Adjustable drilling platform device for ring header eccentric hole

A drilling platform and annular header technology, which is applied in the directions of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problem of inconvenient rotation in the drilling process, poor adaptability, and can not meet the requirements of different diameter ring header drilling. Hole requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

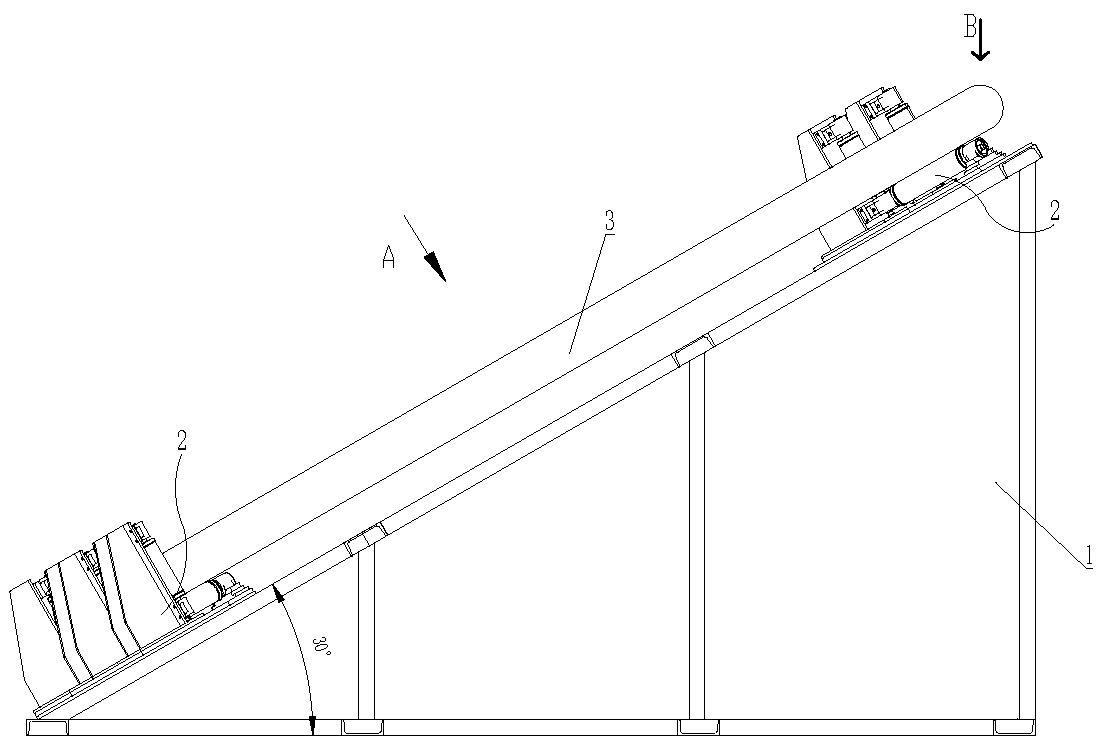

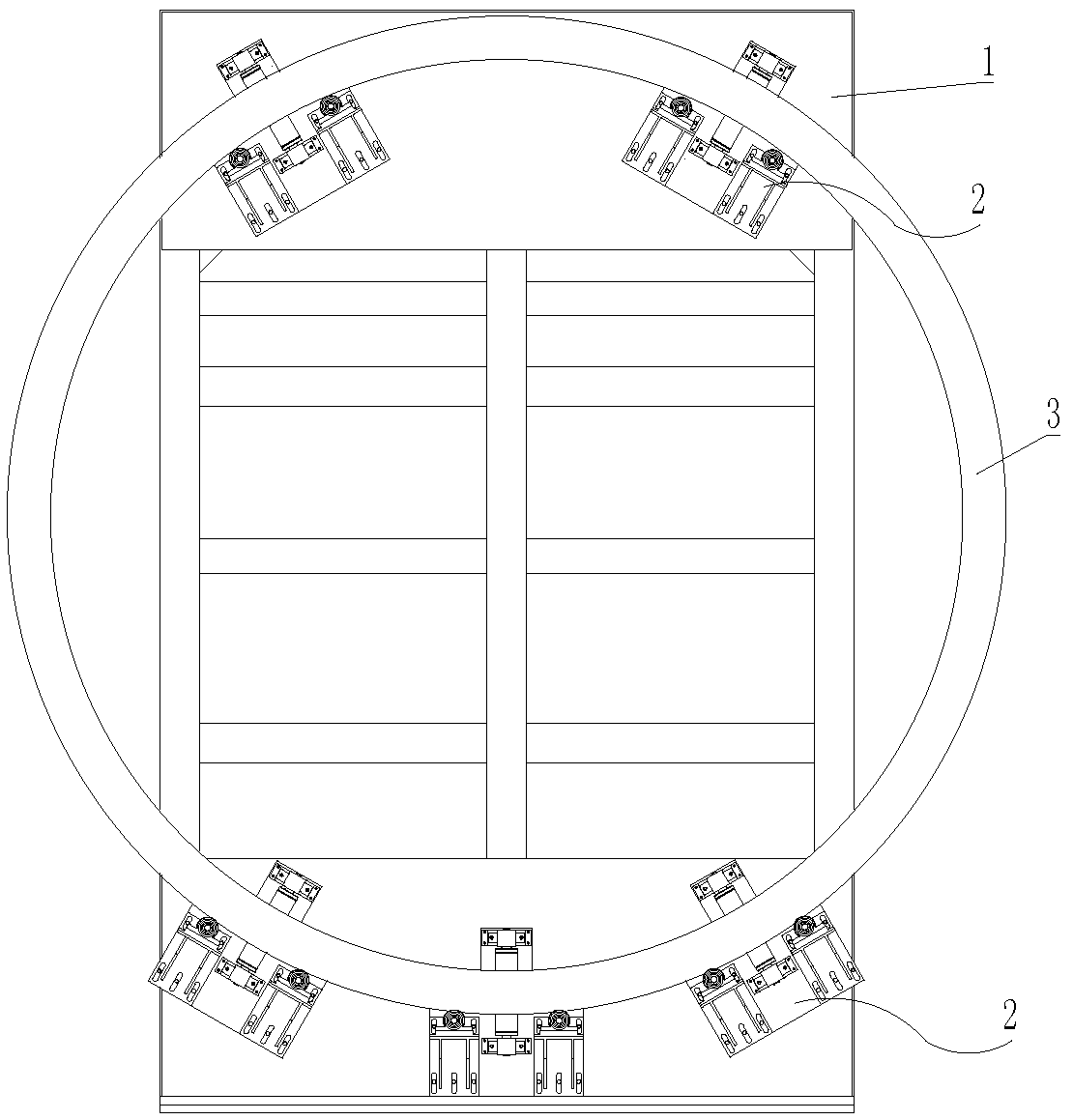

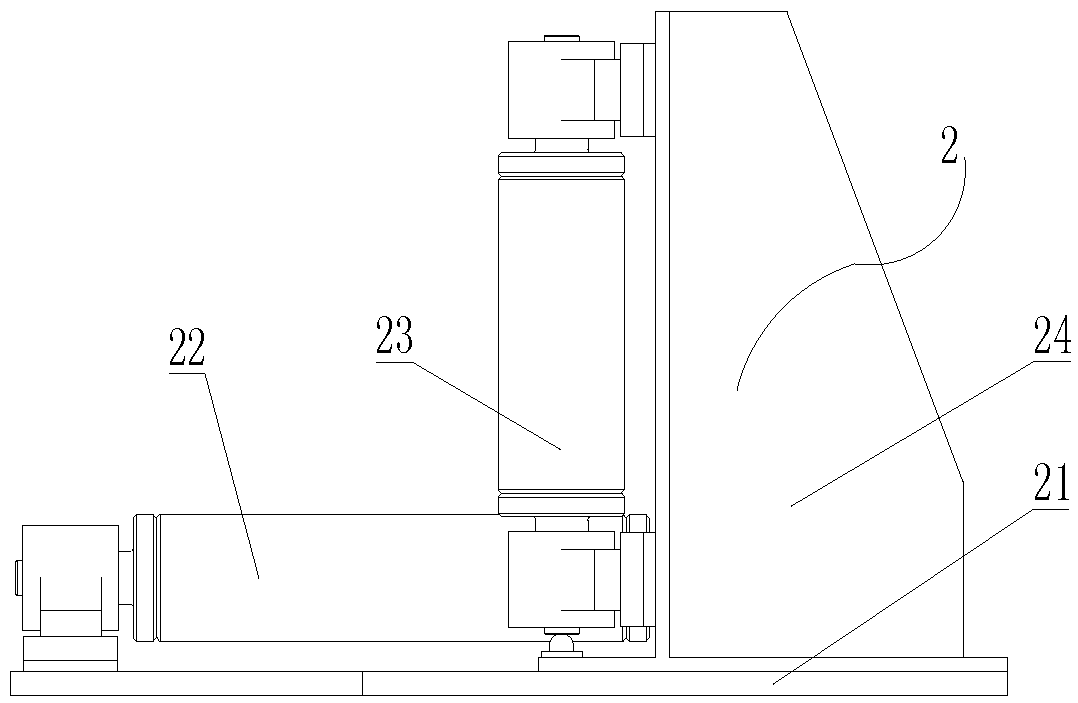

[0021] Such as Figure 1 to Figure 8 As shown, an annular header eccentric hole adjustable drilling platform device includes an angle bracket 1 welded by section steel. The angle bracket 1 includes a horizontal plate and a vertical plate, and one end of the horizontal plate is welded vertically to one end of the vertical plate. , the other end of the horizontal plate and the other end of the vertical plate are welded with inclined plates connected at a certain angle to the horizontal plate and the vertical plate respectively. In this embodiment, the angle between the inclined plate and the horizontal plate is 30 degrees, and the module The bottom end of the bottom plate 21 of the type roller frame 2 is fixedly installed on the top end face of the inclined plate; at least three modular roller frames 2 are installed on the angle bracket 1, and five modular roller frames 2 are installed in this embodiment. The roller frame 2 includes horizontal rollers 22 and two sets of vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com