Embedded rudder surface control mechanism of unmanned aerial vehicle

A control mechanism and rudder surface technology, applied in the directions of non-power amplification, aircraft transmission, aircraft power transmission, etc., can solve the problems of small space inside the wing and difficult to achieve, and achieve convenient installation, easy engagement, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

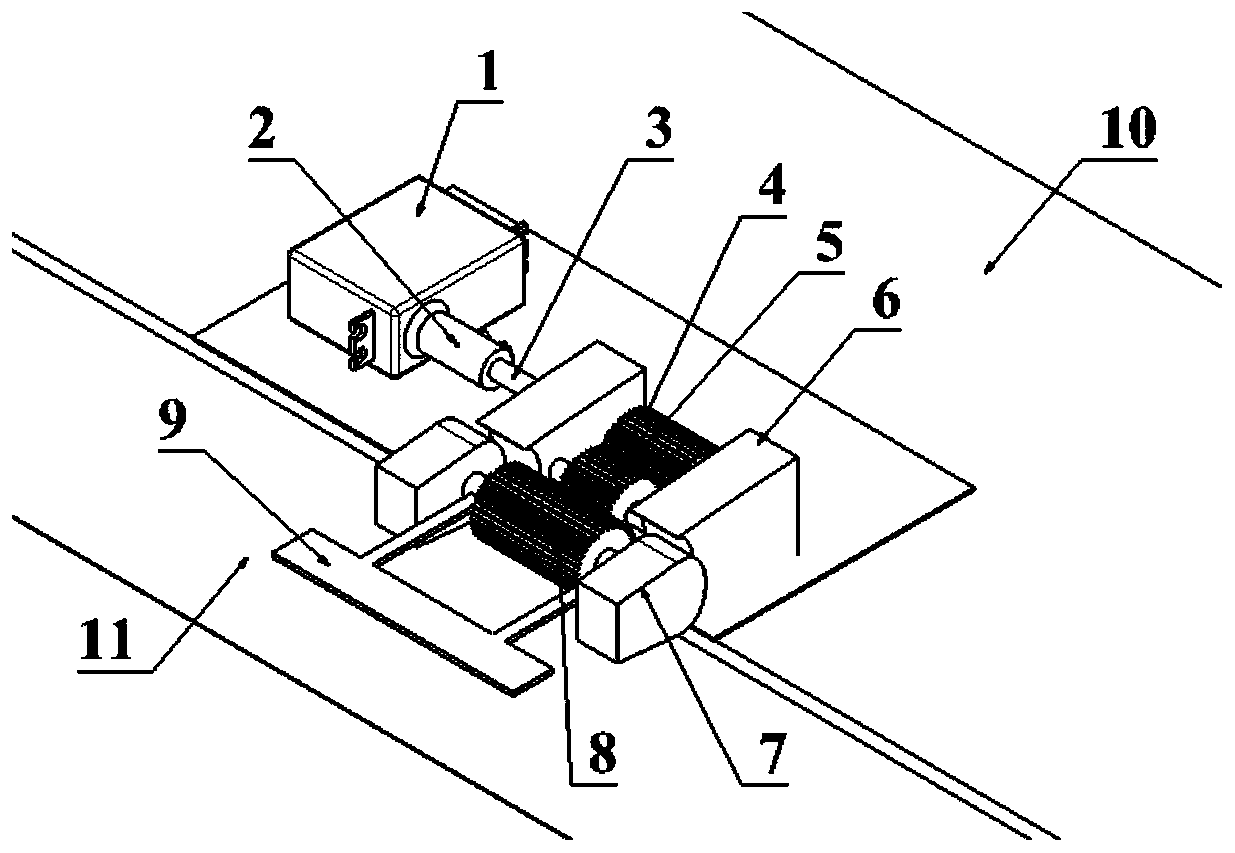

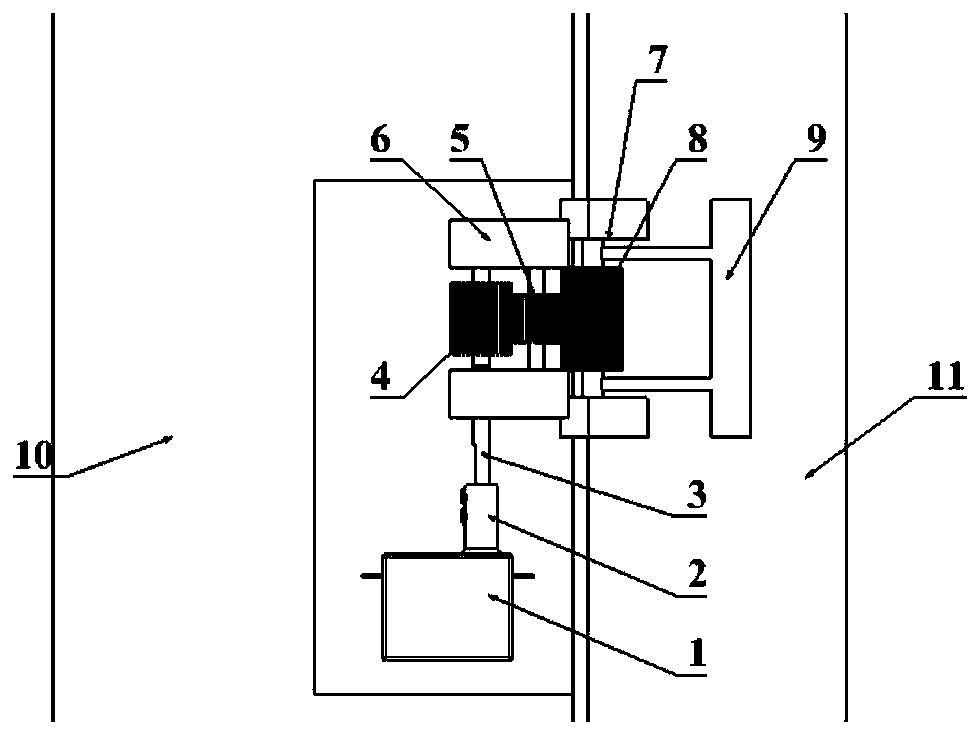

[0024] An embodiment of the present invention is a built-in unmanned aerial vehicle control surface control mechanism.

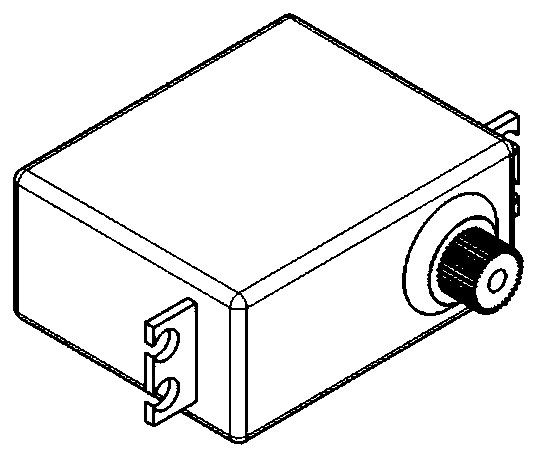

[0025] refer to Figure 1 to Figure 5 In this embodiment, the embedded UAV rudder surface control mechanism consists of a steering gear 1, a connecting sleeve 2, a driving gear shaft 3, a driving gear 4, a driving gear 5, a driving gear mounting seat 6, a driven gear bracket 7, The driven gear 8, the moving plate 9, the wing 10, the rudder surface 11, the end screw 12, the first screw 13 and the second screw 14, wherein the steering gear 1 and the driving gear mount 6 are respectively fixed on the wing 10, the steering gear is located on the side of the end of the driving gear mounting seat 6, the driving gear 4 and the transmission gear 5 are respectively installed in the middle of the driving gear mounting seat 6, the driving gear 4 and the transmission gear 5 are meshed for transmission, and the driving gear shaft 3 protrudes The end of the driving gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com