessary development cost, assembly procedures and assembly hours are avoided.

Owner:COCENTRA PRECISION TECH (JIANGSU) CO LTD

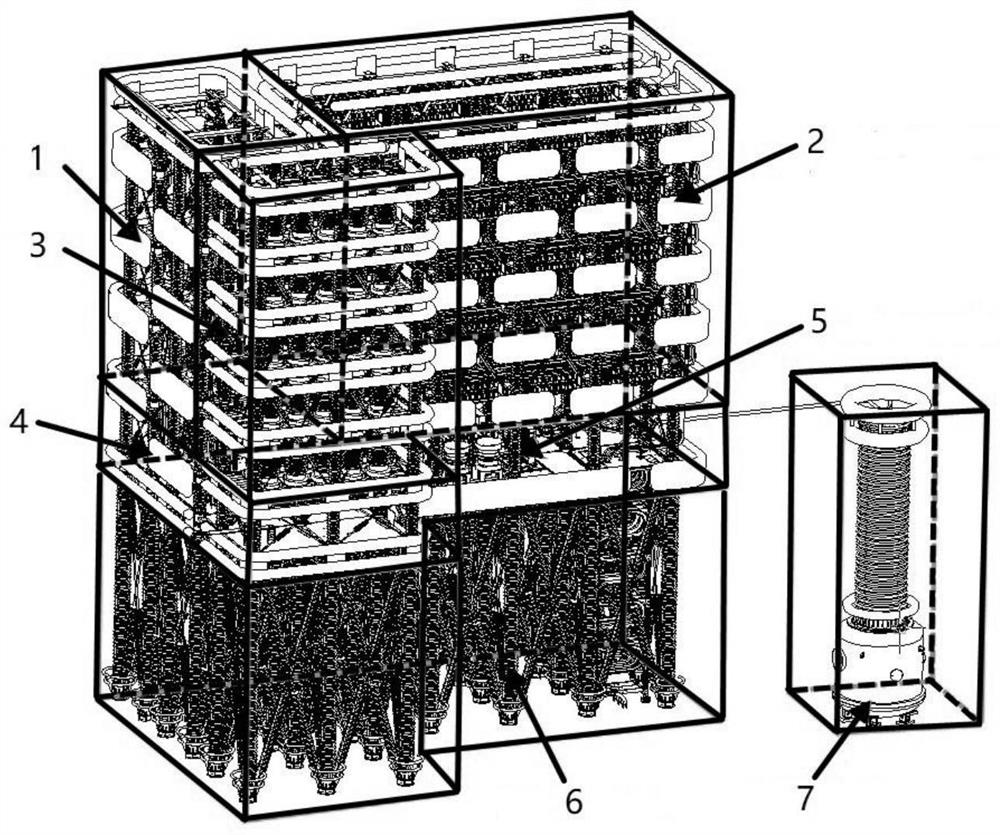

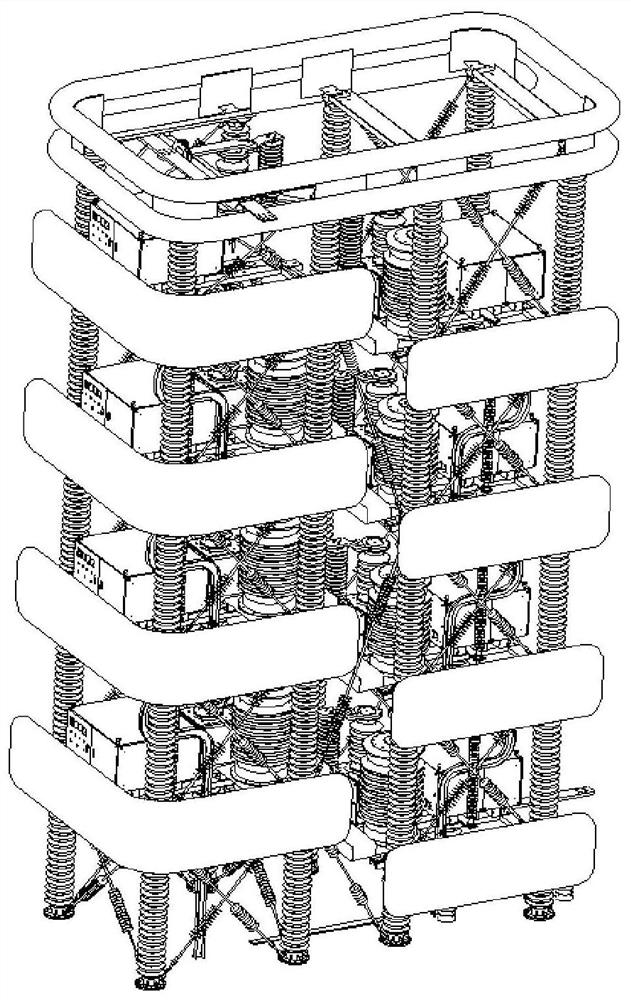

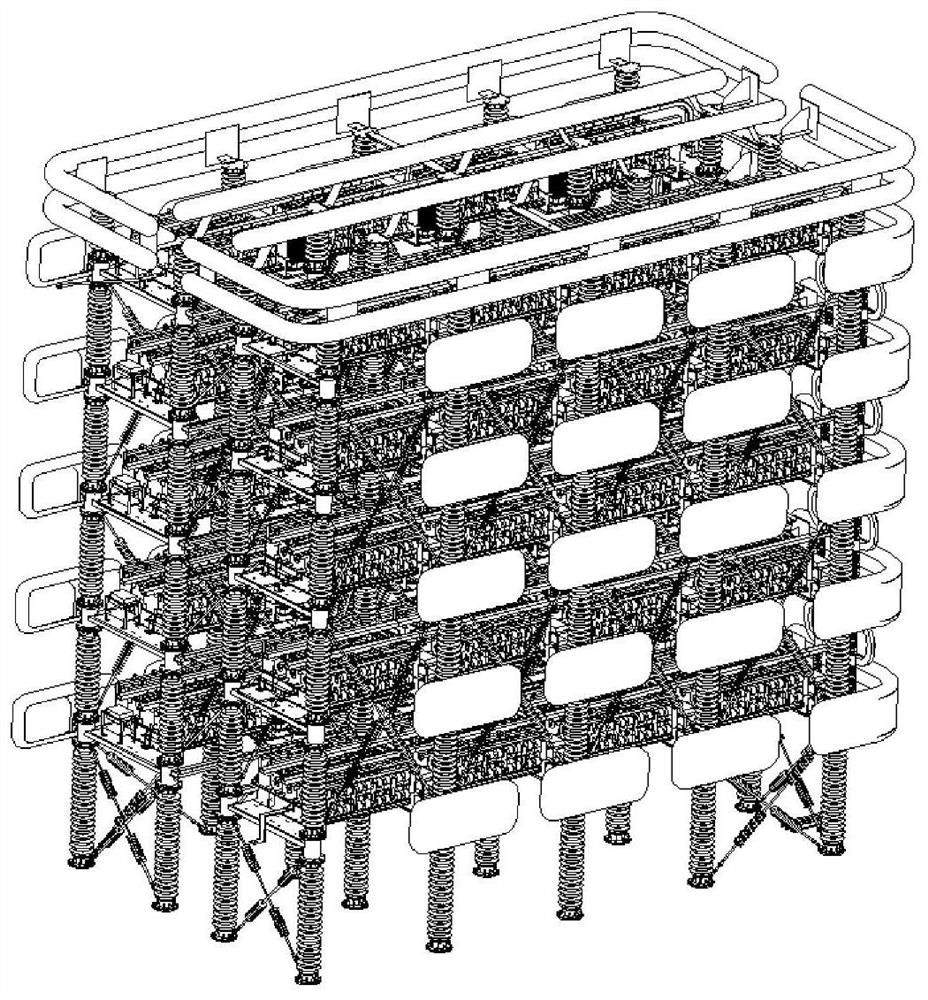

Valve tower of DC circuit breaker

PendingCN111884179ARealize the role of short-distance energy supplyThe role of meeting the safety distanceOverhead installationConversion constructional detailsDc circuit breakerElectronic switch

A valve tower of a DC circuit breaker comprises a rapid mechanical switch tower, a power electronic switch tower, an energy consumption lightning arrester tower, a coupling negative pressure driving device, an insulation supporting platform and an isolation transformer. The insulation supporting platform is arranged at the bottom of the valve tower, a transition layer is arranged at the top of theinsulation supporting platform, the rapid mechanical switch tower, the power electronic switch tower, the energy consumption lightning arrester tower and the coupling negative pressure driving deviceare all installed on the transition layer, and the coupling negative pressure driving device is located in the power electronic switch tower; the rapid mechanical switch tower, the power electronic switch tower and the energy consumption lightning arrester tower are arranged on the transition layer. The power electronic switch tower is located on the side face of the rapid mechanical switch tower, and the energy consumption lightning arrester tower is located in front of the rapid mechanical switch tower. The isolation transformer is arranged on one side of the insulation supporting platformand used for providing electric power for the valve tower. The structure is beneficial to independence among the towers, and the problems of complex structural design, complex electrical connection, complex wiring and the like caused by structural staggering are avoided.

