Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Adjust the transmission ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

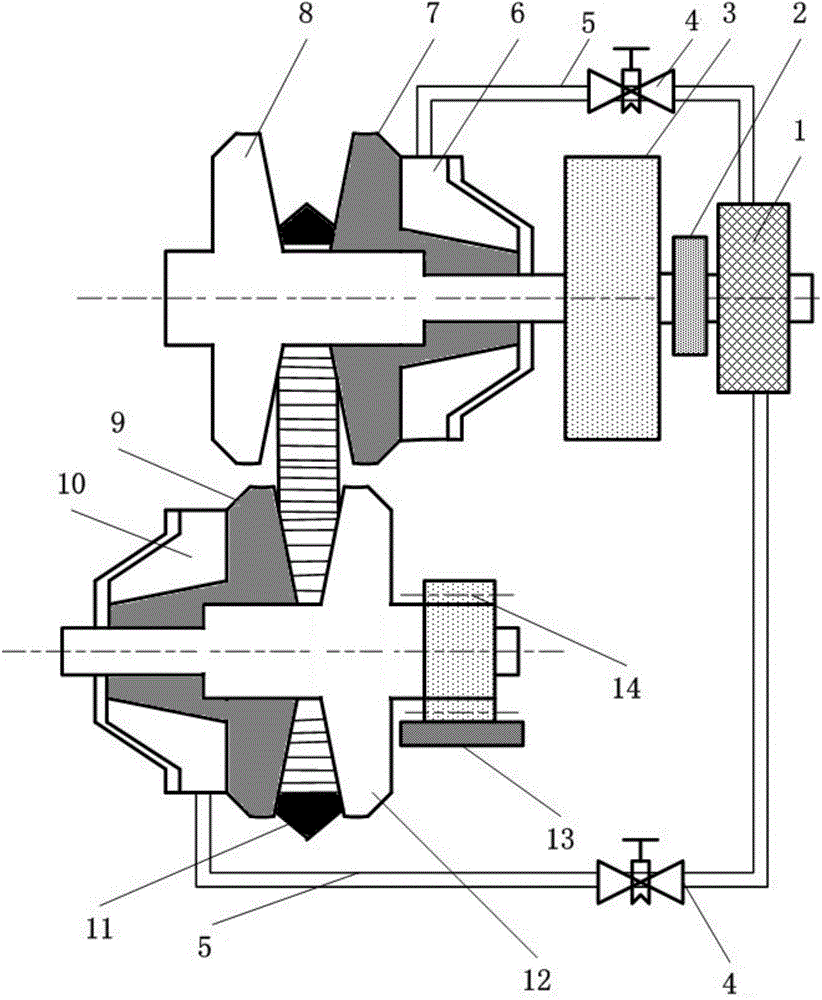

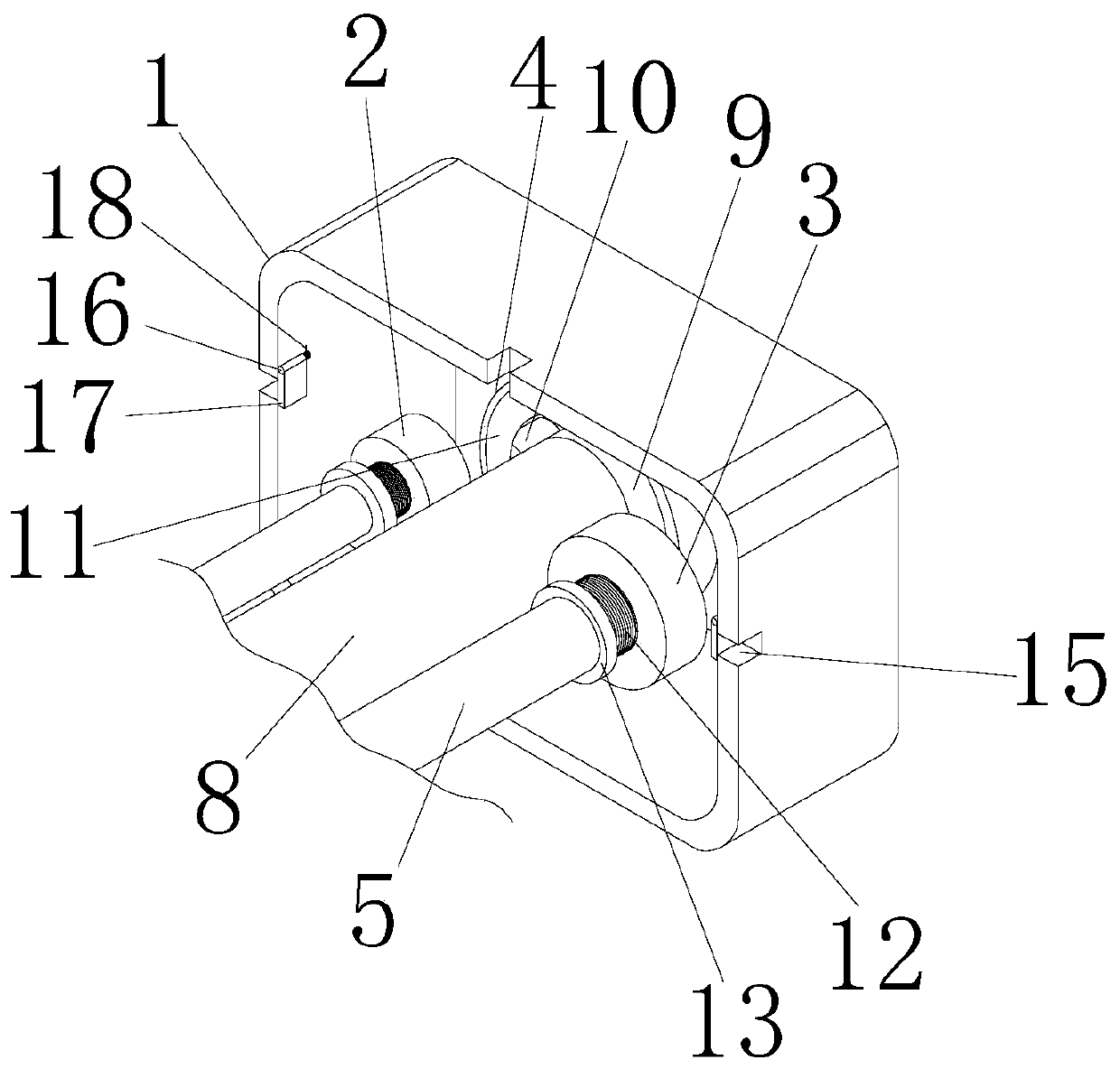

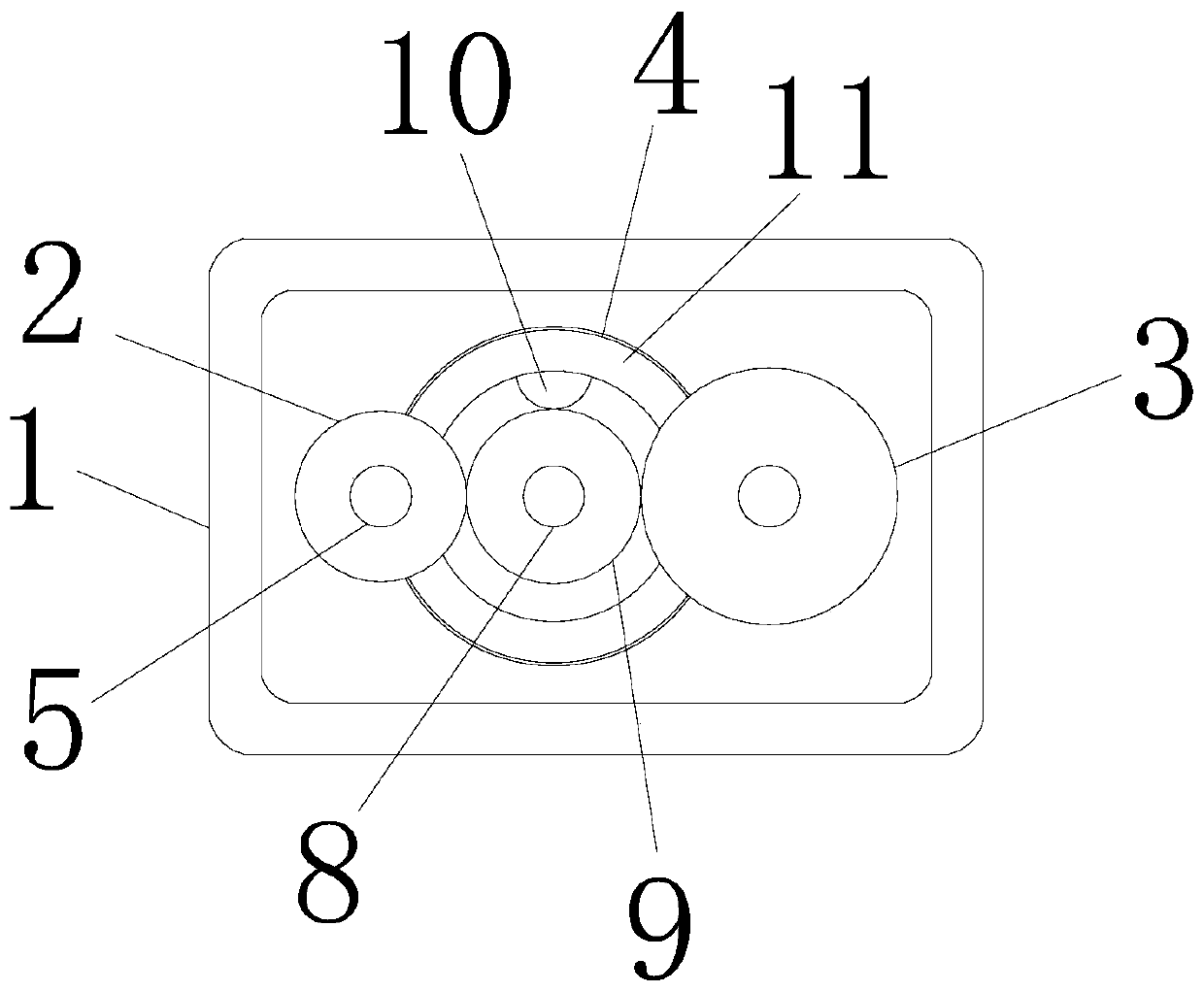

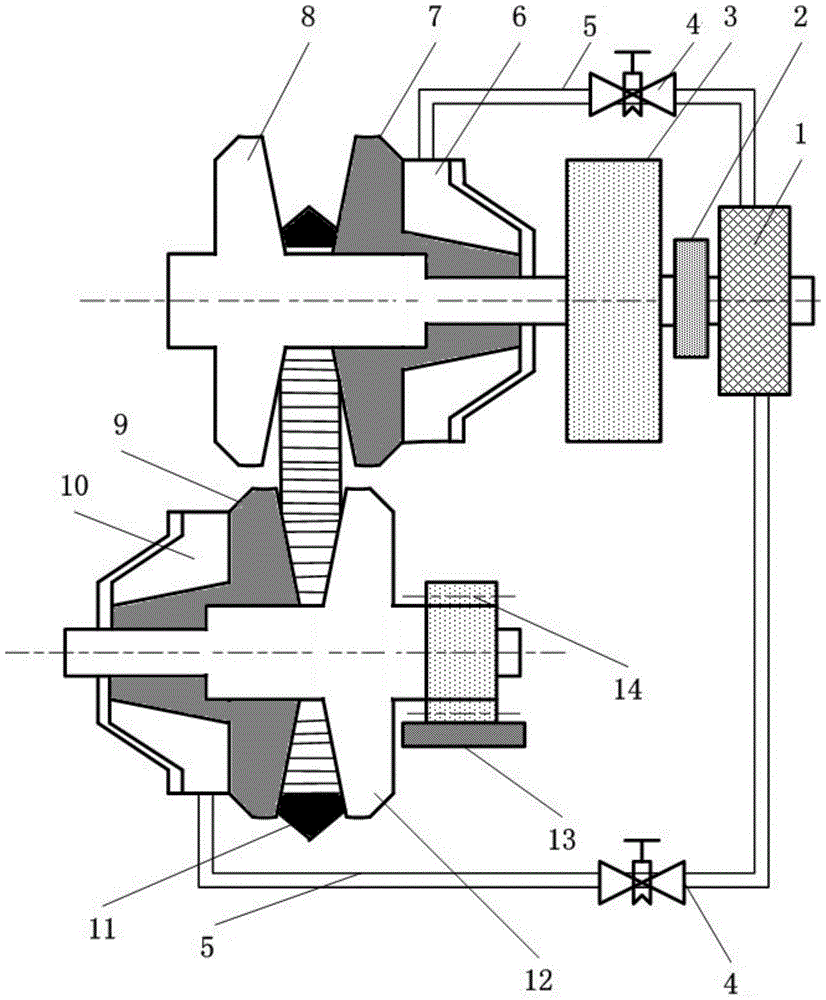

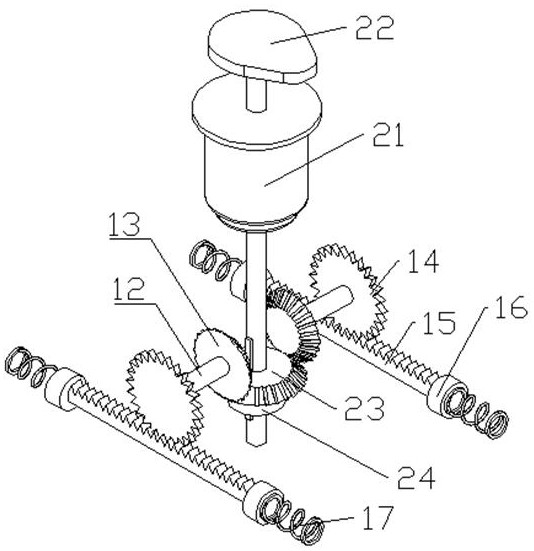

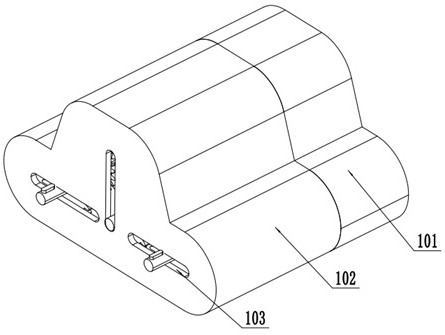

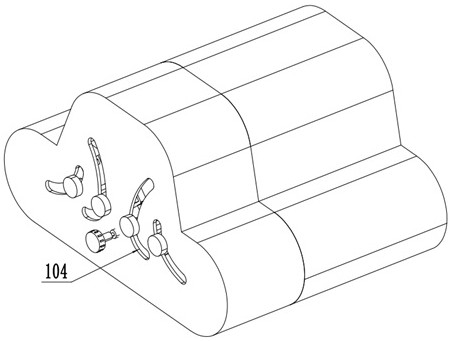

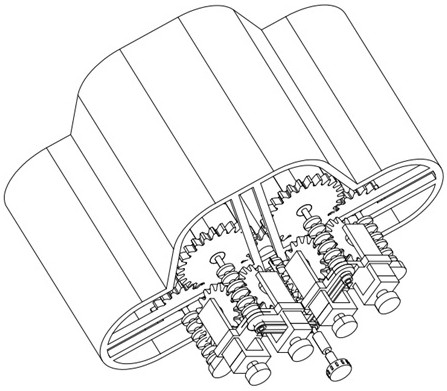

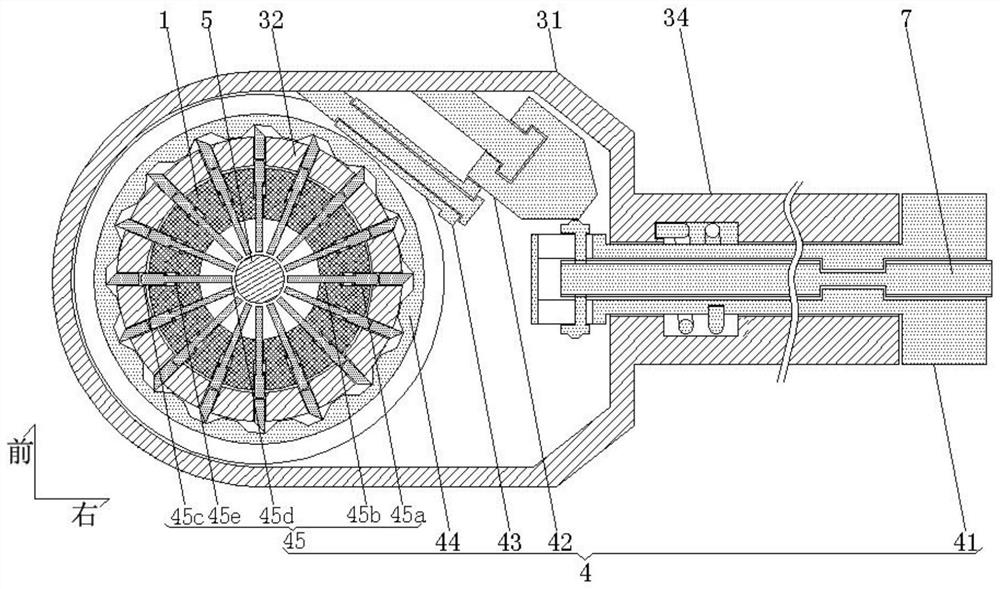

Inertial container device with continuously-adjustable inertia coefficient

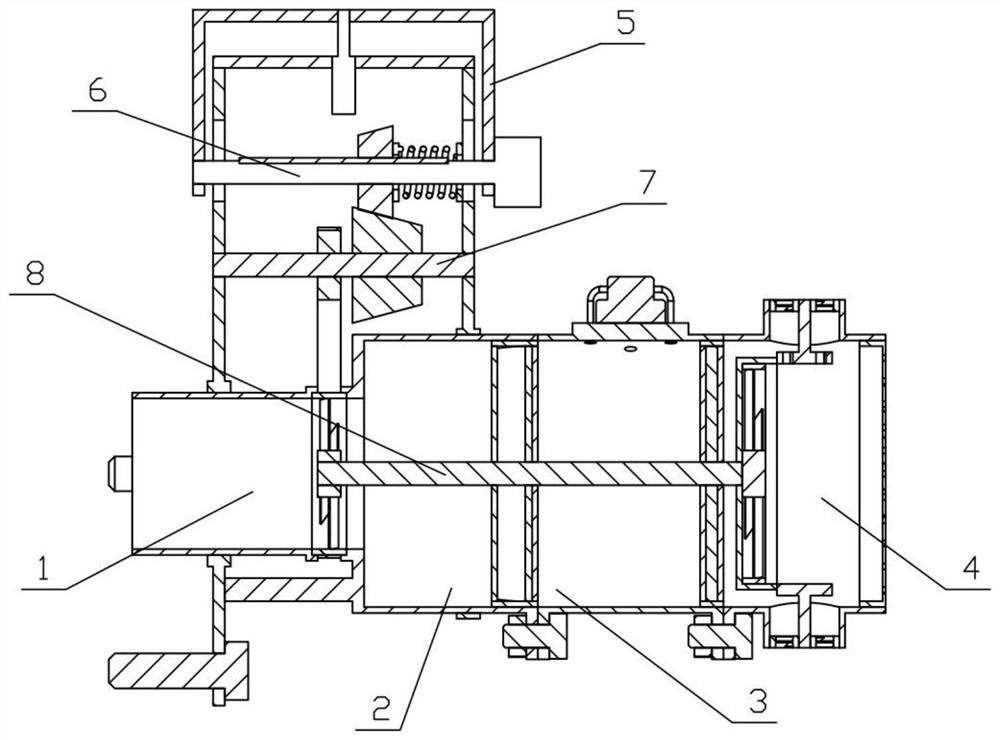

The invention provides an inertial container device with a continuously-adjustable inertia coefficient. The inertial container device comprises a driving wheel, a driven wheel, a gear, a rack / flywheel / hydraulic pump, a driving wheel hydraulic control cylinder and a driven wheel hydraulic control cylinder, wherein a V-shaped groove is formed between the movable part and the fixed part of the driving wheel; the gear is arranged on a driving shaft, and is meshed with the rack; a V-shaped groove is formed between the movable part and the fixed part of the driven wheel; the flywheel is arranged on a driven shaft; the driven wheel is driven by an elastic metal belt arranged in the two V-shaped grooves; the movable parts of the driving wheel and the driven wheel are driven by the driving wheel hydraulic control cylinder and the driven wheel hydraulic control cylinder which are connected with a hydraulic pump respectively. The engagement radius of the metal belt is adjusted through axial movement of the movable part of the driving wheel and the movable part of the driven wheel, so that the transmission ratio between the driving wheel and the driven wheel is adjusted, and continuous adjustment of the inertia coefficient is realized.

Owner:JIANGSU UNIV

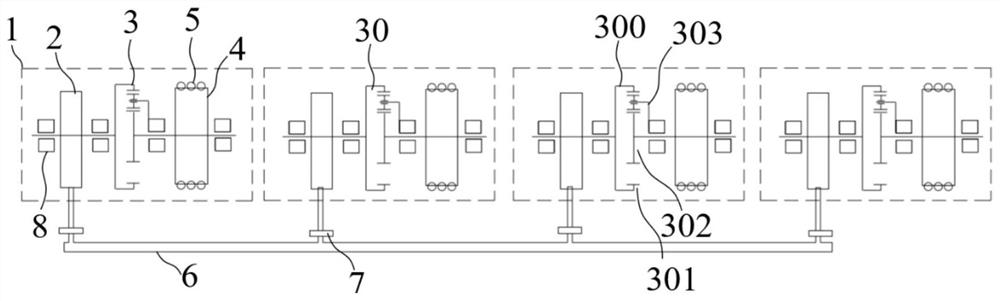

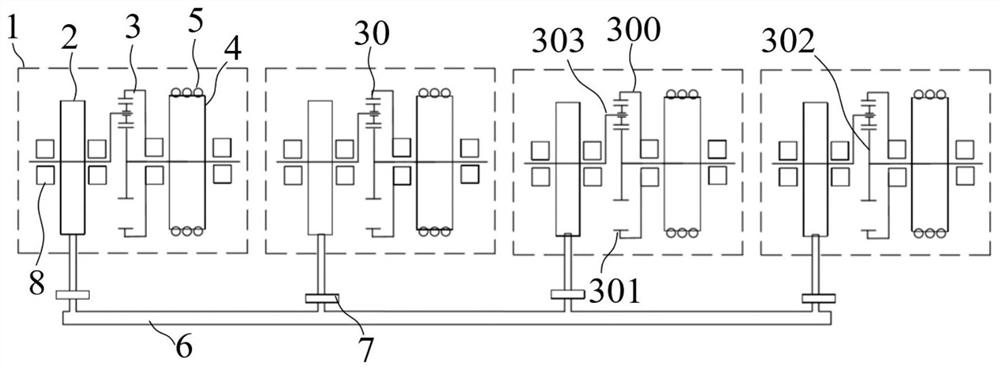

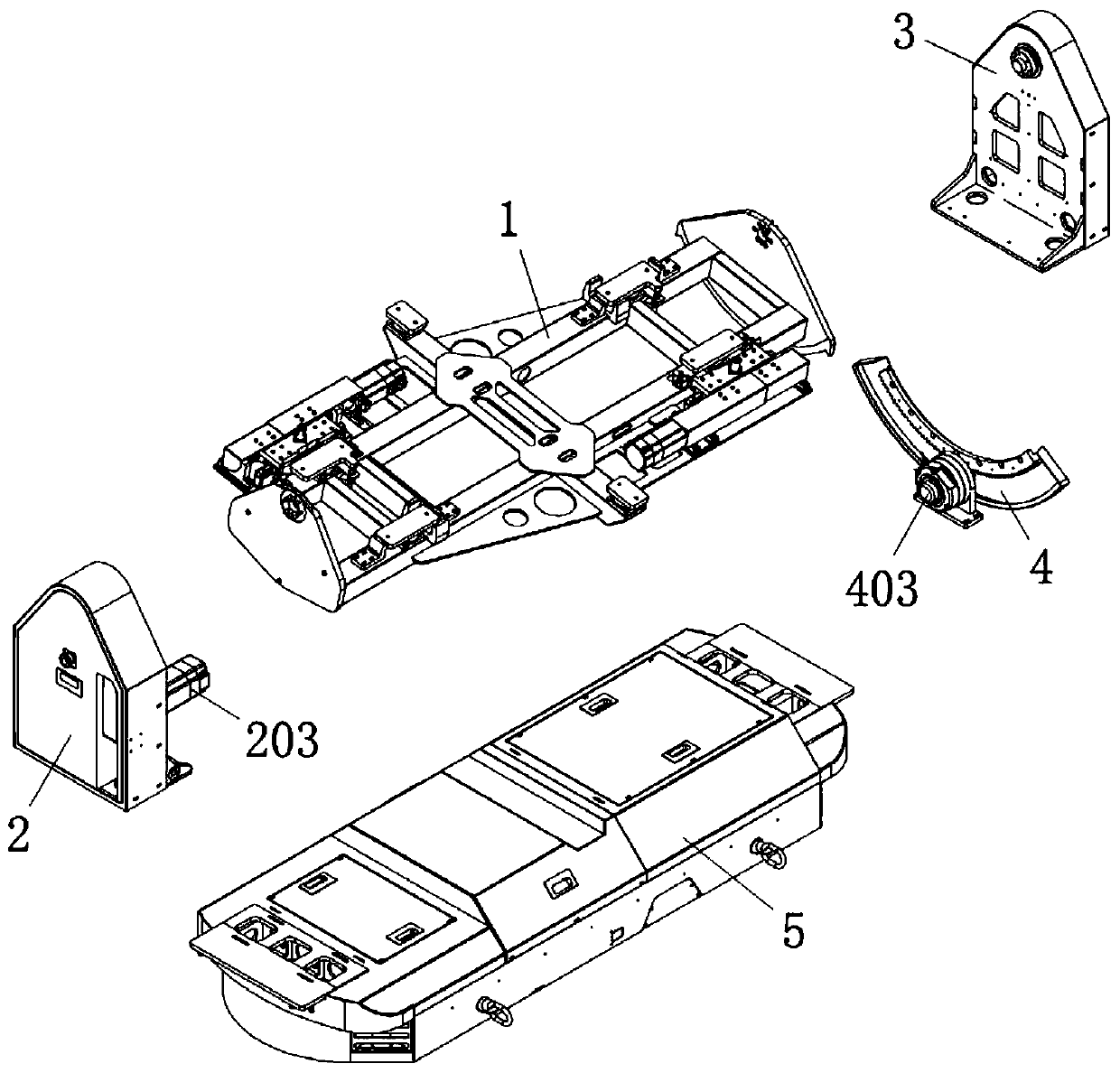

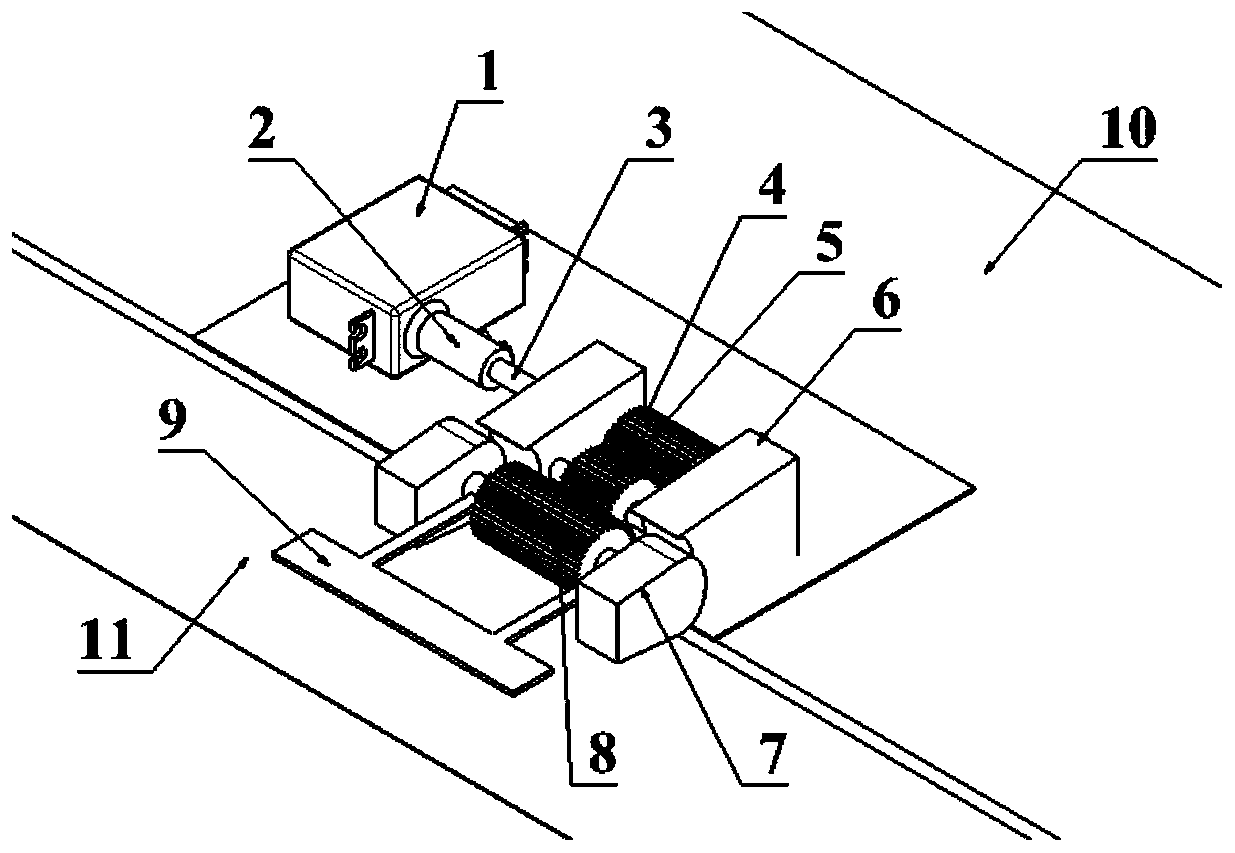

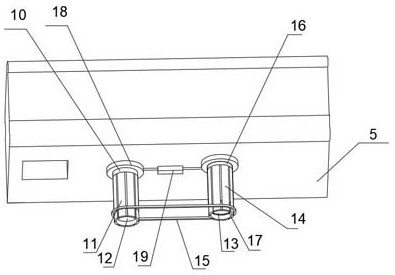

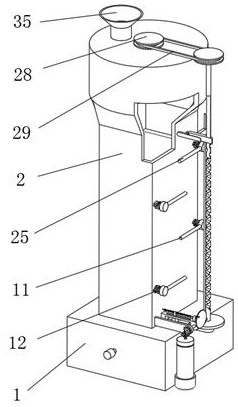

Multi-rope tension balance adjusting device and adjusting method

ActiveCN112357725ALarge amount of adjustment strokeTimely and effective tension balance adjustment processElevatorsMine liftsWire ropeControl engineering

