Microminiature heavy-current electromagnetic relay

An electromagnetic relay, high current technology, applied in electromagnetic relays, electromagnetic relay details, relays and other directions, can solve the problems of increasing the size of the relay, affecting the operating performance, reducing the magnetic efficiency, etc., to achieve compact structure, good angle consistency, The effect of reducing the size of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

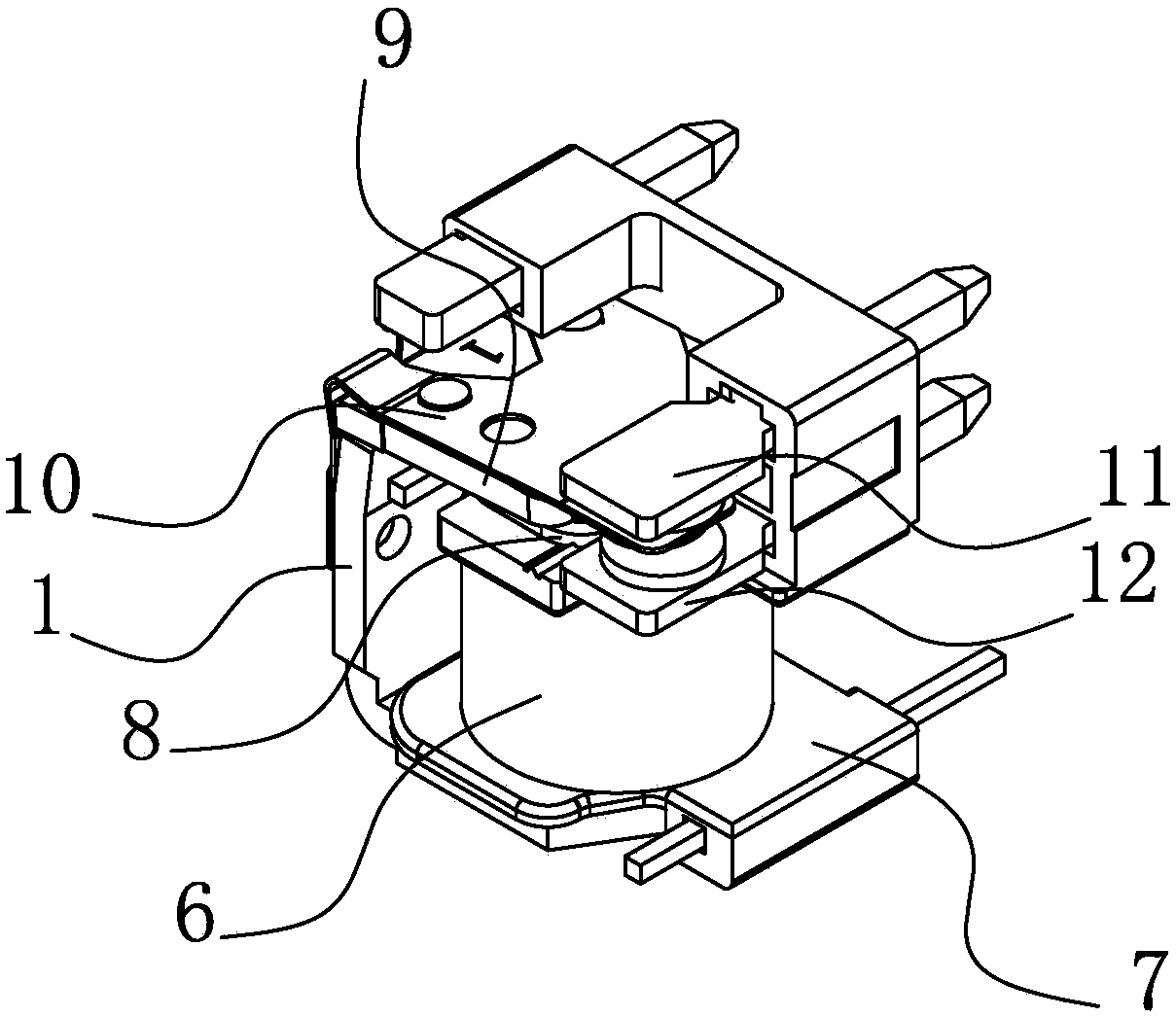

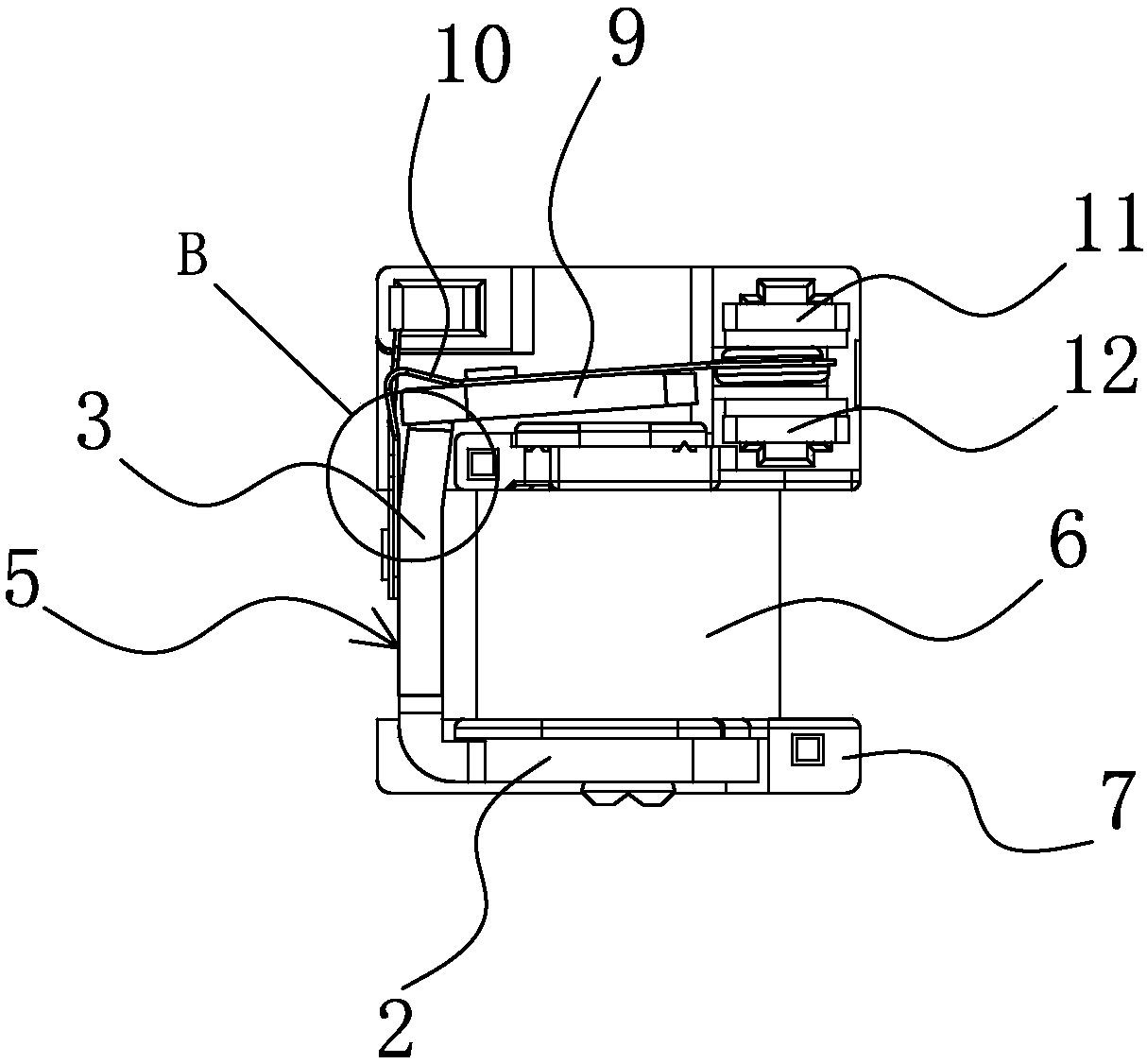

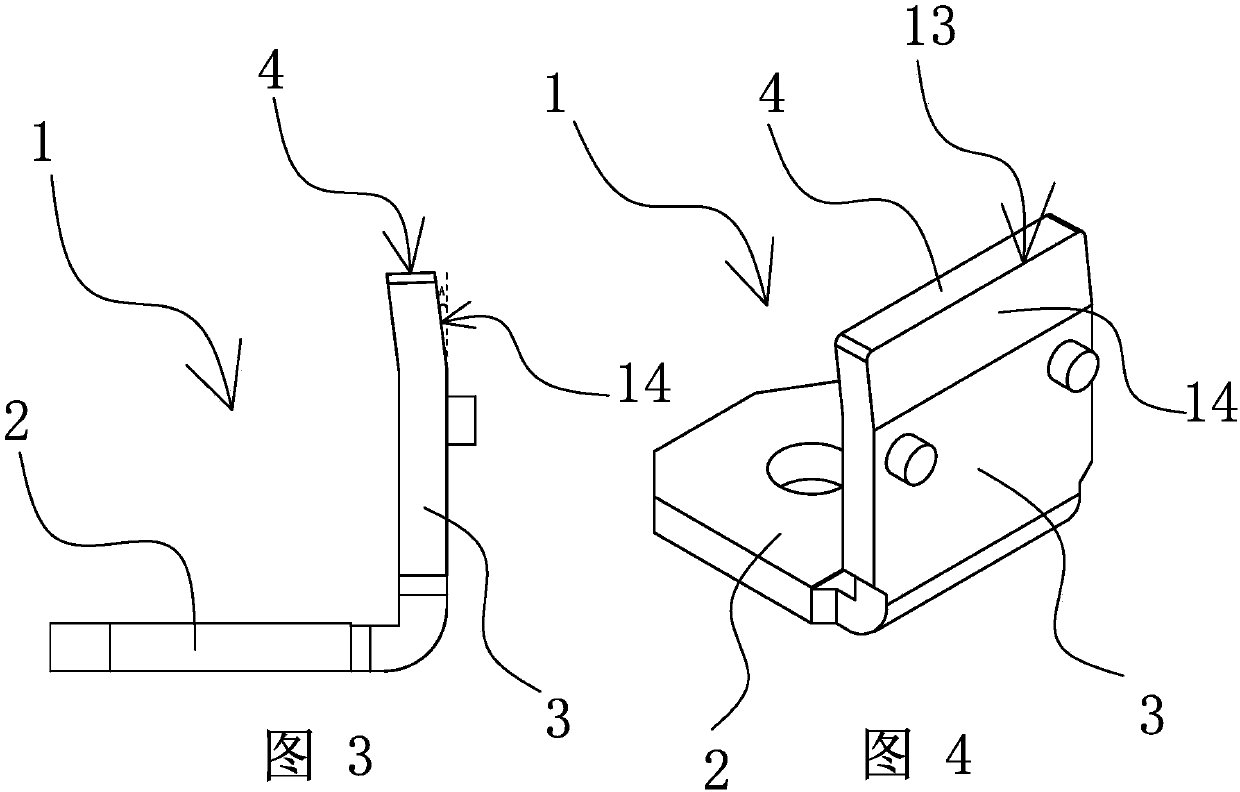

[0019] Such as figure 1 , 2 , 3 and 4, the ultra-small high-current electromagnetic relay includes a housing, a yoke 1, a coil 6, a bobbin 7, an iron core 8, an armature 9, a moving reed assembly 10, and a static reed assembly. The relay of this embodiment is a conversion type (Z type) relay, and its static reed assembly is two, one is a normally closed static reed assembly 11, and the other is a normally open static reed assembly 12, and the movable contact is located at the normal Between the normally closed static contact of the closed static reed assembly 11 and the normally open static contact of the normally open static reed assembly 12. The normally closed static reed assembly 11 and the normally open static reed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com