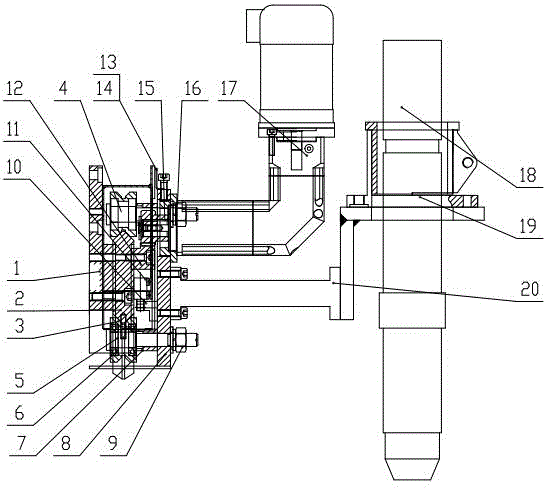

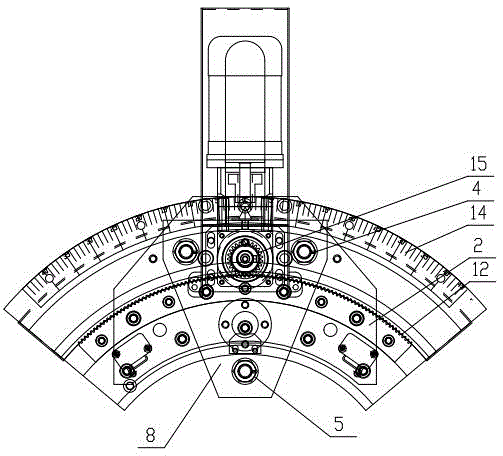

Plasma Cutting Linear Bevel Swing Device

A swing device and plasma technology, applied in the direction of plasma welding equipment, auxiliary equipment, welding/cutting auxiliary equipment, etc., can solve the problems of troublesome adjustment, changing the position of the cutting torch, and cutting can not be adjusted at will, so as to achieve low equipment manufacturing cost , High work efficiency, good cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with specific accompanying drawing and embodiment the present invention will be further described:

[0016] Such as figure 1 and figure 2 As shown, the arc-shaped guide rail 2 is installed on the bottom plate 1 of the plasma cutting linear groove swing device of the present invention, and the arc-shaped rack 12 is installed on the arc-shaped guide rail 2. The arc-shaped guide rail 2 and the arc-shaped rack 12 have the same center, and the arc The upper and lower guide rail surfaces of the guide rail 2 are V-shaped at 90°. There are three installation holes on the rotating plate 8, two fixed shafts 4 on the top, and an eccentric shaft 5 installed at the center of symmetry below, arranged in an inverted "pin" shape, and the three V-shaped cross-section rollers 3 are installed on the fixed shaft through bearings 6. On the shaft 4 and the eccentric shaft 5, the distance between the rotating plate 8 and the arc guide rail 2 is trimmed through the bush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com