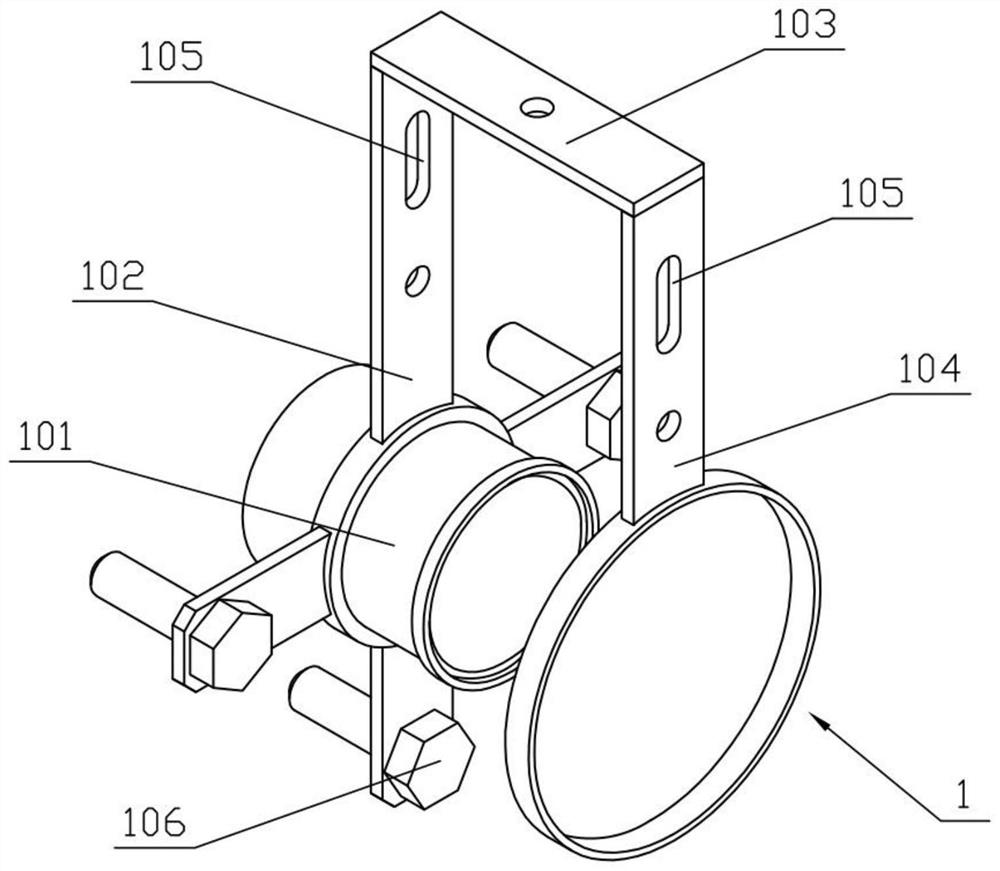

The invention discloses a multi-rope tension balance adjusting device and adjusting method, and belongs to the technical field of multi-rope lifting. The device comprises a plurality of tension balance units, wherein each tension balance unit comprises a hydraulic cylinder, a speed increasing module, a roller and a lifting steel wire rope; the hydraulic cylinder is used for transmitting torque, the speed increasing module is used for speed increasing transmission, one transmission end of the speed increasing module is in transmission connection with the hydraulic cylinder, the roller is in transmission connection with the other transmission end of the speed increasing module, and the lifting steel wire rope is wound on the roller; and the hydraulic cylinders of the tension balance units communicate with one another through communicating pipelines. According to the device, the mechanism that the communicating hydraulic cylinders can automatically balance the hydraulic pressure is utilized, the torque change in the hydraulic pressure balancing process is converted into the rotation of the rollers, then tension balance adjustment such as loosening or tensioning is carried out on the wound lifting steel wire ropes, large-range automatic adjustment can be realized in a limited equipment space, and the effectiveness and timeliness of tension balance adjustment can be guaranteed.

Owner:CHINA UNIV OF MINING & TECH

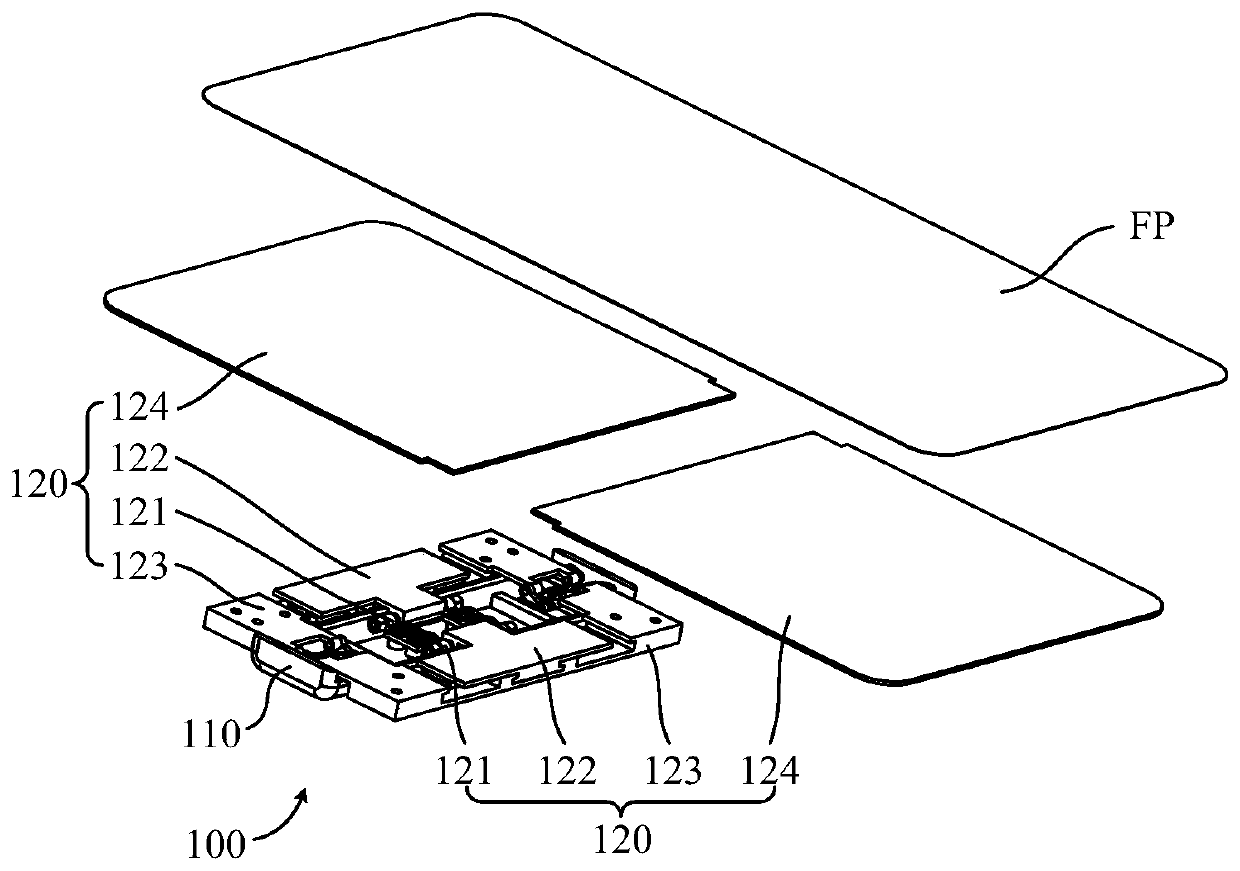

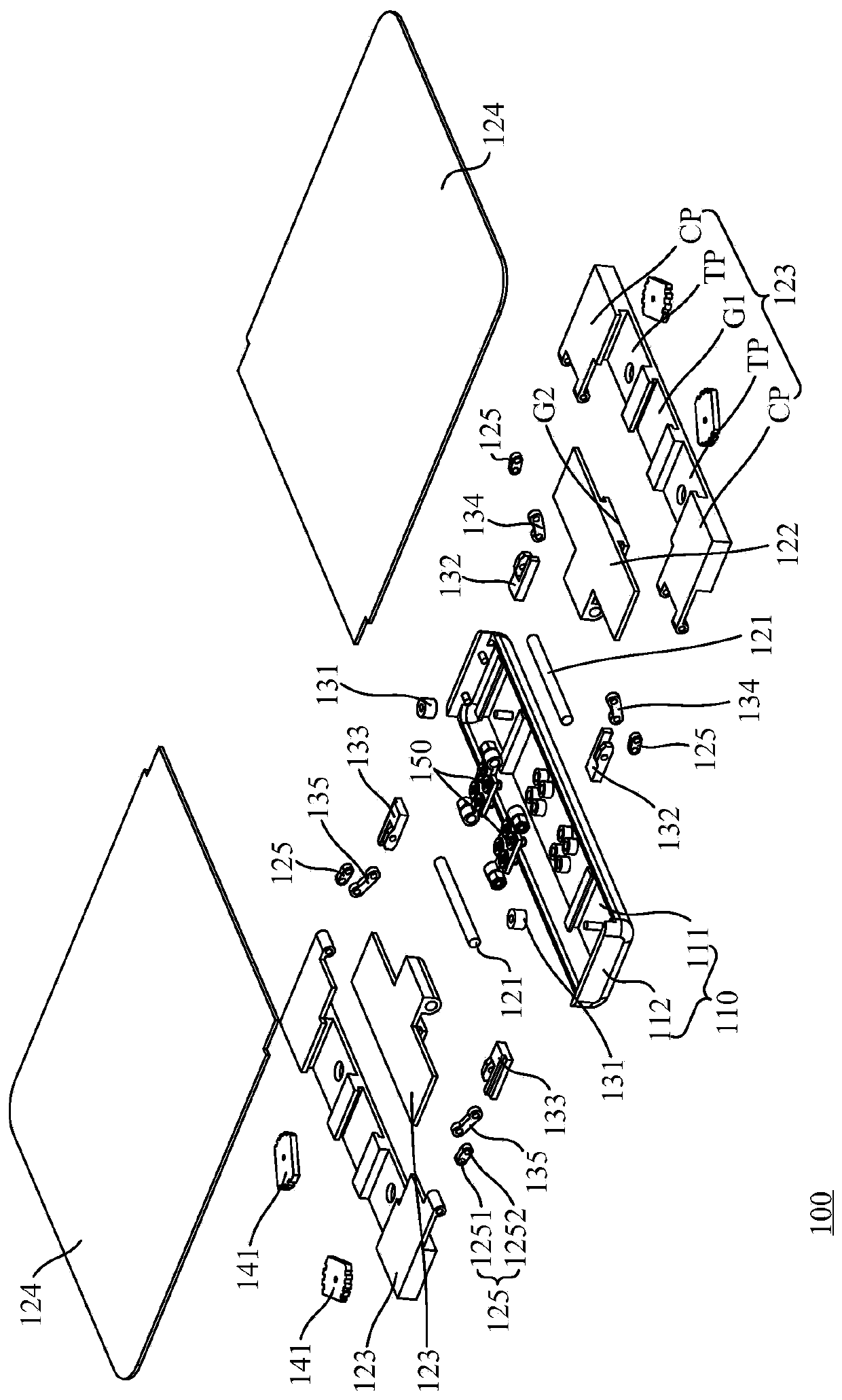

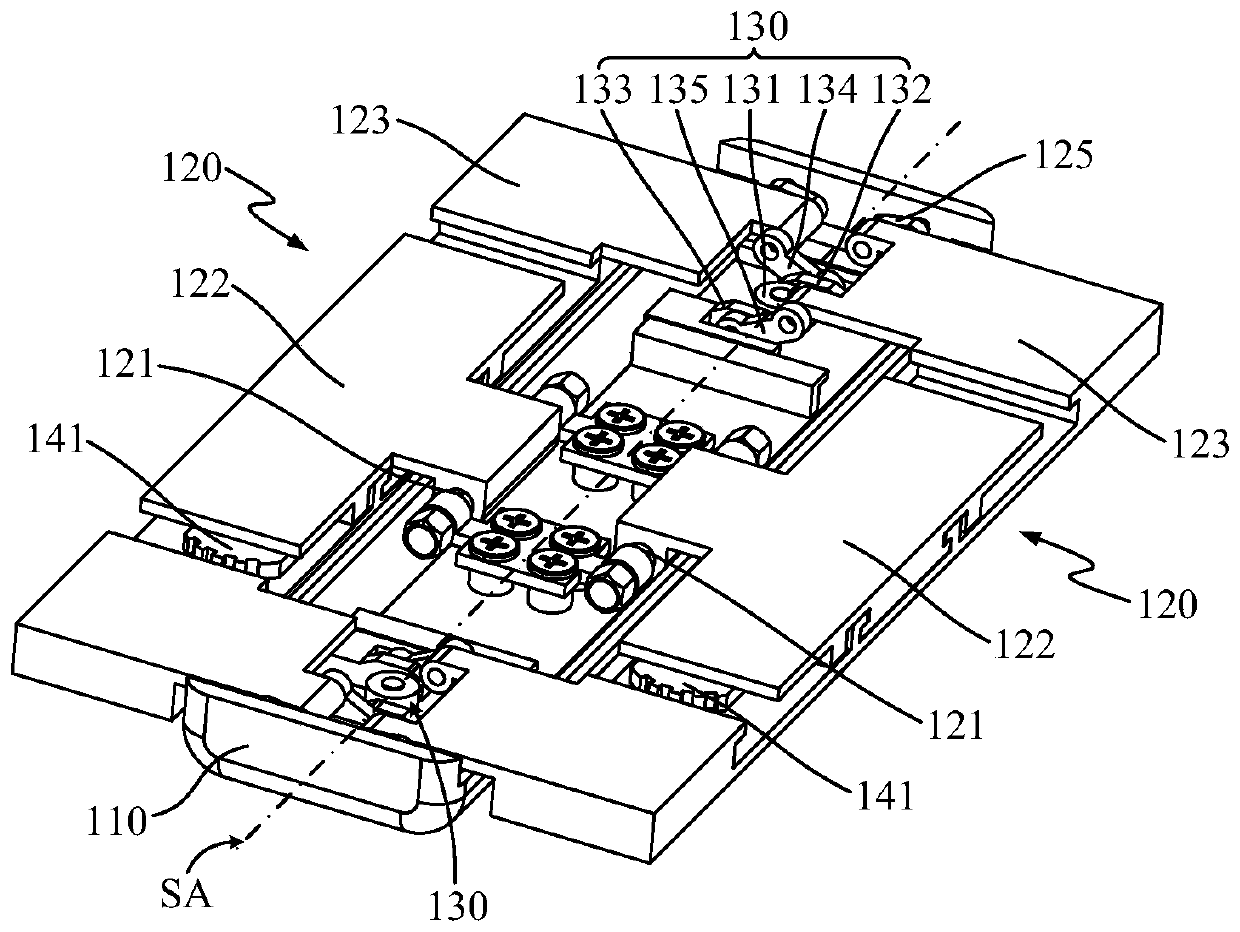

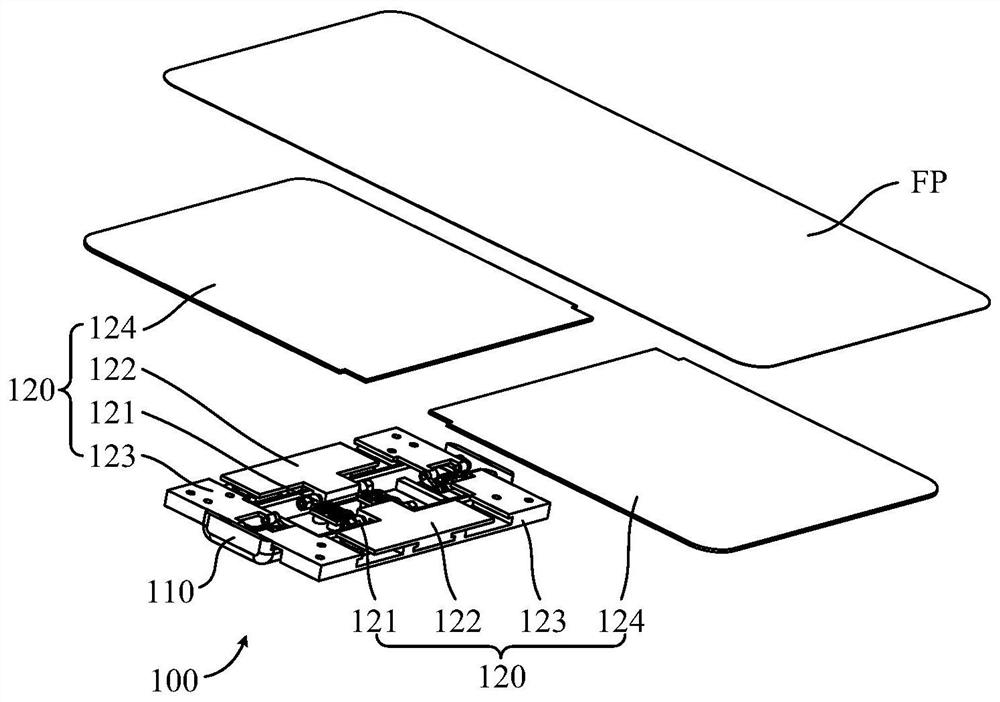

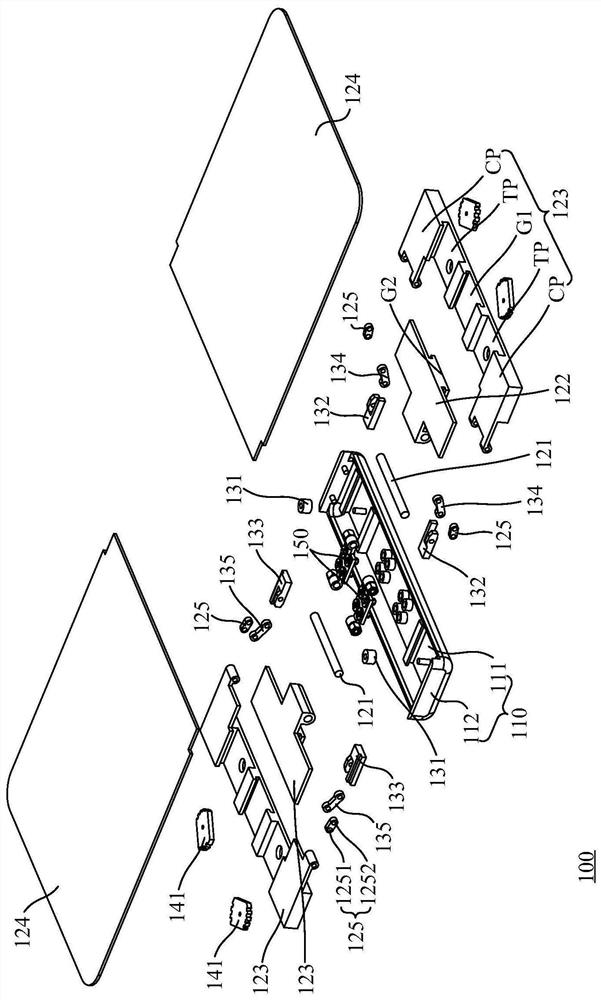

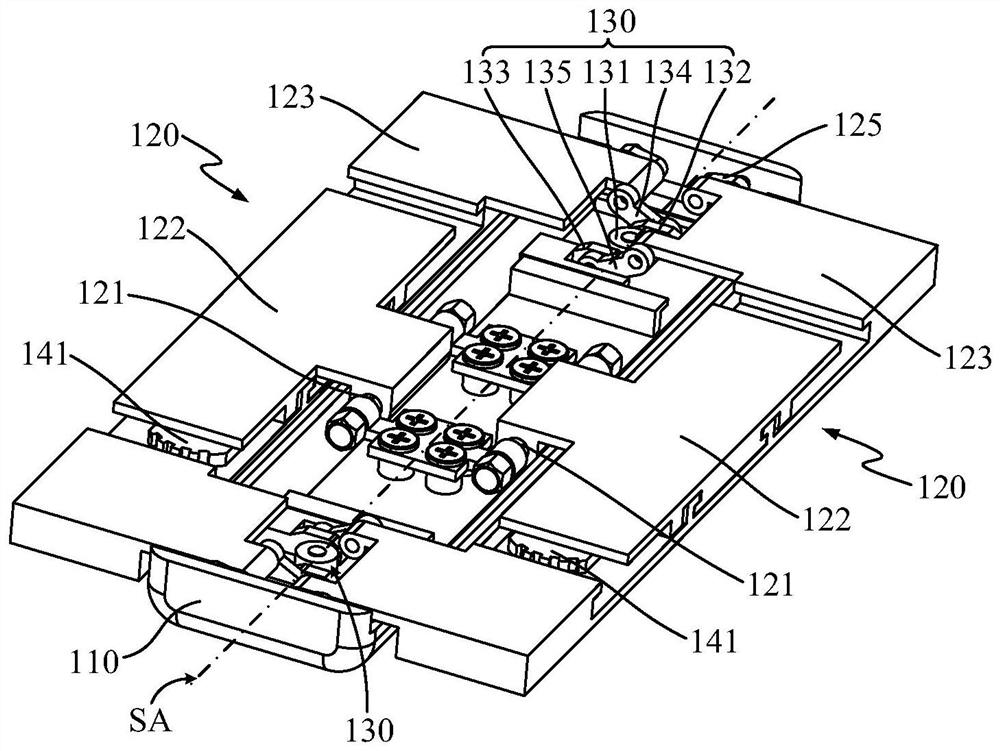

Rotating shaft assembly, display module and display equipment

ActiveCN111246697AAchieve foldingAchieve expansionCasings with display/control unitsCasings/cabinets/drawers detailsAxis of symmetryMechanical engineering

The invention discloses a rotating shaft assembly, a display module and display equipment. The rotating shaft assembly is used for driving a flexible plate to be bent, and comprises a rotating shaft base; and pairs of rotating unit. Each rotating unit comprises a rotary shaft connected with a rotating shaft base, a rotating part connected with the rotary shaft and capable of rotating around the rotating shaft, a sliding part slidably connected with each rotating part, wherein the sliding part is configured to rotate with each rotating part when each rotating part rotates and slides relative toeach rotating part. The assembly also comprises a support part slidably connected with each sliding part, wherein the support part is used for connecting and supporting a flexible plate, a synchronization assembly which enables the displacement of sliding parts of paired rotating units to be symmetrical about the symmetry axis. Stretching or extrusion of the rotating shaft assembly to the flexible plate during rotation change is reduced, and the reliability of the flexible plate during bending or unfolding is improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

