Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

246results about "Using shock-absorbing media" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

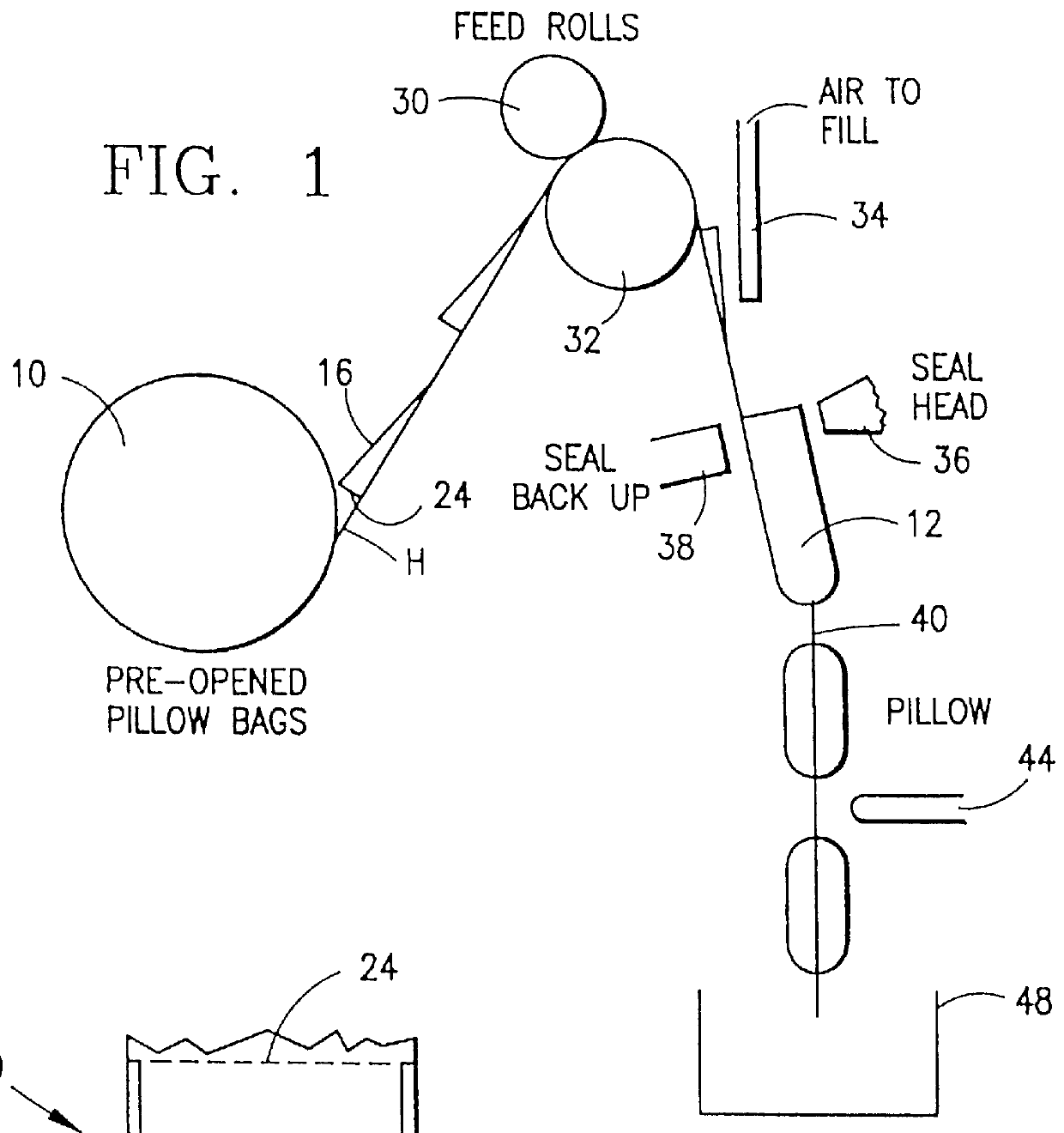

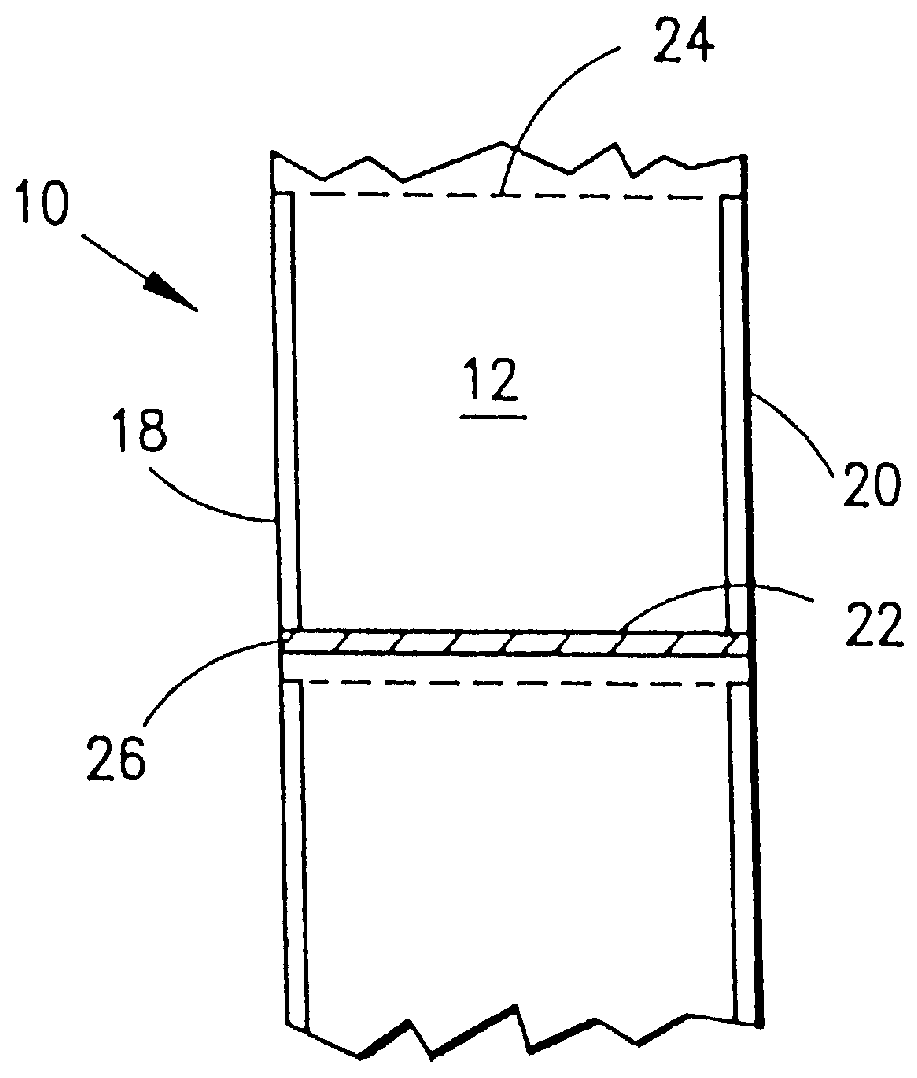

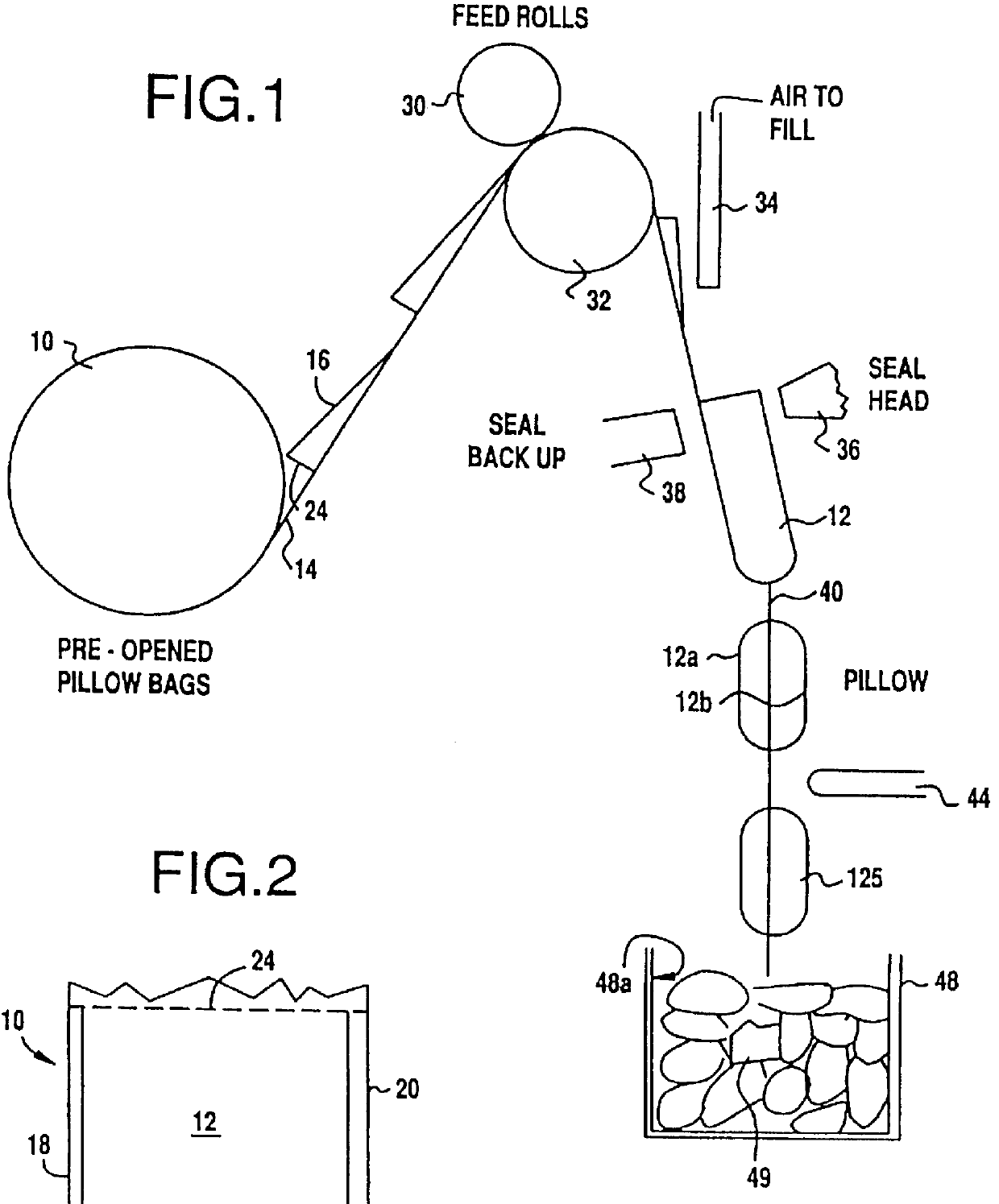

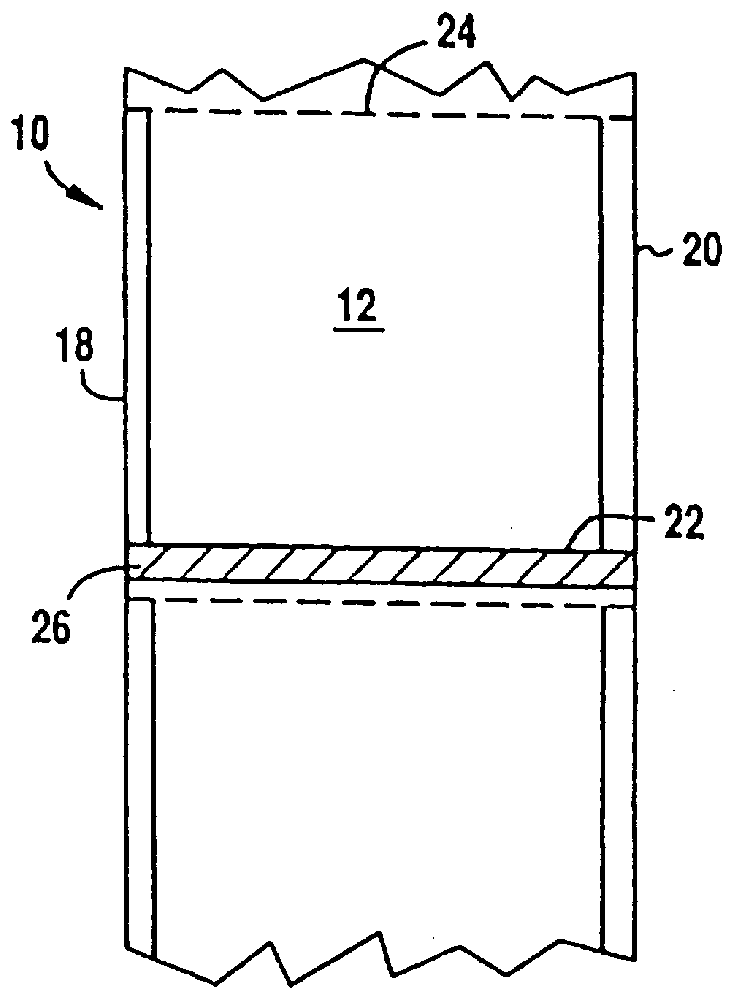

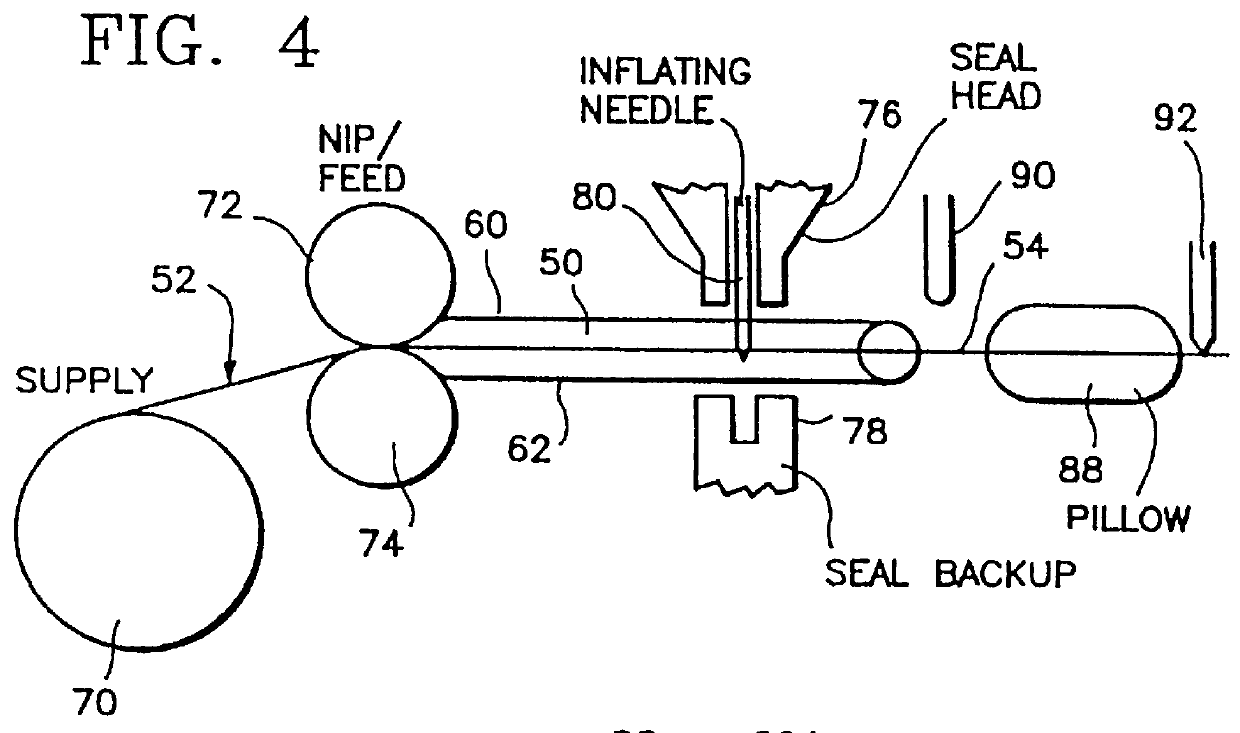

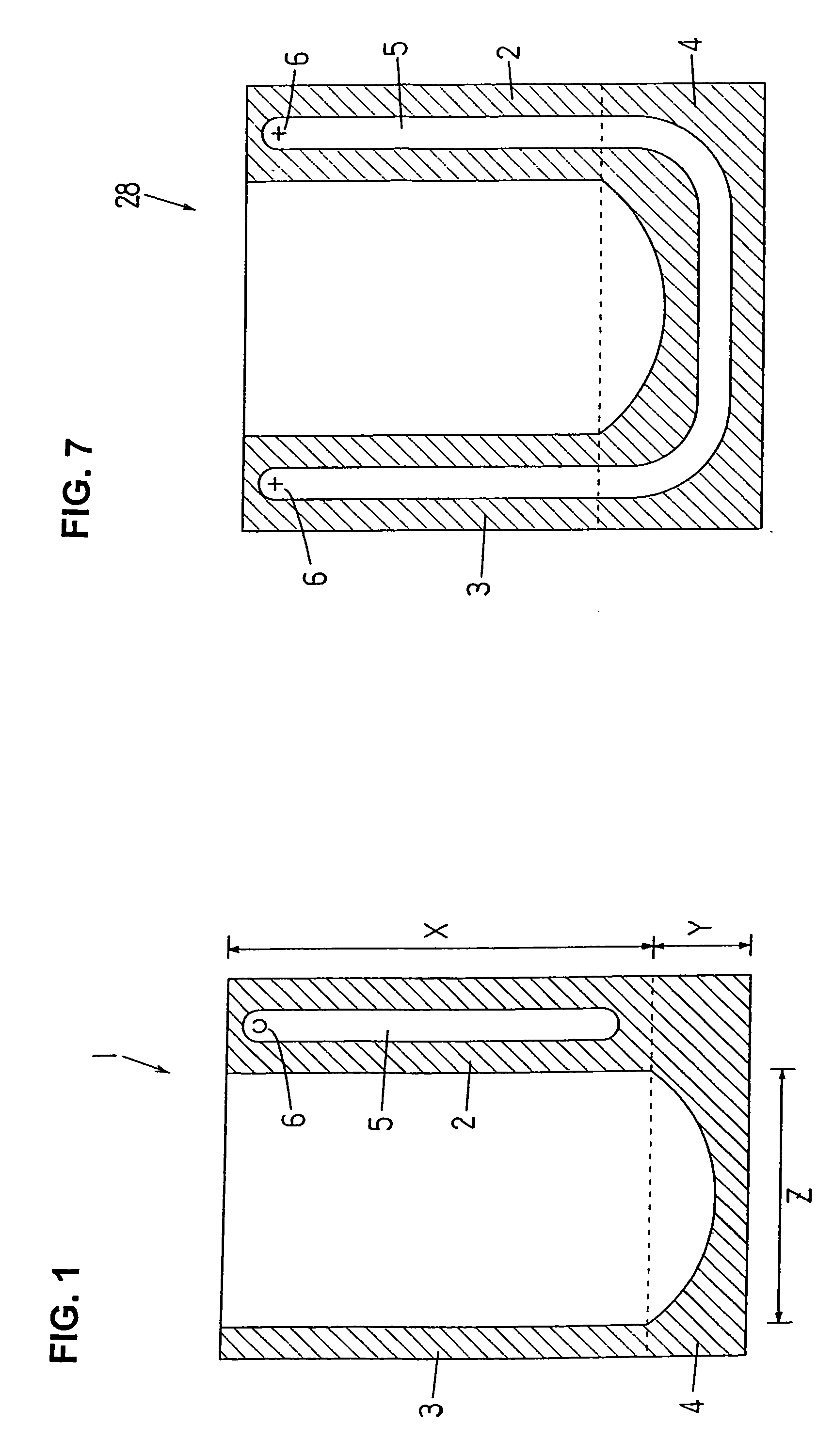

Method for producing inflated dunnage

InactiveUSRE36501E1Easy disposalEasy to reusePreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

A method for producing inflated dunnage on the site of use, comprising providing, in rolled form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the fourth edge of each inflated bag is sealed, the bag being empty except for the air. At least one sealed inflated bag is separated from the roll and placed in a carton to serve as dunnage. In an alternate embodiment, the stock material is provided in a continuous tubular form, and an air inflation needle is used to puncture a surface of the tube for inflation purposes.

Owner:AUTOMATED PACKAGING SYST

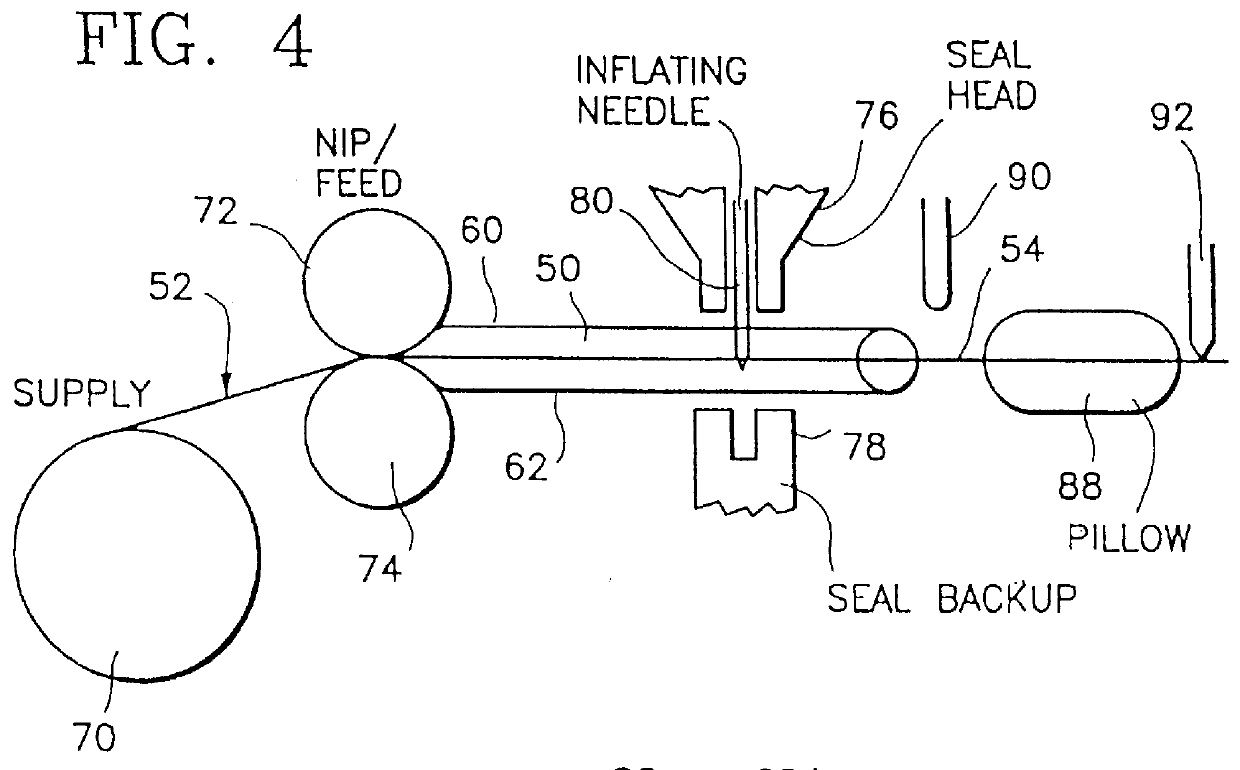

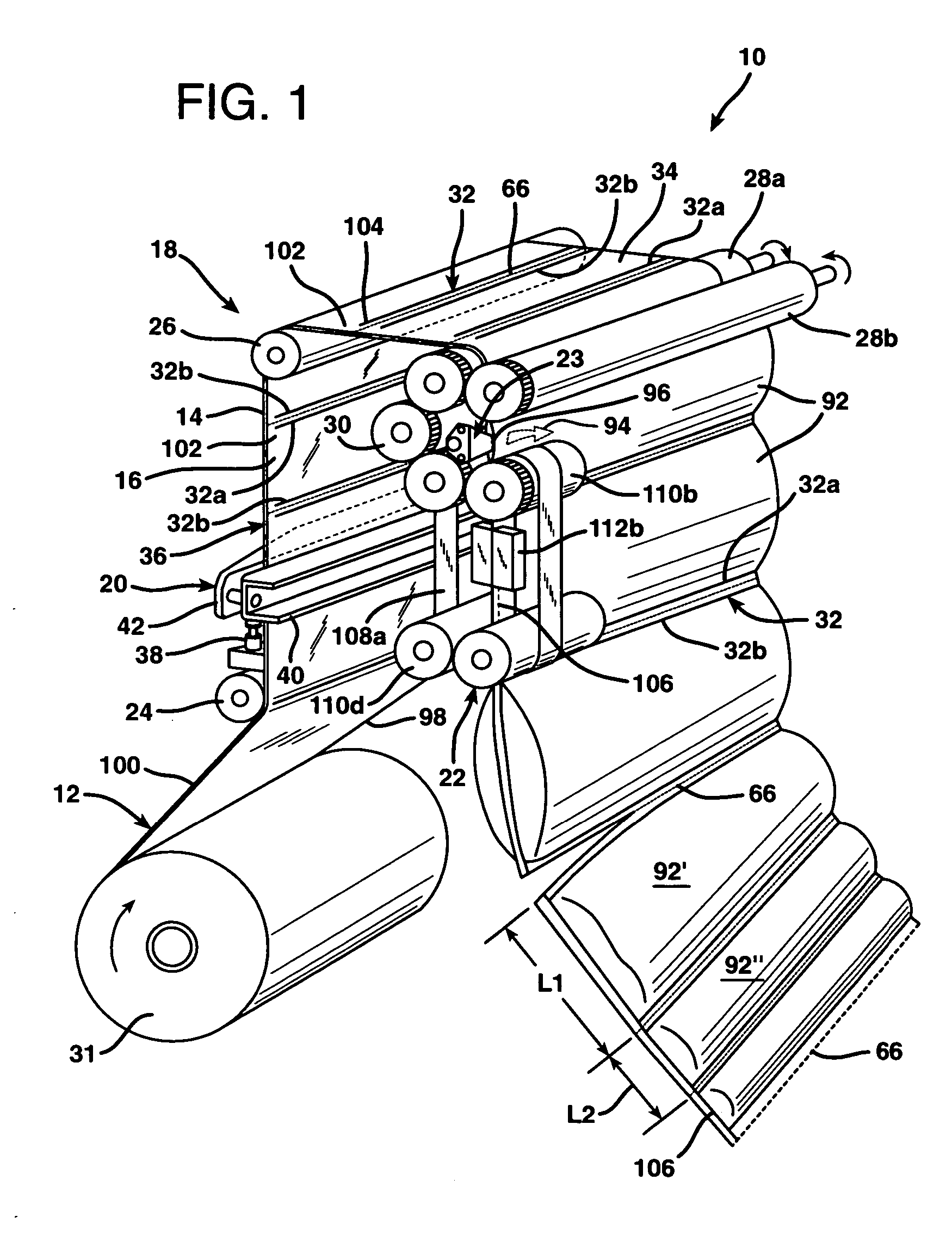

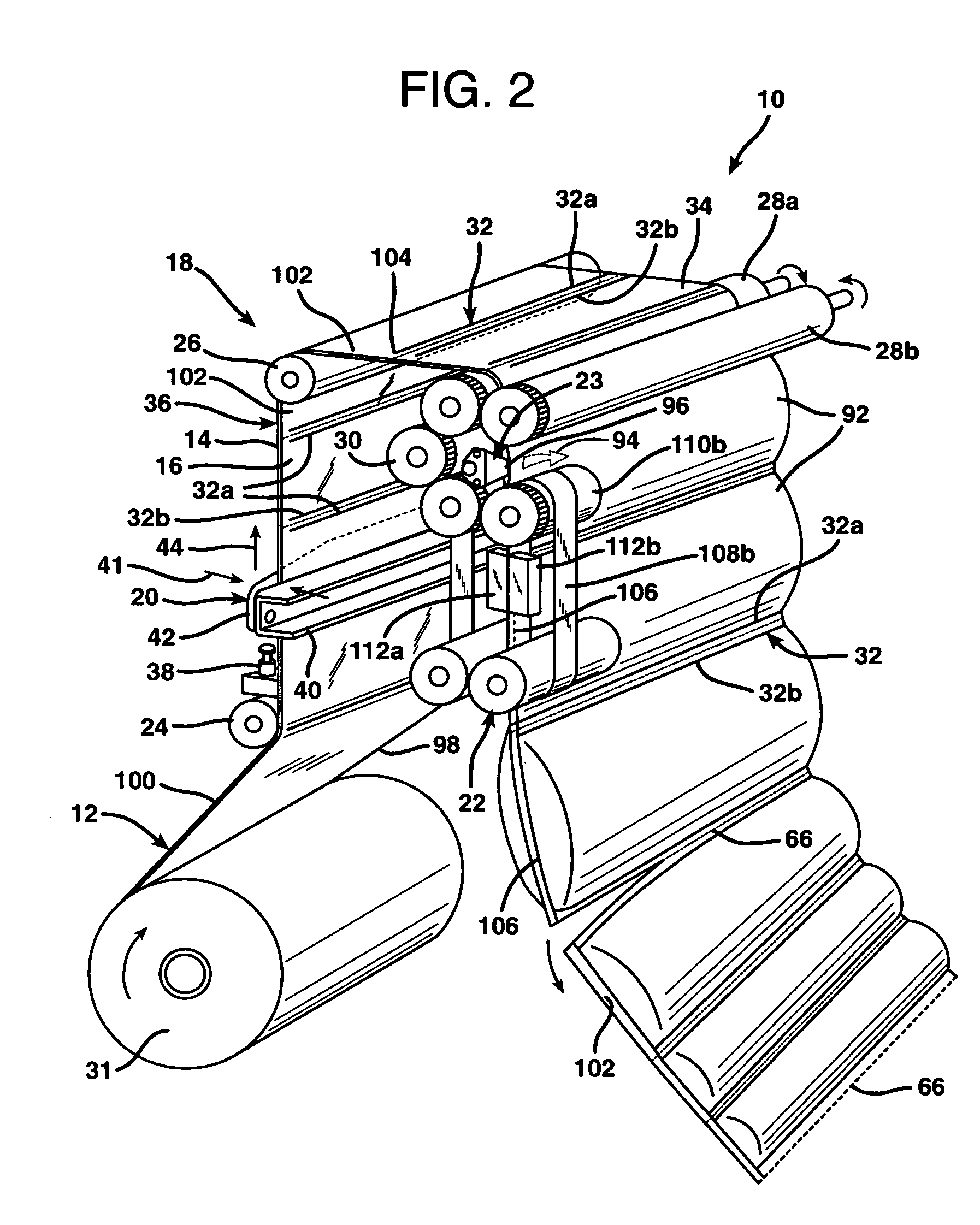

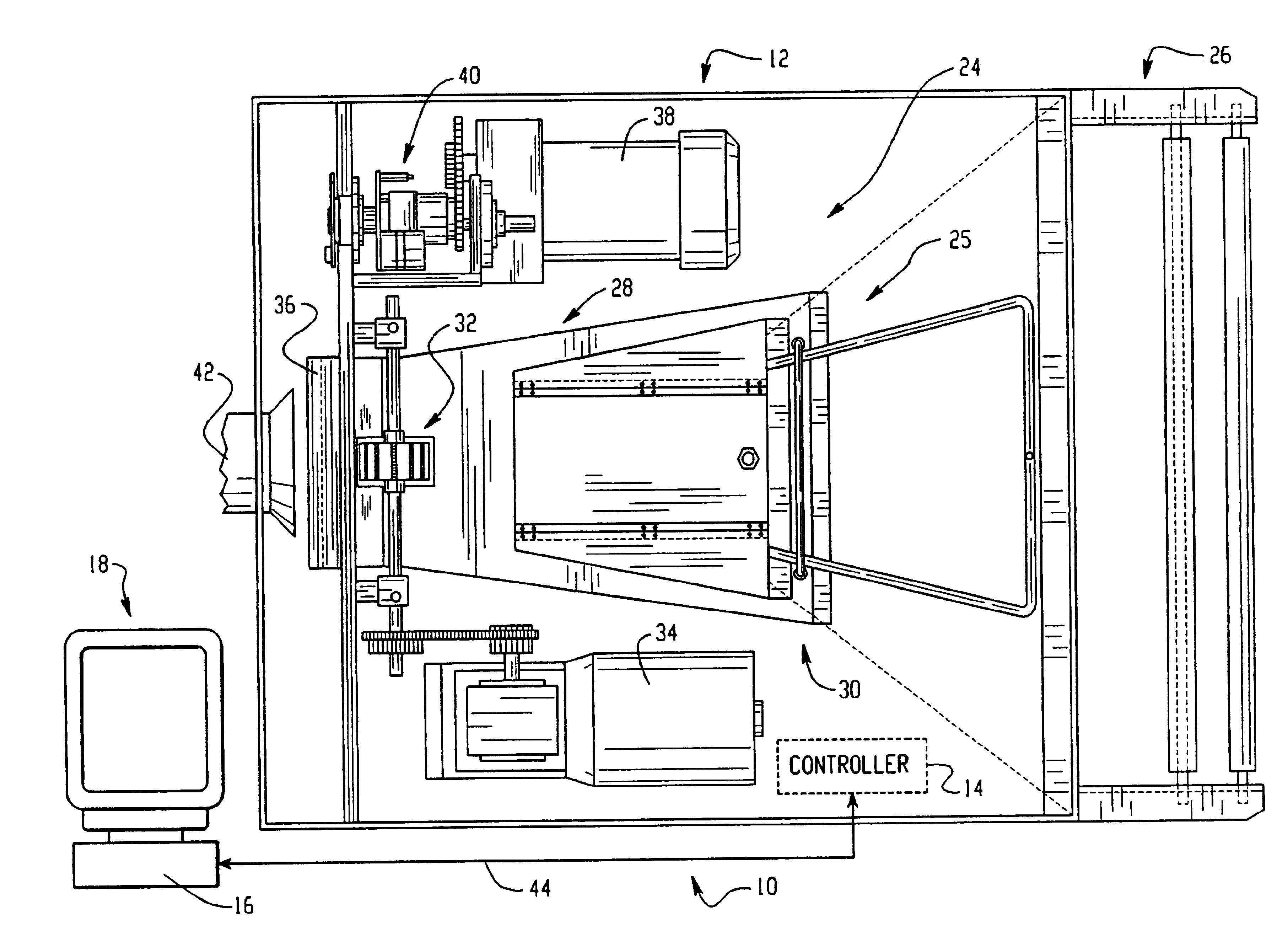

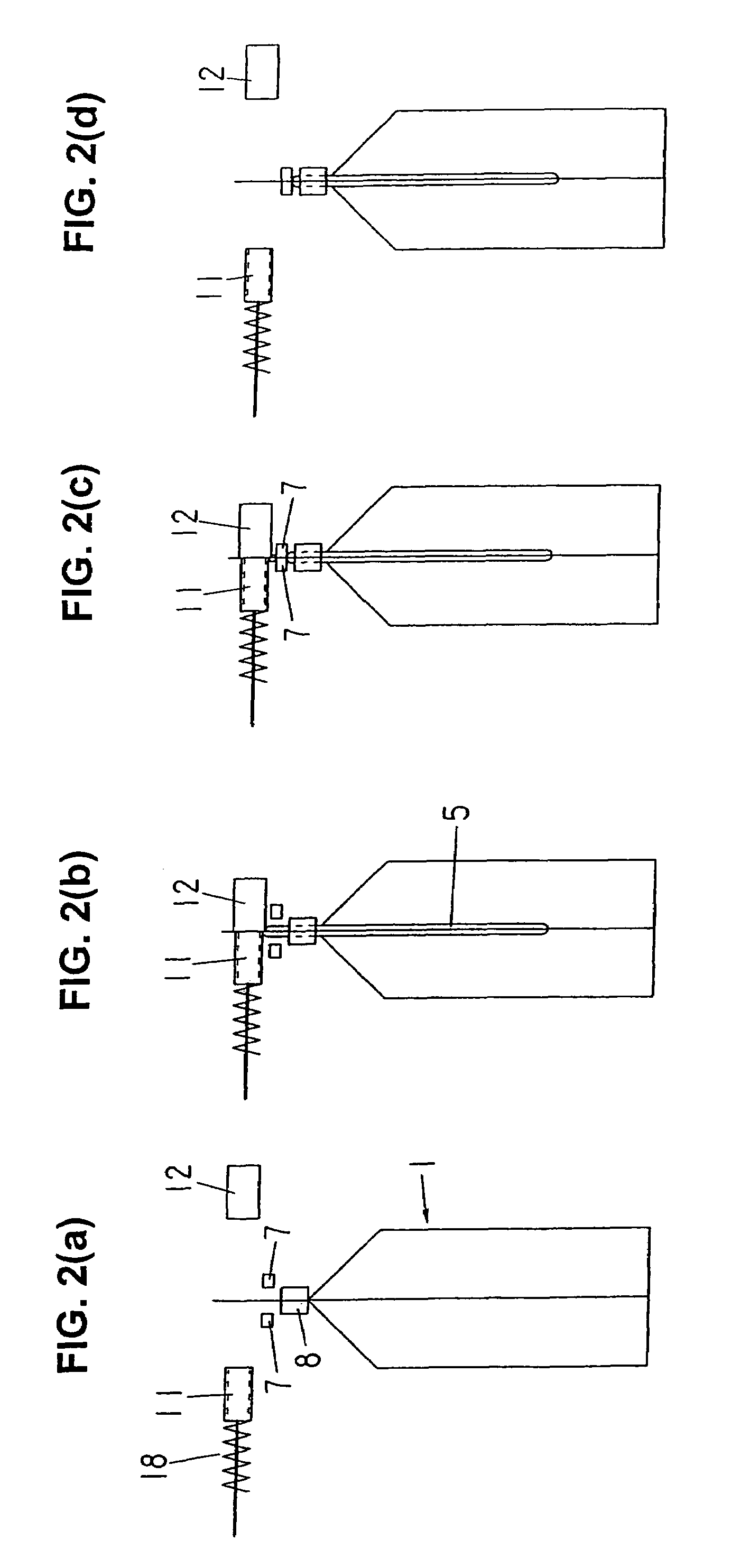

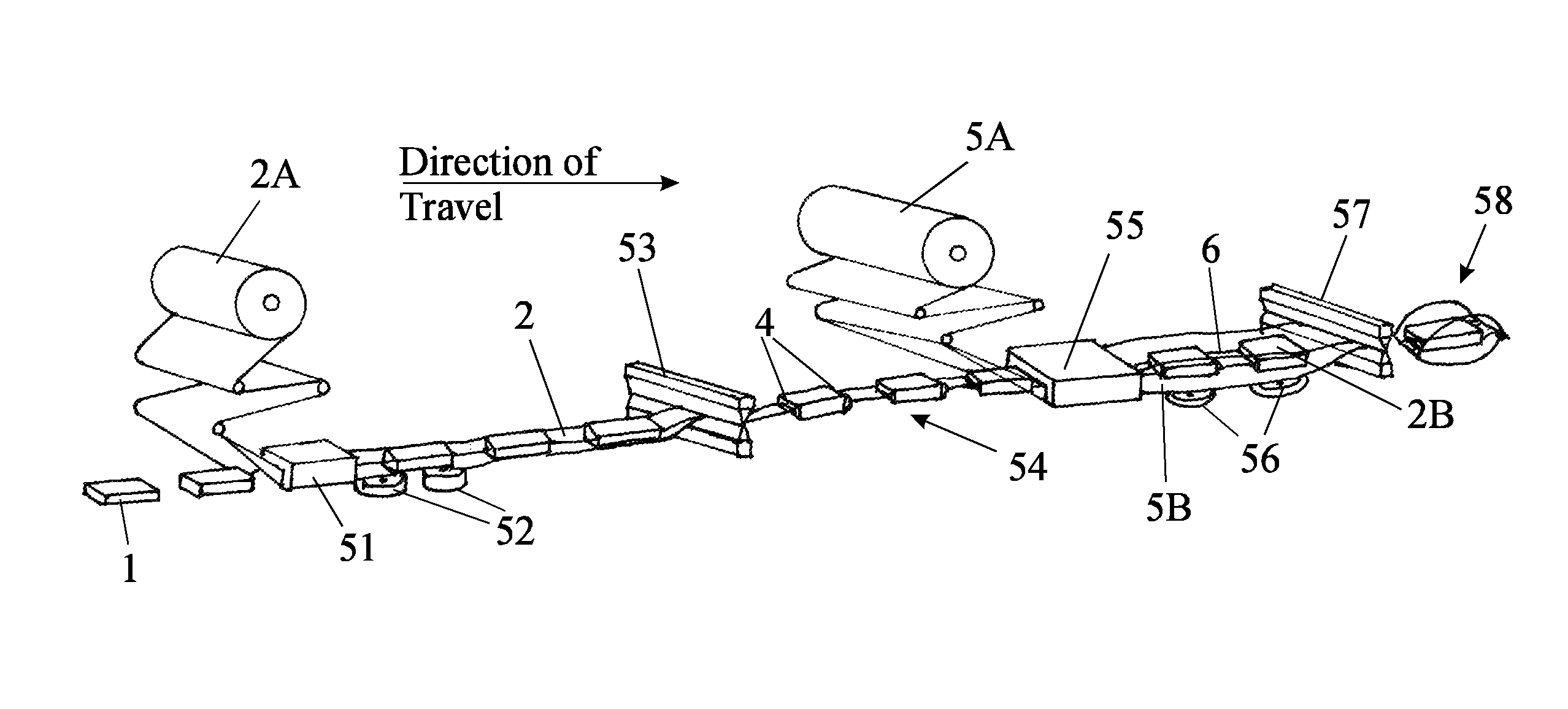

Apparatus and method for forming inflated containers

ActiveUS20060090421A1No sacrifice in production speedImprove sealingCapsPaper/cardboard articlesThin membraneEngineering

An apparatus for forming inflated containers from a film web having two juxtaposed film plies includes: a. a mechanism that conveys the film web along a path of travel; b. a first sealing device for producing one or more seals that bond the film plies together to form a container having at least one opening; c. an inflation assembly for inflating the container by directing a stream of gas into the opening thereof; and d. a second sealing device for sealing closed the opening of the inflated container.

