Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165results about "Measurement gauges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

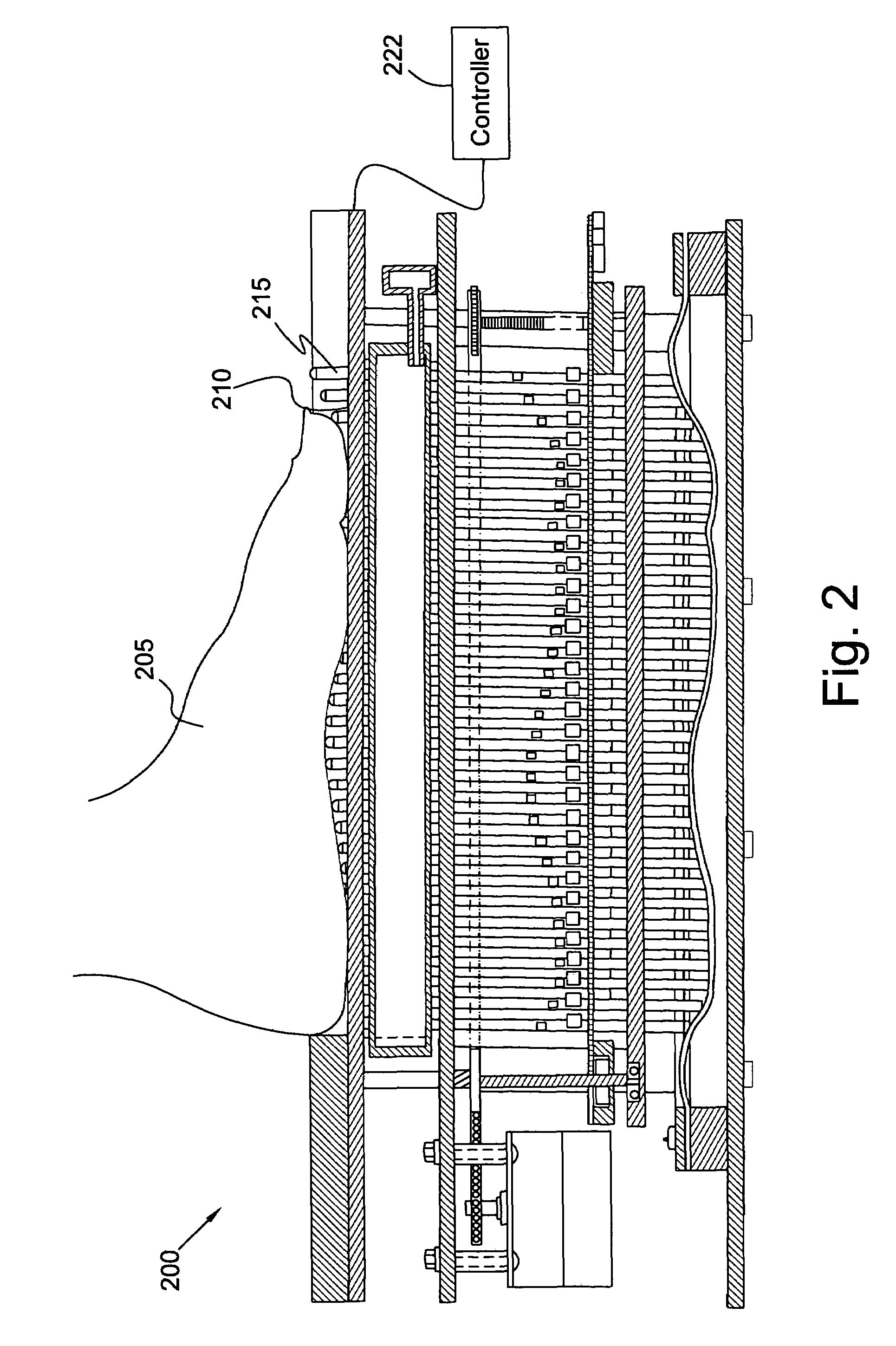

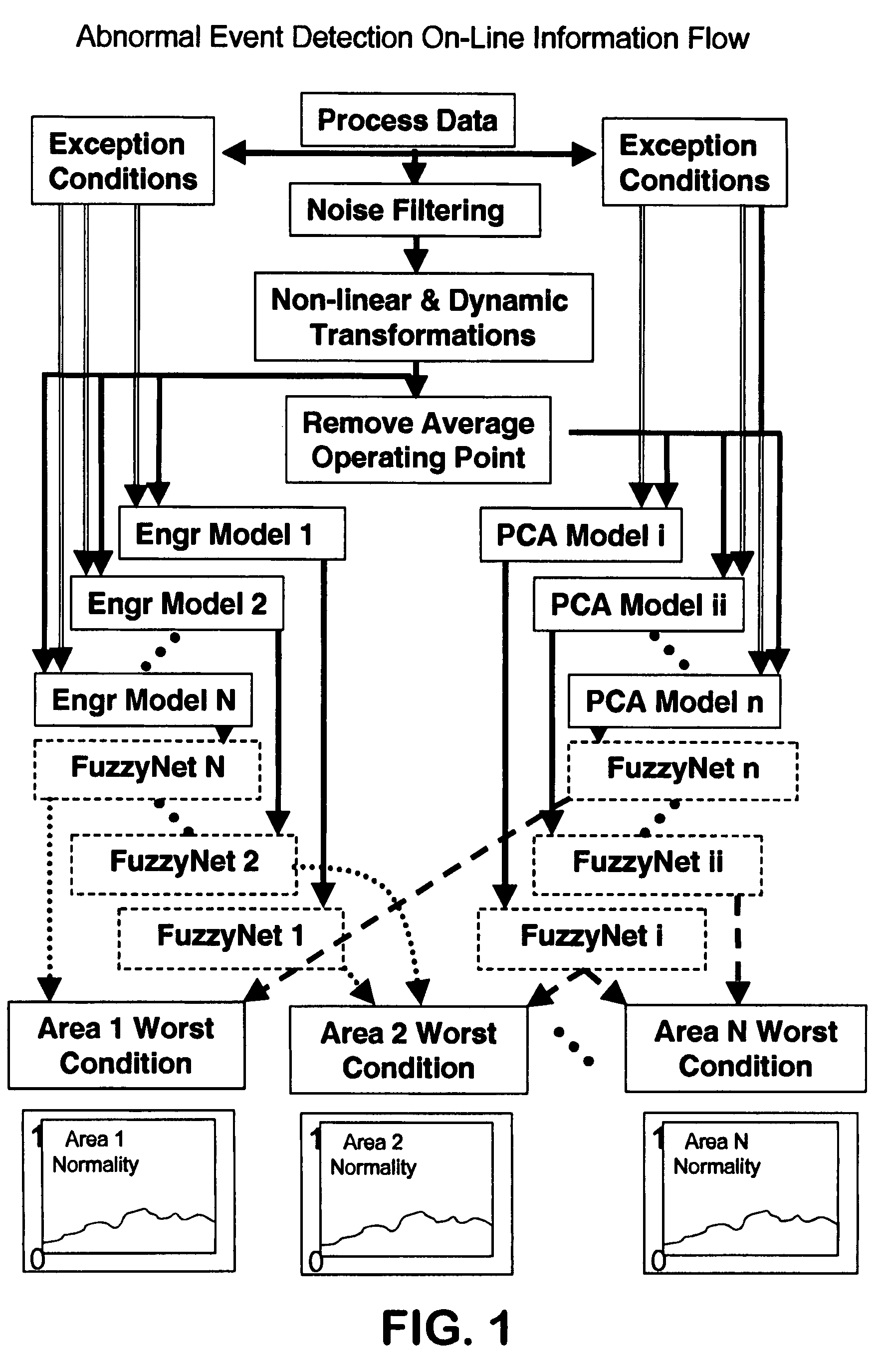

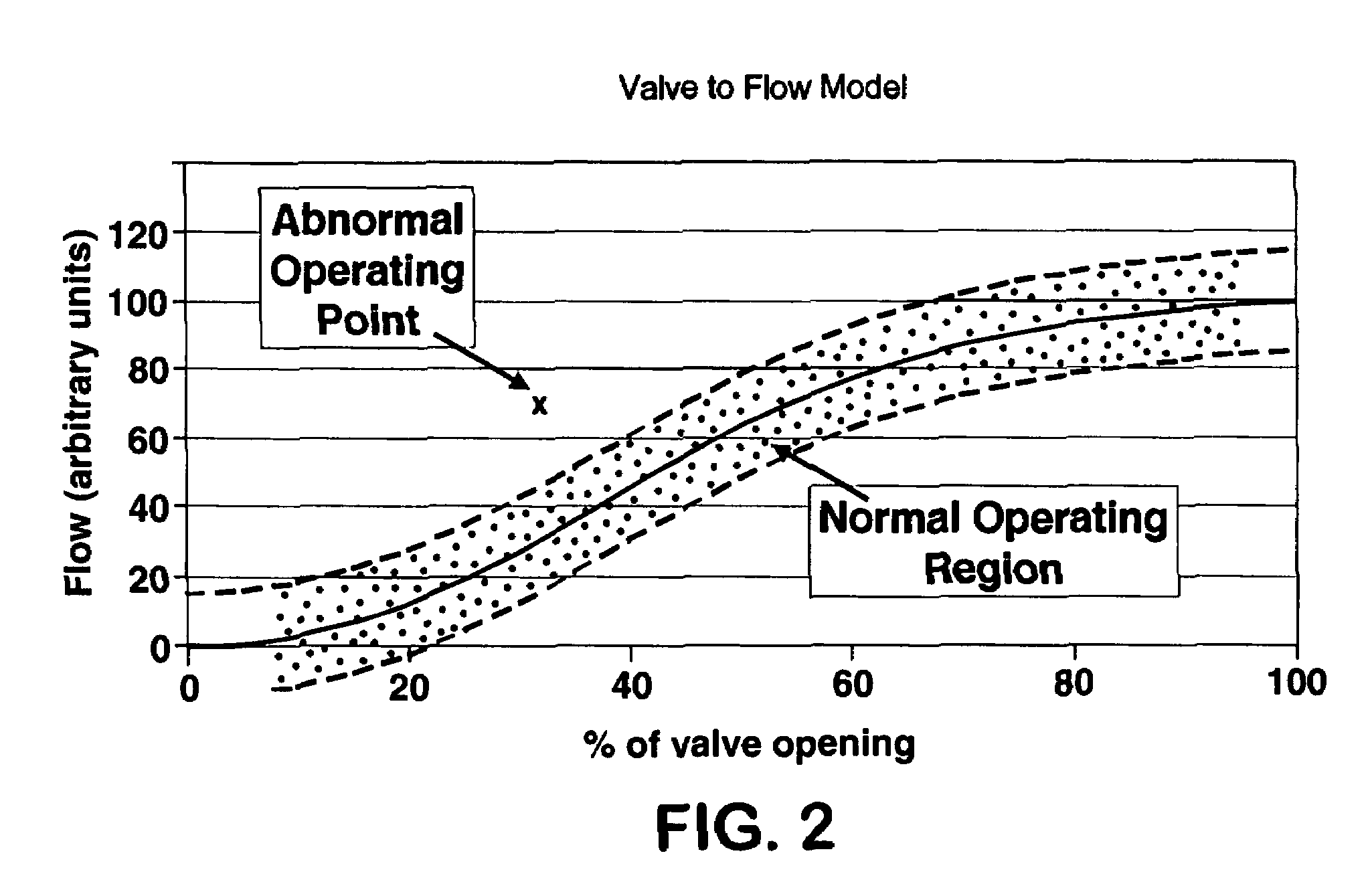

Application of abnormal event detection technology to fluidized catalytic cracking unit

ActiveUS20060073013A1PropellersSpecial data processing applicationsPrincipal component analysisCorrelation analysis

