Transit mixer for free-flowing media

A technology of flowing medium and mixing machine, which is applied in the direction of concrete transportation, cement mixing device, clay preparation device, etc., can solve the problems of complicated installation of supporting roller units, and achieve the effect of saving materials and increasing precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

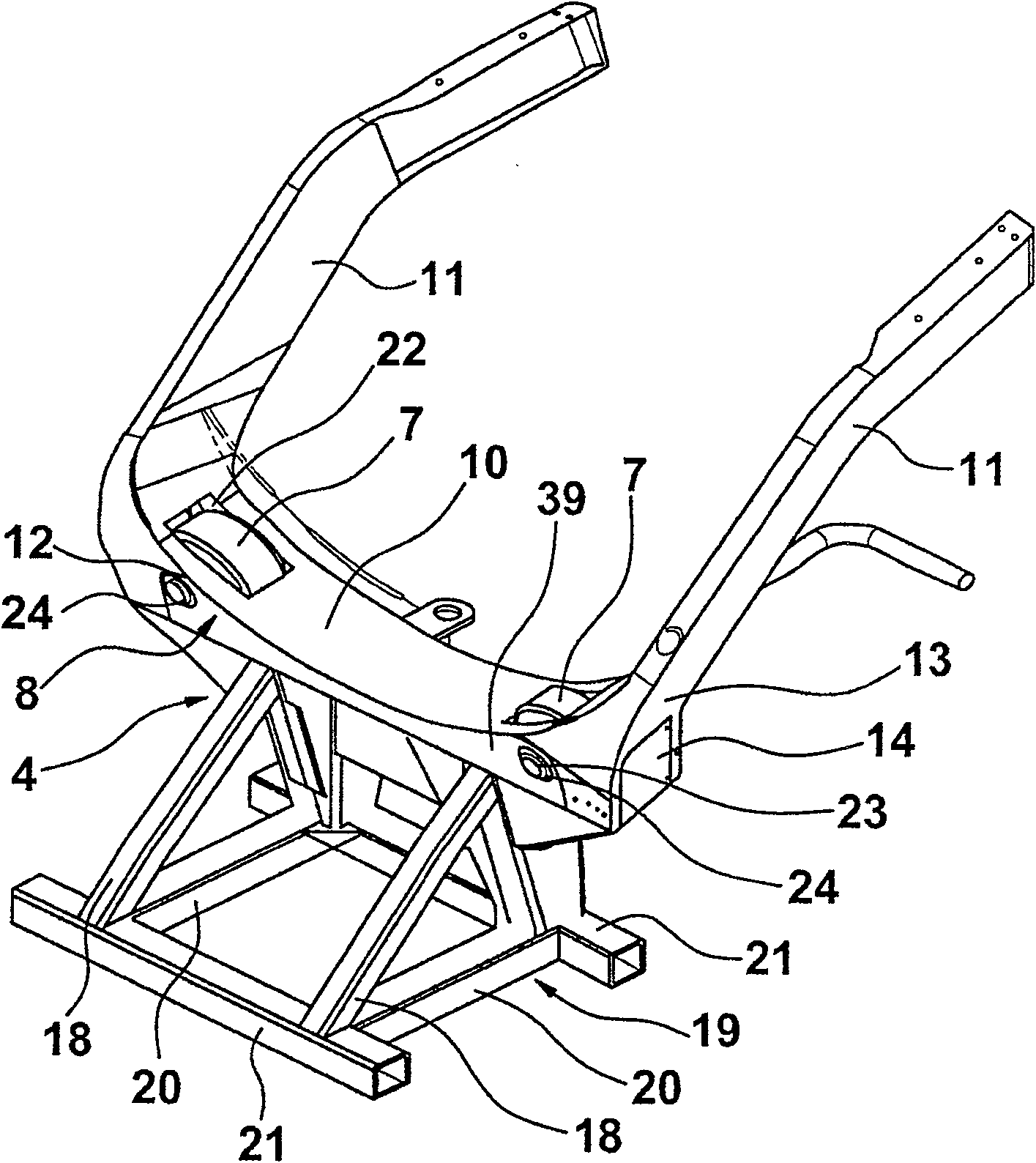

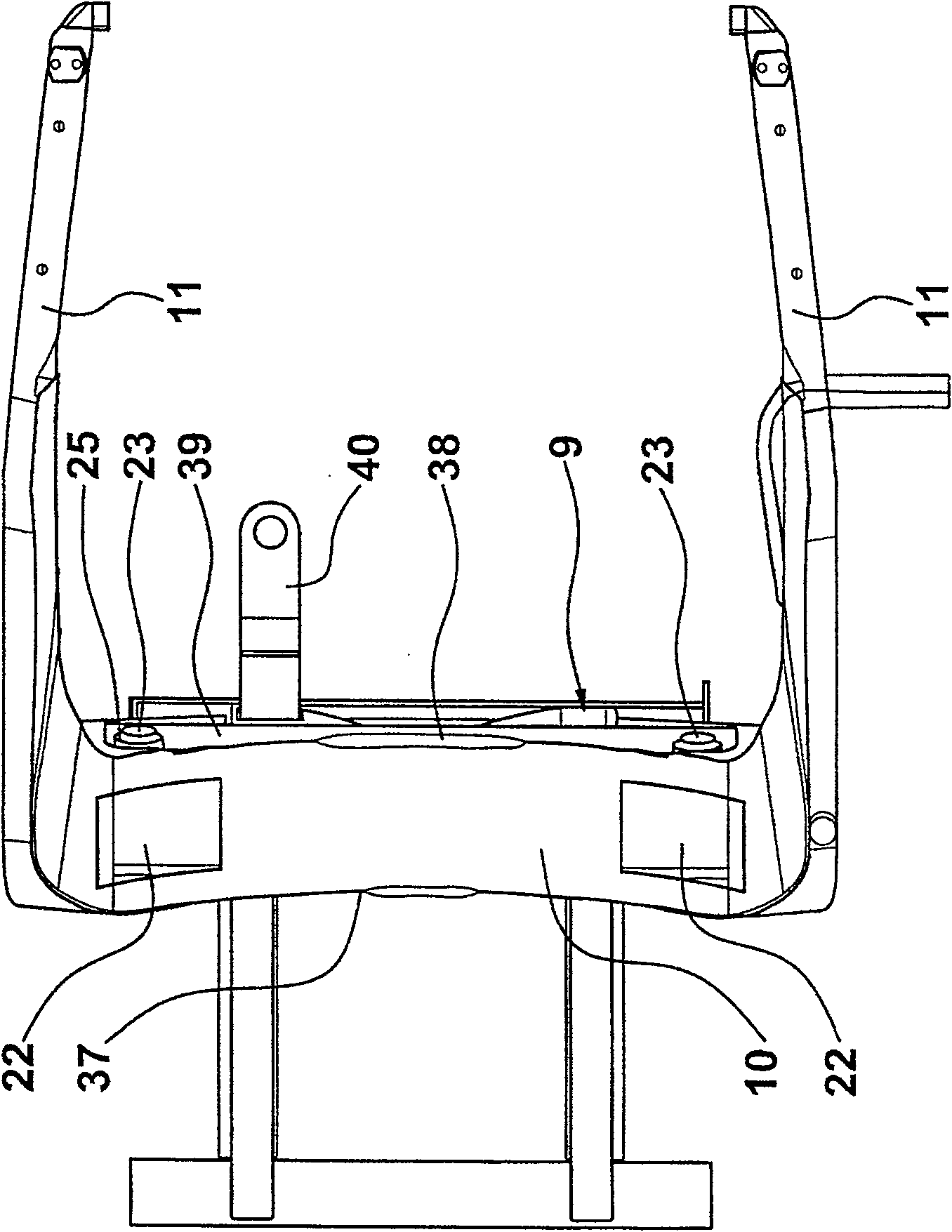

[0035] figure 1 A concrete mixer truck 1 in the form of a truck is shown having a frame 2 generally consisting of two parallel beams supporting front and rear bases 3 and 4 on which are housed and mounted a Similar viscous substances marked 5 agitator drum. A drive for the stirring drum 5 is installed in the area of the front base 3 , but this is only shown schematically here. The mixing drum 5 is rotatably mounted on the base via a running support surface 6 formed on the rear of the drum. For this purpose, if figure 2 As shown, the base 4 has two rollers 7 which are rotatably mounted in the base 4 .

[0036] exist figure 2 and image 3 In the embodiment, the upper part of the base 4 is constituted by a box-shaped housing, which basically consists of a front base wall 8 and a image 3 The front base wall 8 and the rear base wall 9 are connected by a top wall 10 . The top wall has an arch adjusted to the diameter of the running support surface 6 of the mixing drum 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com