Owner:BEIJING POWER EQUIP GRP

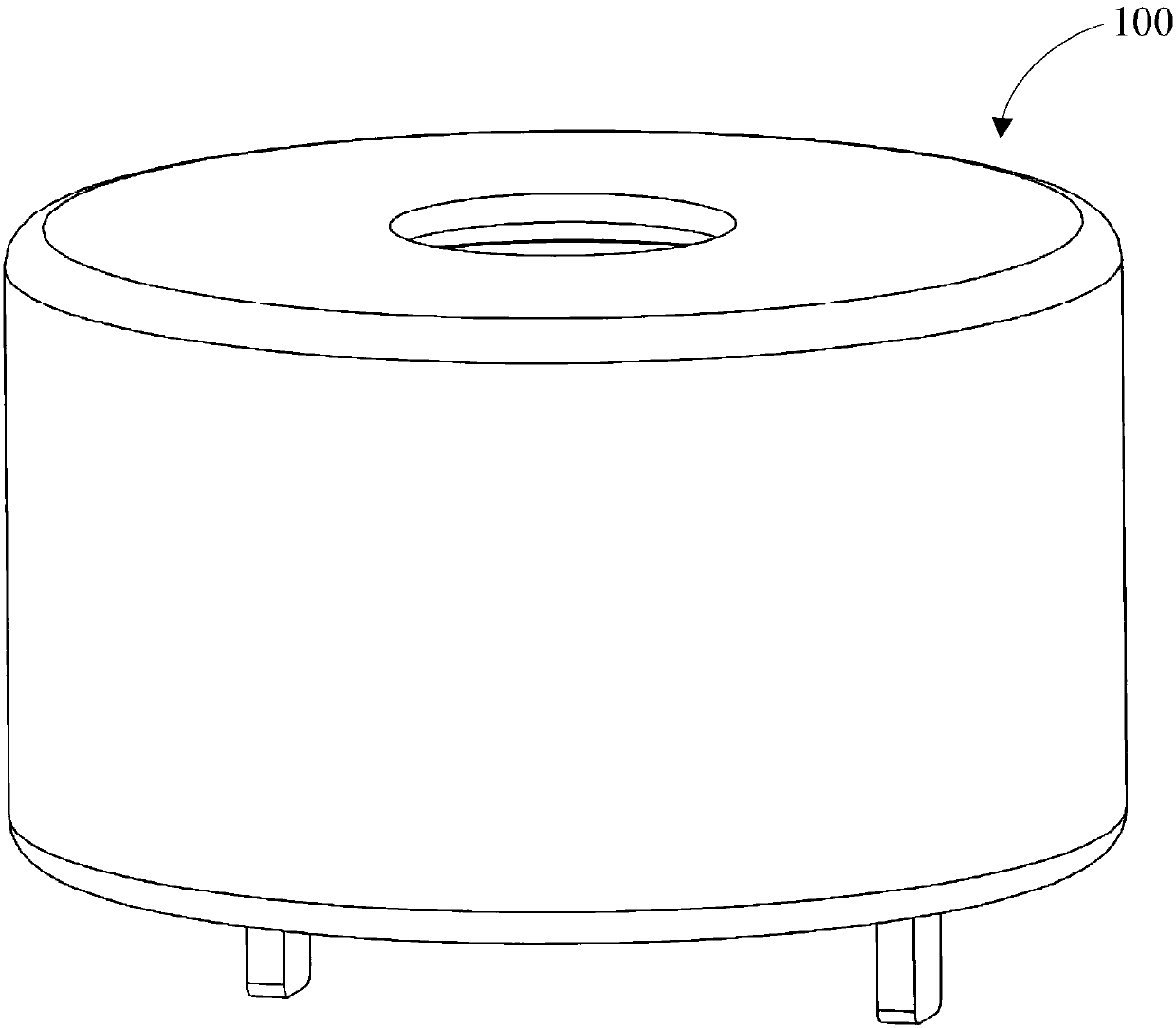

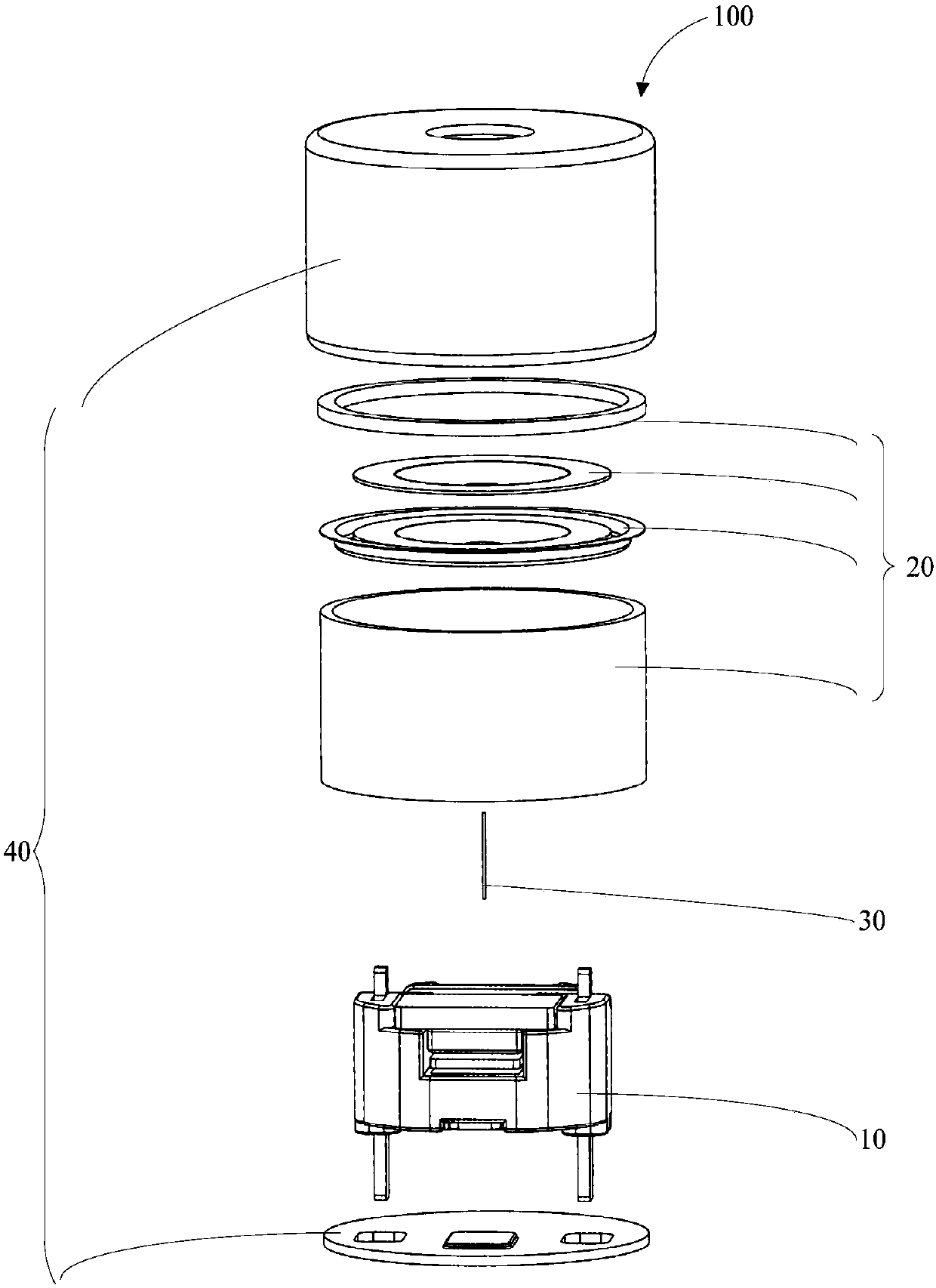

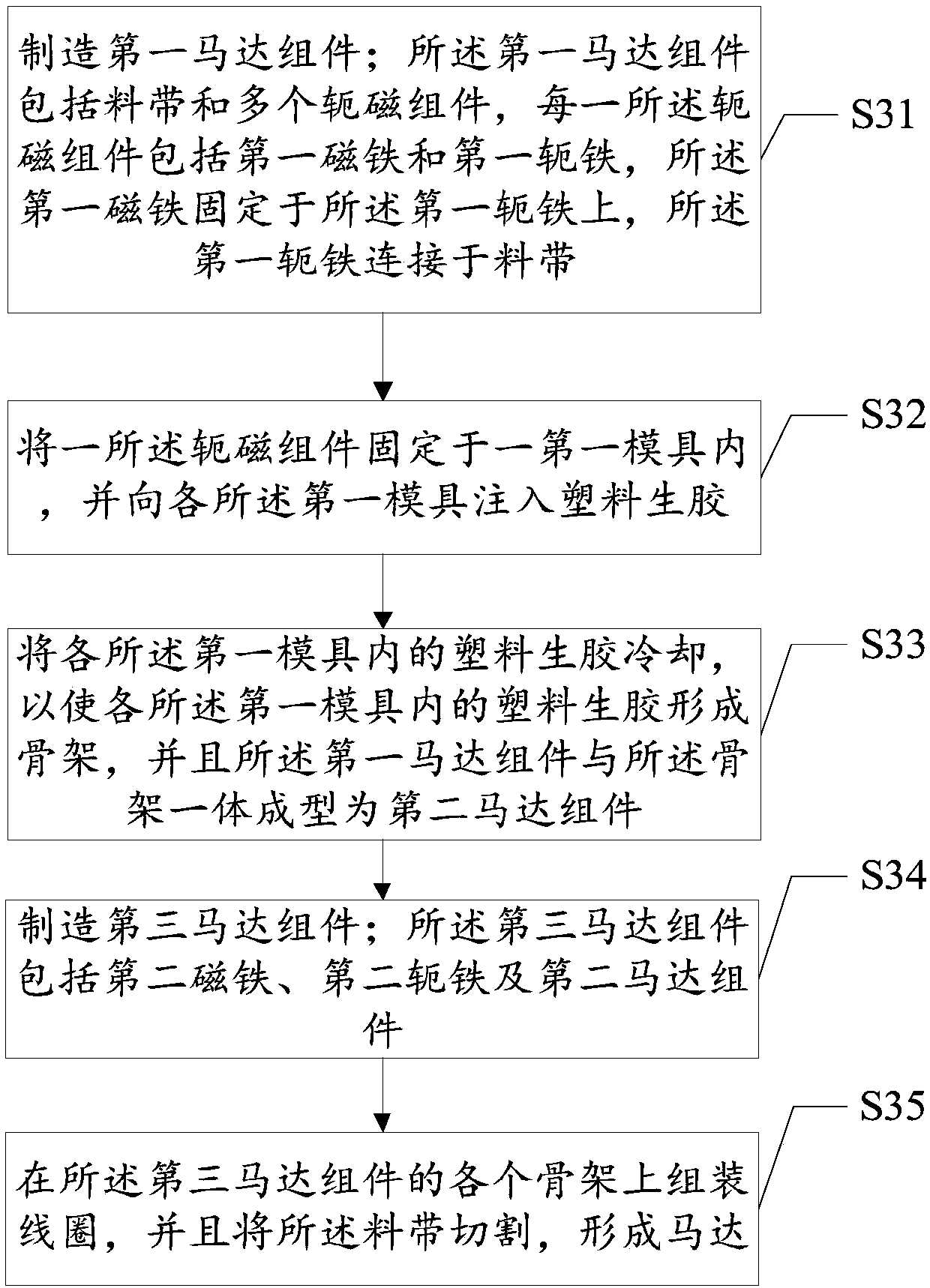

Production method for motor and motor assembly

ActiveCN107801144AAssembly does not affectAssembly precisionElectrical transducersElectric machinesEngineeringMagnet

The embodiment of the invention relates to the field of balanced armature design and discloses a production method for a motor and a motor assembly. The method comprises the steps of producing a yokeiron assembly, wherein the yoke iron assembly comprises a strip and a plurality of pieces of first yoke irons, each piece of the first yoke iron is connected with the strip, a piece of first magnet iswelded on each piece of the first yoke iron, the piece of first magnet and each piece of the first yoke iron form a yoke magnet assembly, and all yoke magnet assemblies and the strip form a first motor assembly; forming skeletons on the yoke magnet assemblies of the first motor assembly to obtain a second motor assembly, assembling second magnet and second yoke iron on the second motor assembly to obtain a third motor assembly; assembling coils on the skeletons of the third motor assembly, and cutting the strip to obtain a plurality of motors. In the mode, the yield of the motors can be realized.

