Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Axial spacing reduced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

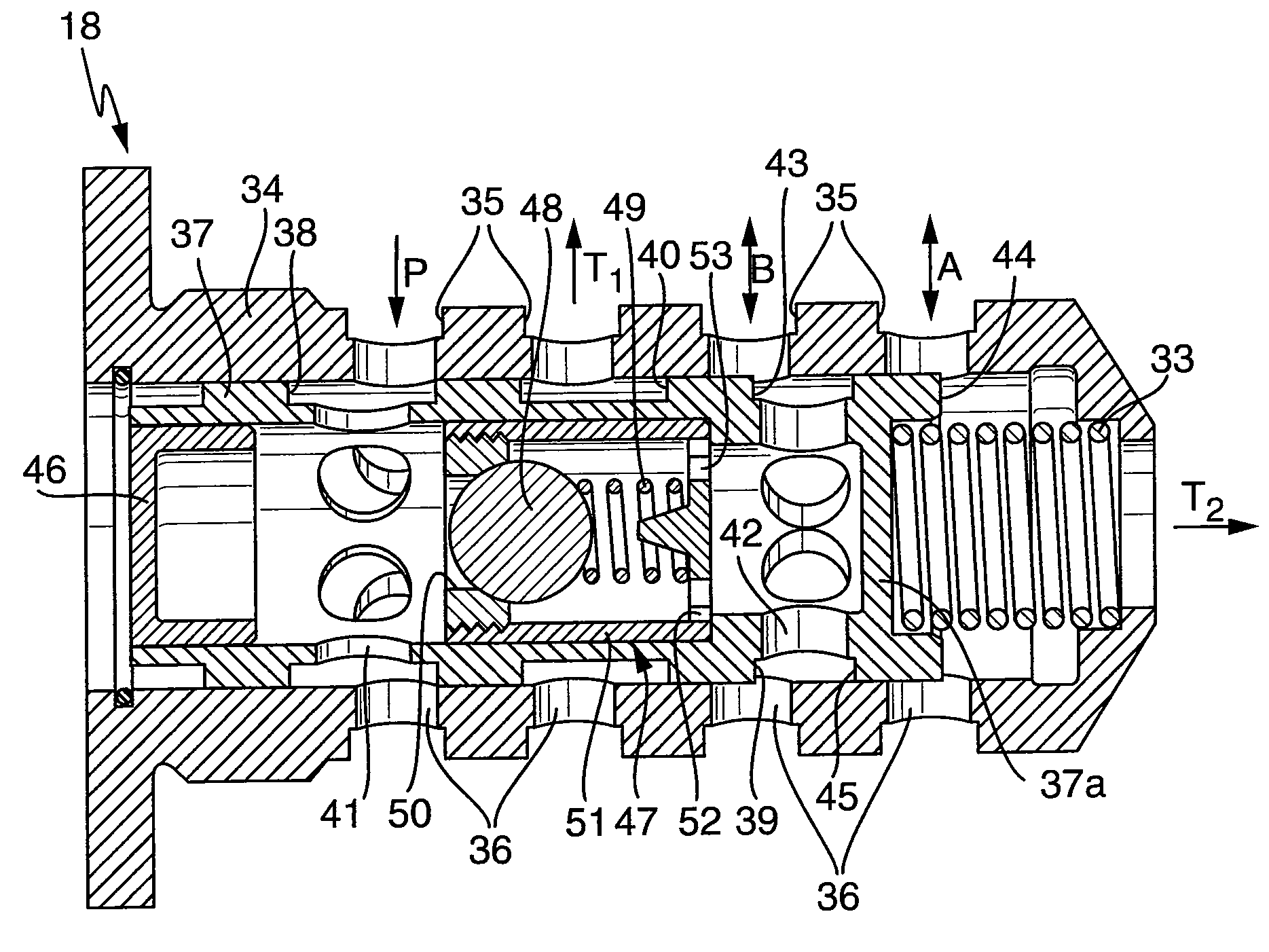

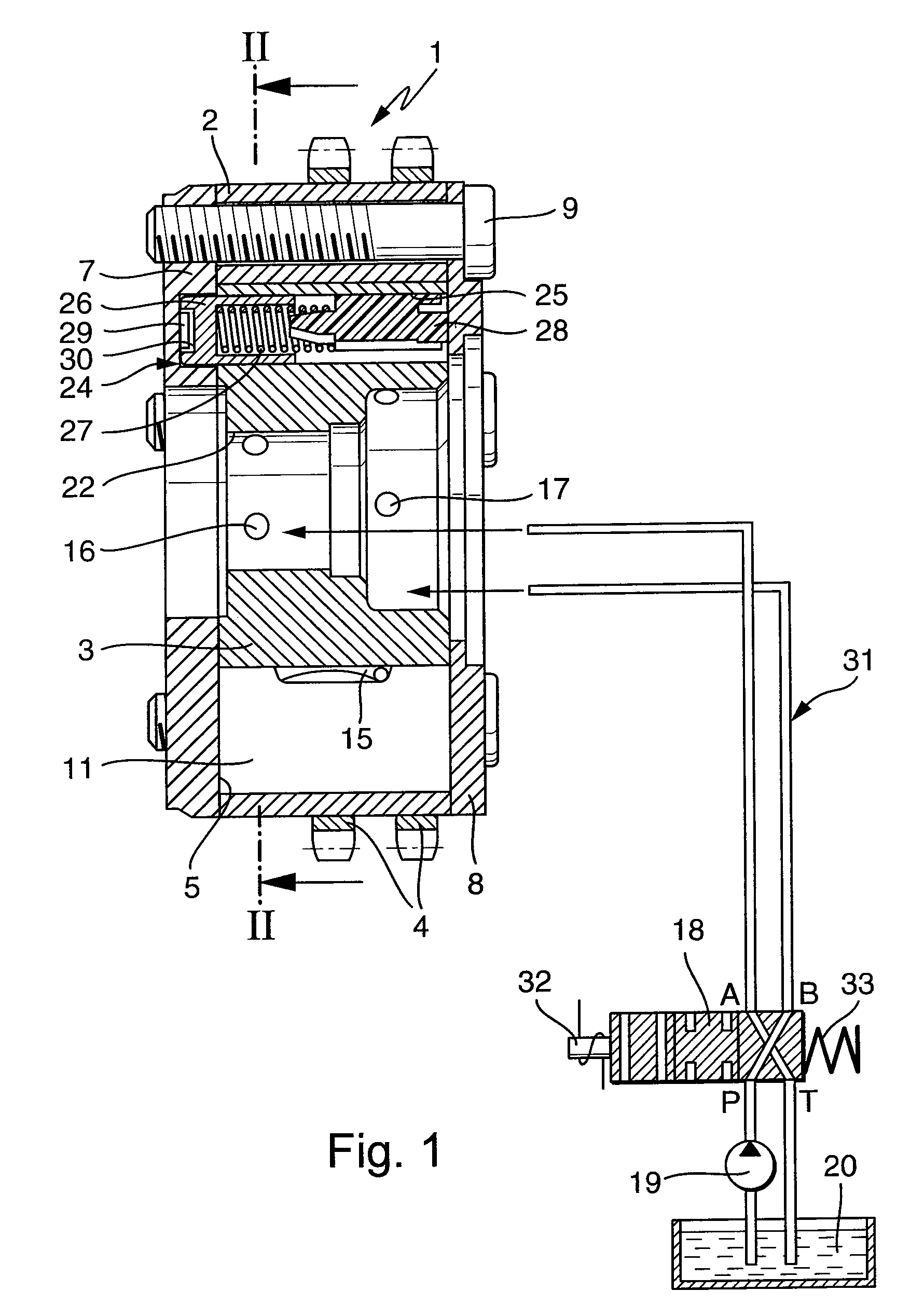

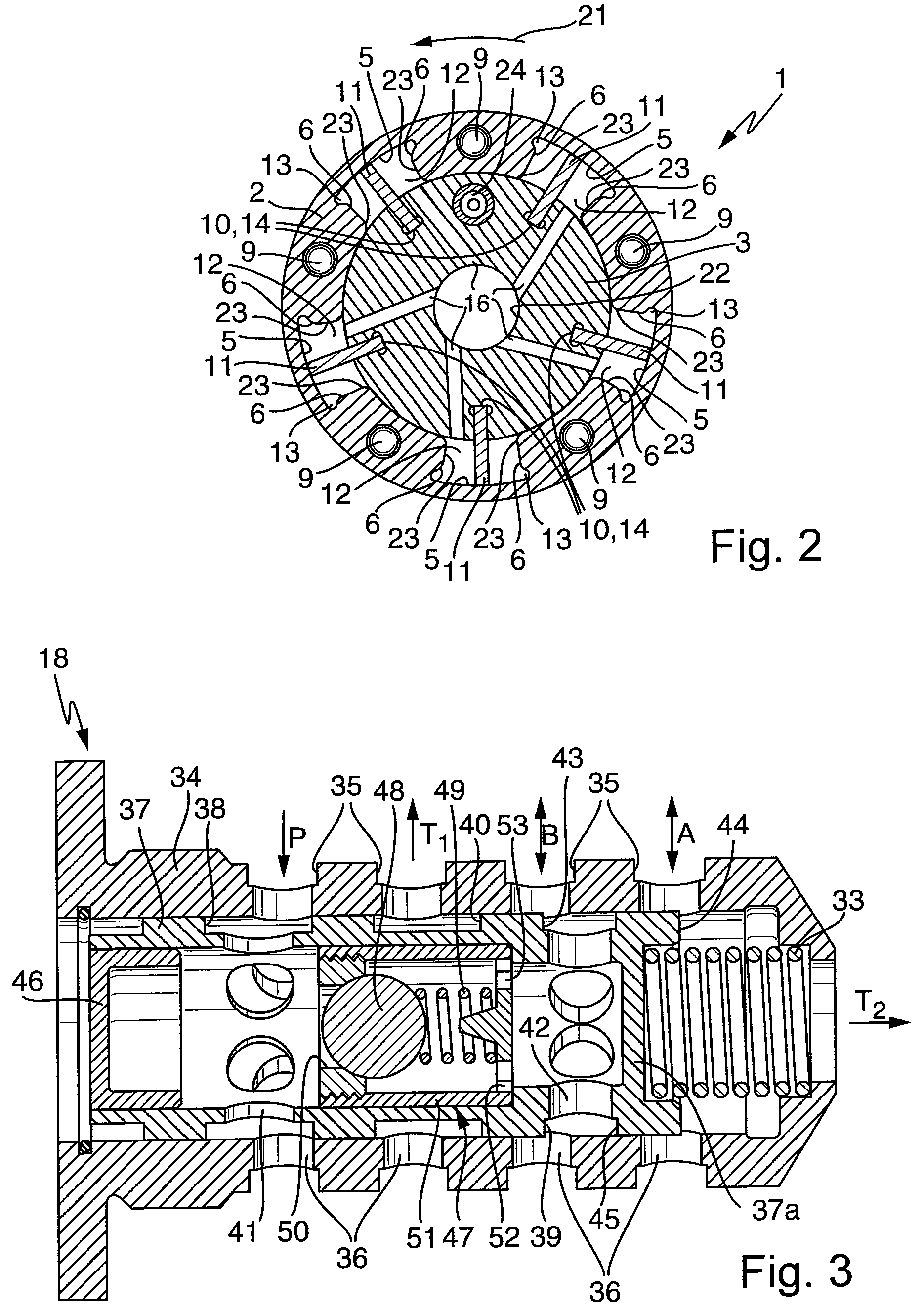

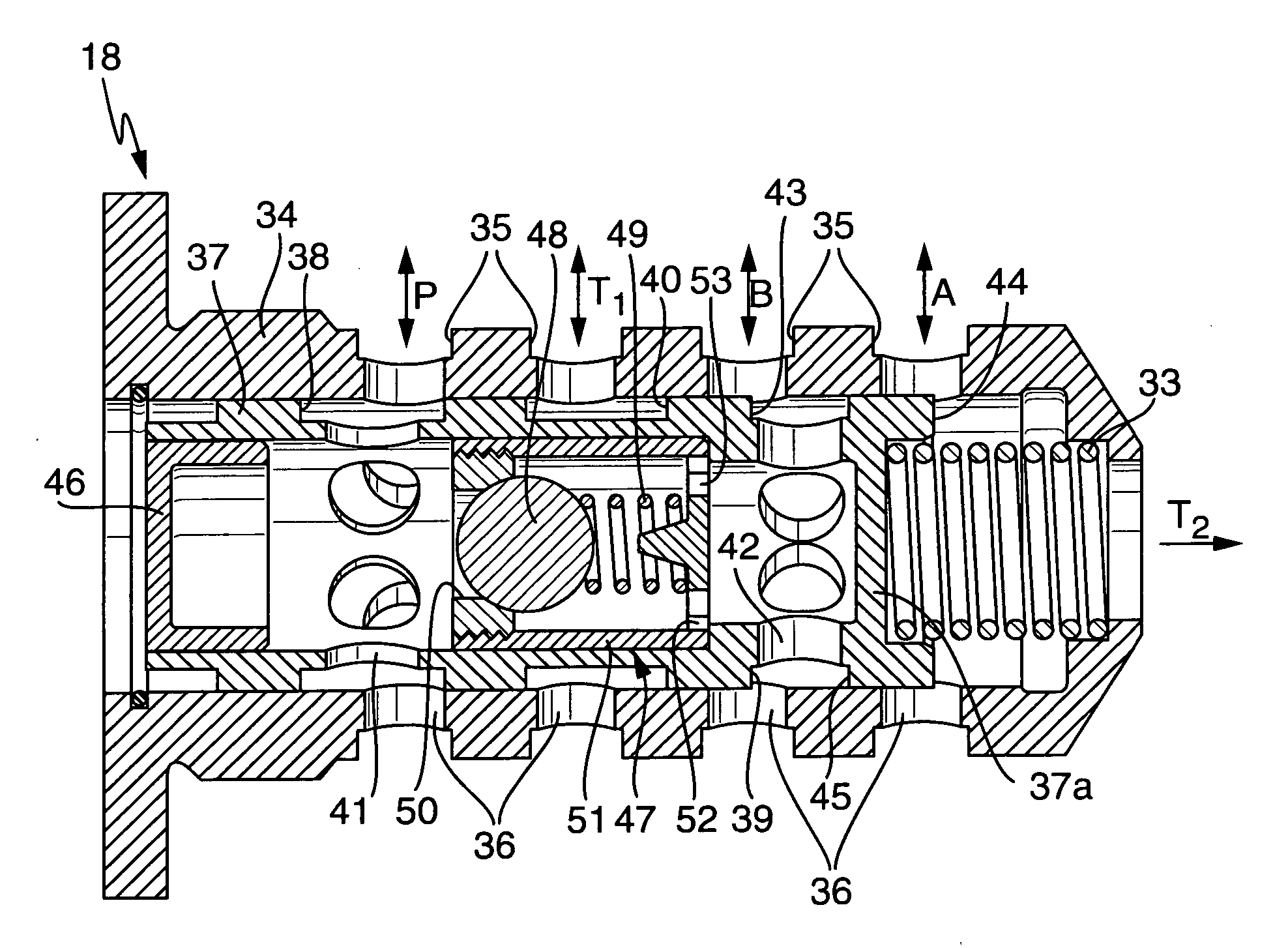

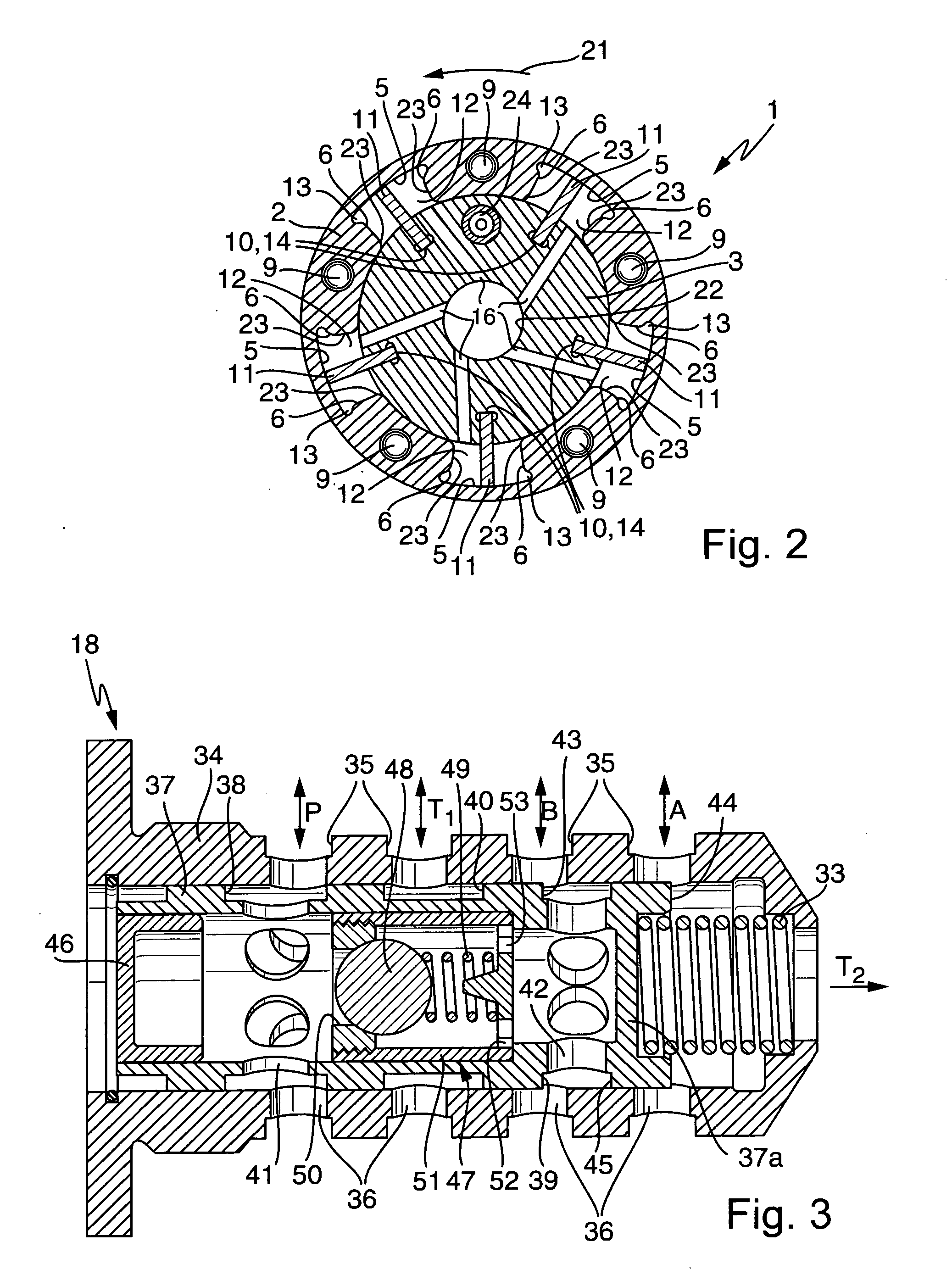

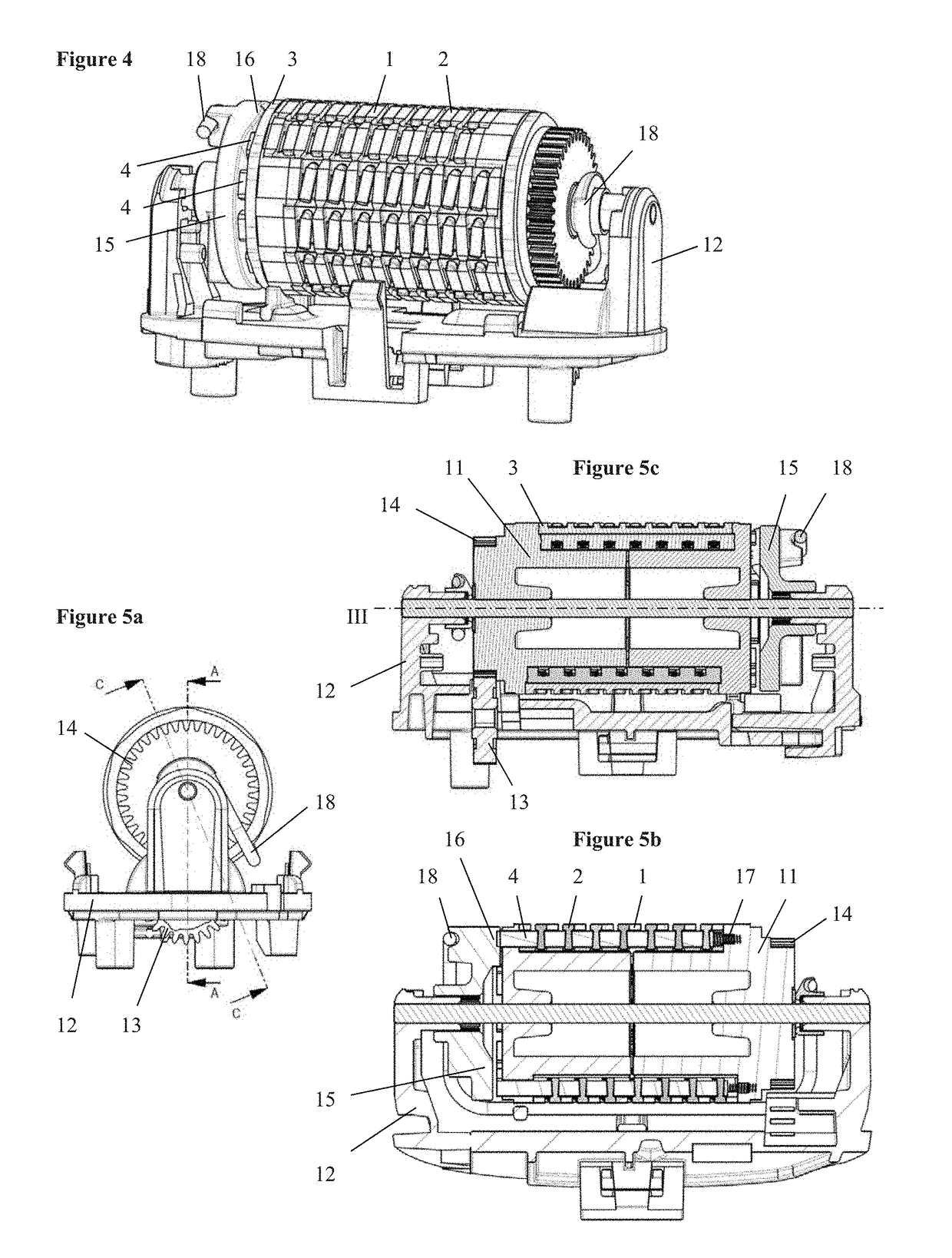

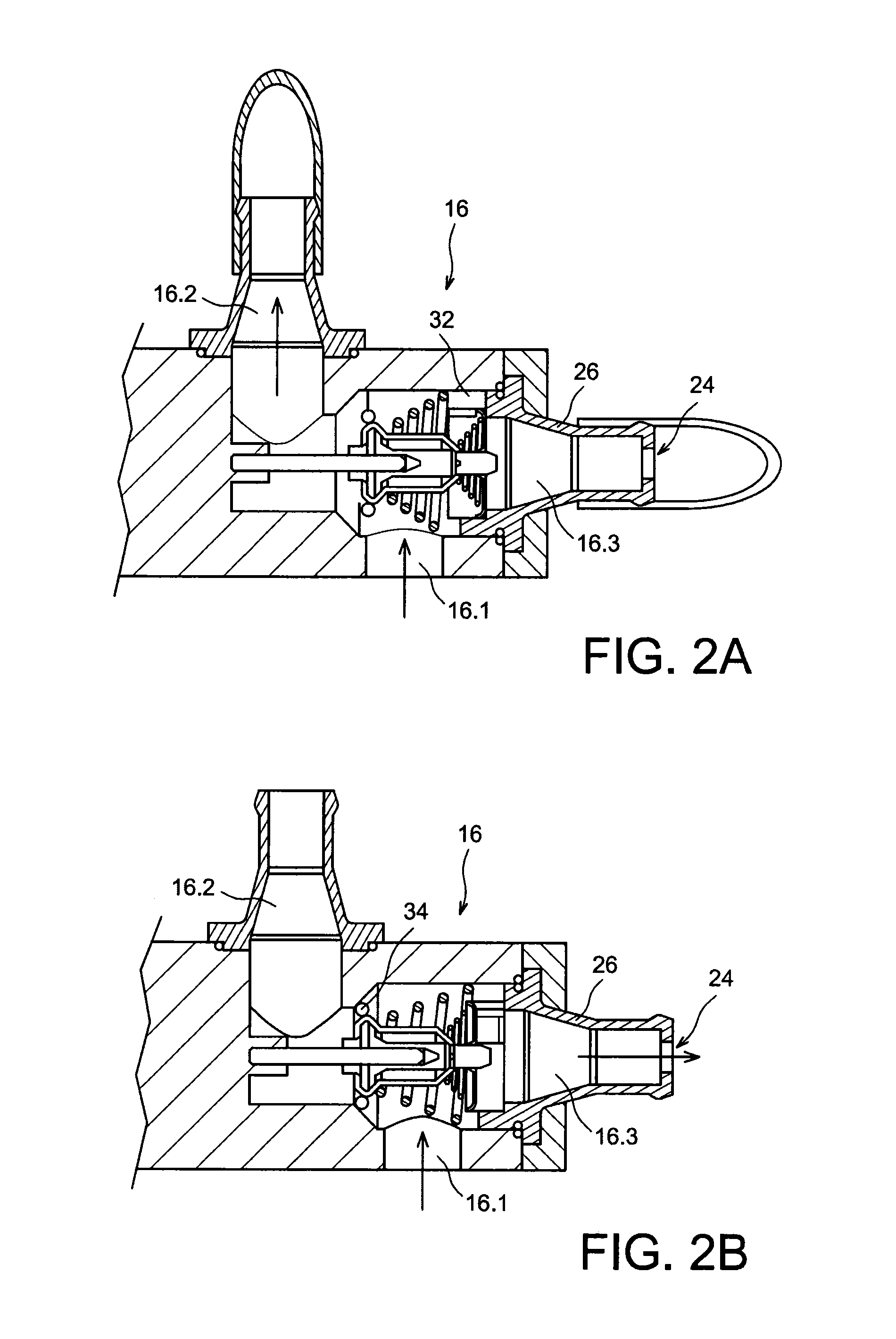

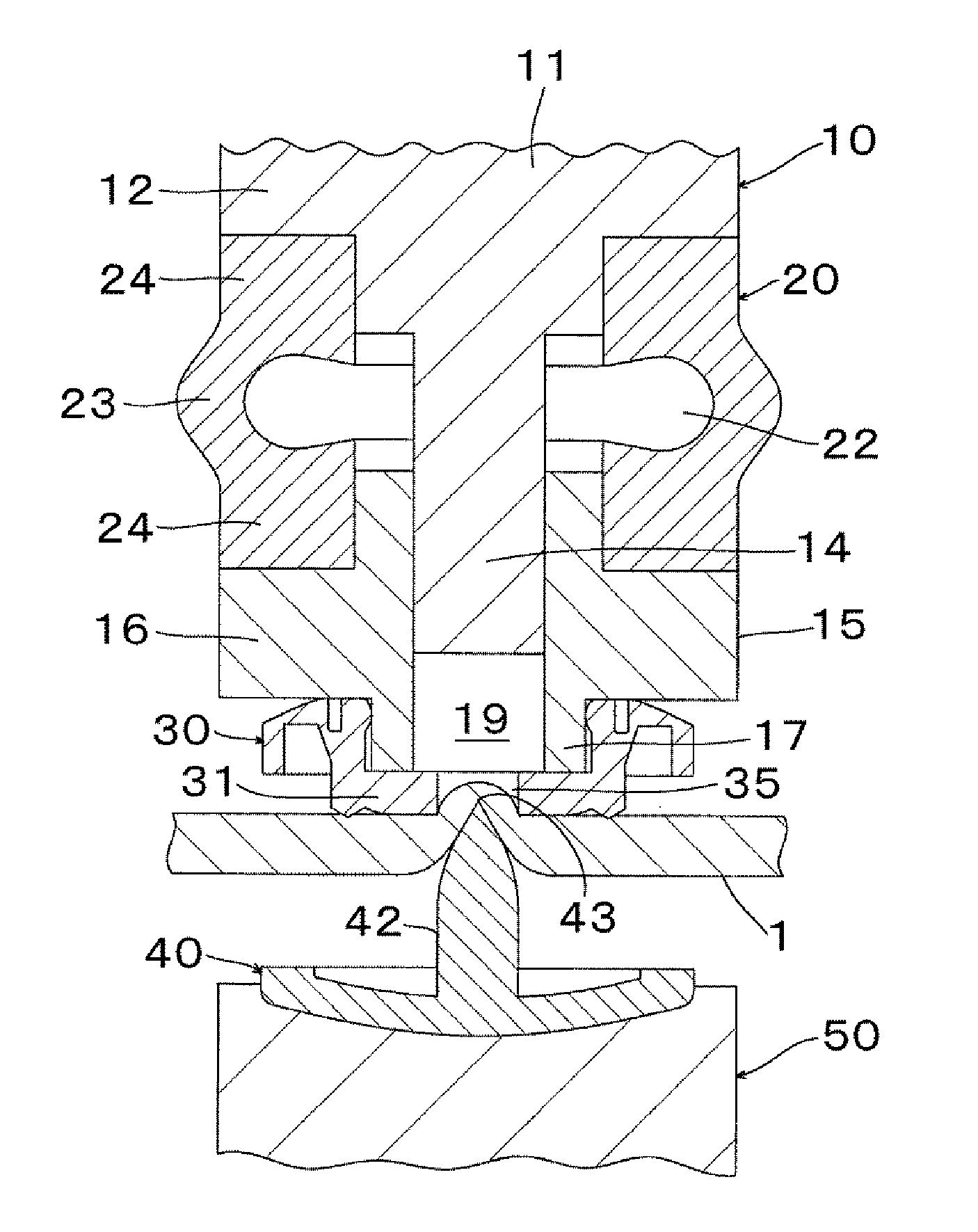

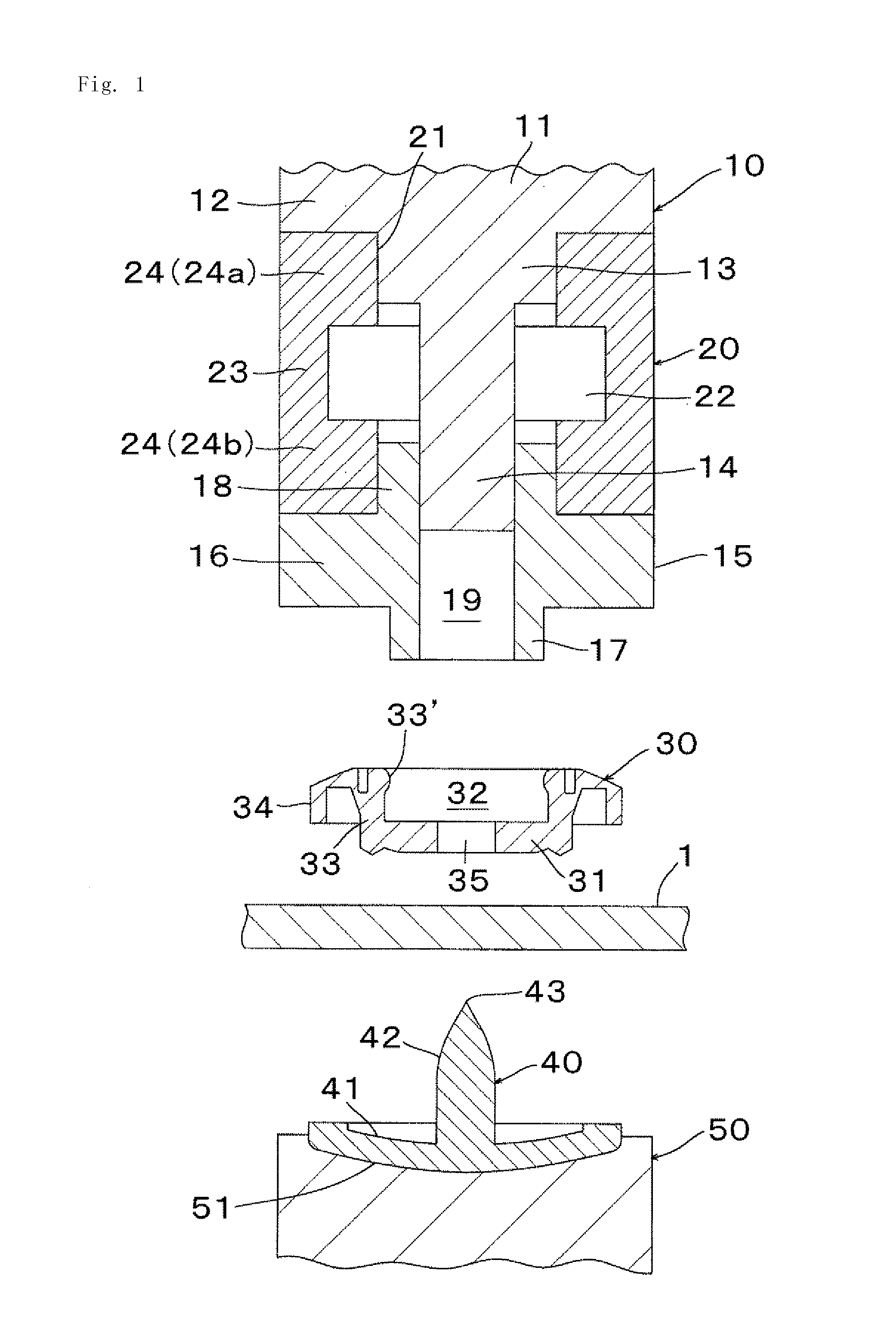

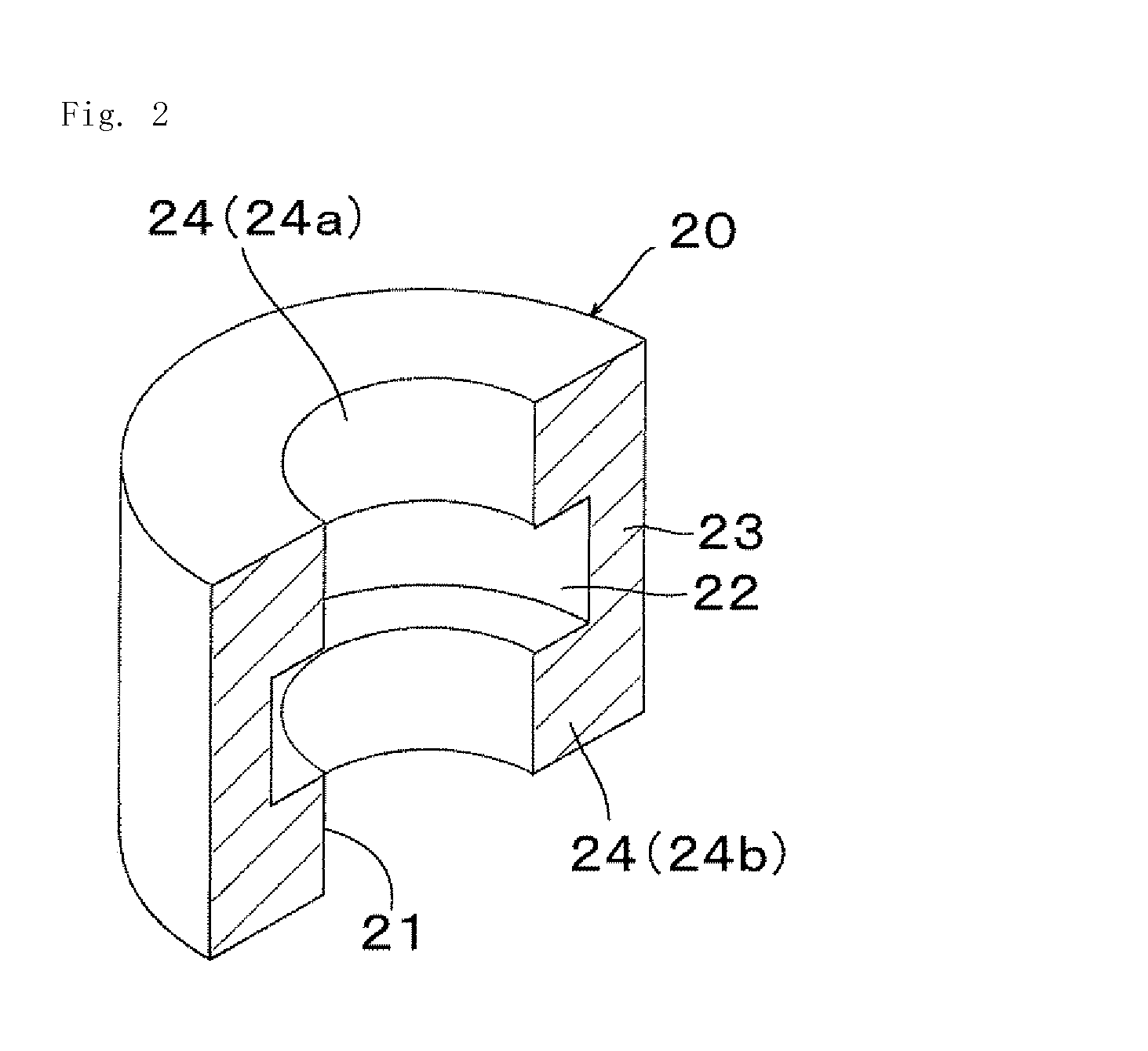

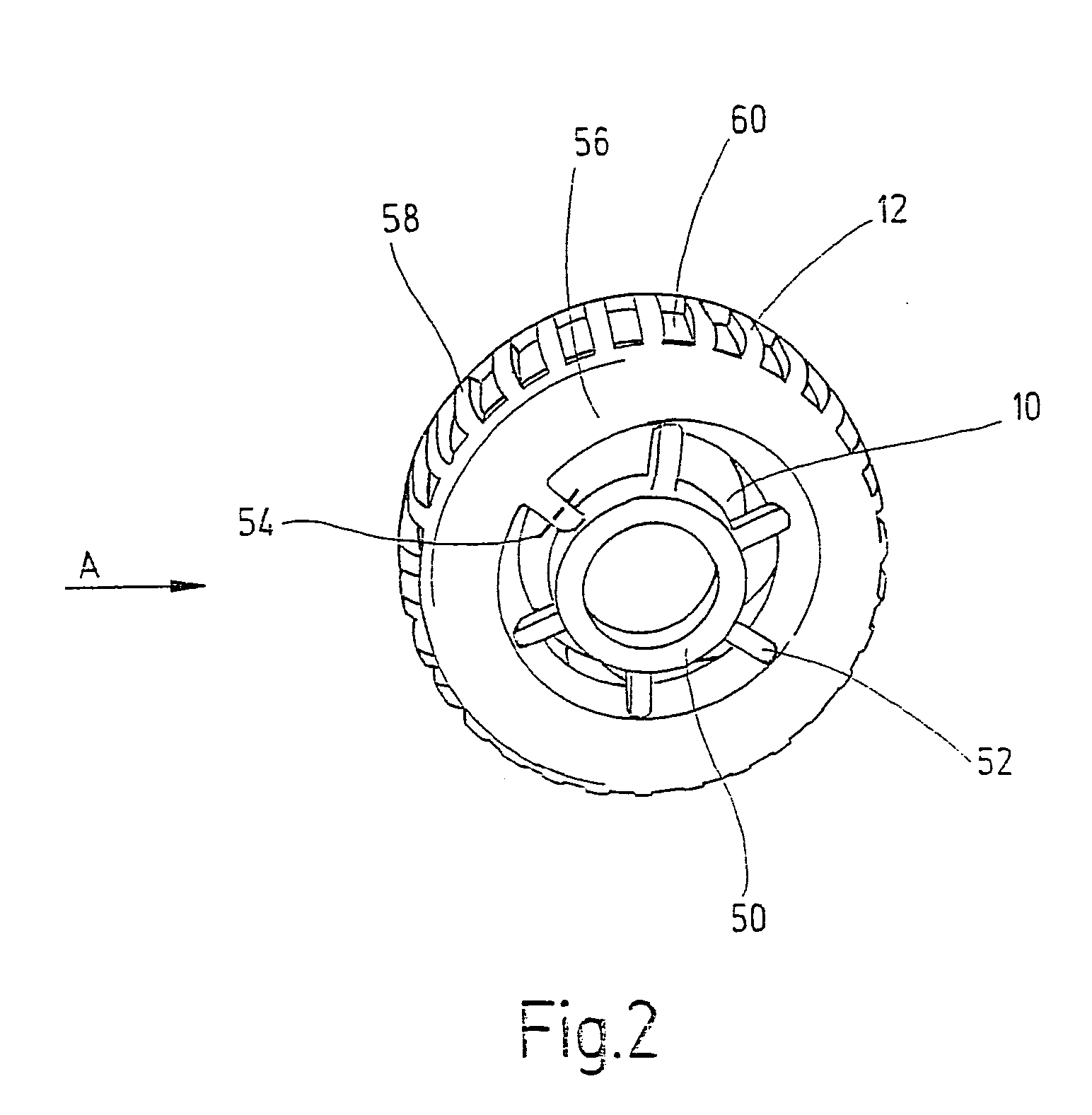

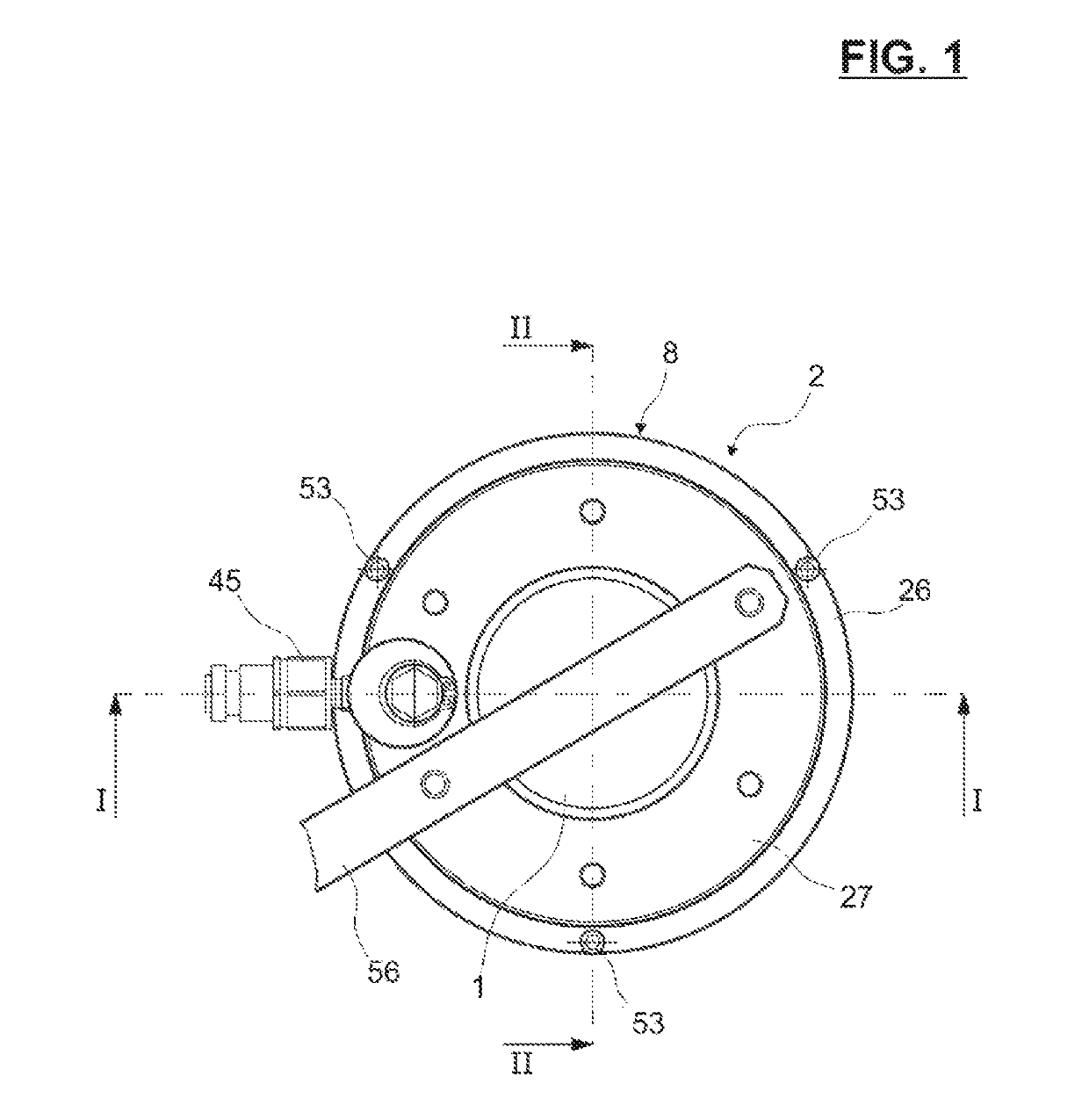

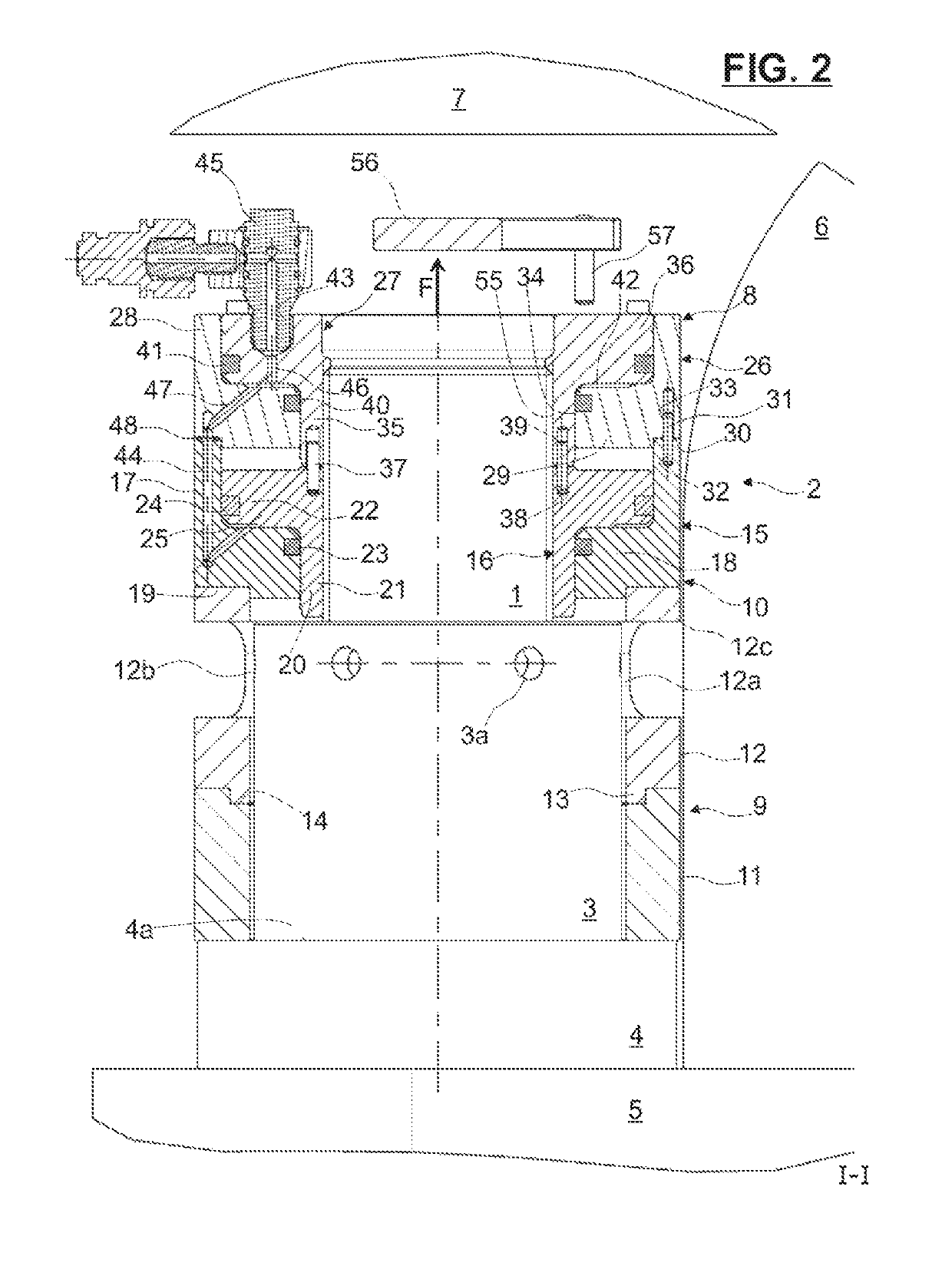

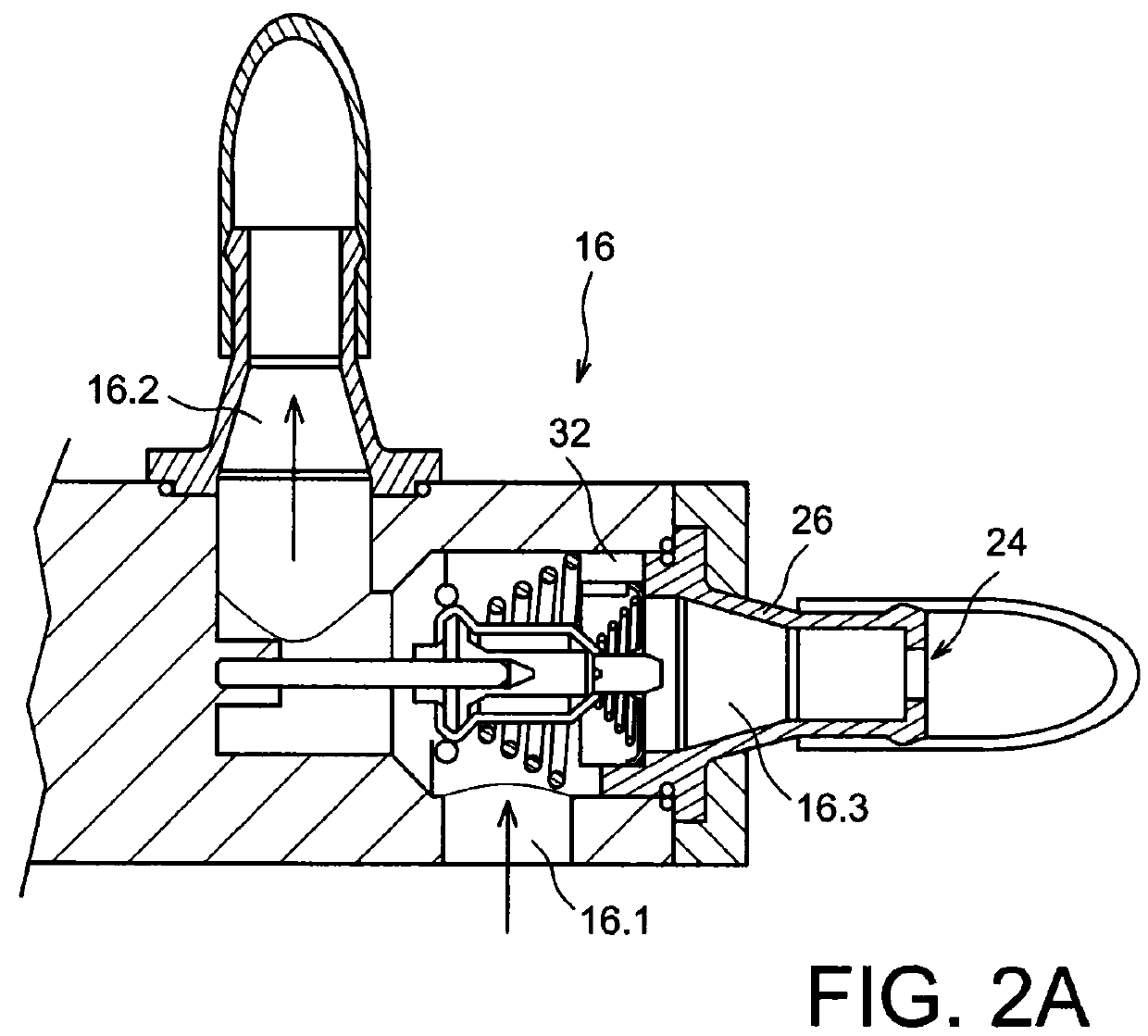

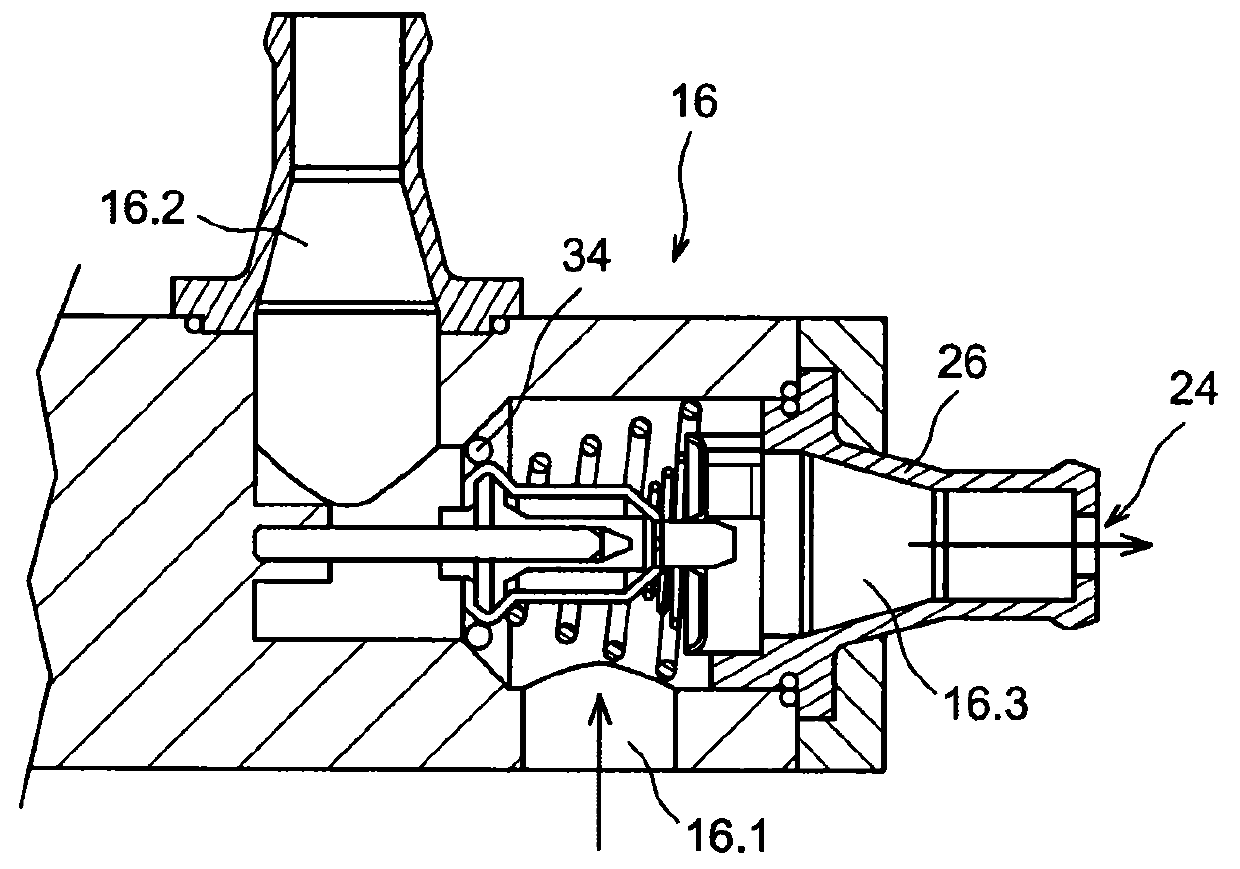

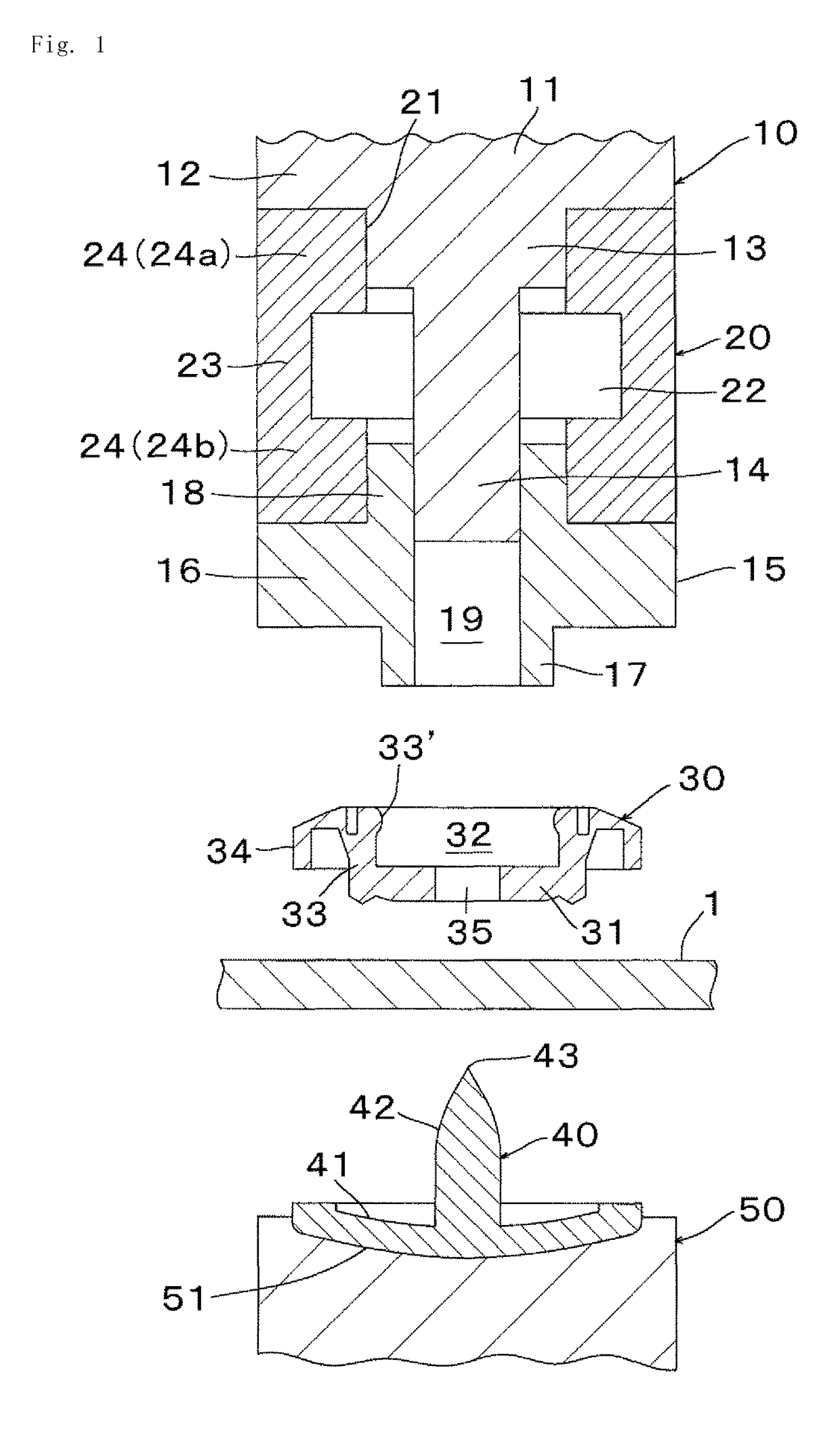

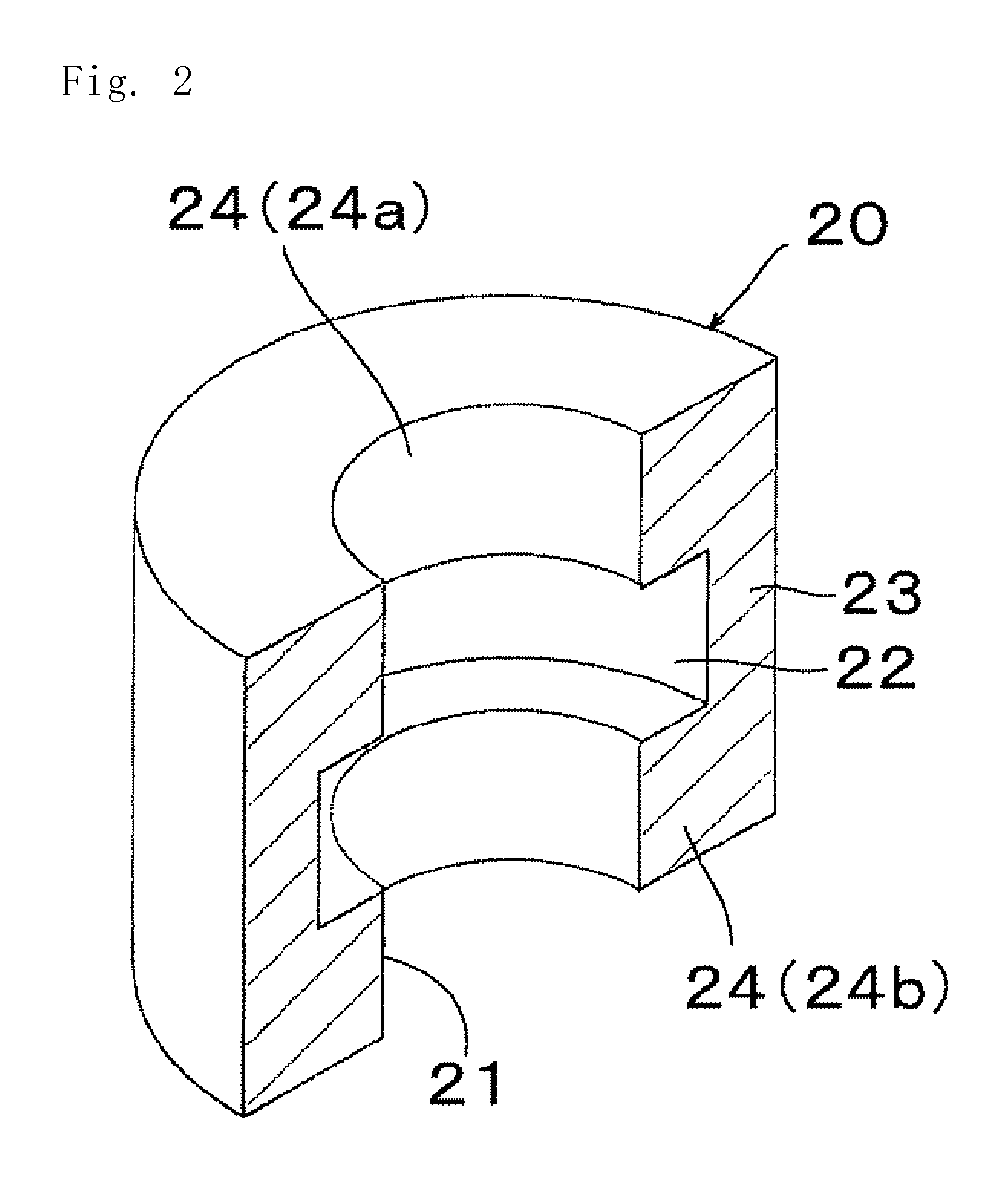

Control valve for a device for changing the control times of an internal combustion engine

