Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about "Sugar extraction from sugar beet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moving bed biomass fractionation system and method

InactiveUS20080029233A1Improve production yieldIncrease pressureWashing/displacing pulp-treating liquorsDigestersChemical reactionFiltration

Countercurrent extraction of lignocellulosic biomass such as trees, grasses, shrubs, and agricultural residues or waste involves the separation of cellulose fibers from other constituents, for subsequent use in the manufacture of paper, plastics, ethanol, and other industrial chemicals. Systems and methods involve continuous, multiple processing steps that may include chemical reactions with mixing at elevated temperature and / or pressure, efficient reagent or solvent utilization, filtration at elevated temperature and / or pressure, controlled discharge of liquid and solid products, and energy recuperation.

Owner:PUREVISION TECH

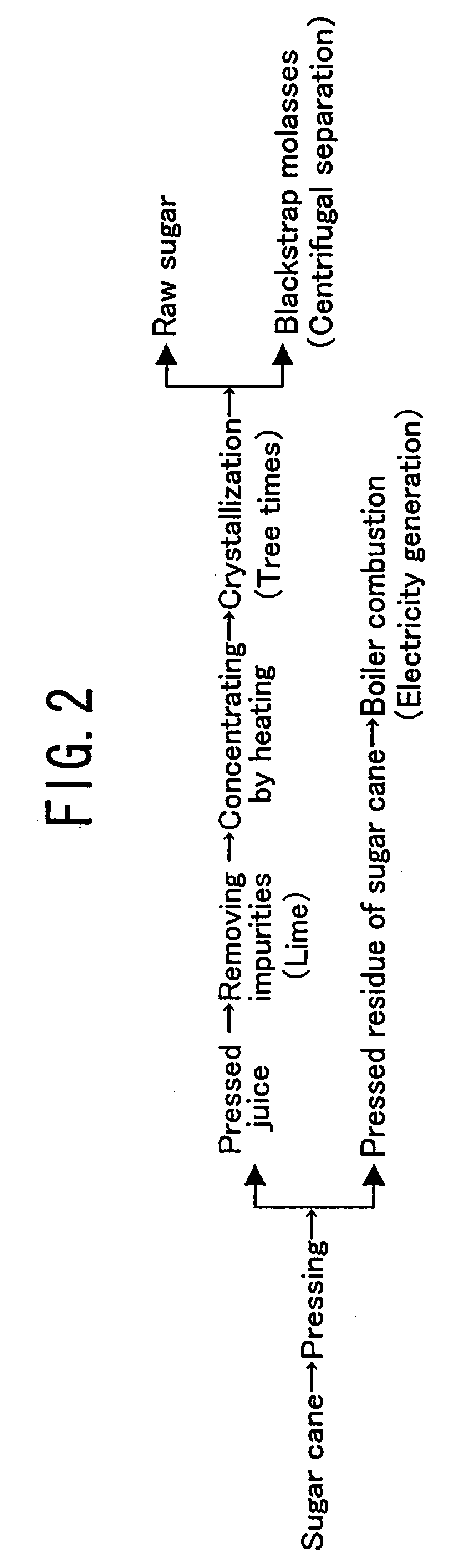

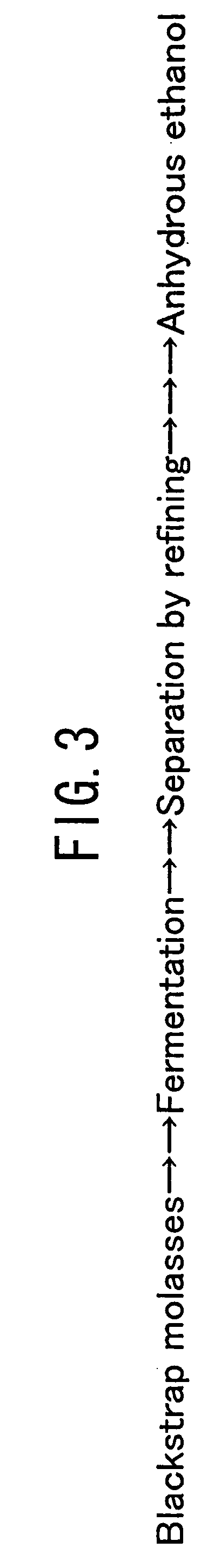

Method for producing sugar and a useful material

InactiveUS20060035355A1Increase volumeReduce productionBiofuelsSugar crystallisationBiotechnologyEngineering

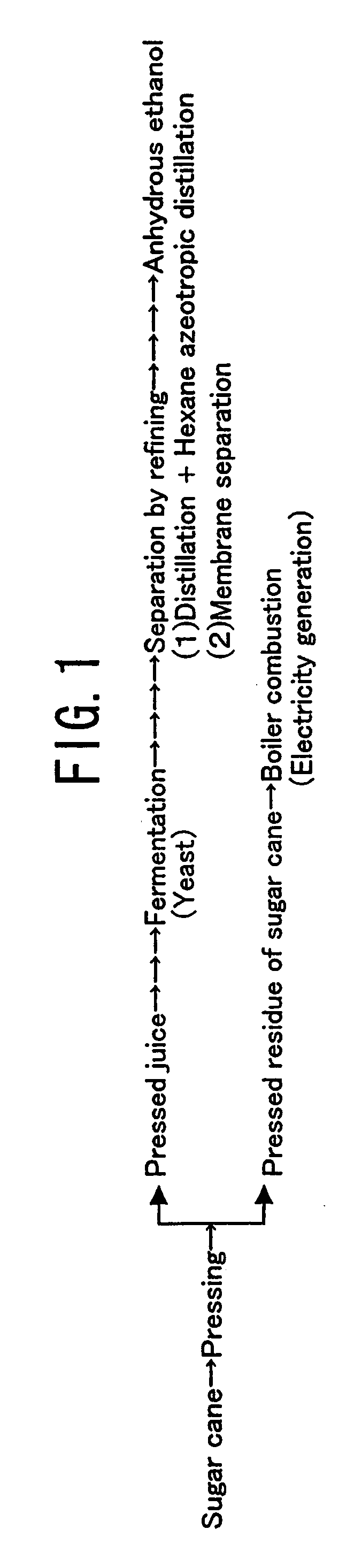

An object of the present invention is to provide a method for producing sugar and ethanol from sugar cane, in which almost all of energy to be consumed in the production processes of the sugar, the ethanol and the like can be supplied by the energy obtained by burning a pressed residue of sugar cane, yet without decreasing the sugar amount to be produced. The present invention provides a method for producing sugar and a useful material from sugar cane, comprising the steps of: (a) producing from sugar cane a pressed juice and pressed residue of sugar cane; (b) producing sugar and blackstrap molasses from said pressed juice; and (c) generating an energy and a useful material by using said pressed juice, said blackstrap molasses and said pressed residue of sugar cane as source materials that have been obtained from said steps (a) and (b), wherein said sugar cane contains an amount of 15% or greater by mass of fiber component in its cane stem region and provides a dry matter yield amount per unit area of 40 t / ha / year or higher; and 90% or more of energy required for all of the steps of said production method is obtained from energy generated by burning said pressed residue of sugar cane.

Owner:ASAHI BREWERIES LTD

Carbohybrate purification using ultrafiltration, reverse osmosis and nanofiltration

InactiveCN1242776APurification using adsorption agentsSugar derivativesEnzymatic synthesisUltrafiltration

The invention provides methods for purifying carbohydrates, including oligosaccharides, nucleotide sugars, and related compounds, by use of ultrafiltration, nanofiltration and / or reverse osmosis. The carbohydrates are purified away from undesired contaminants such as compounds present in reaction mixtures following enzymatic synthesis or degradation of oligosaccharides.

Owner:NEOSE TECH

Process for the production of invert liquid sugar

InactiveUS20040255934A1Purification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

Carbohydrate-enriched plant pulp composition

InactiveUS20120183646A1Attractive propertyGrowth inhibitionDough treatmentTea extractionBiotechnologyPolydextrose

The invention pertains to a plant or vegetable pulp composition comprising: a) plant or vegetable pulp comprising 5-30 wt % cell wall materials comprising or consisting of cellulose, hemicellulose, lignin and / or pectin, and / or fragments and / or hydrolysates thereof, wherein said pulp is obtained by disrupting plant or vegetable cell membranes and removing at least part of the intracellular content; b) 45-85 wt % of one or more water-soluble carbohydrate(s) selected from the group consisting of inulin, oligofructose, fructo-oligosaccharide, galacto-oligosaccharide, glucose, maltose, maltodextrins, polydextrose, sucrose, fructose, lactose, isomaltulose and polyols, and / or combinations thereof; and c) 5-25 wt % water, all numbers based on total weight of said composition. The invention also pertains to the method of preparing such a composition, and the use in (human) food applications.