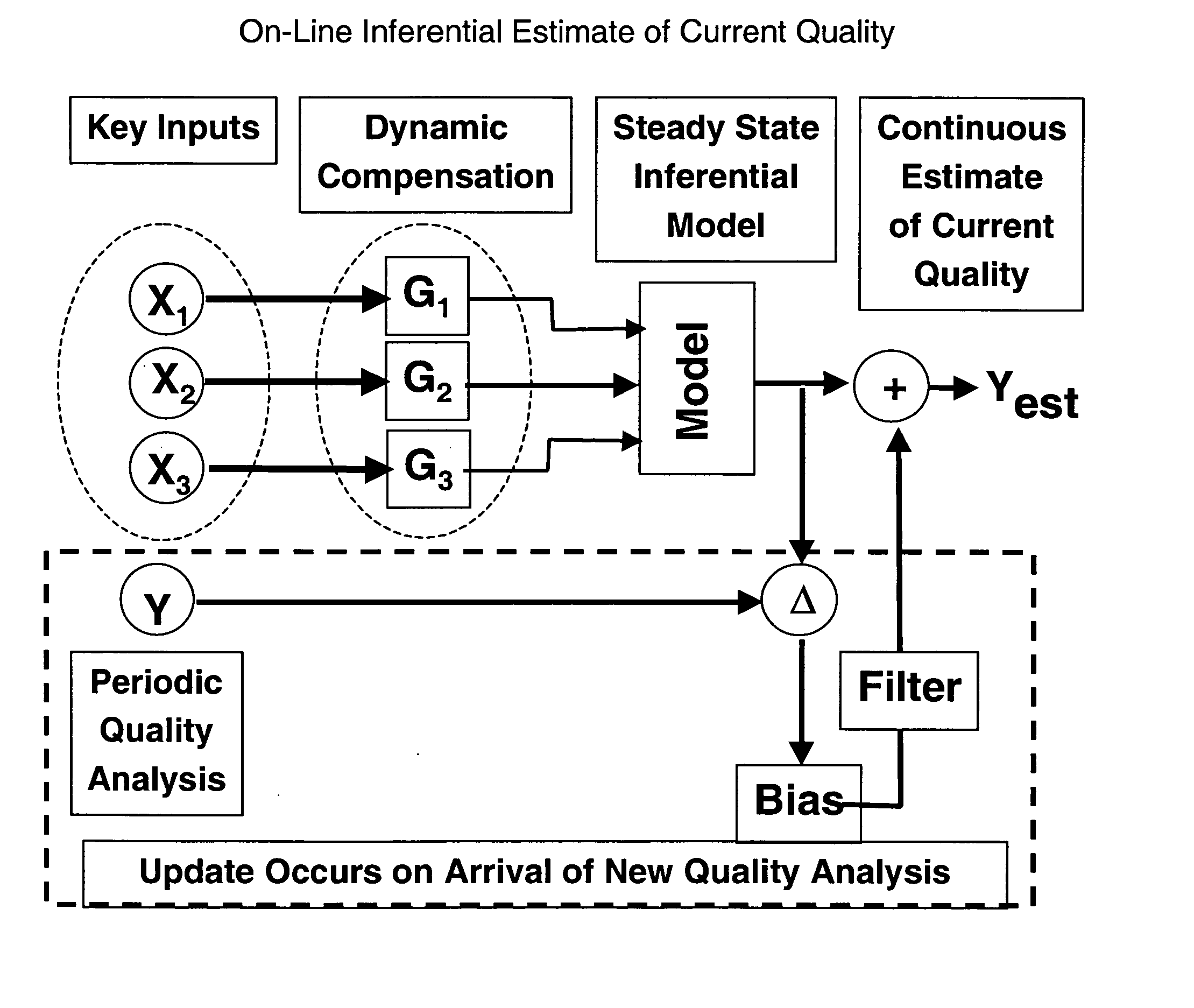

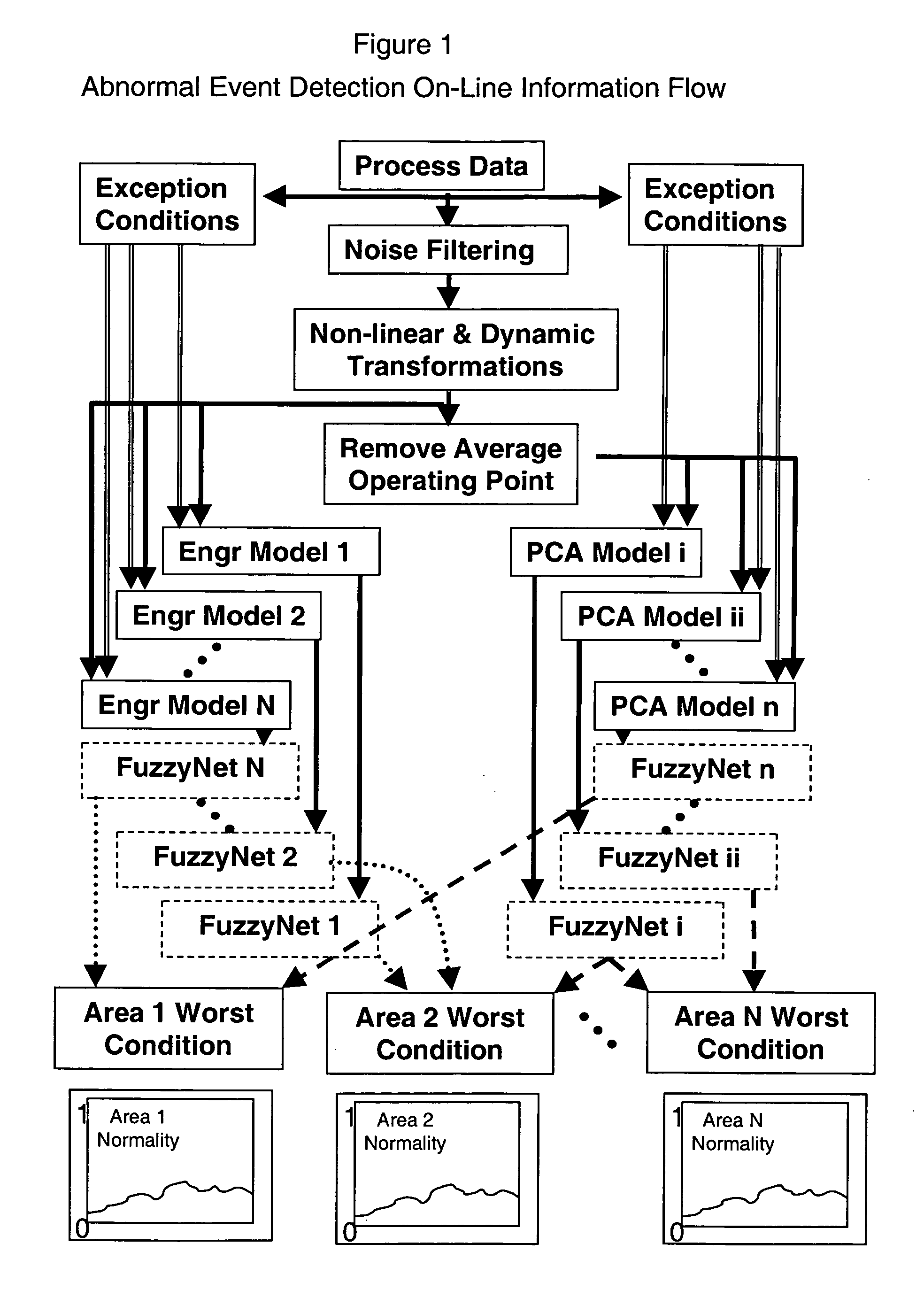

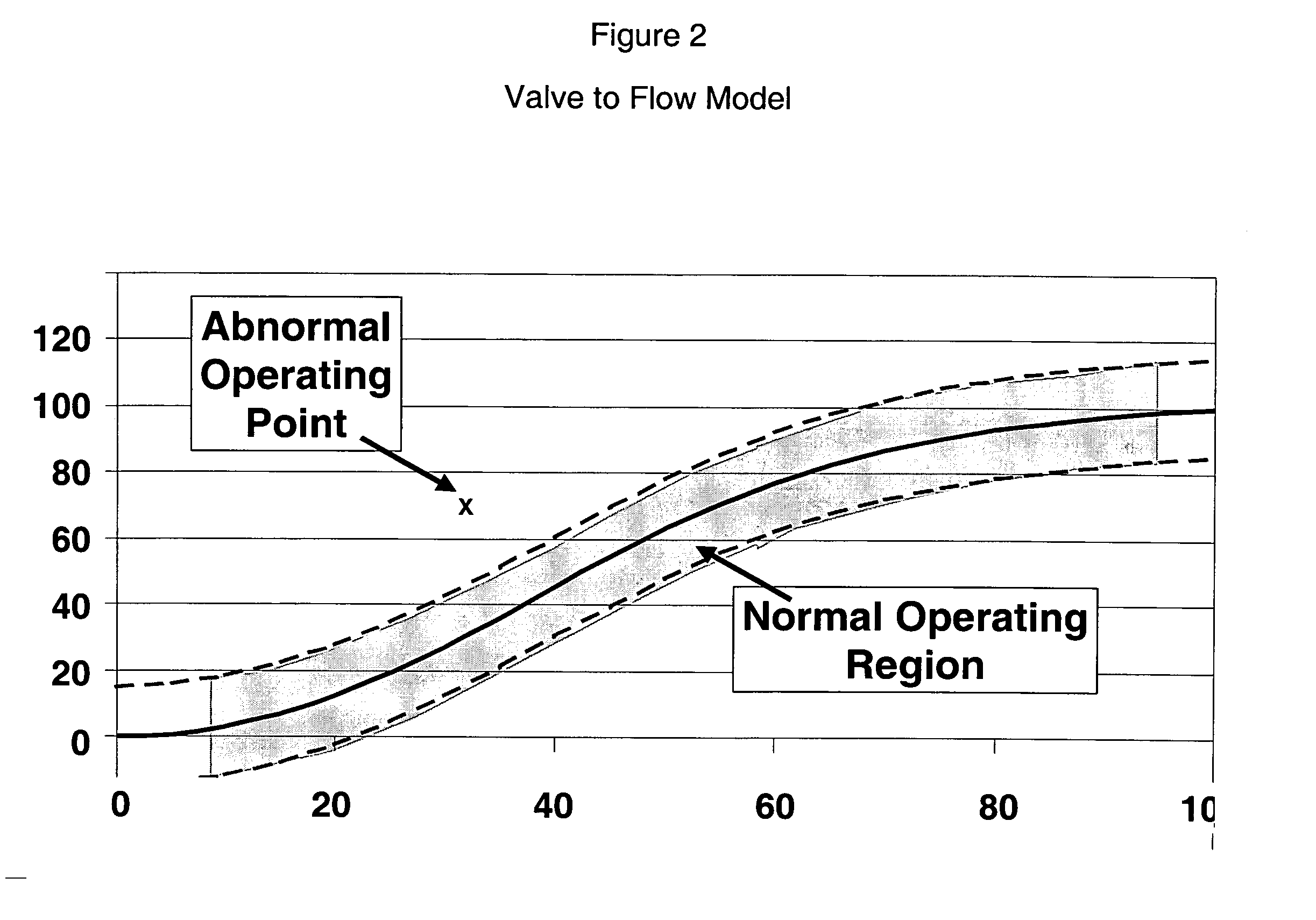

The present invention is a method for detecting an abnormal event for process units of a Fluidized Catalytic Cracking Unit. The method compares the operation of the process units to a statistical and engineering models. The statistical models are developed by principle components analysis of the normal operation for these units. In addition, the engineering models are based on partial least squares analysis and correlation analysis between variables. If the difference between the operation of a process unit and the normal model result indicates an abnormal condition, then the cause of the abnormal condition is determined and corrected.

