Fixed die push-out device

A technology of ejecting device and fixed mold, which is applied in the field of ejecting mechanism of die-casting molds, can solve the problems of inability to ensure that castings are tightly wrapped on the punch, and the wrapping force is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

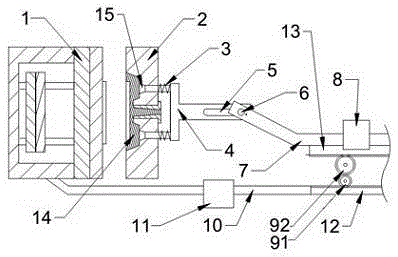

[0015] The reference signs in the drawings of the description include: fixed mold 2, movable mold 1, spring 3, push rod 4, time delay groove 5, driven rod shaft 6, driven rod 7, driven rod guide chute 8, driving rod Gear 91, driven gear 92, driving rod 10, driving rod guide chute 11, driving rack 12, driven rack 13, casting 14, ejection end 15.

[0016] Examples are attached figure 1 Shown: includes fixed mold 2, fixed mold 2 is provided with push rod 4, and push rod 4 is provided with a plurality of ejection ends 15, and each ejection end 15 is provided with spring 3, in order to fix push rod 4 On the fixed mold 2, the other end opposite to the ejection end 15 is provided with a time-delay groove 5, and a driven rod shaft 6 is slidably connected in the time-delay groove 5, and the driven rod shaft 6 is fixed on the driven rod 7. The driven rod 7 is slidably connected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com