Owner:KONINK COOPERATIE COSUN U A

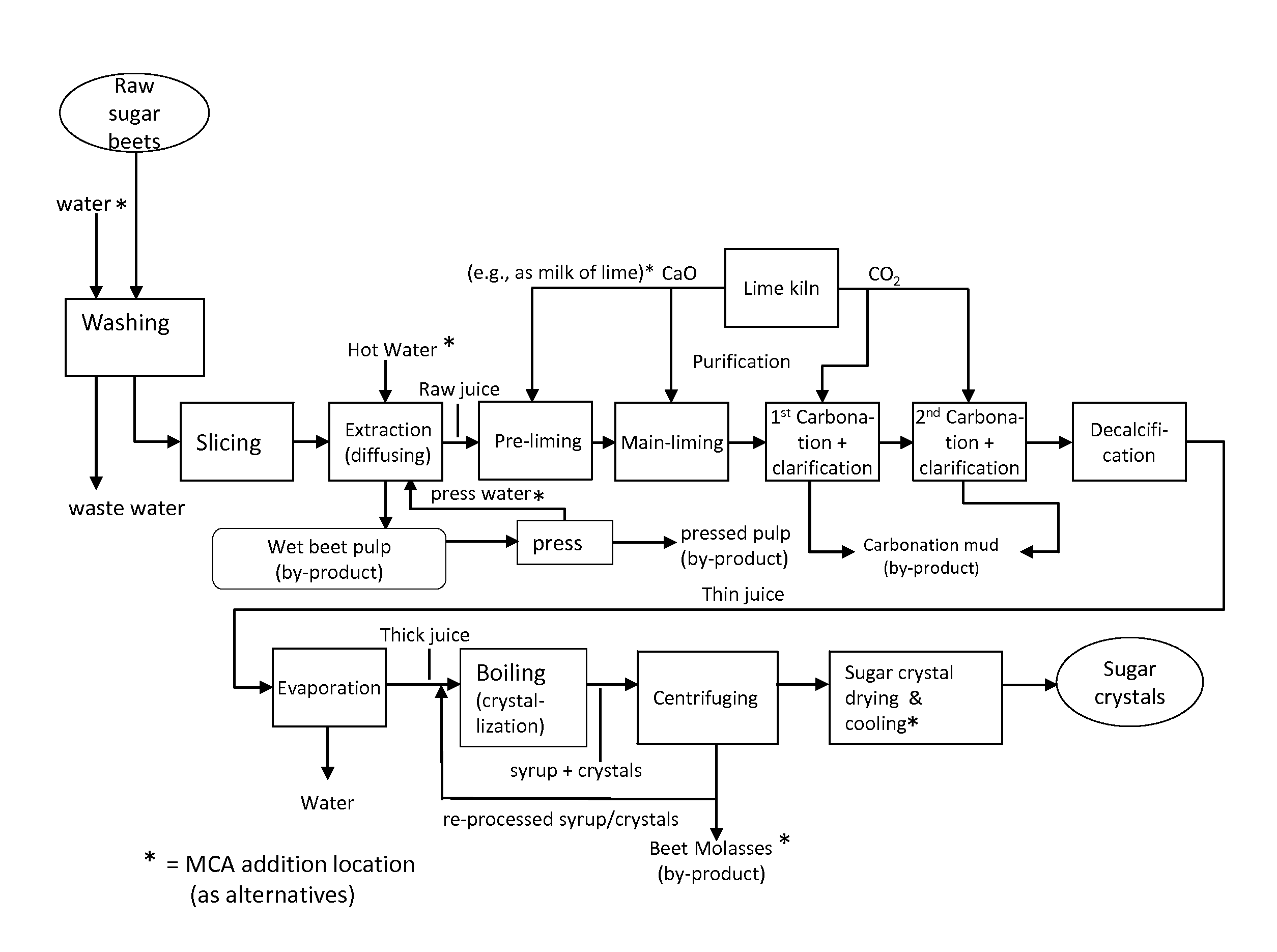

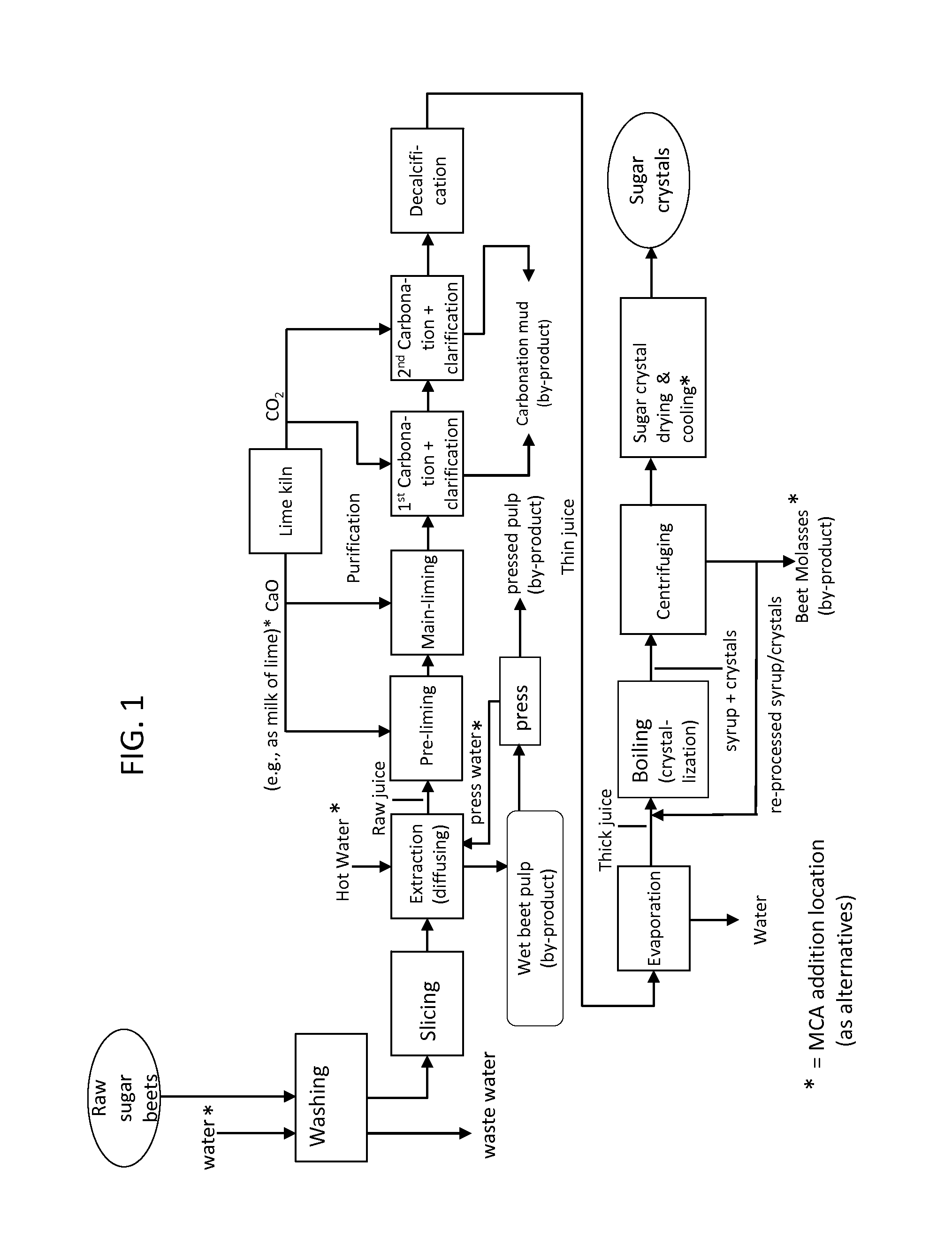

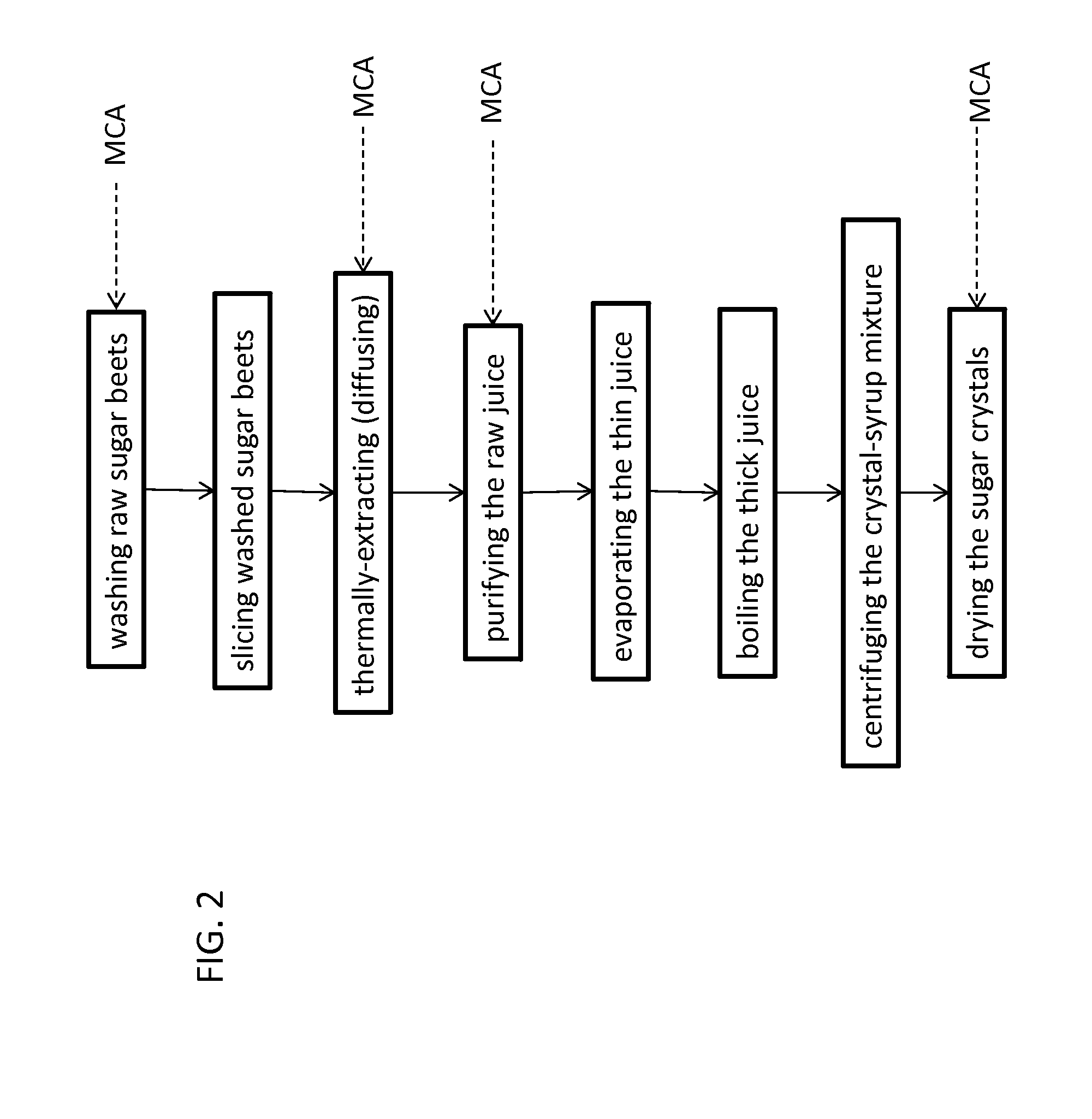

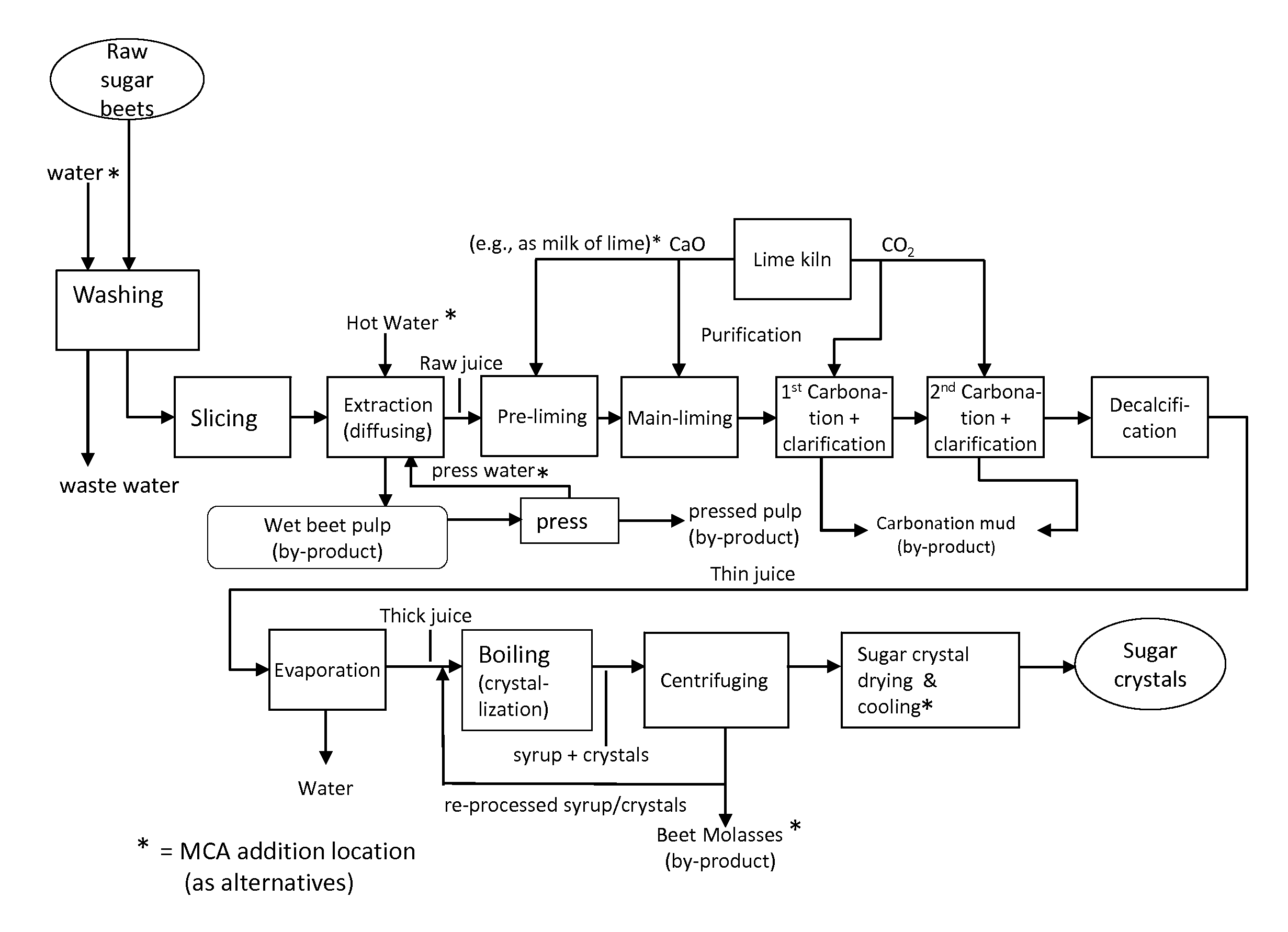

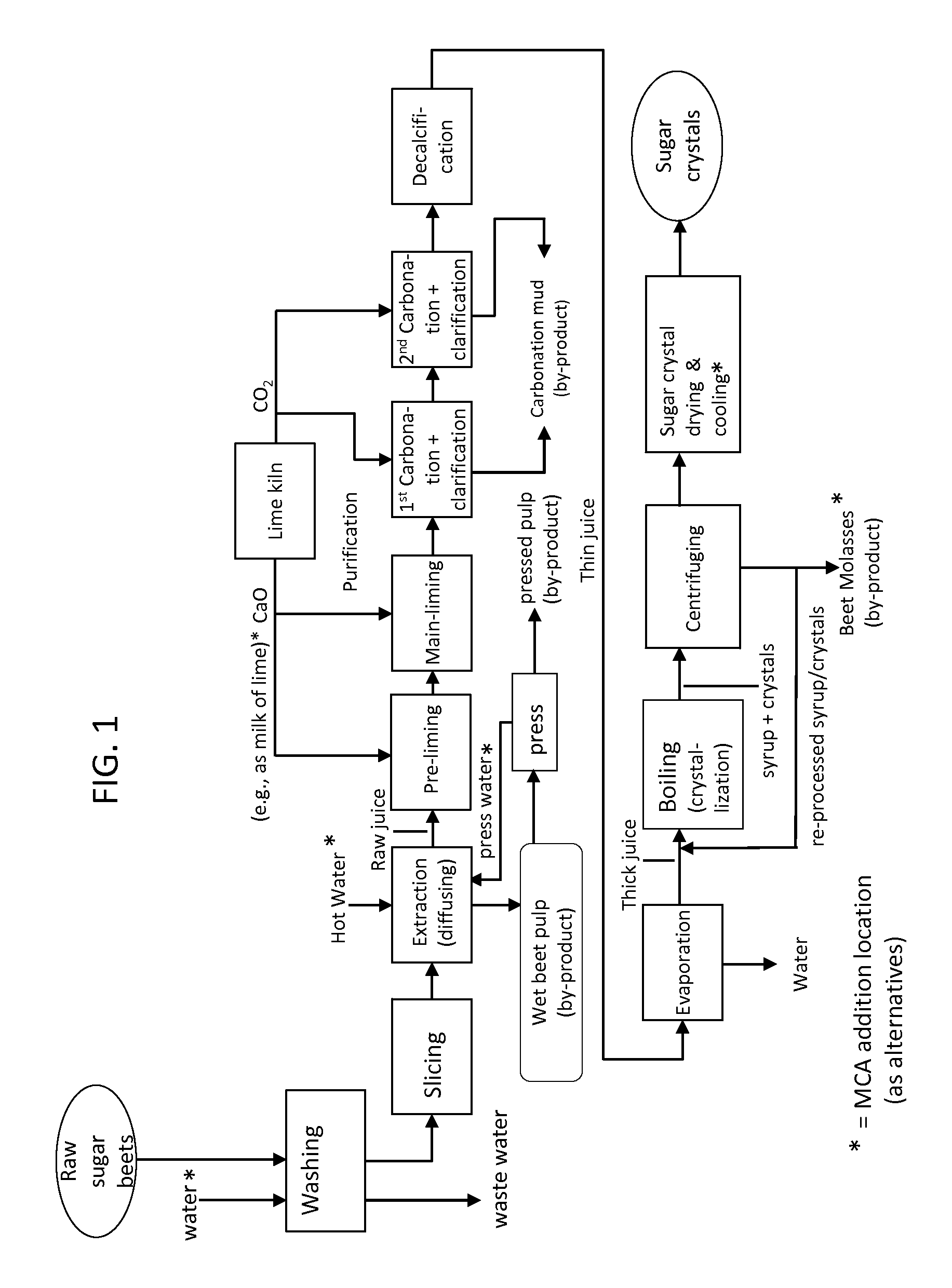

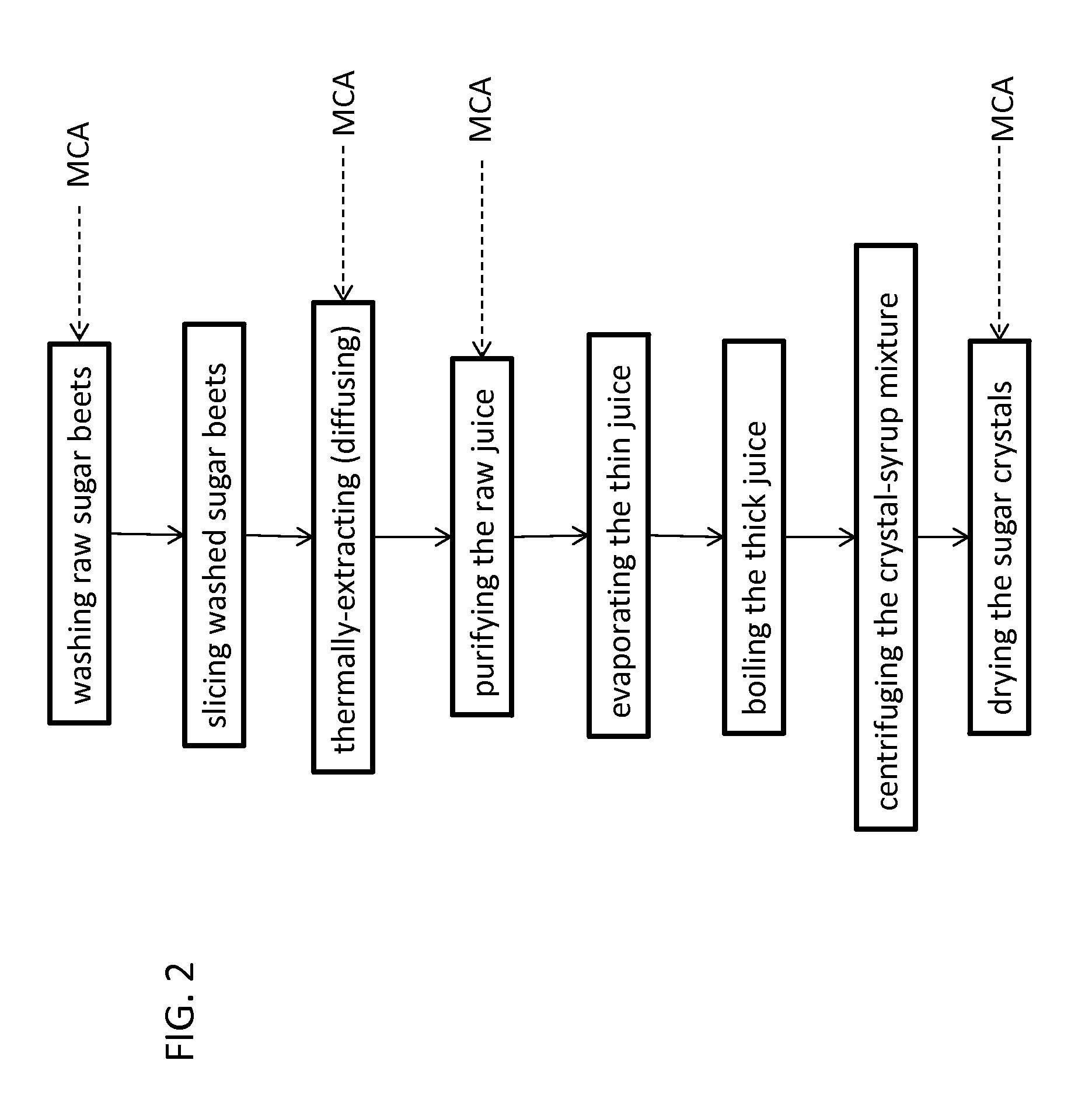

Methods Of Microbiological Control In Beet Sugar And Other Sugar-Containing Plant Material Processing

Methods are described for producing sugar from sugar-containing plant material with microbiological control, which includes treating a sugar-containing plant raw material and / or a component derived therefrom, and / or a medium containing the plant raw material and / or the component, with monochloramine. Monochloramine usage in the method can reduce loss of sugar from bacterial consumptions in the processing of sugar-containing plant materials, such as sugar beets, without causing adverse effects on the sugar product, such as the brightness of white sugar.

Owner:BUCKMAN LAB INT INC

Agricultural extraction products and processes

InactiveUS20080124443A1Fatty oils/acids recovery from wasteInorganic/elemental detergent compounding agentsHigh sodiumFish oil

The inventive developments disclosed in this application include the following features and combinations thereof: extracting oil from spent bleaching earths for animal feed; using earths and acid water as soil amendment / fertilizer; efficient extraction of substances valuable to plants, animals, and humans from plant, animal, and fish oil soapstock, especially using the “interphase” emulsion from soapstock acidulation; use of “black paste” from oil refining as fertilizer component (nutrient source); use of interphase from agricultural oil refining, especially refining of non-degummed oils, as animal feed; use of “oil refining by-products to fertilizers” process and / or KOH refining in conjunction with “Miscella”-type hexane refining or “Zenith” process refining; fertilizers containing silica / silicates from by-products of agricultural oil refining; use of higher-sodium oil refining by-products as fertilizer for sodium-tolerant plants; using by-products of sugar beet refining as nutrient source; agriculturally useful potassium soaps from oil refining; products of the refining of non-degummed agricultural oils having useful biocidal or other biological properties; the use, as a feed additive, of potassium soapstock from the caustic refining of agricultural oils using a potassium caustic (KOH), especially with non-degummed oils, which has unexpected advantages over the use of soapstock from sodium caustic (NaOH) refining, especially from degummed oils.

Owner:DANIELS AGROSCI

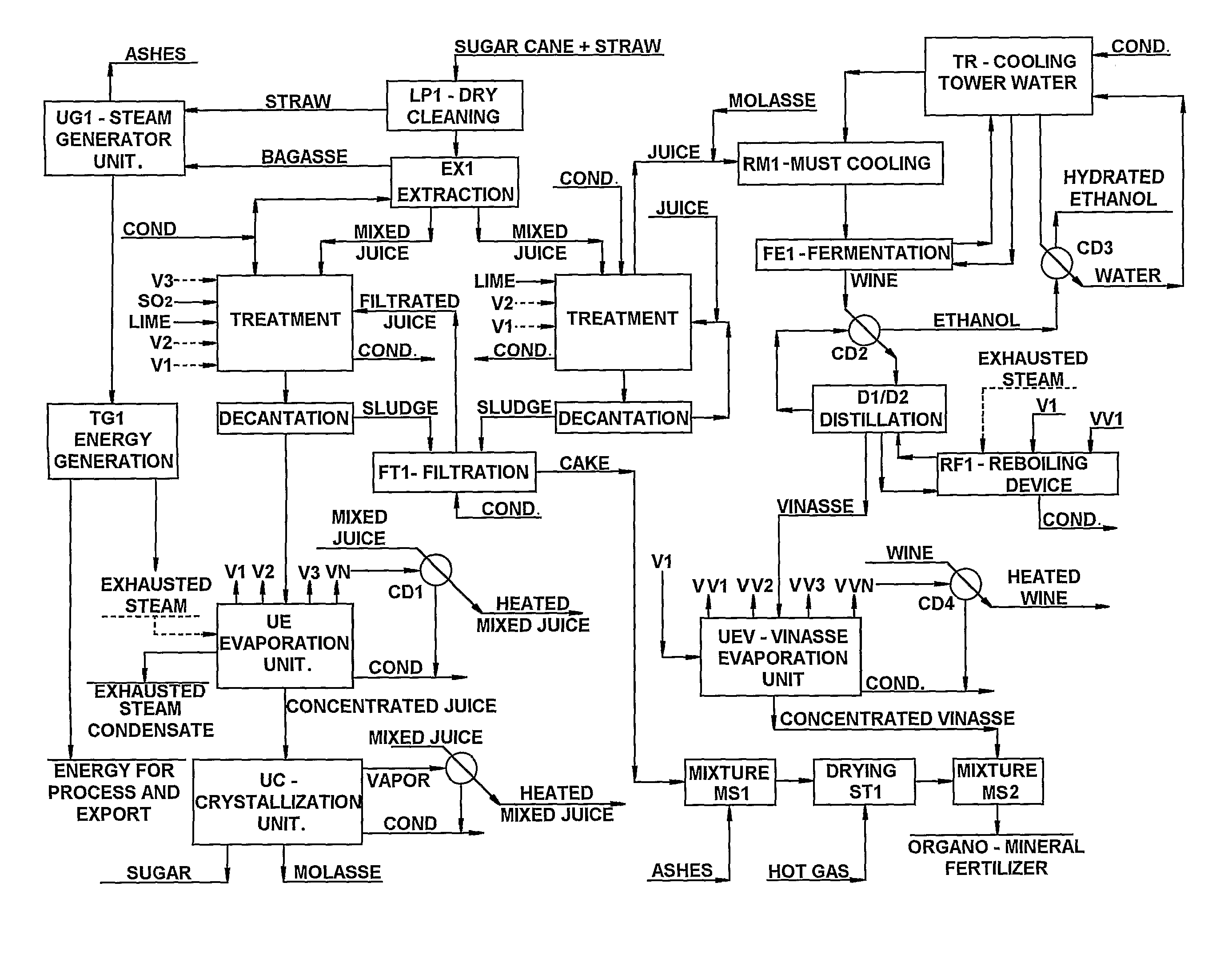

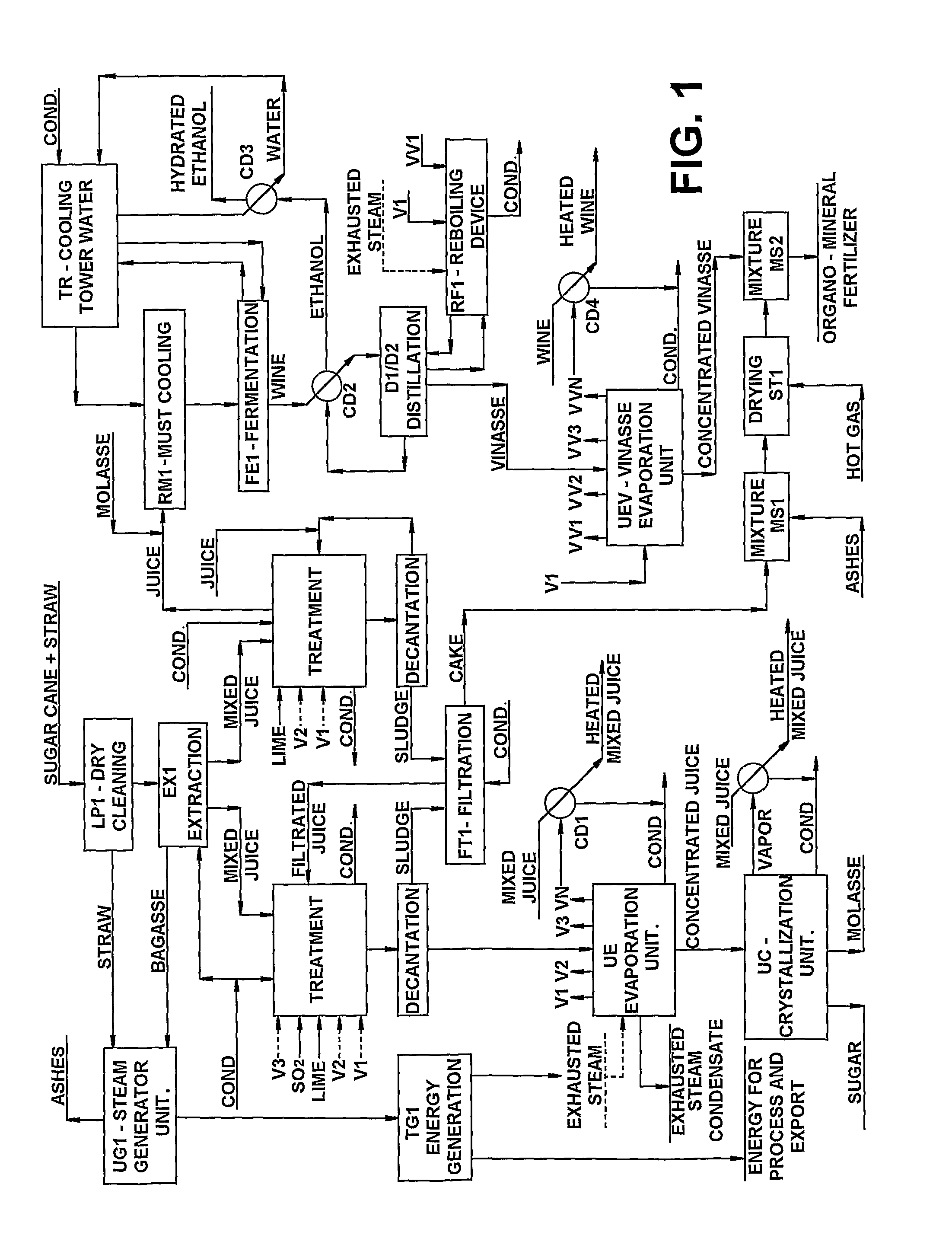

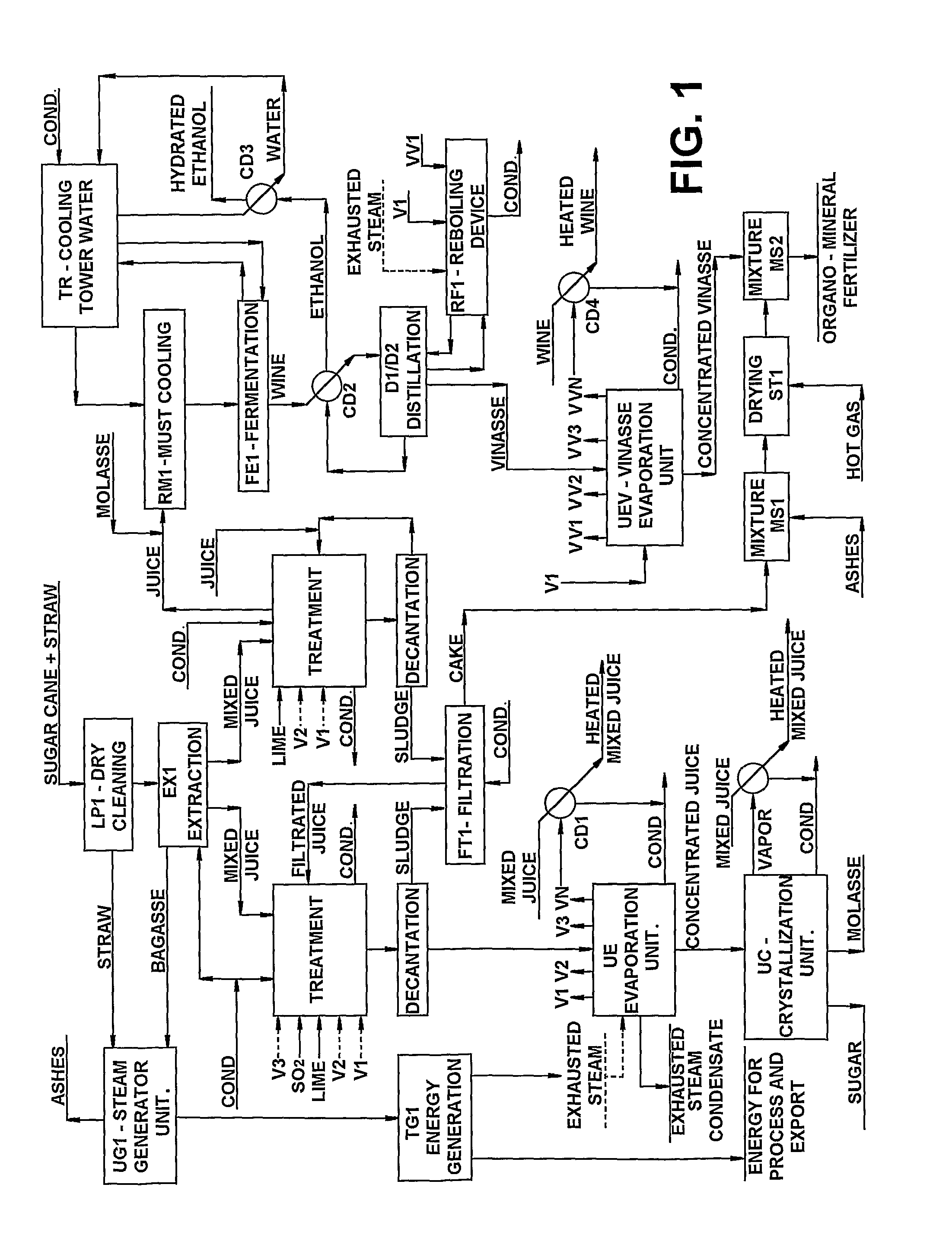

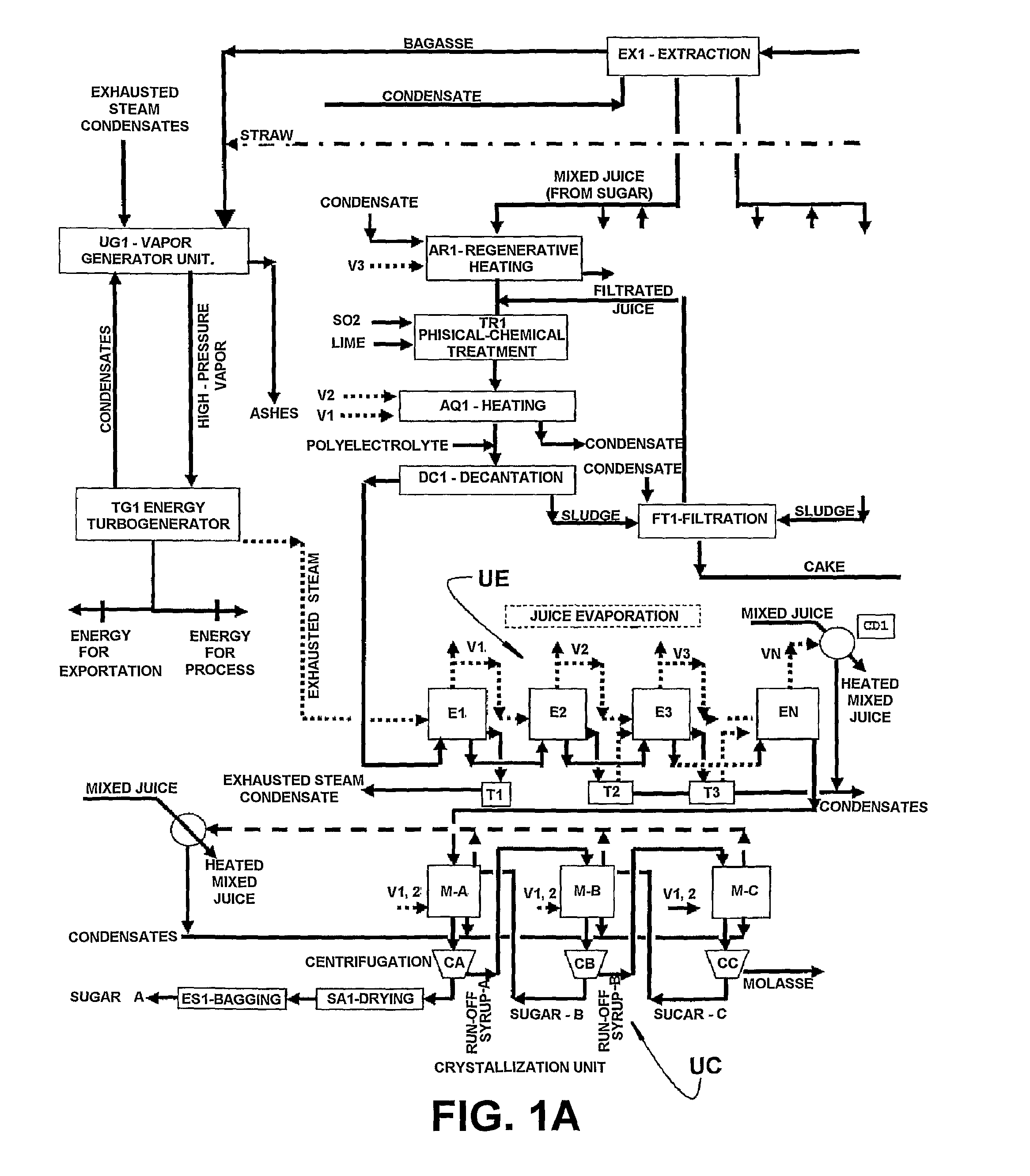

Process for the recovery of water and energy from the processing of sugar cane in sugar and ethanol production mills