Owner:EXXON RES & ENG CO

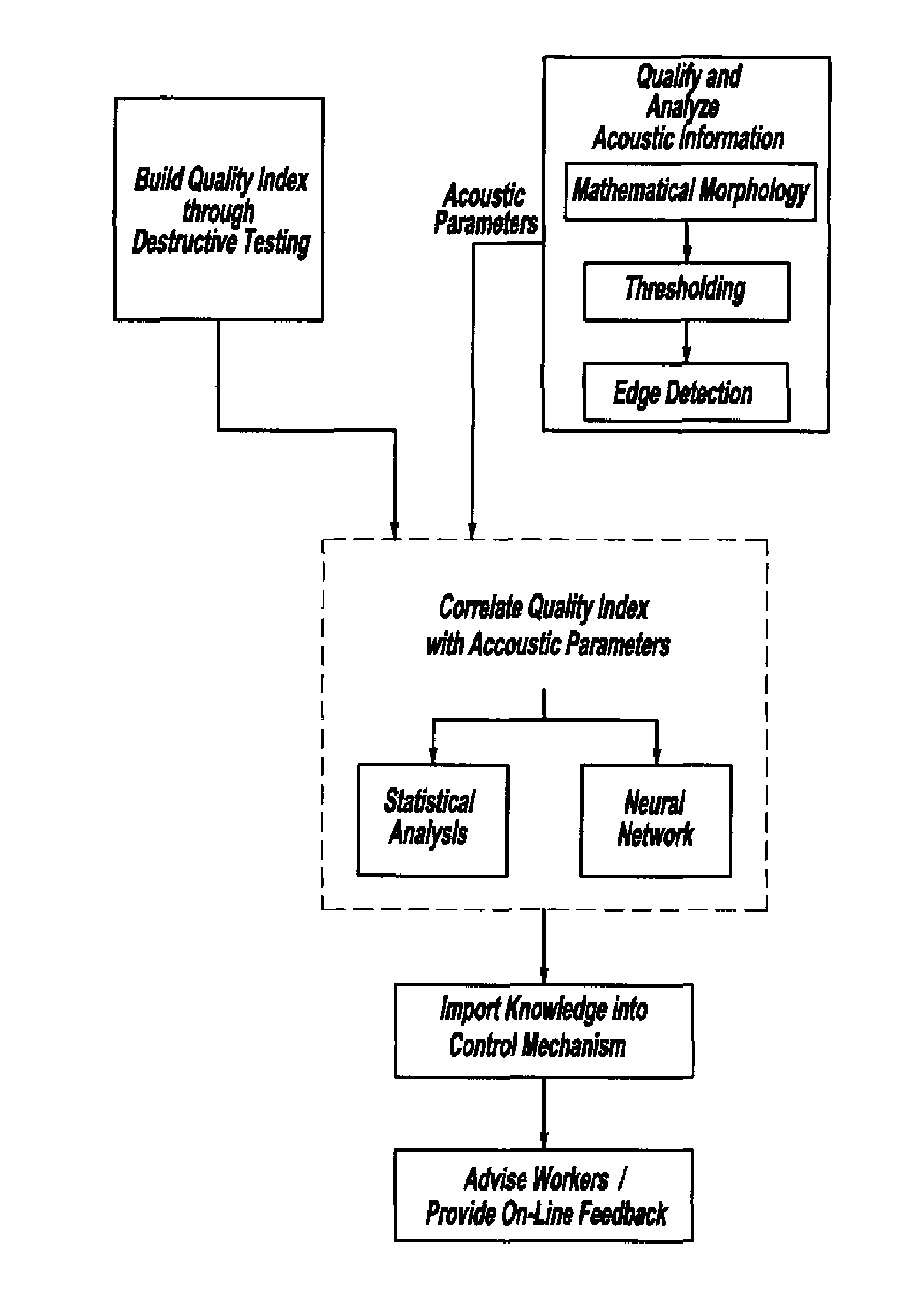

Method And System For Assessing Quality Of Spot Welds

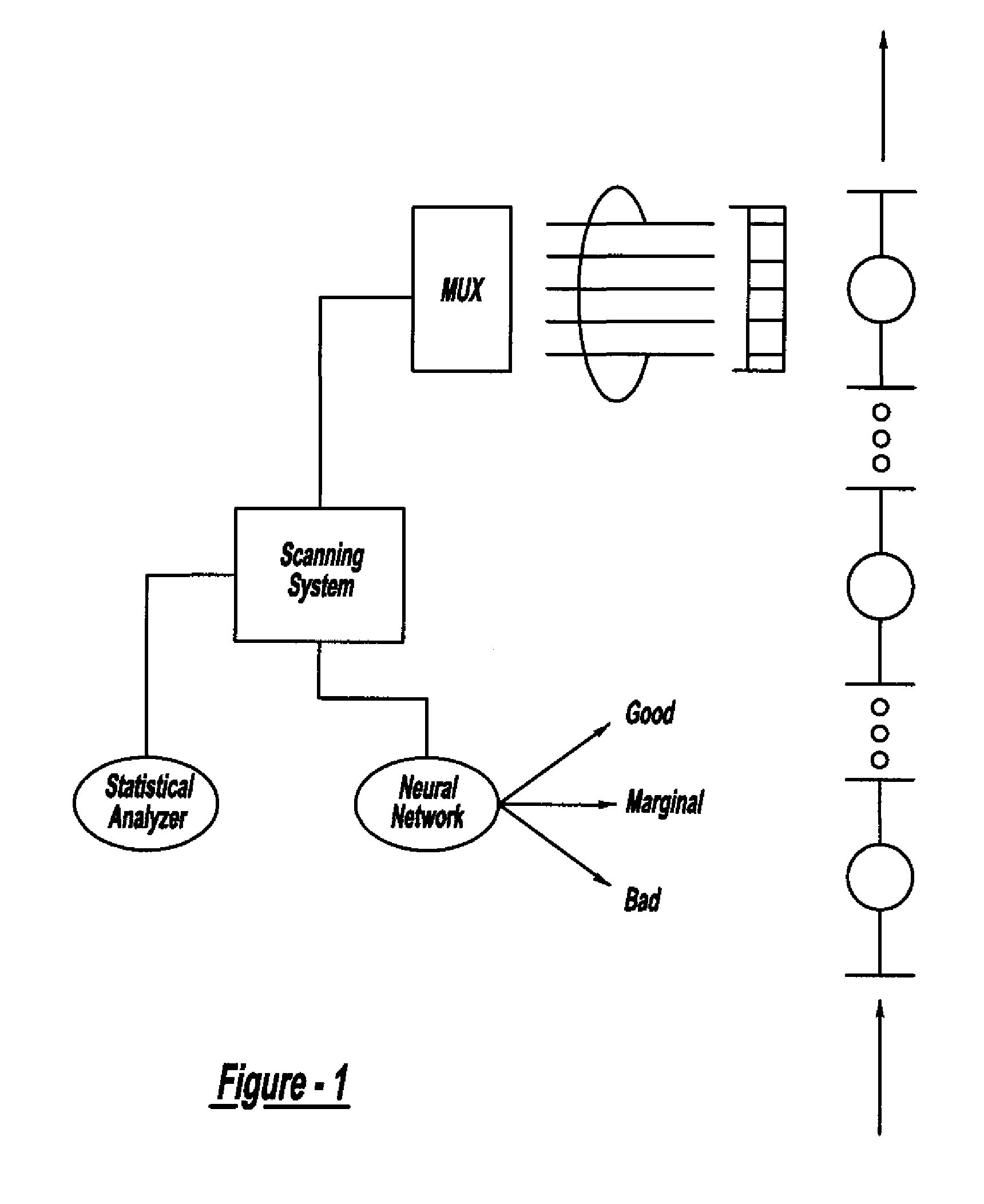

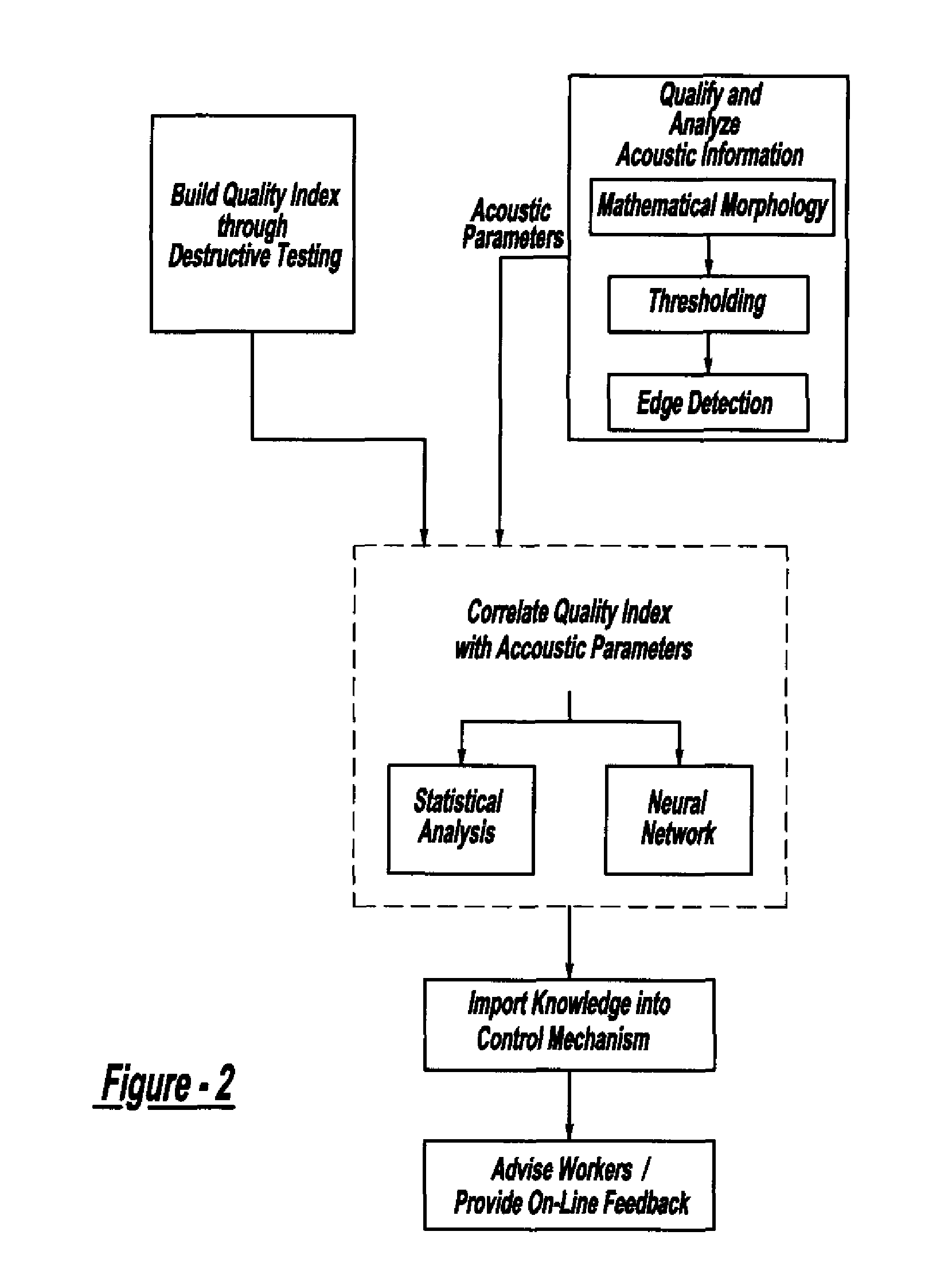

InactiveUS20070038400A1Reduce in quantityReduce manufacturing costMultiple-port networksMagnetic property measurementsDigital dataSonification

A system and method for assessing the quality of spot weld joints between pieces of metal includes an ultrasound transducer probing a spot weld joint. The ultrasound transducer transmits ultrasonic radiation into the spot weld joint, receives corresponding echoes, and transforms the echoes into electrical signals. An image reconstructor connected to the ultrasound transducer transforms the electrical signals into numerical data representing an ultrasound image. A neural network connected to the image reconstructor analyzes the numerical data and an output system presents information representing the quality of the spot weld joint. The system is trained to assess the quality of spot weld joints by scanning a spot weld joint with an ultrasound transducer to produce the data set representing the joint; then physically deconstructing the joint to assess the joint quality.

Owner:FCA US

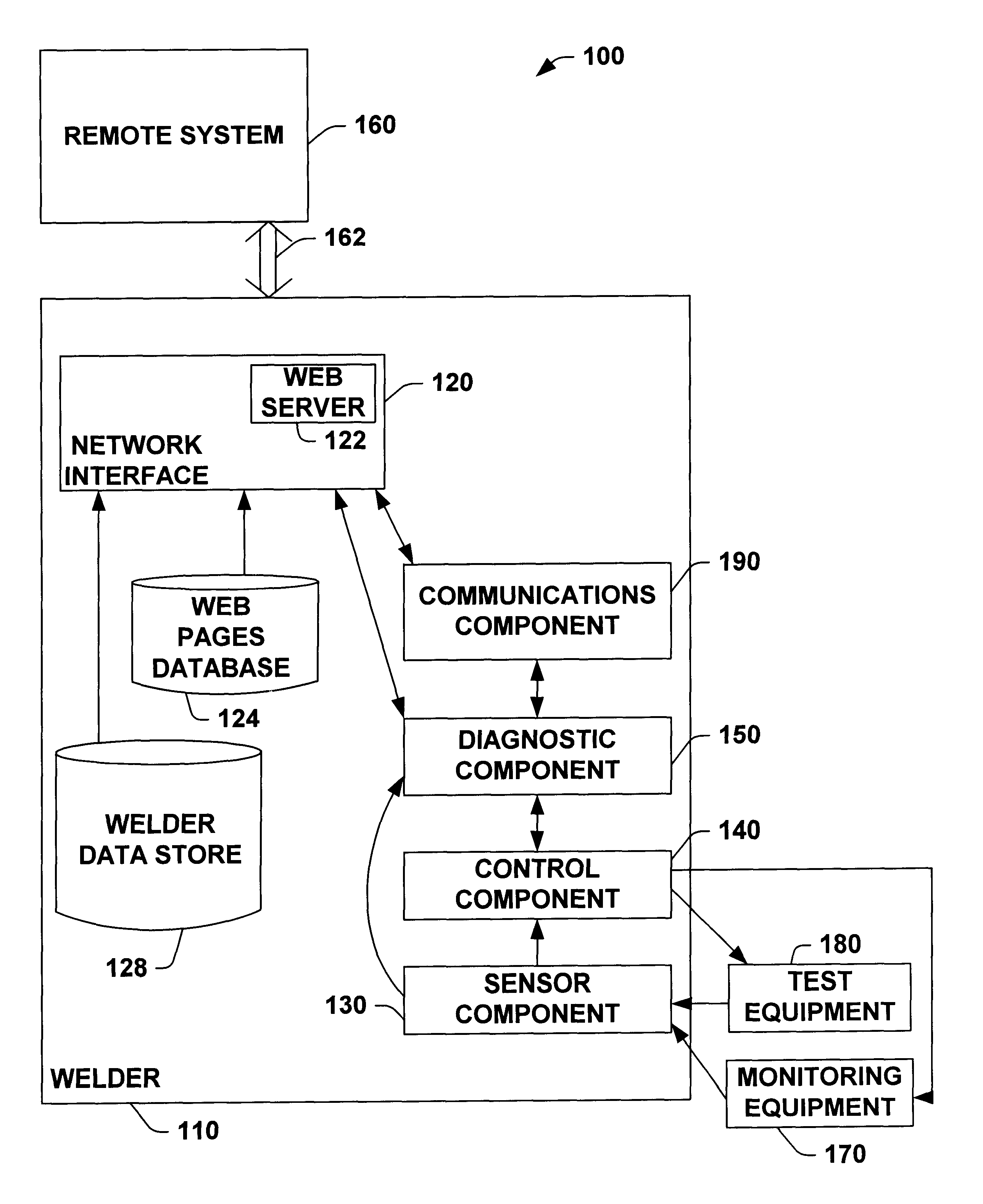

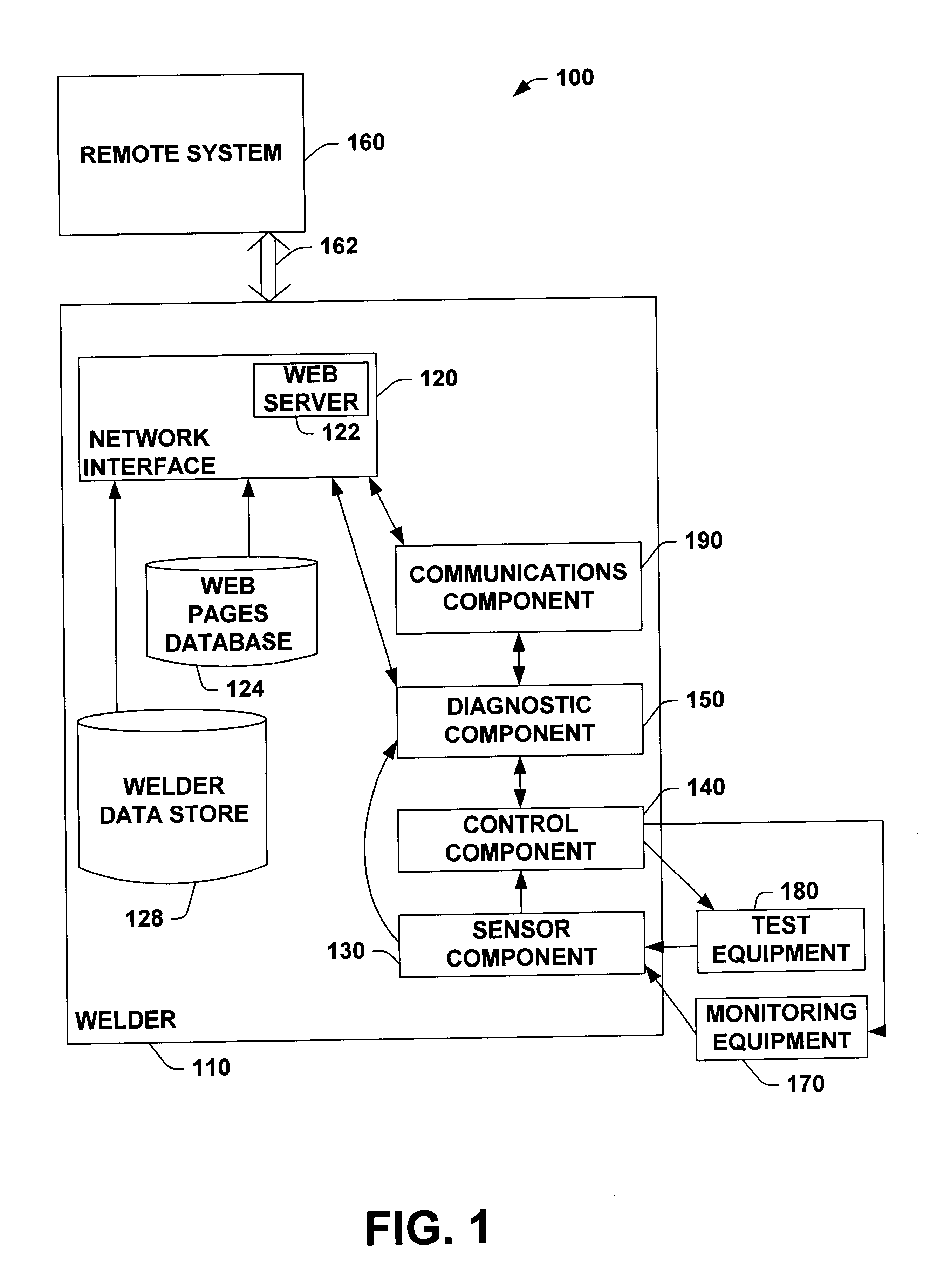

System and method for facilitating welding system diagnostics

InactiveUS6795778B2Facilitate welding diagnosticsBatteries circuit arrangementsArc welding apparatusRemote systemSmart technology

A system and method for facilitating welding system diagnostics is provided. The invention includes a welder, a local system, a remote system, and / or an alarm component. The invention further provides for receiving sensor input(s), performing test sequence(s) based, at least in part, upon the sensor input(s) and / or performing internal diagnostics. The invention further provides for determining a health status of the welder and communicating the health status of the welder to the local system, the remote system and / or the alarm component. The health status of the welder can include welder alarm(s) and / or fault(s). Information regarding the health status of the welder can be sent by telephone, voicemail, e-mail and / or beeper. The welder can communicate with the local system and / or remote system to schedule maintenance. The invention further provides for a expert component to facilitate welding diagnostics based, at least in part, upon the health status of the welder, welder data, an expert data store, a local service support data store, a remote expert data store and / or a remote service support data store. The expert component can employ various artificial intelligence technique(s) (e.g., Bayesian model, probability tree network, fuzzy logic and / or neural network) to facilitate welding diagnostics based, at least in part, upon the health status received from the welder. The expert component can adaptively modify its modeling technique(s) based upon historical success (e.g., learn from success of previous welding diagnostics). The invention further provides for the welder, local system and / or remote system to initiate corrective action, at least temporarily, based, at least in part, upon the health status of the welder.

