Pneumatically adjustable continuously variable transmission (CVT)

A technology for transmissions and pneumatic chambers, applied in transmissions, transmission controls, components with teeth, etc., can solve the problems of uncontrollable or regulated intervention in the transmission ratio of CVT transmissions, etc., to improve fuel consumption and better Drivability and effect of improving emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

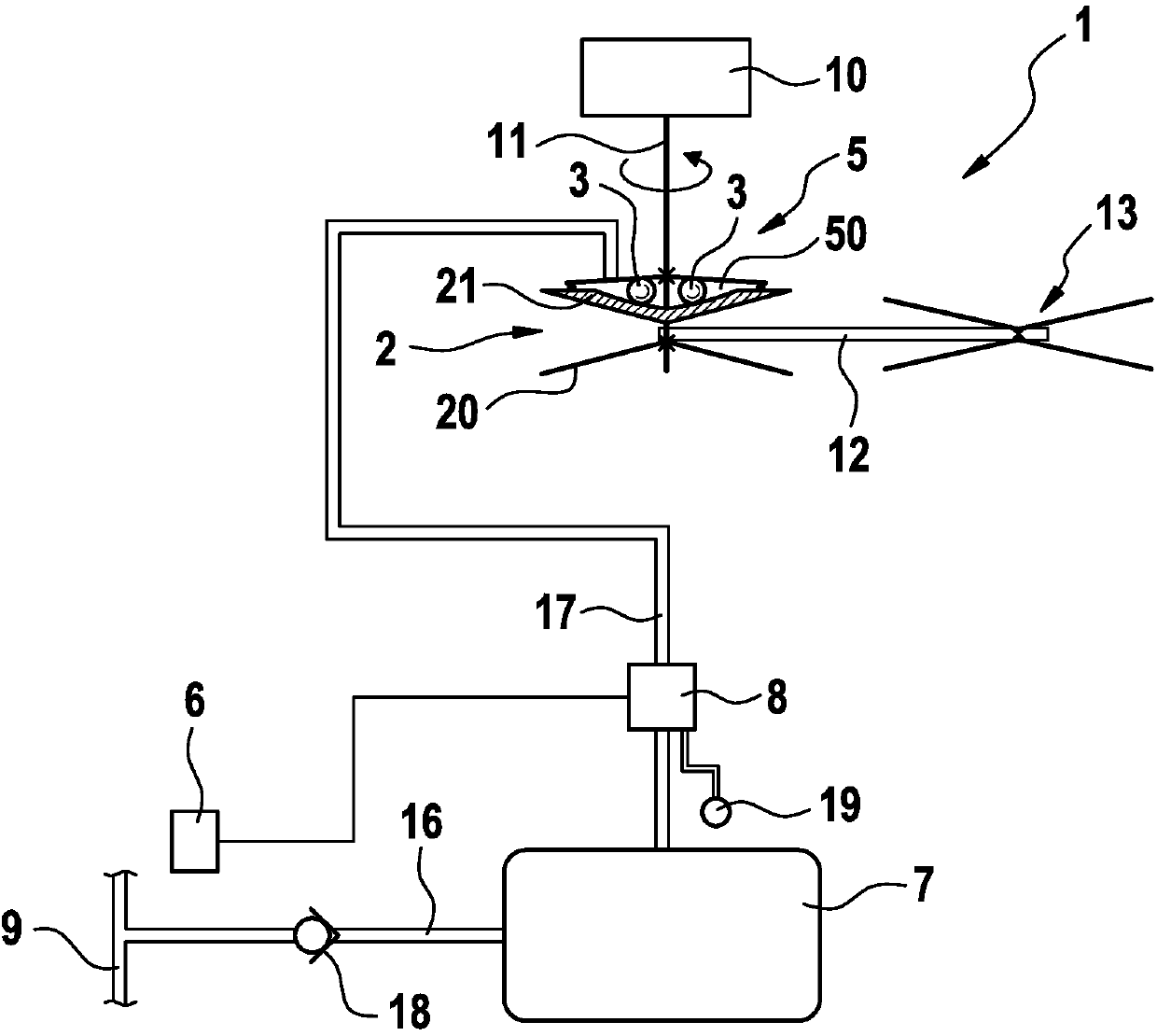

[0022] Refer below Figures 1 to 3 A CVT transmission 1 according to a preferred embodiment of the present invention, that is to say a continuously variable transmission capable of continuous adjustment, is described in detail.

[0023] as by figure 1 It can be seen that the CVT transmission 1 comprises a first cone pair 2 with a fixed cone 20 and an axially movable cone 21 . The second cone pair is provided as driven element 13 . The two cone-disc pairs are connected to one another in a known manner by means of a wrapping means 12 , in particular a belt.

[0024] The first cone pair 2 is arranged on a crankshaft 11 of an internal combustion engine 10 . In this case, the crankshaft 11 is connected to a stationary conical disk 20 .

[0025] The CVT transmission 1 also includes a centrifugal force element 3 which is arranged on an axially movable conical disk 21 . In this embodiment, the centrifugal force element 3 is a ball. Alternatively, solid cylinders or hollow cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com