InactiveUS7533695B2Easy to integrateAxial spacing reducedServomotor componentsMultiple way valvesAxial displacementExternal combustion engine

Owner:SCHAEFFLER TECH AG & CO KG

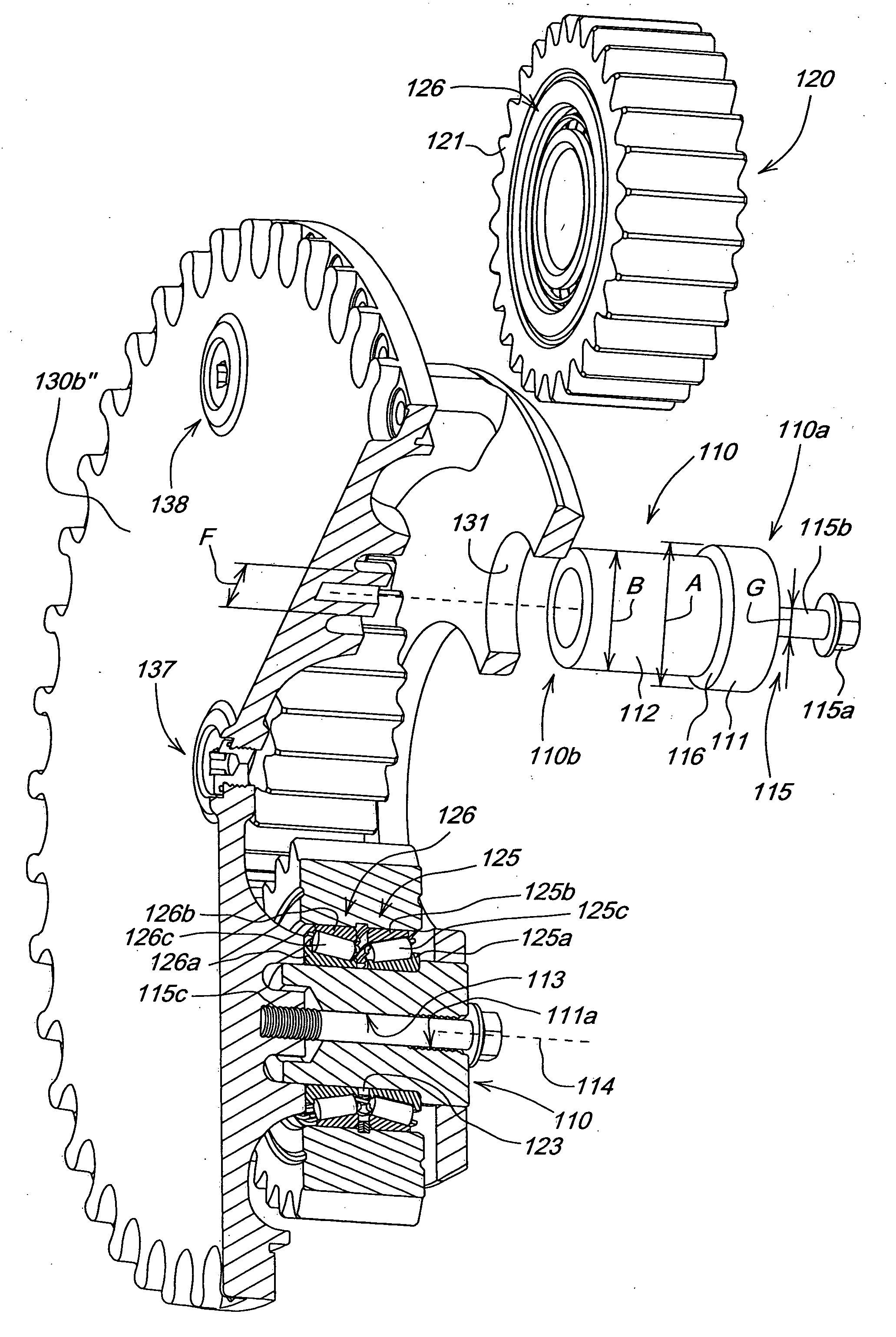

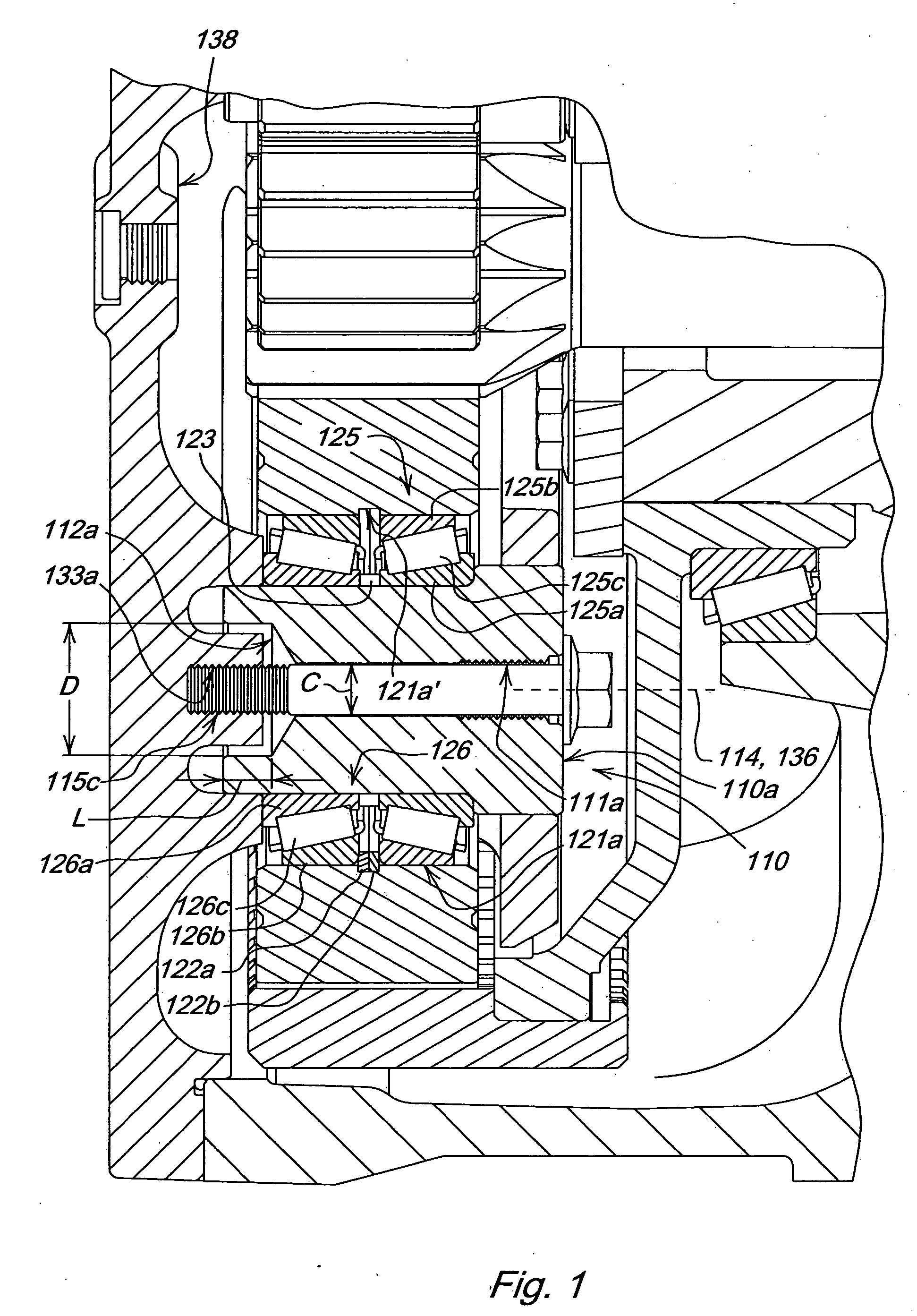

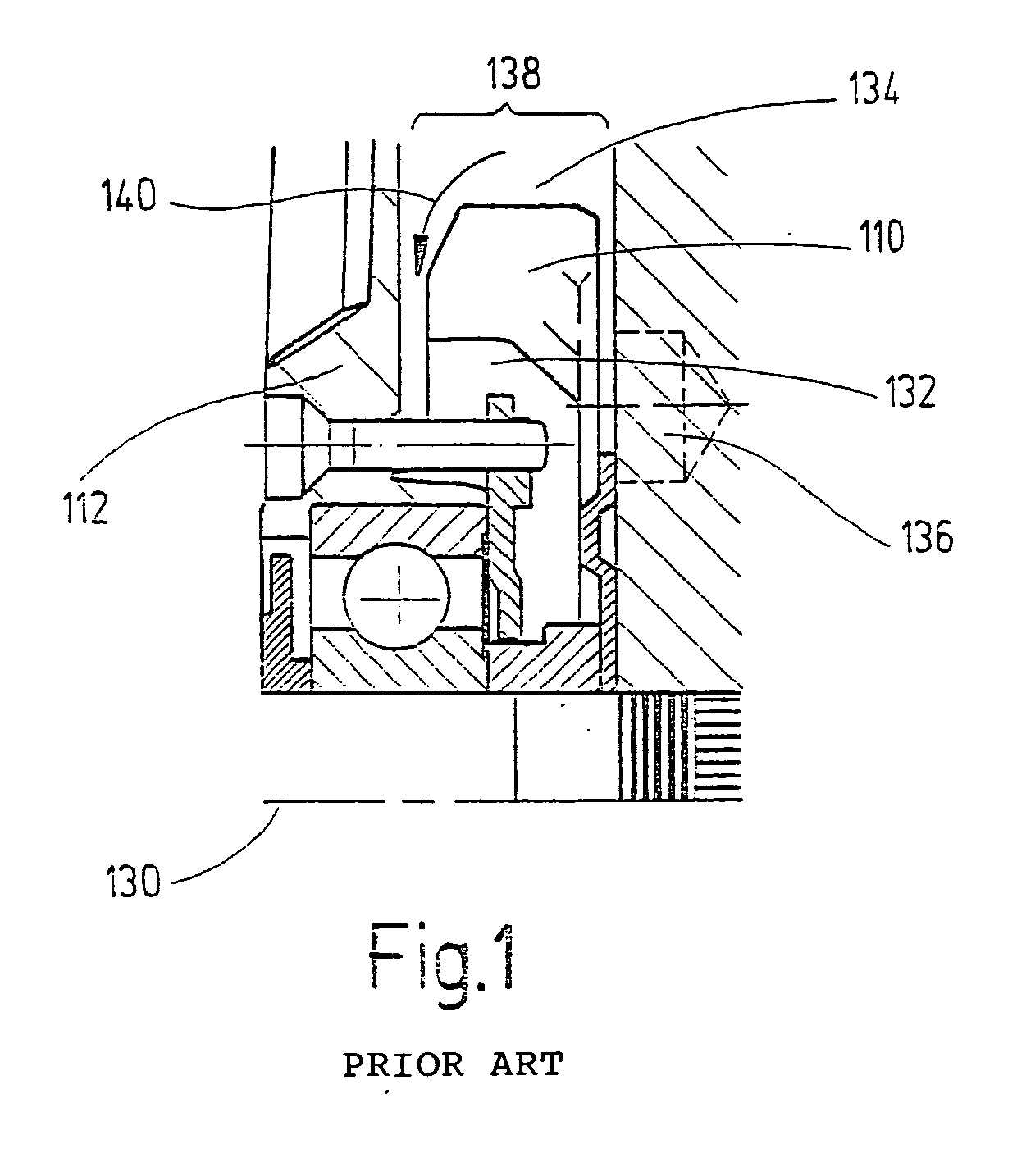

Compact planetary gear assembly

InactiveUS20060293142A1Number of part and potential leakPotential leak pathsRolling contact bearingsGearingEngineeringMechanical engineering

A planetary gear assembly for a final drive with an external surface. Planetary gears are assembled in an integrated planetary gear carrier in which the external surface of the final drive forms a part of the carrier. The external surface is continuous in the vicinity of each planetary gear in the assembly, i.e., there are no holes in the external surface associated with the connection of the planetary gears to the integrated planetary gear carrier.

