Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about "Thicknessing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

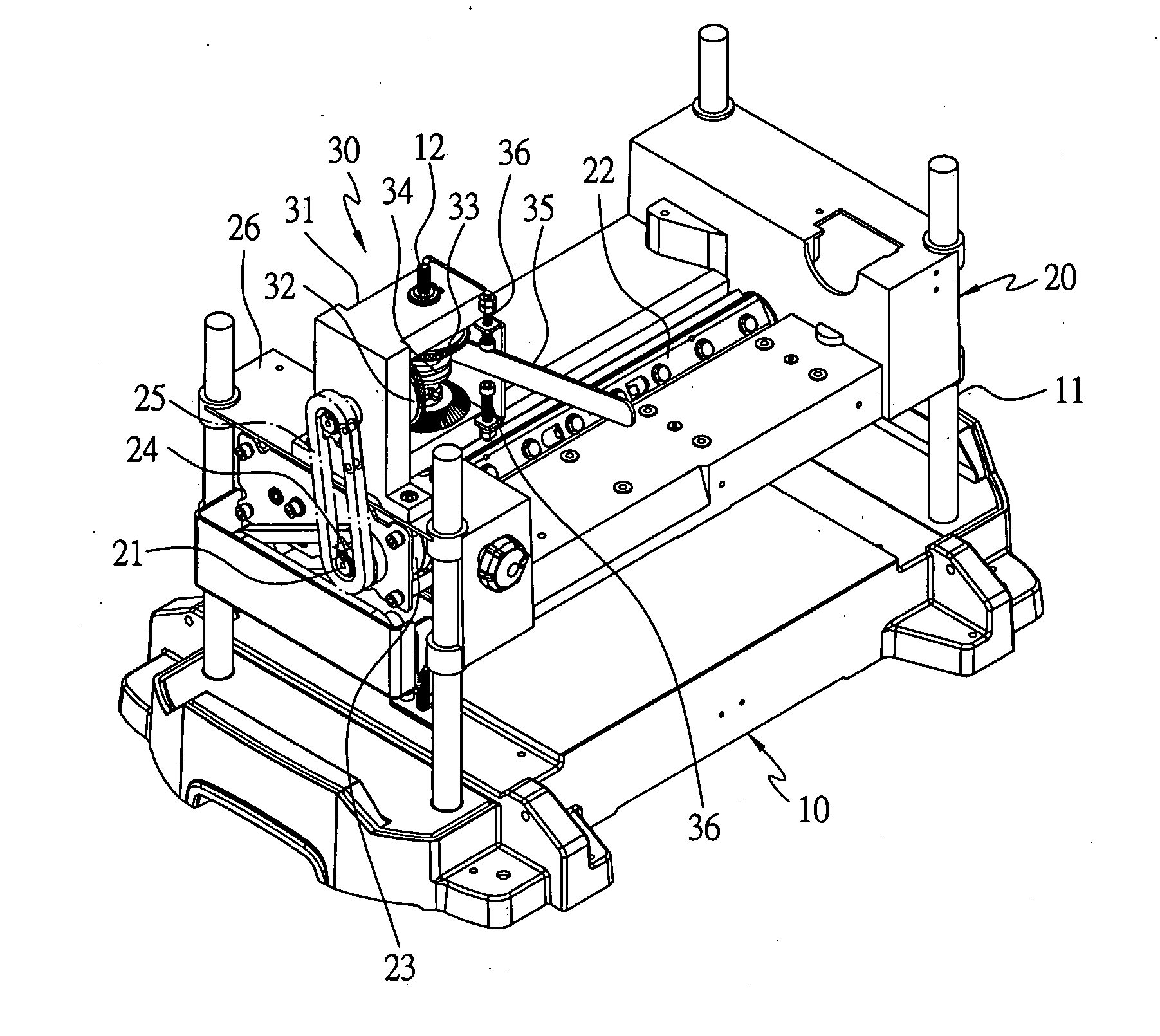

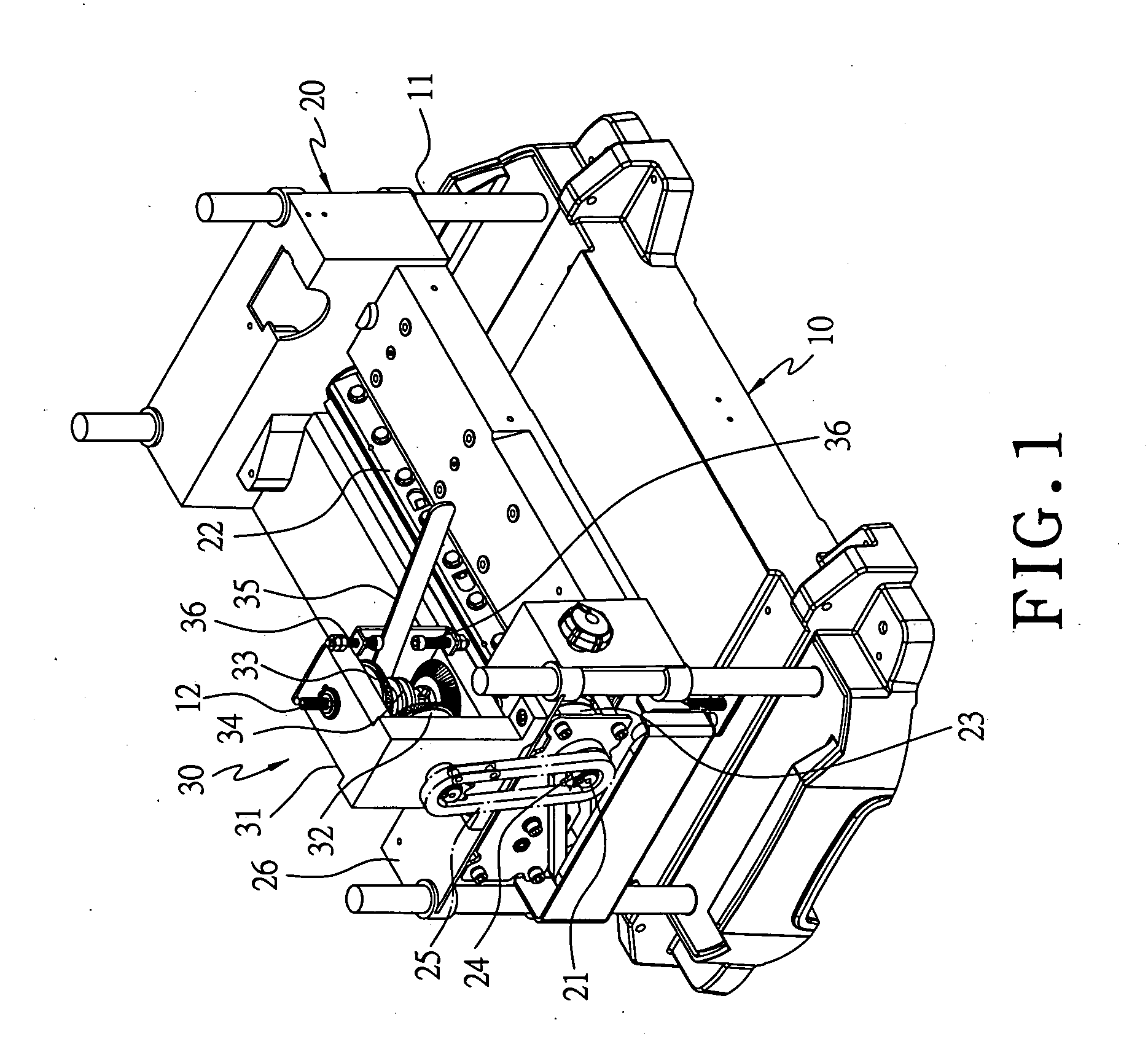

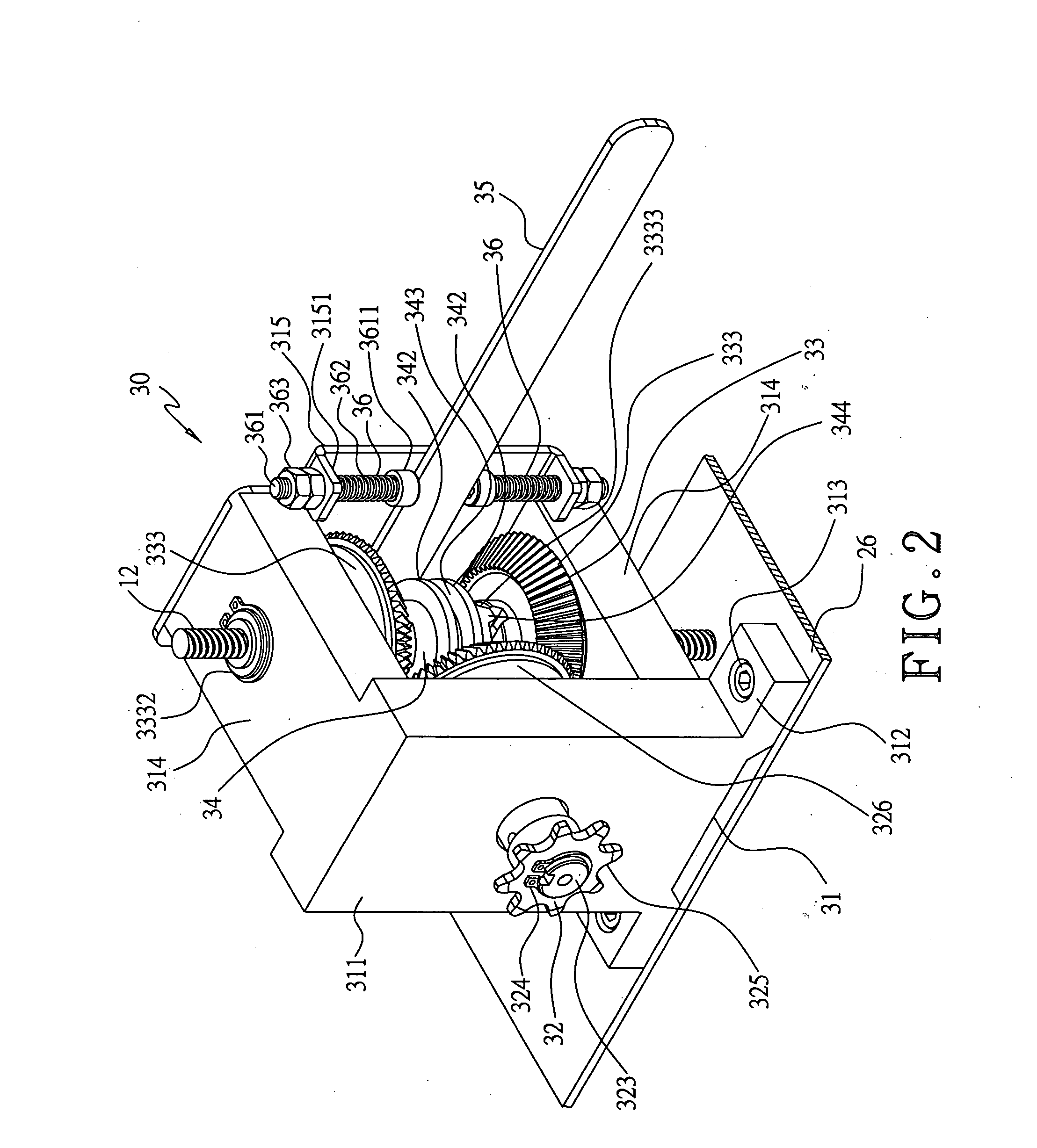

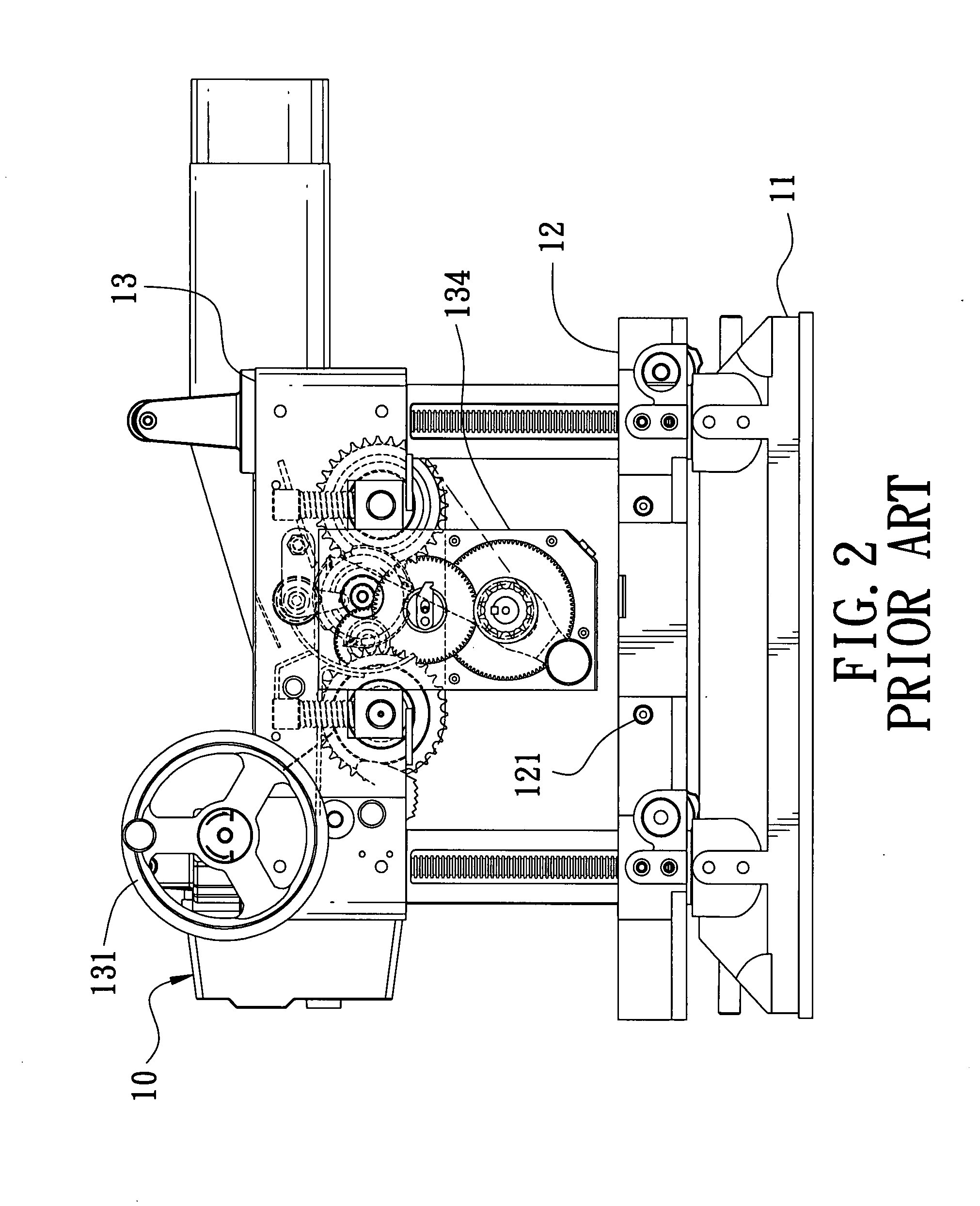

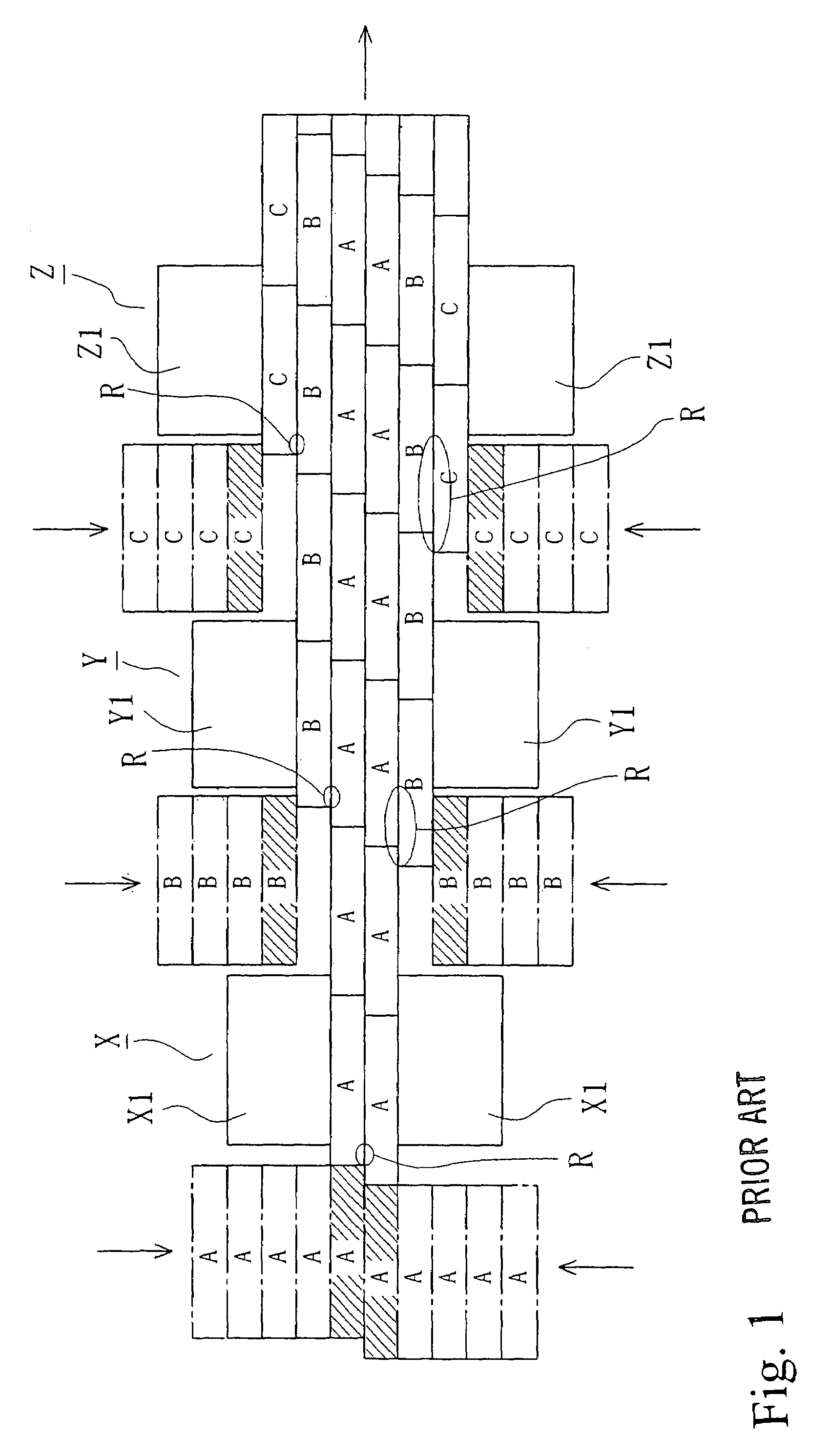

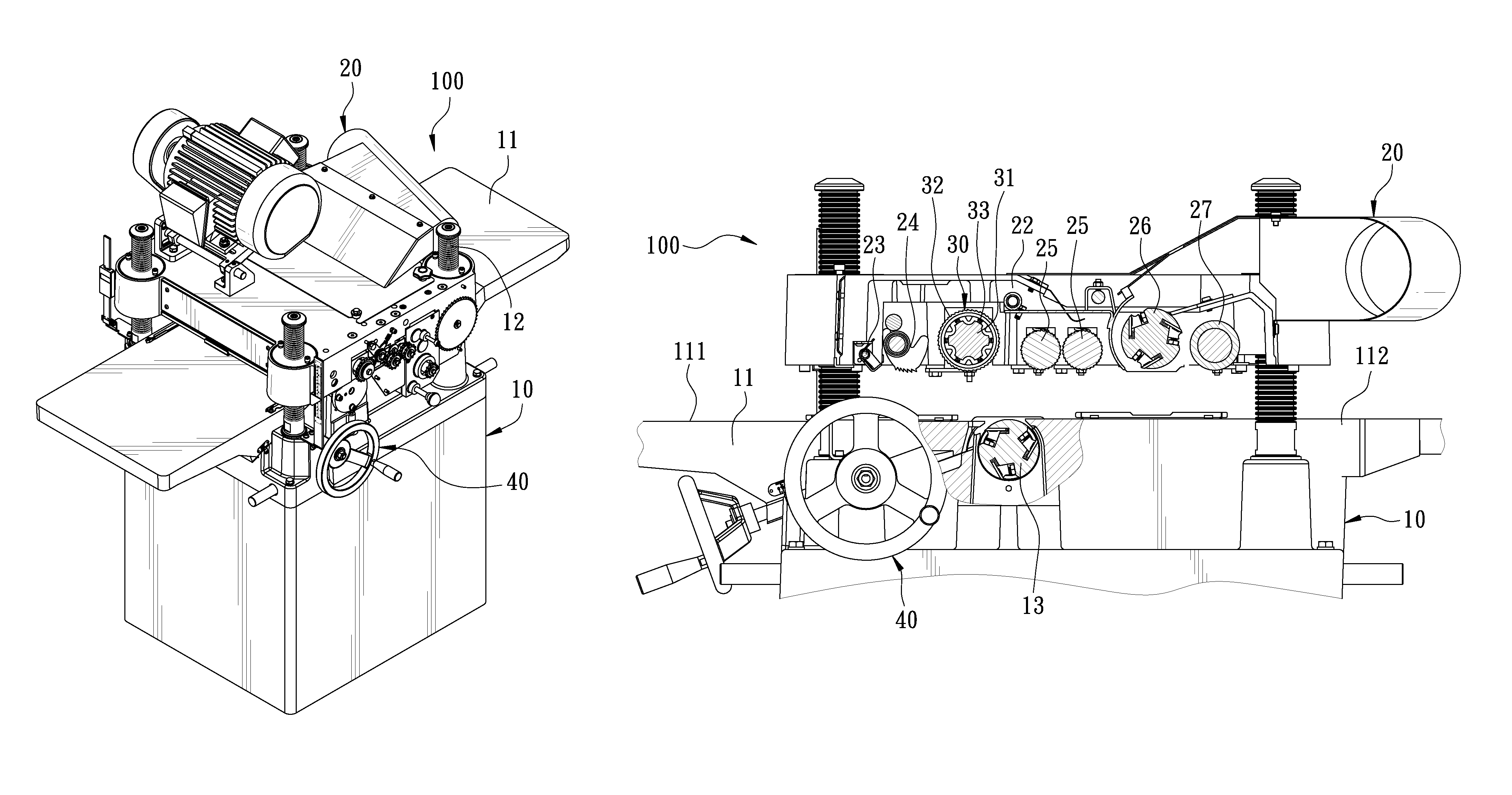

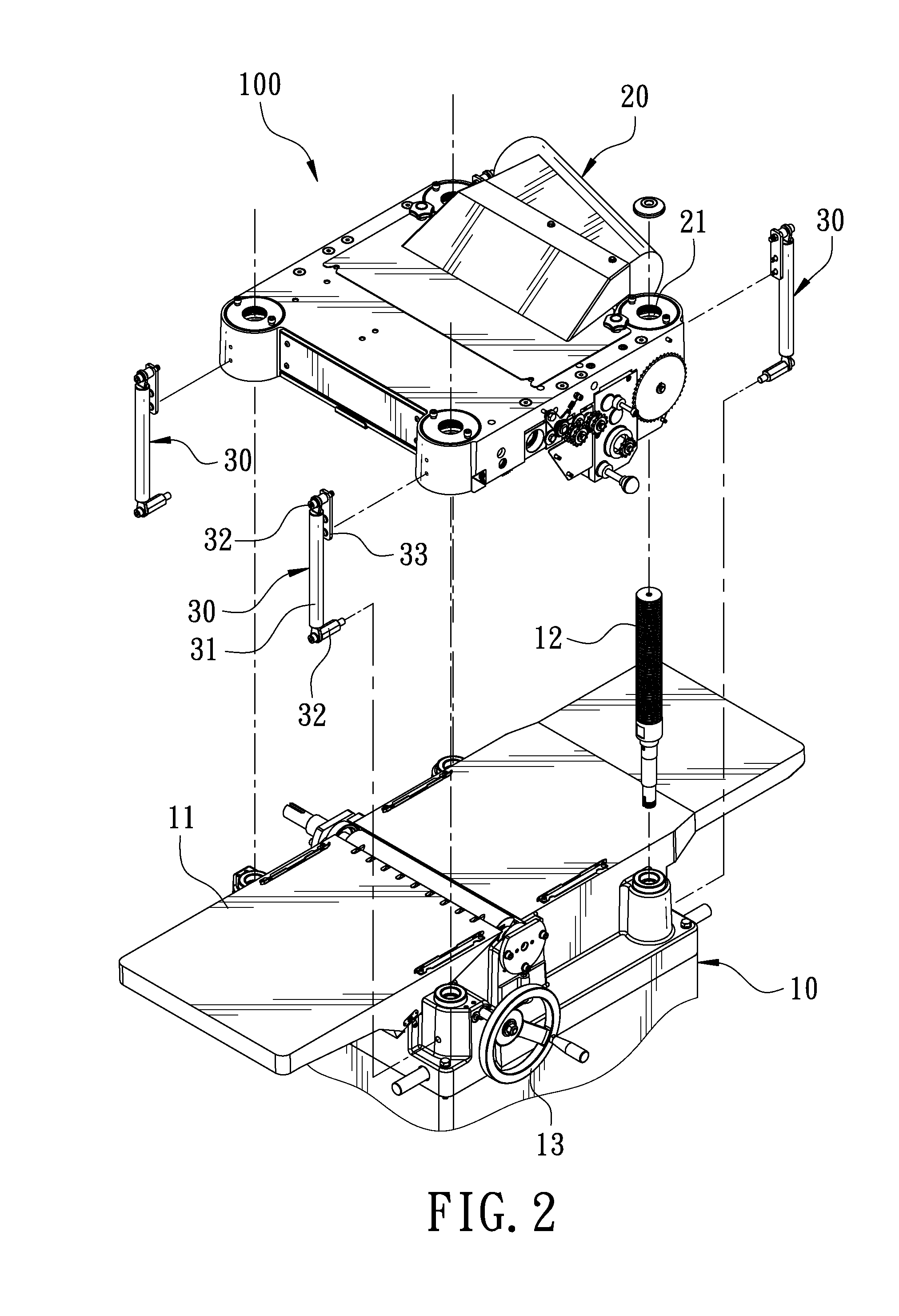

Worktable elevating device for a planer

A worktable-elevating device for a planer is assembled on a worktable, including a base body provided with an input gear unit, two output gear units; a control rod, two elastic compressing units, and a worm holder. The input gear unit is driven by a motor installed on the worktable to rotate and actuate the two output gear units to rotate reversely. The control rod is pulled upward or downward to make the worm holder mesh with one of the two output gear units. As the worm holder and the planing table are screwed on the worm of the base body; therefore when the worm holder is driven to move upward or downward, the worktable will synchronously be moved up or down quickly. When the control rod is released and automatically recovers its original position by the elastic compressing units, the worktable will stop moving up and down.