Owner:SEALED AIR U S

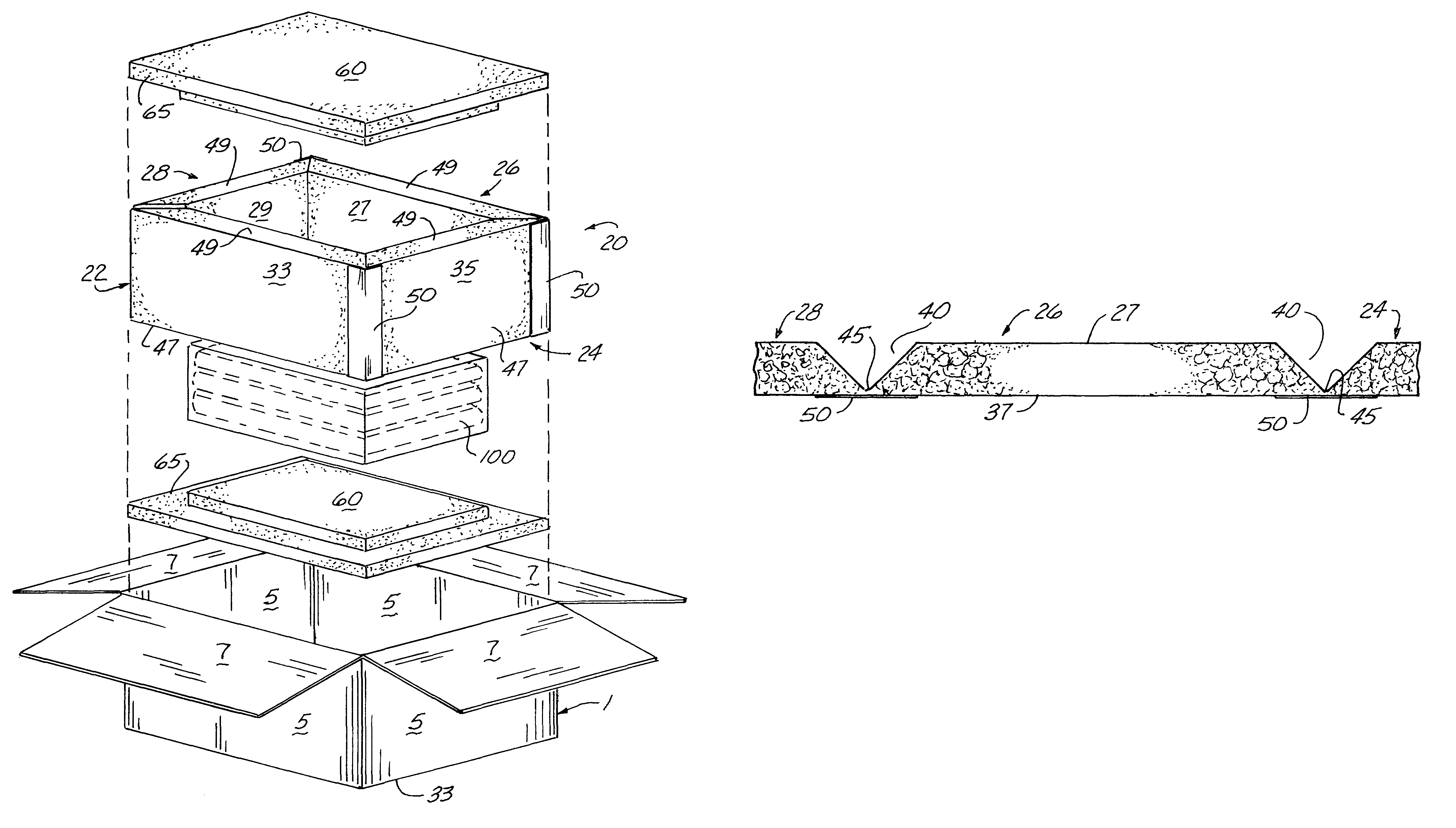

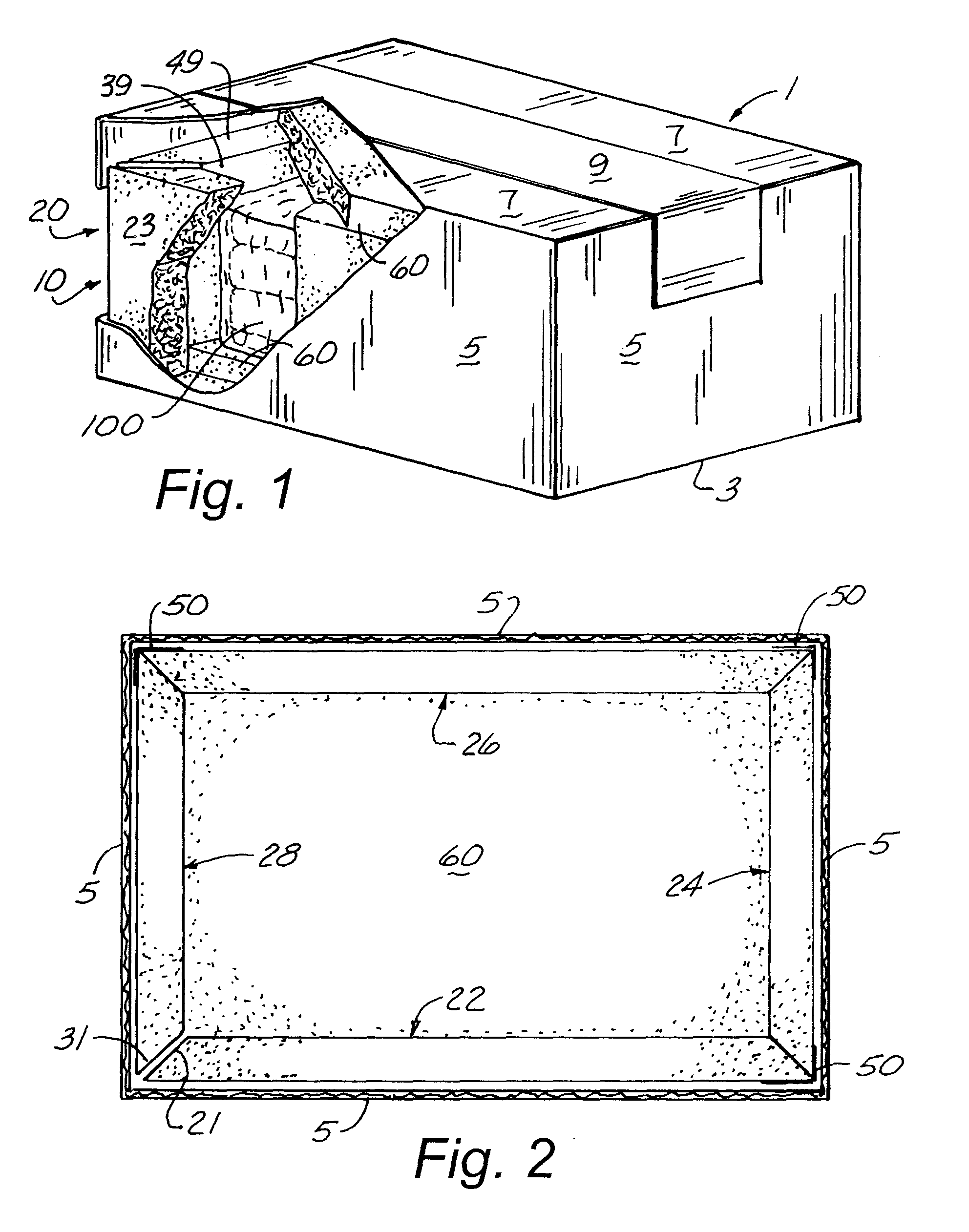

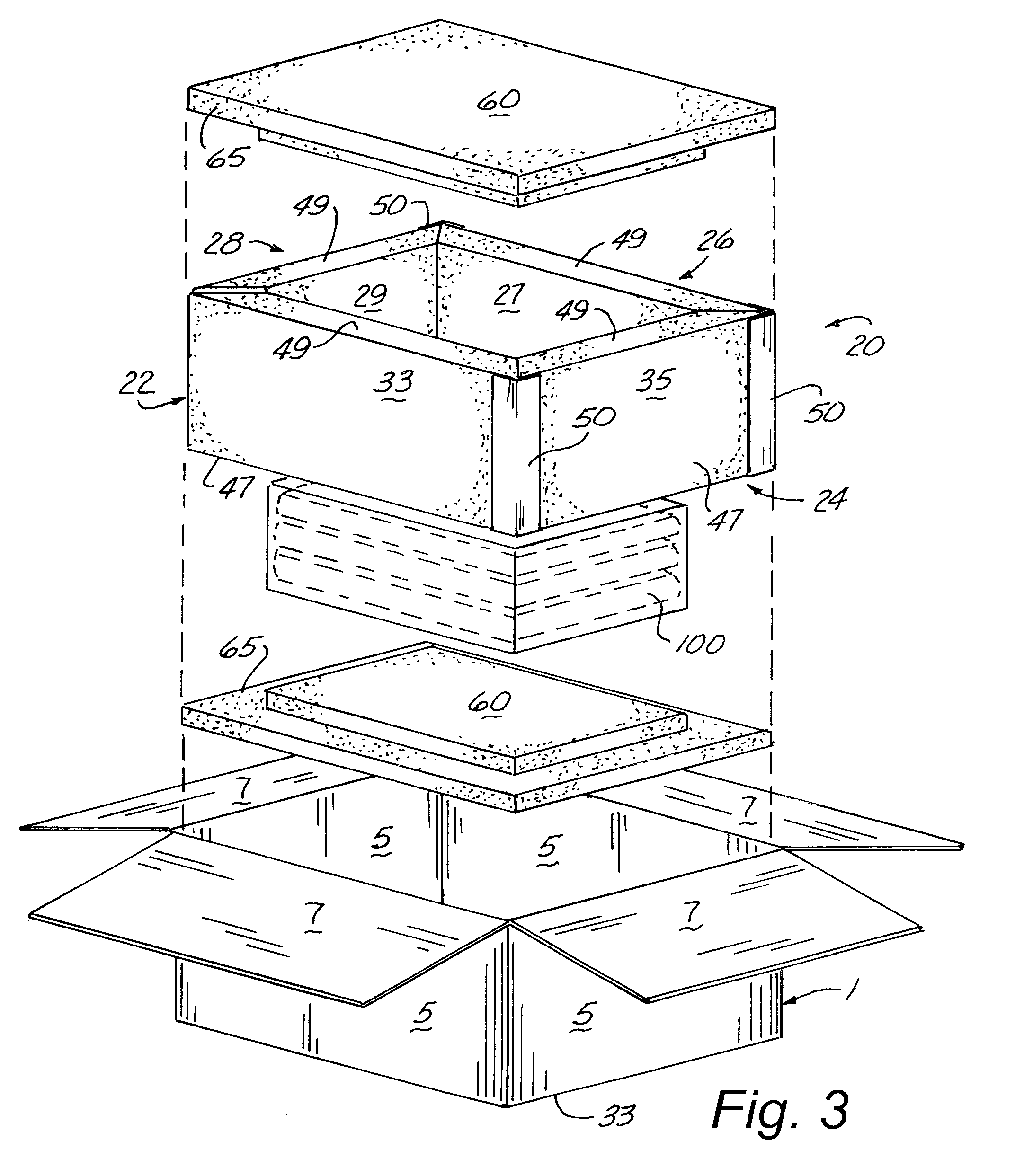

Collapsible foam shipping cooler for perishables and method of making

The present invention provides a collapsible foam shipping cooler and a process for producing the collapsible cooler. The collapsible cooler includes a linear series of attached side panel sections where each of the adjacent side panel sections are separated by a V groove formed by 45° beveled cuts made in a ends of each of the sections, and an adhesive tape flexible hinge is attached on the side of the panels opposite the V groove. The series of attached side panel sections is movable between a collapsed storage mode and an assembled mode where the series of sections are arranged to form a closed rectangular loop with top and bottom perimeter edges. Top and bottom foam panels contact the top and bottom edges of the closed loop to form a closed insulated cooler which is matingly received in a conventional corrugated box shipping container.

Owner:IOWA E P S PROD

Inflated dunnage and method for its production

InactiveUSRE36759E1Reduce slippageEasy to prevent slippingPreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

A method for producing inflated dunnage on the site of use, comprising providing, in web form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the open edge of each inflated bag is sealed, the bag being empty except for the air. A plurality of sealed inflated bags is separated from the web and placed in a carton to serve as dunnage. The bags have a slip resistant outer surface which causes the bags to interlock in the carton and better protect object therein from shock.

Owner:AUTOMATED PACKAGING SYST

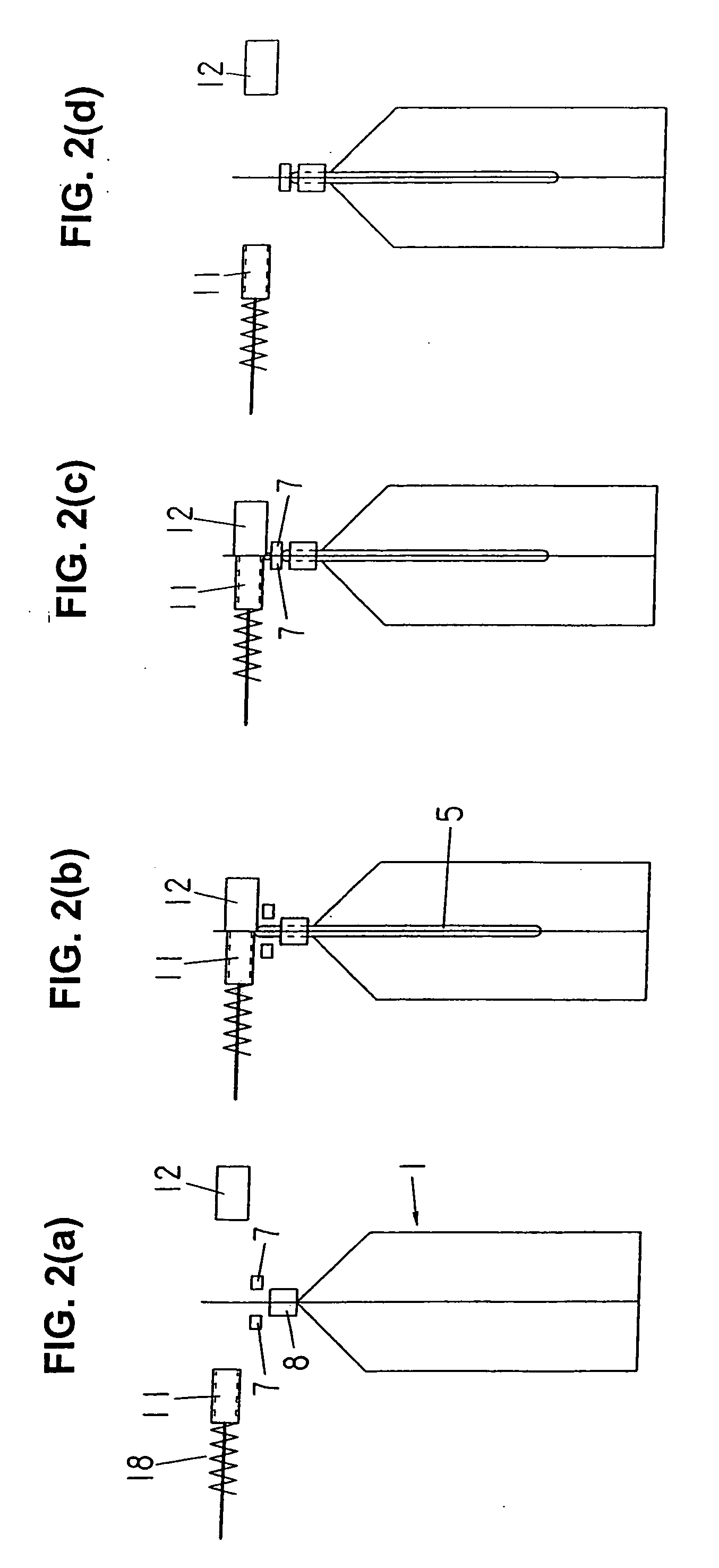

Gas seal-in method for a bag with a gas filling compartment and packaging method for a bag with a gas filling compartment

ActiveUS20070089377A1Automate processingEasy to operateCapsBag making operationsEngineeringPacking method

A method for sealing-in a gas in a gas filling compartment 5 of a bag having a cut-in 6 formed near the upper edge of the gas filling compartment. In the method, two edges of the bag with the contents inserted therein are gripped by grippers and suspended, the blow-in port of a gas (air) blow-in nozzle is brought to contact the cut-in, the back surface side of the bag is supported by a backing member, gas (air) is blown into the gas filling compartment, and the position below the cut-in is held from both sides of the bag by a gas cut-off grippers while the gas blow-in continues, so that the gas inside the gas filling compartment is not allowed to escape from the cut-in, and then the entire bag mouth, including the cut-in, is sealed.

Owner:TOYO JIDOKI CO LTD

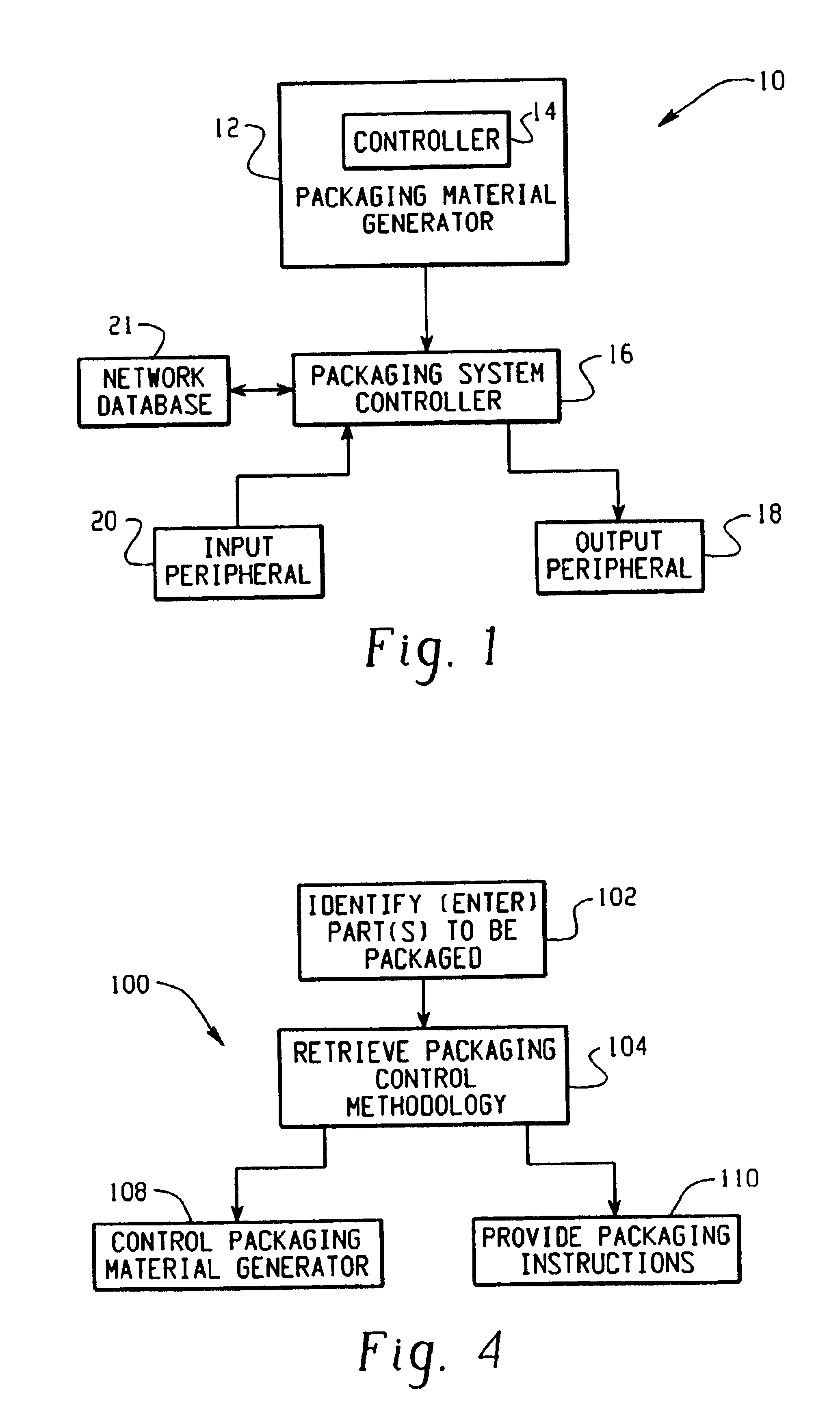

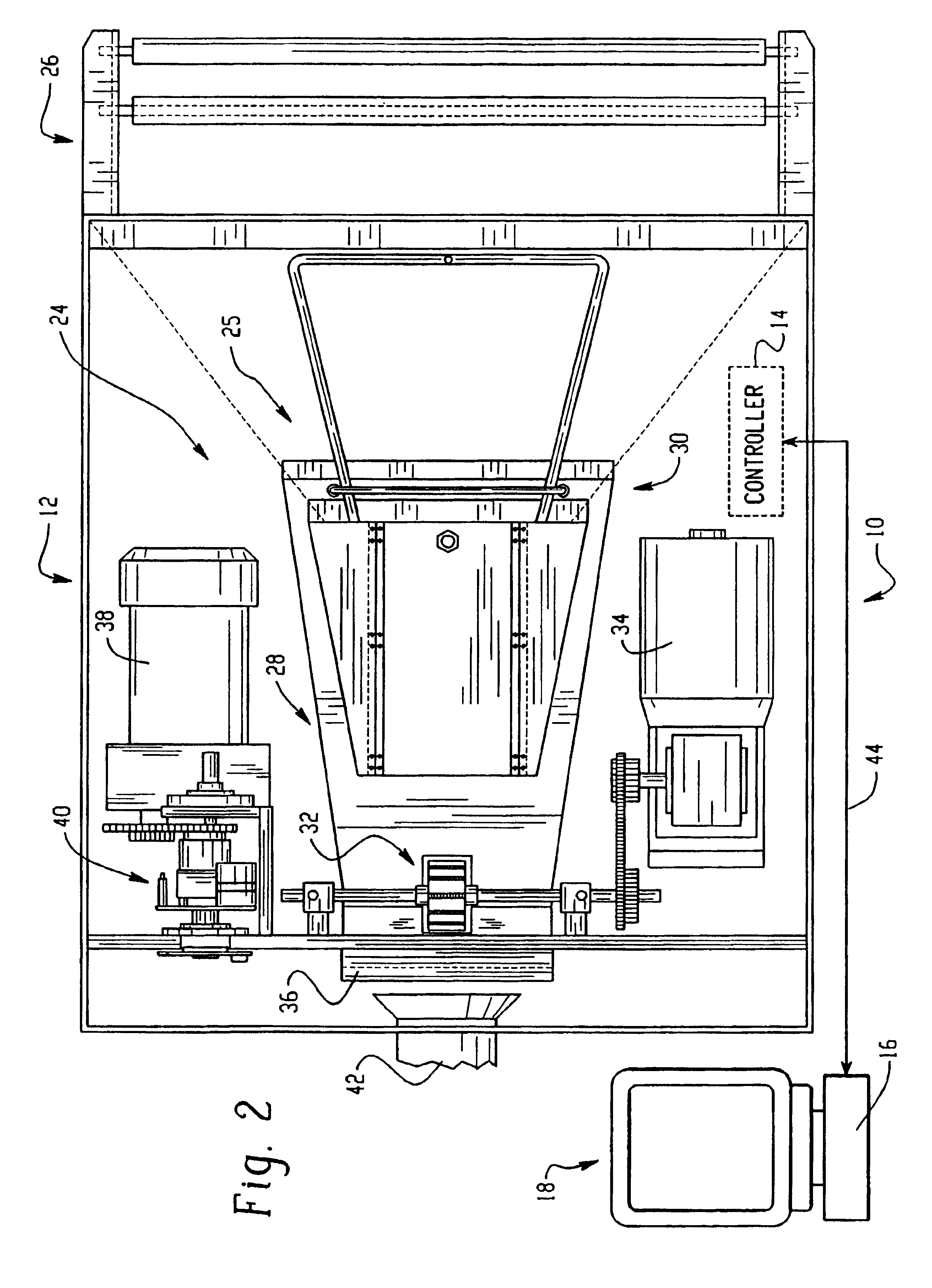

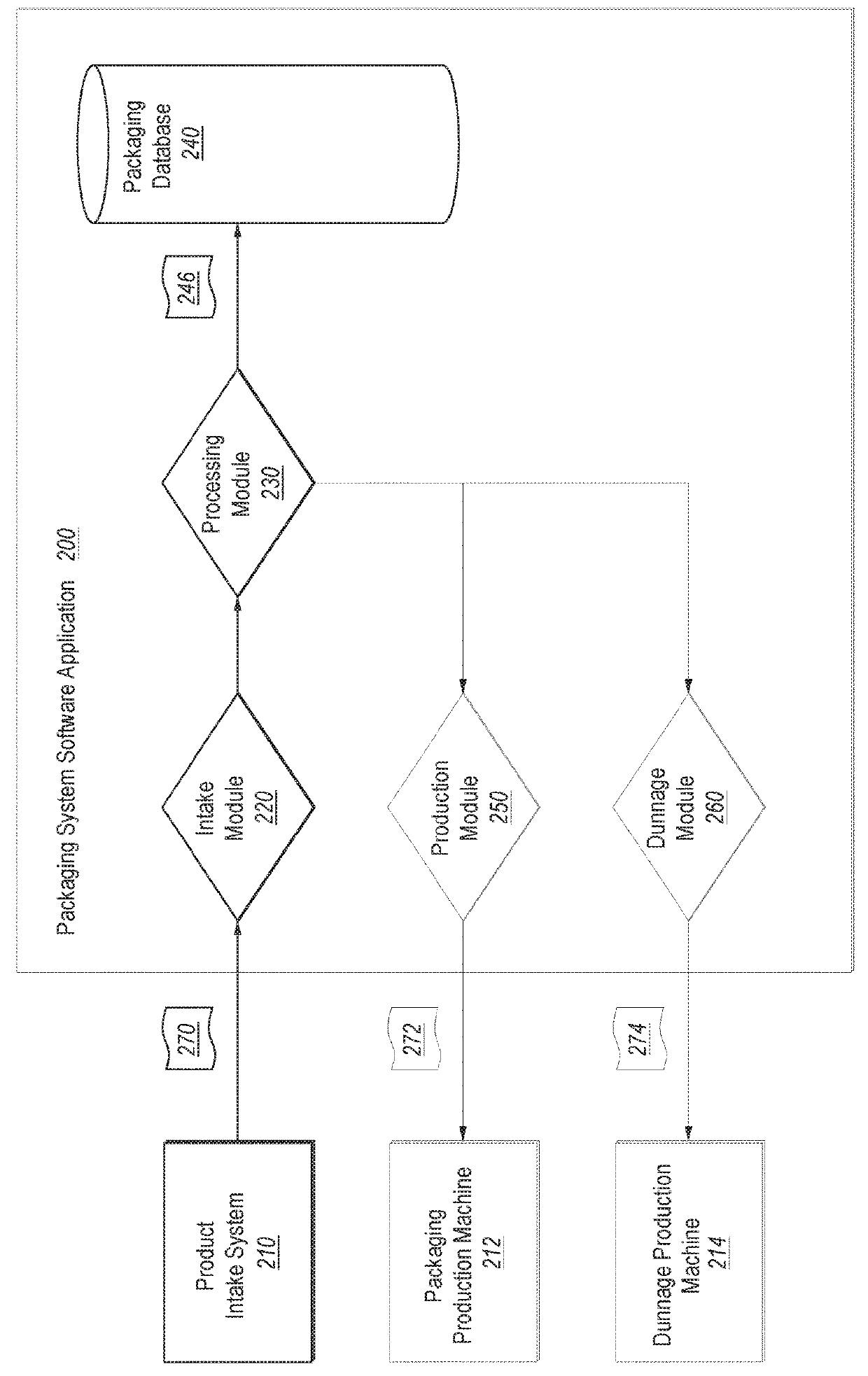

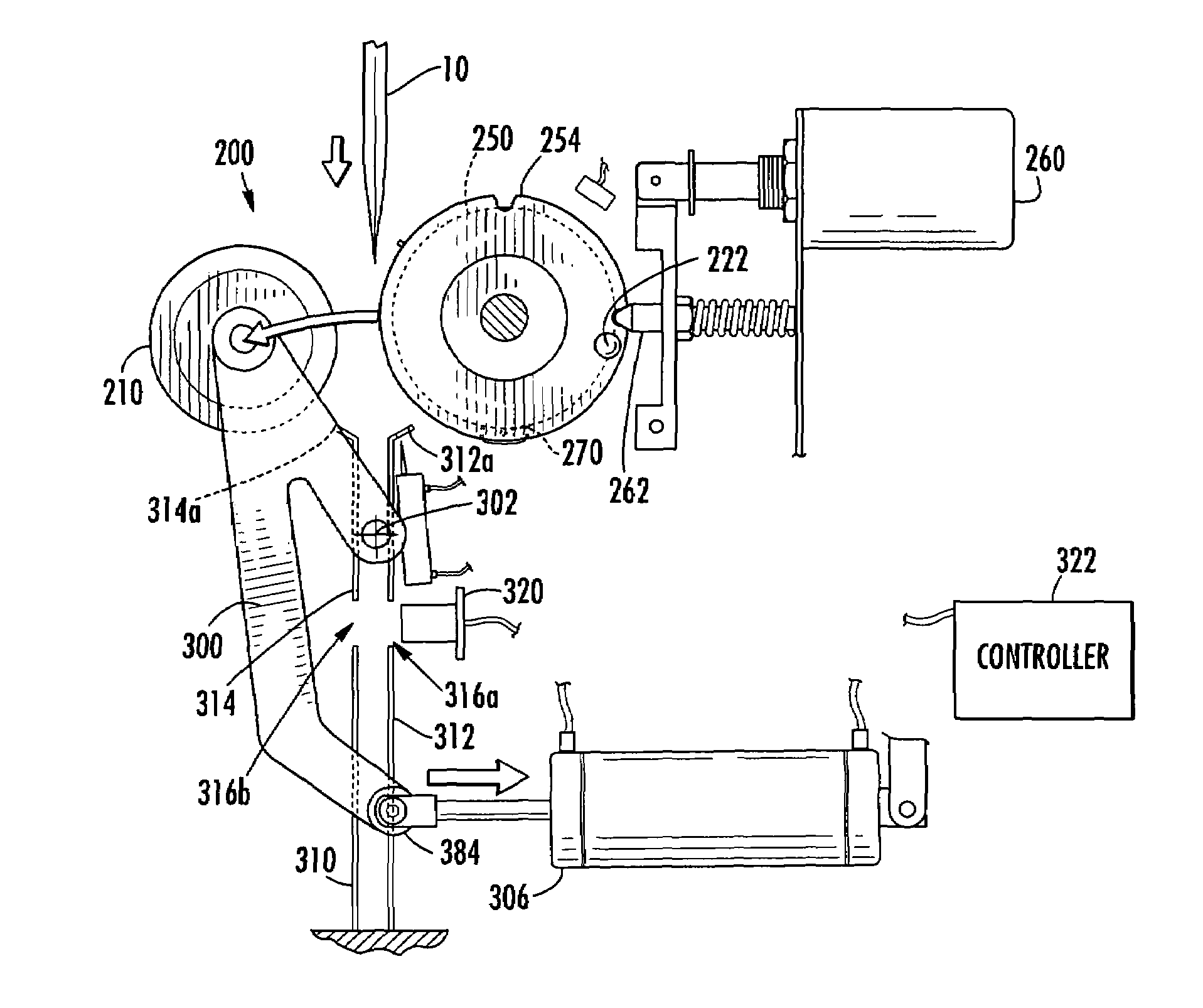

Cushioning conversion system and method

InactiveUS6877297B2Efficient and effective of partMaintained effectively and efficientlyPaper/cardboard articlesOral administration deviceCushioningDunnage

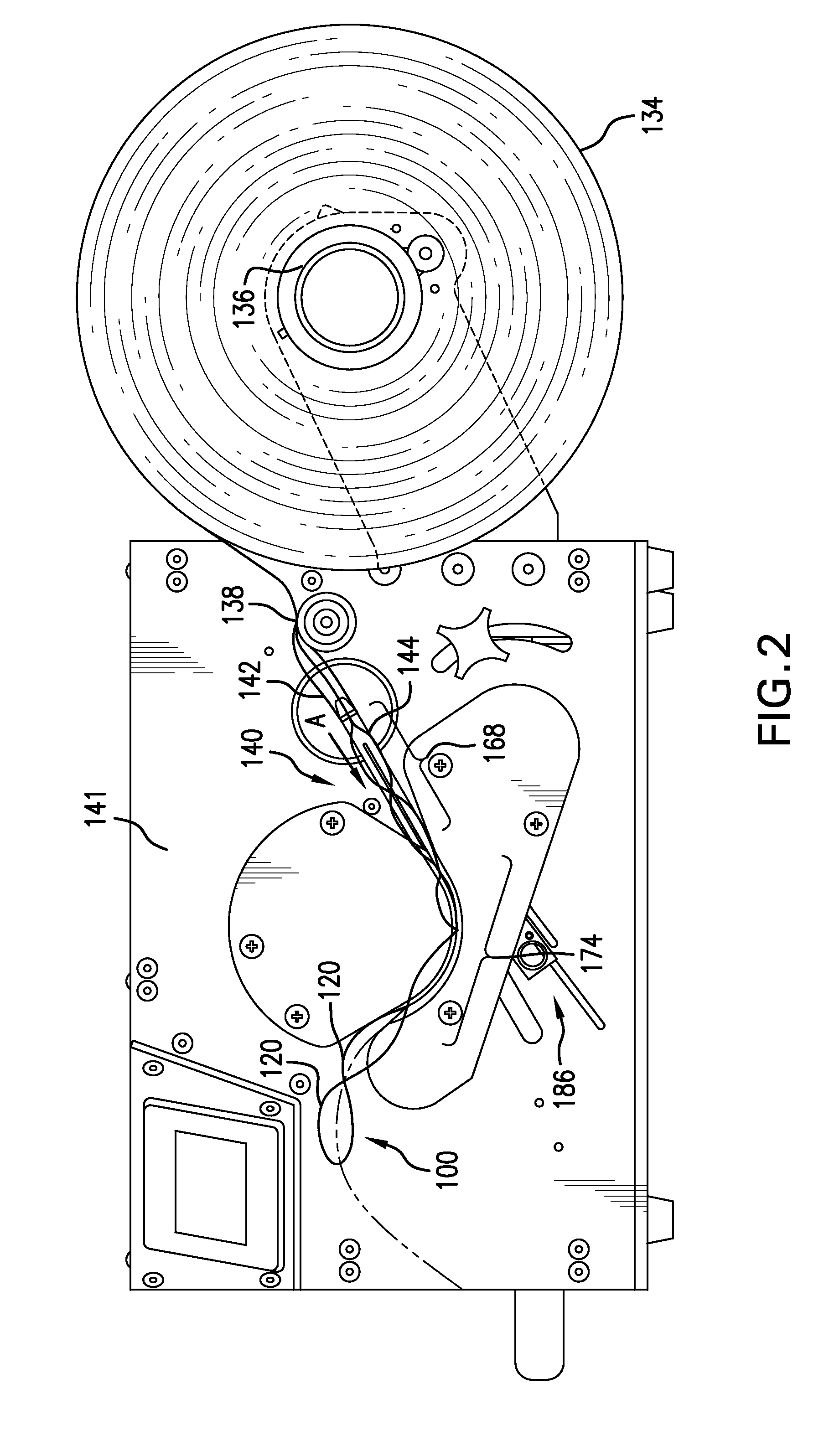

A packaging system includes a cushioning conversion machine for converting stock material into relatively low density cushioning material or dunnage and a packaging system controller. The packaging system controller provides packaging instructions related to a part or parts to be packaged and instructs the cushioning conversion machine to produce the cushioning material. In one aspect of the present invention the packaging system controller provides packaging instructions by retrieving a predetermined set of packaging instructions associated with a particular part. In another aspect of the present invention the packaging system controller provides packaging instructions by determining an optimized packaging methodology using one or more characteristics of the part or parts to be packaged. The packaging system also provides for automated inventory control and productivity monitoring.