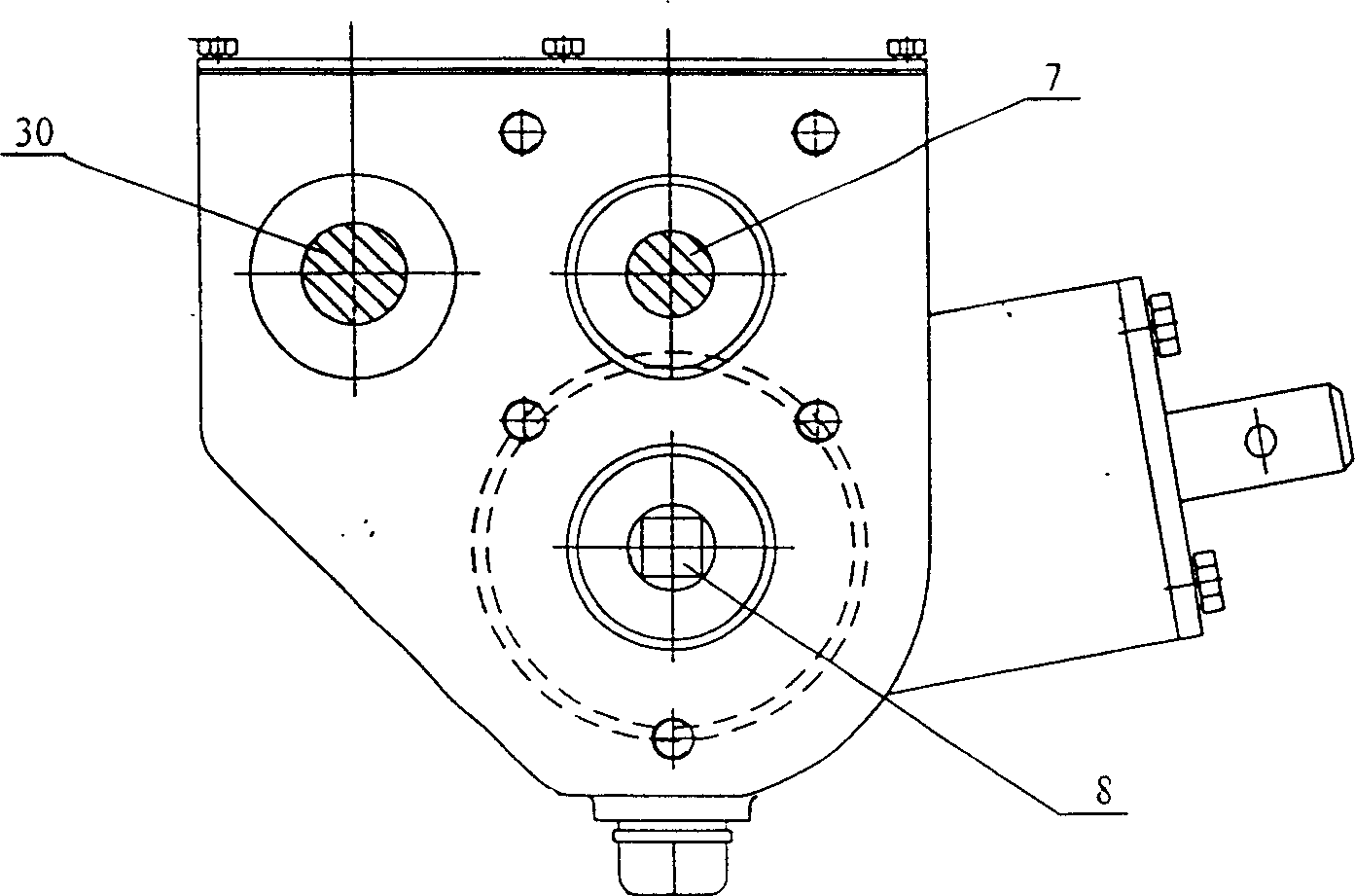

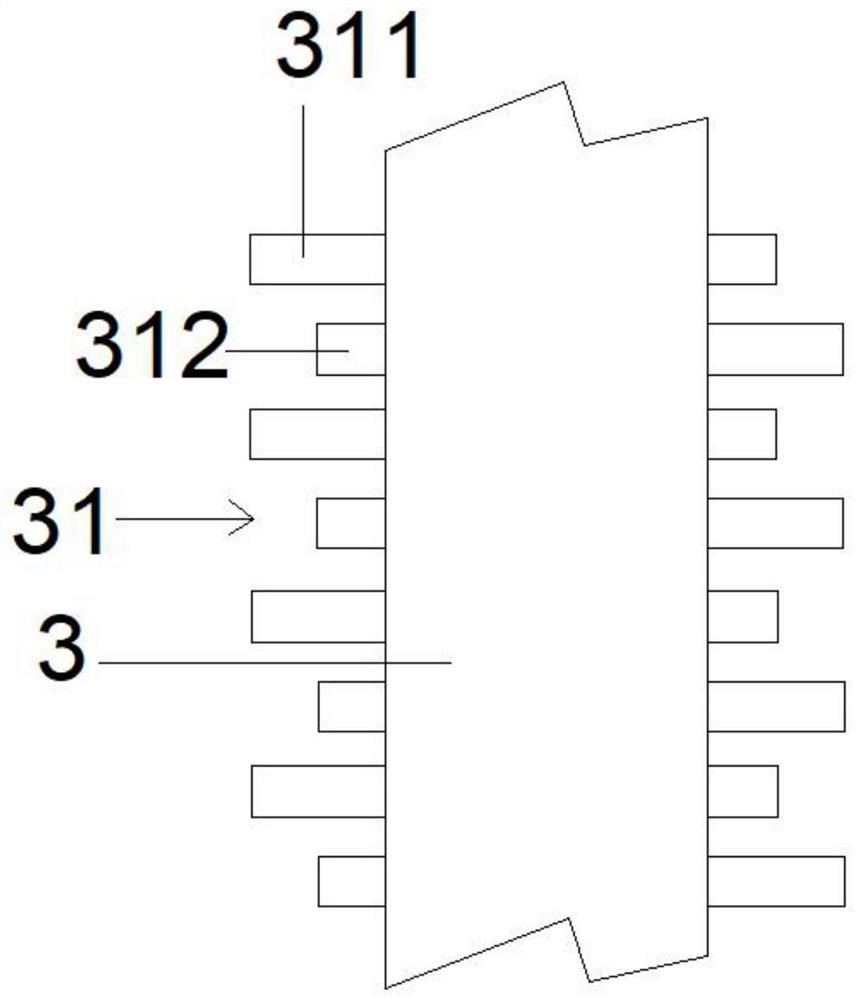

Reduction box

InactiveCN110439987AReduce use costAdjust the transmission ratioGearboxesGearing detailsGear wheelEngineering

The invention relates to the technical field of gearbox, and discloses a reduction box. The reduction box comprises a shell box body, wherein a pinion, a big gear wheel and a matching gear are arranged in the shell box body, the pinion and the big gear wheel both can be pushed backwards so as to stretch out a row of gradually-reduced gears, rotating shafts are movably installed in the pinion and the big gear wheel correspondingly, a telescopic rod is arranged in the matching gear, a fixing ring is movably installed at the side, close to the rear side wall of the shell box body, of the matchinggear. According to the reduction box, through the matching mode of the pinion, the big gear wheel, the matching gear and a movable gear, the reduction gearbox can change more transmission ratios to response the transmission ratio required by different devices, compared with an existing reduction gearbox, the reduction gearbox can cover the wider range, adjust the transmission ratio of the devicemore flexibly without replacing the reduction gearbox to adjust the transmission ratio, so that the use cost of a manufacturer is reduced while the use is convenient.

Owner:高邮市金瓯机电有限公司

Fixed die push-out device

The invention discloses a fixed die push-out device. The fixed die push-out device comprises a fixed die. The fixed die is provided with a push rod. The push rod is provided with a plurality of ejecting ends. Springs are arranged at the ejecting ends and used for fixing the push rod to the fixed die. The ejecting ends and the fixed die are in a pressed and sealed state. A delay groove is formed in the power end of the push rod. A driven rod shaft is in sliding connection in the delay groove and is fixed to a driven rod. The driven rod is connected to a drive rod through a gear and rack combination. The drive rod is fixed to the fixed die, and the drive rod moves along with the fixed die. The fixed die push-out device which utilizes die sinking force, and is compact in structure, simple and efficient is provided to achieve the purpose of pushing a casting out of the fixed die according to the casting shape, the technology requirement and other reason requirements.

Owner:CHONGQING YINGRUISHENG DIE CASTING

Turnover mechanism and carrying device

The invention provides a turnover mechanism and a carrying device. The turnover mechanism comprises a turnover platform, a driving assembly, a supporting assembly and a brake assembly, wherein the turnover platform is used for bearing cargos; the driving assembly is connected to one end of the turnover platform and used for driving the turnover platform to overturn facing at least one side; the supporting assembly and the driving assembly are relatively connected to the other end of the turnover platform, and the supporting assembly is used for supporting turnover of the turnover platform; andthe brake assembly is connected with the end, close to the supporting assembly, of the turnover platform, and is used for locking a turnover angle of the turnover platform. According to the turnovermechanism, the brake assembly is arranged at the other end of the turnover platform opposite to the driving assembly, through the cooperation of the brake assembly and the driving assembly, the turnover platform is locked at a preset turnover angle, during braking, two ends of the turnover platform are simultaneously contained, so that braking force of the turnover platform and holding power of the turnover angle are improved, and the turnover requirement of current larger cargos are met.

Owner:HUAXIAO PRECISION SUZHOU

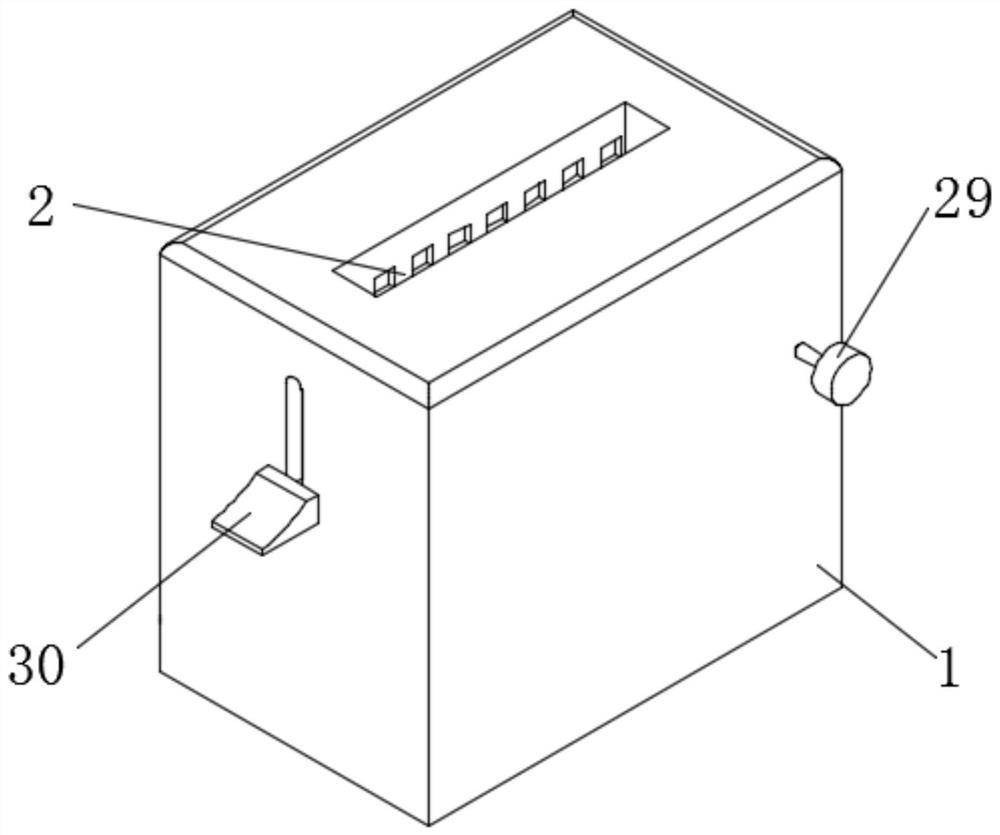

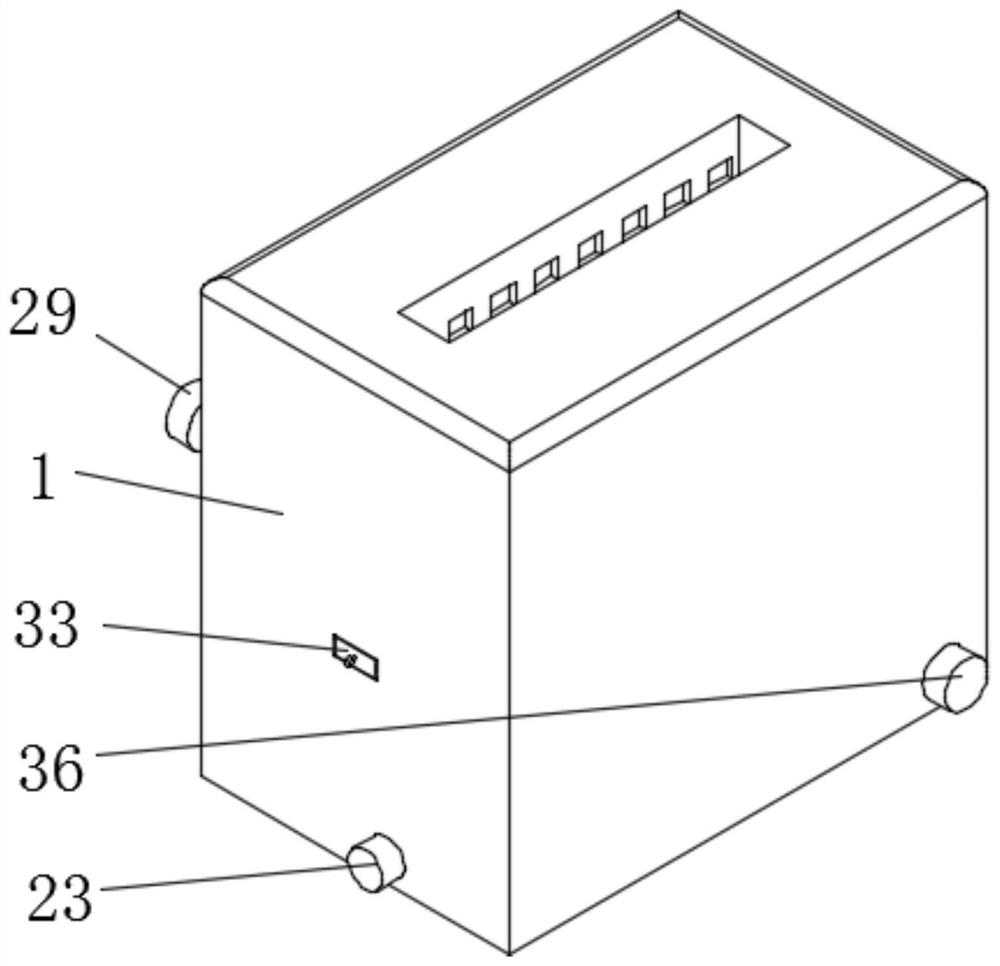

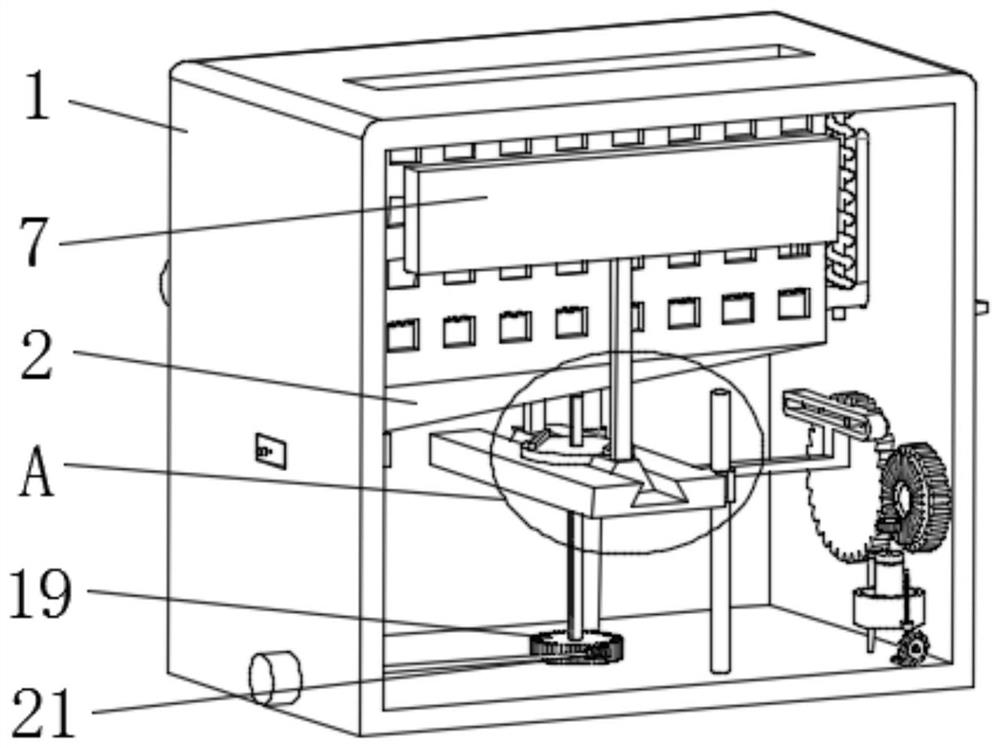

Uniform toaster based on Internet of Things

The invention discloses a uniform toaster based on the Internet of Things, and relates to the field of toasters, the uniform toaster comprises a main box body, a square hole is formed in the top side of the main box body, a baking net cage is fixedly installed in the main box body, and the baking net cage is matched with the square hole in size and position; and two sliding rods are fixedly mounted on the inner wall of the bottom side of the main box body, and the two sliding rods are movably connected with the same mounting block in a sleeving mode. According to the invention, the itinerant motor and the baking plate are started, the itinerant motor rotates to drive the speed regulation turntable to rotate through the rotating gear so as to drive the rotating fluted disc to rotate, and the rotating fluted disc rotates to drive the sliding groove rod to reciprocate through the sliding bolt so as to drive the mounting block to reciprocate; the mounting block moves to drive the two baking plate to vertically reciprocate through the trapezoidal blocks and the supporting rods, so that the baking plate can uniformly bake the sliced bread, and the situation that the central position of the bread is easily burnt and the edge position of the bread is insufficiently baked due to non-uniform heating is avoided.

Owner:广州萌务网络科技有限公司

Transmission

PendingCN108458075AImprove continuityRealize stepless speed changeGearingEngineeringElectrical and Electronics engineering

The invention discloses a transmission which comprises a driven lever, a driving lever and a one-way transmission device. The one-way transmission device is in transmission connection with one end ofthe driven lever, the other end of the driven lever is in sliding connection with the driving lever, a front fixed shaft is rotationally connected to the driving lever, and the driving lever can drivethe driven lever to rotate around the one-way transmission device when rotating around a front fixing shaft; the length of a force arm of the driven lever is adjustable, the length of the driven lever is adjusted, and therefore the transmission ratio of the driven lever to the driving lever can be adjusted; through multi-stage lever transmission, the swing angle of the driving lever can be reduced, the rotating angle is within the labor-saving zone, and the force saving effect can be achieved; and the driving lever and the driven lever are in threaded connection through a length adjusting rod, the length adjusting continuity can be improved, and infinitely variable speed can be achieved.

Owner:李仕奇

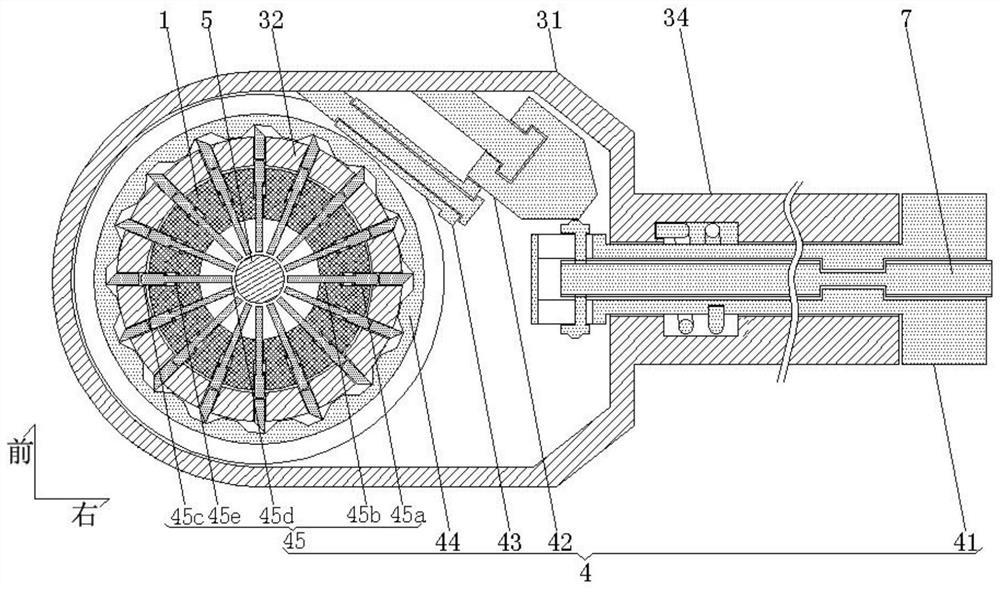

Embedded rudder surface control mechanism of unmanned aerial vehicle

ActiveCN110745234AShorten the lengthAdjust responsivenessWithout power ampliicationWeight reductionGear wheelUncrewed vehicle

The invention discloses an embedded rudder surface control mechanism of an unmanned aerial vehicle. The embedded rudder surface control mechanism consists of a steering engine, a driving gear, a transmission gear and a driven gear. The steering engine and a driving gear mounting seat are fixed in a wing, the steering engine is arranged on one side of the driving gear mounting seat, and the drivinggear and the transmission gear are arranged in the middle of the driving gear mounting seat. The two ends of a connecting sleeve are connected with the steering engine and a rotating shaft of the driving gear correspondingly. The driven gear and an actuating piece are installed in the steering engine through a driven gear bracket, the actuating piece is fixedly connected with a rotating shaft ofthe driven gear, the rotating shaft of the driven gear coincides with a rotating shaft of a rudder surface, and the transmission gear and the driven gear are meshed at a gap between the rear edge of the wing and the front edge of the rudder surface. The steering engine drives the driving gear to rotate and drives the driven gear to rotate through the transmission gear, and the driven gear drives the actuating piece to rotate to extrude the rudder surface, and therefore the rudder surface is driven to rotate. The rudder surface control mechanism is simple in structure and convenient to install;and the transmission ratio of the steering engine and the rudder surface can be adjusted by changing the number of teeth of each gear, so that the control precision is adjusted.

Owner:XIAN AISHENG TECH GRP +1

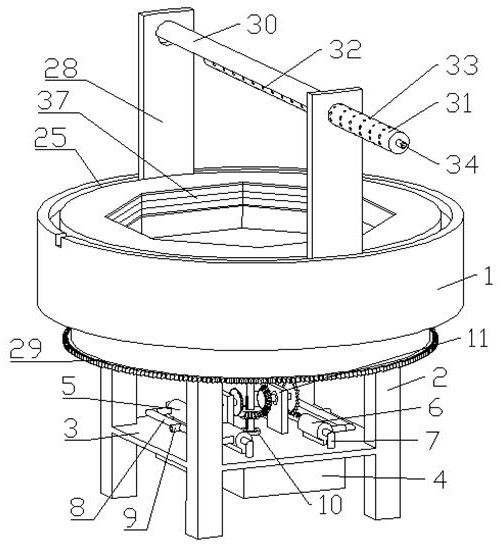

Box moving mechanism of high-speed rice transplanter

InactiveCN1543761AShorten the power transmission distanceImprove transmission efficiencyTransplantingGear wheelDrive shaft

The invention discloses a case shifting device for high speed rice transplanting machines, which includes a power-driven transmission arrangement for the sorting and sowing device mounted in the housing, a transverse arrangement and a longitudinal seedling arrangement, wherein a three-shaft design is employed for the sorting and sowing transmission shaft, the helical shaft and the case shifting shaft. The sorting and sowing transmission shaft is provided with a transmission chain wheel, the case shifting arrangement can be placed at the center of the high speed rice transplanting machine.

