Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Accurate angle positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

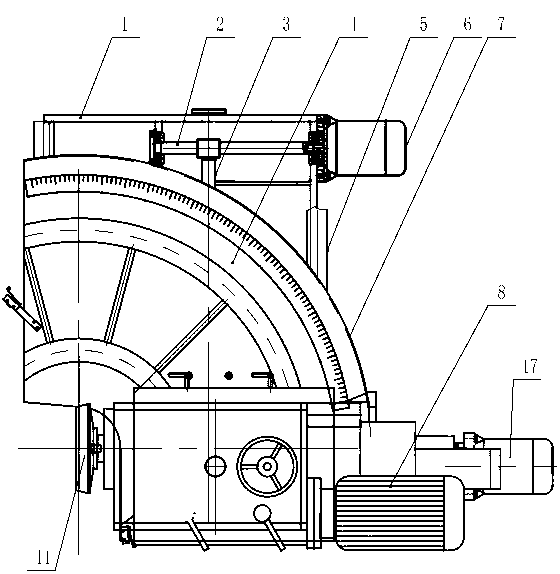

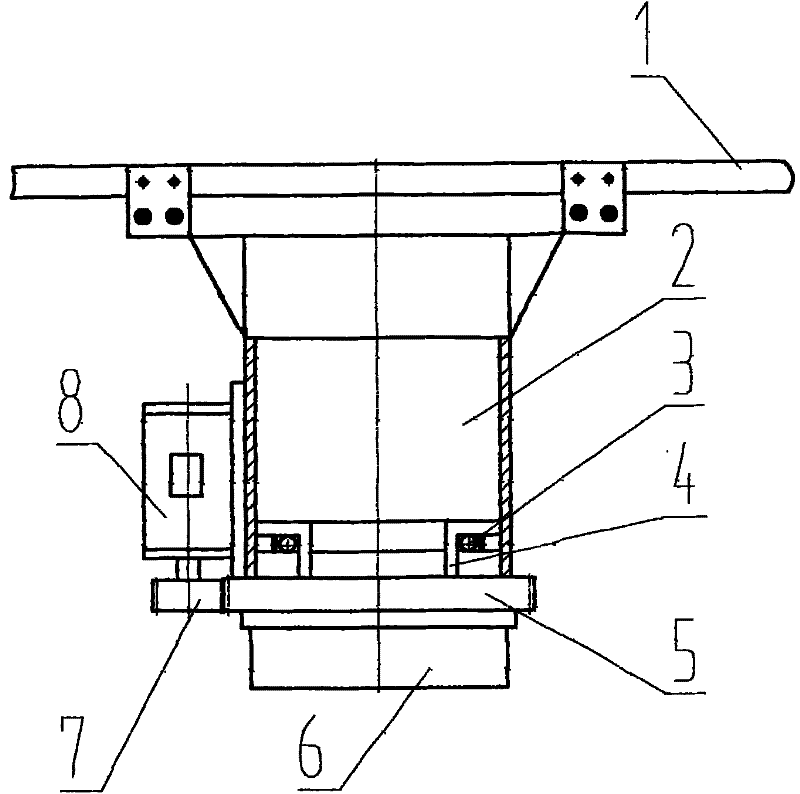

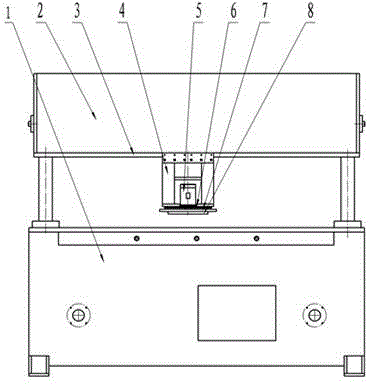

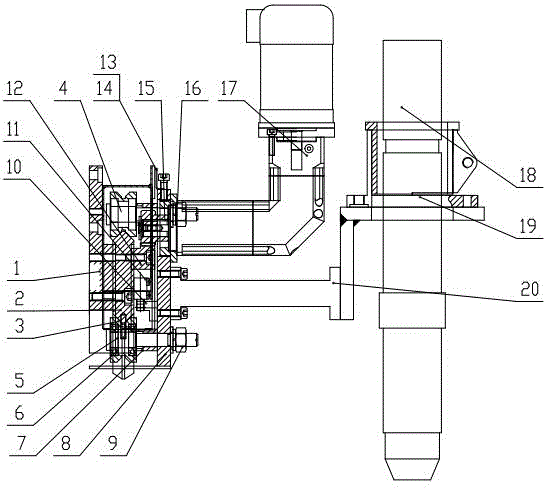

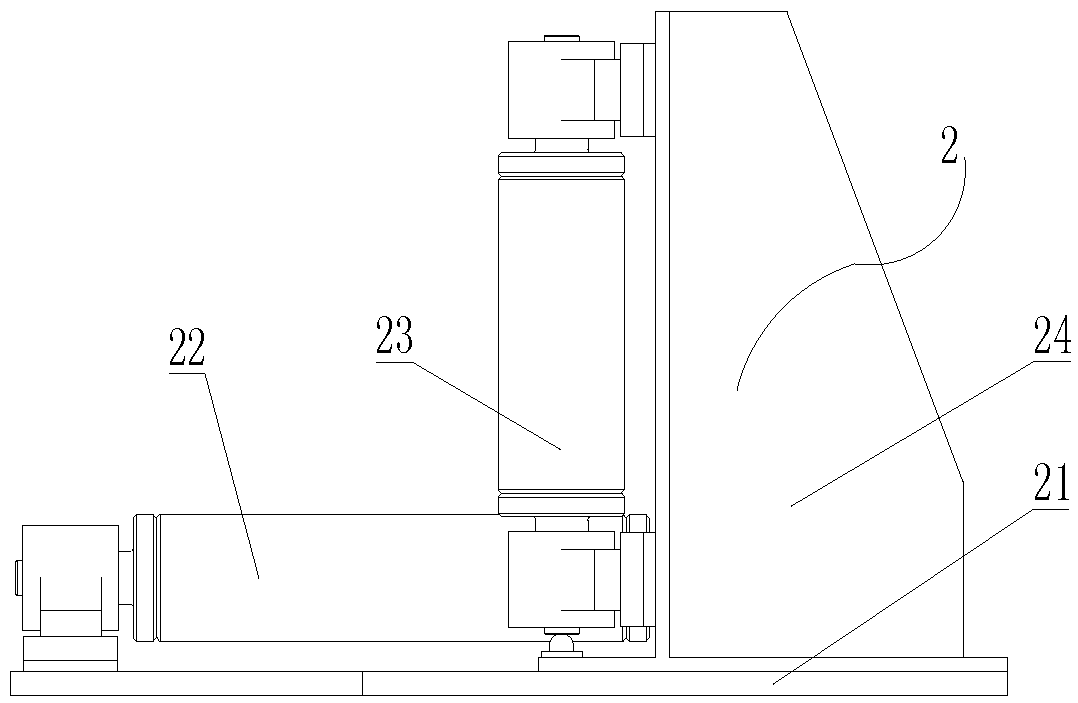

Lifting rotary adjusting mechanism for milling head of edge milling machine

InactiveCN102699692AIncrease contact surfaceLarge flip angleLarge fixed membersMilling equipment detailsMilling cutterEngineering

The invention relates to a lifting rotary adjusting mechanism for the milling head of an edge milling machine. The lifting rotary adjusting mechanism comprises a milling power head, a circular arc rotary part and a lifting part, wherein an arc-shaped guide rail is arranged on the front side of an arc-shaped guide rail seat; and the milling power head is matched with the arc-shaped guide rail through an arc-shaped guide groove. Compared with the prior art, the lifting rotary adjusting mechanism adopting the structure that a single shaft is taken as a rotating center has the advantages that the contact surface between the guide rail and the guide groove is larger, the stability is enhanced, milling cutter heads with larger specifications can be hung, and better machining precision can be guaranteed; and the overturning angle is large and can be 85 degrees, so that the angle positioning is more accurate. During the overturning process, a milling cutter head is kept in the rotation center all the time, that is, approximately the milling cutter head is kept on the edge of a sheet metal all the time, so that positioning can be fulfilled efficiently.

Owner:WUXI HUALIAN PRECISION MACHINERY

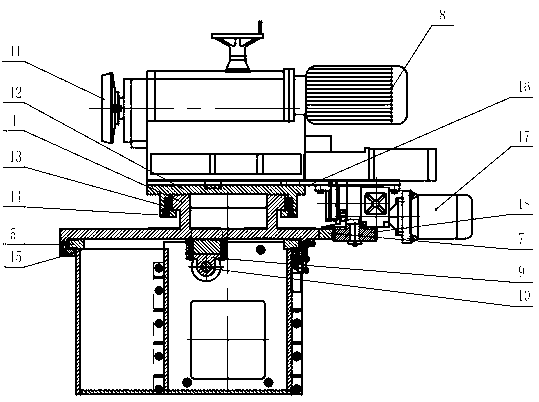

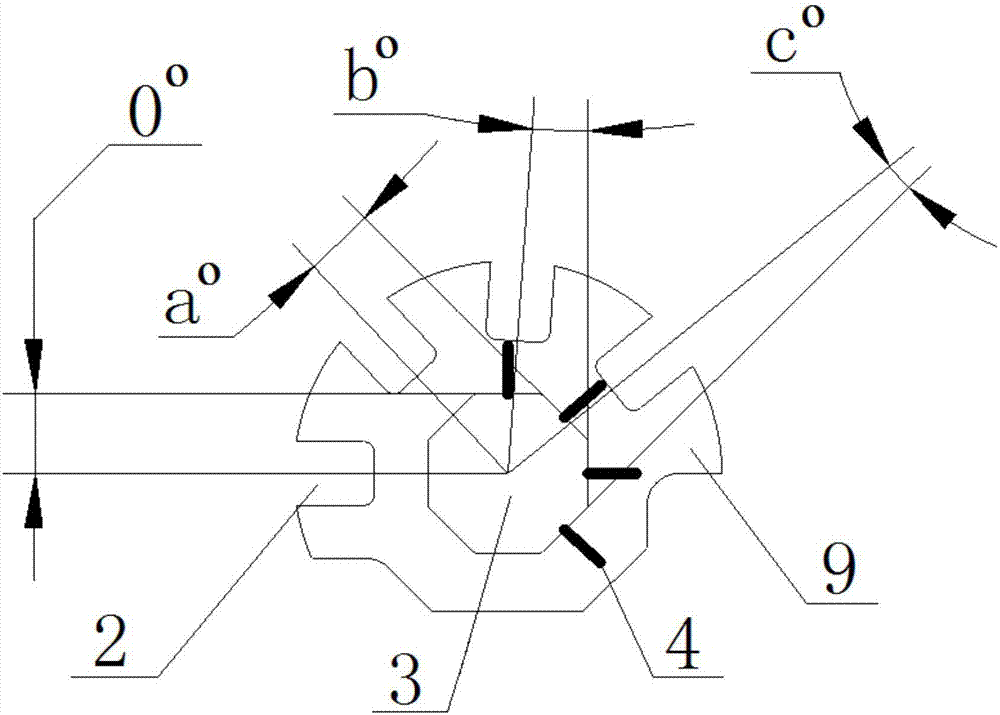

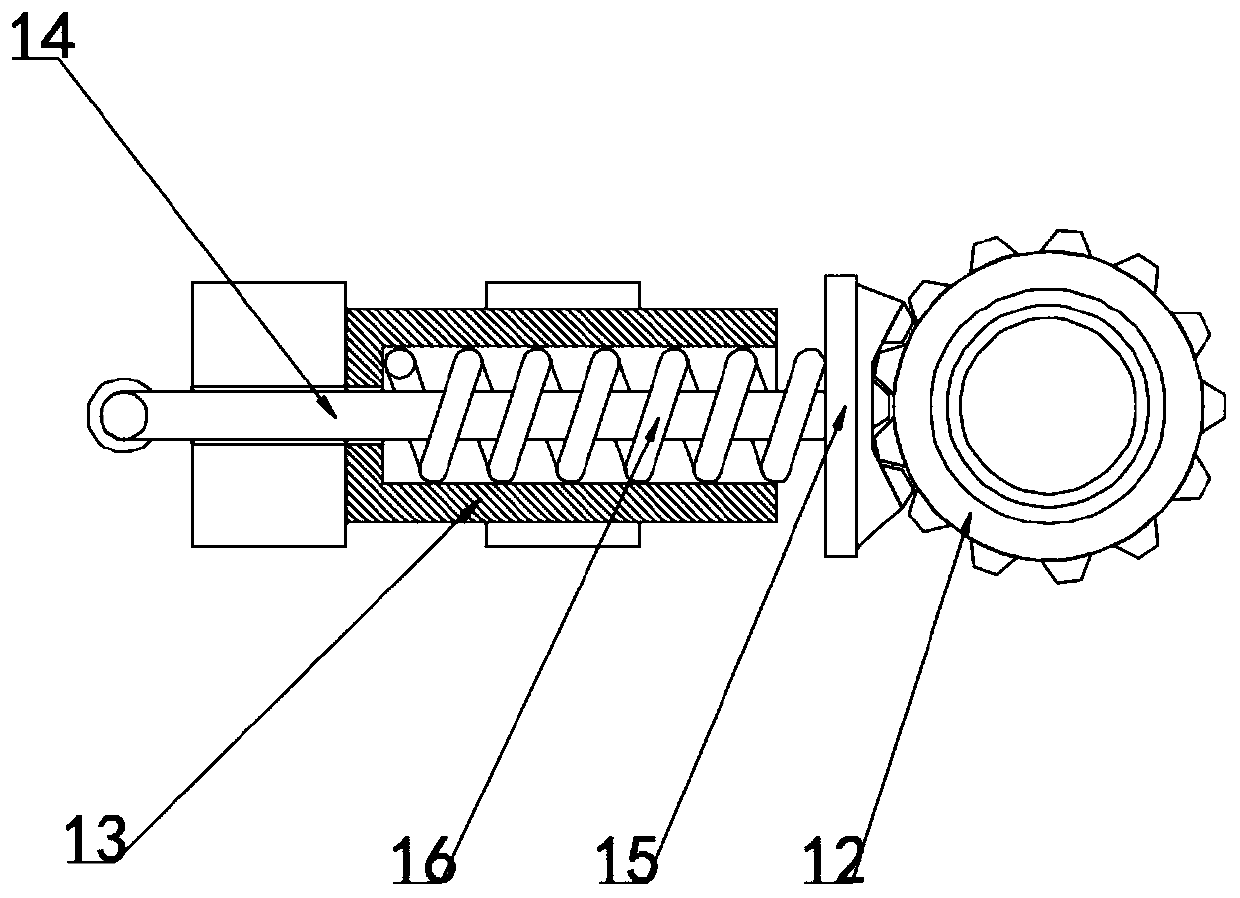

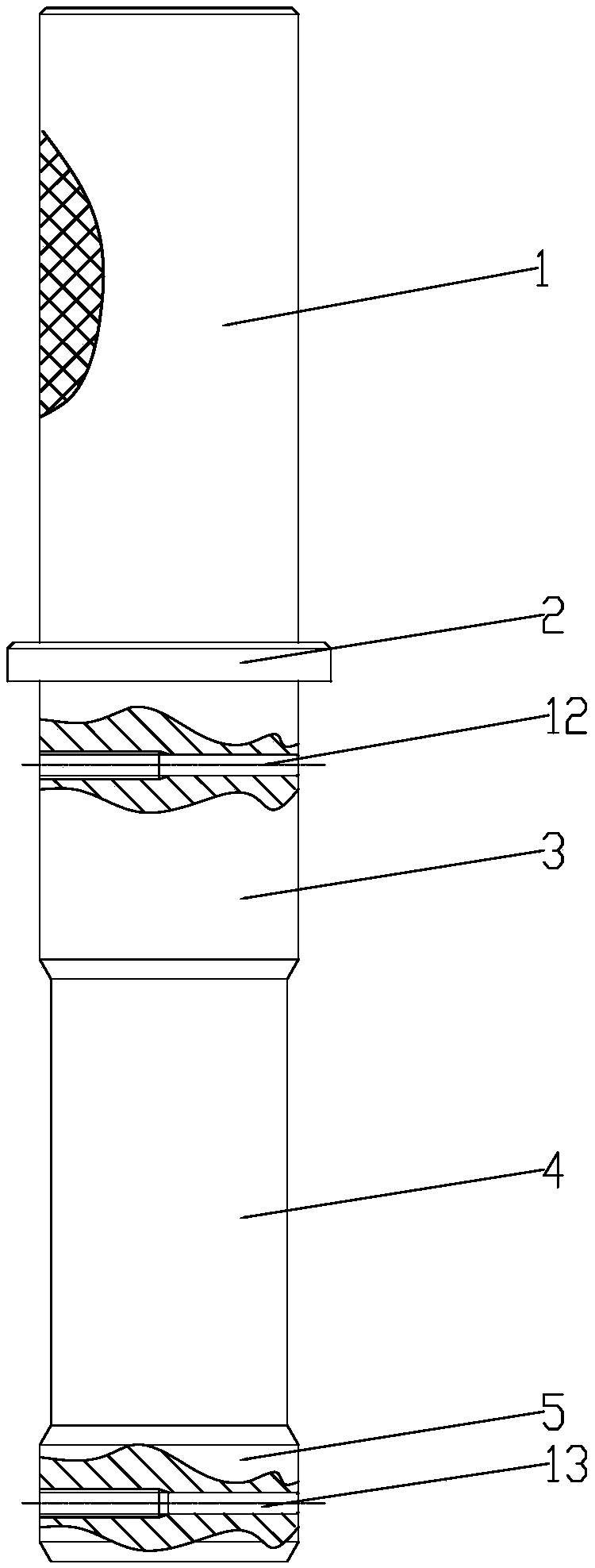

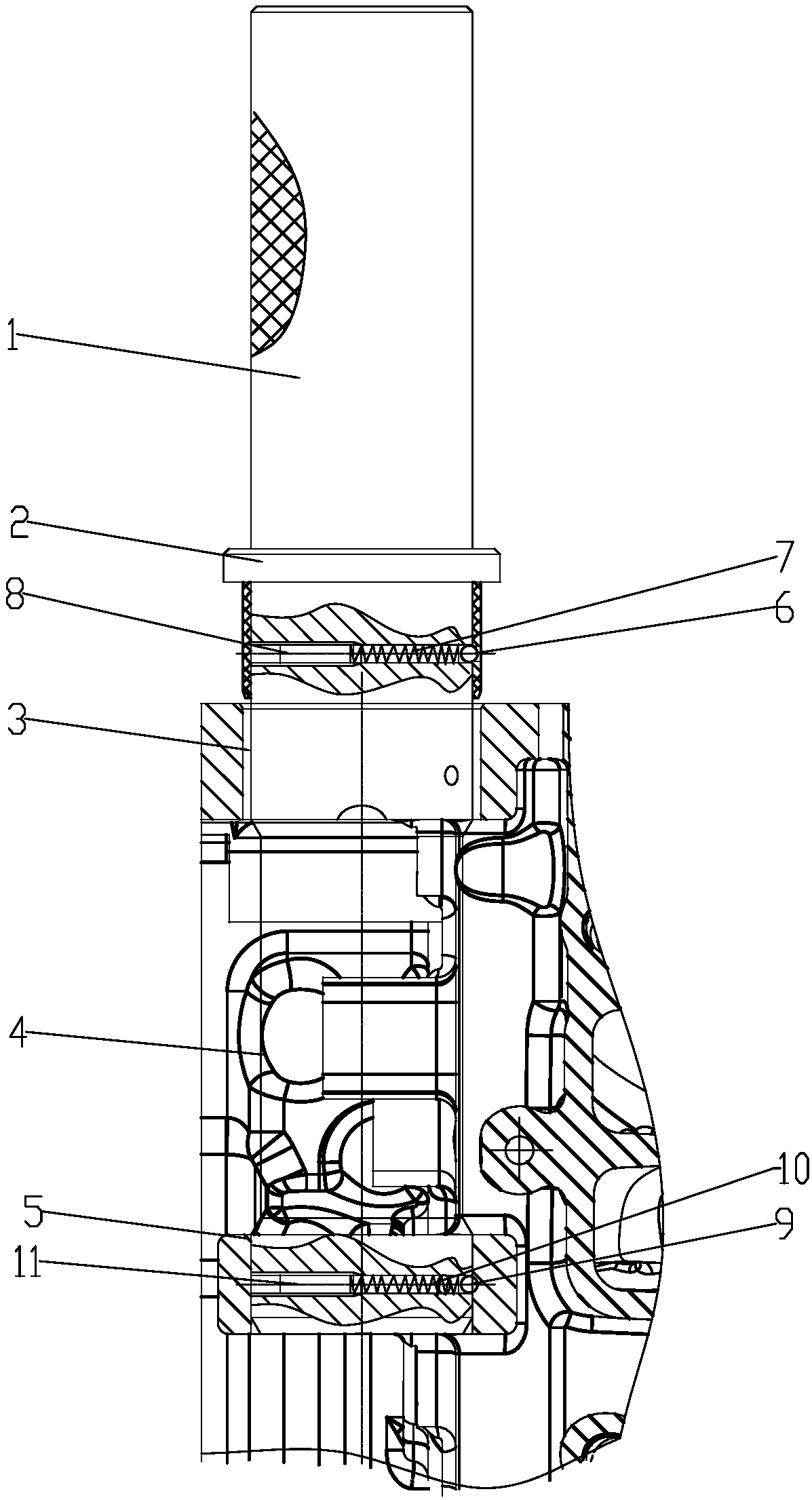

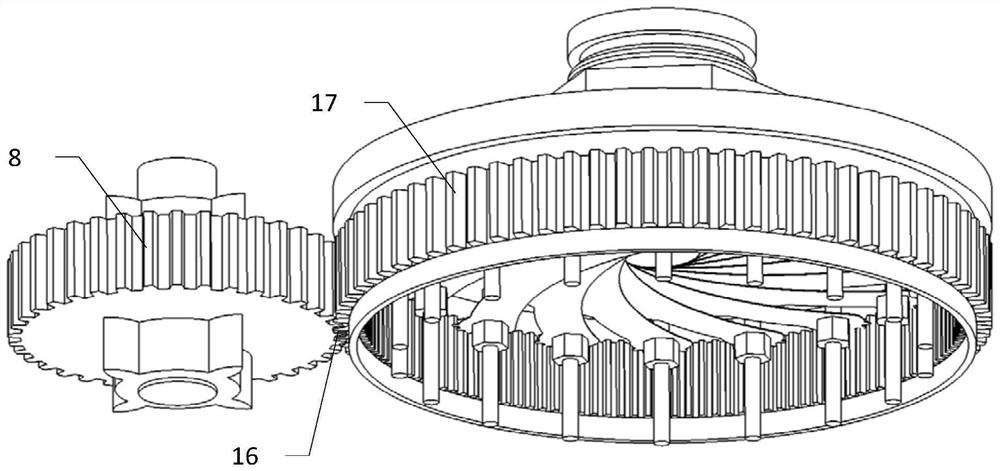

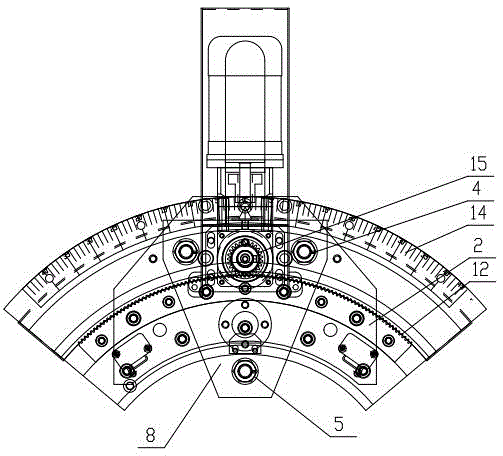

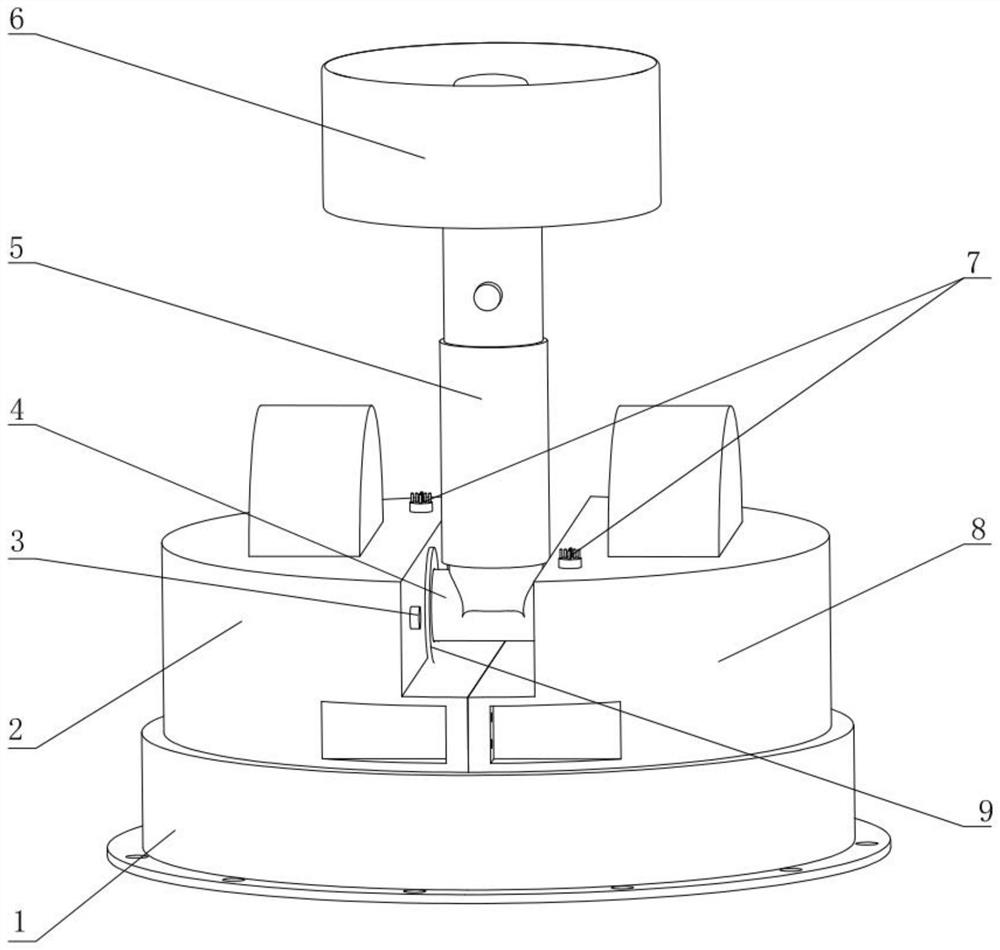

Mechanism for intelligently controlling moving head of multi-station material forming machine to rotate

