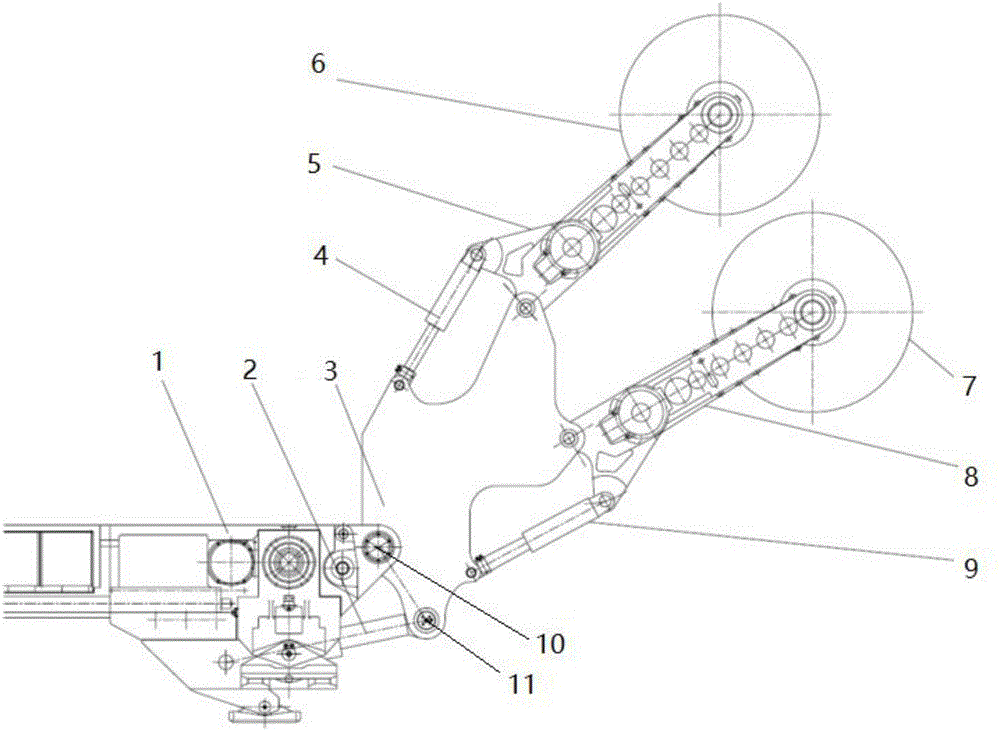

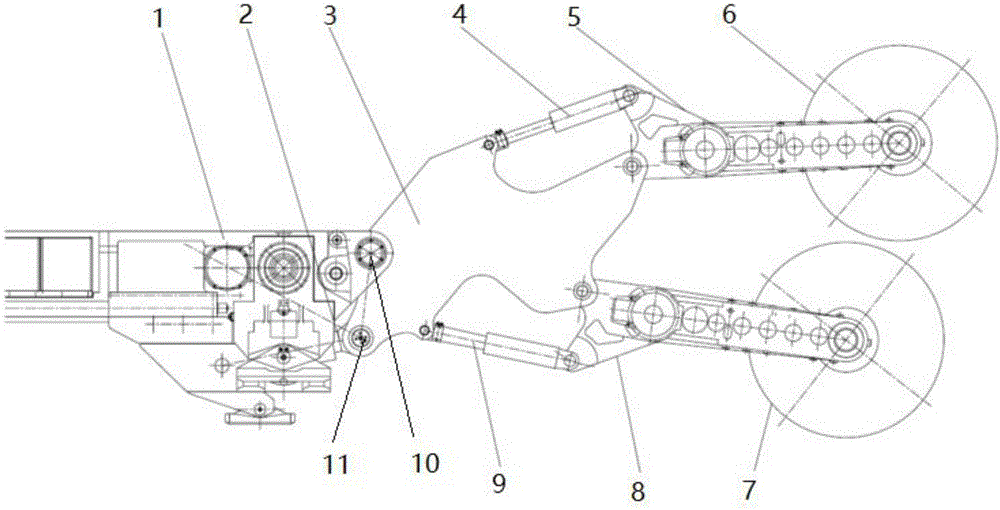

Shearer with four rocker arm structure

A technology of coal shearer and drum, applied in the field of drum shearer, to achieve the effect of solving the stability of the fuselage, the difficulty of processing, the reduction of manufacturing cost, and the reduction of traction load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

[0022] like figure 1 and figure 2 As shown, the roller shearer with four rocker arm structures proposed by the present invention includes a fuselage 1 and a rocker arm structure, and the two ends of the fuselage 1 are symmetrically provided with a rocker arm structure, and the rocker arm structure includes a transition frame 2, The main height adjustment oil cylinder 3 arranged between the transition frame 2 and the fuselage 1, the upper height adjustment oil cylinder 4 arranged at the upper end of the transition frame 2, the lower height adjustment oil cylinder 5 arranged at the lower end of the transition frame 2, The upper rocker 6 arranged on the side of the transition frame 2, the lower rocker 7 arranged on the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com