Owner:LINCOLN GLOBAL INC

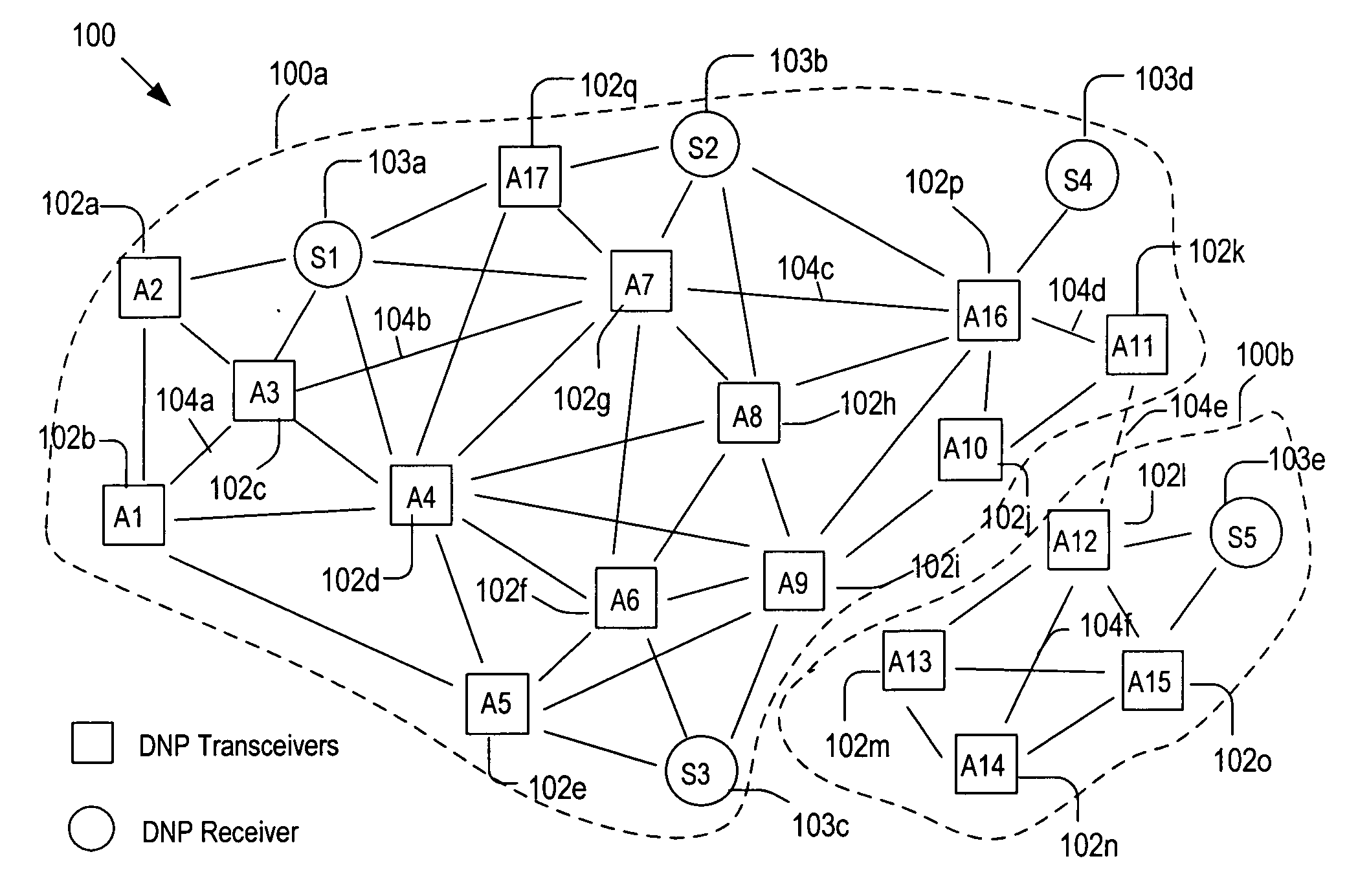

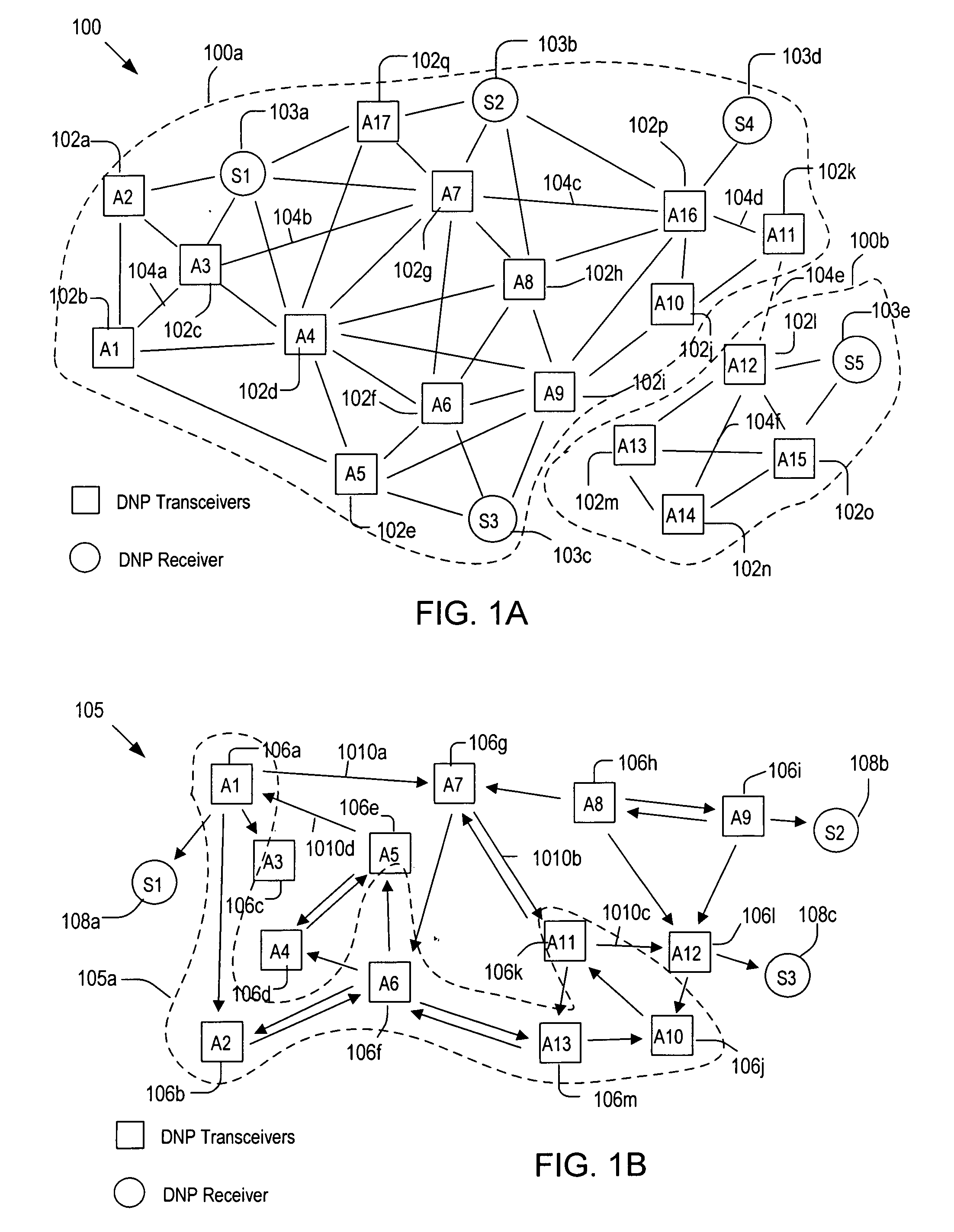

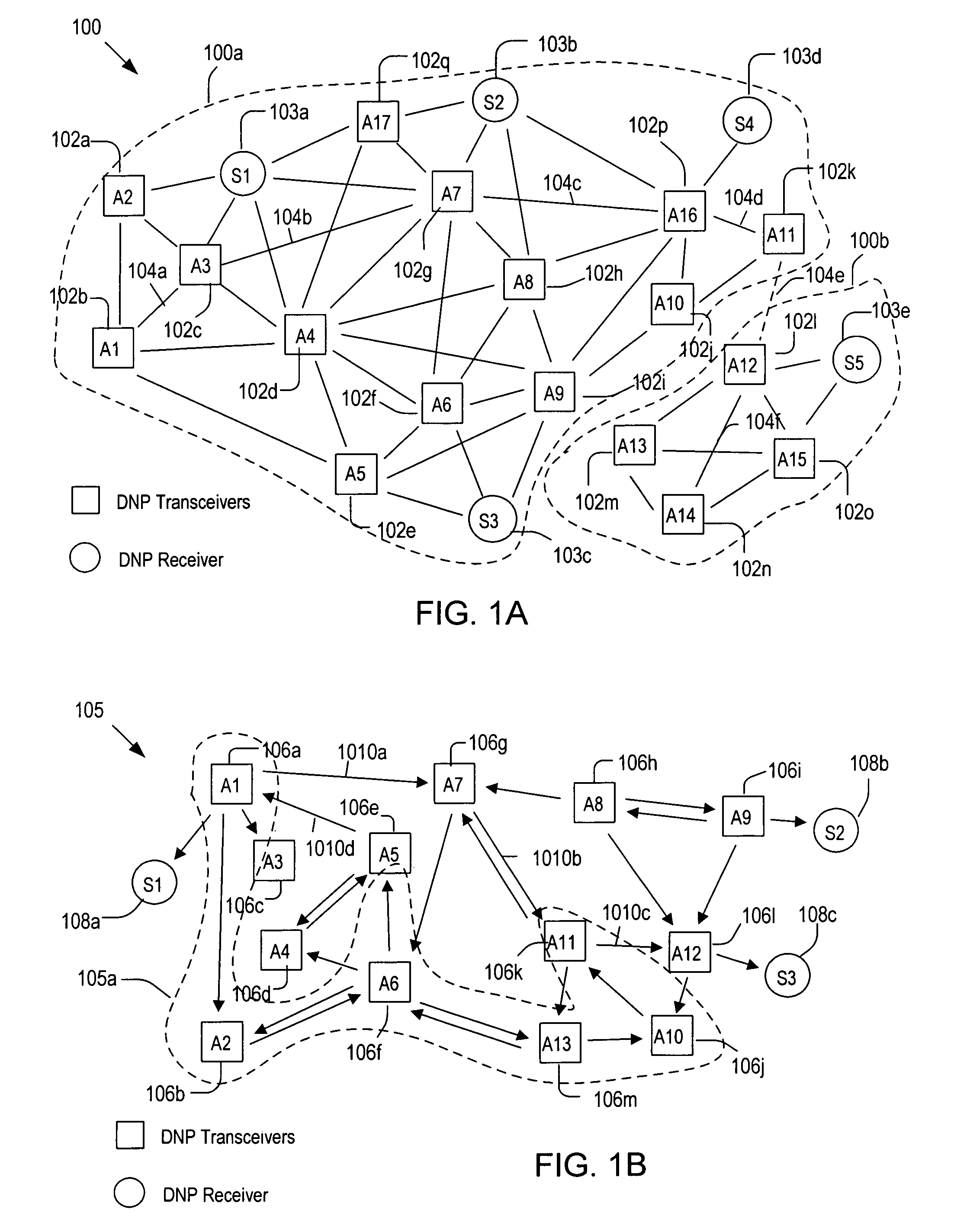

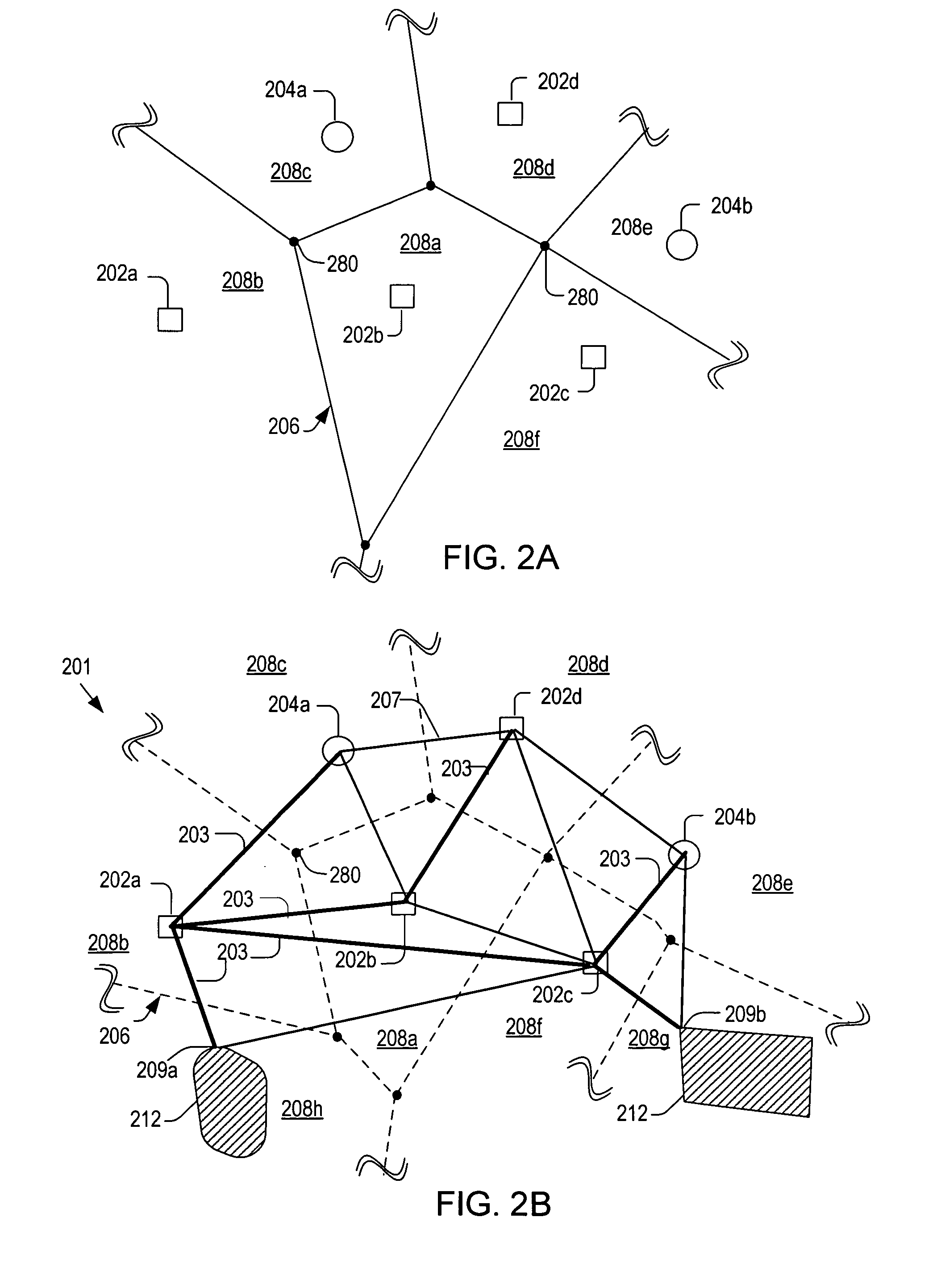

Methods of networking interrogation devices for structural conditions

InactiveUS20060287842A1Vibration measurement in solidsSpecial data processing applicationsDirected graphUndirected graph

Methods of operating an interrogation system that has a plurality of patches attached to a host structure. Each patch is capable of generating a diagnostic wave and / or developing a sensor signal in response to the diagnostic wave. In each method, a Euclidean undirected graph is generated by forming a plurality of paths, wherein each path connects two of the patches and the length of the path is shorter than a preset limit. Then, a directed graph is generated by assigning a propagation direction of the diagnostic wave to each path. Structural condition index (SCI) values are measured by use of the directed graph and, based on the SCI values, the host structure is scanned for anomalies. The directed graph is reconfigured to enhance accuracy in determining the shape and location of the anomalies.