InactiveCN102452100AExercise is easy and convenientAccurate angle positioningMetal working apparatusFixed frameGear wheel

The invention discloses a mechanism for intelligently controlling a moving head of a multi-station material forming machine to rotate. The mechanism mainly comprises a shifting guide rail, a moving head body, a plane bearing, a connecting shaft, a main drive gear, a cutting die fixing frame, a motor gear and a servo motor, wherein the shifting guide rail is arranged on two sides of the lower end of an upper machine body; the moving head body is arranged at the lower end of the shifting guide rail on the two sides, and is formed by welding a steel plate; the plane bearing is arranged in the moving head body, and is connected with the moving head body through the connecting shaft; the main drive gear is fixed at the lower end of the connecting shaft; the cutting die fixing frame is arranged at the lower end of the main drive gear; the servo motor is arranged on the side face of the moving head body; and the motor gear is arranged at the lower end of the motor, and is matched with the main drive gear, and drags the main drive gear to rotate so as to drive the cutting die fixing frame rotate 360 degrees. The mechanism has a reasonable and compact structure; the servo motor drags the cutting die fixing frame to move so as to drive a cutting die to rotate, so that the blanking efficiency is high, the angle of the cutting die is positioned more accurately, the cutting die moves more easily and conveniently, and the work efficiency and blanking quality are effectively improved.

Owner:YANCHENG XIONGYING PRECISION MACHINERY

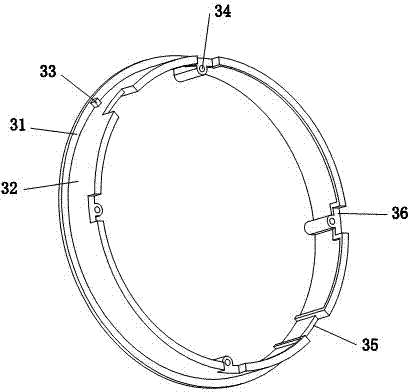

Multi-angle angle gauge block

ActiveCN106930965AGood angle consistencyGuaranteed performancePump componentsEngine fuctionsEngineeringAngle gauge

The invention provides a multi-angle angle gauge block. The multi-angle angle gauge block is used for adjusting the angle of a stator blade in a casing, a shaft neck is arranged on the stator blade, positioning pins are arranged on the casing, the angle gauge block is circular, N square grooves matched with the positioning pins are circumferentially arranged on the outer edge of the end face of the angle gauge block, the value range of N is larger than 1, the positions of N square grooves sequentially correspond to N adjusting angles of the stator blade, a polygon through hole is formed in the center of the angle gauge block, and is provided with M sides, M is equal to 2N, and the polygon through hole is in a regular polygon shape; the center lines perpendicular to the bottom faces of the square grooves pass through the center point of the polygon through hole, the center line of one square groove is further perpendicular to one set of opposite sides of the polygon through hole, and the included angle between the center line and the vertical line of the side, corresponding to the center line, of the polygon through hole is the adjusting angle.

Owner:AECC SHENYANG ENGINE RES INST

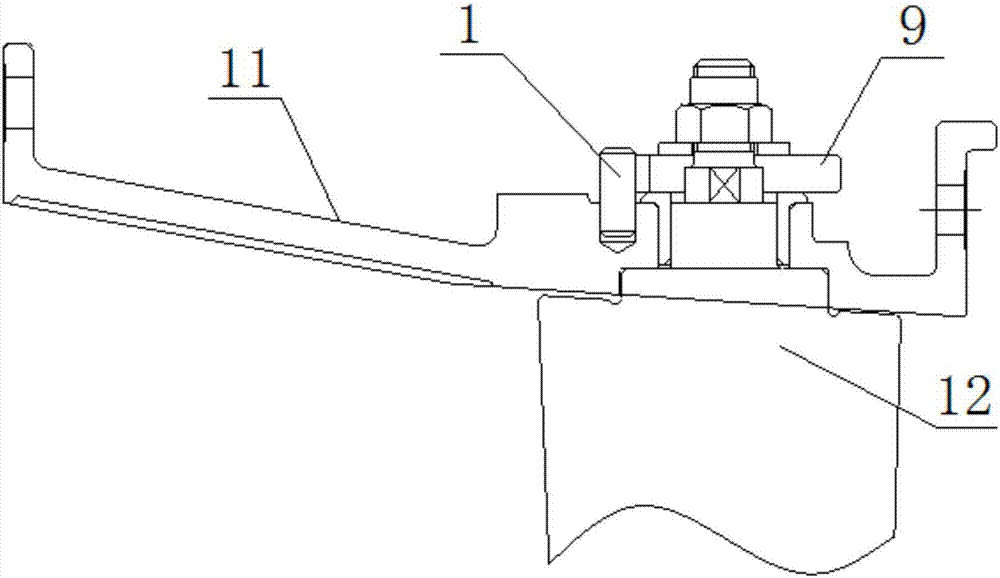

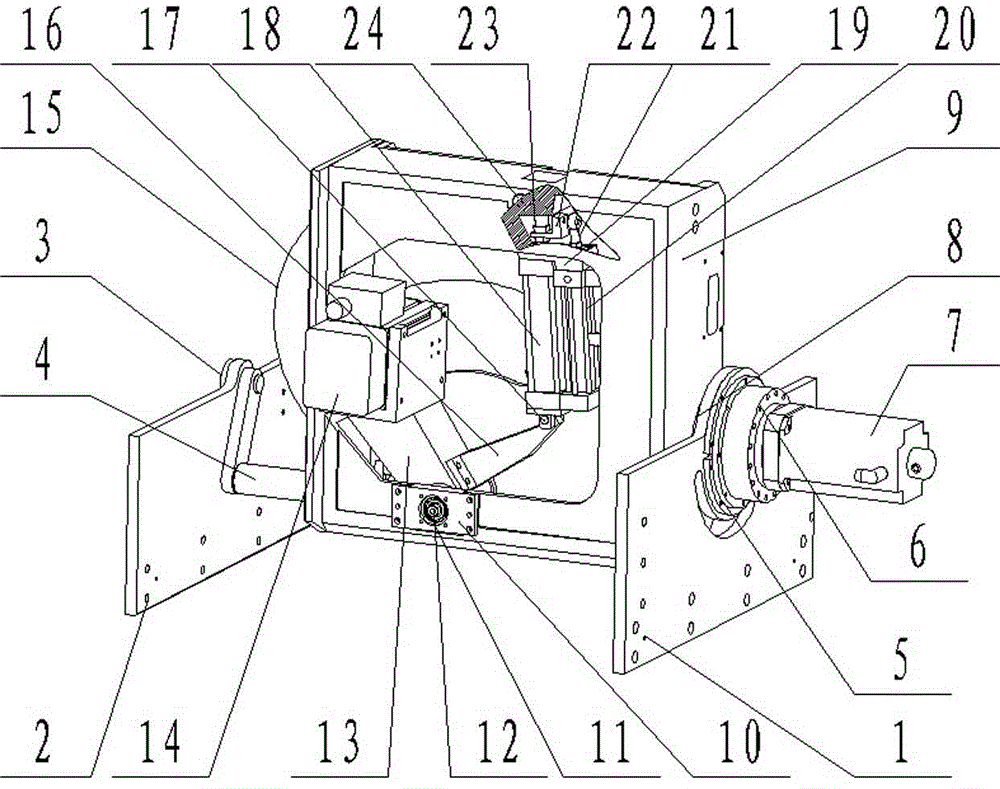

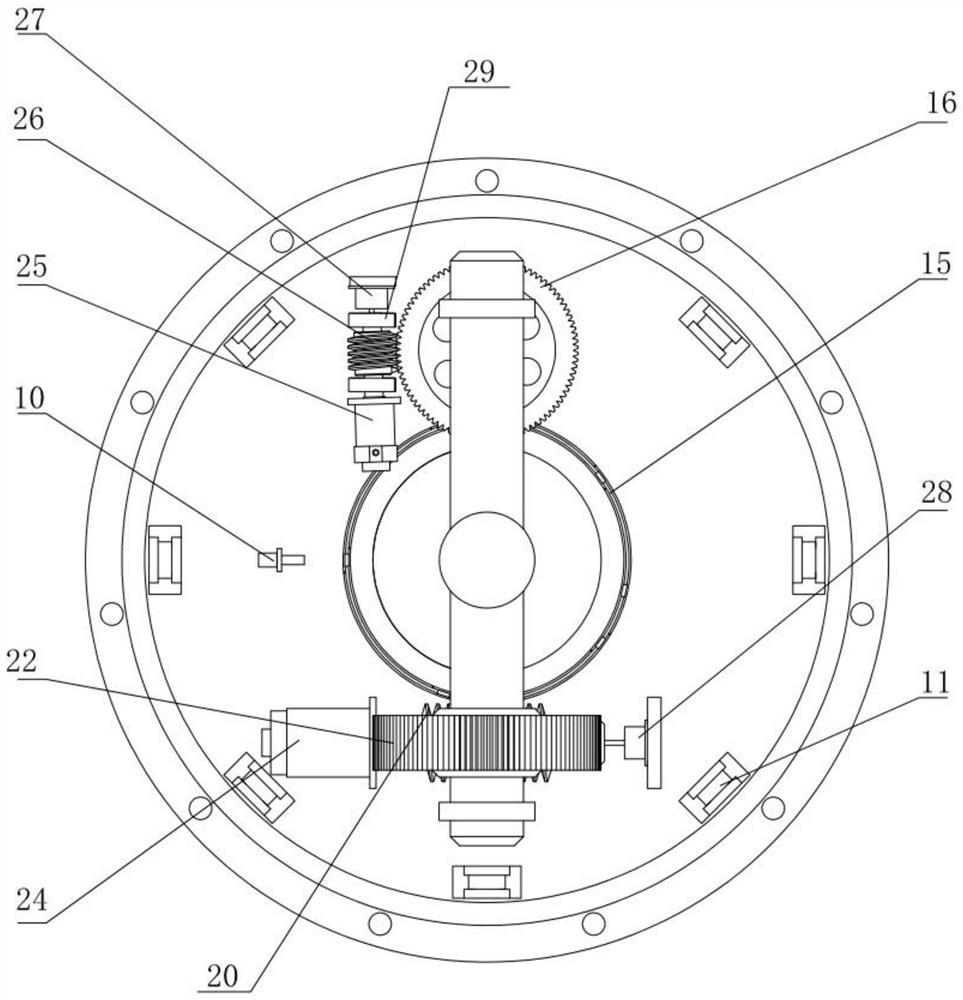

Moving head rotating mechanism of multi-axis linked three-dimensional moving head hydraulic cutting machine

InactiveCN104476584AExercise is easy and convenientAccurate angle positioningMetal working apparatusEngineeringMulti axis

The invention provides a moving head rotating mechanism of a multi-axis linked three-dimensional moving head hydraulic cutting machine. The moving head rotating mechanism is mainly composed of a lower body, an upper body, a movement guide rail, a moving head frame, a rotating servo motor, a rotating gear, a cutting tool holder and a cutting tool; the moving head rotating mechanism of the multi-axis linked three-dimensional moving head hydraulic cutting machine is reasonable and compact in structure; the rotating motion of a cutting die is realized by driving a cutting die holder to move by use of the servo motor, and therefore, the blanking efficiency is high and the cutting die is more accurate in angle positioning; besides, the cutting die is easier and more convenient to move, and the working efficiency and the blanking quality are effectively improved.

Owner:JIANGSU MAOLONG MACHINERY MFG

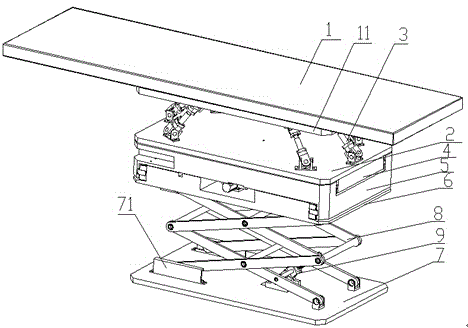

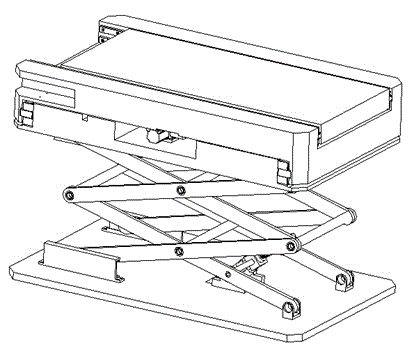

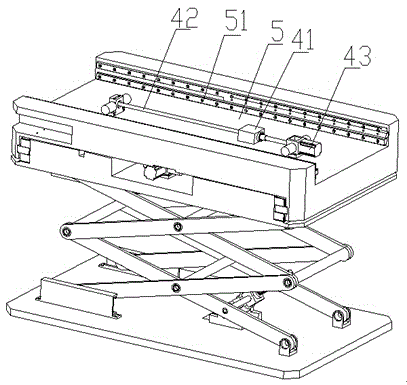

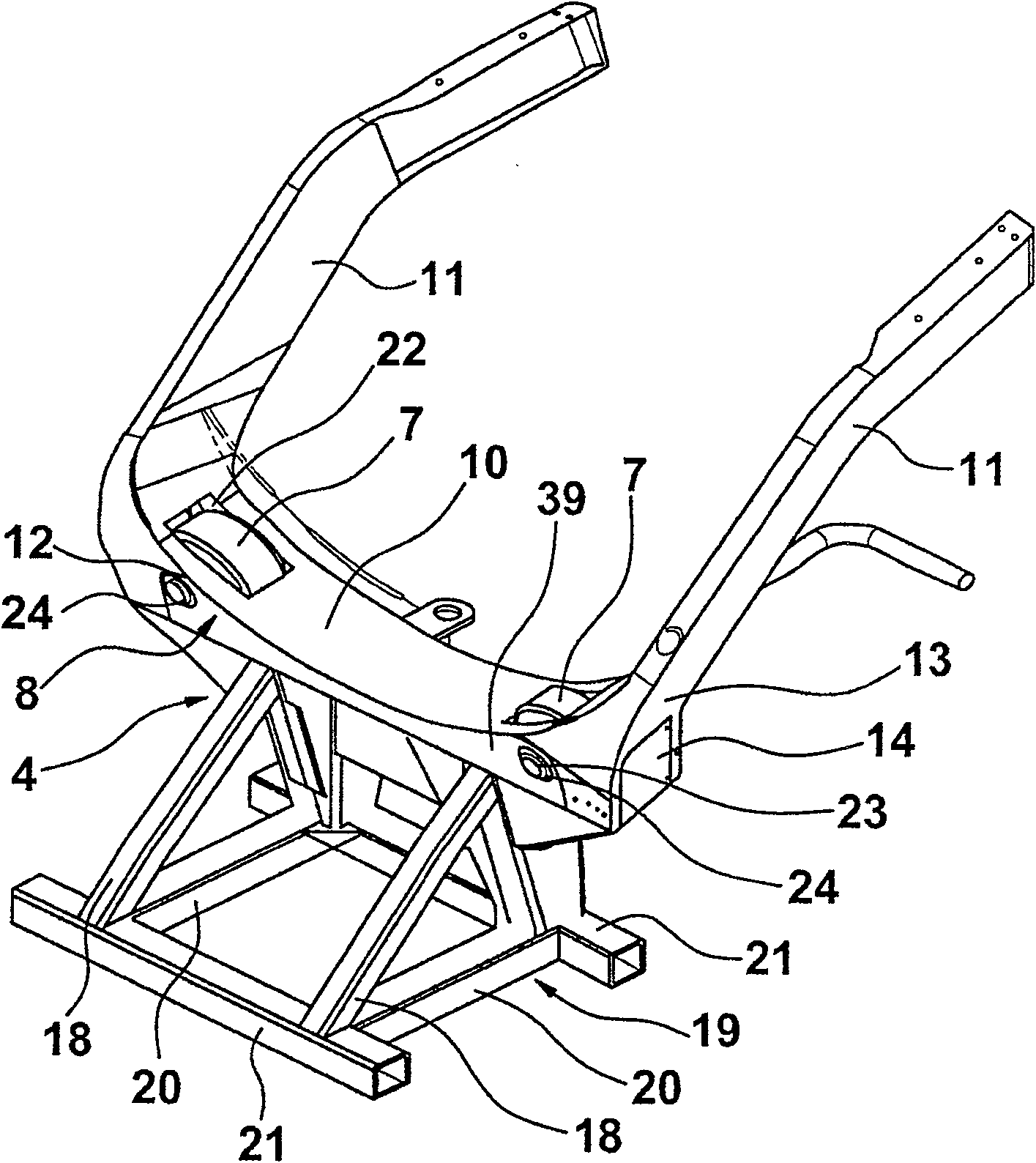

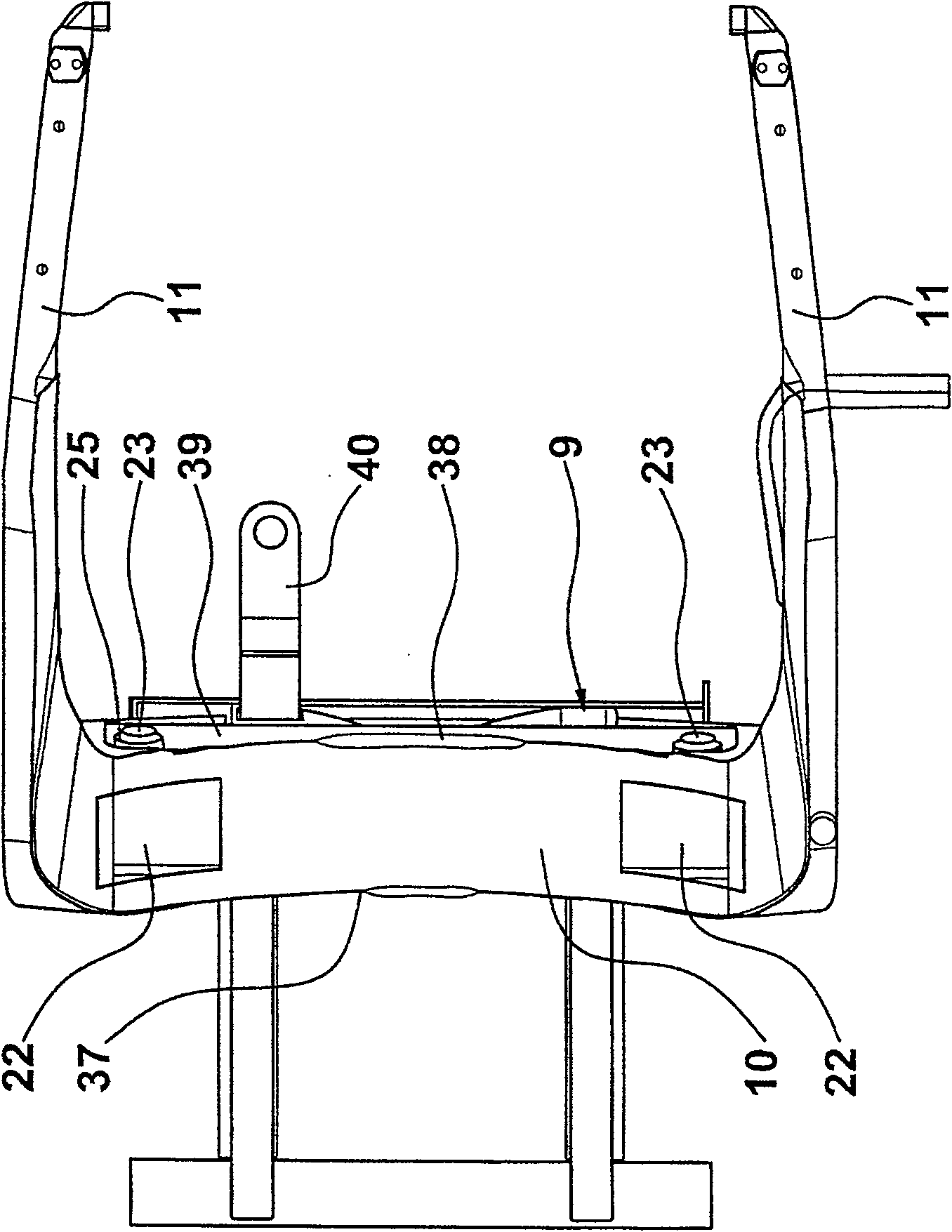

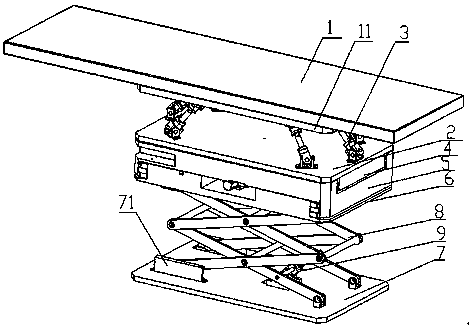

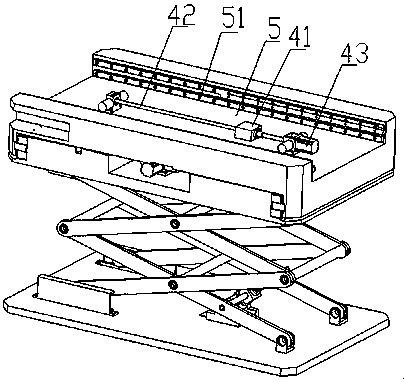

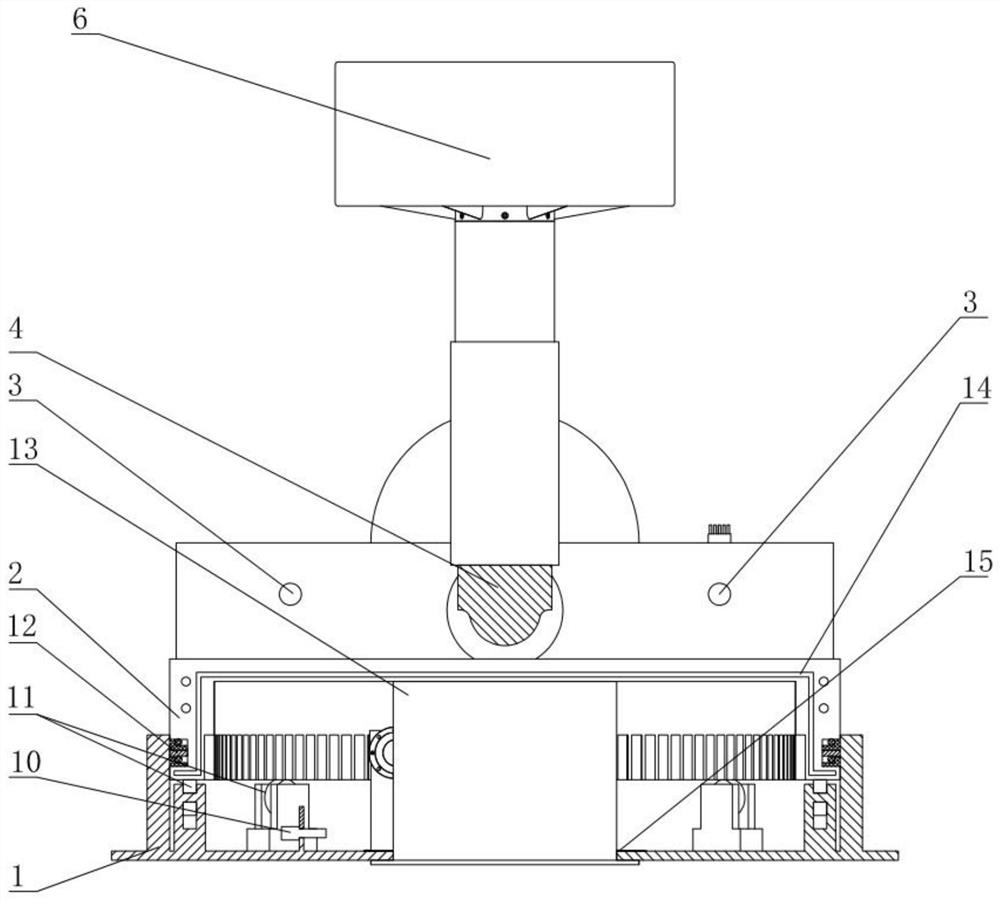

Accurate set-up treatment bed

ActiveCN106267573AAccurate angle positioningImprove carrying capacityLight therapyMulti degree of freedomSmall footprint

The invention discloses an accurate set-up treatment bed, which comprises a set-up platform and a substrate. A multi-degree-of-freedom parallel mechanism is arranged between the set-up platform and the substrate. A horizontal motion control assembly and a vertical motion control assembly are arranged in sequence under the substrate. The horizontal motion control assembly comprises a first direction control assembly and a second direction control assembly. The first direction and the second direction are perpendicular in a horizontal plane; movement in the first direction and the second direction is horizontal movement; and the vertical motion control assembly drives the horizontal motion control assembly to move up and down. Through major change of the treatment bed and fineness control of the parallel mechanism, adjustment of the angle and position can be realized very well; and meanwhile, the accurate set-up treatment bed is small in land occupation area, is wider in application range and is enhanced in practicality.