Owner:浙江工程学院

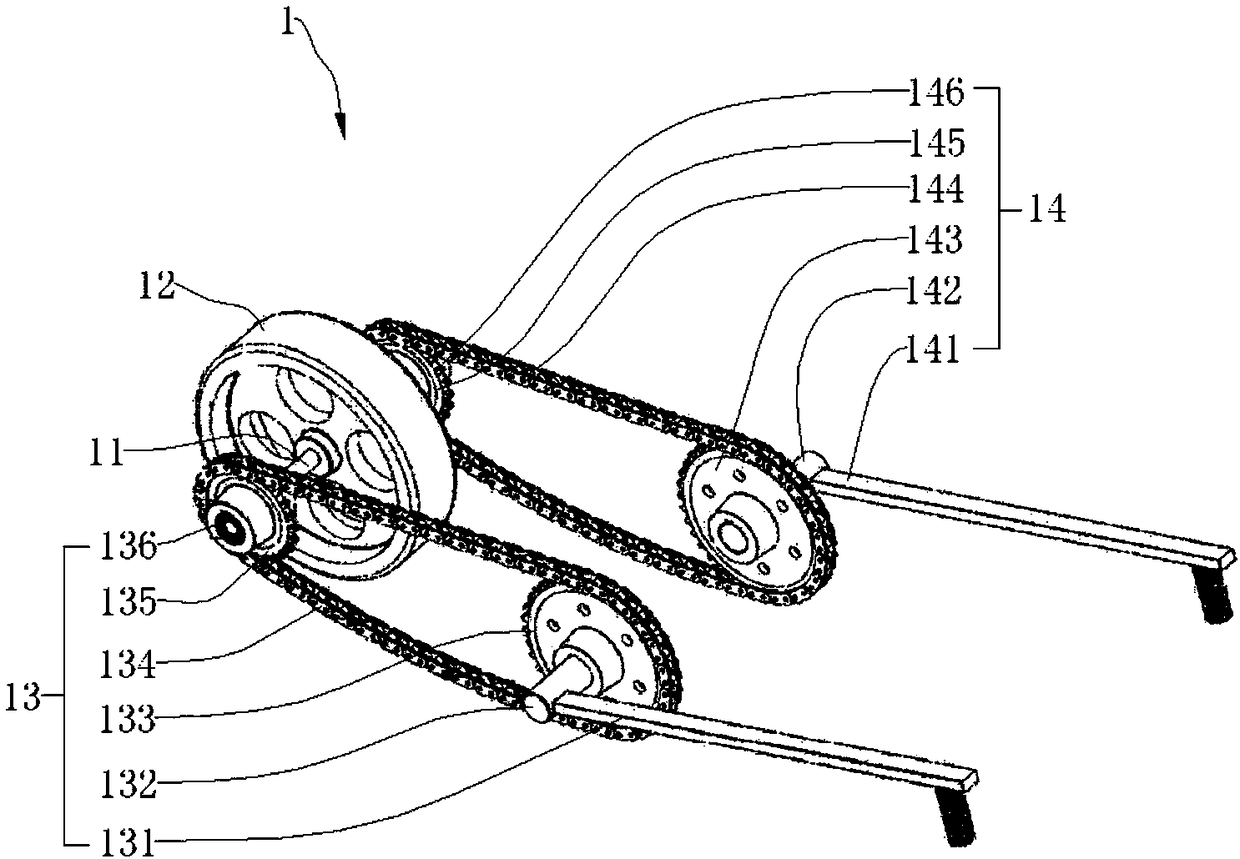

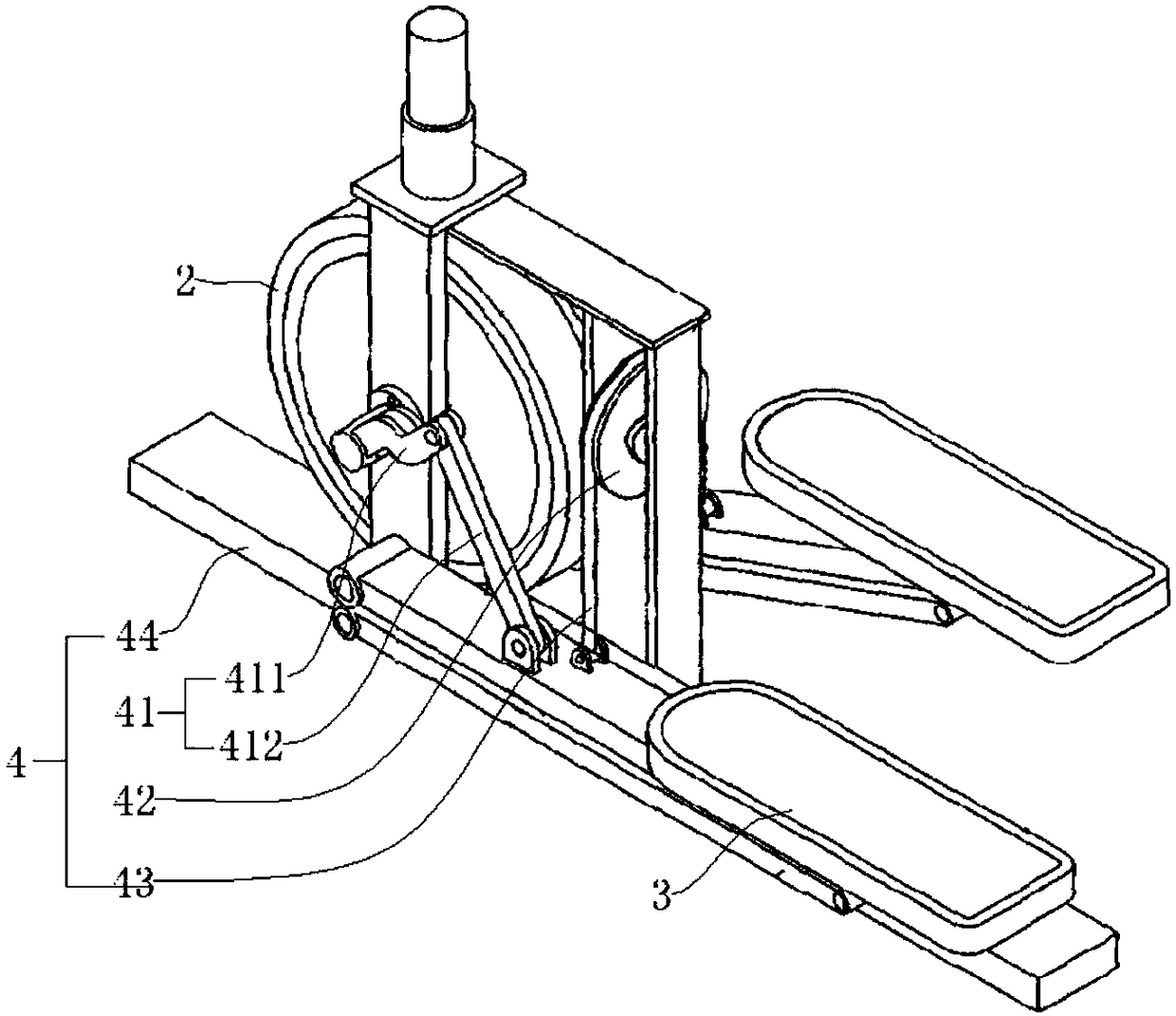

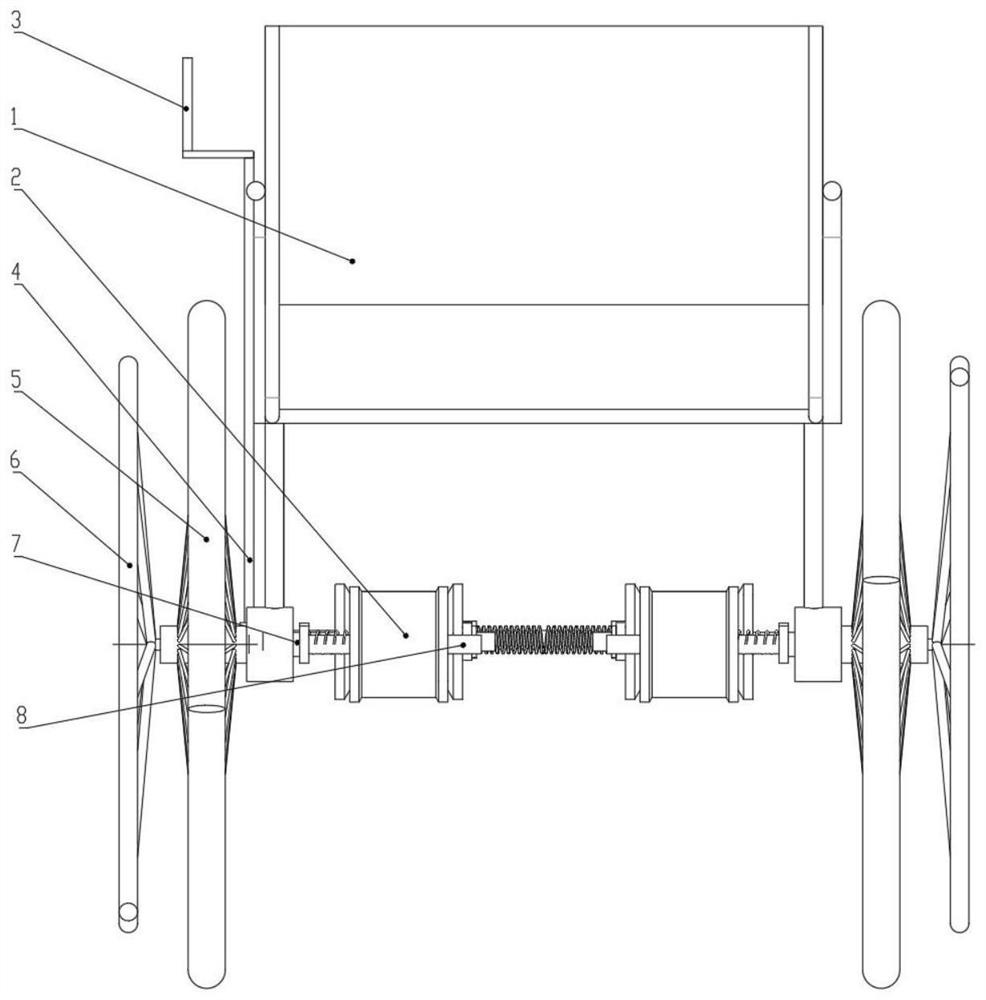

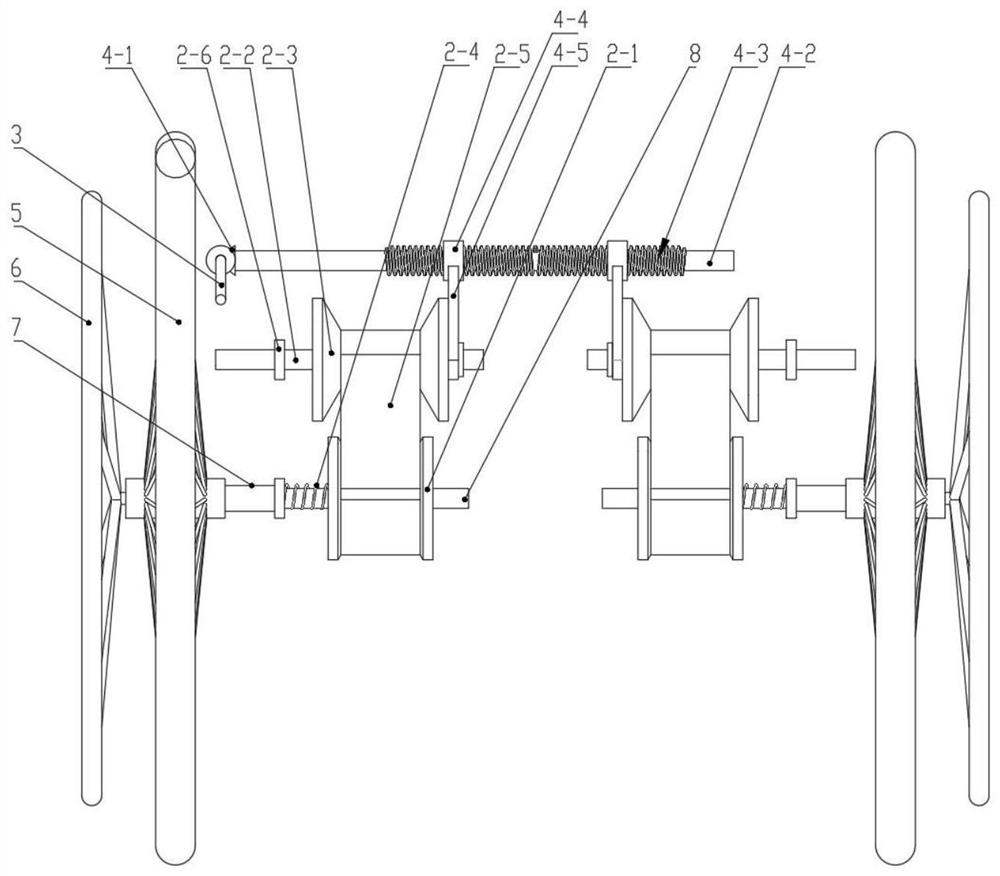

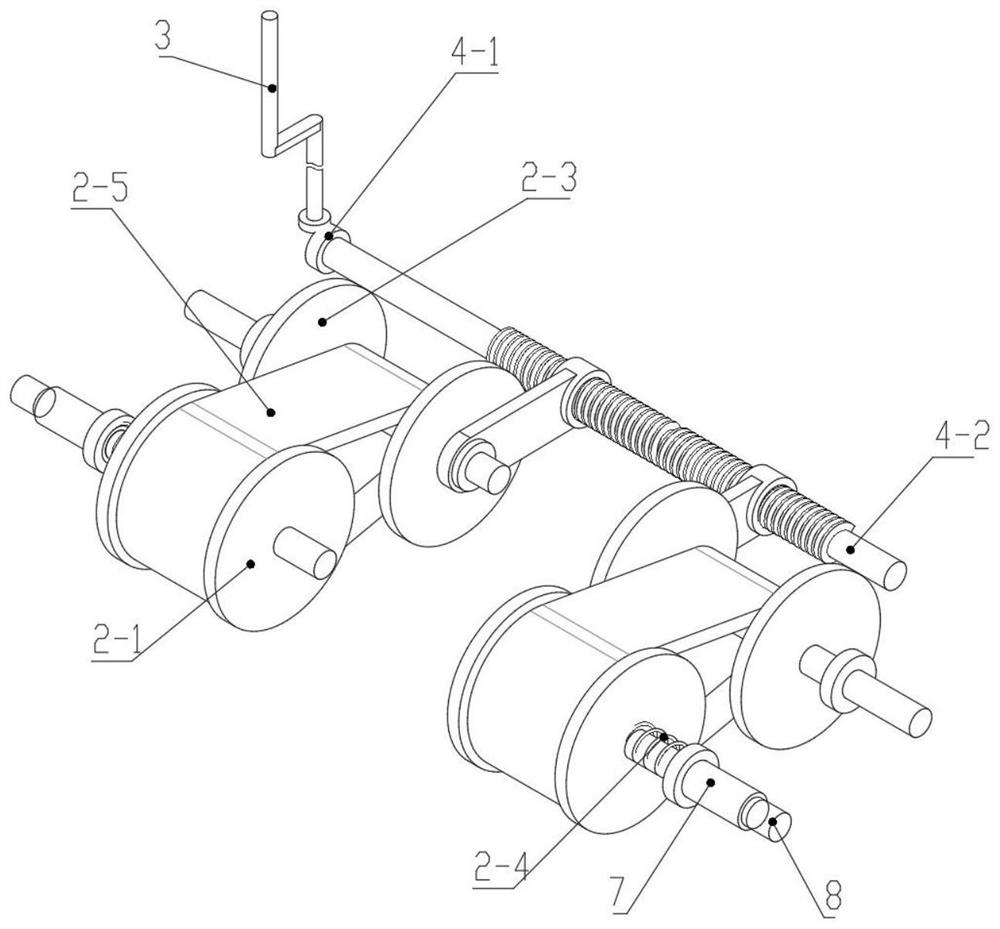

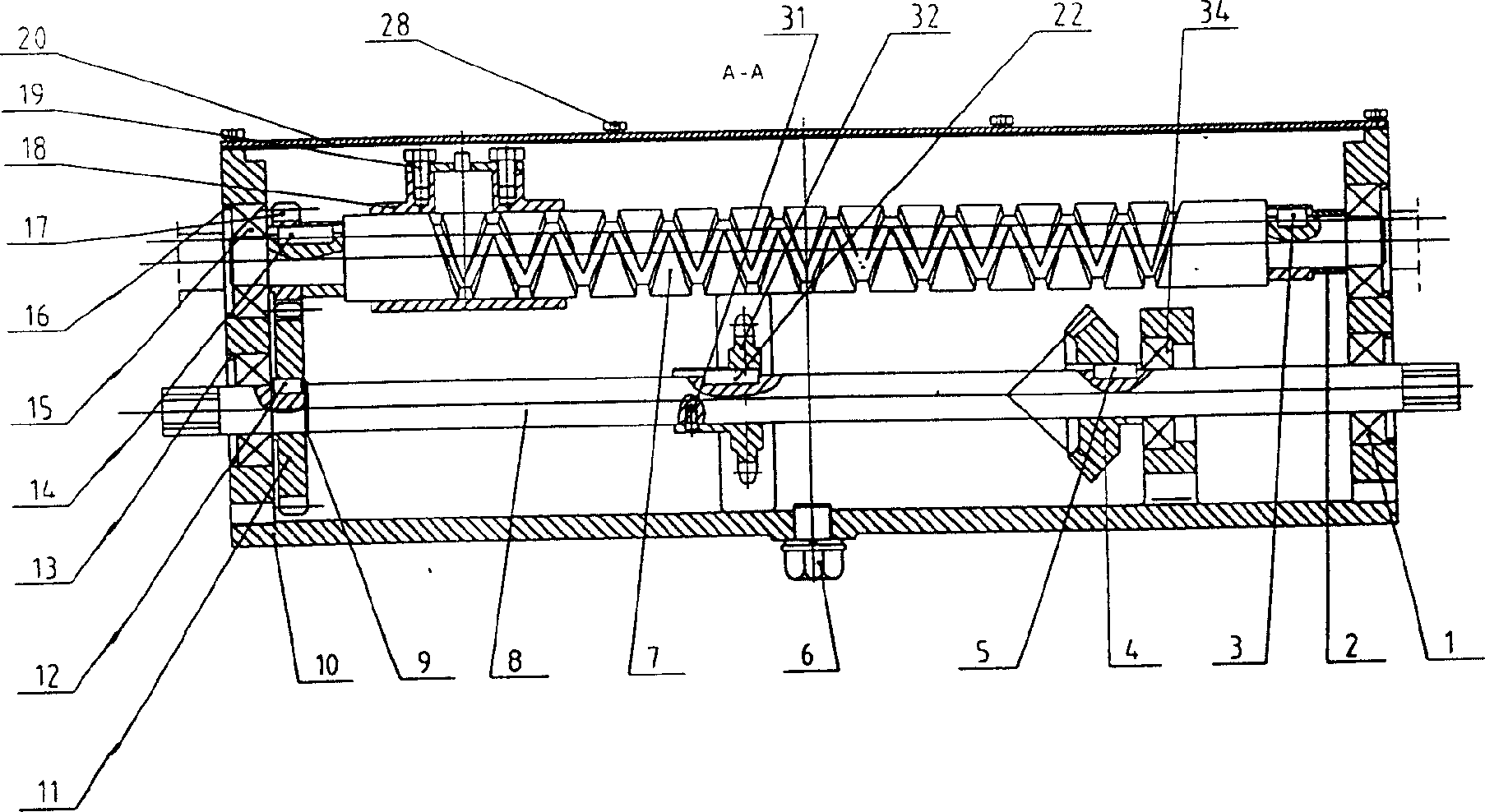

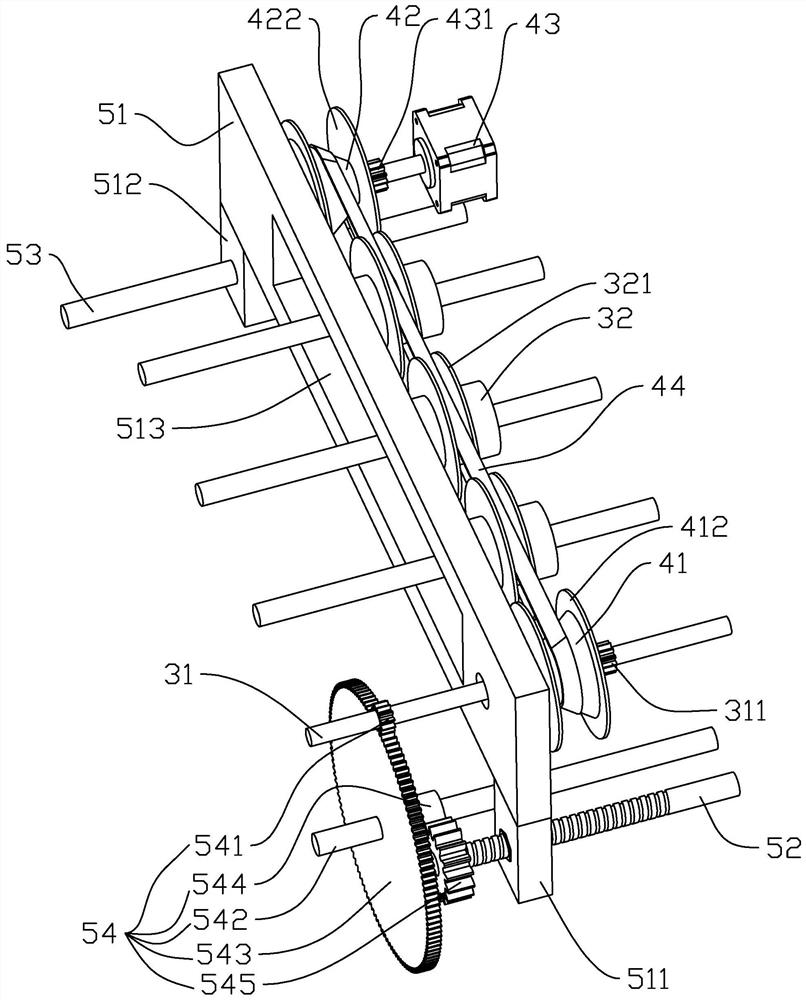

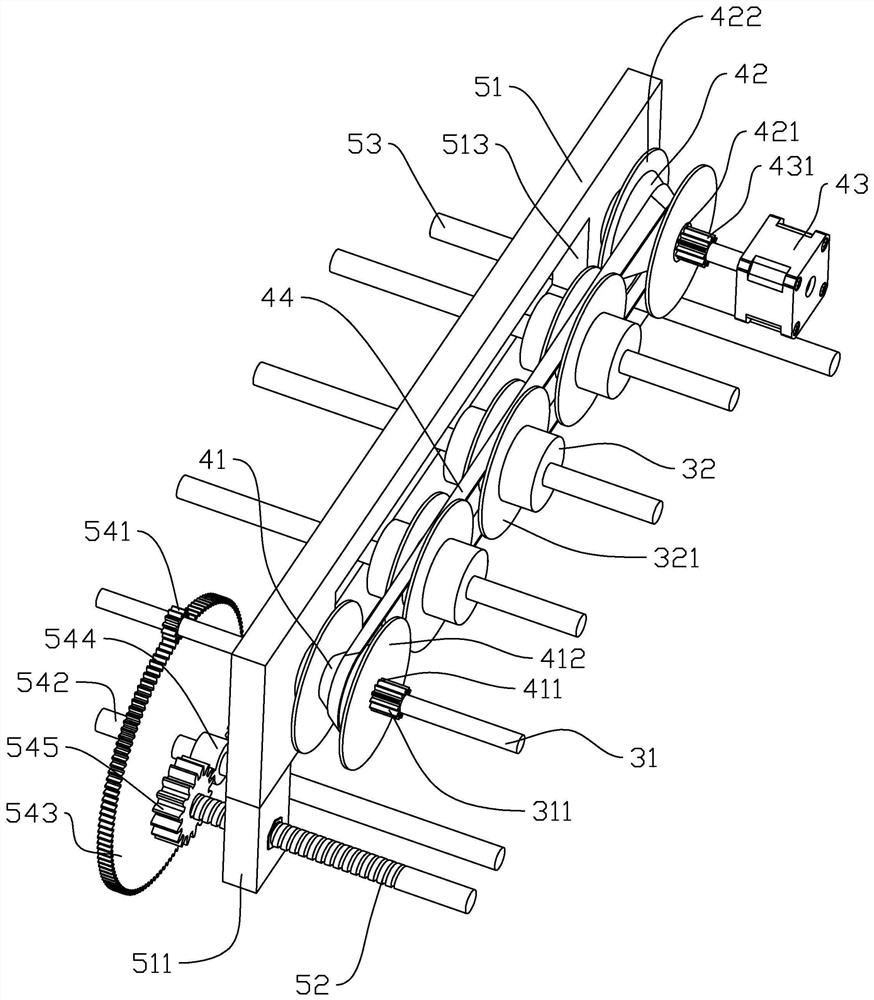

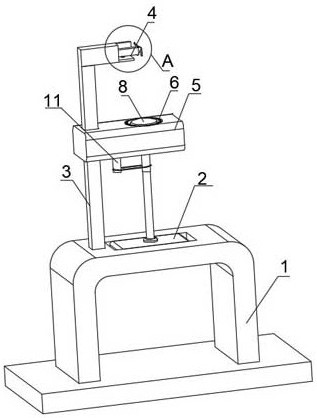

A manual wheelchair with infinitely adjustable transmission ratio

ActiveCN111658351BAdjust the transmission ratioSolve the problem of strenuous uphillWheelchairs/patient conveyanceDrive shaftManual wheelchair

The invention discloses a manual wheelchair with infinitely adjustable transmission ratio. The existing manual wheelchair climbs a slope very strenuously; the present invention comprises a chair frame, a hand wheel assembly and a continuously variable transmission. Two hand wheel assemblies are respectively arranged on both sides of the bottom of the chair frame. The hand wheel assembly includes a main wheel, a hand wheel rim, a tubular axle and a drive shaft. Tubular axles are supported at the bottom of the chair frame. The main wheels are fixed to the outer ends of the tubular axles. The driving rotating shaft is arranged coaxially with the tubular wheel shaft, and constitutes a rotating pair. The outer end of the hand wheel ring is fixed with the drive shaft. There are two continuously variable transmissions. The two continuously variable transmissions correspond to the two hand wheel assemblies respectively to realize the stepless adjustment of the transmission ratio between the drive shaft and the tubular wheel shaft. The invention separates the fixed wheels and the hand wheel rim in the prior art into mutual rotation, and adjusts the transmission ratio of the wheel and the hand wheel rim by setting a continuously variable transmission, which is convenient for users to adjust according to their own strength and current road conditions. Adjust the transmission ratio.

