Micro piezoelectric sprayer based on iris turbofan and nozzle aperture regulation and control method

A turbofan and iris technology, which is applied in the field of micro-piezoelectric nozzles and nozzle aperture control based on iris turbofans, can solve the problems of extremely high technical requirements for small-sized nozzles, inability to complete sub-micron pixels, and reduced production efficiency. Adjust the nozzle size flexibly, avoid cumbersome operation and error problems, and solve the effect of nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

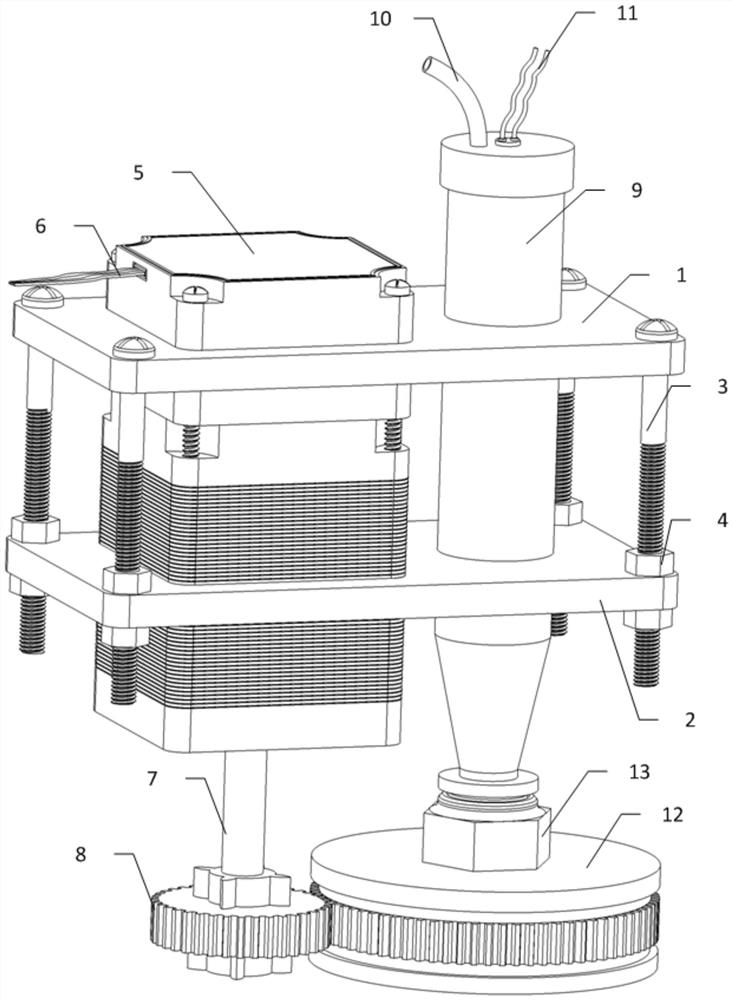

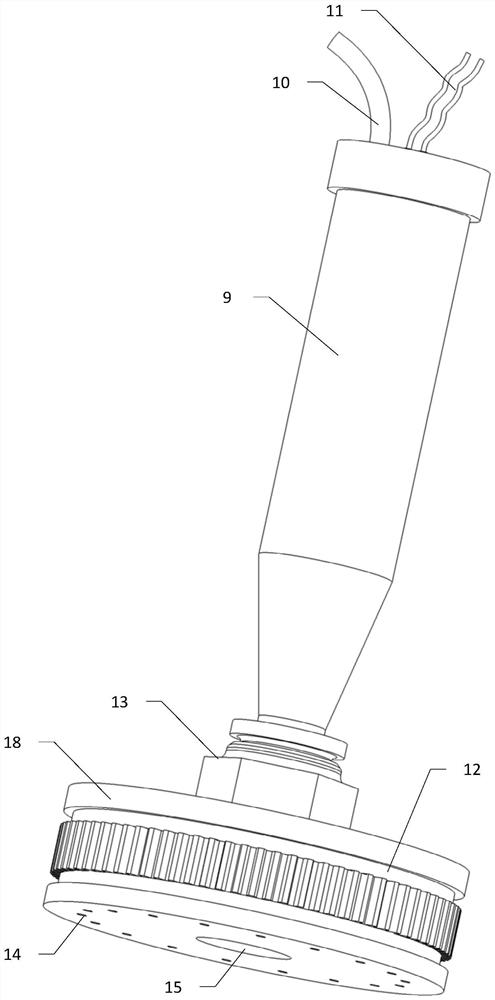

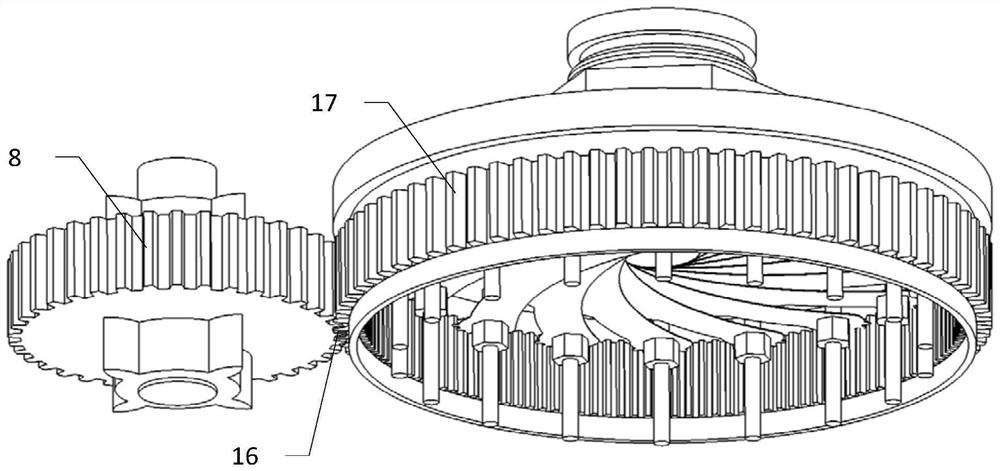

[0042] Such as Figure 1-7 As shown, the micro piezoelectric nozzle based on the iris turbofan in this embodiment includes a fixed frame, a micro motor 5 , a piezoelectric nozzle 9 , and an iris turbofan 12 .

[0043] The fixing frame is composed of a first fixing plate 1, a second fixing plate 2, bolts 3 and nuts 4. The first fixed plate 1 and the second fixed plate 2 are respectively square plates, the first fixed plate 1 and the second fixed plate 2 are arranged in parallel with each other, and are respectively provided with bolts 3, micro motors 5 and piezoelectric nozzles 9 Matching chimeric sites. The upper and lower parts of the micro-motor 5 and the piezoelectric nozzle 9 are respectively embedded in the first fixed plate 1 and the second fixed plate 2 . The bolts 3 and the nuts 4 are detachably connected with the first fixing plate 1 and the second fixing plate 2 through thread fit.

[0044] The micro-motor 5 is connected with a control line 6, and the micro-motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com