Owner:CHUANG BOR YANN

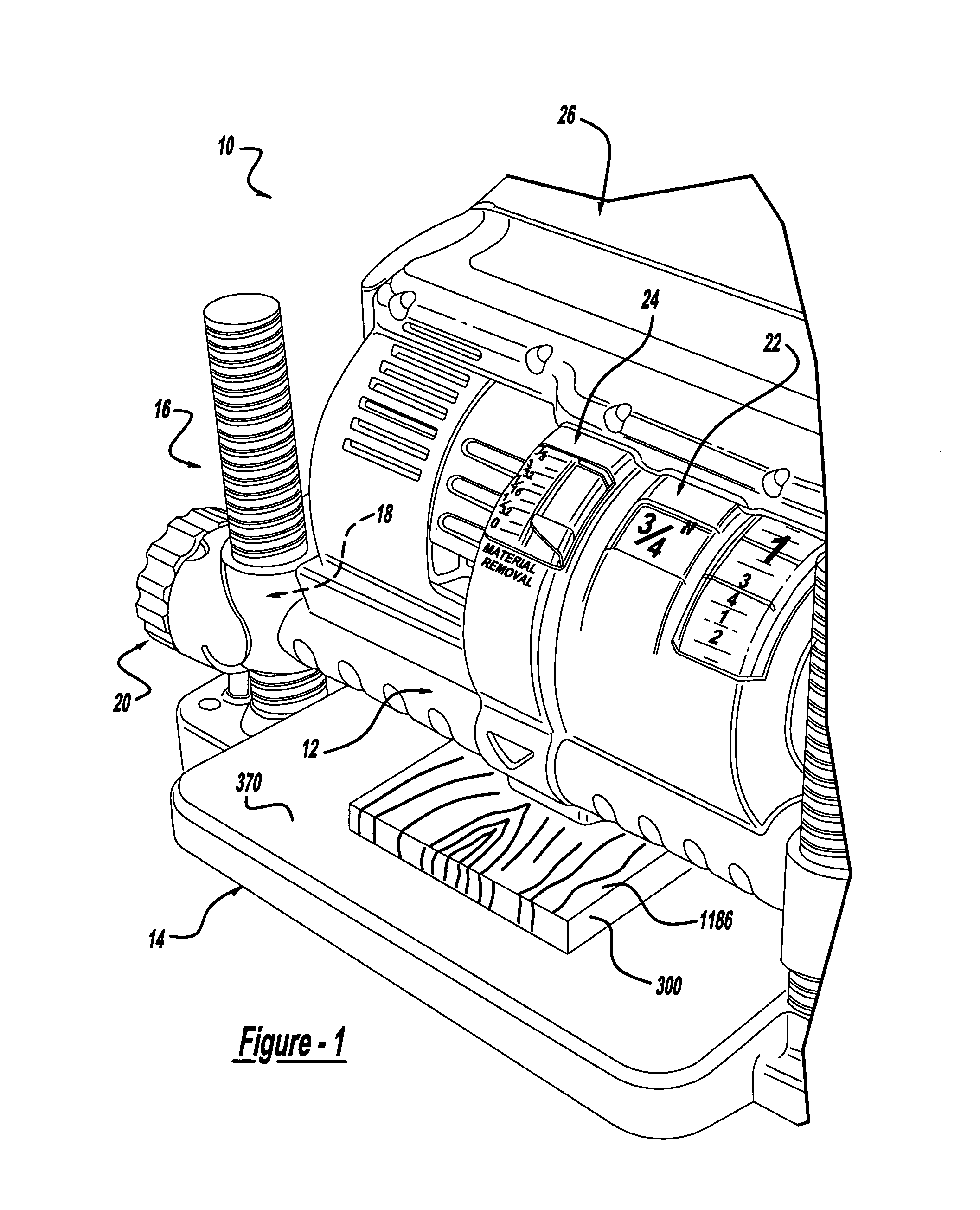

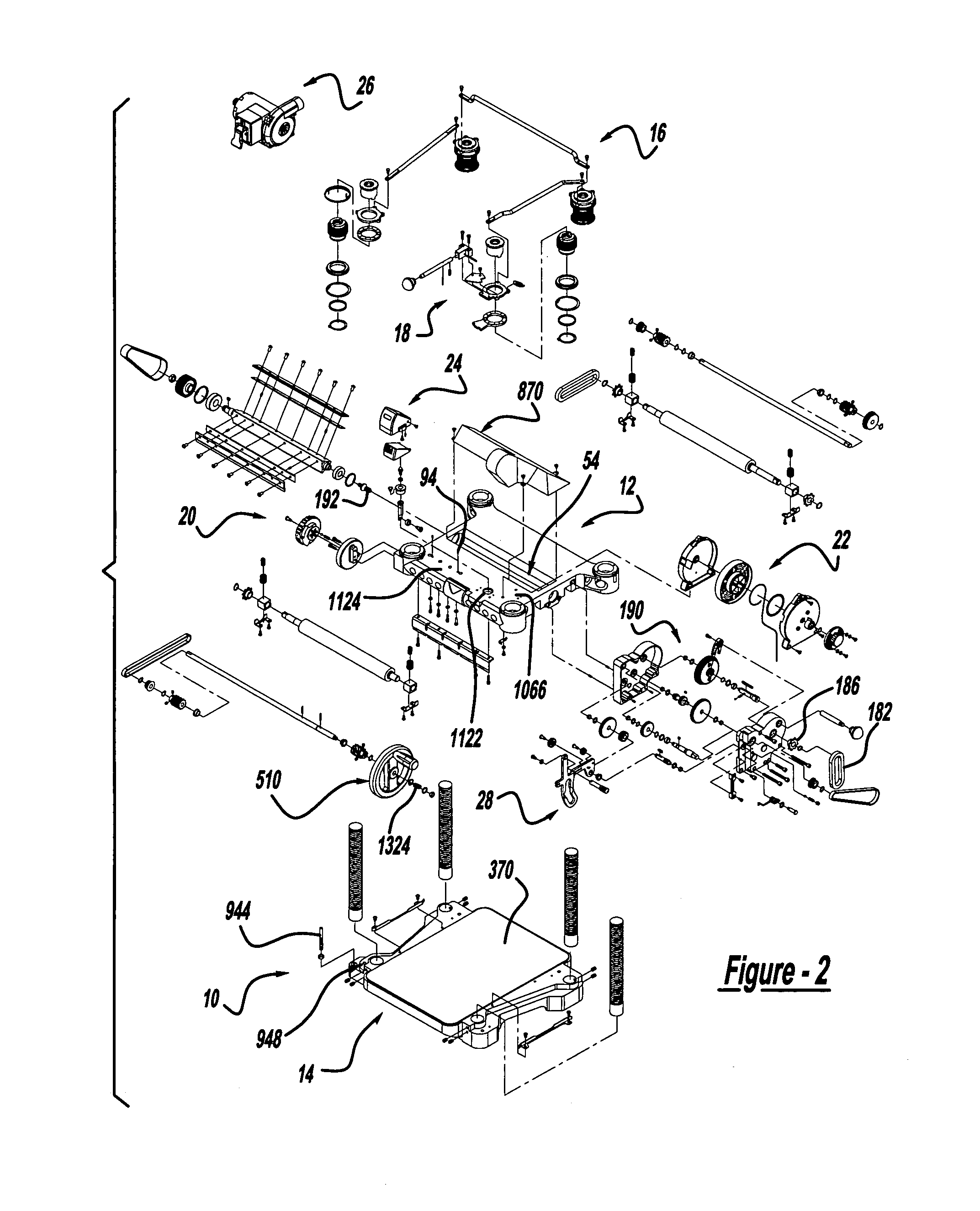

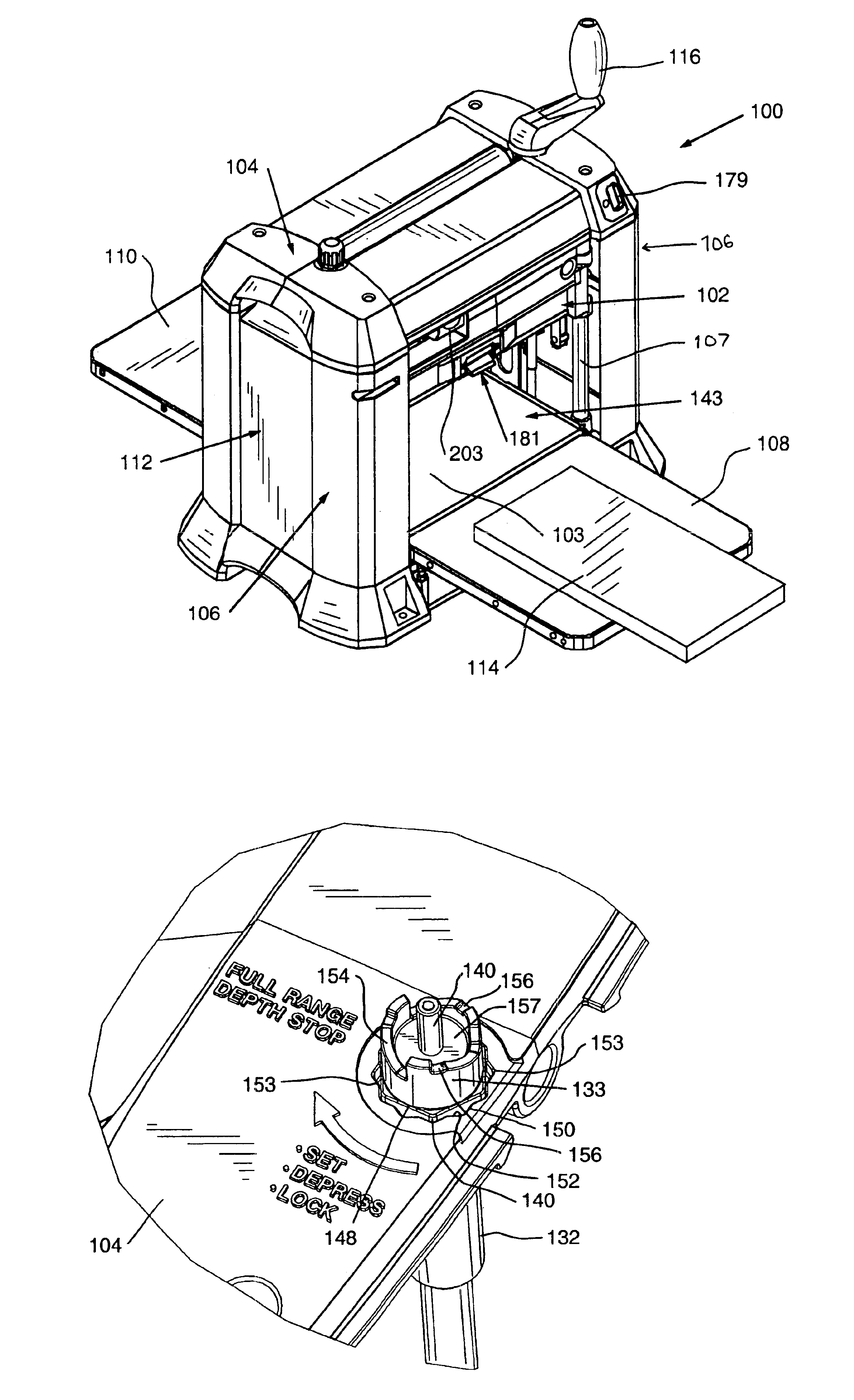

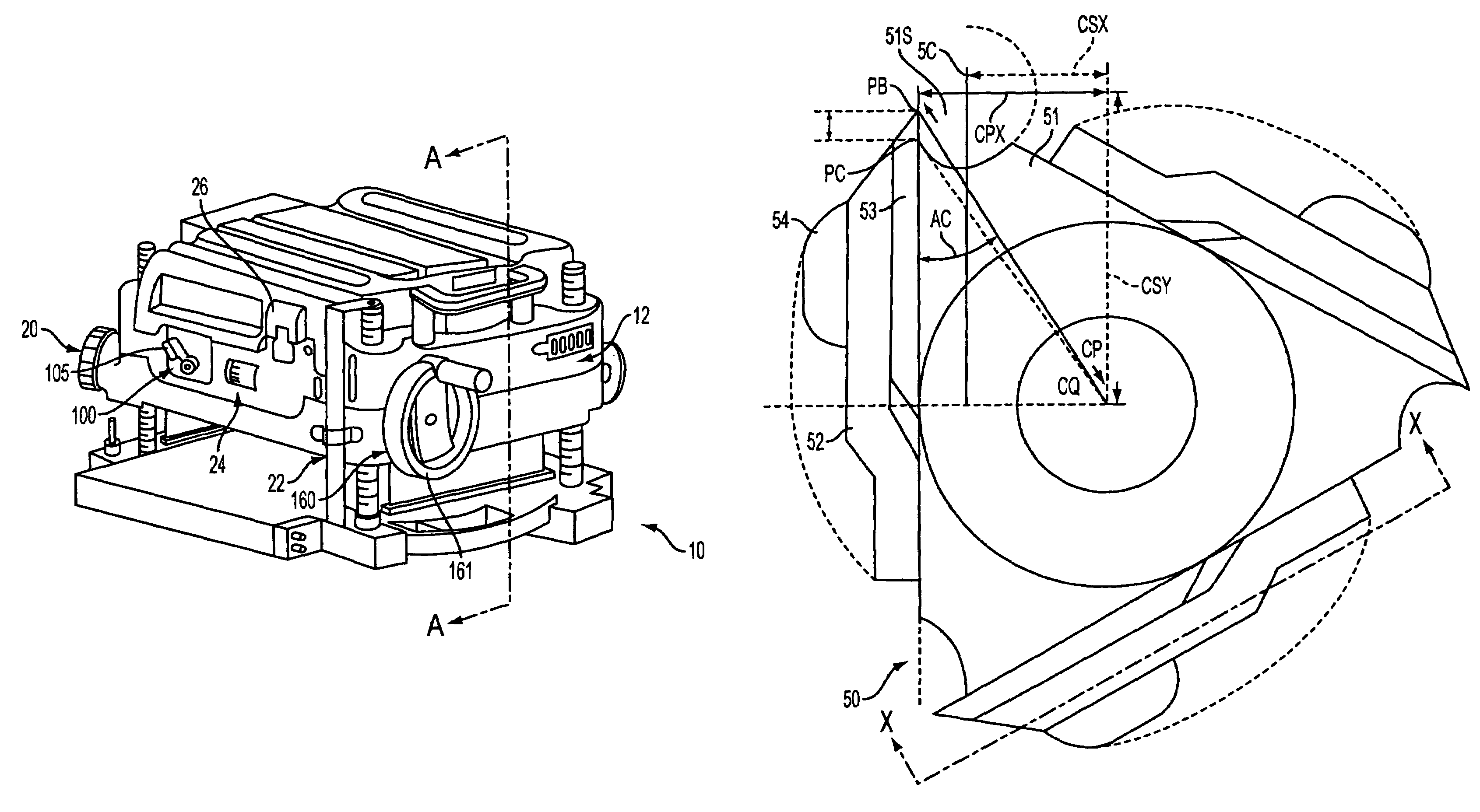

Portable power planer

InactiveUS6886615B2Avoid distanceWood feeding arangementsThicknessing machinesPortable powerKnife blades

A portable power planer for planing the top surface of a workpiece. The portable power planer includes a base, which defines a reference surface, a cutting blade, which defines a cutting plane, and a setting mechanism may be employed to prevent a distance between the reference surface and the cutting plane from being adjusted to a dimension that is smaller than a height dimension that is selected from a group of predetermined dimensions. The setting mechanism includes first and second stop members, one being coupled to the base and the other being associated with the cutting blade. One of the stop members includes a plurality of differently dimensioned sectors or contact points that may be selectively positioned inline with the other stop member to inhibit movement of the cutting blade toward the base if the dimension therebetween is equal to a dimension associated with a given one of the contact points.

