Horizontal type micro equipped water-turbine generator set

A technology for generator sets and generators, applied in the directions of engine components, machines/engines, mechanical equipment, etc., can solve problems such as inapplicability of horizontal water turbines, and achieve the effect of reducing the amount of excavation and concrete, the flow rate is small, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

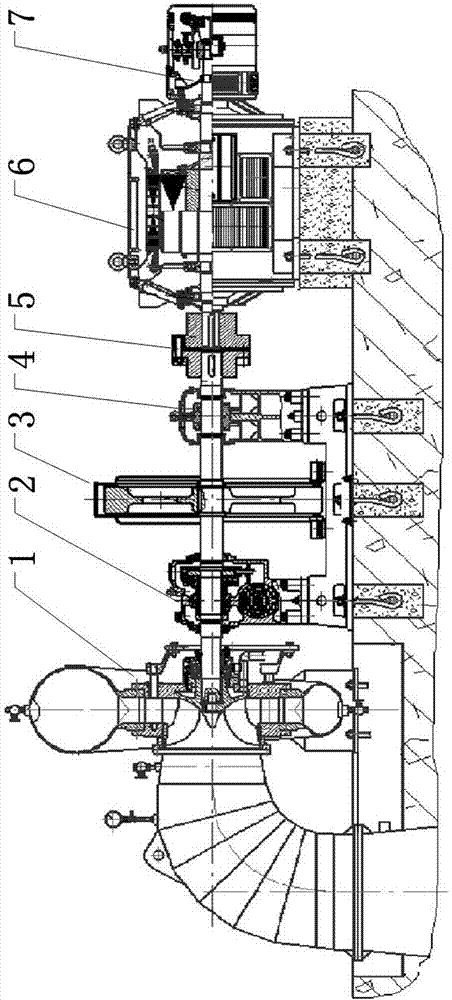

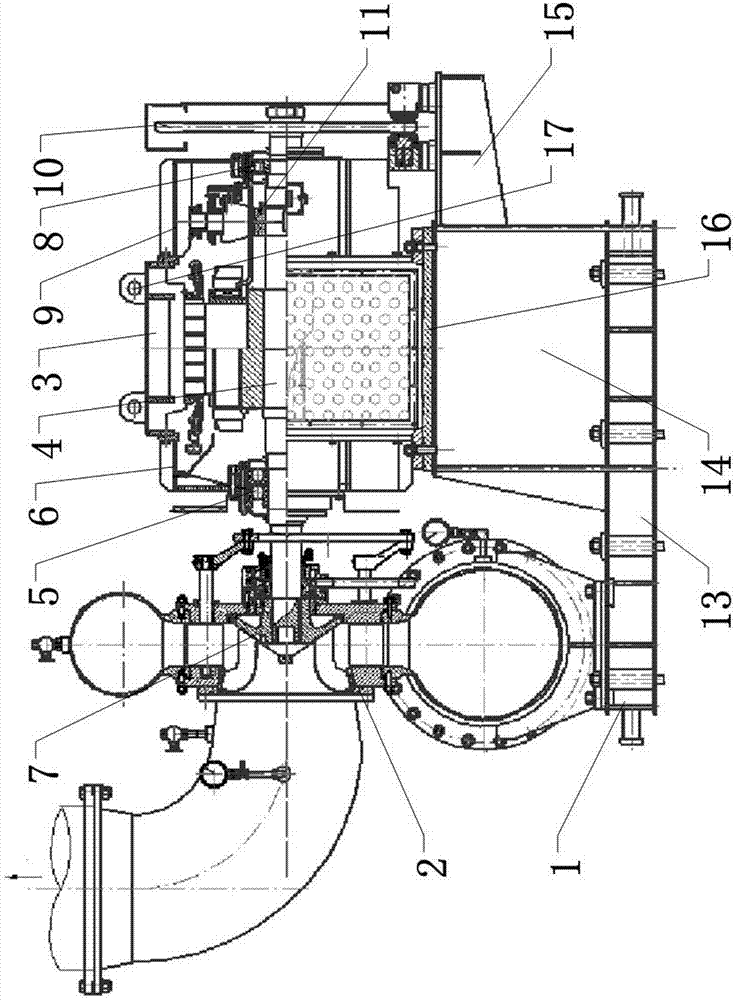

[0034] Such as figure 2 and image 3 As shown, a horizontal micro-integrated hydro-generator set includes a chassis 1 arranged on the ground foundation, a micro-turbine 2 fixedly installed on the upper left side of the chassis 1 and a micro-hydro turbine 2 fixedly installed on the upper right side of the chassis 1 The miniature brushless excitation generator 3 .

