Multi-rope tension balance adjusting device and adjusting method

A balanced adjustment device and technology for balanced adjustment, applied in transportation and packaging, sustainable buildings, elevators, etc., can solve problems affecting riding comfort and safety, unbalanced tension of steel wire ropes, shortened life of steel wire ropes, etc., and achieve simple structure, Ease of adjustment and low cost of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

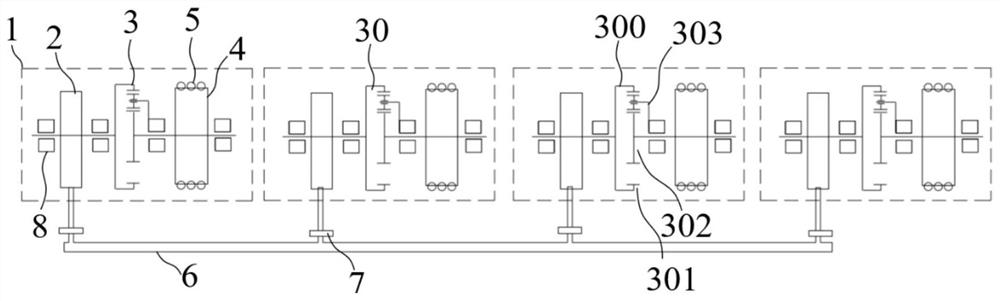

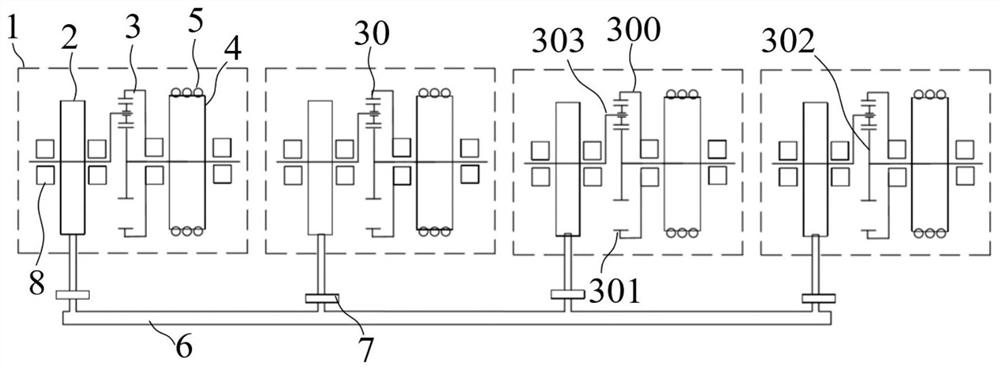

[0055] The multi-rope tension equalization adjustment device of this embodiment includes several tension equalization units 1, and the tension equalization units 1 include:

[0056] hydraulic cylinder 2, which transmits torque;

[0057] Speed-up module 3, its speed-up transmission, the transmission end of speed-up module 3 is connected with hydraulic cylinder 2 transmission;

[0058] The drum 4 is connected to the other transmission end of the speed-increasing module 3 through transmission;

[0059] Elevate the wire rope 5, which is wound on the drum 4;

[0060] The hydraulic cylinders 2 of each tension equalization unit 1 communicate with each other through a communication pipeline 6 .

[0061] In this embodiment, there are multiple tension equalization units 1, such as figure 1 As shown, corresponding to the number of wire ropes in the multi-rope hoisting system, the hydraulic cylinder 2 in the tension equalization unit 1 is used to transmit torque, more specifically, to ...

Embodiment 2

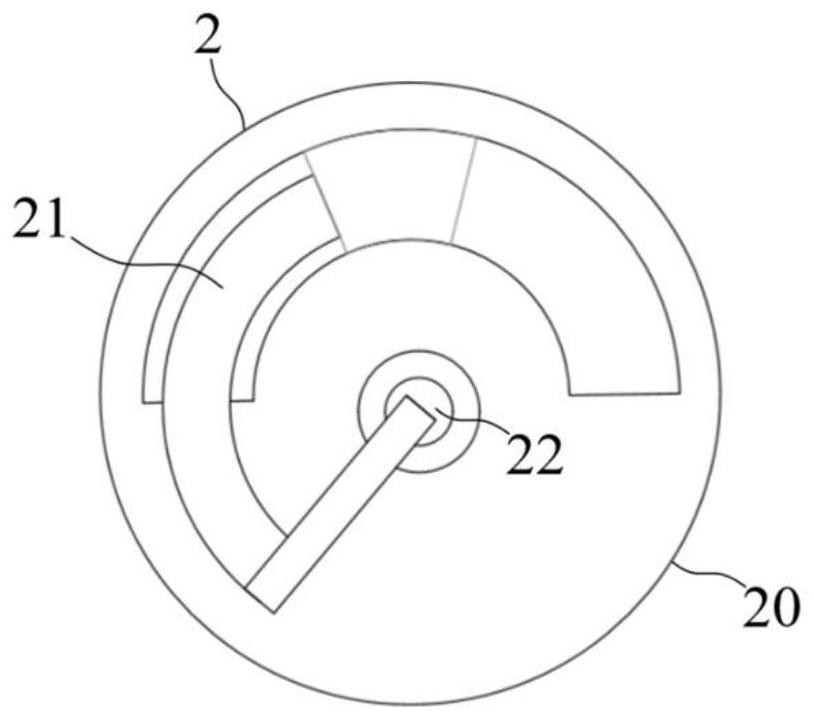

[0065] The multi-rope tension balance adjusting device of this embodiment is further improved on the basis of Embodiment 1, and the hydraulic cylinder 2 is an annular hydraulic cylinder or a swing hydraulic cylinder.

[0066] This embodiment lists two specific forms of the hydraulic cylinder 2 used in this application.

[0067] Such as ring hydraulic cylinders, such as image 3 As shown, it includes a circular cylinder 20, an annular plunger 21 and a transmission shaft 22. The transmission shaft 22 can be rotated in the range of 0~180° through the oil in and out of the circular cylinder 20; similarly, the swing hydraulic The cylinder can also make the transmission shaft 22 rotate at different angles through the change of hydraulic pressure in the cylinder, and transmit torque.

[0068] The hydraulic cylinder 2 of this embodiment cooperates with the speed-increasing module 3, which can directly and effectively output torque and cause the required rotation of the drum 4. At the...

Embodiment 3

[0070] The multi-rope tension equalization adjusting device of this embodiment is further improved on the basis of Embodiment 2, and a valve 7 is provided at the connection between the hydraulic cylinder 2 and the communication pipeline 6 of each tension equalization unit 1 .

[0071] The valve 7 can control and cut off the communication state between the corresponding hydraulic cylinder 2 and other hydraulic cylinders 2. When the length difference of each lifting wire rope 5 is too large or exceeds the automatic adjustment stroke of the device, the hydraulic cylinder 2 corresponding to the lifting wire rope 5 will be lifted through the valve 7. Disconnect the connection with other hydraulic cylinders 2, rotate the drum 4 to wind the rope, and adjust each hoisting wire rope 5 individually until the tension is the same, then open the valve 7, and the multi-rope tension balance adjustment device can operate normally at this time.

[0072] In this embodiment, by adding the valve 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com