Larch vertical wood integrated floor and manufacturing method thereof

A technology for larch and flooring, which is applied in the manufacture of veneer, the joining of wooden veneers, and the processing of wood, can solve the problems of poor dimensional stability of wooden floors, low comprehensive utilization rate of wood, destruction of forest resources, etc. Long service life, low production cost, good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

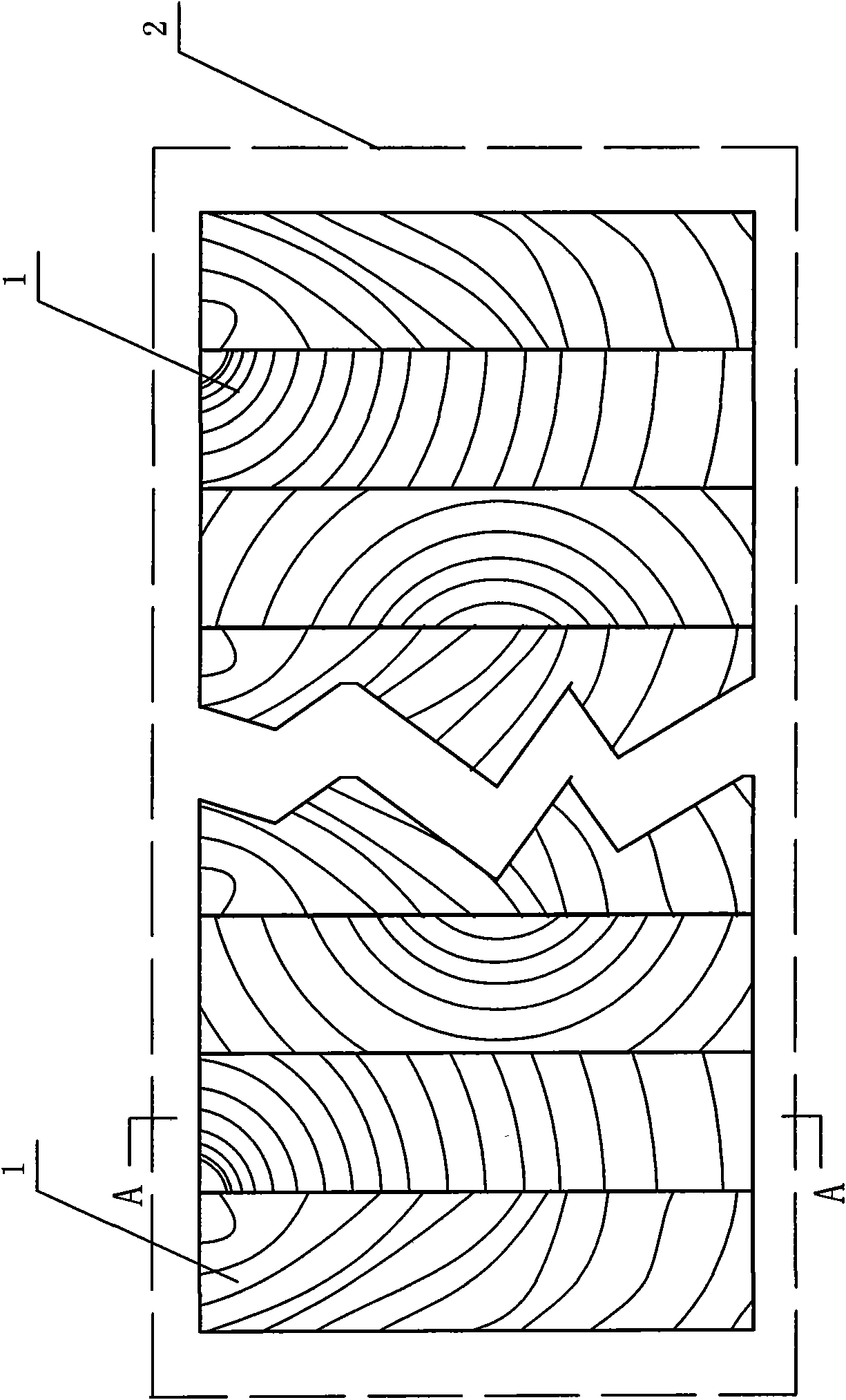

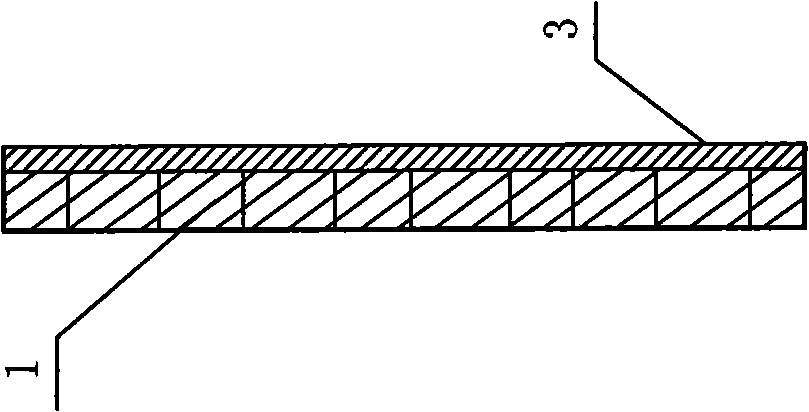

[0037] Larch vertical wood integrated flooring, including multiple cross-cut wood panels 1 and a layer of rotary-cut veneer 3; the sides of multiple cross-cut larch cross-cut wood panels 1 are coated with known national standard waterproofing The board glue is spliced with each other to form a floor strip 2 with a set length, width and thickness; a layer of rotary-cut veneer 3 is arranged on the back of the floor strip 2, and the rotary-cut veneer 3 is a veneer layer that is cut longitudinally from a log . The rotary cut veneer 3 is adhesively connected to the back of the floor strip 2 . The rotary-cut veneer 3 and the floor strip 2 are fixedly pasted together, which greatly enhances the combination strength of the floor strip 2 . During the decoration, multiple floor strips 2 are spliced and laid to form a larch vertical wood integrated floor.

