Expansion Apparatus and Method for Producing Interlocking Expanded Slit Sheet Packaging Material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

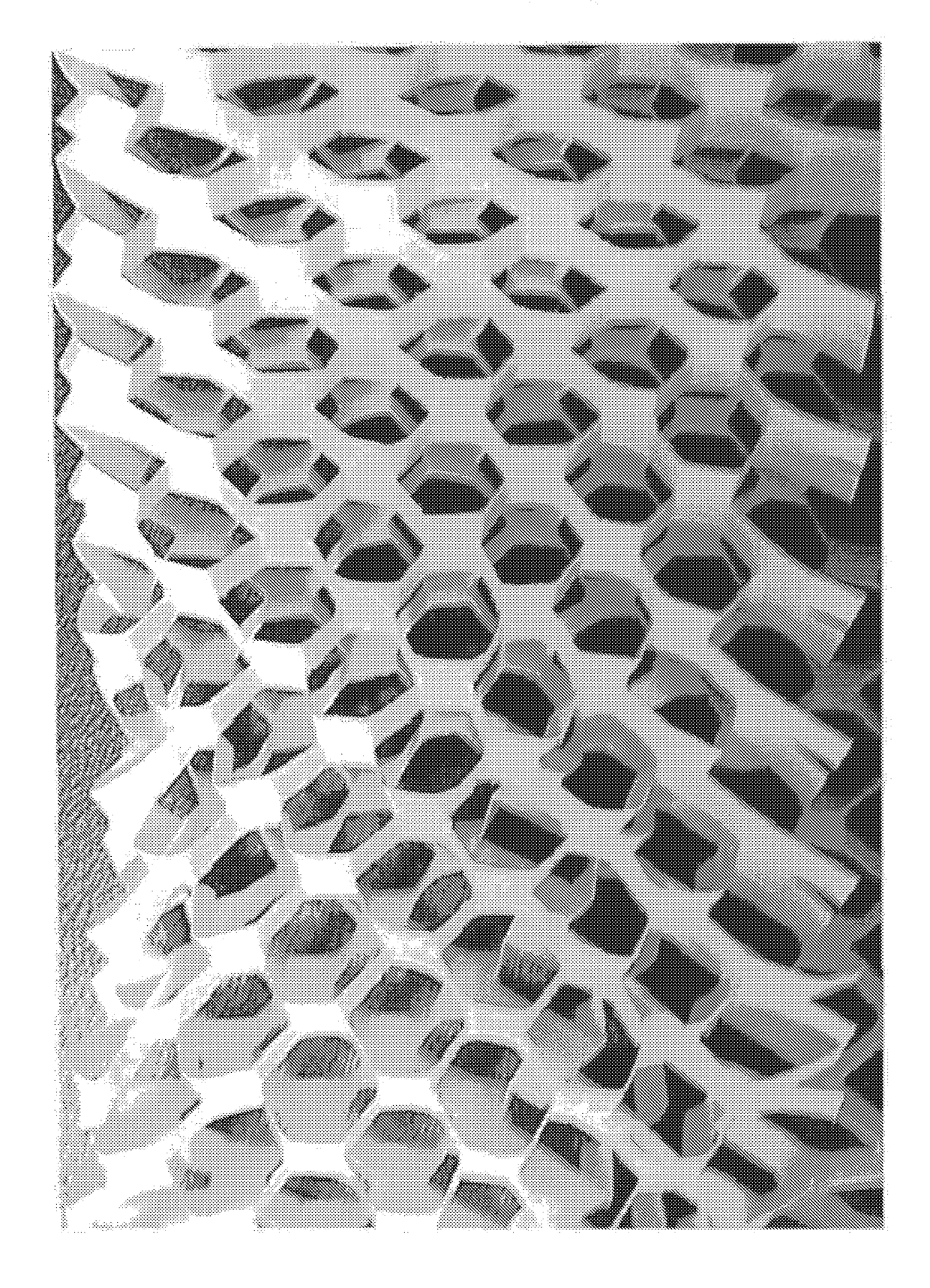

Image

Examples

examples

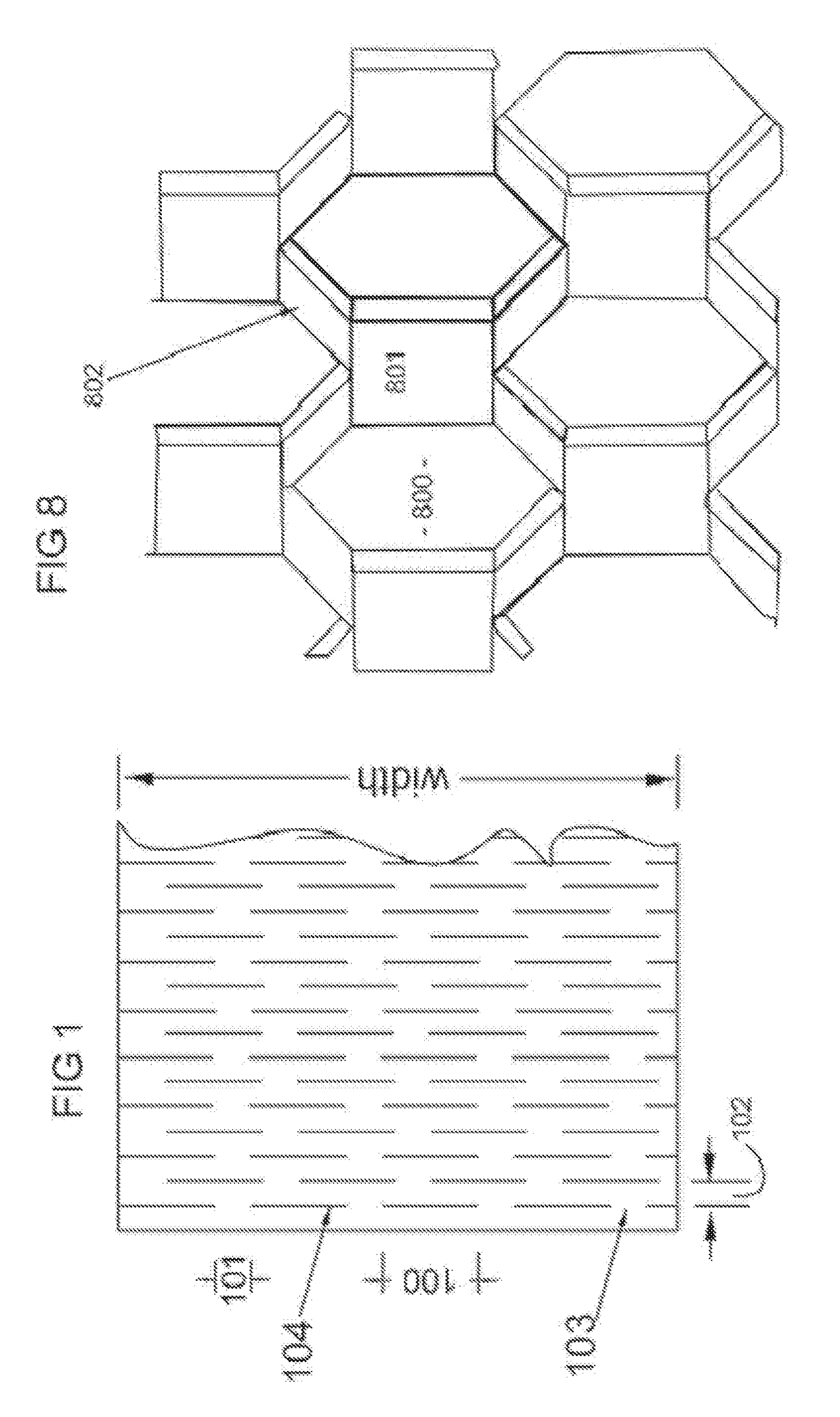

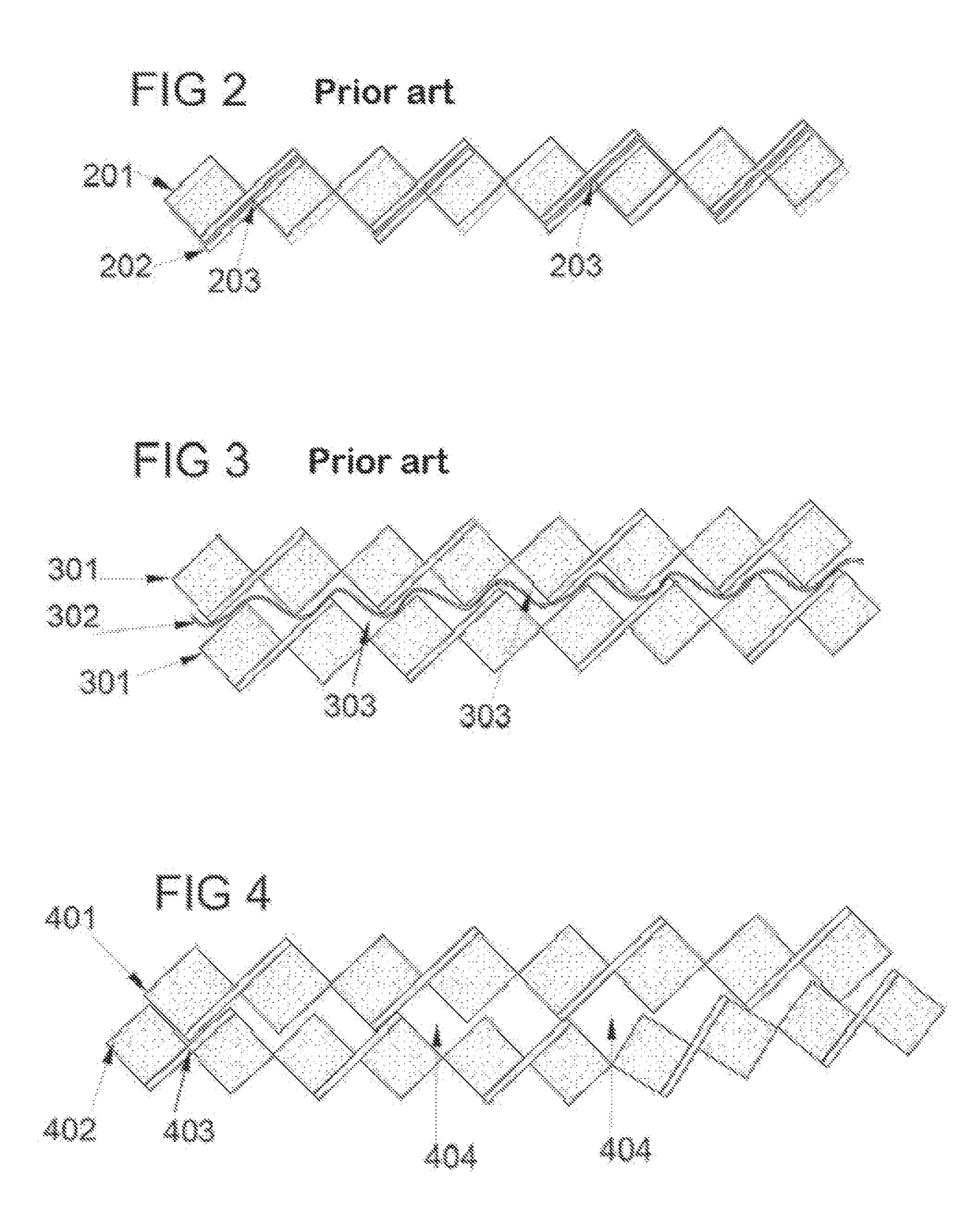

[0073]The first slit sheet pattern creates a ¼″ tall lead wall with each hexagonal side approximately being 3 / 16″ long. The second slit sheet pattern is also ¼″ tall by using the ⅛″ row spacing. The legs of the cell are approximately 10-30% less or more to create an interlocking composite product. In this case the preferred size would be 4″ slit×0.15″ un-slit creating a cell that will be 20% smaller than the first slit sheet pattern.

[0074]The second expanded slit sheet pattern creates a cell that easily could fit inside the first expanded slit sheet material but is inhibited by the increase in quantity of the smaller cell size causing a miss-match of cells trying to fit within each other.

[0075]In order for the operator to receive both slit sheet expanded materials at the same speed a special expander is required. The first expanded sheet layer expands from 1″ to approximately 2⅛″ inches depending upon paper strength and thickness. In the present invention the 60 pound basis weight p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com