Owner:RANPAK CORP

Replaceable blade

ActiveUS20140261752A1Wrapping material feeding apparatusPaper/cardboard articlesEngineeringBiomedical engineering

A flexible structure inflation device, comprising an inflation assembly configured for insertion between first and second overlapping film layers of a web of material, the inflation assembly having a fluid conduit configured directing a fluid in between the layers to inflate the web; and a cutting member held magnetically in an operative position adjacent the inflation assembly to cut the film passing over the inflation assembly.

Owner:PREGIS INNOVATIVE PACKAGING

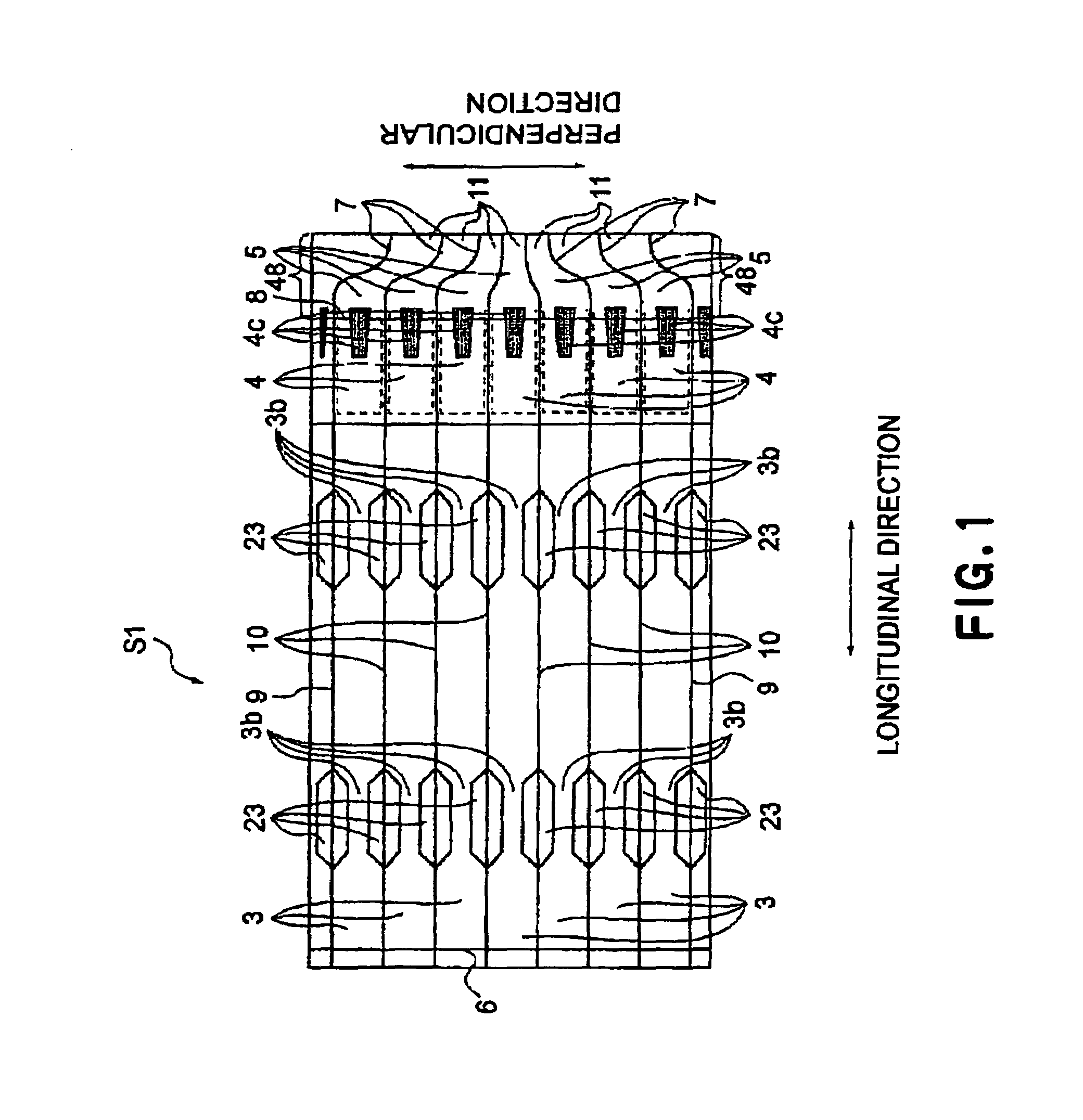

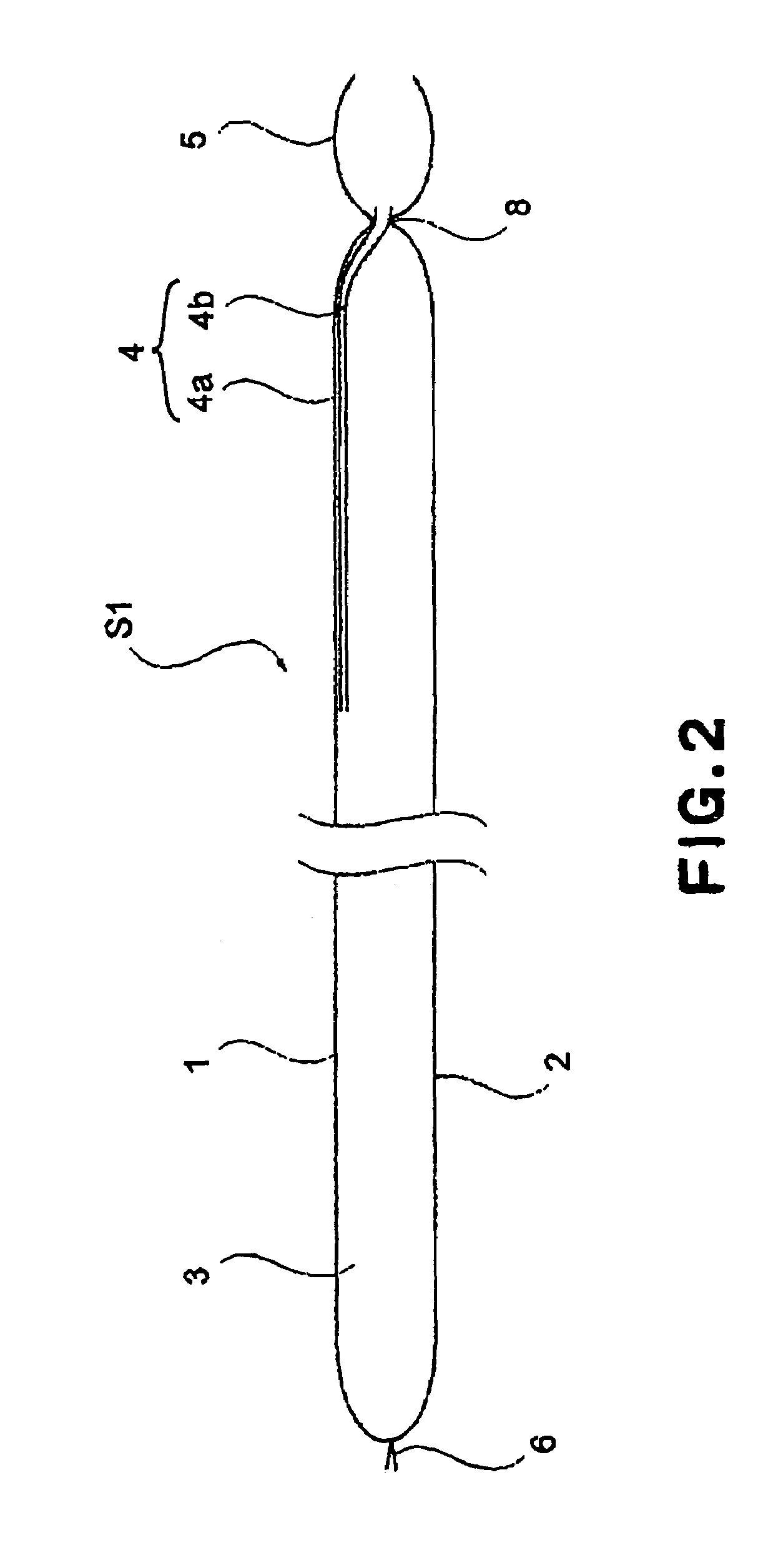

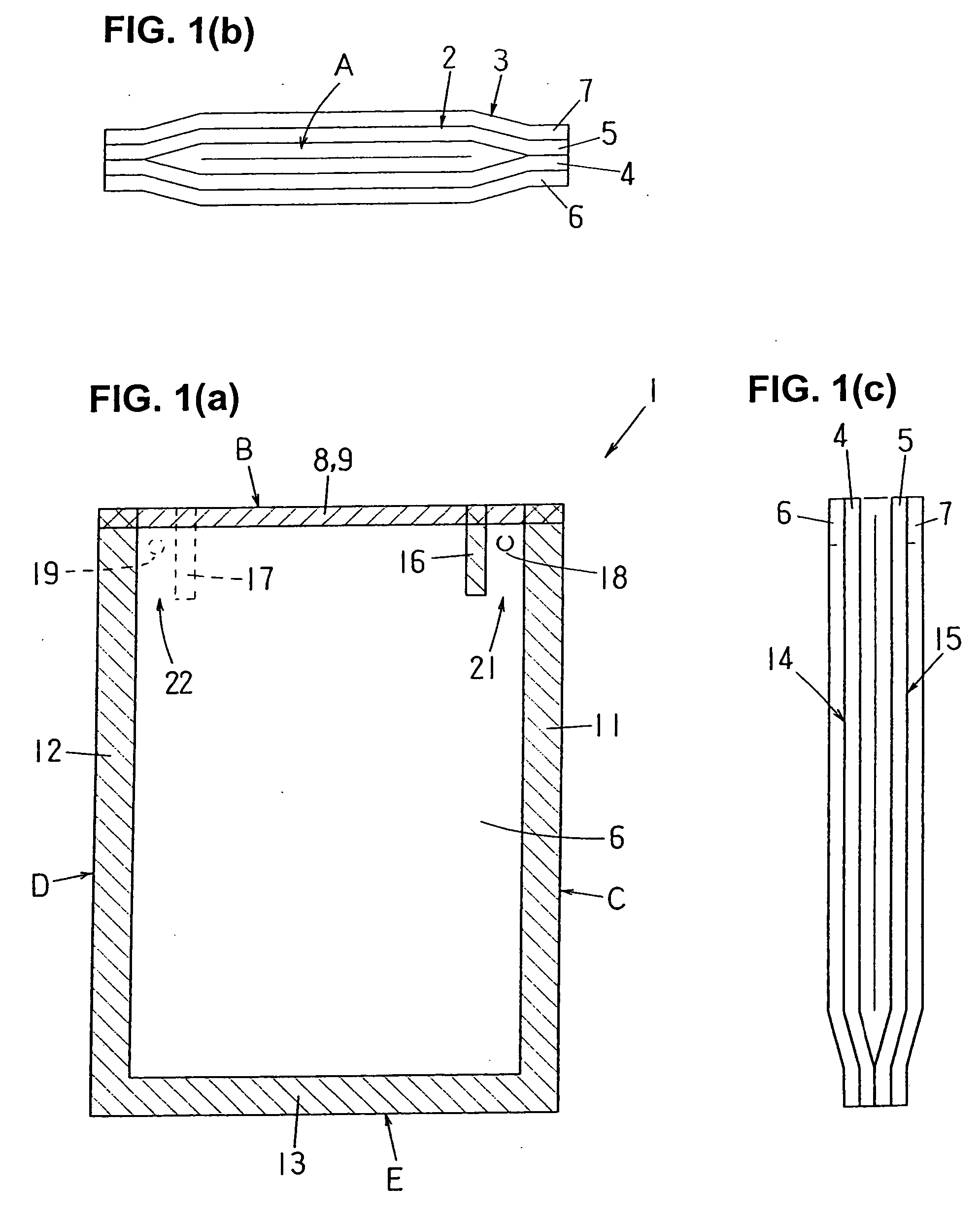

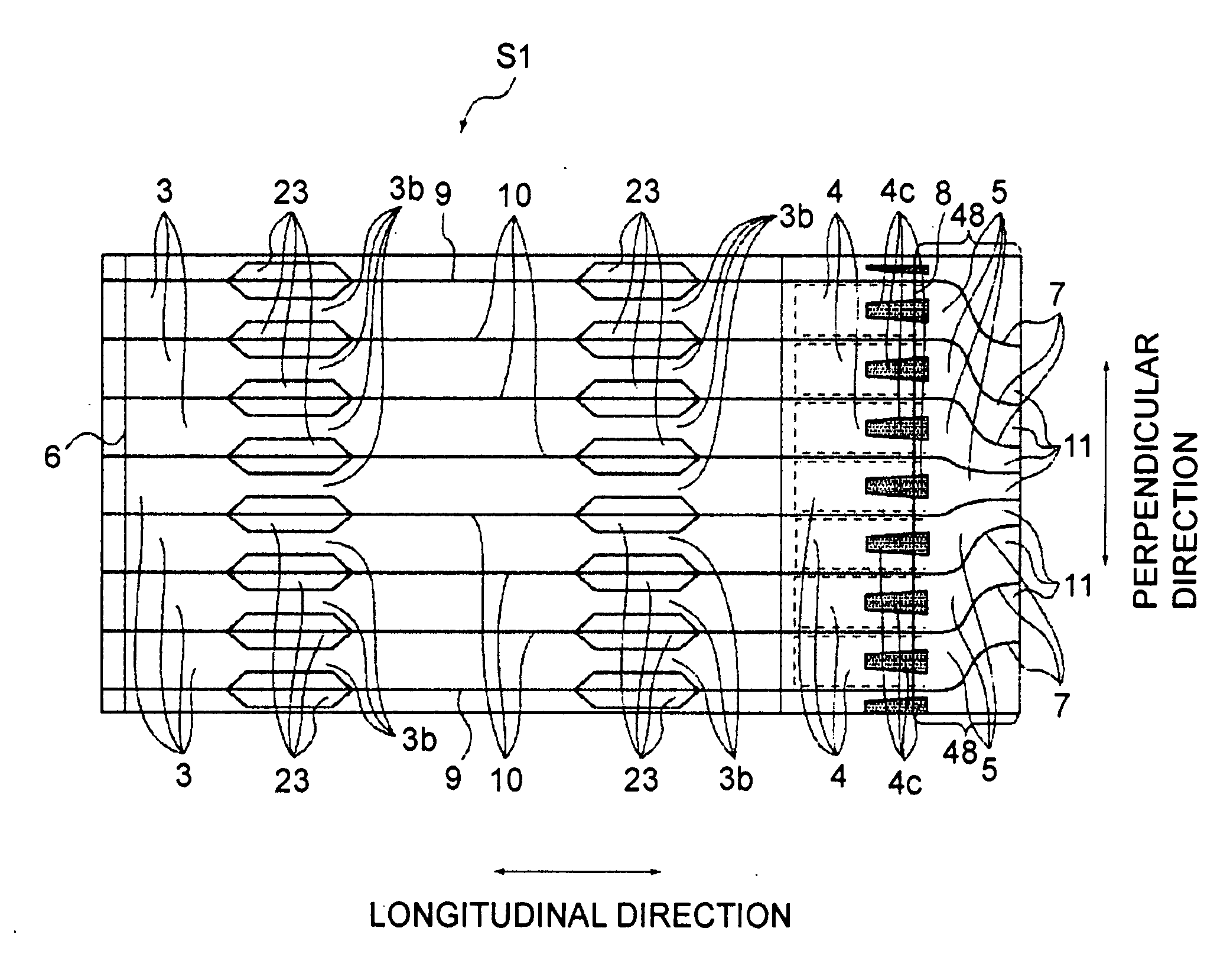

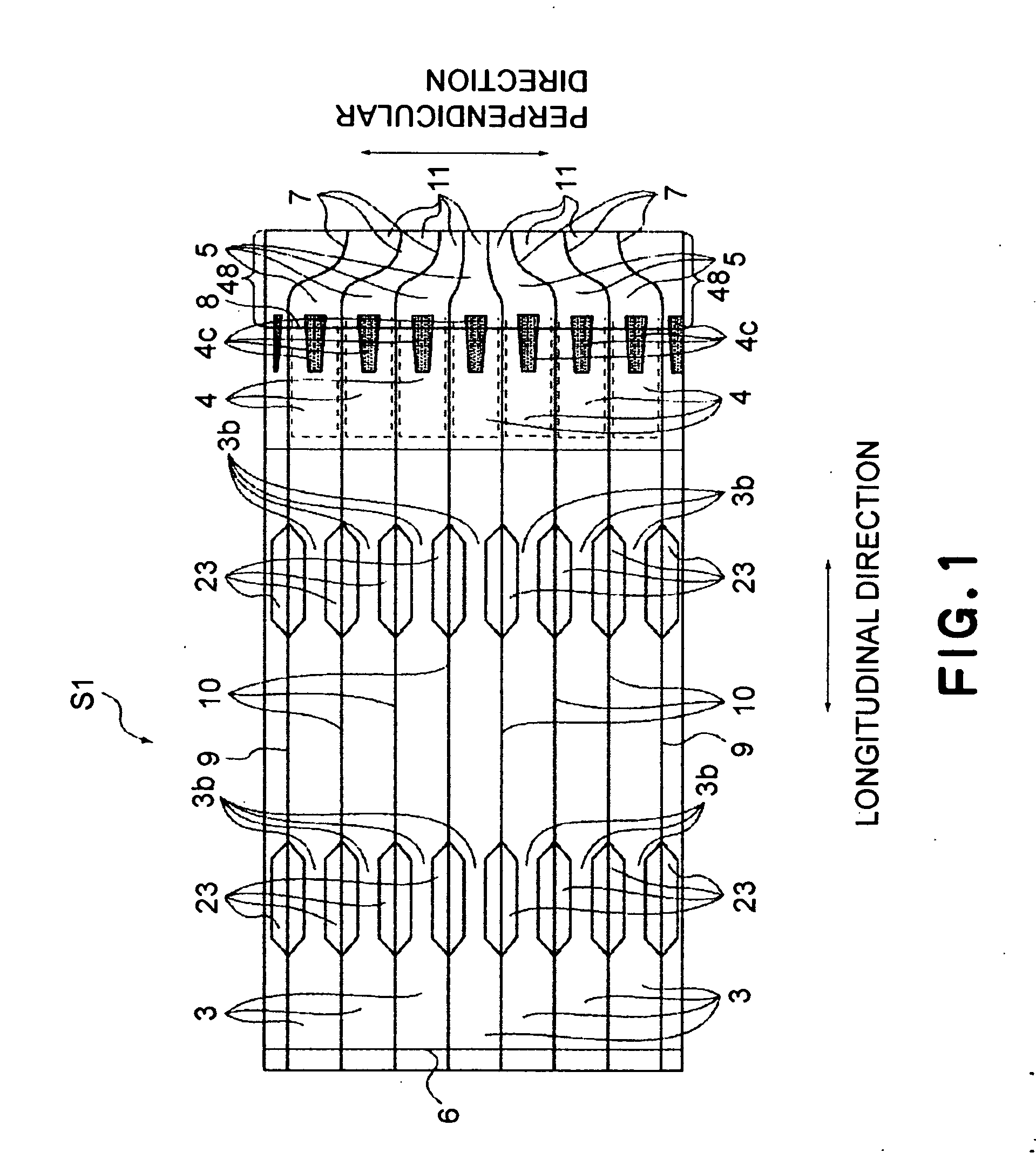

Packing method, packing member and manufacturing method therefor

ActiveUS7128211B2Prevent backflowPackaging vehiclesPaper/cardboard articlesCheck valvePacking method

A packing member for packing an article, includes a medium accommodating portion for accommodating medium; a non-return valve for passing the medium to the medium accommodating portion and stopping the medium away from the medium accommodating portion; an introducing portion for introducing the medium into the medium accommodating portion with the non-return valve from an outside of the packing member to balloon the medium accommodating portion; and a sealing region, disposed upstream of the non-return valve with respect to a direction of the introduction of the medium from the introducing portion toward the non-return valve, for sealing against the introduction of the medium to prevent leakage from the introducing portion to an outside of the packing member, the sealing region being sealed to keep the medium in the medium accommodating portion.

Owner:CANON KK

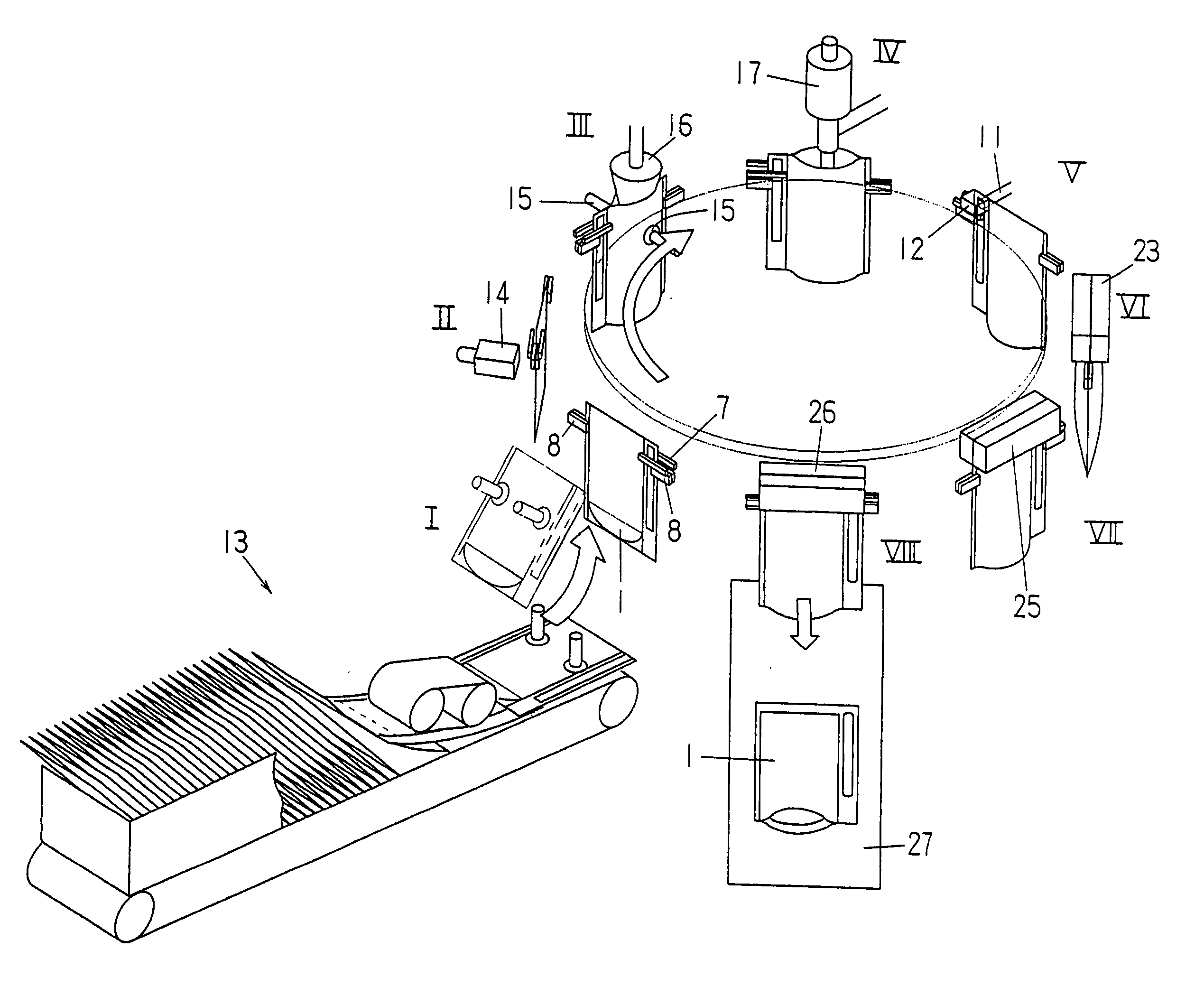

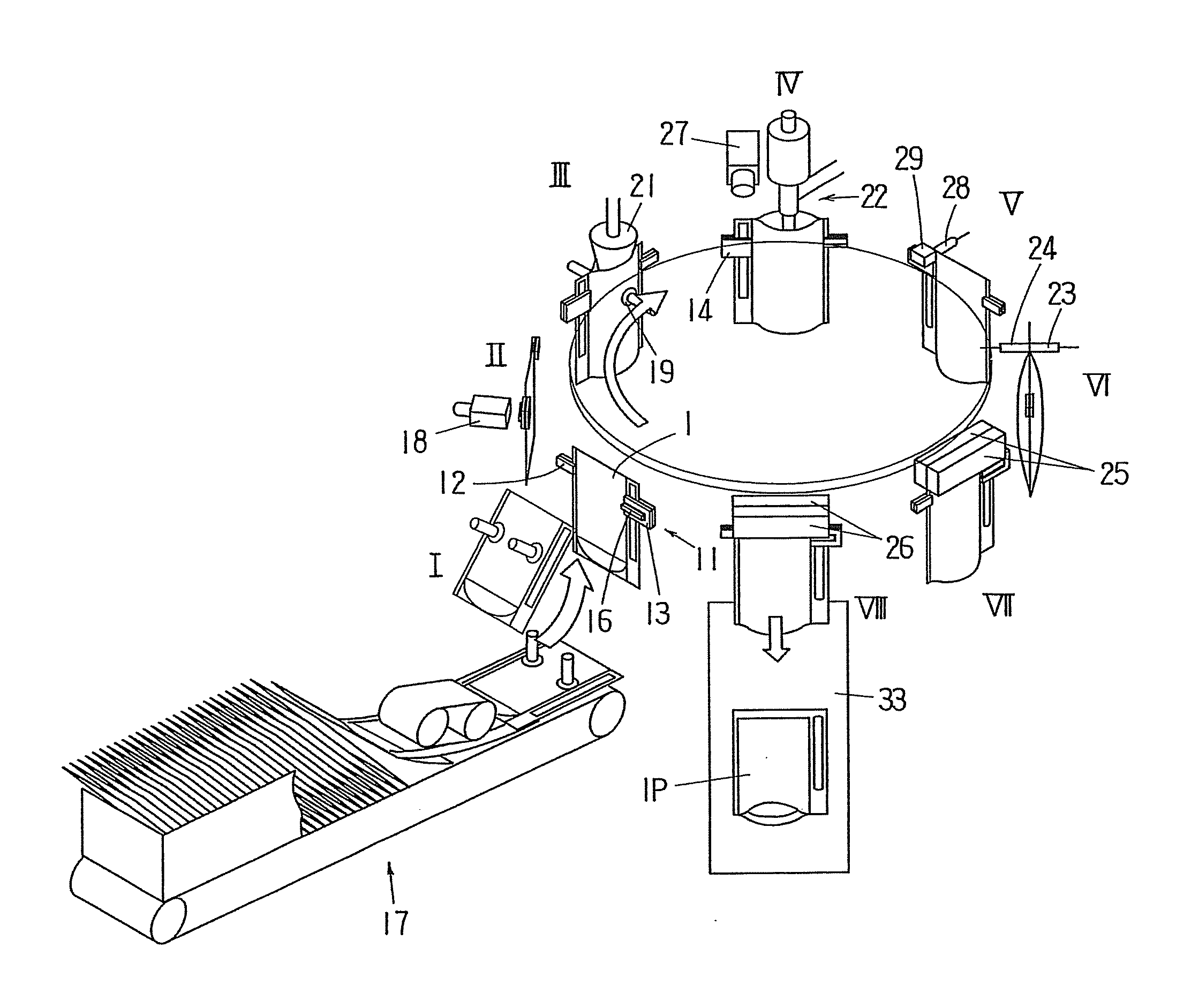

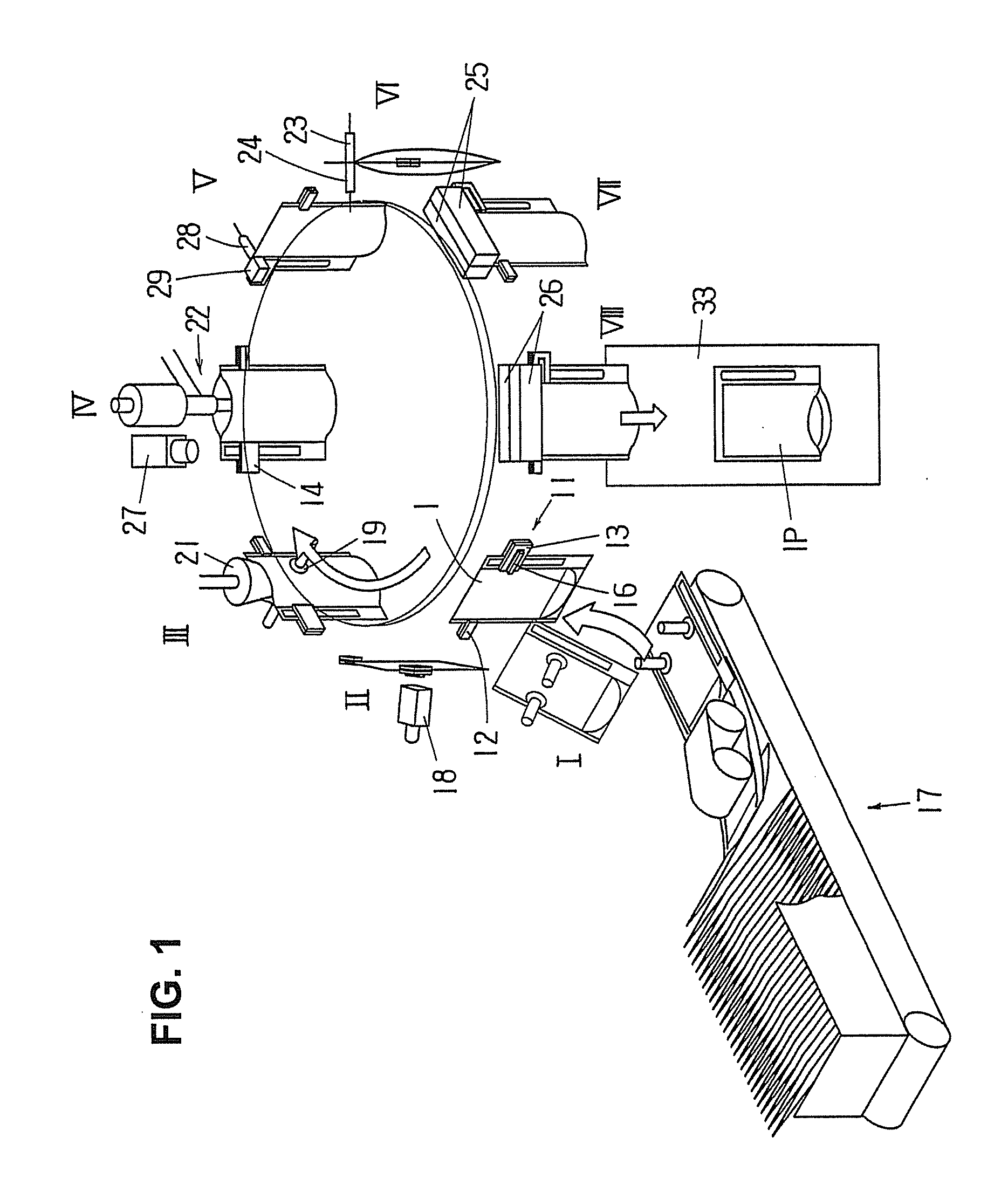

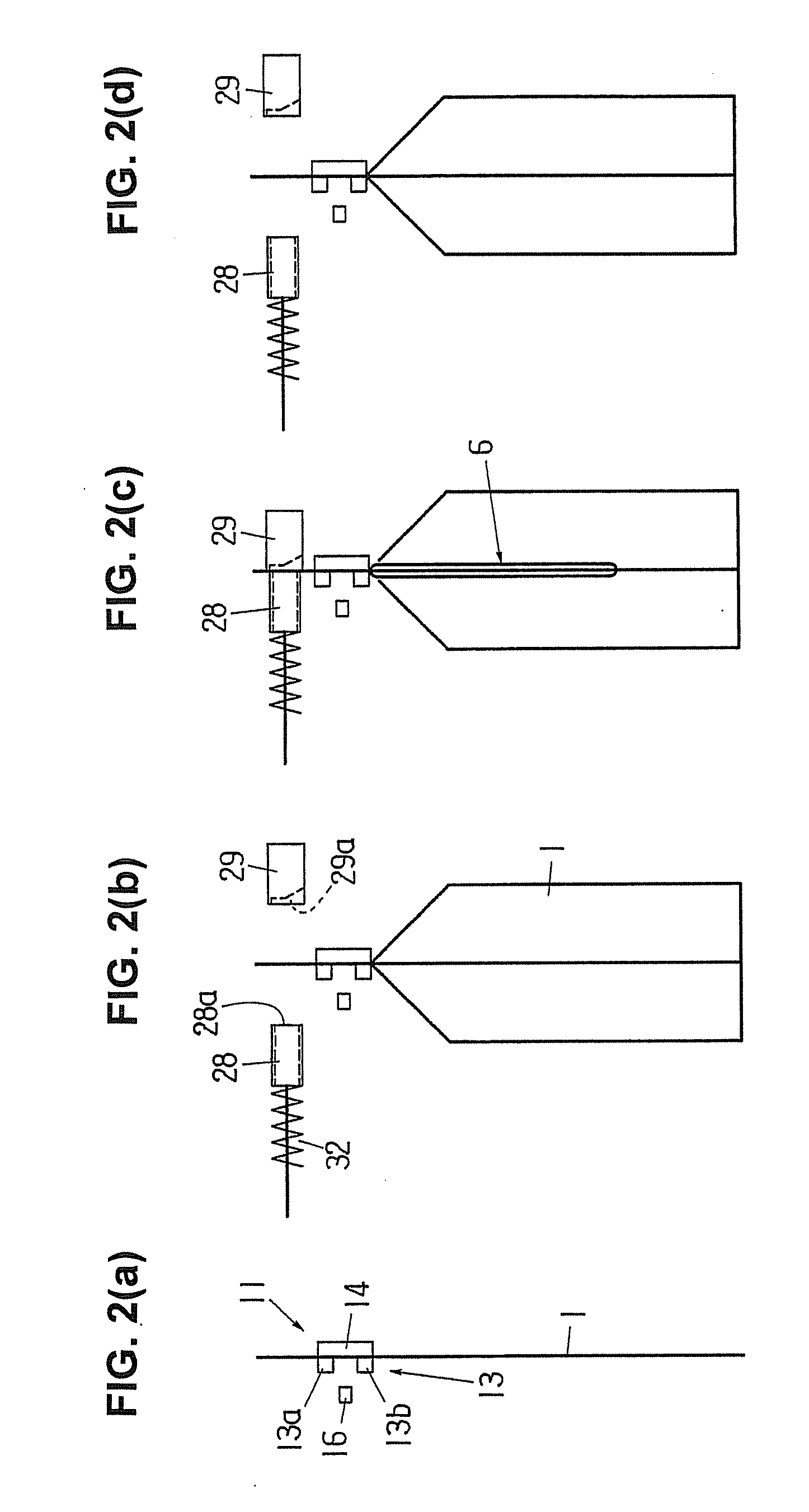

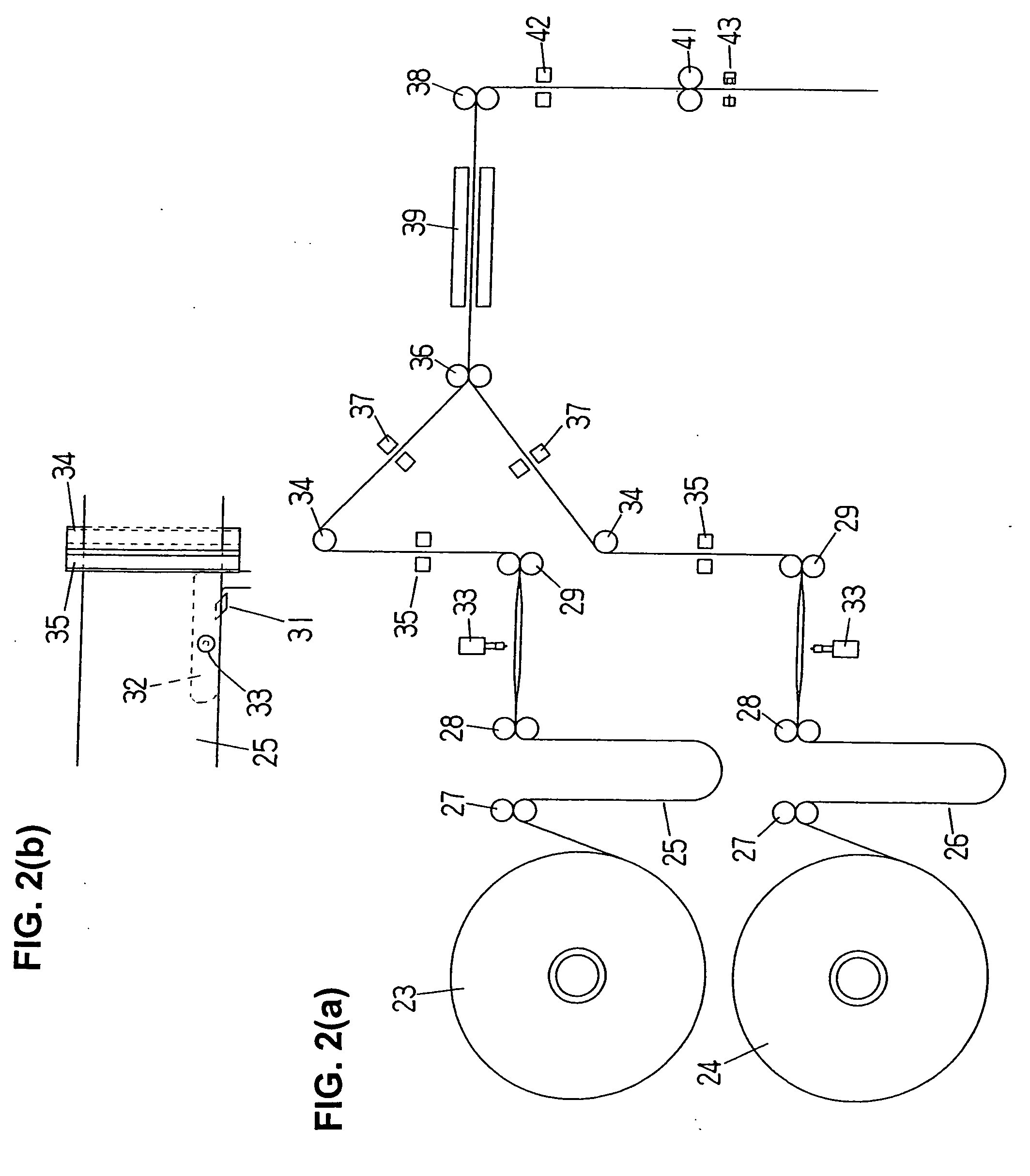

Gas Charging Method and Gas Charging Apparatus for Bag Equipped with Gas Compartment Portion

InactiveUS20140250834A1Evenly filledWithout loss of productivityCapsCap application using vaccuumEngineeringElectrical and Electronics engineering

In a method and apparatus for charging a gas into a gas compartment portion (6) of a bag (1), after a pre-heating step which is performed in stop position (IV) so that the gas compartment portion of the bag is heated by a heated gas-blowing nozzle (27), a preliminary gas injection step for injecting gas into the gas compartment portion is performed by a gas blowing nozzle (28) and a receiving member (29) in stop position (V). Then, a gas filling step is carried out in stop position (VI) by gas injection nozzles (23, 24), and the incision (9) in the gas compartment portion is sealed in stop position (VII). In the following pre-heating step, the front and rear film sheets (7, 8) of the gas compartment portion are softened, and in the preliminary gas injection step, the film sheets are separated and their adhesion is eliminated.