Owner:SUZHOU AIN INTELLIGENT EQUIP

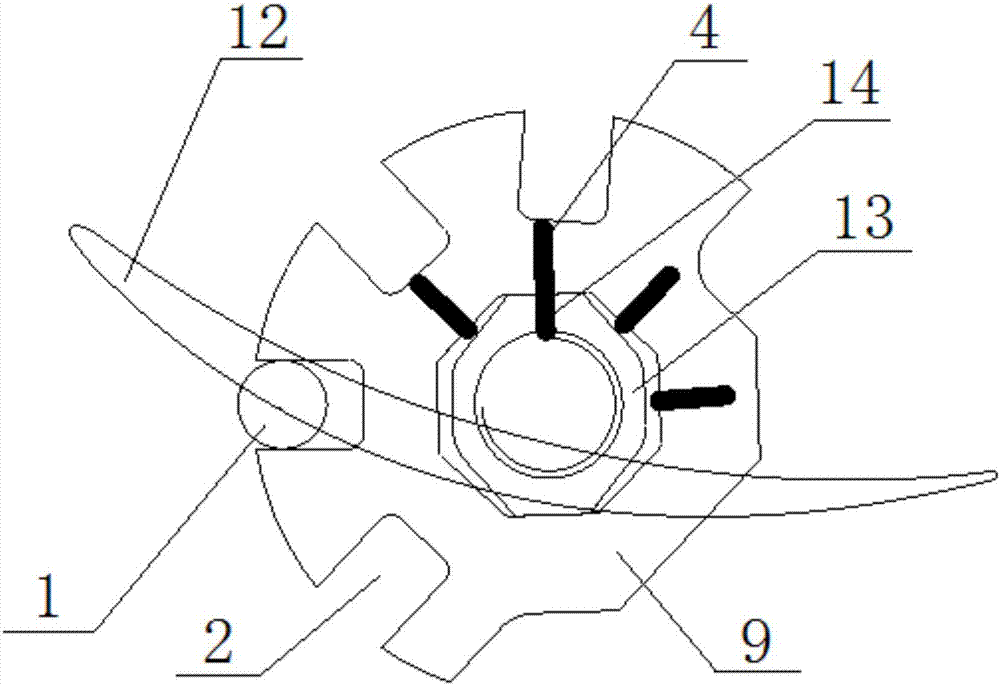

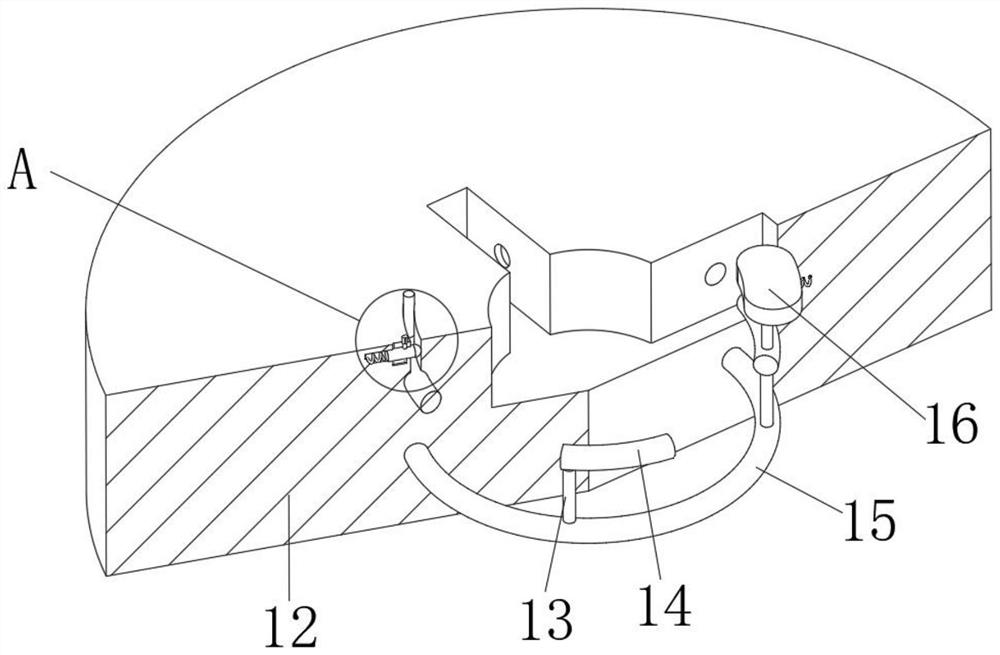

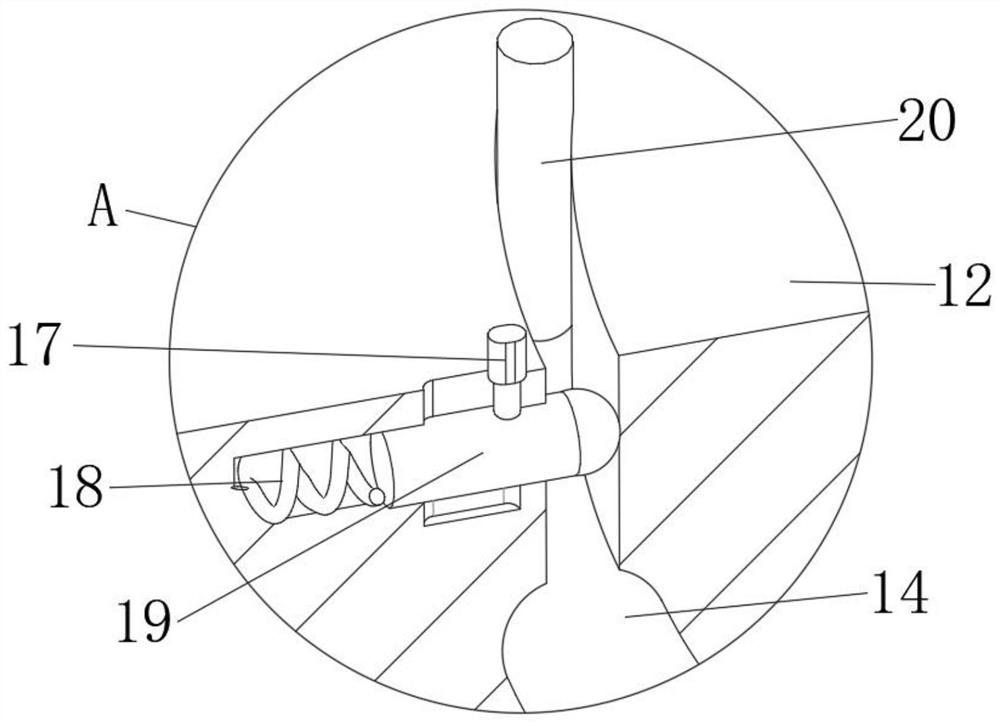

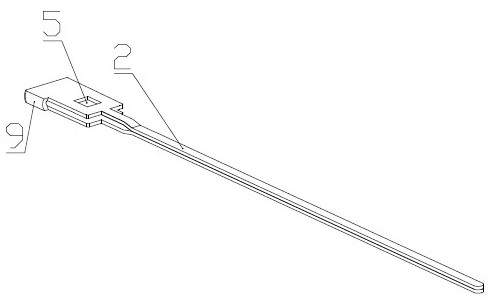

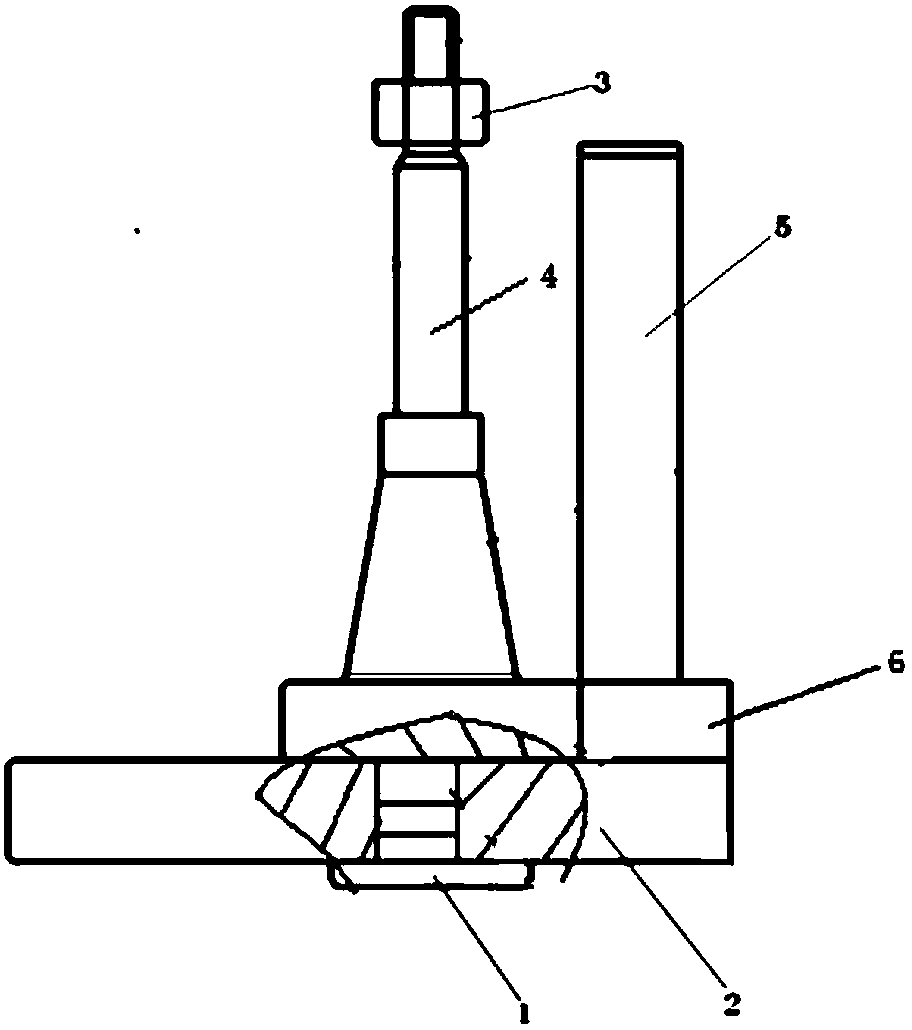

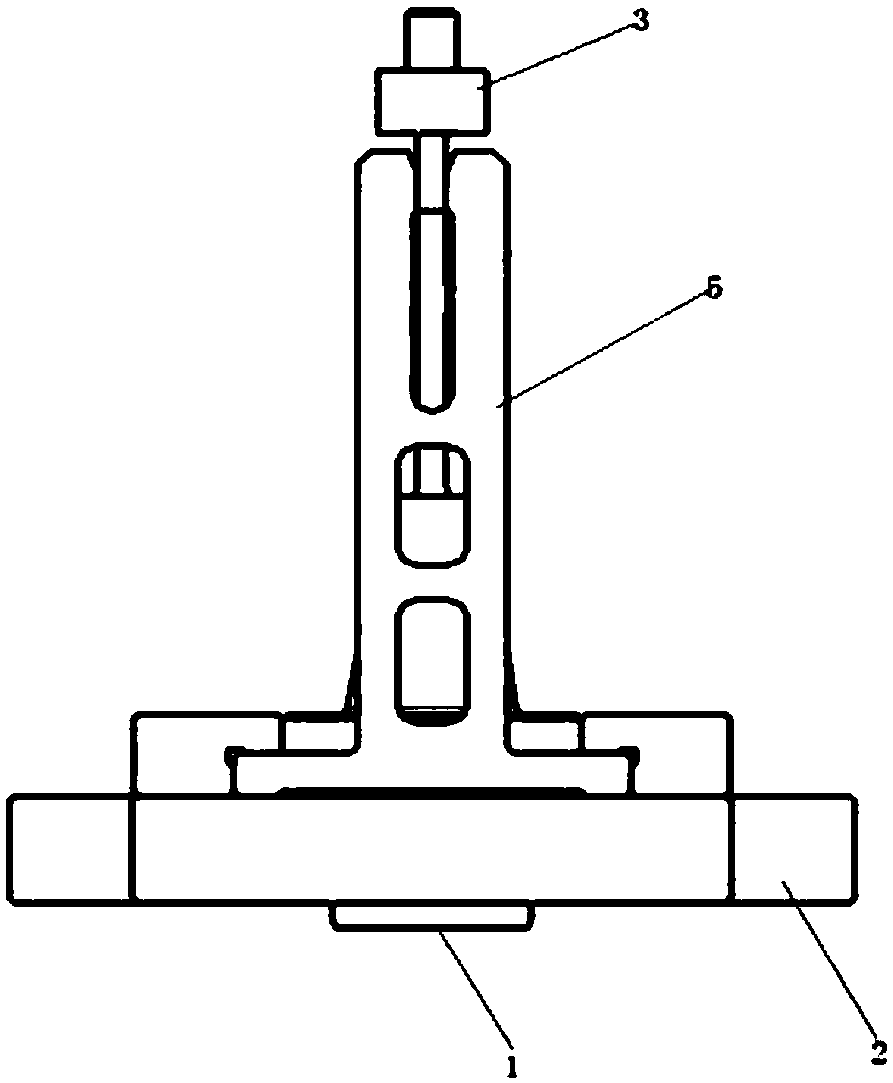

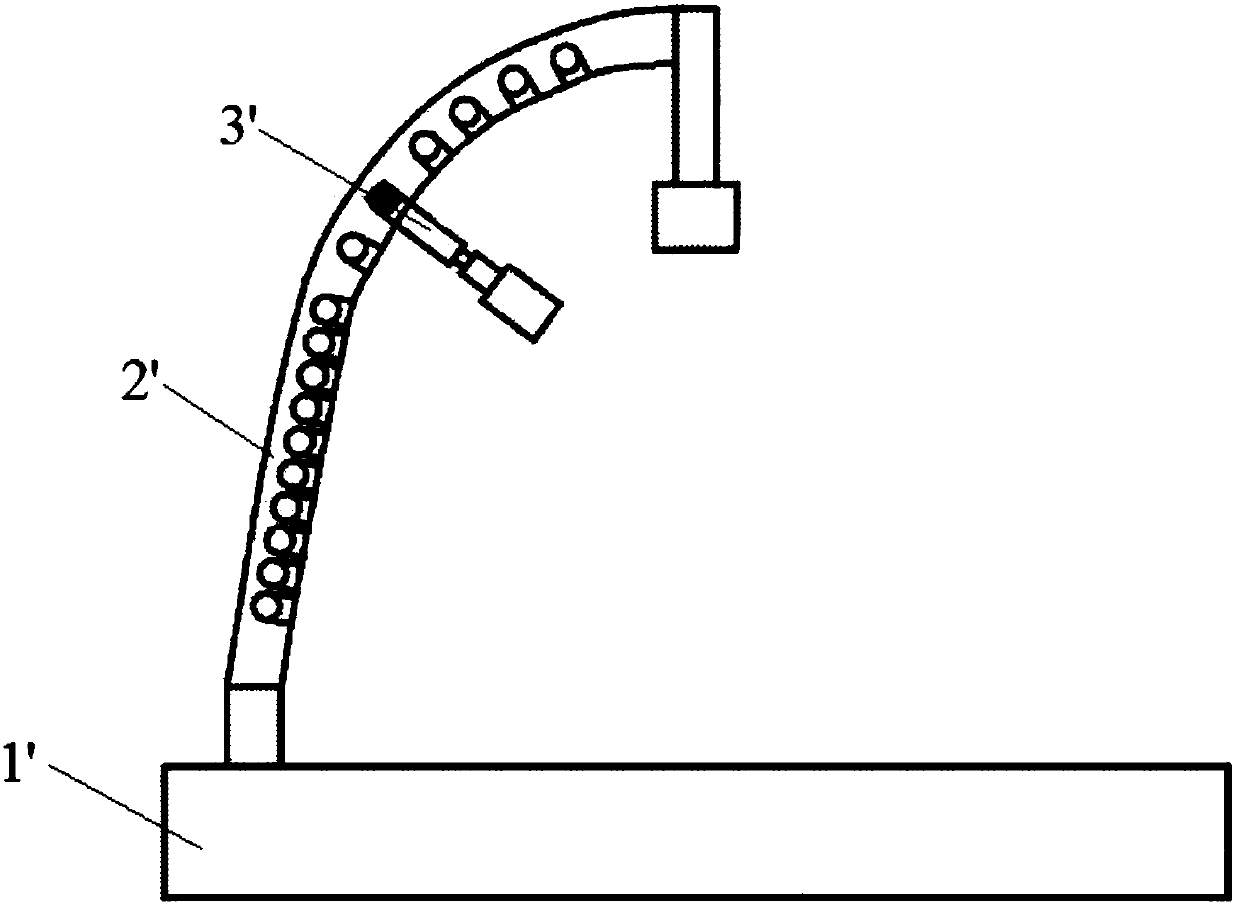

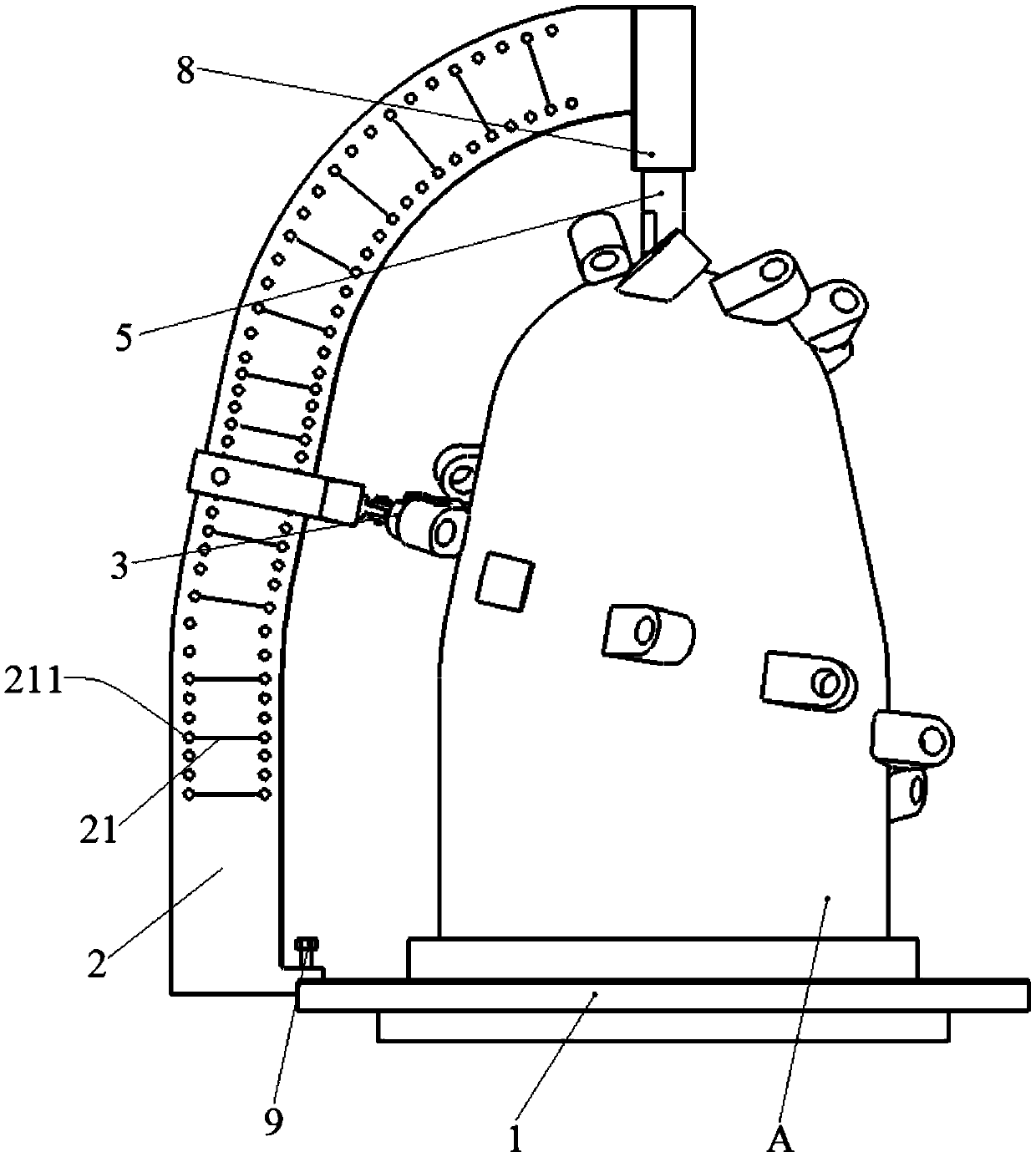

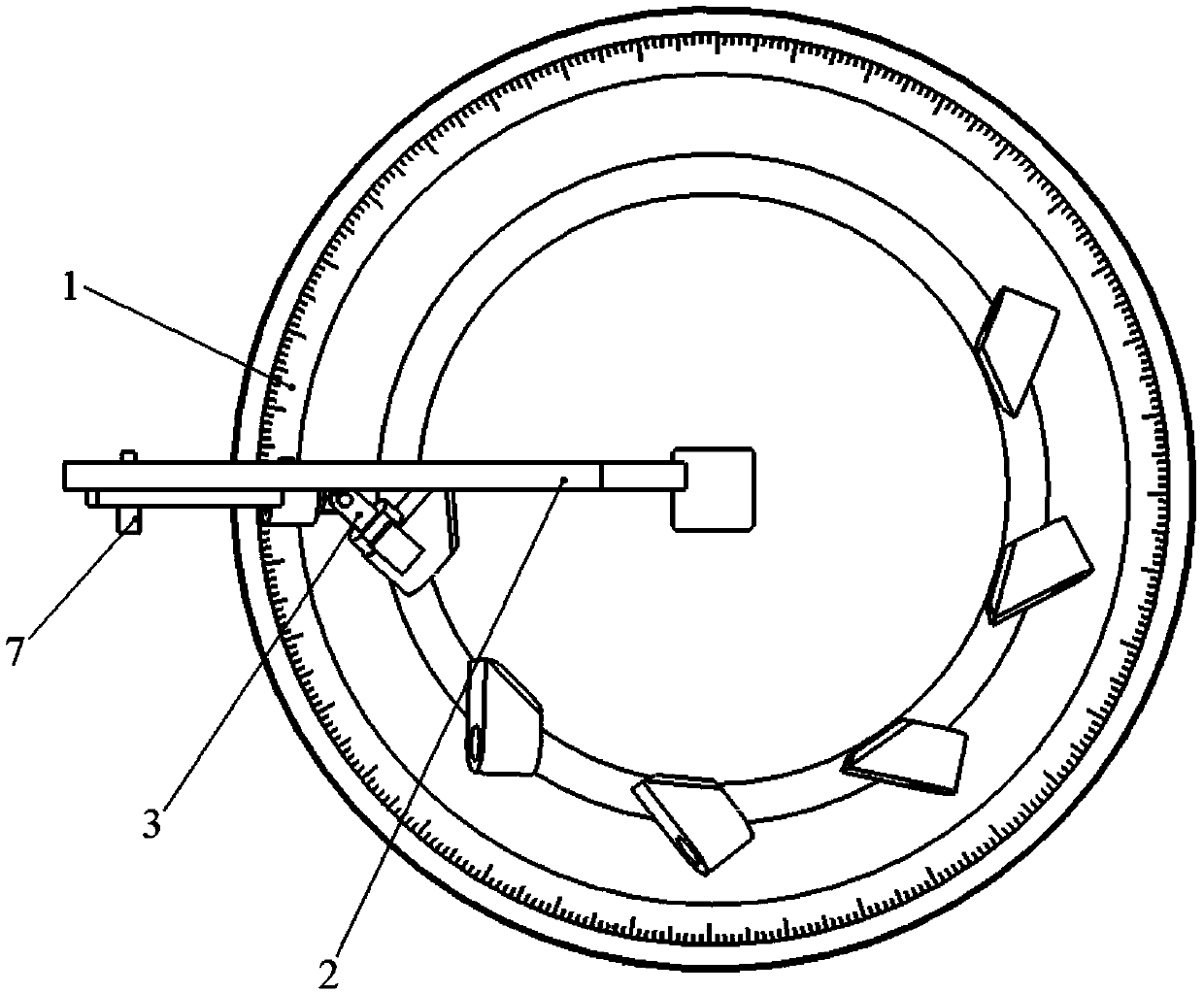

Toothholder positioning tool for cutting head

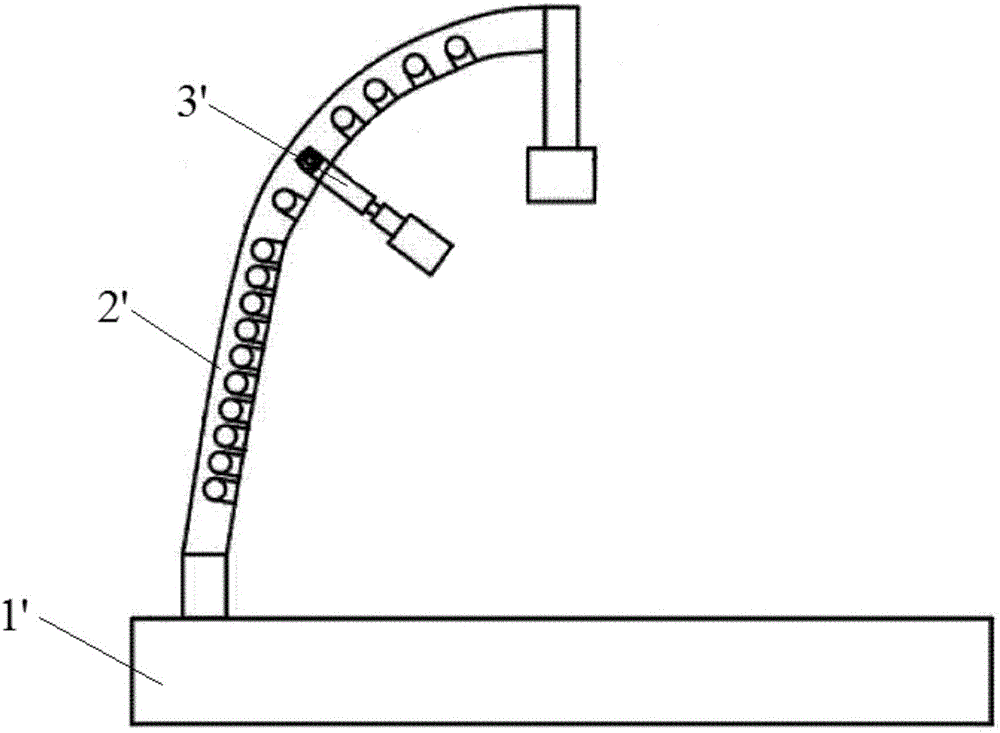

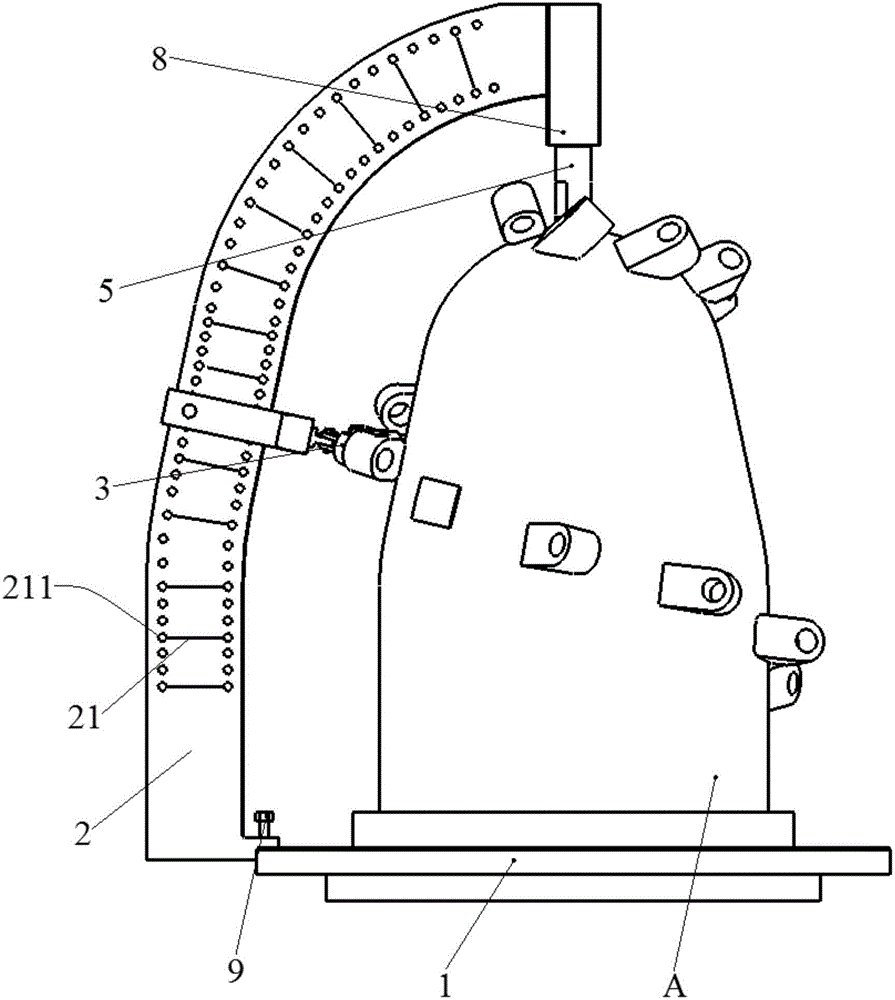

The invention discloses a toothholder positioning tool for a cutting head. The toothholder positioning tool for the cutting head is used for providing positioning for the toothholder when the toothholder is connected on a cutting head body of the cutting head. The toothholder positioning tool comprises an installing platform, a curved plate and a positioning structure; the installing platform is used for placing and fixing the cutting head body; the curved plate is installed on the installing platform; and the positioning structure comprises a connection portion connected with the curved plate and a fixing portion used for fixing the toothholder, the connection portion is connected with a positioning portion installed on the curved plate to define a first axis line, an included angle between the fist axis line and the water level is the chamfer of the toothholder, the fixing portion rotates around the first axis line relative to the connection portion to adjust the rotation angle of the toothholder. Compared with the prior art, the toothholder positioning tool can adjust the rotation angle of the toothholder, so that angle positioning of the toothholder is more accurate; in addition, according to the toothholder positioning tool, the angel of the toothholder is positioned by directly adjusting the installing process corner of the toothholder, so that the cutting function angle of cutting teeth is positioned, and positioning is more accurate.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD +1