Owner:BLACK & DECKER INC

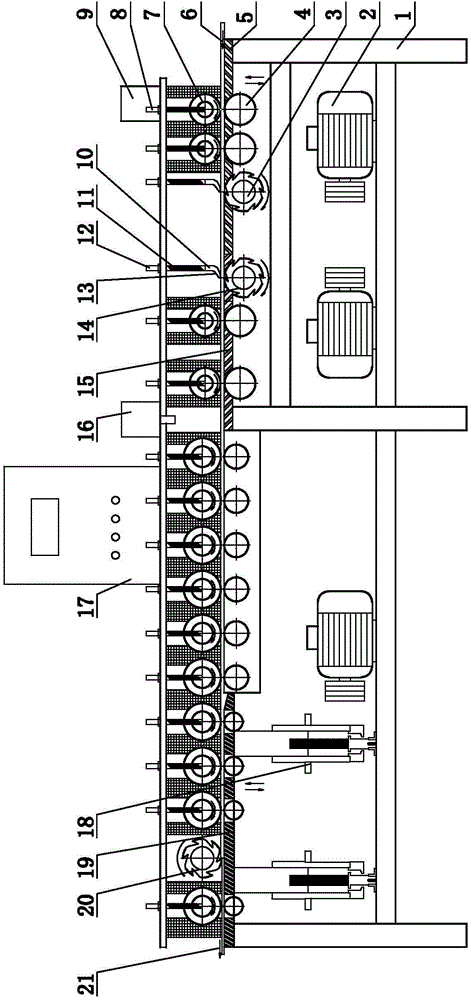

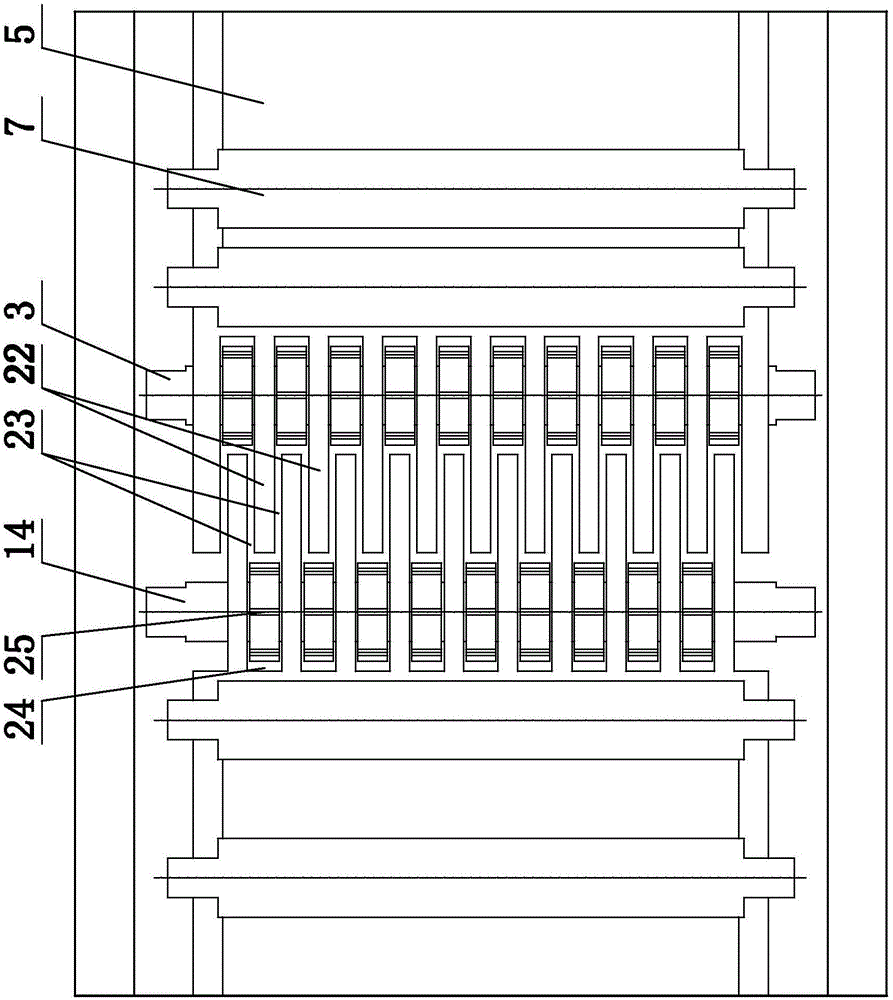

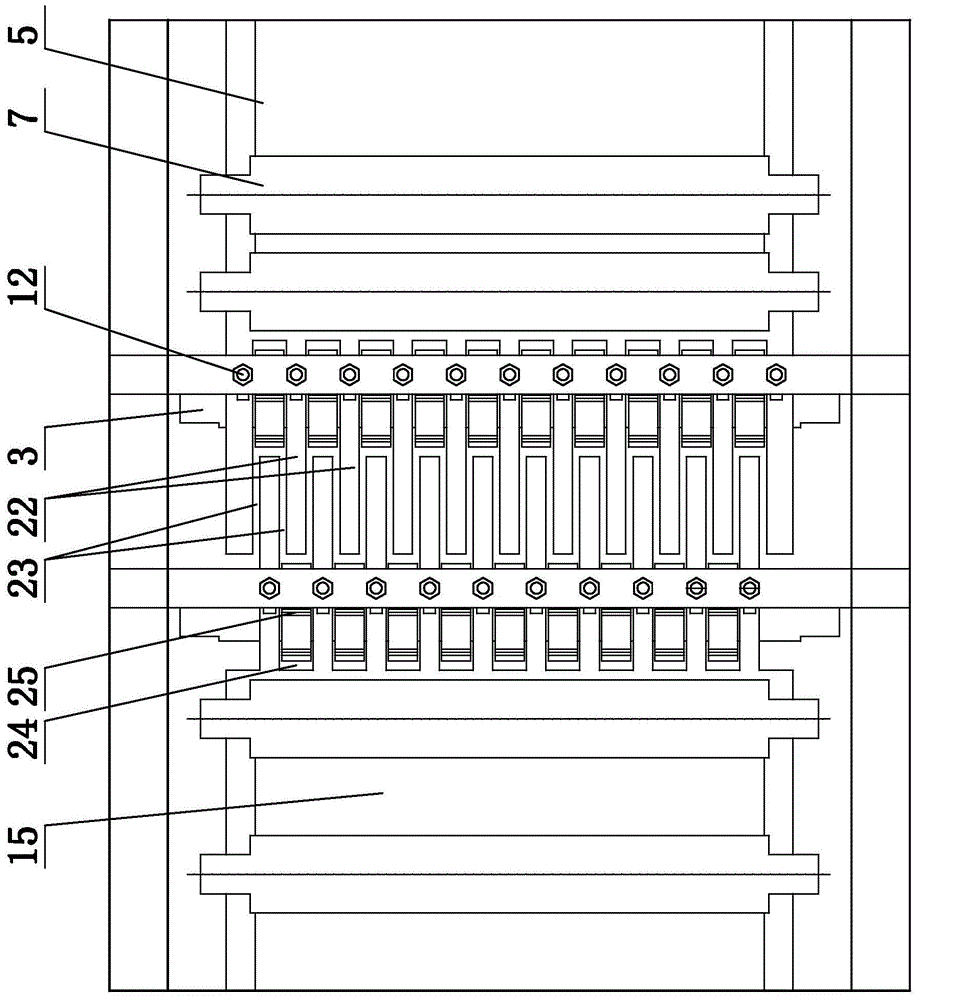

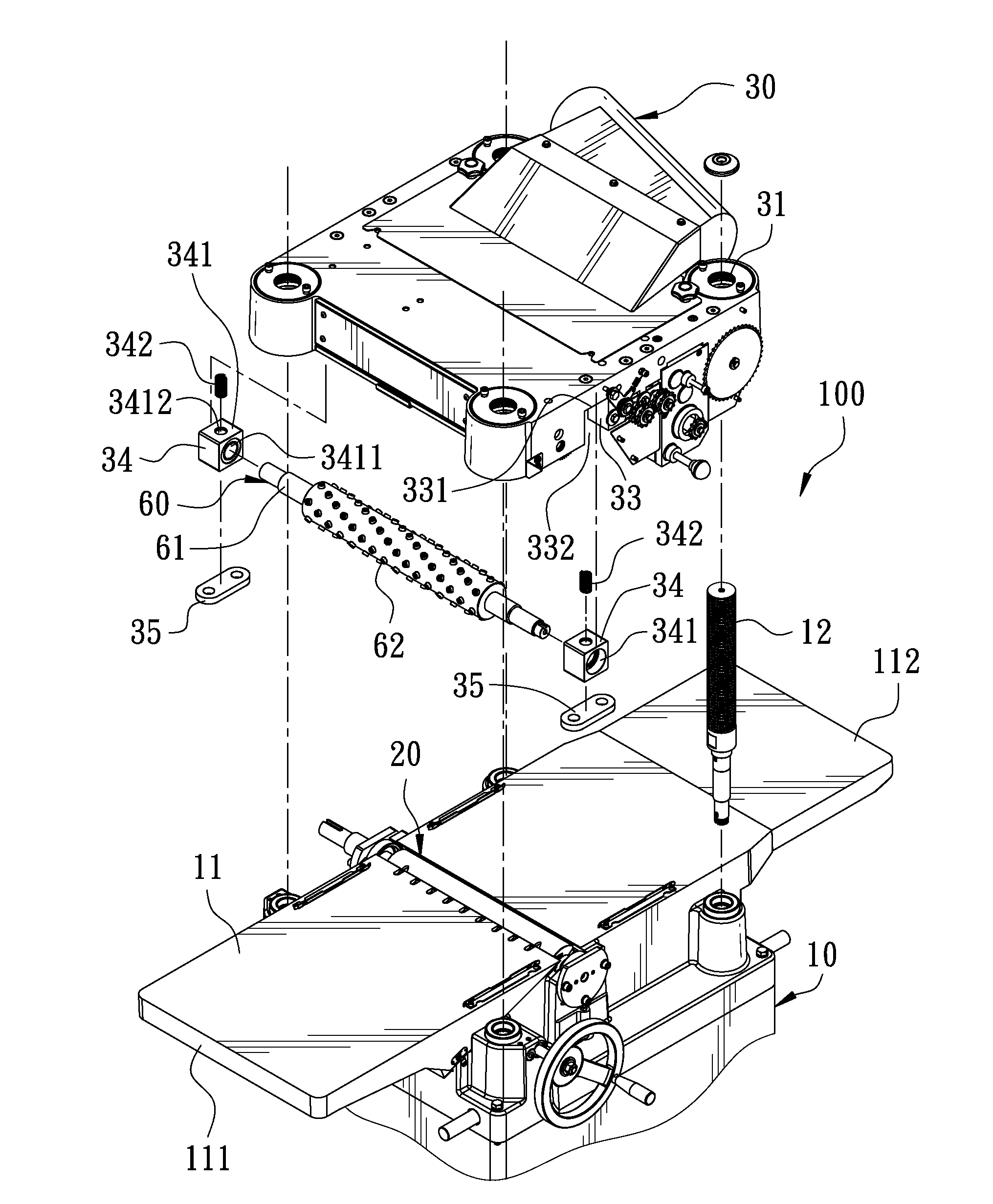

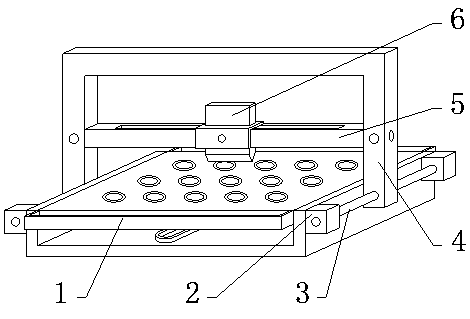

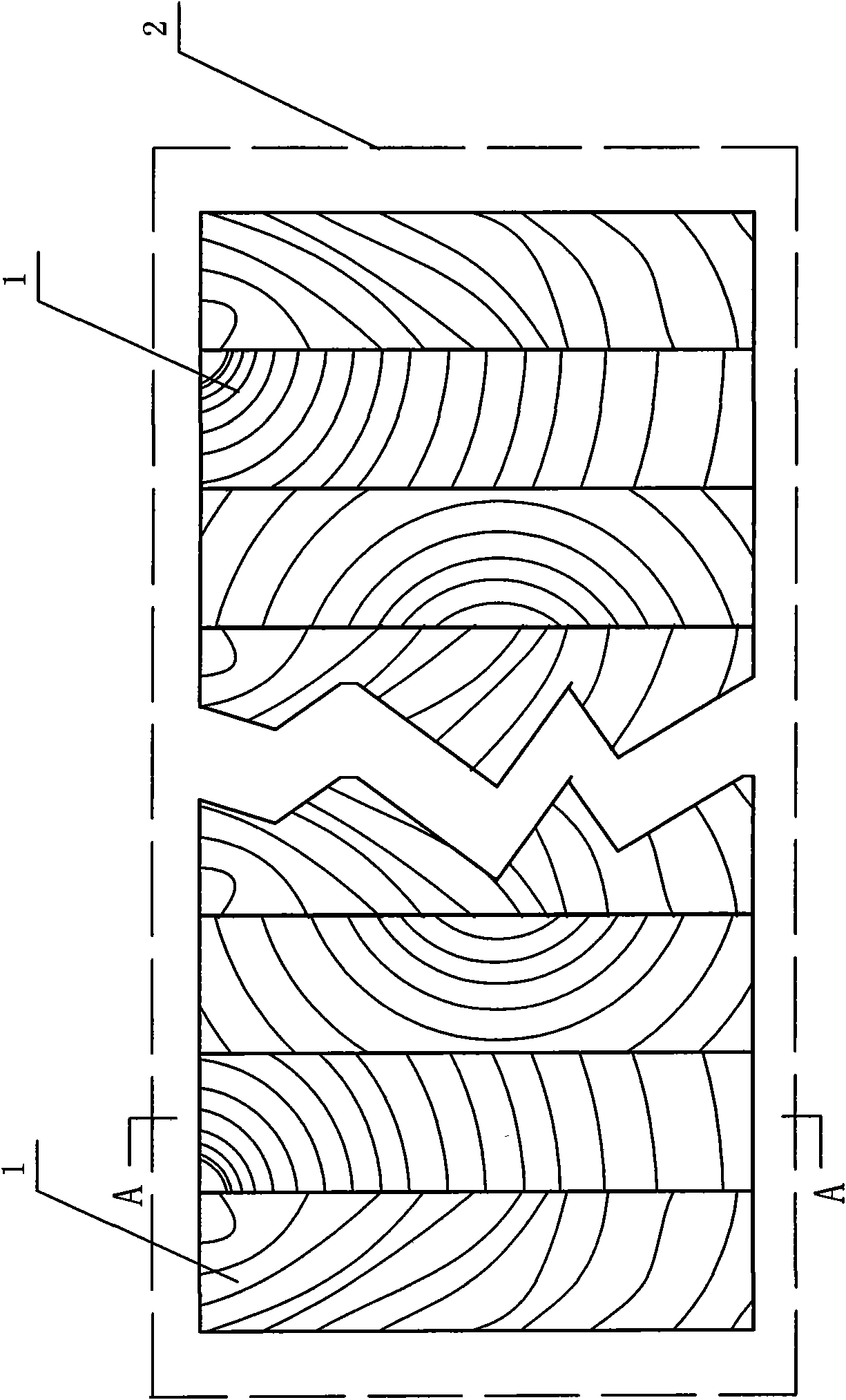

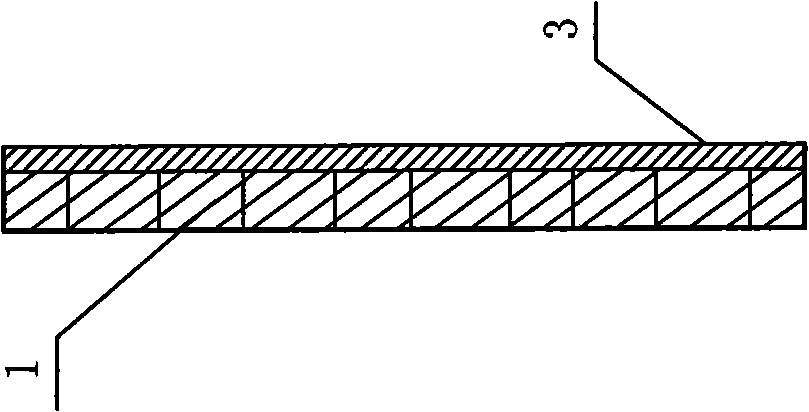

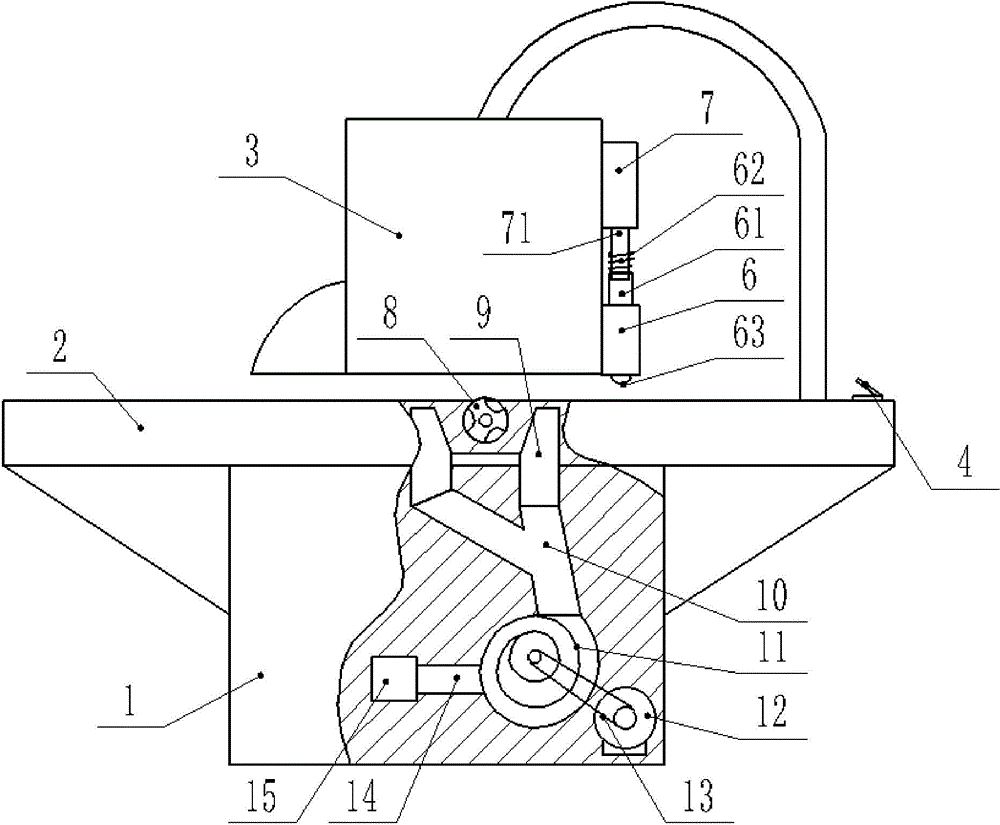

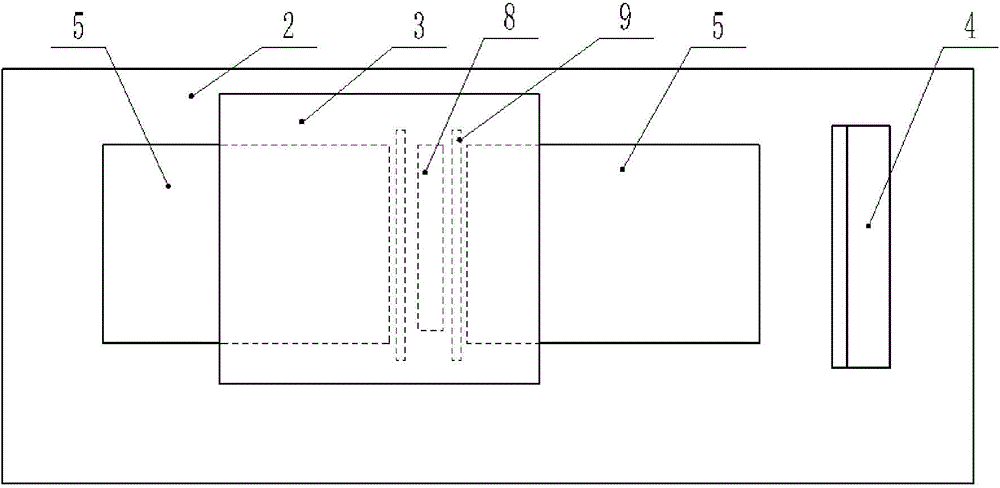

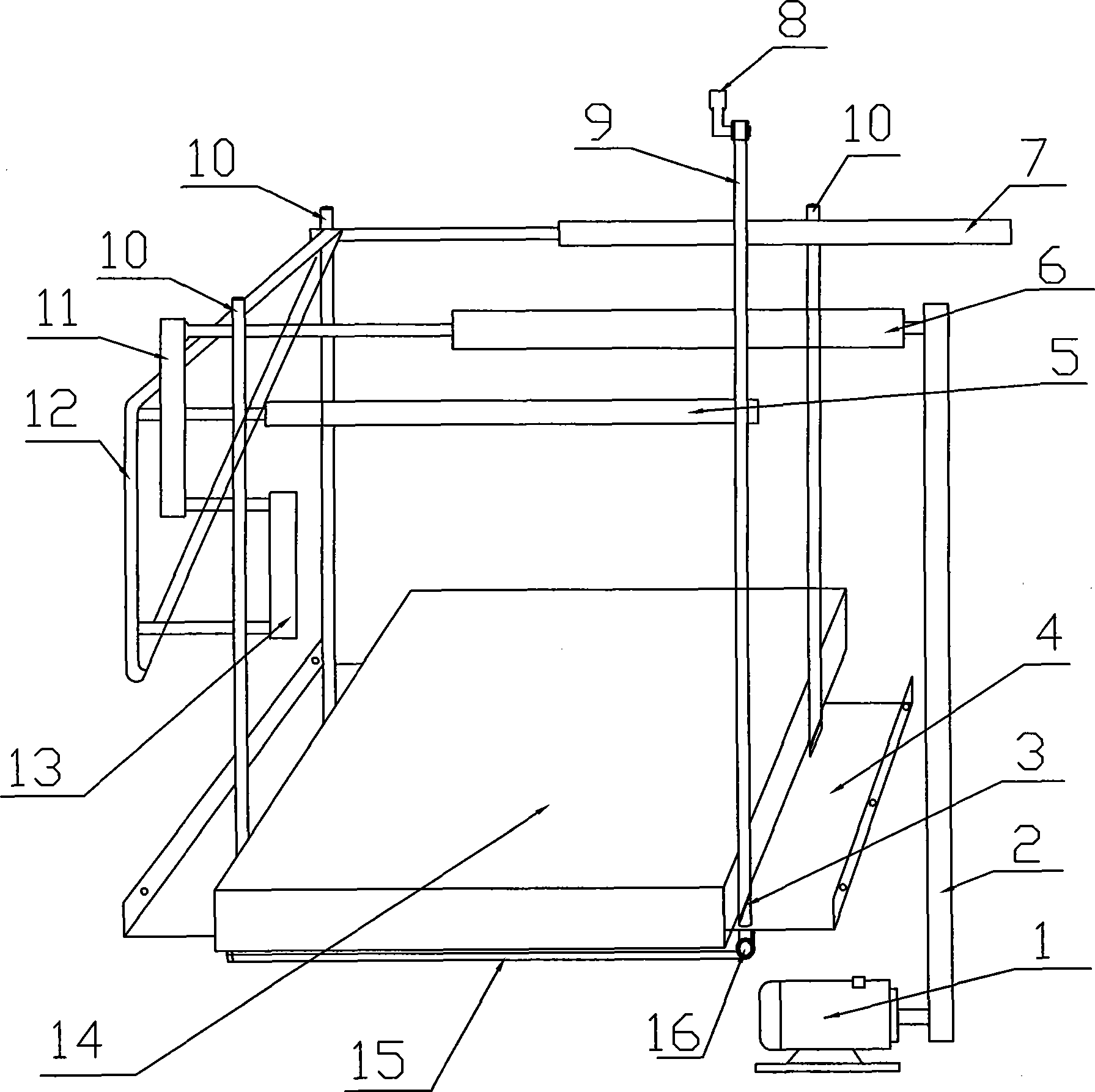

Automated green-removing and yellow-removing double-sided planing machine for bamboo flattened plate

ActiveCN104526779AHigh precisionConsistent thicknessThicknessing machinesCane mechanical workingAgricultural engineeringElectric machinery

The invention relates to an automated green-removing and yellow-removing double-sided planing machine for a bamboo flattened plate. A knife roller driving motor (2) and a precision screw rod type lifter (18), as well as a matching servo motor are arranged in a lower layer of a frame, upper and lower feeding rollers (7, 4) and an upper feeding roller driving servo motor are arranged above and below a middle three-section type worktable, front and middle knife rollers (3, 14) are arranged below front and middle worktables, planing-assisting compressors are arranged over the two knife rollers, a rear knife roller (20) is arranged above a rear worktable (19), the lifter (18) is arranged below the rear worktable (19), the adjacent sides of the front and the middle worktables form comb-like structures which are opposite to each other, comb teeth and comb seams are interlaced mutually, the planing-assisting compressor is correspondingly arranged on each comb tooth, and pressing pieces are laminated with the comb teeth. The machine is used for removing green and removing yellow of the bamboo section flattened plate, can realize constant-amount green removal and constant-thickness yellow removal and complete the operation in one flow process, and has the advantages of labor saving, high efficacy, consistent product thickness and high utilization rate of bamboo materials; and through the design of the comb-like worktables and the planing-assisting compressors, the planing defects, namely head hitting, tail jumping and knife jumping, are avoided.

Owner:浙江德长竹木有限公司

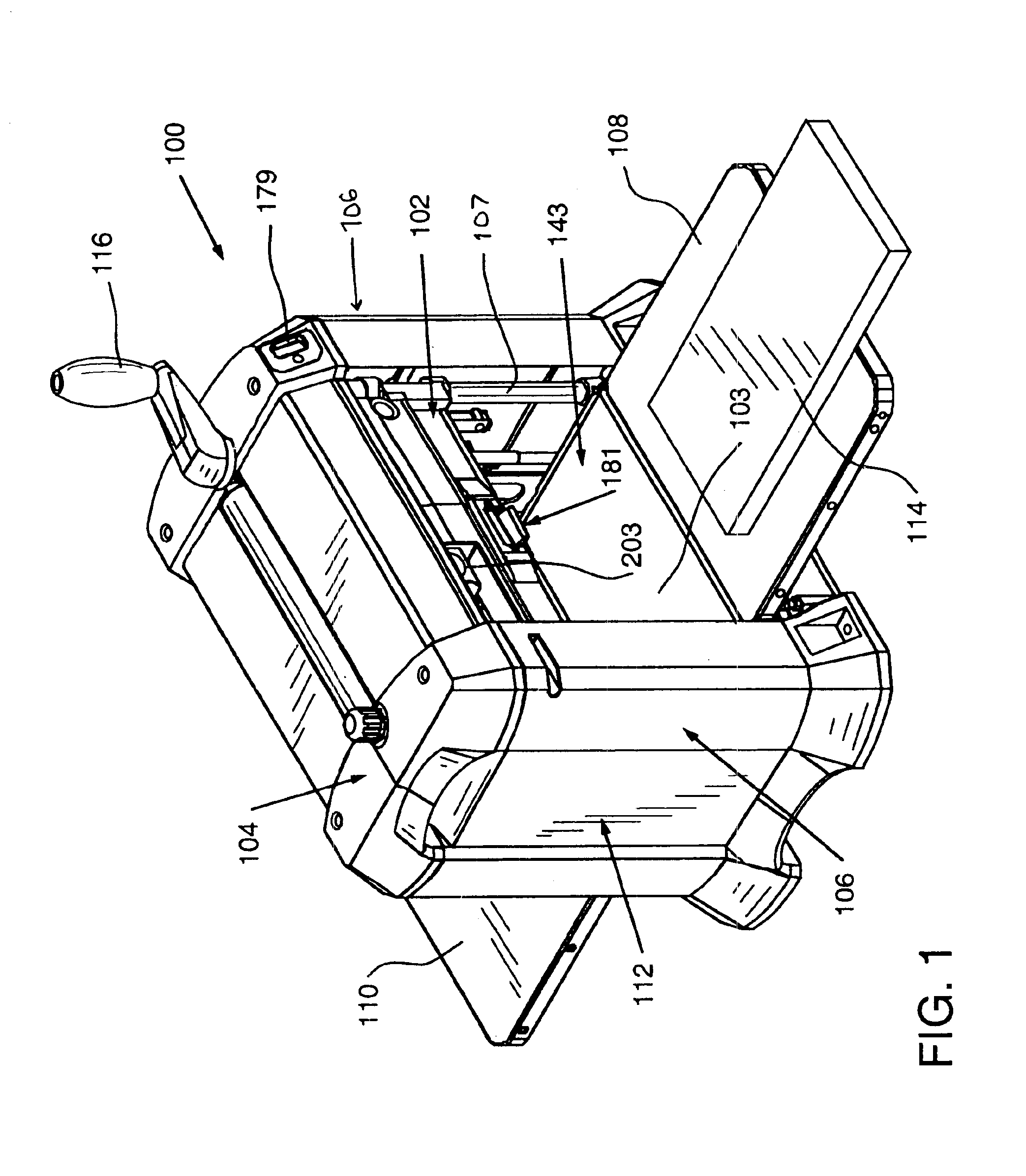

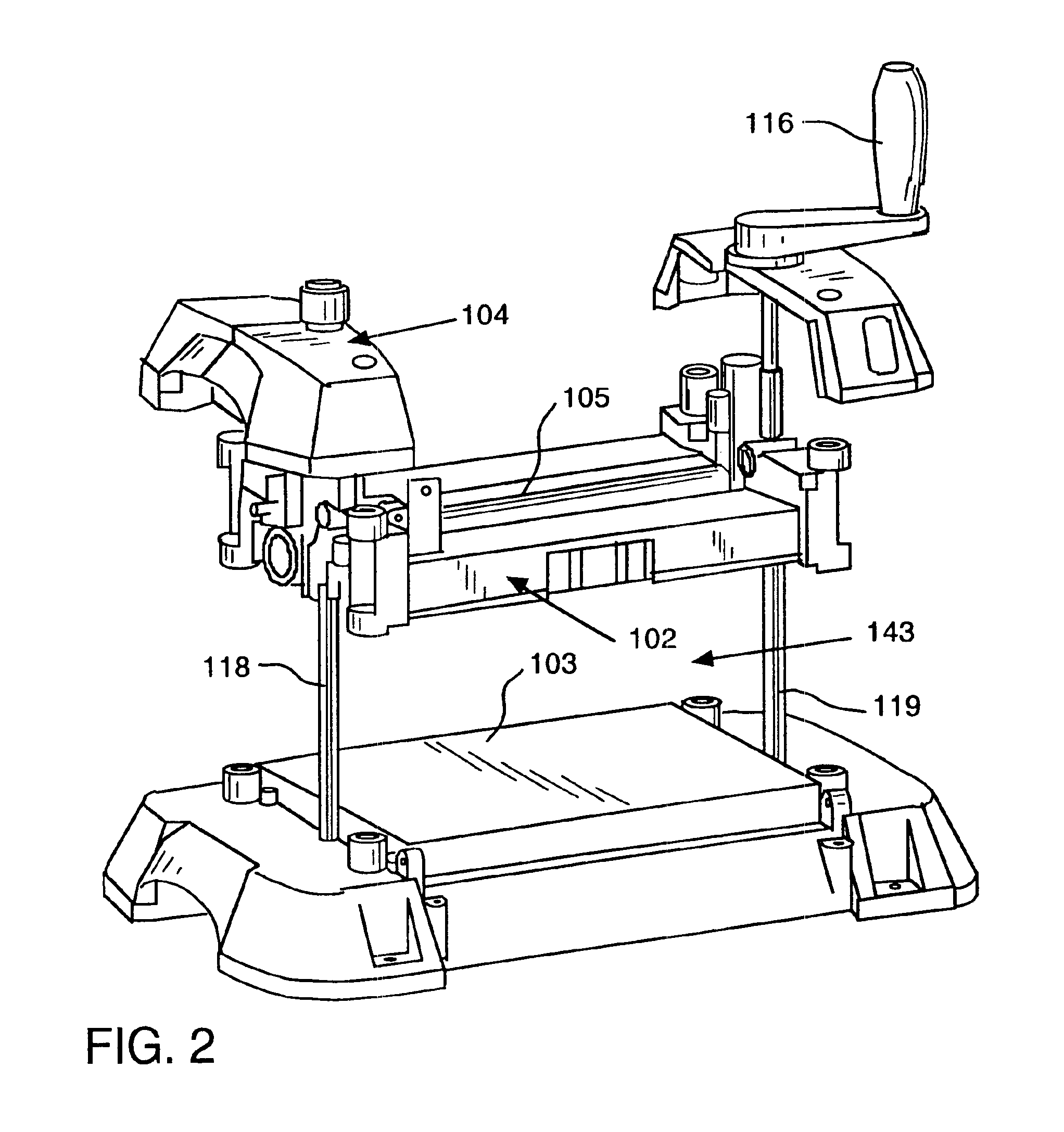

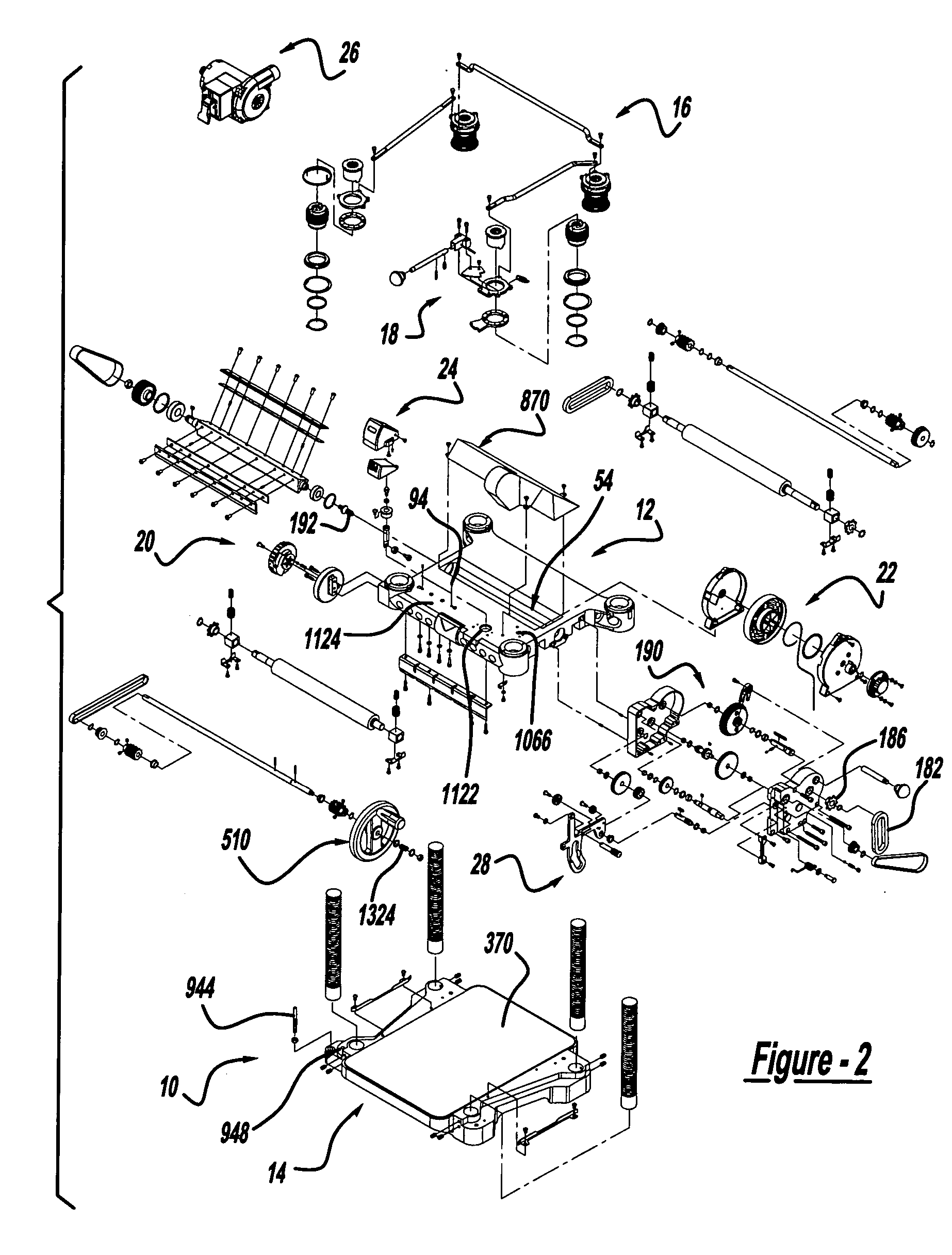

Planer apparatus

InactiveUS6951231B2Attach and detachPrecision positioning equipmentThicknessing machinesLocking mechanismEngineering

A planer having a base, a first support member attached to the base and supporting a cutterhead for selective travel in a first direction toward the base and a second opposite direction, a top frame attached to the first support member and a depth stop mechanism attached to the top frame for selectively preventing travel of the cutterhead in the first direction beyond a pre-selected distance from the base. A depth measuring device including a retractable tape may be attached to the cutterhead. A workpiece level indicator plate movable between an engaged position and a disengaged position may be attached to the planer to indicate contact with a workpiece. A locking mechanism for locking a pivotable infeed table of a planer in the upright position for storage, and thereby switching off power to the planer is also disclosed. The planer may include a readily attachable and detachable dust removal assembly.