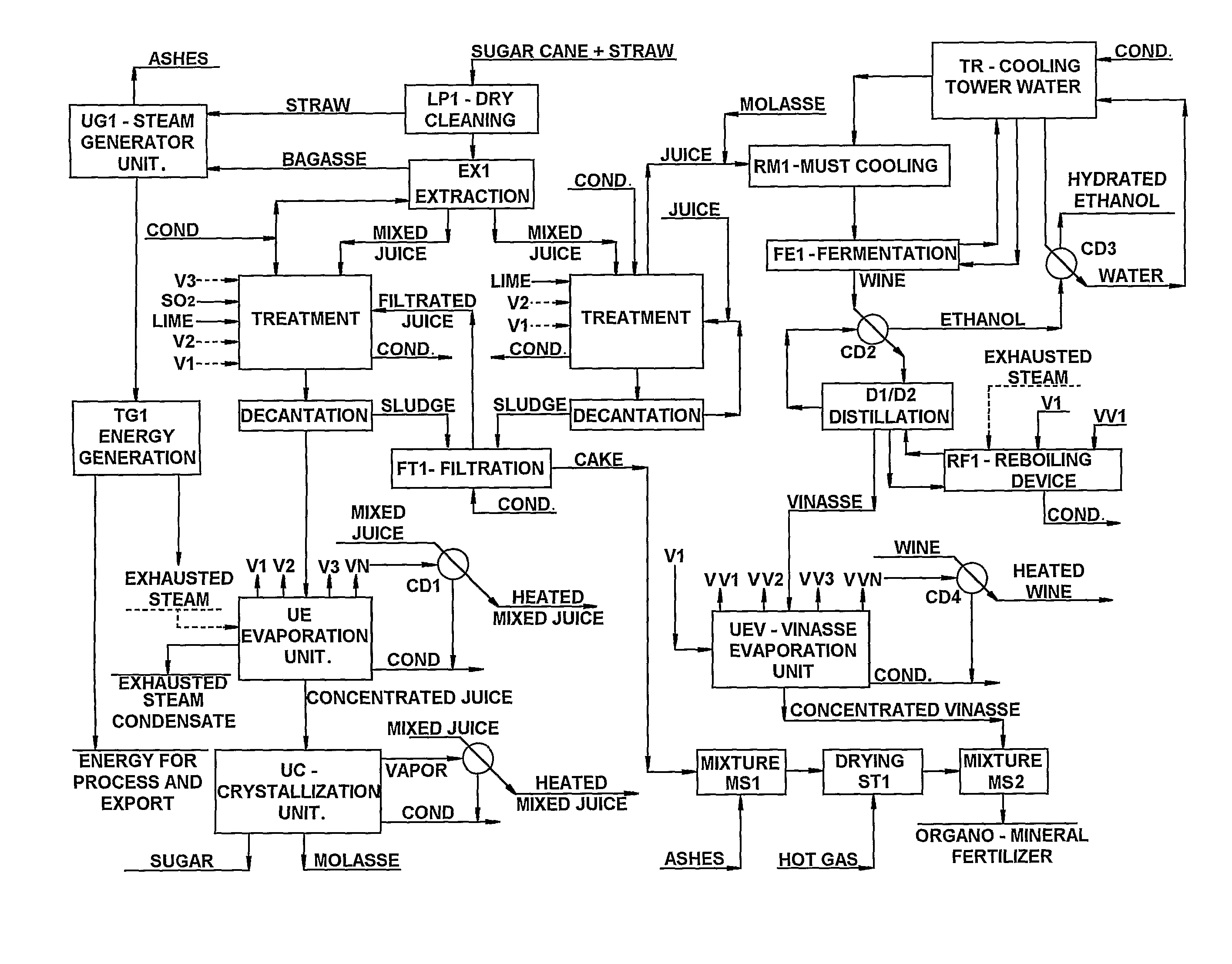

ActiveUS20110232343A1Reduce consumptionEconomic savingsBio-organic fraction processingSugar crystal separationThermal energyCooling tower

A process is proposed for recovery of water in the sugar cane processing in production mills of sugar and alcohol or only alcohol (ethanol). In the process, the thermal energy available in the exhausted steam from the electric energy generation turbines is transferred to the different mixed juice processing phases, with the reuse of the exhausted steam condensates in the boilers and of the other condensates, after using thermal energy, for imbibition, in the juice extraction phase, for cooling in the process, after passing through cooling towers, for other industrial uses and for possible treatment or use in the irrigation out of the productive system in the mill

Owner:DEDINI S A IND DE BASE

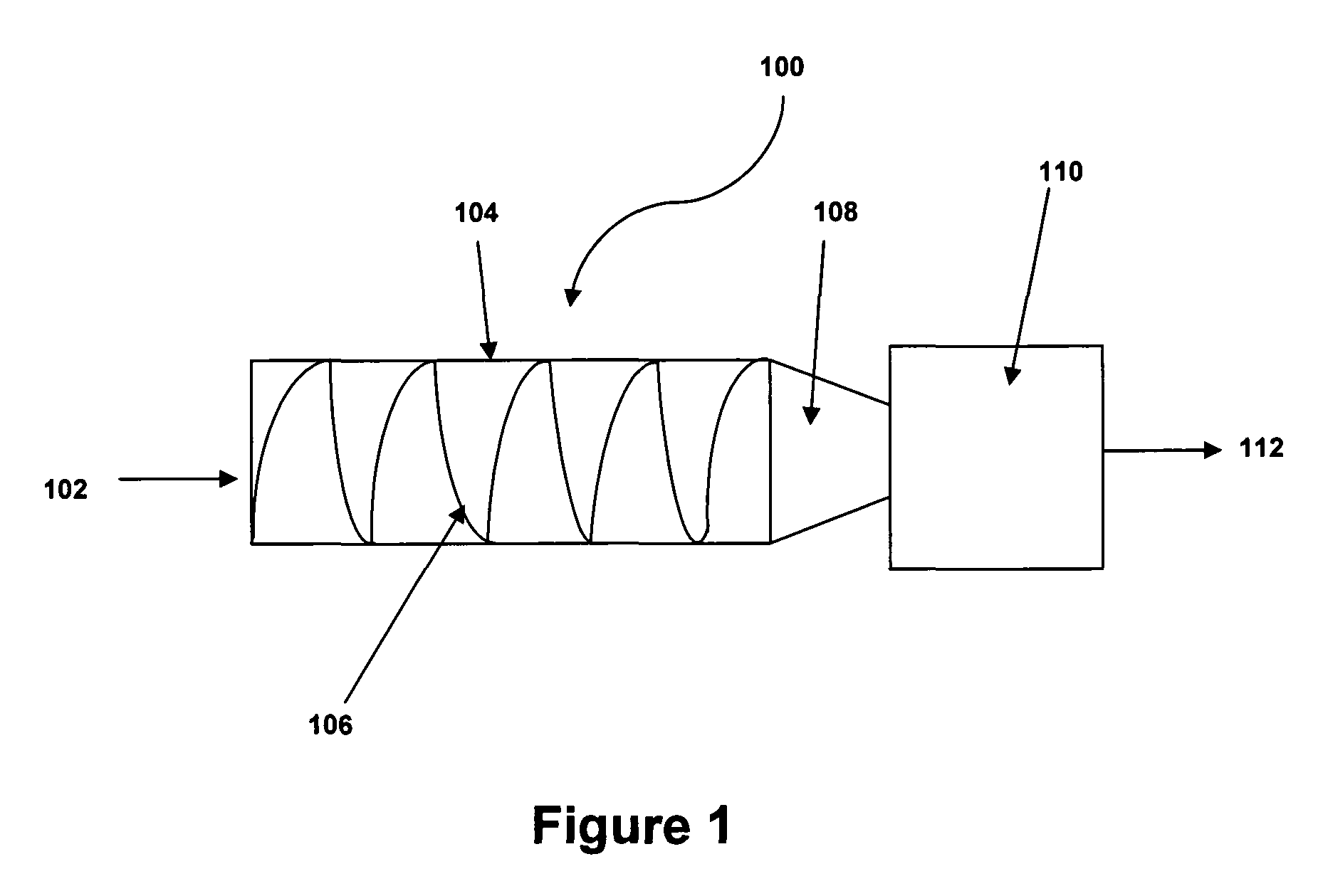

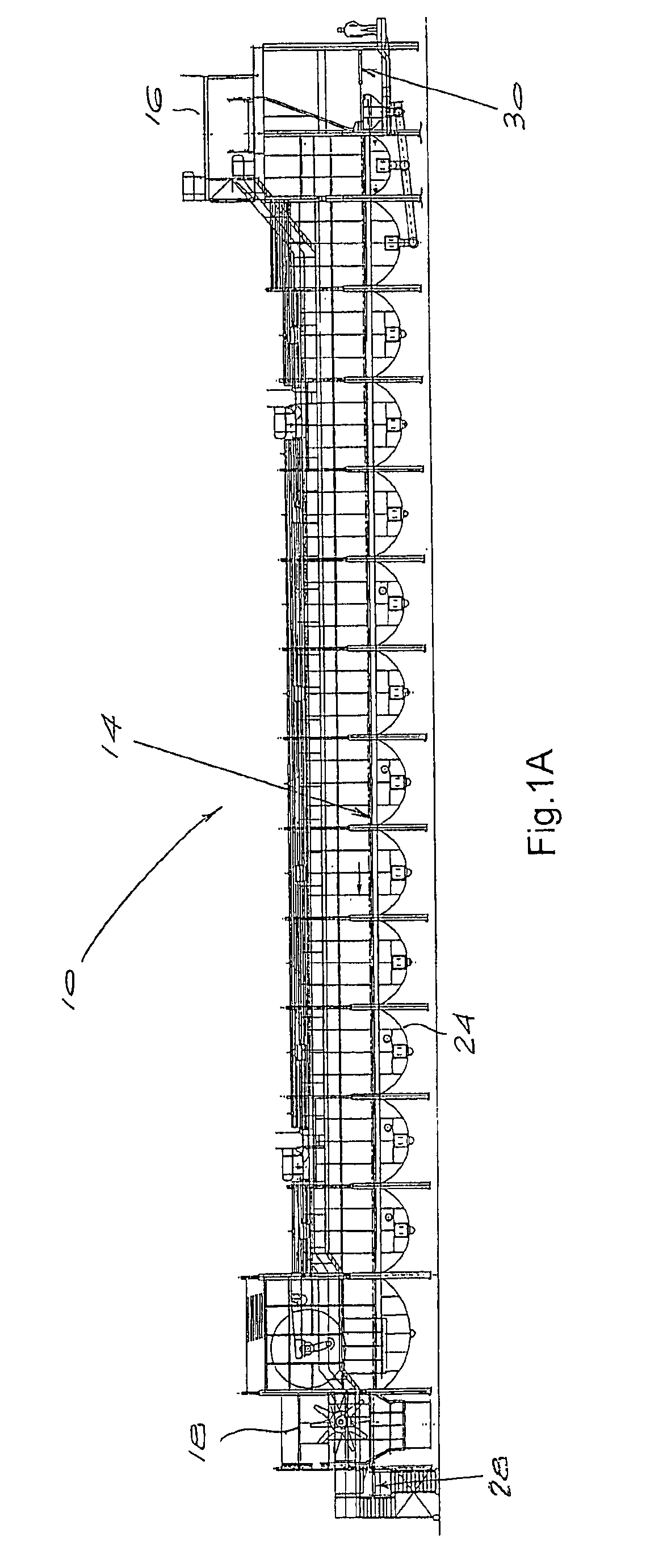

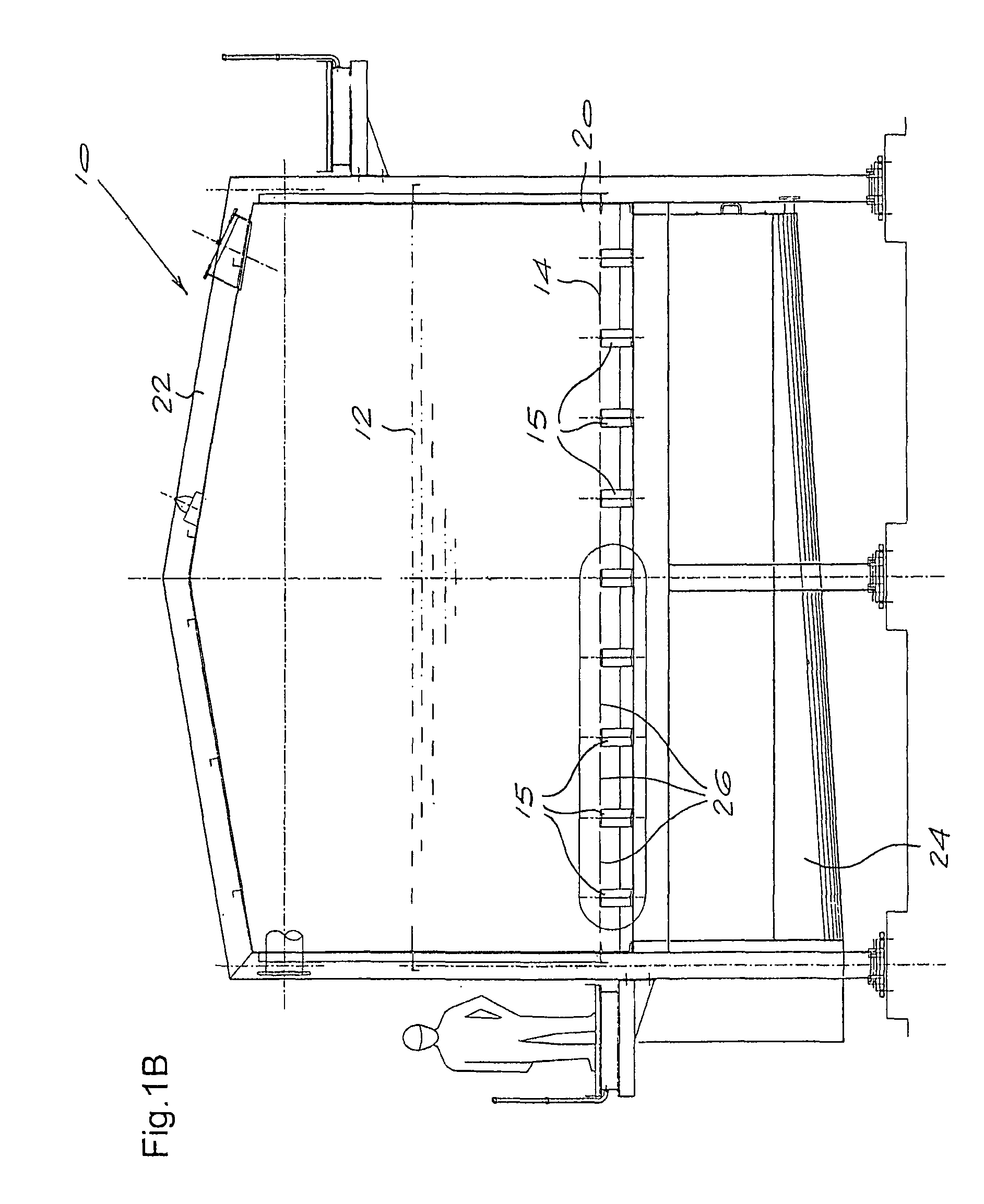

Biomass Processor

ActiveUS20090241944A1Facilitated releaseIncrease shear forcePressurized chemical processSugarcane cuttingFiberBiomedical engineering

