A multi-angle angle gauge block

A multi-angle, gauge block technology, applied in non-variable pumps, pump control, pump components, etc., can solve problems such as poor angle consistency of stator blades, large number of components, and influence on fan performance, and achieve good angle consistency , Accurate angle positioning, guaranteed performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

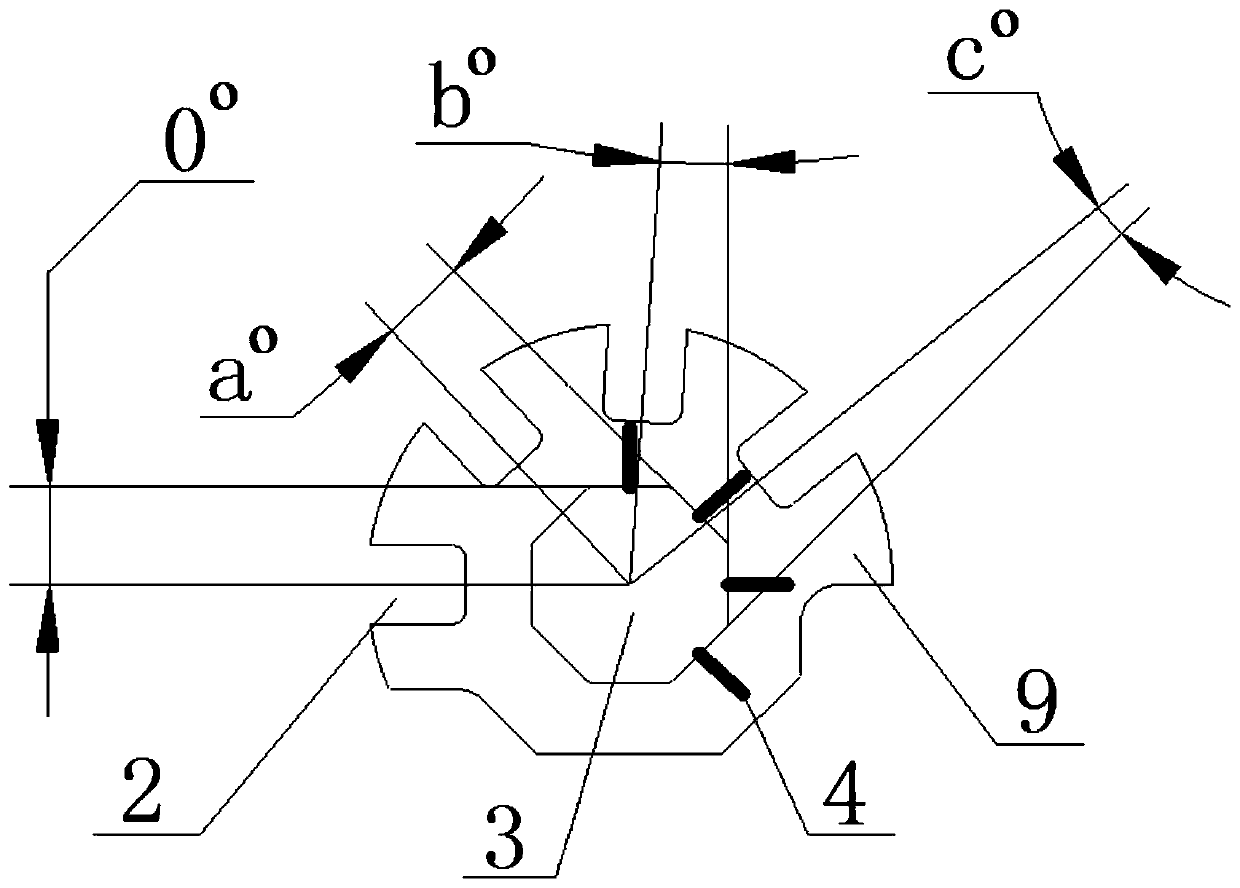

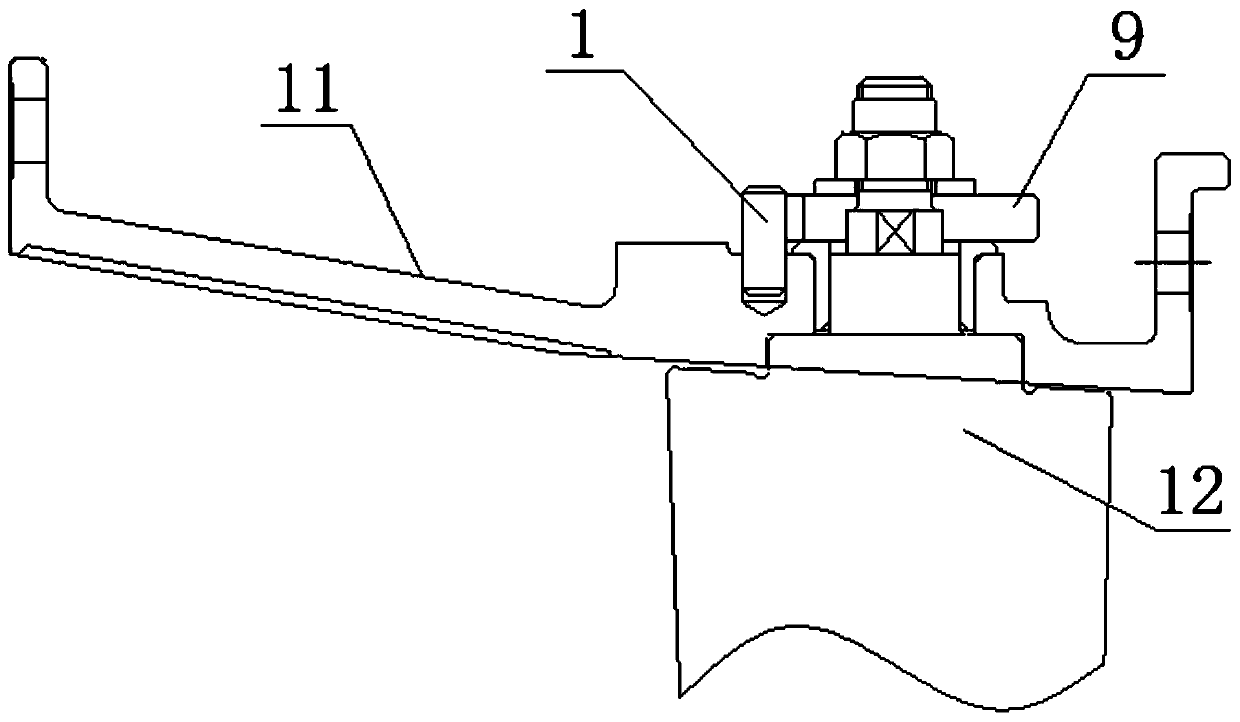

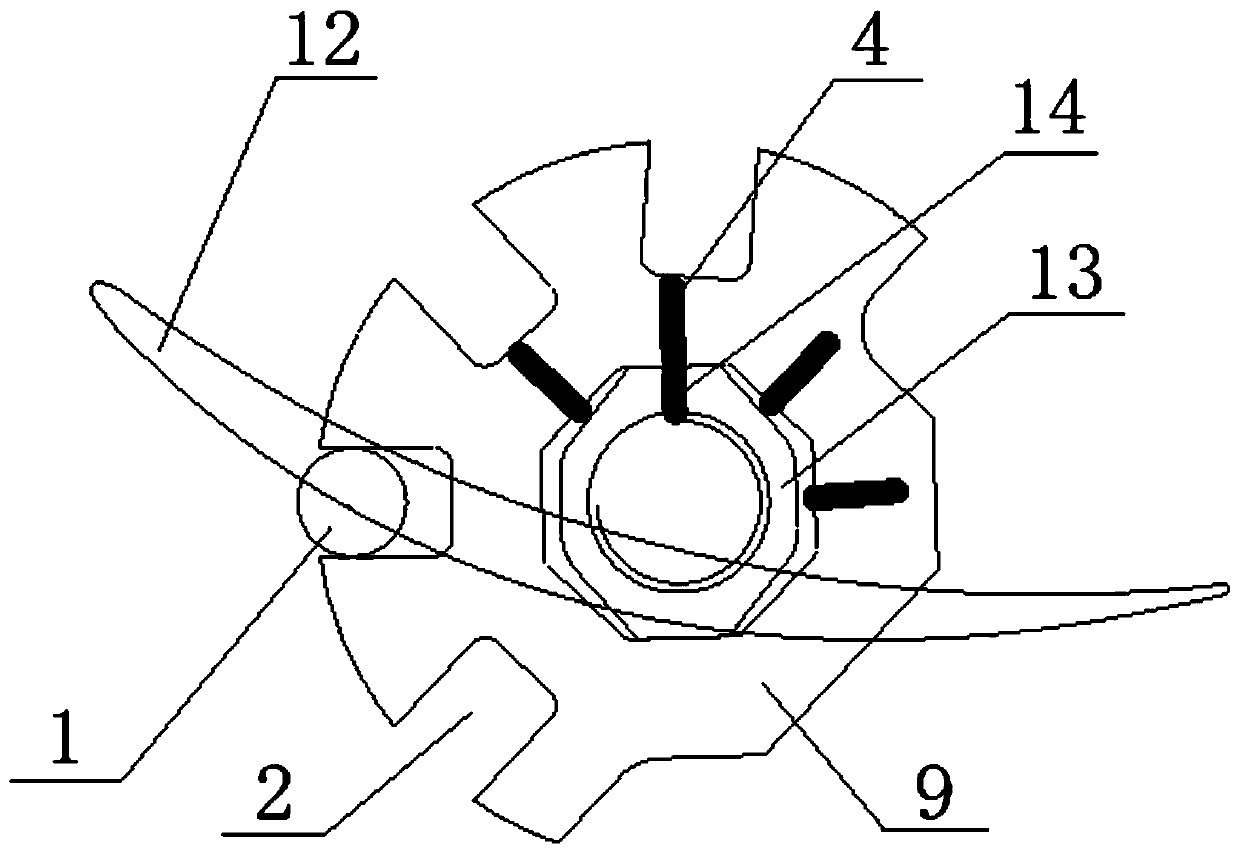

[0023] like image 3 As shown, when it is necessary to adjust the stator blade 12 from a certain angle to an angle a, the angle gauge block 9 is first picked up from the casing 11 and separated from the positioning pin 1 and the journal 13, the angle gauge block 9 is rotated and The octagonal through hole 3 is re-set on the journal 13, and at the same time, the journal mark 14 is aligned with the error-proof mark 4 of the angle a. At this time, the square groove 2 corresponding to the angle a cannot fall on the positioning pin 1. Rotate the angle gauge block 9 so that the square groove 2 can fall to the positioning pin 1. At this time, the journal 13 rotates synchronously under the action of the octagonal through hole 3, so the stator blades 12 also rotate synchronously, and the second rotation angle gauge block The angle of 9 is the adjustment angle, that is, the angle a; it should be noted that the adjustment angle is not the rotation angle, the adjustment angle is the final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com