Owner:DEERE & CO

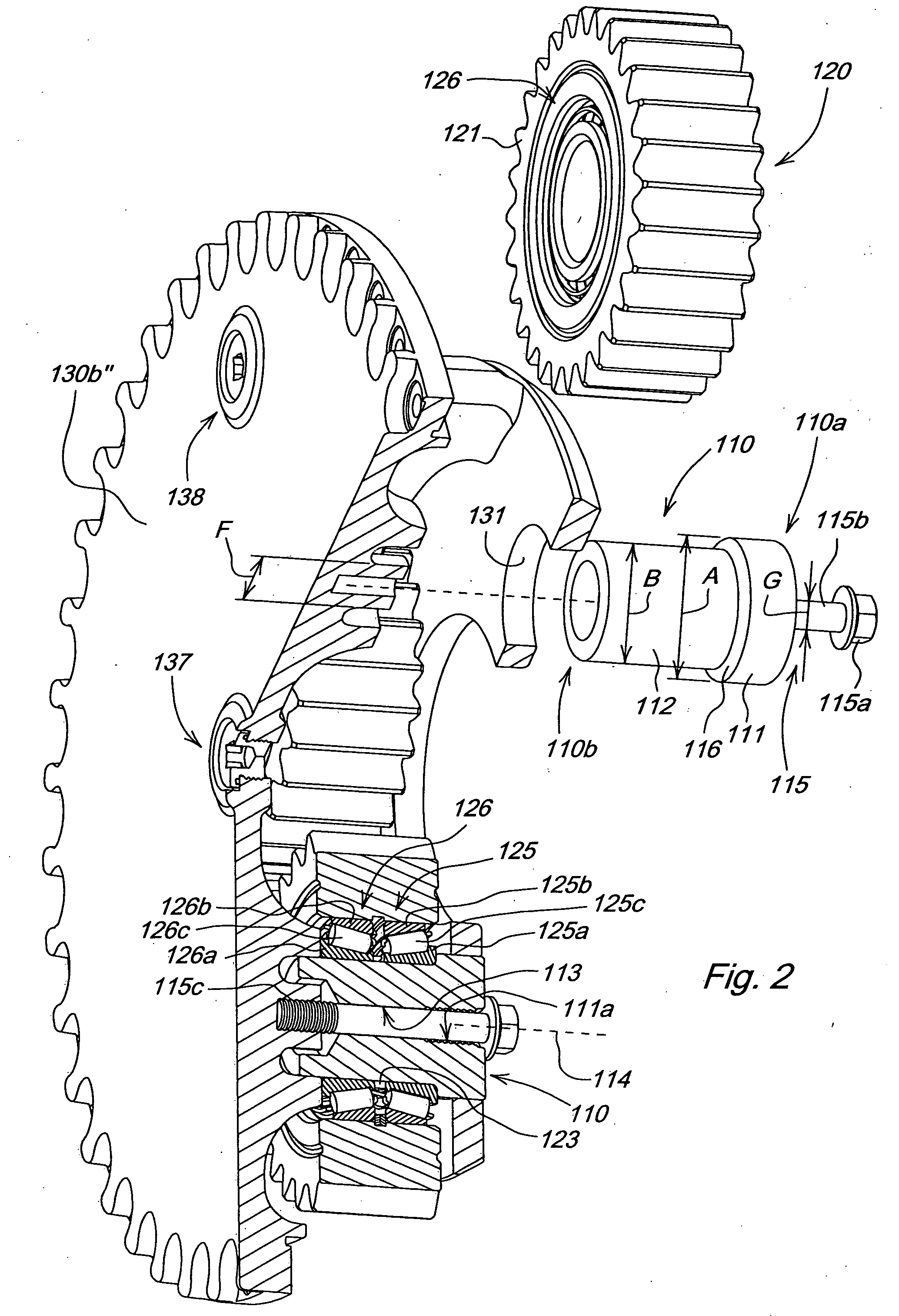

Control valve for a device for changing the control times of an internal combustion engine

InactiveUS20050252561A1Improve stabilityIncreased torsional rigidityServomotor componentsMultiple way valvesAxial displacementFuel tank

A control valve for a device for changing the control times of an internal combustion engine, having a substantially hollow-cylindrical valve housing, a control piston which is arranged within the valve housing and can be displaced axially, a pressure medium connection, two operating connections, and at least one tank connection. The operating connections, the pressure medium connection and the tank connection are formed as radial connections. It is possible for the operating connections to be connected to the pressure medium connection and the tank connection by axial displacement of the control piston within the valve housing. The operating connections are arranged adjacently.

Owner:SCHAEFFLER TECH AG & CO KG

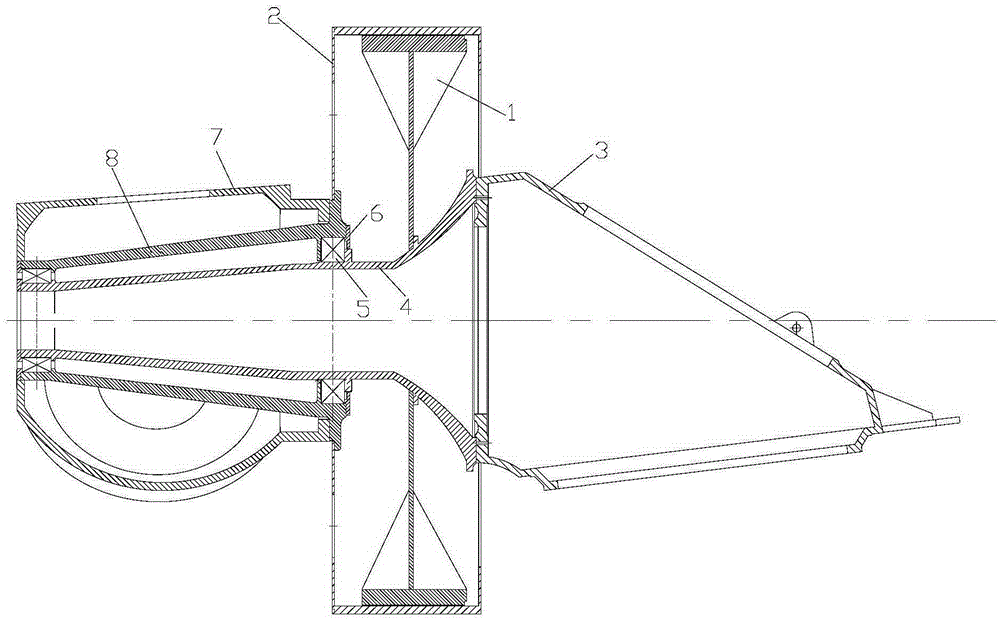

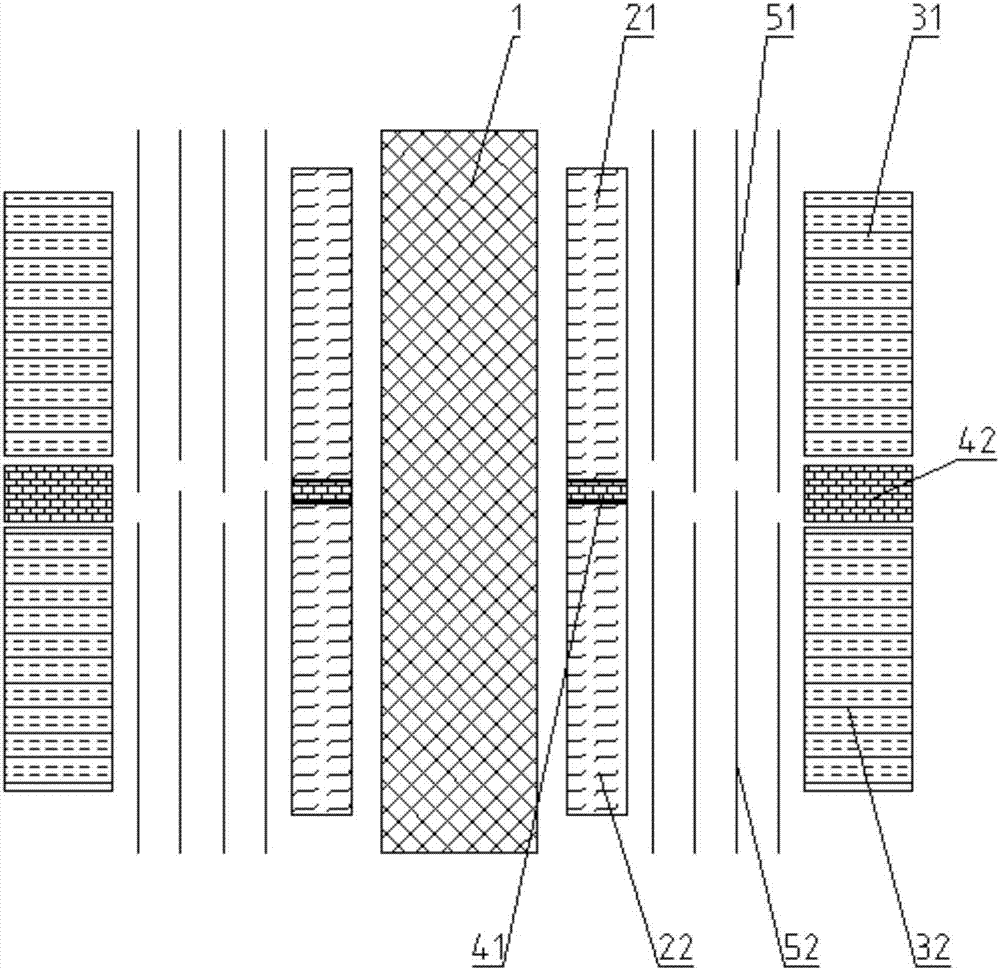

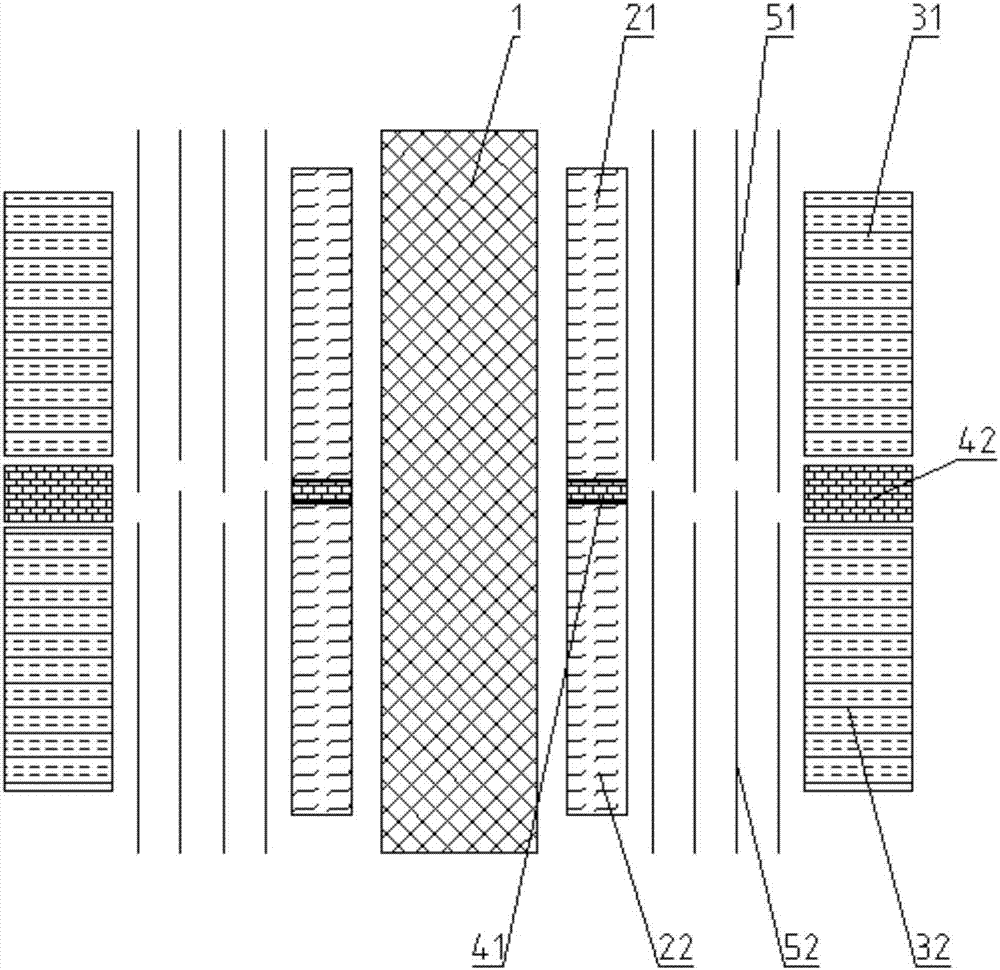

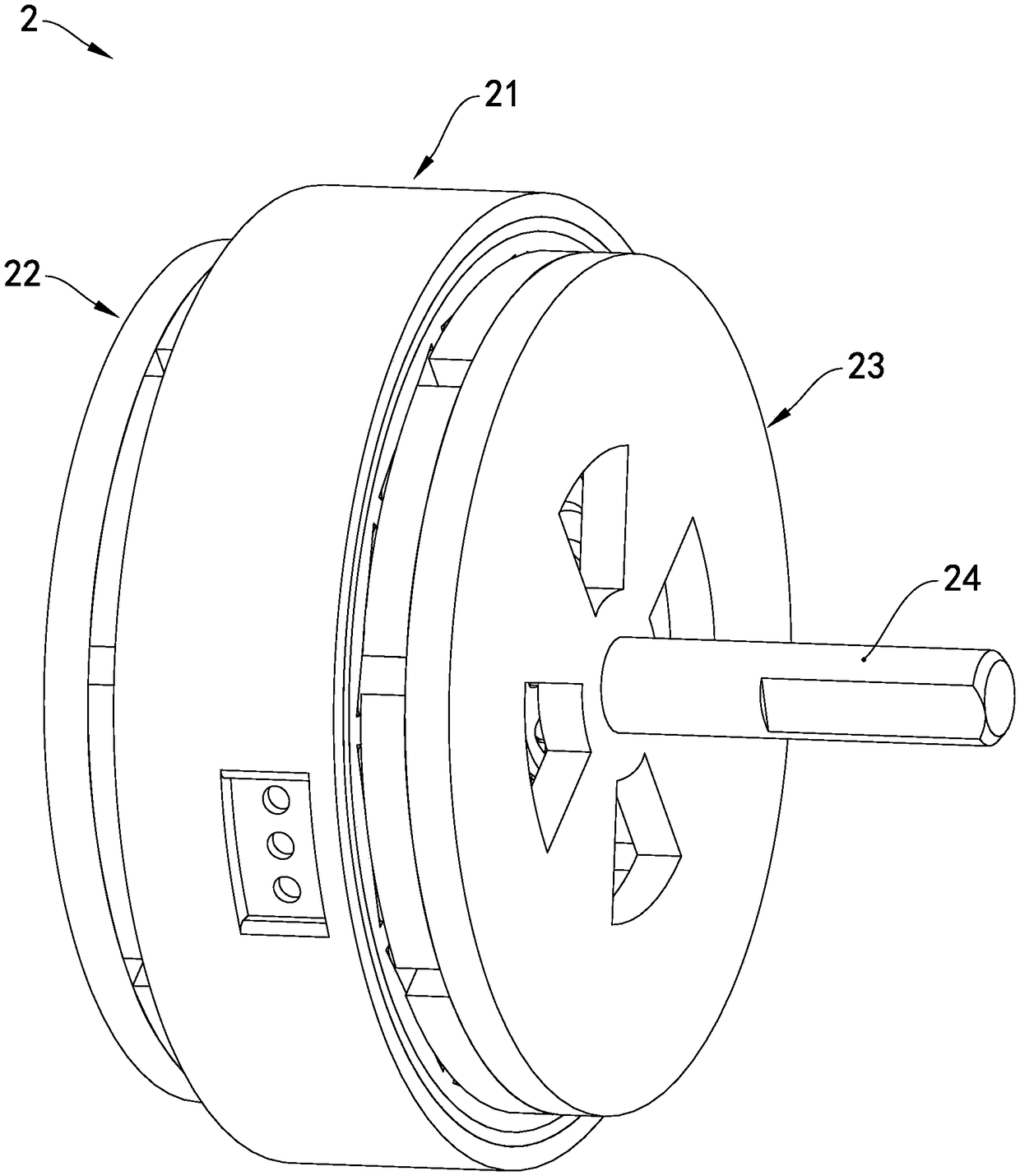

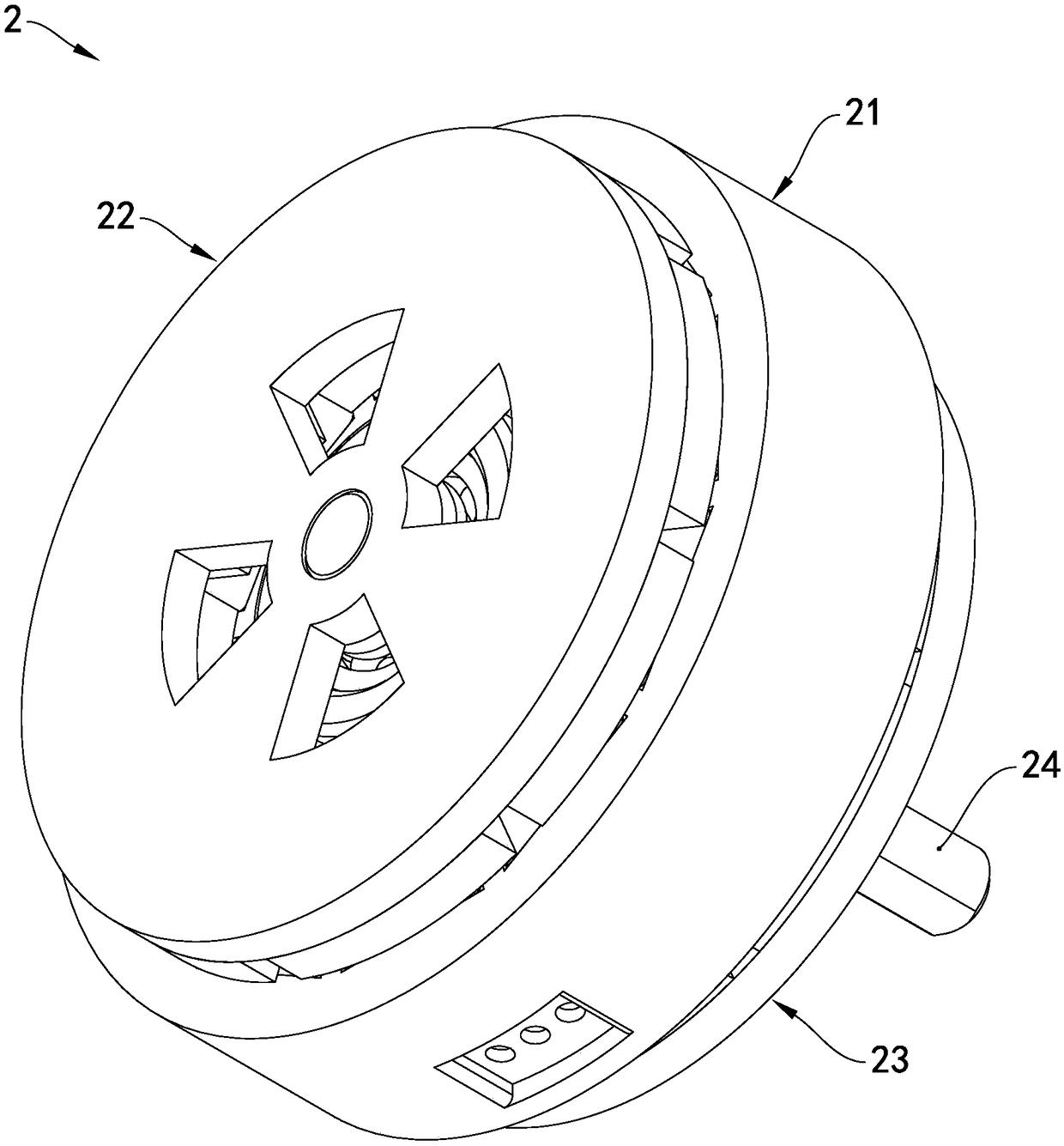

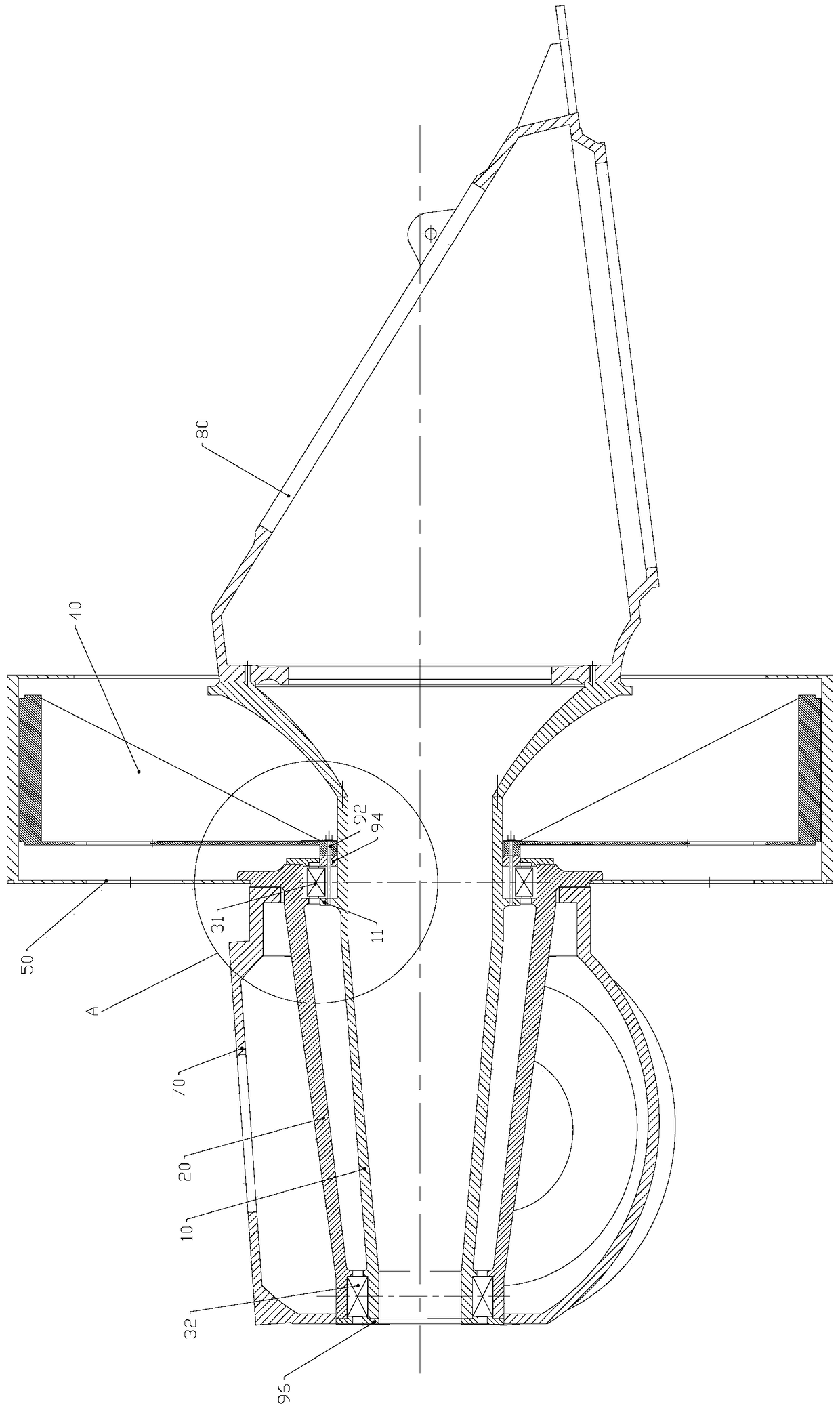

Wind driven generator and wind generating set

ActiveCN105298754AAxial spacing reducedReduce relative displacementWind motor combinationsMachines/enginesWind drivenStator

The invention provides a wind driven generator and a wind generating set. The wind driven generator comprises a fixed shaft, a movable shaft, a stator and a rotor. The movable shaft is arranged on the fixed shaft in a sleeving manner through a bearing assembly and can rotate relative to the fixed shaft; the bearing assembly comprises a first bearing, the inner ring of the first bearing is fixedly arranged on the fixed shaft, and the movable shaft is fixedly connected to the outer ring of the first bearing; the stator is fixedly connected to the inner ring of the first bearing; and the rotor is fixedly connected to the movable shaft, and the position of the rotor on the movable shaft corresponds to the first bearing in the radial direction. The wind driven generator can well ensure the air gap uniformity in the running process, and the weight of the fixed shaft does not need to be increased.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

Separator grease retention and feed system for wheel spindle bearings

InactiveUS20050058377A1Reduces and eliminates drawbackMinimum frictionRolling contact bearingsCastorsLubricationLubricant

A separator for a bearing comprising a frame including a plurality of cavities for receiving rolling elements and further including a lubrication channel in fluid communication with at least one of the plurality of cavities. This separator may be a component of a bearing including an inner race, an outer race, and a plurality of rolling elements disposed in each of the plurality of cavities of the separator and set to be in movable contact with the outer race and inner race of the bearing. A lubricant is introduced into the lubrication channel and flows into each of the plurality of cavities which provides evenly distributed lubrication to each rolling element of the bearing assembly.

Owner:DELPHI TECH INC

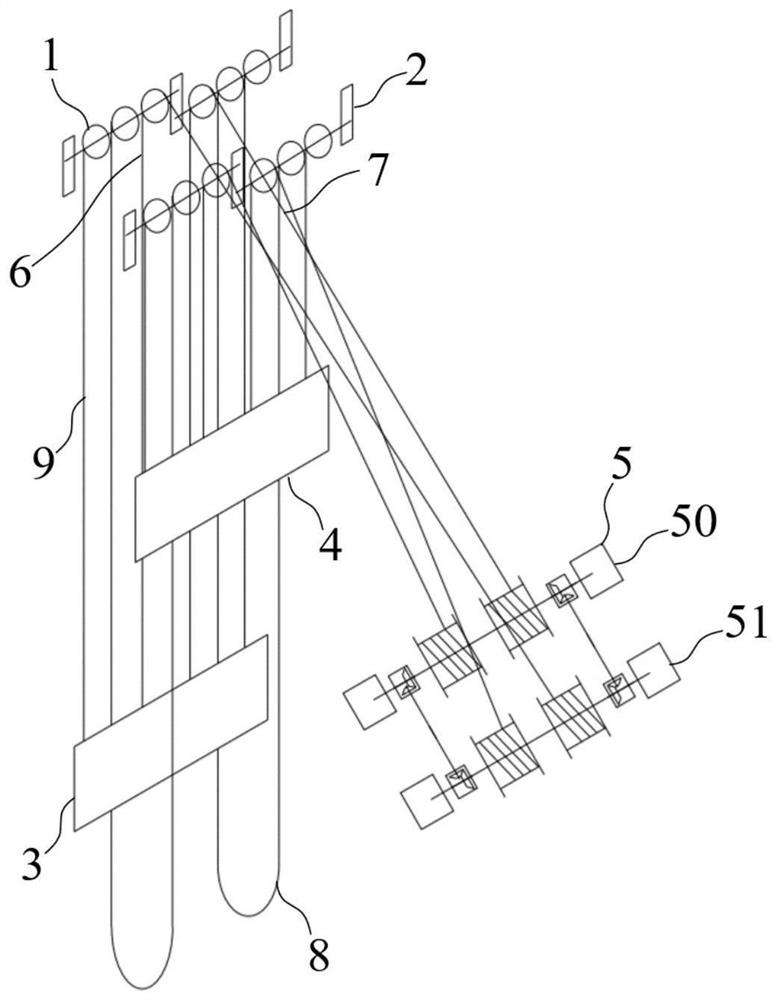

Multi-rope lifting system for ultra-deep vertical shaft and guiding method of multi-rope lifting system

ActiveCN112357724AReduce traction loadExtend effective lifeElevatorsMine liftsStructural engineeringMechanical engineering

The invention discloses a multi-rope lifting system for an ultra-deep vertical shaft and a guiding method of the multi-rope lifting system, and belongs to the technical field of mine lifting. The multi-rope lifting system comprises an upper guiding wheel system, a lower guiding wheel system, a front lifting container, a rear lifting container, a driving unit, a front lifting rope, a rear lifting rope, a tail rope and a plurality of balance head ropes, wherein the front lifting rope is lapped on the upper guiding wheel system, one end of the front lifting rope is connected with the top of the front lifting container, and the other end of the front lifting rope is connected with the driving unit; the rear lifting rope is lapped on the lower guiding wheel system, one end of the rear lifting rope is connected with the top of the rear lifting container, and the other end of the rear lifting rope is connected with the driving unit; one end of the tail rope is connected with the bottom of thefront lifting container, and the other end of the tail rope is connected with the bottom of the rear lifting container; and the balance head ropes are lapped on the upper guiding wheel system, one end of each balance head rope is connected with the top of the front lifting container, and the other end of each balance head rope is connected with the top of the rear lifting container. According tothe multi-rope lifting system, the balance head ropes are arranged, so that the traction load borne by the driving unit is greatly reduced, the effective service life of the driving unit is greatly prolonged, and the multi-rope lifting system for the ultra-deep vertical shaft can carry out lifting operation with larger load.