Owner:CHANG TYPE INDAL

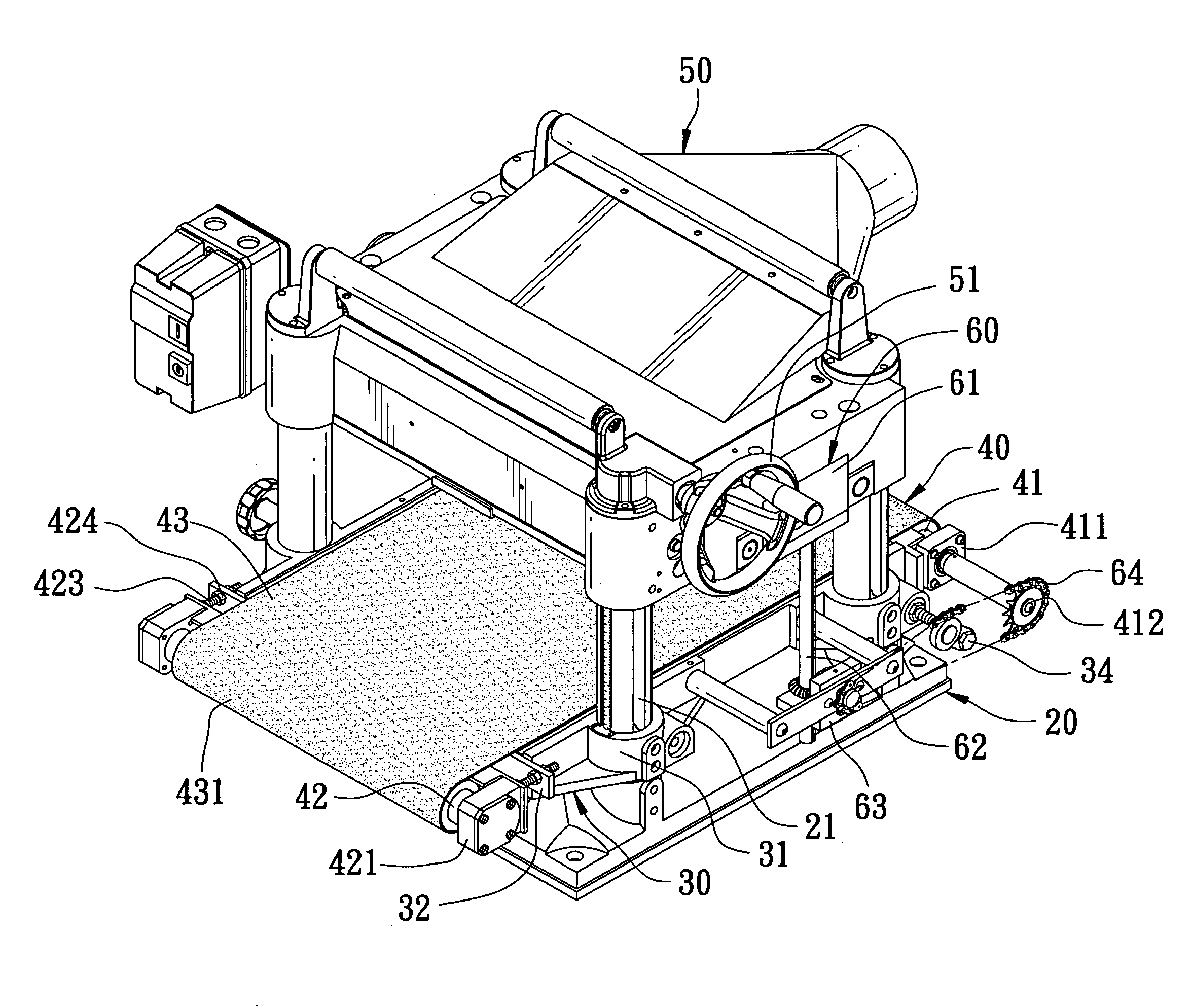

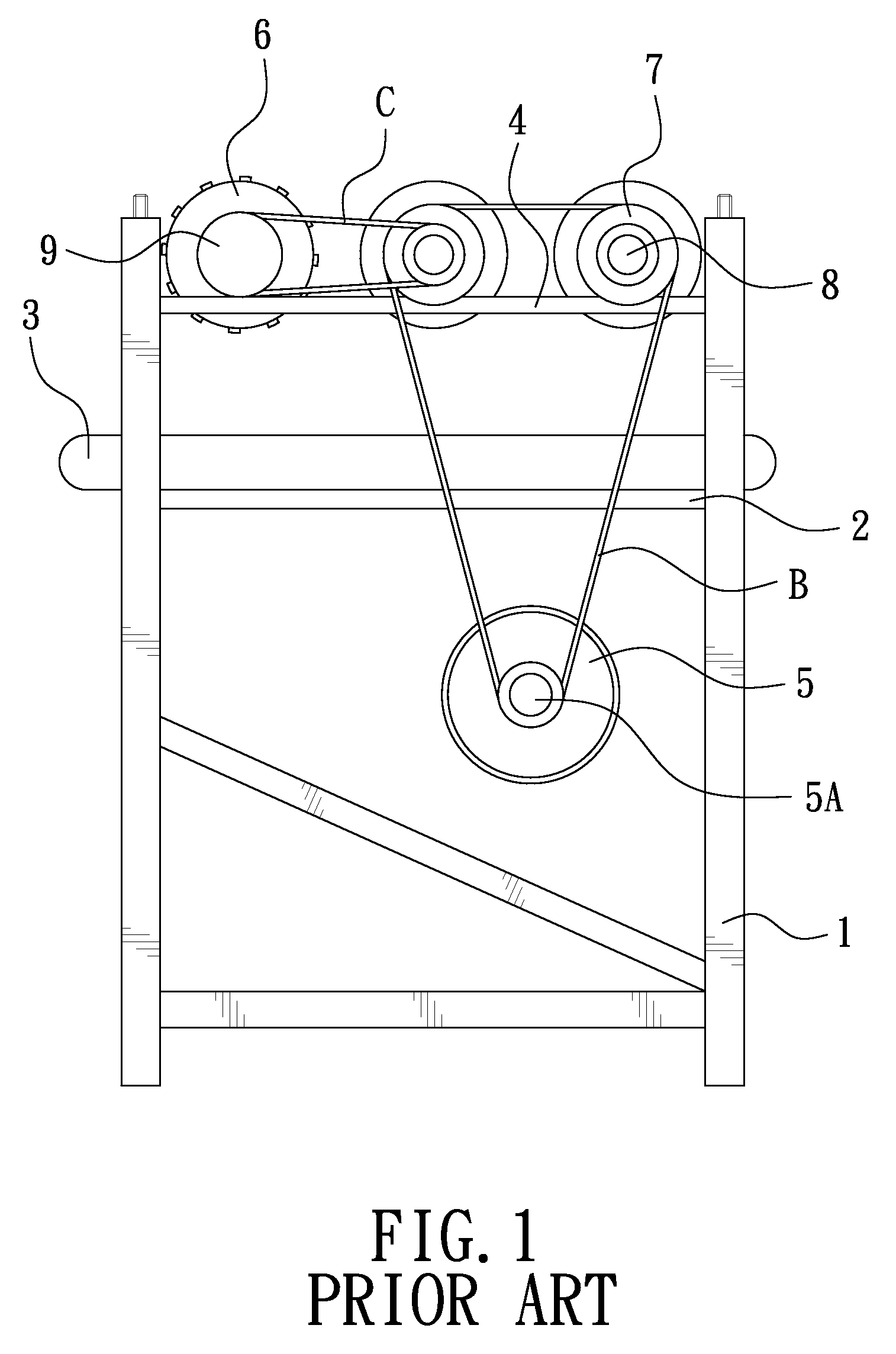

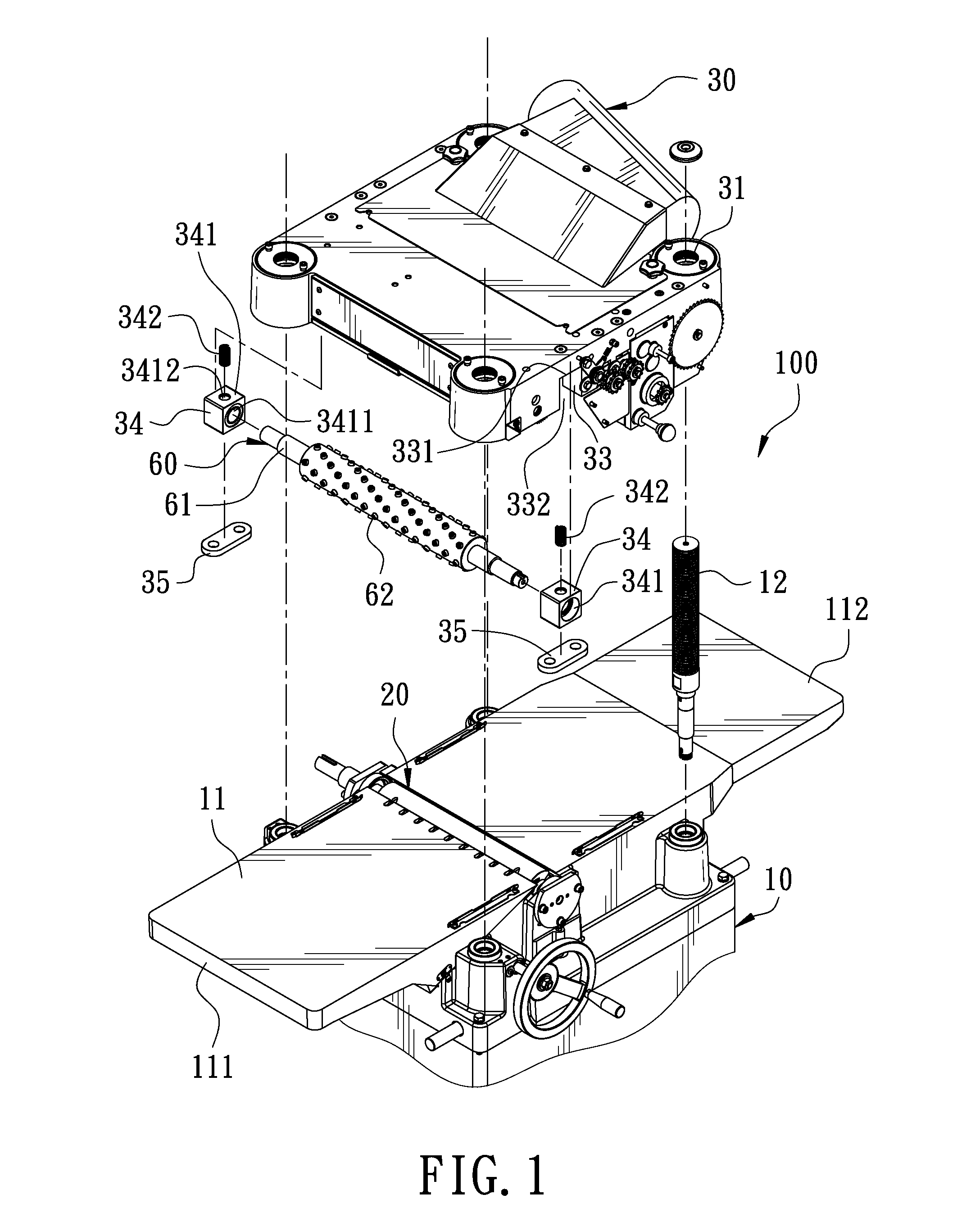

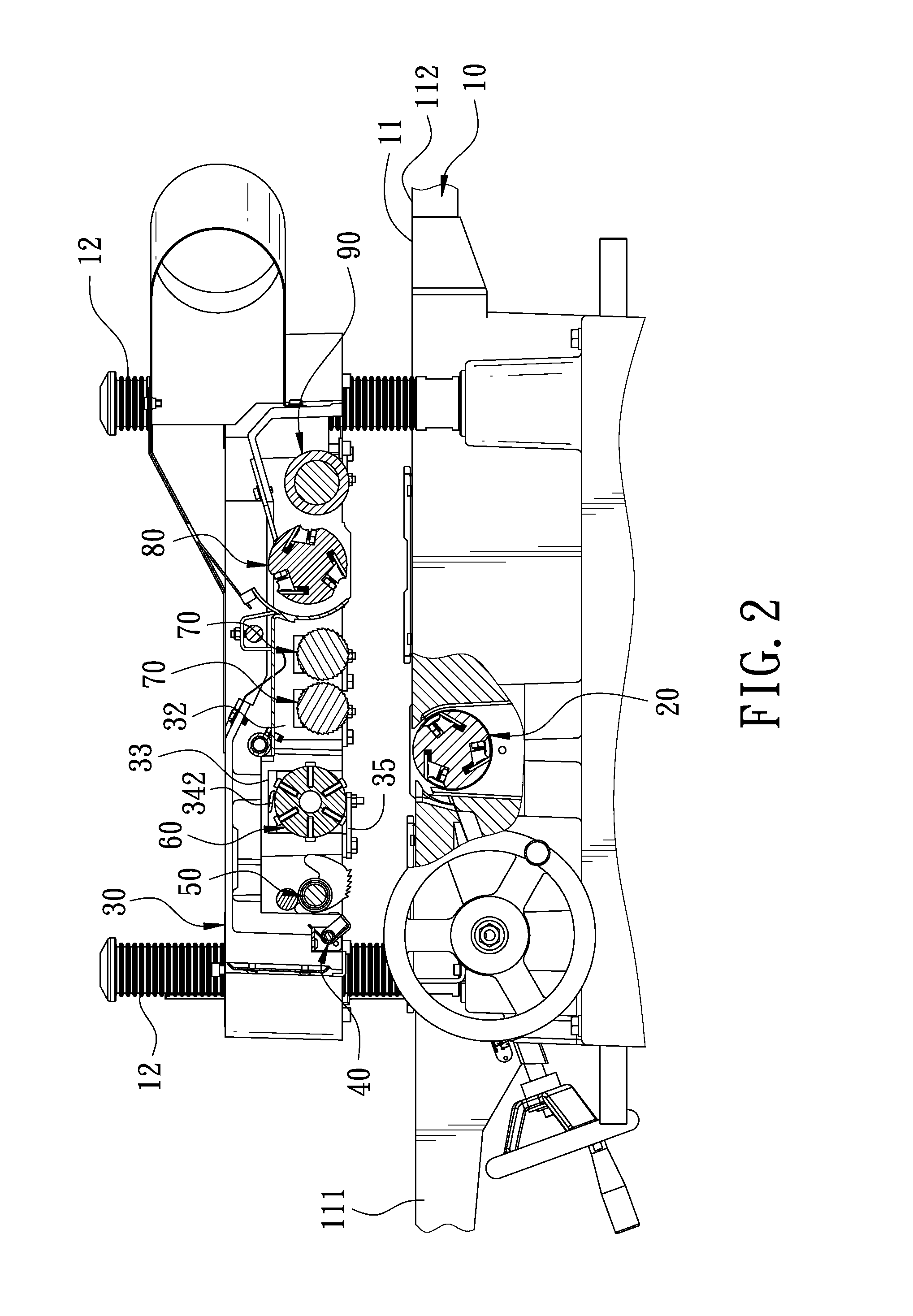

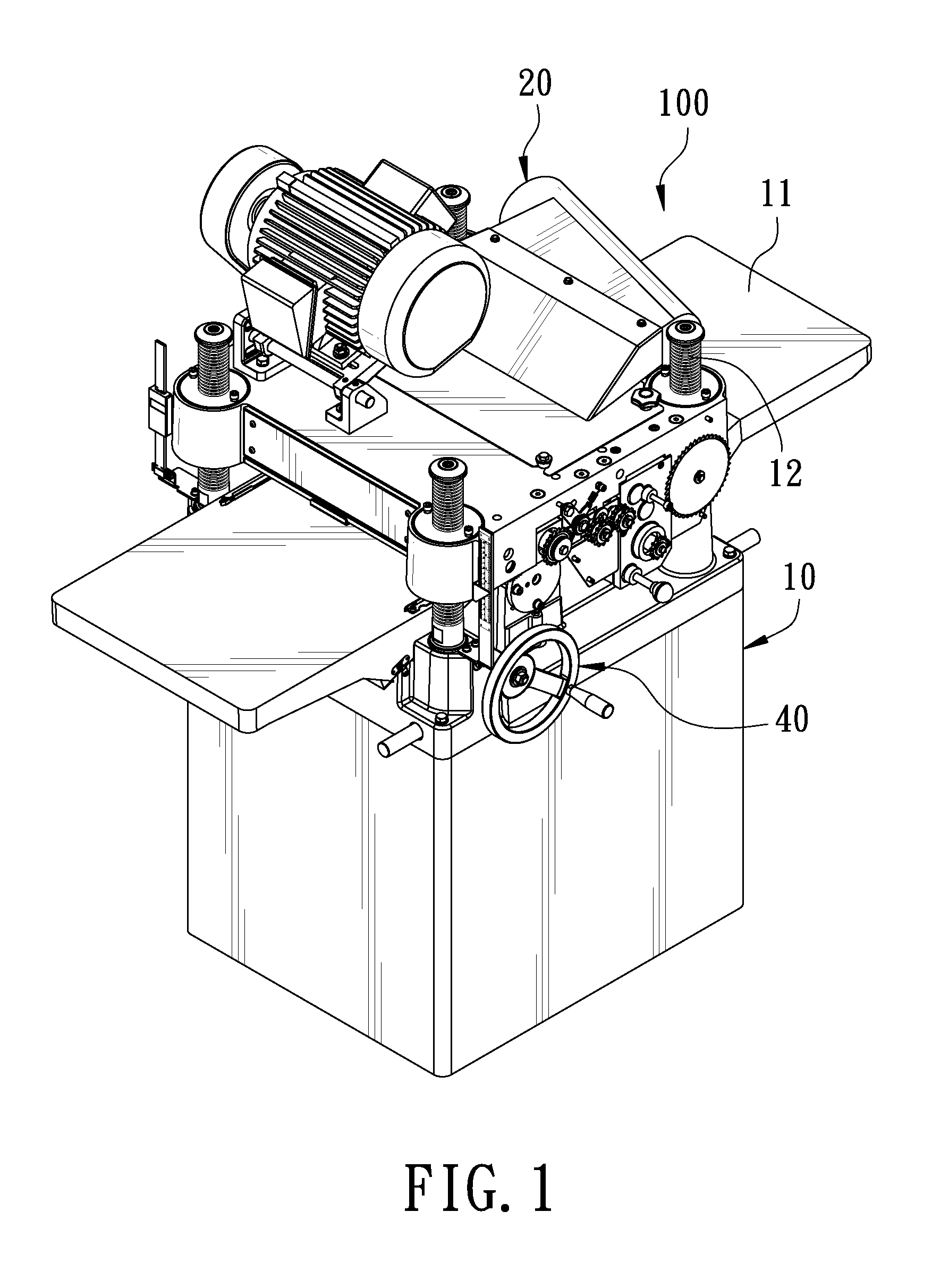

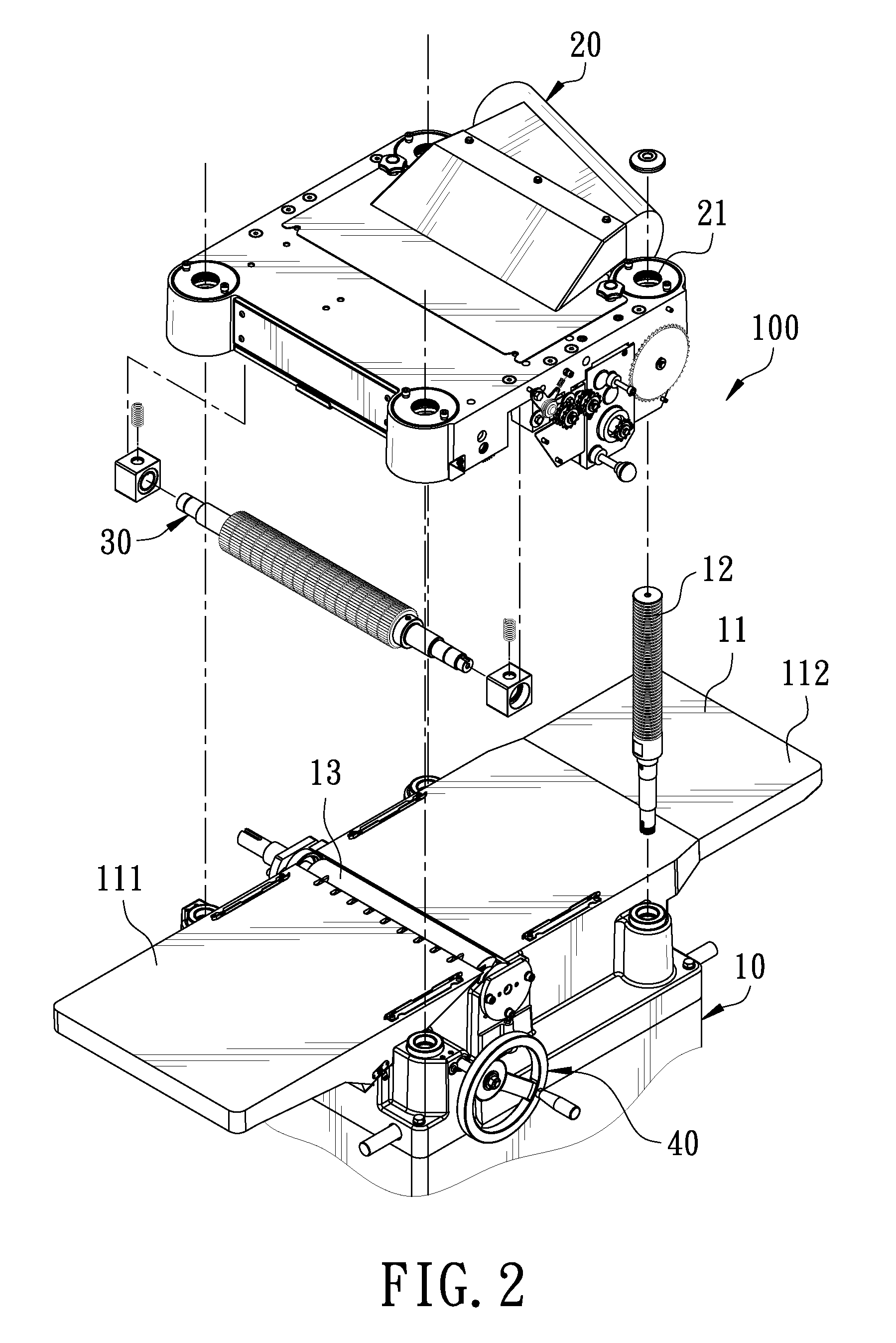

Work feeding and conveying mechanism for a planing machine

InactiveUS20080230149A1Increase coefficient of frictionProcess stabilityWood feeding arangementsThicknessing machinesEngineeringDrive shaft

