Crushing system with two rotating disk sections and uses thereof

A technology of grinding and disc, applied in the direction of application, extracting juice from sugar cane, leaching sugar from sugar beet, etc., can solve the problems of loss of liquid extraction efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

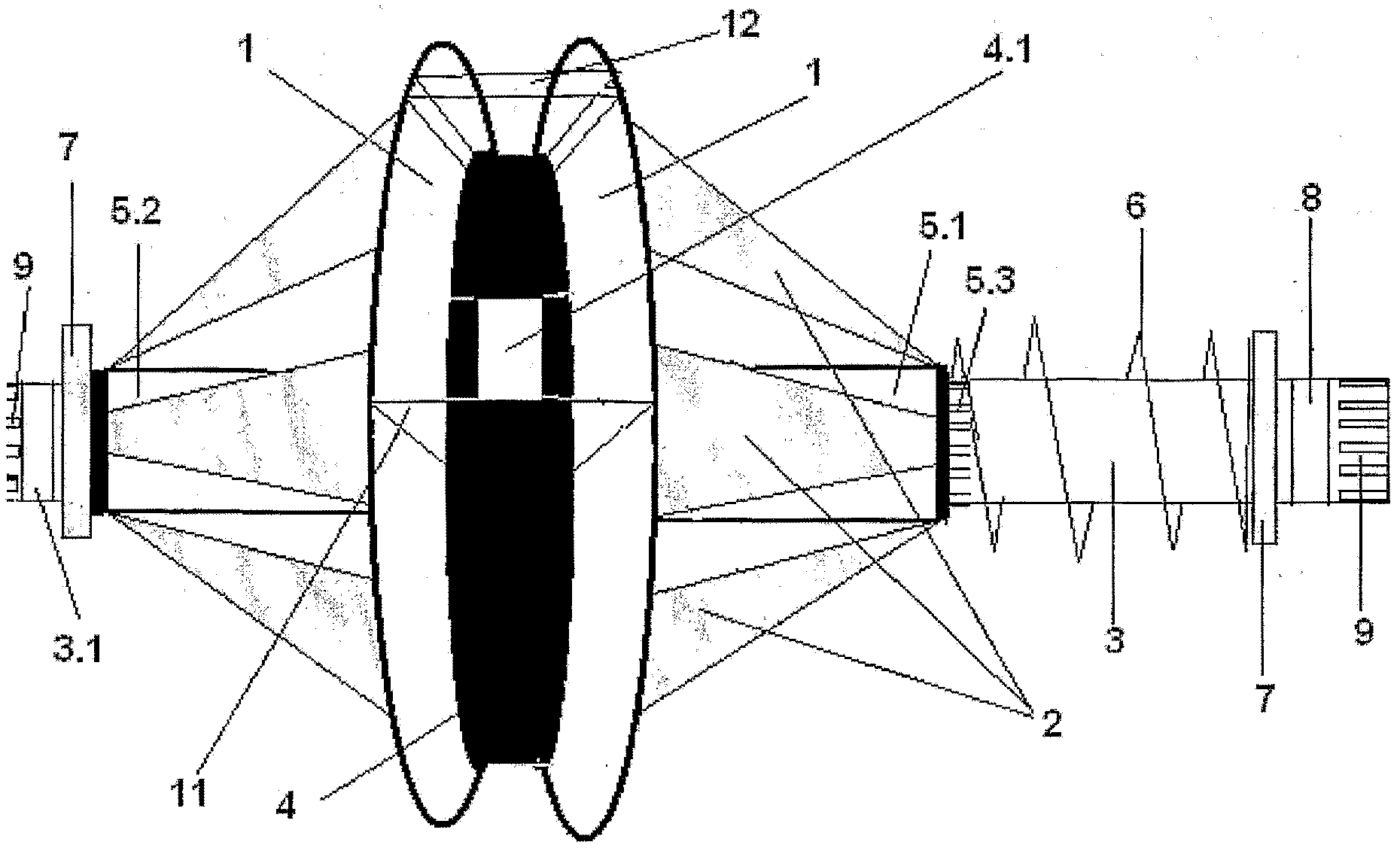

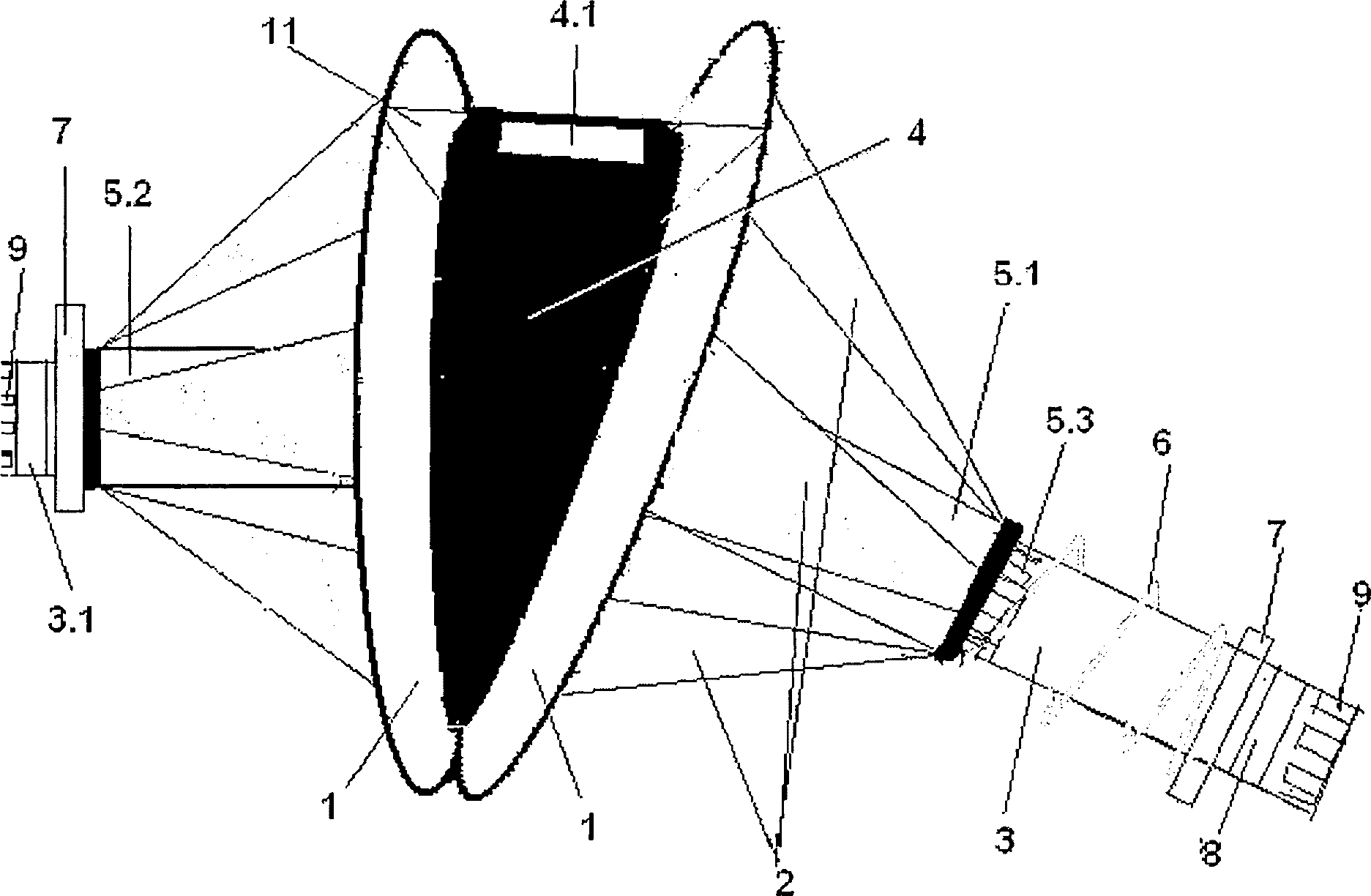

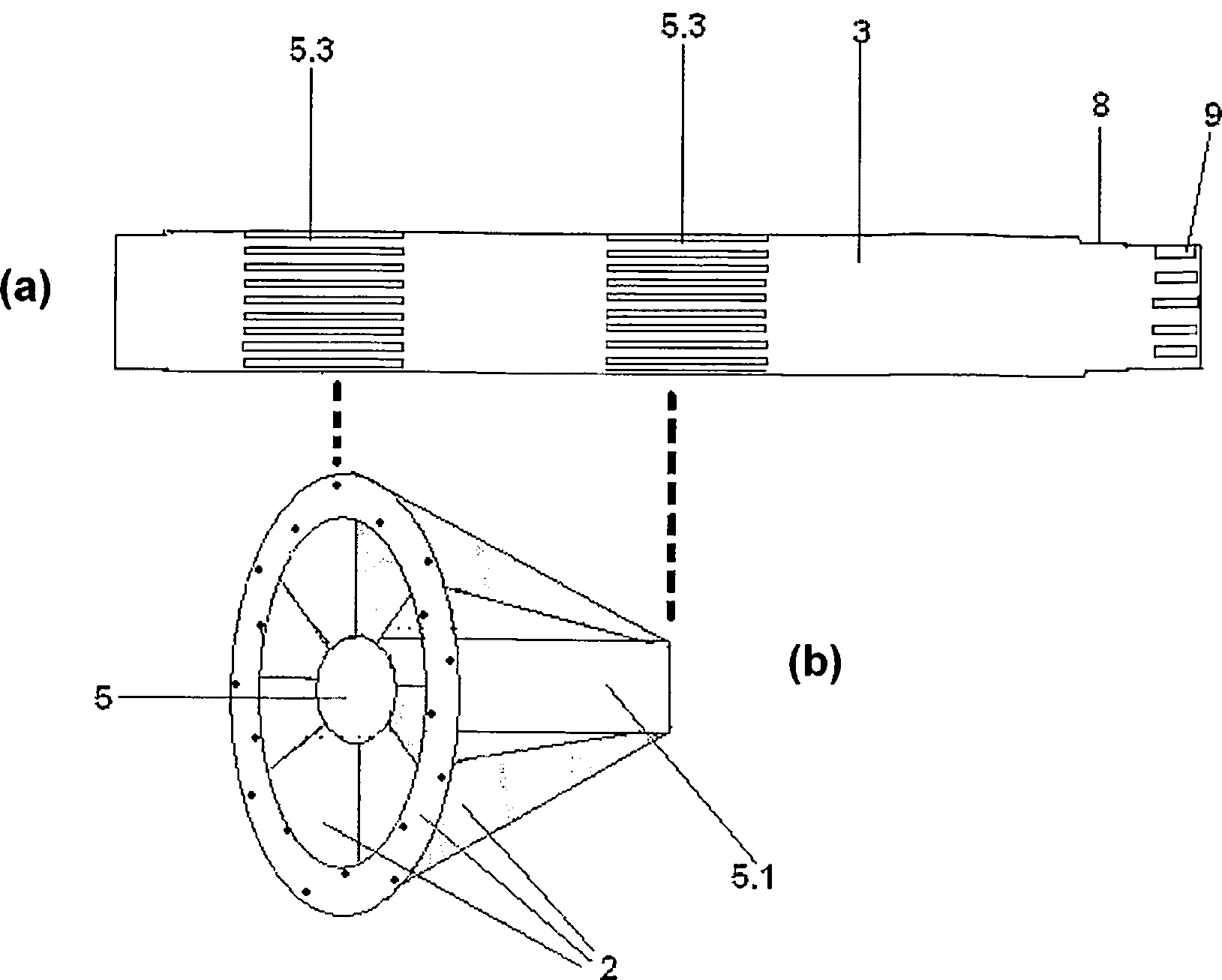

[0031] This example relates to the implementation of a milling system primarily for milling sugar cane using compression, which has two rotating disc sections with only one inclined axis. This tilt axis rotation allows the lower portion of the disc section to remain together at all times, allowing high compression work without material repulsion.

[0032] figure 1 The general outline of the above system is shown, the key components of the system are: the raised disc part 1; the support 2 holding the raised disc part; the inclined shaft 3 of the support supporting the disc part; the supporting disc Part of the fixed shaft 3.1 of the bracket; the inner seal 4 arranged between the disc parts, which is characterized