Automated green-removing and yellow-removing double-sided planing machine for bamboo flattened plate

A flat-panel and bamboo display technology, which is applied in the field of automatic double-sided planers, can solve the problems of imperfect planing of corners or recesses, low production efficiency, and a large number of operators, so as to improve the utilization rate of bamboo and ensure planing The effect of high quality and finished product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

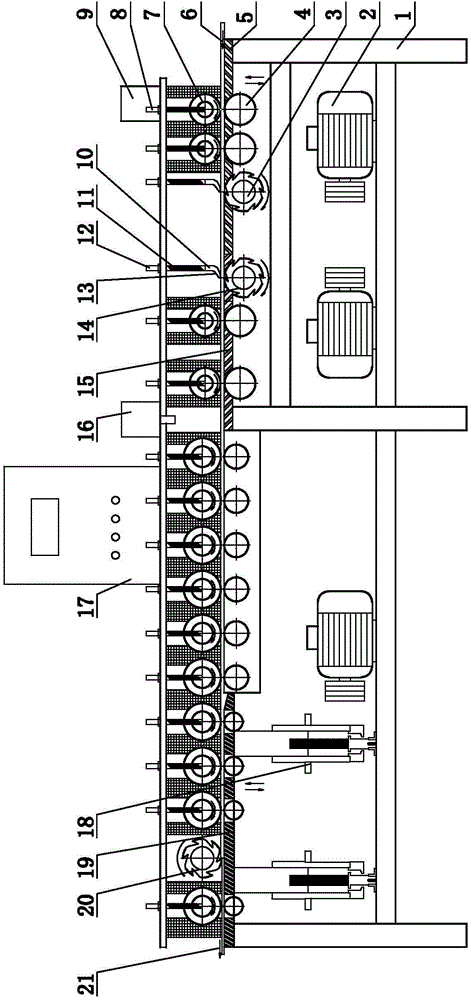

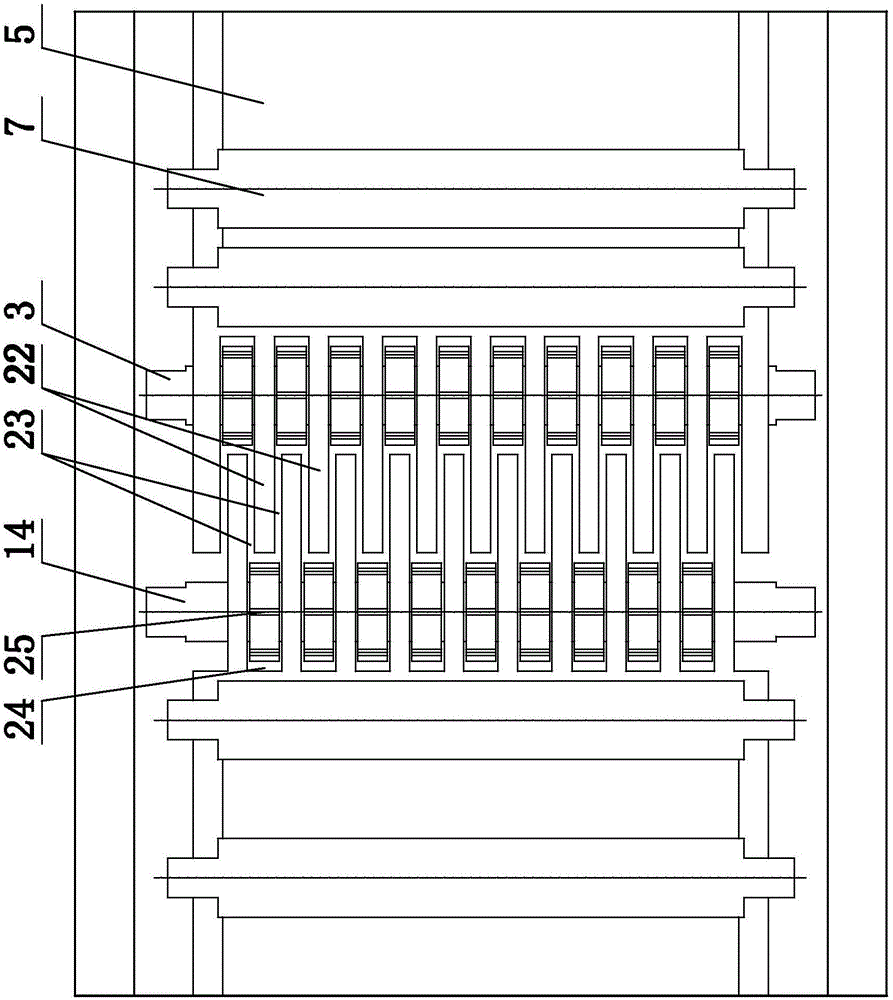

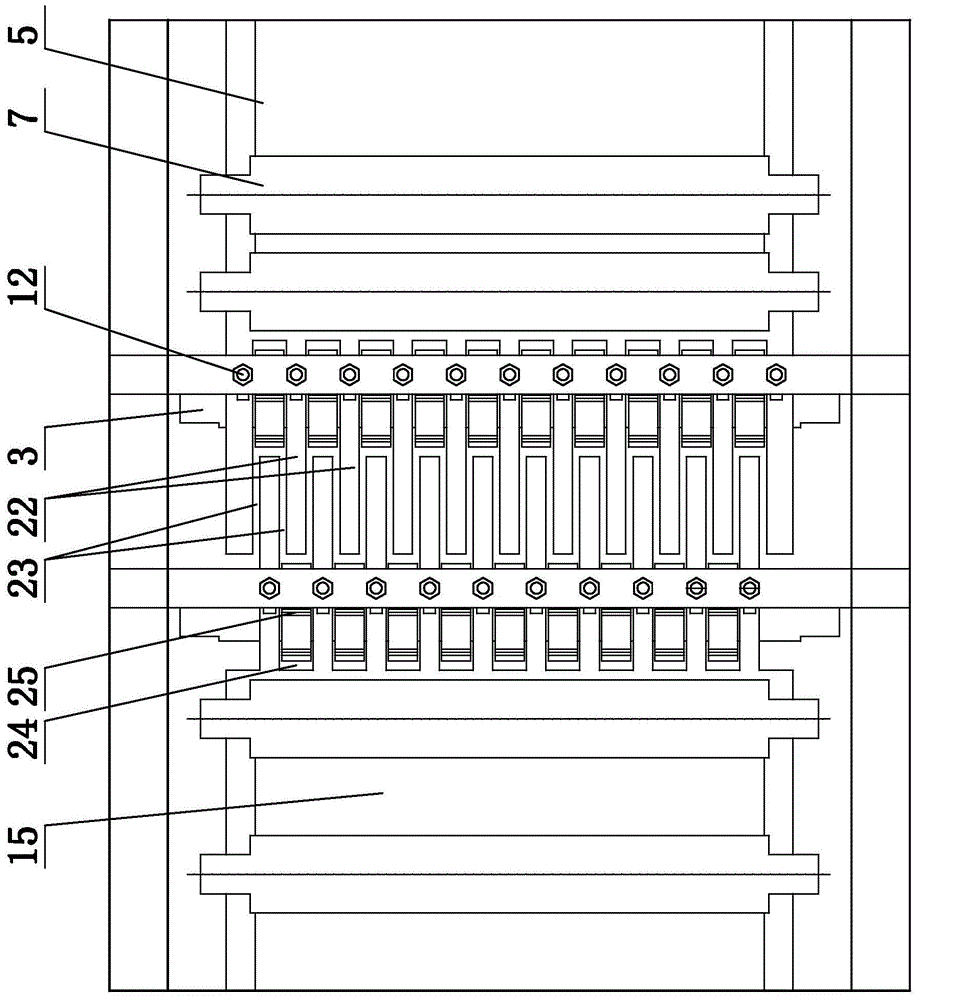

[0014] The present invention is explained below in conjunction with embodiment and with reference to accompanying drawing: see figure 1 , this automatic double-sided planer for removing blue and yellow on the bamboo flat plate includes a frame, a motor, a compactor, a feed roller, a knife roller and a workbench. The whole machine and its components are arranged horizontally and horizontally. The lower layer of the frame 1 has a knife roller driving motor 2, a precision screw type lifter 18 and its matching servo motor, and there are paired matching upper feeding rollers 7 and lower feeding rollers 4 above and below the three-stage workbench in the center. Each upper feed roller is connected with a compactor 8 and a shared upper feed roller drive servo motor 9, the three-section workbench is the front workbench 5 near the right end, namely the feed end 6, and the left end is the discharge end 21 is the rear workbench 19, there is a middle workbench 15 between the two workben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com