Owner:TOYO JIDOKI CO LTD

Gas seal-in method for a bag with a gas filling compartment and packaging method for a bag with a gas filling compartment

Owner:TOYO JIDOKI CO LTD

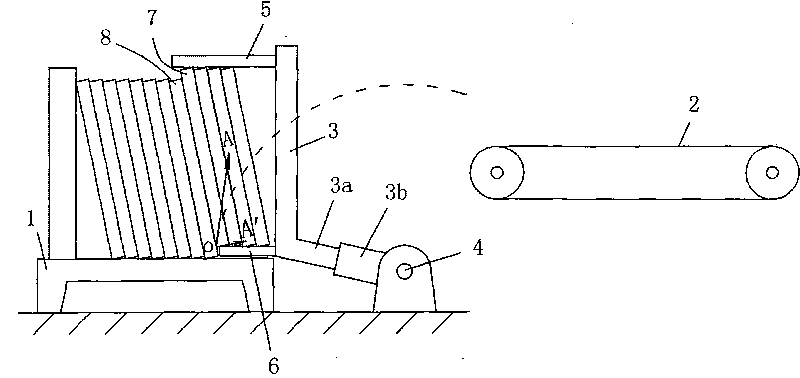

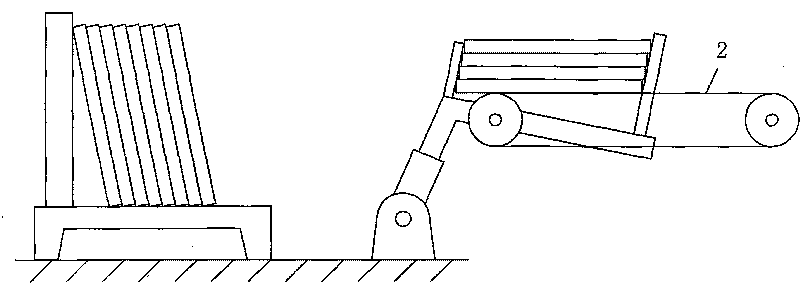

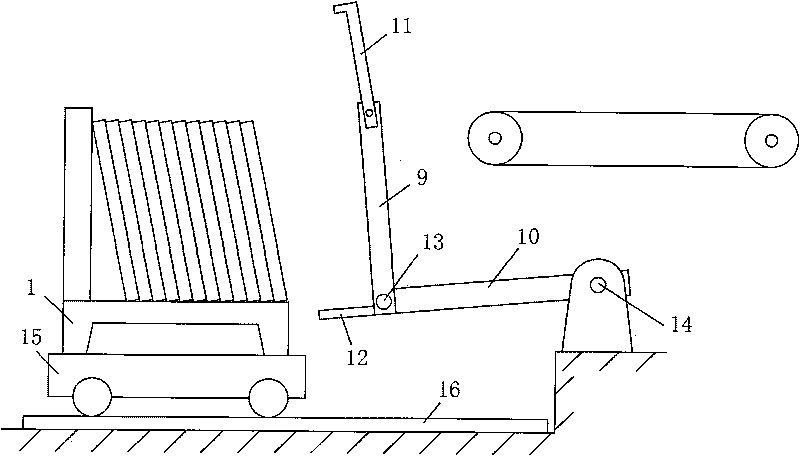

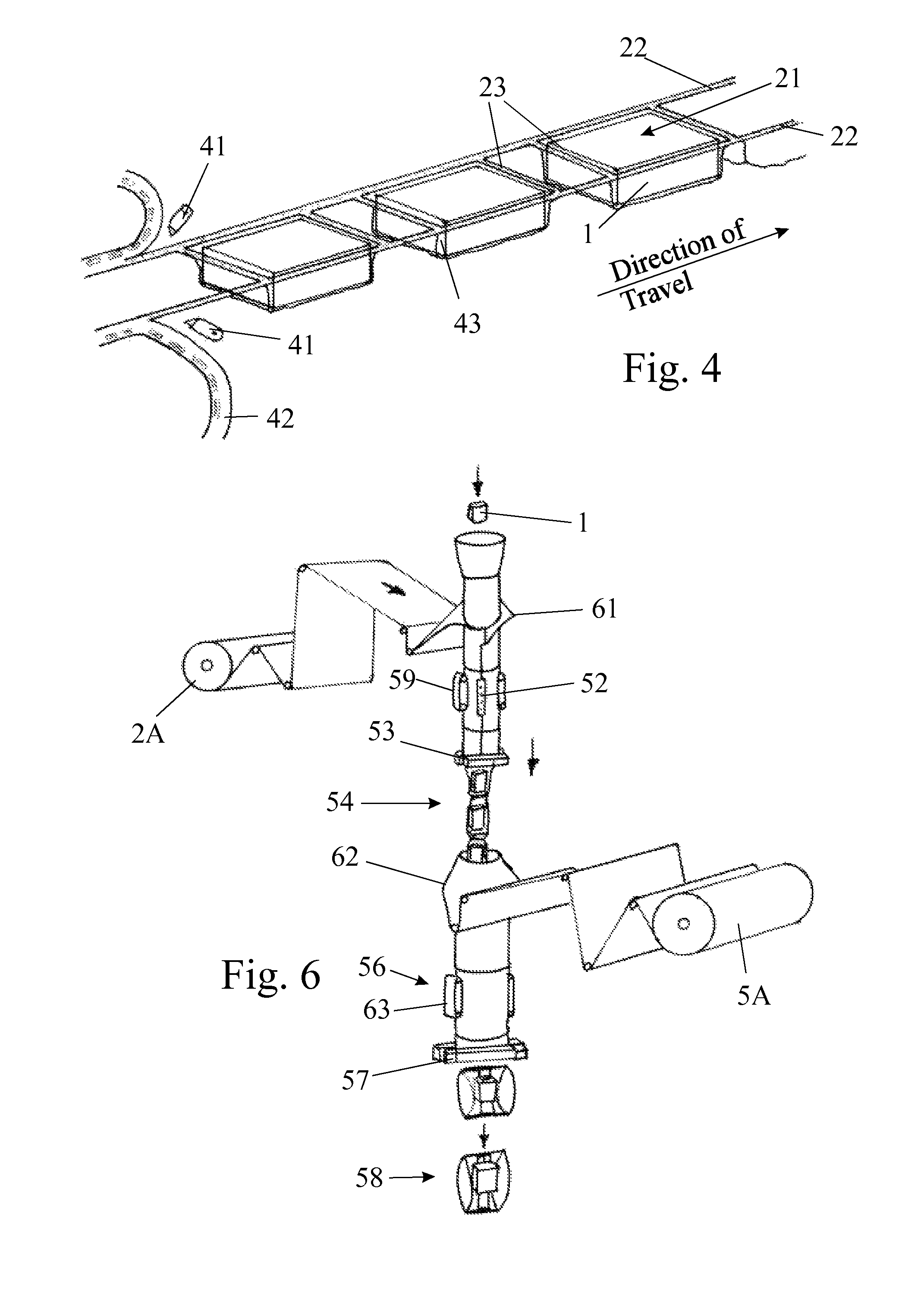

Production line for automatic boxing of wall and floor tiles

ActiveCN101700814AAvoid chippingNo scratchesWrapper folding/bending apparatusShock-sensitive articlesCardboardBrick

The invention discloses a production line for automatic boxing of wall and floor tiles, comprising a conveyor line for conveying tile bodies and paper boards, a tile loading mechanism, a paper board extracting mechanism, a paper box shaping mechanism and a palletizing mechanism, wherein the four mechanisms are arranged along the conveyor line; in the tile loading mechanism, the tile bodies have component motion vertical to the plane of the tile bodies at the initial time when swing arms drive the tile bodies to rotate, thus avoiding the edges of the tile bodies from being damaged; in the paper board extracting mechanism, stoppers are used for forcing the paper boards to bend, thus avoiding two layers of paper boards from being taken out simultaneously; in the paper box shaping mechanism, the paper boards bearing the tile bodies naturally slide on rollers and stop, thus avoiding dislocation between the tile bodies and the paper boards as well as between the tile bodies due to instant stop of the paper boards; and in the palletizing mechanism, an elevating mechanism is only used for driving a manipulator and a translational mechanism to go up and down, thus ensuring the mechanical structure to be simplified and easy to maintain. The invention improves the boxing quality of the production line from multiple aspects.

Owner:GUANGDONG EDING IND

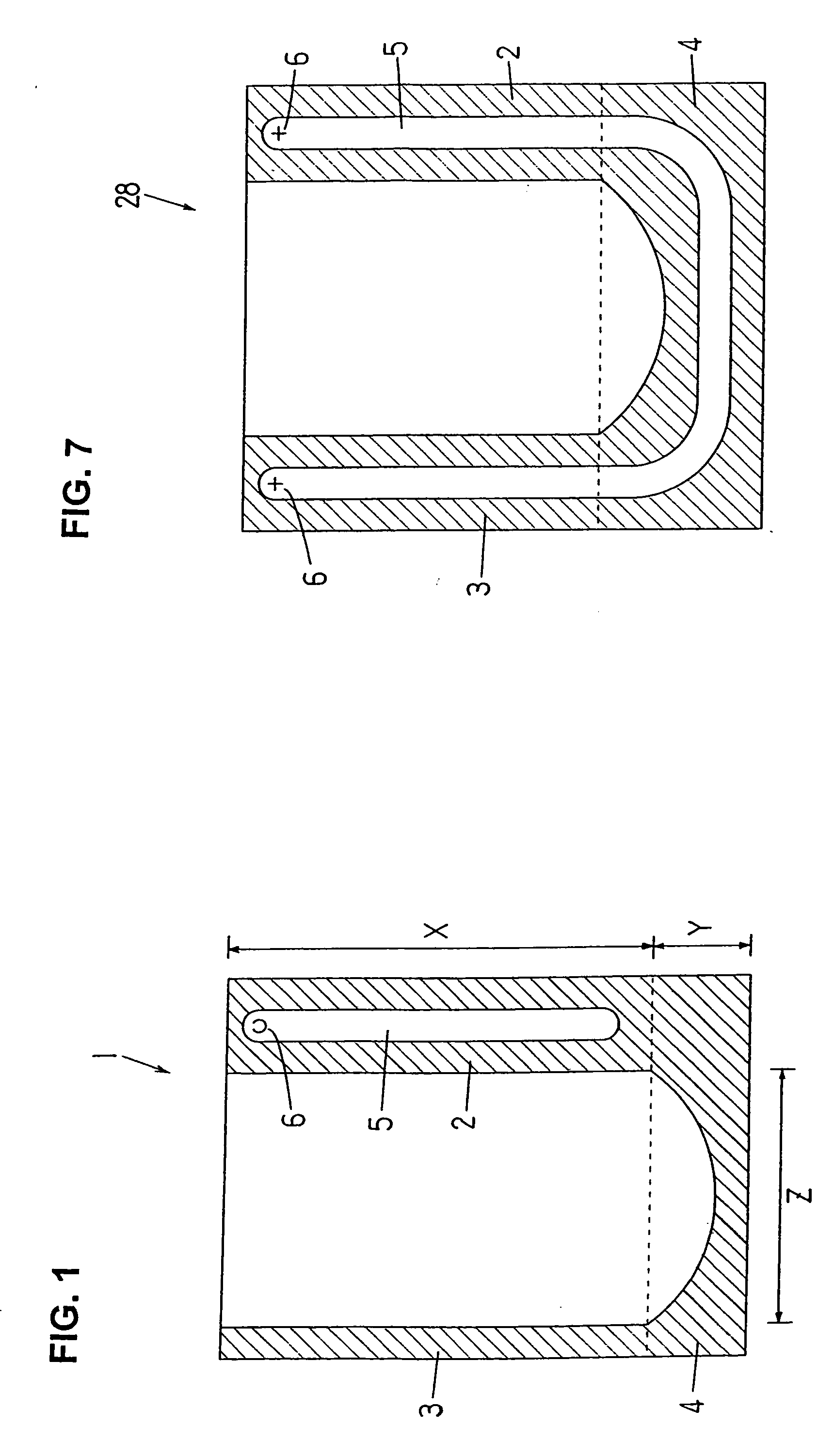

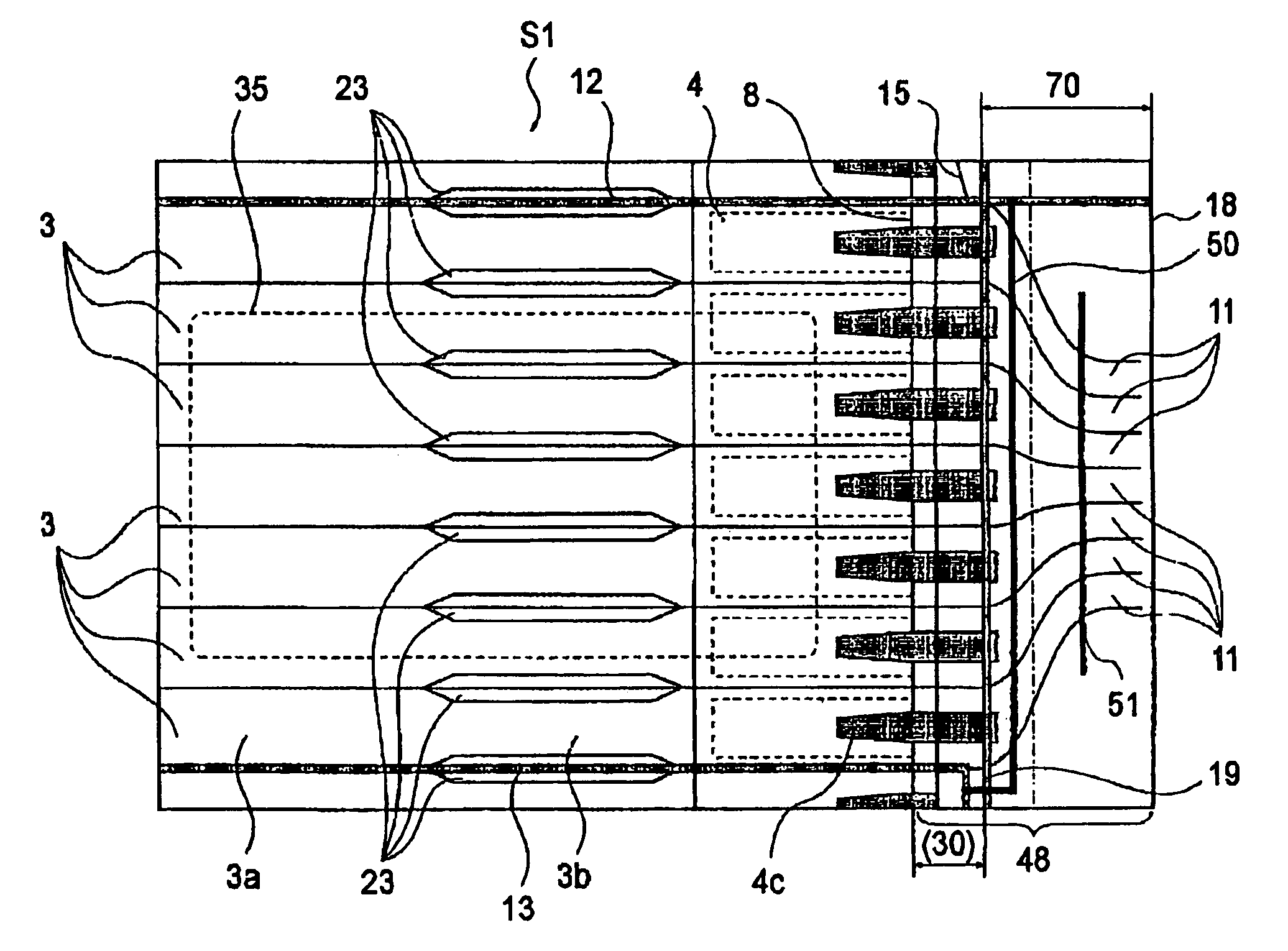

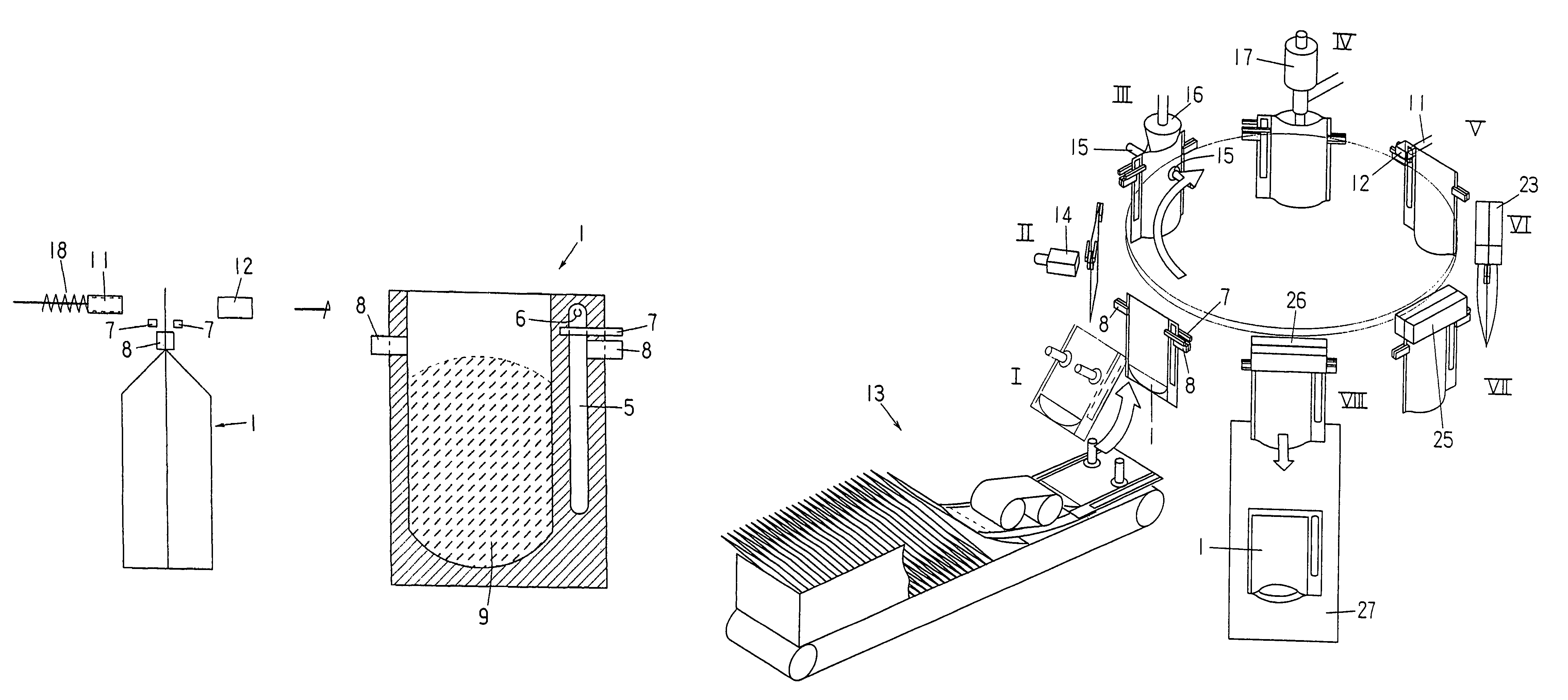

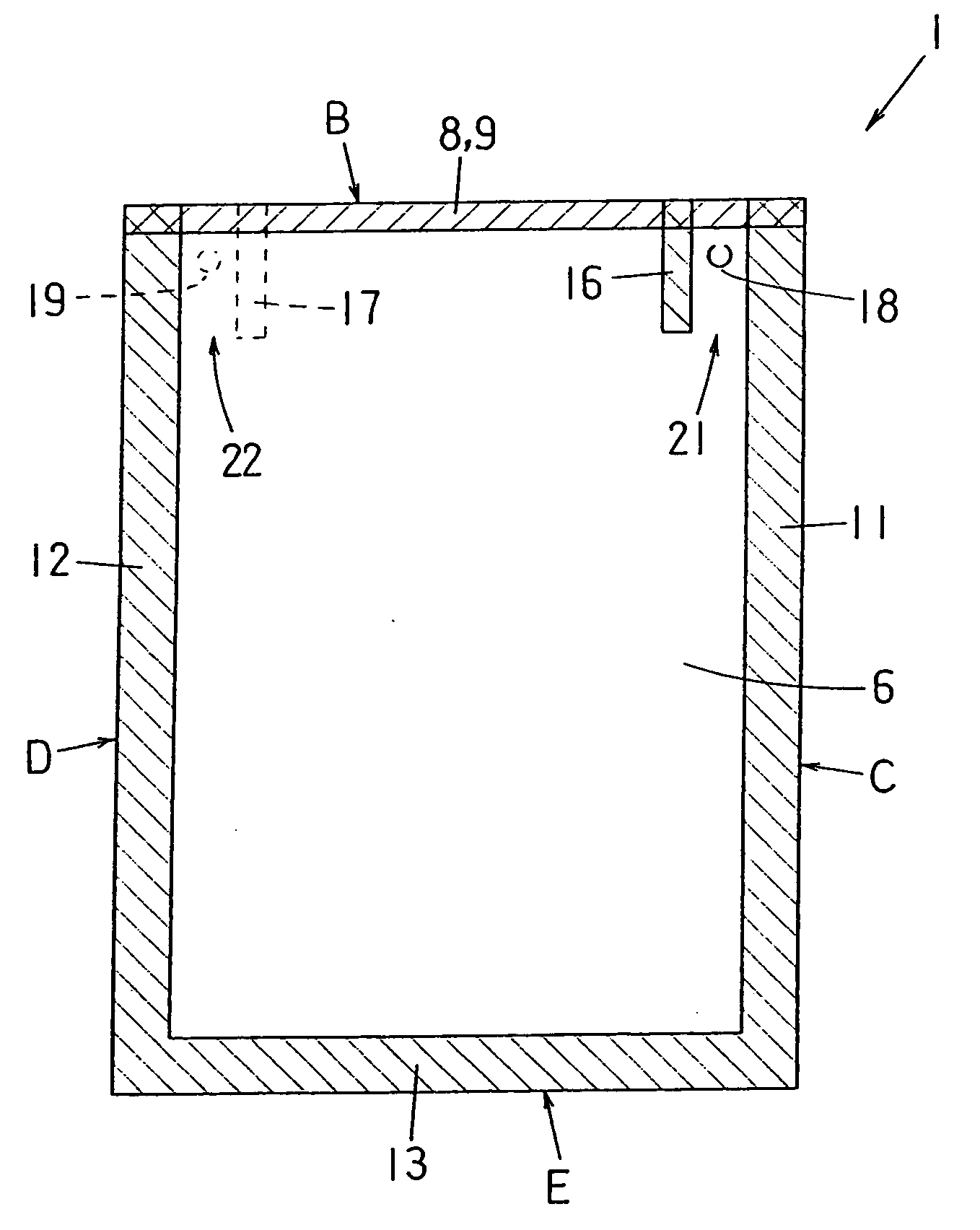

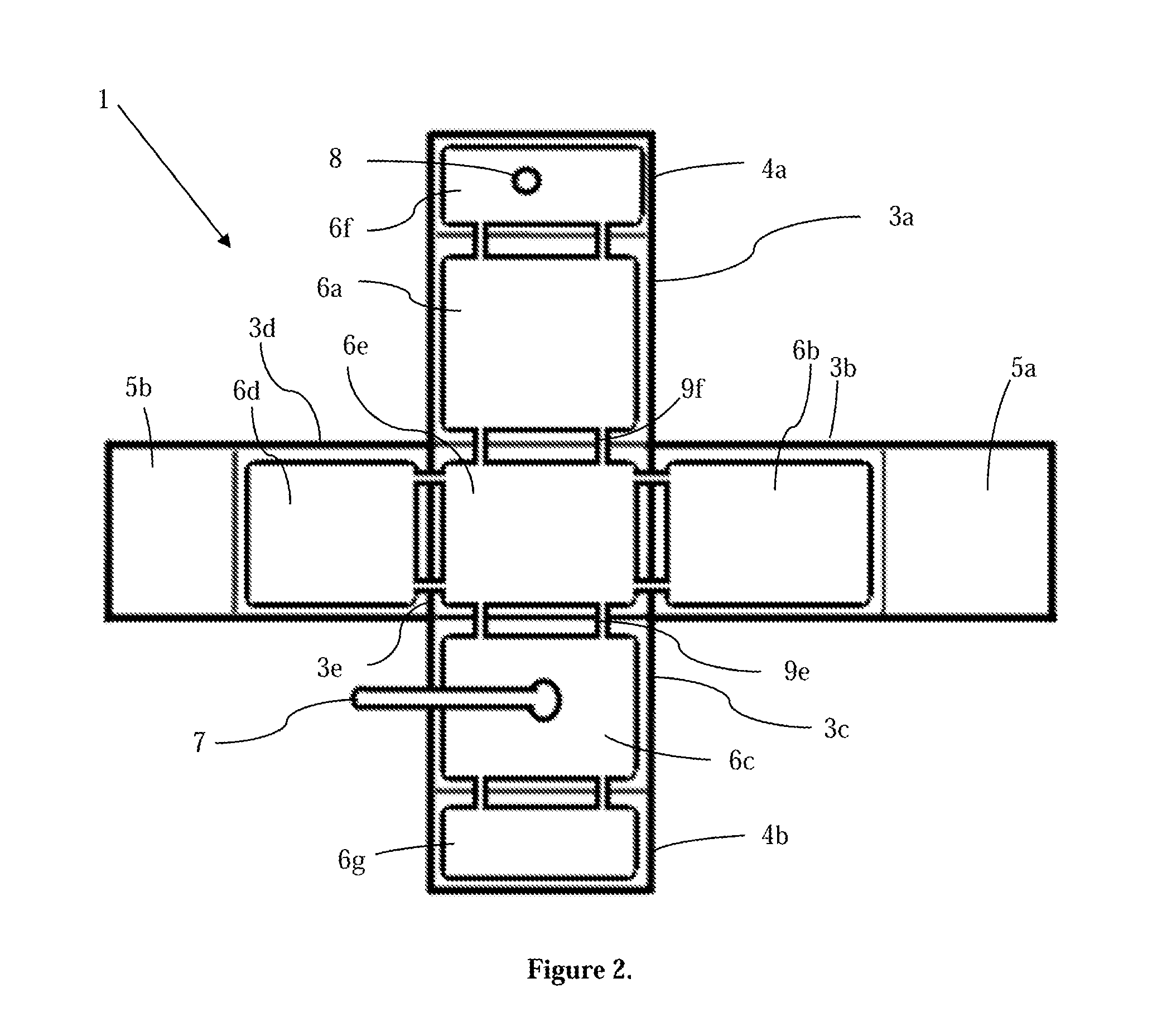

Bag with a gas filling compartment, method for manufacturing the same, method for sealing gas in the same and method for packaging the same

A bag made of an outer bag 3 and an inner bag 2. The inner bag, inside the outer bag, has an opening in the upper edge, and the inner and outer bags are sealed along the upper edges, on either side of the respective bags, to form sealed portions 8 and 9, and the inner bag and outer bag are further sealed together at two lateral side edges and lower edge to form sealed portions 11 and 12 and sealed portion 13, thus forming gas filling compartments 14 and 15. Cut-ins 18 and 19 are formed in the upper comers of the outer bag, and supplemental sealed portions 16 and 17 connected to the sealed portions 8 and 9 are formed. Air (gas) is blown into the gas filling compartments 14 and 15 through the cut-ins and then the overall bag mouth including the cut-ins is sealed.

Owner:TOYO JIDOKI CO LTD

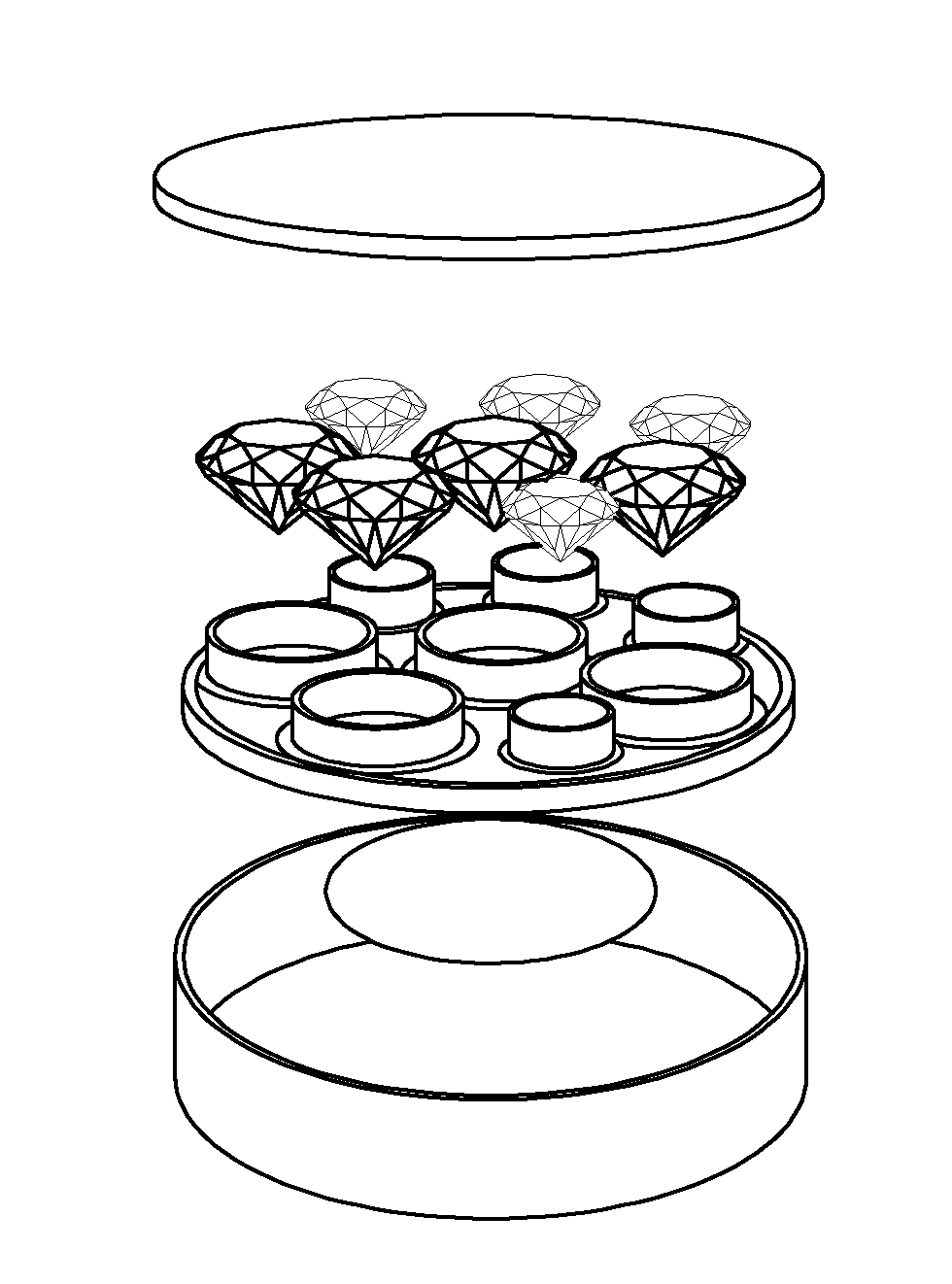

Method for closing cartridges, supporting structure for supporting cartridge closures and transport or packaging container

ActiveUS20180134423A1Simple processAccurate distancePharmaceutical containersPackage sterilisationEngineeringSyringe

In a method for closing a plurality of medical cartridges (5) a closure nest for supporting a plurality of closures is used, comprising a planar supporting plate having a plurality of receptacles having a plurality of tubular receptacles (61) and retaining structures for reliably accommodating the closures (200). In the method the plurality of medical cartridges (5) is supported in a corresponding cartridge nest. The closure nest is disposed above the cartridge nest so that the receptacles of the closure nest are precisely aligned with the receptacles of the cartridge nest. The closures (200) are then pushed downward out of the receptacles of the closure nest and into the cartridges (5), while the cartridges are supported by the cartridge nest. The closure nest can be directly fed on existing filling and stoppering machine set-ups for processing sealed prefillable syringe barrels, basically without the necessity of changing the set-up.

Owner:SCHOTT POONAWALLA PVT LTD

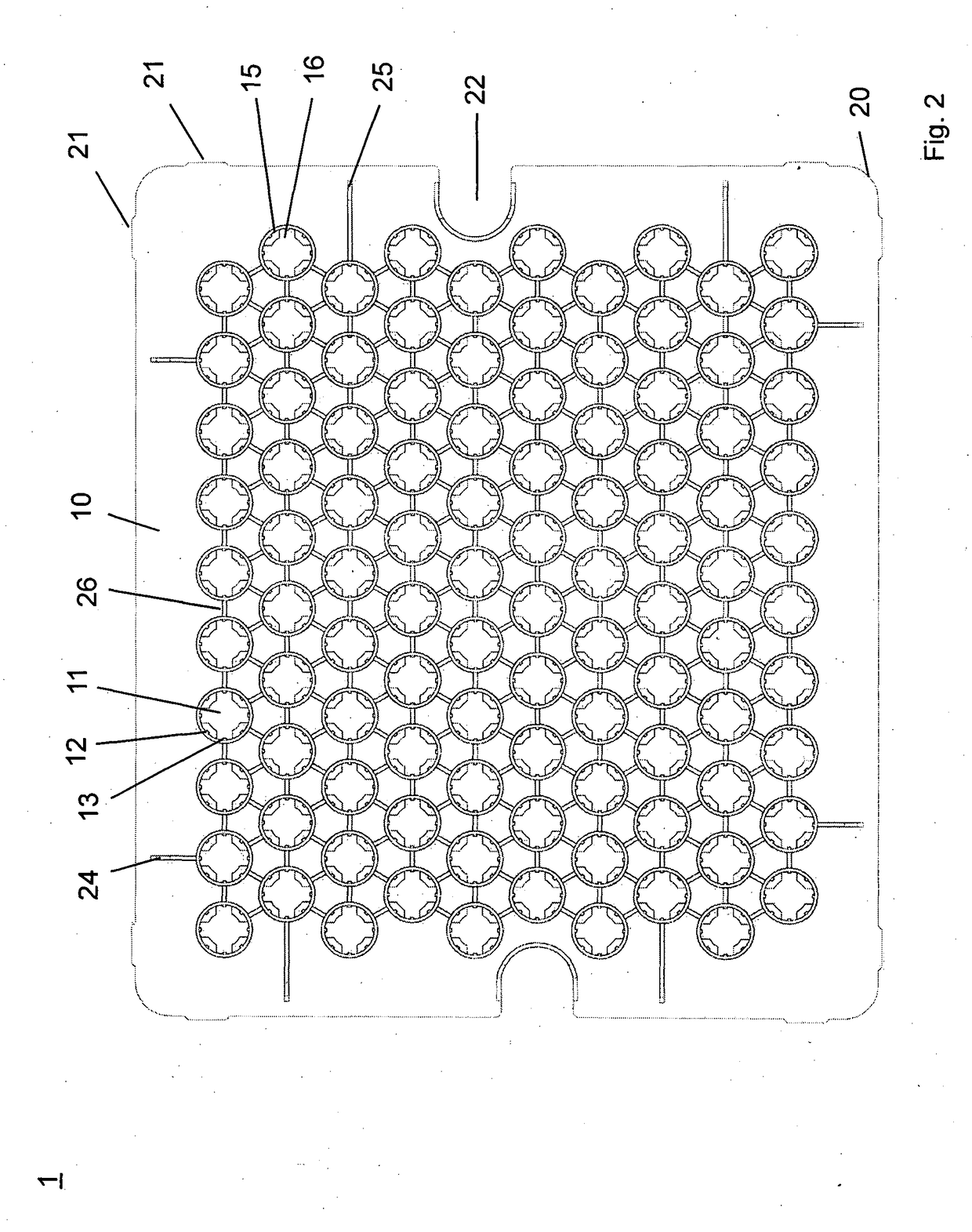

Dunnage and packaging optimization

Systems are provided for automatically optimizing packaging and dunnage for a group of objects. The systems calculate dimensions for a custom-made packaging template. The dimensions for the custom-made packaging template are adjusted to allow for a specific amount of dunnage. The systems generate a packaging command that causes a packaging-production machine to generate custom-made packaging templates based upon the calculated dimensions for the custom-made packaging template. The systems also generate a dunnage command that causes a dunnage-production machine to generate the specific amount of dunnage.