Owner:BIOMASS TECH PTY LTD

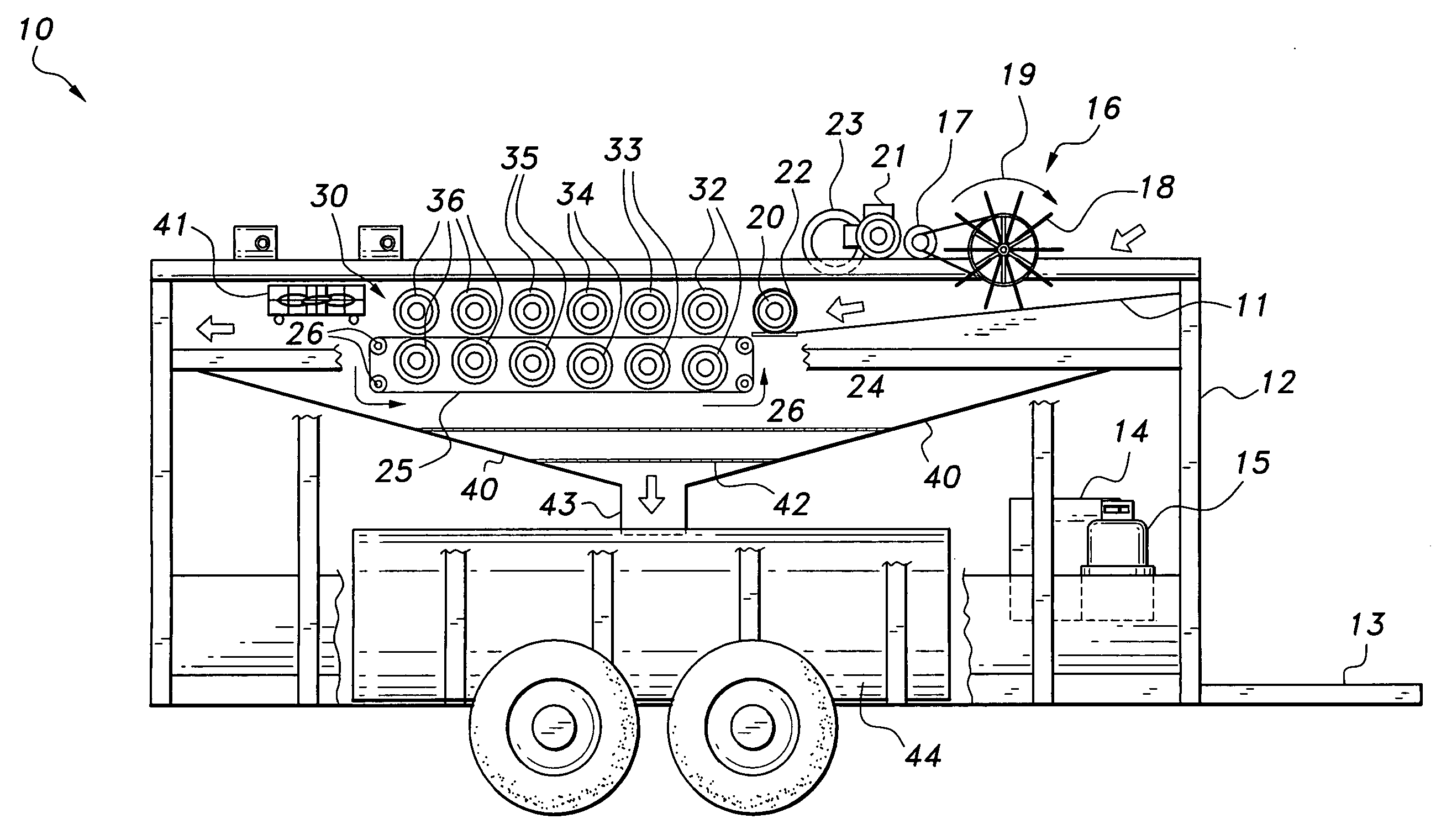

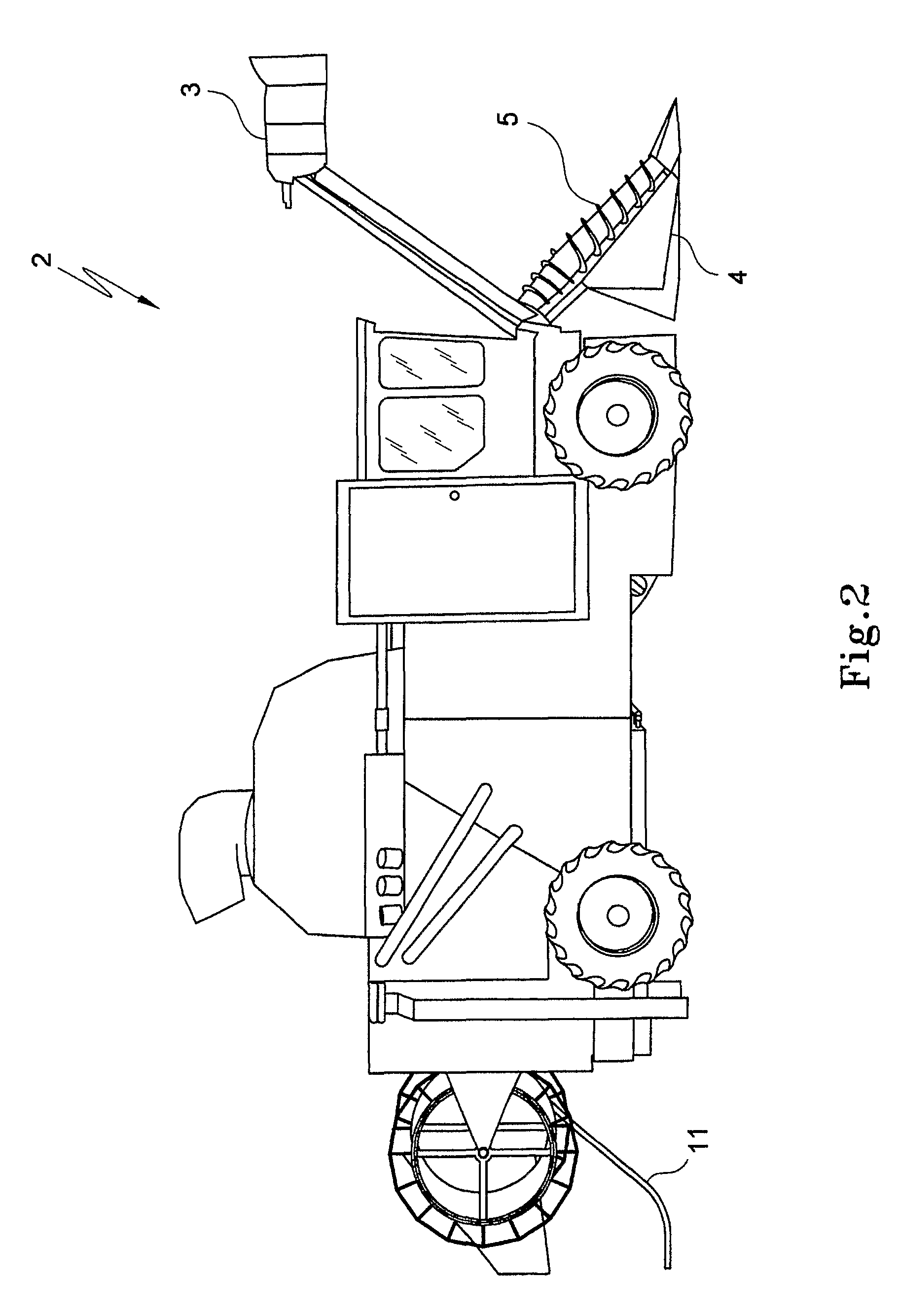

Cane juice extractor

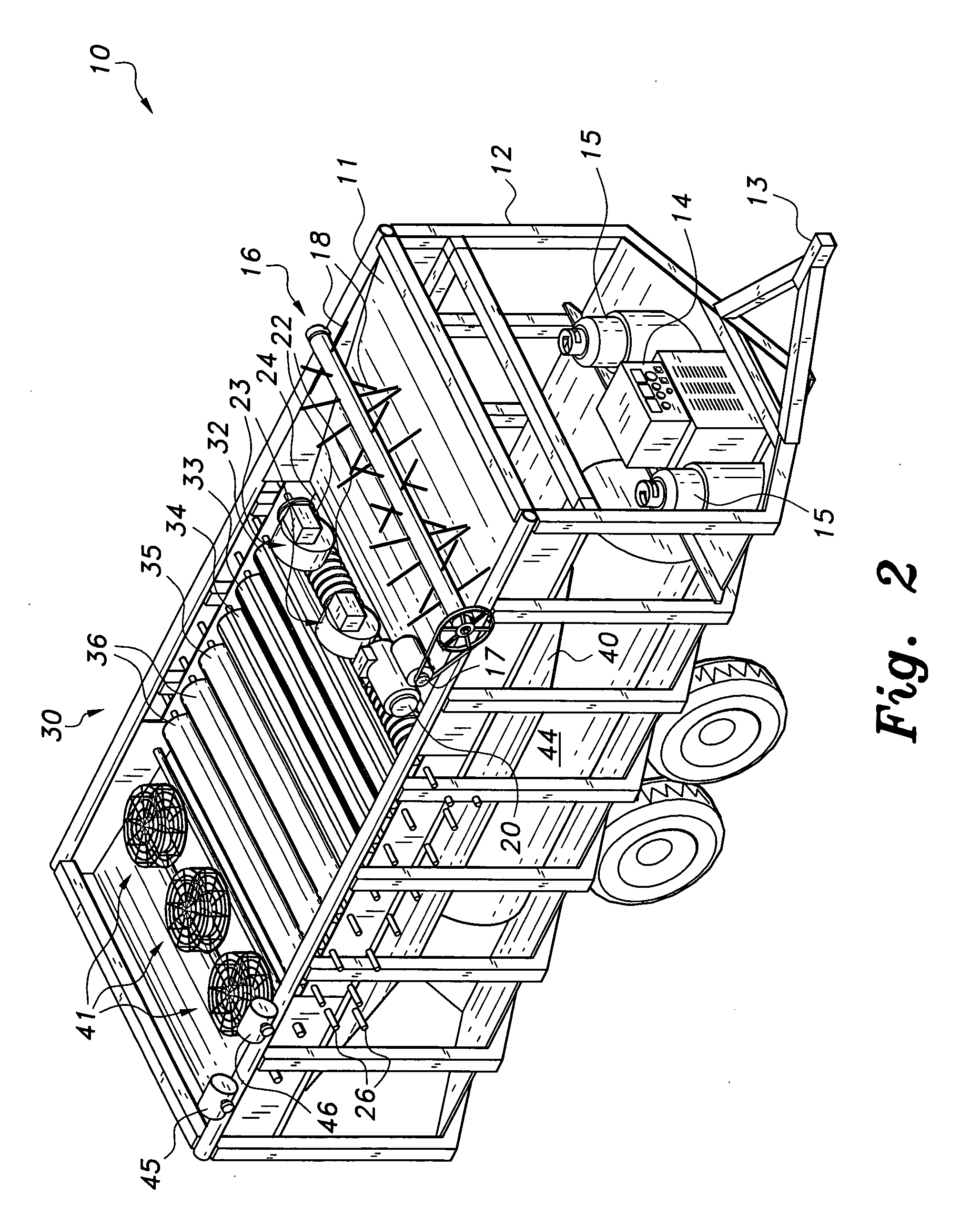

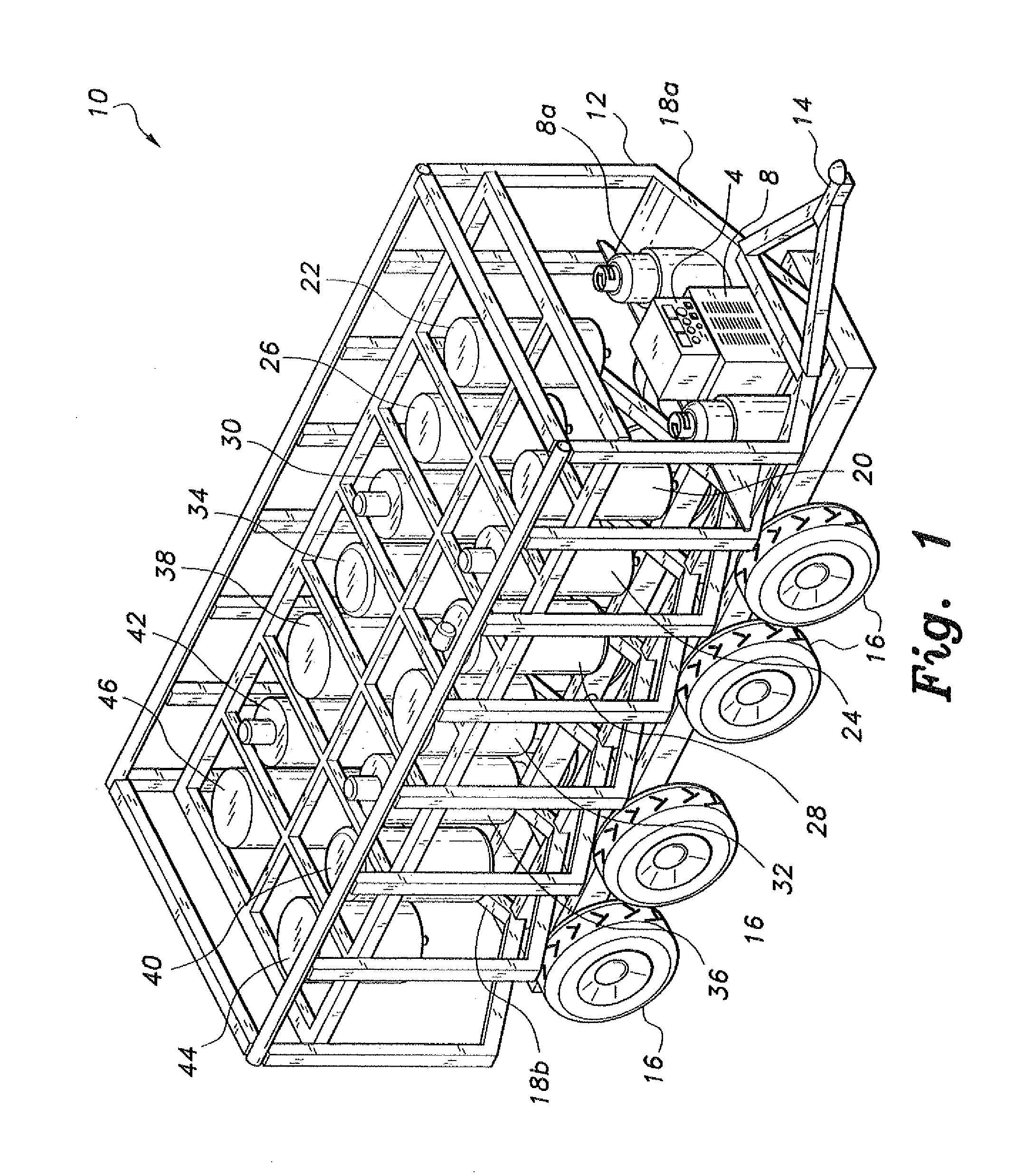

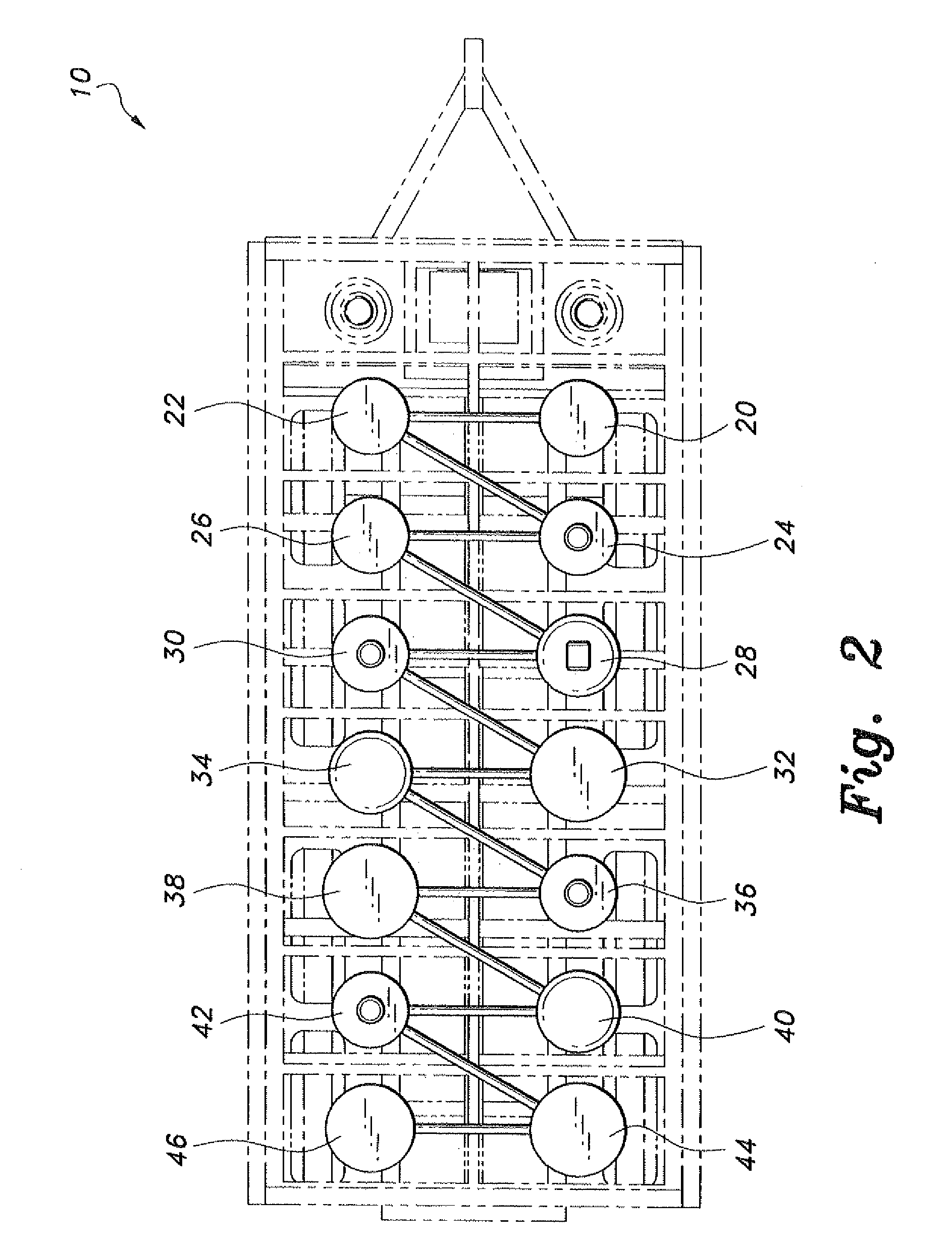

ActiveUS20100307483A1Readily apparentPressurized chemical processJuice extraction from sugarcanePulp and paper industryTruck

The cane juice extractor includes a wagon that may be hitched to or towed alongside a harvesting machine or combine for application in-field. The wagon includes a frame having an upper deck and a lower deck. The upper deck includes an inlet side where harvested cane may be fed for juice extraction and an outlet side for disposing the pulp. Rotating feeders feed the cane to a cutting station on the upper deck. The cutting station comminutes the cane into billets that are carried by an endless belt through a series of compression roller sets. Each set of rollers compress the cut cane down to smaller dimensions to extract the juice. A chute disposed between the upper and lower decks collects the juices and funnels them into a juice storage tank on the lower deck. The pulp is expelled from the outlet side to the field.

Owner:STEGEMAN JOSEPH

Process for the production of invert liquid sugar

InactiveUS6916381B2Reduce amountFew stepsPurification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

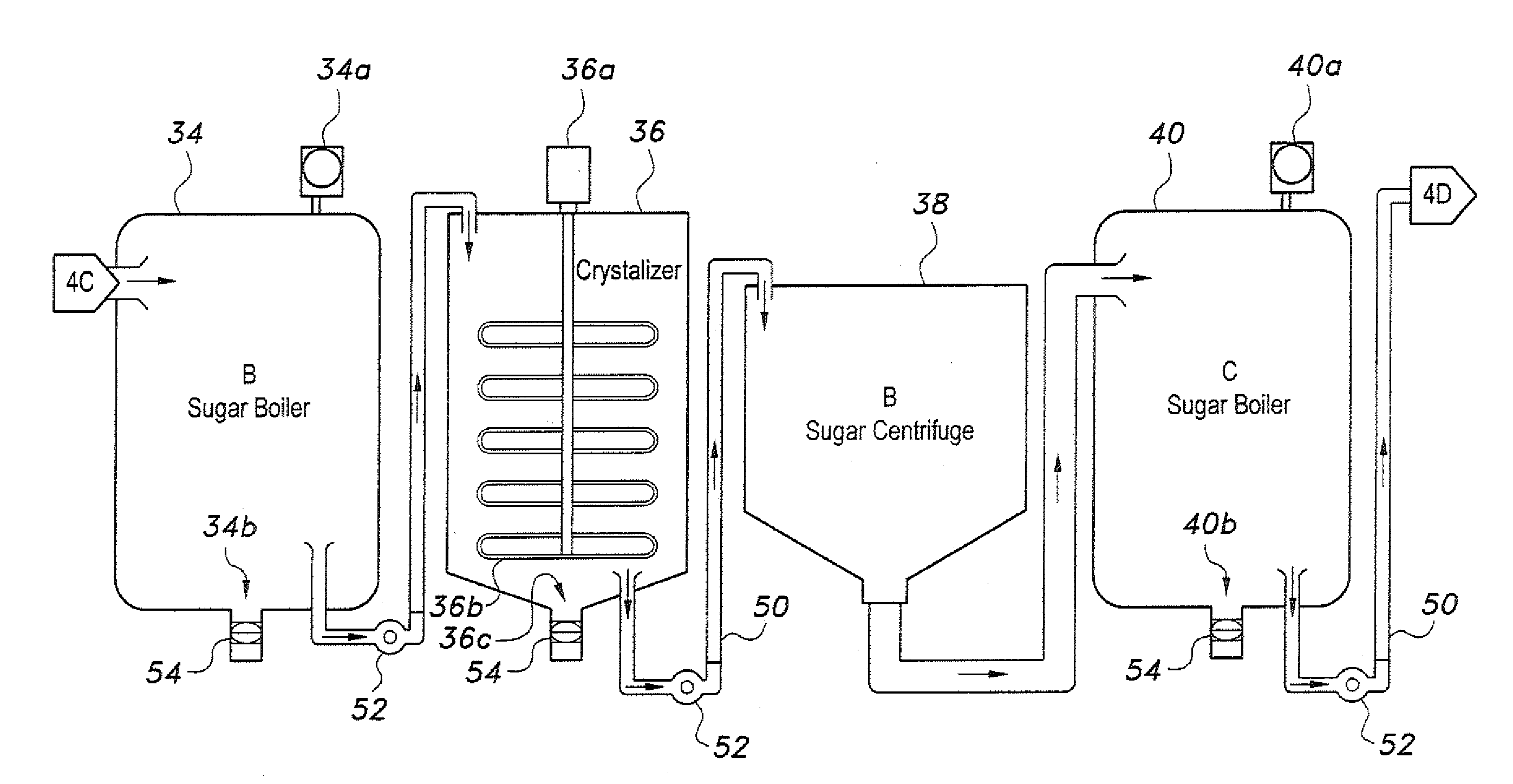

Portable sugar mill

InactiveUS20130042858A1Readily apparentSugar crystal separationCentrifugal force sediment separationFruit juiceSaccharum

The portable sugar mill is established on a mobile platform for transport to the harvesting field, so that the juice of the harvested sugar cane may be processed and refined in the field. The portable sugar mill converts the juice, which contains sucrose, into raw sugar crystals (brown sugar) and molasses. The portable sugar mill includes a separator tank, a pre-heating tank, a clarifier, and three successive stages of evaporative crystallization and separation of crystals from syrup. The portable sugar mill has a programmable logic controller and a plurality of sensors, control relays, pumps, motors, heaters, and valves that operate automatically under direction of the programmable logic controller.

Owner:JEDWIN MARKETING

Cane juice extractor

The cane juice extractor includes a wagon that may be hitched to or towed alongside a harvesting machine or combine for application in-field. The wagon includes a frame having an upper deck and a lower deck. The upper deck includes an inlet side where harvested cane may be fed for juice extraction and an outlet side for disposing the pulp. Rotating feeders feed the cane to a cutting station on the upper deck. The cutting station comminutes the cane into billets that are carried by an endless belt through a series of compression roller sets. Each set of rollers compress the cut cane down to smaller dimensions to extract the juice. A chute disposed between the upper and lower decks collects the juices and funnels them into a juice storage tank on the lower deck. The pulp is expelled from the outlet side to the field.