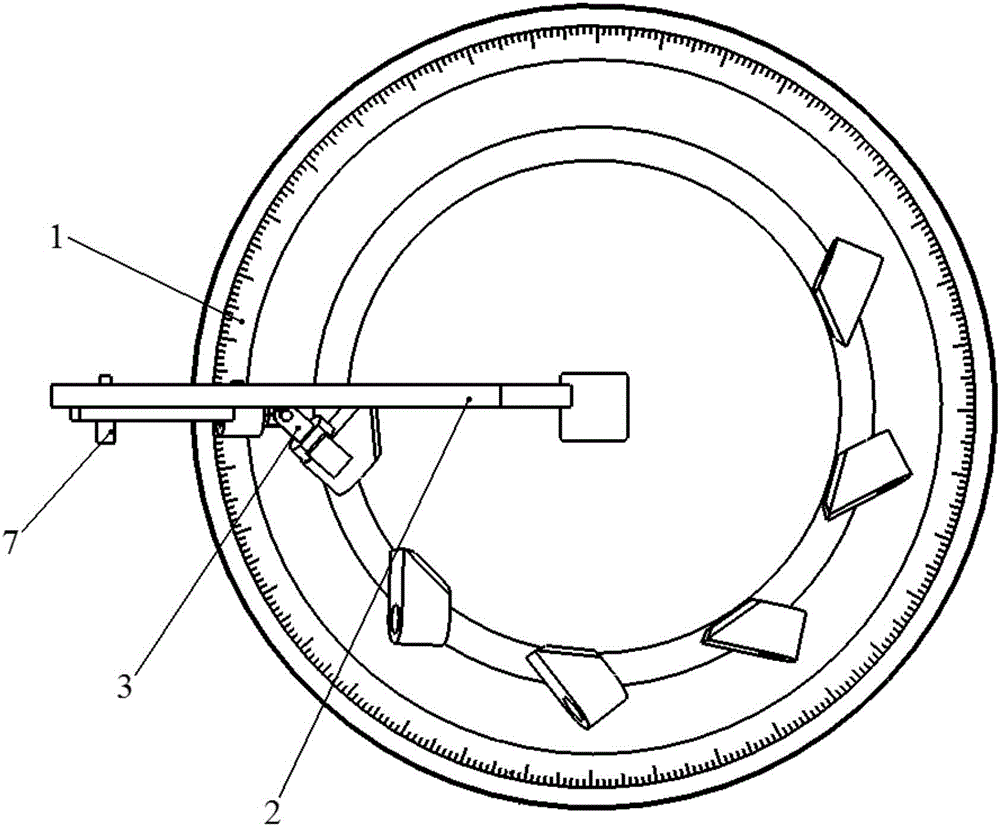

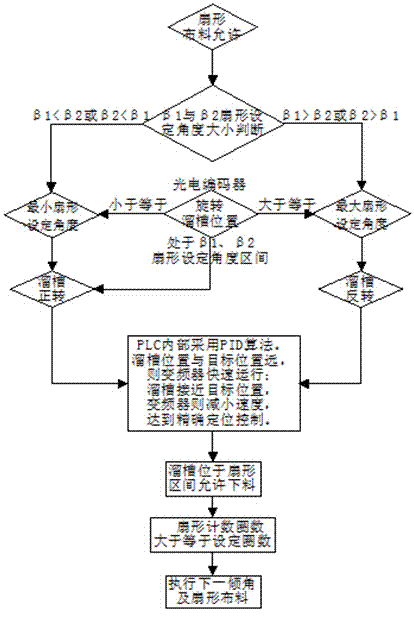

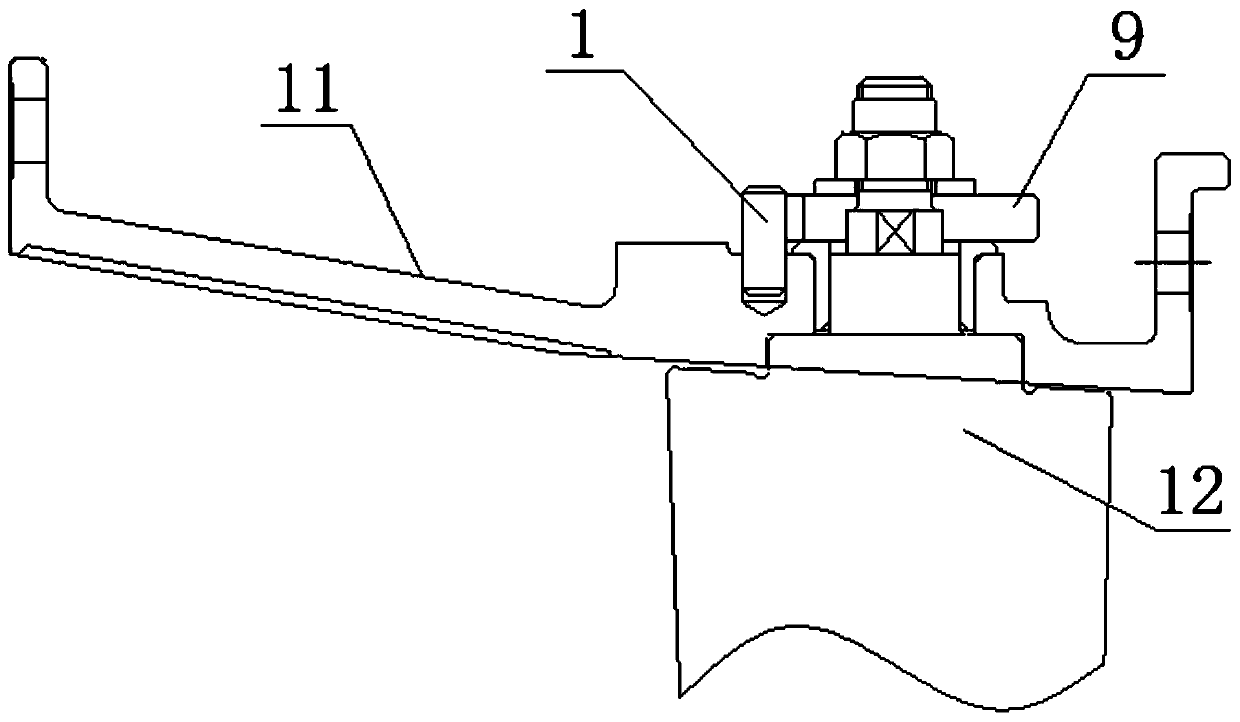

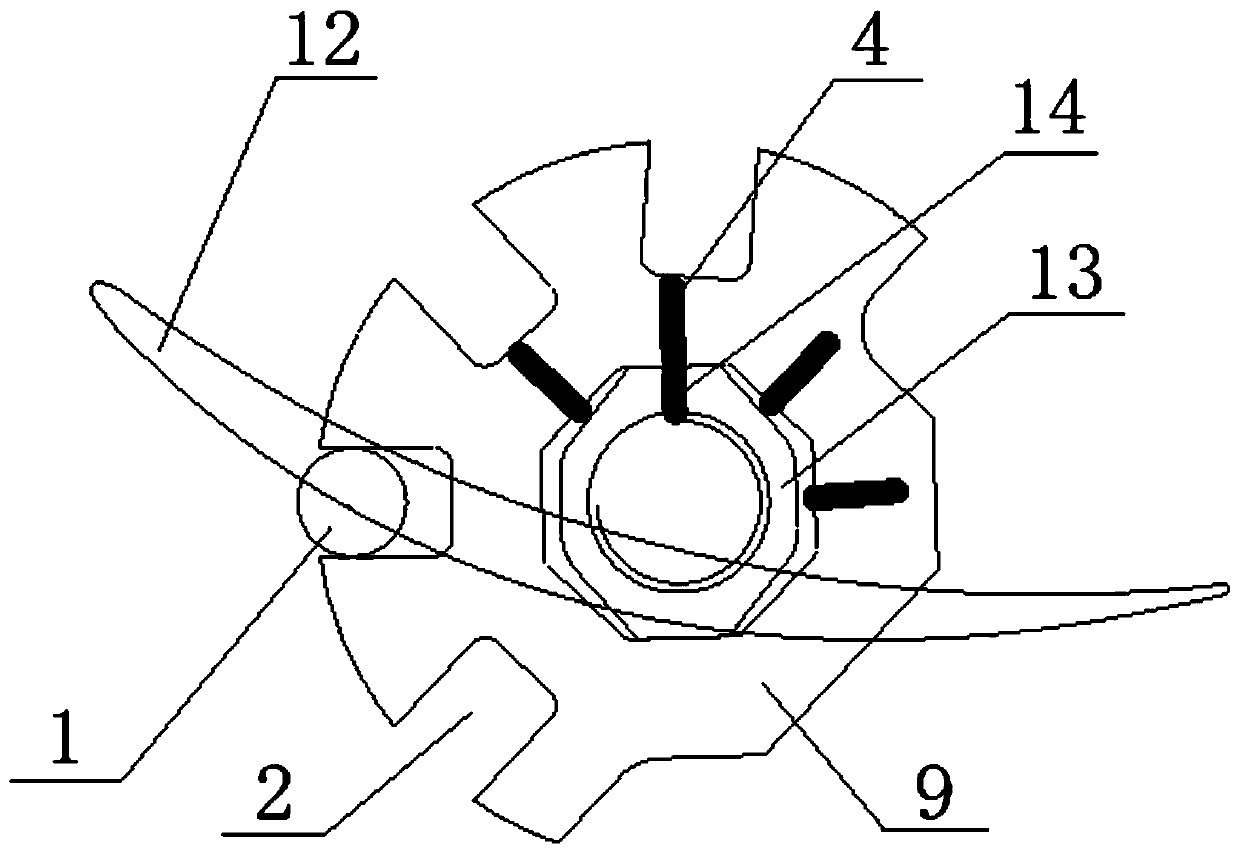

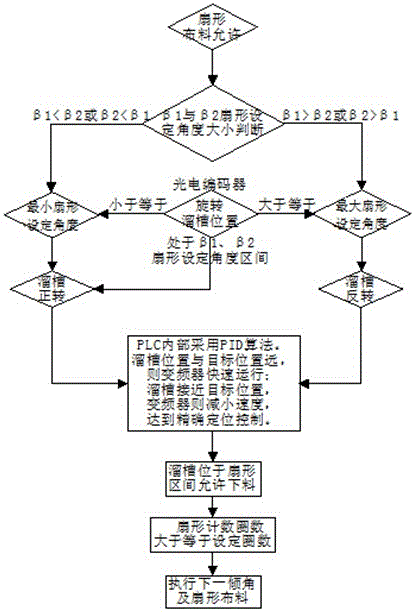

Method for automatically controlling and rapidly, accurately and precisely locating fan-shaped distribution of bell-less blast furnace

ActiveCN104774988AAccurate angle positioningFast angular positioningBell-and-hopper arrangementBlast furnace detailsSurface shapePosition angle

The invention discloses a method for automatically controlling and rapidly, accurately and precisely locating fan-shaped distribution of a bell-less blast furnace. The method comprises the following specific steps of setting allowance of fan-shaped distribution, and setting a first fan-shaped set angle beta1 and a second fan-shaped set angle beta2; judging a fan-shaped set angle; collecting position data of a rotary chute in real time, carrying out angle conversion to obtain a circumferential position angle of the current rotary chute, and comparing with the first fan-shaped set angle beta1 and the second fan-shaped set angle beta2; and allowing blanking when the rotary chute is in the target position of the fan-shaped distribution. According to the invention, the angle location of fan-shaped distribution of a blast furnace chute is more precise and rapid; the idle running time and the distribution waiting time of a rotary motor are shortened; two numerical values of the fan-shaped set angle can be arranged freely; the wrong arrangement phenomenon of the numerical values does not exist; by means of precise distribution angle, a reasonable surface shape and ore-to-coke ratio distribution are formed in a blast furnace; and beneficial conditions are created for stability operation of the blast furnace.