Owner:CHINA UNIV OF MINING & TECH

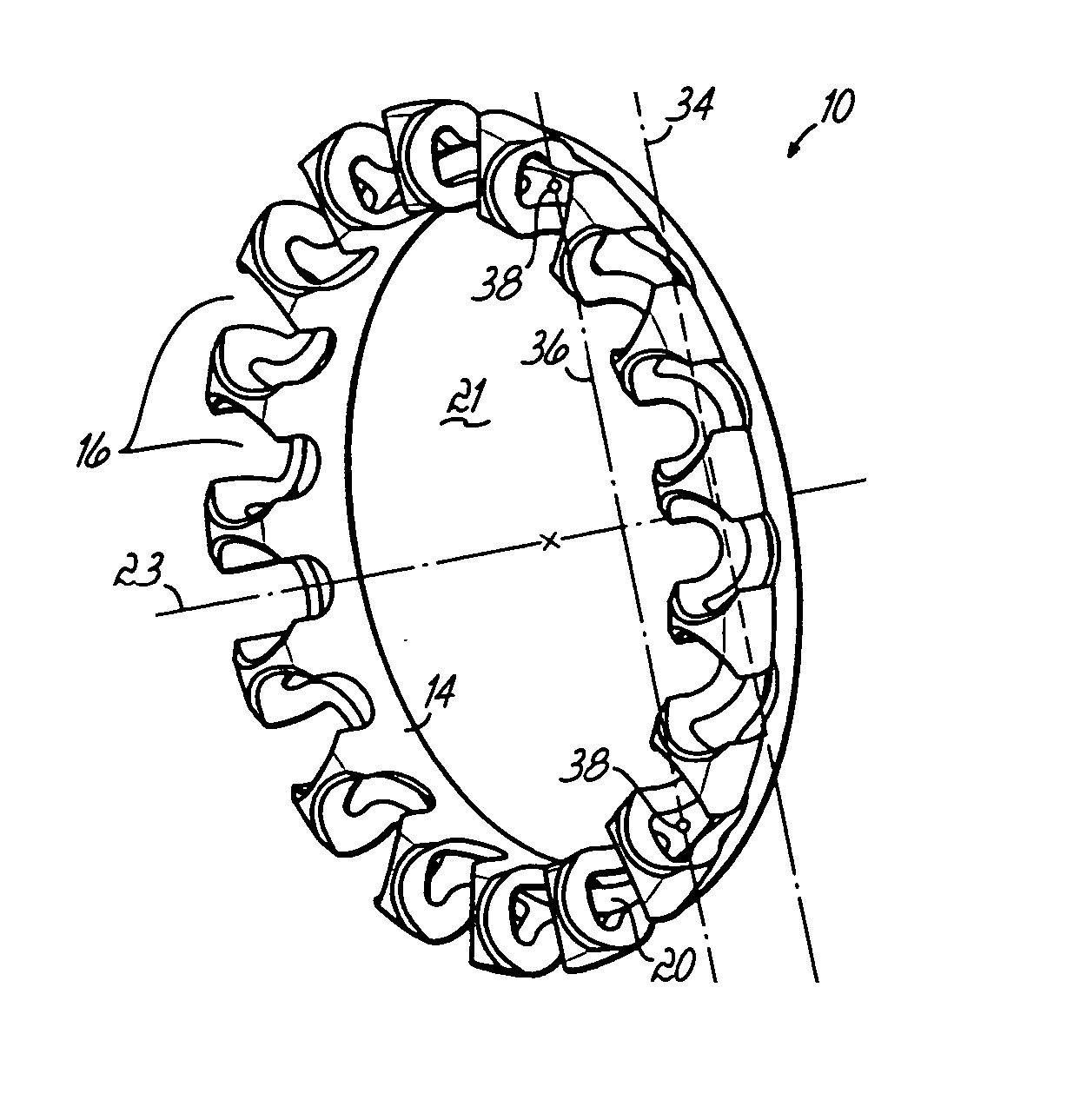

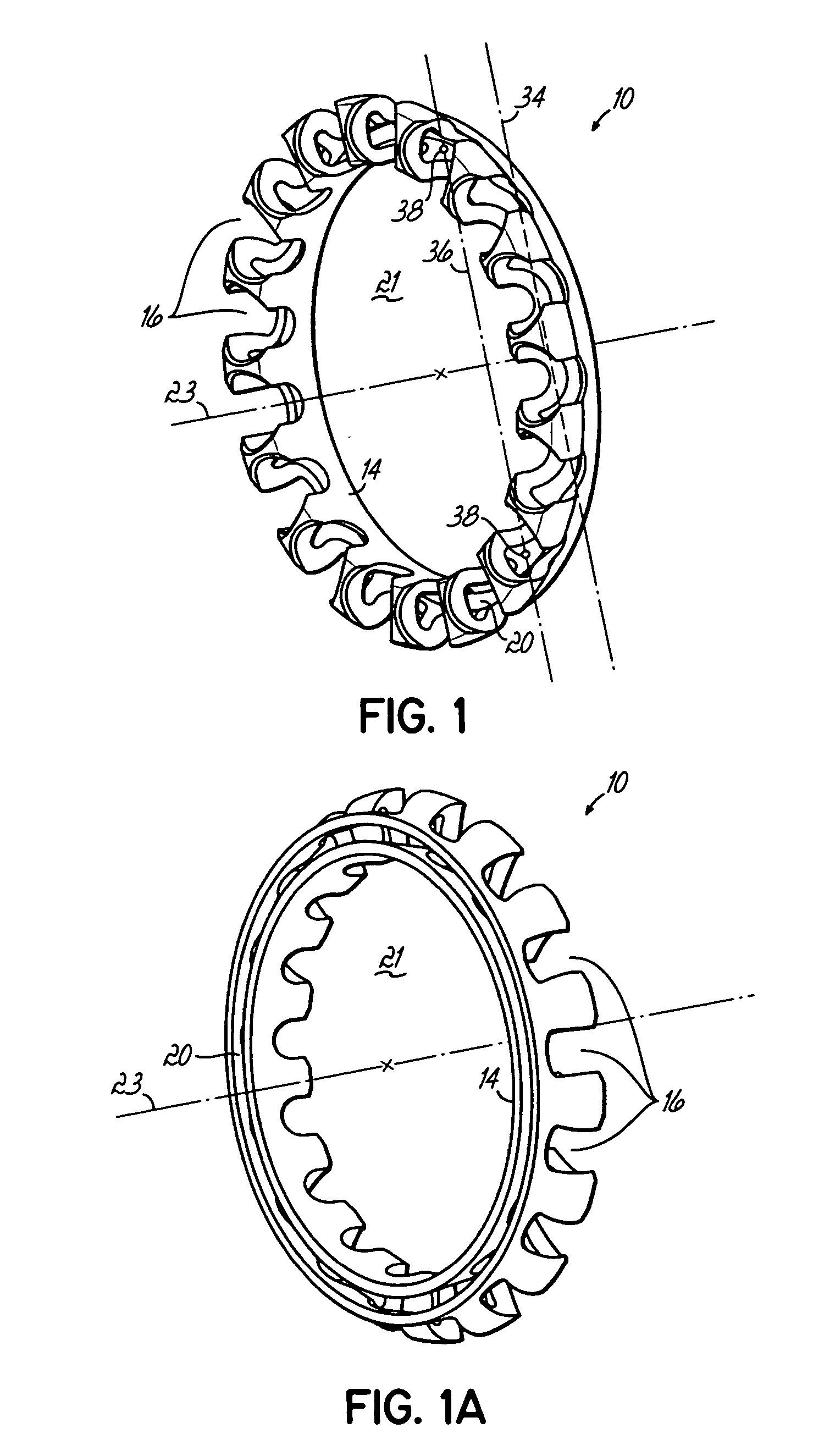

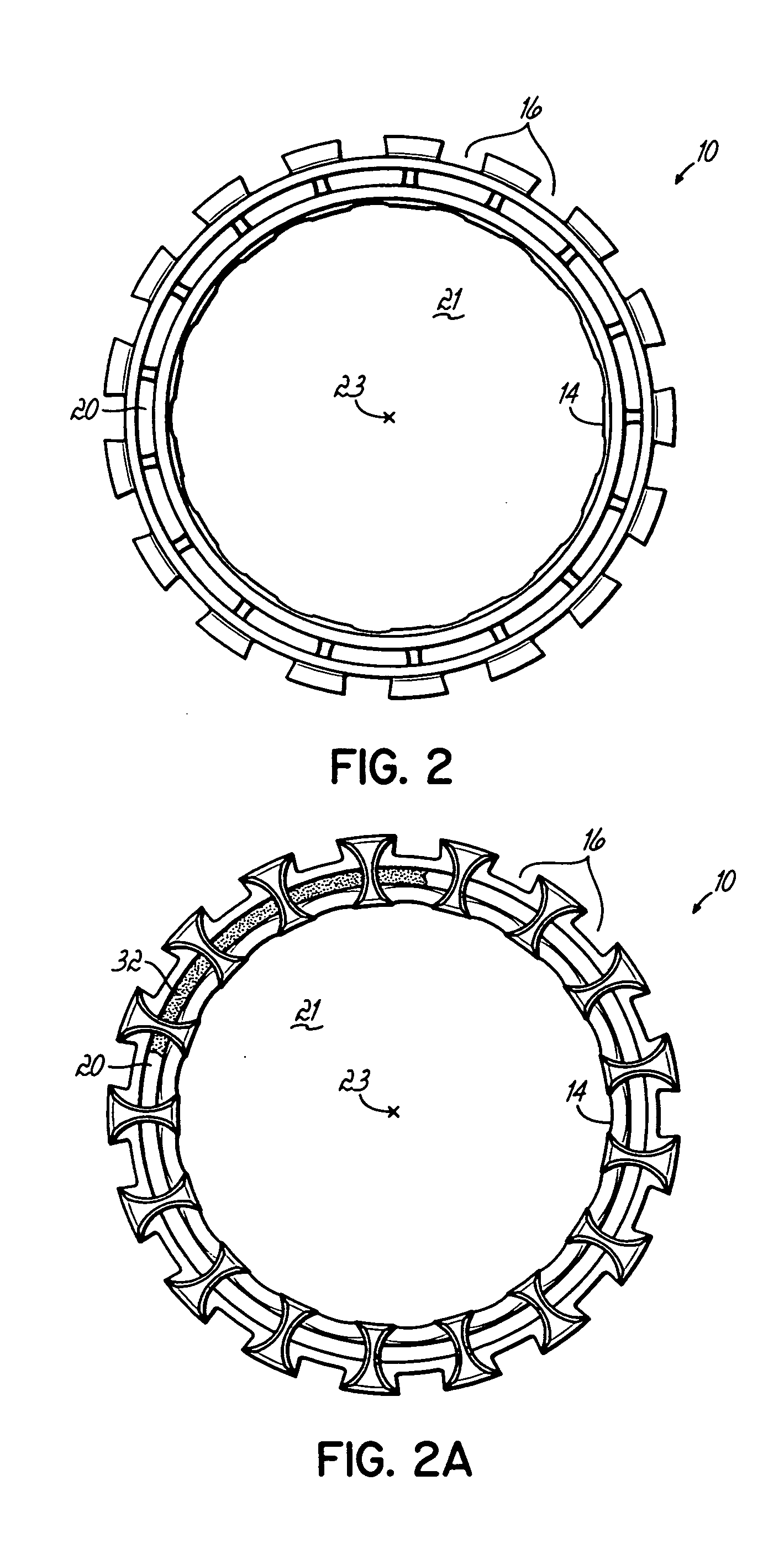

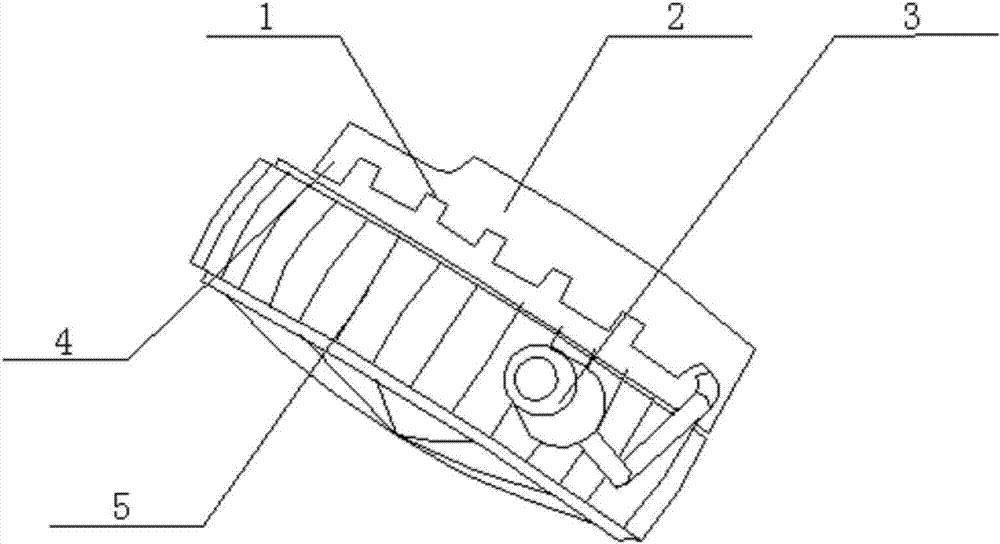

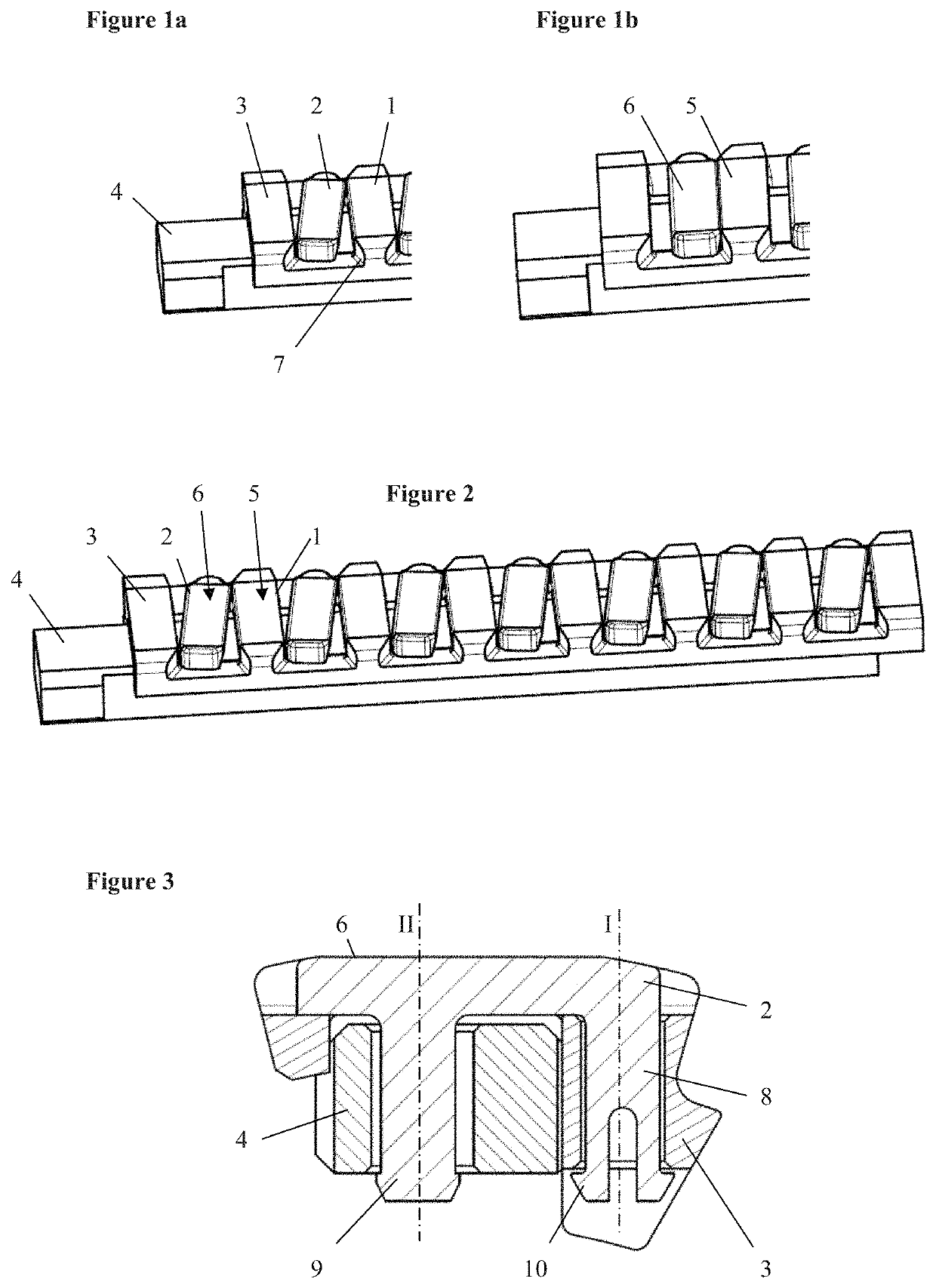

Perforating Gun Assembly and Method of Forming Wellbore Perforations

ActiveUS20150368996A1Low flow resistanceReduced flow convergenceFluid removalCharge carrierShaped charge

A perforating gun assembly used to form perforations in a wellbore includes a charge carrier having a longitudinal axis, and multiple groups of shaped charges that are disposed on the charge carrier. Two or more of the shaped charges within each group are arranged to generate jets oriented substantially along respective axes that converge towards one another. Also, two or more of the groups of shaped charges overlap one another in a longitudinal direction of the charge carrier.