Embodiment 2

[0039] The manufacturing method of the larch vertical log integrated floor, including the wood drying process, the rough processing process of the floor board and the finishing process of the floor board;

[0040] Described wood drying procedure:

[0041] First of all, a number of specifications boards are stacked and air-dried in a natural state, and then sent to the drying room for degreasing treatment at 120°C and low-temperature drying at 50°C. When the moisture content of the boards is 8%, the boards are Send it into a constant temperature room at 40°C, and keep the temperature controlled and balanced for 40 days.

[0042] The rough processing procedure of the floor strips:

[0043] 1) Cut the dried multi-standard board squares into multiple wooden strips according to the set length through the cross-cutting machine, place them on the planer, and make the two adjacent sides of the wooden strips perpendicular to each other. , and then place the wooden planks on the plane...

Embodiment 3

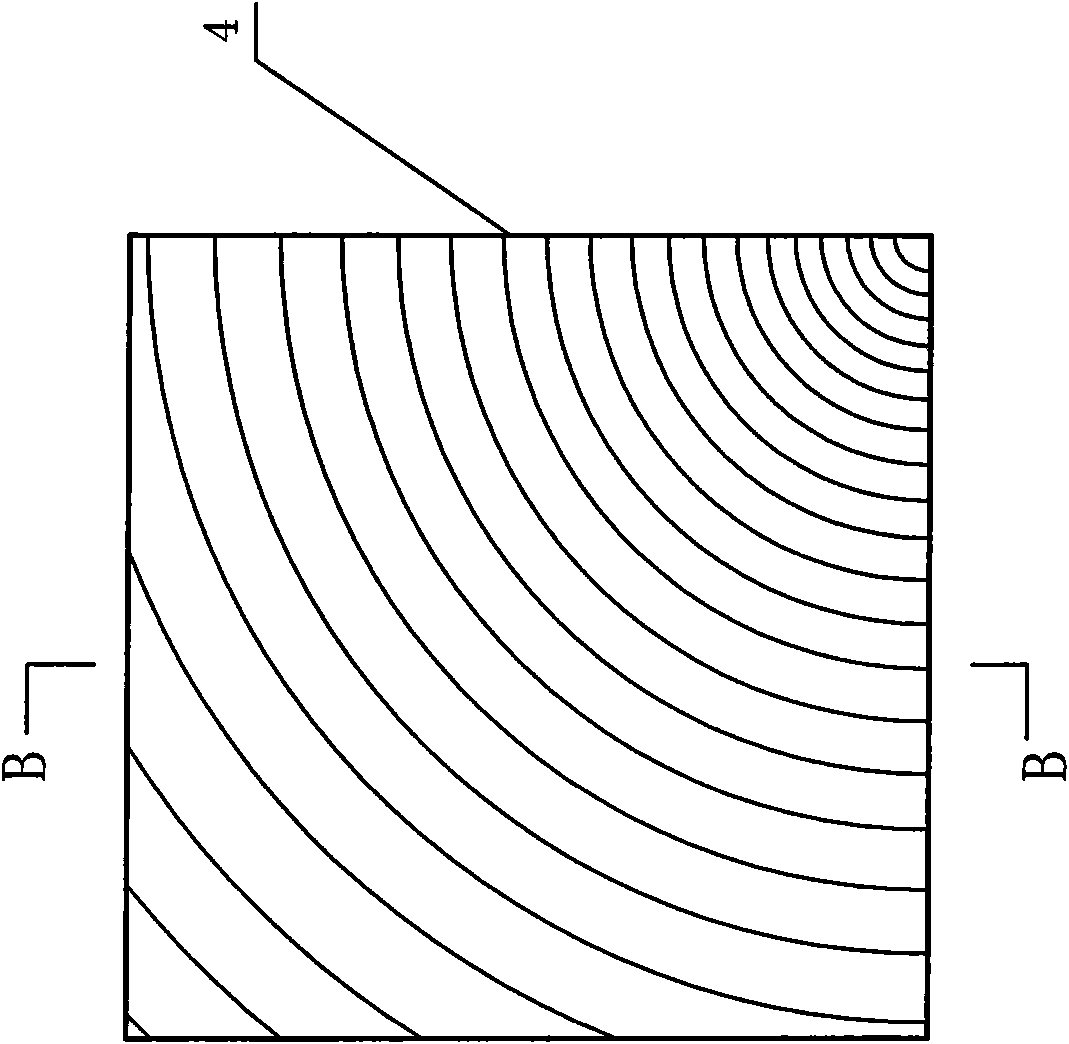

[0051] The third embodiment is basically the same as the first embodiment, except that the third embodiment is an integral cross-cut wooden board, which is processed into an integrated floor board 4 according to the set length, width and thickness. The 4-style floor boards are spliced and laid to form a larch vertical wood integrated floor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com