Box moving mechanism of high-speed rice transplanter

A technology of a box-moving mechanism and a rice transplanter, which is applied in the fields of transplanting machinery, application, agriculture, etc., can solve the problems such as the inability to meet the performance requirements of high-speed rice transplanters, shorten the power transmission distance, simplify the design of the box-moving mechanism, and achieve a compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

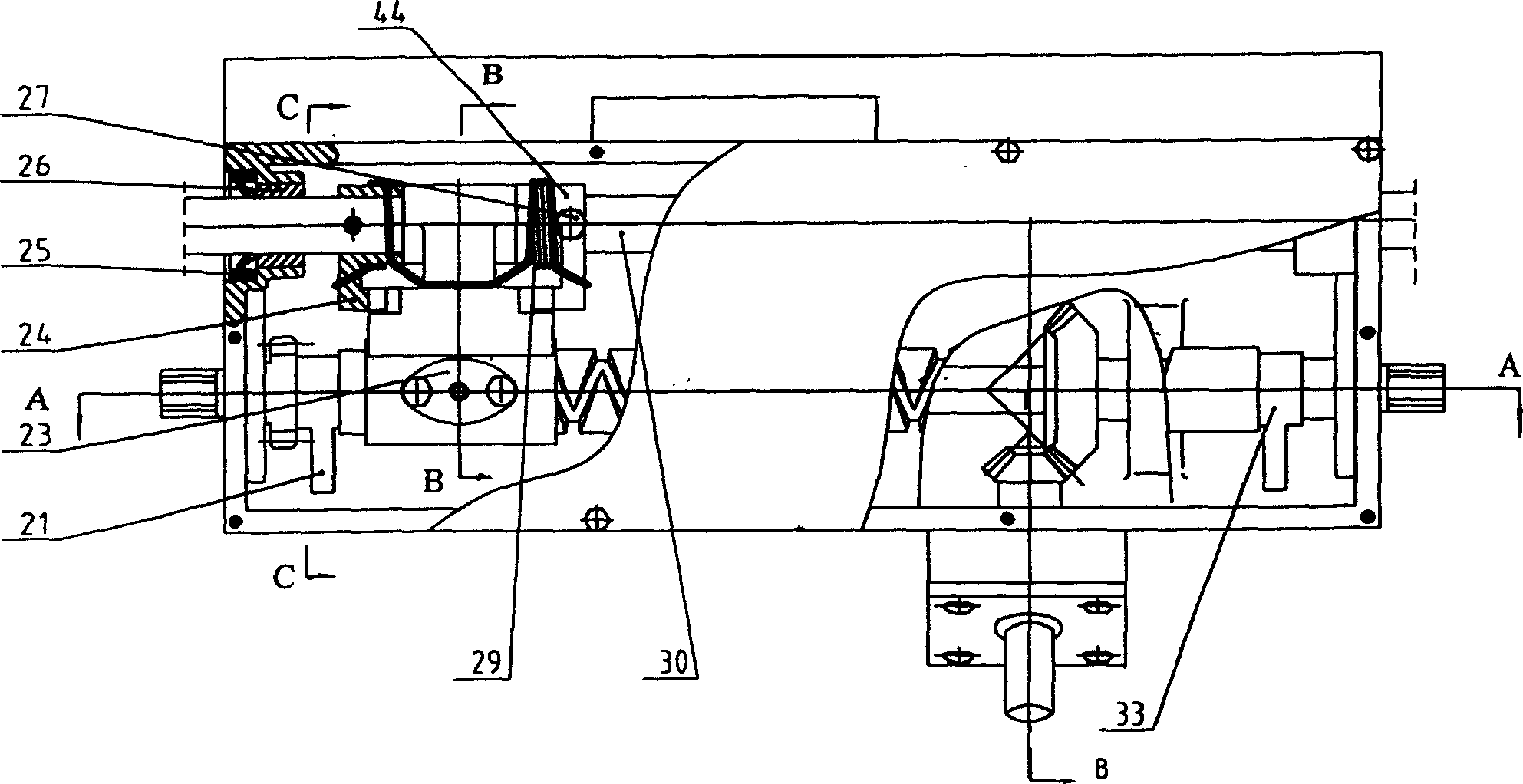