Owner:SHENZHEN EVERWIN PRECISION TECH

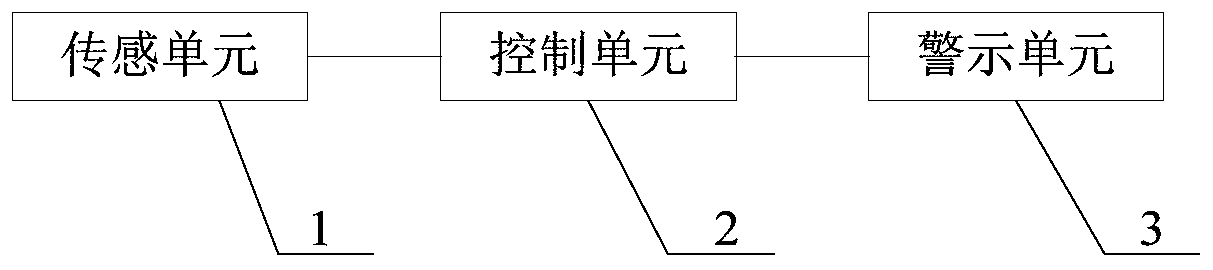

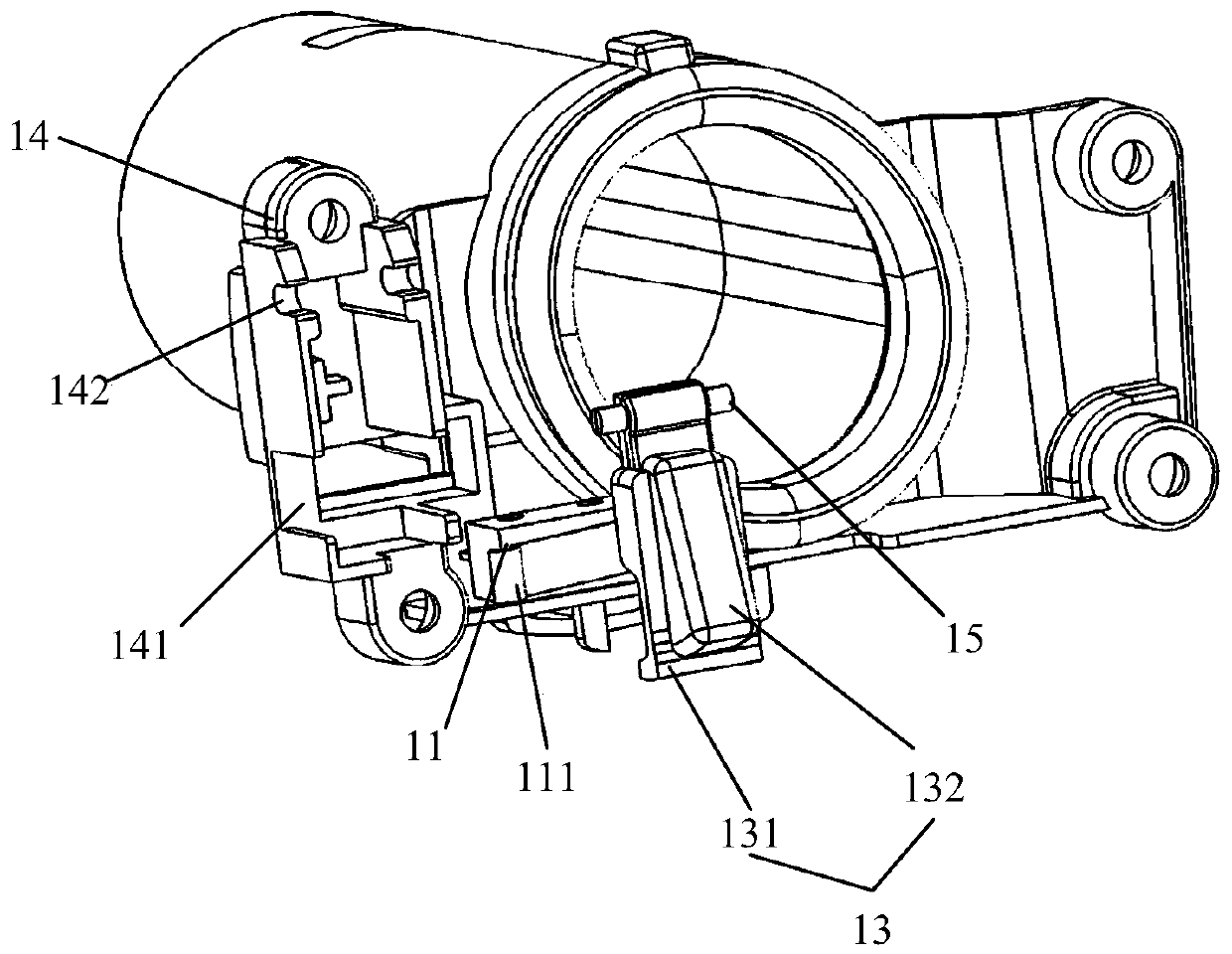

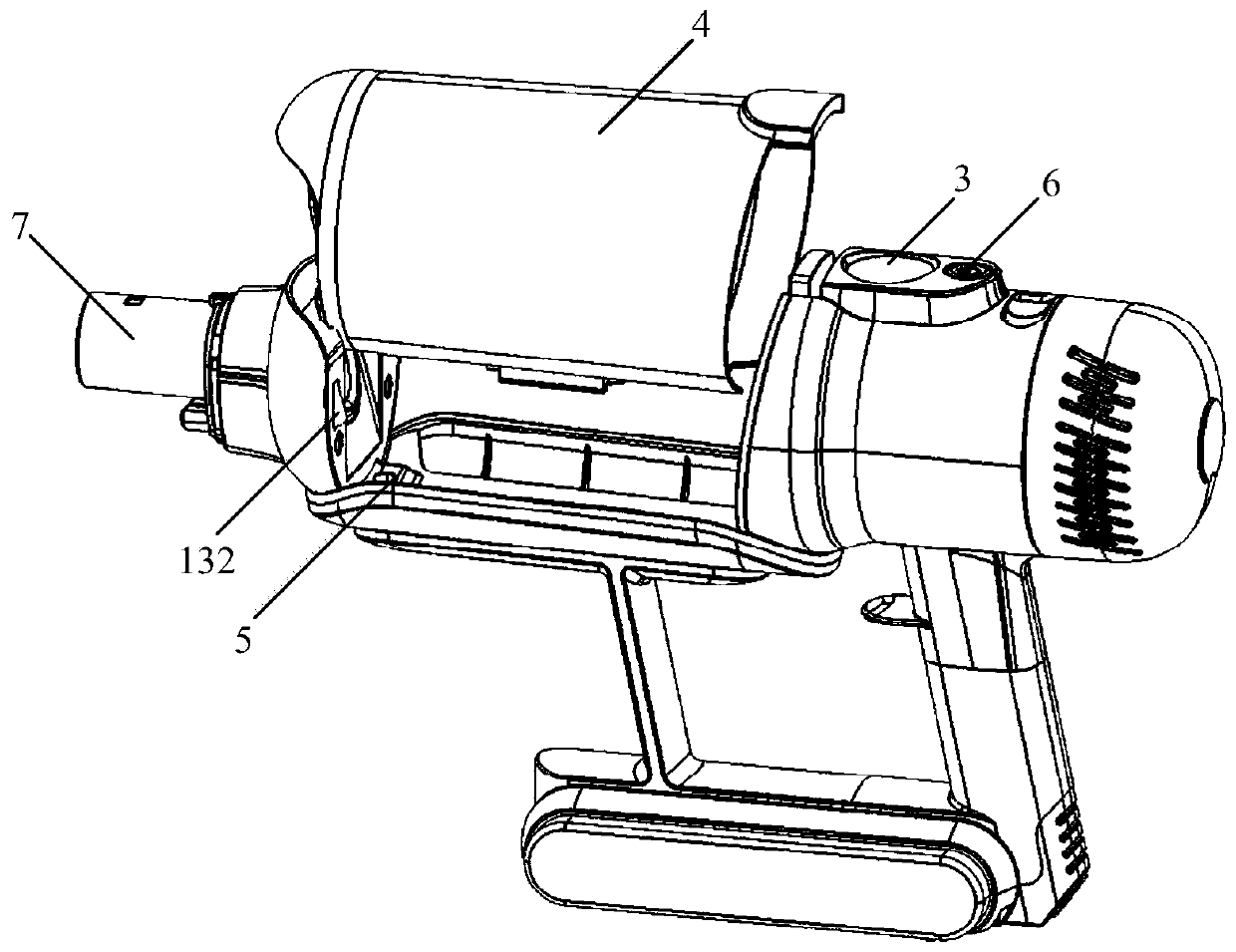

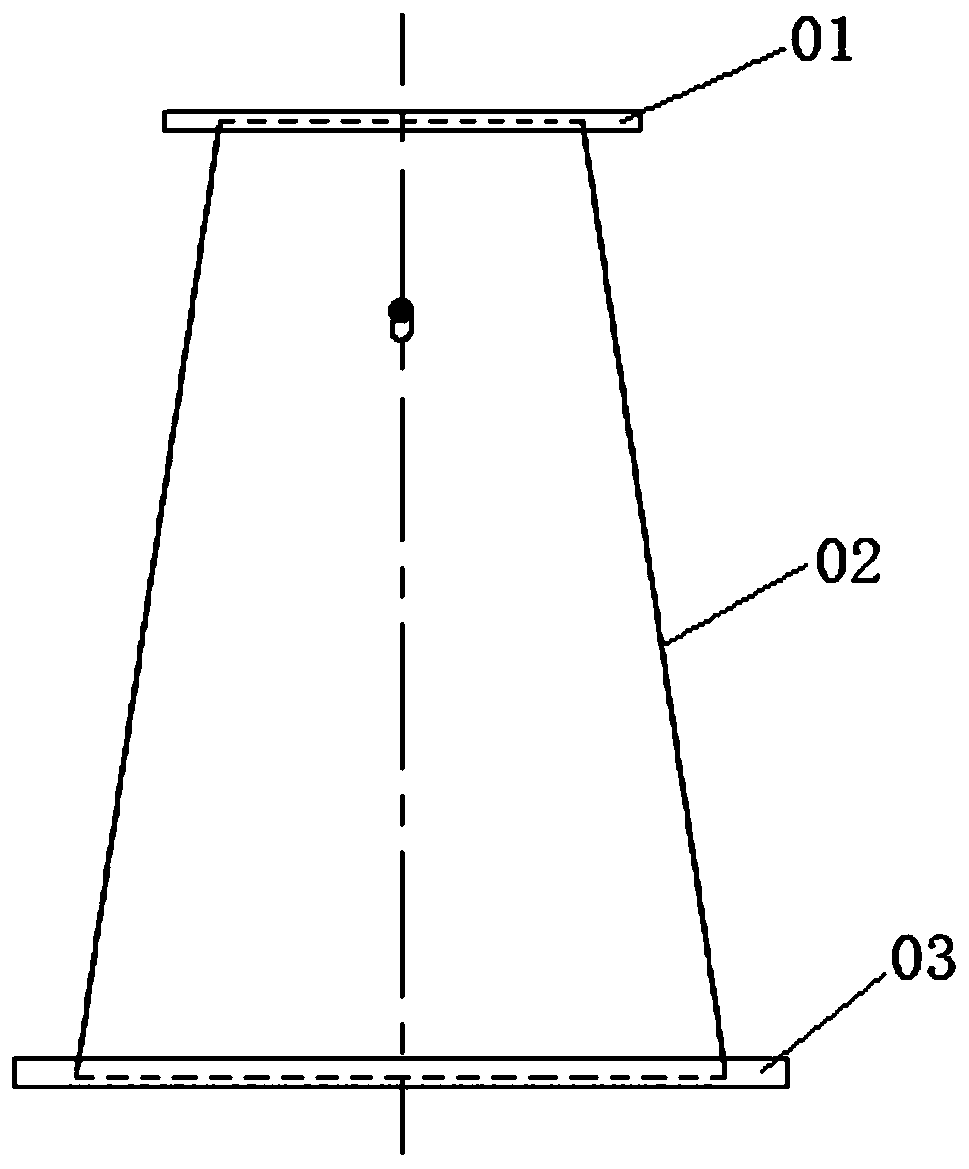

Startup detection device of dust removal instrument, dust collector and startup detection method

PendingCN111297261AAvoid unnecessary lossAvoid enteringElectric equipment installationDust controlControl cell

The invention relates to a startup detection device of a dust removal instrument, a dust collector and a startup detection method, belongs to the technical field of cleaning equipment, and aims to solve the problem that an existing dust collector cannot automatically detect whether a dust collection cup body is assembled in the dust collector. The startup detection device comprises a sensing unit,a control unit and a warning unit, and the sensing unit is used for detecting whether the dust removal instrument is provided with a dust collection cup or not and transmitting a generated signal tothe control unit; the control unit controls whether the motor of the dust removal instrument