Owner:ADVANCED STRUCTURE MONITORING

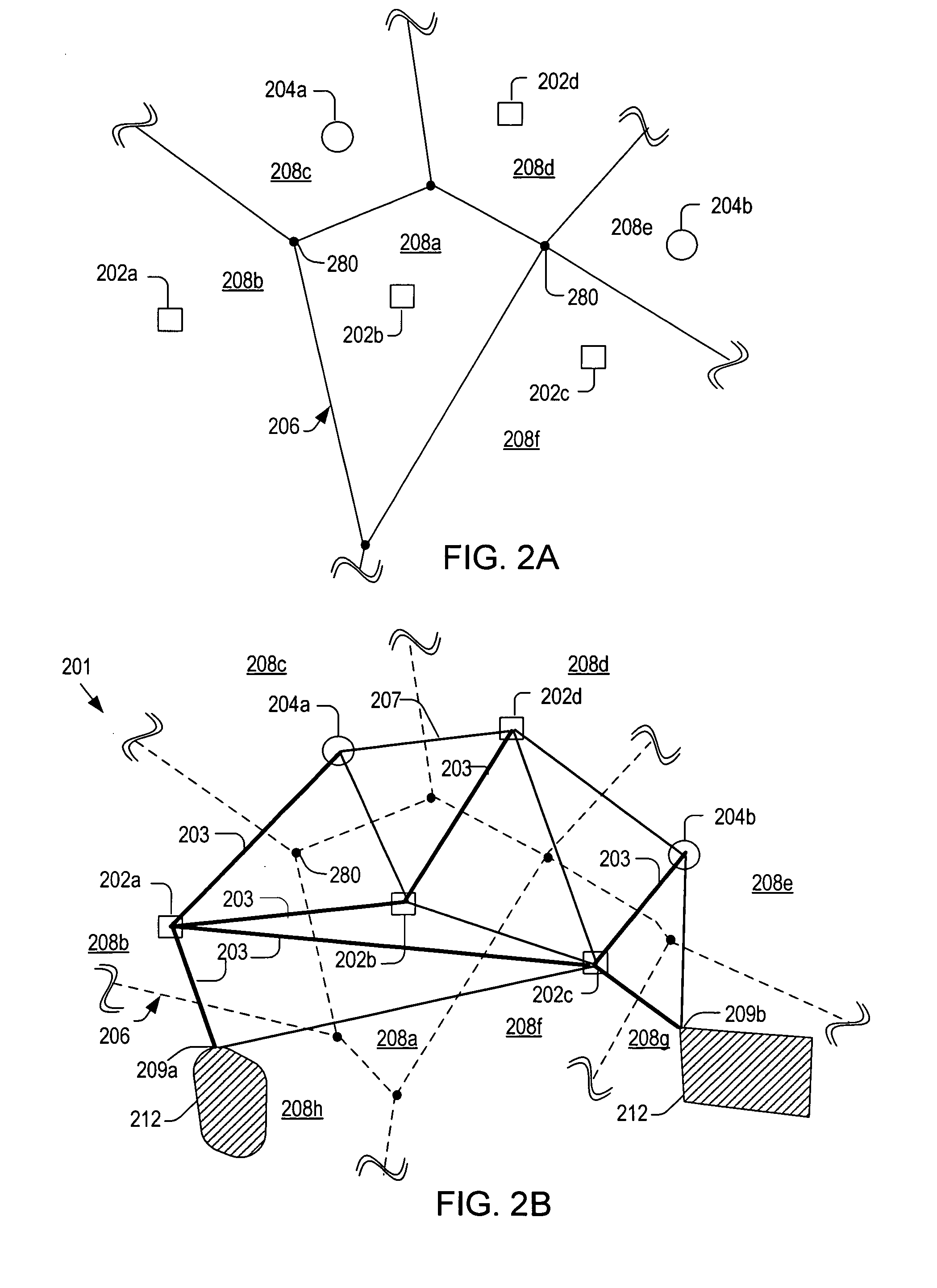

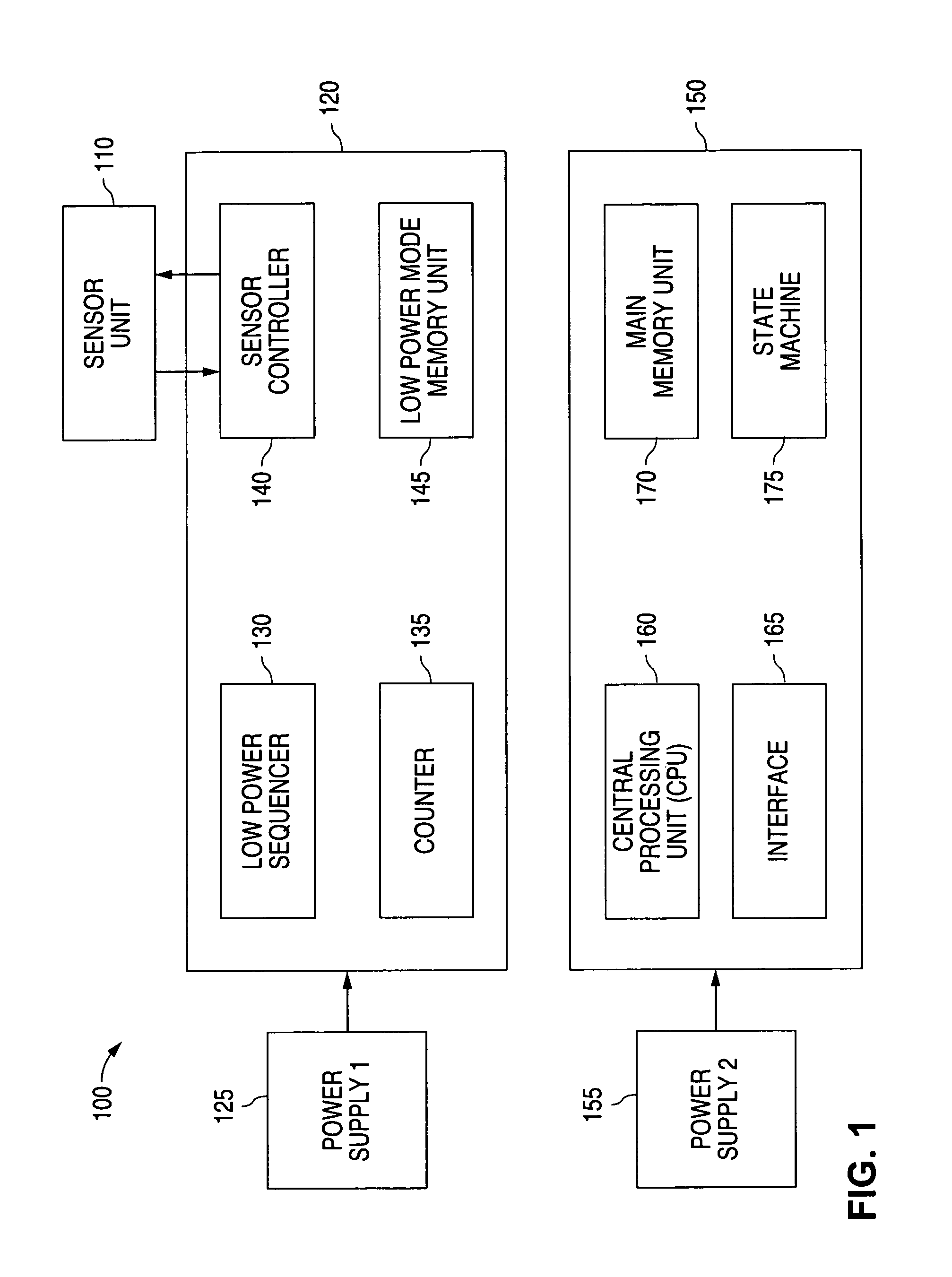

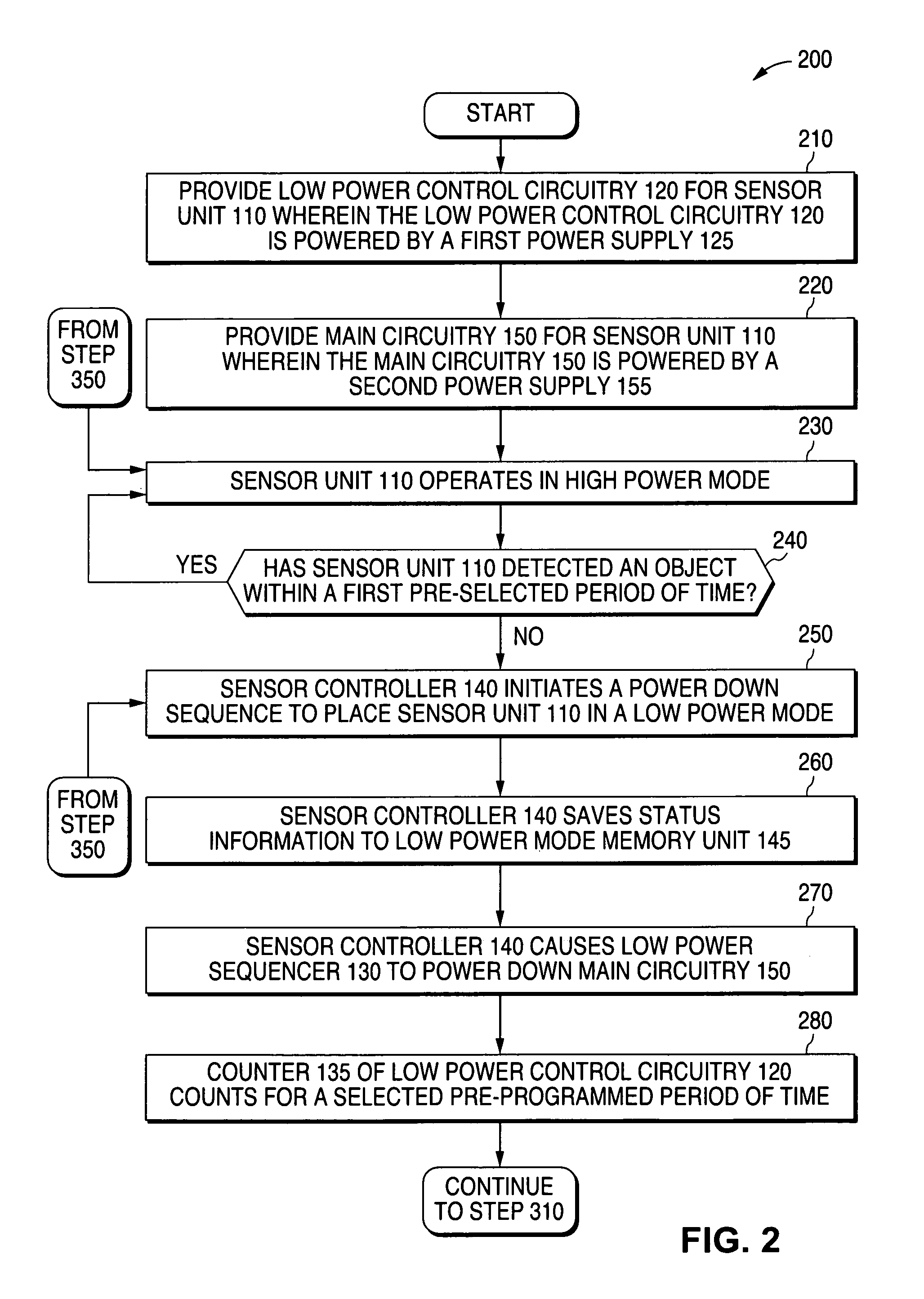

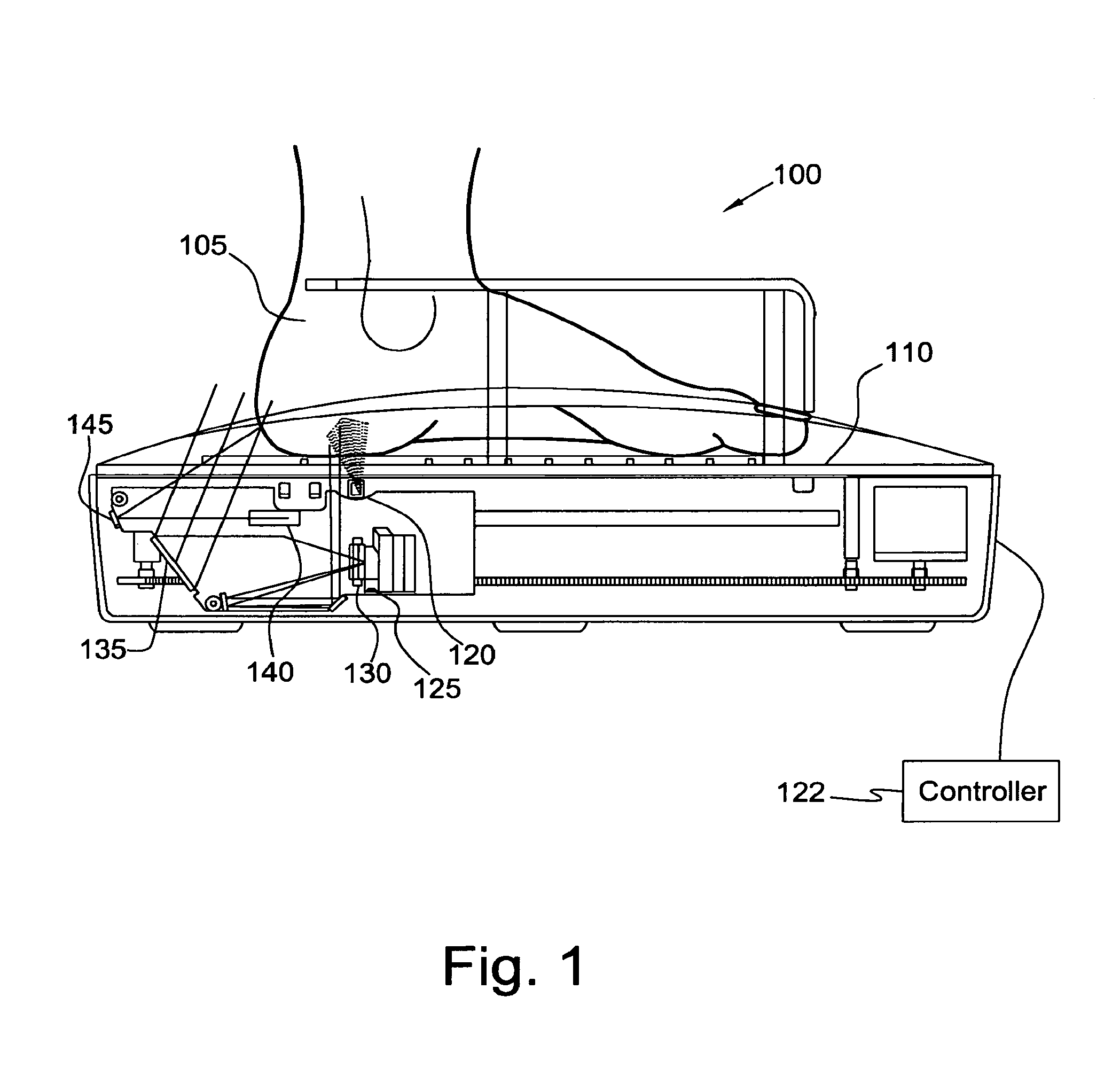

System and method for minimizing power consumption for an object sensor

A system and method is disclosed for minimizing power consumption of a sensor unit that is capable of detecting an object. Main circuitry operates the sensor unit in a high power mode of operation when the sensor unit detects an object. Low power control circuitry operates the sensor unit in a low power mode of operation when the sensor unit does not detect an object within a pre-determined period of time. The low power control circuitry also comprises a counter to periodically determine when to restore the sensor unit to a high power mode of operation. One advantageous embodiment of the sensor unit is a fingerprint sensor unit for detecting a finger to obtain fingerprint information.

