Hoisting and piling structure of container

A container and stacking technology, which is applied in the field of container lifting and stacking structures, can solve problems such as low precision, corner ears 21 not centered, large process rounded corners, etc., to achieve simple assembly and avoid assembly process problems , the effect of connection strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

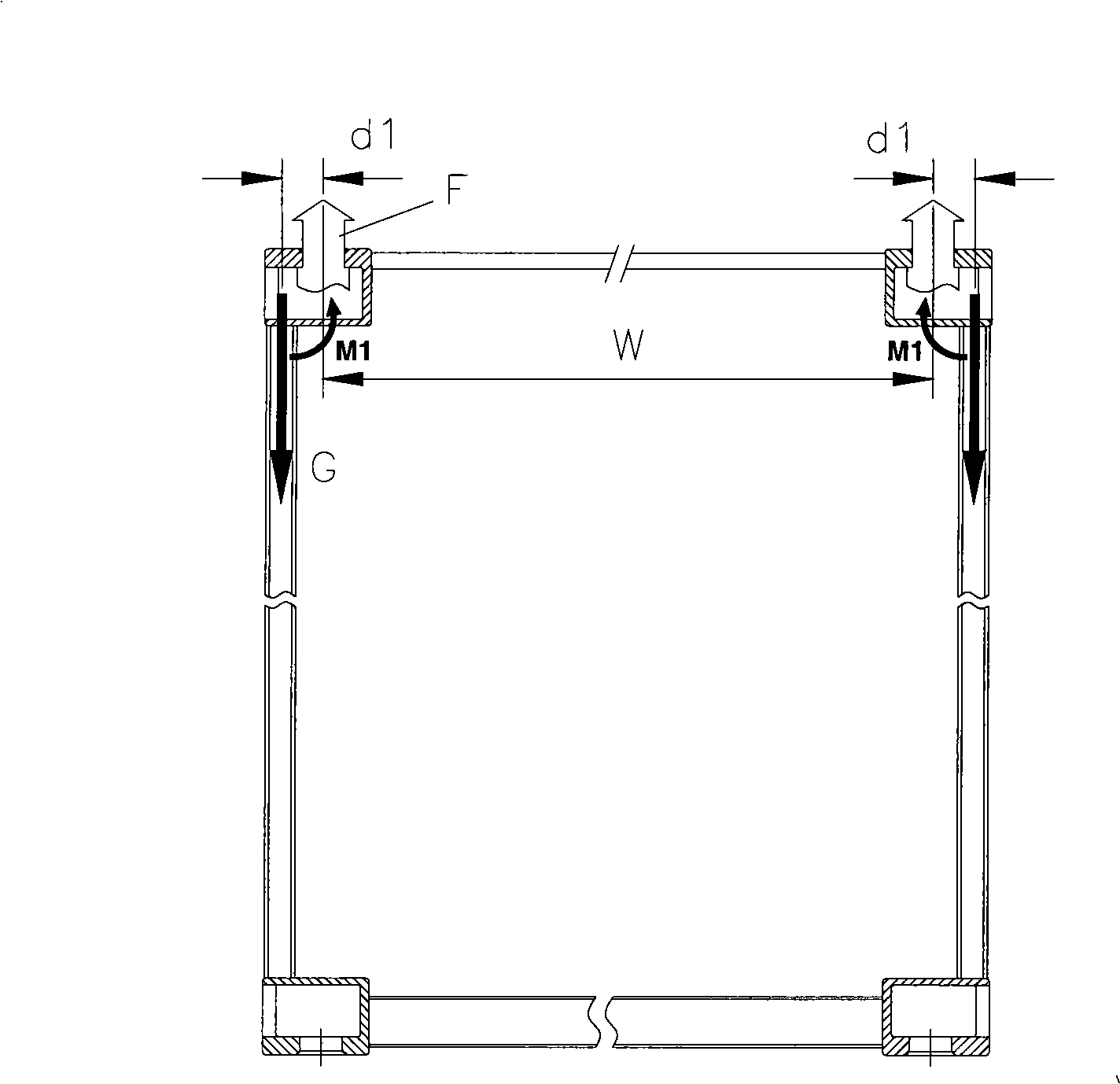

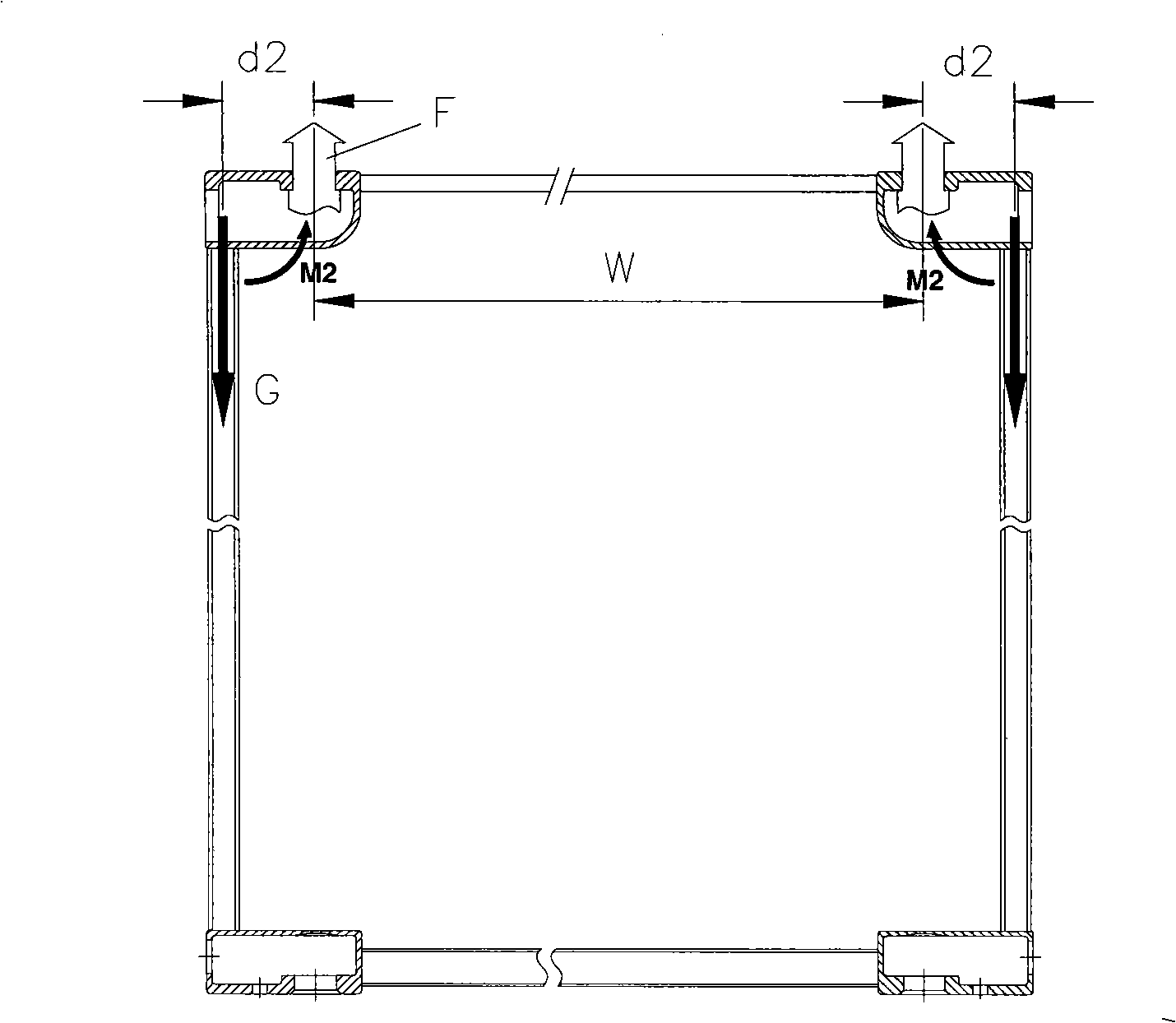

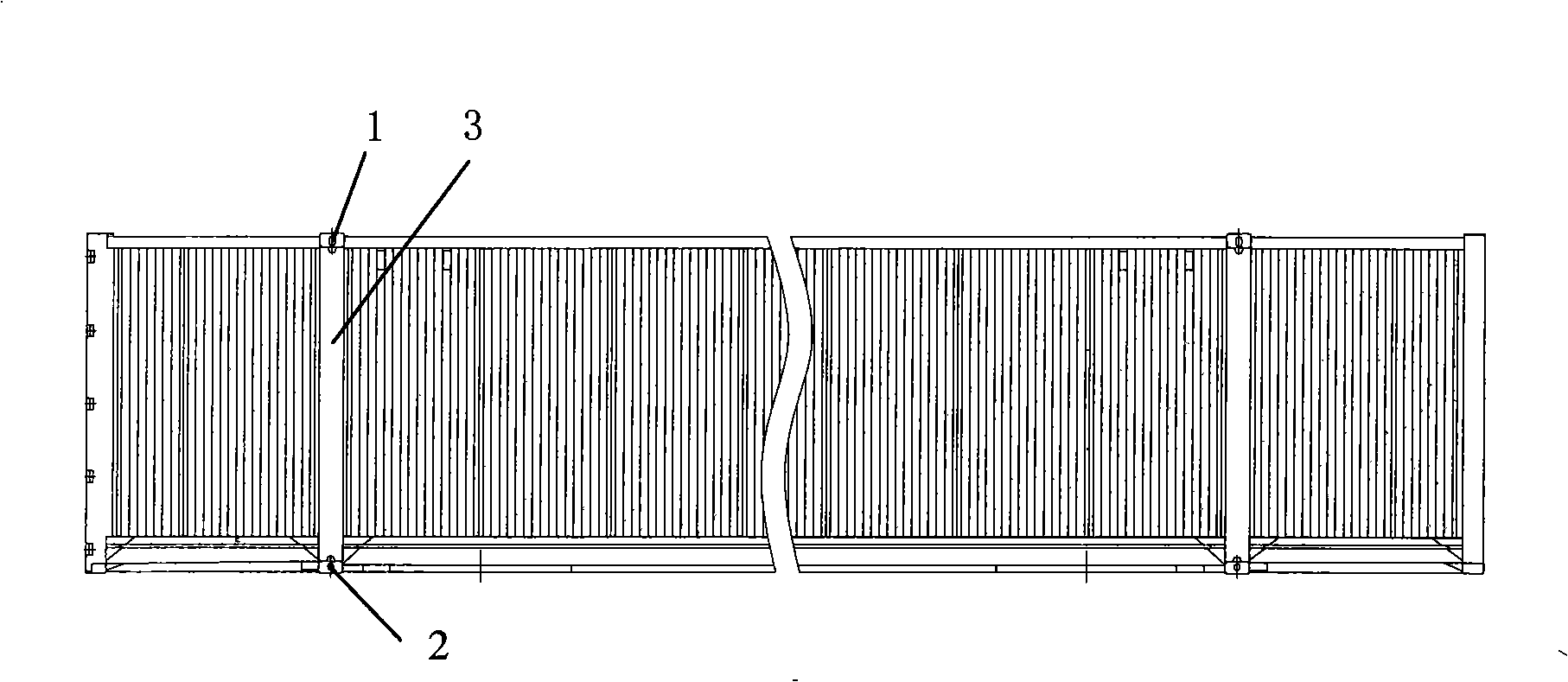

[0035] Such as Figure 9-12 As shown, in the first embodiment of the present invention, the container lifting and stacking structure includes corner posts 6 , top corner pieces 4 and bottom corner pieces 5 respectively located at the top and bottom of the corner posts 6 . The corner post 6 includes an inner corner post 61 and an outer corner post 62 parallel to each other. Both the top corner piece 4 and the bottom corner piece 5 have ears for welding with the corner post 6 . A first ear 41 extending downward is provided on the bottom surface of the top corner piece 4 , and a second ear 51 extending upward is provided on the bottom corner piece 5 . The shapes of the two ears 41, 51 may be trapezoidal, rectangular or other shapes. There is a certain distance between the first ear 41 and the outer surface of the corner piece 4 for placing the upper end of the outer corner post 62 . There is also a certain distance between the second ear 51 and the outer surface of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com