Owner:XINXING DUCTILE IRON PIPES CO LTD

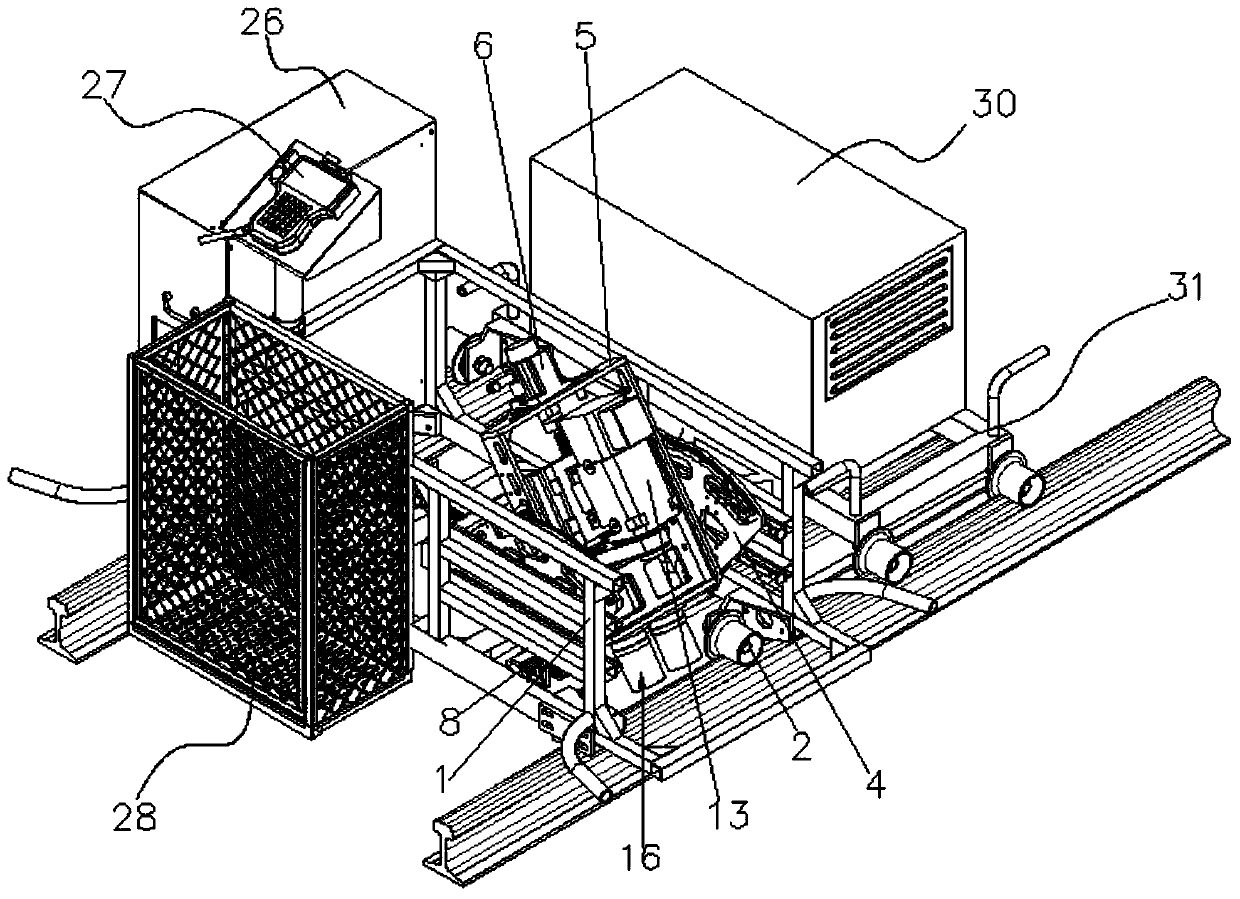

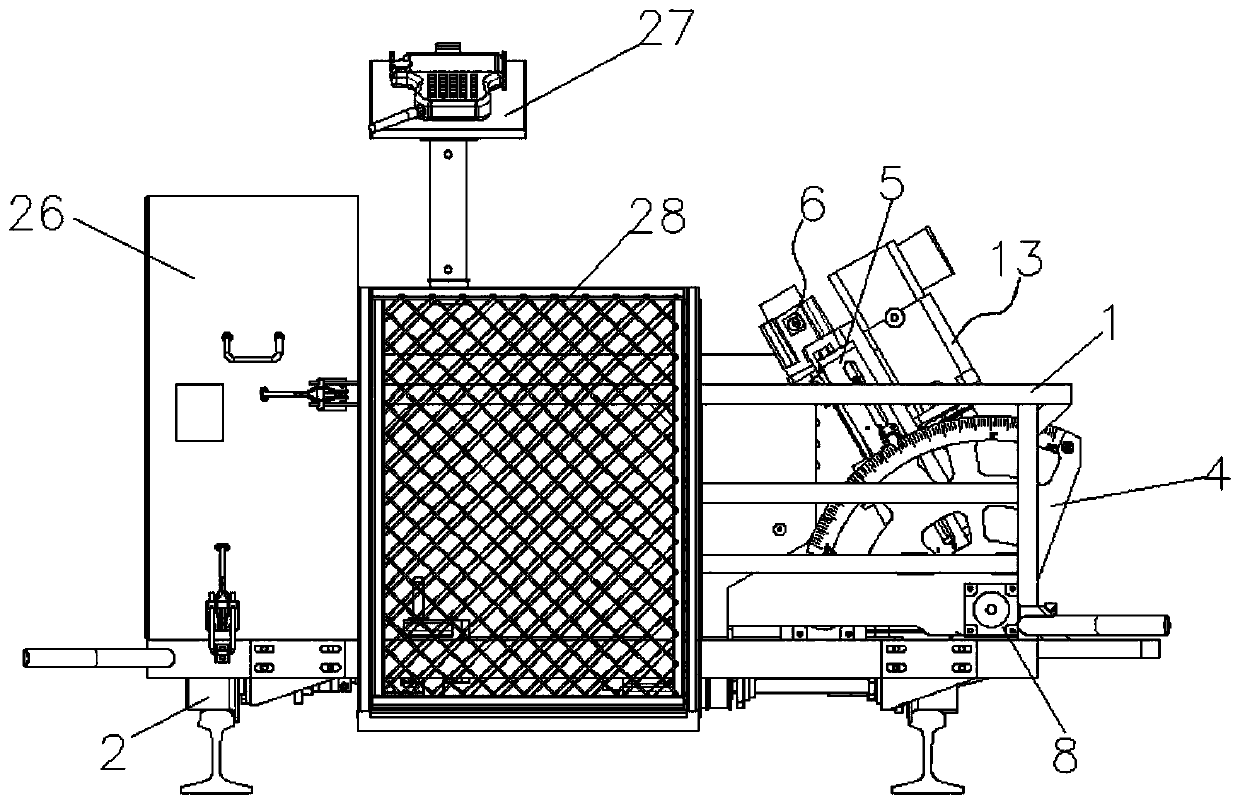

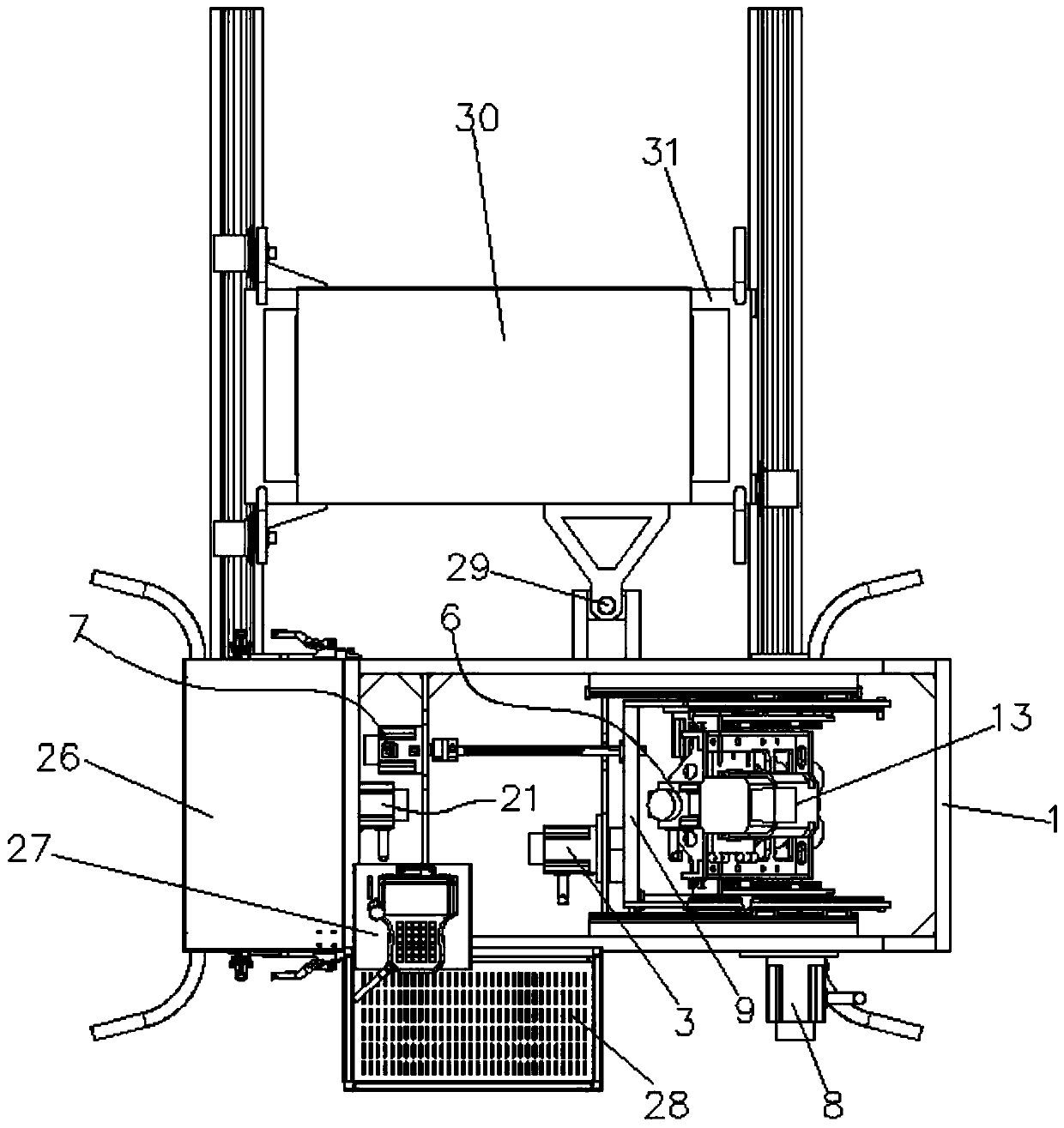

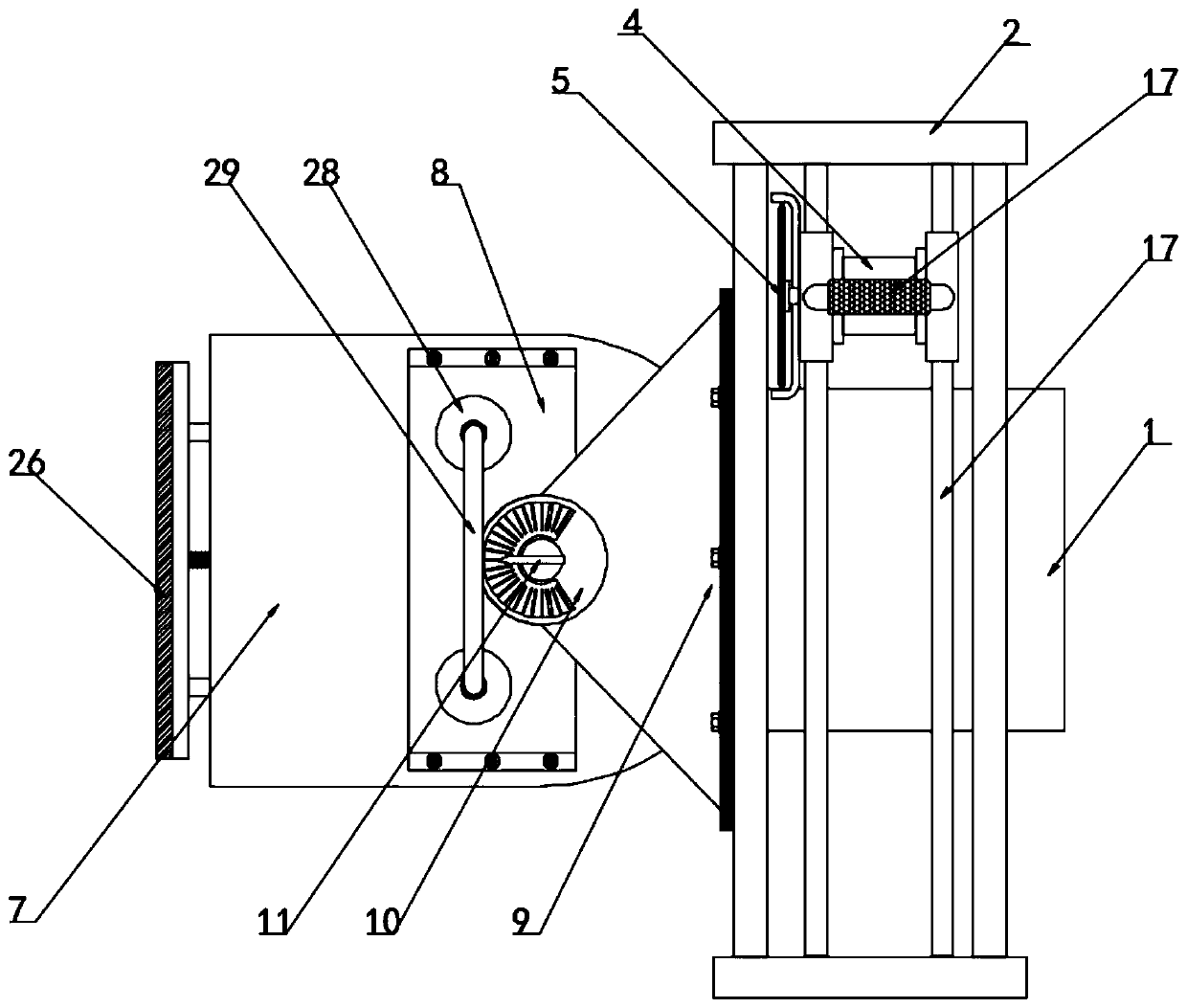

Programmable intelligent rail polishing vehicle

PendingCN110295521AGuaranteed DistortionMaintain motor loadRailway track constructionSTI OutpatientVehicle frame

Owner:安徽辉瑞轨道智能设备有限公司 +1

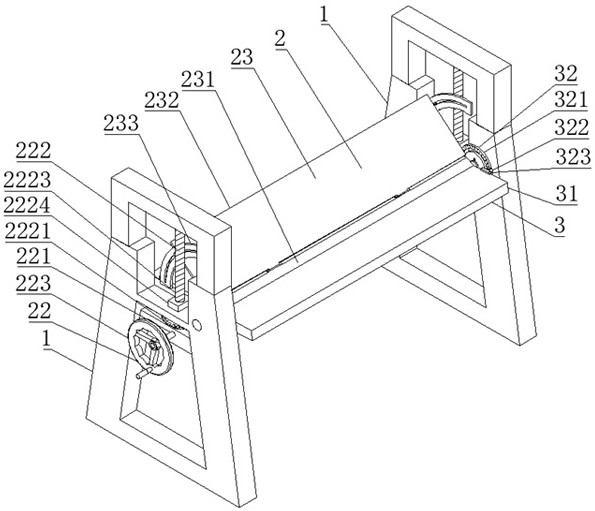

Ceramic tile cutting method for construction site

InactiveCN111251471AAchieve fixationEasy to cutWorking accessoriesStone-like material working toolsStructural engineeringMechanical engineering

The invention discloses a ceramic tile cutting method for a construction site and particularly relates to the technical field of ceramic tile cutting. The ceramic tile cutting method comprises a basebracket, wherein a cutting bracket is fixedly arranged on one side of the top of the base bracket; a directional sliding rod and a cutting machine are fixedly arranged in the cutting bracket; the cutting machine is in sliding fit with the directional sliding rod; a dicing saw wheel is fixedly arranged at the output end of the cutting machine; a rotary shaft is fixedly arranged on the other side ofthe top of the base bracket; a rotation cutting platform is fixedly arranged at the top of the rotary shaft; and a compressing rack is fixedly arranged at the top of the rotation cutting platform. According to the ceramic tile cutting method, a ceramic tile is placed on the rotation cutting platform, the rotation cutting platform drives the ceramic tile to rotate, and a scale pointer is utilizedto carry out angle position on an angle dial, so that the ceramic tile can be conveniently cut at different angles, angle positioning is precise, and the ceramic tile is cut on the construction site to further improve the working efficiency.

Owner:张媛淇

Mounting tool for camshaft bushing

InactiveCN107553393AGuarantee that the installation is qualifiedImprove installation efficiencyMetal-working hand toolsScrew threadLubricant

The invention relates to a camshaft bush installation, in particular to a camshaft bush installation tool, which belongs to the technical field of camshaft bush installation equipment. It includes a pressing rod, and the pressing rod includes a handle part, a convex shoulder part, a bush installation part, a transition part and a guide positioning part. The bush installation part is provided with a first positioning hole in the radial direction, and the first through hole section is provided with a The first positioning steel ball, the part of the first positioning steel ball can protrude from the outer surface of the bushing installation part; the internal thread of the first threaded hole section is connected to the first adjusting screw, and the first positioning steel ball and the first adjusting screw are provided with a second positioning screw. A spring, the compression degree of the first spring to the first positioning steel ball can be adjusted through the first adjusting screw. The protruding shoulder of the pressure rod of the present invention realizes the positioning of the installation depth of the bushing, and the guide part realizes the angle positioning of the oil hole of the bushing; The accurate butt joint of the holes realizes the accurate positioning of the bushing angle.

Owner:CHINA FIRST AUTOMOBILE

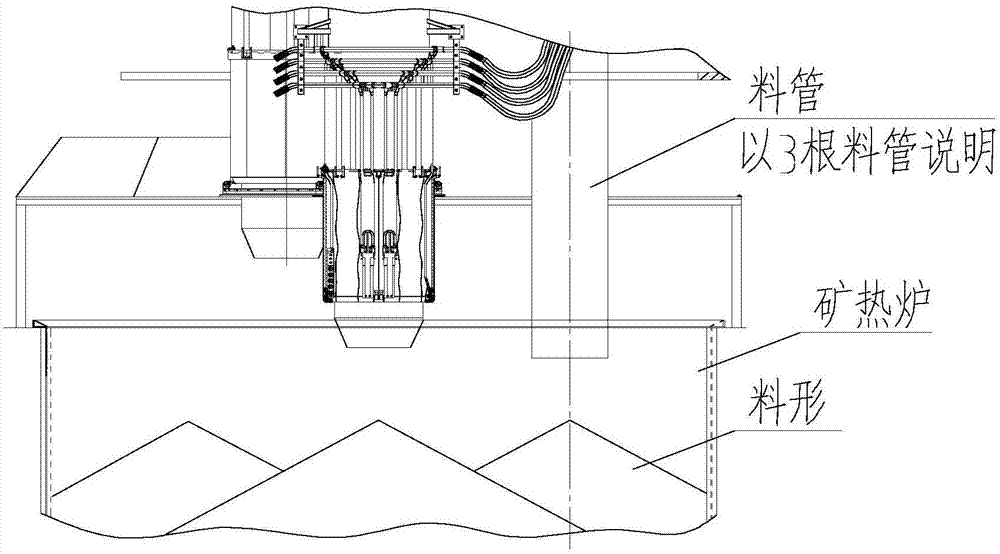

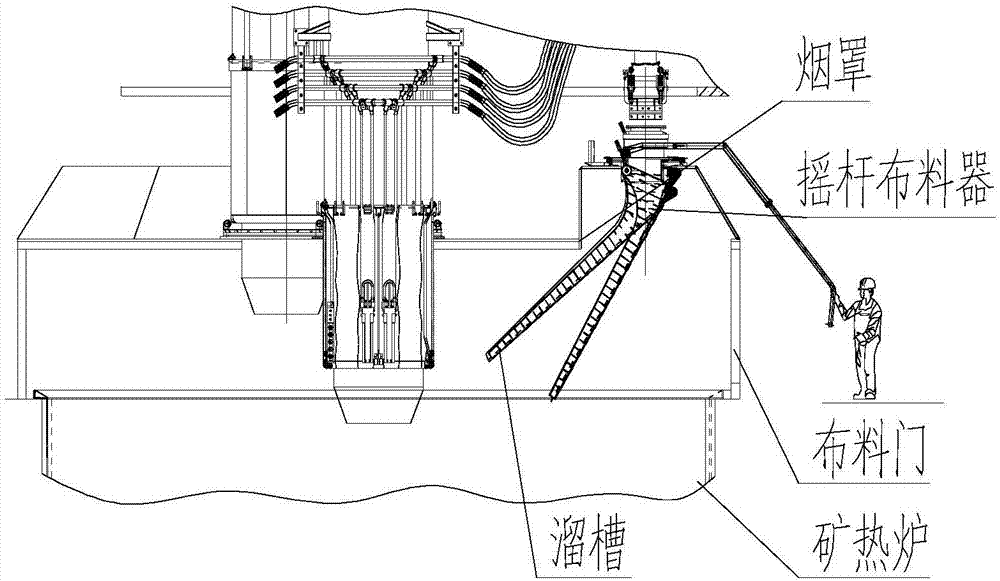

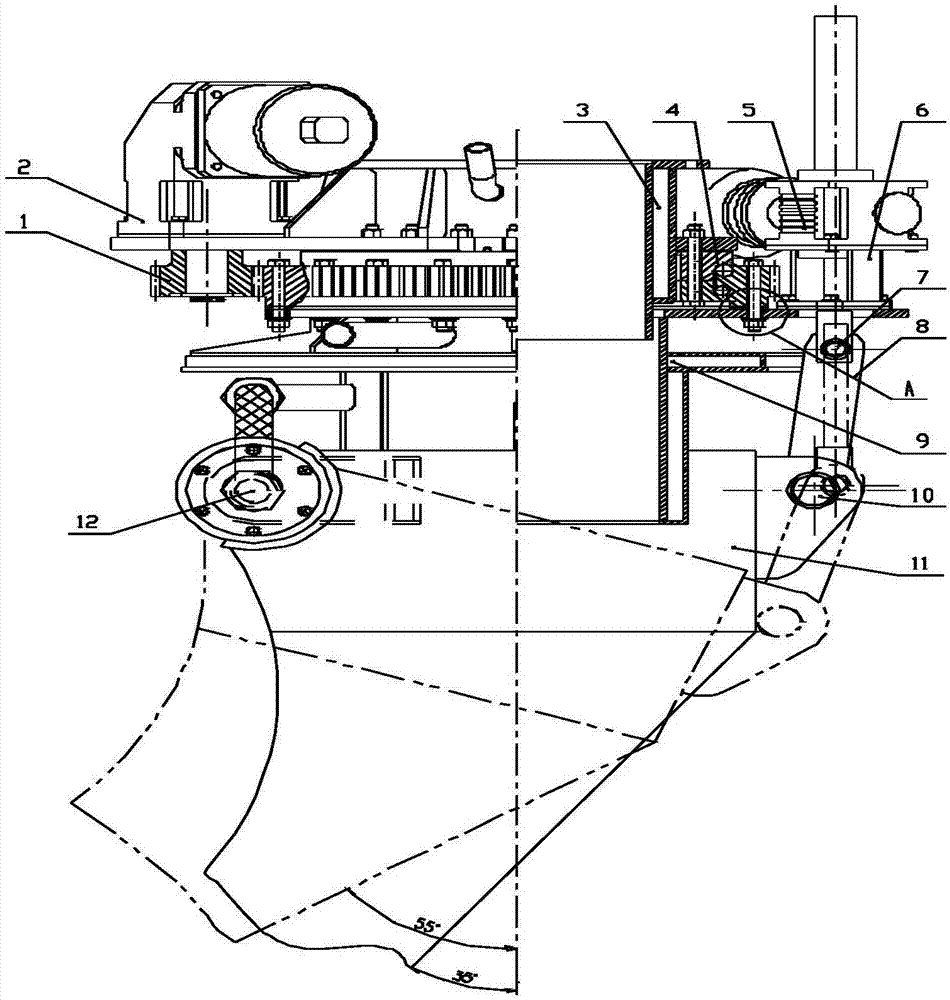

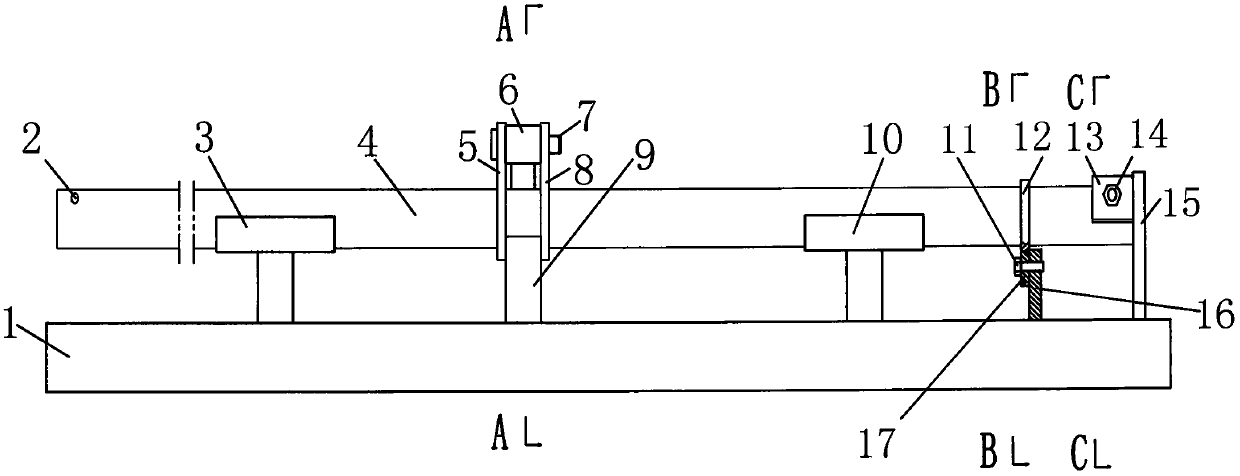

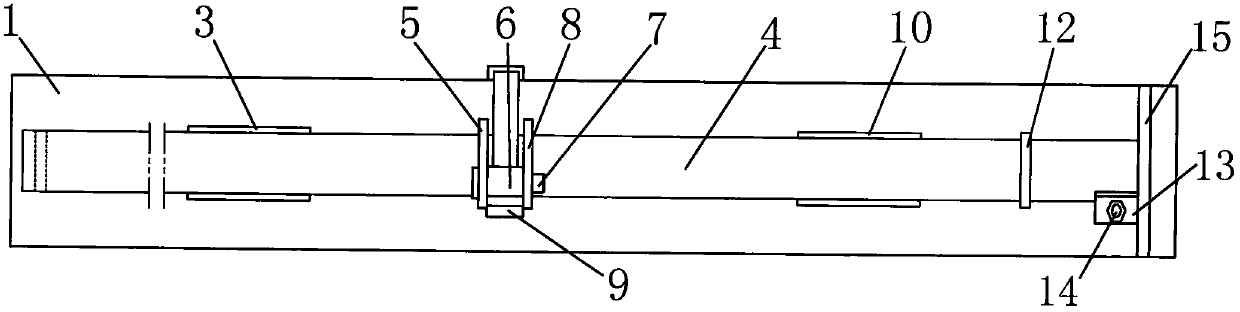

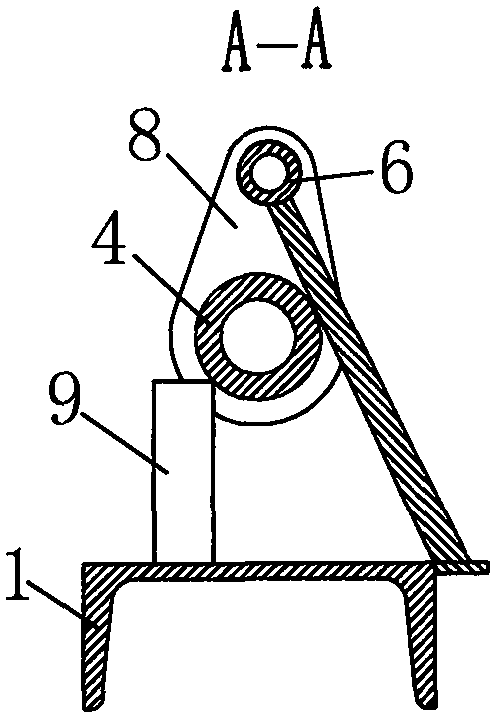

Mechanical transmission submerged arc furnace distributing device

ActiveCN107576197AEvenly distributedReduce internal frictionCharge manipulationMotor driveEngineering

The invention discloses a mechanical transmission submerged arc furnace distributing device. The mechanical transmission submerged arc furnace distributing device comprises a planetary gear motor arranged on a water-cooling center throat pipe, a rotation support arranged on the water-cooling center throat pipe, a rotary sleeve connected with the outer ring of the rotation support, and a water-cooling chute, wherein an output shaft of the planetary gear motor is provided with a pinion, and the planetary gear motor drives the pinion to rotate; the inner ring of the rotation support is close to the water-cooling center throat pipe, a gear on the outer ring of the rotation support is engaged with the pinion, and the pinion can drive the rotation support to rotate through the outer ring; the rotary sleeve is connected with the outer ring of the rotation support, and the pinion of the planetary gear motor rotates the rotation support to drive the rotary sleeve to rotate; and the water-cooling chute is connected with the planetary gear motor through a connection rod of a lead screw elevator, and the planetary gear motor drives the water-cooling chute to swing through the connection rod ofthe lead screw elevator. The mechanical transmission submerged arc furnace distributing device can distribute materials onto different ring faces, automatic feeding of any point in a submerged arc furnace is achieved, materials are distributed more evenly, enlargement of the submerged arc furnace is facilitated, and inner consumption of the submerged arc furnace is reduced.