[0035] The internal rotation of the miniature brushless excitation generator 3 is provided with a main shaft 4, and the front end of the main shaft 4 is arranged in the front end cover 6 of the miniature brushless excitation generator 3 through two ball bearings 5, and the front end of the main shaft 4 The front end is fixedly arranged on the runner 7 of the micro-hydraulic turbine 2 .

[0036] The rear end of the main shaft 4 is arranged in the rear end cover 9 of the miniature brushless excitation generator 3 through a cylindrical roller bearing 8 , and a flywheel 10 is fixedly connected to the rear end of the m...

Embodiment 2

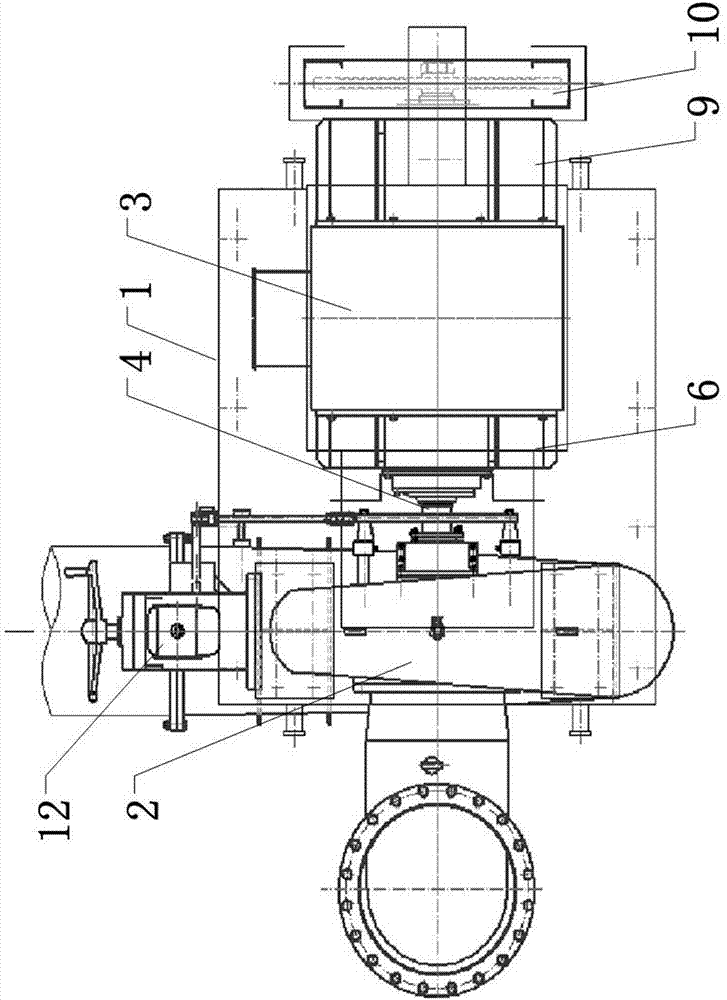

[0040] Such as figure 2 and image 3 As shown, the difference between it and Embodiment 1 is that an AC exciter 11 is arranged on the main shaft 4 and inside the cylindrical roller bearing 8 .

[0041] The side of the micro-turbine 2 is provided with a flashlight dual-purpose governor 12 .

[0042] In this embodiment, in order to further reduce the size of the generator set, the generator set abandons the traditional structural layout of independently setting the AC exciter on the rear main shaft of the hydro-generator, and arranges the AC exciter on the cylinder The main shaft on the inner side of the roller bearing, so that the AC exciter is fully assembled in the rear end cover of the miniature brushless excitation generator, which greatly reduces the volume of the unit, and also avoids the need for on-site assembly and installation of traditional four-point bulk hydro-generator sets. The trouble of debugging the AC exciter.

[0043] In addition, in order to reduce the ...

Embodiment 3

[0045] Such as figure 2 As shown, the difference between it and Embodiment 2 is that the chassis 1 includes a horizontal platform 13, a vertical platform 14 arranged on the upper right side of the horizontal platform 13, and a vertical platform 14 arranged on the right side of the vertical platform 14 Auxiliary stand 15 on the surface.

[0046] In this embodiment, in order to facilitate manufacturing, the chassis adopts a structure including a horizontal platform, a vertical platform and an auxiliary platform, and the horizontal platform, the vertical platform and the auxiliary platform can be fabricated separately and then welded together, thereby improving Chassis manufacturing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com