Owner:CHUANG BOR YANN

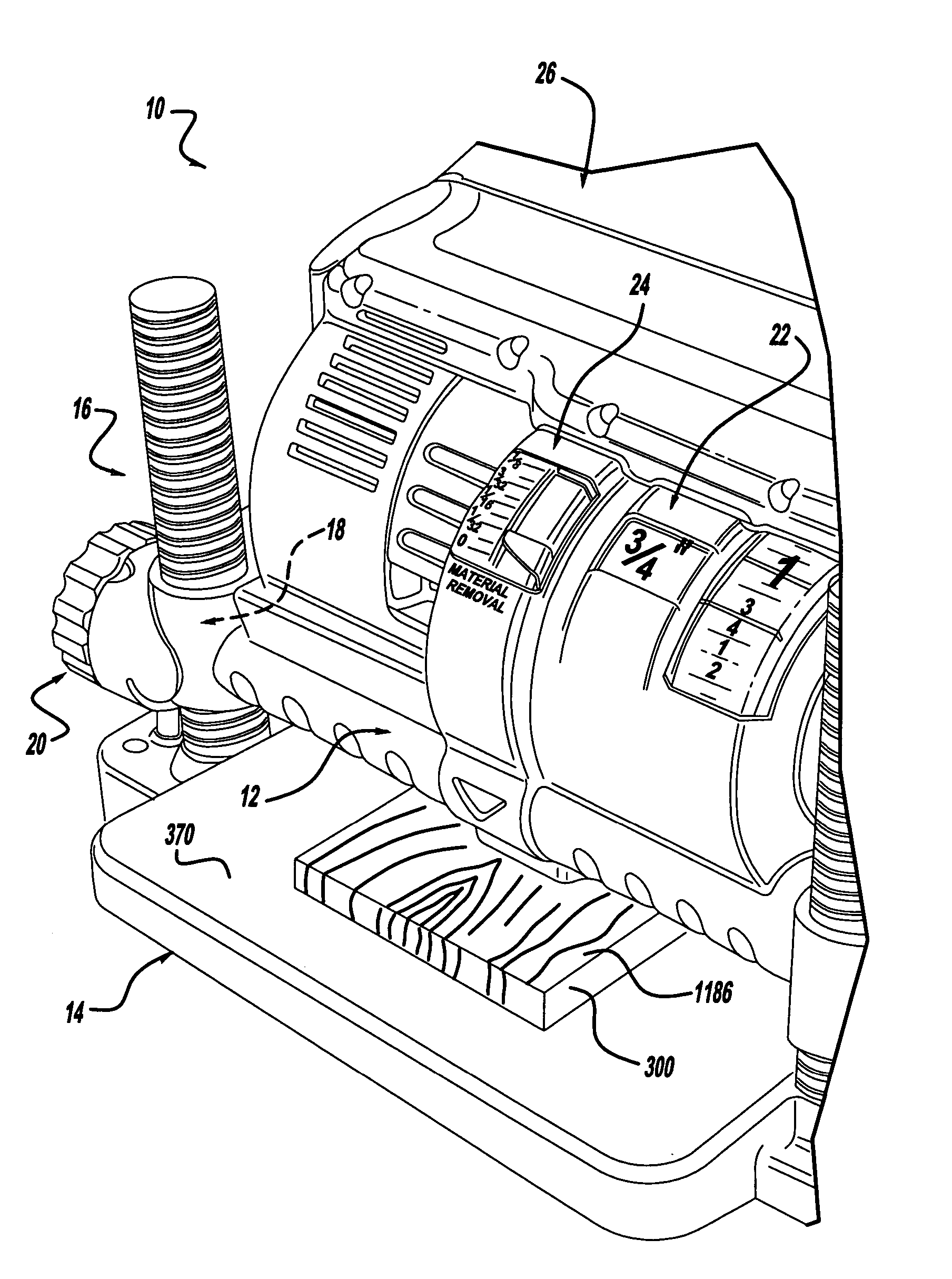

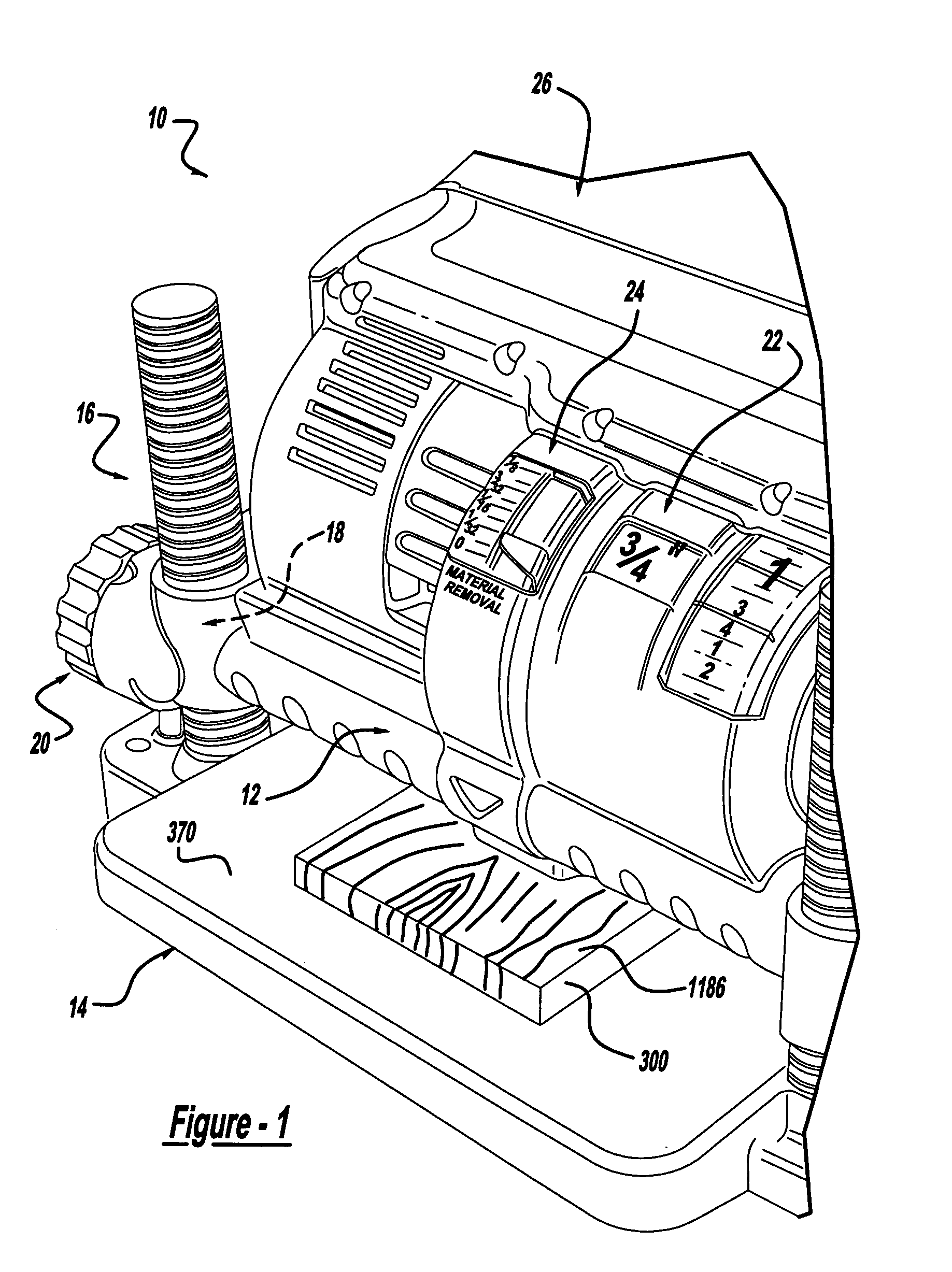

Portable wood planer

InactiveCN1513648APrecision positioning equipmentThicknessing machinesMaterial removalLocking mechanism

An improved portable wood planing machine for the surface planing of wooden planks or boards is provided. In an exemplary embodiment, the planing machine includes a carriage assembly locking mechanism for locking the carriage assembly relative to a plurality of vertical support columns to thereby vertically fix the carriage assembly. In one form, the carriage assembly locking mechanism includes a plurality of levers which cooperate to engage the support columns of the carriage assembly. The exemplary embodiment further includes a depth stop adjustment mechanism which allows the operator to accurately select a minimum workpiece depth from one or more predetermined depths and a material removal indicator assembly operable for enabling the user of the planing machine to accurately determine the amount of material to be removed during each pass of the workpiece.

Owner:BLACK & DECKER INC

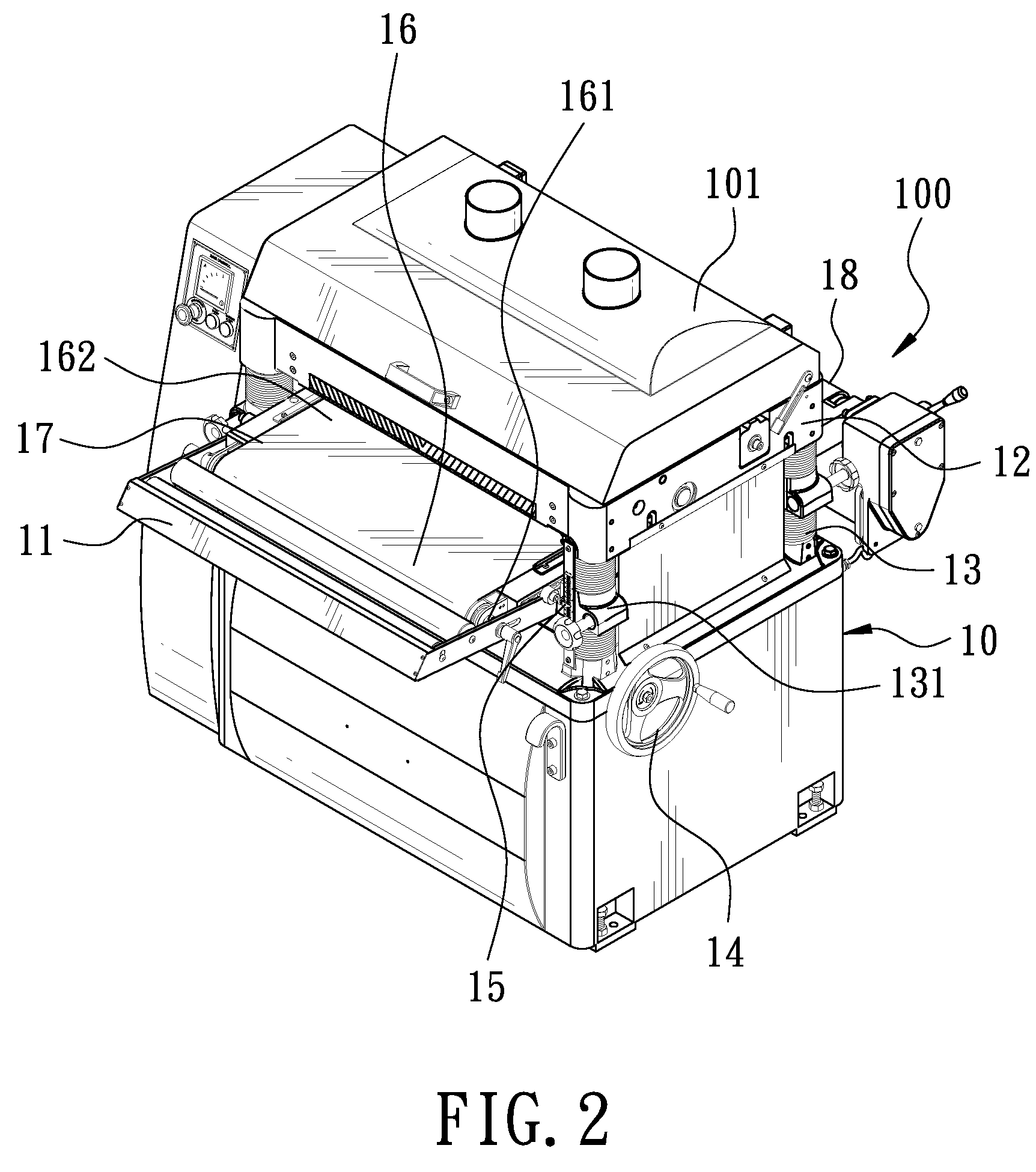

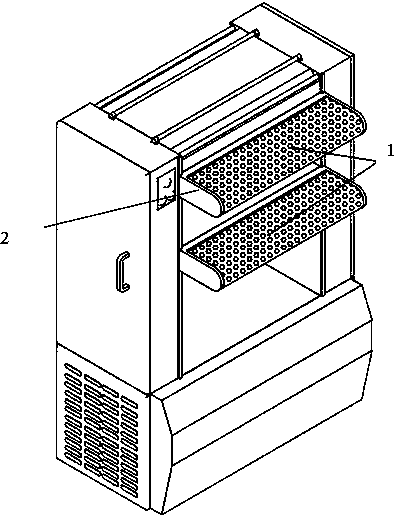

Planing and polishing machine

InactiveUS7607970B1Improve efficiencyImprove precisionEdge grinding machinesThicknessing machinesDrive wheelEngineering

A planning and polishing machine includes a base, an intermediate base installed with a conveying device for laying a workpiece, and an upper base pivotally fixed with at least a planer and a grinding roller. A driving motor is installed below the conveying device, with its shaft engaged with a first driving wheel and a second driving wheel with different diameters. The first driving wheel and the blade are mounted by a first driving element, and the second driving wheel and the grinding roller are mounted by a second driving element. When the driving motor is turned on to draw the first driving element and the second driving element, the blade and the grinding roller are to be meanwhile driven to rotate in different rotating speeds, enabling the blade to powerfully plane the surface of a wood, achieving a high precision and efficiency of planning and polishing.

Owner:CHUANG BOR YANN

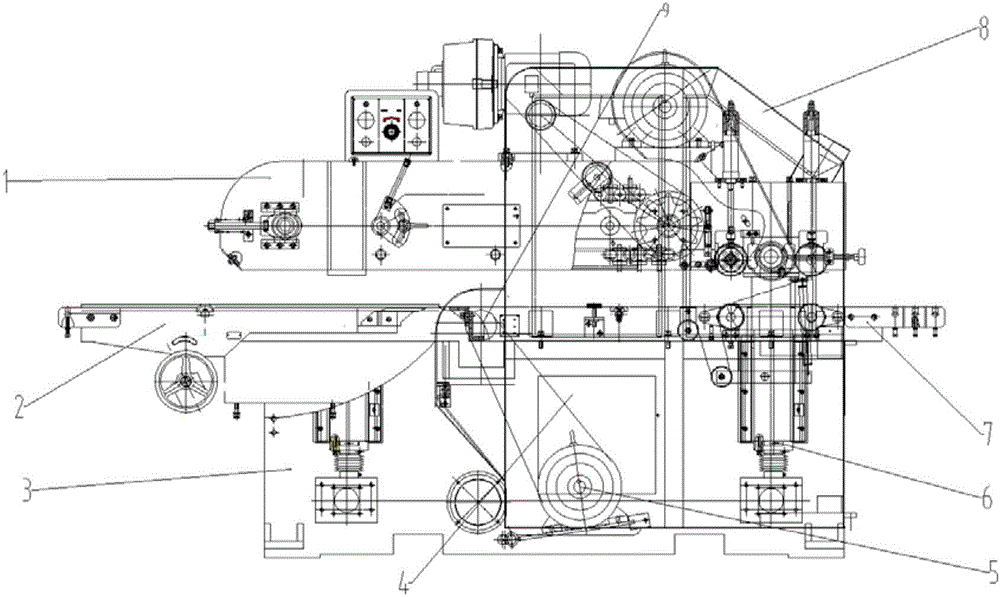

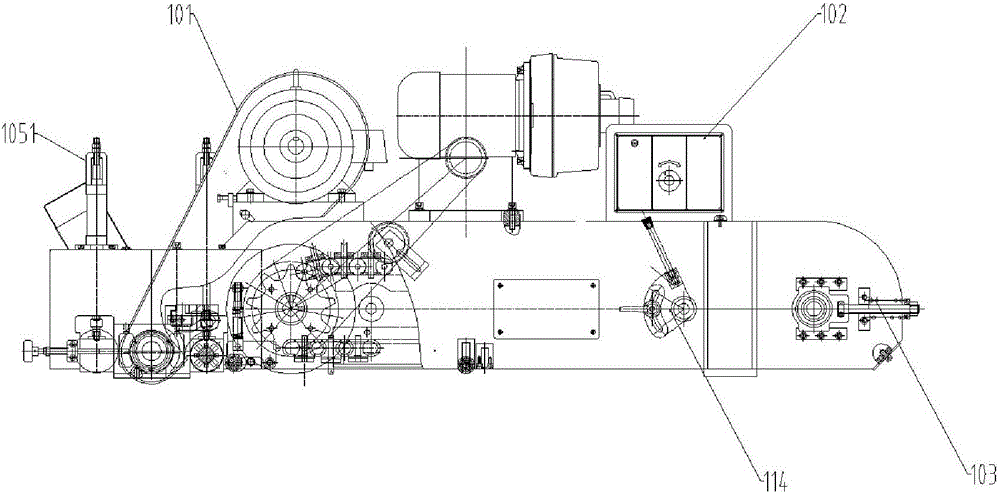

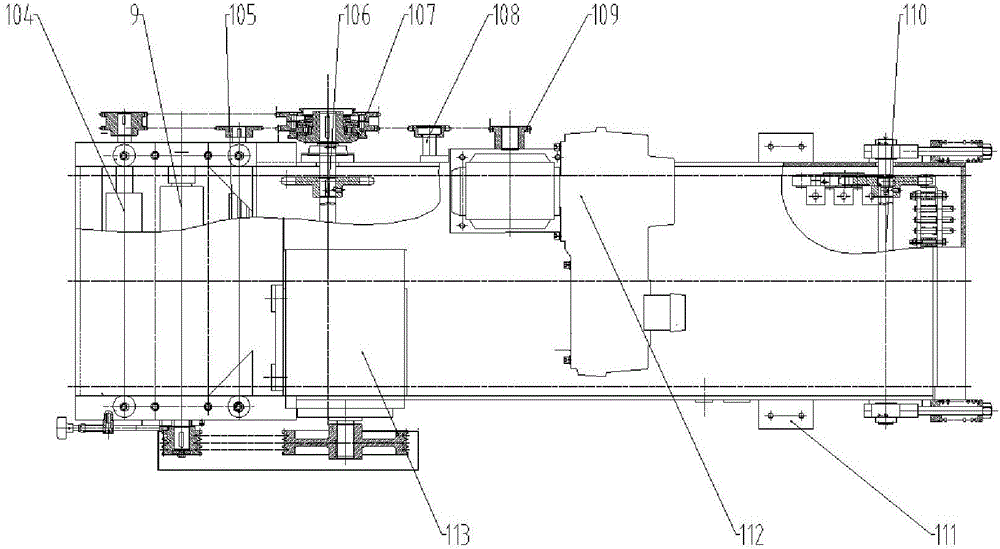

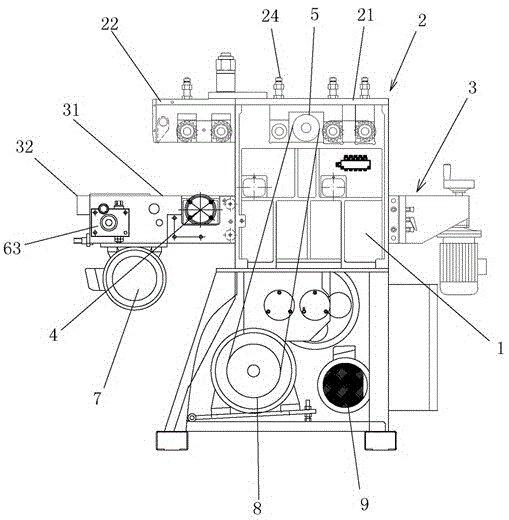

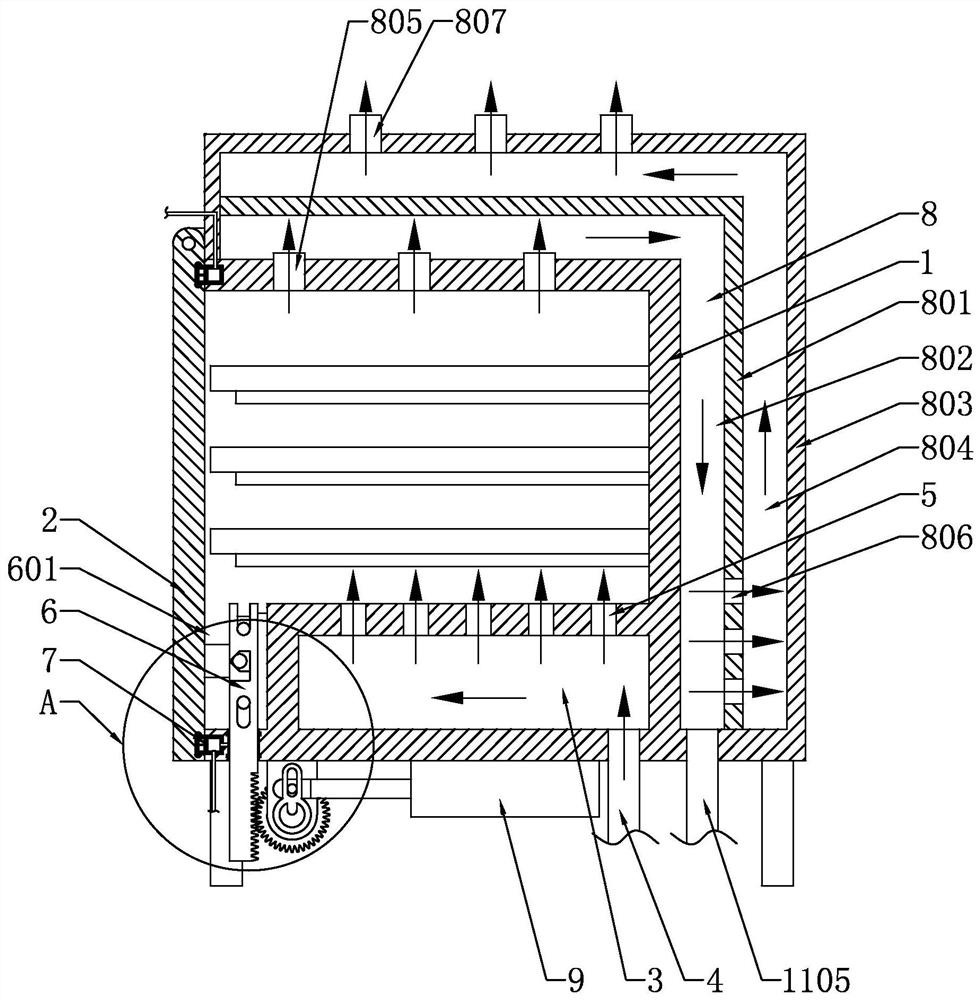

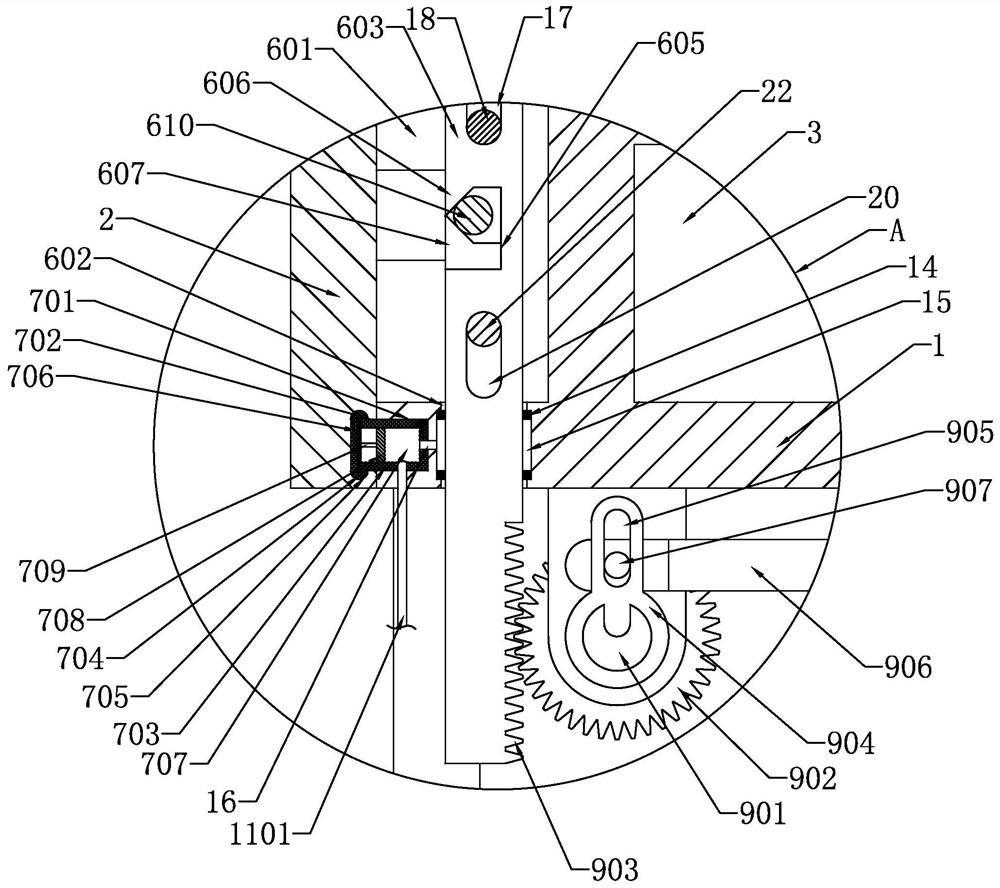

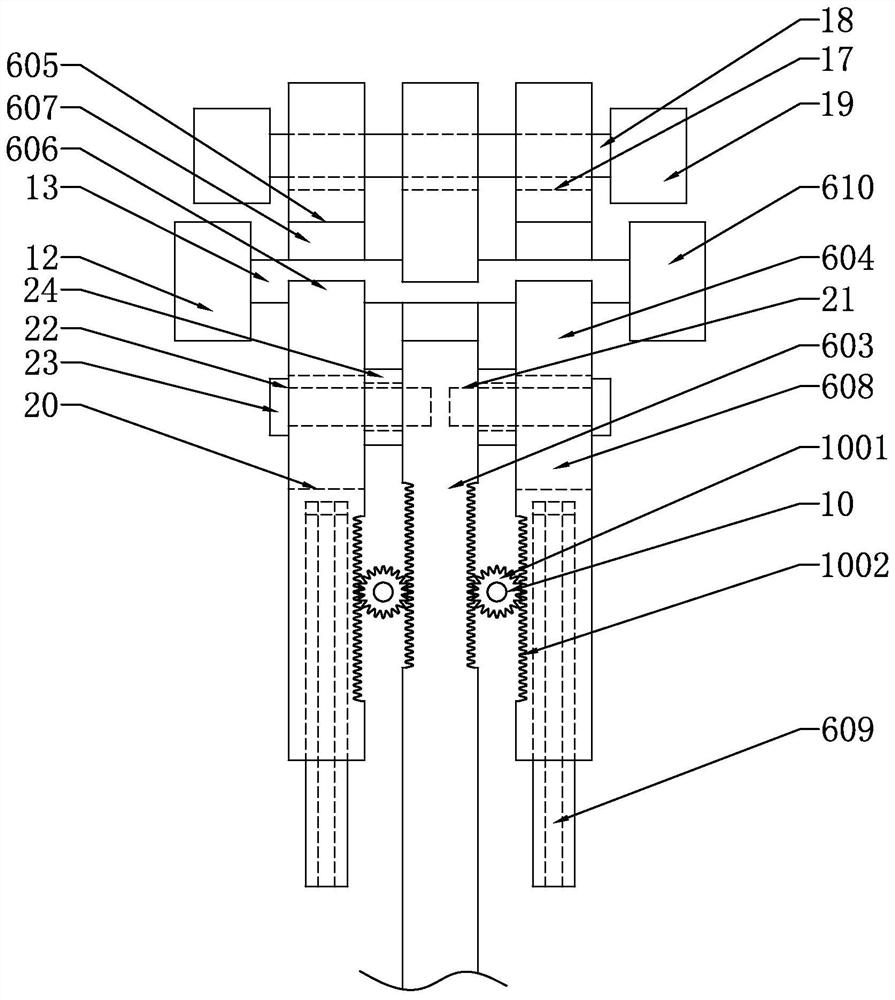

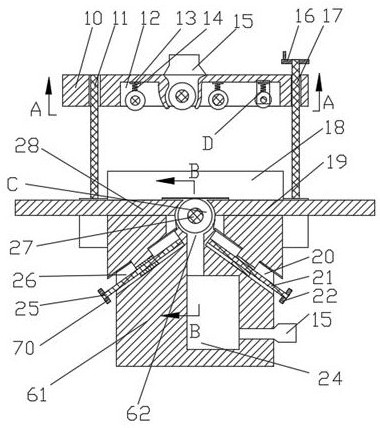

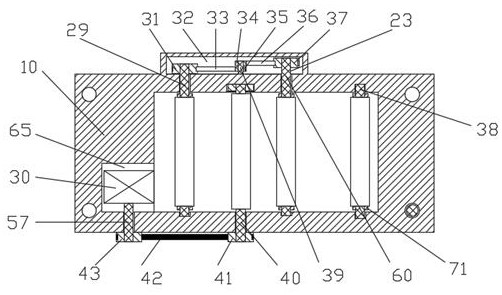

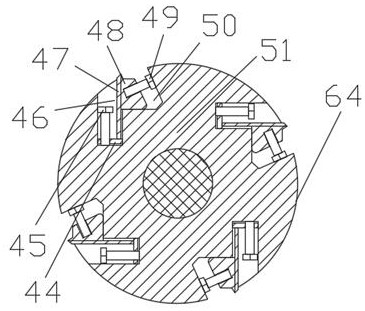

Heavy-cut double-faced woodworking thickness planer and processing method thereof