Owner:STEGEMAN JOSEPH

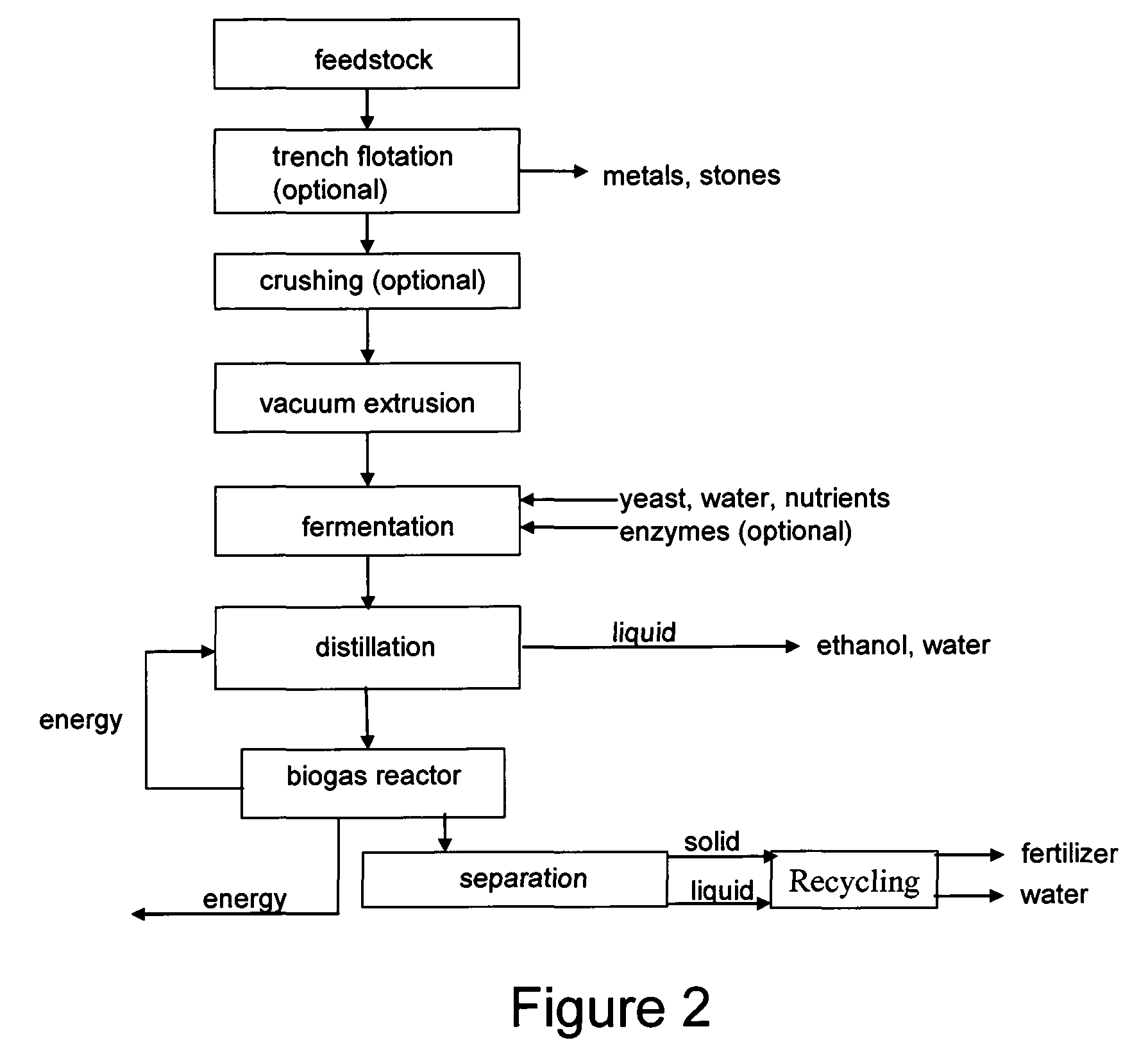

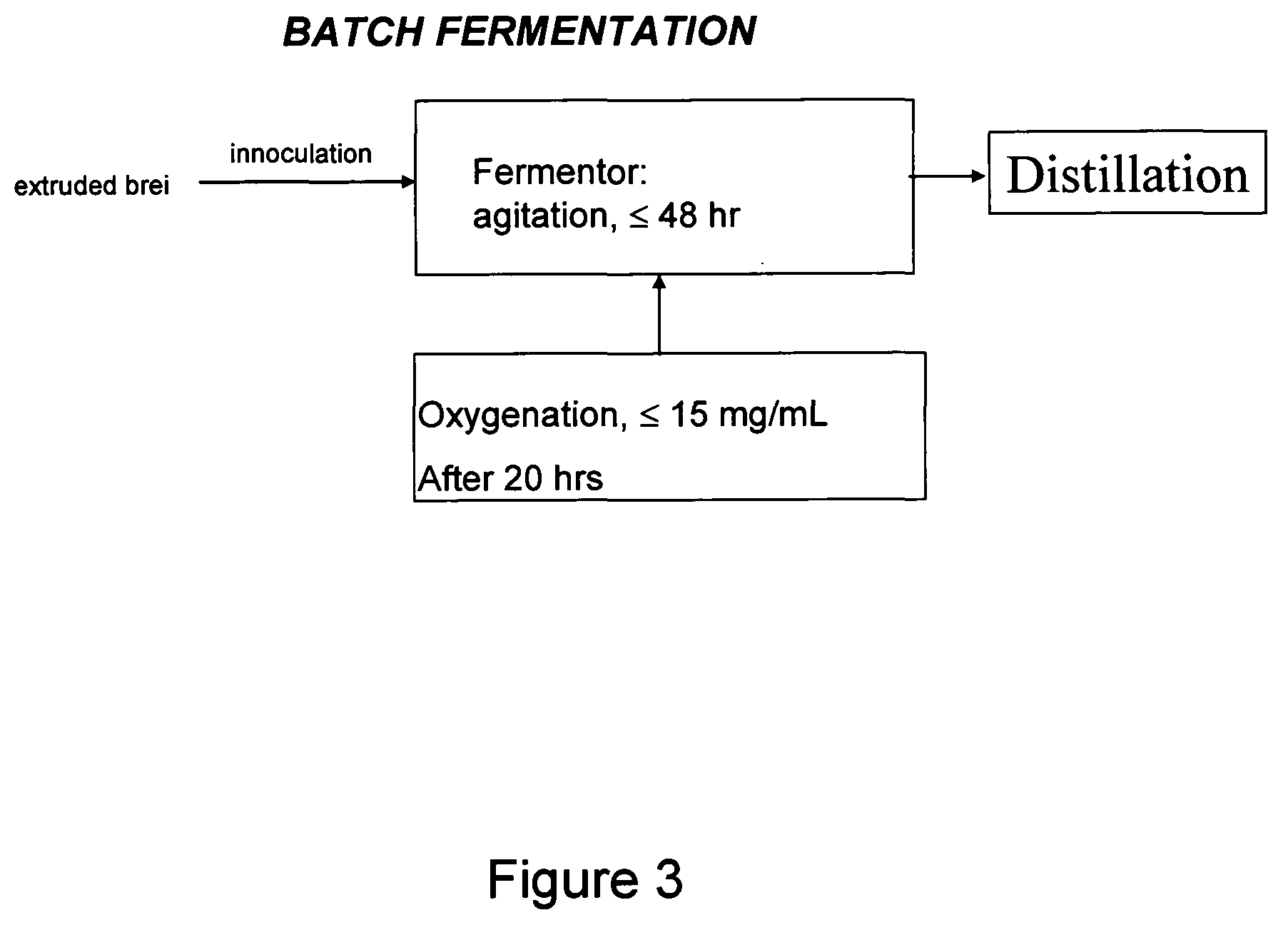

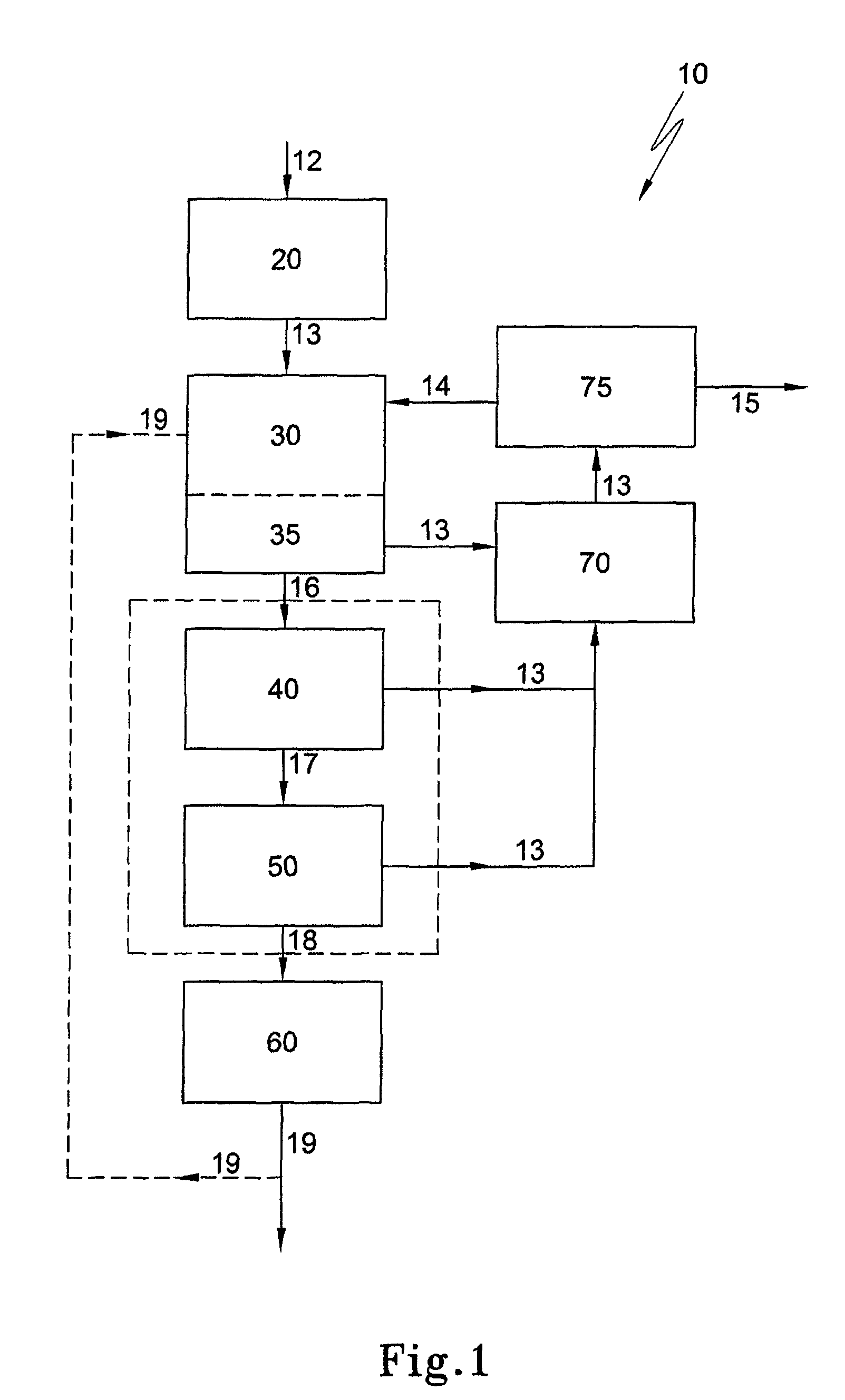

Process for providing ethanol from plant material

ActiveUS20110020891A1Bio-organic fraction processingBiological substance pretreatmentsSubject matterPlant cell

The presently disclosed subject matter relates to processes that comprise the vacuum extrusion of plant materials. In some embodiments, the plant materials are subjected to a change in pressure of −3 kPa or more. The vacuum extrusion can be used to break open the cell walls of the plant material and of any undesirable micro-organisms associated with the plant material. In some embodiments, the vacuum extrusion can be used as a step in a process for producing ethanol from plant materials, such as from sugar beets. In some embodiments, the vacuum extrusion can be used in a process for providing a desired plant cell-derived molecule, such as a sugar or starch.

Owner:SYNGENTA PARTICIPATIONS AG

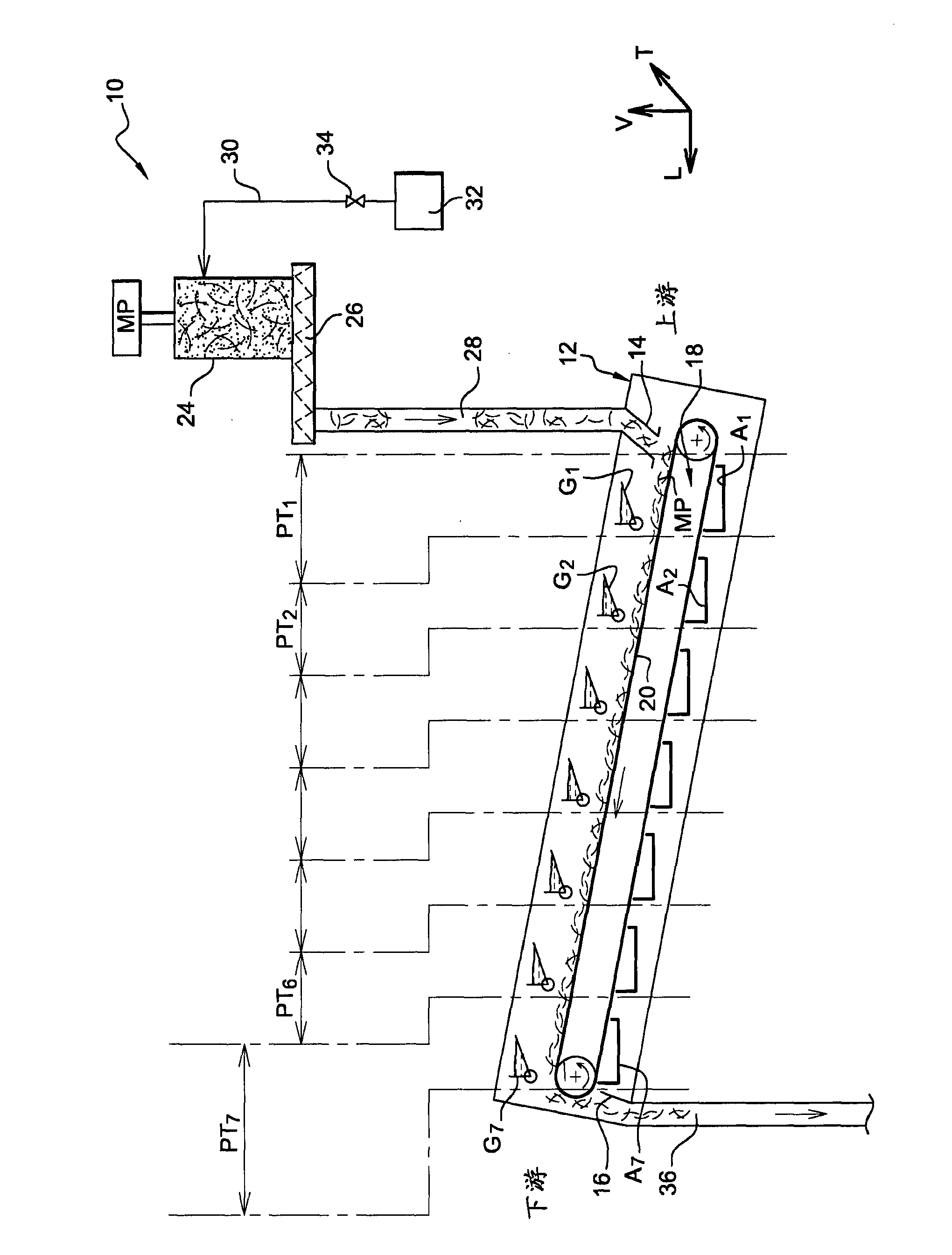

Method for pretreating plant starting material for the production, from sacchariferous and lignocellulosic resources, of bioethanol and/or of sugar, and plant

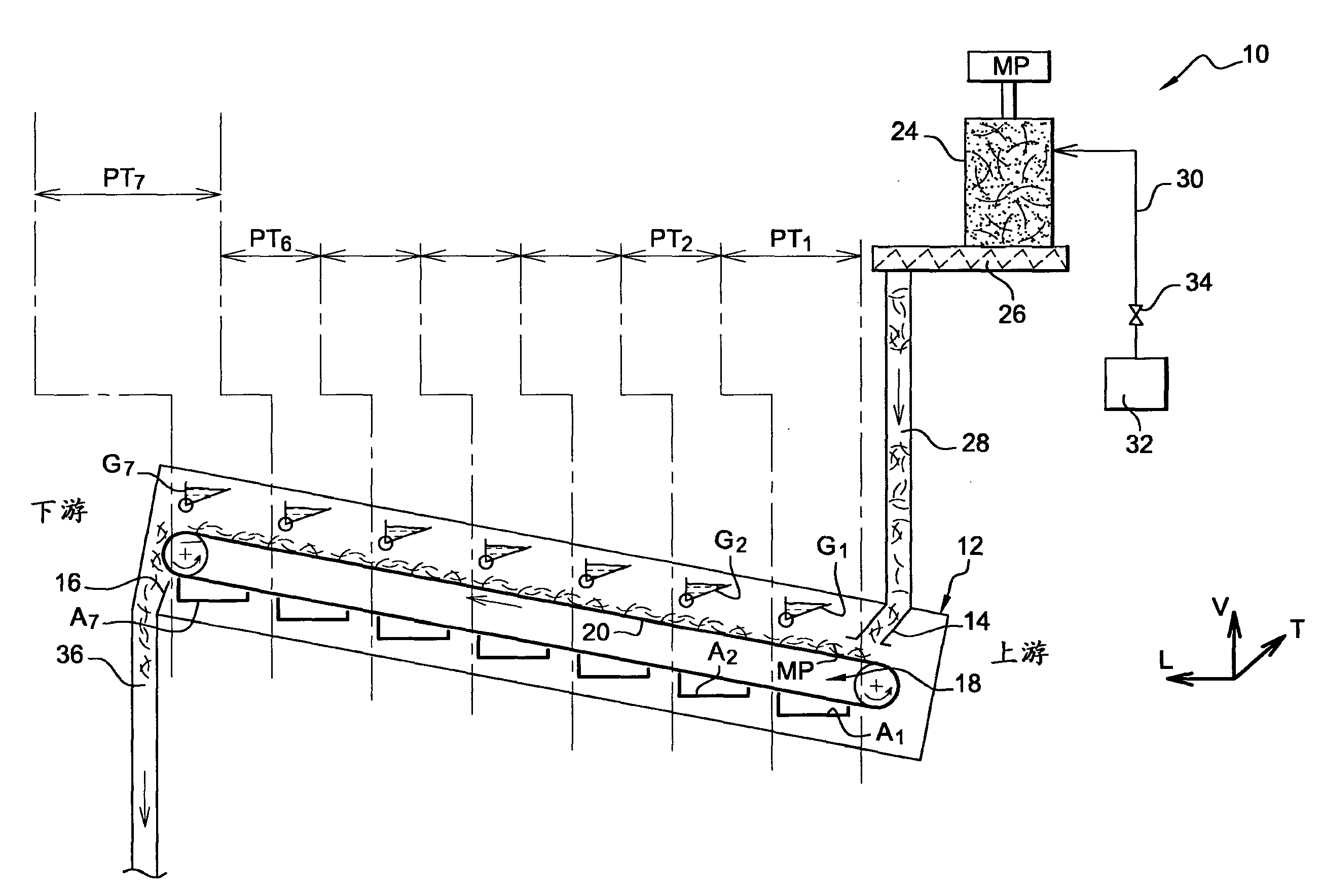

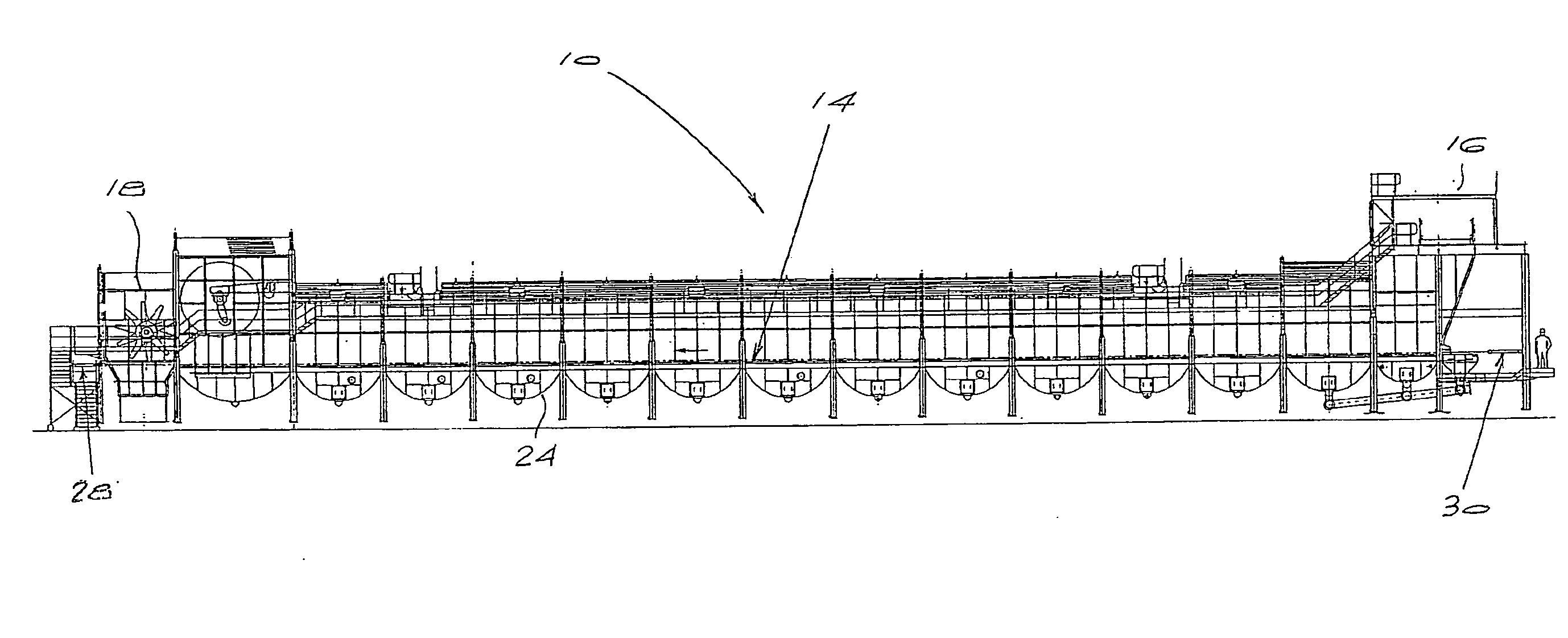

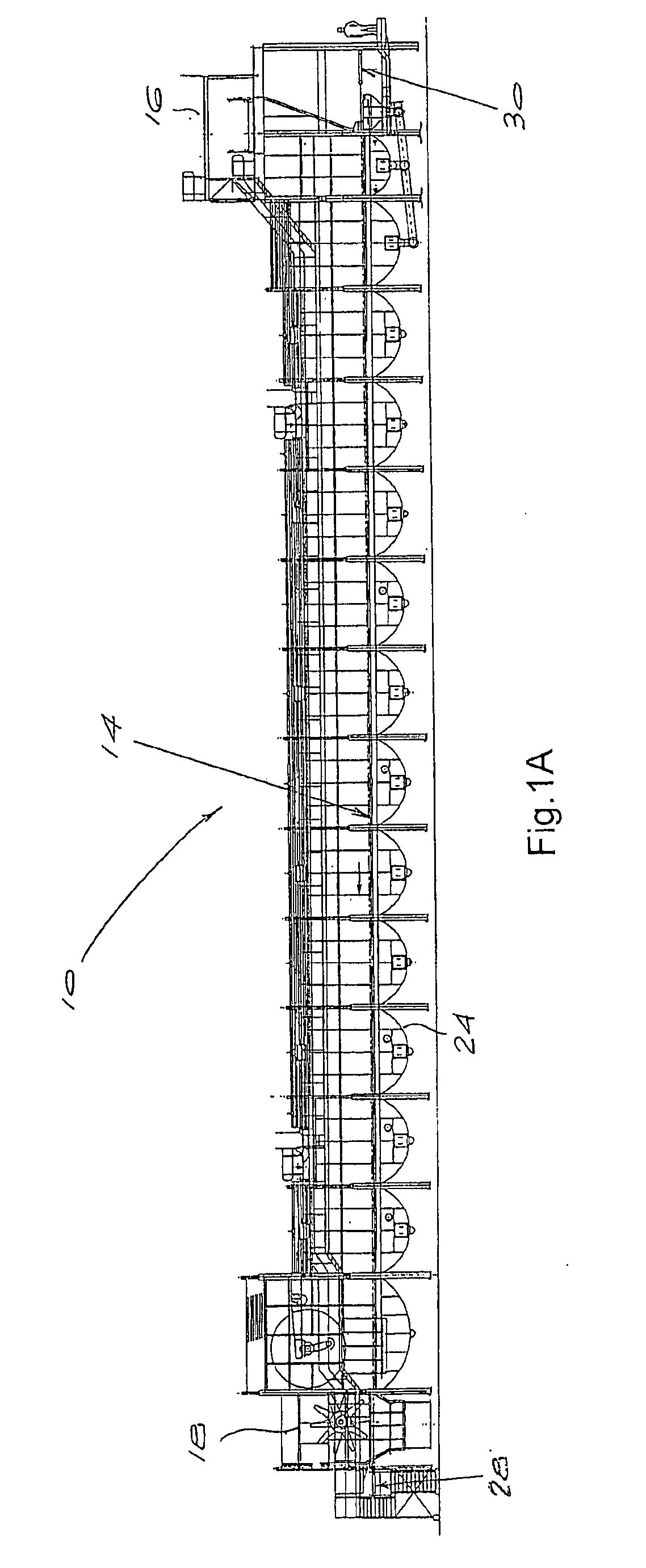

The invention proposes a method for pretreating plant starting material for the purpose of producing bioethanol and / or sugar by means of a common chamber (12), characterized in that: -during one period, the plant material (MP), introduced into the common pretreatment chamber, is a lignocellulosic plant starting material, the pretreatment of which is aimed at separating the cellulose, the hemicelluloses and the lignins so as to obtain a pretreated plant material that canbe hydrolysed and fermented for the production of bioethanol; -during another period, the plant material (MP), introduced into the common pretreatment chamber, is a sacchariferous plant starting material, the pretreatment of which is aimed at extracting therefrom, by diffusion, a sugar juice for the production of sugar and / or of bioethanol.

Owner:CIE IND DE LA MATIERE VEGETALE

Method for producing soft white sugar

The invention belongs to the food industry, and particularly relates to a method for producing soft white sugar, in particular, the method is as follows: beet or sugar cane is processed to obtain diffusion juice, the diffusion juice is filtered to obtain high-purity sugar juice, the high-purity sugar juice is heated in a container evaporating tank for evaporating water, after sugar juice concentration reaches 70-rix, the sugar juice is sent to a crystallization step; concentration is continued to until sugar crystals are precipitated, and solid-liquid separation and cleaning are performed in aseparator; the separated sugar crystals are placed in a screw conveyor, fructose syrup is added, a dryer is used for drying to obtain the soft white sugar, and the drying time is about 7-8 minutes. The method adopts the fructose syrup as invert sugar in the production to improve the production quality of the soft white sugar while reducing the production cost, and brings huge market benefits to aproduction enterprise.