Owner:HANGZHOU DIANZI UNIV

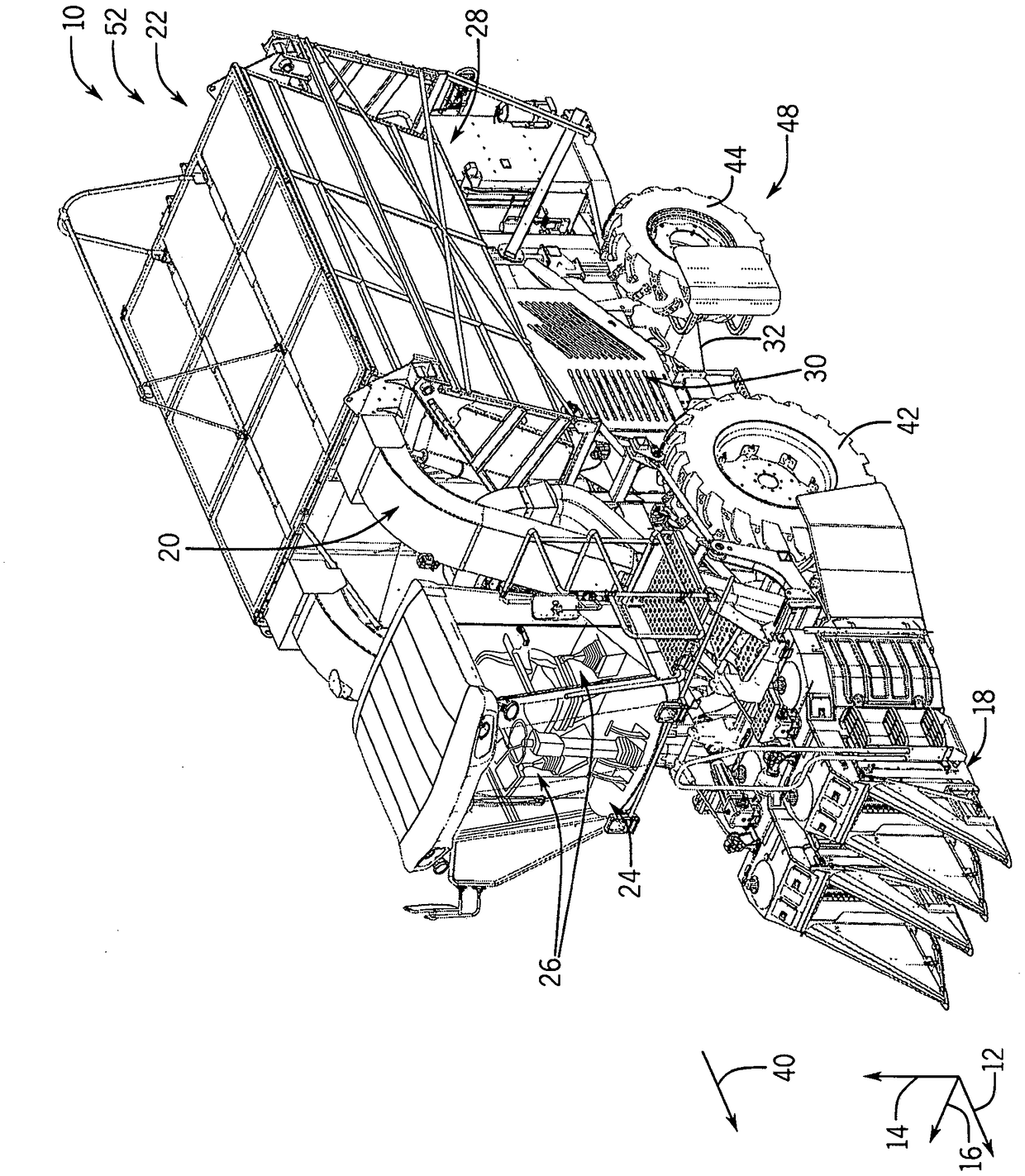

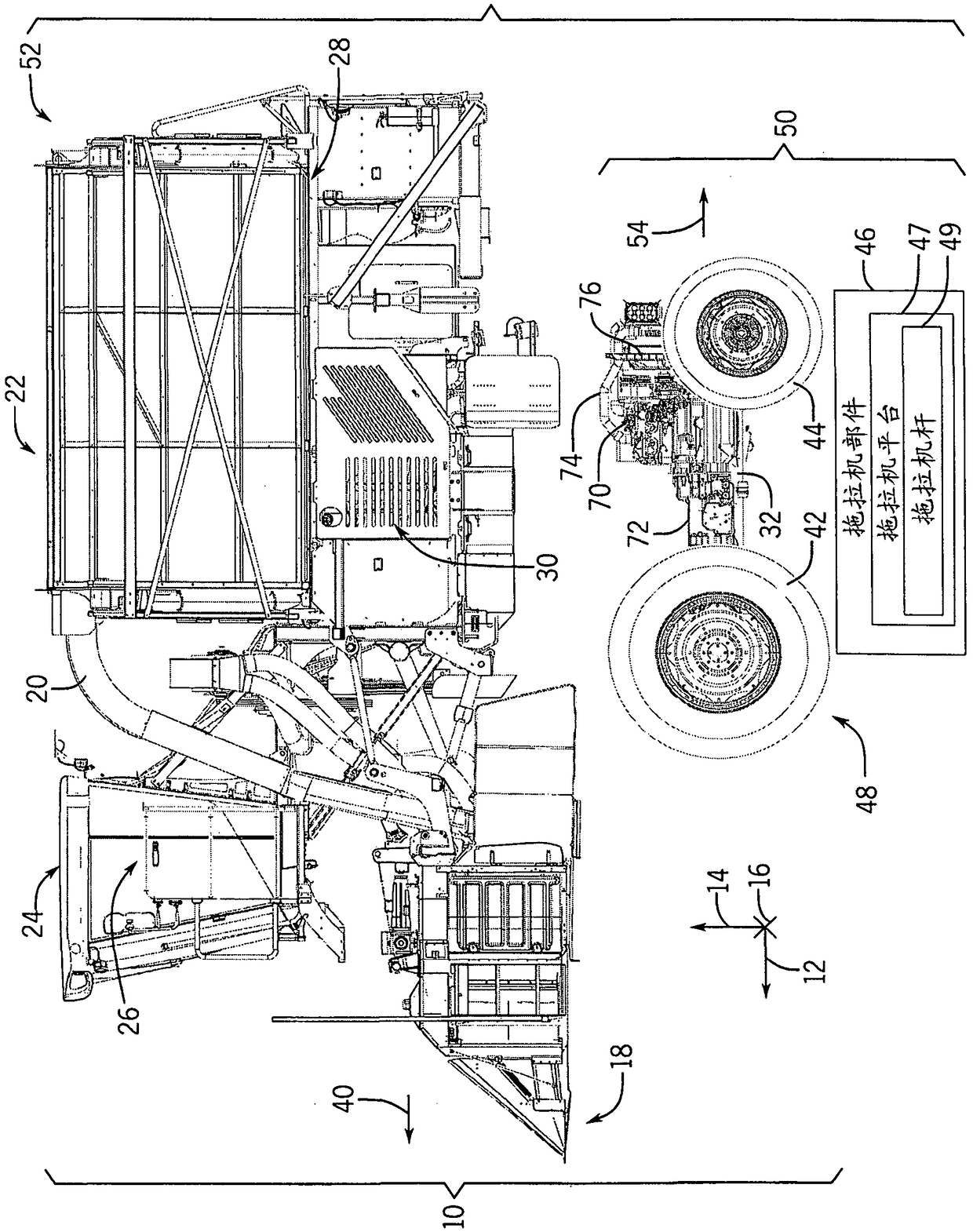

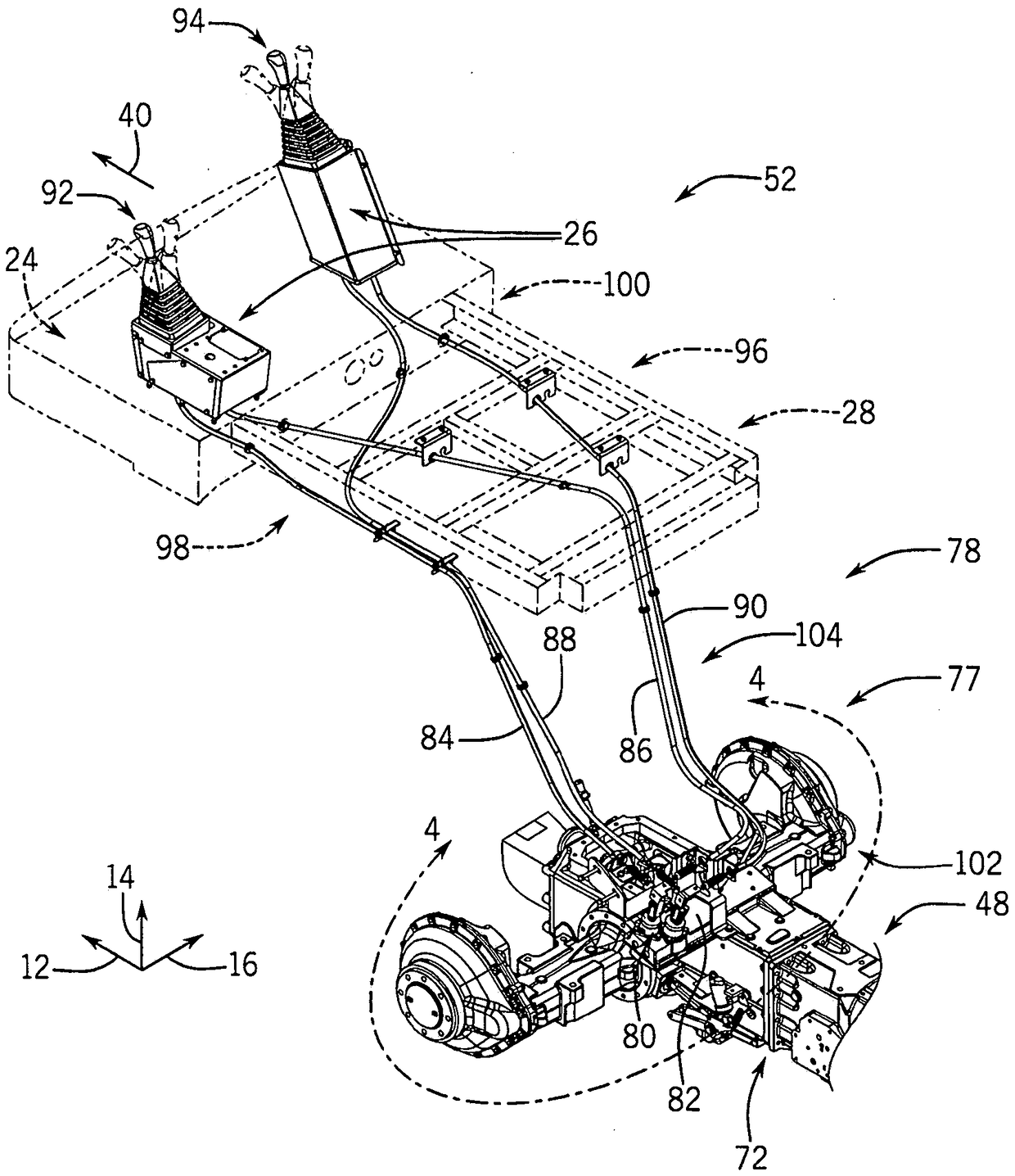

Agricultural harvester transmission systems and methods

ActiveCN109197166AAdjust the transmission ratioHarvestersGearing controlAgricultural engineeringPowertrain

The present invention relates to agricultural harvester transmission systems and methods. In one embodiment, a system includes a harvester assembly configured to be coupled to a powertrain of an agricultural vehicle to facilitate converting the agricultural vehicle into a harvester. The harvester assembly includes a platform configured to support an operator, one or more harvester rods supported on the platform, and a mounting bracket. The mounting bracket is configured to be coupled to a transmission housing of the transmission of the powertrain that supports the agricultural vehicle. A plurality of cables are configured to extend from the one or more harvester rods to one or more transmission rods extending from the transmission housing to enable the operator to adjust a transmission ratio of the transmission through the one or more harvester rods . The invention also relates to a method for converting the agricultural vehicle into a harvester.

Owner:CNH IND INDIA PVT LTD

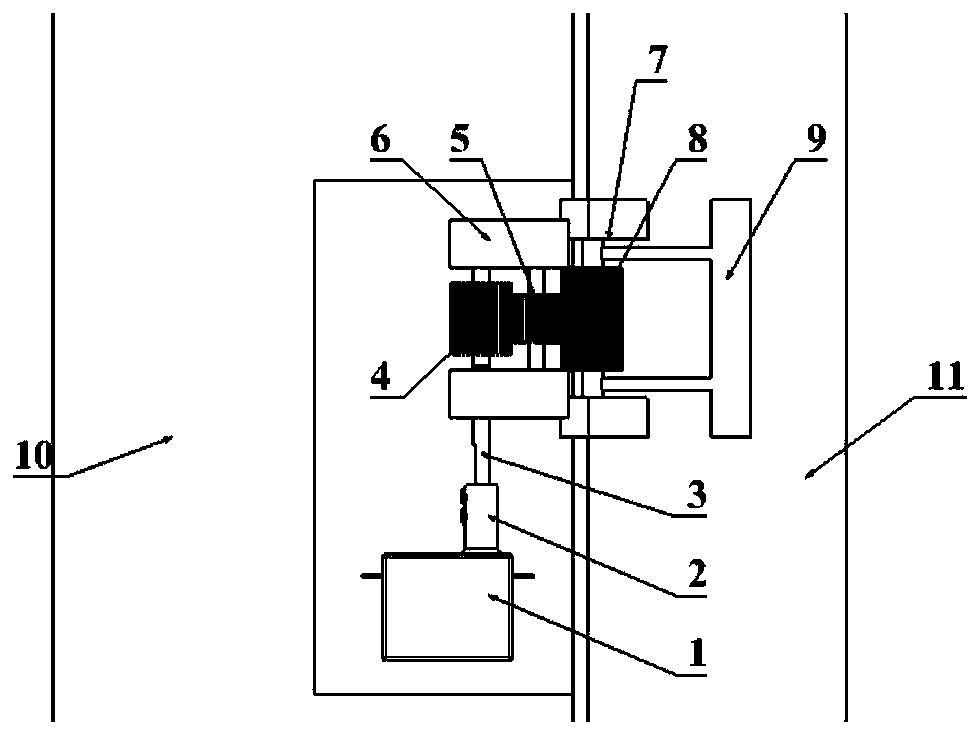

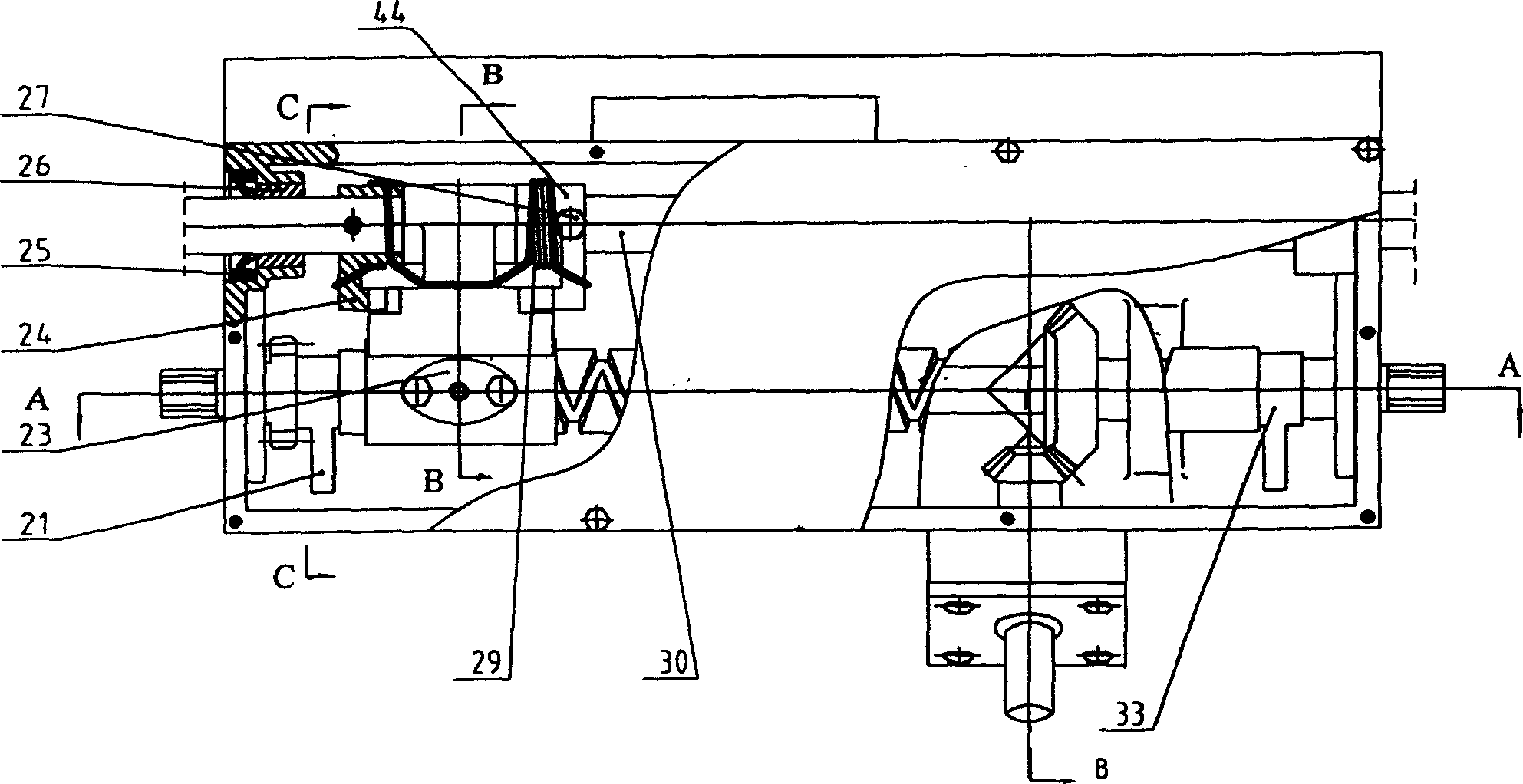

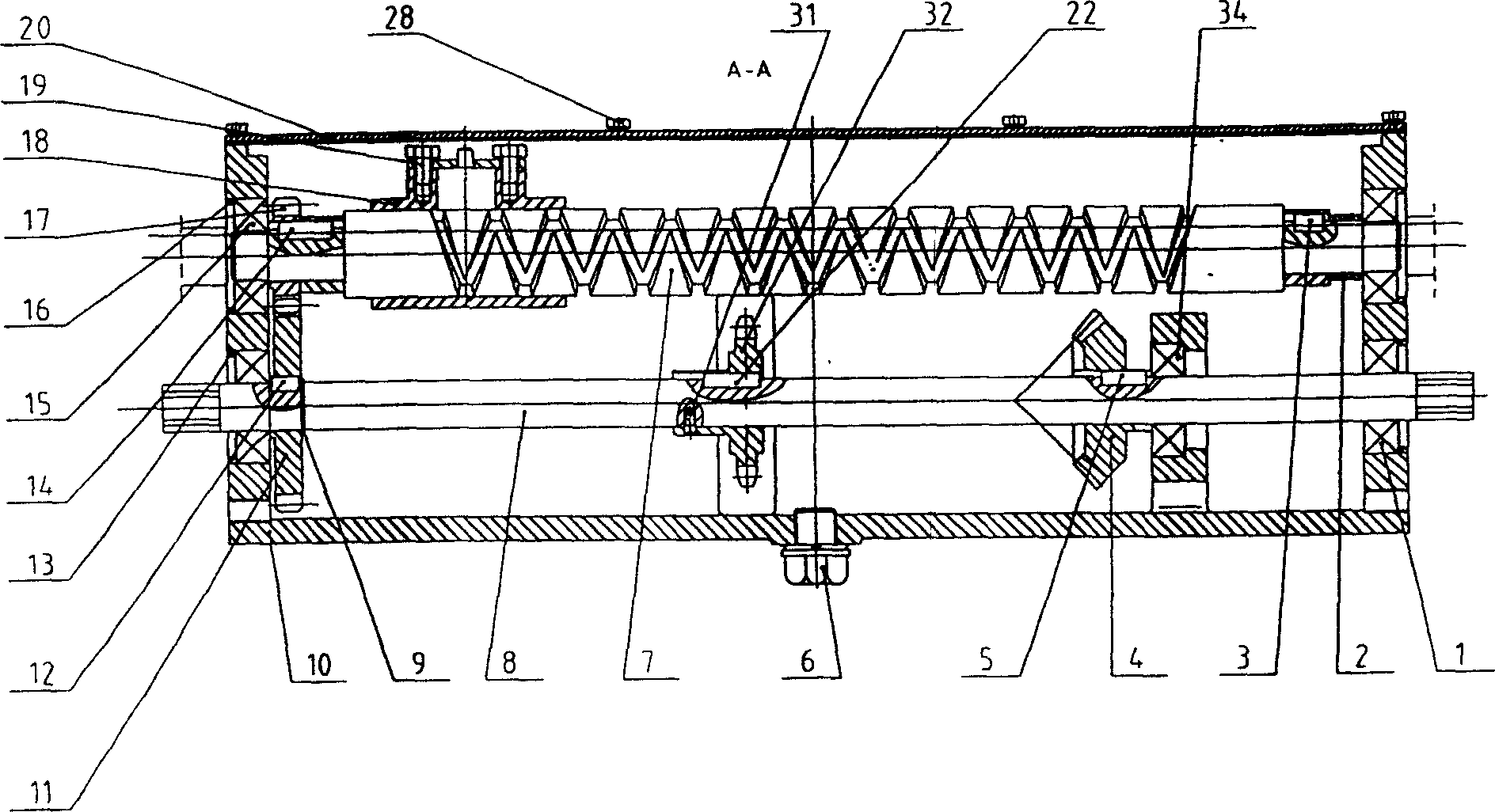

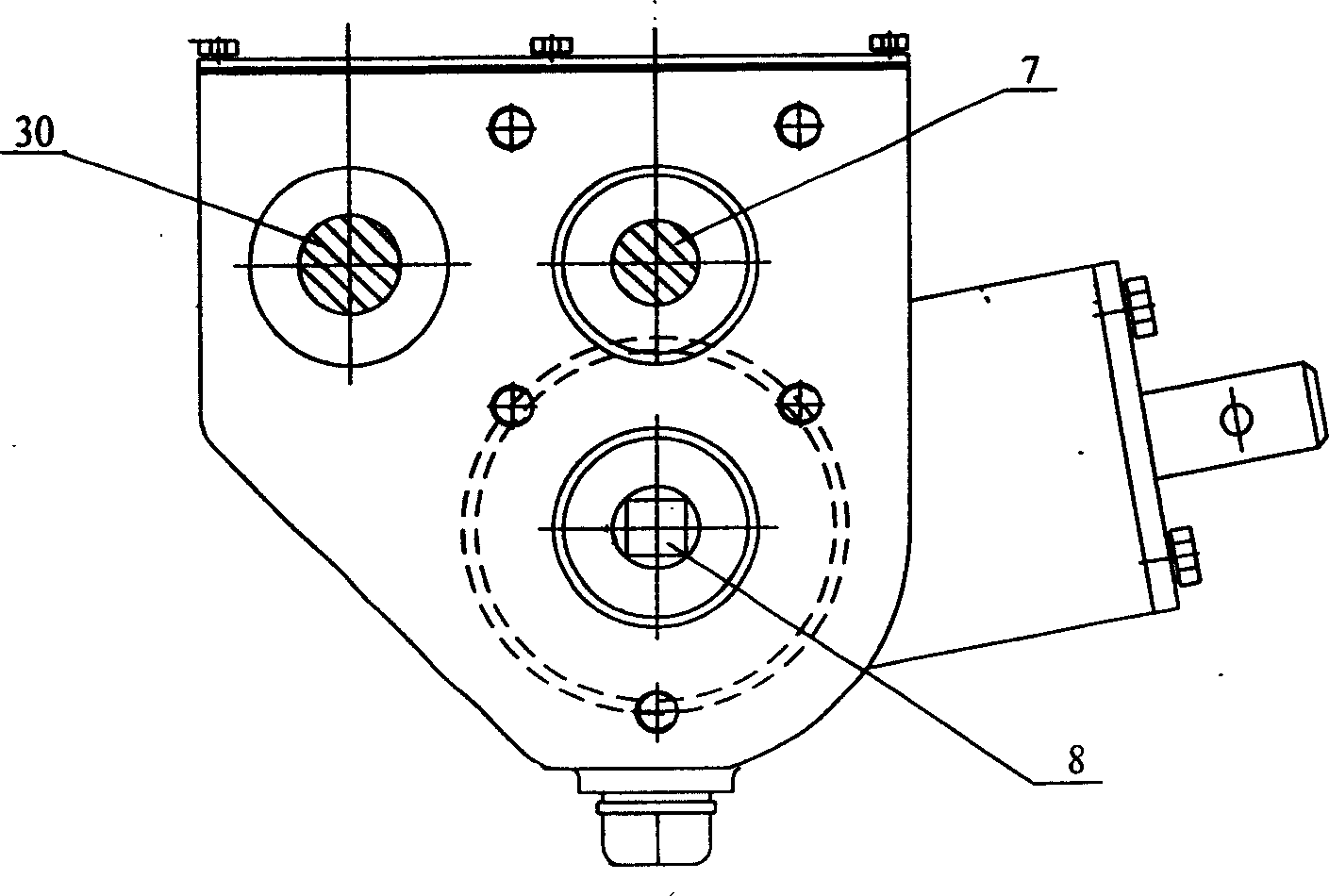

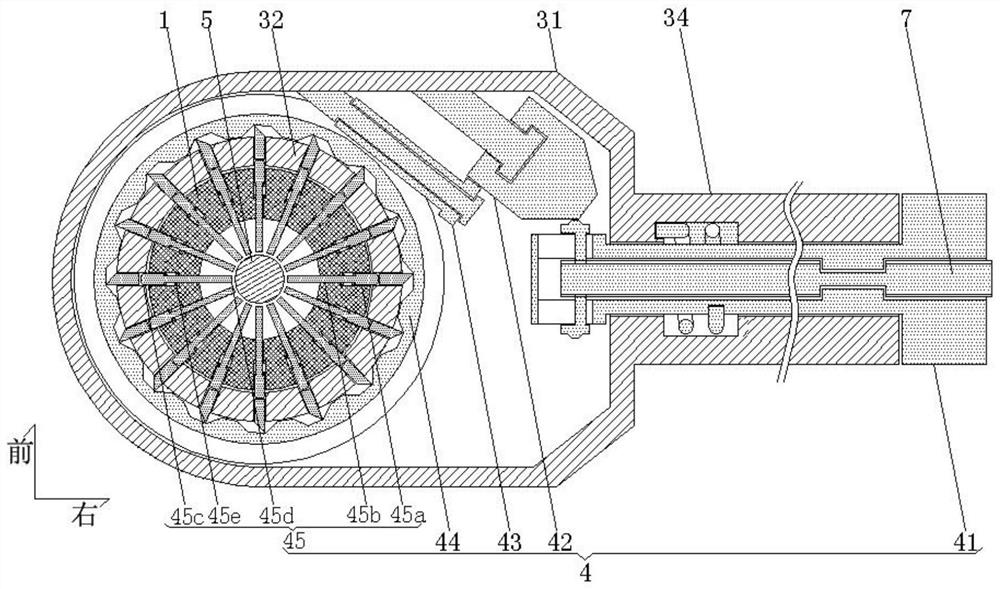

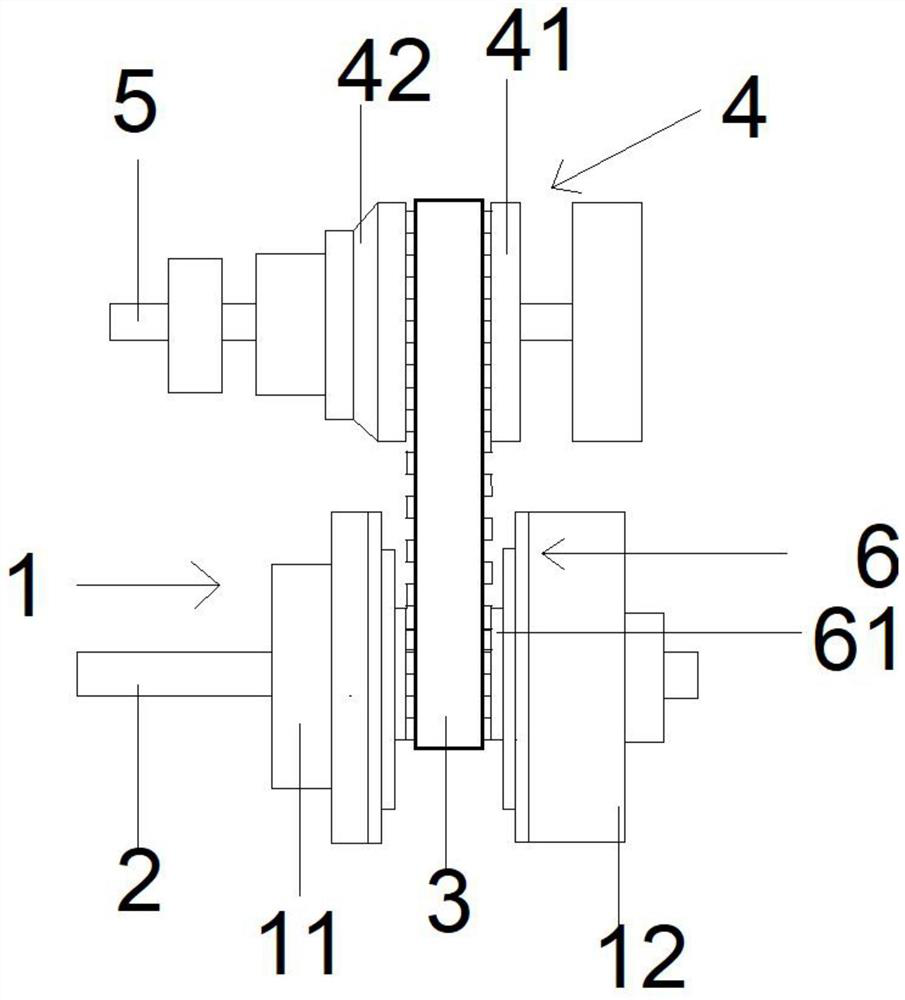

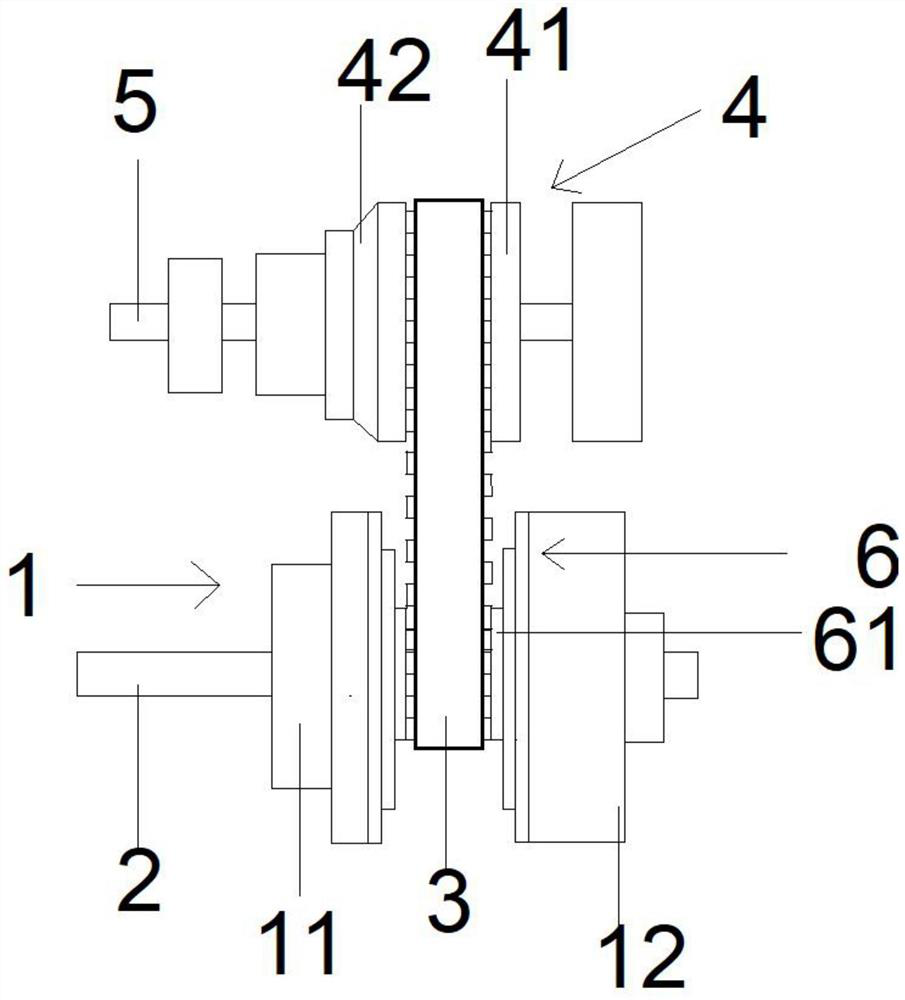

An Inerter Device with Continuously Adjustable Inertia Coefficient

InactiveCN104405826BEngagement radius adjustmentAdjust the transmission ratioGearingFlywheelsFreewheelDrive wheel

The invention provides an inertial container device with a continuously-adjustable inertia coefficient. The inertial container device comprises a driving wheel, a driven wheel, a gear, a rack / flywheel / hydraulic pump, a driving wheel hydraulic control cylinder and a driven wheel hydraulic control cylinder, wherein a V-shaped groove is formed between the movable part and the fixed part of the driving wheel; the gear is arranged on a driving shaft, and is meshed with the rack; a V-shaped groove is formed between the movable part and the fixed part of the driven wheel; the flywheel is arranged on a driven shaft; the driven wheel is driven by an elastic metal belt arranged in the two V-shaped grooves; the movable parts of the driving wheel and the driven wheel are driven by the driving wheel hydraulic control cylinder and the driven wheel hydraulic control cylinder which are connected with a hydraulic pump respectively. The engagement radius of the metal belt is adjusted through axial movement of the movable part of the driving wheel and the movable part of the driven wheel, so that the transmission ratio between the driving wheel and the driven wheel is adjusted, and continuous adjustment of the inertia coefficient is realized.

