Base producing model for large mold

A modular and large-scale technology, which is applied in the field of making molds on the base of large modules, can solve the problems of poor component interchangeability, large randomness, and impossible maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in detail below: In the long-term engineering production process, the inventor found that the production of large modules is laborious and laborious, and is not conducive to replacement and maintenance. After long-term research and experiments, he invented a special module for large The manufacturing form of the base of the module and the processing and manufacturing method of the base.

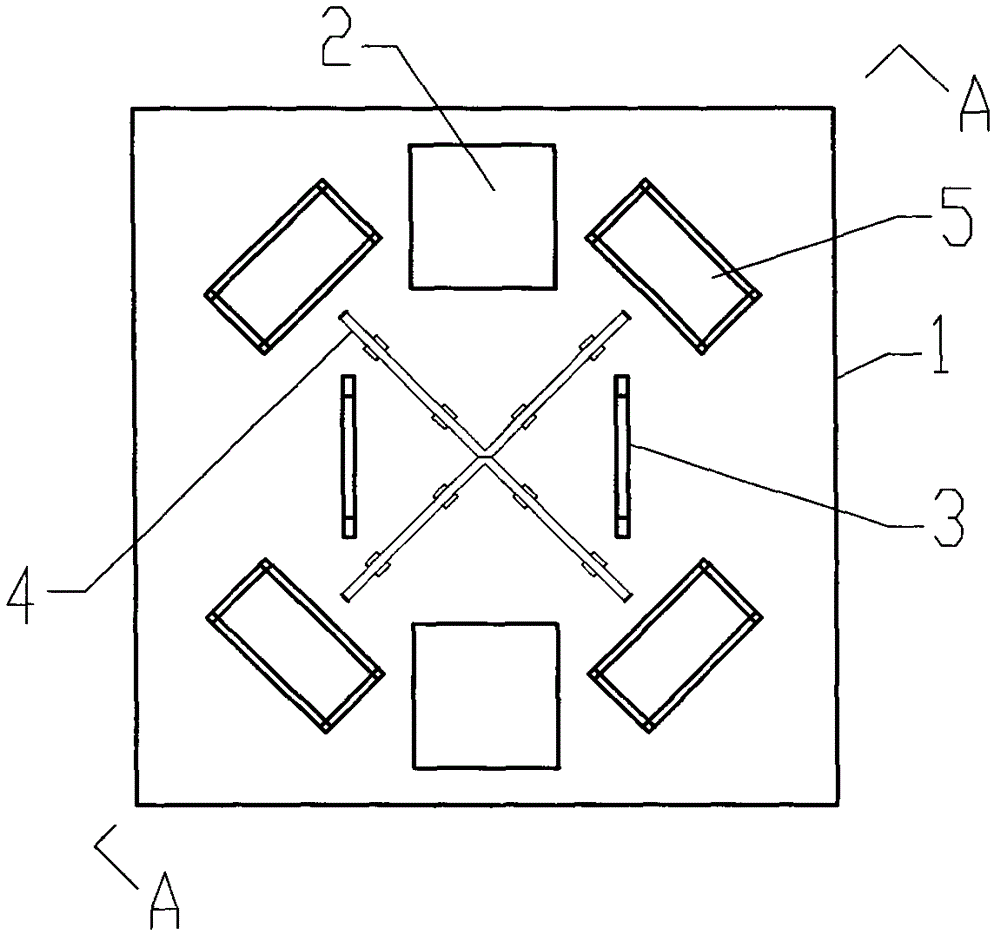

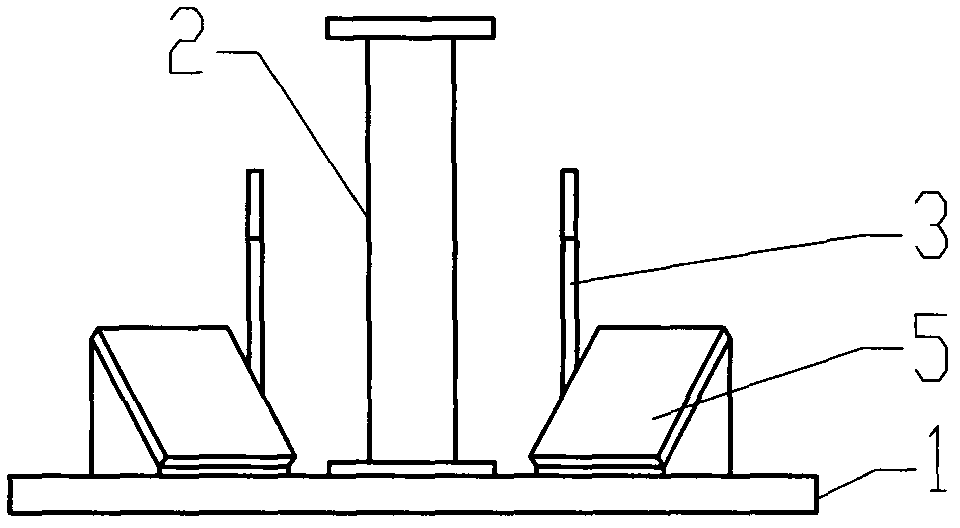

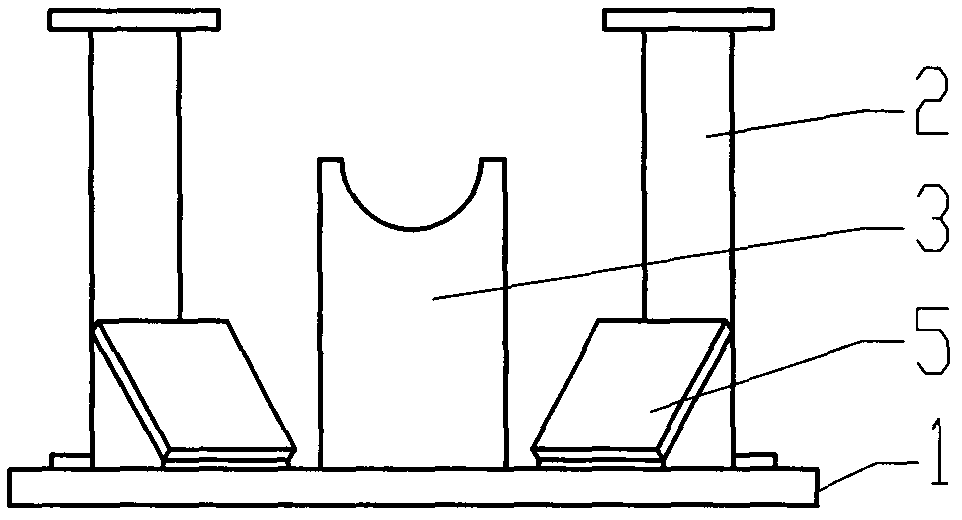

[0026] Such as figure 1 The base of a large module is made of a mold, including an upper tire frame and a lower tire frame, wherein the upper tire frame is composed of a grooved connecting plate 6 and a disc 7, and the disc is welded at the center of the bottom surface of the grooved connecting plate. Such as Figure 5 with Image 6 As shown; the upper tire frame is connected by the connecting plate and the bracket of the lower tire frame; figure 1 , figure 2 with image 3 As shown, wherein the lower tire frame is made up of base plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com