Owner:DELPHIAN BALLISTICS

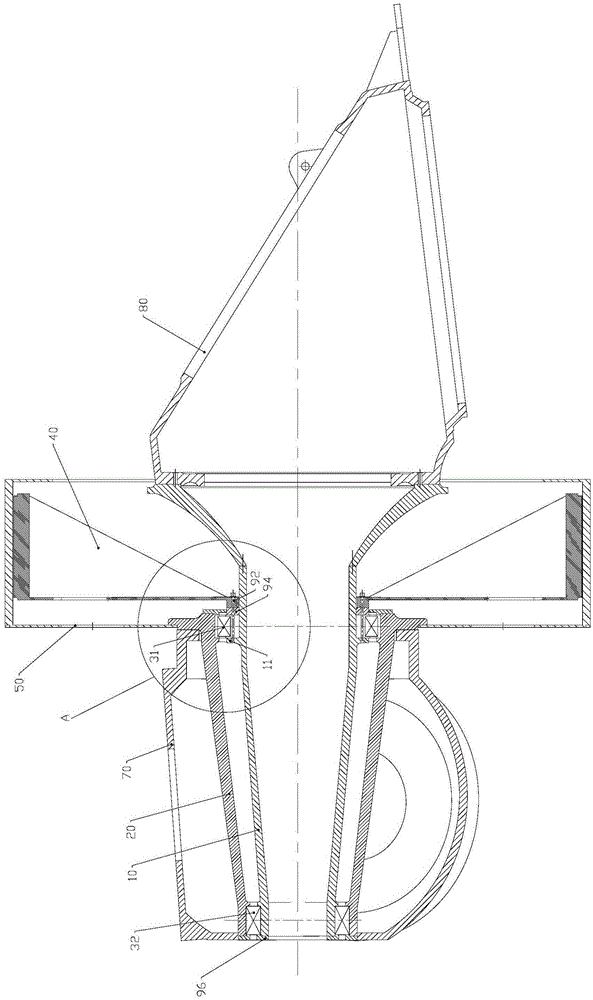

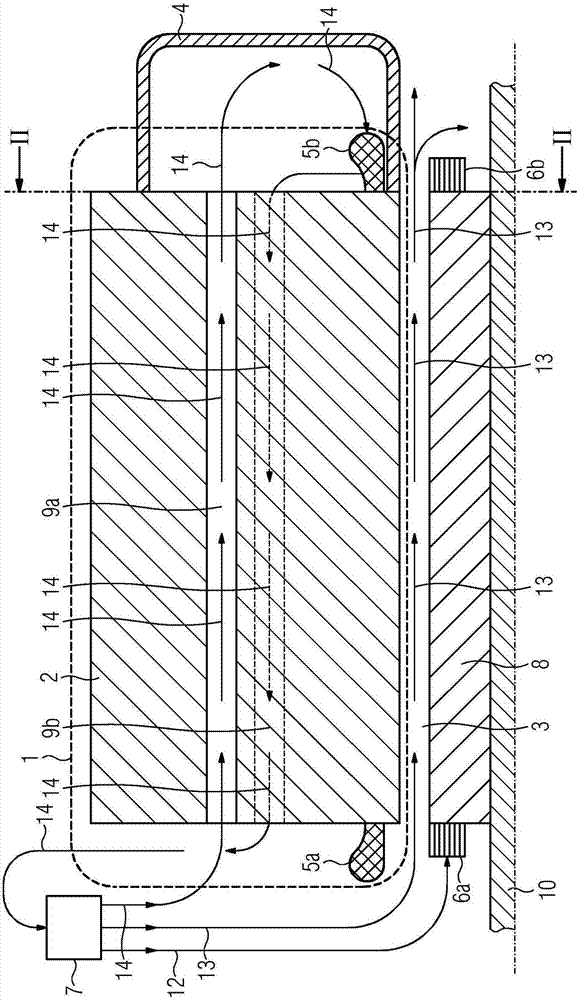

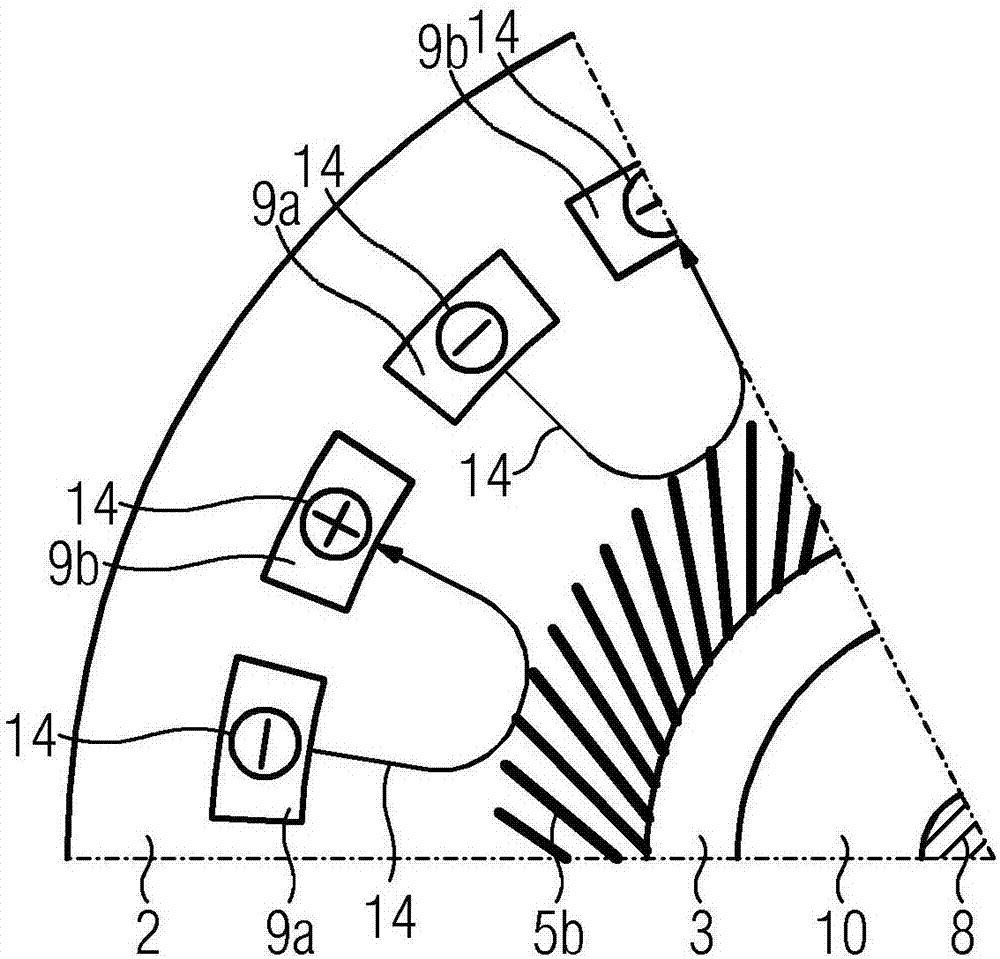

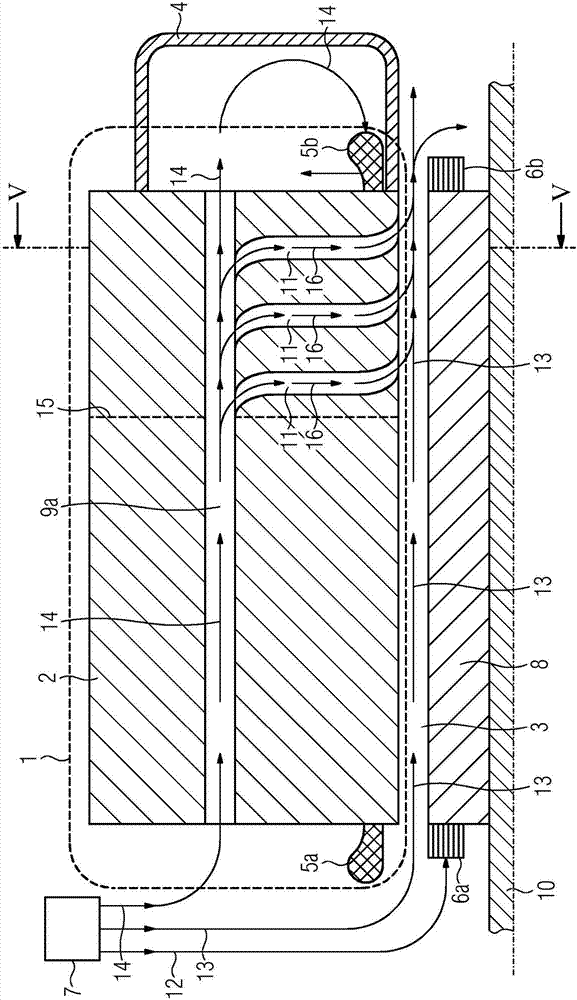

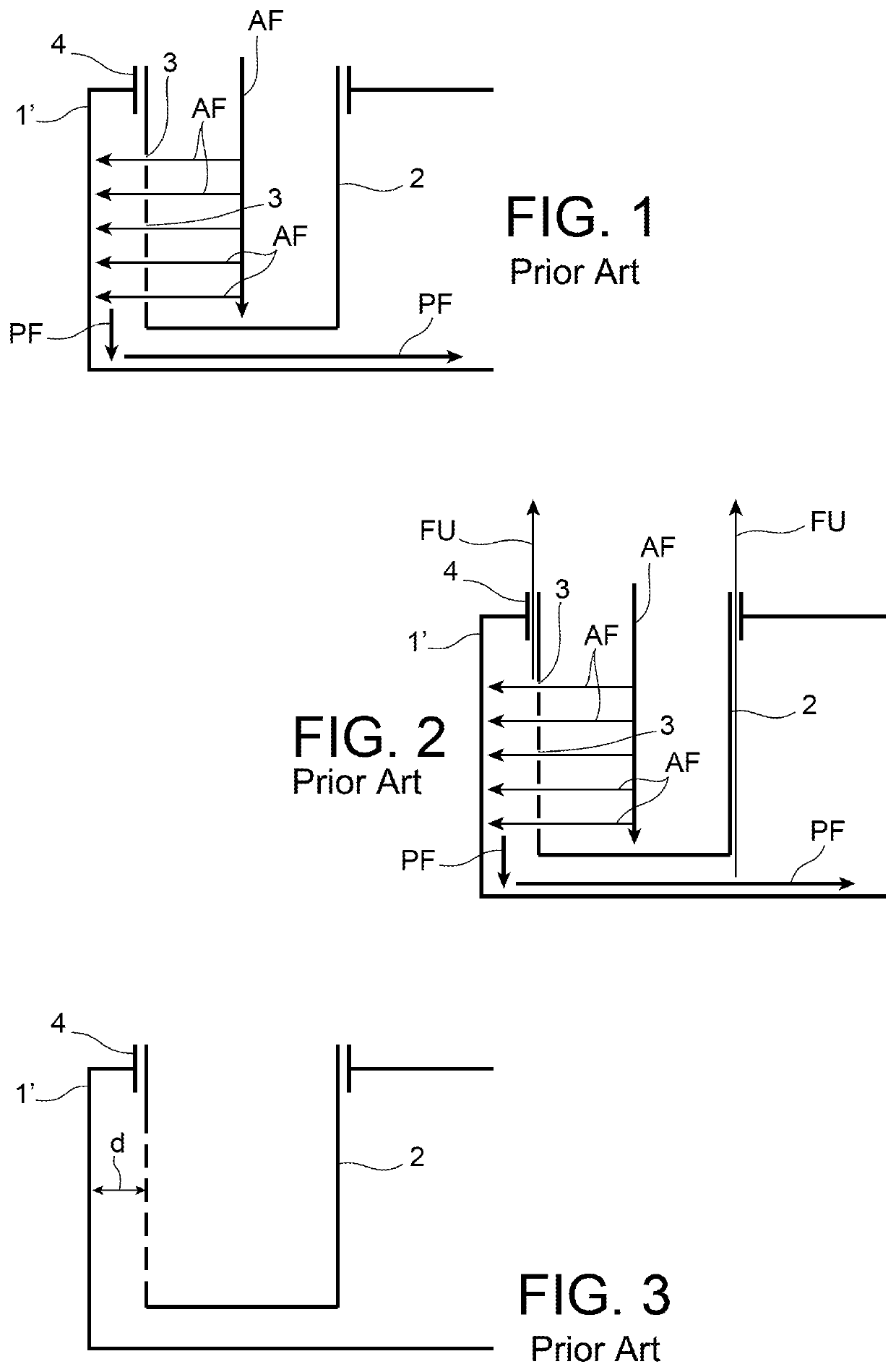

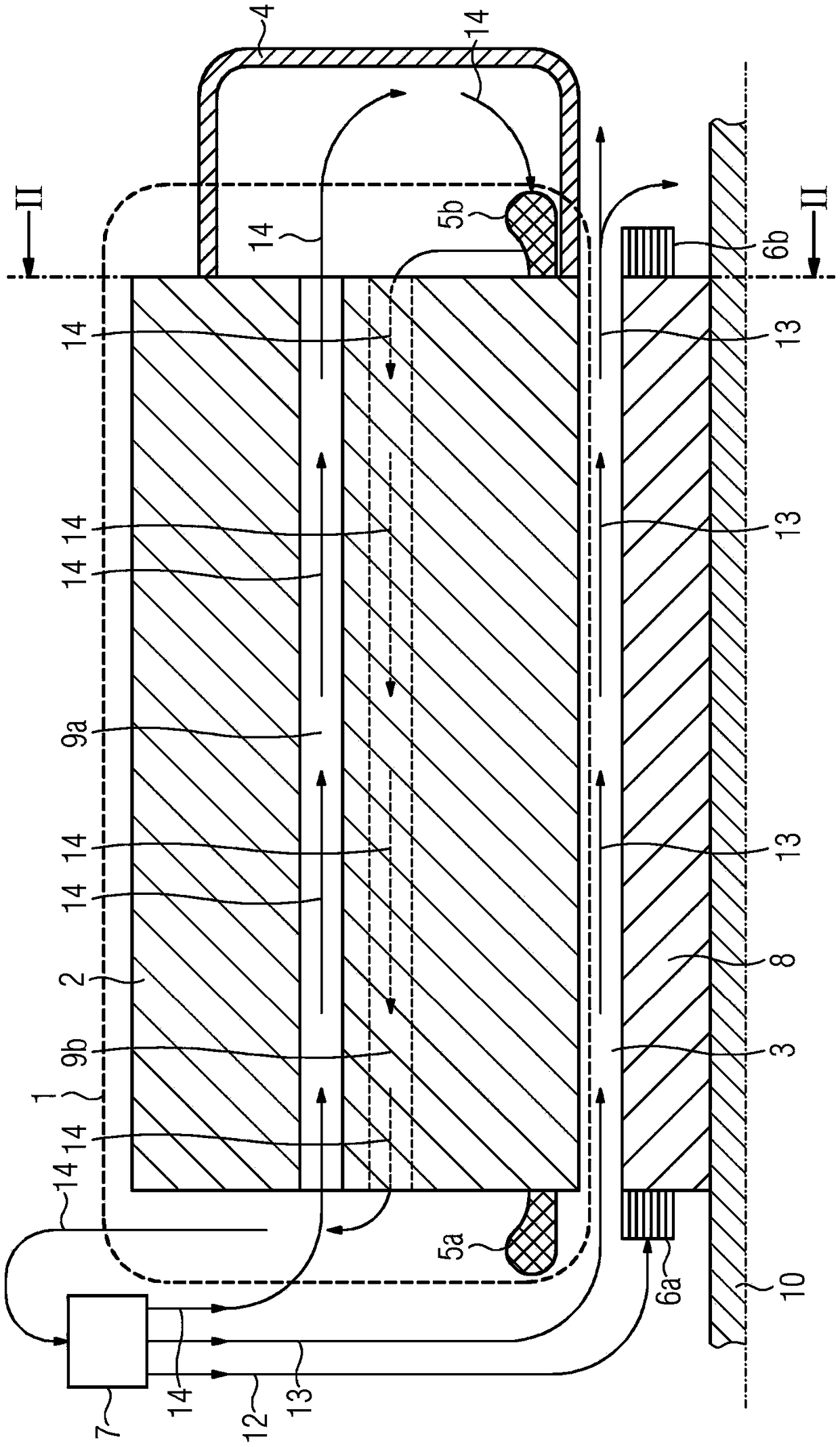

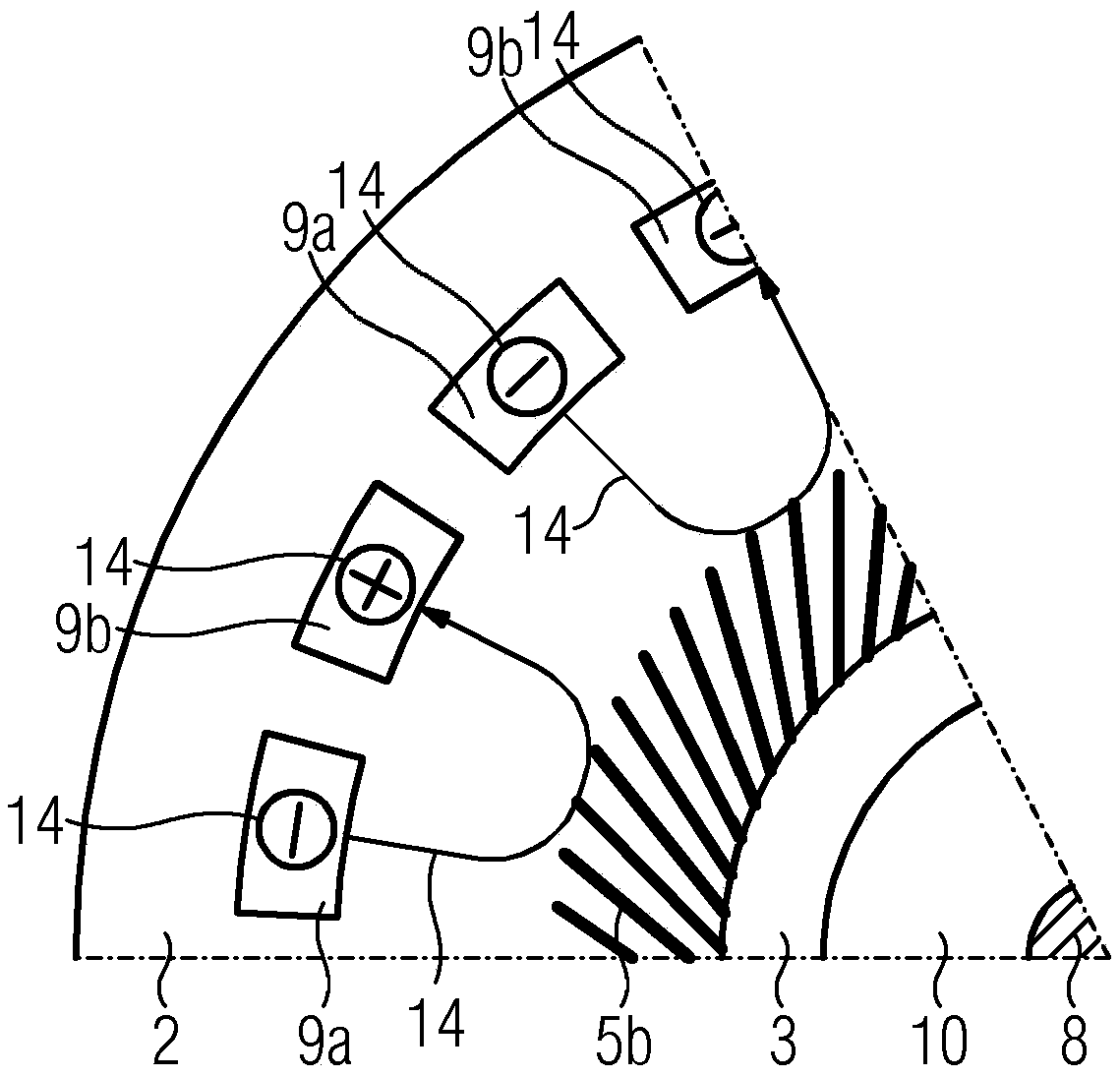

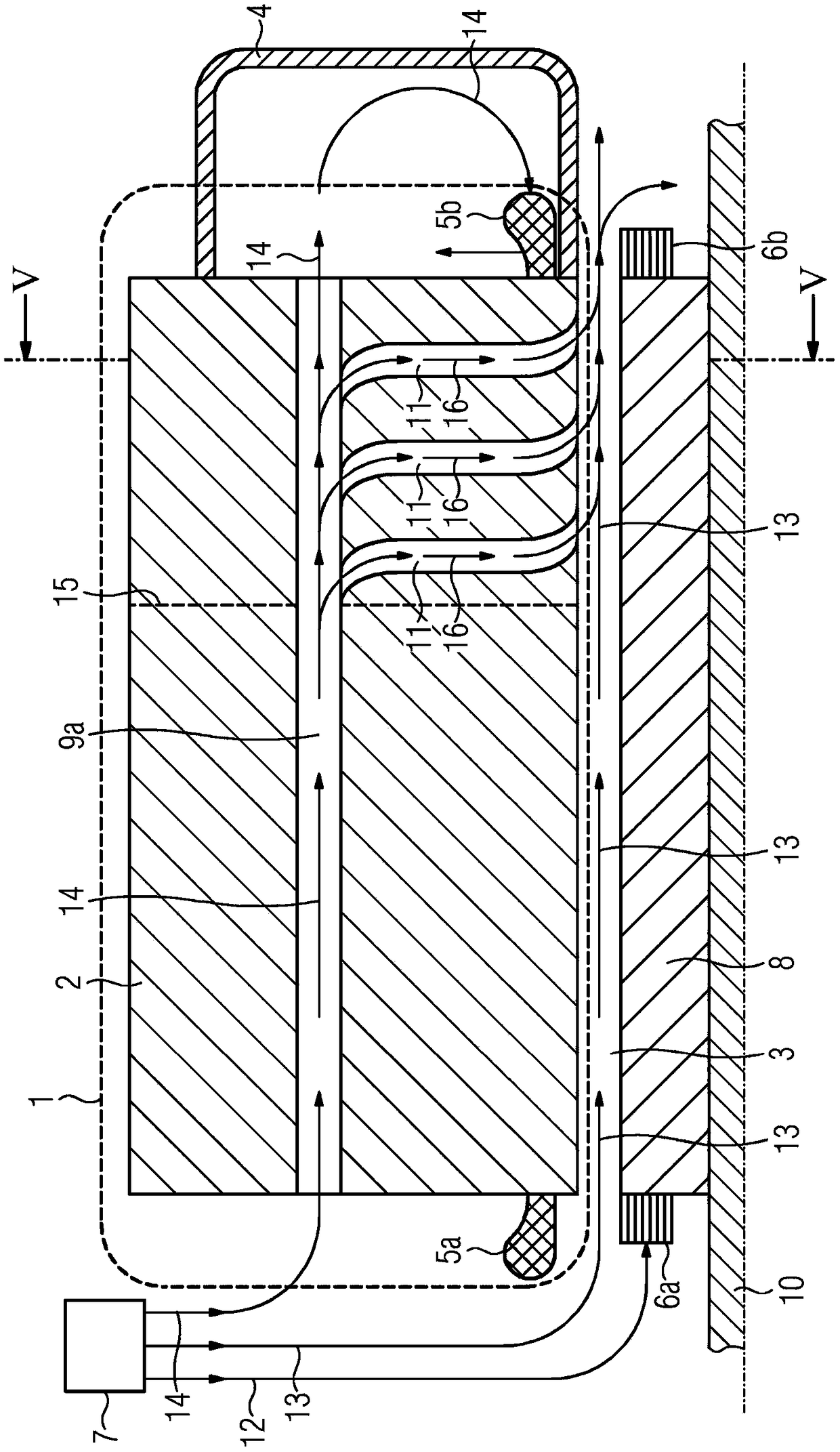

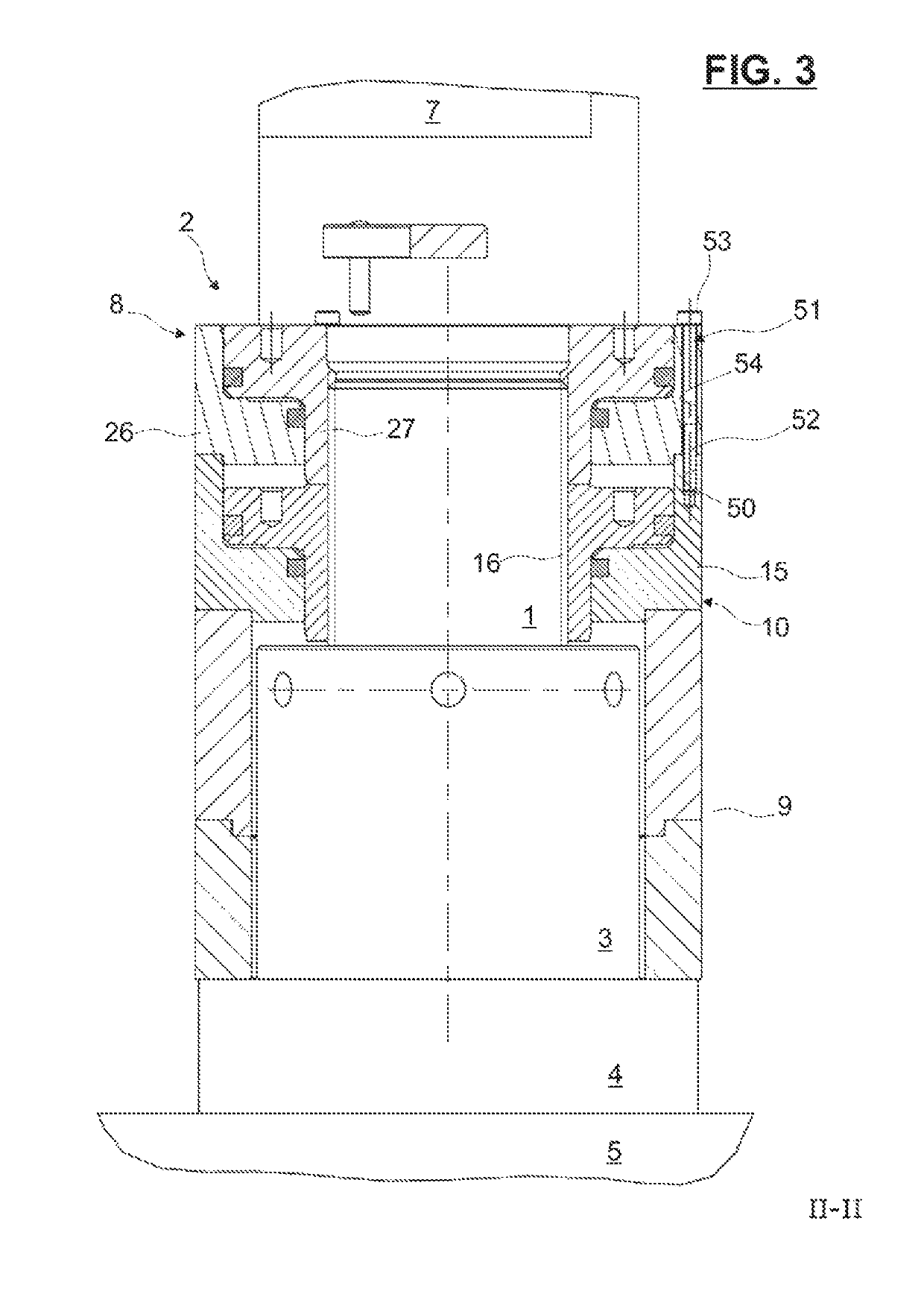

Electrical rotating machine with one-sided cooling and method for one-sided cooling

InactiveCN107005107AImprove cooling effectReduce complexityMagnetic circuit stationary partsCooling/ventillation arrangementAxial distanceConductor Coil

The invention relates to an electrical rotating machine, comprising a stator (1), a rotor (8) and a turbomachine (7), which is provided to cool the electrical rotating machine on the one side, wherein the stator (1) comprises a laminated stator core (2), a front stator winding head (5a) and a rear stator winding head (5b), wherein the rotor (8) comprises a rear rotor winding head (6b). In order to improve cooling during the one-sided ventilation, in particular with respect to the prior art, with regard to a uniform temperature distribution, it is suggested that the laminated stator core (2) comprise channels (9a, 9b) extending in the axial direction, which are provided to cool the rear stator winding head (5b) with a second cooling air flow (14) generated by the turbomachine (7), wherein at least one first channel (9a) is provided to guide a second cooling air flow (14) generated by the turbomachine (7) through the laminated stator core (2) to the rear stator winding head (5b), wherein an air guide (4), which is fastened to the laminated stator core (2) on the side of the rear stator winding head (5b), is provided to bypass the second cooling air flow (14) via the rear stator winding head (5b), wherein at least one second channel (9b) is provided to guide the second cooling air flow (14) back from the rear stator winding head (5b) through the laminated stator core (2), wherein at least two radial slits (11) arranged in the axial direction, which are arranged radially between the channels (9a, 9b) running in the axial direction and an air gap (3) between the laminated stator core (2) and the rotor (8) and are connected to each other, are provided to cool the laminated stator core (2), in particular the stator windings, and / or the rear rotor winding head (6b), wherein the axial distance between the radial slits (11) to the side of laminated stator core (2) which faces away from the turbomachine (7) is reduced and is provided to compensate for a temperature gradient caused by one-sided cooling.

Owner:SIEMENS AG

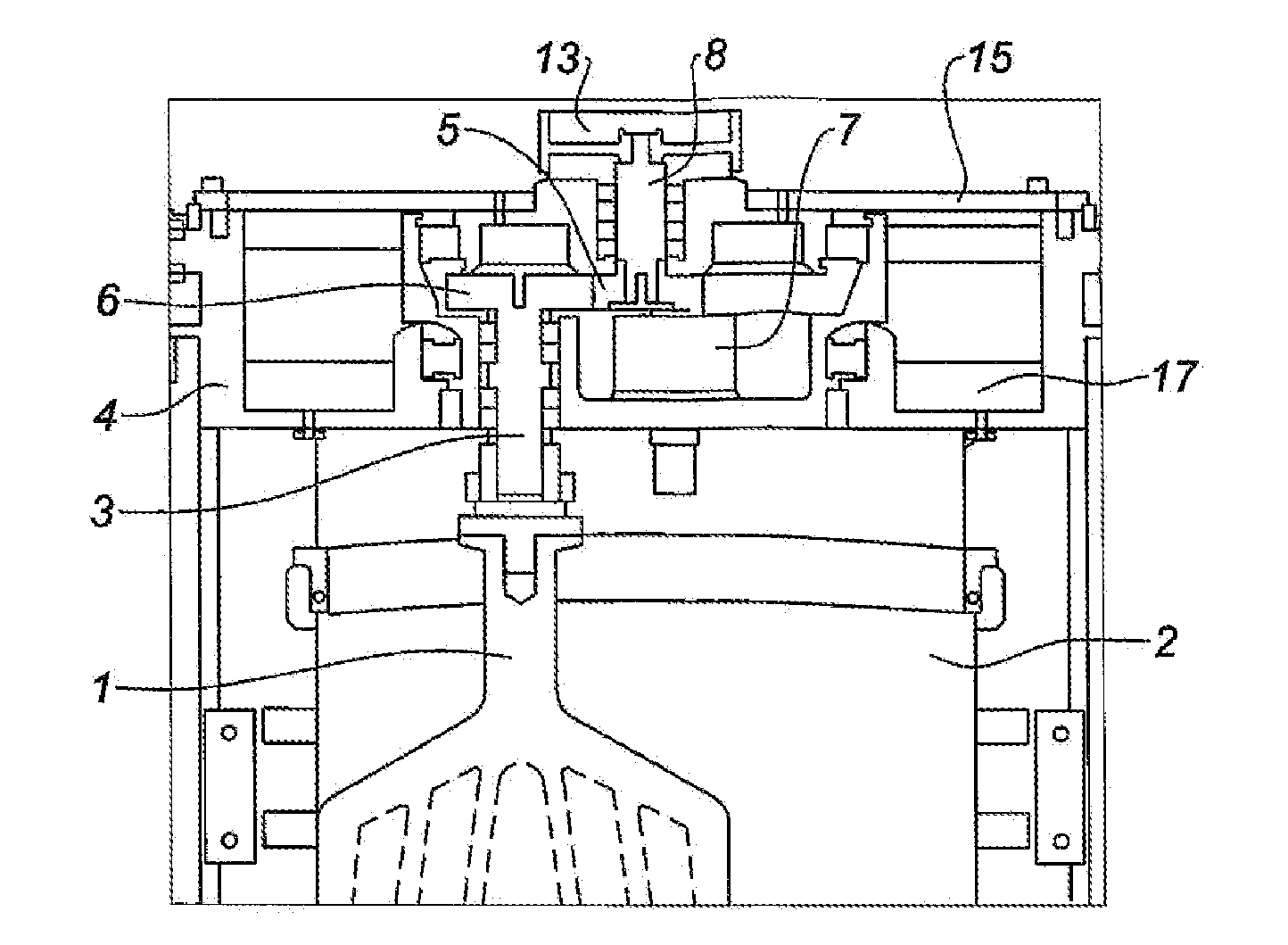

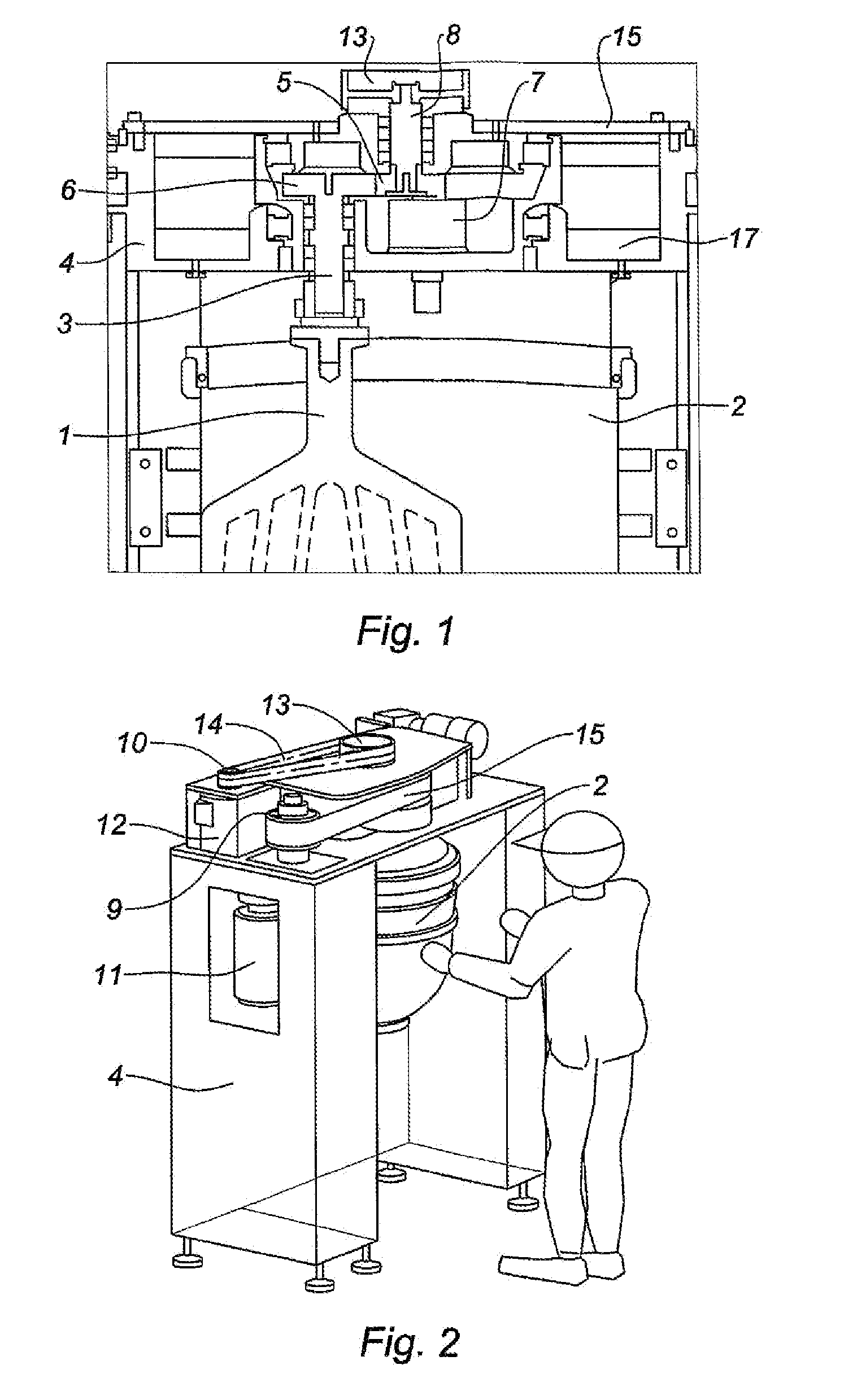

Epilating device

ActiveUS20180360186A1Axial spacing reducedGood hair removal effectHair-singeingSkin contactBiomedical engineering

An epilating device having a frame, a pair of clamping elements with a first clamp and a second clamp mounted in the frame, wherein each clamp has a skin contact surface facing towards the user's skin. The first clamp and the second clamp being inclined with respect to each other in the open position and being parallel to each other in the closed position.

Owner:BRAUN GMBH

Axial-radial turbomachine

InactiveUS20130028724A1Small wall thicknessReliable deformationPump componentsStatorsInterior spaceImpeller

Axial-radial flow machine having an axial portion with at least one axial stage, a radial portion with at least one radial stage, a housing having an interior space with a dividing wall extending in a radial direction dividing the housing in an axial direction into a first partial space in which the axial portion is received and a second partial space in which the radial portion is received, and a shaft that extends in axial direction through the interior space and through the dividing wall and on which impellers of the axial portion and of the radial portion are received. A radial gap is formed between the dividing wall and a fluid guiding element of the radial portion. The fluid guiding element is axially fixed to the housing so as to be adjacent to the dividing wall. A plurality of fixing units which are distributed in circumferential direction are arranged in the radial gap, each of which fixing units axially fixes the dividing wall to the fluid guiding element.

Owner:MAN ENERGY SOLUTIONS SA

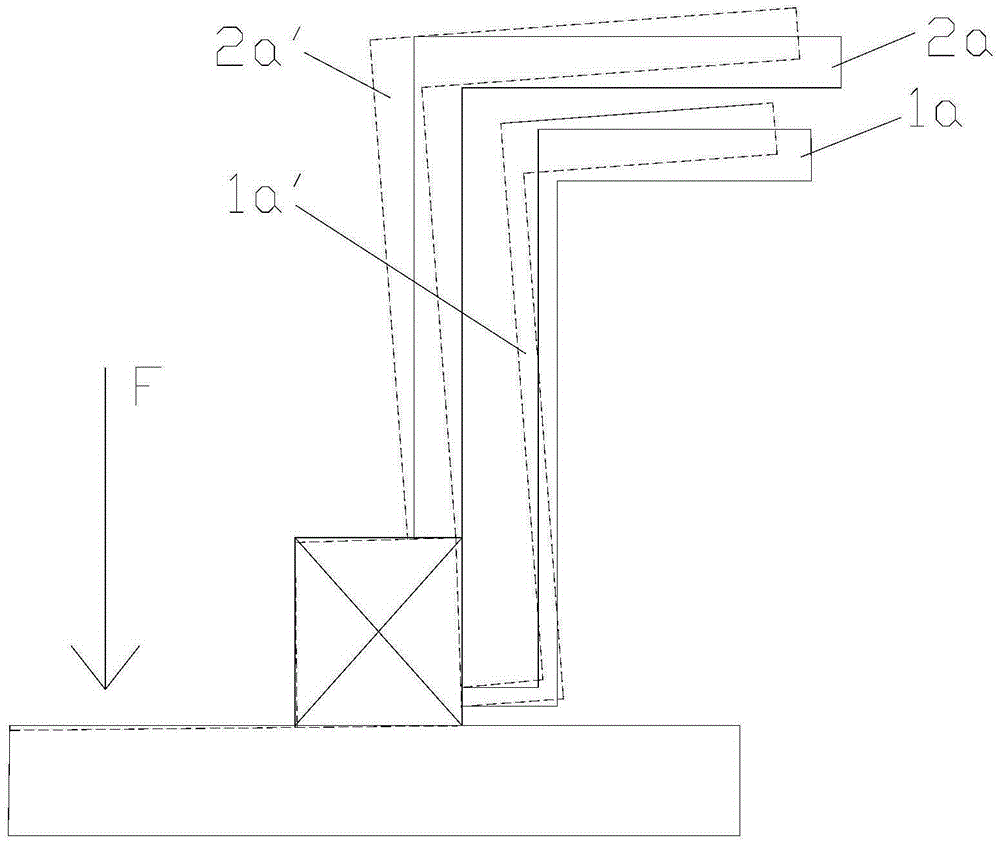

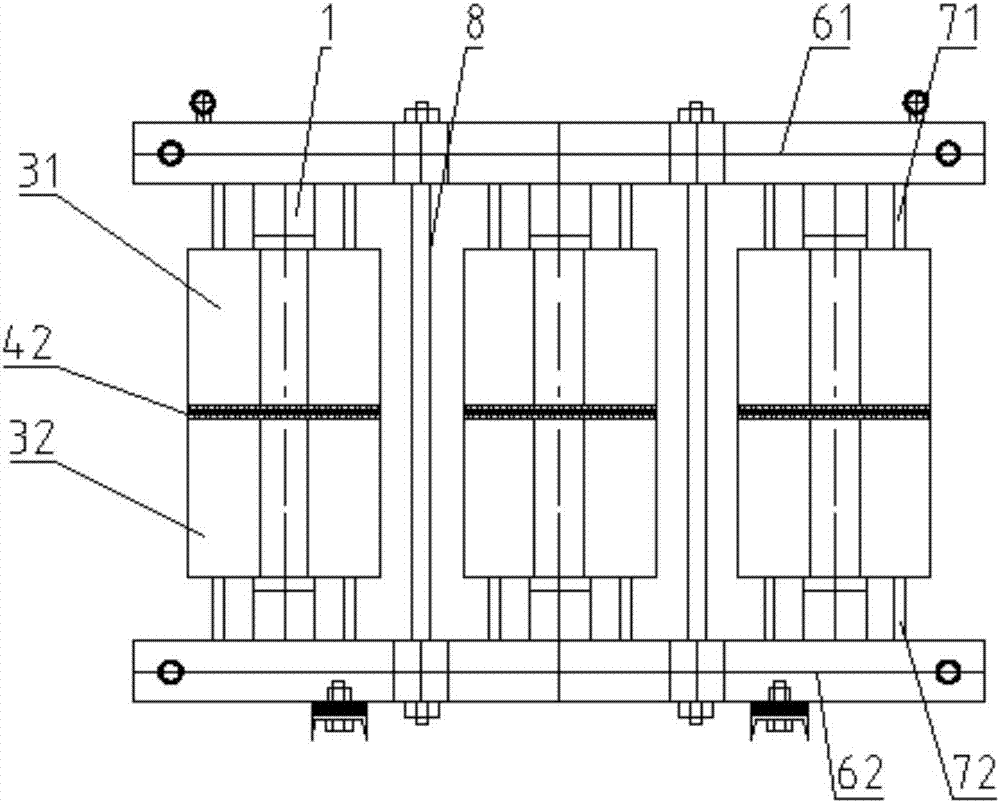

Dry transformer

PendingCN108010689AImprove insulationPrevent discharge effectTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresHigh pressureTransformer

The invention discloses a dry transformer which comprises an upper clamping plate, a lower clamping plate and a transformer body mounted between the upper clamping plate and the lower clamping plate.The transformer body comprises an iron core, an upper low-voltage coil, an upper high-voltage coil, a lower low-voltage coil and a lower high-voltage coil, the upper low-voltage coil and the upper high-voltage coil sequentially sleeve the upper end of the iron core, the lower low-voltage coil and the lower high-voltage coil sequentially sleeve the lower end of the iron core, an inner gasket is arranged between the upper low-voltage coil and the lower low-voltage coil, an outer gasket is arranged between the upper high-voltage coil and the upper high-voltage coil, an upper folding screen is arranged between the upper low-voltage coil and the upper high-voltage coil, a lower folding screen is arranged between the lower low-voltage coil and the lower high-voltage coil, and a gap is reserved between the upper folding screen and the lower folding screen. By arranging the upper folding screen and the lower folding screen and reserving the gap therebetween, insulativity can be improved, and discharging effect among high-and-low-voltage coils is prevented effectively; axial interval is reduced, so that length of the iron core is reduced, size of the transformer is reduced, and making costcan be saved.