Owner:PACKSIZE

Method and apparatus for shock-absorbing packaging

Owner:ROOSE LARS D

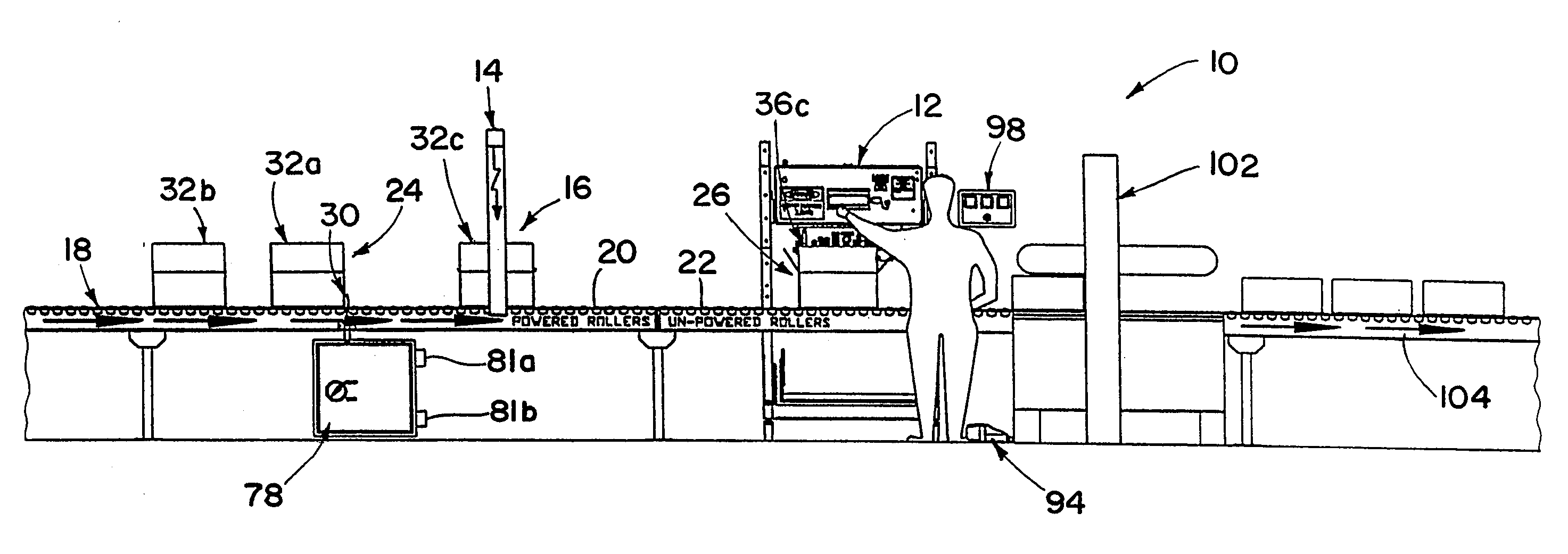

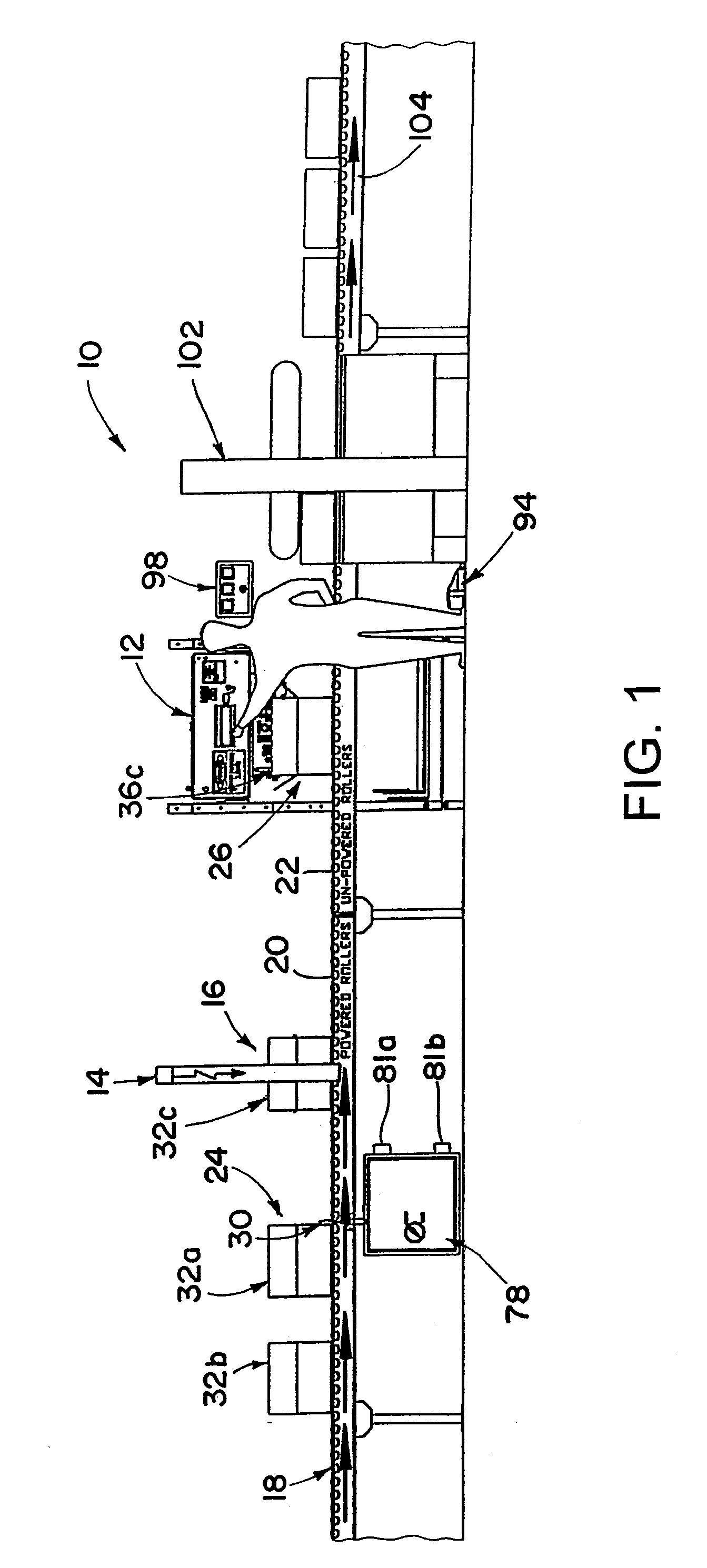

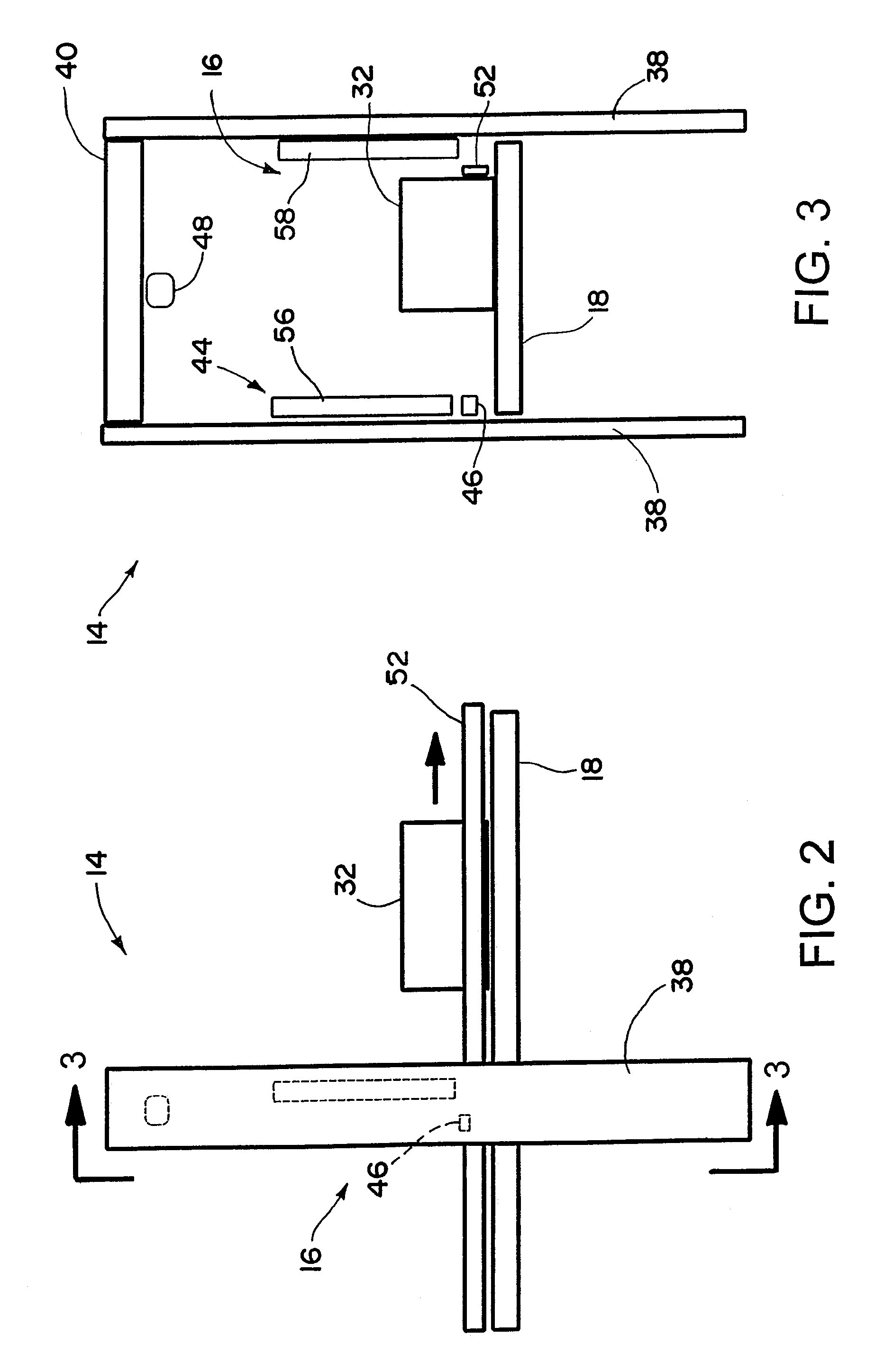

Packaging system with void fill measurement

A system, and associated components and methodology, that provides for automatic determination and supply of an amount of dunnage to fill the void left in a container in which one or more objects have been placed. The system comprises a dunnage dispenser which is operable to dispense a controlled amount of a dunnage, a container scanner, and a logic device. The container scanner includes a height sensor for sensing a height characteristic of a container, a width sensor for sensing a width characteristic of the container, and a contour sensor for sensing a contour characteristic of the objects in the container. The logic device can (1) process sensed characteristic information from the height sensor, width sensor and contour sensor, (2) determine the amount of dunnage needed to fill the void not occupied by the objects, and (3) command the dunnage dispenser to dispense the determined amount of dunnage.

Owner:RANPAK CORP

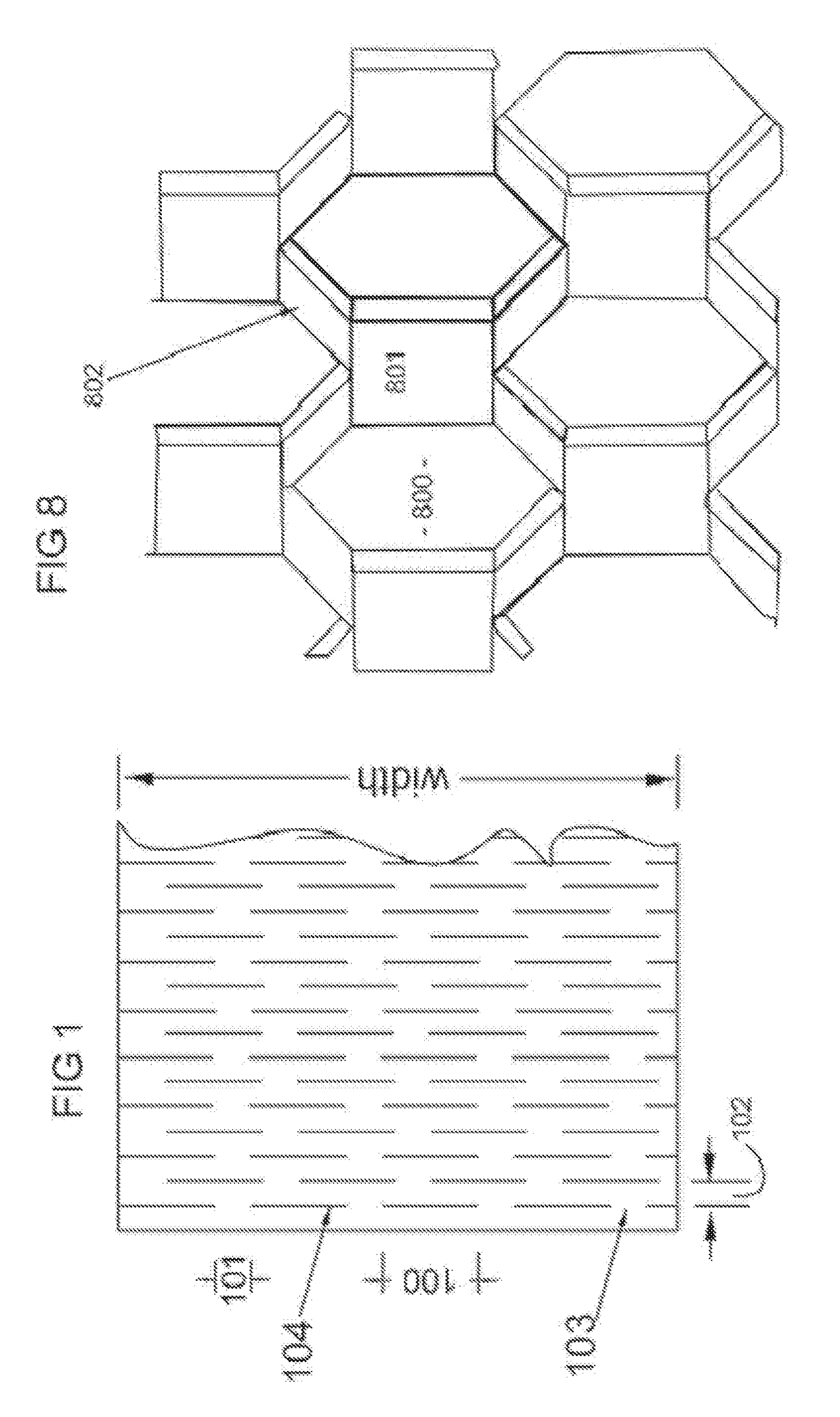

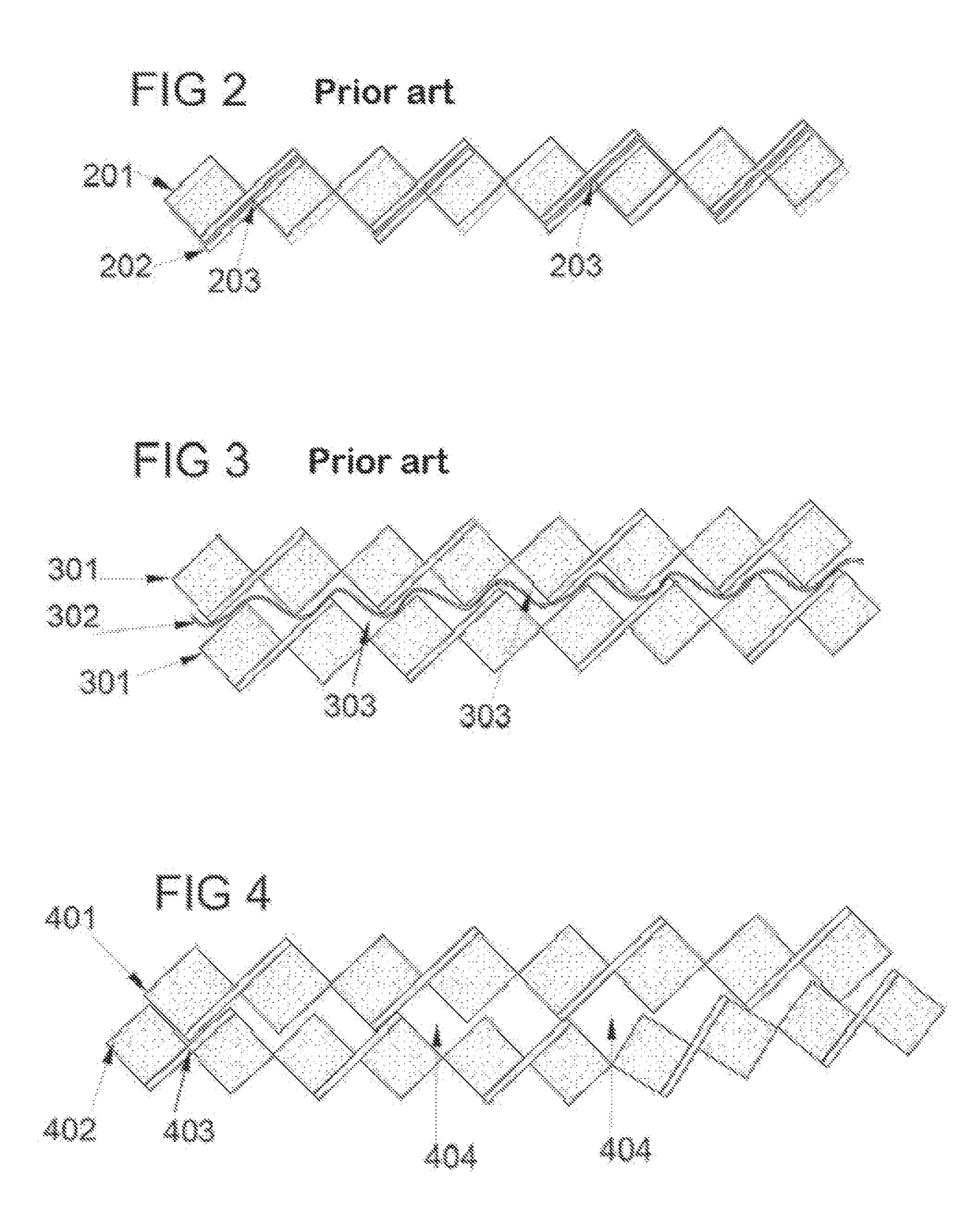

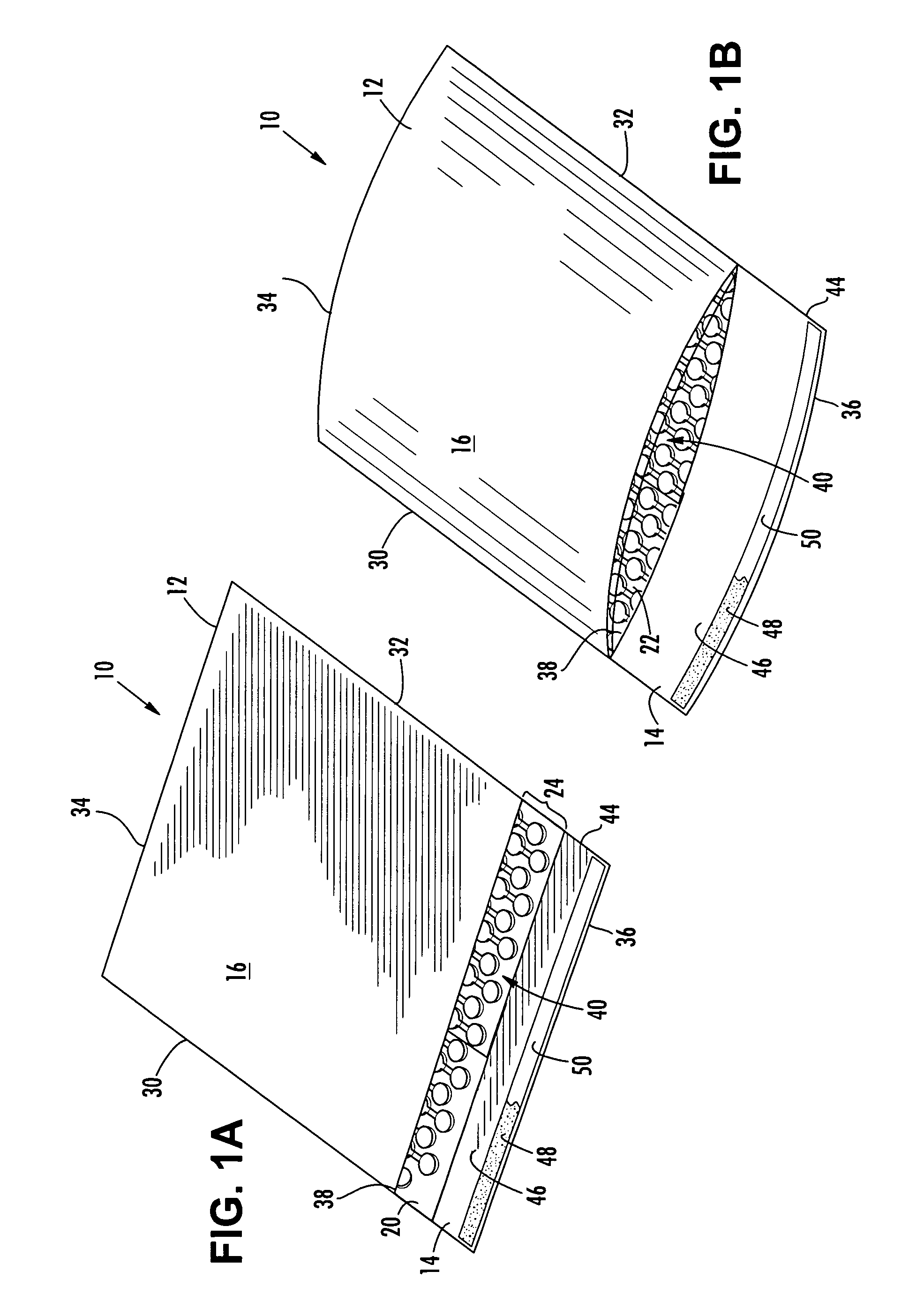

Expansion Apparatus and Method for Producing Interlocking Expanded Slit Sheet Packaging Material

InactiveUS20170203866A1Restricted amountMaximizing thicknessPaper/cardboard articlesWrappingPack materialEngineering

A paper product comprised of two or more slit material layers, each layer having a pattern design to create interlocking layers of expansion sheet packaging materials. Each layer expands to create a three dimensional open netting of cells of hexagons, and the like, and is designed to have limited nesting with its opposing layer, thereby maximizing the thickness of the combined layers as compared to nested layers. The layers having differing slit patterns that produce when expanded, inclined land areas that having different angles of inclination of the land areas, such that adjacent layers can interlock, that is, have a restricted amount of nesting.

Owner:GOODRICH DAVID PAUL

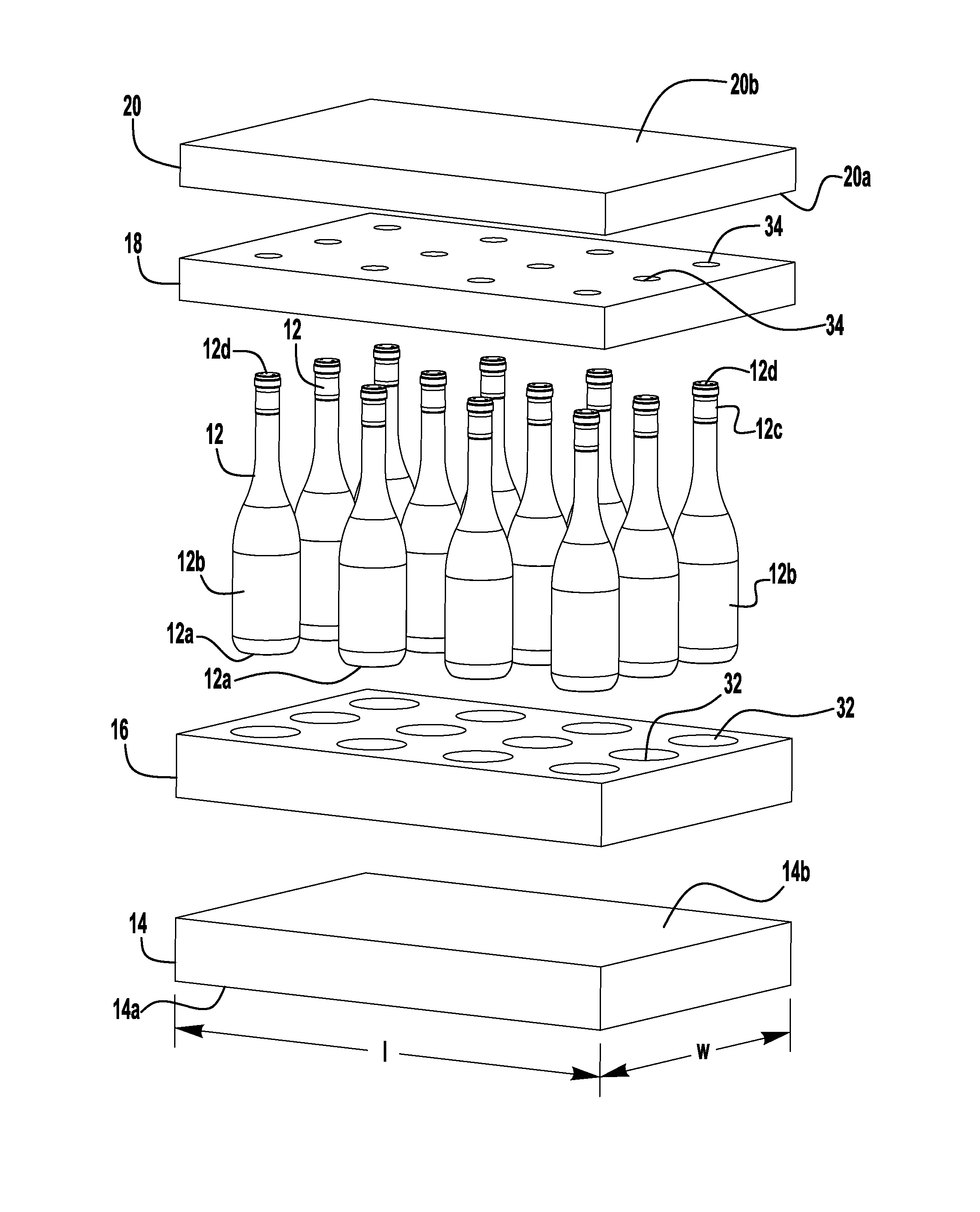

Bottle shipping system

A bottle shipping system and method for packaging bottles that prevents movement of the bottles during transport. The system includes a first foam section is placed on the bottom wall of a carton having a rectangular shaped prism having four side walls, a bottom wall and a top wall to provide a support surface on which the bottles are placed. A second foam section having a first plurality of openings therethrough adapted to receive the body of the bottles is disposed within the carton above the first foam section. A third foam section having a second plurality of openings therethrough adapted to receive the neck of the bottles is disposed between the second foam section and the top wall of the carton. A fourth foam section to provide a buffer surface against which the bottles are pressed is placed against the top wall of the carton.

Owner:DIMAURO PAUL

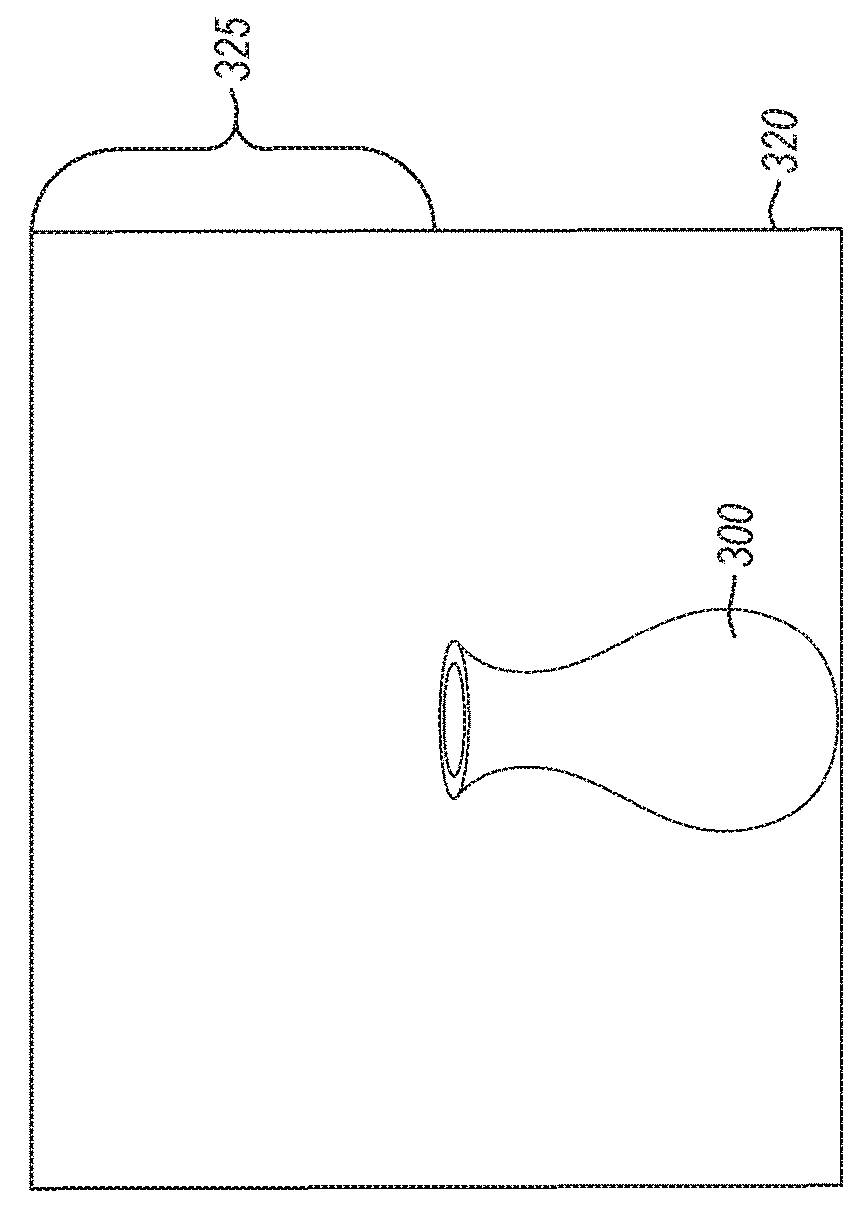

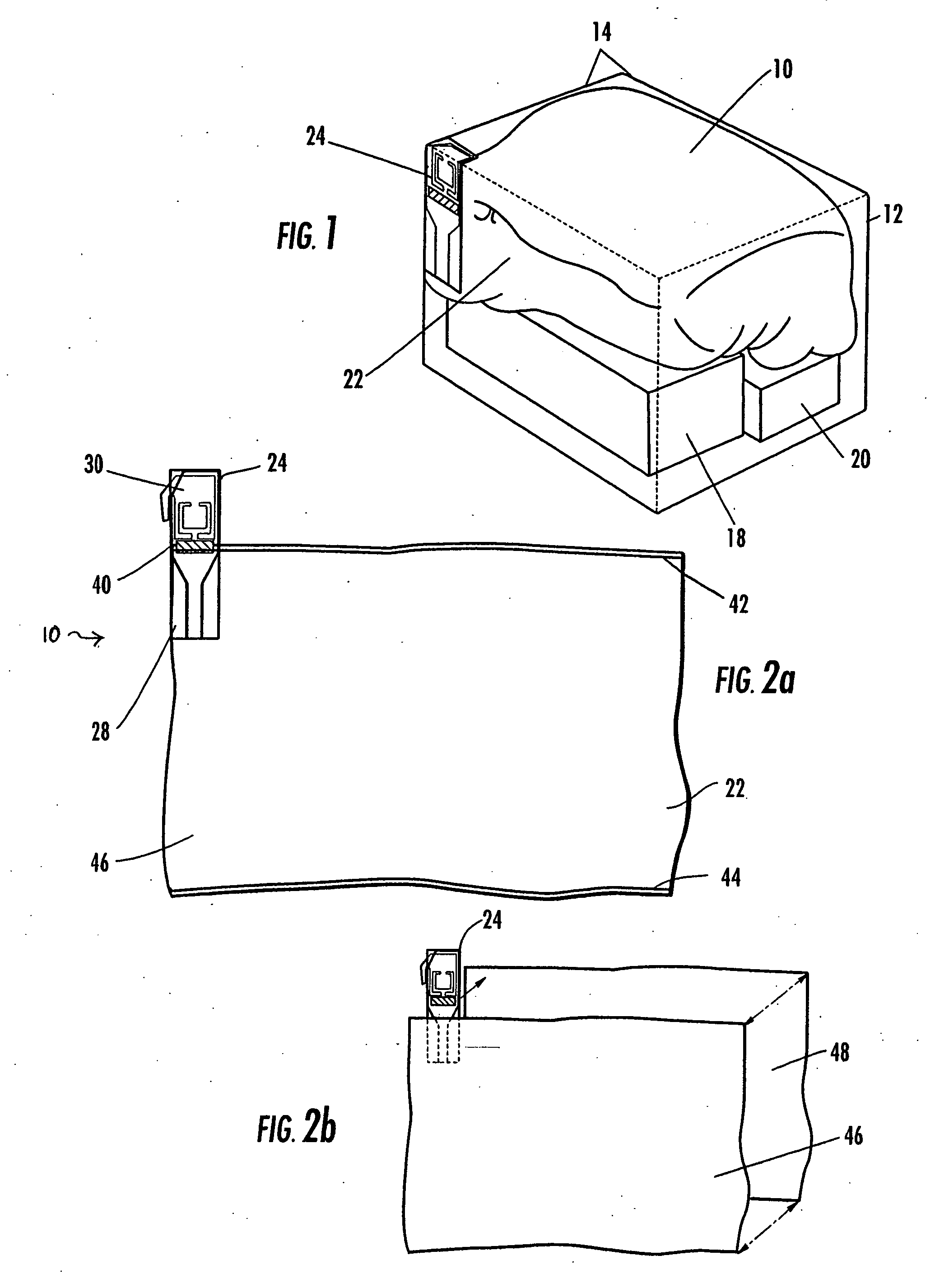

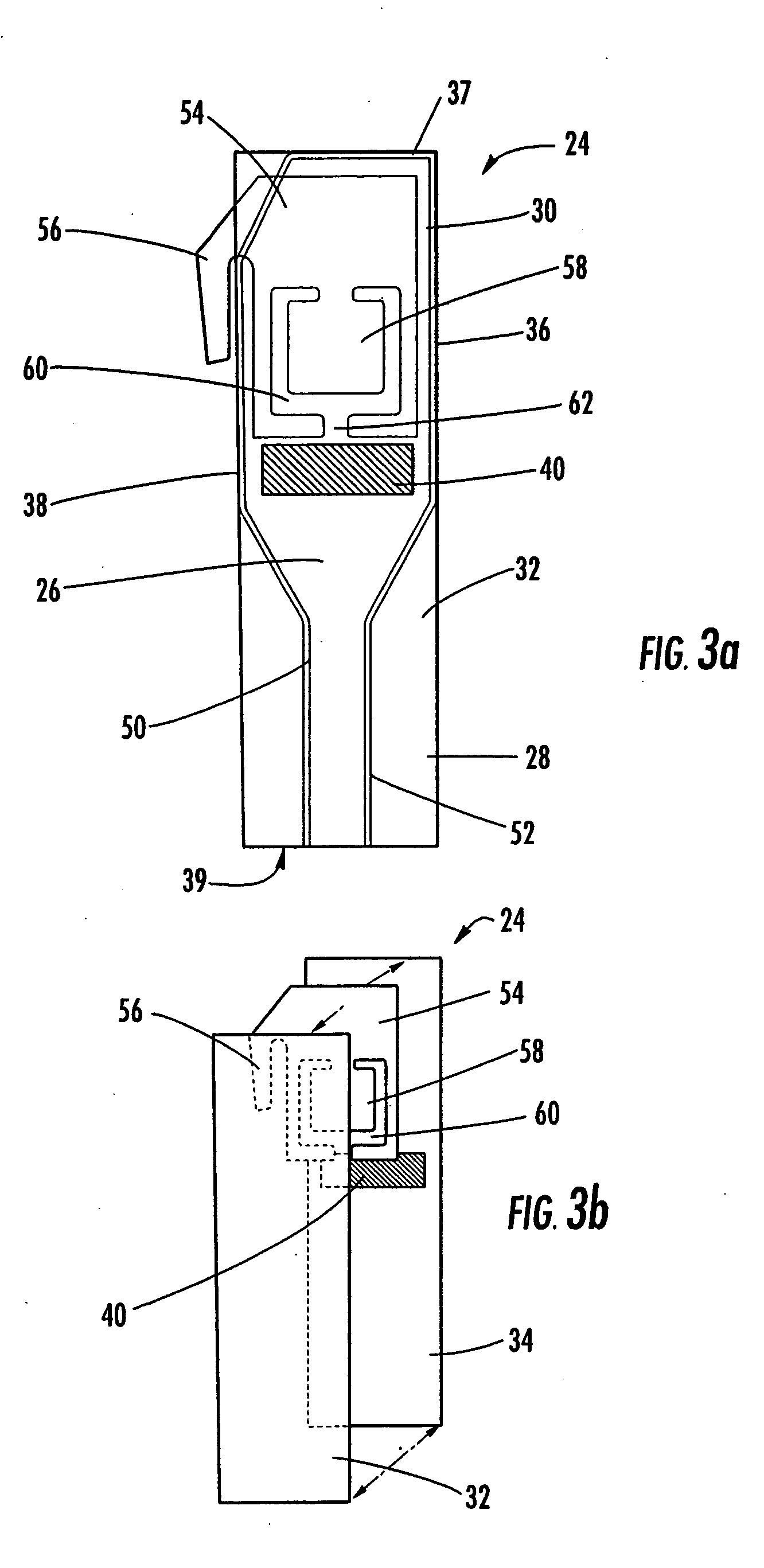

Inflatable mailer, apparatus and method for preparing the same

InactiveUS7621104B2Prevent escapeEasy to inflateEnvelopes/bags making machineryCapsEngineeringNozzle

Owner:SEALED AIR U S

Packing method, packing member and manufacturing method therefor

InactiveUS20060191817A1Improve efficiencySuperior in shipment efficiencyPackaging vehiclesPaper/cardboard articlesEngineeringVALVE PORT

A packing member for packing an article, includes a medium accommodating portion for accommodating medium; a non-return valve for passing the medium to the medium accommodating portion and stopping the medium away from the medium accommodating portion; an introducing portion for introducing the medium into the medium accommodating portion with the non-return valve from an outside of the packing member to balloon the medium accommodating portion; and a sealing region, disposed upstream of the non-return valve with respect to a direction of the introduction of the medium from the introducing portion toward the non-return valve, for sealing against the introduction of the medium to prevent leakage from the introducing portion to an outside of the packing member, the sealing region being sealed to keep the medium in the medium accommodating portion.

