Inflated dunnage and method for its production

a dunnage and inflated technology, applied in the field of inflated dunnage, can solve the problems of far more difficult to produce a web of plastic bags than to convert, and achieve the effects of reducing slippage, increasing slippage, and being easy to open by hand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

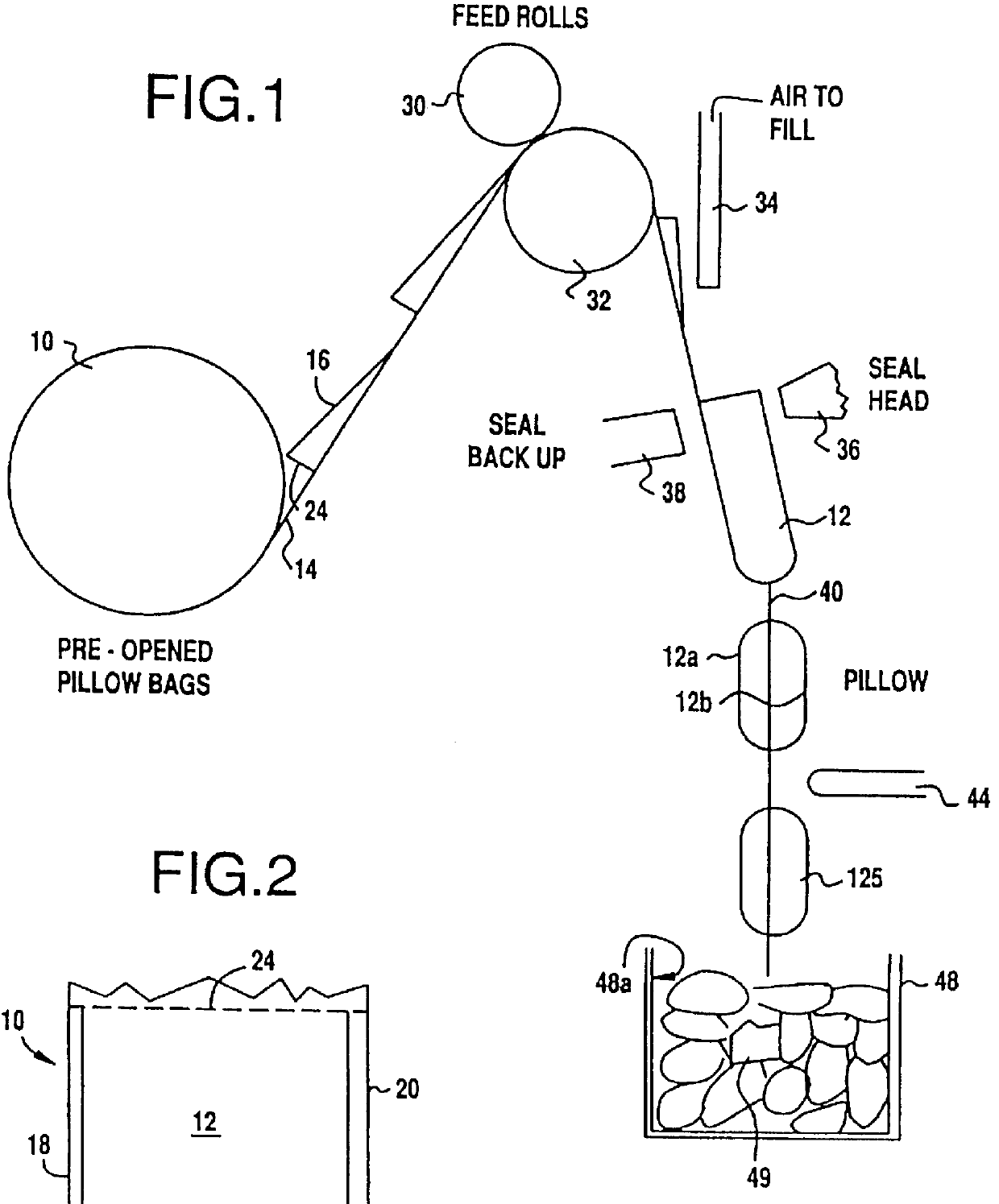

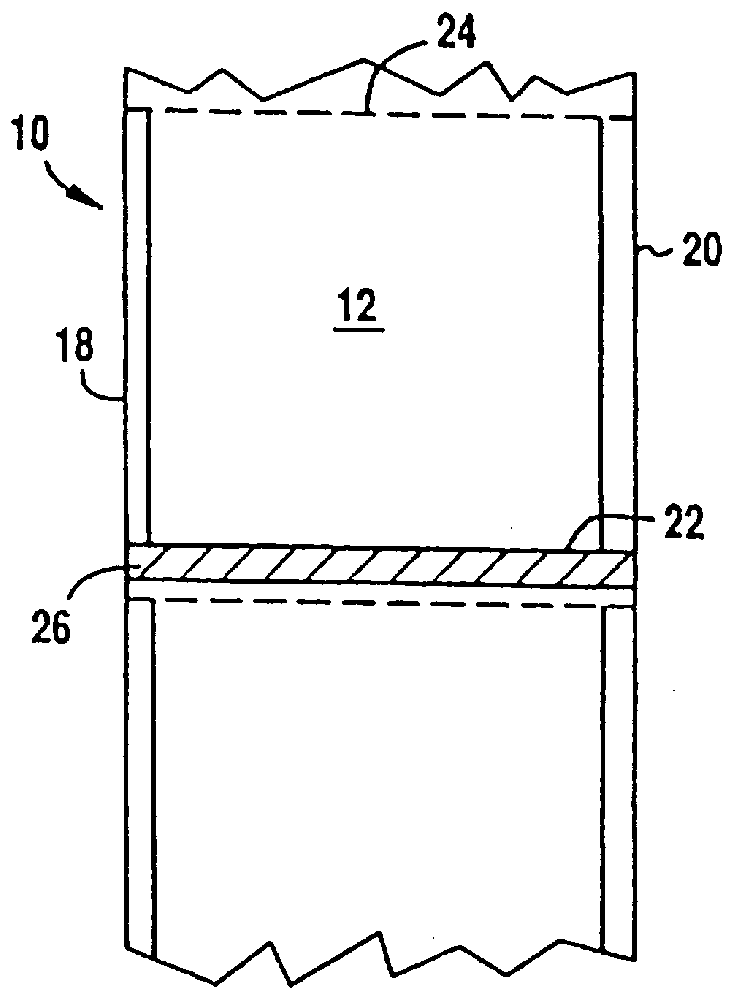

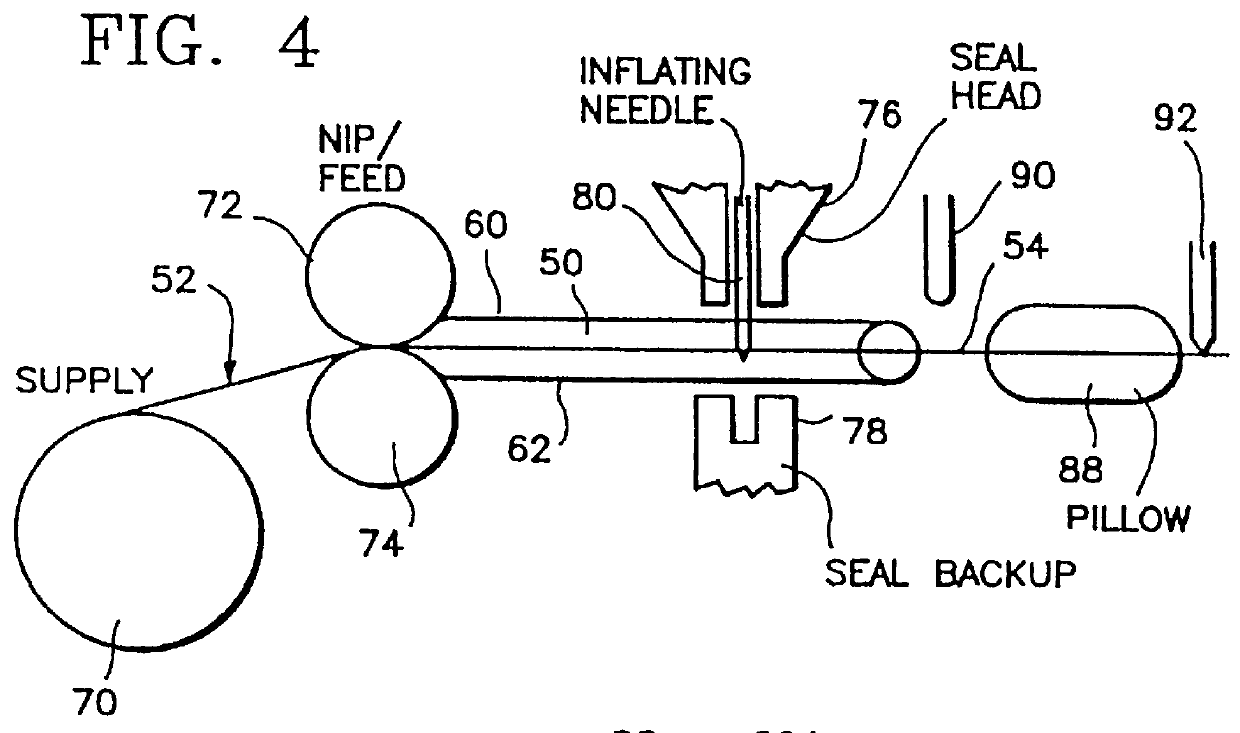

As shown in FIG. 1, the starting material of the process is a roll 10 of plastic bags, the roll comprising a backing sheet 14 and a facing sheet 16. The roll of bags is shown in detail in FIG. 2, each bag 12 formed from a first longitudinal seal 18, a second longitudinal seal 20 and a lateral seal 22. Edge 24 is not sealed. Outer surface 12a is slip resistant; inner surface 12b is more slippery than outer surface 12a to make the bags easier to open. The roll of bags passes between feed rolls 30 and 32, the rolls creating enough tension to cause a slight opening in edge 24. Air tube 34 blows air at slightly opened edge 24, as the bag passes the tube, causing the bag 12 to inflate. The bag then passes between seal head 36 and seal backup 38, which places a lateral seal 40 across edge 24 of the bag. The bags then pass a separating station 44 which is activated at predetermined intervals to cut across lateral seal 40 and form an individual sealed bag 12s, or a unit with multiple sealed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| slip resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com