Owner:JIANGSU UNIV

Land space planning display stand with disaster influence simulation function

InactiveCN114120786AAdjust the rotation speedSpeed adjustmentEducational modelsFixed bearingGear wheel

The invention discloses a territorial space planning display stand with a disaster influence simulation function, and the display stand comprises a main supporting disc, a supporting frame, a supporting plate, a water tank, a left piston cylinder, a right piston cylinder, a water pumping pipe, a water conveying pipe, a lower connecting nozzle, a first electromagnet, a fixed bearing pedestal, a first shaft, a first bevel gear, a first gear, a rack, a sealing piston, a lower spring, a spraying part, and an adjusting part. A supporting frame is fixed to the bottom end of the main supporting disc, a supporting plate is fixed to the bottom of the supporting frame, a water tank is fixed to the bottom end of the supporting plate, and two left piston cylinders are fixed to the left portion of the top end of the supporting plate. The device has the functions of earthquake disaster influence simulation, heavy rainfall disaster simulation, fierce wind disaster simulation and the like at the same time, the moving amplitude of an auxiliary supporting disc can be controlled by controlling the length of each push rod motor extending out of a push rod, and the moving frequency of the auxiliary supporting disc can be controlled by controlling the rotating speed of a first double-shaft motor; therefore, simulation of transverse vibration of different levels of earthquakes is realized.

Owner:王飞燕

Box moving mechanism of high-speed rice transplanter

InactiveCN1250066CShorten the power transmission distanceImprove transmission efficiencyTransplantingGear wheelDrive shaft

The invention discloses a case shifting device for high speed rice transplanting machines, which includes a power-driven transmission arrangement for the sorting and sowing device mounted in the housing, a transverse arrangement and a longitudinal seedling arrangement, wherein a three-shaft design is employed for the sorting and sowing transmission shaft, the helical shaft and the case shifting shaft. The sorting and sowing transmission shaft is provided with a transmission chain wheel, the case shifting arrangement can be placed at the center of the high speed rice transplanting machine.

Owner:浙江工程学院

Shaft assembly, display module and display device

ActiveCN111246697BAchieve foldingReduce stretchCasings with display/control unitsCasings/cabinets/drawers detailsAxis of symmetryDisplay device

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

A transmission device capable of adjusting shaft center distance

ActiveCN113294497BIngenious structureEasy to operateToothed gearingsGearing controlGear wheelElectrical and Electronics engineering

The invention discloses a transmission device capable of adjusting shaft center distance, which comprises an end transmission assembly, a fixed transmission assembly and an intermediate transmission assembly, and a connecting transmission device is arranged between the intermediate transmission assembly, the end transmission assembly and the fixed transmission assembly. The invention drives the two end transmission components to slide on the casing by rotating and connecting the transmission device, and then realizes the adjustment of the center distance of the shaft. The fixed transmission component includes a half gear rod for driving the intermediate transmission component to slide on its axis. Different gear meshing forms can realize the adjustment of the transmission ratio. At the same time, the middle transmission component is equipped with a fixing device for fixing the end transmission component and the middle transmission component. The structure of the invention is ingenious, and it has multiple transmission modes while adjusting the center distance. ,Wide range of applications.

Owner:深圳市恒河新材料有限公司

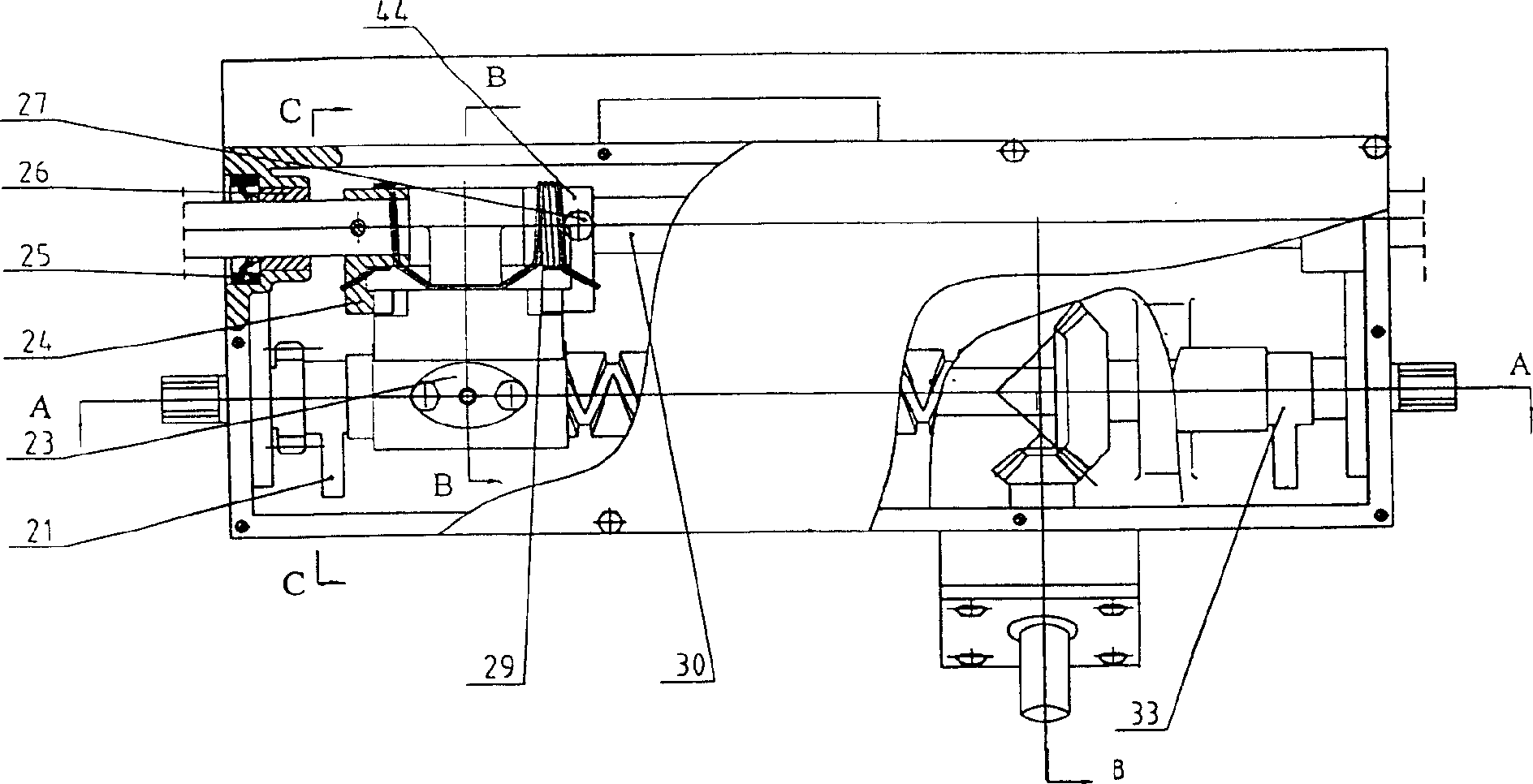

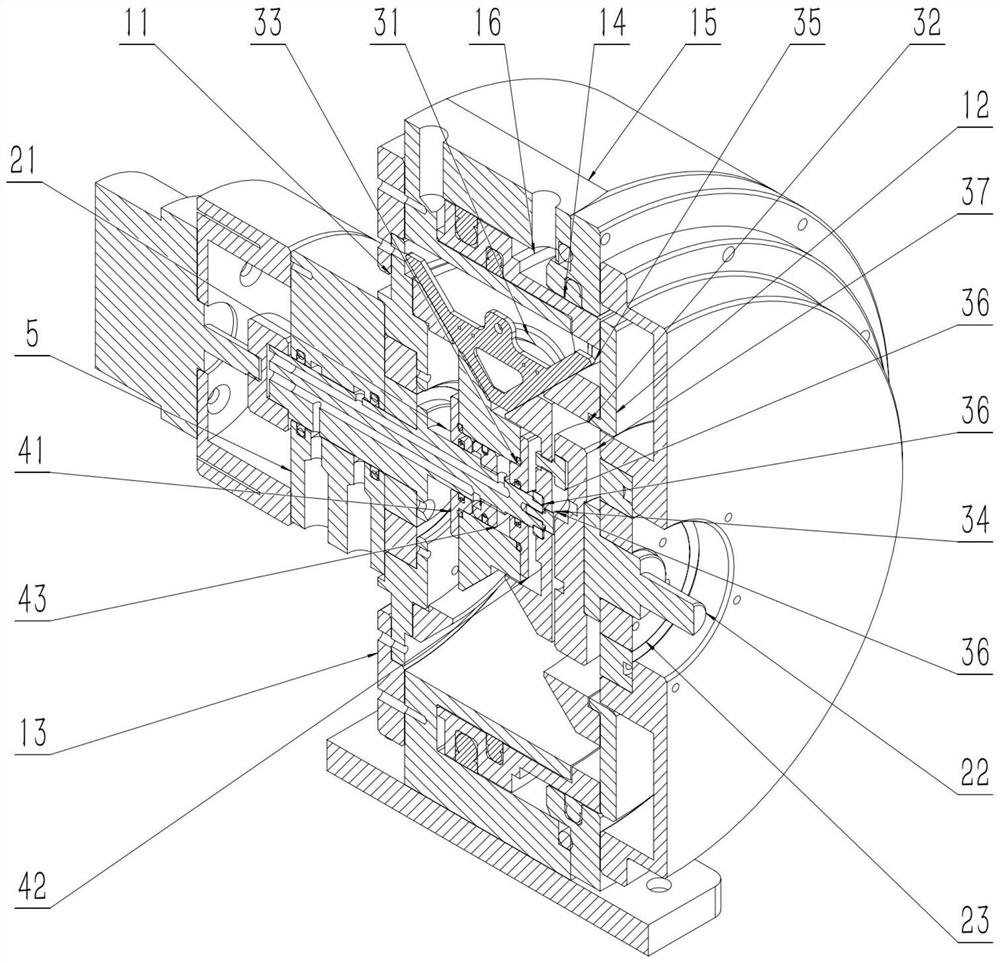

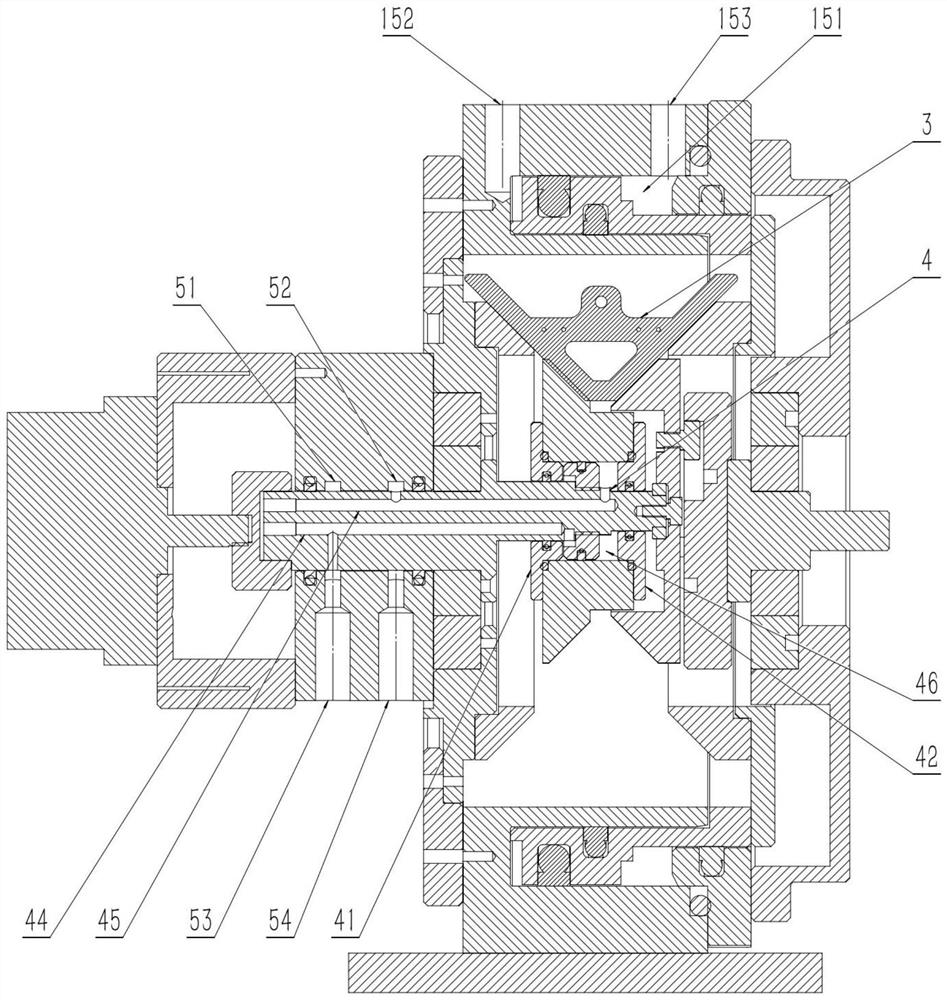

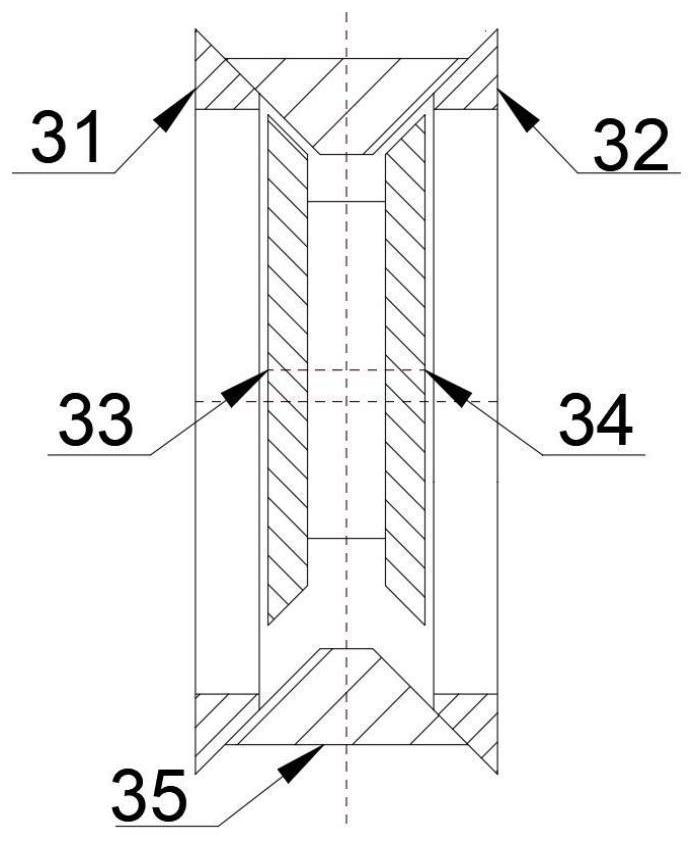

Hydraulic drive robot joint stepless speed change device

PendingCN113374834AAdjust axial spacingChange the effective working radiusToothed gearingsFluid gearingsAxial distanceControl theory

The invention discloses a hydraulic drive robot joint stepless speed change device, and relates to the technical field of speed change devices. A left end cover and a right end cover connected to two ends of an annular cylinder barrel are used as supporting structures; an eccentric input shaft and an eccentric output shaft serving as an input end and an output end are rotationally mounted respectively; and the power of the input end is transmitted to the output end after being autonomously regulated and changed by a belt drive speed change mechanism. According to the hydraulic drive robot joint stepless speed change device provided by the invention, a right sun belt wheel on a right support and a left planet belt wheel on the eccentric output shaft can move in the axial direction under hydraulic driving, so that the axial distance between a left sun belt wheel and the right sun belt wheel and the axial distance between a left planet belt wheel and a right planet belt wheel are adjusted, so that the effective working radius of the pair of sun belt wheels and the effective working radius of the pair of planet wheels are changed, and the adjustment of the transmission ratio, namely stepless speed change, is realized; the output shaft is axially limited and rotatably mounted on the right end cover, so that the axial floating of the output shaft is effectively avoided, and the power output by the stepless speed change device is more stable.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