The invention discloses a heavy-cut double-faced woodworking thickness planer and a processing method thereof. The heavy-cut double-faced woodworking thickness planer structurally comprises a lathe bed assembly, a front worktable assembly, bed legs, a control box, a motor belt tensioning assembly, a lifting transmission assembly, a rear worktable assembly, a rear cover and planer assemblies, wherein the front worktable assembly and the rear worktable assembly are fixed on bed legs and are respectively provided with a front worktable carrier roller and a rear worktable carrier roller, and a pressing roller and a feeding roller assembly are arranged on the lathe bed assembly and are used for conveying timbers; one planer assembly is connected between the front worktable assembly and the rear worktable assembly, the other planer assembly is arranged on the lathe bed assembly, and the planer assemblies are respectively used for planing the upper and lower surfaces of the timbers; the lifting transmission assembly is used for controlling the height, relative to the bed legs, of the lathe bed assembly through the transmission of a lead screw so as to realize the thickness regulation of the planed timbers; and after the planer assemblies are drawn out and plane cutters are replaced, the planer assemblies can be put back, so that processing requirements of different timbers can be conveniently and rapidly met.

Owner:JINGHUA POWERFUL WOODWORKING MACHINERY

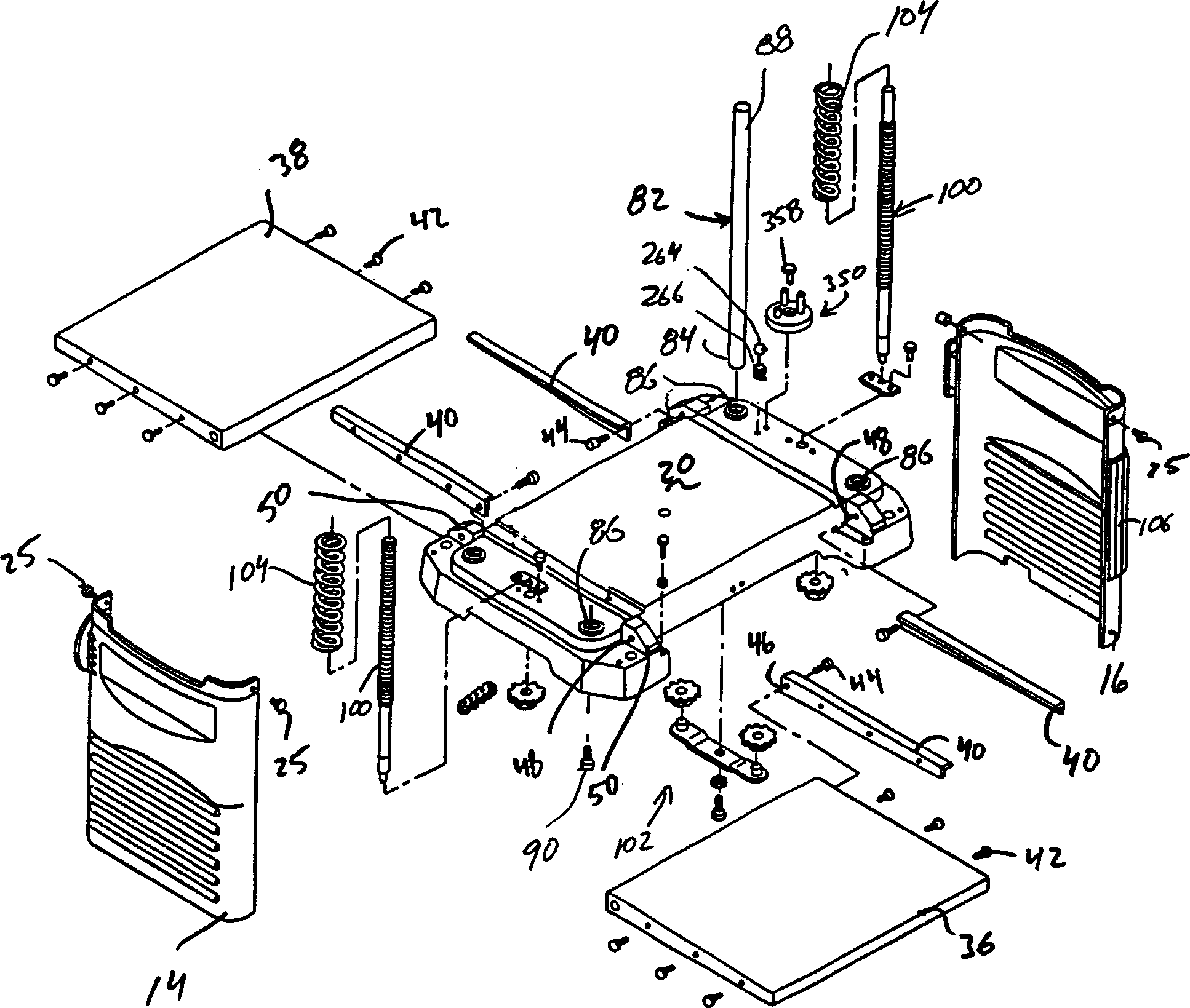

Multi-piece machine tool base

A power tool having a base assembly with a first portion, which defines an upper surface, and a second portion that defines a lower surface. The first and second portions may be castings and are coupled to one another without machining the upper surface of the first portion or the lower surface of the second portion. After assembly of the base portion, the upper surface of the second portion is machined to define a flat reference surface. Construction of the power tool in this manner provides a robust base assembly that is relatively inexpensive to manufacture. A related method is also provided.

Owner:WIXEY BARRY +3

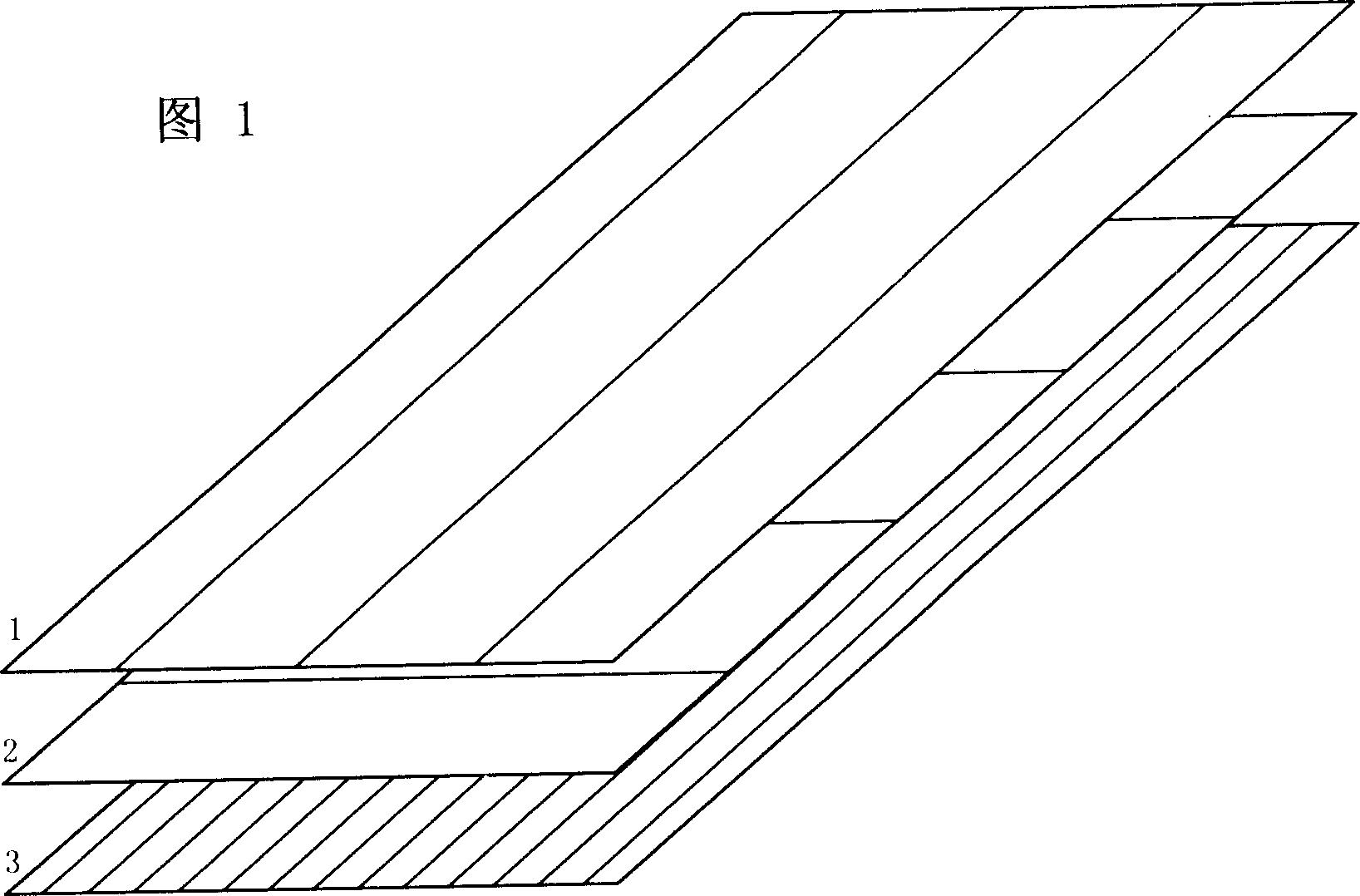

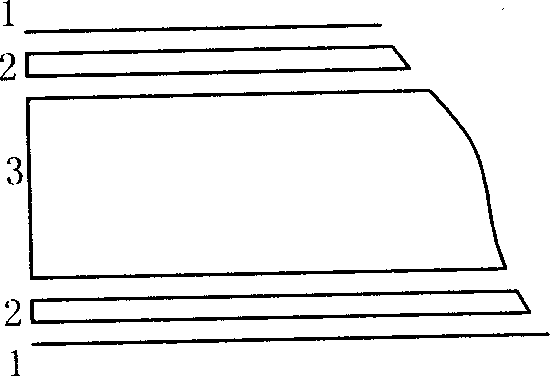

Thin shell structure reinforced type artificial board

InactiveCN1657243AEfficient use ofIncrease profitThicknessing machinesCane mechanical workingThin shellsSurface layer

A thin-shell structure reinforced artificial board is composed of two composite surface layers and a sandwich layer. Its preparing process includes such steps as applying isocyanate adhesive to bamboo curtain, immersing a single wood board in phenolic resin, combining them together, hot pressing to obtain said composite surface layer, preparing sandwich layer from the quickly growing wood (poplar wood), applying adhesive, combining it with two surface layers, and hot pressing.

Owner:NANJING FORESTRY UNIV

Planer & thicknesser

A planer and thicknesser comprising a frame having a passageway that substantially extends through the frame. The planer and thicknesser further comprises an upper table having front and rear sections mounted on the frame, wherein a slot is located between the front and rear sections of the upper table, and a lower table moveably mounted within the passageway. The planer and thicknesser also comprises a cutting drum rotatably mounted within the frame such that a portion of the cutting drum projects upwardly through the slot and a portion of the cutting drum projects downwardly into the passage way. The planer and thicknesser also comprises a cover mounted above the upper table capable of being moved from a first position where it covers a portion of the cutting drum to a second position where it does not cover a portion of the cutting drum.

Owner:BLACK & DECKER INC

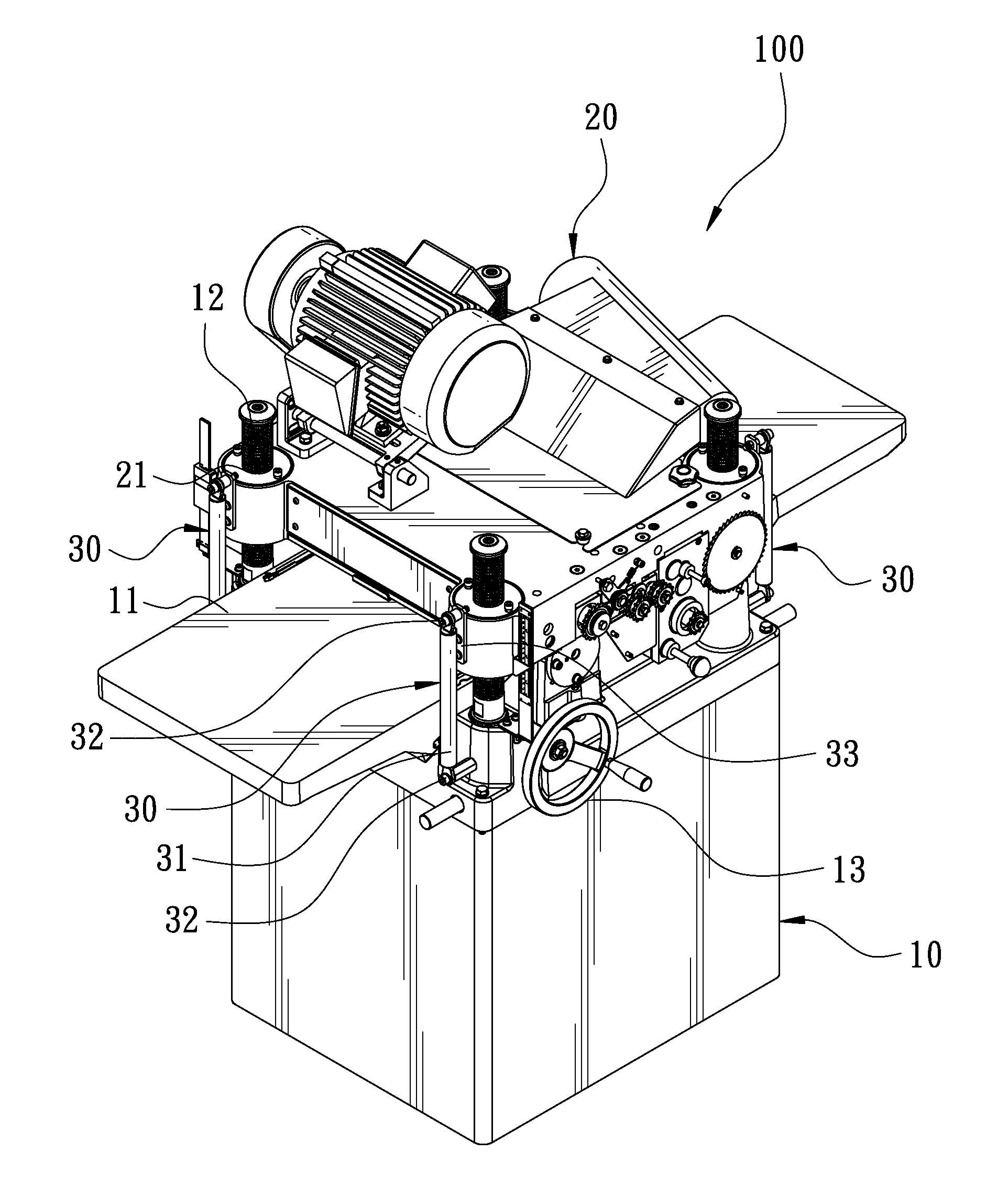

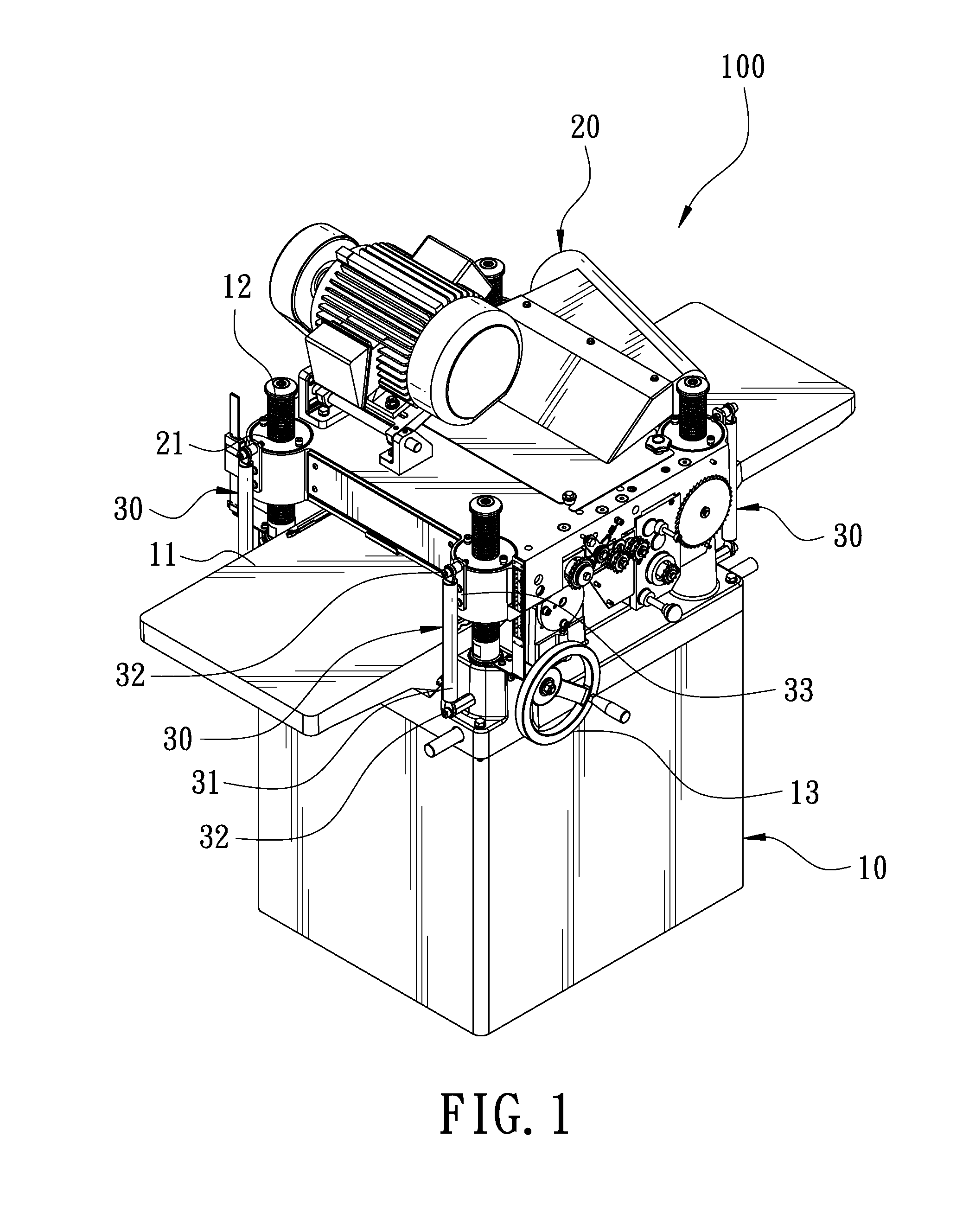

Two-sided wood working planner

InactiveUS20120175019A1Efficient pressingWood feeding arangementsThicknessing machinesPoint contactWoodworking

A two-sided wood working planner includes a base which is coupled with an adjustment seat. The adjustment seat includes a front press rod, at least one rear press rod and an upper plane blade which are pivotally connected in the adjustment seat. The adjustment seat further includes two movable units at two opposing sides thereof. The front press rod has a rod body. The rod body has an outer wall provided with a plurality of protruding members. Each of the protruding members has a head extended out of the outer wall of the rod body. When the front press rod is operated to send the material, the protruding members will hold against the workpiece to form point contact with the workpiece. In this way, the workpiece can be pressed effectively and the workpiece won't be deformed, so that the two-sided wood working planner can exactly plane the workpiece.

Owner:CHUANG BOR YANN

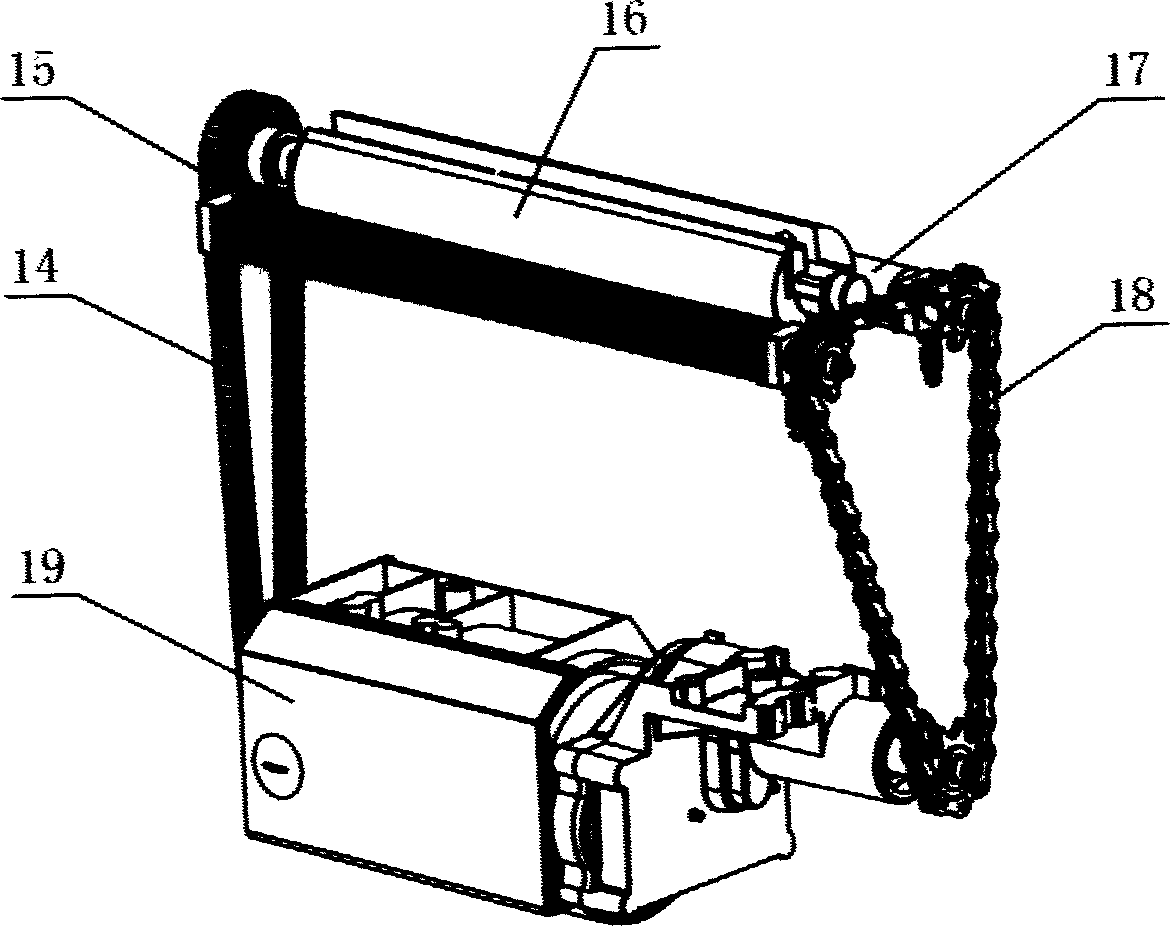

Combined wood planing machine

InactiveCN1864952AReasonable structureSimple structureThicknessing machinesSmoothing machinesEngineeringWoodworking

The invention relates to a combined woodworking planer, which is characterized in that: the upper parts of left and right side plates are connected to the plane platform that formed by fixed platform and movable platform; the blade axle is arranged between the fixed and movable platforms; two sides of blade axle are arranged with front and back rolling axles which are geared with one output axle of motor at the lower part of left and right side plates; another output axle of motor is geared with the blade axle; the thickness platform is arranged under the plane platform; the thickness platform via one group of lead screw is matched with the base at the lower part of it; the lower ends of said lead screws are geared matched via transmission chains. The inventive combined woodworking planer has simple structure, with plane and thickness functions, to reduce the cost and save resource.

