A large mobile graphitization system

A mobile and graphitization technology, applied in the field of large-scale mobile graphitization systems, can solve the problems of high temperature injury of operators, difficulty in collecting flue gas, and low resistance of furnace cores, so as to shorten the transmission distance, reduce the difficulty of production, reduce The effect of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

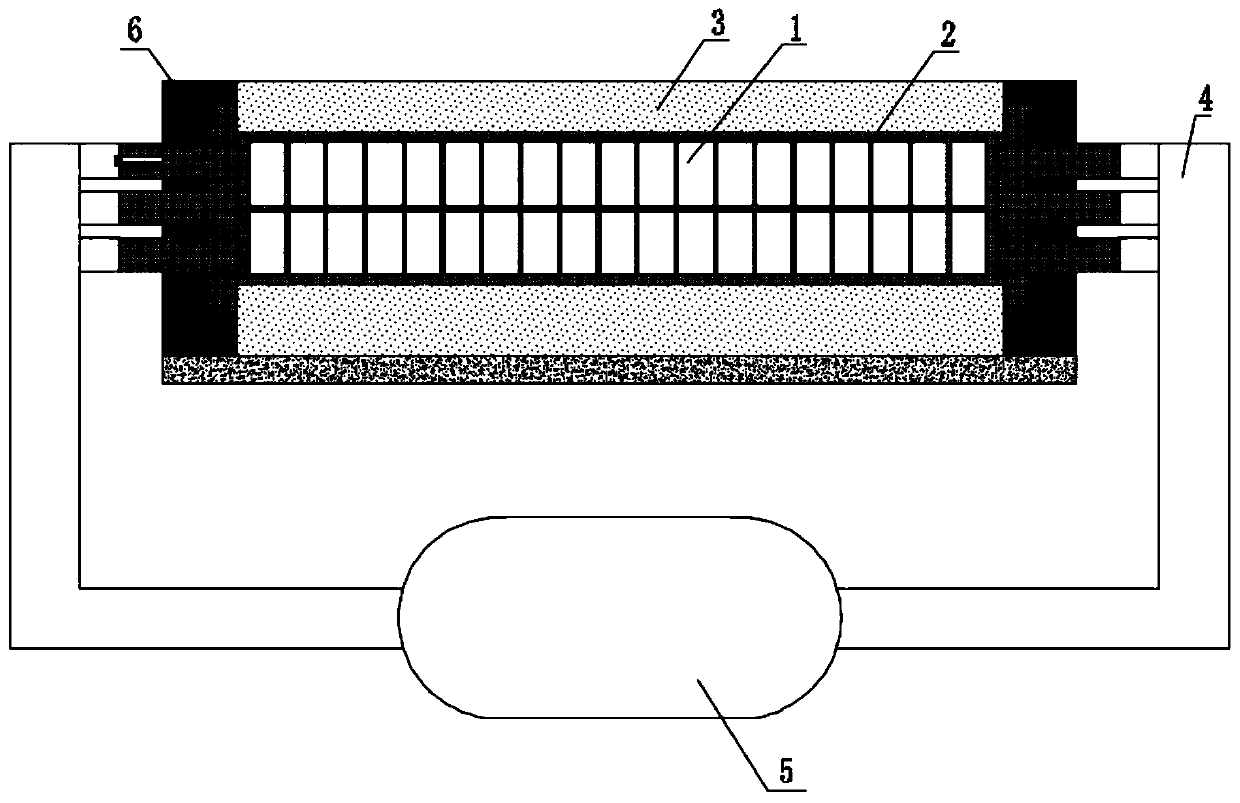

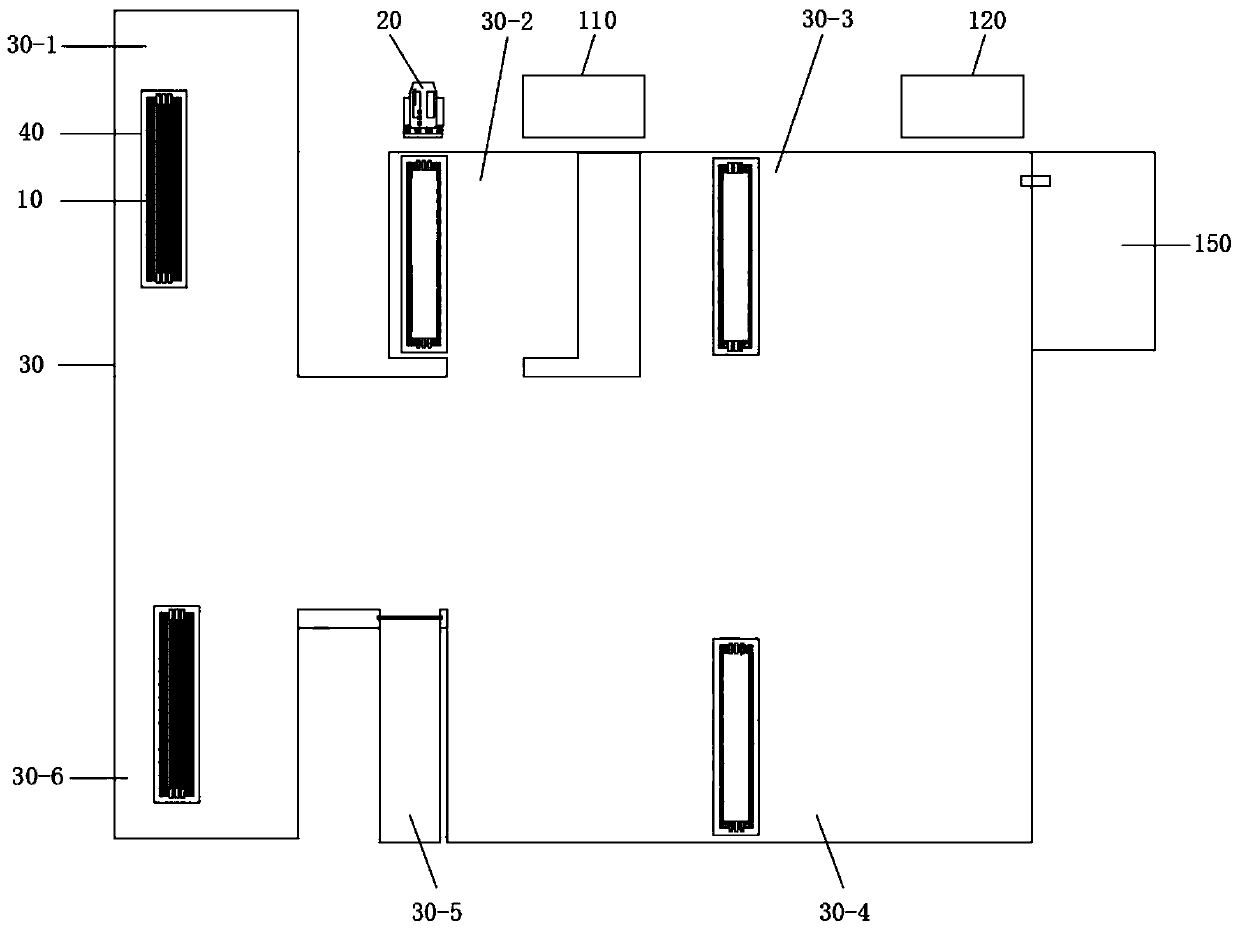

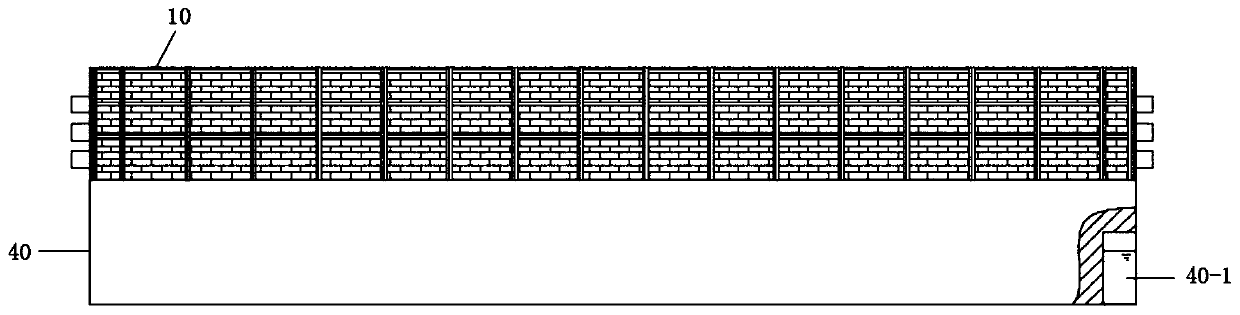

[0039] Embodiment 1: as Figure 2 to Figure 4 As shown, a large-scale mobile graphitization system according to the embodiment of the present invention includes a graphitization furnace 10, a transformer 20, and a pool 30. The hoist (not shown in the figure) pulls the graphitization furnace 10 to move in the pool 30, and the transformer 20 is arranged on the outer edge of the pool 30; it also includes a furnace loading station, a furnace discharge station, a power transmission station, a first cooling station, and a second cooling station. 2. Cooling station and furnace building maintenance station.

[0040] Such as figure 2 As shown, the pool 30 is divided into a furnace loading station area 30-1, a power transmission station area 30-2, a first cooling station area 30-3, a second cooling station area 30-4, and a furnace building maintenance station area 30-5 and the furnace station area 30-6 correspond to the furnace loading station, power transmission station, first cooli...

Embodiment 2

[0054] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the buoyant tank 40 is a solid tank structure filled with foam plastic.

[0055] The working process of the present invention is: in the furnace charging station area 30-1 of the pool, the furnace charging product composed of the material to be graphitized and the crucible 140 is hoisted into the graphitization furnace 10 through the crucible hoisting system 60, and the new The purchased thermal insulation material and resistance material are delivered to the graphitization furnace 10 through the resistance material hopper 71 and the thermal insulation material hopper 72 of the refill system 70, and then the graphitization furnace 10 is pulled by the hoist to walk in the pool 30 to the pool 30 in sequence The power transmission station area 30-2, the first cooling station area 30-3, the second cooling station area 30-4 and the furnace station area 30-6;

[0056] When the graphitization furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com