by two separate chambers, namely, the shaft 10 for assembling the supporting bracket ( Figure 6 shown) and another large chamber 4.2 along the full length of the remaining part, which is arranged in the joint area between the two disk parts (hidden in this figure); ...

Embodiment 2

[0046] This example relates to an implementation of a milling system utilizing compression primarily for milling sugarcane, the system having two rotating disk sections with two inclined axes, as Figure 7 shown.

[0047] The structure and function of the system are figure 1 and 2 Identical as shown, so that the support 2 supporting the disc part forms a fixed part and a movable part, driven by a compression actuator 6 (represented by a spring), allowing the rotation of the disc part 1 always joined at its bottom. The difference here is the main shaft 17, which becomes a single piece with an advantageous slope (functioning as the tilting axis 3 and the horizontal fixed axis 3.1). In this case the holder 4 used between the two discs is symmetrical (where the top is less wide than the bottom), has no cavity and rotates with the disc part 2 . The parts supporting the disc part are slidable by means of sets of movable part sleeves 5.1 and 5.4 and fixed part sleeves 5.2 and 5.4.1...

Embodiment 3

[0050] This example involves proposing Figure 8 The illustrated dual milling system utilizing compression, having two rotating disc sections with inclined axes, is primarily used for milling sugar cane.

[0051] In this embodiment, the two inner disk parts are fixed on the same course, called inner shafts 3.2, while the other two outer drives are located on two shafts 3 inclined to the horizontal plane of the inner shafts.

[0052] The structure and function of the system are figure 1 and 2 Identical as shown, so that the support 2 supporting the disc part forms a fixed part and a movable part, driven by a compression actuator 6 (represented by a spring), allowing the rotation of the disc part 1 always joined at its bottom. The difference here is the inner shaft 3.2 of the double system, containing the installation of the inner disc part acting as the fixed part of the two mills, while the outer inclined shaft 3 supports the movable part. In this embodiment, the holder 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com