Owner:SYNAPTICS INC +1

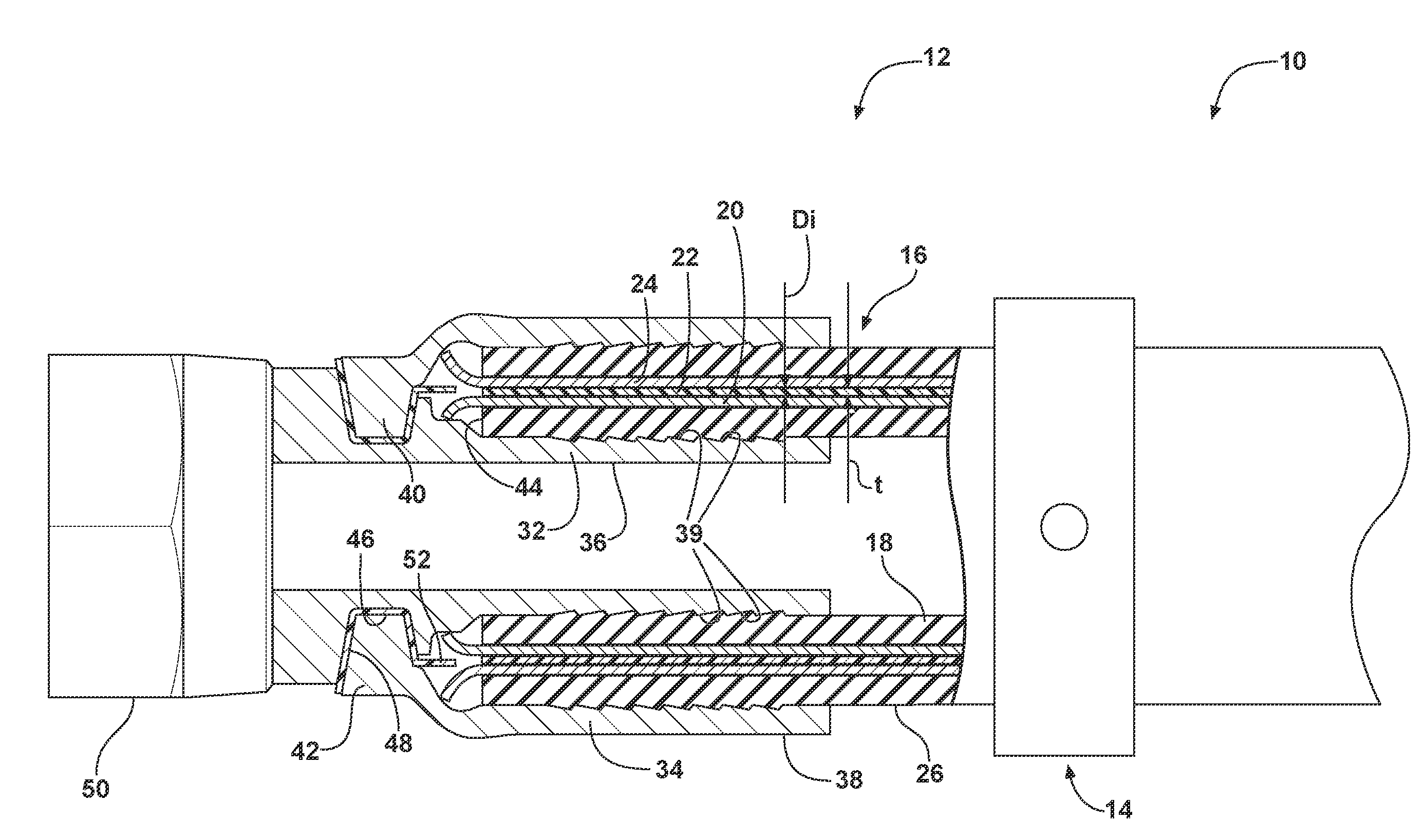

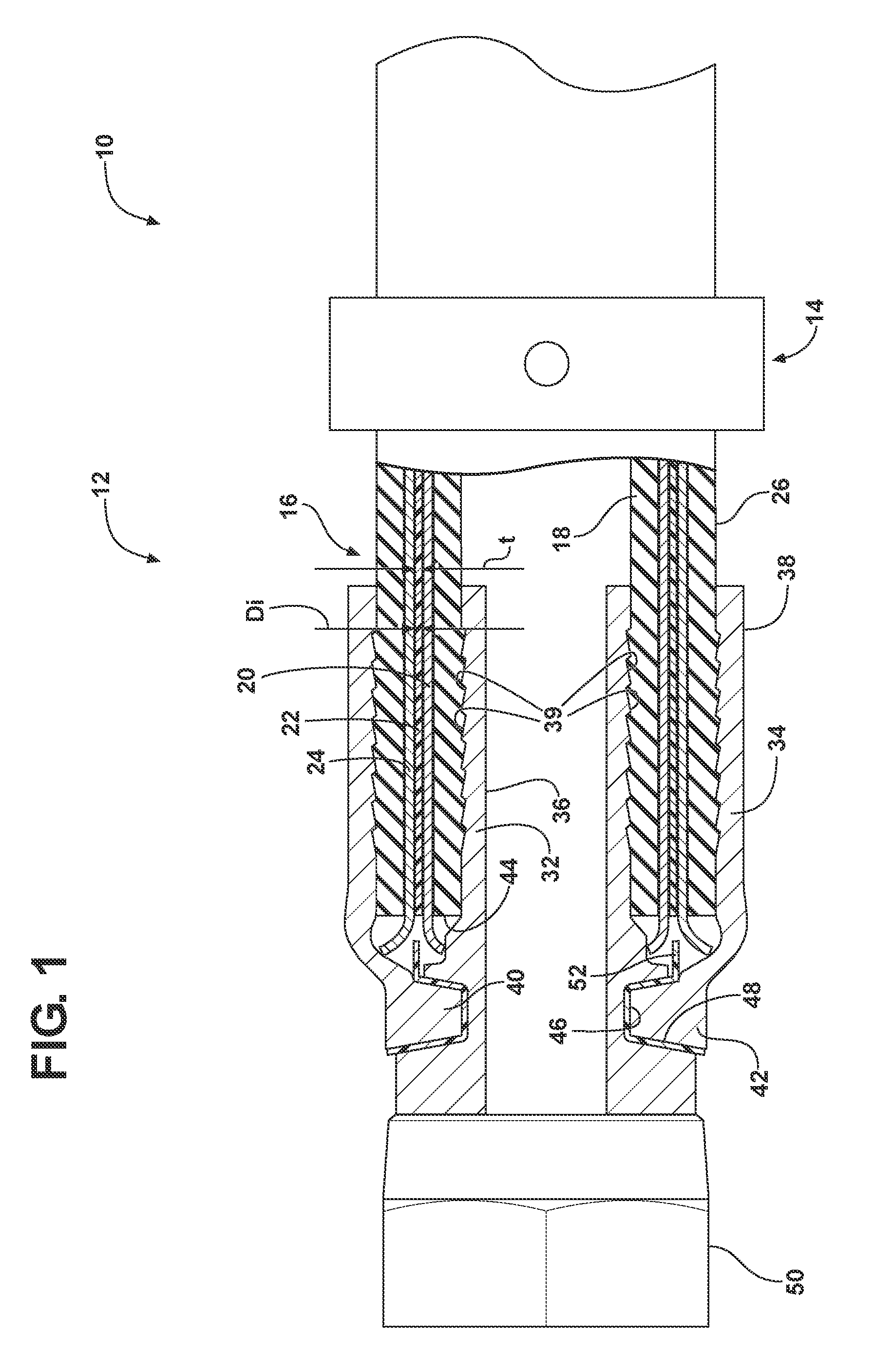

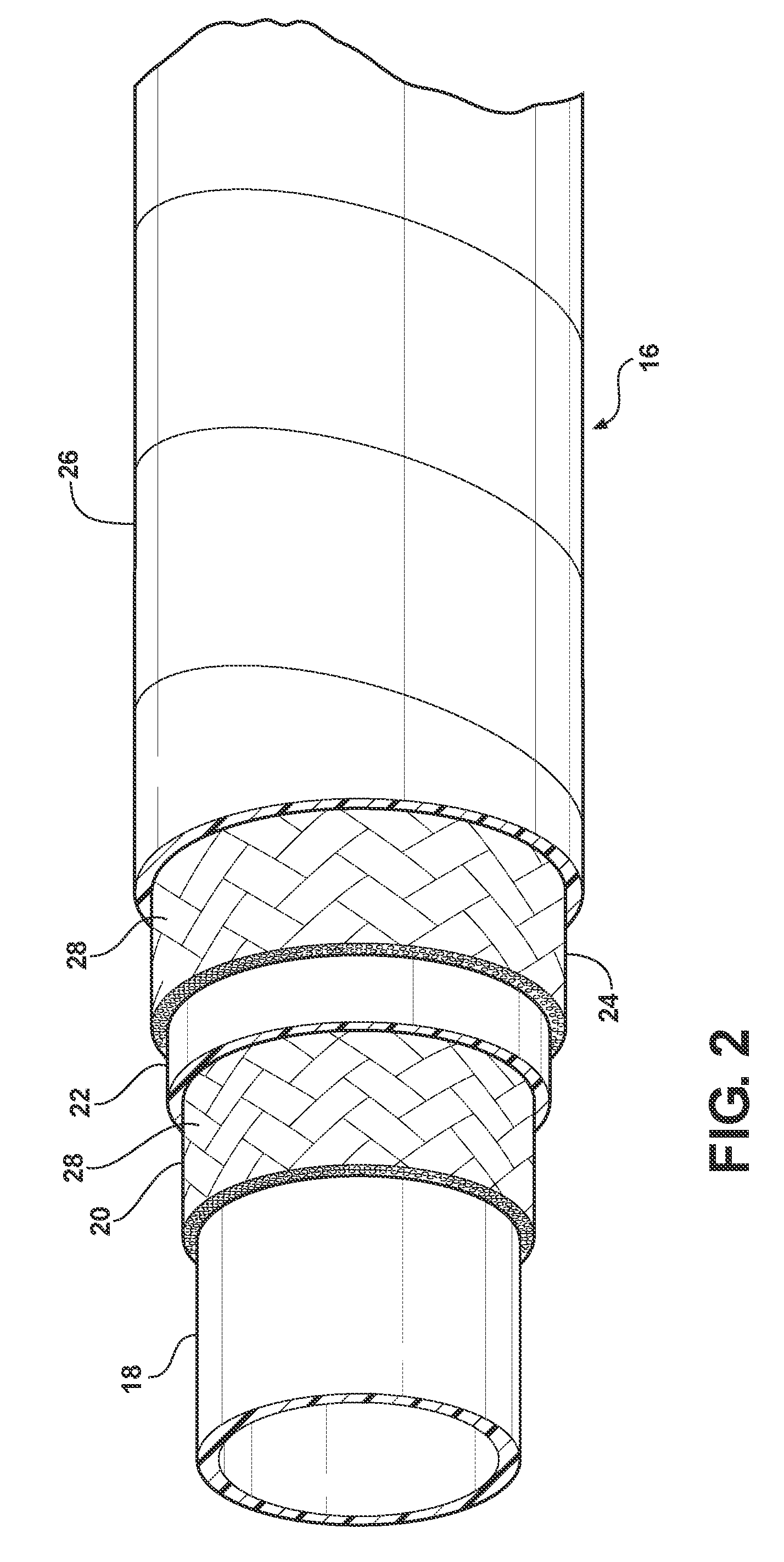

Degradation detection system for a hose assembly

A hose fault detection system includes a hose assembly including a hose having first and second conductive layers. The hose assembly has an electrical characteristic. A fault detector is in electrical communication with the first and second conductive layers. The fault detector includes an indicator operatively connected to the hose assembly. A method for monitoring the structural integrity of a hose assembly includes providing a fault detection system having a hose assembly including a hose having a first conductive layer and a second conductive layer. The hose assembly has an electrical characteristic. The electrical characteristic of the hose assembly is compared to a threshold value. A visual indicator in operative communication with the hose assembly is illuminated when the electrical characteristic goes beyond the threshold value.