Owner:CANON KK

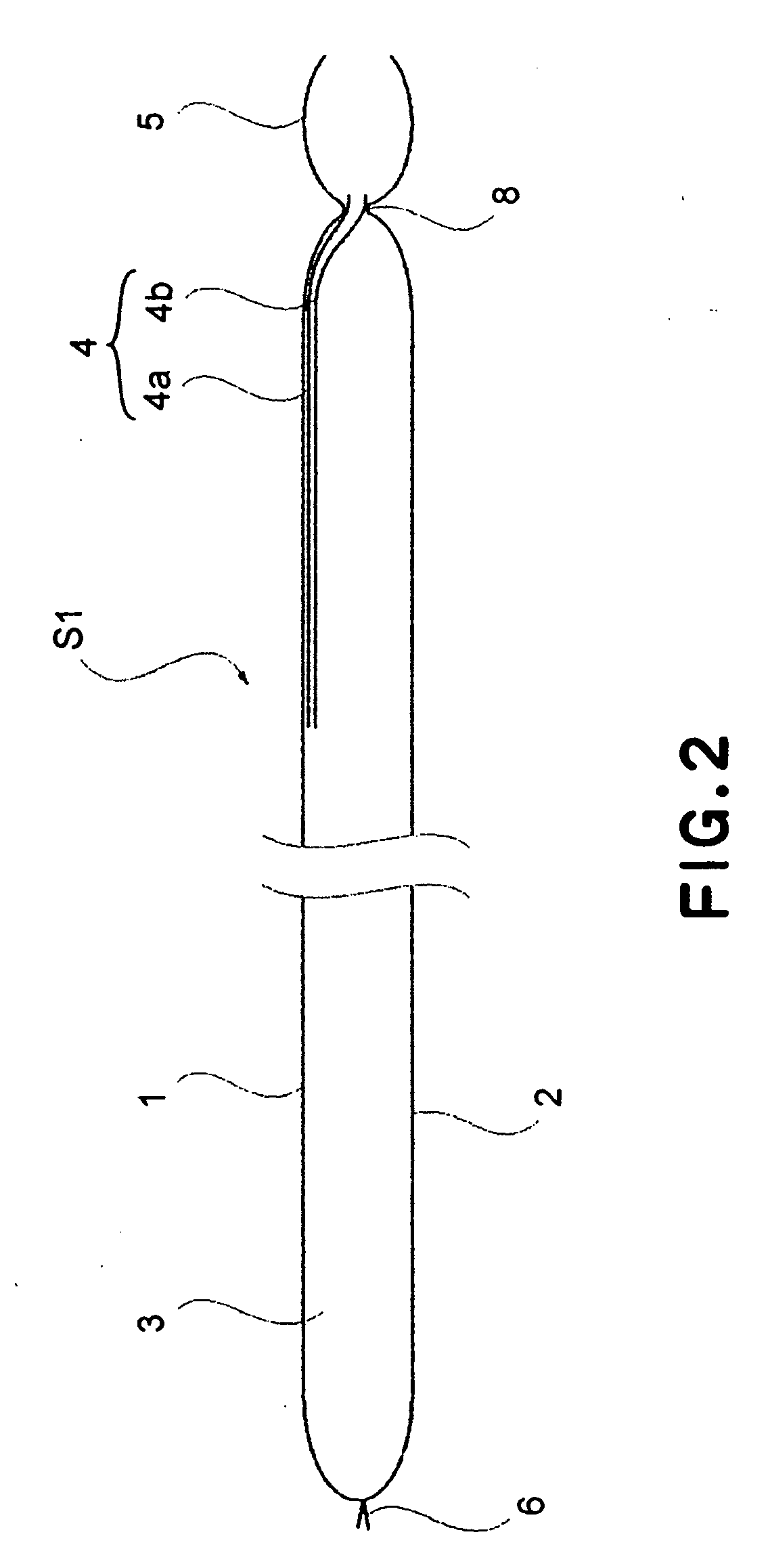

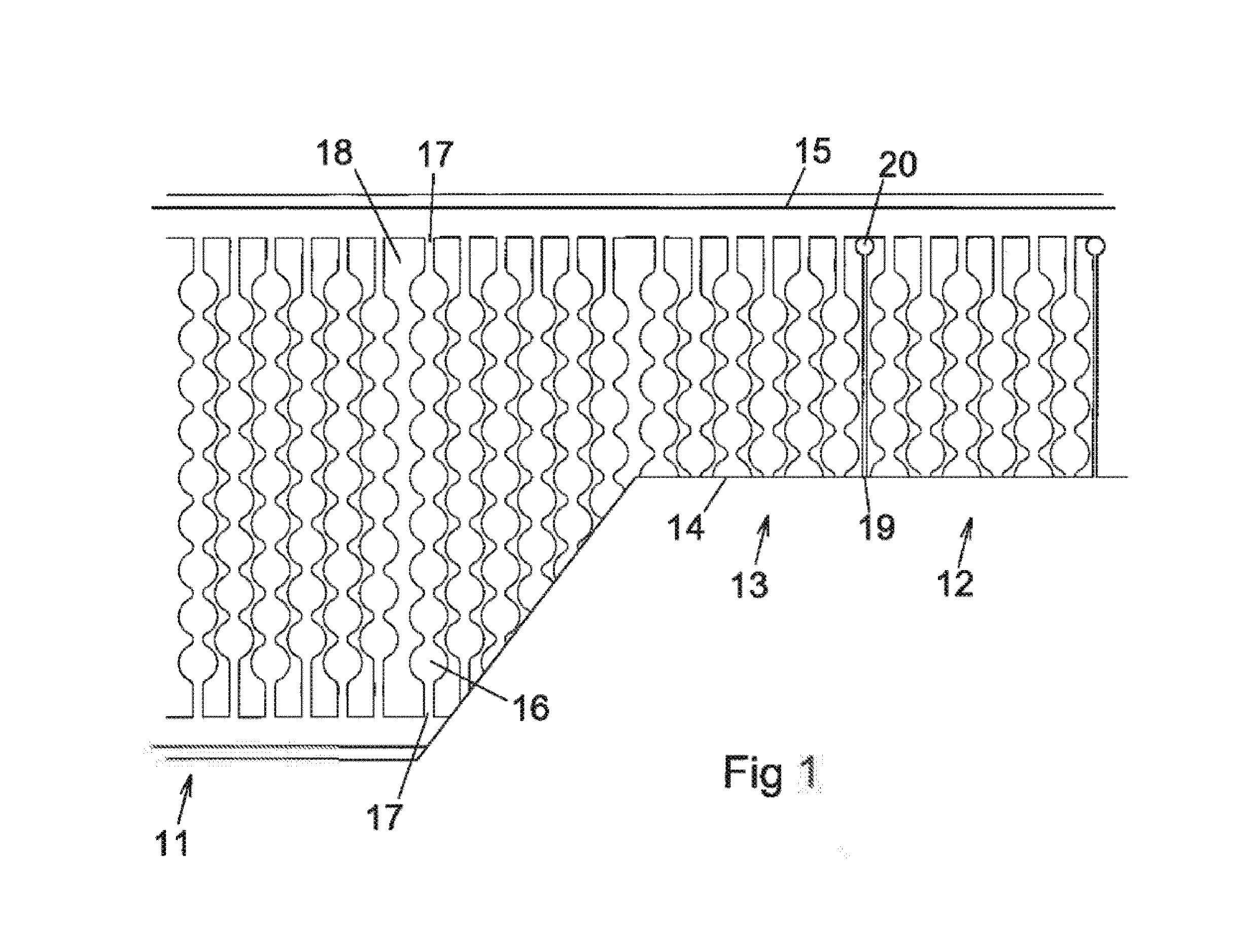

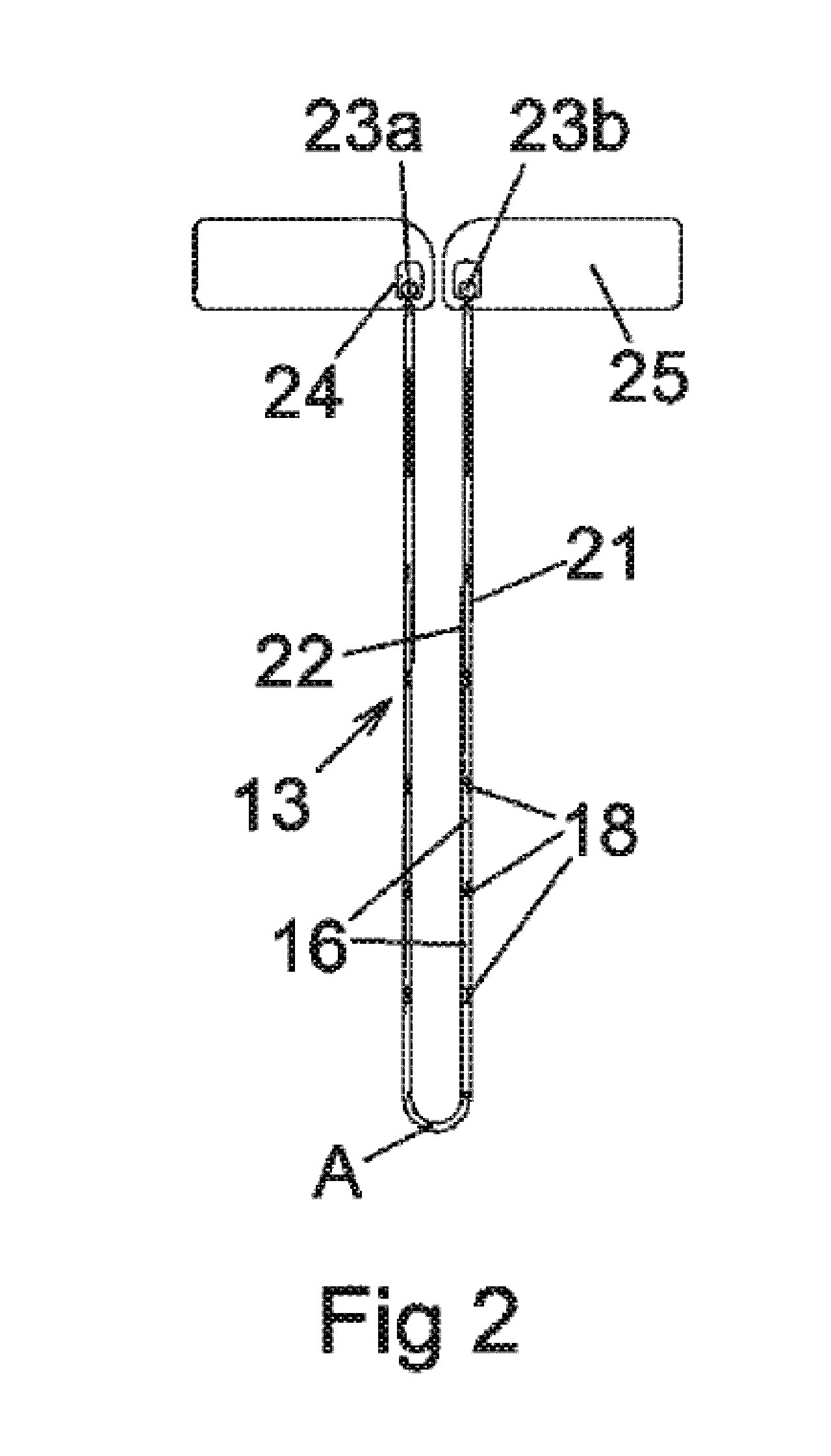

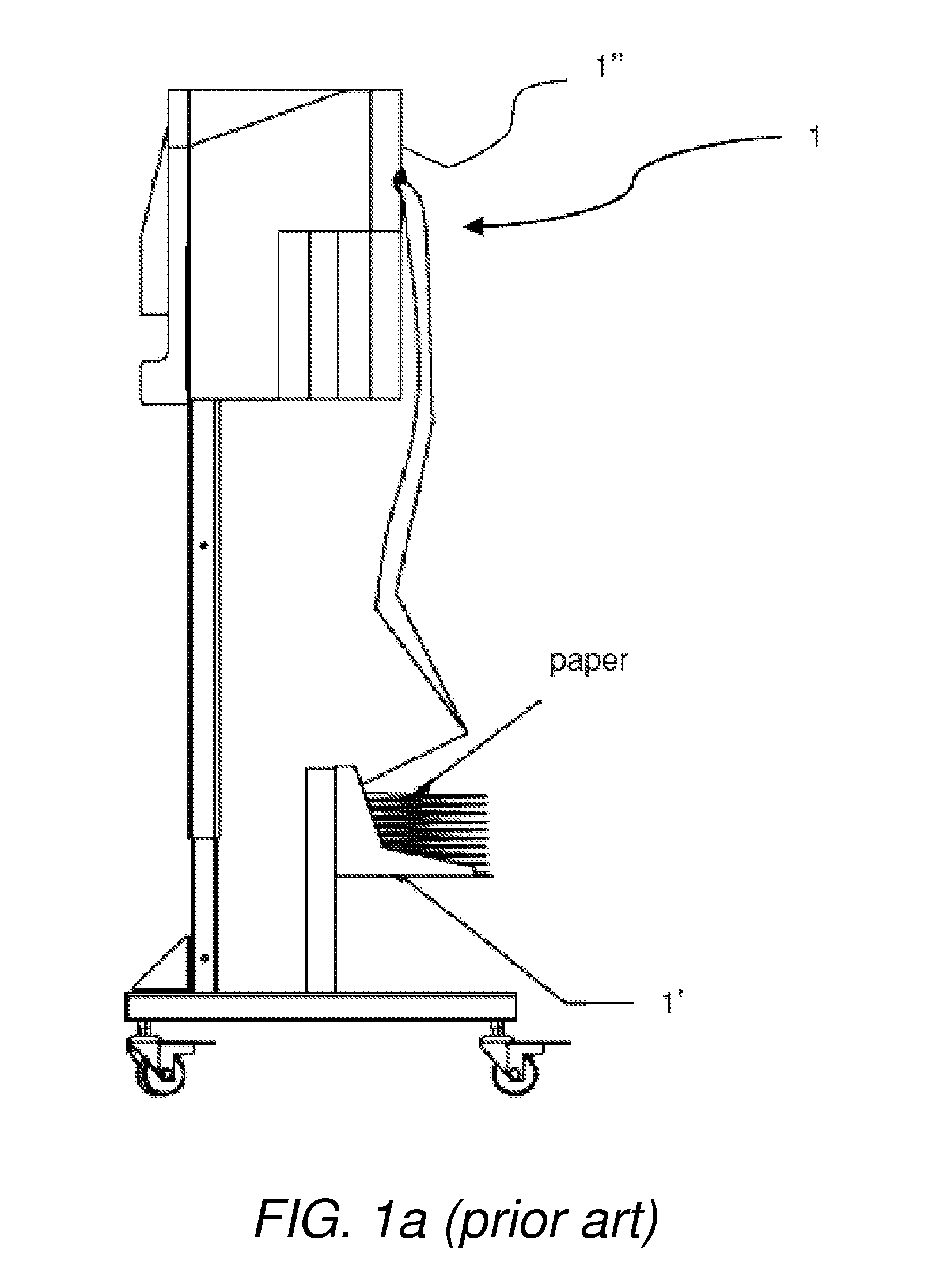

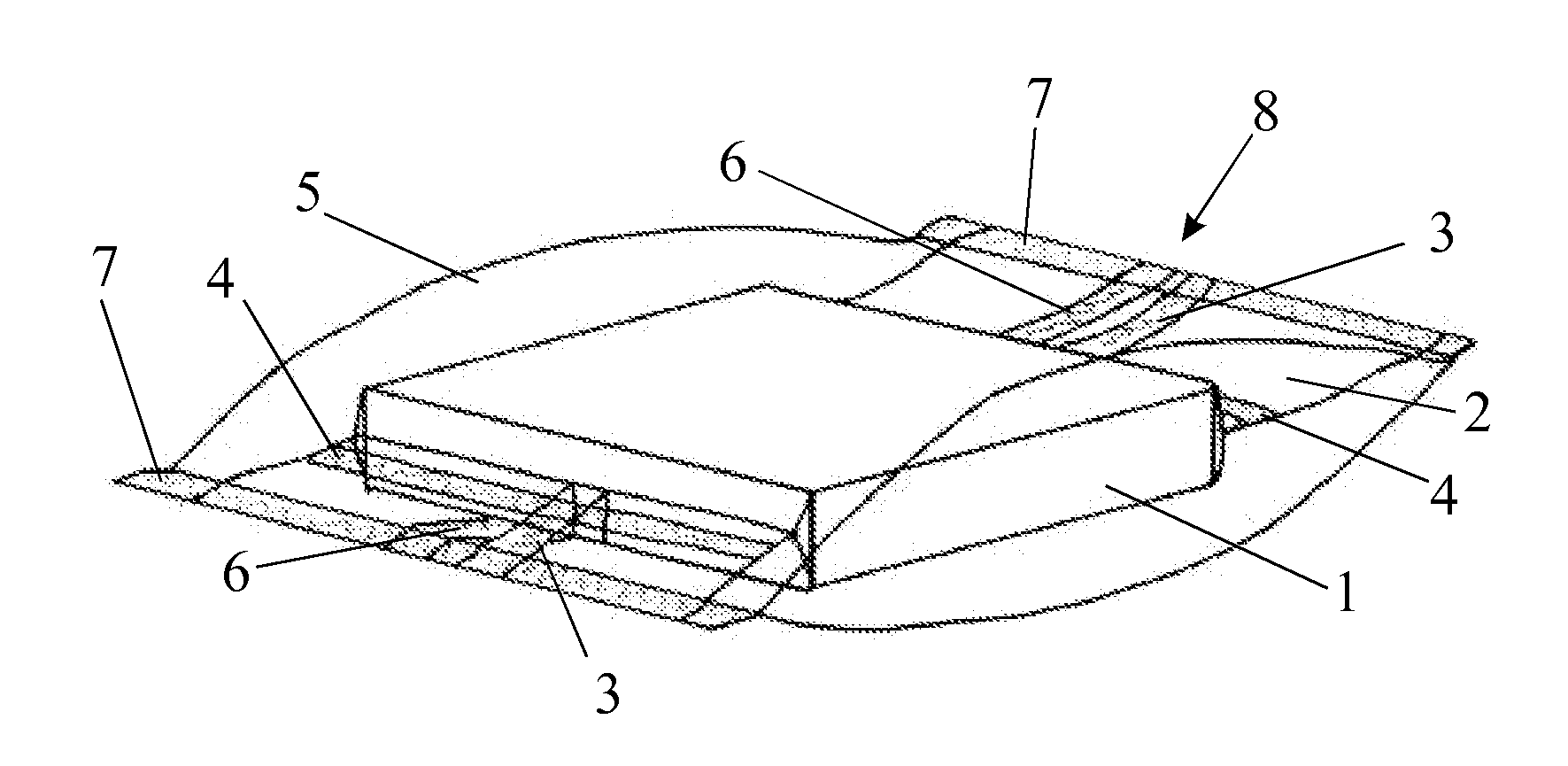

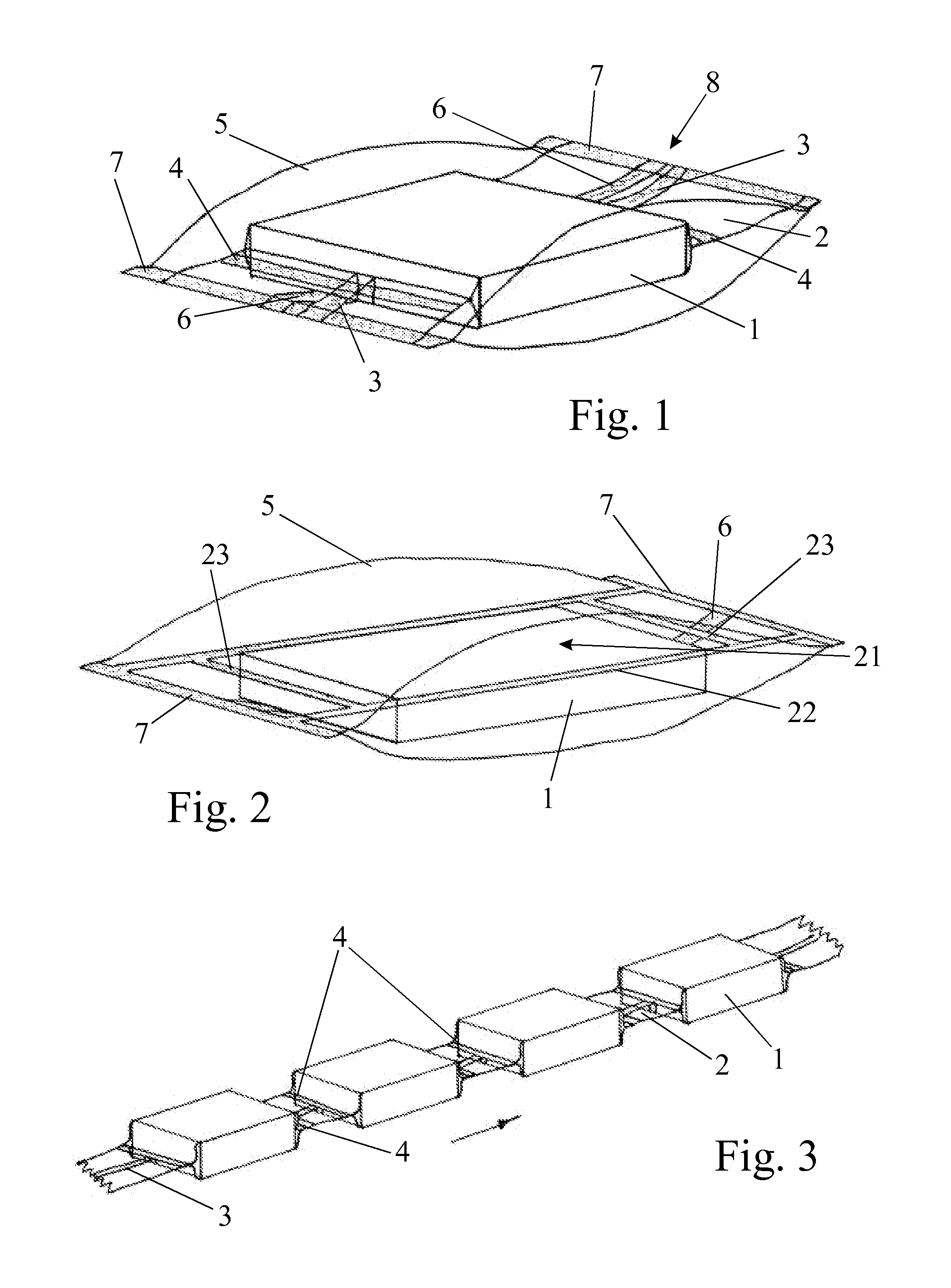

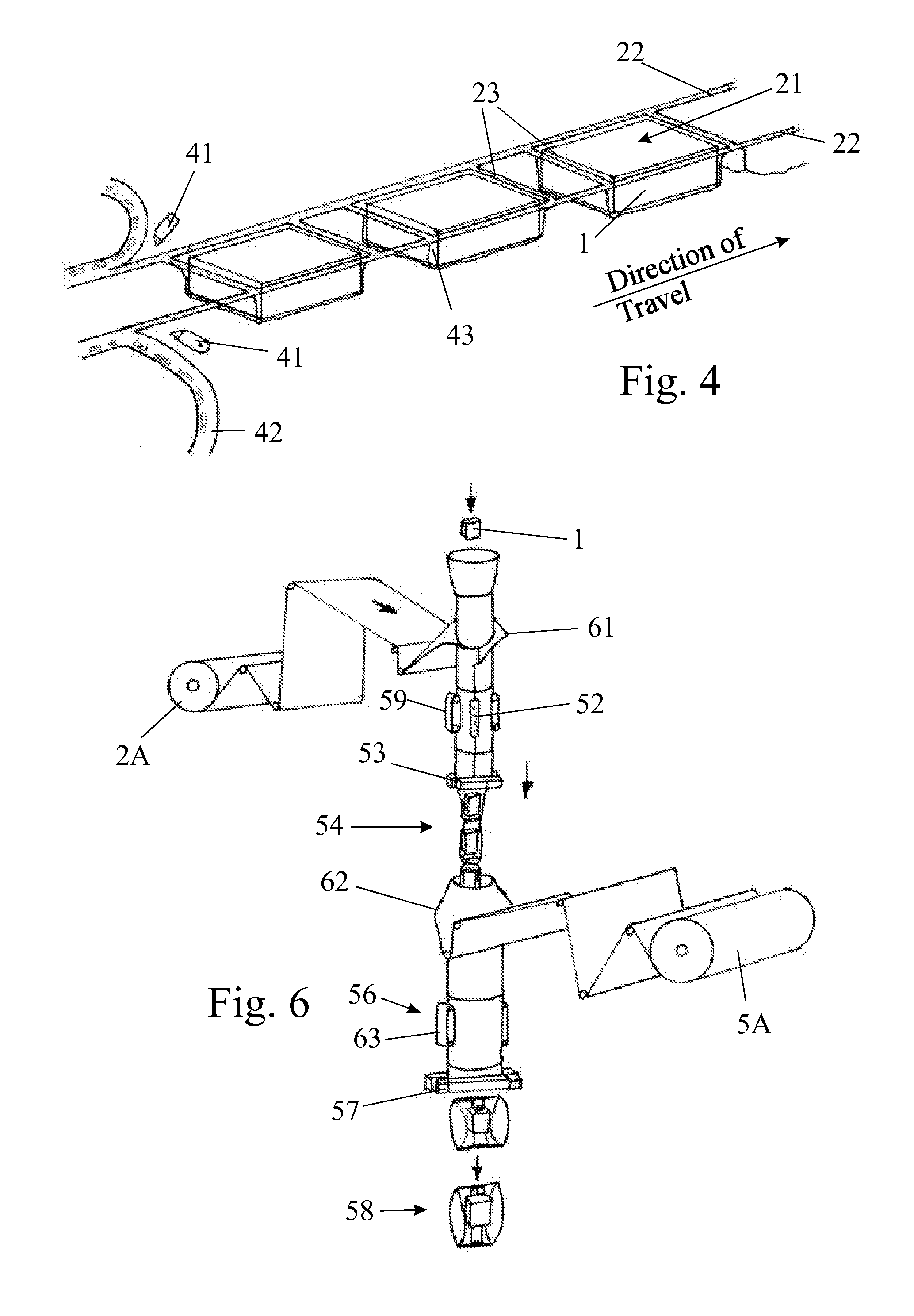

Device for producing shock-absorbing inflatable package and method for filling it

InactiveUS20140130461A1LessSimplify handling and packingOpening closed containersBottle/container closureEngineeringWork in process

Bag blank (13) comprising an inflatable package blank (11) on a running web, which package blank (11) comprises a semi-finished product consisting of a first plane plastic sheeting (21) and a second plane plastic sheeting (22), which plastic sheetings abut with their plane surfaces against each other and are interconnected by welds (18) so that a series of delimited transverse chambers (16) is formed between the two plastic sheetings (21,22) across the surface of the entire package blank (11), this semi-finished product being folded or welded together along a longitudinal centre line (14) so that its two long sides are parallel and face in the same direction, and that a first longitudinal suspension arrangement (15, 23a, 43a) is connected to the edge along the first long side of the package blank (11) or the bag blank (13), and that a second longitudinal suspension arrangement (23b, 43b) is applied at the edge along the second long side of the package blank (11) or the bag blank (13), as well that the bag blank (13) is provided with transverse full-penetration weldings (18) having a length that has been terminated a distance from the longitudinal suspension arrangements.

Owner:PRONOVA

Packaging system and method

Owner:DUBBLE BUBBLE

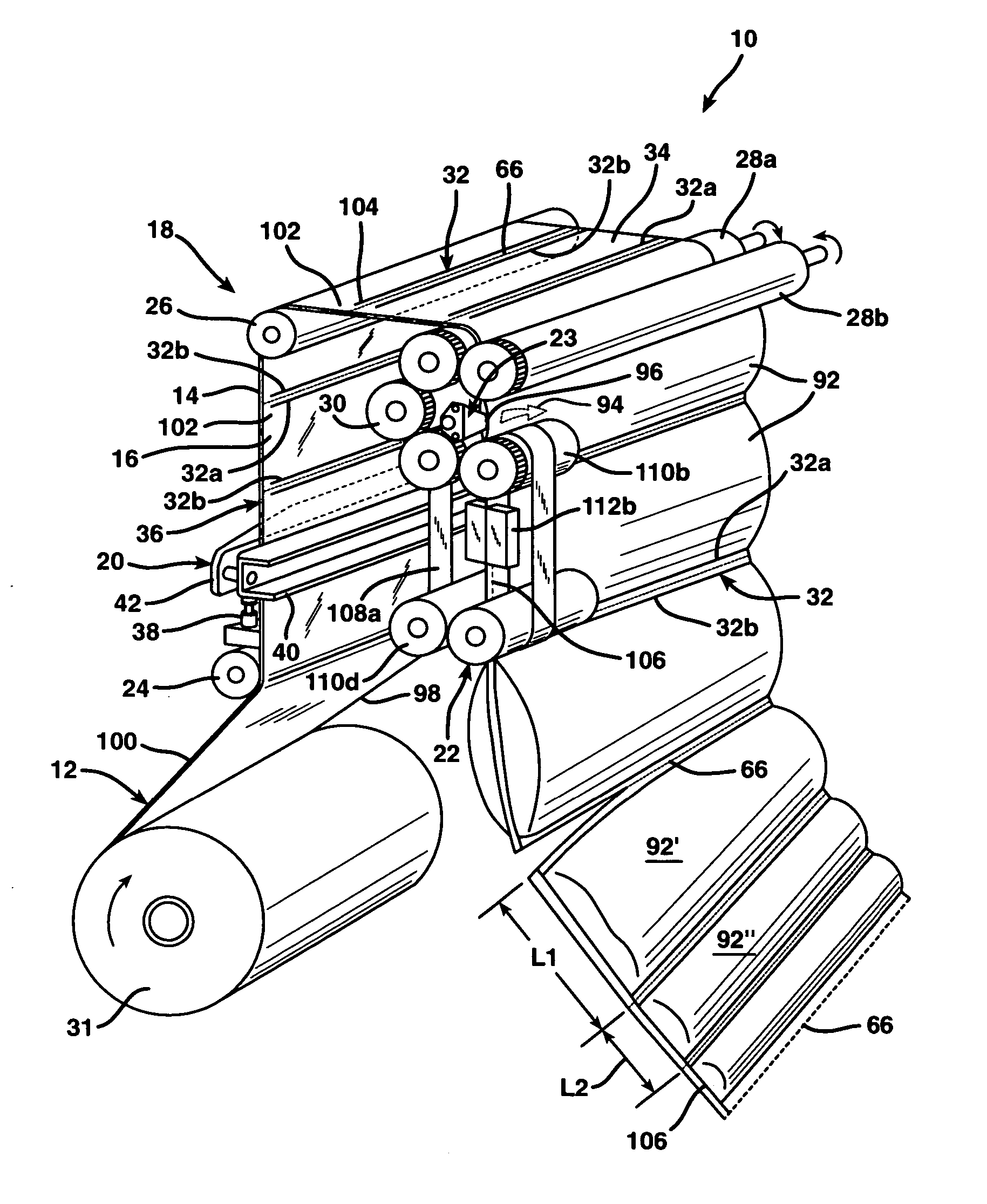

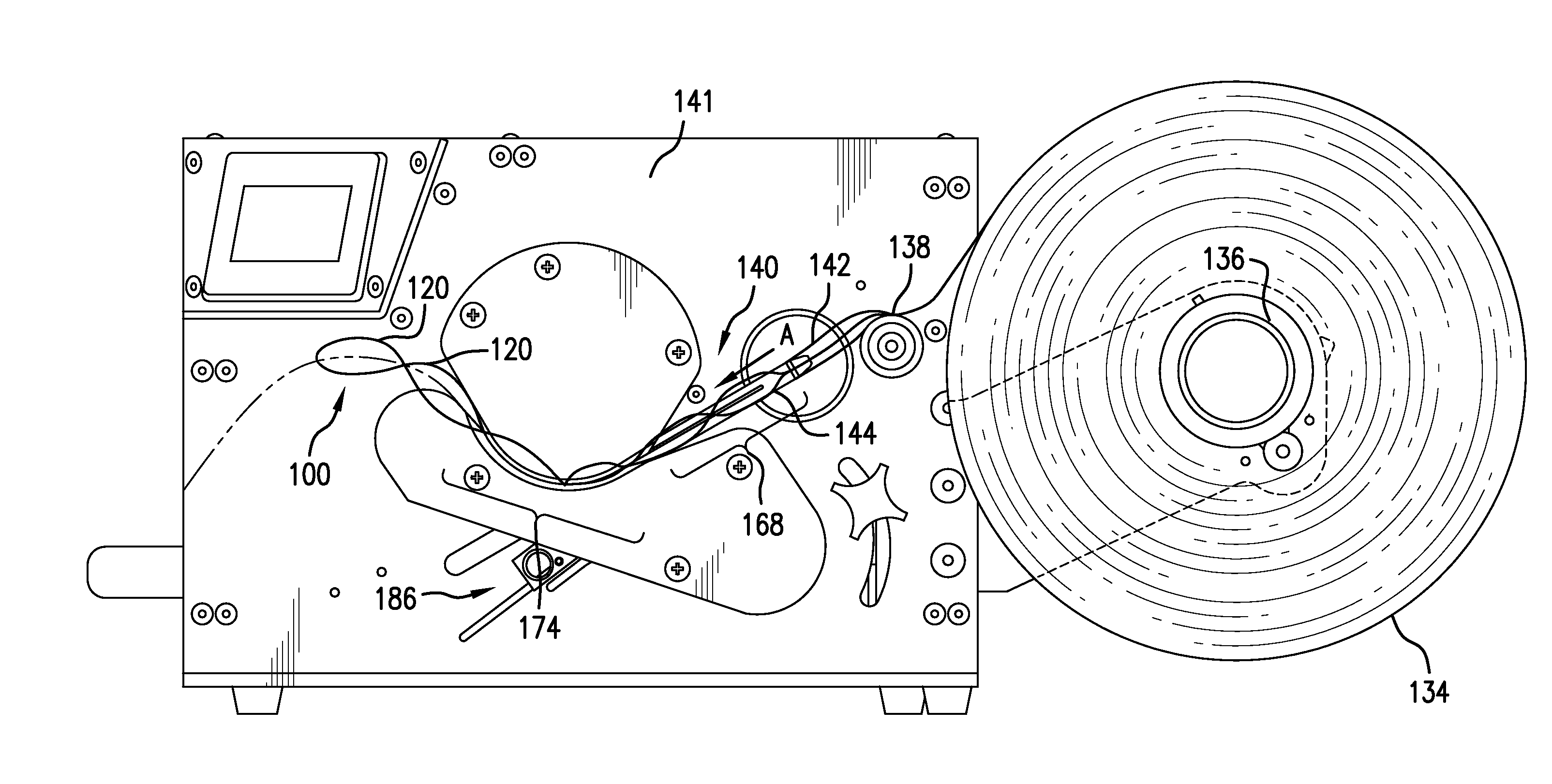

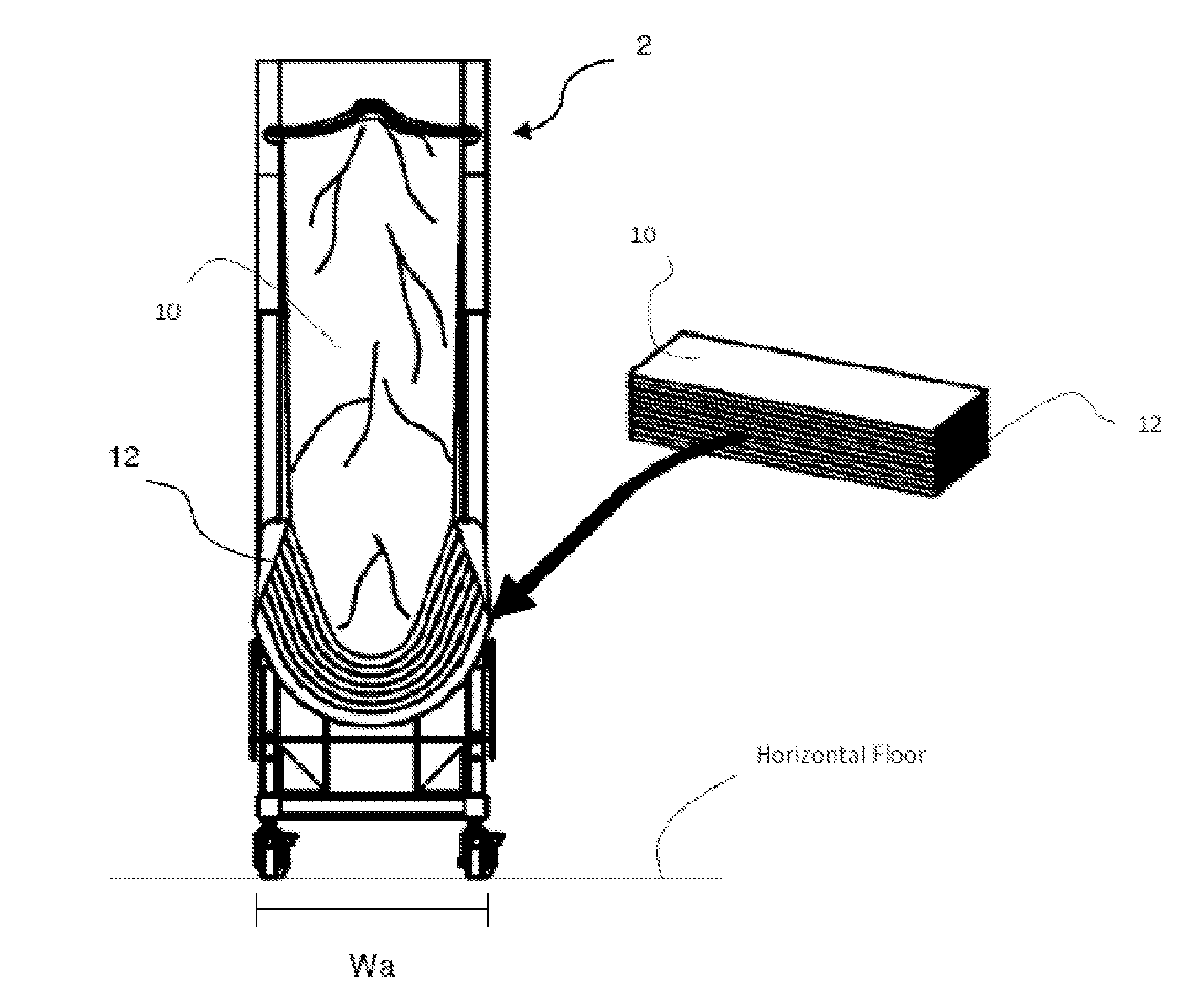

Apparatus, systems and methods for configuring/ feeding sheet stock material for a dunnage system and for generating upright edge dunnage strips

InactiveUS20160082685A1Maximum widthPaper/cardboard articlesUsing shock-absorbing mediaDunnageEngineering

Various embodiments for stock material for dunnage systems are provided with multi-directional perforation lines, including laterally and longitudinally extending perforations. The stock material can be configured in fan-fold or rolled form, and can be pre-folded. The perforations can help weaken the configured stock material to conform to holding trays. The holding trays can hold horizontally aligned fan-fold stacks of the stock material. Also, the configured stock material can be fed to a dunnage system have forming members that rotate about a vertical axis to generate cushioning strips with a vertical width greater than a horizontal width. Various methods and systems are also provided for making and using the same.