Owner:BERIS ENG & RES CORP

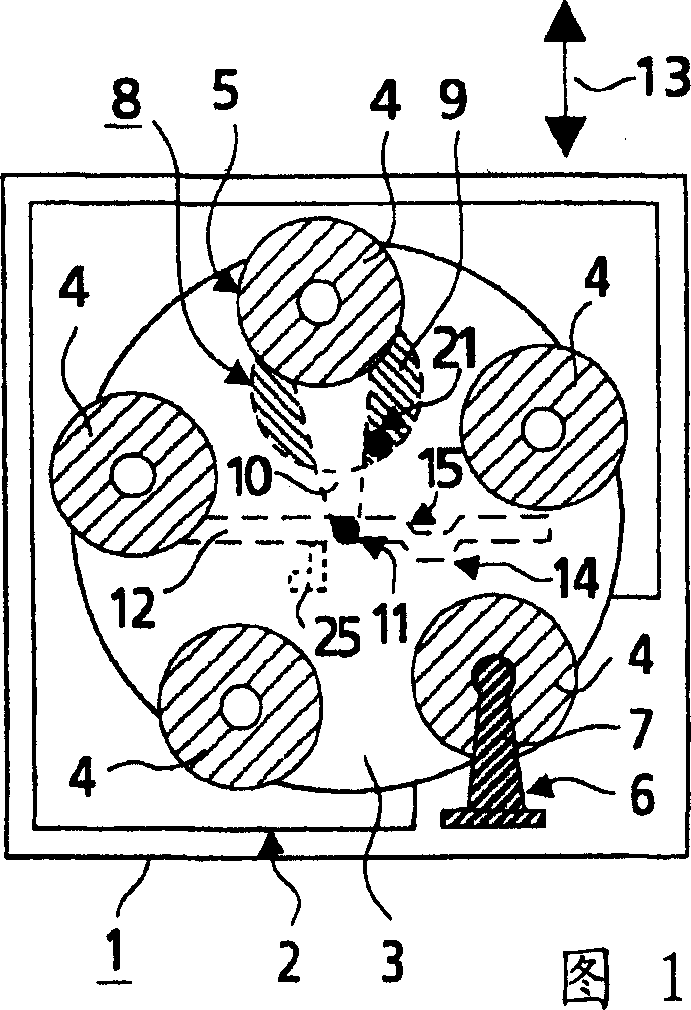

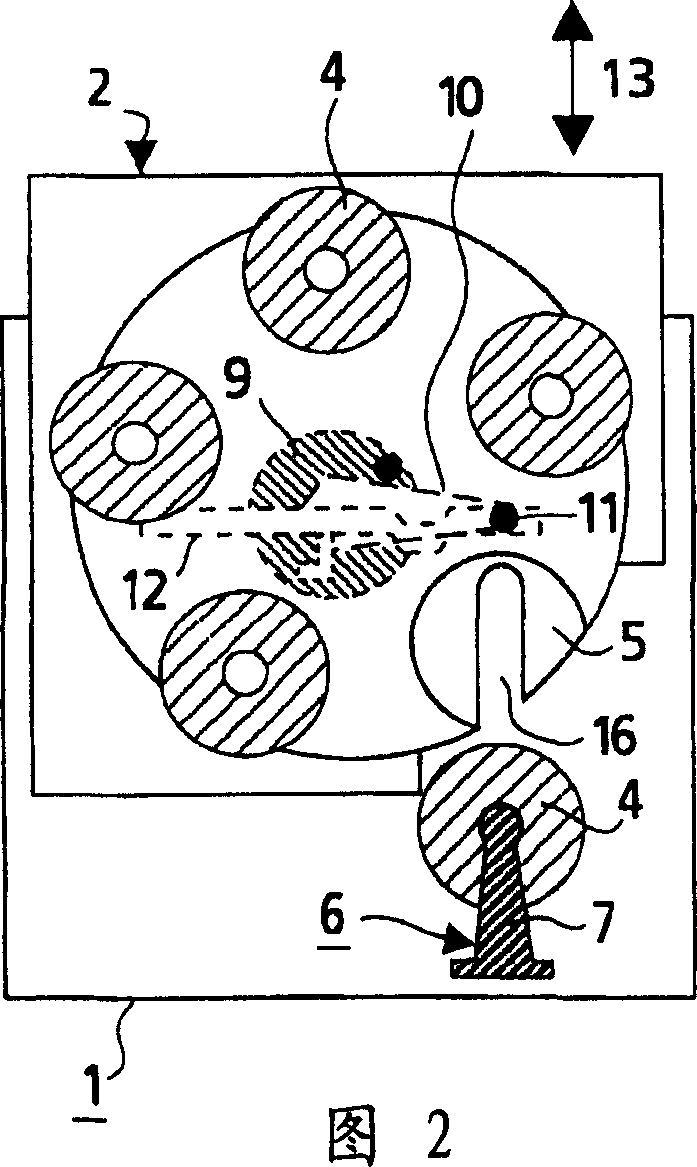

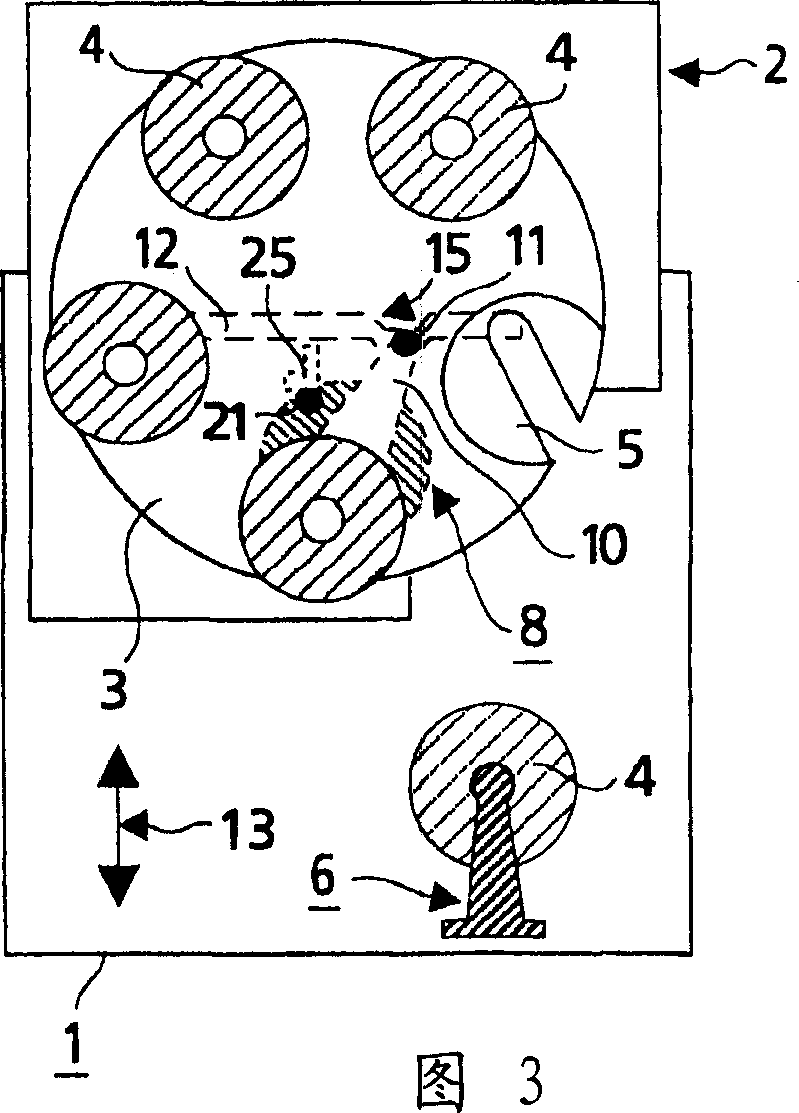

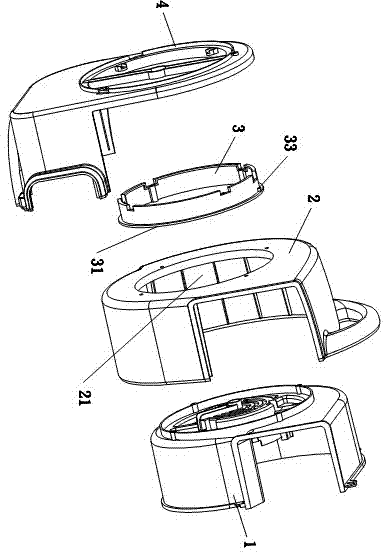

CD changing device

InactiveCN1492419APush to avoidAvoid collisionCarrier constructional parts dispositionRecord information storageEngineeringOptical recording

The present invention relates to a CD changer of the 'carousel type', in which three or five optical recording media, referred to below as disk, are arranged on a rotatable disk holder, the carousel. It has a drawer (2) which can be moved between a retracted and an extended position by a drawer movement mechanism (8). The object of the invention is to propose a solution which improves the functionality of the CD changer. It is proposed in the invention that the drawer has a stop (15, 25) which, in the extended position, bears against a pin (11, 21) of the drawer movement mechanism (8), and which, when force acts on the drawer (2), exerts on the drawer movement mechanism a force which is directed in the radial direction of said mechanism.

Owner:THOMSON LICENSING SA

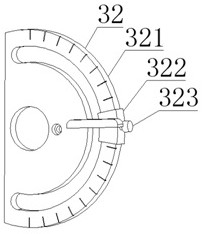

Angle-controllable manual angle folding device for metal plate machining and construction technology

ActiveCN114042784ASimple processing technologyQuick installationMetal working apparatusStructural engineeringMachining process

The invention relates to an angle-controllable manual angle folding device for metal plate machining and a construction technology. The angle-controllable manual angle folding device for metal plate machining comprises a rack. The device also comprises a clamping device arranged on the rack and used for loosening and clamping the plate; a bending device comprising an overturning plate rotationally connected with the rack and an angle control instrument panel for limiting the overturning angle of an overturning plate; and a distance controller comprising a positioning part, and the positioning part is arranged to be placed between the two forming faces of the bent plate when the plate is bent so as to control the distance between the two forming faces after the plate is bent; a multi-curvature flat lock catch system plate bending device meets the bending requirement for various plate modeling designs of a multi-curvature flat lock catch system, angle positioning is accurate, the plate machining process is simple, the lock catch connecting quality is greatly improved, the machining and construction efficiency is improved, the construction cost is reduced, rapid machining and installation of plates are achieved, and the construction precision is guaranteed.

Owner:CHINA CONSTR EIGHTH ENG DIV

A multi-angle angle gauge block

ActiveCN106930965BGood angle consistencyGuaranteed performancePump componentsEngine fuctionsEngineeringAngle gauge

The invention provides a multi-angle angle gauge block. The multi-angle angle gauge block is used for adjusting the angle of a stator blade in a casing, a shaft neck is arranged on the stator blade, positioning pins are arranged on the casing, the angle gauge block is circular, N square grooves matched with the positioning pins are circumferentially arranged on the outer edge of the end face of the angle gauge block, the value range of N is larger than 1, the positions of N square grooves sequentially correspond to N adjusting angles of the stator blade, a polygon through hole is formed in the center of the angle gauge block, and is provided with M sides, M is equal to 2N, and the polygon through hole is in a regular polygon shape; the center lines perpendicular to the bottom faces of the square grooves pass through the center point of the polygon through hole, the center line of one square groove is further perpendicular to one set of opposite sides of the polygon through hole, and the included angle between the center line and the vertical line of the side, corresponding to the center line, of the polygon through hole is the adjusting angle.

Owner:AECC SHENYANG ENGINE RES INST

A fast and precise positioning method for automatic control of fan-shaped material distribution in bellless blast furnace

ActiveCN104774988BAccurate angle positioningFast angular positioningBell-and-hopper arrangementBlast furnace detailsPosition angleRunning time

The invention discloses a method for automatically controlling and rapidly, accurately and precisely locating fan-shaped distribution of a bell-less blast furnace. The method comprises the following specific steps of setting allowance of fan-shaped distribution, and setting a first fan-shaped set angle beta1 and a second fan-shaped set angle beta2; judging a fan-shaped set angle; collecting position data of a rotary chute in real time, carrying out angle conversion to obtain a circumferential position angle of the current rotary chute, and comparing with the first fan-shaped set angle beta1 and the second fan-shaped set angle beta2; and allowing blanking when the rotary chute is in the target position of the fan-shaped distribution. According to the invention, the angle location of fan-shaped distribution of a blast furnace chute is more precise and rapid; the idle running time and the distribution waiting time of a rotary motor are shortened; two numerical values of the fan-shaped set angle can be arranged freely; the wrong arrangement phenomenon of the numerical values does not exist; by means of precise distribution angle, a reasonable surface shape and ore-to-coke ratio distribution are formed in a blast furnace; and beneficial conditions are created for stability operation of the blast furnace.

Owner:XINXING DUCTILE IRON PIPES CO LTD

5G antenna and 5G antenna mounting base

InactiveCN113013580AEasy to assemble and disassembleEasy to useAntenna supports/mountingsStructural engineeringMechanical engineering

Owner:SHENZHEN SHUNDACHENG TECH CO LTD

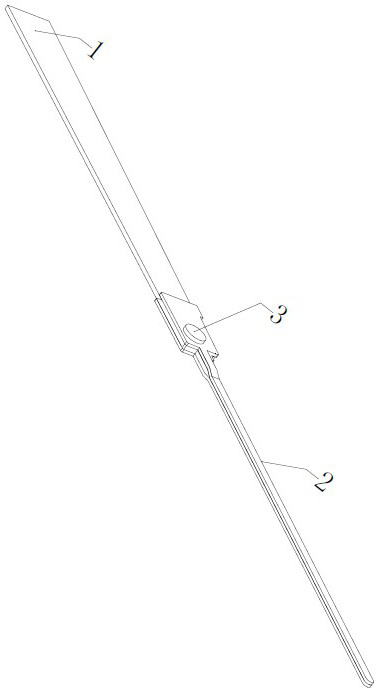

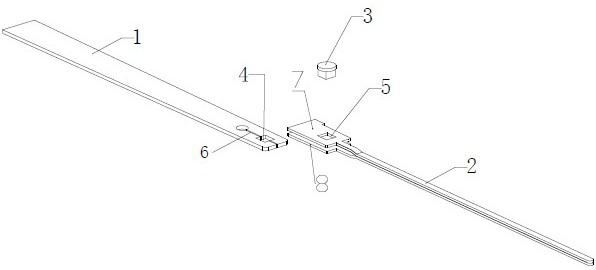

Folding glasses temple

PendingCN112114442AAccurate angle positioningQuality is easy to controlNon-optical partsEyewearMechanical engineering

The invention discloses a folding glasses temple, belonging to the field of glasses. The folding glasses temple comprises a first glasses temple, a second glasses temple and a connecting piece hingedwith the first glasses temple and the second glasses temple, wherein the connecting piece is in a polygonal column shape; the end part of the first glasses temple is provided with a first mounting hole; the second glasses temple is provided with a second mounting hole; the shape of the first mounting hole and the shape of the second mounting hole correspond to the connecting piece; and one of thefirst mounting hole and the second mounting hole is in running fit with the connecting piece, and the other one of the first mounting hole and the second mounting hole is in fixed fit with the connecting piece. The folding glasses temple has the advantages of being accurate in positioning and good in practicability.

Owner:WENZHOU XIANGTONG GLASSES

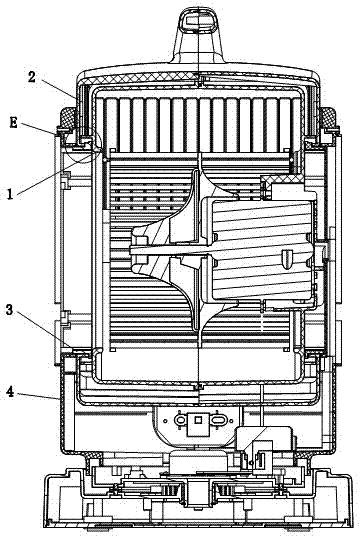

Pitching mechanism of centrifugal type blower

InactiveCN102338113BRealize regulationRealize stepless adjustmentPump componentsPump installationsStructural engineeringAir blower

The invention discloses a pitching mechanism of a centrifugal type blower, which comprises an air flue and a housing, wherein the air flue is arranged in the housing. The pitching mechanism of the centrifugal type blower is characterized by also comprising a pitching bracket and a supporting housing, wherein the pitching bracket is shaped as a short ring column body with an outward flange, the housing is provided with an inner flanged circular hole, the end edge of the inner flanged circular hole is provided with a limit groove, the short ring column body of the pitching bracket penetrates through the inner flanged circular hole from the inner side of the housing and is tightly matched with the inner flanged circular hole, a limit rib arranged at the inner side of the flange is matched inthe limit groove and enables the flange to be tightly attached on the end edge of the inner flanged circular hole, the end of the short ring column body is fixed on a support housing, and one end of the air flue, which is towards the pitching bracket, is tightly attached with the flanged end of the pitching bracket. By adopting the structure that the pitching bracket is matched and limited with the supporting housing and the air flue, the pitching mechanism effectively realizes the pitching regulation and the pitching angle stepless regulation of the centrifugal type blower, and has the advantages of simple structure, convenience for installation, stronger mechanical strength, accuracy and reliability in angle positioning and high maneuverability.

Owner:MIDEA GRP CO LTD

Round bale baler motor shaft welding tool

ActiveCN106695223BSimple structureQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesPulp and paper industryUltimate tensile strength