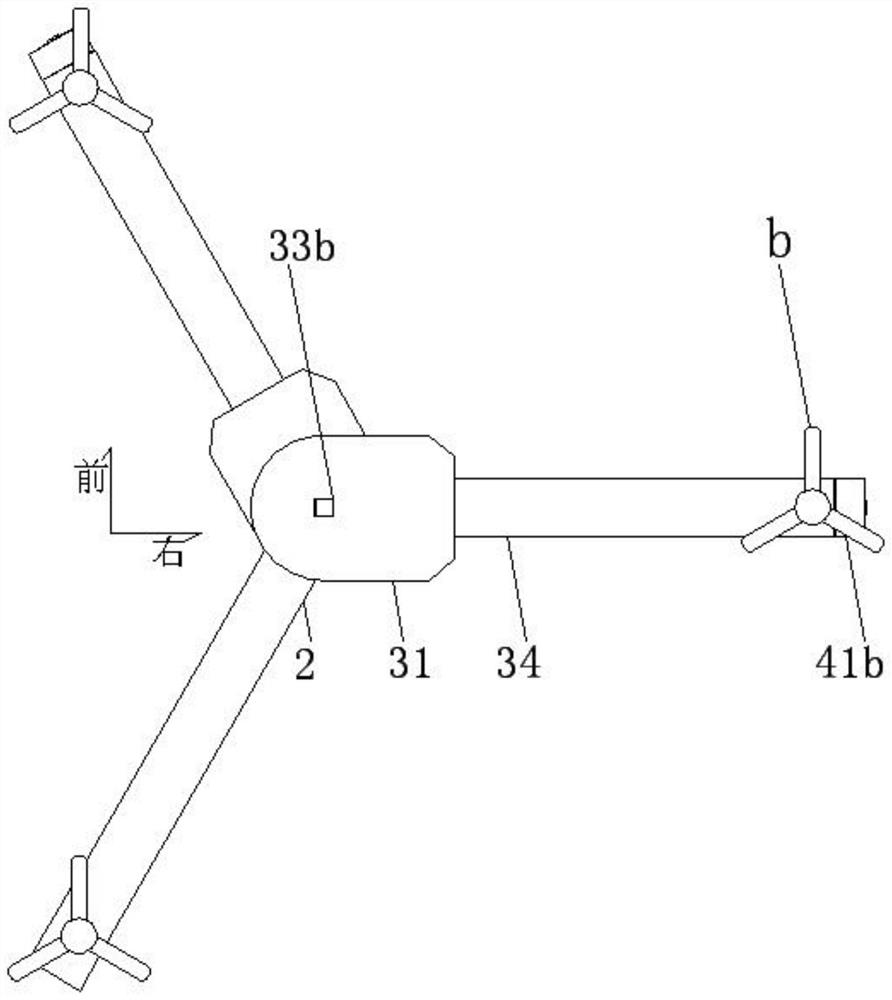

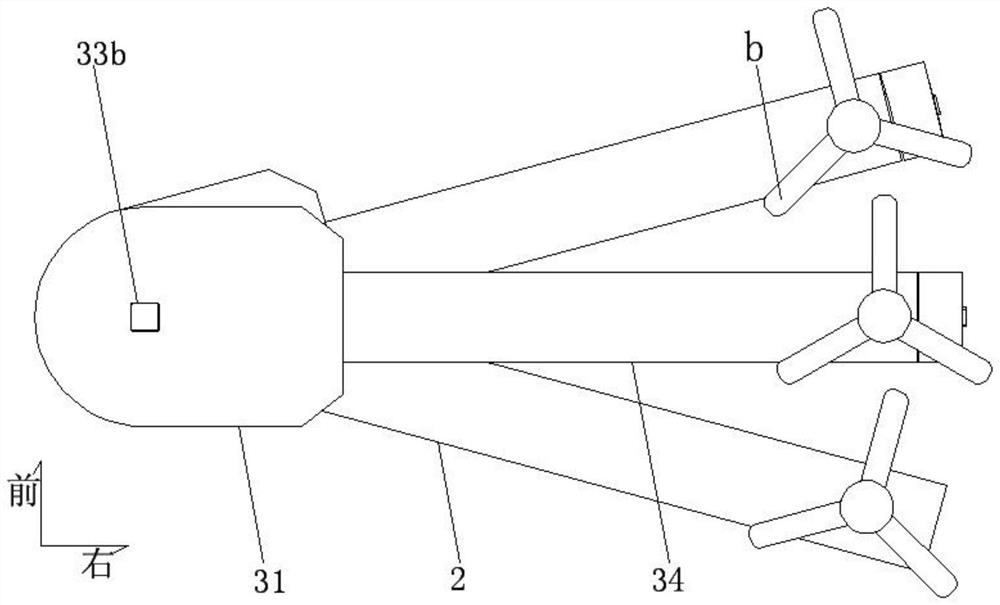

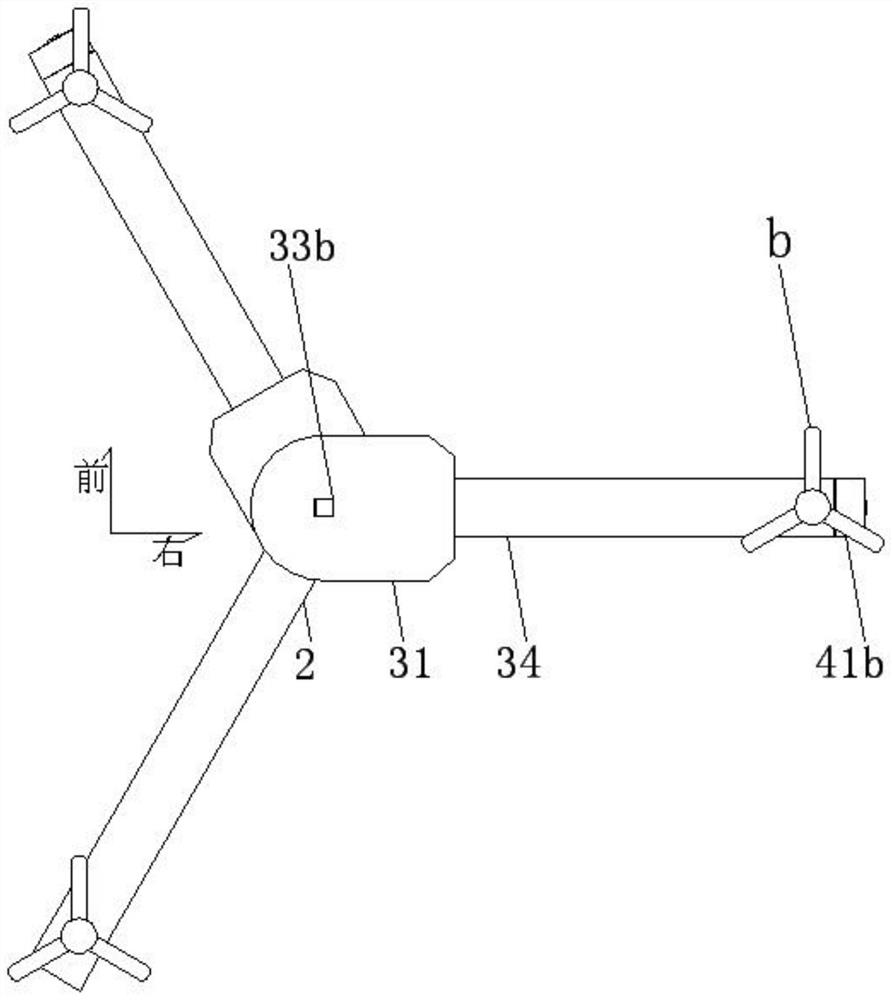

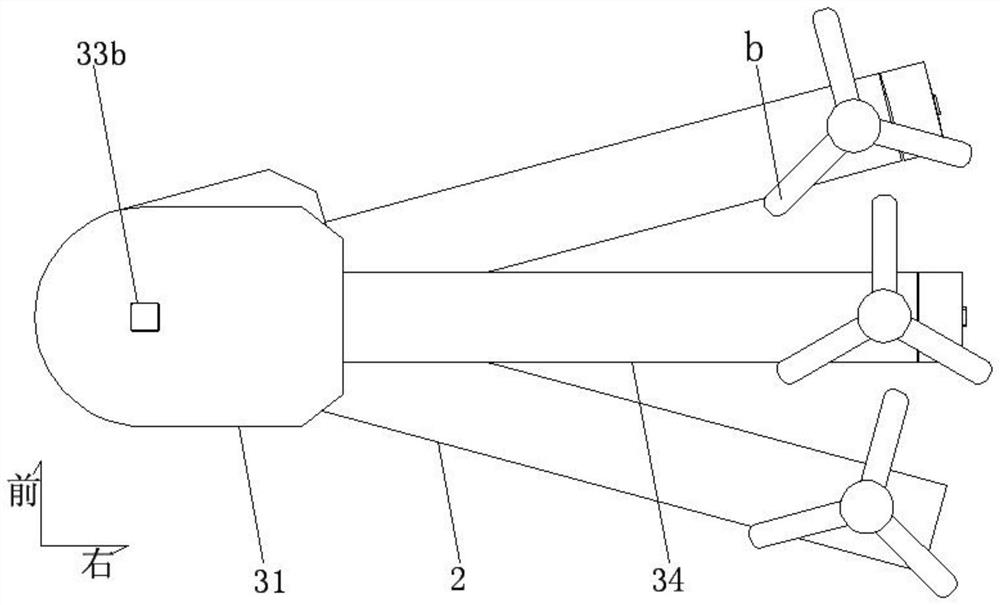

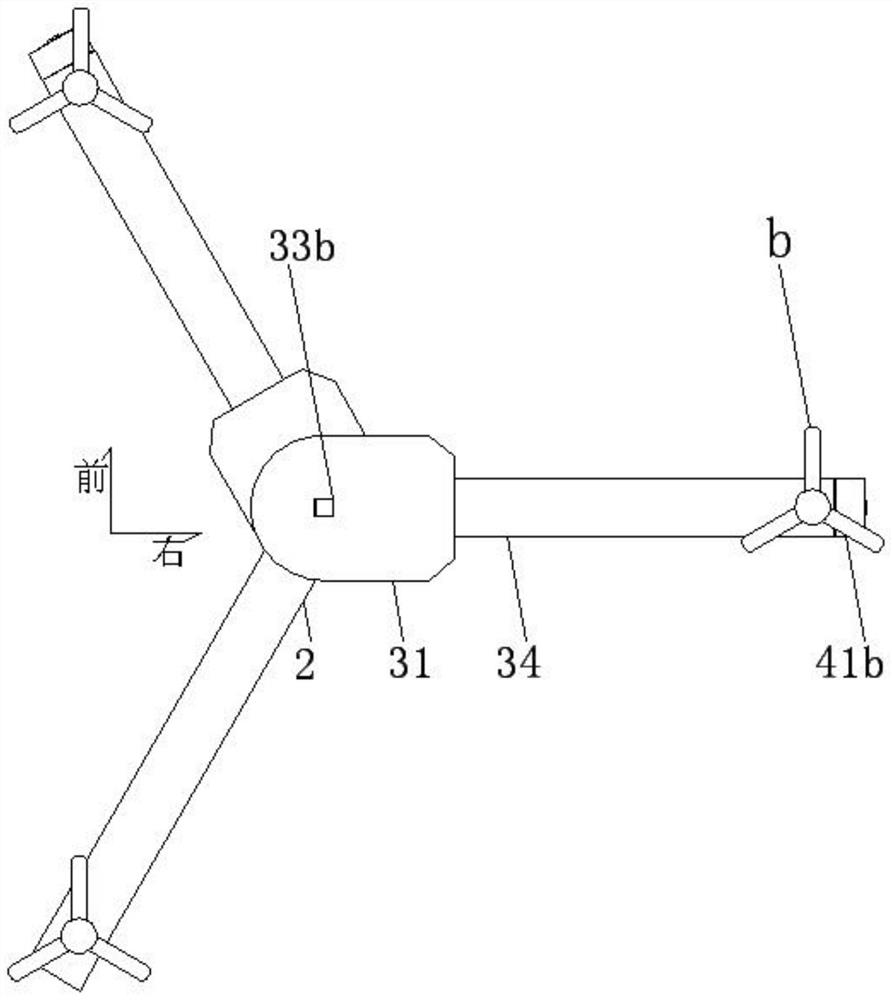

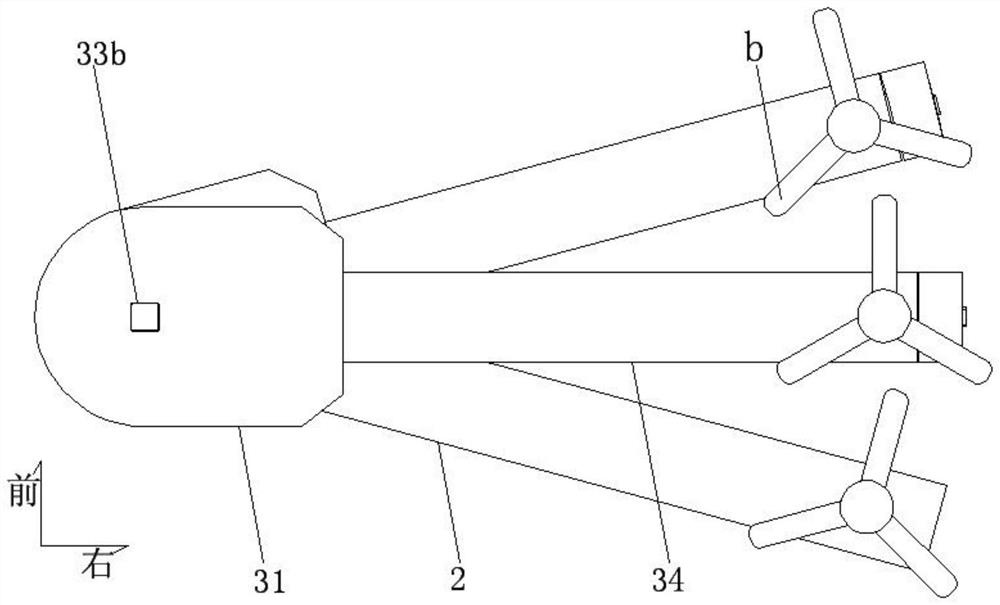

Self-locking unmanned aerial vehicle articulated arm

InactiveCN112046725ABreakthroughWith structural stabilityFuselage framesAir-flow influencersUncrewed vehiclePulley

The invention discloses a self-locking unmanned aerial vehicle articulated arm. The self-locking unmanned aerial vehicle articulated arm at least comprises a longitudinal middle shaft, a detachable side arm, movable side arms and radial lock bodies, the movable side arms comprise hollow shell-shaped middle shells, and further comprise external lantern rings, internal mandrels and side arm bodies,the radial lock bodies comprise input assemblies, cone pulley assemblies, worm assemblies, worm gear assemblies and elastic lock cylinders, and the self-locking unmanned aerial vehicle articulated armfurther comprises axial lock bodies, telescopic lock heads and adjusting assemblies.

Owner:惠民县昌诺医疗器械有限公司

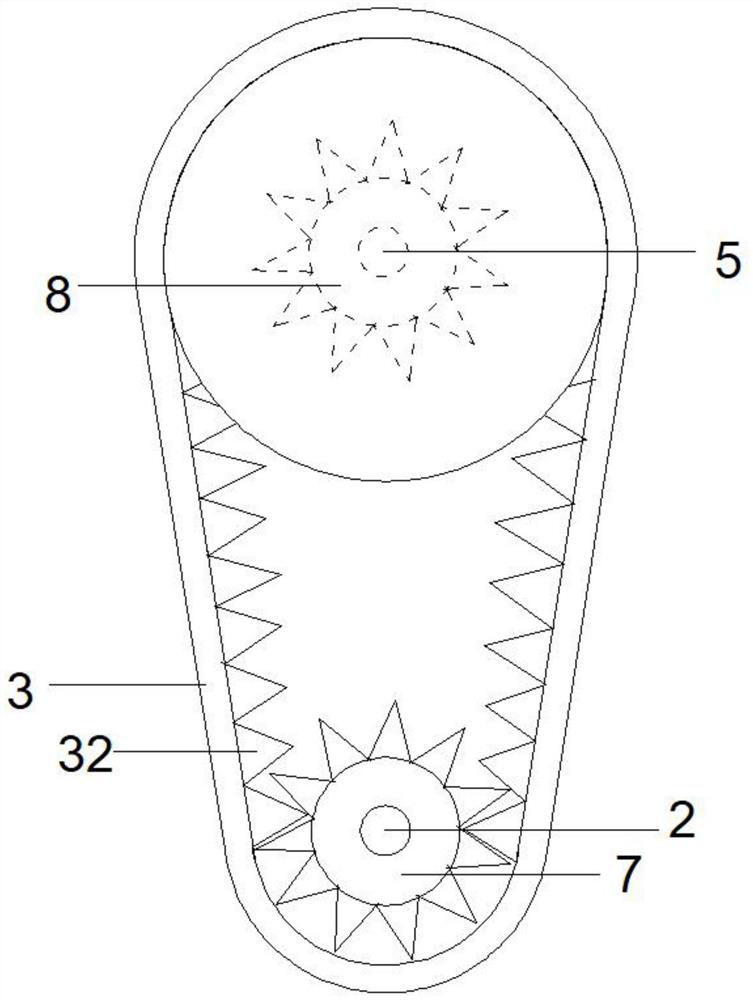

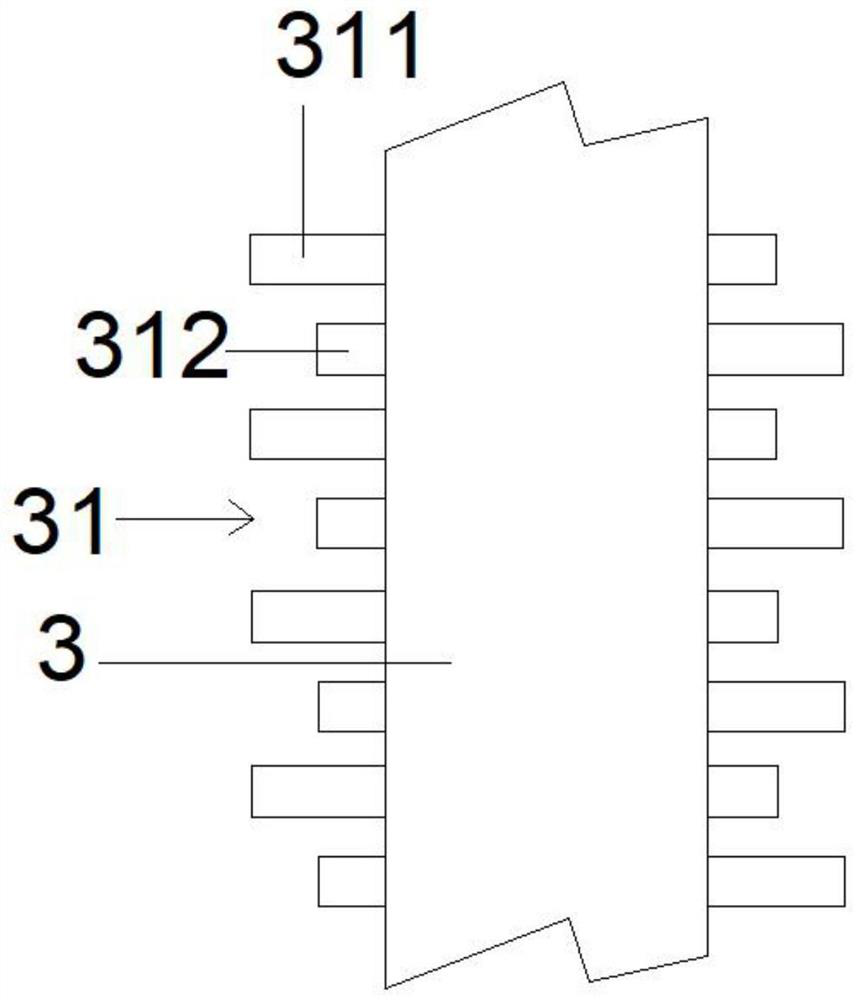

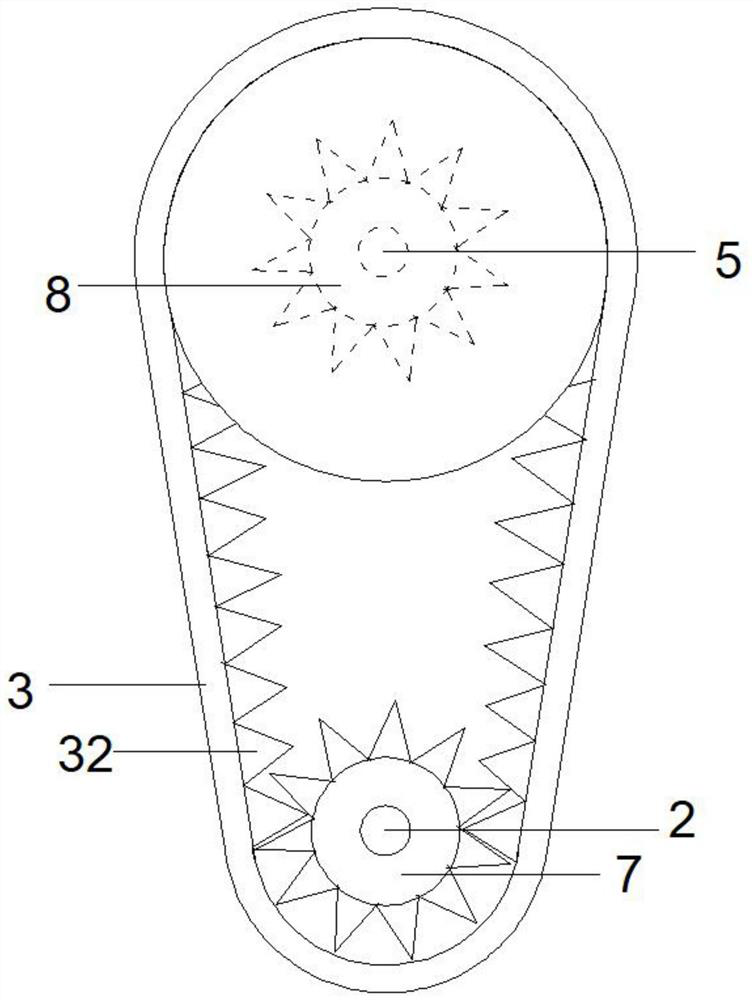

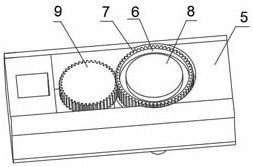

A non-slip continuously variable transmission structure

ActiveCN111963638BNot easy to slipImprove transmission efficiencyGearingGear lubrication/coolingBlock and tackleEngineering

The present invention provides a non-slip continuously variable gearbox structure, which includes a driving pulley assembly, an input shaft, a transmission chain, a driven pulley assembly and an output shaft, the driving pulley assembly is sleeved on the input shaft, and the driven pulley The assembly is sleeved on the output shaft, the transmission chain is erected between the driving pulley assembly and the driven pulley assembly, and when the driving pulley assembly rotates, the transmission chain can drive the driven pulley assembly to follow the rotation, the driving pulley assembly and the driven pulley assembly A clamping portion is provided at the joint between the movable pulley assembly and the transmission chain, and the transmission chain can be tightly installed on the driving pulley assembly and the driven pulley assembly through the clamping portion. Both sides of the transmission chain are provided with installation teeth, and the installation teeth engage with the fixed pulley at the driving end and the moving pulley at the driving end, and the cogs provided on the fixed pulley at the driven end and the moving pulley at the driven end, so that the The transmission chain is not easy to slip, and can improve the transmission efficiency of the gearbox.

Owner:华德风

Continuously-variable transmission gearbox structure difficult to slip

ActiveCN111963638ANot easy to slipImprove transmission efficiencyGearingGear lubrication/coolingControl engineeringControl theory

The invention provides a continuously-variable transmission gearbox structure difficult to slip. The continuously-variable transmission gearbox structure difficult to slip comprises a driving pulley assembly, an input shaft, a transmission chain, a driven pulley assembly and an output shaft. The driving pulley assembly is arranged on the input shaft in a sleeving way; the driven pulley assembly isarranged on the output shaft in a sleeving way; the transmission chain is erected between the driving pulley assembly and the driven pulley assembly; when the driving pulley assembly rotates, the transmission chain can drive the driven pulley assembly to follow and rotate; clamping parts are arranged on the butt-joint parts between the driving pulley assembly and the transmission chain as well asbetween the driven pulley assembly and the transmission chain; and the transmission chain can be tightly arranged on the driving pulley assembly and the driven pulley assembly through the clamping parts. Installation teeth are arranged on two sides of the transmission chain and mesh with tooth sockets arranged on a driving end fixed pulley, a driving end movable pulley, a driven end fixed pulleyand a driven end movable pulley, so that the transmission chain is not easy to slip, and the transmission efficiency of a gearbox can be improved.

Owner:华德风

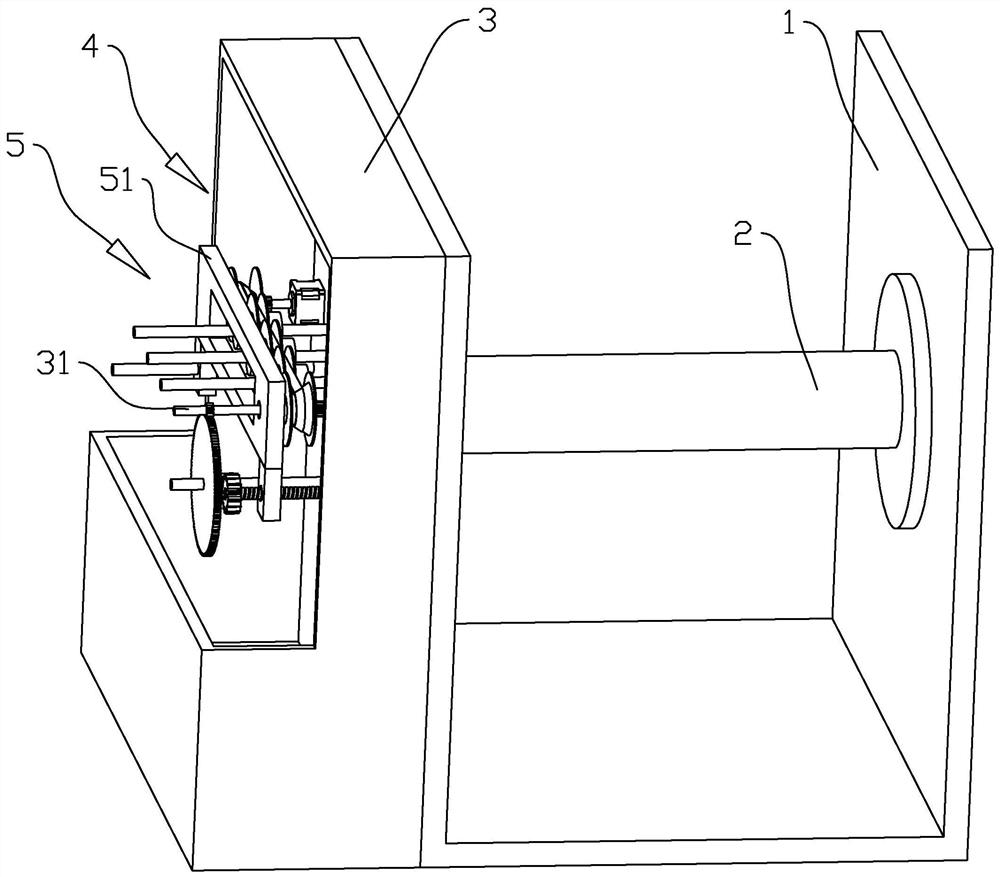

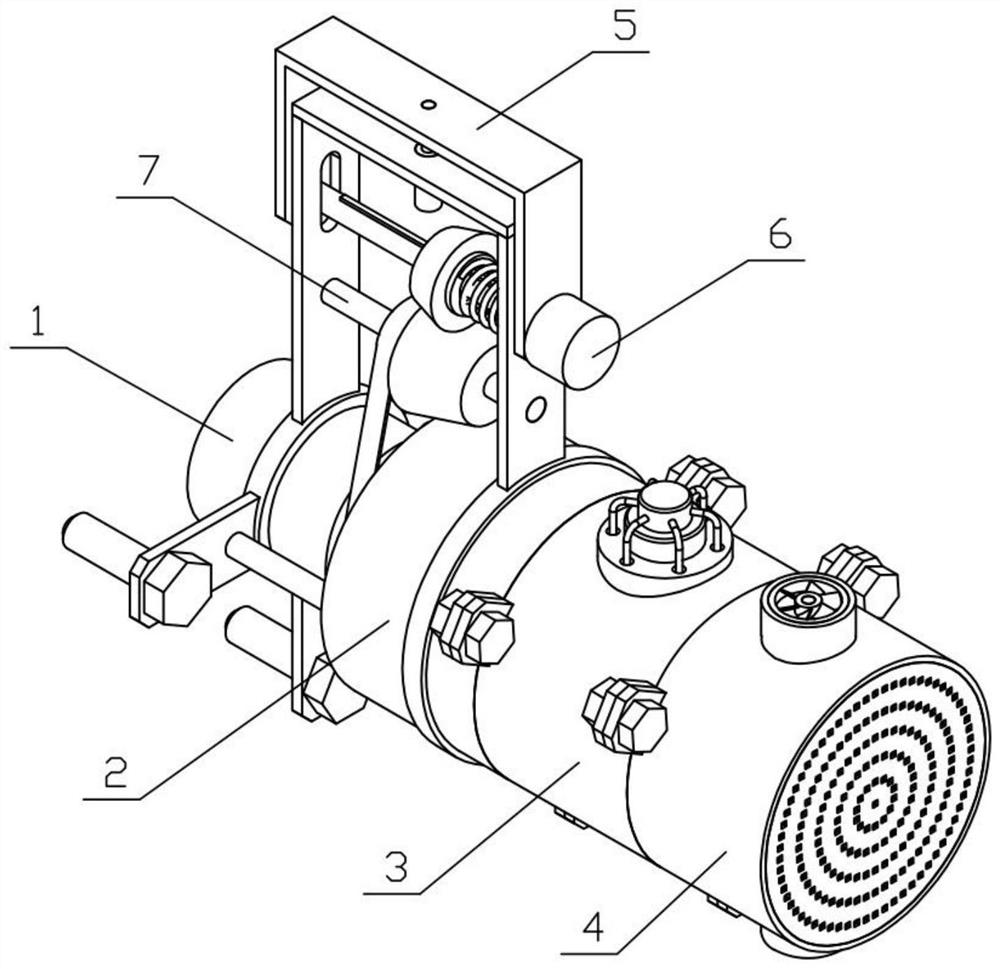

A high-efficiency cable retracting device

The present application relates to a high-efficiency cable retracting device, which includes a frame, a wire wheel rotatably installed in the frame, a drive box fixed on one side of the frame, and a drive box arranged in the drive box. A drive assembly; a drive shaft coaxial with the wire wheel and fixed is rotatably connected to the drive box; the drive assembly includes a driven wheel sleeved on the drive shaft, a drive shaft fixed in the drive box The motor, the driving wheel sleeved on the output shaft of the driving motor, and the closed transmission belt; the two ends of the transmission belt are respectively sleeved on the driving wheel and the driven wheel, and the transmission belt and the driving wheel The wheel surface of the driving wheel and the wheel surface of the driven wheel are offset; the drive box is also provided with an adjustment assembly for adjusting the transmission ratio between the driving wheel and the driven wheel according to the number of turns of the drive shaft. This application has the effect of preventing cable damage.

Owner:以太龙精密机械江苏有限公司

Angle adjusting method of self-locking unmanned aerial vehicle articulated arm

InactiveCN112046726ABreakthroughWith structural stabilityFuselage framesAir-flow influencersPulleyUncrewed vehicle

The invention discloses a self-locking unmanned aerial vehicle articulated arm. The self-locking unmanned aerial vehicle articulated arm at least comprises a longitudinal middle shaft, a detachable side arm, movable side arms and radial lock bodies, the movable side arms comprise hollow shell-shaped middle shells, external lantern rings, internal mandrels and side arm bodies, the radial lock bodies comprise input assemblies, cone pulley assemblies, worm assemblies, worm gear assemblies and elastic lock cylinders, and the self-locking unmanned aerial vehicle articulated arm further comprises axial lock bodies, telescopic lock heads and adjusting assemblies.

Owner:惠民县昌诺医疗器械有限公司

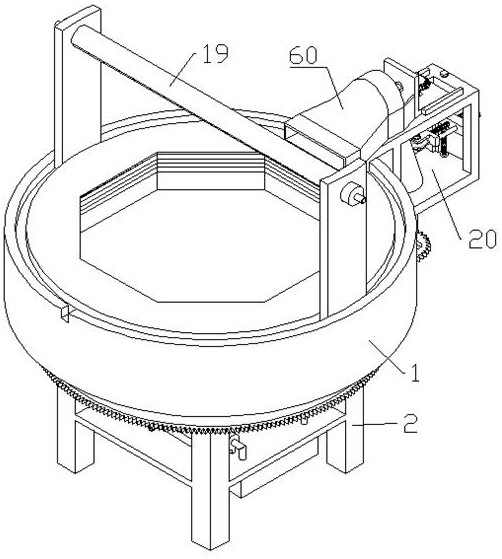

A quartz glass mound making machine

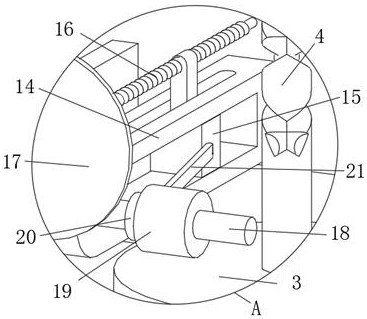

ActiveCN113429119BAdjust the transmission ratioSigns to avoid being pulledGlass shaping apparatusEngineeringSilica glass

The invention discloses a quartz glass mound making machine, which comprises a base plate, a screw lifter is arranged on the upper surface of the base plate, a swing table mechanism is arranged on the upper end of the screw lifter, and a support is fixedly connected to the upper surface of the base plate. A frame, the support frame is provided with a detection mechanism for detecting the feeding speed. In the present invention, in the process of making mounds, the detection mechanism is used to detect the change of the cutting speed, so as to control the operation of the oil pump, and the oil pump controls the flow of hydraulic oil in the pipeline, so as to cooperate with the push rod and the push ring to change a plurality of first arc-shaped plates and the distance between the second arc-shaped plate, so as to realize the adjustment of the transmission ratio between the screw rod and the round tube, to achieve the purpose of adjusting the rotation speed of the turntable, and to avoid the appearance of glass being pulled on the appearance of the molten mound, so that the crystal grains slide along the stress direction, It is not obvious that it is pulled out and the structure of the fused mound is uneven.

