Multi-rope lifting system for ultra-deep vertical shaft and guiding method of multi-rope lifting system

A technology for lifting systems and vertical shafts, which is applied to lifting equipment, elevators, transportation and packaging in mines. It can solve the problems of large gear size, large moment of inertia, large load, etc., and achieve reduced axial spacing and uniform traction force distribution. , The effect of prolonging the effective service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

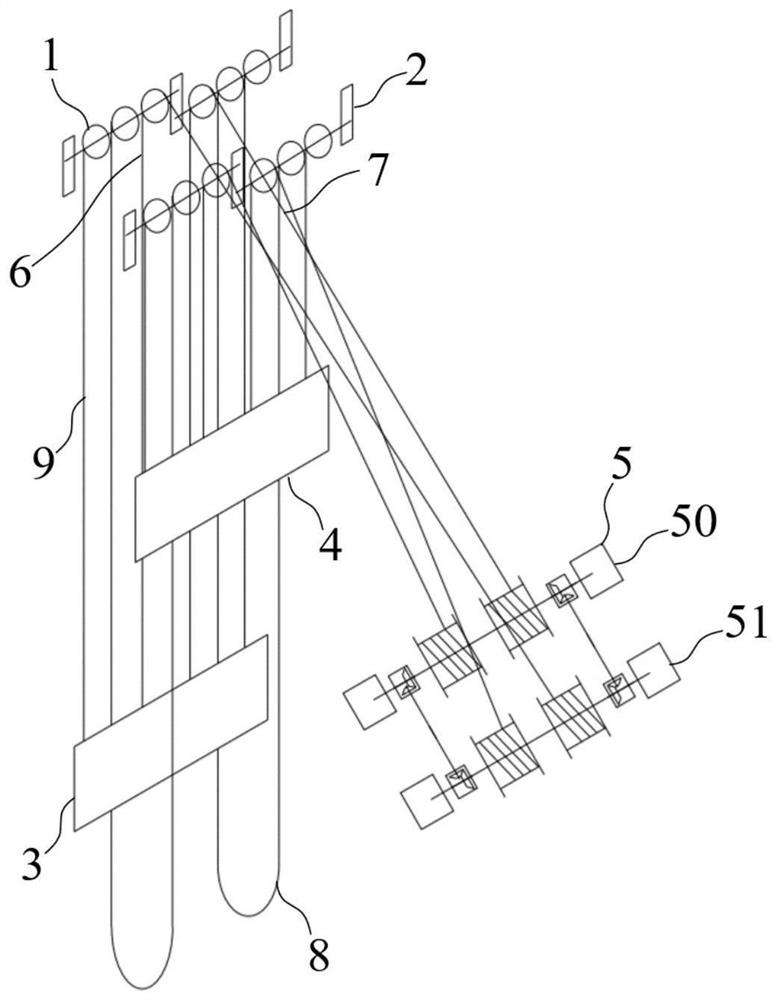

[0086] The ultra-deep vertical shaft multi-rope hoisting system of this embodiment includes,

[0087] The upper guide wheel system 1 is provided with several guide wheels;

[0088] The lower guide wheel system 2 is arranged under the side of the upper guide wheel system 1, and several guide wheels are arranged on the lower guide wheel system 2;

[0089] The front lifting container 3 is located directly below the upper guide wheel train 1;

[0090] The rear lifting container 4 is located directly below the lower guide wheel train 2;

[0091] Drive unit 5, which drives the lifting of the front lifting container 3 and the rear lifting container 4;

[0092] The front lifting rope 6, which has several roots, rides on the upper guide wheel train 1, and one end of the front lifting rope 6 is connected to the top of the front lifting container 3, and the other end is connected to the drive unit 5;

[0093] The rear hoisting rope 7, which has several roots, rides on the lower guide ...

Embodiment 2

[0101] The ultra-deep vertical shaft multi-rope hoisting system of this embodiment is further improved on the basis of Embodiment 1, and the drive unit 5 includes a front drive part 50 and a rear drive part 51 arranged in parallel to each other;

[0102] The front drive unit 50 includes,

[0103] Drive motor-500, which provides driving force;

[0104] Main shaft one 501, which rotates under the drive of drive motor one 500;

[0105] Drum 1 502, which has several, is installed on the main shaft 1 501, and the drum 1 502 is wound with front hoisting rope 6 or rear hoisting rope 7;

[0106] The rear drive unit 51 includes,

[0107] Driving motor 2 510, which provides driving force;

[0108] Main shaft two 511, which rotates under the drive of driving motor two 510;

[0109] Drum 2 512, which has several, is installed on the main shaft 2 511, and the drum 2 512 is wound with front hoisting rope 6 or rear hoisting rope 7;

[0110] The front lifting rope 6 wound on the first dr...

Embodiment 3

[0116] The ultra-deep vertical shaft multi-rope hoisting system of this embodiment is further improved on the basis of Embodiments 1 and 2. At least one front hoisting rope 6 and at least one rear hoisting rope 7 are wound on the front driving part 50, and,

[0117] At least one front lifting rope 6 and at least one rear lifting rope 7 are wound on the rear driving part 51;

[0118] The front hoisting cord 6 and the rear hoisting cord 7 wound around the same drive part are wound in opposite directions.

[0119] The winding mode of the front lifting rope 6 and the rear lifting rope 7 of the present embodiment is as follows: image 3 , Figure 4 and Figure 6 As shown, different hoisting ropes are wound on different drums of the same drive unit.

[0120] Specifically, the front lifting container 3 of the present embodiment is drawn by two front lifting ropes 6, and the rear lifting container 4 is drawn by two rear lifting ropes 7. The upper guide wheel system 1 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com