is started or not according to the signal transmitted by the sensing unit, and the control unit can send aninstruction to the warning unit; and the warning unit sends warning information according to the instruction of the control unit. By arranging the sensing unit, the control unit and the warning unit,whether the dust collection cup is assembled or not can be detected when the dust collector is started, the motor is prevented from being started under the condition that the dust collection cup is not assembled, and unnecessary loss of electric energy and waste of time and physical strength of a user are avoided.

Owner:PUPPY ELECTRONICS APPLIANCES INTERNET TECH (BEIJING) CO LTD

A process method for group welding of diffuser tubes in marine diesel engines

ActiveCN108581395BSolve the problem of slow deliveryGuaranteed assemblyWelding apparatusTurbochargerMarine engineering

The invention discloses a technological method for assembly and welding of a diffuser tube in a marine diesel engine. According to the technological method, the adaptation to the relative position between a top flange and a bottom flange can be achieved by replacing a tapered tube in the diffuser tube with a plurality of positioning ribs; on the one hand, the problem that the tapered tube is slowly delivered during the pre-assembly process can be solved and the normal assembly of a main machine can be guaranteed; on the other hand, the onsite assembly and welding of the diffuser tube can be changed into welding in a steel structure workshop through the use of the positioning ribs, the restrictions to the operation space and the operation position during the welding of the diffuser tube canbe changed, and the problem about large assembly and welding deformation can be solved; meanwhile, the process of flatness detection after welding is added in the technological method and the millingprocessing is achieved, so that the problem about assembly flatness errors can be solved; and an expansion joint is arranged on a turbocharger as well as the expansion and contraction quantity of theexpansion joint reaches 3 mm, so that the proper milling operation can be prevented from influencing the assembly.