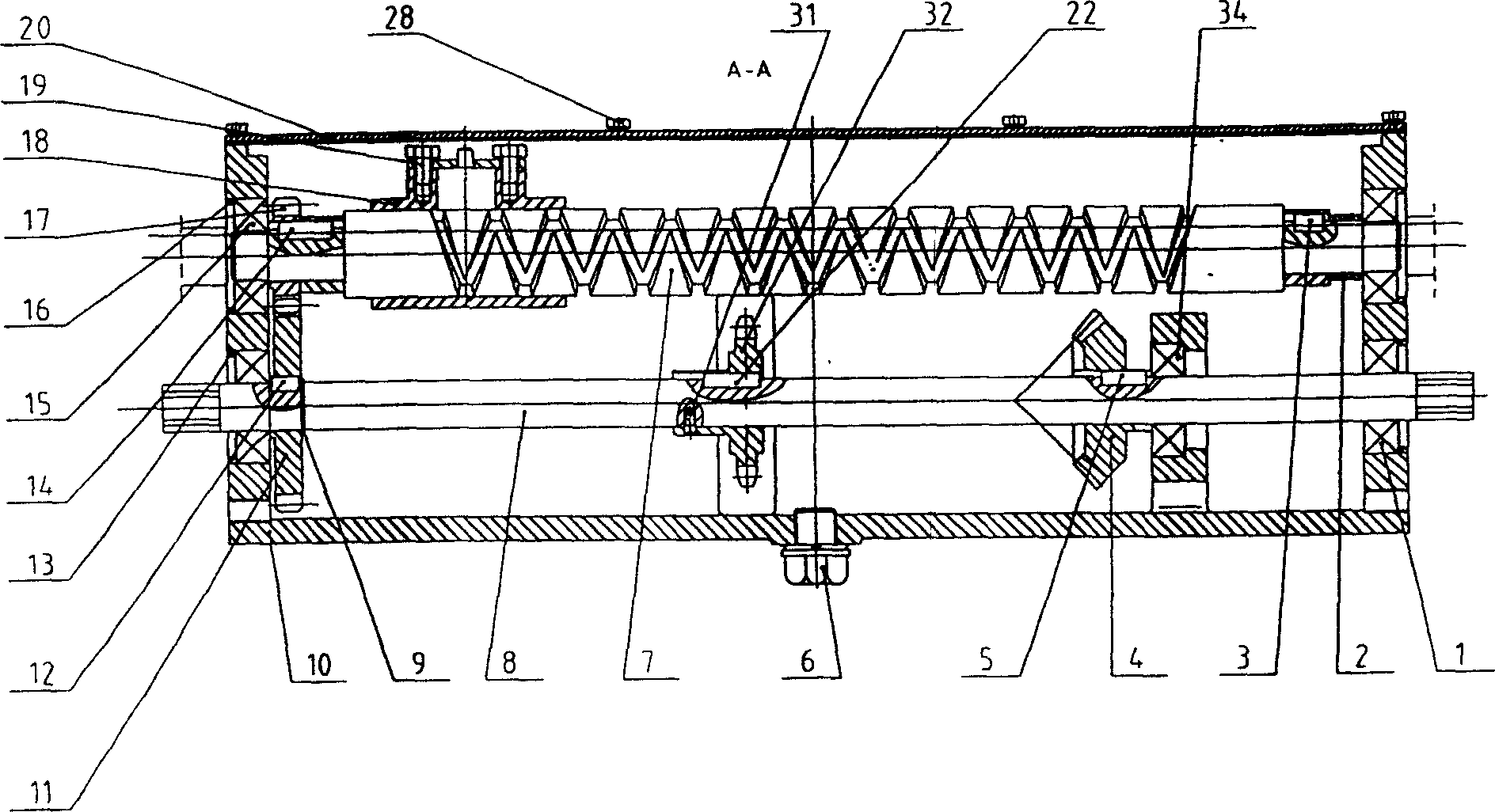

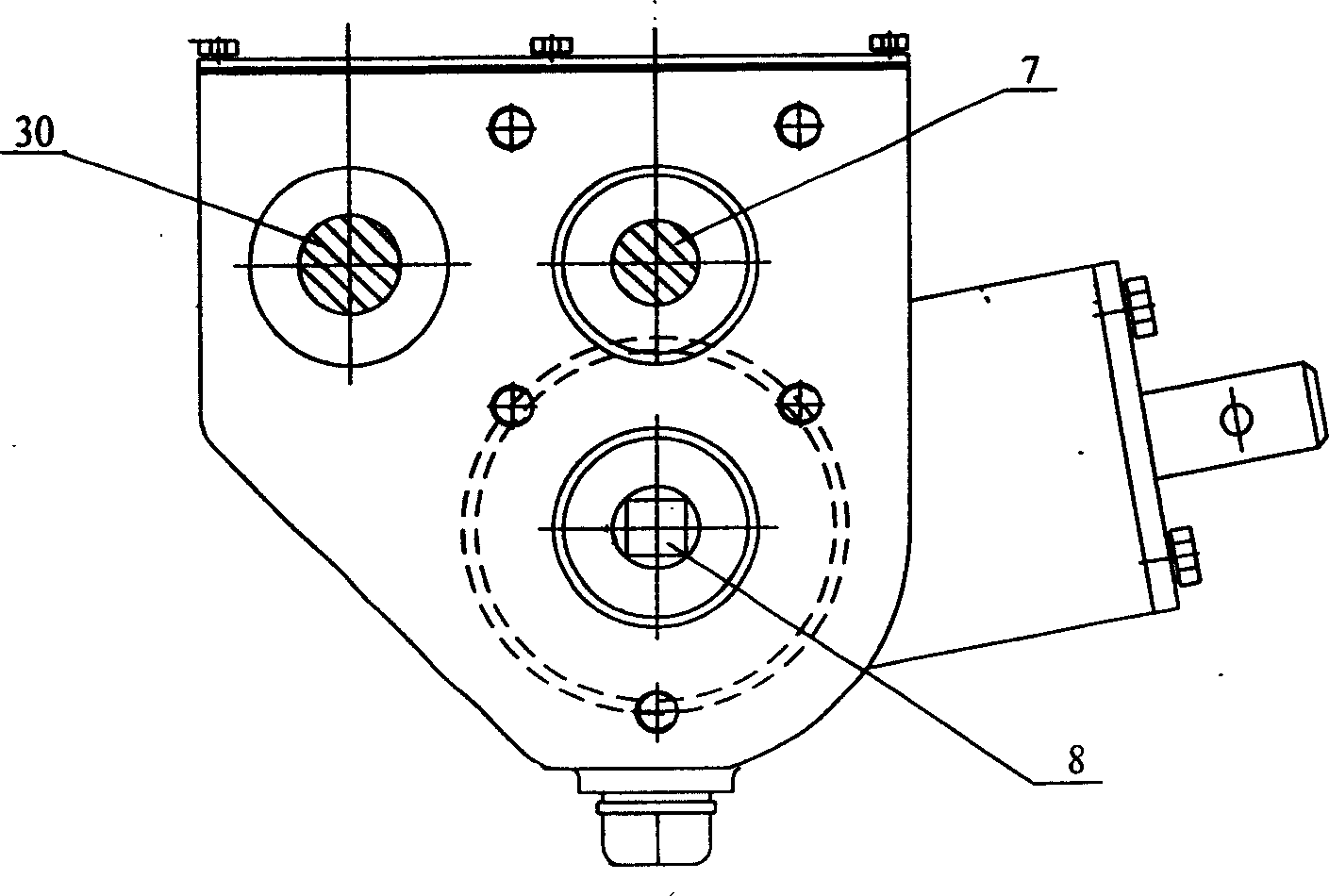

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the power is connected with the bevel gear shaft 38 of the power input of the shift case after the transmission output, so as to realize the connection of power. In the moving box 10, the bevel gear shaft 38 is connected with the bevel gear 4 to complete the power steering, the power changes from longitudinal to horizontal rotation, and the power is transferred from the split transmission through the bevel gear 4, the key 3 and the split drive shaft 8 all the way. The two ends of the shaft 8 are transmitted to the splitting mechanism; one way is to output the power from the middle of the box body 10 to the splitting mechanism through the key 22 and the center sprocket 32; The split drive shaft 8 is transferred to the screw shaft 7; the screw shaft 7 drives the box moving shaft 30 to reciprocate laterally through the slider 36, the sliding sleeve 18, the left return shift fork 24, the right return shift for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com