Owner:叶伟豪

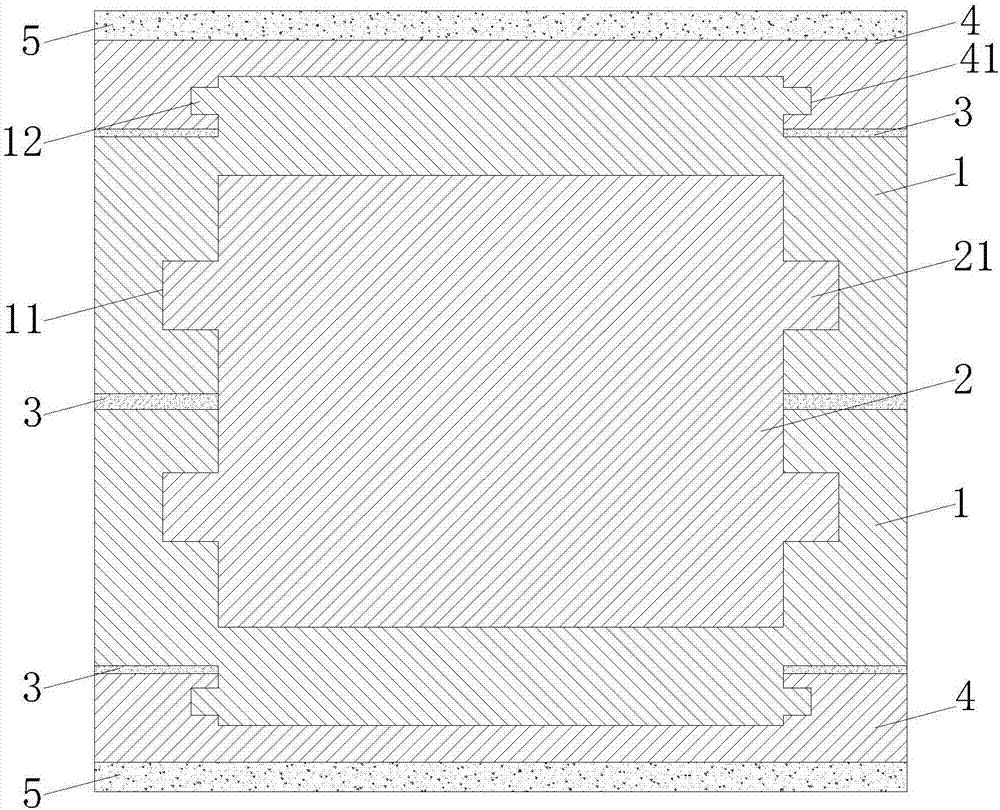

Novel paint-free plate and manufacturing technology thereof

InactiveCN107053354AWith fire performanceWaterproofPlywood pressesThicknessing machinesManufacturing technologyAdhesive

The invention discloses a novel paint-free plate and a manufacturing technology thereof. The novel paint-free plate comprises core plates, a connecting plate and panels, wherein the connecting plate is arranged in a cavity between the upper and lower layers of core plates, the contact surfaces of the core plates are hermetically glued by adding an adhesive layer, the contact surfaces of the core plates and the panels are hermetically glued by adding adhesive layers, and the core plates, the connecting plate and the panels, which are treated, are put and soaked in a solution containing positive ions and negative ions. According to the novel paint-free plate and the manufacturing technology thereof, connecting plate convex blocks of the connecting plate are inserted into grooves of the core plates, and core plate convex blocks of the core plates are inserted into panel grooves of the panels, so that the stable connection of the core plates, the connecting plate and the panels is realized, and the service life is prolonged; hermetic gluing is realized as long as the adhesive layers are arranged among the mutual contact surfaces, the usage of an adhesive is small, and the problem that the existing paint-free plate produces a large quantity of harmful gas and hurts the human body is solved; and at the same time, the plate is firstly soaked in lime water and then soaked in a sodium silicate solution, so that the novel paint-free board is fireproof and waterproof.

Owner:安徽忠盛新型装饰材料有限公司

Wood planing device

InactiveCN108748410AAdsorption immobilizationEasy to lift and supportWood feeding arangementsThicknessing machinesEngineeringMechanical engineering

Owner:董道明

Larch vertical wood integrated floor and manufacturing method thereof

InactiveCN101666154AIncrease profitRealize comprehensive utilizationThicknessing machinesWood treatment detailsLarchAdhesive

The invention discloses a larch vertical wood integrated floor, which comprises a plurality of transected boards and a layer of peeled veneer; lateral surfaces of the transected boards are coated witha waterproof plate alignment adhesive, and the transected boards are mutually spliced into a floor board with set length and width; and the back face of the floor board is provided with the peeled veneer which is connected with the floor board through an adhesive. A method for manufacturing the larch vertical wood integrated floor comprises the following processes of drying of wood, rough machining of the floor board, and finish machining of a floor block. The larch vertical wood integrated floor has scientific and reasonable design, rich originality, simple structure, low manufacturing costand beautiful appearance, is elegant, graceful, durable, compact in structure, stable and reliable when used for decorating the interior, and has strong practicability, affordability, no pollution orvolatilization of harmful gas. After related data is consulted, the larch vertical wood integrated floor is not adopted domestically at present. The larch vertical wood integrated floor is suitable tobe used in places with noise and required to be quiet such as airports, stations, seaports, department stores, libraries, museums, schools, hotels and households.

Owner:金钟锡

Wood processing thicknesser

InactiveCN106272722AEasy to cleanSimple structureThicknessing machinesBark-zones/chip/dust/waste removalPulp and paper industryClassification treatment

The invention discloses a wood processing thicknesser, which comprises a base table, a chip discharging device, a working table arranged on the base table, and a pressing table positioned above the working table, wherein the working table is provided with a conveying belt device, an attachment material scraping plate and a cutter shaft, the conveying belt device is a double-section conveying belt conveying structure and is arranged on the middle portion of the working table, chip discharging grooves, a wind sucking pipe and an exhaust fan are arranged inside the chip discharging device, the two sets of the chip discharging grooves are respectively arranged on both side of the cutter shaft, the lower ends of the two sets of the chip discharging grooves are communicated to the wind sucking pipe, the wind sucking pipe is connected to the exhaust fan, the exhaust fan and a motor belt form a transmission connection through a belt, and the left side of the exhaust fan is connected to a discharging channel. According to the present invention, the structure is simple, the use is convenient, the wood chips produced during the working process of the thicknesser can be effectively cleaned, the wood chips can be subjected to the classification treatment according to the actual needs after the wood chips are centralized, and a lot of the wood chips can be subjected to secondary recycling.

Owner:苏州欧复能新材料科技有限公司

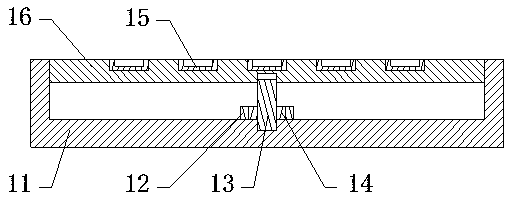

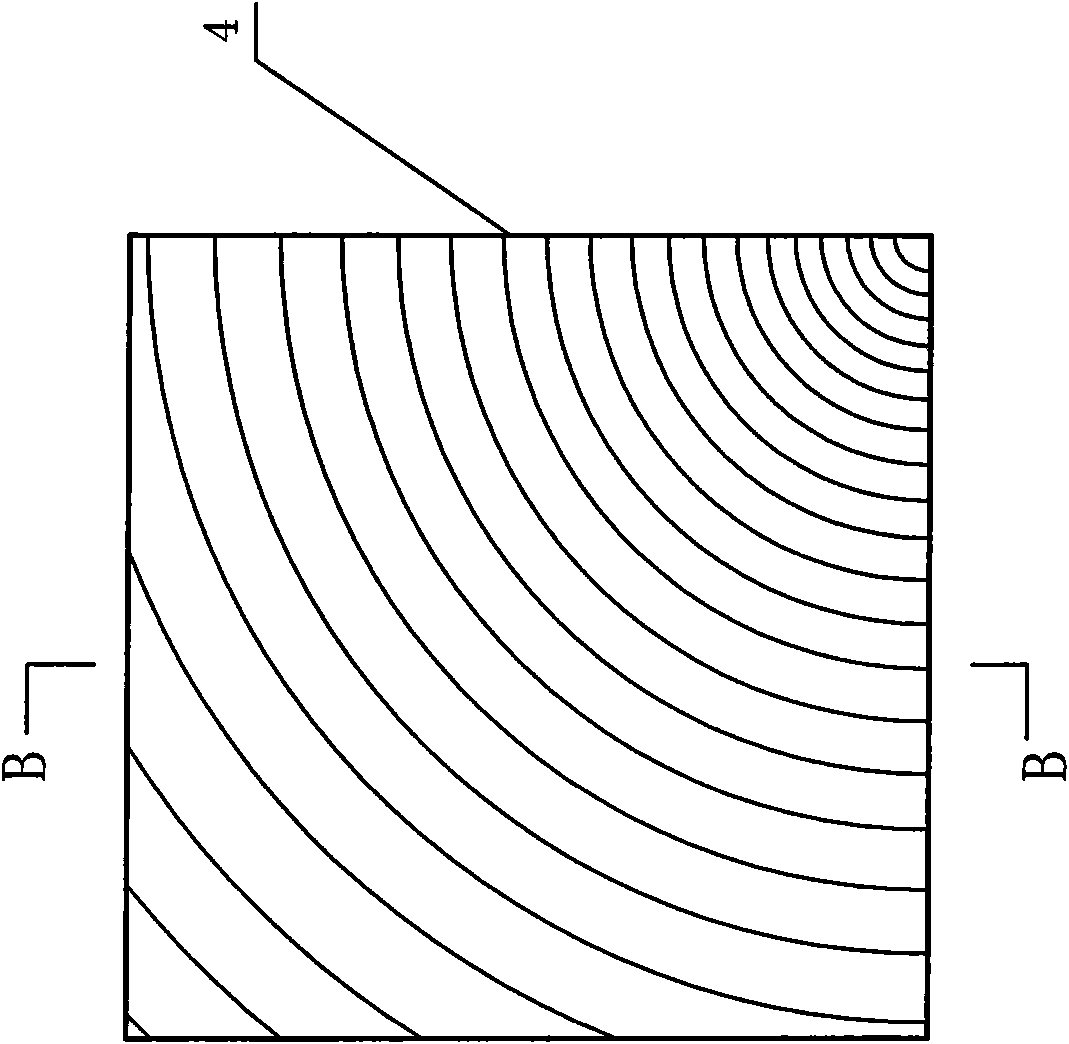

Double-side planer for machining bamboo flattened plate

PendingCN106926323APrevent disengagementImprove surface qualityThicknessing machinesStructural engineeringMechanical engineering

The invention discloses a double-side planer for machining a bamboo flattened plate. The double-side planer comprises a frame, a conveying mechanism and a planing mechanism; the planing mechanism comprises a worktable mounted on the frame, a planing tool, and a pressing piece driven by multiple elastic presses; the pressing piece is formed by transversely arranging multiple pressing units independent from each other; each pressing unit is independently acted on the bamboo flattened plate; the pressing piece comprises a feed end pressing piece and a discharge end pressing piece; in a feeding direction of the bamboo flattened plate, the pressing unit of the feed end pressing piece comprises a guide front end and a pressing back end; the guide front end is higher than the pressing back end; a bamboo flattened plate guide inclined port is formed between the guide front end and the worktable; and a pressing force applying point of the pressing back end is positioned near a planing tool cutting point. The force applying point of the pressing piece is nearer the planing tool cutting point, so that the feeding is smoother, the bamboo flattening plate is prevented from deviating from the planing tool cutting point due to warping, the planing quantity consistency is improved, and the surface quality of a flat plate is improved.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

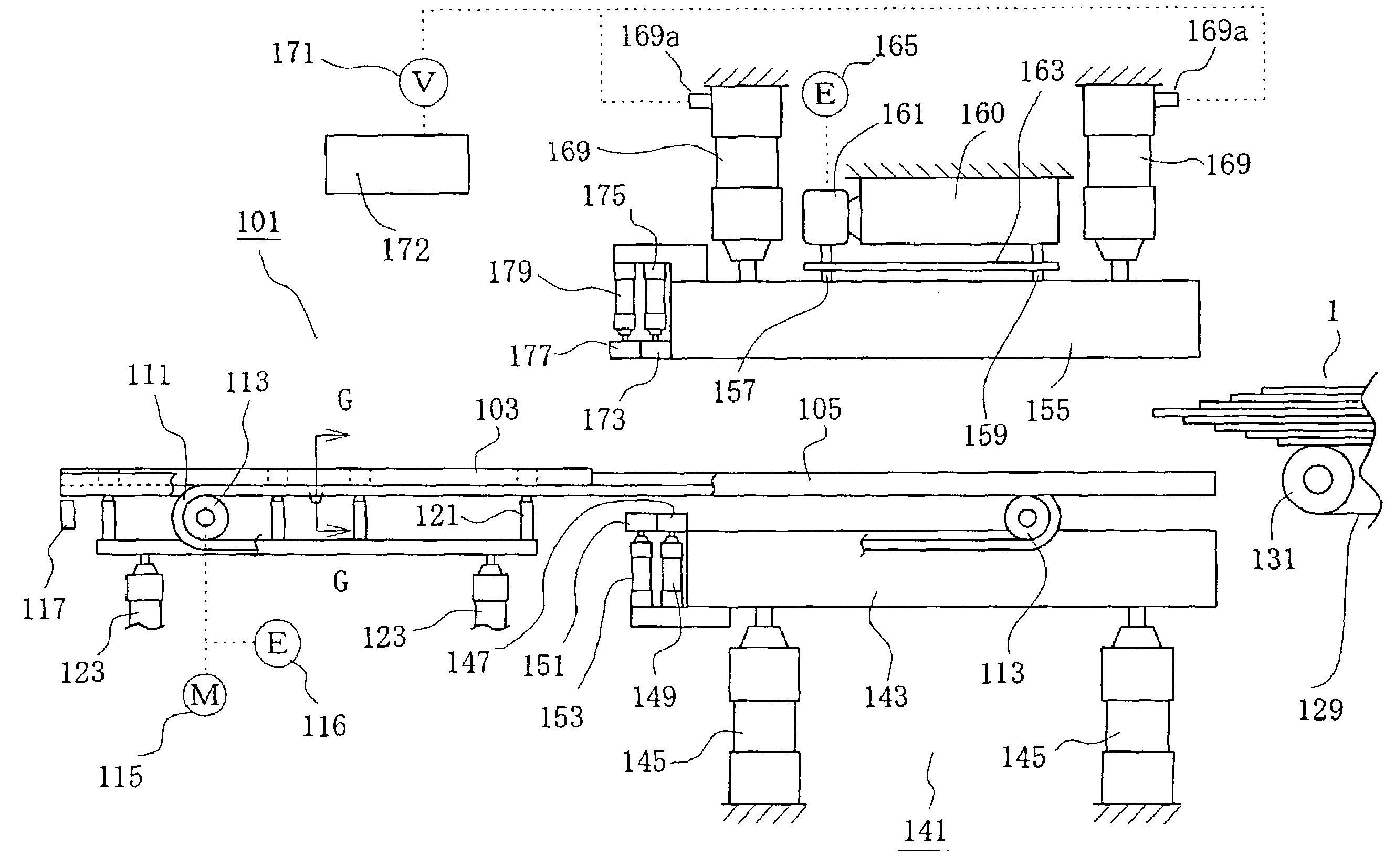

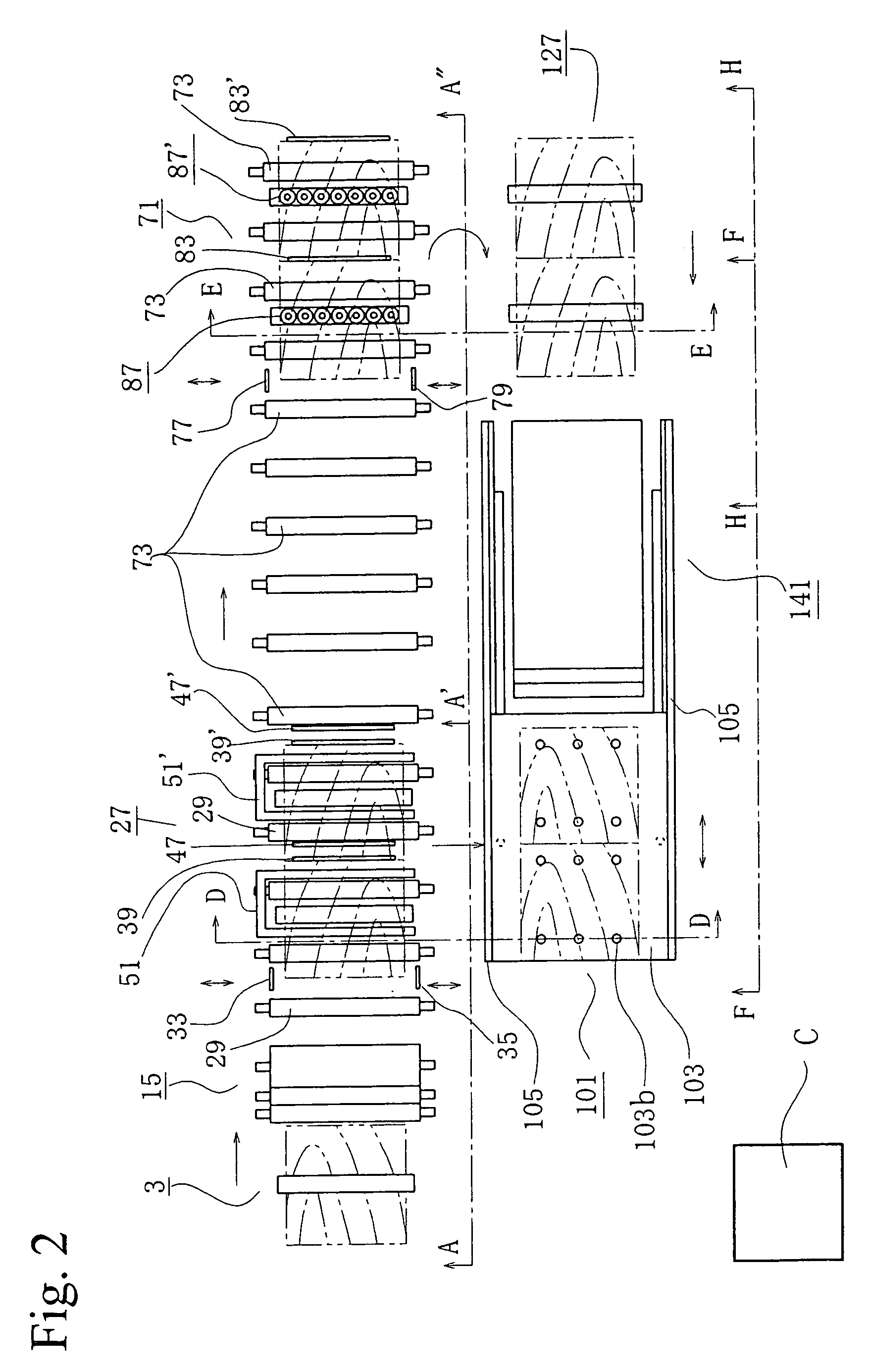

Method and apparatus of pressing in manufacturing glued laminated wood

A method and an apparatus of wood pressing usable in manufacturing glued laminated wood such as laminated veneer lumber (LVL) using a number of wood veneer sheets are disclosed. A hot press used for wood pressing includes a pair of heating plates which are disposed one above the other and have pressing surfaces facing each other. The paired heating plates are both movable toward and away from each other. In operation, firstly one of the heating plates is moved toward the other heating plate to a position where the pressing surface of the one heating plate is spaced from a surface to which a veneer sheet is to be glued by a distance corresponding to the thickness of the veneer sheet. Then, the other heating plate is moved toward the one heating plate until a desired pressure is produced pressing.