Owner:INTERTAPE POLYMER CORP

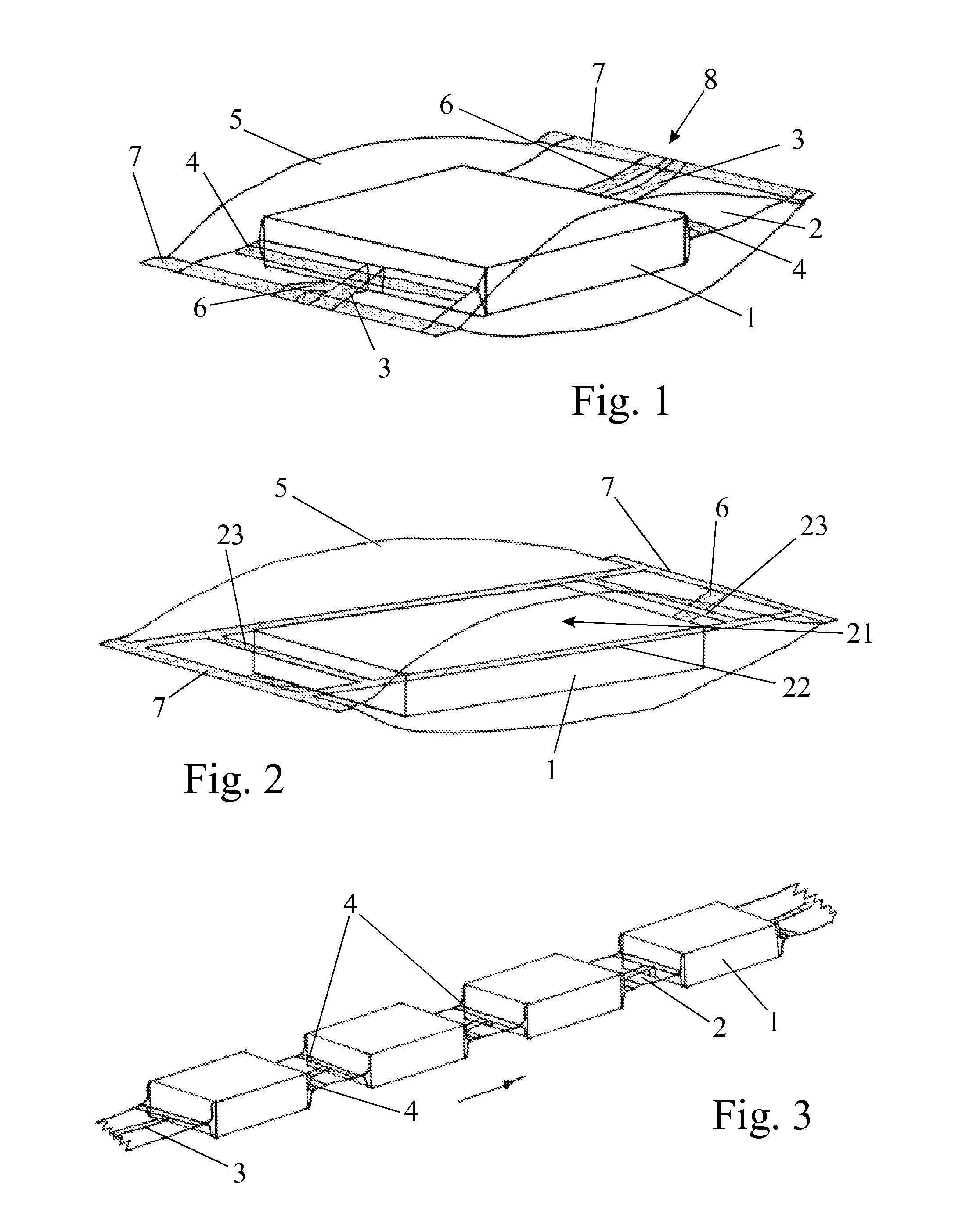

Packaging System and Method

A package for an article (1) comprises a pressurised outer bag (5) having gas-tight seals (7) at opposite ends, and an inner web for supporting the article within the outer bag. The web extends along the length of the outer bag and is secured to the outer bag only at the gas-tight seals (7). The web is maintained under sufficient tension by the pressure within the outer bag to suspend the article within the bag and to maintain a space between the article and the outer bag on all sides of the article.

Owner:DUBBLE BUBBLE

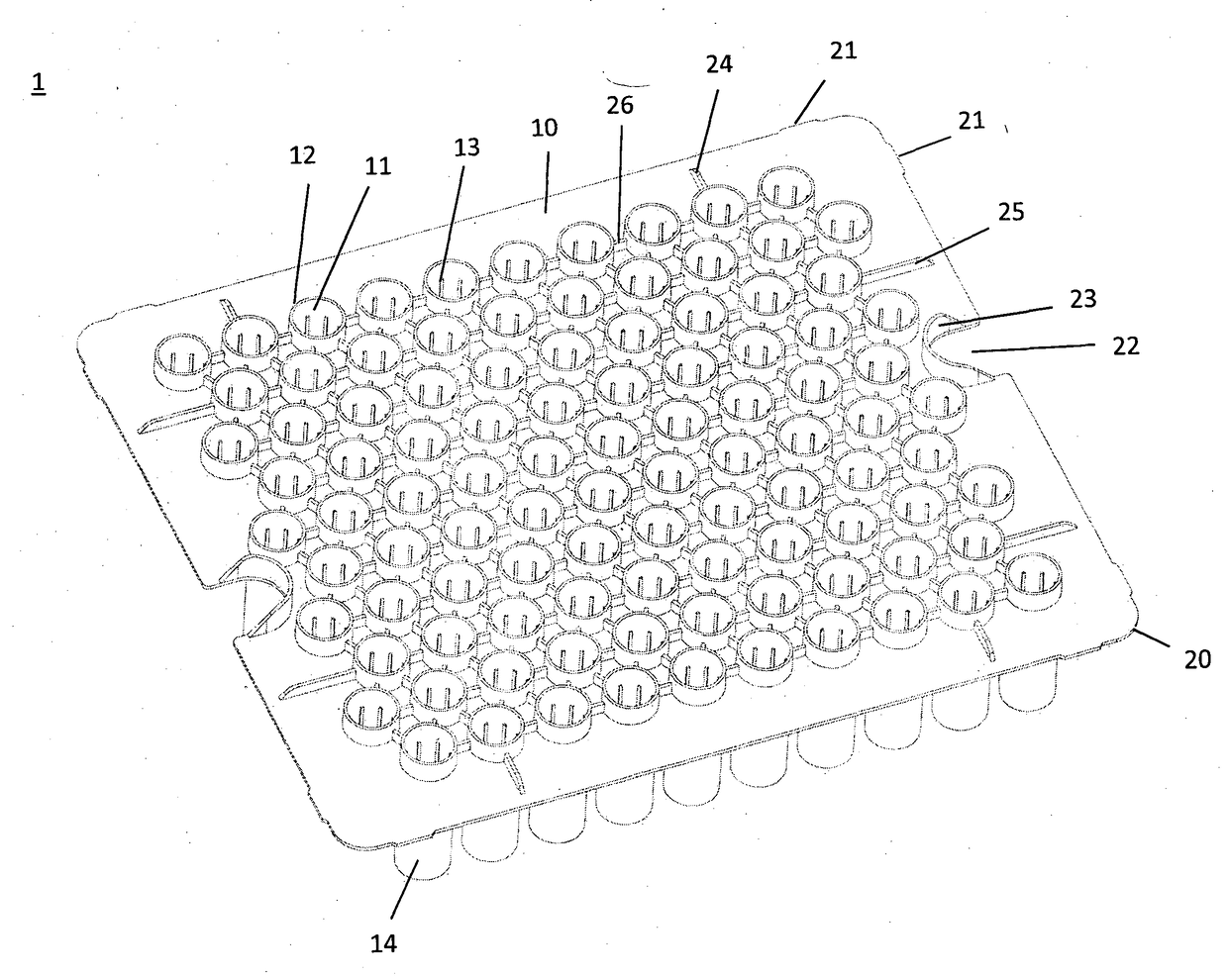

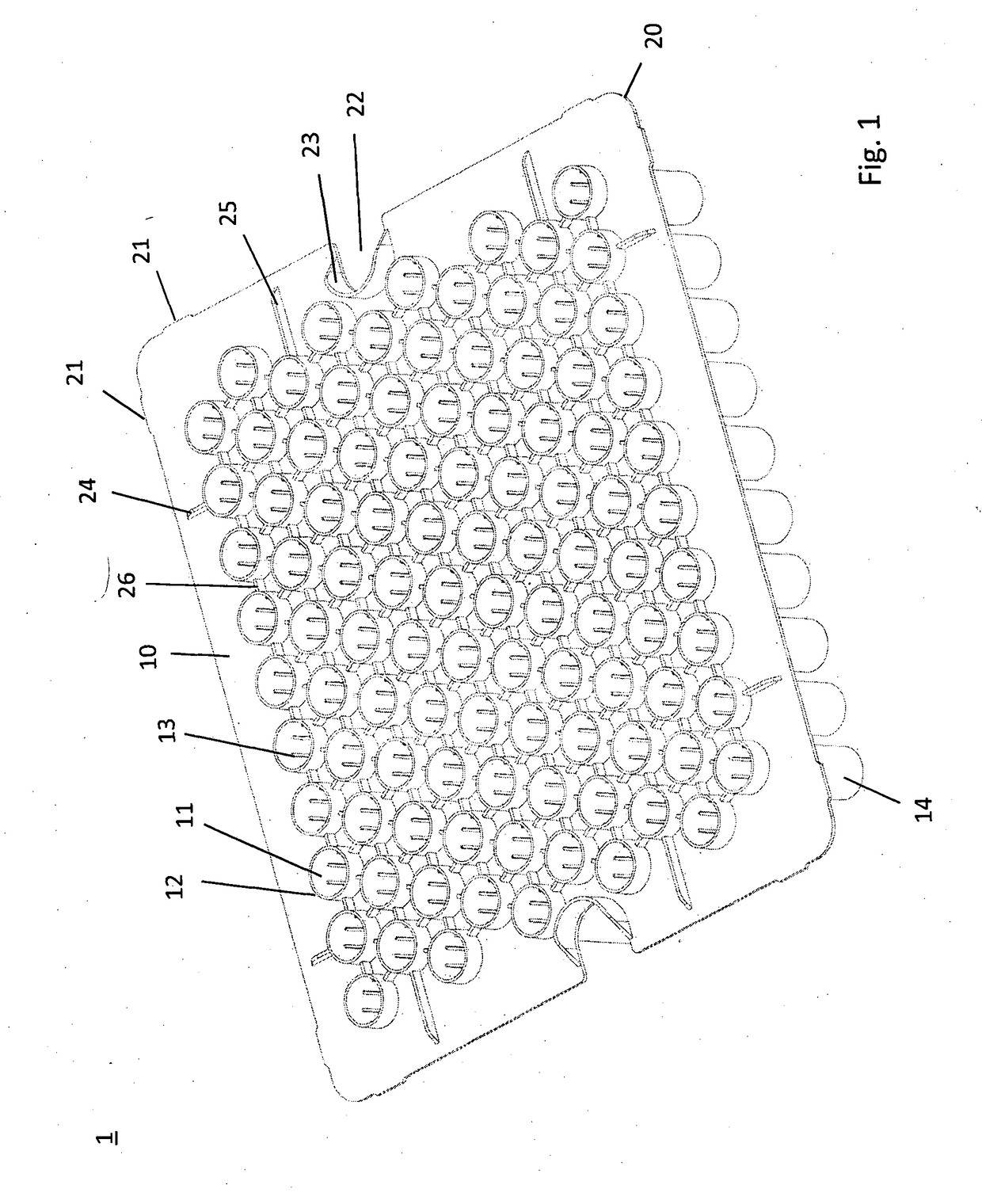

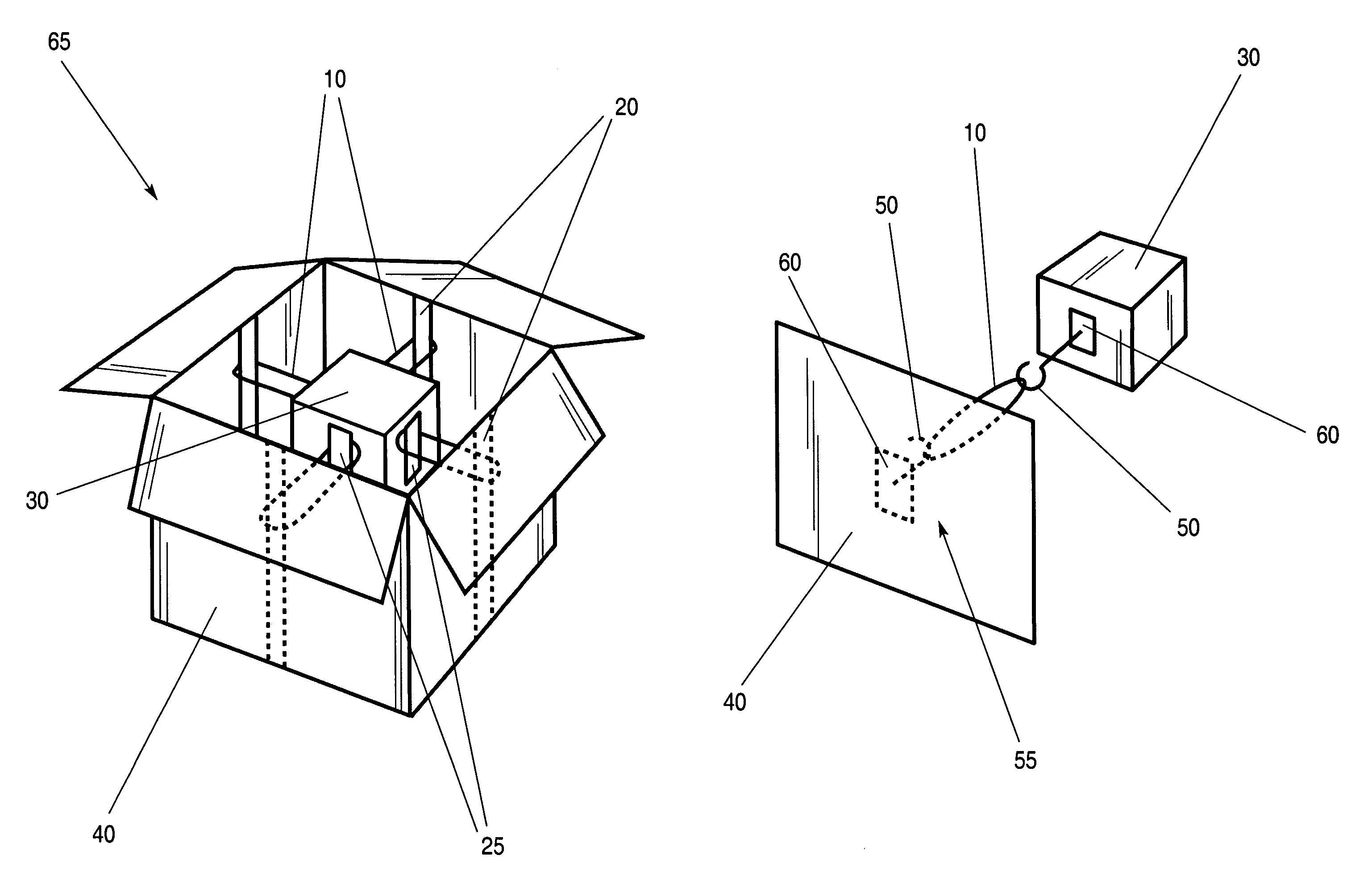

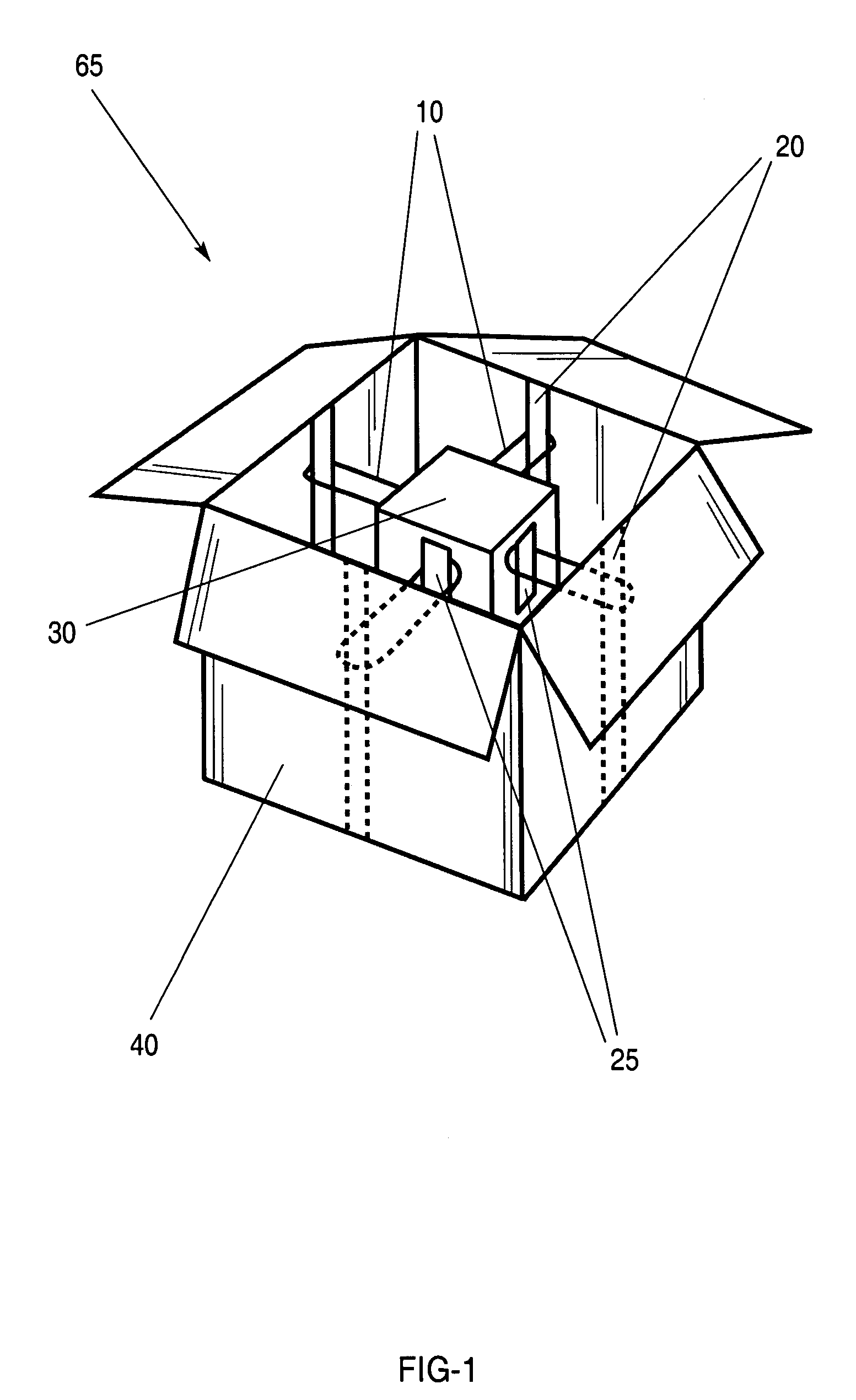

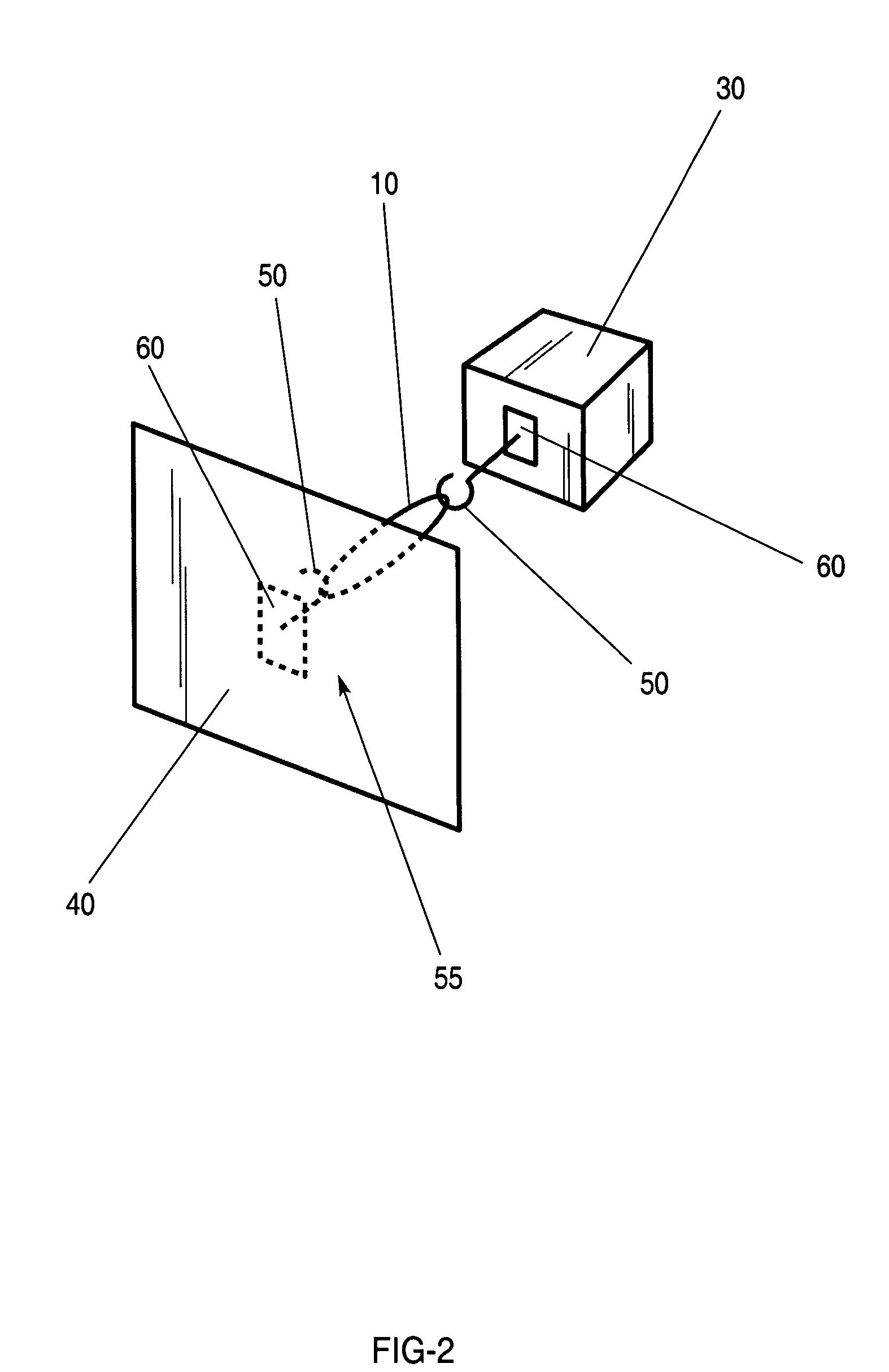

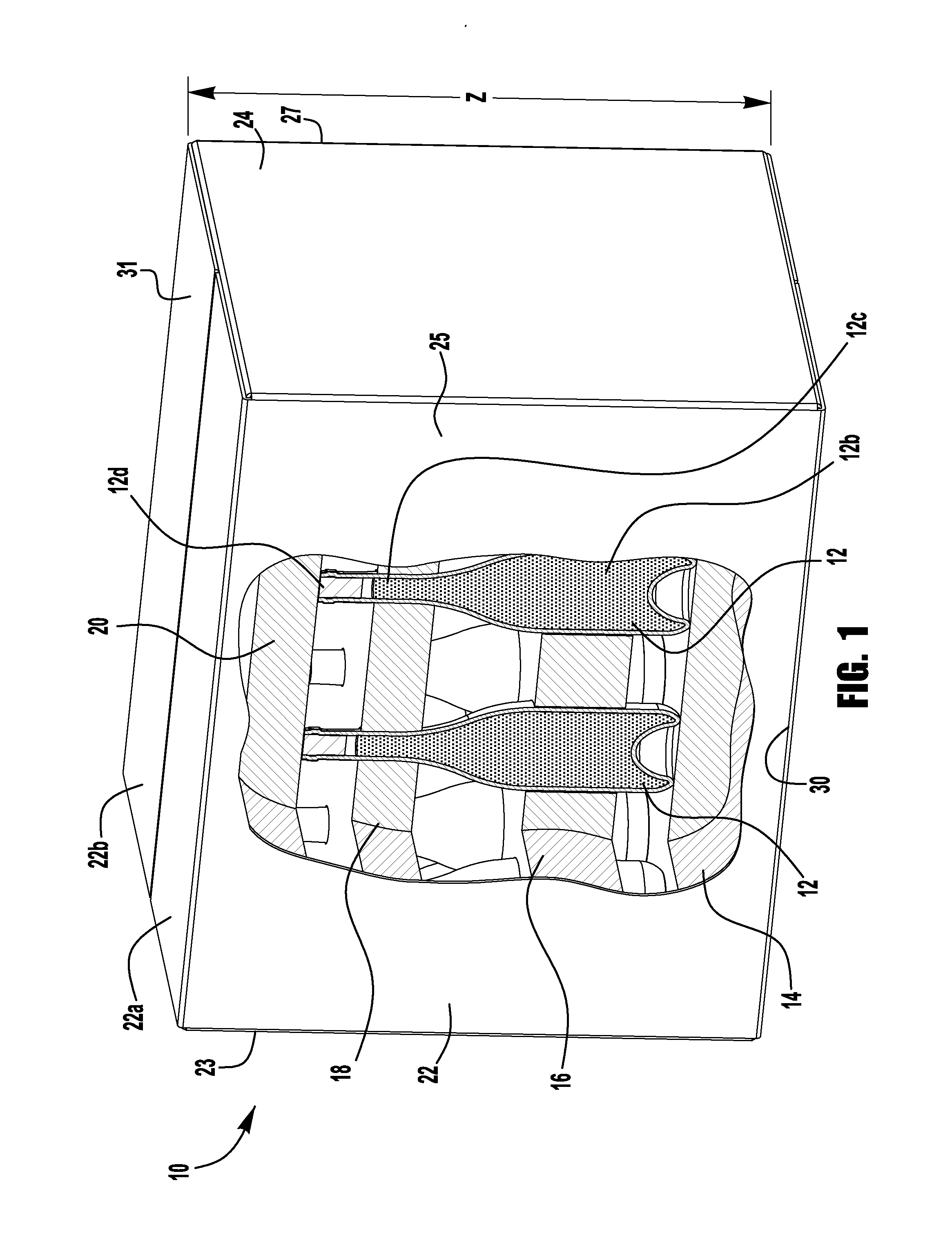

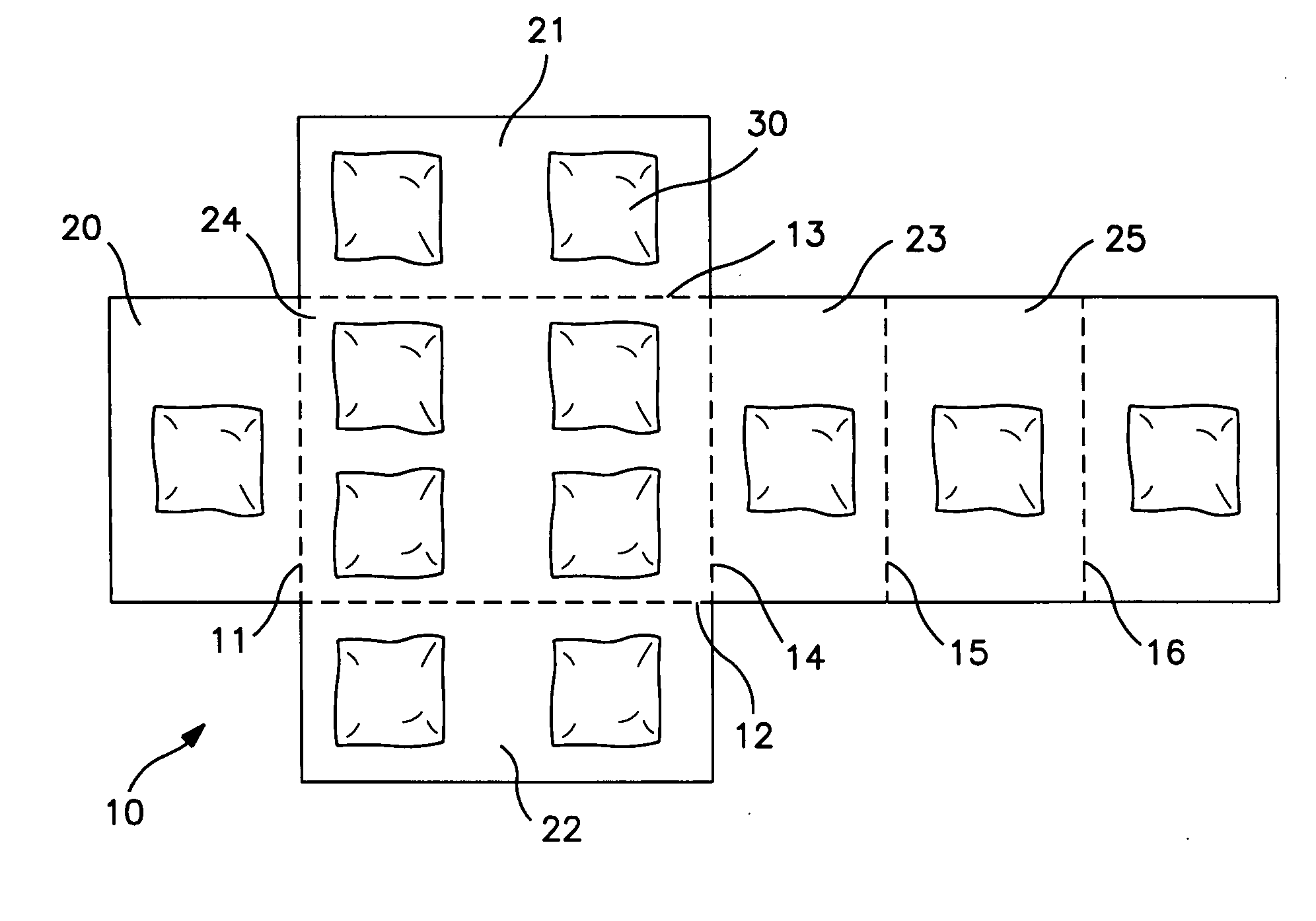

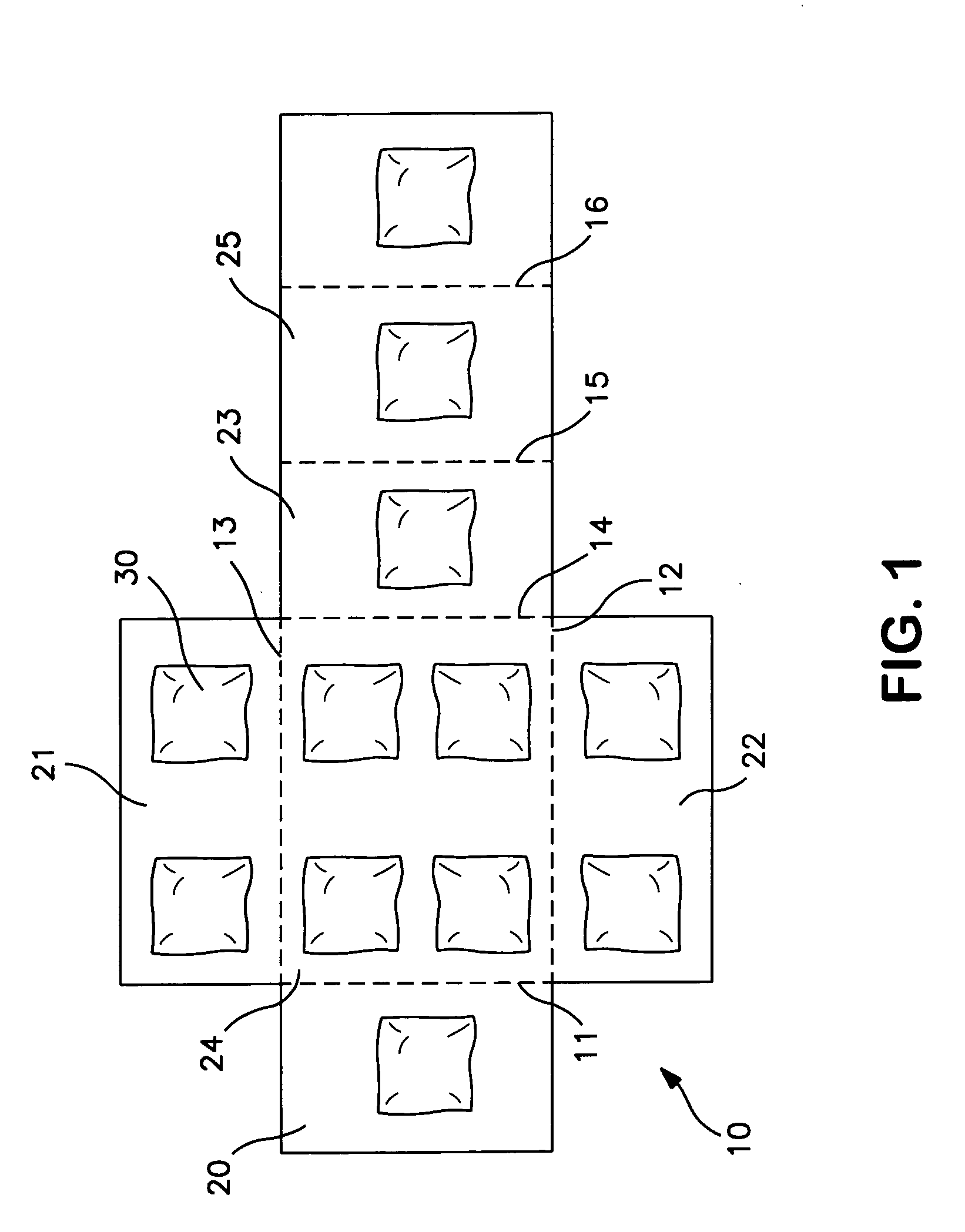

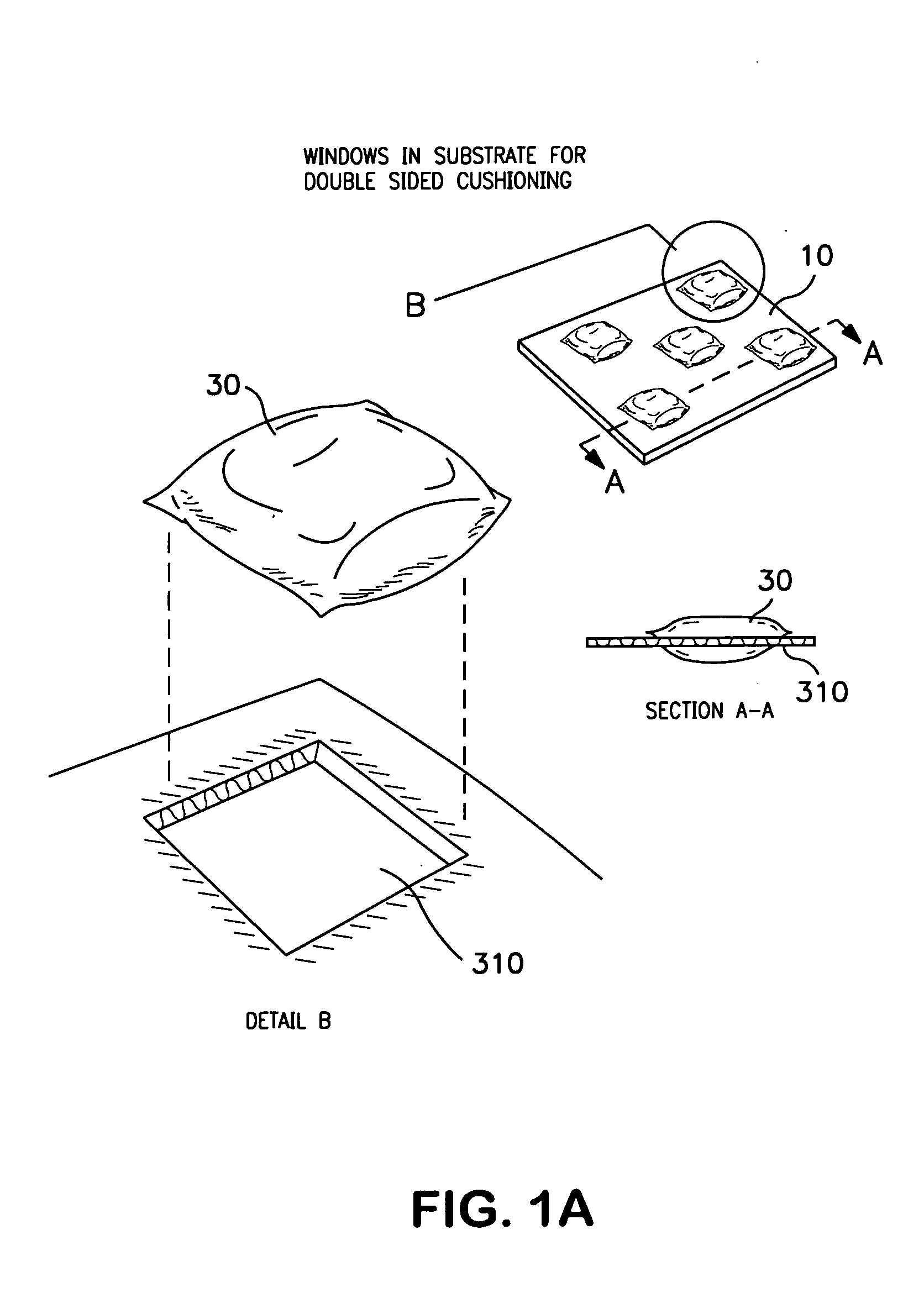

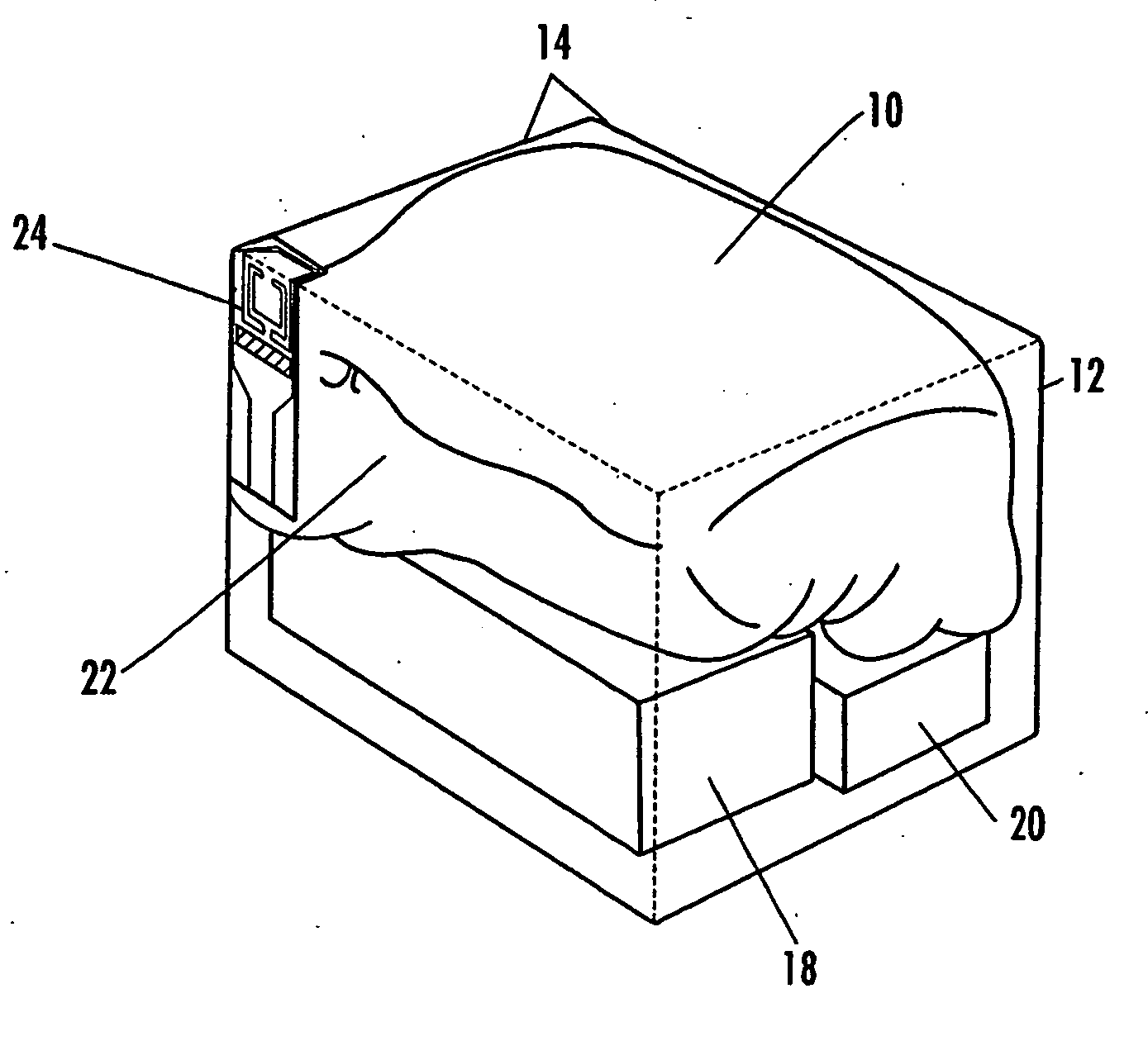

Packaging assemblies and method of fabricating same

A packaging assembly in which discrete cushioning or blocking and bracing members are strategically positioned so as to provide improved protection of an article such as during shipment and storage. The assembly includes a substrate and a predetermined 2- or 3-dimensional pattern of cushioning members such as inflated (e.g., gas-filled) bags selectively and optionally independently affixed to the substrate. The pattern of cushioning members is predetermined in the x, y and z directions such that, when the substrate is positioned about the article, e.g., by folding the substrate, point contact between the cushioning members and the article is created. A method of fabricating a shock protective assembly for packaging an article is also disclosed.