Owner:内蒙古佰惠生新农业科技股份有限公司 +1

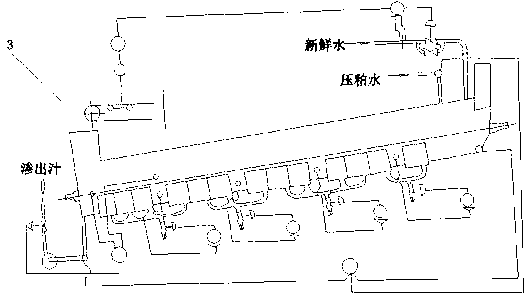

Method and apparatus for transporting a product within a diffuser

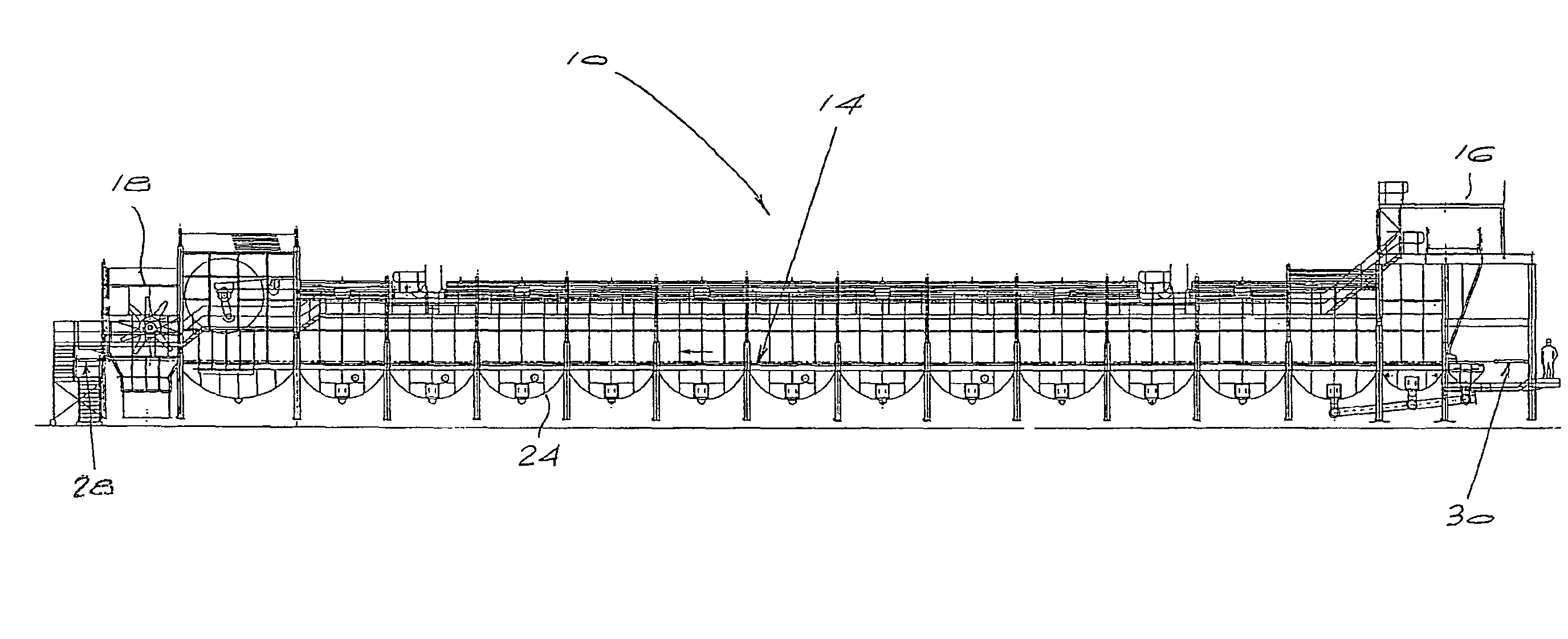

A method and apparatus for transporting a product within a diffuser during a continuous lixiviation process. The apparatus comprises at least one screen deck for the continuous lixiviation process and at least one longitudinal transport zone, the longitudinal transport zone extending between an inlet and outlet of the diffuser. The transport zone may include a plurality of transport zones. A drive means is arranged to move the longitudinal transport zone at a first speed towards the outlet end of the diffuser and to retract the longitudinal transport zone at a second speed which is substantially faster than the first speed towards the inlet end of the diffuser, so that the transport zone drive the product towards the outlet of the diffuser.

Owner:BOSCH PROJECTS

Process for the recovery of water and energy from the processing of sugar cane in sugar and ethanol production mills

ActiveUS8617315B2Reduce consumptionEconomic savingsBio-organic fraction processingOrganic compound preparationThermal energyCooling tower

A process is proposed for recovery of water in the sugar cane processing in production mills of sugar and alcohol or only alcohol (ethanol). In the process, the thermal energy available in the exhausted steam from the electric energy generation turbines is transferred to the different mixed juice processing phases, with the reuse of the exhausted steam condensates in the boilers and of the other condensates, after using thermal energy, for imbibition, in the juice extraction phase, for cooling in the process, after passing through cooling towers, for other industrial uses and for possible treatment or use in the irrigation out of the productive system in the mill.

Owner:DEDINI S A IND DE BASE

Biomass processor

ActiveUS7959736B2Facilitated releaseFacilitates at least partial releasePressurized chemical processSugarcane cuttingFiberBiomedical engineering

A process (10) and apparatus (2) for extracting juice from a fibrous material. The process (10) comprises a step of feeding the fibrous material (13) into a receiving chamber (30) having a fluid contained therein. The fibrous material (13) is then combined with the fluid in the receiving chamber (30) to form a first fluid mixture. The first fluid mixture is then passed through at least one cell disruptor device (40) to facilitate at least partial release of juice from the fibrous material into the first fluid mixture, thereby forming a second fluid mixture having a relatively higher released juice content than said first fluid mixture with relatively finely disrupted fibrous material suspended therein. The second fluid mixture is then collected.

Owner:BIOMASS TECH PTY LTD

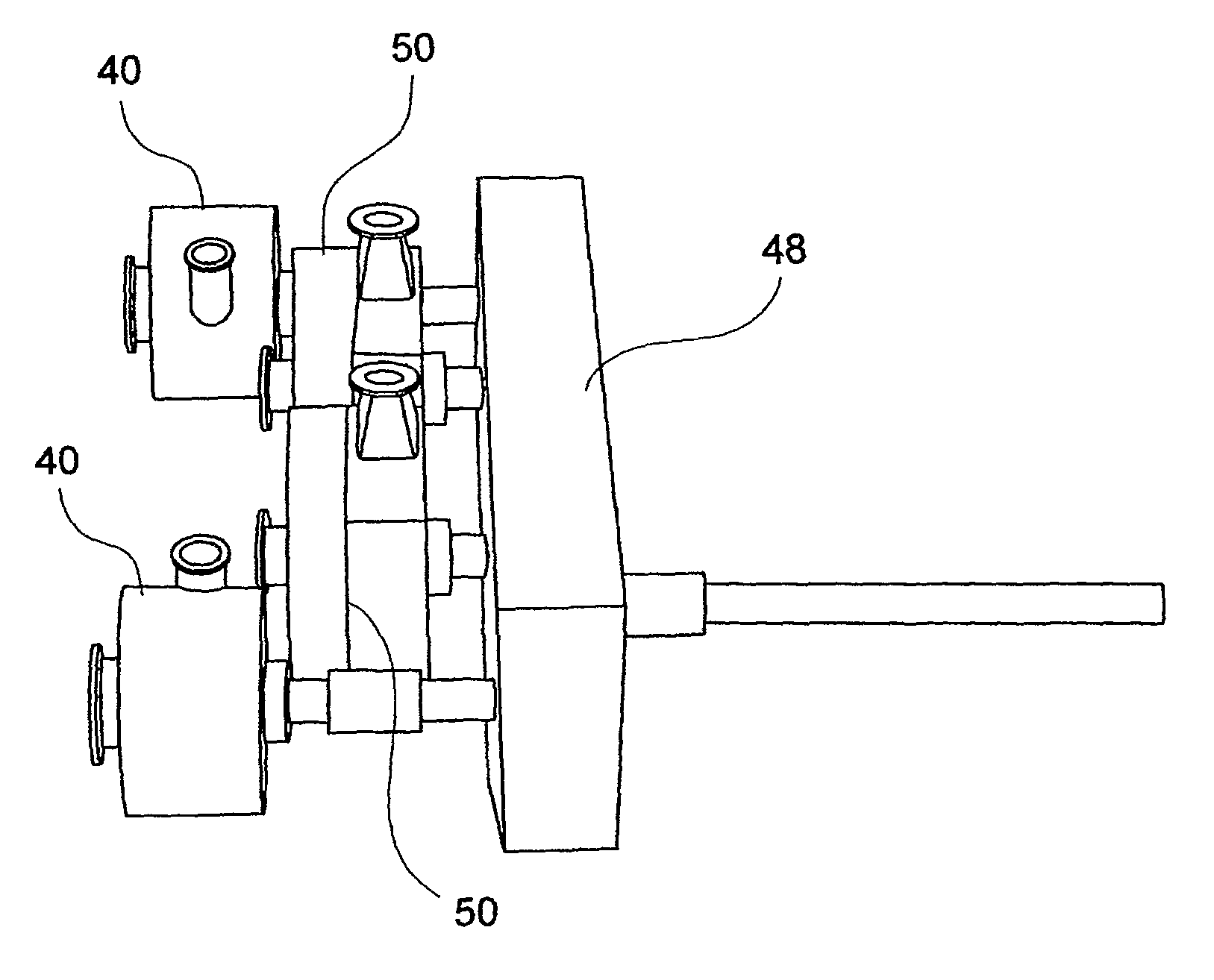

Crushing system with two rotating disk sections and uses thereof

The present invention relates to a crushing system with two rotating disk sections which allows applying high pressures without the problem of raw material rejection and with a reduced number of crushing cycles, thus shortening the crushing time. Pressure is gradually distributed between the two similar rotating disk sections which are arranged face to face and connected to non-aligned shafts, such that the lower sides of the disk sections remain always joined. The disk section mounting assembly is independent and has different features, forming a fixed part and a movable part for adjusting the vegetable mass being compacted. This crushing system has structural features that allow different uses (in isolation, in tandem or in combination), and the serial combination thereof in appropriate industrial infrastructures or in harvesters of standing crops, such as sugar cane.

Owner:A・L・科拉迪 +2

Agricultural extraction products and processes

InactiveUS7074252B2Useful biocidal propertyFatty oils/acids recovery from wasteBiocideHigh sodiumFish oil

The inventive developments disclosed in this application include the following features and combinations thereof: extracting oil from spent bleaching earths for animal feed; using earths and acid water as soil amendment / fertilizer; efficient extraction of substances valuable to plants, animals, and humans from plant, animal, and fish oil soapstock, especially using the “interphase” emulsion from soapstock acidulation; use of “black paste” from oil refining as fertilizer component (nutrient source); use of interphase from agricultural oil refining, especially refining of non-degummed oils, as animal feed; use of “oil refining by-products to fertilizers” process and / or KOH refining in conjunction with “Miscella”-type hexane refining or “Zenith” process refining; fertilizers containing silica / silicates from by-products of agricultural oil refining; use of higher-sodium oil refining by-products as fertilizer for sodium-tolerant plants; using by-products of sugar beet refining as nutrient source; agriculturally useful potassium soaps from oil refining; products of the refining of non-degummed agricultural oils having useful biocidal or other biological properties; the use, as a feed additive, of potassium soapstock from the caustic refining of agricultural oils using a potassium caustic (KOH), especially with non-degummed oils, which has unexpected advantages over the use of soapstock from sodium caustic (NaOH) refining, especially from degummed oils.

Owner:DANIELS AGROSCI

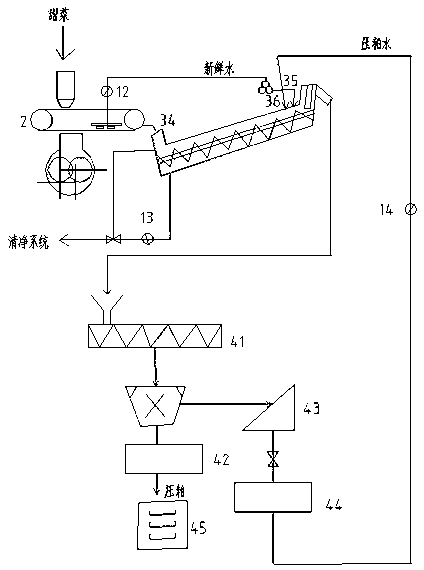

Low-frequency high-energy ultrasonic-coupled fluidized beet-exudating method and device

ActiveCN103014182AChange physical and chemical propertiesFast and efficient exudation processEnergy based chemical/physical/physico-chemical processesSugar extraction from sugar beetUltrasonic sensorFluidized bed

The invention discloses a low-frequency high-energy ultrasonic-coupled fluidized beet-exudating method and device. Three or more large-amplitude ultrasound transducers are assembled into a group and sealed inside a box body to manufacture a plate-type immersed ultrasonic extracting device, wherein the plate-type immersed ultrasonic extracting device resonates at the same frequency to form a single-sided radiator so as to achieve a quick and efficient exudating process. The method and the device can shorten the exudating time and reduce the water consumption and the workload of an evaporating working section, thus reducing the coal consumption and the steam consumption and achieving aims of saving energy, protecting environment and improving the production efficiency.

Owner:SOUTH CHINA UNIV OF TECH

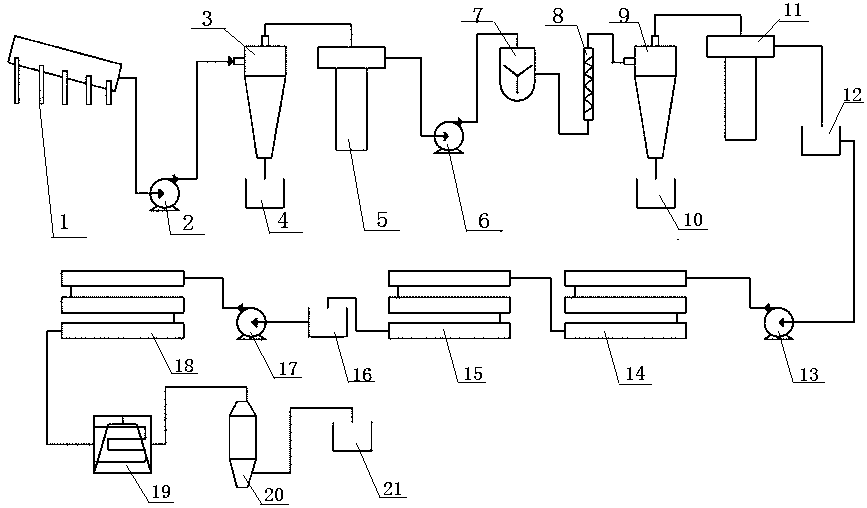

System and technology for continuous film production of beet sugar

ActiveCN109355440AImprove concentration efficiencyReduce chromaSugar crystallisationPurification by physical meansUltrafiltrationReverse osmosis

The invention relates to a system and technology for continuous film production of beet sugar and belongs to the field of sugar making. The system comprises a juice penetration device (1), a liquid rotation device I (3), a high-frequency vibration sieve I (5), a mixer (7), a static mixer (8), a liquid rotation device II (9), a high-frequency vibration sieve II (11), an ultrafiltration membrane (14), a nanofiltration membrane (15), a reverse osmosis membrane unit (18), an evaporator (19) and a crystallizer (20). According to the system for continuous film production of the beet sugar, intelligent continuous operation is achieved, the step of cleaning lime is omitted, and environmental pollution is not caused. Compared with clear juice in the prior art, the sugar degree of the obtained pre-concentrated juice is increased by 10-16 wt%, and the evaporation load can be lowered by 60-70% through increase of the sugar degree; the efficiency is improved, and the cost is lowered.

Owner:四川绿沃创新环保工程有限公司

Sugar production method

InactiveCN101400807APurification using alkaline earth metal compoundsSugar extraction from sugar beetNitrogenSlurry

The inventive method consists in forming nonsucrose precipitates during a sucrose extraction process in a diffuser by binding nitrogen-containing and nonnitrogenous high-molecular nonsucroses and colloidal dispersion agents, deposing nonsucrose precipitates on beet cossets and in removing them from a diffusion juice with a beet pulp, aggregating nonsucrose dispersed particles in the diffusion juice neutral-acid medium, flocculating said particles and removing them together with a precipitate by filtering or separating, defecating a filtrate, coagulating and flocculating a defecated juice nonsucroses in an alkaline medium, separating the precipitate, neutralising the purified juice, thickening it and in boiling a fillmass. The method uses in said production process the synergism of the interaction of inorganic coagulants of metal salts solutions and organic flocculants of synthetic polymers, thereby making it possible to substantially improve the purity of sugar-containing solutions and to reduce a production process at a lime / carbon dioxide purification plant.

