Method for automatically controlling and rapidly, accurately and precisely locating fan-shaped distribution of bell-less blast furnace

A clockless, precise positioning technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of unfavorable blast furnace normal production, easy to set wrong values, non-execution of fan-shaped material distribution, etc., to shorten the waiting time for material distribution, accurate positioning, Effect of shortening idling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

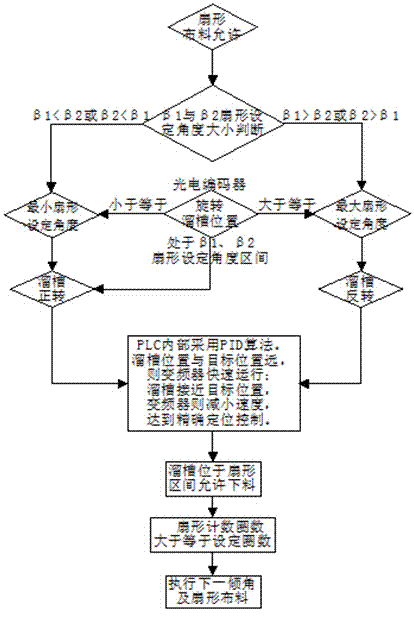

[0018] see figure 1 , a method for automatic control of fast and precise positioning of blast furnace fan-shaped cloth without material bell, the specific steps are as follows:

[0019] (1) Set the material distribution mode of the chute to allow fan-shaped material, set four material inclination angles, and set the first fan-shaped setting angle β1 and the second fan-shaped setting angle β2; the first fan-shaped setting angle β1 and the second fan-shaped setting angle As long as the fixed angle β2 is in the range of 0-360° during setting, its value can be set arbitrarily, so as to avoid the wrong value set at the weighing and feeding station, so that the fan-shaped fabric does not execute;

[0020] (2) Determine the size of the first sector setting angle β1 and the second sector setting angle β2, if the first sector setting angle β1 is greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com