Owner:海门裕隆光电科技有限公司

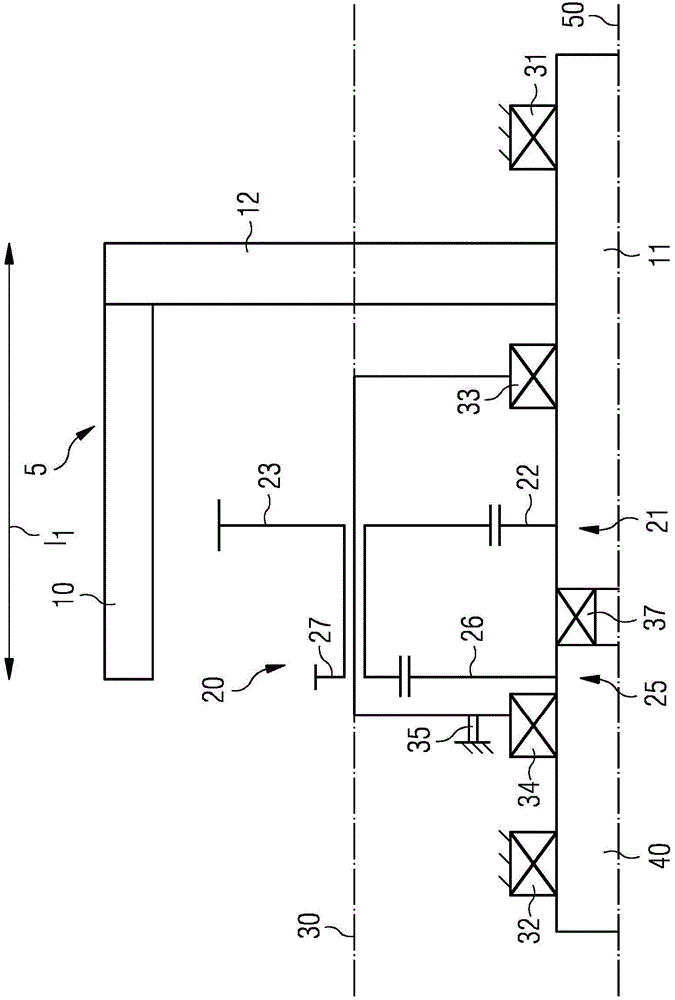

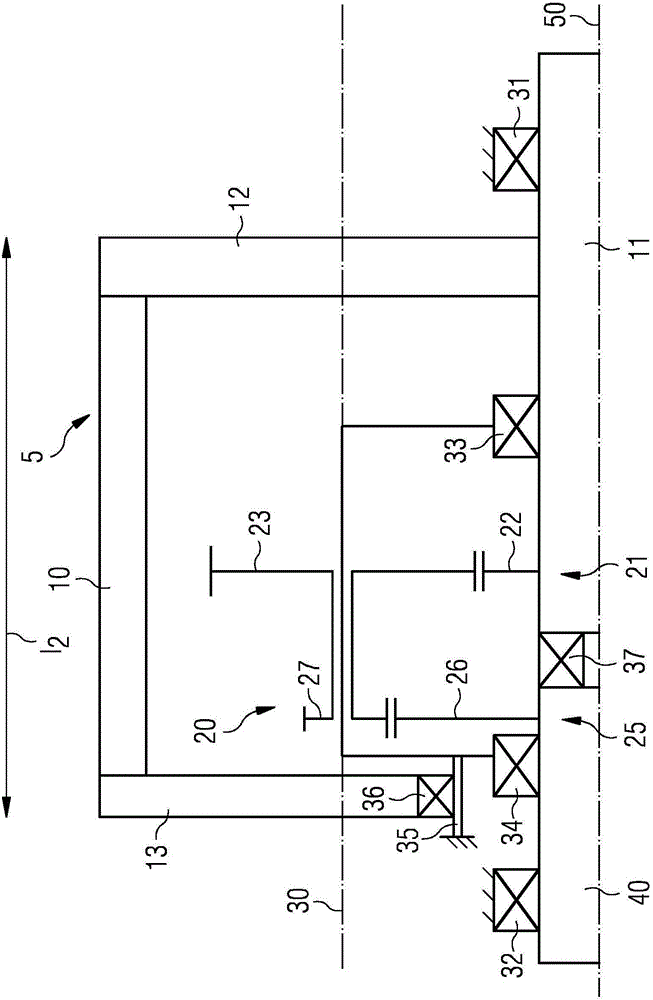

Drive device having an electrical drive machine

InactiveCN103958239ASmall sizeOmit shellElectric propulsion mountingToothed gearingsElectricityEngineering

The invention describes a drive device, in particular for a vehicle, having an electrical drive machine (5), which is coupled to a drive axle by means of a gear arrangement (20). The gear arrangement (20), comprising a gear mechanism and / or a differential, is integrated within the rotor (10) of the electrical drive machine (5).

Owner:SIEMENS AG

Pre-adjusting method of self-locking type unmanned aerial vehicle hinged arm

InactiveCN112046727ABreakthroughWith structural stabilityFuselage framesAir-flow influencersUncrewed vehiclePulley

The invention discloses a self-locking type unmanned aerial vehicle hinged arm which at least comprises a longitudinal middle shaft, a detachable side arm, movable side arms and a radial lock body. Each hinged side arm comprises a hollow shell-shaped middle shell, and further comprises an external lantern ring, an internal mandrel and a side arm body. The radial lock body comprises an input assembly, a cone pulley assembly, a worm assembly, a worm gear assembly and an elastic lock cylinder. The self-locking type unmanned aerial vehicle hinged arm further comprises an axial lock body, a telescopic lock head and an adjusting assembly.

Owner:惠民县昌诺医疗器械有限公司

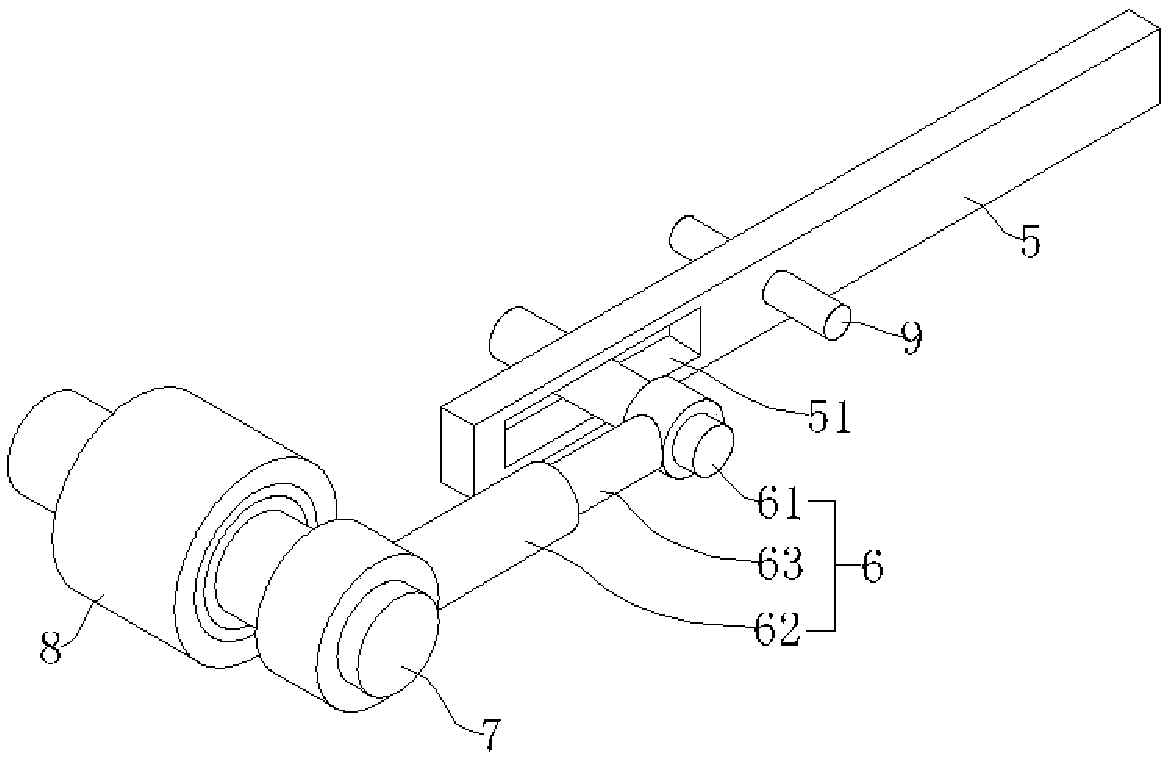

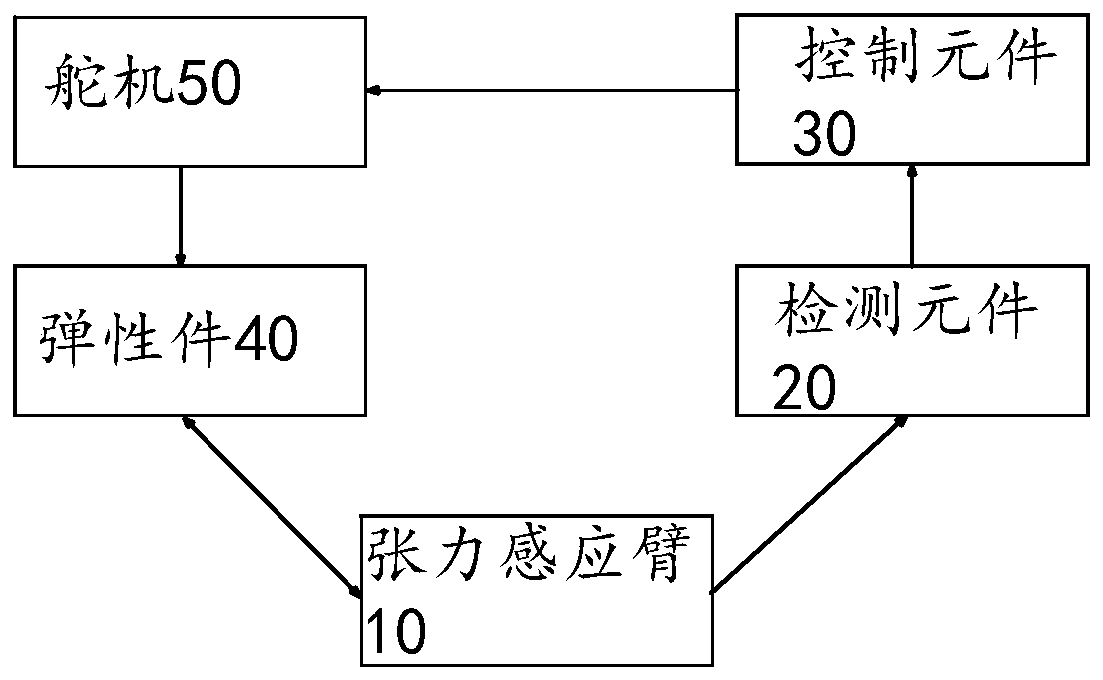

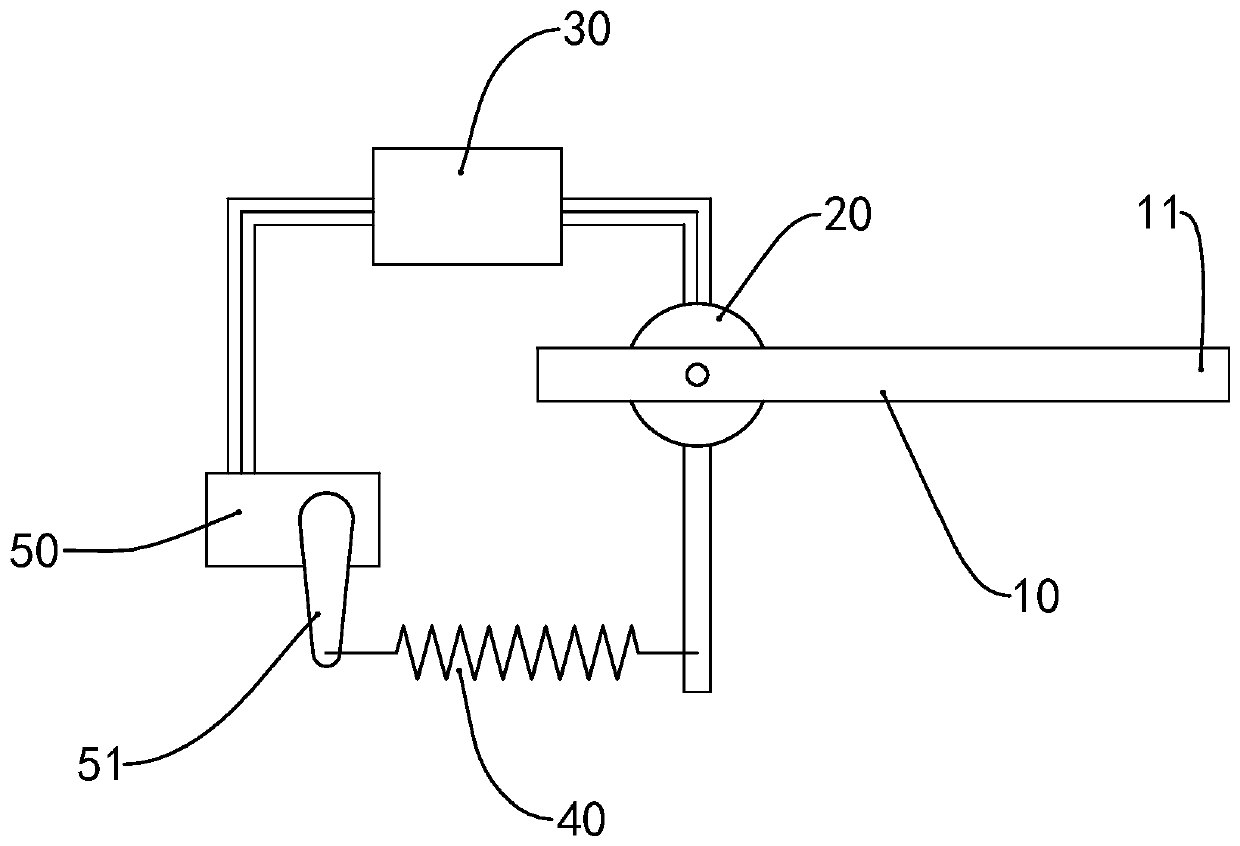

Tension adjustment device and winch device for mooring unmanned aerial vehicle and tension adjustment method

PendingCN110001997AIncrease stretch lengthReduce stretch lengthWinding mechanismsFor captive aircraftsControl signalEngineering

The invention relates to a tension adjustment device and winch device for mooring an unmanned aerial vehicle and a tension adjustment method. The tension adjustment device comprises a tension induction arm, a detection element, a control element and an elastic part; the detection element is connected with the tension induction arm and outputs detection signals according to rotation of the tensioninduction arm; the control element receives the detection signals and outputs control signals according to the detection signals; the tension induction arm is connected to a first end of the elastic part; the tension adjustment device for the mooring unmanned aerial vehicle further comprises a steering engine; the steering engine comprises a swing arm, and the swing arm is connected with a secondend of the elastic part; the steering engine receives the control signals and drives the swing arm to swing according to the control signals; when the tension induction arm rotates in the direction ofstretching the elastic part, and the swing arm sings in the direction of shrinking the elastic part; and when the tension induction arm rotates in the direction of shrinking the elastic part, and theswing arm swings in the direction of stretching the elastic part. According to the tension adjustment device, the load of the unmanned aerial vehicle when rising is reduced, and taking up of the unmanned aerial vehicle is facilitated when falling.

Owner:SANGAIR TECH

An intelligent fresh air system

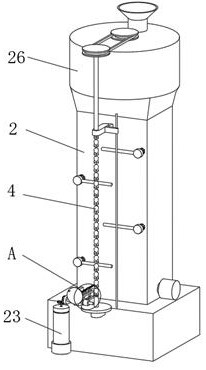

ActiveCN111256270BAdjustable speedThe adjustment mechanism can adjust the speedMechanical apparatusLighting and heating apparatusThermodynamicsWind system

The present invention relates to a fresh air system, more specifically an intelligent fresh air system, which includes a mounting bracket, a purification mechanism I, a purification mechanism II, an air outlet mechanism, an adjustment mechanism, a power mechanism, a transmission mechanism and an air inlet mechanism. Drive the transmission mechanism to rotate, and the transmission mechanism drives the air intake mechanism to rotate. When the air intake mechanism rotates, the outdoor air is sucked into the purification mechanism Ⅰ, and the air enters the purification mechanism Ⅱ through the purification mechanism Ⅰ to complete the first filtration, and the air passes through the purification mechanism Ⅱ enters the air outlet mechanism to complete the second filtration, the air enters the air outlet mechanism and is mixed with indoor air for a certain amount of heat exchange and discharged into the room, the adjustment mechanism can be activated to adjust the transmission ratio between the power mechanism and the transmission mechanism, and then adjust The rotation speed of the air intake mechanism adjusts the speed of the air intake.

Owner:SHANDONG TONGCHUANG COMPOUND MATERIAL CO LTD

Condiment raw material drying device with good drying effect

InactiveCN112361788AAdjustment timeAvoid drying effect reductionDrying gas arrangementsDrying chambers/containersElectric machineryEngineering

The invention discloses a condiment raw material drying device with a good drying effect and relates to the field of the condiments. The device comprises a base, wherein a drying box body is fixedly mounted on the top side of the base, a transitional box body is fixedly mounted on the top side of the drying box body, a scattering box is fixedly mounted on the top side of the transitional box body,and the transitional box body communicates with the scattering box and the drying box body. According to the invention, the motor rotates to drive a convex shaft to rotate by a bevel gear, the convexshaft rotates to drive a transmission roller to rotate, the transmission roller rotates to drive a transmission plate to rotate, the transmission plate rotates to drive a reciprocating lead screw torotate, the reciprocating lead screw rotates to drive a moving block to move, the moving block moves to be in contact with a rotating rod to drive the rotating rod to rotate to further drive a screenplate to rotate, so that condiment raw materials can be transferred to each screen plate layer by layer. Therefore, the contact time and area between the condiment raw materials and hot air can be improved, and the condiment raw material drying device is high in drying speed and uniform to dry and good in drying effect.

Owner:含山县全味调味品制造有限公司

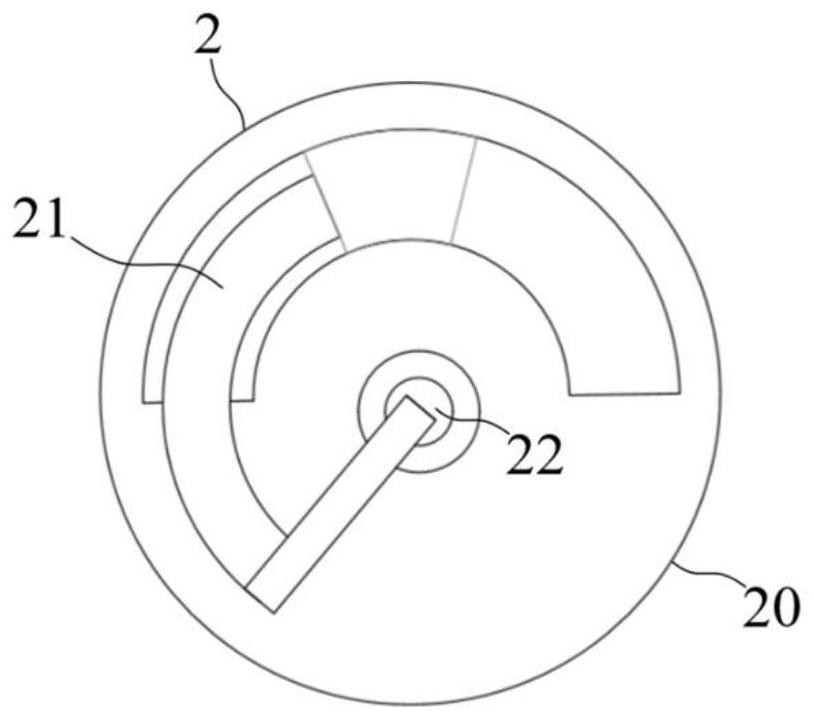

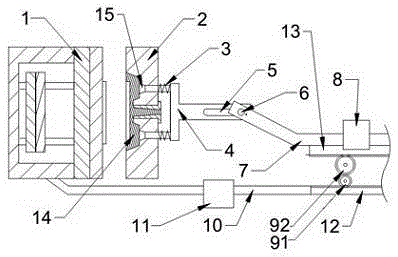

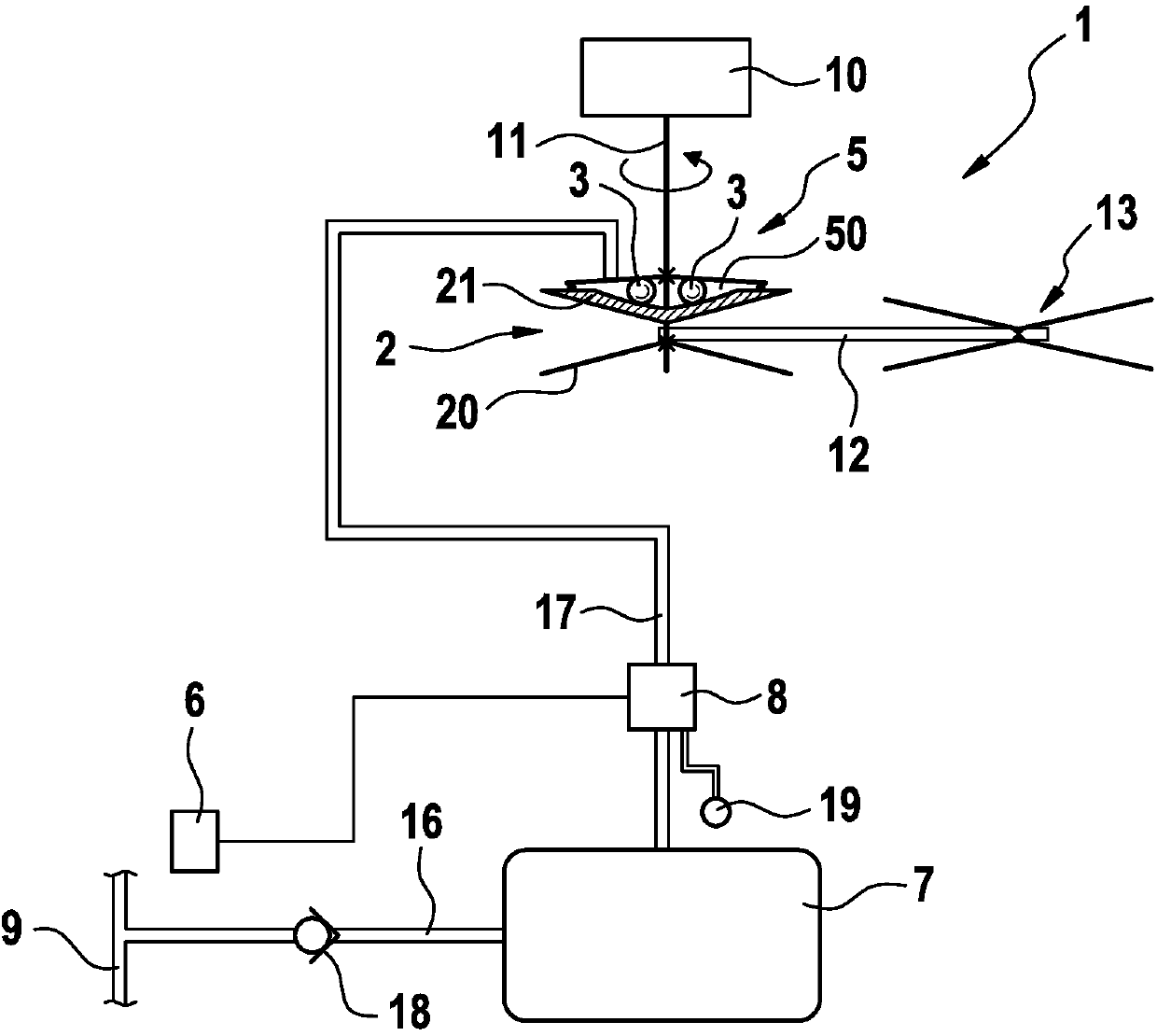

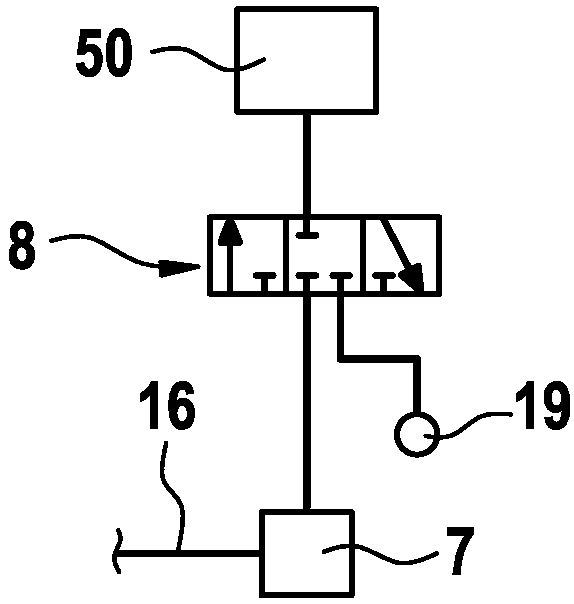

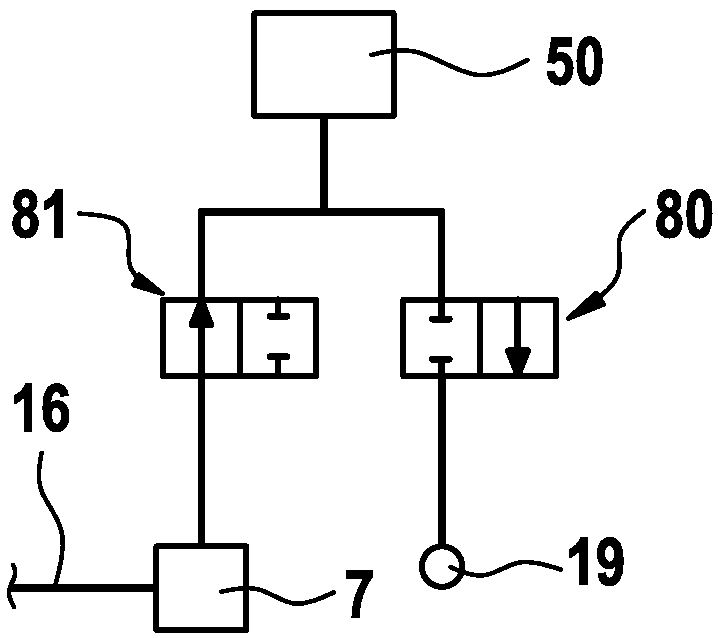

Pneumatically adjustable continuously variable transmission (CVT)

InactiveCN107850194AImprove emission characteristicsIncrease fuel consumptionGearingPortable liftingEngineeringControl unit

The invention relates to a continuously variable transmission (CVT) comprising: a V-pulley (2) that includes at least one axially movable conical disk (21); an adjusting device (5) for adjusting a position of the axially movable conical disk (21); and a control unit (6) designed to actuate the adjusting device (5) in order to change the position of the axially movable conical disk (21). The adjusting device (5) is a pneumatic adjusting device that moves the axially movable conical disk (21) by a pneumatic force.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com