Rotating electric machine with one-sided cooling and method for one-sided cooling

A technology for rotating electric machines and cooling air, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., which can solve problems such as long structural lengths, and achieve the effects of saving costs and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

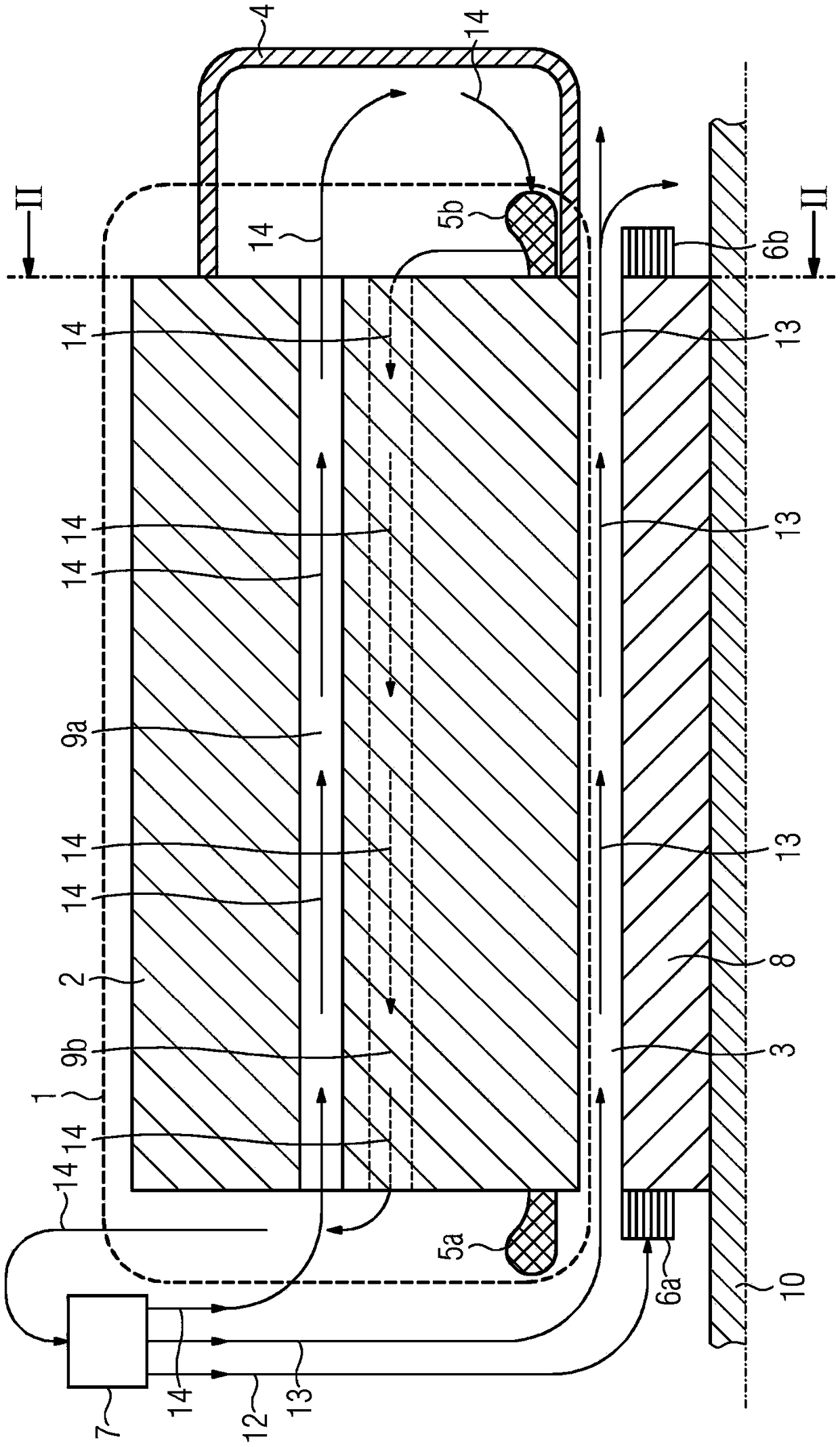

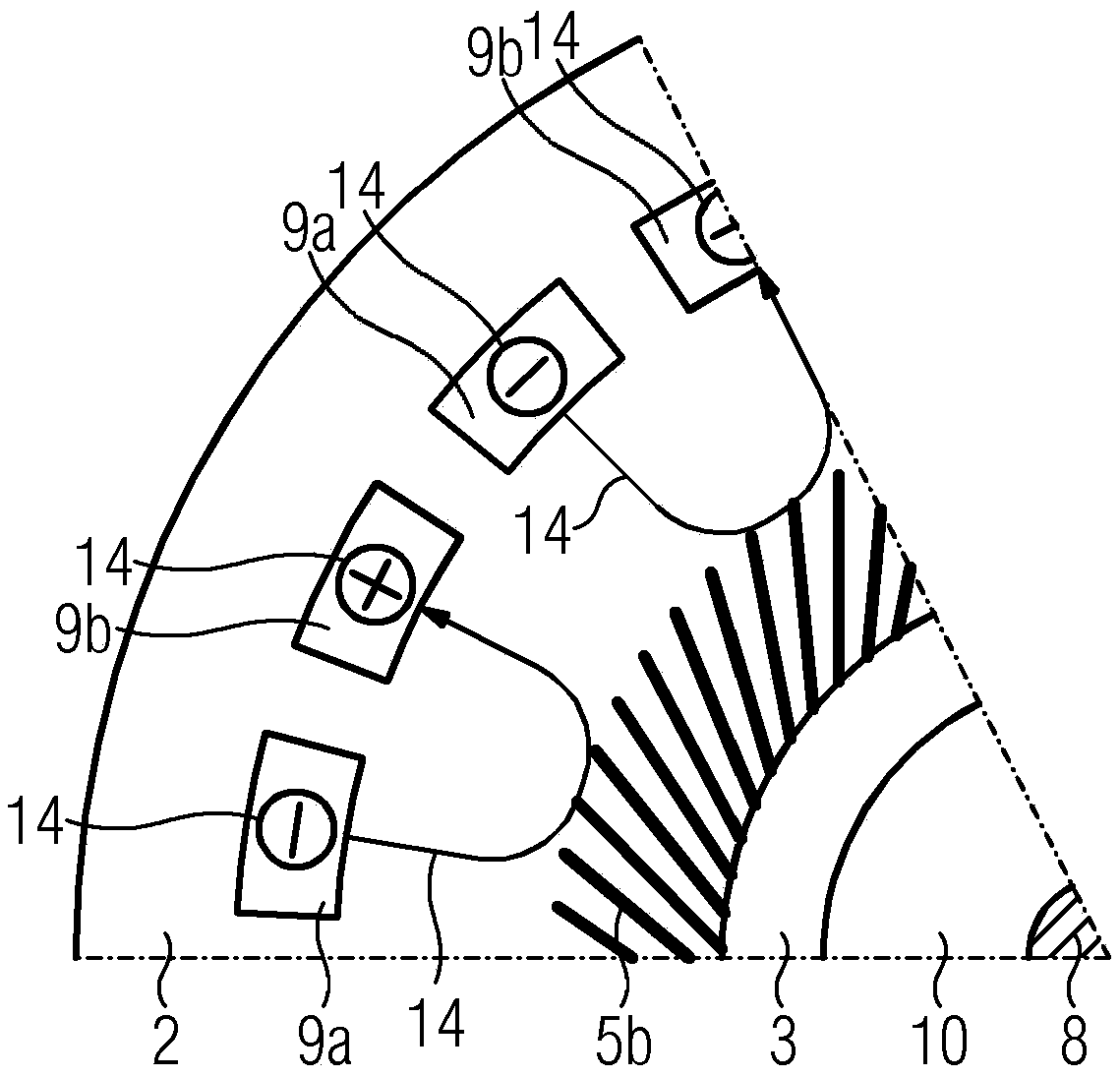

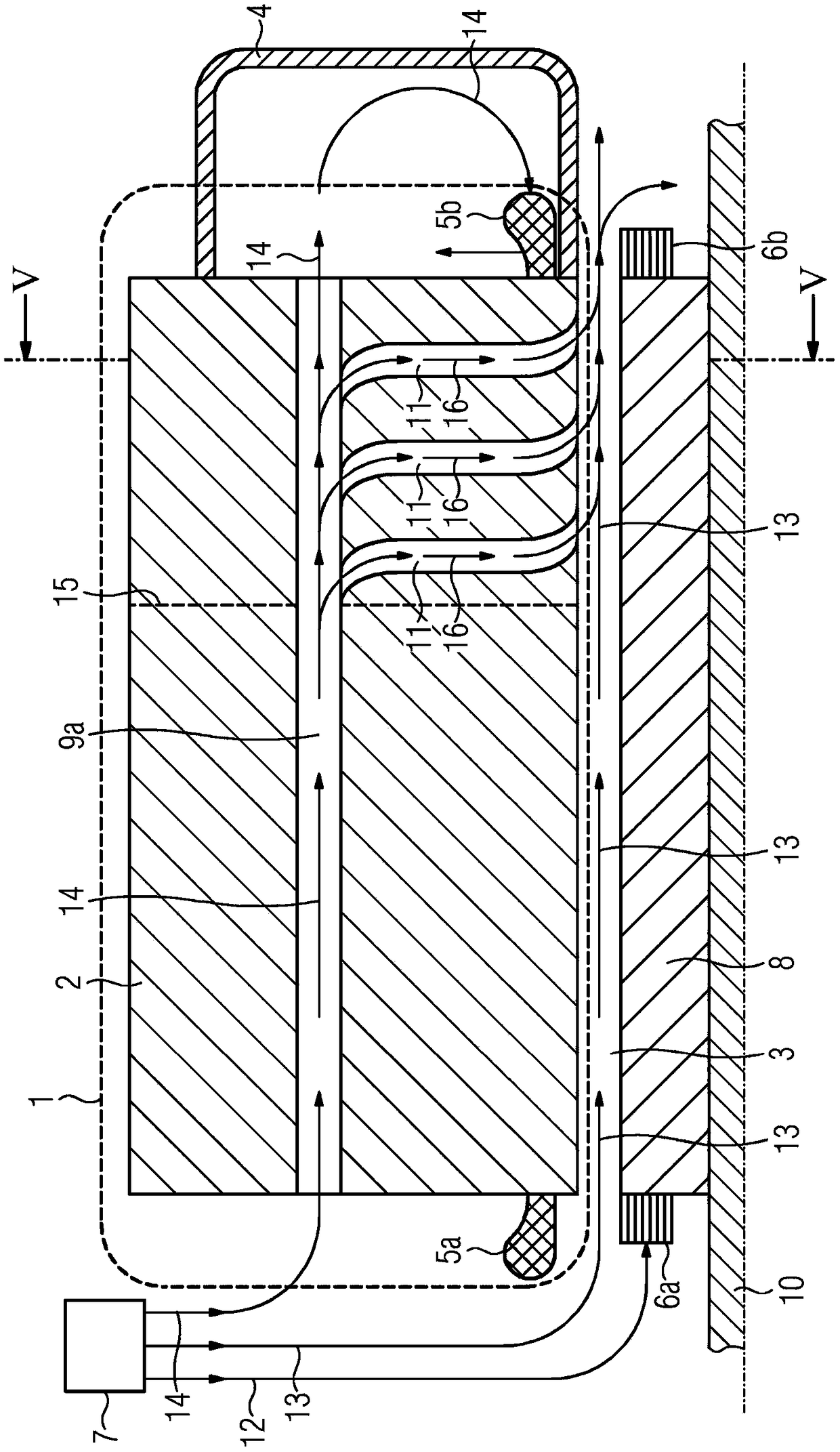

[0025] figure 1 A longitudinal sectional view of a first embodiment of a rotating electrical machine is shown, which is rotationally symmetrical in the axial direction, wherein only the upper part of the machine is shown. Such machines, especially motors, have a power of more than 10 megawatts and a diameter of more than 5 meters. The rotating electrical machine has a stator 1 with a stator lamination stack 2 , a front stator winding head 5 a and a rear stator winding head 5 b. Furthermore, the rotating electrical machine has a rotor 8 with a front rotor winding head 6 a and a rear rotor winding head 6 b and a shaft 10 . The hydrodynamic machine 7 produces a cooling air flow 12 , 13 , 14 , in particular under pressure, by means of which the machine is cooled on one side. The front rotor winding head 6 a and the front stator winding head 5 a are directly cooled by means of a third cooling air flow 12 , while a first cooling air flow 13 passes from the pressure side of the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com