Owner:DANFOSS POWER SOLUTIONS II TECH AS

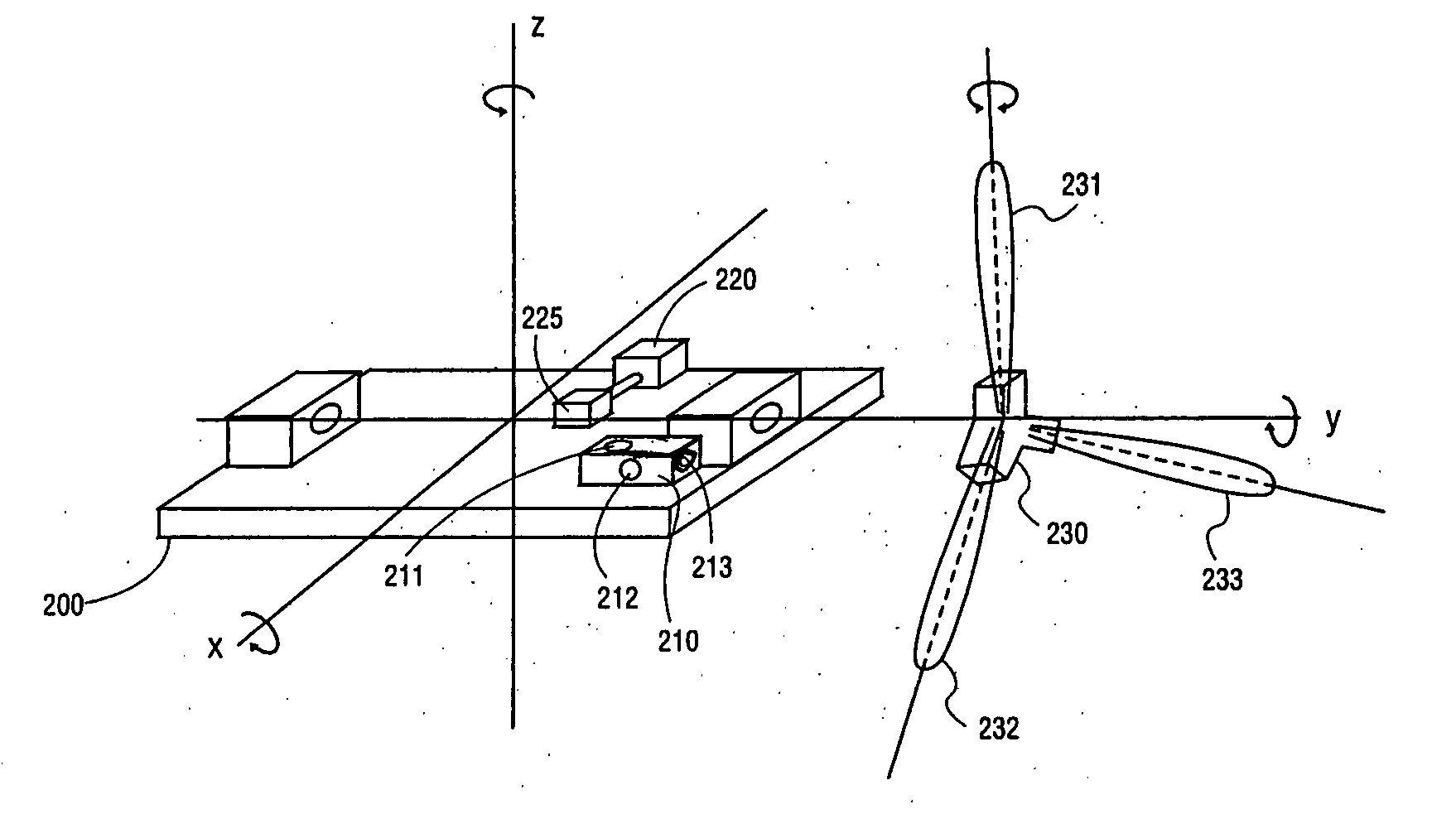

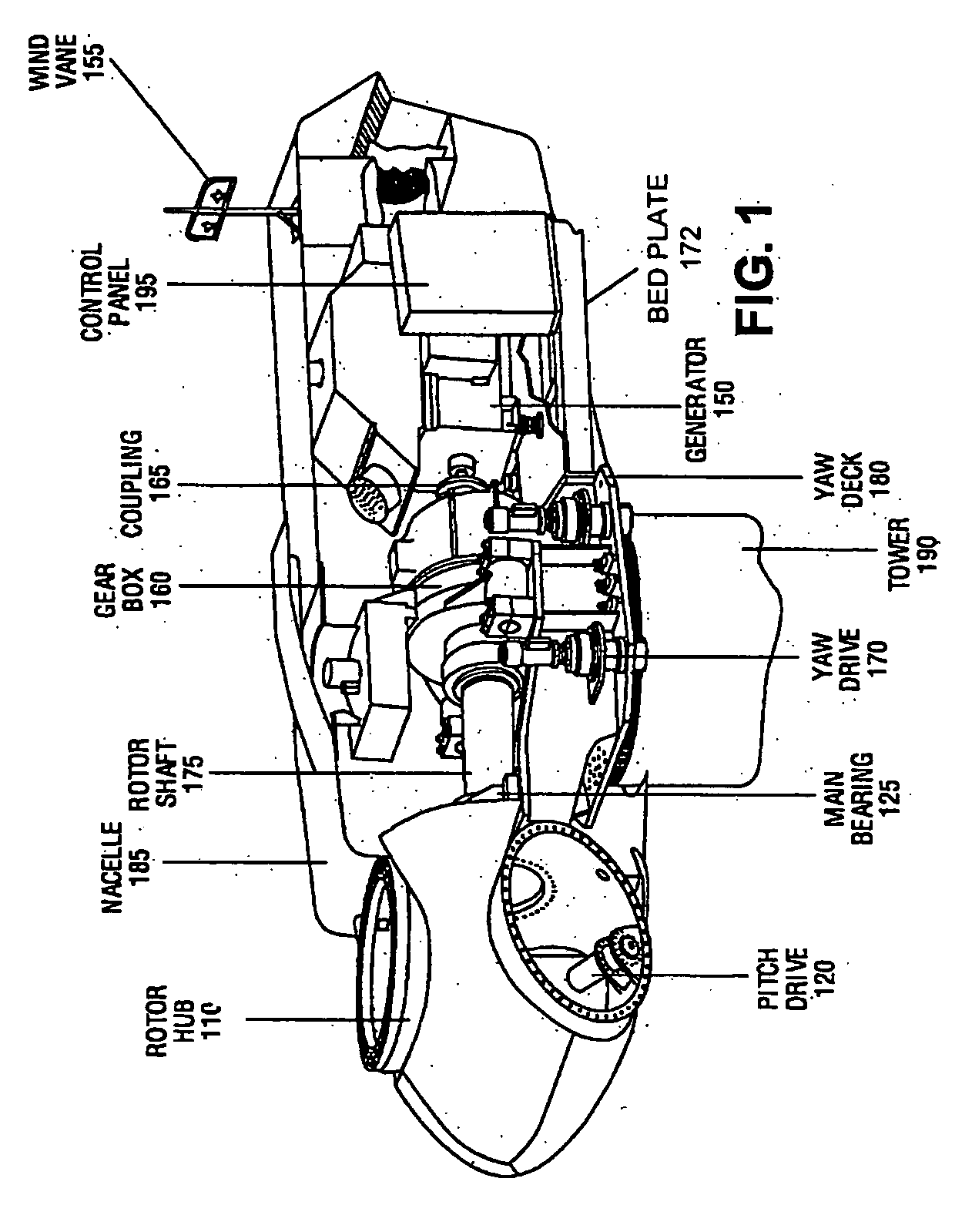

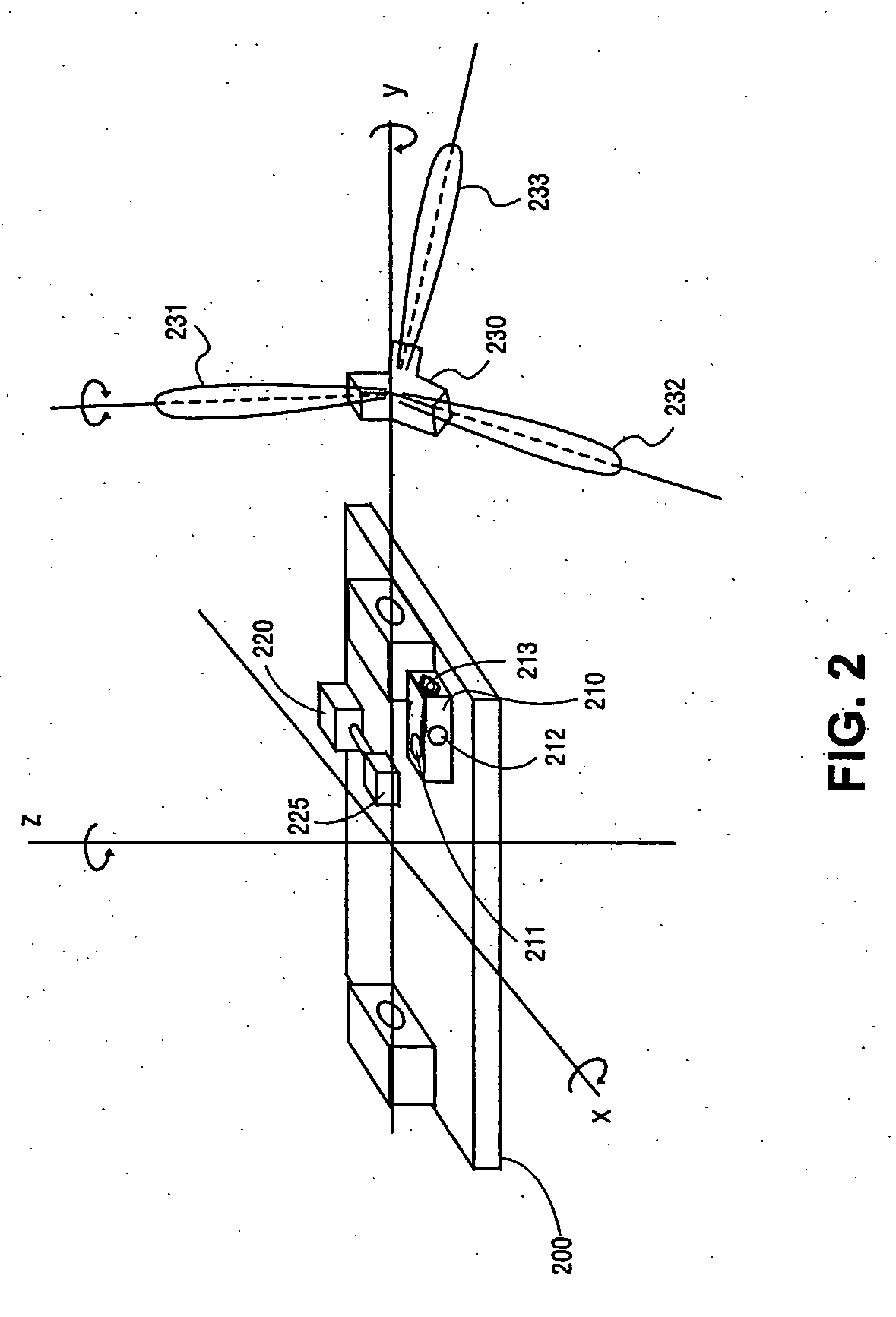

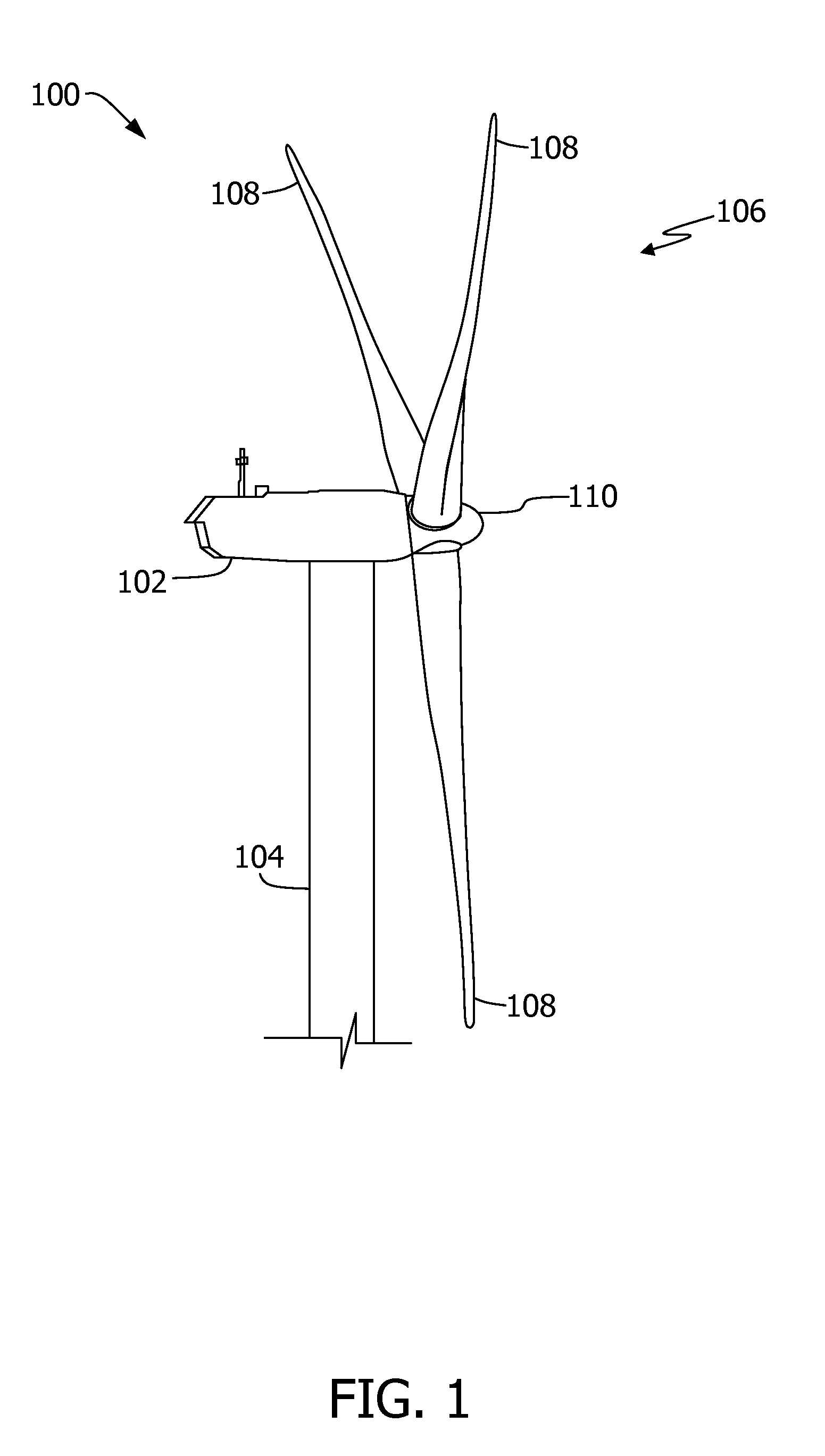

Methods and apparatuses for wind turbine fatigue load measurement and assessment

Techniques and apparatuses for wind turbine component fatigue load measurement and assessment are disclosed. In one embodiment the component is a tower, fore-aft and side-to-side signals from a two-axis accelerometer attached to a bedplate of a wind turbine are used to measure tower fatigue loads. A yaw axis azimuth position signal can also be used for tower fatigue load measurement and assessment.