Owner:阿凡纳希·麦列茨维奇·金姆 +1

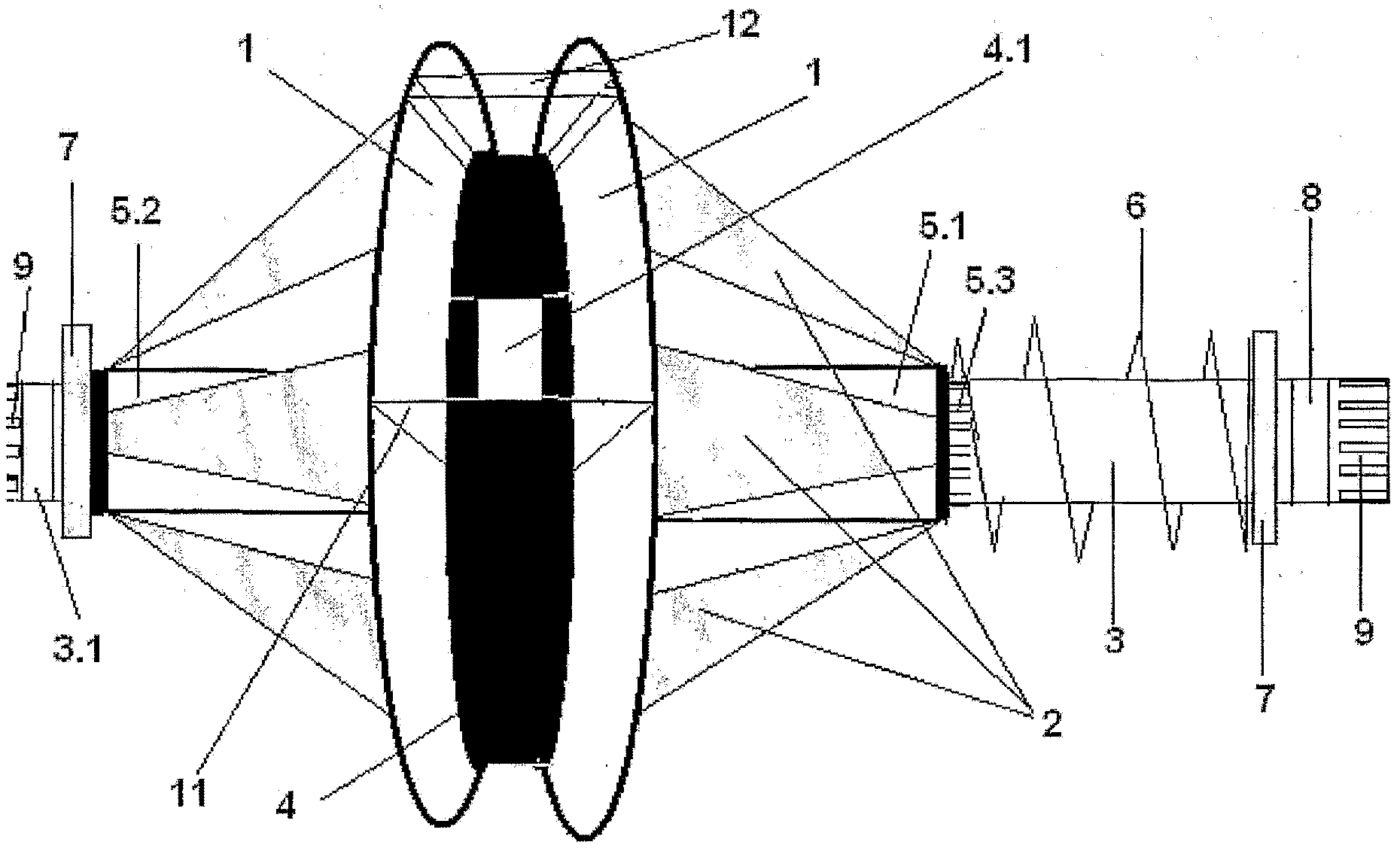

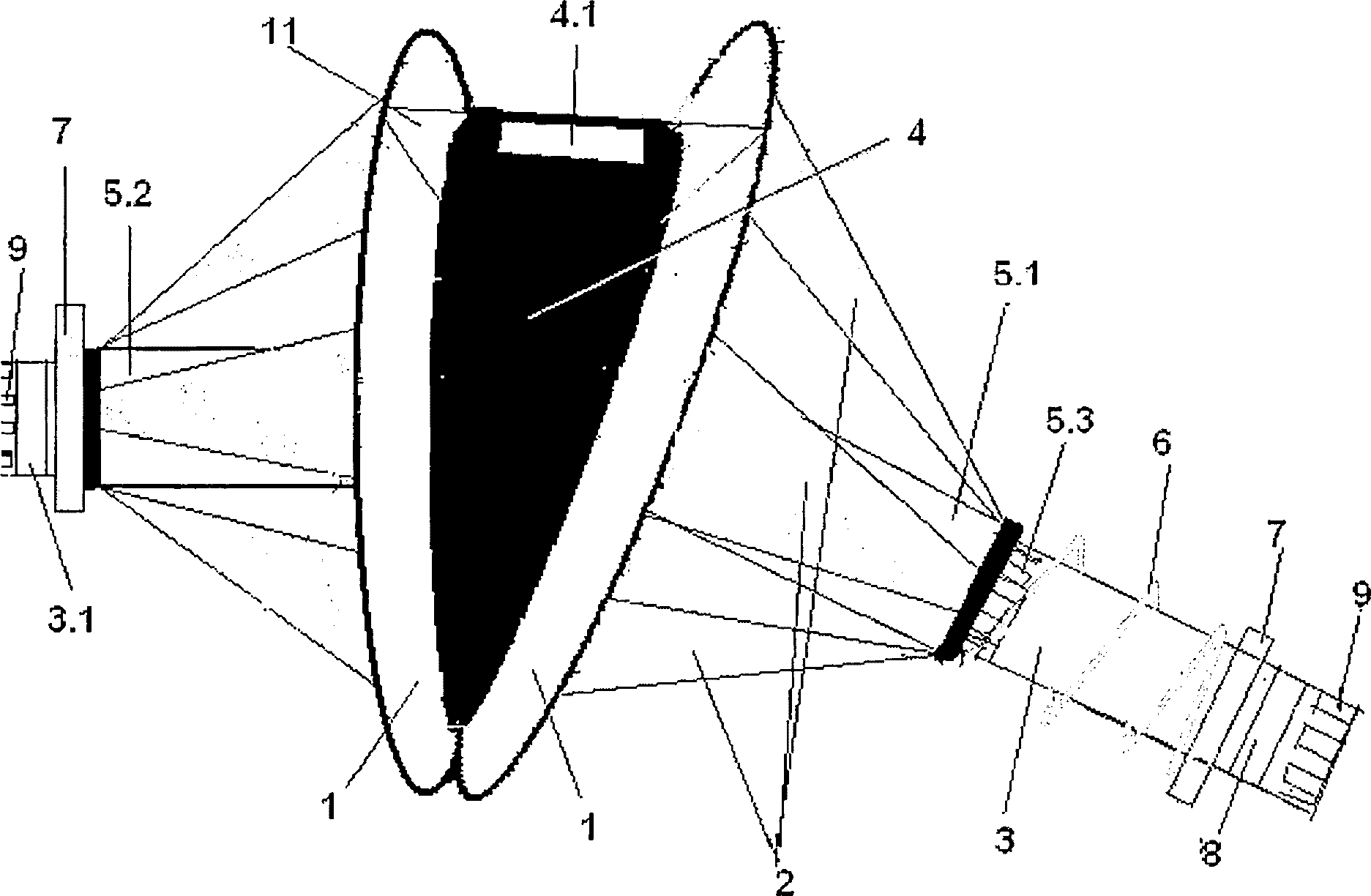

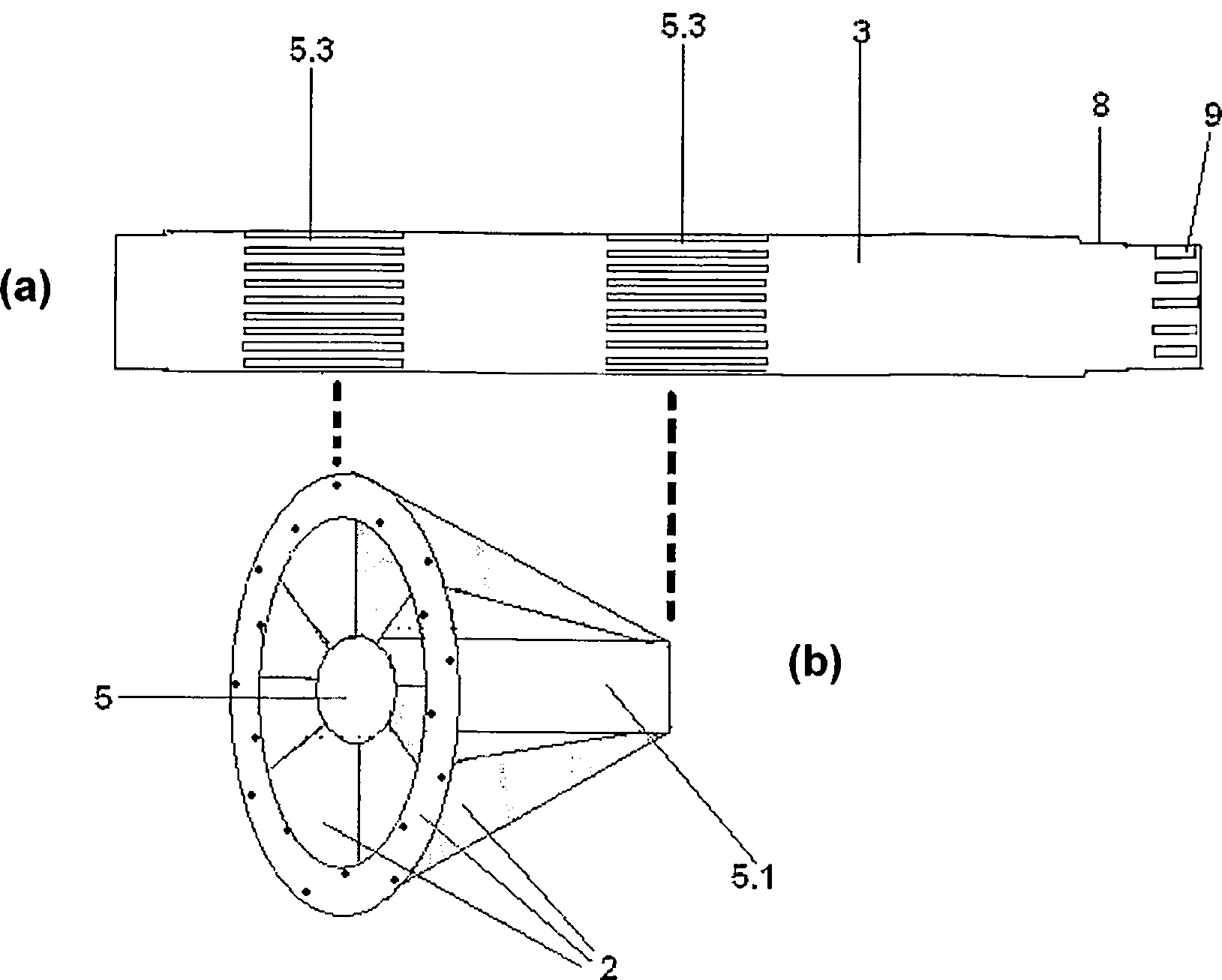

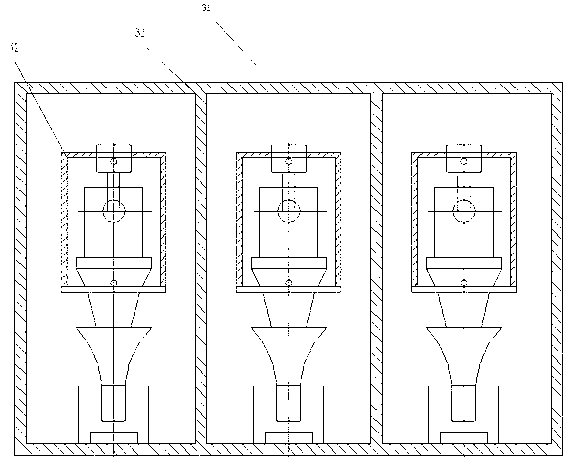

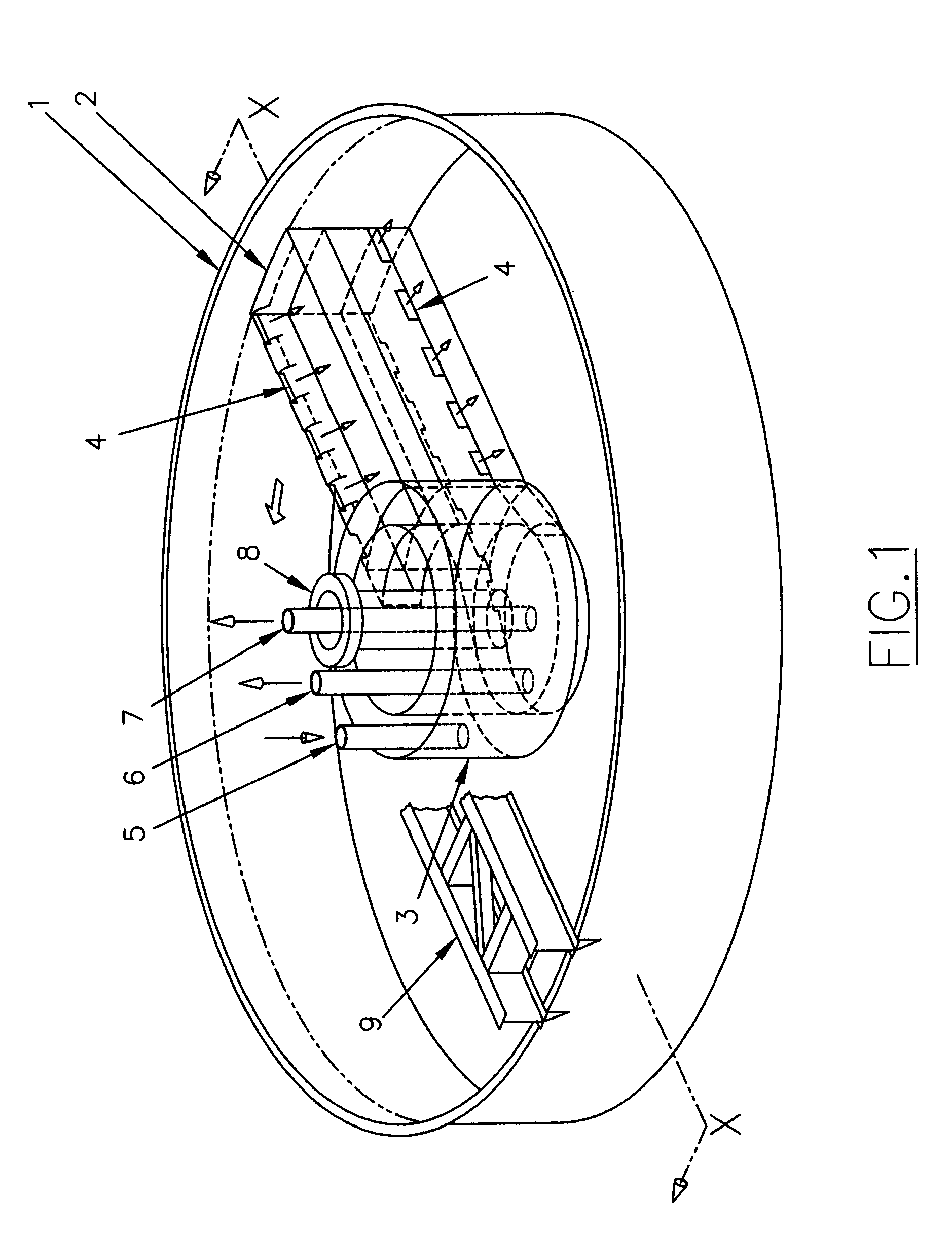

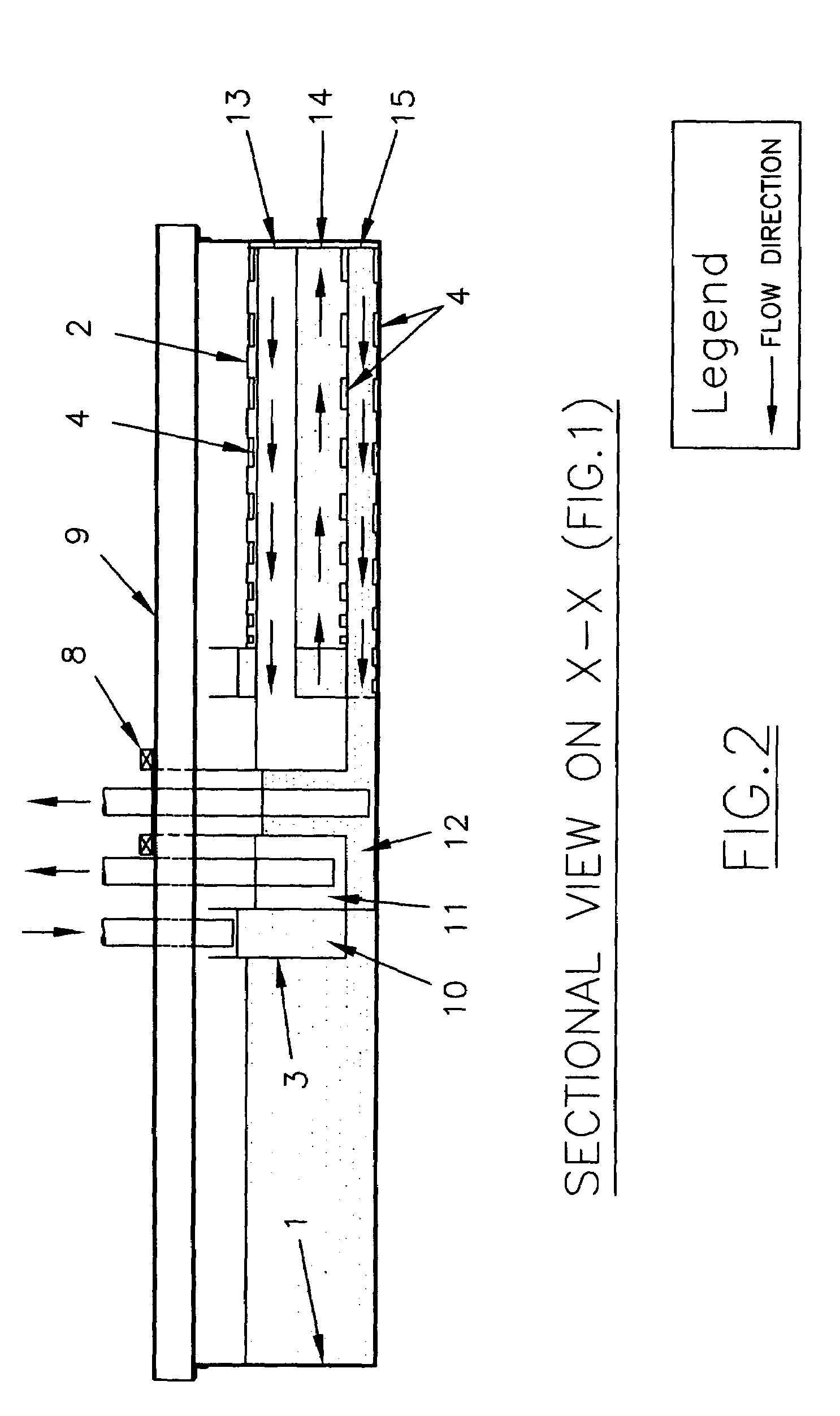

Reactor system for electroporation

ActiveUS9340842B2Better dampeningContributes positivelyBioreactor/fermenter combinationsElectrotherapyReactor systemNuclear engineering