Owner:LINYING COUNTY YING MACHINERY MFG

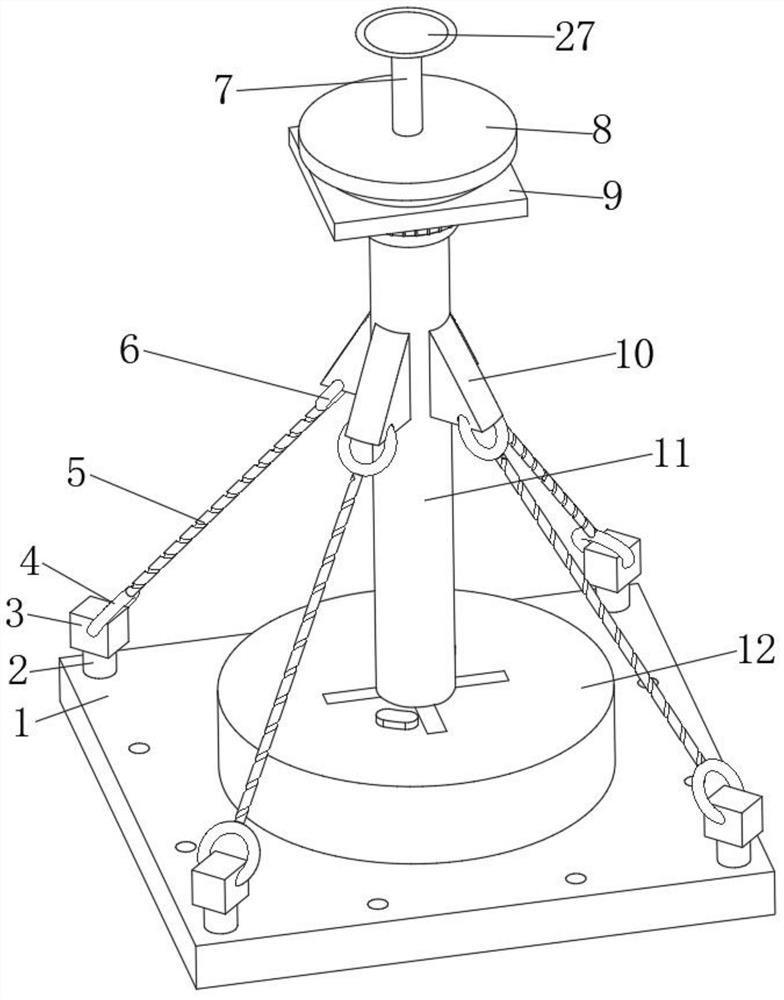

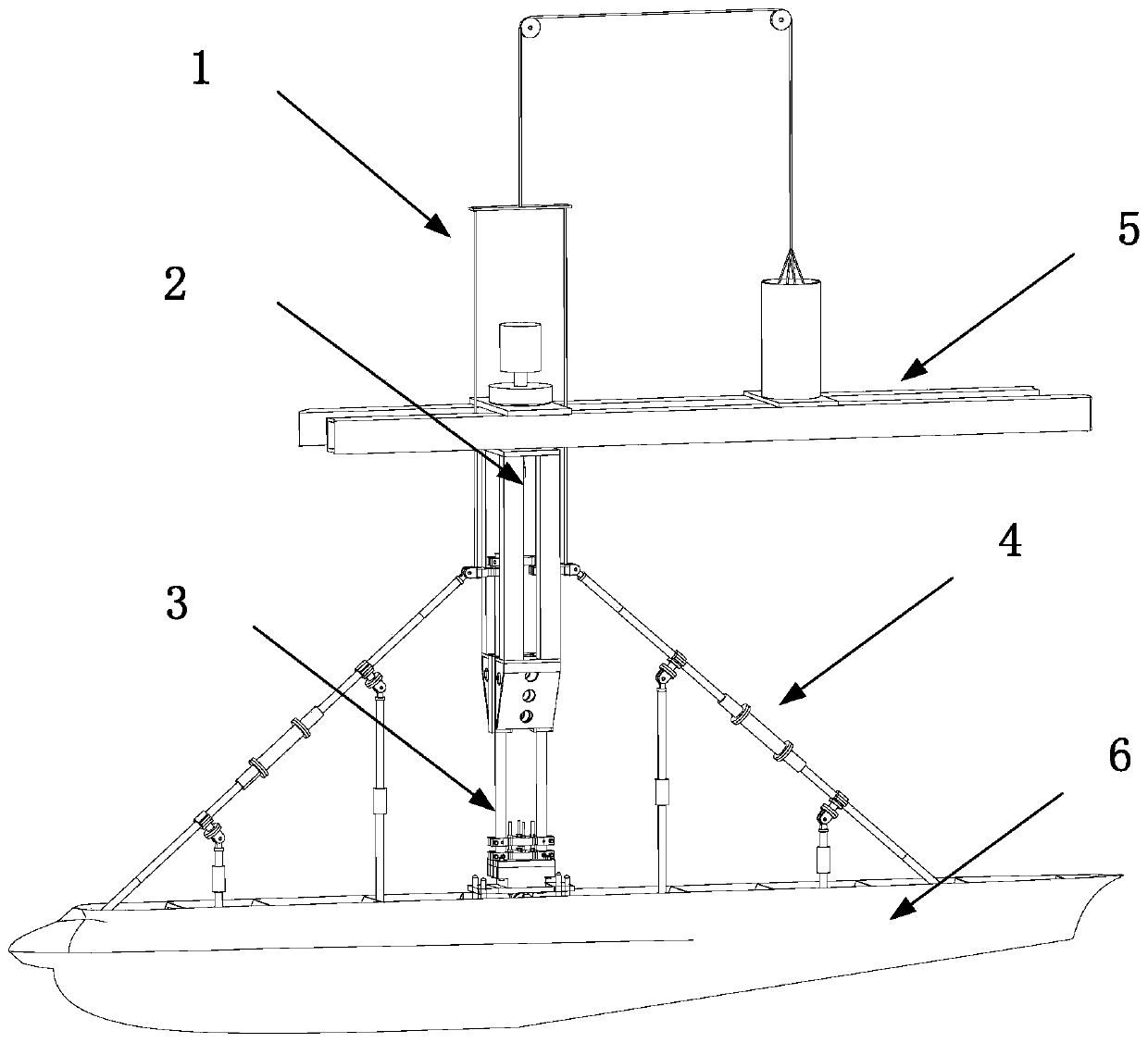

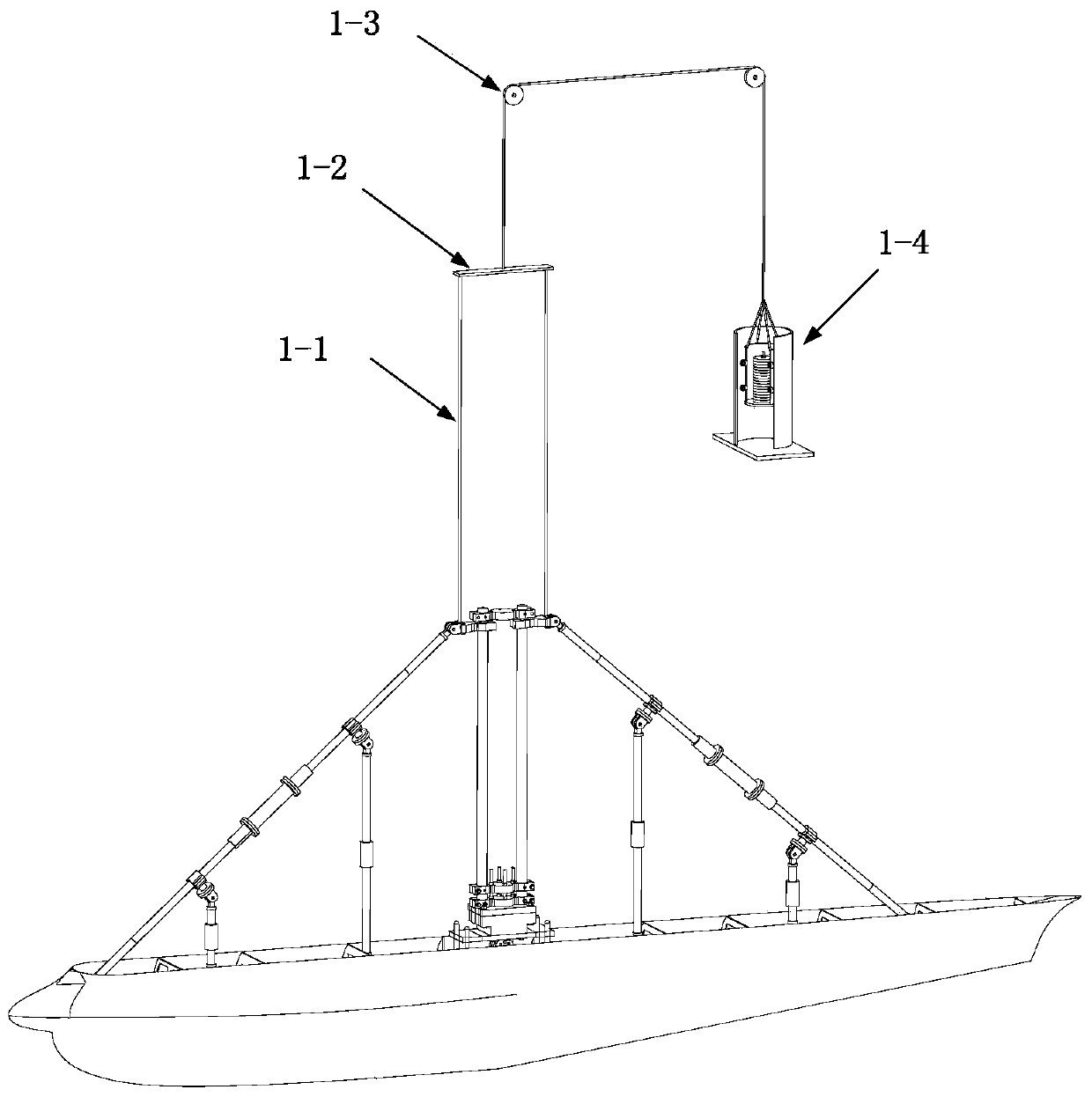

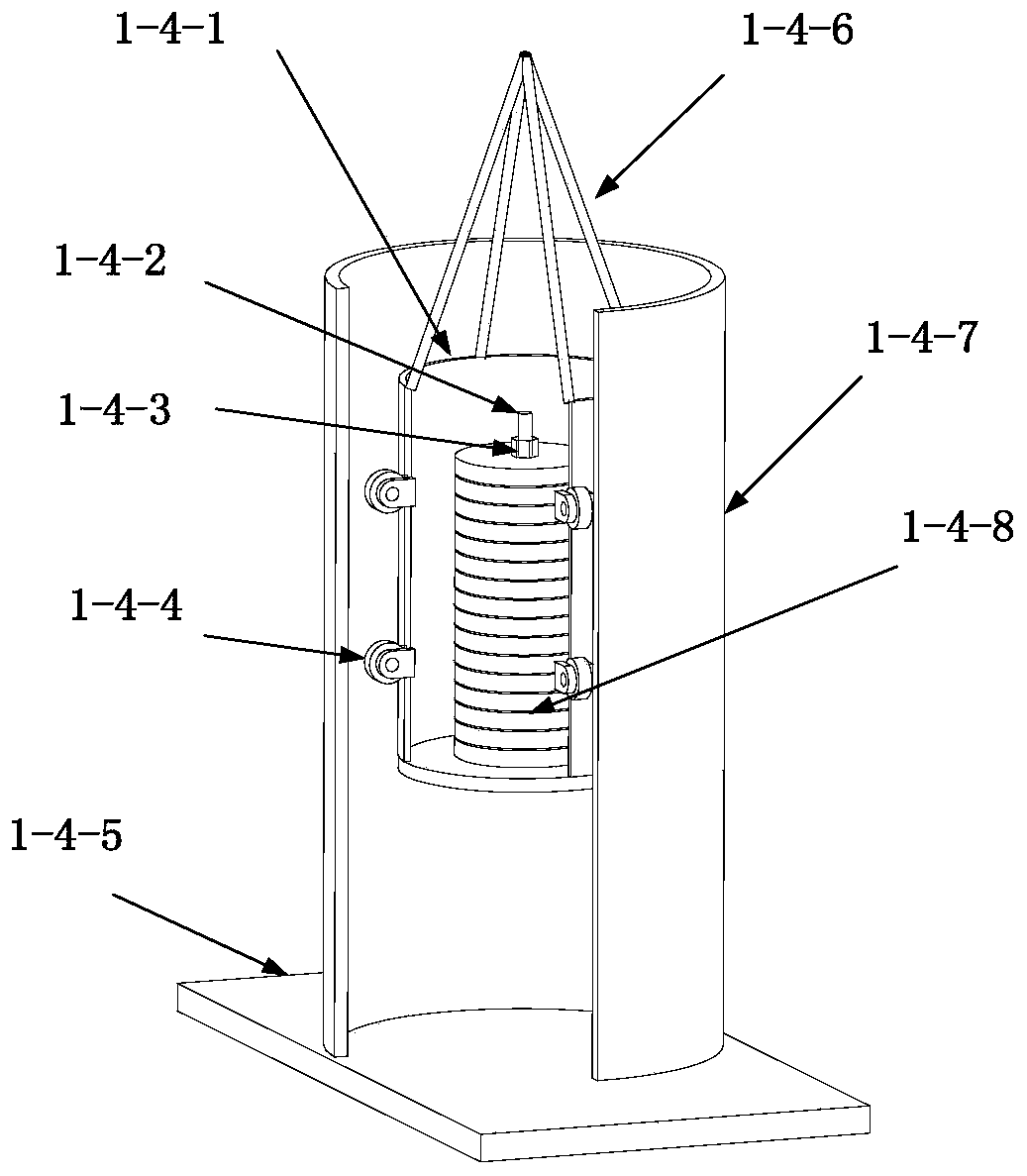

A new type of water surface drag test device platform based on two degrees of freedom

ActiveCN109596309BMaximum unloading error reductionAvoid rocking motionHydrodynamic testingMarine engineeringKeel

Owner:CHINA SPECIAL TYPE FLIER RES INST

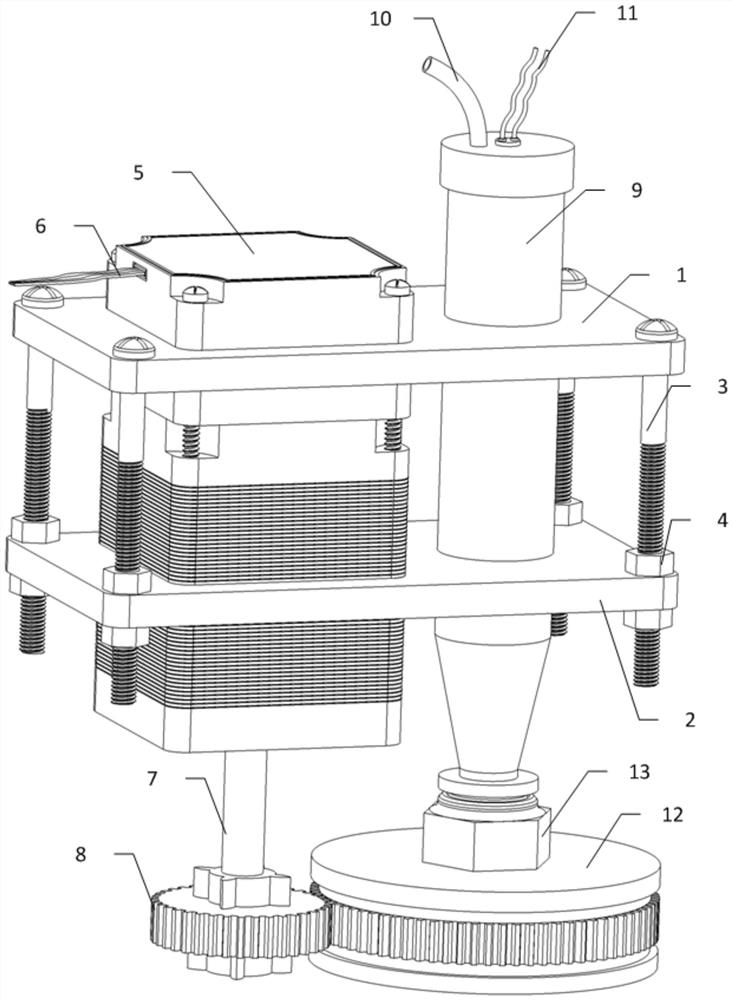

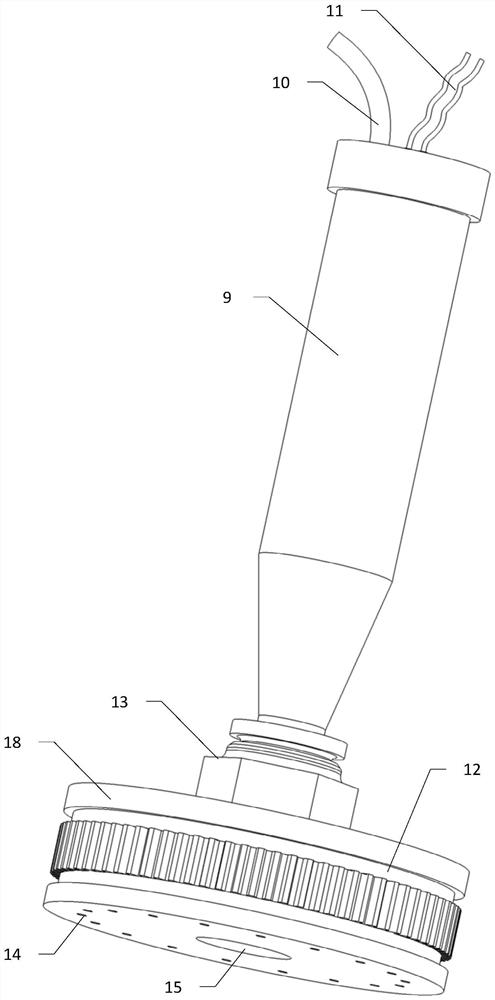

Micro piezoelectric sprayer based on iris turbofan and nozzle aperture regulation and control method

The invention discloses a micro piezoelectric sprayer based on an iris turbofan and a nozzle aperture regulation and control method. The micro piezoelectric sprayer based on the iris turbofan comprises a micro motor of a driving gear, the iris turbofan meshed with the driving gear, and a piezoelectric sprayer body arranged above the iris turbofan. And the exterior of the iris turbofan is meshed with the driving gear through an outer driven gear and an inner driven gear which are integrally formed. The interior of the iris turbofan is meshed with the inner driven gear through a plurality of thin metal blades provided with blade gears, and the multiple blades are overlapped to form a nozzle with the adjustable hole diameter. The piezoelectric nozzle has the beneficial effects that the aperture size of the nozzle can be flexibly adjusted, the function that one piezoelectric nozzle is used for jet printing of different precision sizes is achieved, and the requirements of various jet printing targets are met.