Owner:XINXIANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +1

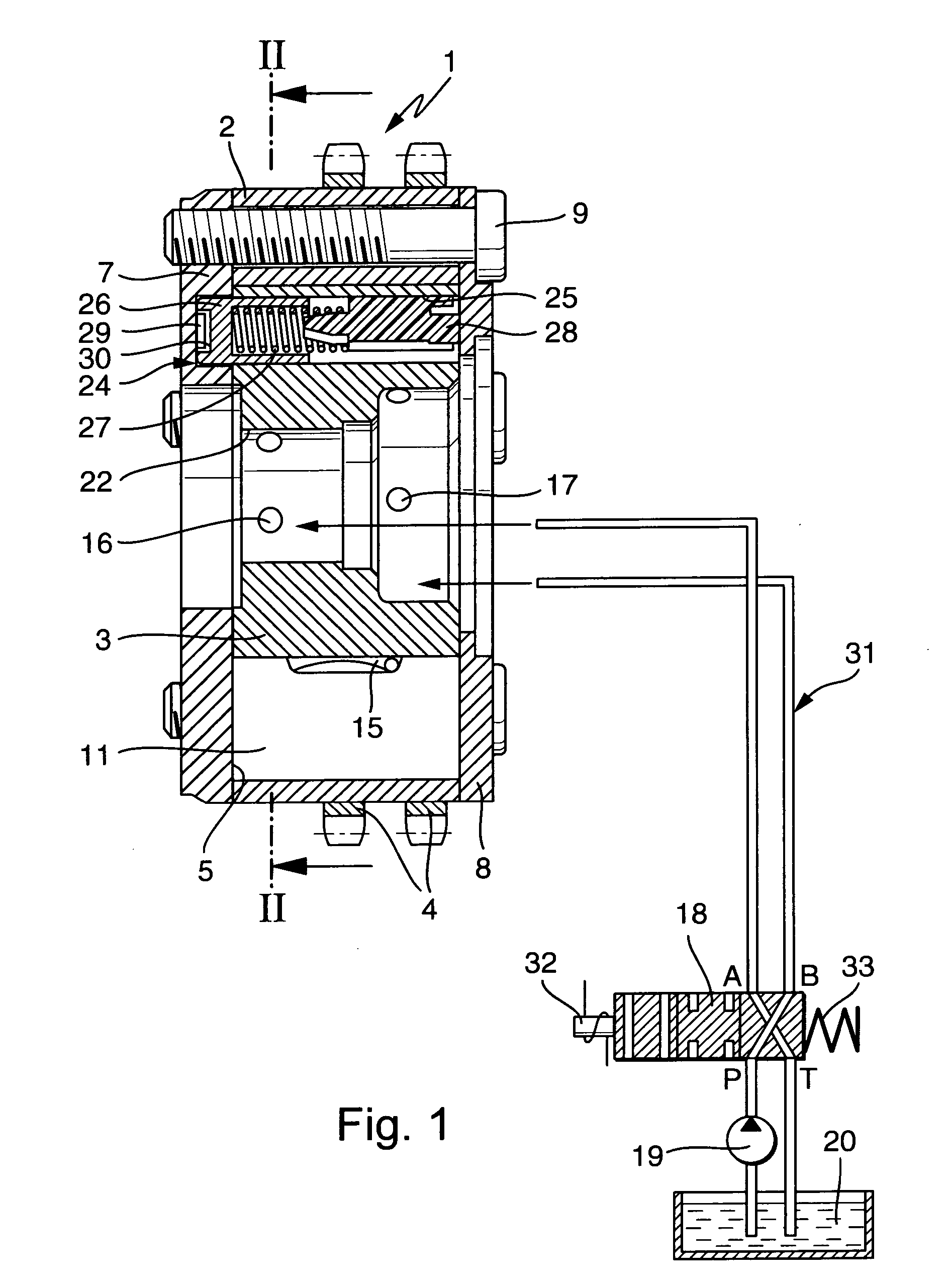

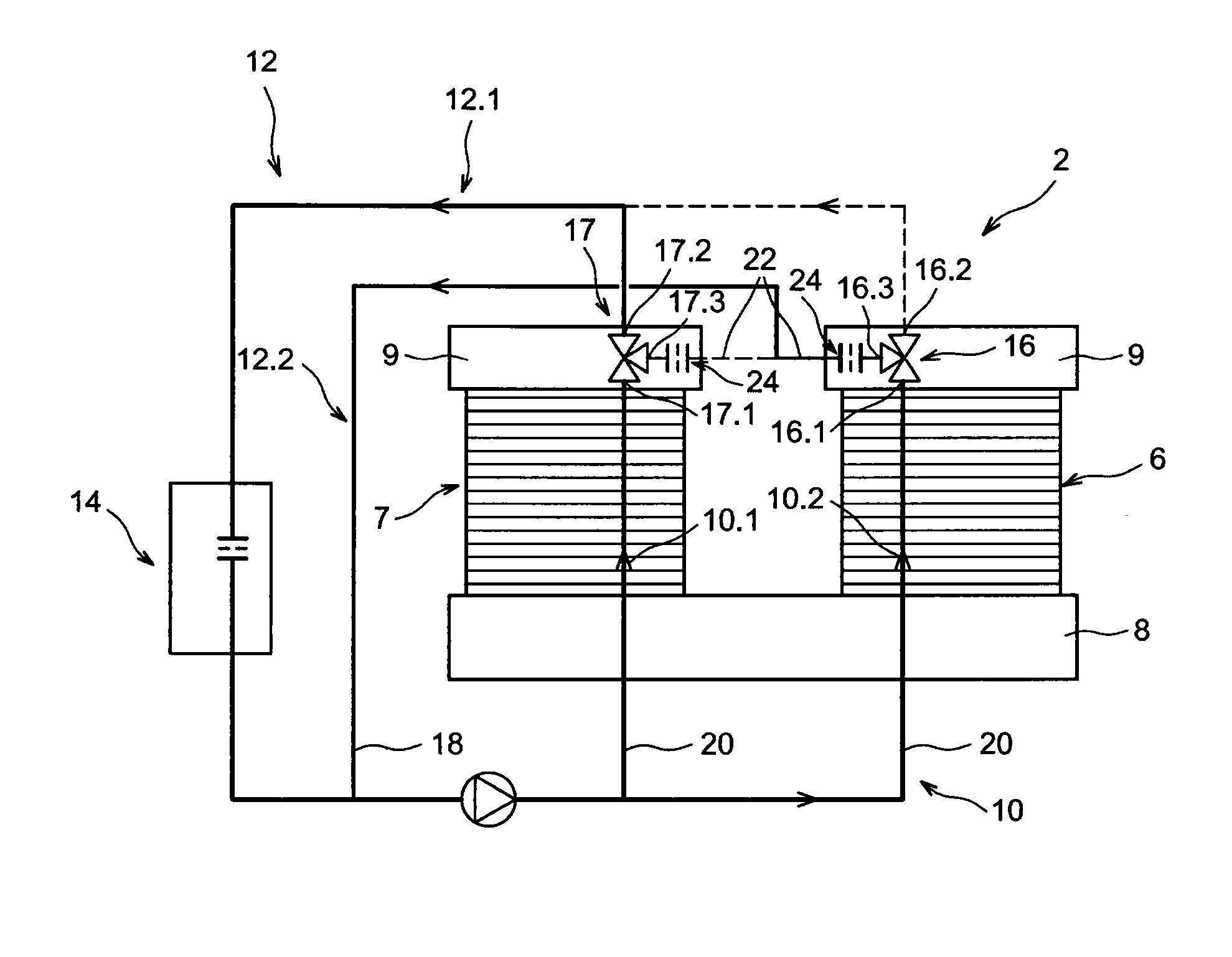

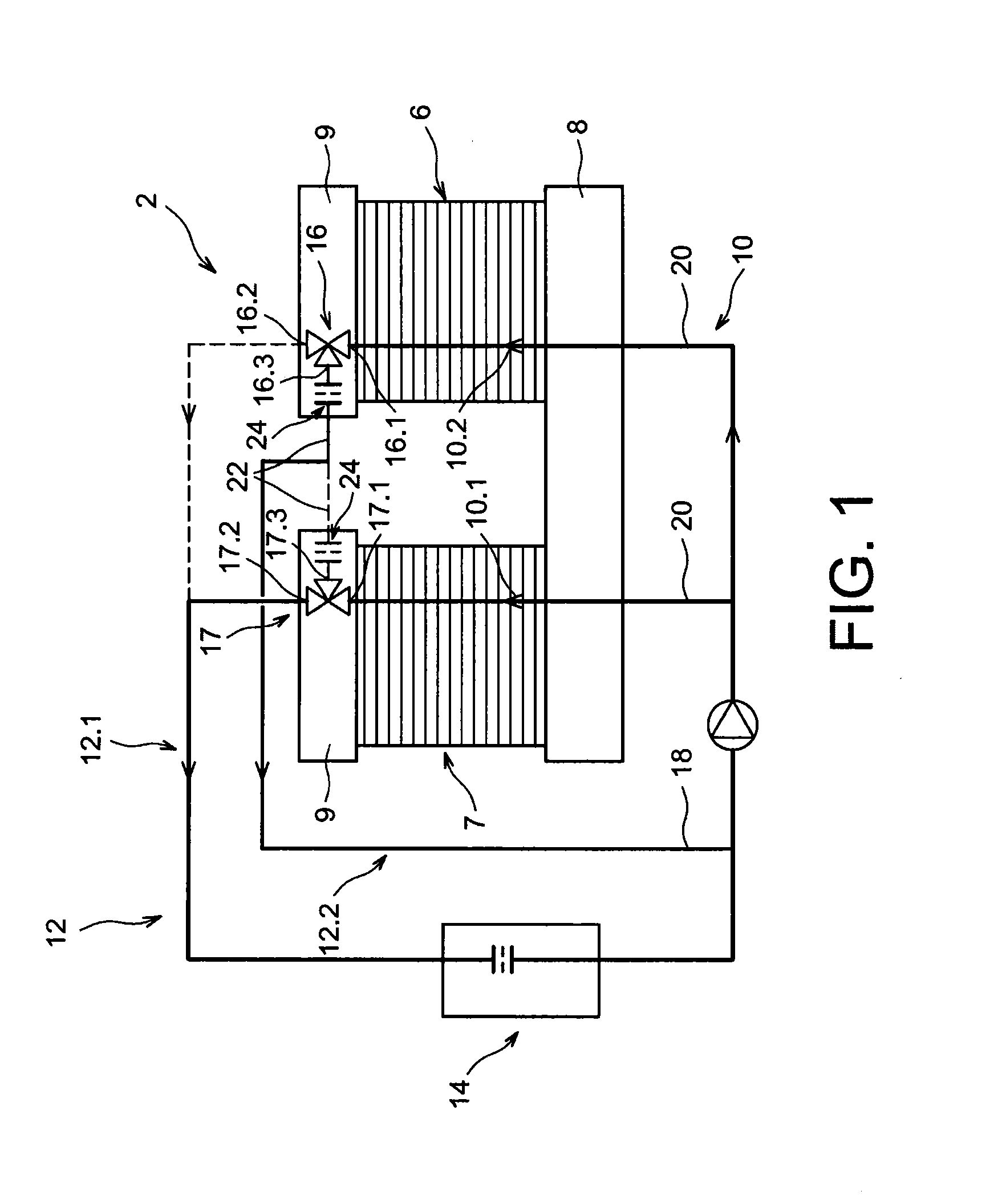

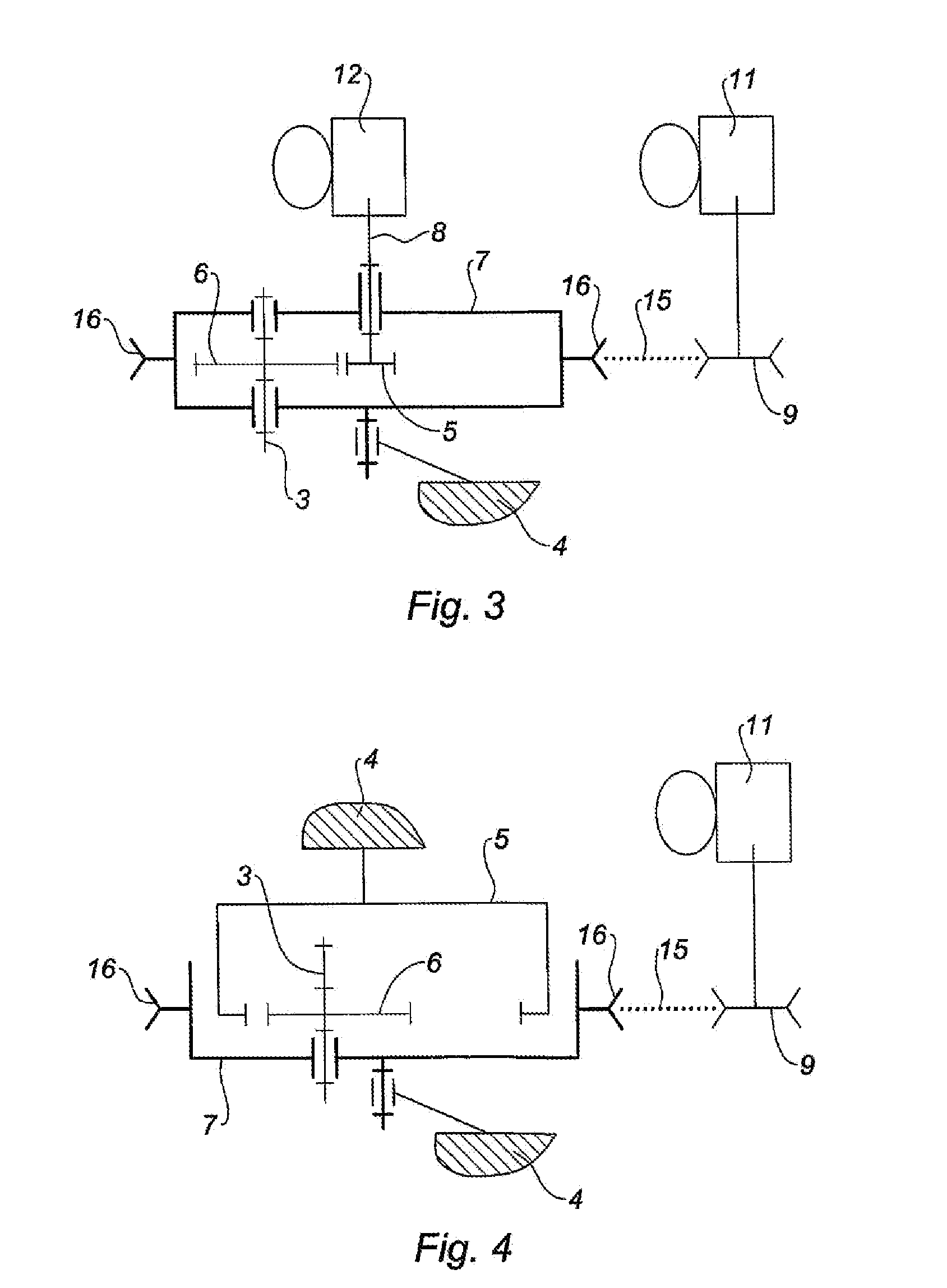

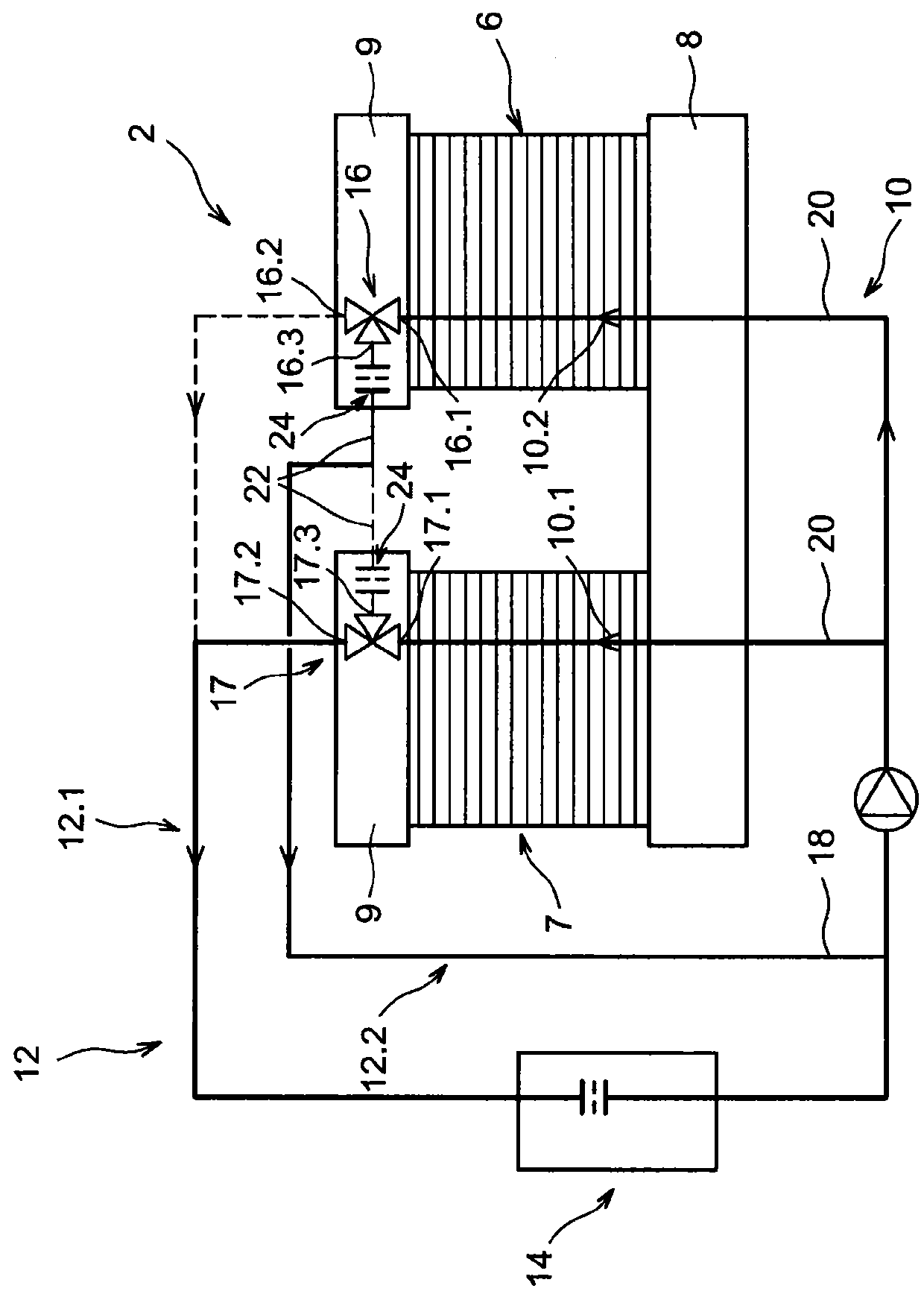

Fuel cell with improved thermal management

A fuel cell including at least two stacks of electrochemical cells, a heat management system including a circuit for flowing a coolant into each of the stacks fed in parallel, and an outside circuit for flowing the coolant outside the stacks. The outside circuit includes a first subcircuit including a heat exchanger and a second subcircuit directly connected to an inlet of the inside circuit, and controlling valves for controlling flow of the coolant toward either or both subcircuits as a function of temperature of the coolant at an output of each of the stacks. The second outside subcircuit includes a mechanism increasing its head loss such that it is close or equal to that of the first outside subcircuit.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

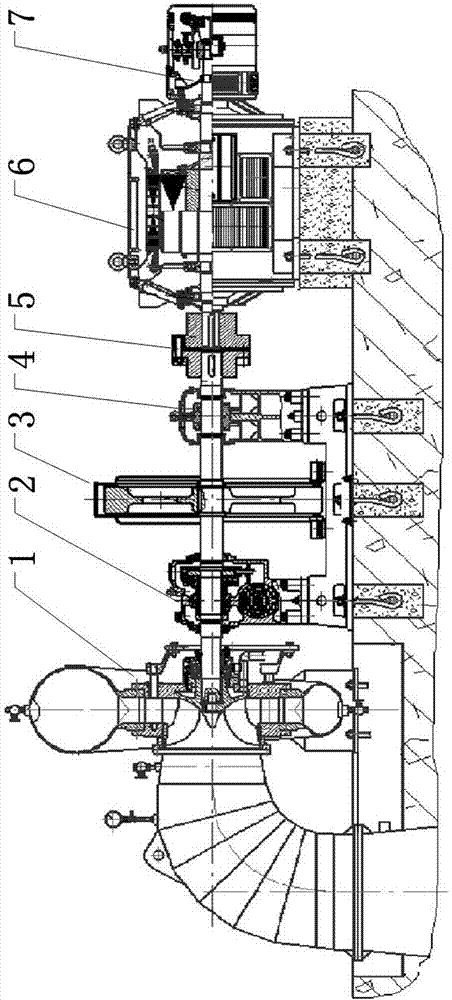

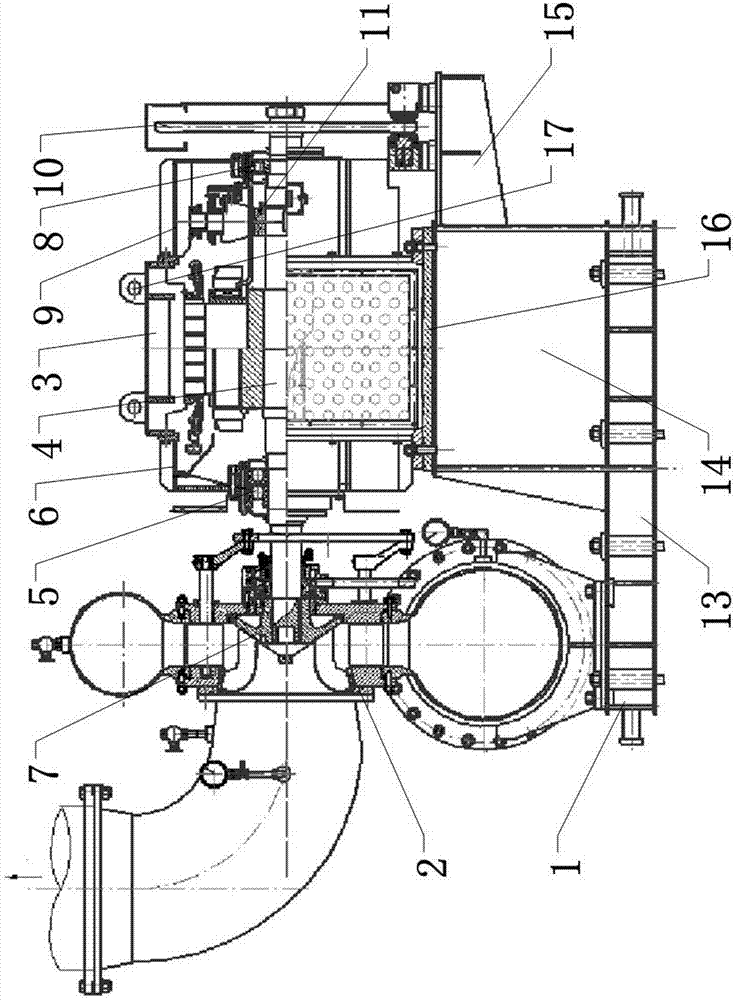

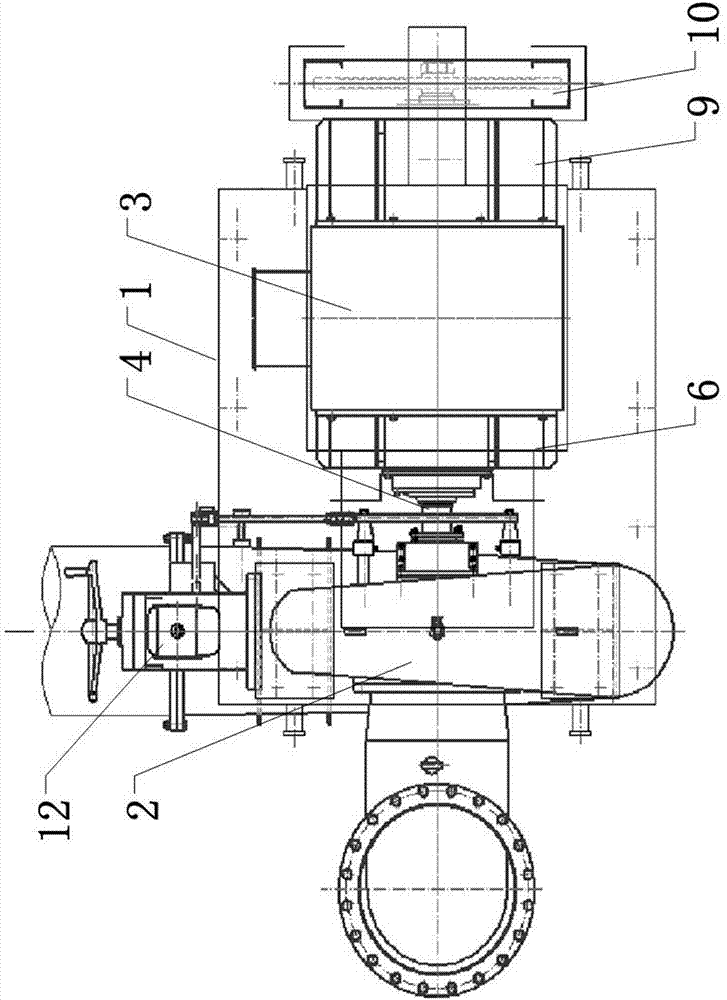

Horizontal type micro equipped water-turbine generator set

InactiveCN107178461AUse low headReduce trafficMachines/enginesEngine componentsBall bearingWater turbine

The invention discloses a horizontal micro-integrated hydro-generator set, which comprises a chassis arranged on the ground foundation, a micro-turbine fixedly installed on the left side of the upper part of the chassis, and a miniature water turbine fixedly installed on the right side of the upper part of the chassis. Brush excitation generator; the internal rotation of the miniature brushless excitation generator is provided with a main shaft, and the front end of the main shaft is arranged in the front end cover of the miniature brushless excitation generator through two ball bearings, and the front end of the main shaft It is fixedly arranged on the runner of the micro-turbine; the rear end of the main shaft is arranged in the rear end cover of the miniature brushless excitation generator through a cylindrical roller bearing, and the rear end of the main shaft is fixedly connected with a flywheel. The invention can not only develop and utilize the recyclable or multi-functional hydraulic resources hidden in daily production and daily life, but also has a simple structure and does not require complex on-site assembly and debugging, which greatly shortens the construction time of hydropower stations.

Owner:河南瑞发水电设备有限责任公司

Gearbox for a mixer-blender

InactiveUS20110292757A1Eliminate needReduce needRotary stirring mixersTransportation and packagingEngineeringPlanet

The present invention relates to a gearbox for a mixer-blender including a planet wheel (5), a planet carrier (7) comprising a body defining an enclosure, at least one planet gear (6) provided with external teeth and pivotably mounted on the planet carrier (7), said planet gear (6) meshing with the planet wheel (5), and characterised in that the body of the planet carrier (7) is shaped so as to engage with a driving member such that said driving member rotates the planet carrier (7).

Owner:VMI INC

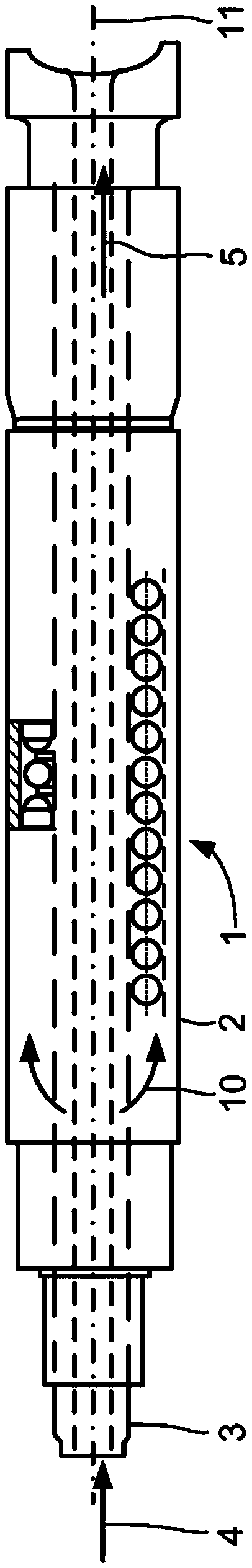

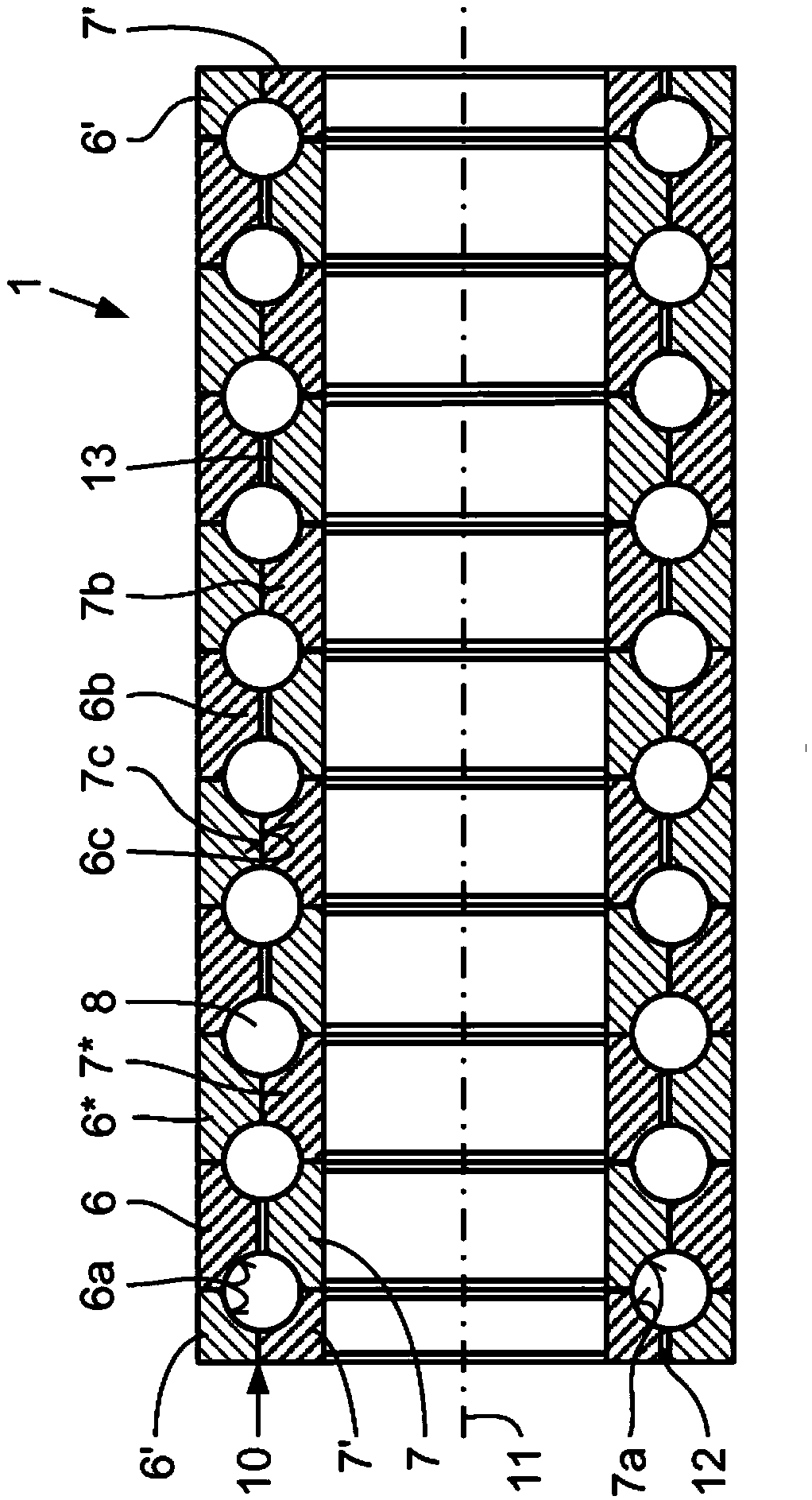

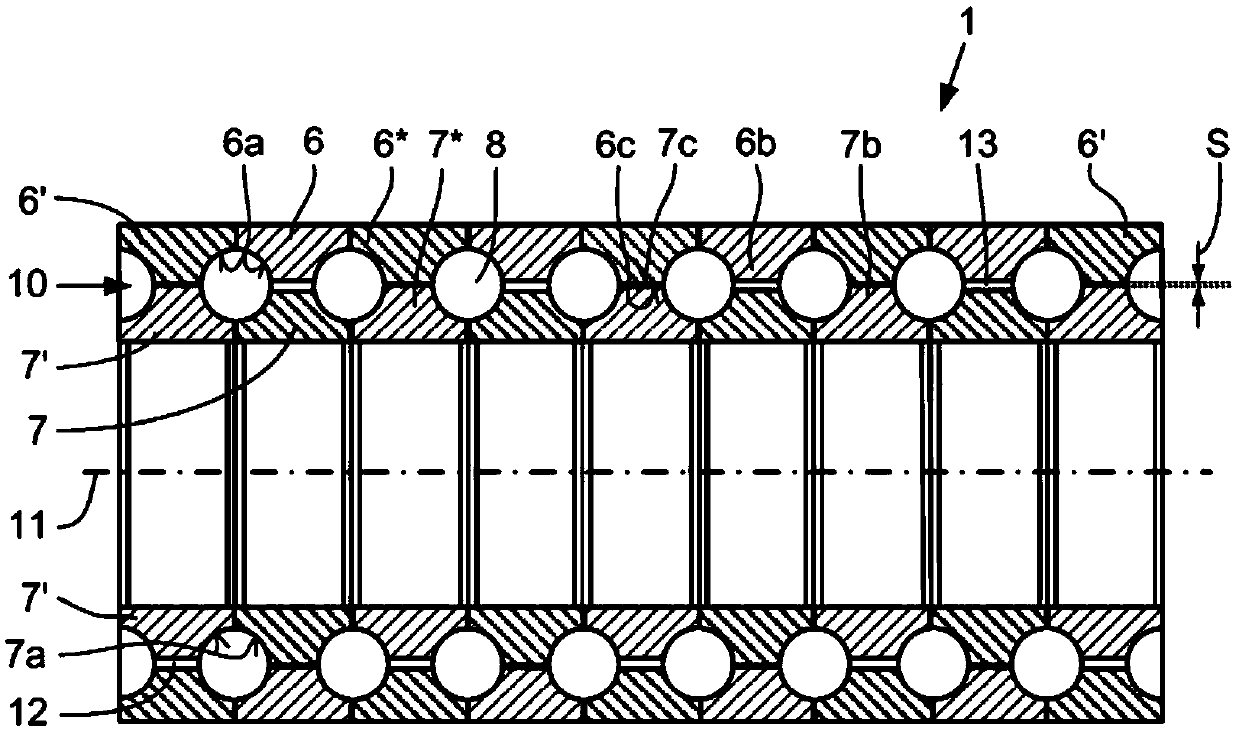

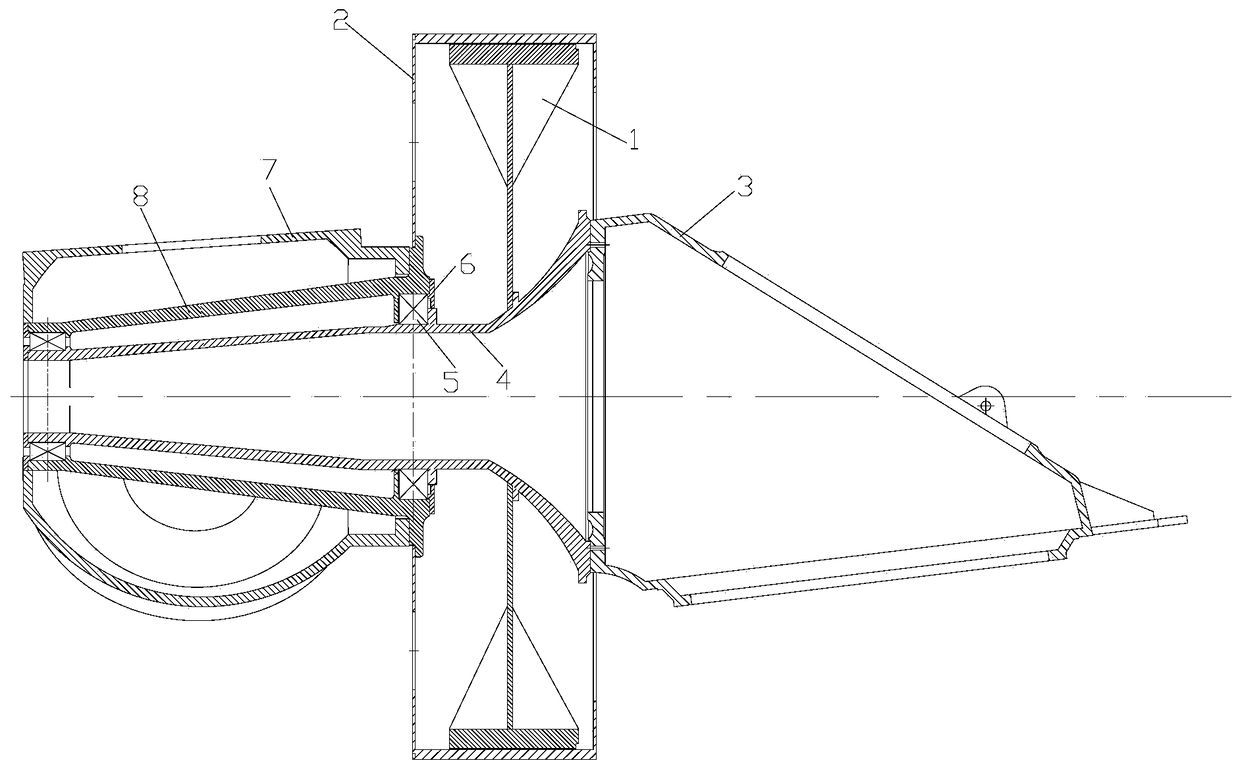

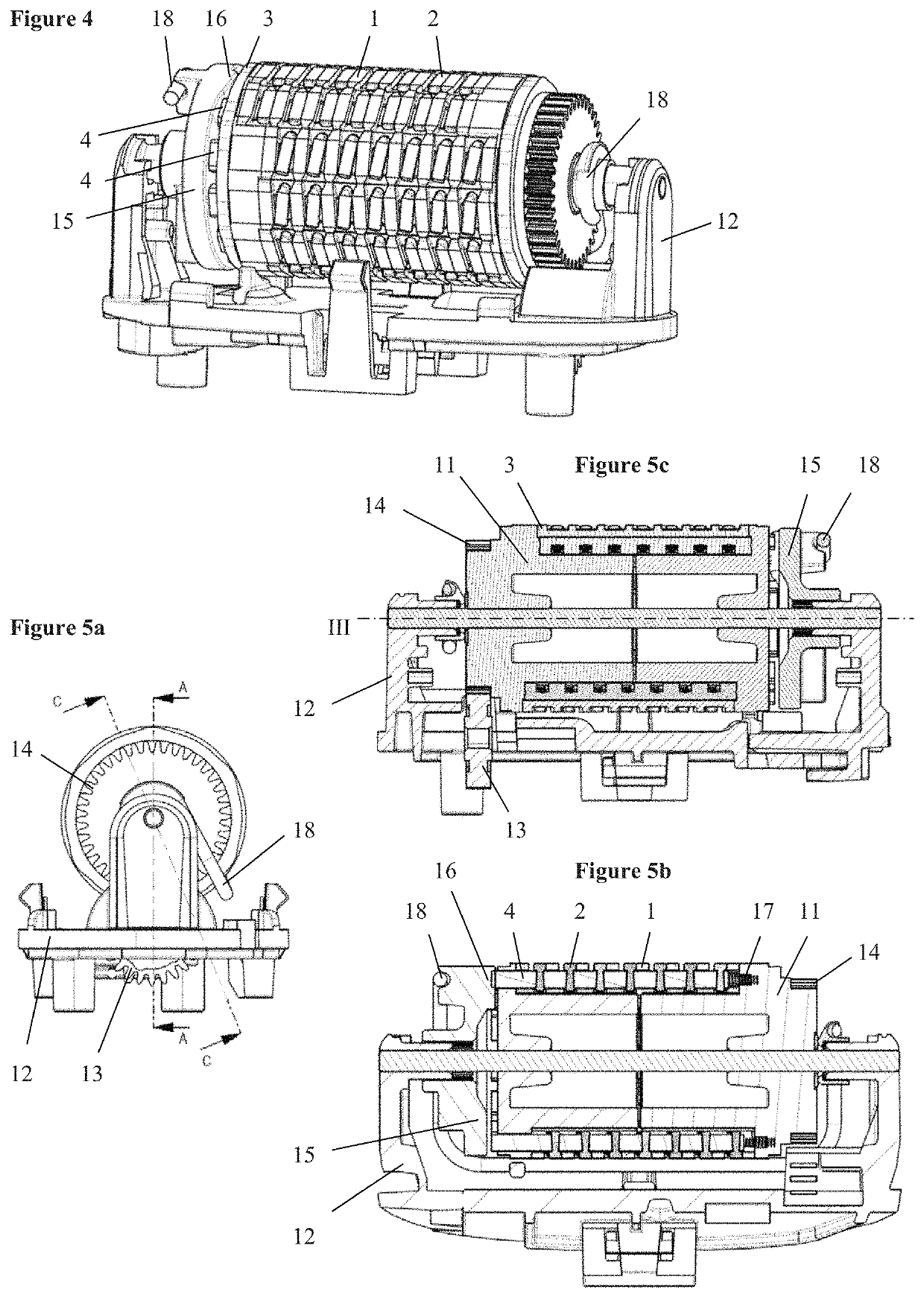

Bearing units for deep drilling units

ActiveCN106795912BShorten the axial lengthSmall radiusRotary combination bearingsDrilling accessoriesEngineeringPlain bearing

The present invention relates to a bearing apparatus for a deep drilling apparatus by flushing liquid through the drill (1), the bearing apparatus having a plurality of radial external and radial internal bearing rings (6,7), wherein the radial external bearing ring (6) is coaxially arranged on the radial inner bearing ring (7), wherein radially between the bearing ring (6) is provided with a ball (8,9), the ball rolls within the bearing groove (6a, 7a), and wherein the bearing groove (6a, 7a) Axially bounded on both sides by a convex shoulder (6b, 7b), the convex shoulder having a convex shoulder surface (6c, 7c) stretched parallel to the longitudinal axis of the bearing (11). In order to shortly constitute such a bearing apparatus (1) in the axial extension of the axial direction is connected to at least one plain bearing (1), and in order to simplify the construction, the radial external bearing ring (6) of the convex shoulder surface (6c, 7c) and the radial internal bearing ring (7) of the convex shoulder surface (7c) of the outer diameter (Da) is designed to be such that the convex shoulder surface (6c, 7c) undertakes the function of a parallel radial plain bearing having radial clearance (S).

