Motor

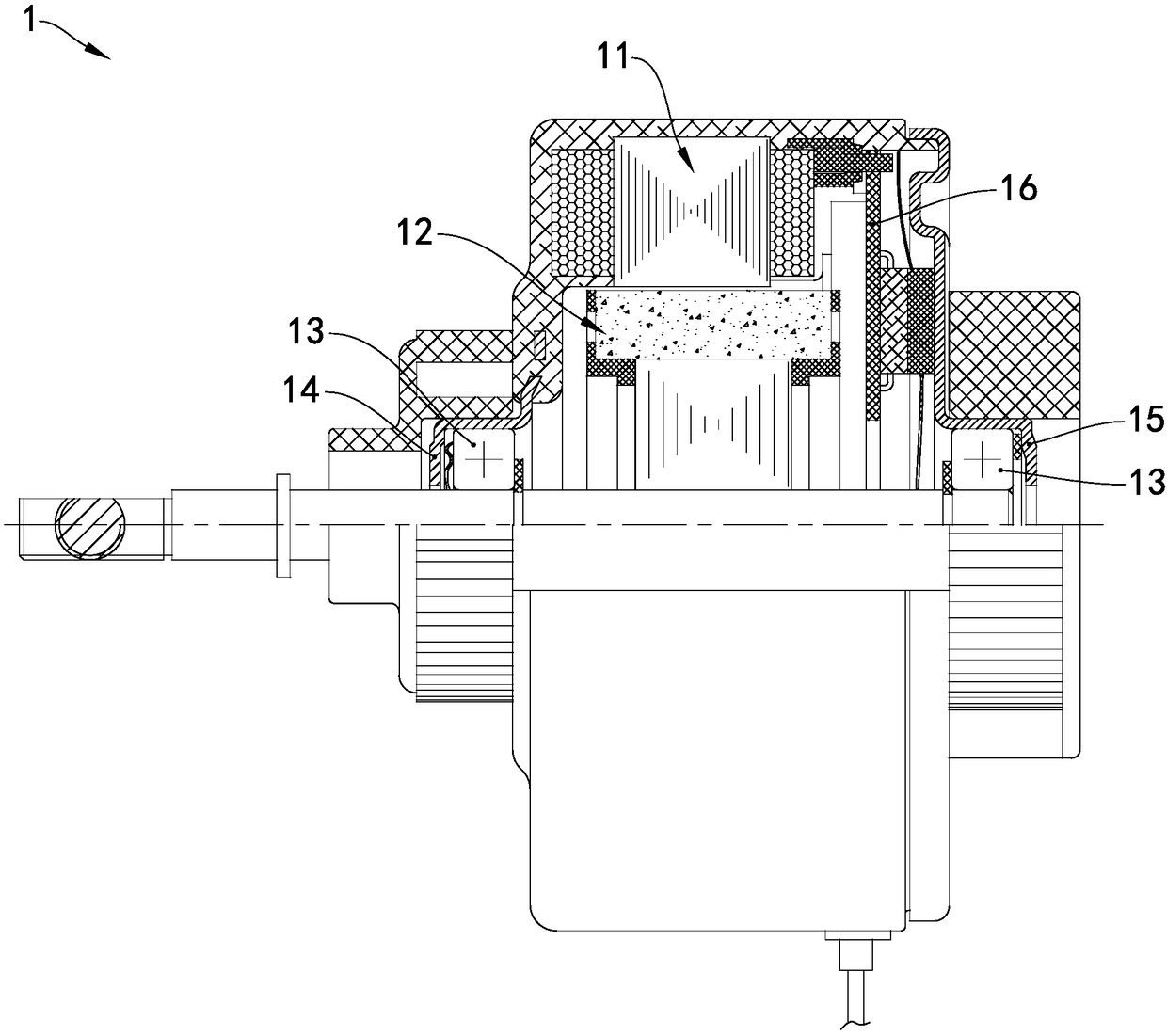

A technology for rotors and plastic seals, applied in the field of ultra-thin permanent magnet brushless DC motors, which can solve the problems of increasing the axial thickness of the motor 1, increasing the axial thickness of the motor 1, and the large volume of the motor 1, and shortening the axial direction The effect of thickness, high motor efficiency, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

