System for and method of processing sugar cane

A technology of sugarcane, sugarcane juice, applied in the field of raw sugarcane processing, which can solve the problems of delay, discoloration of sugarcane juice, reduction of final product quality and health benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

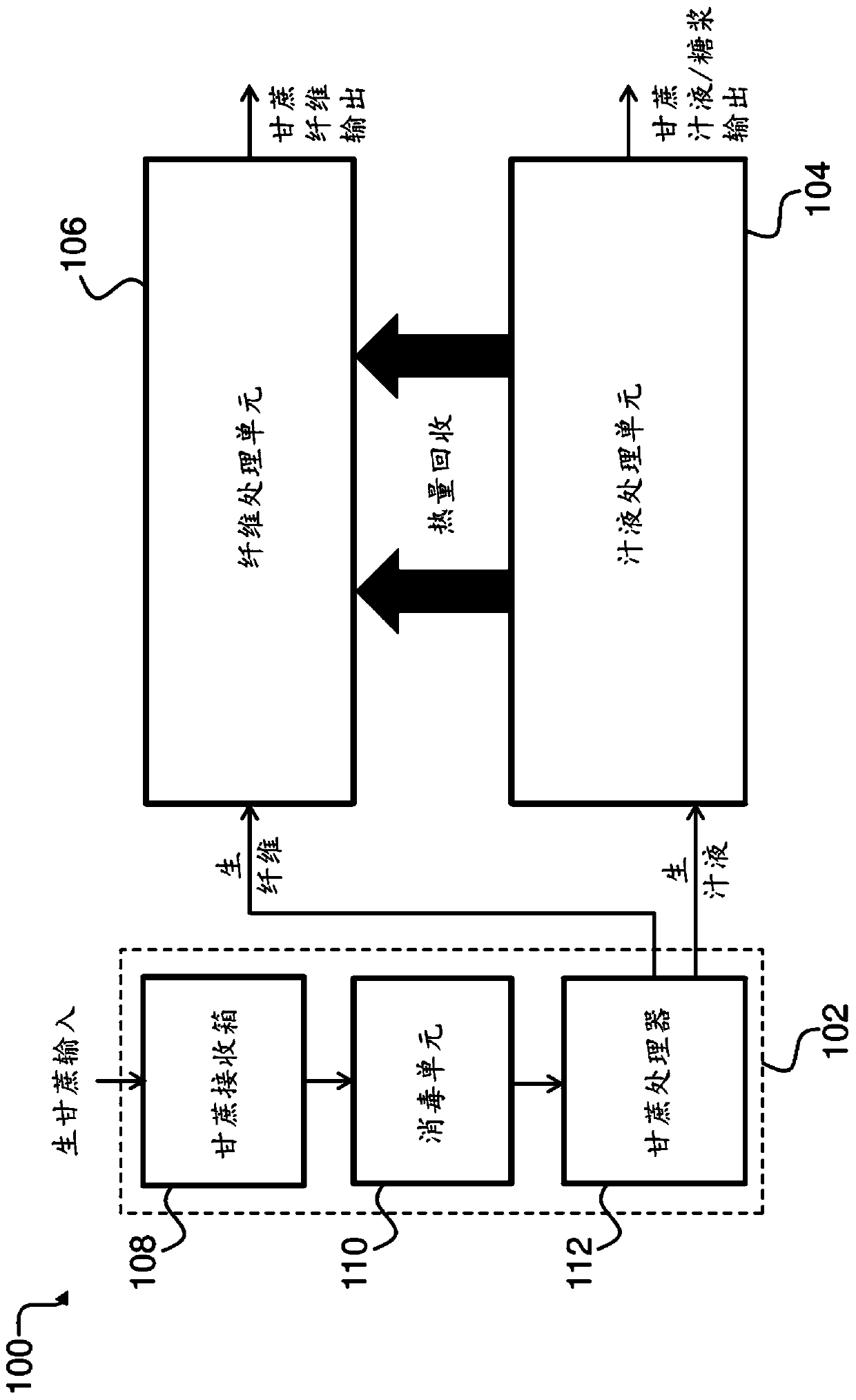

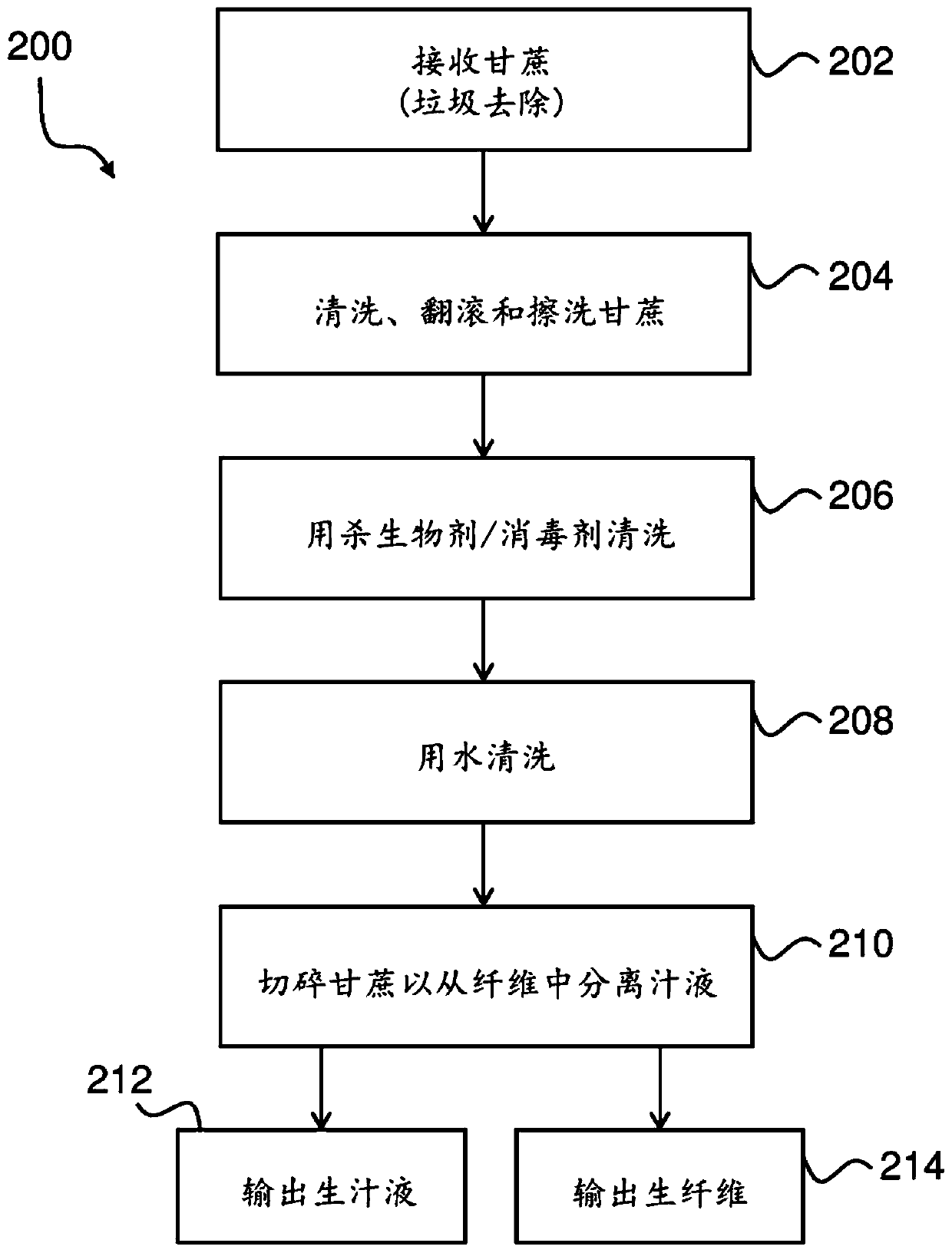

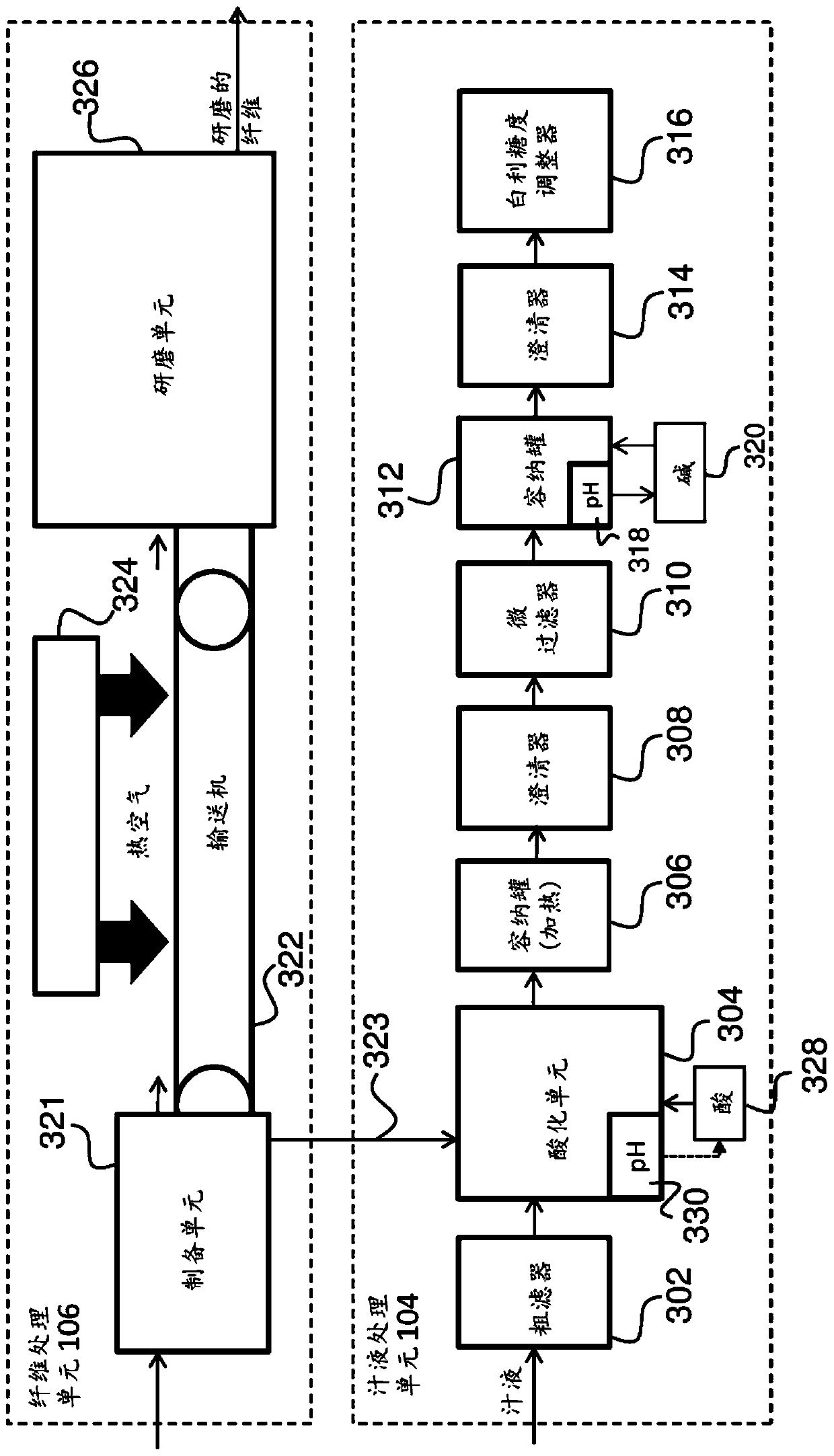

[0073] The embodiments of the present disclosure cover the whole process method of sugarcane juice and fiber production, which can realize the efficient conversion of freshly cut sugarcane into food-grade stable sugarcane juice, syrup and powder, thereby maximizing the preservation of vitamins and sugars present in sugarcane products. Mineral levels. The embodiments described herein can help increase the efficiency of processing sugarcane in a microbiologically controlled environment with little or no loss of health-promoting compounds in the final product.

[0074] For example, the inventors have developed a two-stage process that includes a separate juice clarification step. In the first clarification step, cellulose and chlorophyll are aggregated and removed from the juice. In the second clarification step, polyphenol oxidase (PPO) is removed from the juice. By inactivating chlorophyll and PPO during the removal process, enzymatic browning is substantially eliminated. The o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com