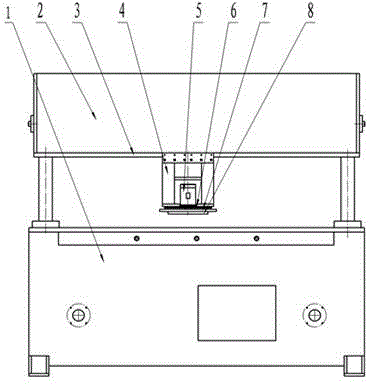

Moving head rotating mechanism of multi-axis linked three-dimensional moving head hydraulic cutting machine

A three-dimensional moving, multi-axis linkage technology, applied in metal processing and other directions, can solve the problems of high labor intensity, the moving head of the four-column cutting machine cannot be rotated, and the speed is slow. Reasonably compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The invention is mainly composed of a lower body, an upper body, a moving guide rail, a moving head frame, a rotating servo motor, a rotating gear, a tool fixing seat and a tool. The upper end of the lower body is the upper body, the moving guide rails are installed on both sides of the lower end of the upper body, the moving head frame is installed on the lower end of the moving guide rails on both sides, the moving head frame is welded by steel plate, and the plane bearing is installed inside, connected by the connecting shaft, The lower end of the connecting shaft fixes the rotating gear, the lower end of the rotating gear is equipped with a tool holder, the side of the moving head frame is equipped with a rotating servo motor, and the lower end of the rotating servo motor is equipped with a motor gear, the motor gear cooperates with the rotating gear, and the motor gear drives the rotating gear to rotate. The tool at the lower end of the tool holder can rotate 360 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com