Owner:MEINAN MASCH WORKS INC

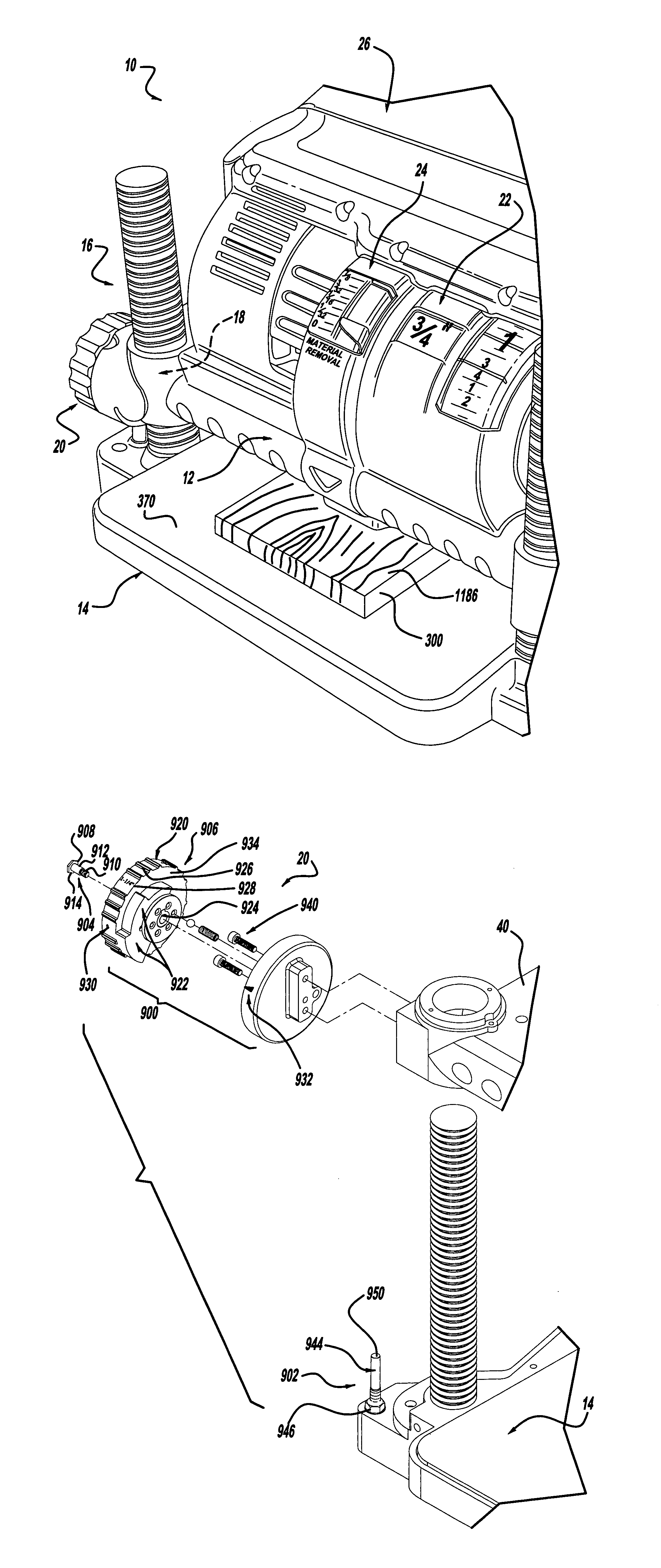

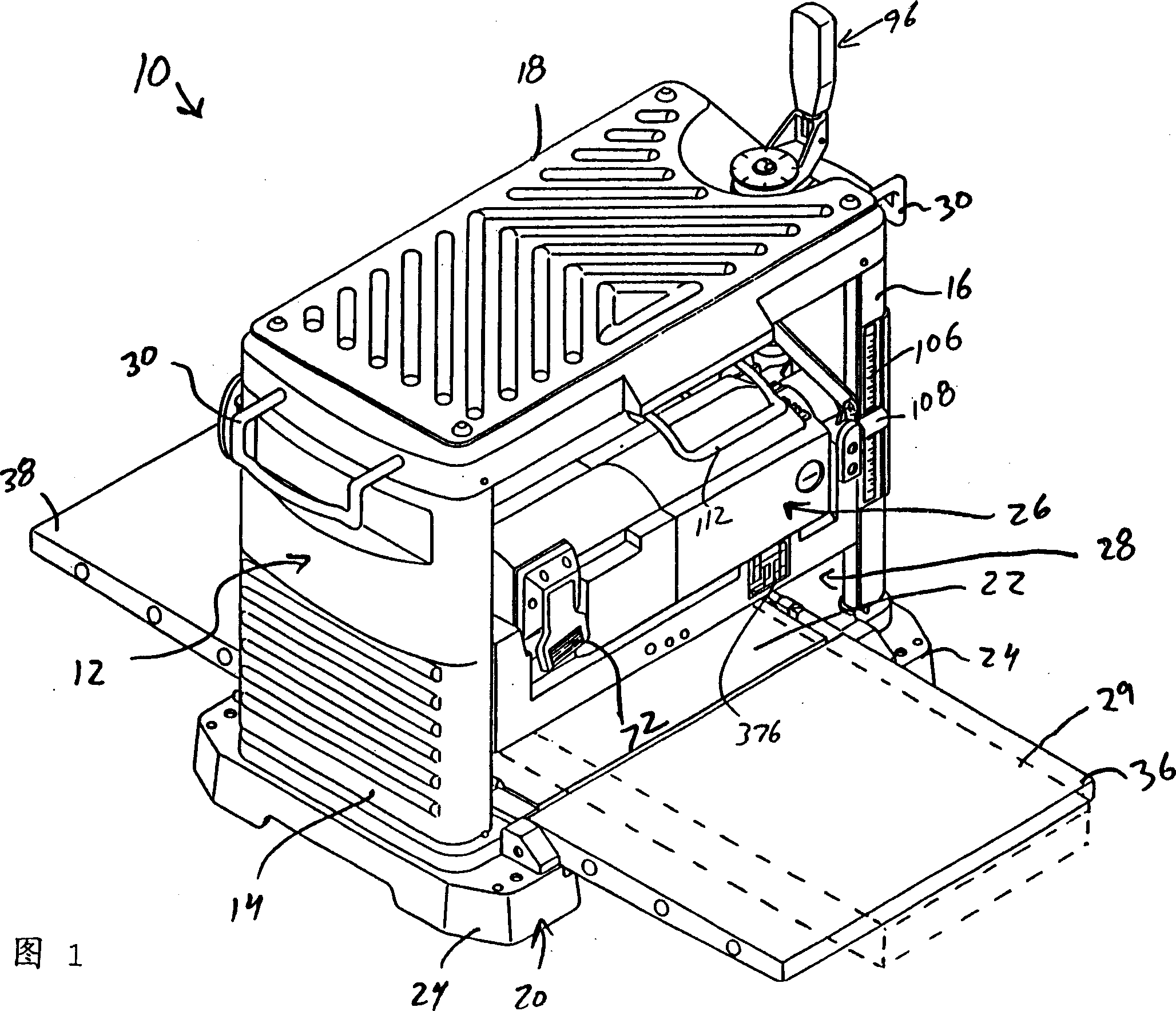

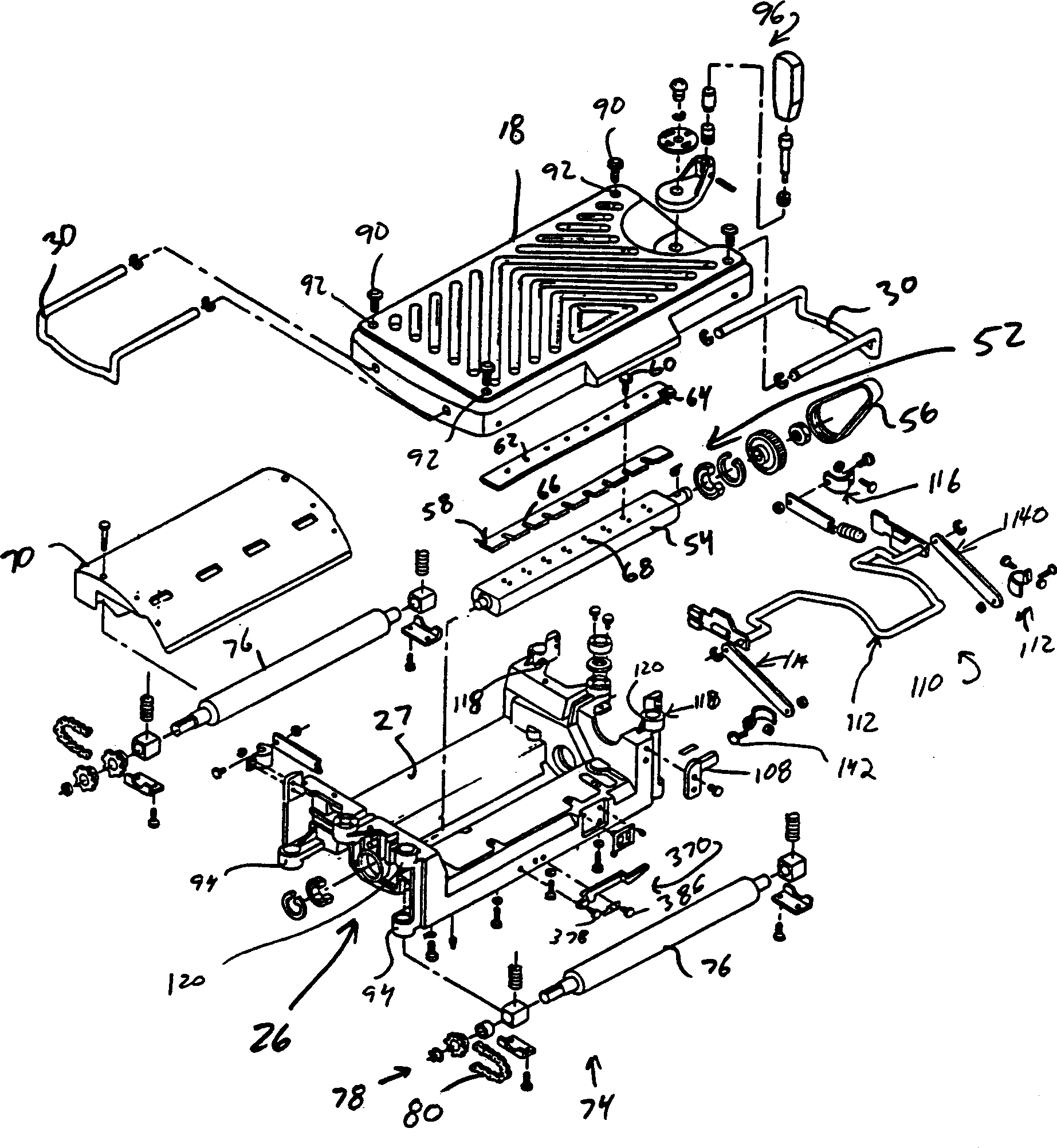

Portable power planer

A portable power planer for planing the top surface of a workpiece. The portable power planer includes a base assembly, a carriage assembly disposed above the base assembly, the carriage assembly includes a cutterhead assembly, the carriage assembly being vertically movable to change distance between the base assembly and the carriage assembly, a hand crank attached to the carriage assembly for changing the distance between the base assembly and the carriage assembly, a material removal gauge disposed on the carriage assembly, a switch disposed on the carriage assembly, and a height scale disposed on the base assembly, wherein the material removal gauge, the switch and the height scale are on the front side of the power planer, and the hand crank is substantially on the front half of the power planer.

Owner:BLACK & DECKER INC

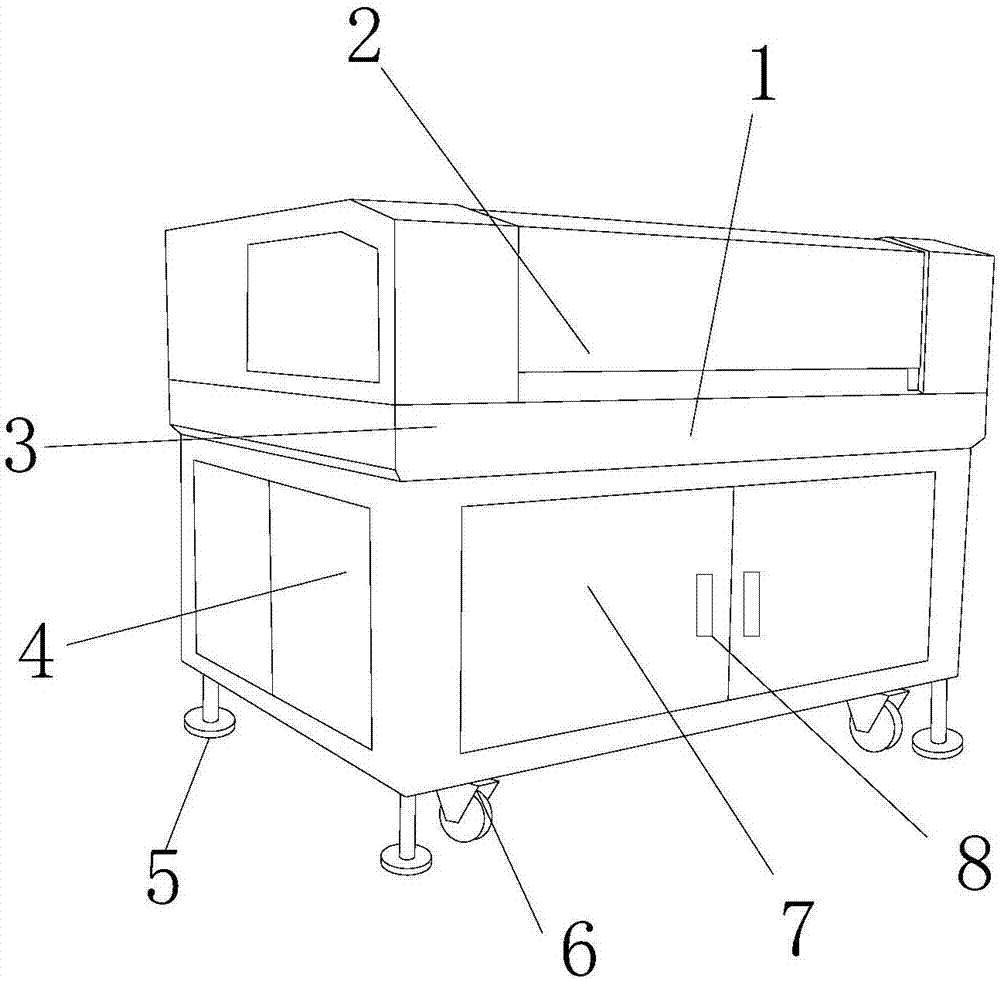

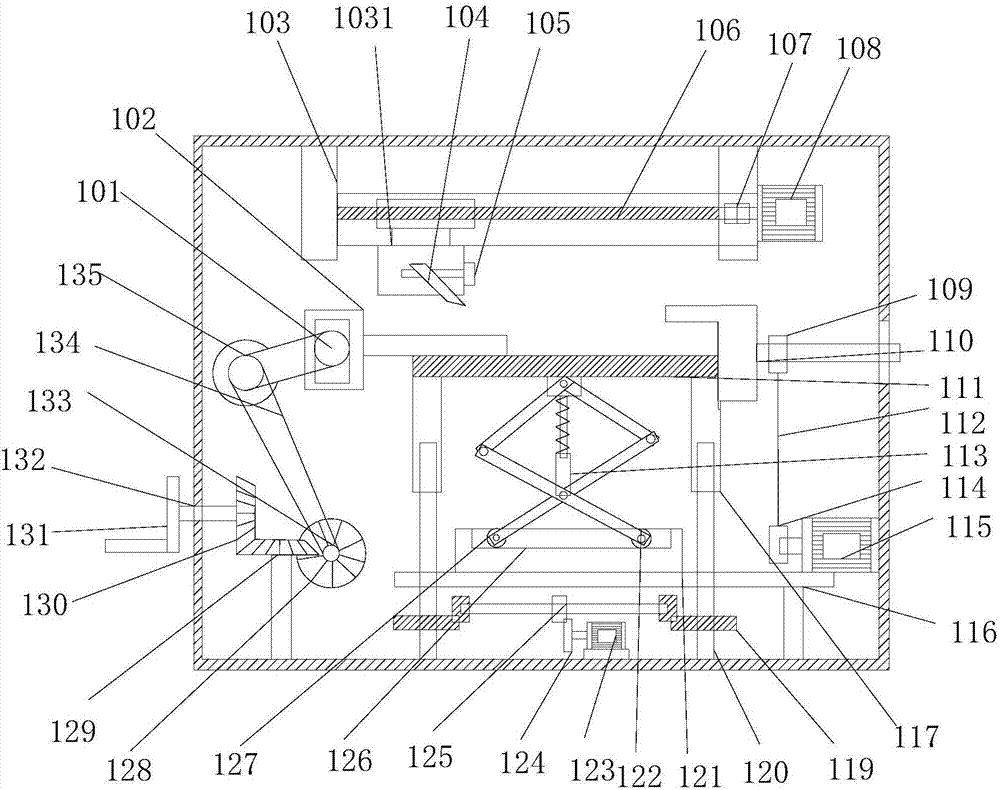

Rough planing device for machining bamboo toys

ActiveCN107972128AMove quicklyEasy to disassemble and replaceThicknessing machinesEngineeringMachining

The invention discloses a rough planing device for machining bamboo toys. The rough planing device structurally comprises a rough planing device body, a top cover, a machine body, a side door, supporting feet, moving wheels, movable doors and door handles. The rough planing device body is mounted in the machine body; the side face of the top cover and the top of the machine body are in clearance fit; the side face of the side door is fixedly connected with the interior of the side face of the machine body; the moving wheels are sequentially connected into a rectangular structure to be arrangedat the bottom of the machine body; and the tops of the supporting feet are vertically connected with the bottom of the machine body. According to the rough planing device body of the rough planing device for machining the bamboo toys, bamboos can be quickly and powerfully polished; a cutter can quickly move and meanwhile is conveniently disassembled to be replaced, so that the working efficiencyis improved; a bottom supporting frame is conveniently and quickly adjusted, meanwhile, impact force can be buffered, the impact force applied into the device is reduced, and the service life is prolonged; and during machining, the bamboos can be automatically fixed and adjusted in position, and thus use safety is improved.

Owner:山东省大善堂文化传媒有限公司

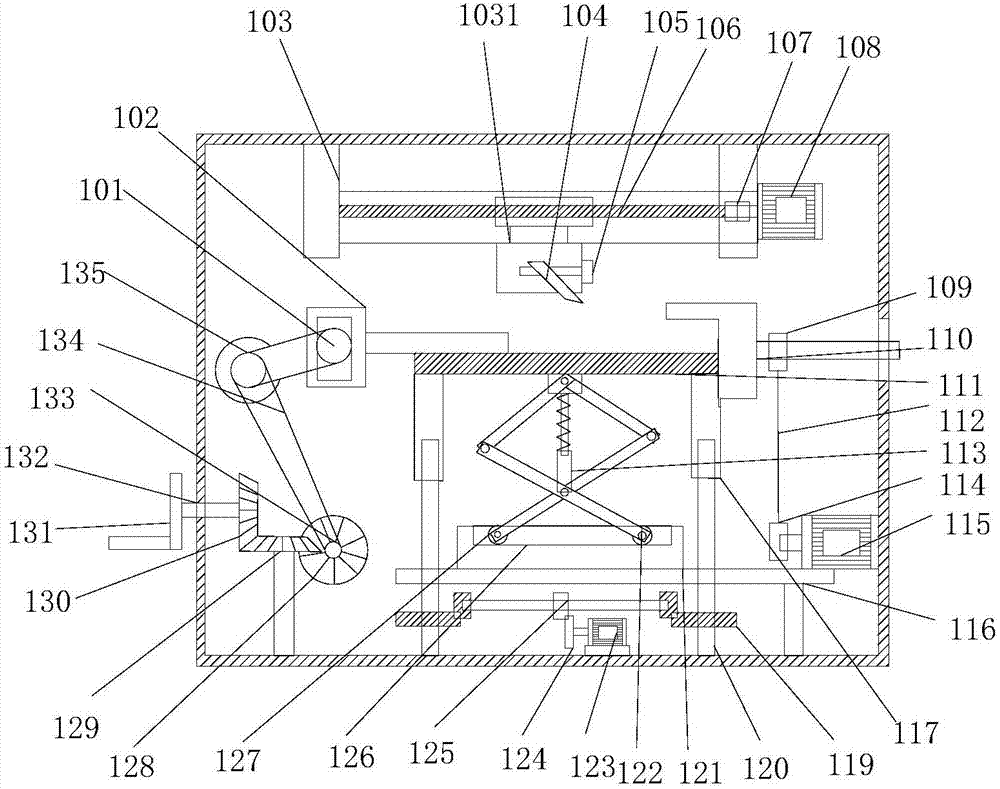

Automatic feeding device of thicknesser

InactiveCN104070564ALabor savingImprove ergonomicsWood feeding arangementsThicknessing machinesSheet filmEngineering

The invention discloses an automatic feeding device of a thicknesser. Films are fixed on the surfaces of upper and lower feeding belts at a feeding hole to form a conveying wheel structure with films; the feeding surface of each film is in a concave-convex shape. The automatic feeding device has the advantages that processed timer is arranged at the feeding hole and then is automatically fed for thicknessing through the film wheels, so that the labor force is saved, and the work efficiency is improved.

Owner:LIUZHOU LIUCHENG HONGSEN FURNITURE MFG

Thickness planer for forming solid wood lines

InactiveCN109093771AHeight adjustableImprove use comfort performanceThicknessing machinesSolid woodArchitectural engineering

The invention discloses a thickness planer for forming solid wood lines. The thickness planer comprises a worktable, a clamping unit and a working unit, wherein the lower surface of the worktable is fixedly connected with a bottom plate through two lifting devices; each lifting device comprises a threaded rod fixedly connected with the lower surface of the worktable, the rod wall of the threaded rod is movably sleeved with a sleeve, the lower end of the sleeve is fixedly connected with the upper surface of the bottom plate, the inner wall of the sleeve is rotationally connected with a threadedbarrel which is in threaded connection with the threaded rod, the lower end of the threaded barrel is fixedly connected with a driven bevel gear which is movably arranged on the rod wall of the threaded rod in a sleeving manner, a through hole is formed in the outer wall of the sleeve, and a rotating rod is rotationally connected in the through hole through a bearing. Height of the thickness planer can be adjusted according to the height of a user, use comfort is improved, automatic rotation of the rotating rod can be avoided, and stability of the lifting devices is improved.

Owner:柳州市品尚木业有限公司

Two-sided planer

Owner:CHUANG BOR YANN

Two-sided wood working planner

InactiveUS20120132319A1Avoid adjustmentEliminate backlashWood feeding arangementsThicknessing machinesEngineeringScrew thread

Owner:CHUANG BOR YANN

Efficient multi-sawtooth thicknessing machine for trees

InactiveCN111391026AEasy for automatic loadingReduce labor intensityThicknessing machinesElectric machineryEngineering

The invention discloses an efficient multi-sawtooth thicknessing machine for trees. The efficient multi-sawtooth thicknessing machine comprises a machining mechanism and a feeding mechanism, the machining mechanism is composed of a workbench, a control panel, a mounting groove, a first servo motor, a driving chain wheel, a driven chain wheel, cutting rollers, a supporting frame, a pressing air cylinder, a fixing frame, a driven pressing roller, a driving pressing roller, a first driven belt wheel, a second servo motor and a driving belt wheel, and a material conveying groove is formed in the top of the workbench. According to the efficient multi-sawtooth thicknessing machine for the trees, the structure is simple and flexible; through the arrangement of a feeding motor and a conveying motor, during work, automatically feeding on materials can be conveniently carried out through a clamping plate and a lifting electric telescopic rod, manual feeding is avoided, the labor intensity of workers is reduced, the feeding speed is increased; and through the arrangement of the pressing rollers and the plurality of cutting rollers, under the condition that the plurality of cutting rollers work at the same time, the cutting speed is greatly increased, the machining time is shortened, and the machining efficiency is greatly improved.

Owner:WENZHOU CHUYING TECH CO LTD

Planning machine tool used in wood processing

InactiveCN101544002AImprove transmission efficiencyImprove stabilityWood feeding arangementsThicknessing machinesLow noiseWood machining

The invention relates to a planning machine tool used in wood processing, which belongs to the technical field of wood planing and machining machinery and comprises a planing tool shaft below a footstock, a feeding roller, a discharge roller and a work table, wherein the work table is provided with a lifting driving mechanism consisting of four screw mandrels and nuts, the screw mandrels are distributed at two sides of the work table with two on each side, and the lower ends of the screw mandrels are fixed on a base; the feeding roller is of a helical steel roller; the discharge is of rubber and a micromachine and a micro high-efficient gear-box are adopted. The invention has the advantages of simple and reasonable structure, small volume and light weight. The planning machine tool used for planing wood with width of 250 mm and height of 10 mm has a weight of only over 30 kg. because four screw mandrels and the nuts are arranged at two sides above the base, the work table keeps horizontally without inclining when working and is parallel to the planing tool shaft, thereby ensuring high assembly precision and good quality. The planning machine tool has low requirement or processing position precision, low manufacture cost, stable use performance, high transmission efficiency, low noise and long service; in addition, the work table has good stability and rigidity.

Owner:杨高怀

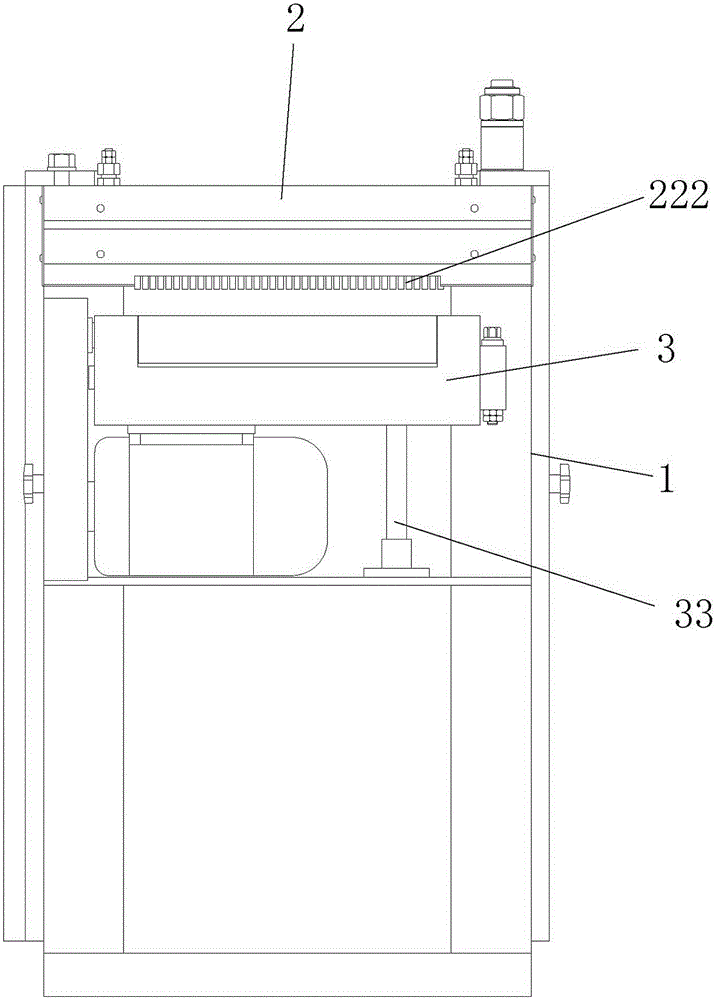

Double-surface thicknessing machine

InactiveCN105150288AReduce intensityEasy to operateWood feeding arangementsThicknessing machinesMachineUltimate tensile strength

The invention discloses a double-surface thicknessing machine, particularly relates to a double-sided thicknessing machine capable of thicknessing both the upper surface and the lower surface of woods and belongs to the technical field of wood-working machines. The double-surface thicknessing machine comprises two parts which are used for applying pressure in two corresponding directions to generate clamping effect during working, wherein a first thicknessing cutter is arranged on one part; a second thickenssing cutter is arranged on the other part; at least one of the two parts is provided with a workpiece pushing mechanism, so that the workpieces are relatively fixed all the time in the process of being thickenssed; at least one part is a split structure; the split structure is split to form an operation area for conveniently assembling and disassembling the thicknessing cutters relative to the other part. The double-surface thicknessing machine is simple and novel in structure, simple to operate and convenient to use; a feeding roller can be removed from the upper part of the lower thickenssing cutter by just rotating a rotation table to a certain angle; the enough space is provided for assembling and disassembling the lower thickenssing cutter; the double-surface thicknessing machine is convenient to assemble, disassemble and repair; the labor intensity of workers is reduced; the replacement speed and the cutter assembling accuracy are improved.

Owner:ANJI DEMAI BAMBOO & WOOD MACHINERY

Production technology and production equipment for wooden door with smooth paint surface

InactiveCN113442253AObvious beneficial effectThicknessing machinesWood treatment detailsFiberPulp and paper industry

The invention discloses a production technology and production equipment for a wooden door with a smooth paint surface. The production technology comprises the steps of plate drying, plate pressing, cutting, sanding, framing, wood wool removing, paint spraying, drying and packaging forming. Lignin fibers can be dissolved by using fiber digestion enzyme, wood wool is removed, after the wood wool is dissolved and removed by using the fiber digestion enzyme, on the basis of the characteristics of the fiber digestion enzyme, wood wool dissolving impurities on the upper surface of a wooden door protection layer can be directly cleaned away with clean water, and cleaning is thorough, convenient and simple; the protective layer is coated on the surface of the wooden door, so that the moisture content of the wooden door is guaranteed, moisture loss of the wooden door is prevented, erosion of outside harmful substances to the surface of the wooden door is better prevented, and the corrosion resistance is good; and due to the fact that the fiber digestion enzyme is used for removing the wood wool, the surface of the wooden door can be smooth, and painting is easier.

Owner:郑曦

Surface planing and thicknessing machine

InactiveCN111730690AAvoid pollutionAffect personal healthThicknessing machinesBark-zones/chip/dust/waste removalWood shavingsEngineering

The invention discloses surface planing and thicknessing machine. The surface planing and thicknessing machine comprises a thicknessing shell, wherein an upper shaft roller cavity with a downward opening is formed in the thicknessing shell, and a roller transmission cavity is formed in the front side of the upper shaft roller cavity; a planing machine base is arranged on the lower side of the thicknessing shell, and a lower planing tool placement cavity with an upward opening is formed in the planing machine base; the lower cavity wall of the lower planing tool placement cavity communicates with the upper cavity wall of a shaving storage cavity, the left cavity wall of the shaving storage cavity communicates with the upper shaft roller cavity through a wood shaving flying channel, and a tool mechanism is arranged in the lower planing tool placement cavity; and a thicknessing mechanism is arranged in the upper shaft roller cavity, and a planing mechanism is arranged in the lower planingtool placement cavity. The device is simple in structure and convenient to operate, and the device combines planing with thicknessing on the basis of a common wood planing machine, so that the working time is saved, and the working efficiency is improved; and meanwhile, shavings generated by planing are collected and treated, so that the situation that the personal health of a user is affected bythe fact that the surrounding environment is polluted is prevented.

Owner:温州市景润机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com