Owner:SCHAEFFLER TECH AG & CO KG

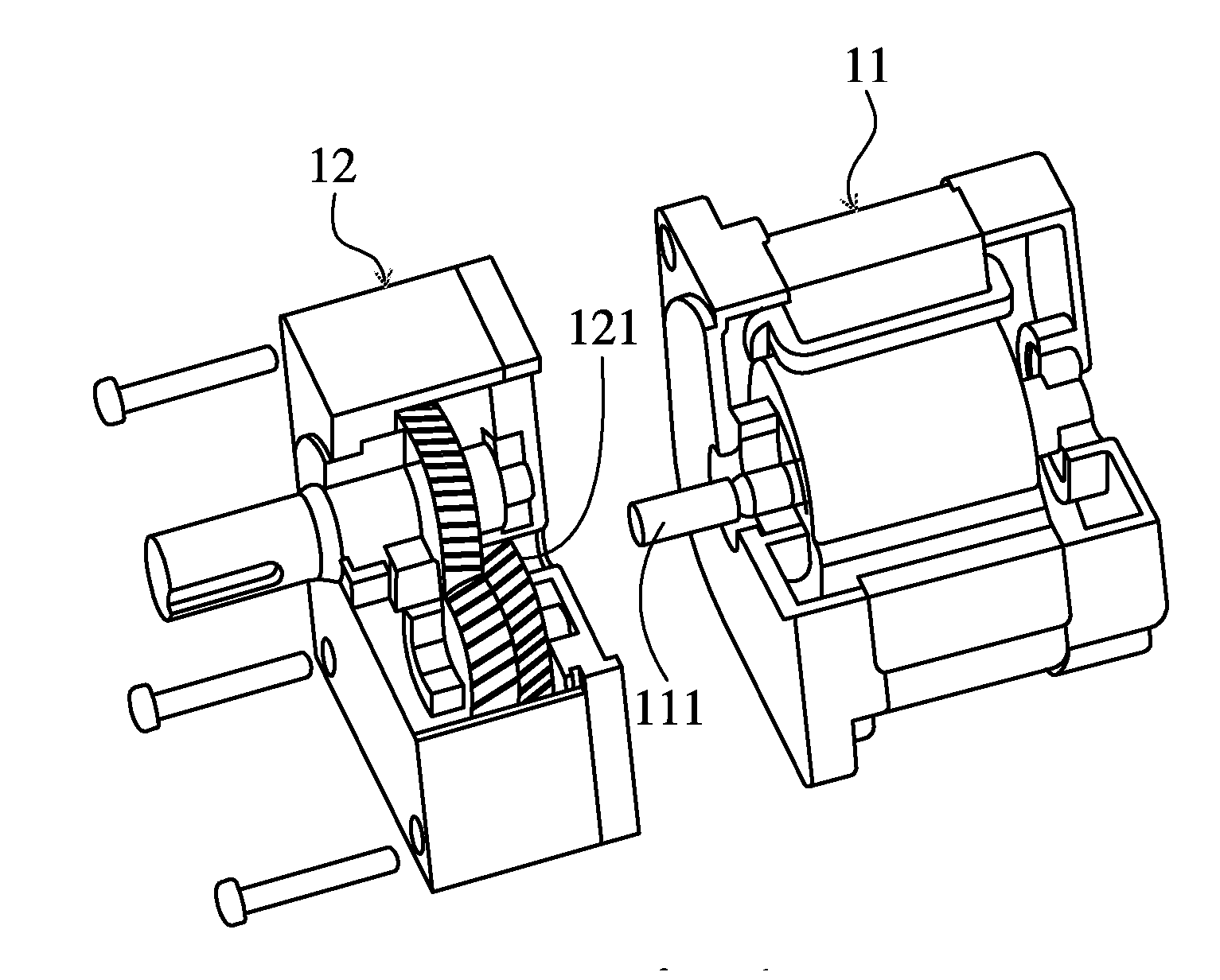

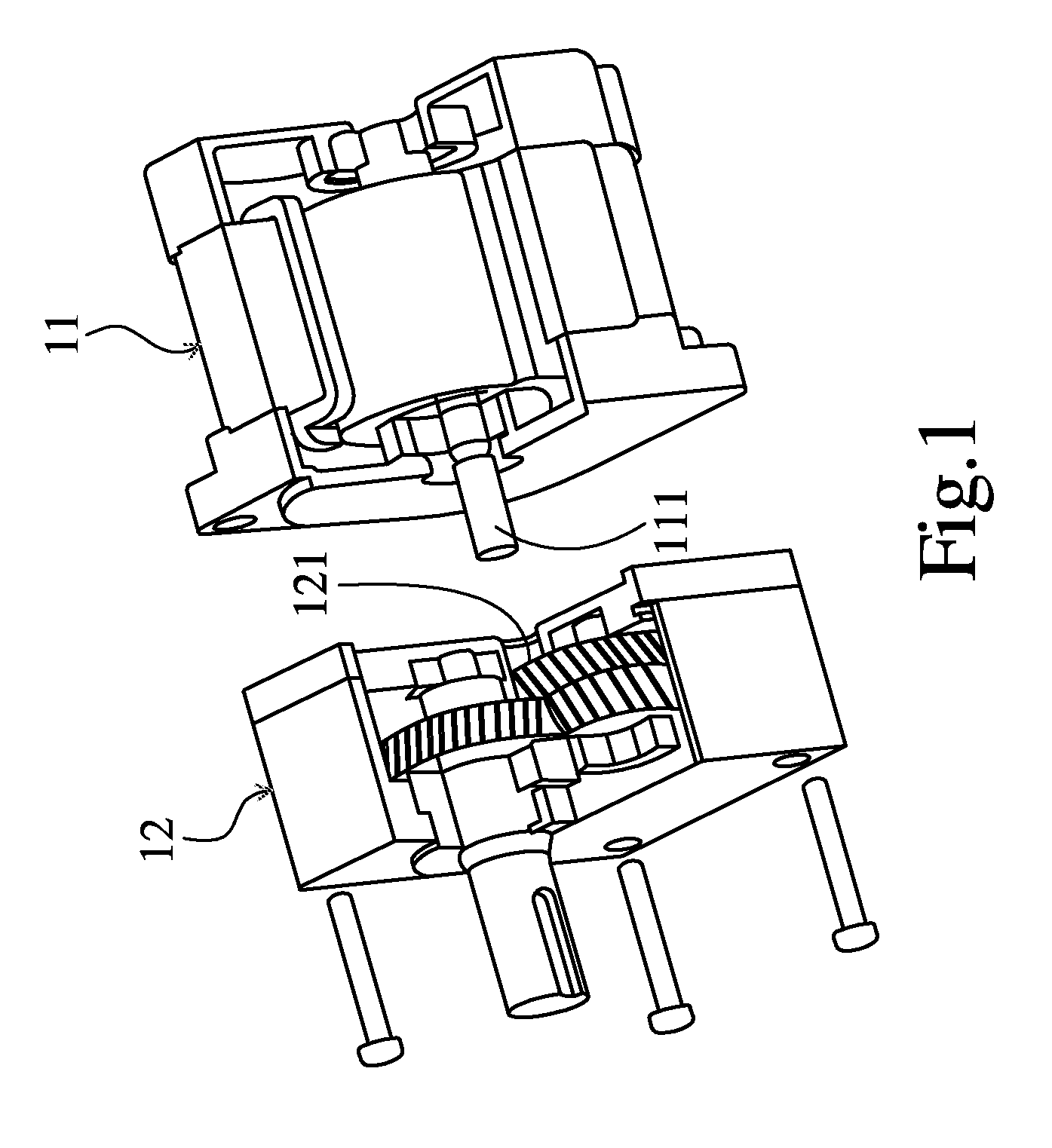

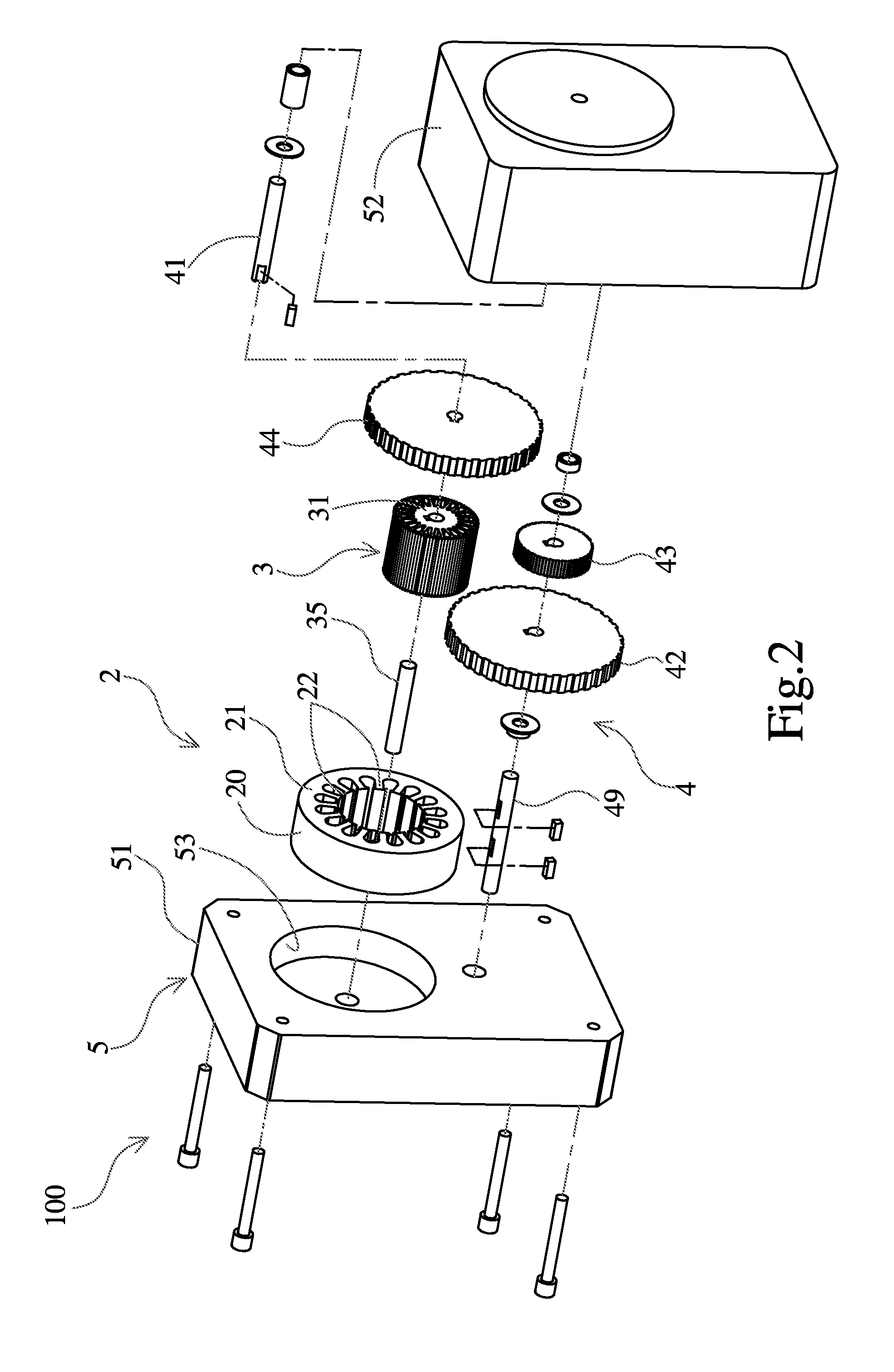

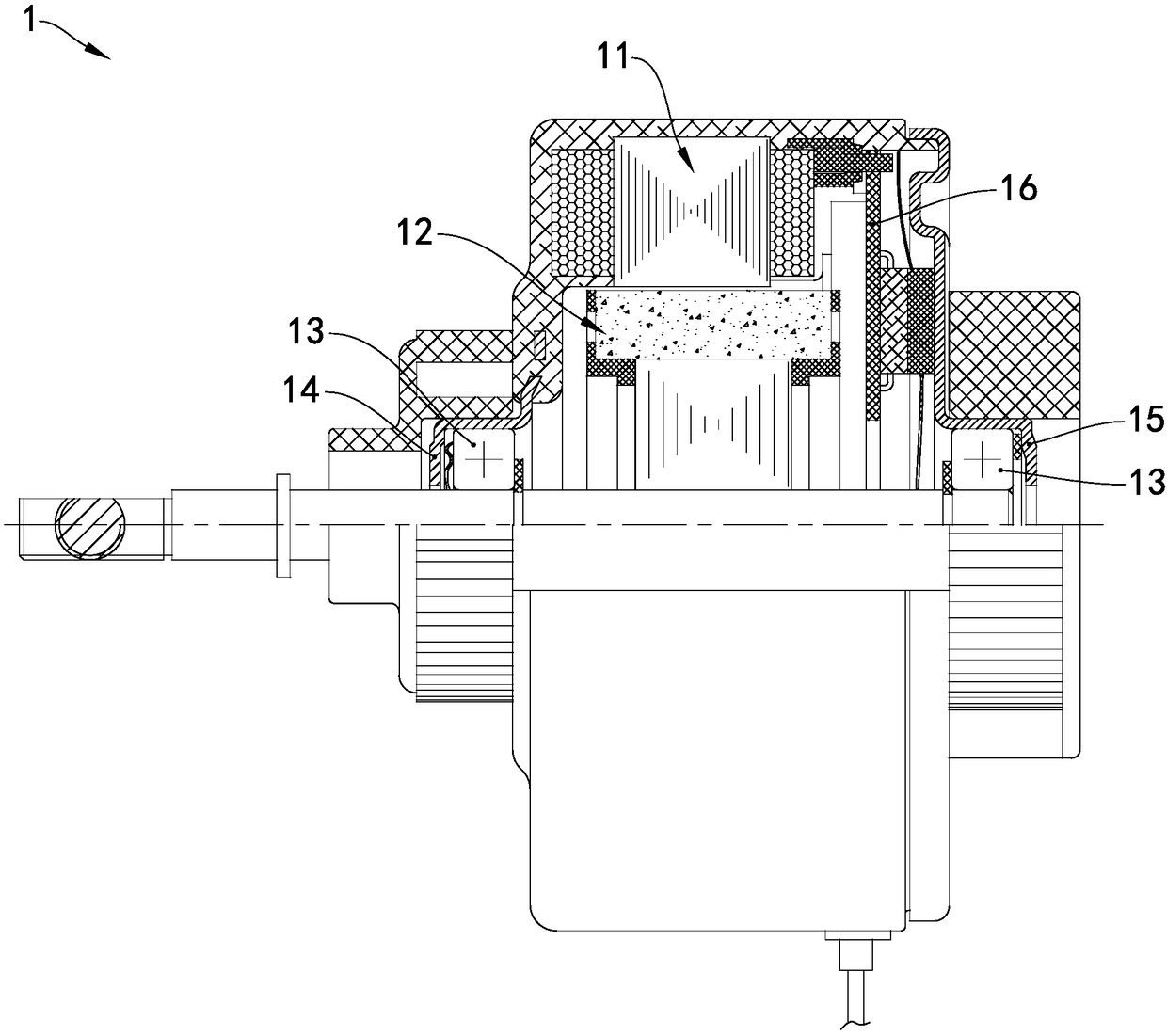

Ac motor with reduction mechanism

InactiveUS20150364970A1Axial spacing reducedEnergy lossSynchronous motorsMechanical energy handlingElectric machineMechanical energy

An AC motor with a reduction mechanism is disclosed. The AC motor has a stator unit, a rotor unit, and a reduction transmission unit. An axial space of the AC motor can be substantially reduced by providing the reduction transmission unit directly built in the AC motor, and a path of the power transmission between the rotor unit and an output shaft can be reduced, so that the loss of the mechanical energy can be lowered.

Owner:NAT CHENG KUNG UNIV

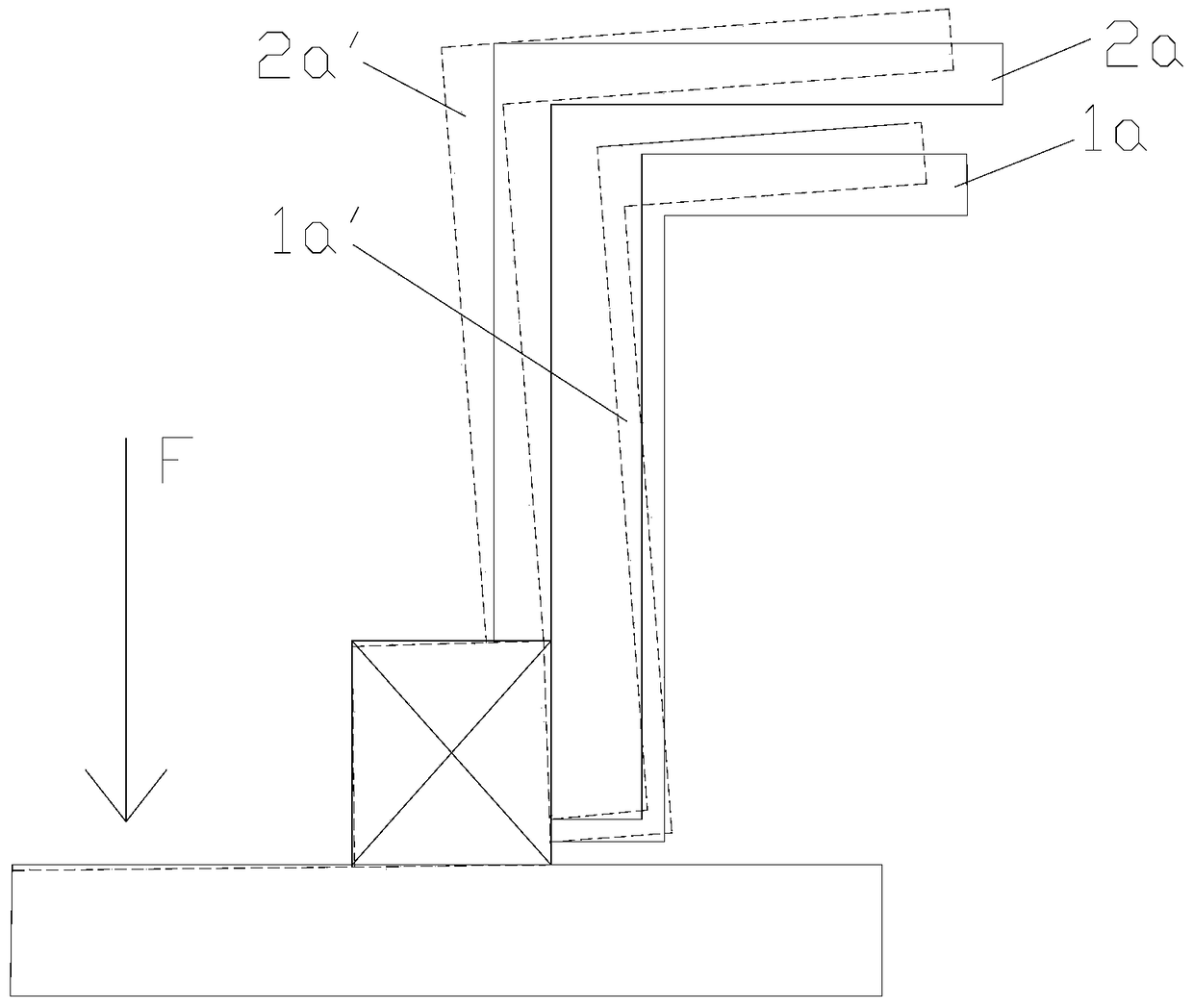

Heightened gear plate limiting device for hay mower

The invention discloses a heightened gear plate limiting device for a hay mower. The heightened gear plate limiting device comprises a heightened gear plate, two or more saw teeth are arranged on the periphery of the heightened gear plate, the saw teeth are in matched connection with an adjusting handle, and the outer side face of the heightened gear plate is connected with coaxial hay mower rear wheels; the saw teeth are arranged on the periphery of the heightened gear plate, axial extending segments are arranged on the two saw teeth at the left end and the right end, and the axial distance between the extending segments and the hay mower rear wheels is smaller than the diameter of the adjusting handle. Through the extending segment structures at the left end and the right end, on the basis of not additionally increasing the limiting, the axial distance between the extending segments and the hay mower rear wheels is reduced, and therefore the adjusting handle cannot be separated from the device, the stroke of the adjusting handle is limited, and the peril incidents caused by grounding of blades controlled by the heightened gear plate are prevented.

Owner:陈斌

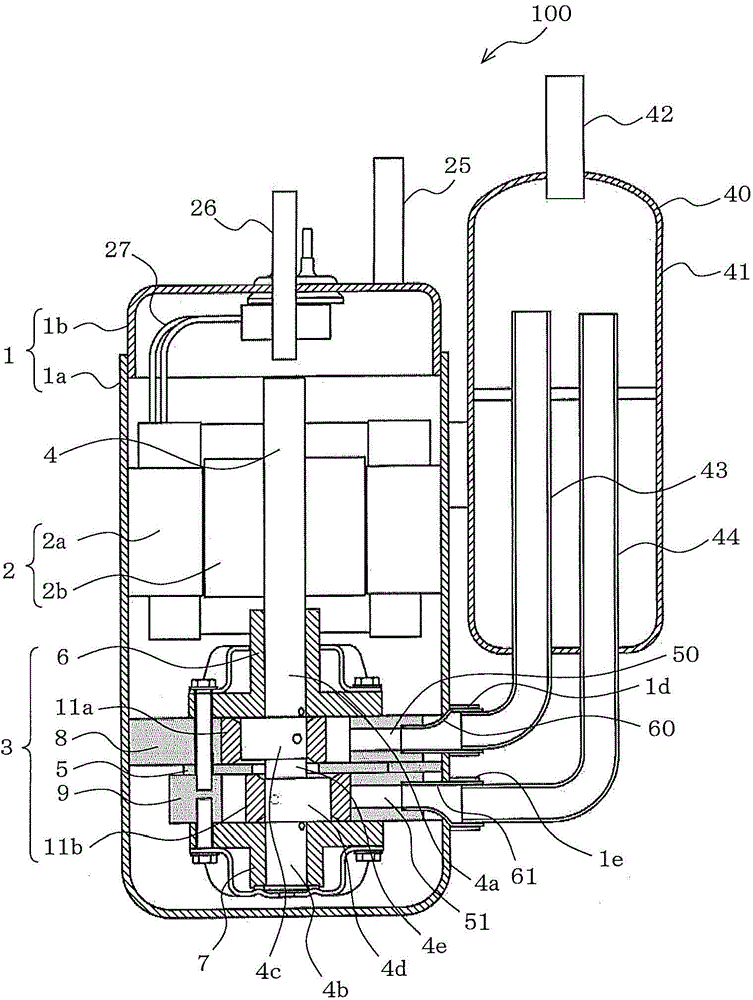

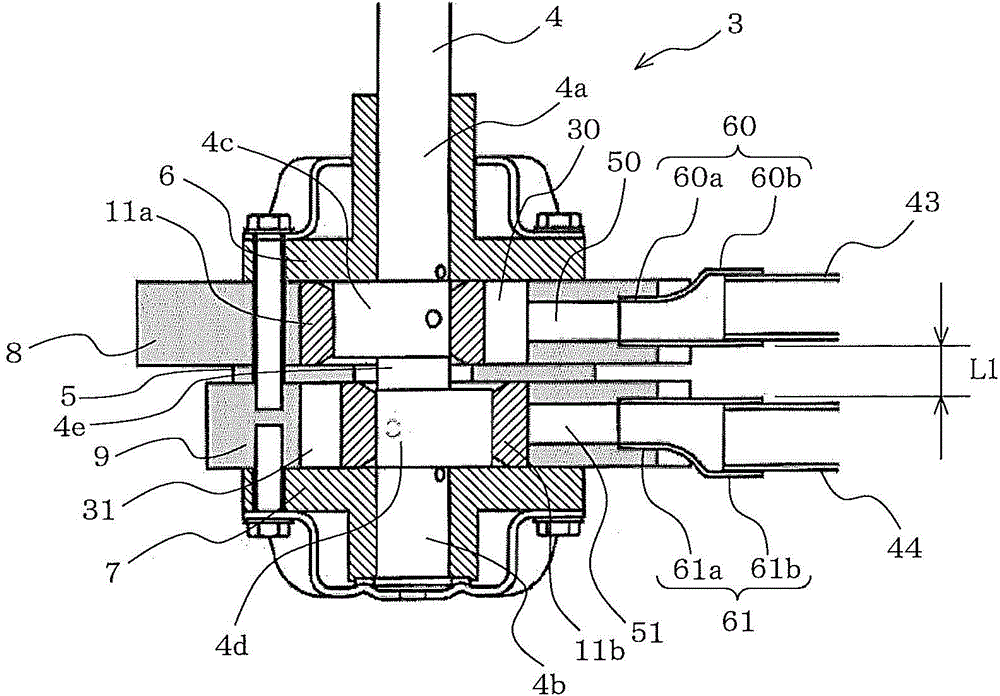

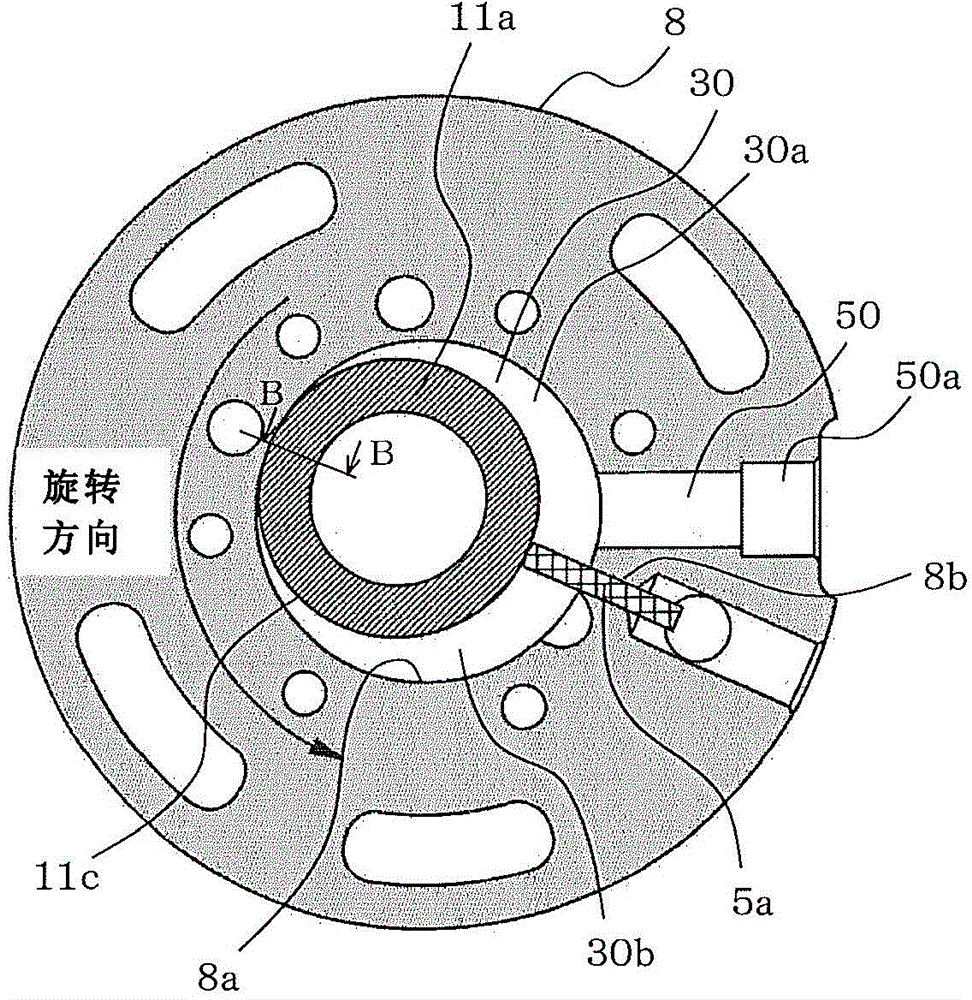

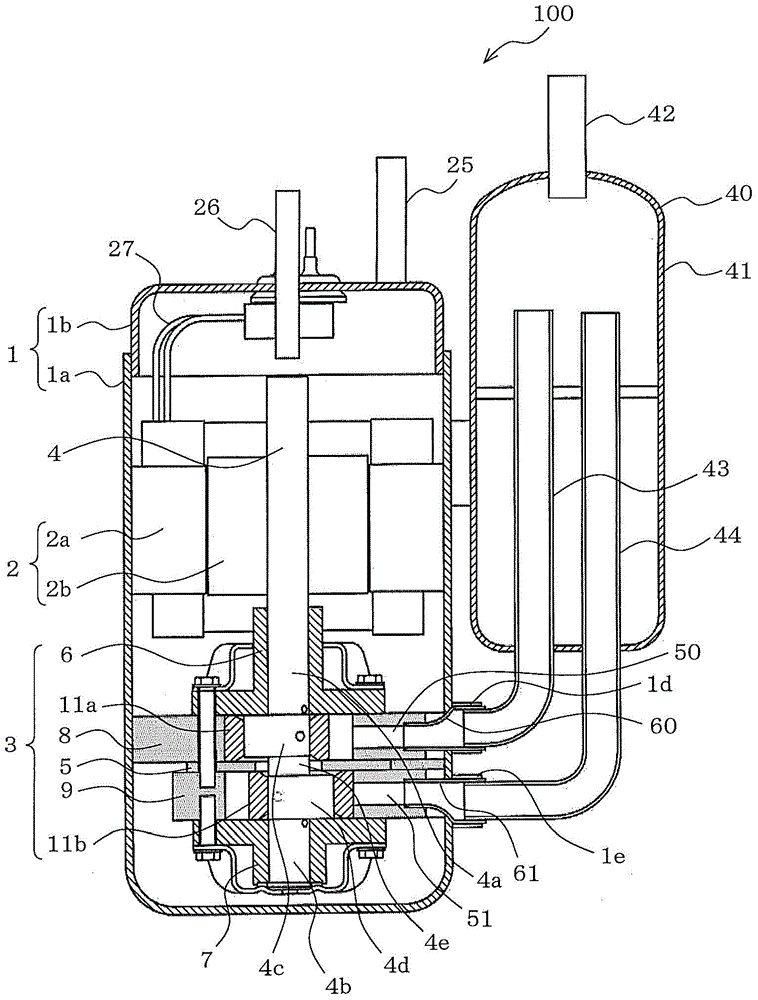

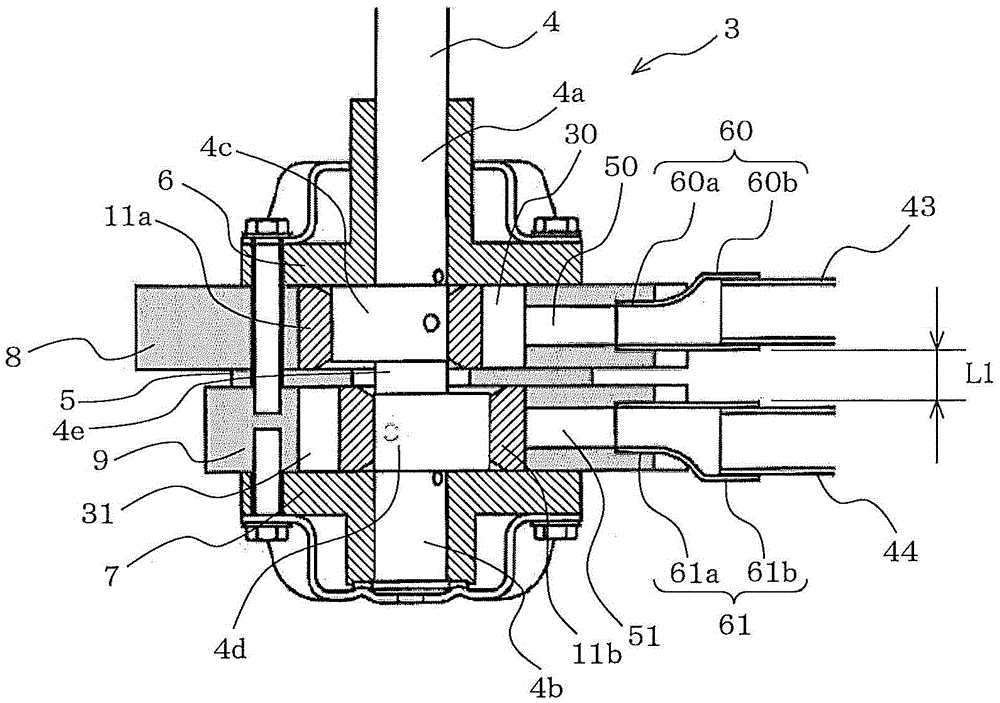

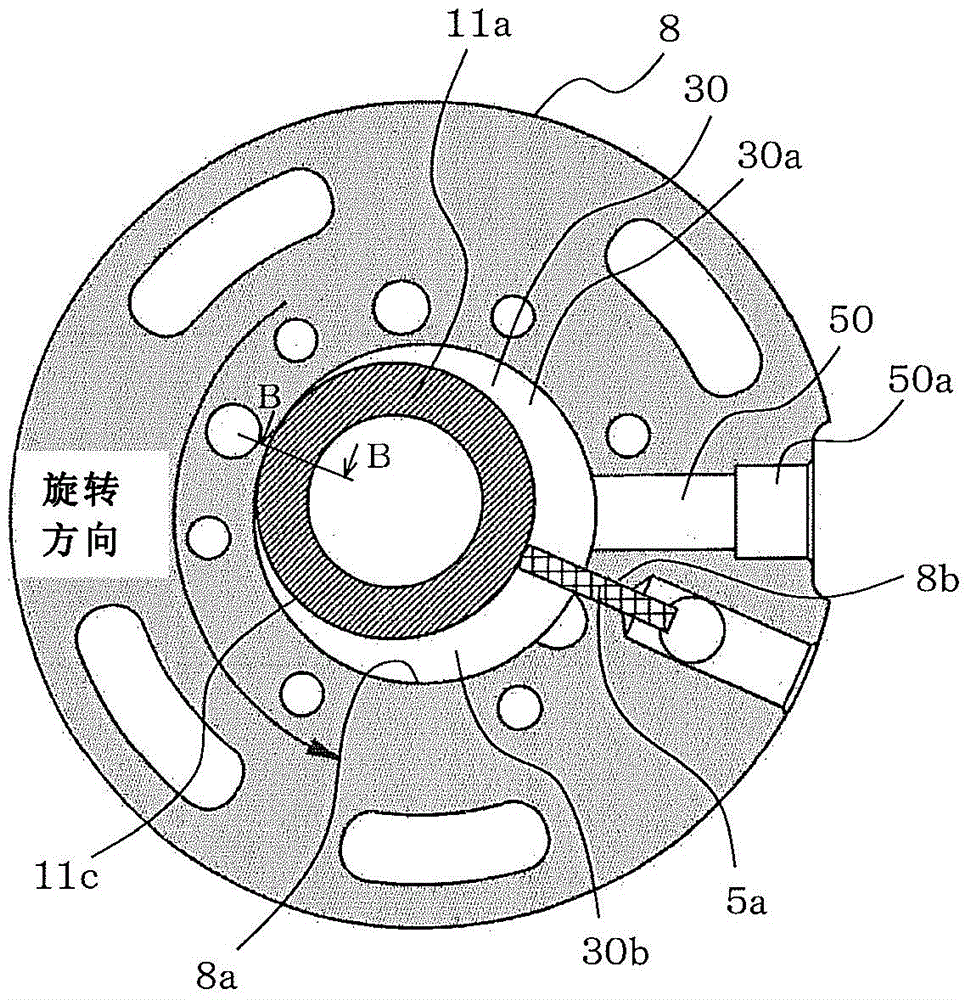

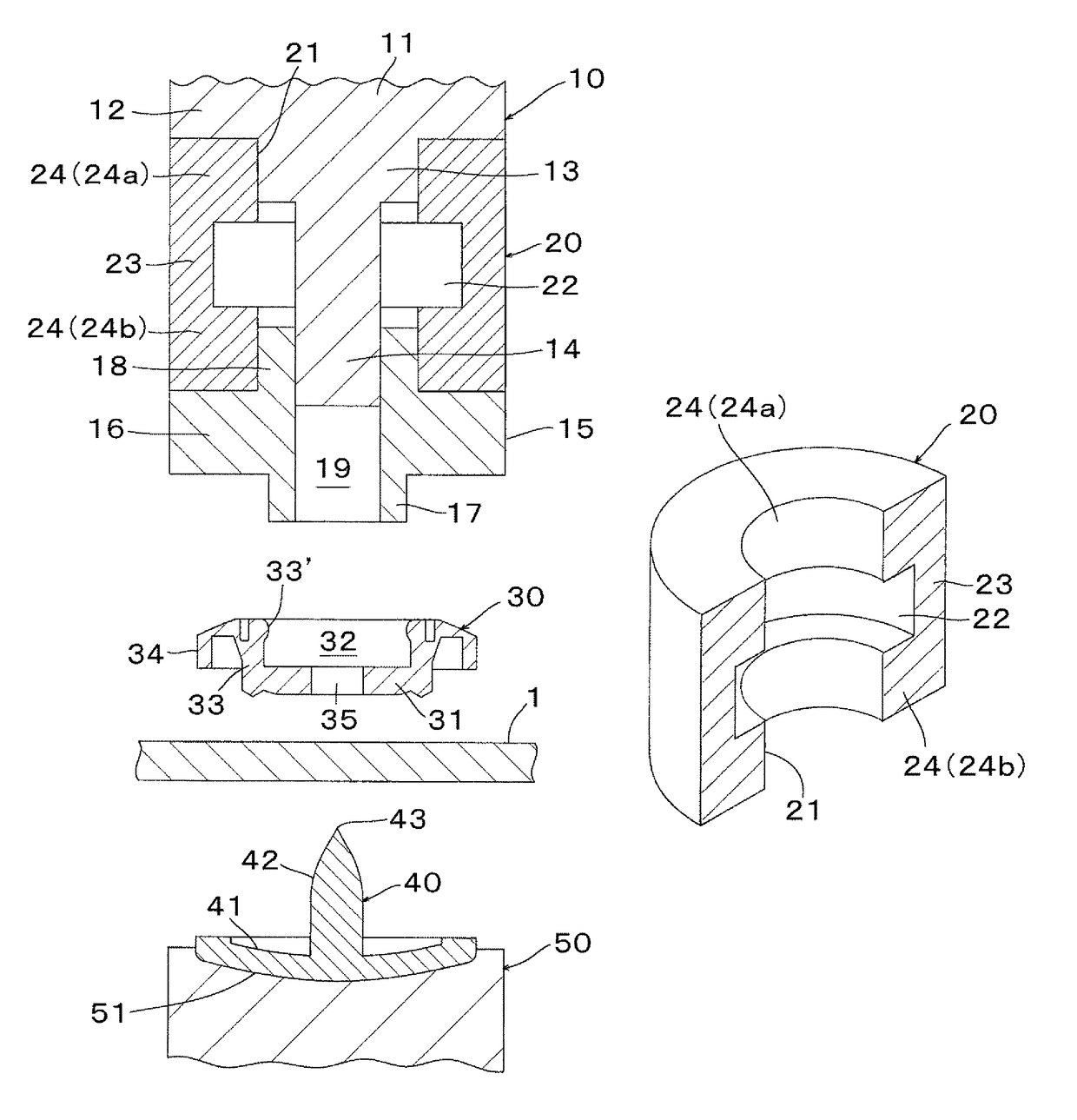

Rotary compressor

ActiveCN104074764AImprove efficiencyAxial spacing reducedRotary/oscillating piston combinations for elastic fluidsMachines/enginesRefrigerantEngineering

The invention relates to a rotary compressor (100). A motor (2) and a compression mechanism (3) driven by a crankshaft (4) via the motor (2) are disposed in a sealed container (1). A first cylinder (8) and a second cylinder (9) are disposed in the compression mechanism (3), and are independently connected with suction pipes (43,44)of coolant gas. The cylinders (8,9) are respectively provided with cylindrical cylinder chambers (30,31), which are provided with suction ports (50,51) in a radially-penetrating manner. The rotary compressor is provided with connecting suction ports (50,51) and connecting pipes (60,61) of the suction pipes (43,44). The central shafts of the suction port side connecting parts (60a,61a) of the connecting pipes (60,61) are eccentric toward the adjacent direction by comparing with the central shaft of the suction pipe side connection parts (60b,61b).

