Planning machine tool used in wood processing

A machine tool and wood technology, applied in the field of wood planing processing machinery, to achieve the effects of long service life, low processing position accuracy requirements, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

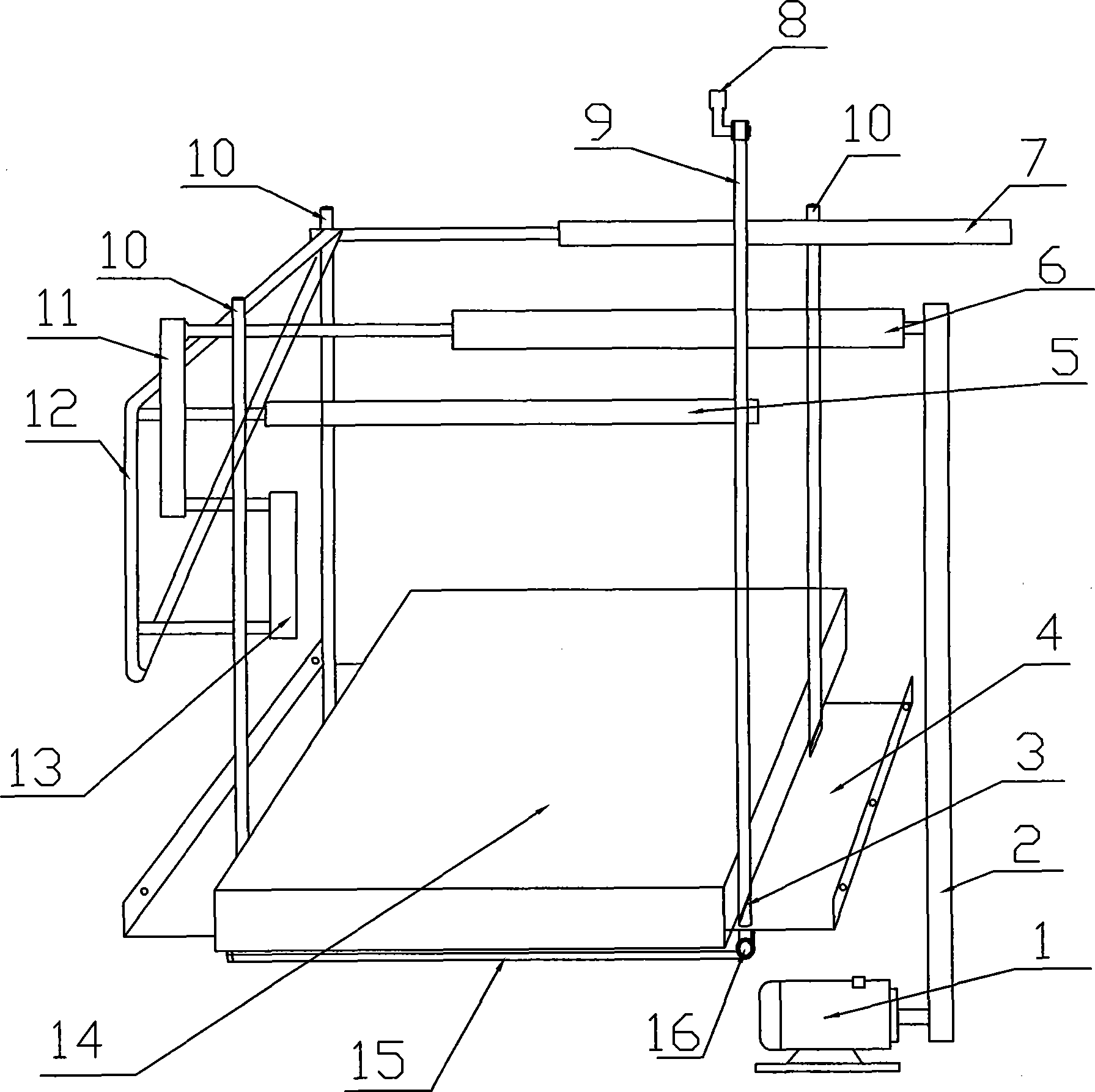

[0008] Such as figure 1 As shown, under the top seat of the machine body, a planer shaft 7, a feed roll 5, a discharge roll 7 and a worktable 14 are provided. The feed roll 5 adopts a steel helical steel roller (the tooth line of the helical steel roller is The roll center lines are not parallel). The workbench 14 is provided with a lifting drive mechanism composed of four screw rods 9, 10 and a nut 3. The screw rods are arranged on both sides of the workbench, two on each side. The screw rods are connected to both sides of the workbench by nuts, and the lower end of the screw rod is fixed at On the base 4, a connecting crank 8 is provided on the top of the screw rod 9. The feed roller 5 is a helical toothed steel roller. The discharge roller 7 is made of rubber as a rubber roller. The motor 1 adopts a micro motor, which is arranged at the bottom of the machine body, and the gearbox 13 adopts a micro high efficiency gearbox. The motor 1 and the planer shaft 6 (knife body) are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com