Round bale baler motor shaft welding tool

A technology of motorized shafts and round bales, which is applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems that the quality of the moving shaft cannot be guaranteed, the welding accuracy of the moving shaft is low, and the labor intensity is high, so as to improve the Quality and interchangeability, simple structure, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the drawings.

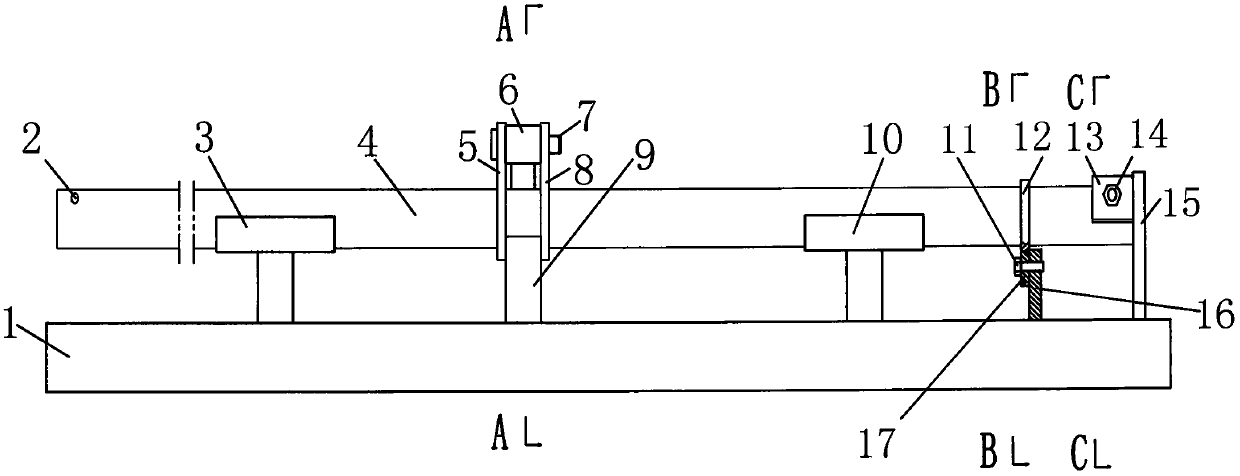

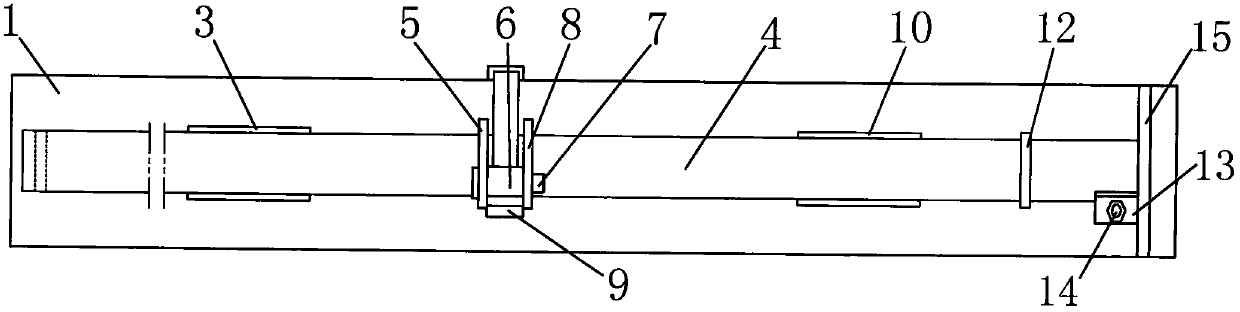

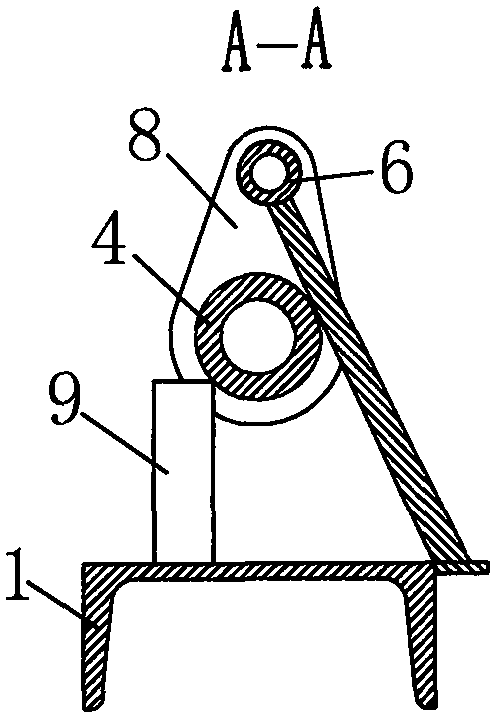

[0017] Such as Figure 1-Figure 7 As shown, the motorized shaft welding tool for round bale pressing includes a bottom plate 1, on which a first bracket 3, a second bracket 10, a flange positioning plate 16, and a moving shaft tube end positioning plate 15 are fixed. ; The flange positioning plate 16 is provided with a flange lower hole positioning block 17; the moving shaft tube end positioning plate 15 is fixed with a moving shaft tube deflection fixing hole positioning plate 13, and the moving shaft tube deflection fixing hole positioning plate A positioning pin 14 is provided for the pivoting fixed hole of the moving shaft tube; the middle position of the bottom plate 1 is fixed with the oil top nostril positioning sleeve 6, the oil top nose front width positioning plate 9, the oil top nostril positioning sleeve 6, the oil top nose front width positioning The board 9 is up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com