Owner:中船发动机有限公司

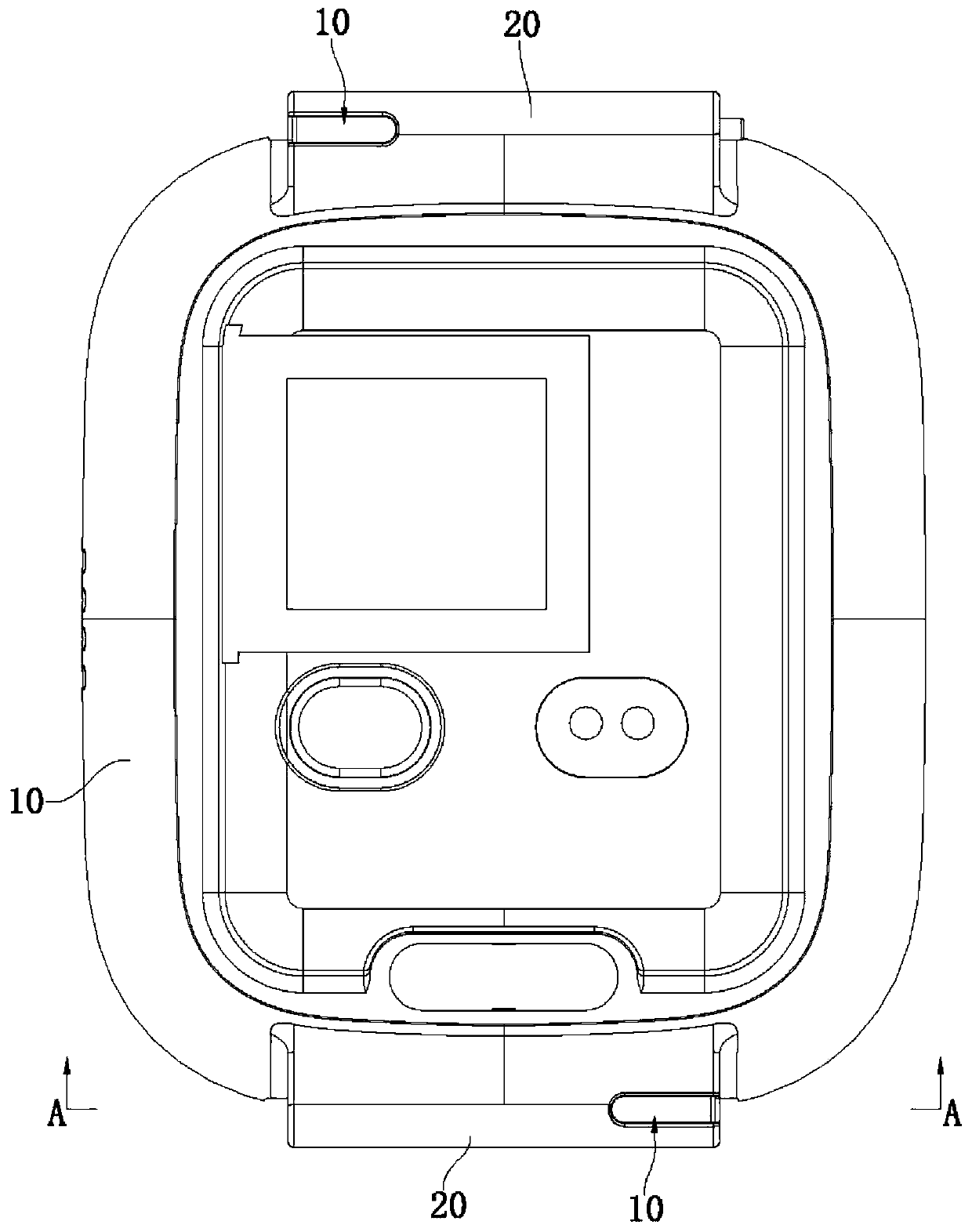

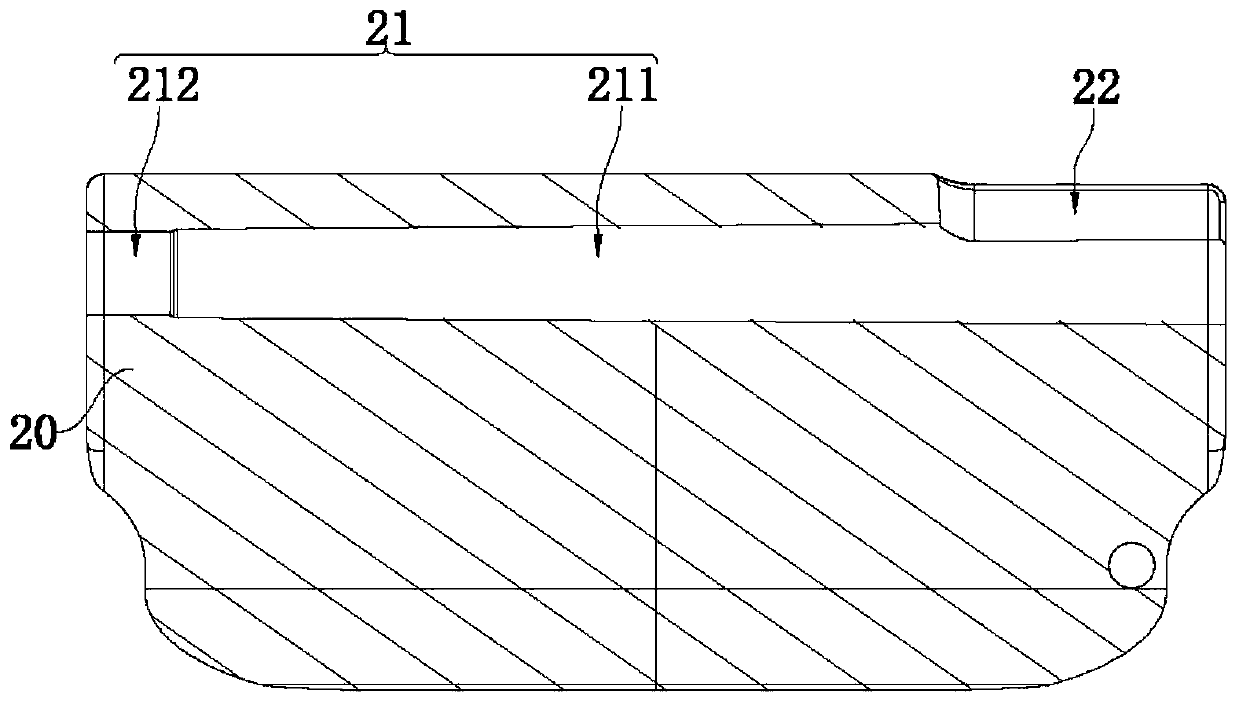

Wearable device and its host chassis structure

ActiveCN107048624BReduce resistanceReduce work intensityBraceletsClockwork casesInterference fitUltimate tensile strength

The invention relates to the technical field of electronic products and particularly relates to a wearable device and a host bottom case structure thereof. The host bottom case structure comprises a bottom case body, wherein connection parts for being connected with a watch strap extend at two opposite sides of the bottom case body; a raw earhole which runs through two ends of each connection part is formed in the connection part; and each raw earhole comprises a large-diameter hole segment and a small-diameter hole segment which are sequentially arranged and are used for being in clearance fit with a raw trunnion. The wearable device plays a role in locking the raw trunnions through interference fit of the raw trunnions and the small-diameter hole segments of the corresponding raw earholes, and plays a role in reducing resistance when the raw trunnions are inserted into the corresponding raw earholes through clearance fit of the raw trunnions and the large-diameter hole segments of the corresponding raw earholes, the resistance generated during assembly is reduced and the work intensity of a worker is reduced. In addition, the clearance fit positions of the large-diameter hole segments of the raw earholes and the corresponding raw trunnions can be enlarged, so that the strength of a mold of producing the bottom case body of the wearable device is also improved, and meanwhile, assembly is not affected when a mold slide pin slightly deforms.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com