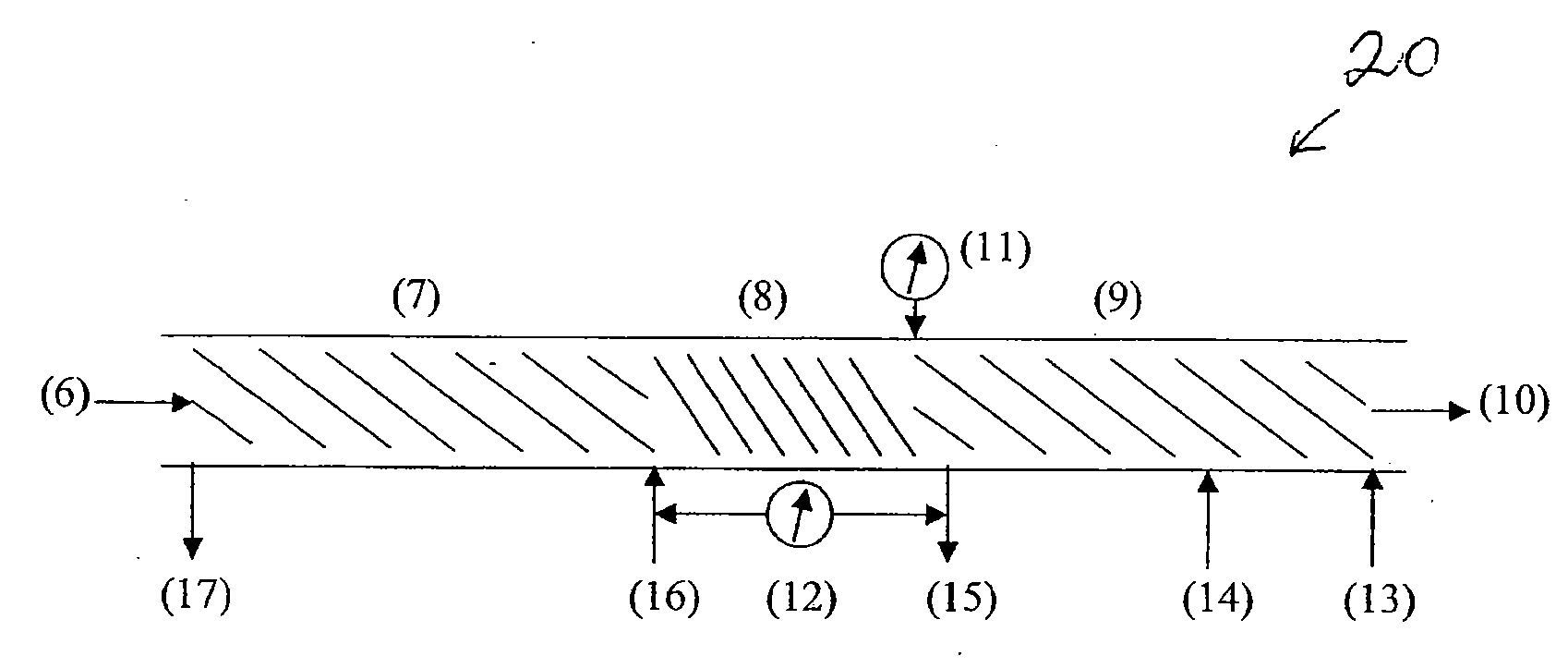

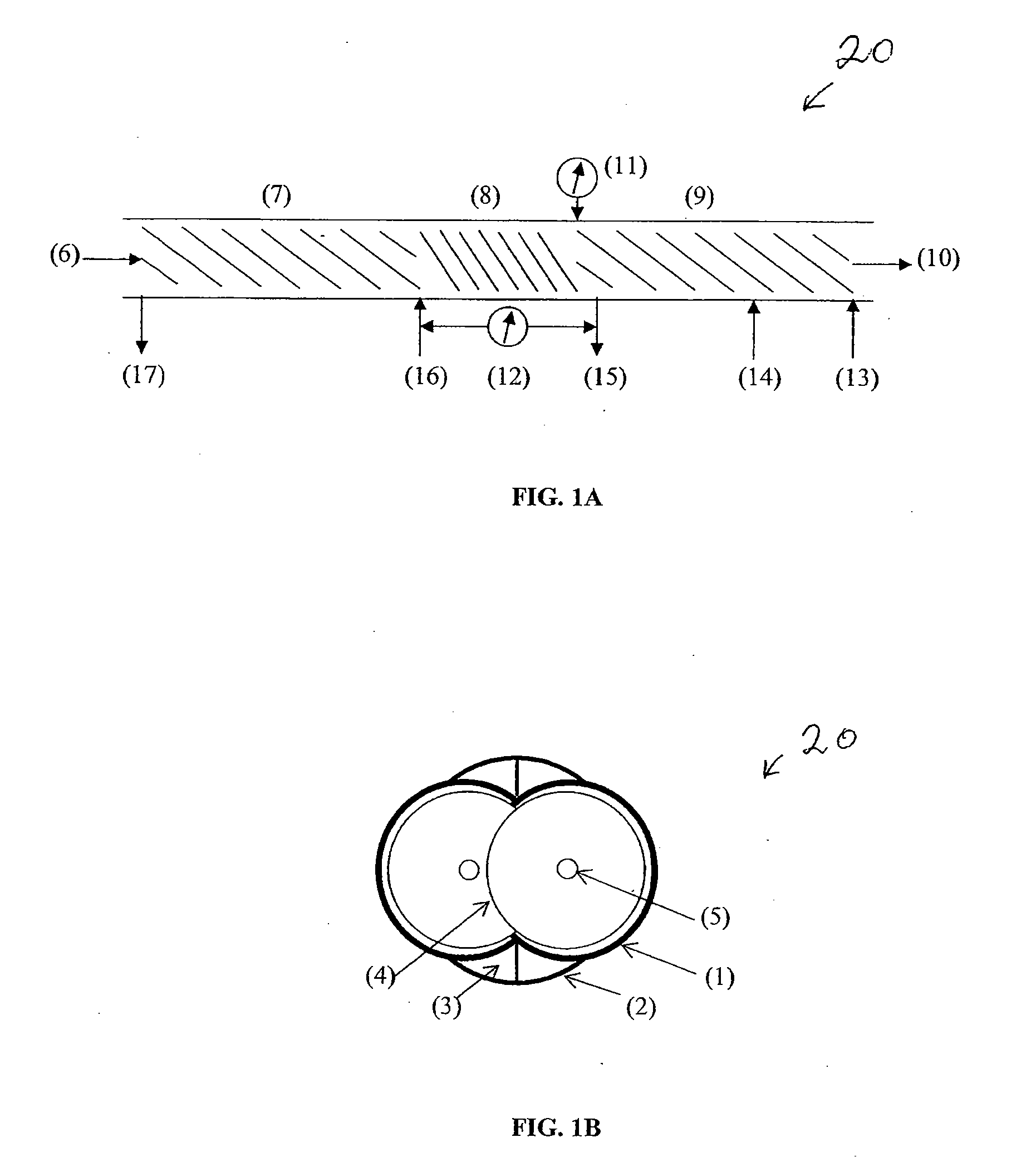

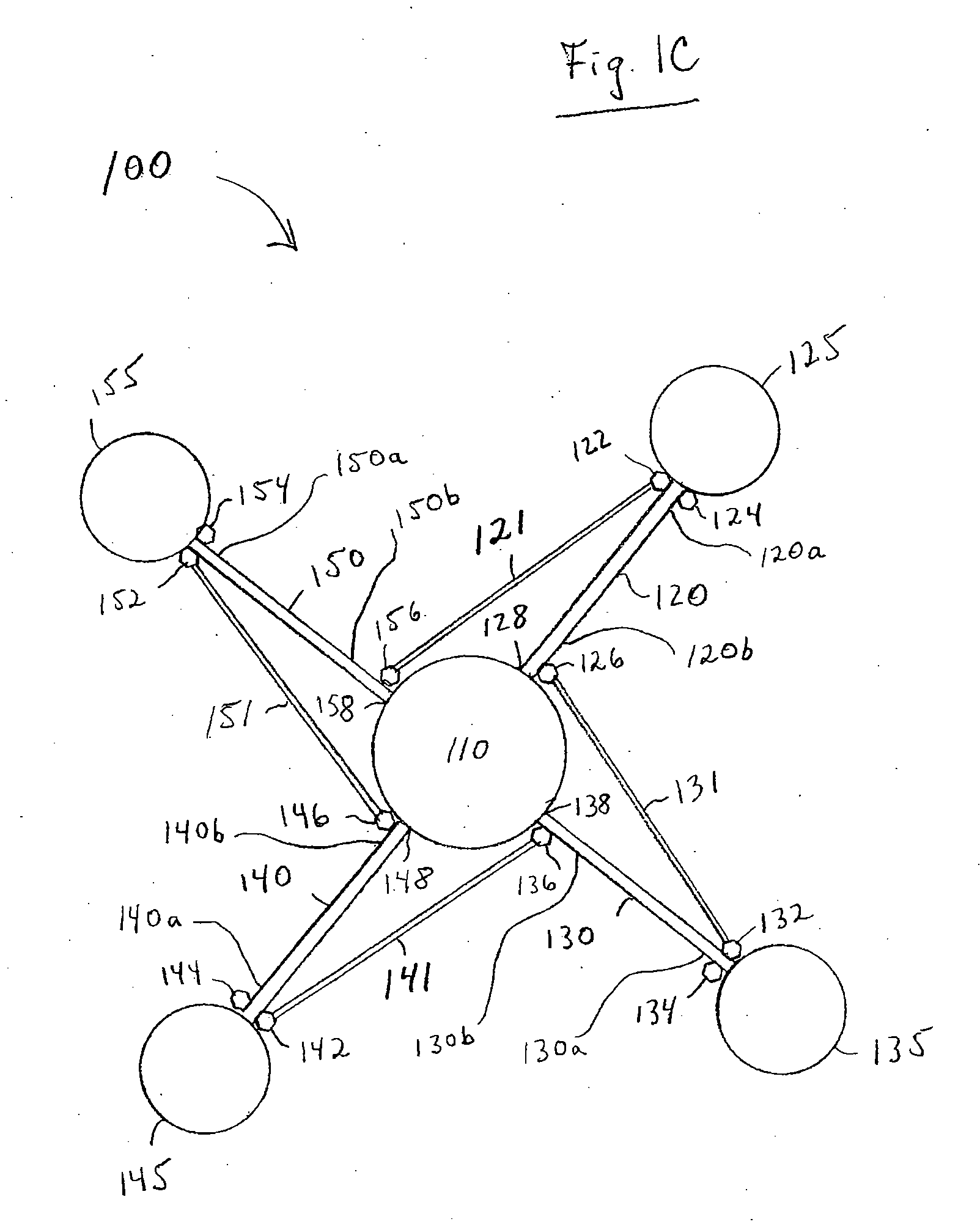

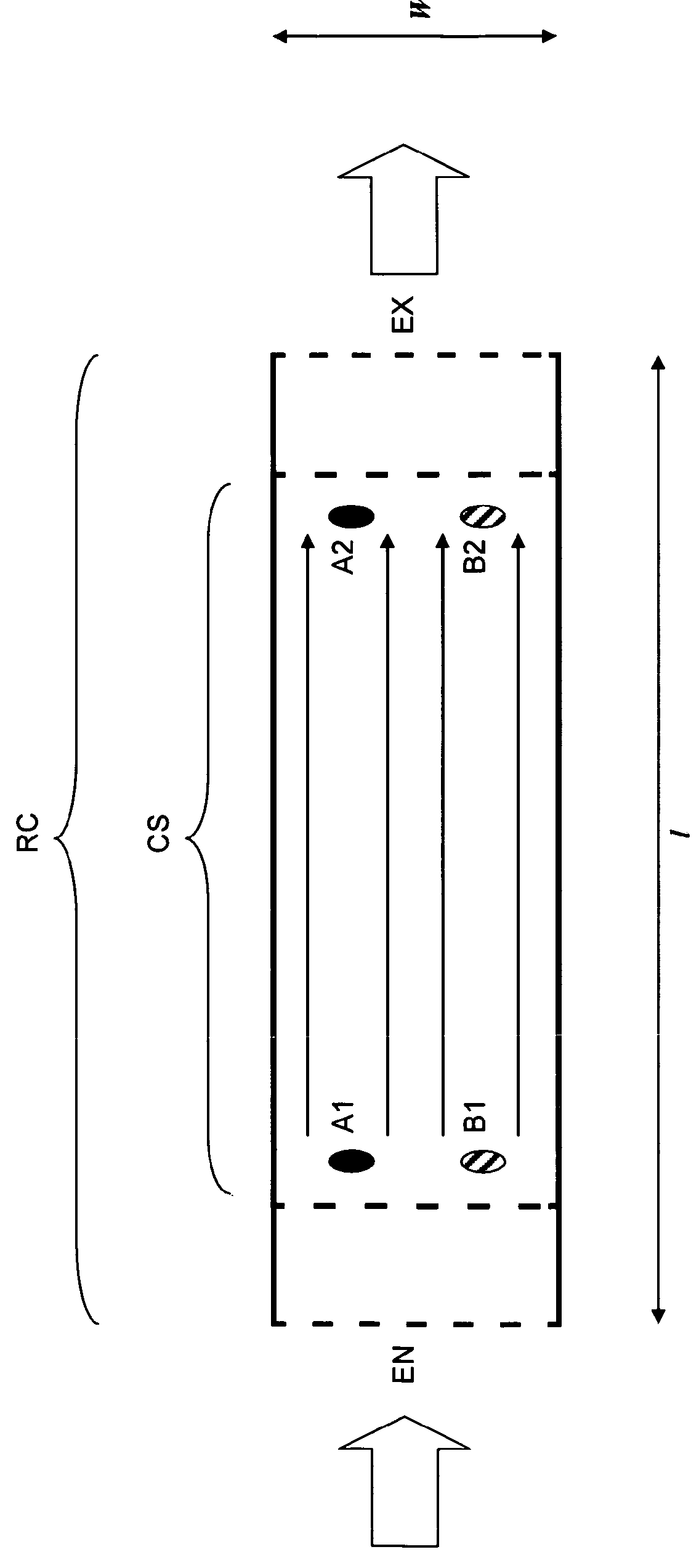

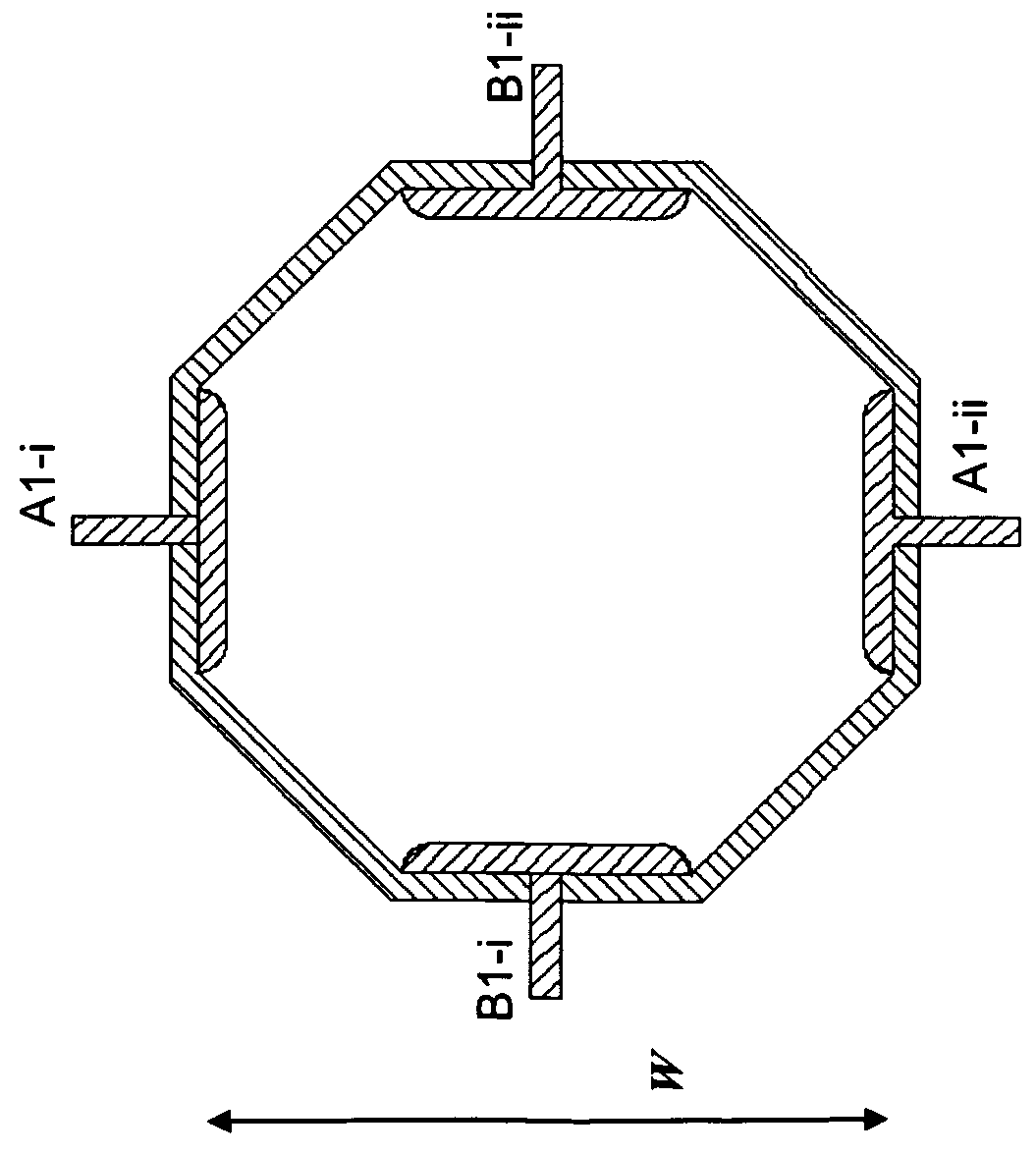

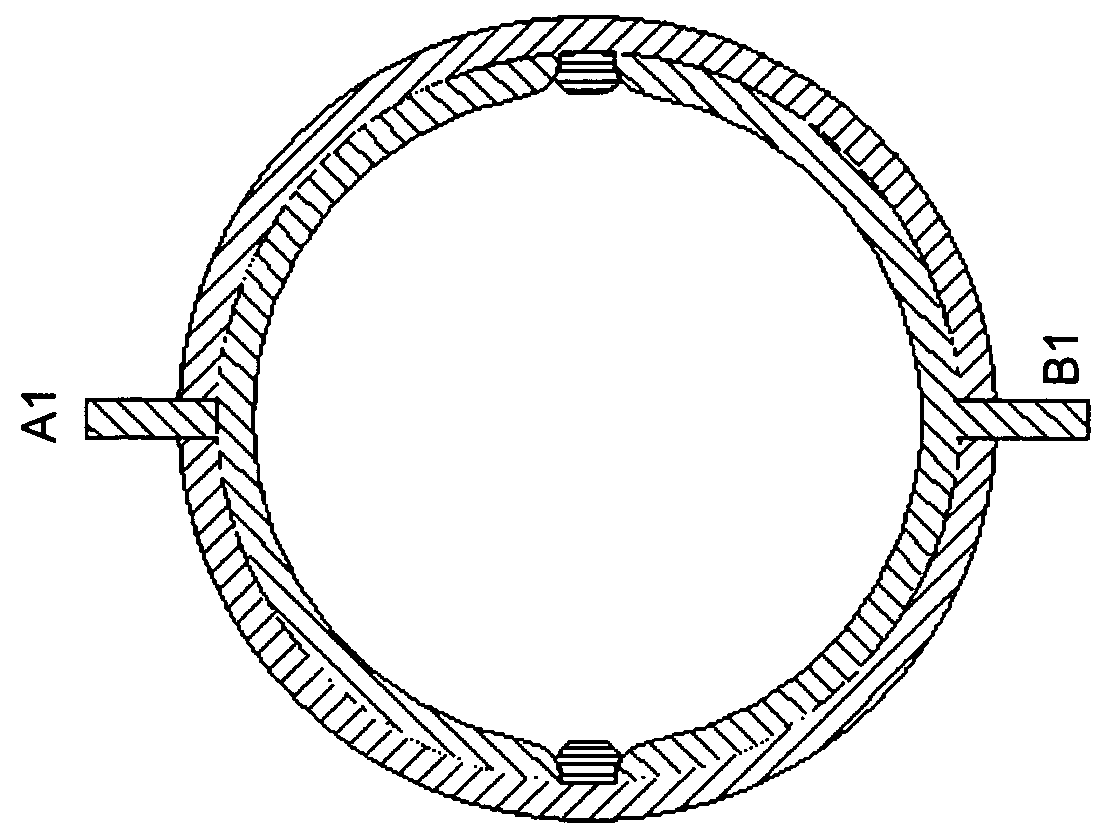

A reactor system, for electroporation includes a reactor chamber having a length and a width, whereby the reactor chamber contains a central section along its length. A first pulse generator to which two electrodes (A1) and (A2) are connected are located in the reactor chamber in the central section of the reactor chamber such that they are, when measured in the length direction of the reactor chamber, at least a distance equalling half the width of the reactor chamber apart. A second pulse generator to which two electrodes (B1) and (B2) are connected are located in the reactor chamber in the central section of the reactor chamber such that they are, when measured in the length direction of the reactor chamber, at least a distance equalling half the width of the reactor chamber apart.

Owner:SUDZUCKER AG MANNHEIM OCHSENFURT

Method and apparatus for transporting a product within a diffuser

A method and apparatus for transporting a product within a diffuser during a continuous lixiviation process. The apparatus comprises at least one screen deck for the continuous lixiviation process and at least one longitudinal transport zone, the longitudinal transport zone extending between an inlet and outlet of the diffuser. The transport zone may include a plurality of transport zones. A drive means is arranged to move the longitudinal transport zone at a first speed towards the outlet end of the diffuser and to retract the longitudinal transport zone at a second speed which is substantially faster than the first speed towards the inlet end of the diffuser, so that the transport zone drive the product towards the outlet of the diffuser.

Owner:BOSCH PROJECTS

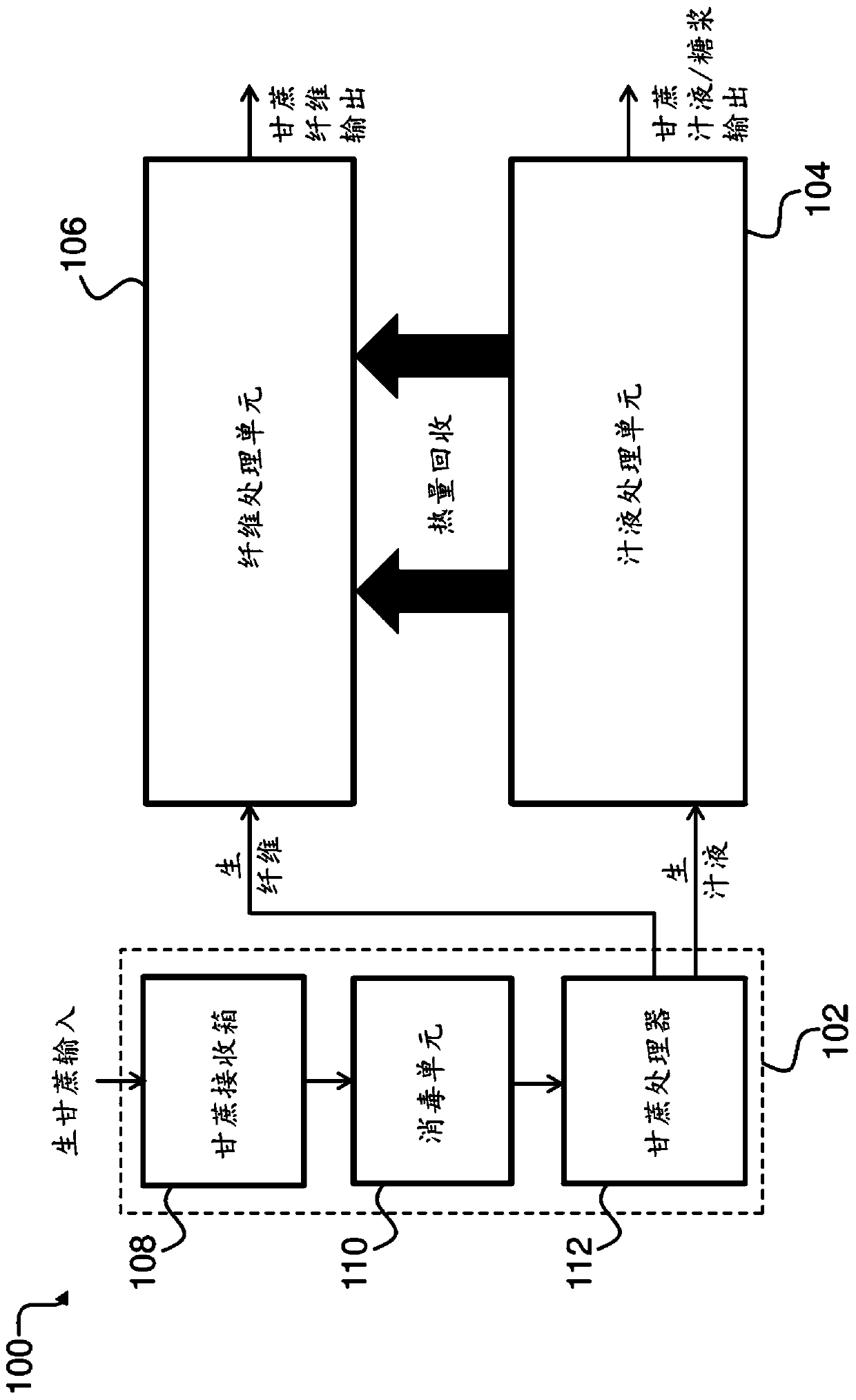

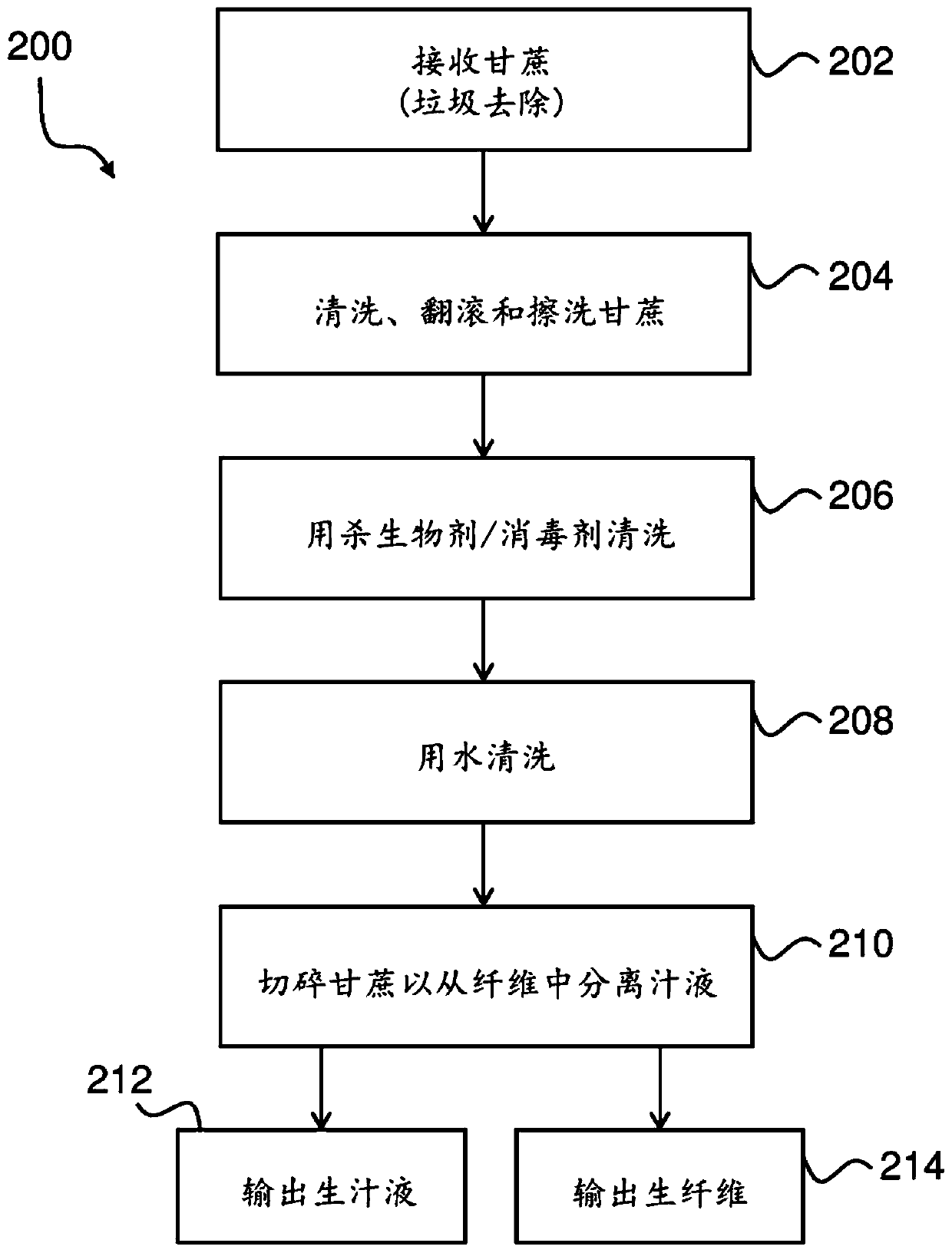

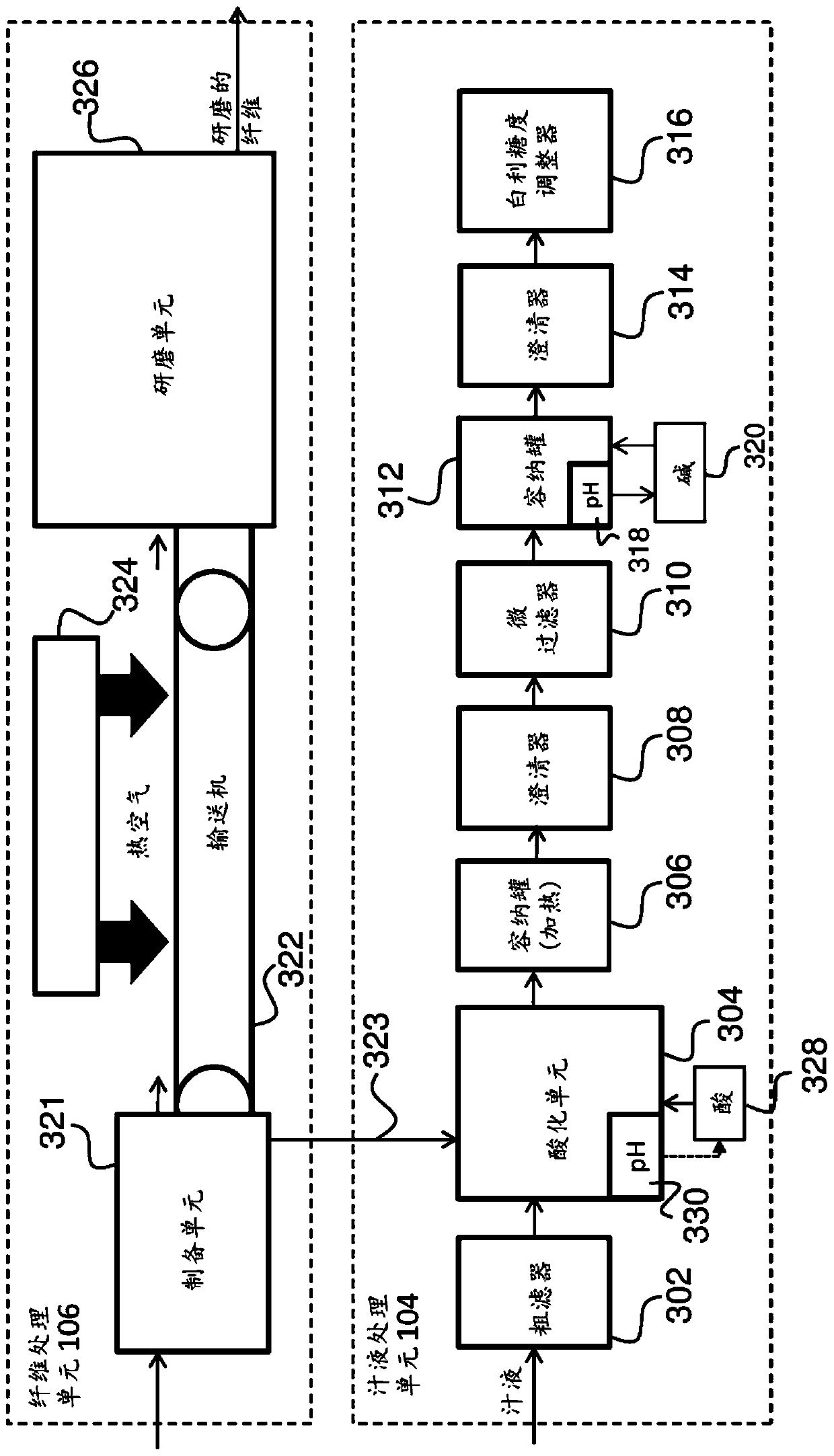

System for and method of processing sugar cane

A method of processing raw sugar cane juice comprises: reducing the pH of the sugar cane juice to a pH at which microbiological activity is substantially eliminated; separating chlorophyll from the sugar cane juice; separating particles having a diameter greater than 0.5 microns from the sugar cane juice; denaturing polyphenol oxidase (PPO) in the sugar cane juice by pasteurisation; separating thedenatured polyphenol oxidase from the sugar cane juice.

Owner:BIOMASS TECH PTY LTD

Technology for enhancing stevia rebaudiana soaking capability by virtue of vibrating screen

InactiveCN107988437AImprove soaking effectAvoid wastingPurification by physical meansSugar extraction from sugar beetLiquid glucoseProcess engineering

The invention discloses a technology for enhancing stevia rebaudiana soaking capability by virtue of a vibrating screen. The technology comprises the following steps: harvesting, soaking, separating and vibrating, flocculating, filtering and adsorbing, separating, concentrating, carrying out refined filtration, drying and sieving. The technology disclosed by the invention has the advantages that one vibrating screen is added after separation, liquid glucose and granule stevia rebaudiana leaves are further separated, the liquid glucose obtained through separation enters a flocculation working procedure, and the obtained granule stevia rebaudiana leaves are fed into a soaking pool to be soaked again, so that the soaking capability of stevia rebaudiana is improved, and resource waste is avoided; and the technology disclosed by the invention is simple, low in equipment requirement and strong in operability and has a good social popularization and application value.

Owner:GANSU WESTSUN FOOD

Sugar juice clarifier apparatus

InactiveUS7160394B2Short retention timePressurized chemical processJuice extractionJuice clarificationRetention time

An apparatus for the continuous process of raw mixed sugar juice clarification by means of the settlement of insoluble particles and juice precipitate in a cylindrical clarifier tank that permits non-turbulent vertical subsidation and short retention time of the sugar juice in a relatively large, non-turbulent settling sector of the contents of the cylindrical clarifier tank which is maintained by the continuous rotary advancement of the raw mixed sugar juice entry and clear sugar juice and precipitate extraction station arm that rotates within and around the center of the annular shaped cylindrical clarifier tank. The rotating arm has three internal radial compartments which provide for the introduction of raw mixed sugar juice and the extraction of clear sugar juice and precipitate, in and out of the annular clarifier tank in the immediate vicinity of the respective leading and trailing faces of the rotating arm, through adjustable slots on the leading and trailing faces of the arm.

Owner:WRIGHT RICHARD WILFRED

Methods of microbiological control in beet sugar and other sugar-containing plant material processing

Methods are described for producing sugar from sugar-containing plant material with microbiological control, which includes treating a sugar-containing plant raw material and / or a component derived therefrom, and / or a medium containing the plant raw material and / or the component, with monochloramine. Monochloramine usage in the method can reduce loss of sugar from bacterial consumptions in the processing of sugar-containing plant materials, such as sugar beets, without causing adverse effects on the sugar product, such as the brightness of white sugar.

Owner:BUCKMAN LAB INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com