Owner:MITSUBISHI ELECTRIC CORP

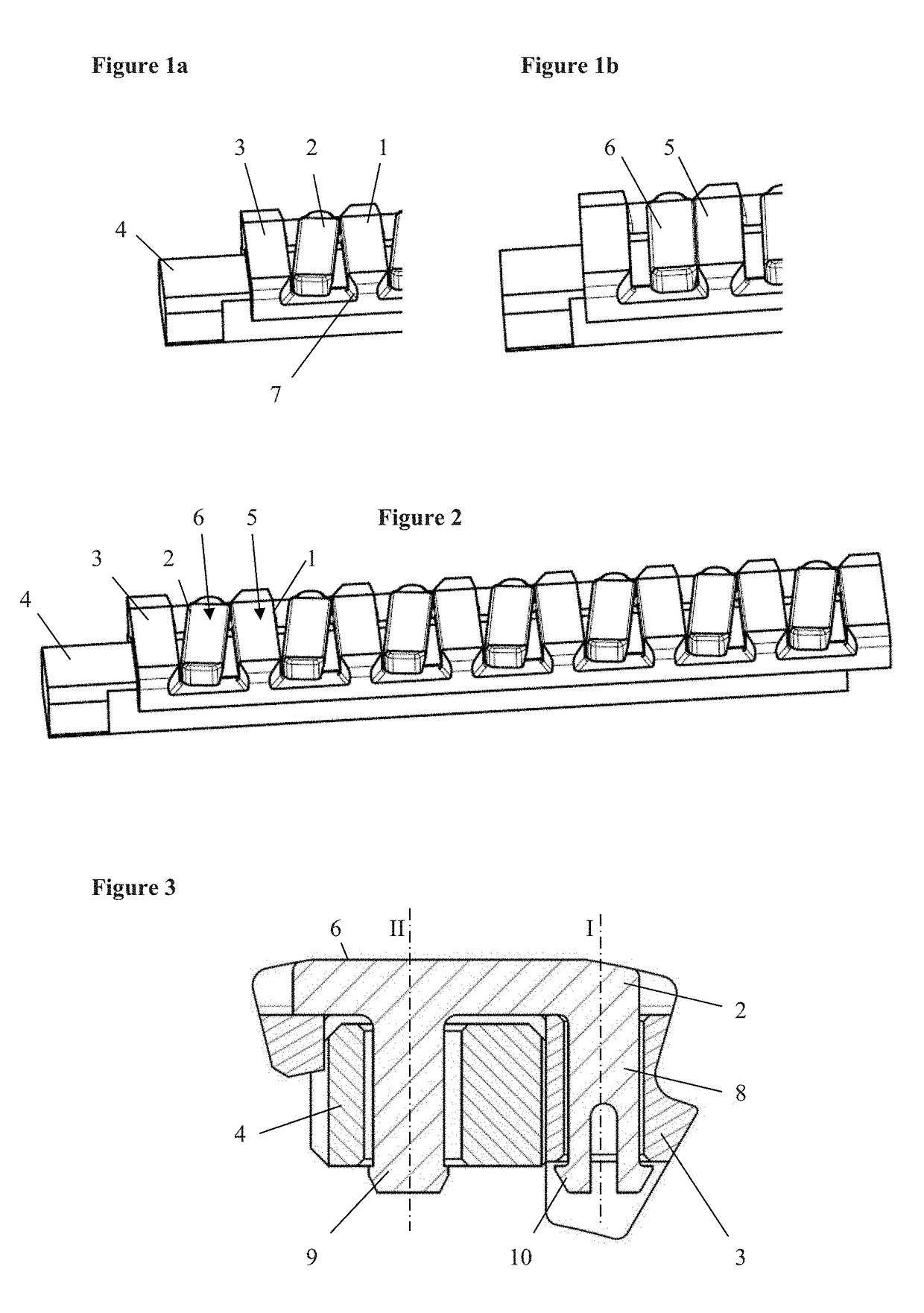

Upper Die for Fastening Button

ActiveUS20120298308A1Reduce deformationAxial spacing reducedButtonsLamination ancillary operationsEngineeringMechanical engineering

Owner:YKK CORP

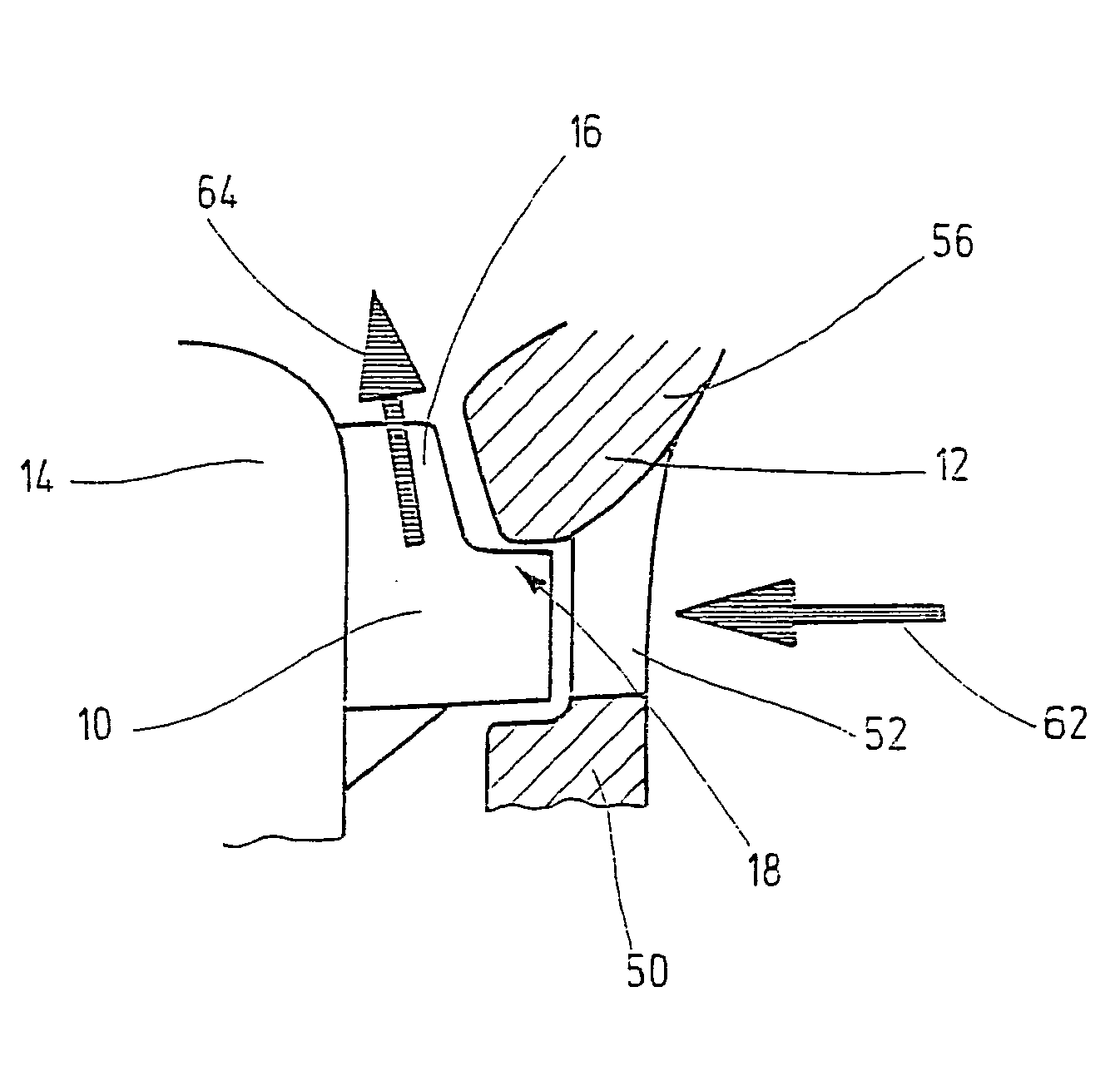

Fan arrangement for an electrical machine

InactiveUS20030228217A1Constant flow cross sectionPrevent backflowPump componentsReaction enginesElectric machineMagnet

The invention relates to a fan apparatus for an electrical machine, with a fan (10), which can be rotated around an axis, wherein air flows into the fan (10) in the axial direction and out of the fan (10) in the radial direction, a bearing plate (12), and a magnet wheel (14), wherein a flow conduit (16) is at least partially bounded by the bearing plate (12) and the magnet wheel (14) and the flow cross section of the flow conduit (16) is essentially constant in the radial direction.

Owner:ROBERT BOSCH GMBH

Motor

PendingCN108880162AReduce axial thicknessRealize the purpose of ultra-thinWindingsMagnetic circuit rotating partsElectric machineEngineering

The invention provides a motor, which comprises a stator assembly and a rotor assembly, wherein the rotor assembly is located at an axial end of the stator assembly; the stator assembly is provided with a plastic package part and a circular terminal plate; the terminal plate is plastically packaged into the plastic package part; the plastic package part is plastically coated with a plurality of stator poles uniformly in the circumferential direction; the rotor assembly is located at the axial end of the stator assembly; and the circular terminal plate is plastically packaged into the plastic package part, so that the axial thickness of the motor is reduced and the ultrathin target of the motor is achieved. Therefore, the motor is small in overall volume, light in weight, simple in structure, low in production cost and high in cost performance.

Owner:GREE ELECTRIC APPLIANCES INC

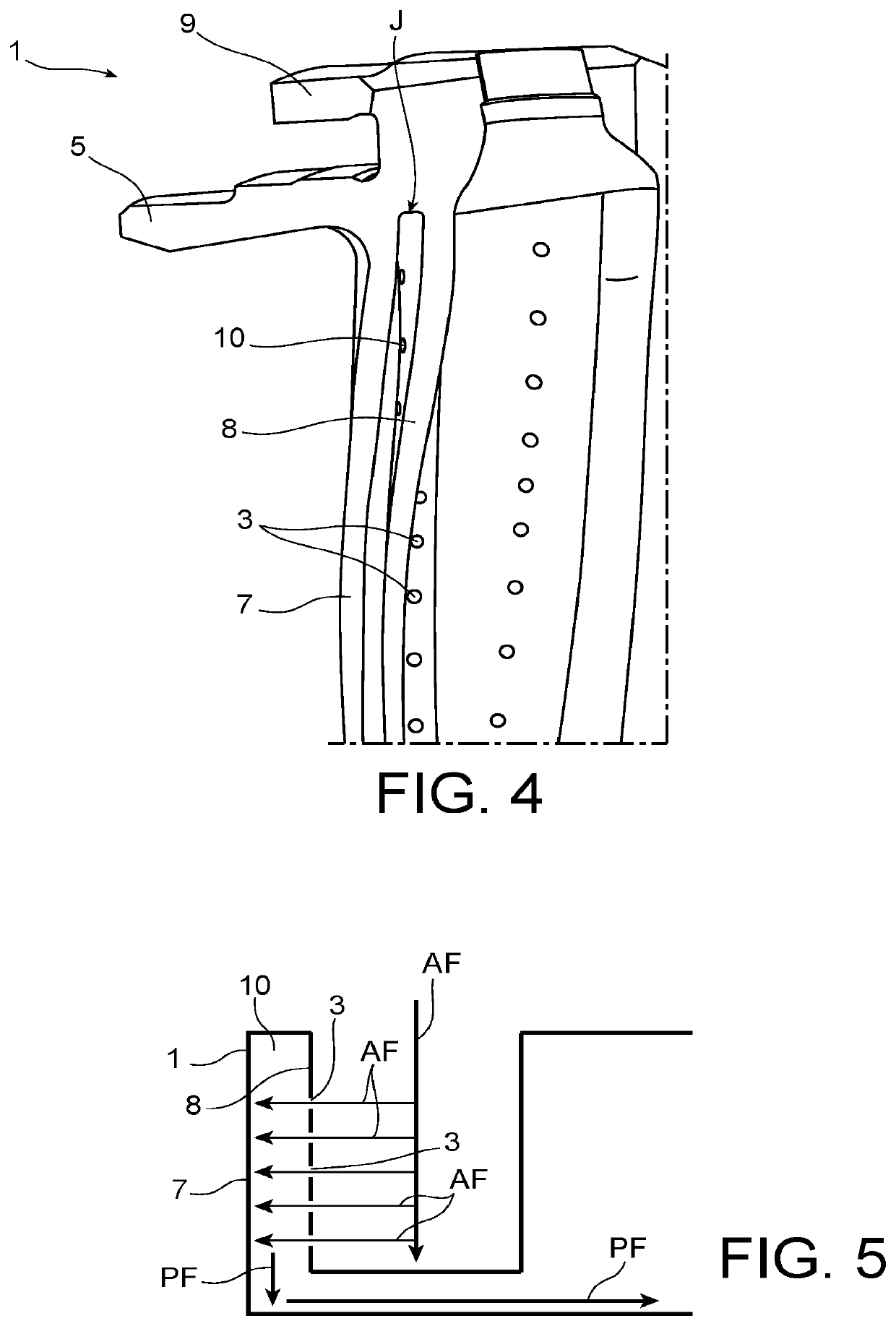

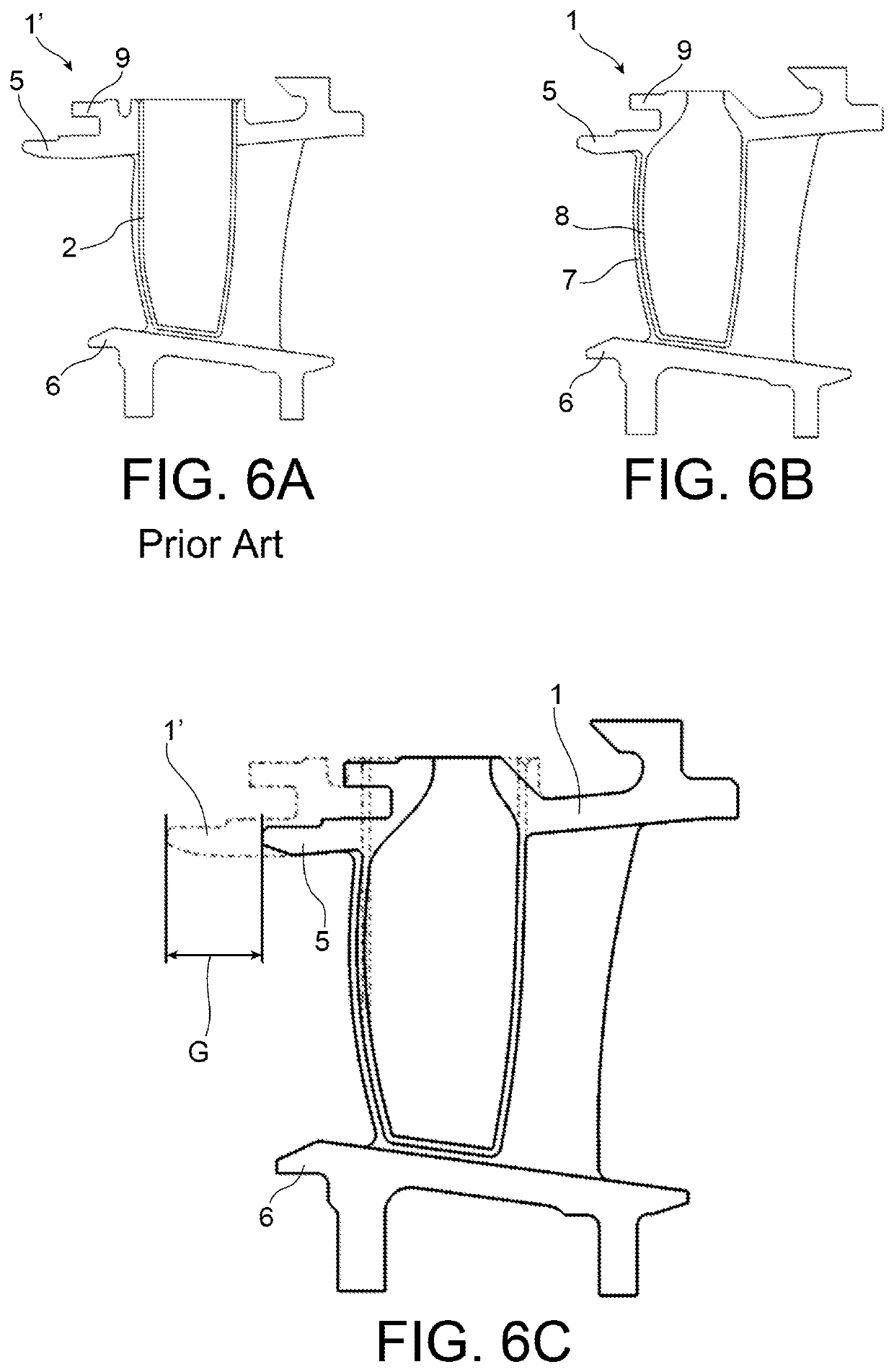

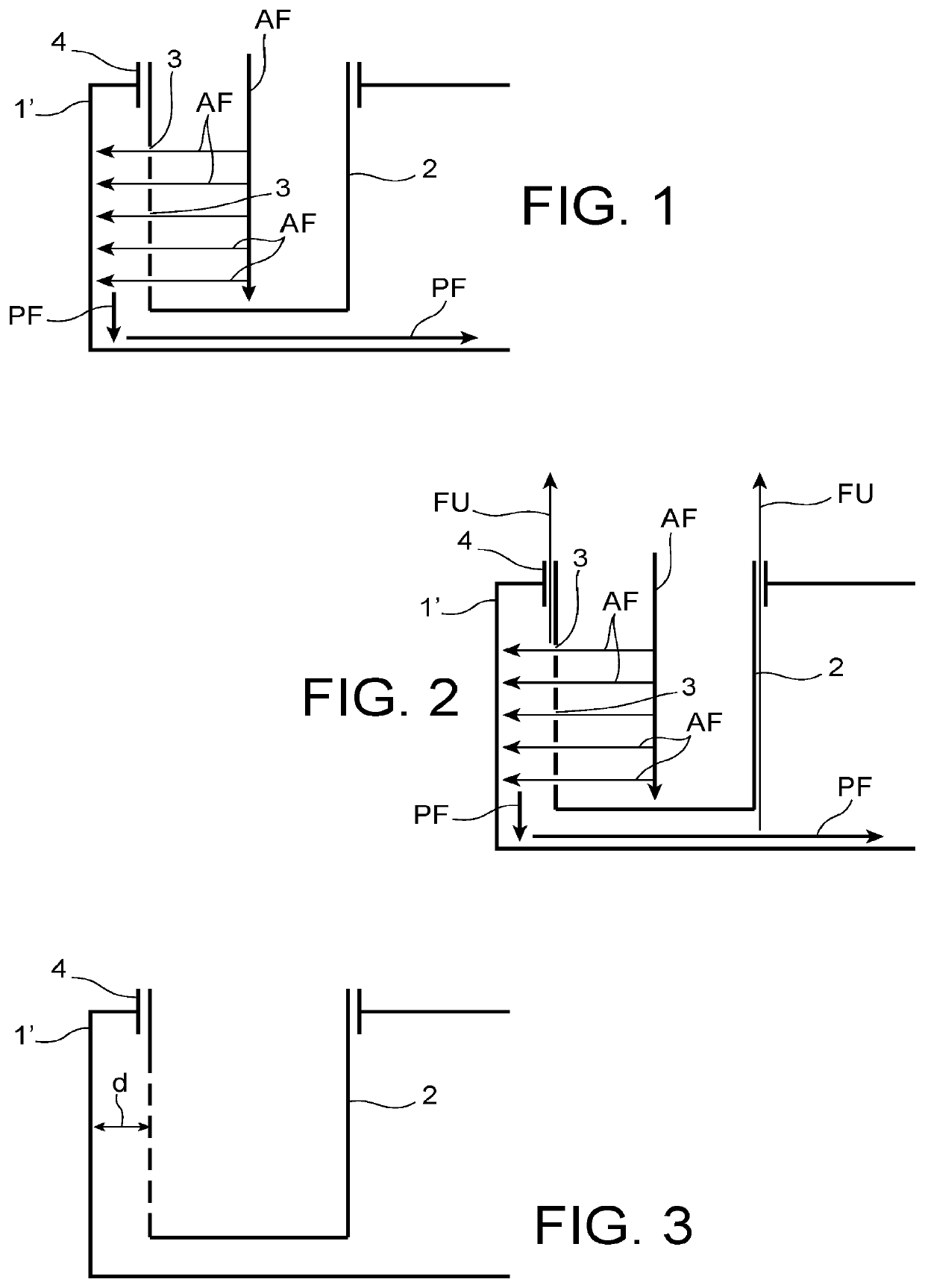

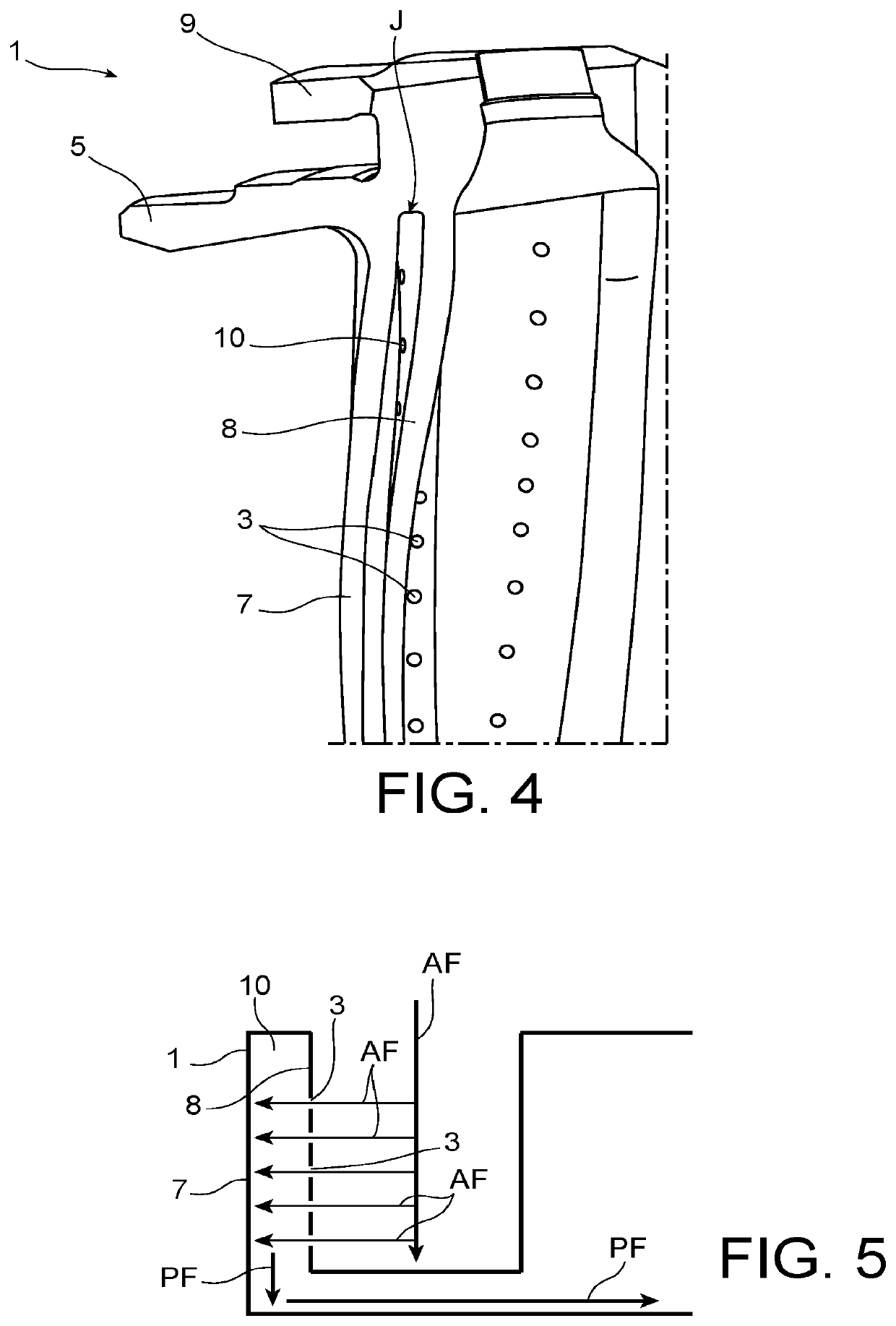

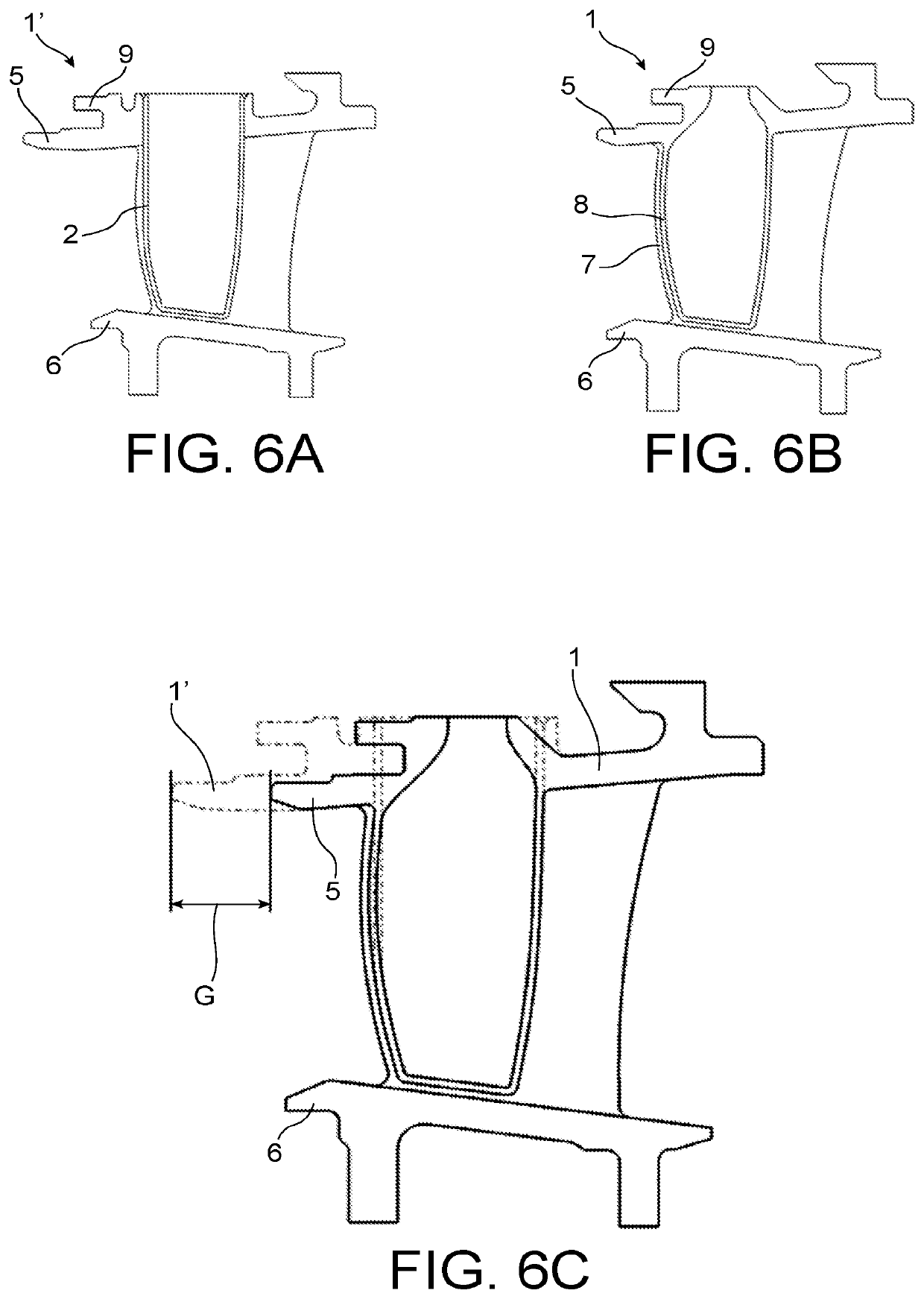

Turbine stator vane comprising an inner cooling wall produced by additive manufacturing

ActiveUS11492911B2Axial spacing reducedReduced space requirementsAdditive manufacturing apparatusBlade accessoriesEngineeringTurbine

A stator vane of a turbine of a gas turbine engine, including an outer platform and an inner platform between which there extends an outer wall forming an outer skin, wherein it includes an inner wall, forming an inner skin, facing the outer wall so as to define an inter-skin cavity between the outer wall and the inner wall, the inner wall including a plurality of cooling orifices for impingement cooling of the outer wall, the outer wall and inner wall being produced by additive manufacturing.

Owner:SAFRAN HELICOPTER ENGINES

Wind turbines and wind turbines

ActiveCN105298754BAxial spacing reducedPrevent air gap changesMachines/enginesWind motor combinationsWind drivenEngineering

The invention provides a wind driven generator and a wind generating set. The wind driven generator comprises a fixed shaft, a movable shaft, a stator and a rotor. The movable shaft is arranged on the fixed shaft in a sleeving manner through a bearing assembly and can rotate relative to the fixed shaft; the bearing assembly comprises a first bearing, the inner ring of the first bearing is fixedly arranged on the fixed shaft, and the movable shaft is fixedly connected to the outer ring of the first bearing; the stator is fixedly connected to the inner ring of the first bearing; and the rotor is fixedly connected to the movable shaft, and the position of the rotor on the movable shaft corresponds to the first bearing in the radial direction. The wind driven generator can well ensure the air gap uniformity in the running process, and the weight of the fixed shaft does not need to be increased.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Epilating device

ActiveUS10905217B2Axial spacing reducedEasy to guideHair-singeingPhysical medicine and rehabilitationSkin contact

An epilating device having a frame, a pair of clamping elements with a first clamp and a second clamp mounted in the frame, wherein each clamp has a skin contact surface facing towards the user's skin. The first clamp and the second clamp being inclined with respect to each other in the open position and being parallel to each other in the closed position.

Owner:BRAUN GMBH

Turbine stator vane comprising an inner cooling wall produced by additive manufacturing

ActiveUS20210003015A1Axial spacing reducedReduced space requirementsAdditive manufacturing apparatusBlade accessoriesEngineeringTurbine

A stator vane of a turbine of a gas turbine engine, including an outer platform and an inner platform between which there extends an outer wall forming an outer skin, wherein it includes an inner wall, forming an inner skin, facing the outer wall so as to define an inter-skin cavity between the outer wall and the inner wall, the inner wall including a plurality of cooling orifices for impingement cooling of the outer wall, the outer wall and inner wall being produced by additive manufacturing.

Owner:SAFRAN HELICOPTER ENGINES

Rotating electric machine with one-sided cooling and method for one-sided cooling

InactiveCN107005107BImprove cooling effectReduce complexityMagnetic circuit stationary partsCooling/ventillation arrangementElectric machineEngineering

The invention relates to a rotating electrical machine having a stator (1), a rotor (8) and a hydrodynamic machine (7) provided for cooling the rotating electrical machine on one side, wherein the stator (1) has a stator lamination stack (2), front stator winding head (5a) and rear stator winding head (5b), wherein the rotor (8) has a rear rotor winding head (6b). In order to improve cooling in the case of one-sided ventilation compared to the prior art, in particular with regard to a uniform temperature distribution, it is proposed that the stator lamination pack (2) has channels (9a, 9b) extending in the axial direction, which are provided for cooling of the rear stator winding head (5b) by means of a second cooling air flow (14) generated by the hydrodynamic machine (7), wherein at least one first channel (9a) is provided for the second cooling air flow (14) generated by the hydrodynamic machine (7) The cooling air flow (14) is directed through the stator lamination stack (2) to the rear stator winding head (5b), where the air is fixed on the side of the stator lamination stack (2) on the side of the rear stator winding head (5b) A guide device (4) provided for routing a second cooling air flow (14) via the rear stator winding head (5b), wherein at least one second channel (9b) is provided for routing the second cooling air flow ( 14) Leading from the rear stator winding head (5b) back through the stator lamination stack (2), wherein at least two radial cutouts (11) arranged in the axial direction in each case are provided for cooling the stator lamination stack (2 ), in particular the stator winding and / or the rear rotor winding head (6b), wherein the radial cutouts are arranged radially in the passages (9a, 9b) extending in the axial direction and between the stator laminations (2) and the rotor (8 ) between the air gaps (3) and connect the two to each other, wherein the axial spacing between the radial cutouts (11) is towards the side of the stator lamination stack (2) facing away from the hydrodynamic machine (7) Smaller and set to compensate for temperature gradients created by one-sided cooling.

Owner:SIEMENS AG

Rod tensioning device and assembly process of such a device on a rod

ActiveUS10245689B2Easy to installAxial spacing reducedMetal working apparatusMetal-working hand toolsActuatorControl theory

The invention concerns a rod tensioning device having a first actuator, at least a second actuator and a tubular support sleeve dedicated to radially surround a threaded rod. Each of the actuators provides a cylinder, and a piston sliding in the cylinder and forming with the cylinder an annular chamber dedicated to be supplied with pressurized fluid. According to the invention, the at least second actuator is temporary axially arranged between the first actuator and the tubular support sleeve for a temporary blockwise assembly, the pistons of two axially adjacent actuators being indexed in rotation together.

Owner:AB SKF

Fuel cell with improved thermal management

ActiveUS9337500B2Heat imbalanceReduced cross sectionFuel cells groupingFuel cell auxillariesControl flowFuel cells

A fuel cell including at least two stacks of electrochemical cells, a heat management system including a circuit for flowing a coolant into each of the stacks fed in parallel, and an outside circuit for flowing the coolant outside the stacks. The outside circuit includes a first subcircuit including a heat exchanger and a second subcircuit directly connected to an inlet of the inside circuit, and controlling valves for controlling flow of the coolant toward either or both subcircuits as a function of temperature of the coolant at an output of each of the stacks. The second outside subcircuit includes a mechanism increasing its head loss such that it is close or equal to that of the first outside subcircuit.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Rotary compressor

ActiveCN104074764BImprove efficiencyAxial spacing reducedRotary/oscillating piston combinations for elastic fluidsMachines/enginesEngineeringCrankshaft

The present invention relates to a rotary compressor (100), which has a motor (2) and a compression mechanism (3) driven by the motor (2) via a crankshaft (4) in a closed container (1). ) in the first cylinder (8) and the second cylinder (9) are independently connected to the suction pipes (43, 44) of the refrigerant gas, wherein the cylinders (8, 9) have cylindrical cylinder chambers (30 , 31), a suction port (50, 51) is formed radially through the cylinder chamber (30, 31), and the rotary compressor has a connection connecting the suction port (50, 51) and the suction pipe (43, 44) Tubes (60, 61), connecting tubes (60, 61) The central axis of the suction port side connecting part (60a, 61a) and the central axis of the suction pipe side connecting part (60b, 61b) are in the direction closer to each other eccentric.

Owner:MITSUBISHI ELECTRIC CORP

Upper die for fastening button

ActiveUS9596900B2Make the flexibility of the elastic member differentReduce deformationButtonsLamination ancillary operationsEngineeringThick wall

Owner:YKK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com