Owner:SEALED AIR U S

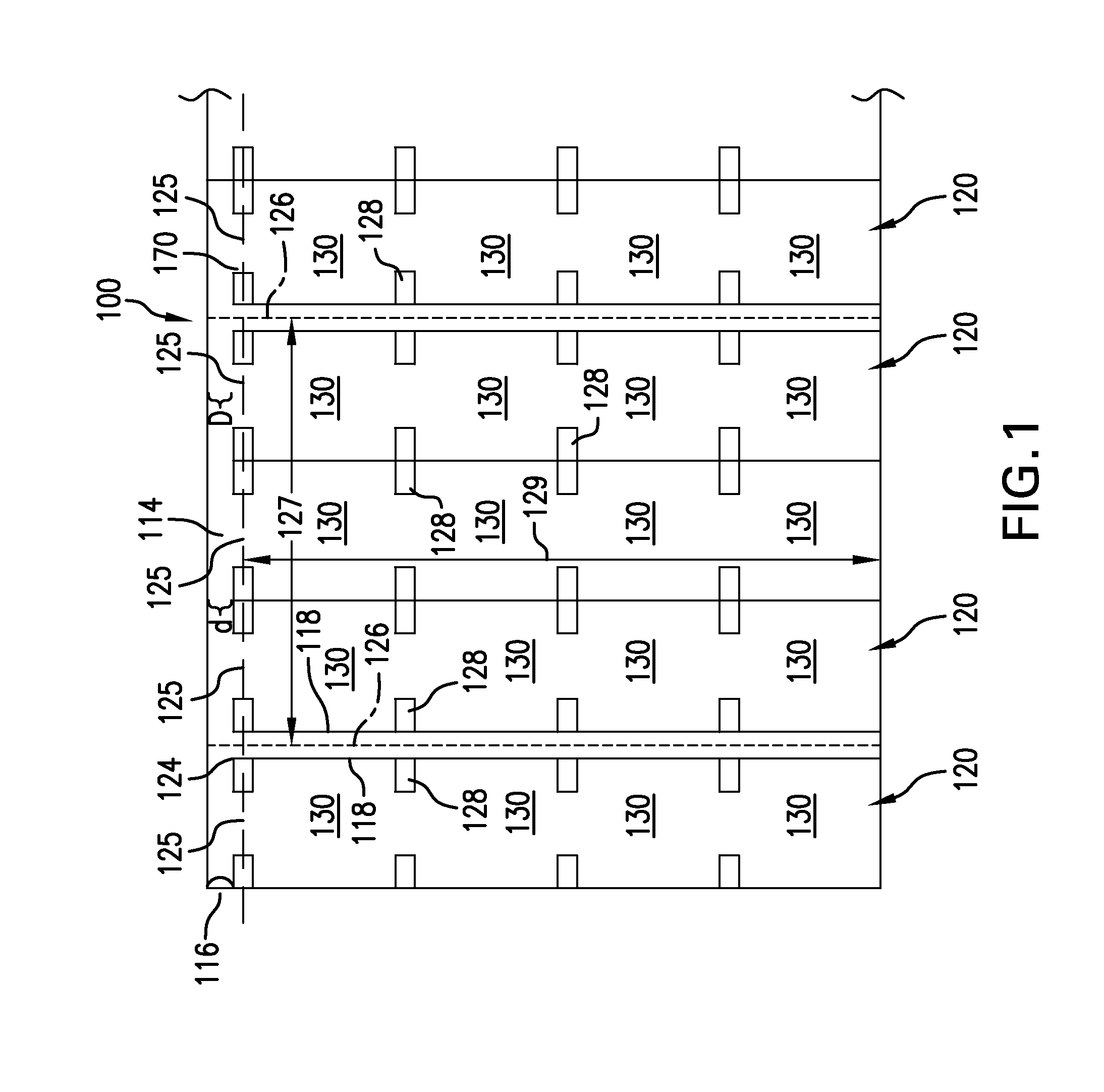

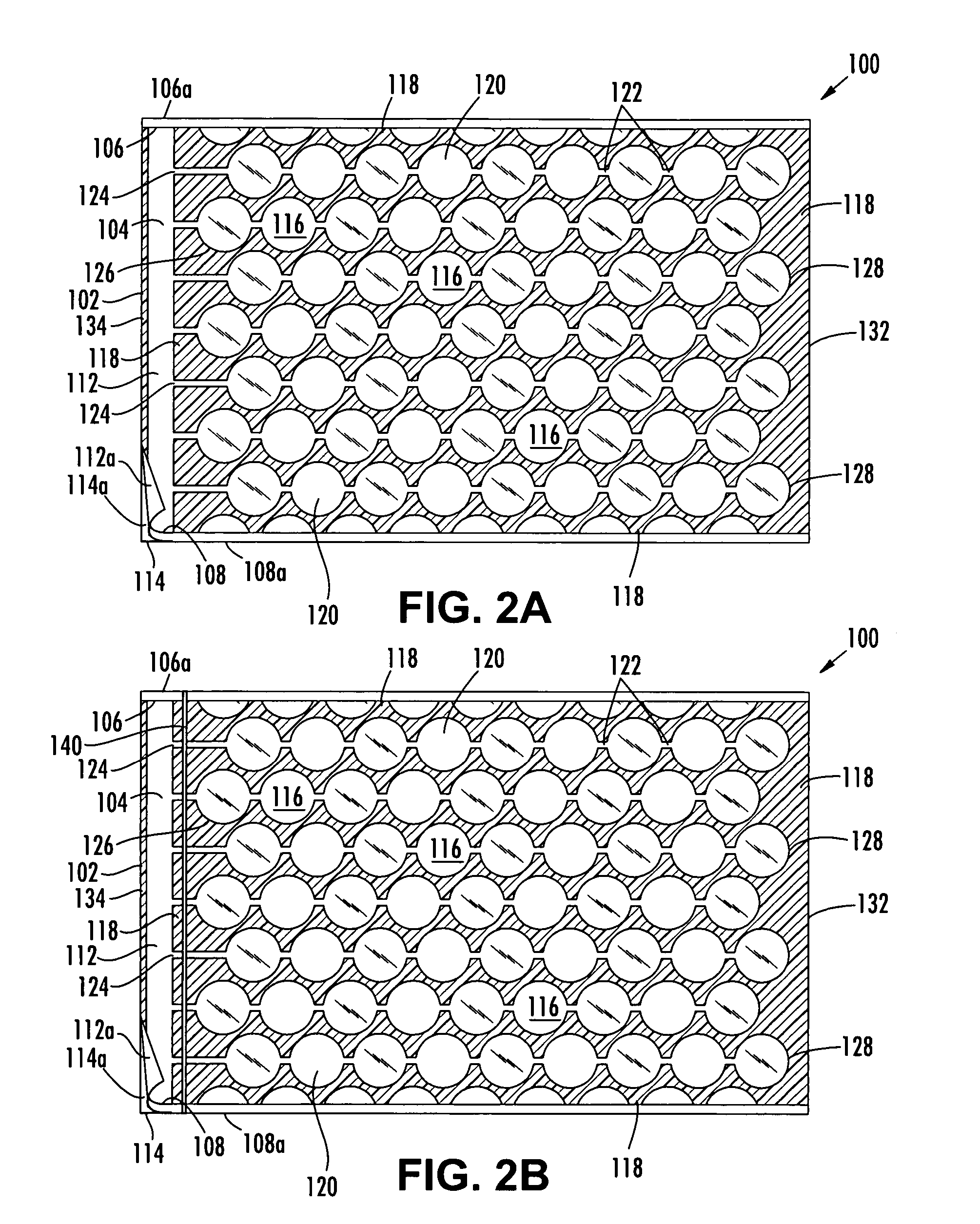

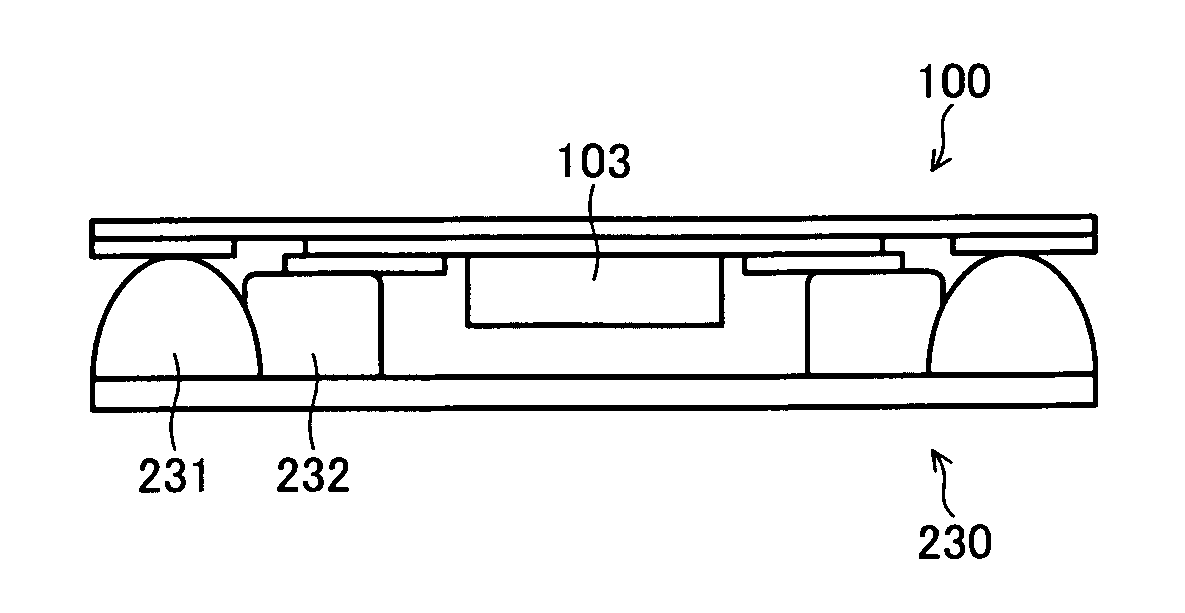

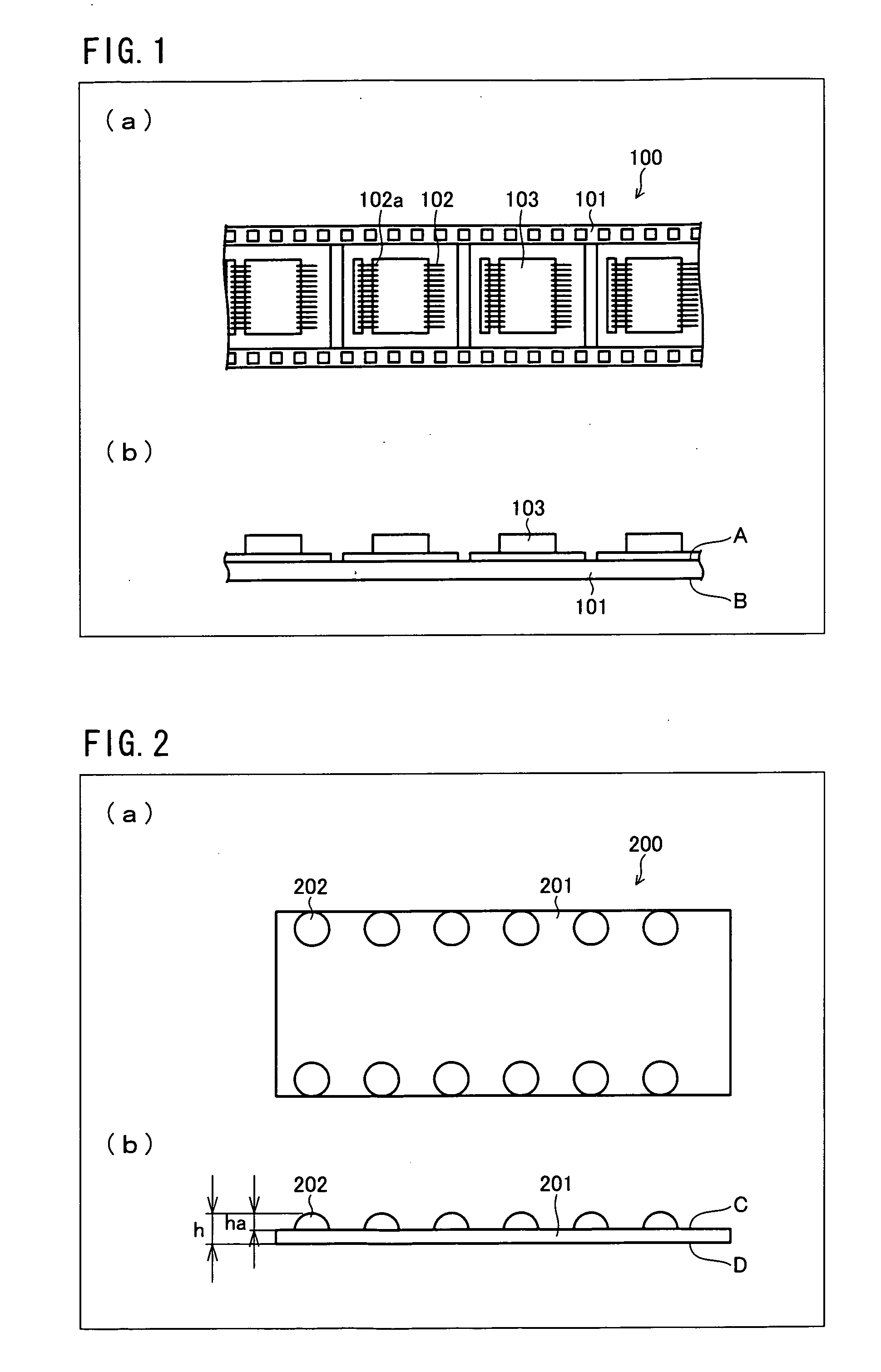

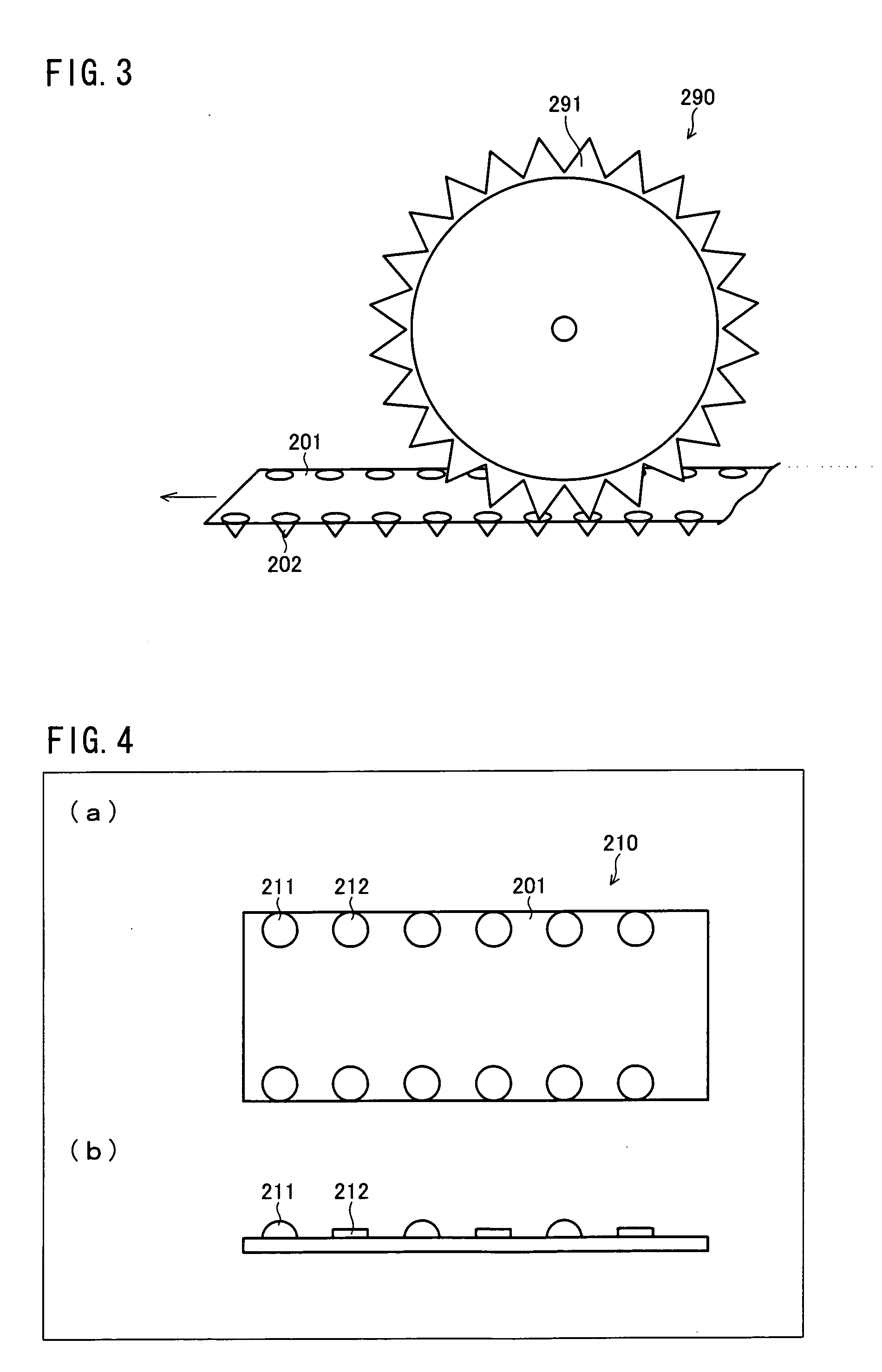

Semiconductor apparatus packaging structure, semiconductor apparatus packaging method, and embossed tape

ActiveUS20100230793A1Avoid damageReduce the overall heightLayered productsSemiconductor/solid-state device detailsSemiconductor chipTotal thickness

A TAB tape (100) packaging structure in which (i) the TAB tape (100) including a plurality of semiconductor chips (103) which are fixed, on a film (101) on which wiring patterns are repeatedly provided and (ii) an embossed tape (200) which is electroconductive and has embossed parts (202) which are sequentially provided on a first surface of and in a longitudinal direction of a film (201) are wound on a reel which is electroconductive is arranged such that the TAB tape (100) and the embossed tape (200) are wound on the reel, while (i) a first surface of the film (101) on which surface the plurality of semiconductor chips (103) are fixed and (ii) the first surface of the film (201) on which surface the embossed parts (202) protrude are overlapping and facing each other, and the embossed tape (200) has a total thickness of not less than (t+0.4) mm and not more than 1.1 mm in a case where each of the plurality of semiconductor chips (103) has a thickness of t (0.2≦t≦0.625) mm and the film (201) has a substantial thickness of 0.125 mm. This realizes packaging of a TAB tape in a desired winding length while sufficiently securing protection of the TAB tape during shipping and transportation.

Owner:TAIWAN SEMICON MFG CO LTD

Method for packaging polycrystalline silicon

ActiveUS20130042582A1Avoid stickingSolid materialShock-sensitive articlesEngineeringPolycrystalline silicon

A method is disclosed for packaging polycrystalline silicon, in which a plastic bag is filled with polycrystalline silicon by means of a filling device, which has a freely suspended energy absorber consisting of a nonmetallic low-contamination material, wherein the plastic bag is pulled over the energy absorber and filled with polycrystalline silicon, and the plastic bag is lowered downward during the filling, so that the silicon slides into the plastic bag. Also disclosed is a method for packaging polycrystalline silicon, in which a plastic bag is filled with polycrystalline silicon by means of a filling device, wherein a storage container has an opening through which it is filled with silicon, the plastic bag being pulled over the storage container after filling the storage container with silicon and the storage container subsequently being rotated so that the silicon slides out of the storage container into the plastic bag.

Owner:WACKER CHEM GMBH

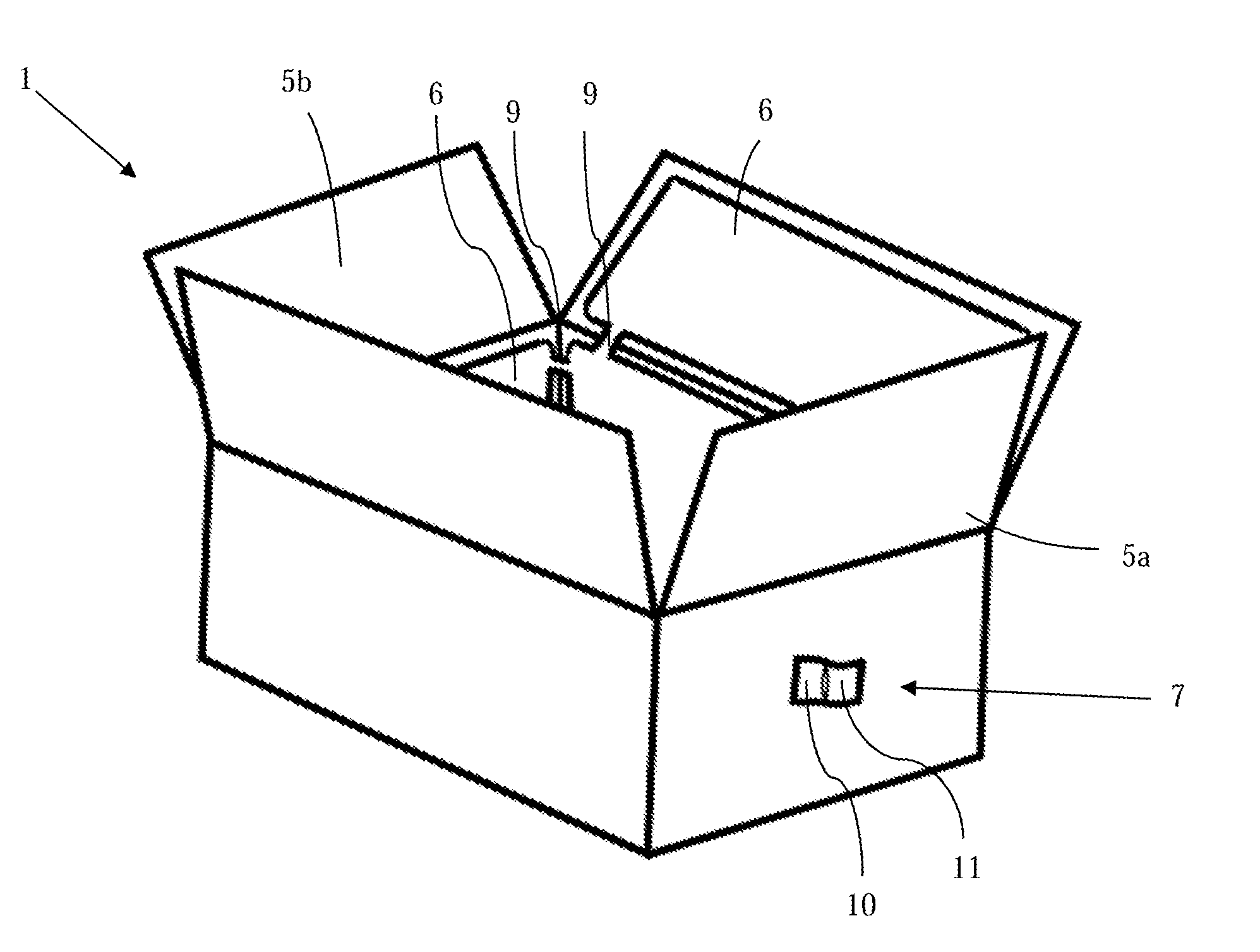

Inflatable box and method of use thereof

InactiveUS20140224699A1Reduce weightEasy to useUsing shock-absorbing mediaContainers to prevent mechanical damageEngineeringGas-filled tube

An inflatable box or tube container and method of use are disclosed. The inflatable container may be designed in any shape or size and be made up of any rigid material. The box is uniquely designed to allow for a simple one-step process using a box with an integrated inflating tube and bottom liner to expand internally by inflation with a gaseous fluid, thereby three-dimensionally cushioning an article to be shipped. This completely protects the article and removes the need for peanuts, paper or other fillers in boxes used for shipping goods once the box is closed. The box may further include a bleed valve that releases the gaseous fluid if the inflating tube and / or bottom liner are over-inflated.

Owner:SMITH JACK V

Inflatable dunnage bags and methods for using and making the same

InactiveUS20070172326A1Easy and consistent methodProtect the backEnvelopes/bags making machineryBag making operationsDunnageEngineering

An inflatable dunnage bag for filling empty space within a container is provided. The inflatable dunnage bag includes a bag portion and a valve assembly. The valve assembly is connected to the bag portion and defines a passageway through which a fluid is introduced into the bag portion during an inflation process. The valve assembly may include a backing plate, a flap, a projection, or combination thereof. The backing plate may be positioned between front and back walls of the valve assembly and be configured to protect the back wall from an inflation nozzle inserted through the front wall during the inflation process. The backing plate may include a flap adapted to further protect the back wall and help direct the fluid flow toward the bag portion. The projection, such as a hook, is configured to position the valve assembly to a predetermined area of the container.

Owner:SEALED AIR U S

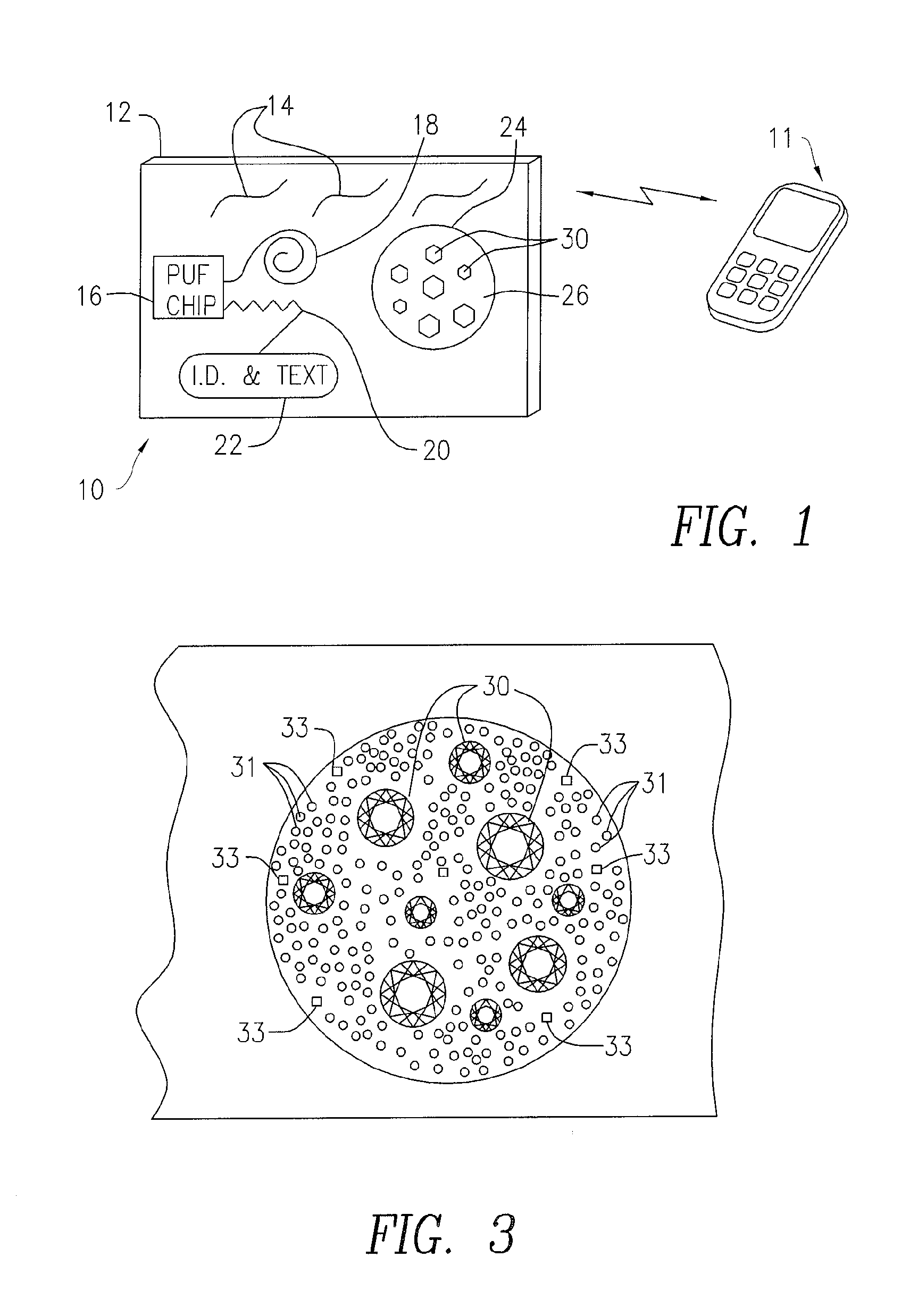

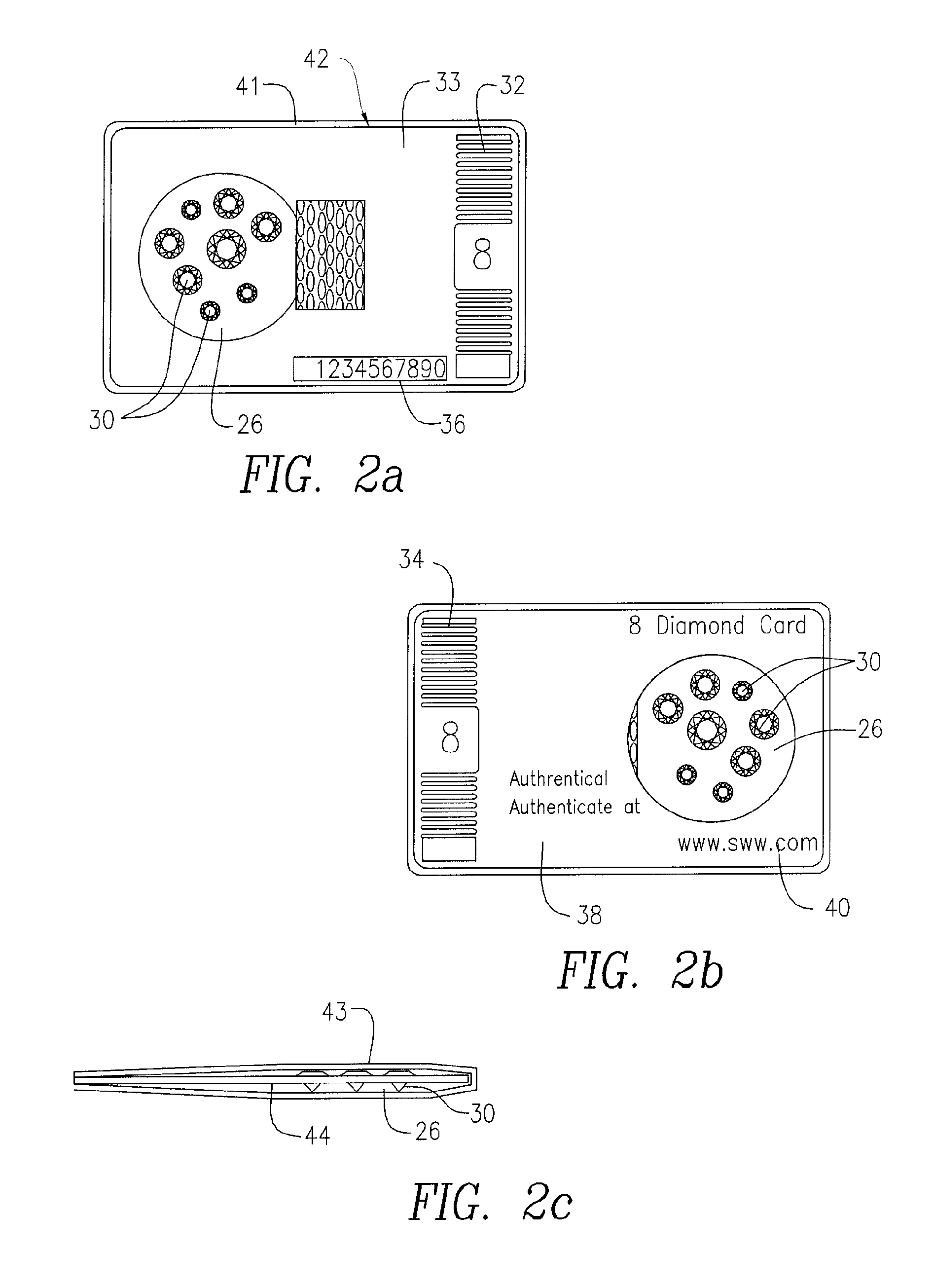

Secure diamond smart cards and exchange systems therefor

InactiveUS20150223580A1Improve reliabilityHighly secureDigital data authenticationBuying/selling/leasing transactionsCredit cardSmart card

A tamperproof diamond package comprises a package body; at least one chip embedded in the package body and at least one antenna configured to enable communication with the chip; anti-counterfeiting visual impressions on the package body; a diamond pouch formed at a predetermined section within the package body; andone or more diamonds located inside the diamond pouch and an outer covering encasing the package body and configured to reveal any tampering with the one or more diamonds located in the diamond pouch. The diamond package can be credit card shaped and also contains serial number and website information and be provided in nominal dollar values. An associated diamond exchange system utilizes the diamond packages and provides a registration server which stores unique identifying information that enable interrogating the individual diamond packages and checking their authenticity with the registration server.

Owner:DIAMOND STANDARD INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com