Owner:SOUTH CHINA UNIV OF TECH

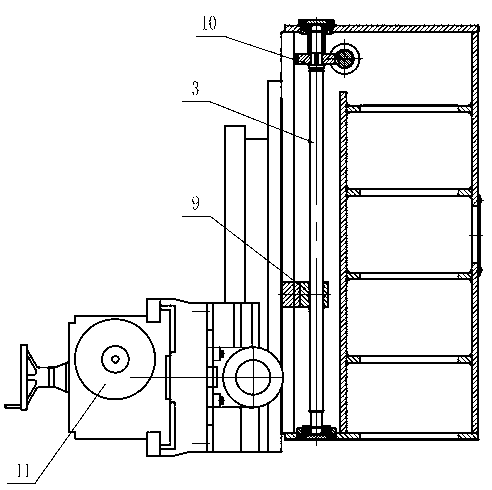

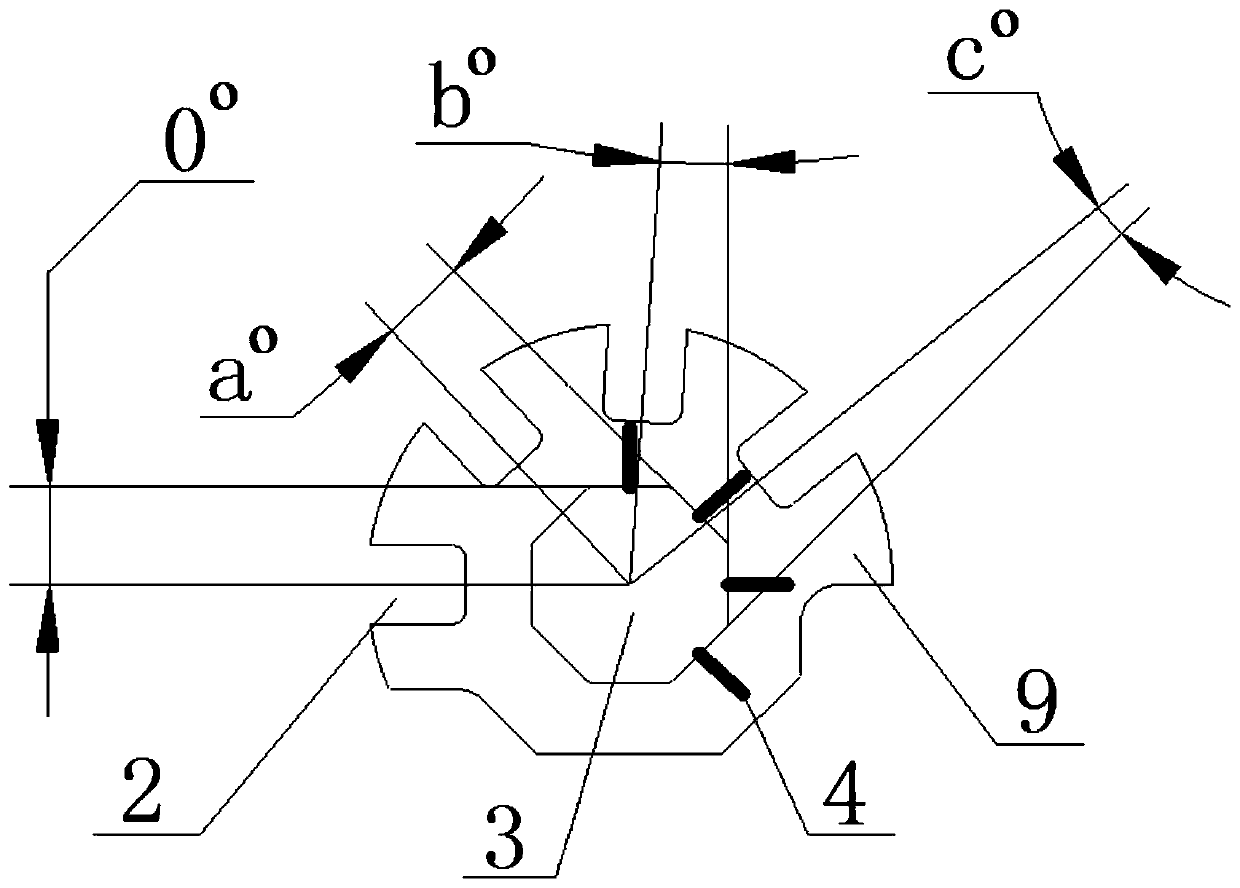

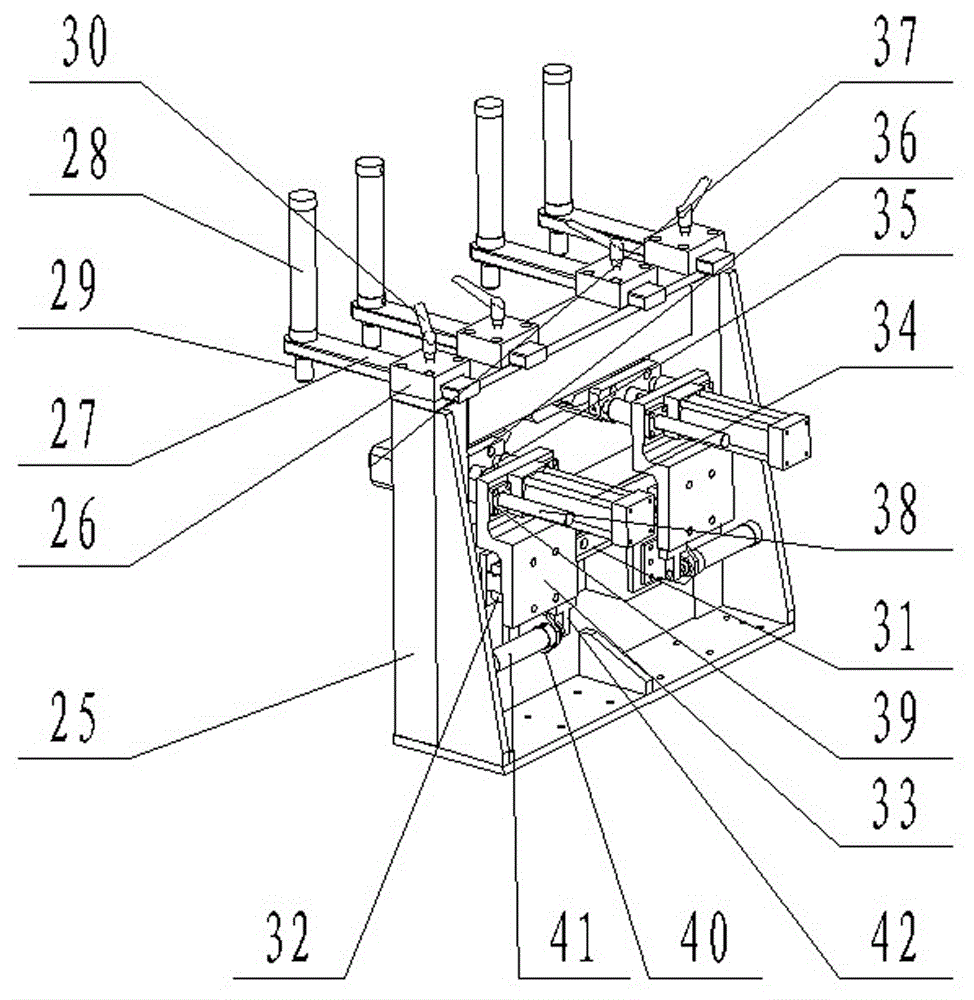

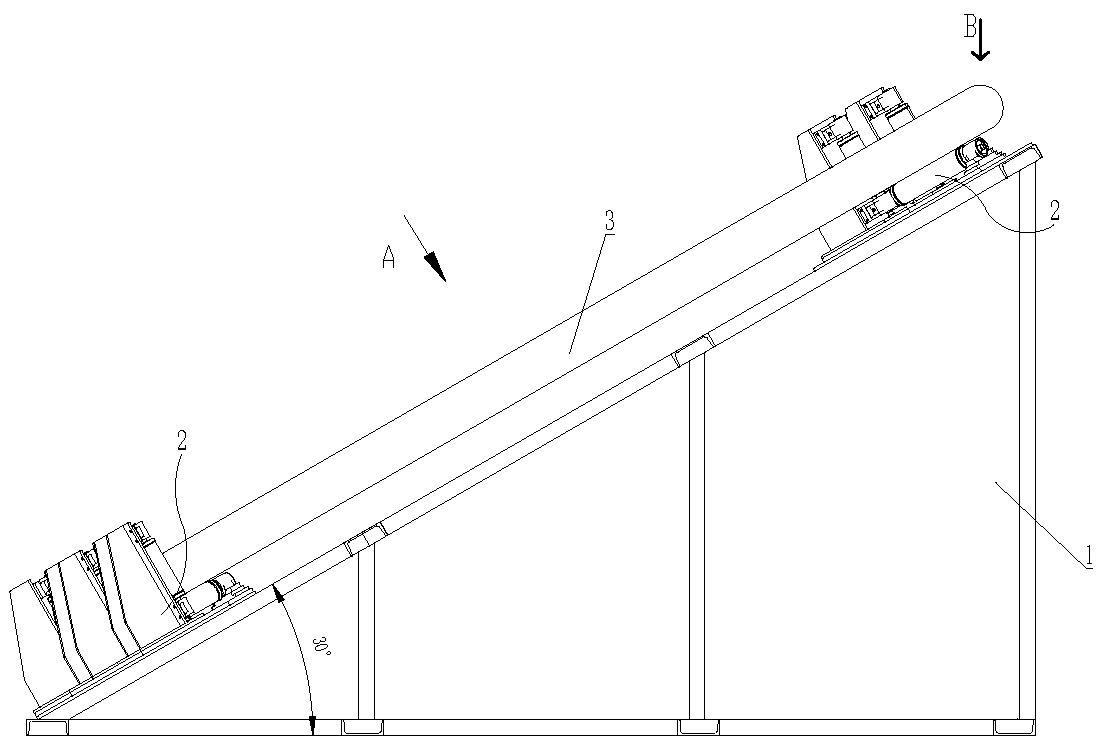

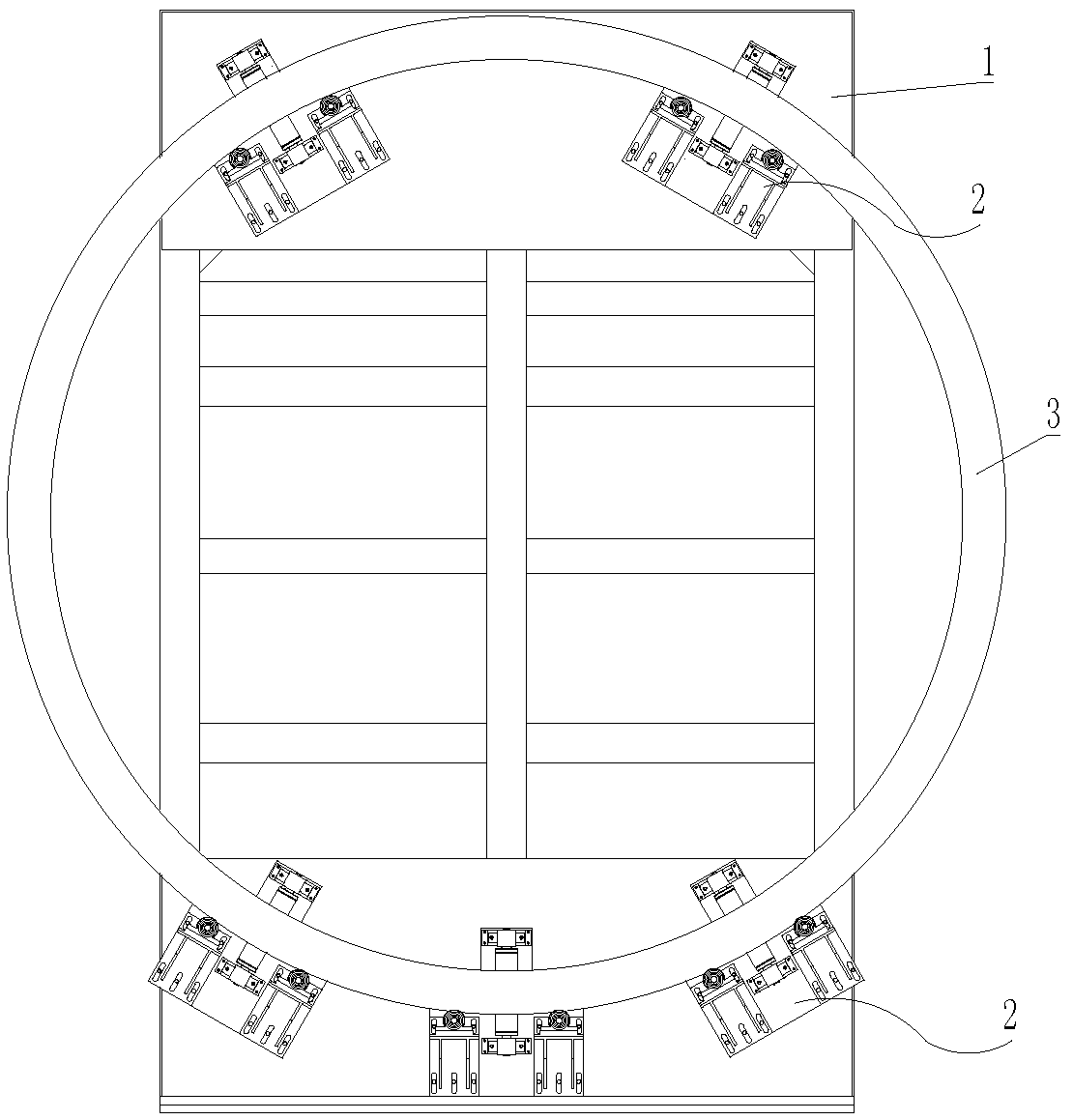

Swing head type automatic sawing processing equipment and processing method thereof

ActiveCN103586533BRealize sawing processSawing process is stable and reliableMetal sawing devicesEngineeringAutomatic testing

The invention discloses front sway type automatic saw cutting machining equipment. The front sway type automatic saw cutting machining equipment comprises a hold-down mechanism, a discharging mechanism and a front sway blade sawing mechanism, wherein the hold-down mechanism, the discharging mechanism and the front sway blade sawing mechanism are arranged on a rack. Swaying of the blade sawing mechanism is completed through a servo motor, and saw cutting machining at any angle from 45 degrees to 135 degrees can be achieved; an air cylinder and a damping cylinder are adopted for feeding of saw blades, the feeding is stable, and cut end faces of sectional materials are smooth and burr-free; after stub bars are cut, the saw blades retreat, are pressed tightly and horizontally and then are released, and therefore the phenomenon of slip can be avoided; the front sway type automatic saw cutting machining equipment is simple in structure, high in automation degree, high in machining accuracy and high in machining efficiency. The method utilizing the equipment to machine the sectional materials includes the following steps: enabling the saw blades to sway to 45 degrees, conveying workpieces, pressing the workpieces tightly, cutting the workpieces to form 45-degree end face angles, pressing tightly and releasing the workpieces and enabling the stub bars to fall, enabling the saw blades to sway to 135 degrees, horizontally pressing the workpieces tightly, moving the workpieces right and conveying the workpieces, pressing the workpieces tightly, cutting the workpieces to form 135-degree end face angles, pressing tightly and releasing the workpieces, moving finished workpieces right to the discharging mechanism through a right workbench, and moving the finished workpieces right to a discharging table through the discharging mechanism.

Owner:济南天辰智能装备股份有限公司

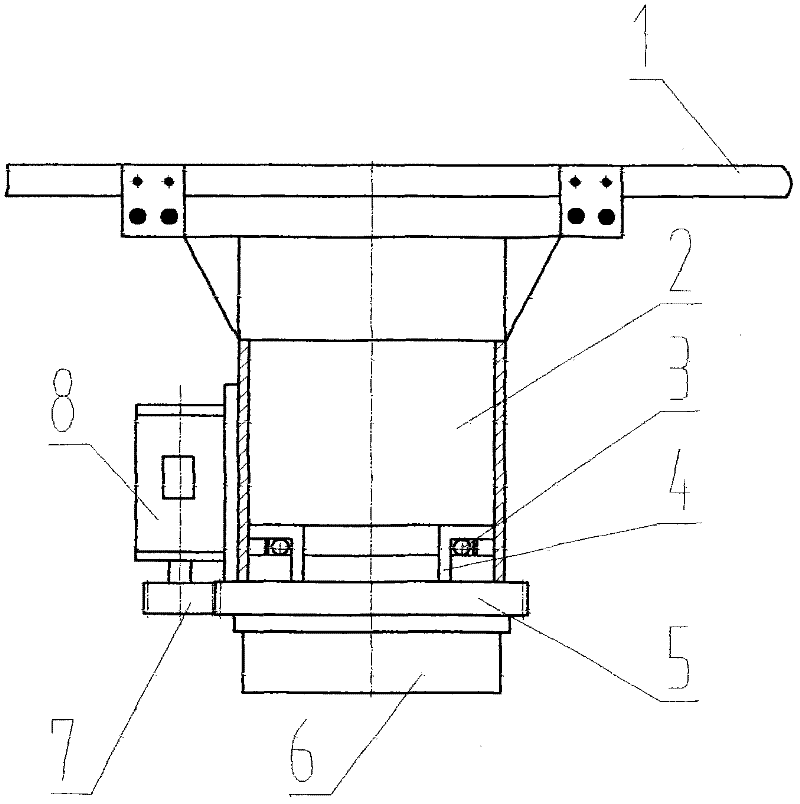

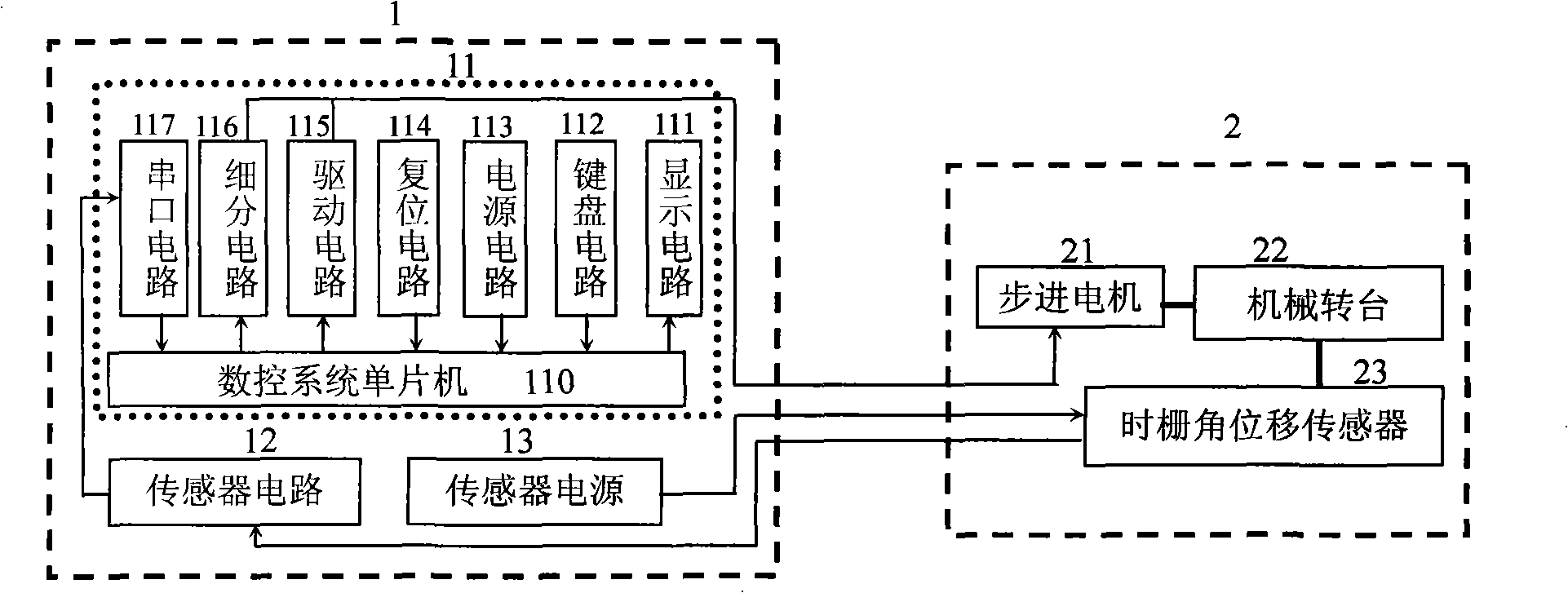

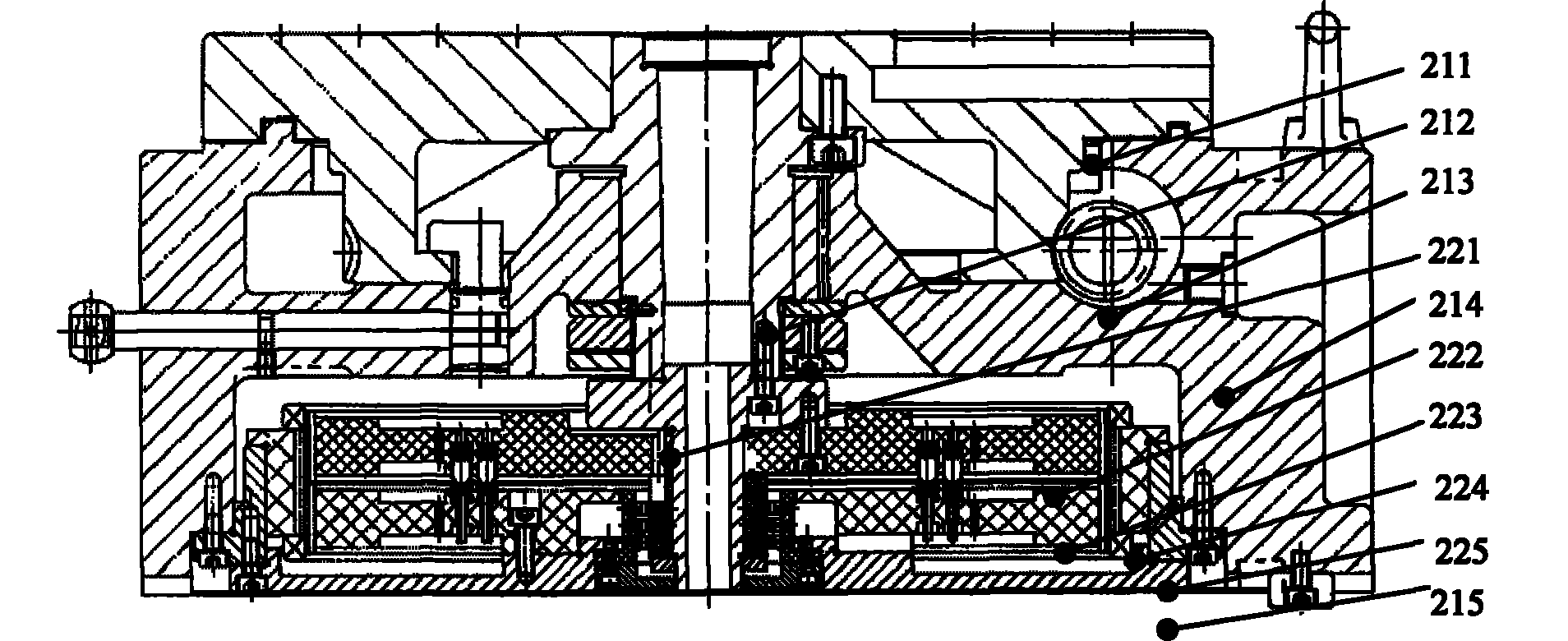

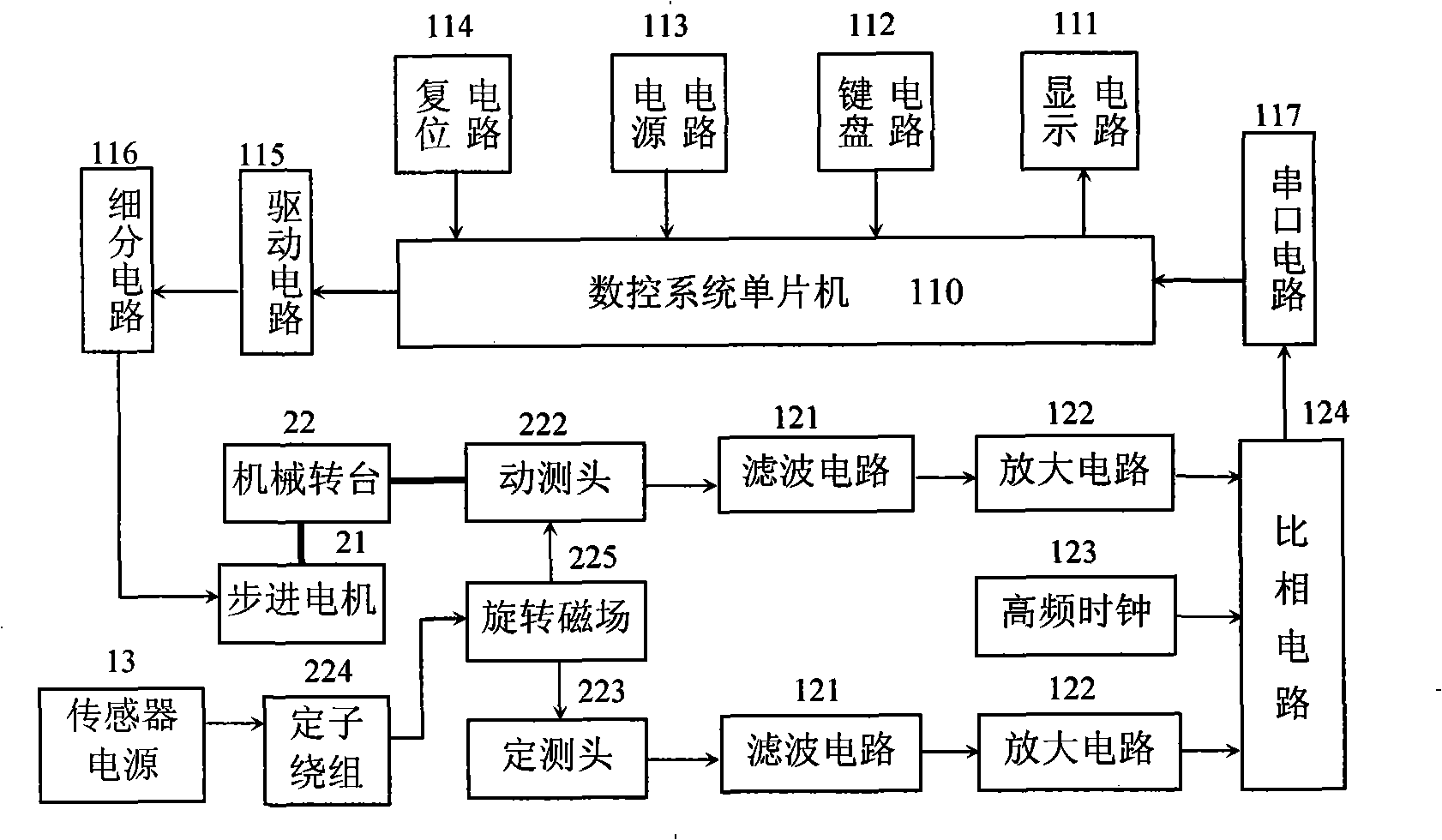

Time fence type numerical control indexing table used for precise measurement

InactiveCN101498924BAccurate angle positioningImprove work efficiencyProgramme controlComputer controlTurn angleNumerical control system

The invention relates to a time fence numerical control indexing turntable used for precision measurement, which comprises a numerical control system based on a single chip microcomputer, a stepping motor, a precision mechanical turntable, and a time fence angle movement sensor. In a precision measurement process, and when the indexing turntable needs to be precisely located and turned to a certain specific angle according to certain steering, an instruction including steering and turning angle information is input through the keyboard of the numerical control system, leading the mechanical turntable to turn according to the steering and the turning angle in the instruction. The time fence angle movement sensor detects the information of the angle turned by the mechanical turntable and feeds back to the numerical control system, thus forming closed loop control, and guaranteeing the turntable to be located to the angle indicated in the instruction, wherein, location precision mainly depends on the precision of the time fence angle movement sensor. As a novel time fence angle movement sensor and the numerical control system based on the stepping motor are adopted, cost on the precise numerical control indexing turntable used for measurement is greatly reduced.

Owner:CHONGQING UNIV OF TECH

Nonstandard guide blade machining device and machining method

InactiveCN108393524AReduce manufacturing costHigh positioning accuracyMilling equipment detailsPositioning apparatusEngineeringMachining

The invention discloses a nonstandard guide blade machining device. The nonstandard guide blade machining device comprises a flange plate; and a second through hole is formed in the circle center of the flange plate. The nonstandard guide blade machining device further comprises a positioning shaft; the positioning shaft comprises a cylinder section, a taper section and a step section axially connected in sequence; a shaft sleeve is arranged on the step section; the bottom end of the cylinder section is radially shrunk as a shaft head; the shaft head is embedded in the second through hole; thetop surface of the flange plate is connected with a pair of rectangular guide blocks; angular positioning forks are clamped in opening grooves of the pair of guide blocks; and U-shaped grooves are formed in the end surfaces, far from the flange plate, of the angular positioning forks. The nonstandard guide blade machining device further comprises a mandrel; and one end of the mandrel is arrangedin the second through hole, and is opposite to the shaft head. The nonstandard guide blade machining device solves the problem of low blade positioning precision in traditional machining.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Transit mixer for free-flowing media

ActiveCN100589950CSave materialHigh precisionConcrete transportationCement mixing apparatusEngineeringMechanical engineering

Owner:STETTER

Plasma Cutting Linear Bevel Swing Device

ActiveCN102699592BHigh degree of automationImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesVertical planeEngineering

Owner:WUXI HUALIAN PRECISION MACHINERY

Adjustable drilling platform device for ring header eccentric hole

The invention provides an adjustable drilling platform device for a ring header eccentric hole. The positioning angle of the eccentric hole can be ensured accurately, the safety and reliability rare improved greatly, usage requirements of ring headers with different diameters can be met, simple and convenient installation and adjustment are achieved, the universality is good, and actual productionand use can be met well. The adjustable drilling platform device comprises an angle bracket formed by welding profile steel, and the angle bracket is provided with at least three modular roller frames with adjustable positions. The modular roller frames comprise horizontally-arranged rollers and vertically-arranged rollers which are fixed on a bottom plate, the horizontally-arranged rollers are installed horizontally at the middle position of the top of the bottom plate, and the vertically-arranged rollers are fixed on a vertically-arranged roller supporting seat perpendicular to the bottom plate.

Owner:WUXI HUAGUANG BOILER

A precise positioning treatment bed

ActiveCN106267573BAccurate angle positioningImprove carrying capacityLight therapyMulti degree of freedomEngineering

The invention discloses an accurate set-up treatment bed, which comprises a set-up platform and a substrate. A multi-degree-of-freedom parallel mechanism is arranged between the set-up platform and the substrate. A horizontal motion control assembly and a vertical motion control assembly are arranged in sequence under the substrate. The horizontal motion control assembly comprises a first direction control assembly and a second direction control assembly. The first direction and the second direction are perpendicular in a horizontal plane; movement in the first direction and the second direction is horizontal movement; and the vertical motion control assembly drives the horizontal motion control assembly to move up and down. Through major change of the treatment bed and fineness control of the parallel mechanism, adjustment of the angle and position can be realized very well; and meanwhile, the accurate set-up treatment bed is small in land occupation area, is wider in application range and is enhanced in practicality.

Owner:SUZHOU AIN INTELLIGENT EQUIP

Tooth seat positioning tool for cutting head

The invention discloses a toothholder positioning tool for a cutting head. The toothholder positioning tool for the cutting head is used for providing positioning for the toothholder when the toothholder is connected on a cutting head body of the cutting head. The toothholder positioning tool comprises an installing platform, a curved plate and a positioning structure; the installing platform is used for placing and fixing the cutting head body; the curved plate is installed on the installing platform; and the positioning structure comprises a connection portion connected with the curved plate and a fixing portion used for fixing the toothholder, the connection portion is connected with a positioning portion installed on the curved plate to define a first axis line, an included angle between the fist axis line and the water level is the chamfer of the toothholder, the fixing portion rotates around the first axis line relative to the connection portion to adjust the rotation angle of the toothholder. Compared with the prior art, the toothholder positioning tool can adjust the rotation angle of the toothholder, so that angle positioning of the toothholder is more accurate; in addition, according to the toothholder positioning tool, the angel of the toothholder is positioned by directly adjusting the installing process corner of the toothholder, so that the cutting function angle of cutting teeth is positioned, and positioning is more accurate.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD +1

Deep sea azimuth propulsion device

ActiveCN110481739BSolve the sealing problemSimple structurePropulsive elementsTransmission with mechanical gearingRotational axisRotation - action

The invention relates to a deep sea full-rotation propelling device which comprises a flange base; a plurality of rotary rollers are evenly distributed in the flange base, and a rotary shell extends into the flange base and makes contact with the rotary rollers. A first motor and a second motor are both arranged in the flange base, and the output end of the first motor transmits a rotating pair tothe rotary shell through a first-stage transmission device to be used for achieving rotation of the rotary shell. A thruster rotating shaft is installed on the rotary shell, the output end of the second motor transmits the rotating pair to the thruster rotating shaft through a second-stage transmission device; one part, exposed out of the rotary shell, of the thruster rotating shaft is connectedwith a propelling mechanism through a connecting piece, and the thruster rotating shaft receives the rotating pair and drives the propelling mechanism to swing. By arranging the first-stage transmission mechanism, the rotating action of the rotary shell can be realized, and by arranging the second-stage transmission mechanism, the swinging action of the propelling mechanism can be realized, so that the continuous high-precision rotation of the whole mechanism in a three-dimensional hemispherical space is realized.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com