Fuqu machine mold

A fire bending machine and mold technology, which is used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of numerical control method to control the bending angle, the angle is not well controlled, and the plate error exceeds the standard, so as to improve the pressing effect and balance. Good performance, not easy to be deformed by compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is described in further detail:

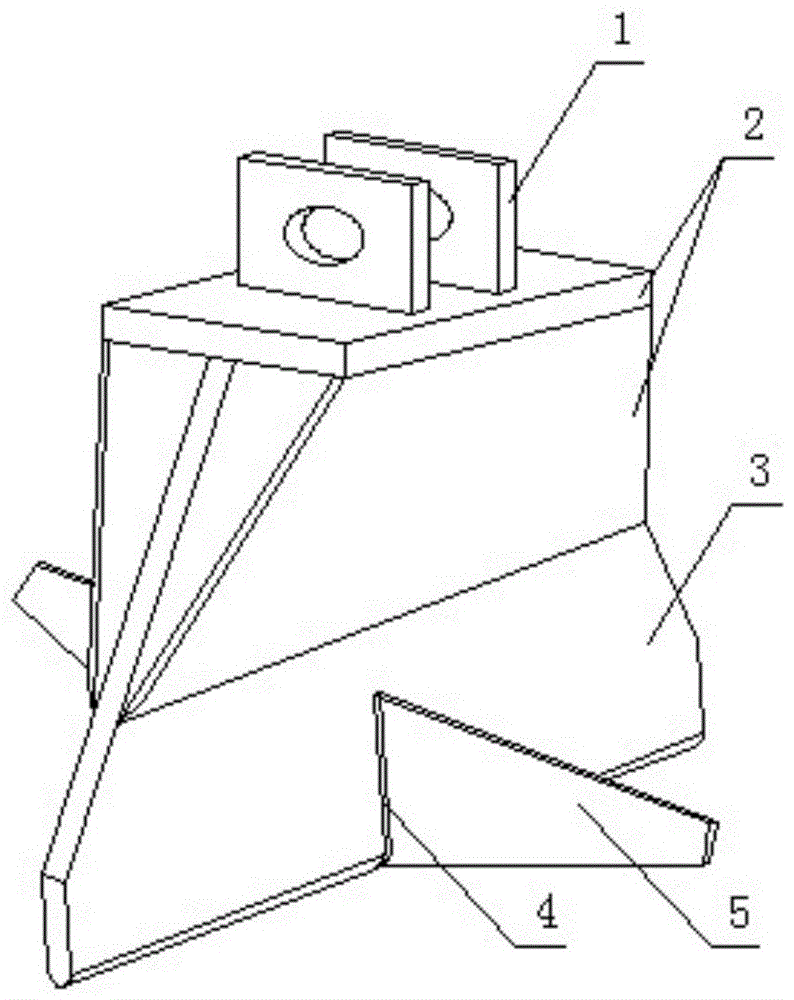

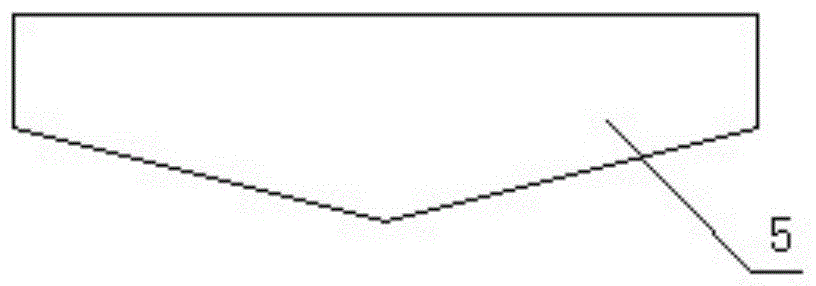

[0016] Many connecting plates are usually used in the construction of iron towers. These connecting plates generally have a certain angle. To ensure their strength, they are all made by the method of fire. There are two types of Huoqu, one is artificial Huoqu, which is not only slow, but also the quality of the finished product is extremely poor, which is far from meeting the production requirements and is only suitable for temporary use. The other is processed by Huoqu machinery. There are many types of Huoqu machinery, but Most of the working principles are the same. They are all equipped with heating equipment and pressure bending equipment. The bending equipment is generally driven by a hydraulic drive mechanism to bend the bending mold. The bending mold includes an upper mold and a lower mold. The elongated groove is set, the elongated pressing plate of the upper mold corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com