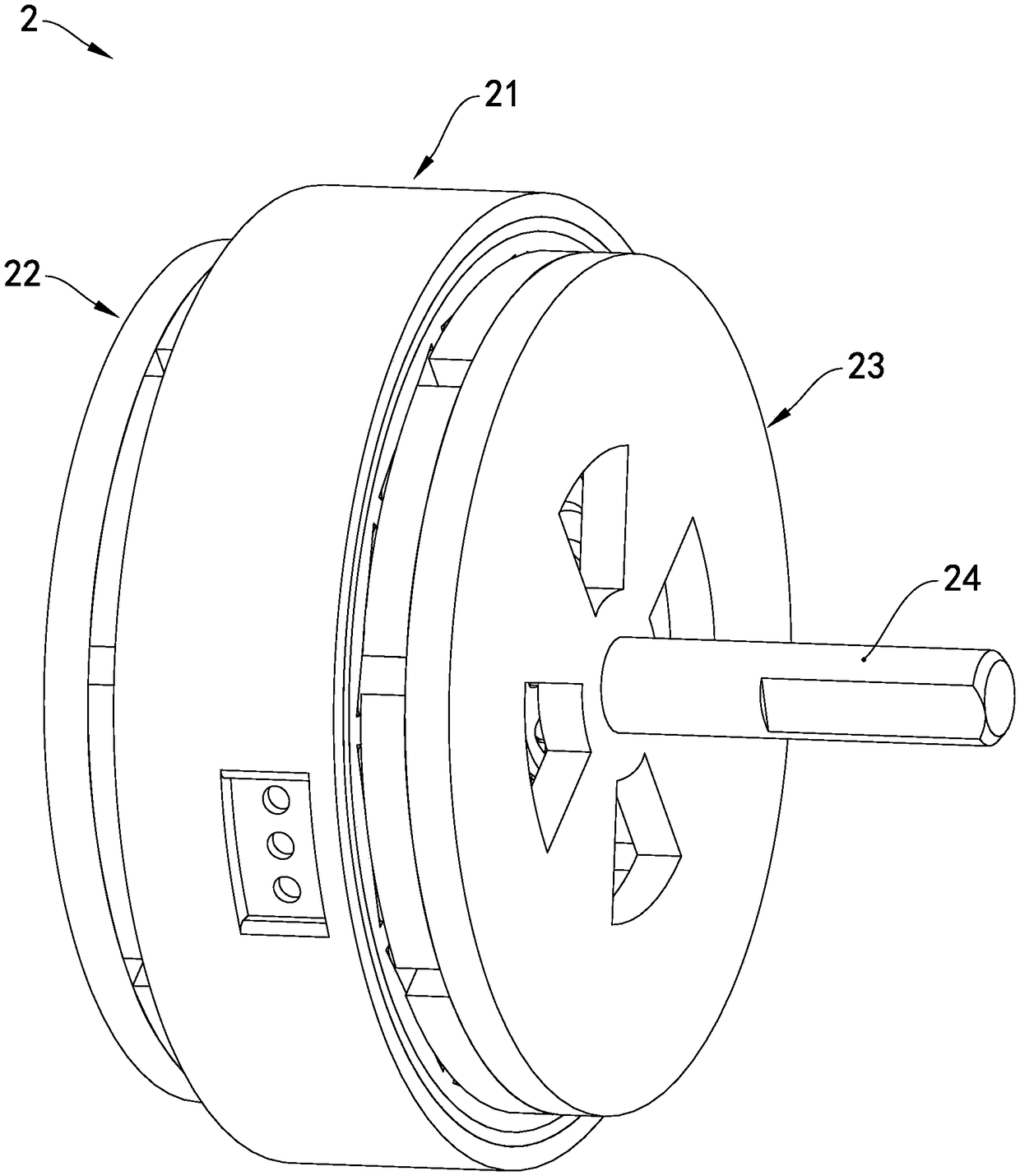

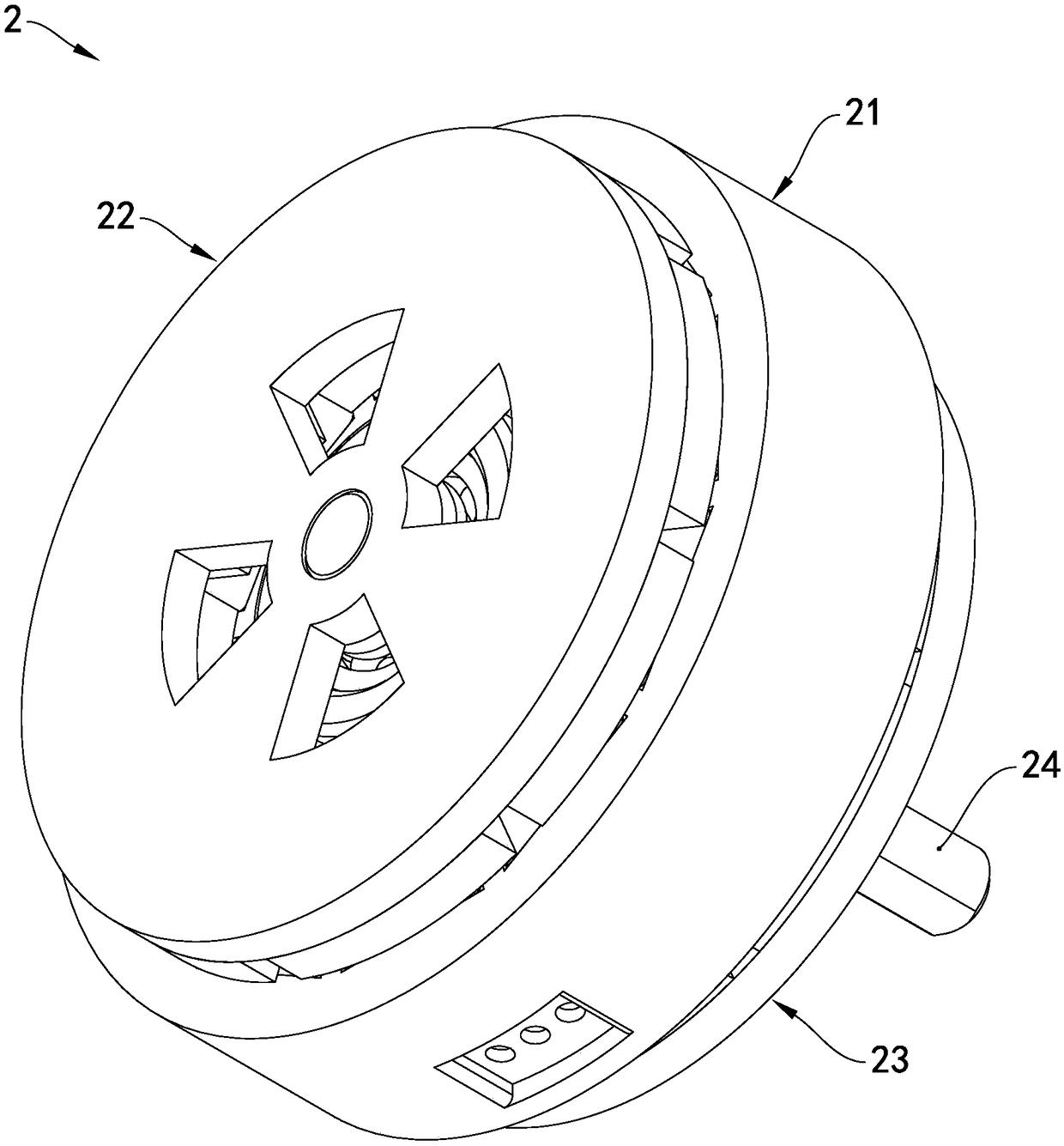

[0035] see figure 2 with image 3 , the motor 2 includes a stator assembly 21 and a rotor assembly, the rotor assembly is located at the axial end of the stator assembly 21, and the rotor assembly may be composed of a single rotor structure, or may be composed of multiple rotor structures. The rotor assembly of this embodiment has a first rotor assembly 22, a second rotor assembly 23, and a rotor shaft 24. The first rotor assembly 22 and the second rotor assembly 23 are located at both ends of the stator assembly 21 in the axial direction, thereby forming A double-rotor structure is adopted, and one end of the rotor shaft 24 is set through the first rotor assembly 22 , the stator assembly 21 and the second rotor assembly 23 .

[0036] see Figure 4 to Figure 9 , the stator assembly 21 includes an annular molded part 211 and an annular terminal board 212, and the molded part 211 is made of molding compound. The plastic package 211 is provided with a shaft hole 2113 axially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com