Owner:GENERAL ELECTRIC CO

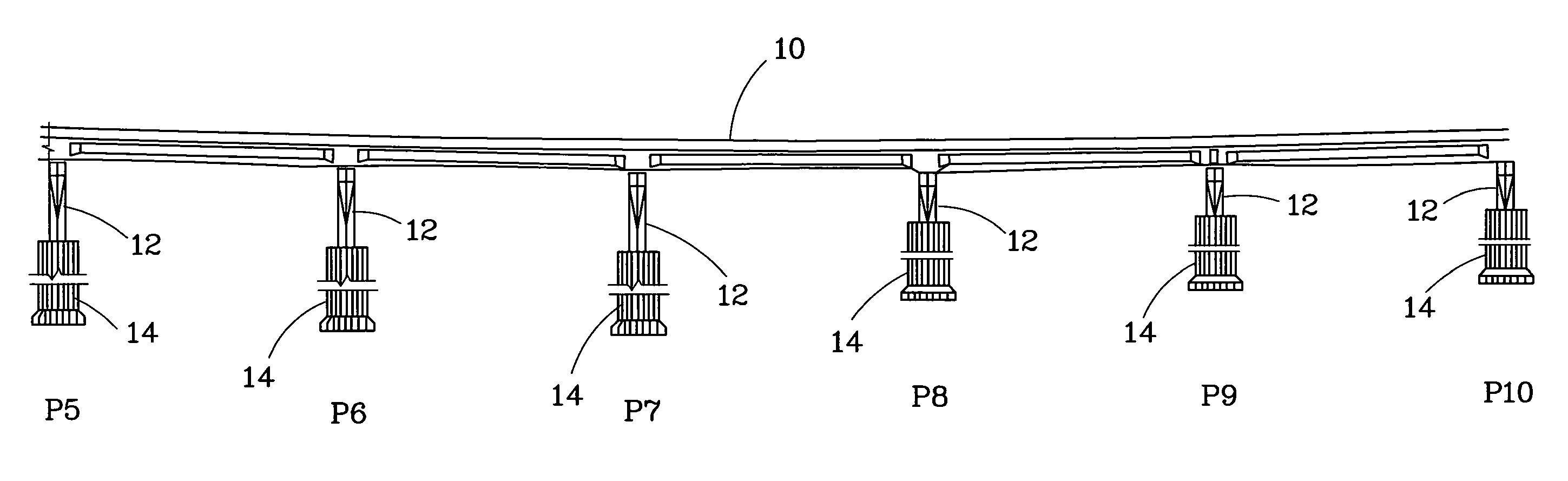

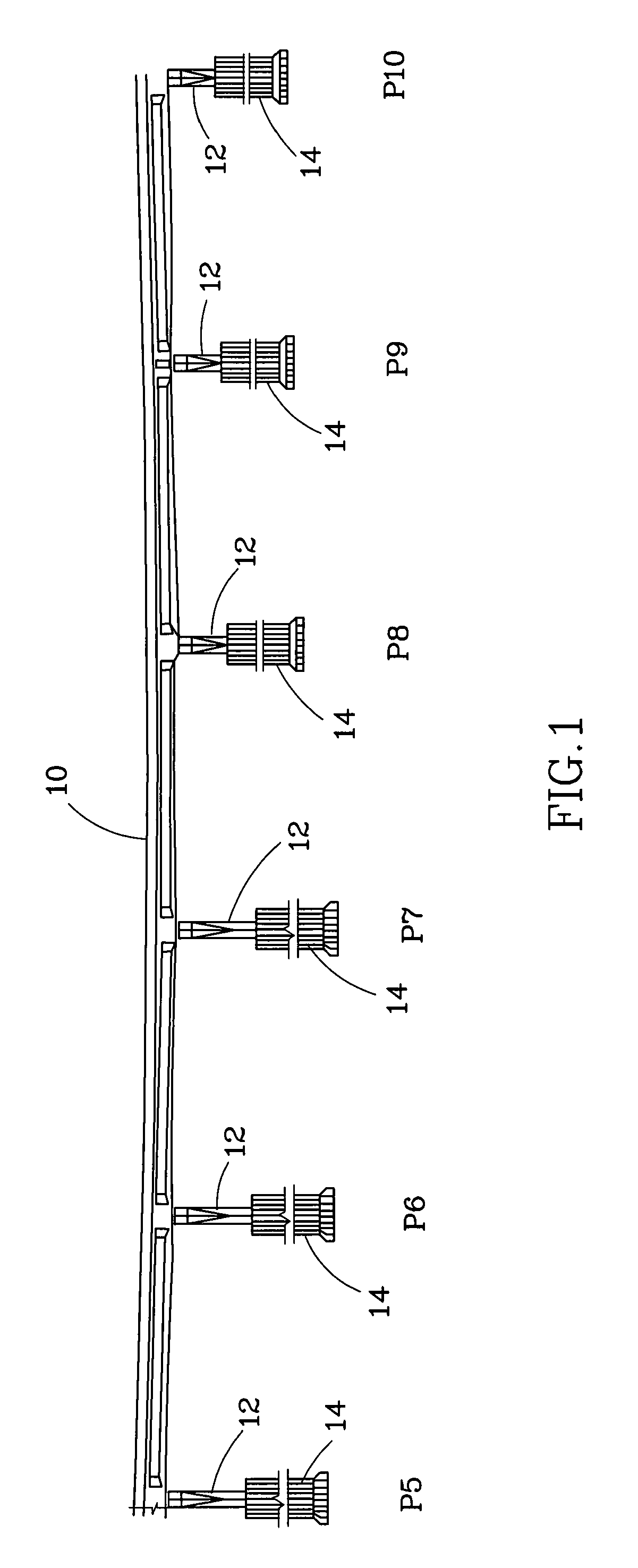

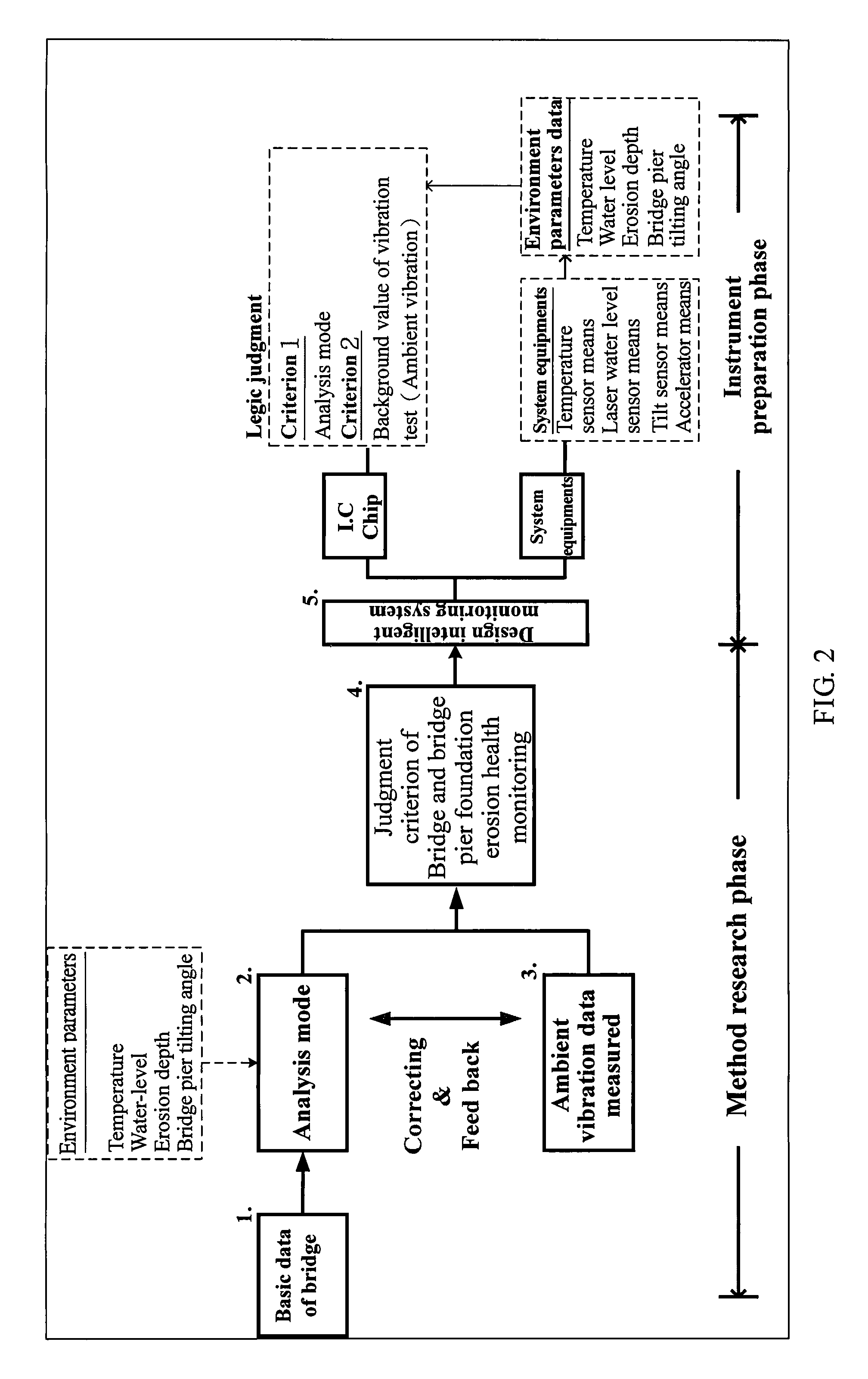

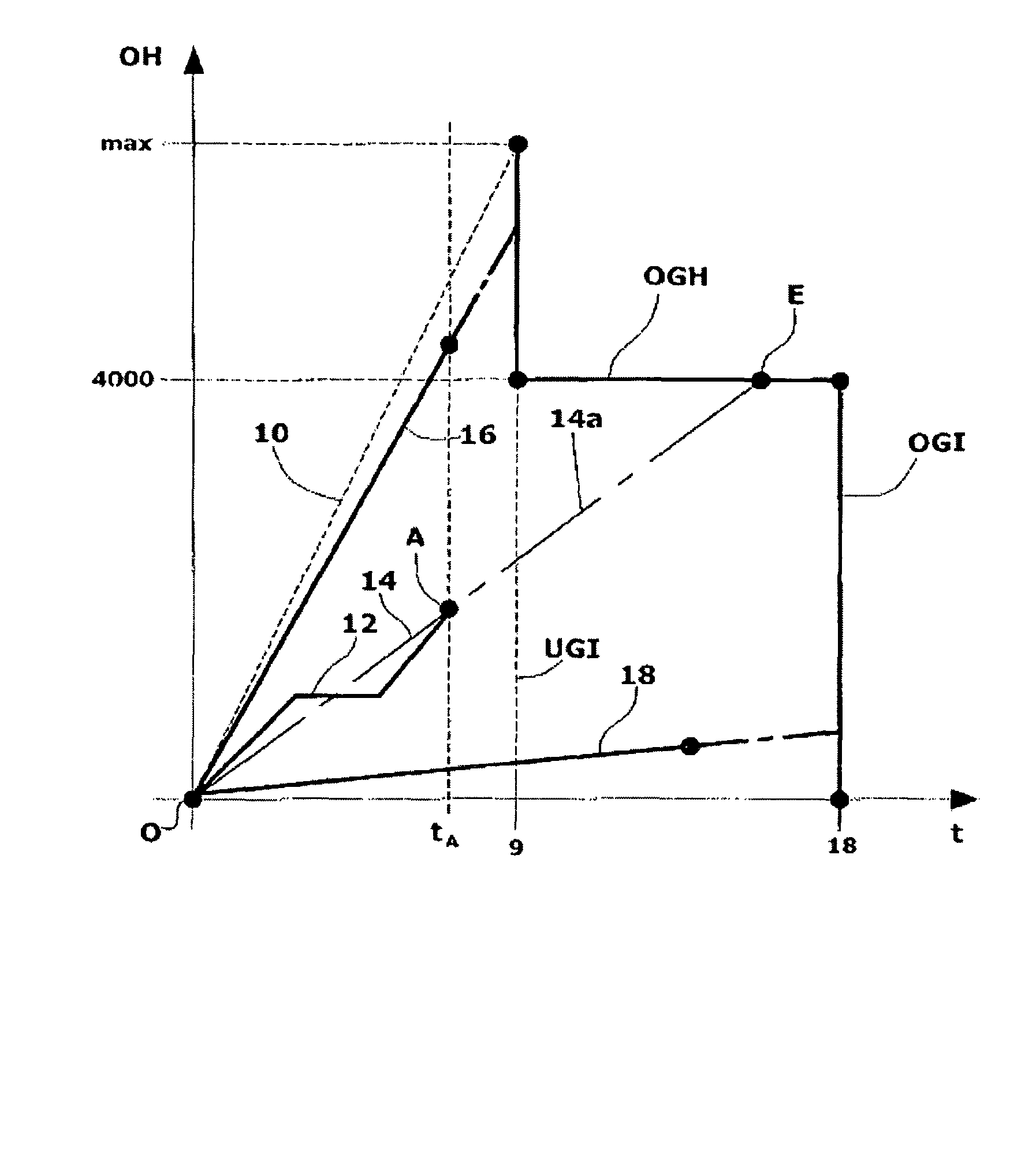

Bridge monitoring and safety evaluation method using a vibration technique

ActiveUS20100242609A1Easy system maintenanceImprove the level ofVehicle testingFluid-tightness measurementStructural monitoringEngineering

The invention relates bridge structure safety evaluation technology by means of combining vibration measuring and structural model analysis techniques for bridge erosion evaluation and pre-warning monitoring applications. This technology can also be applied for long-term bridge structure monitoring and safety evaluation as well as judgment and evaluation of rail structure abnormality.

Owner:LEE WEI FENG

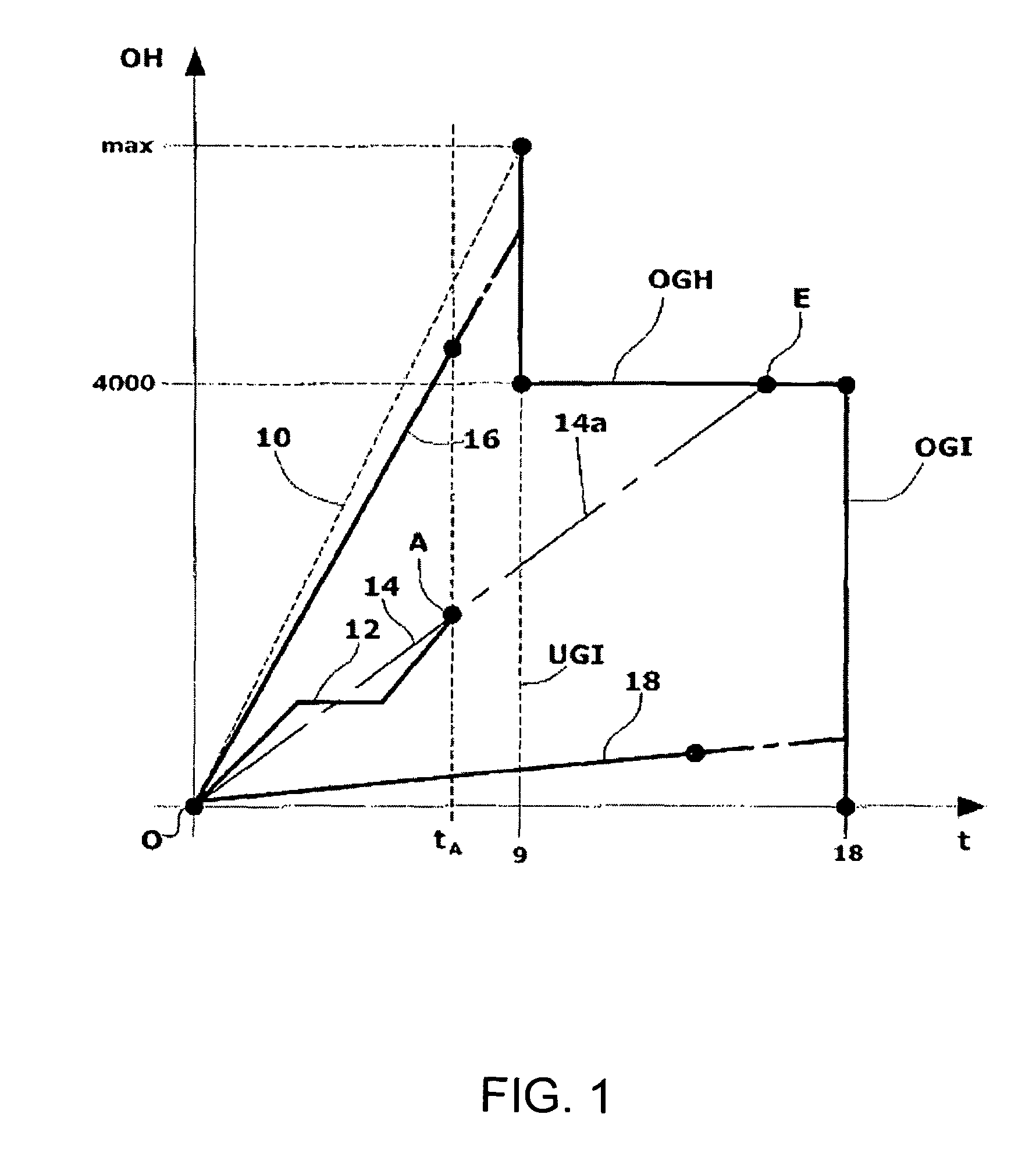

Dialysis machine with servicing indicator

A dialysis machine that monitors an elapsed time and a number of accumulated hours during a current servicing interval is disclosed. The machine executes a machine-servicing algorithm on at least the elapsed time and the accumulated operating hours to generate a projected servicing interval duration. A servicing event indicator displays servicing event schedule information based on the projected servicing interval duration. A transfusion pump, similarly equipped, is also provided.

Owner:B BRAUN MEDIZINTECH

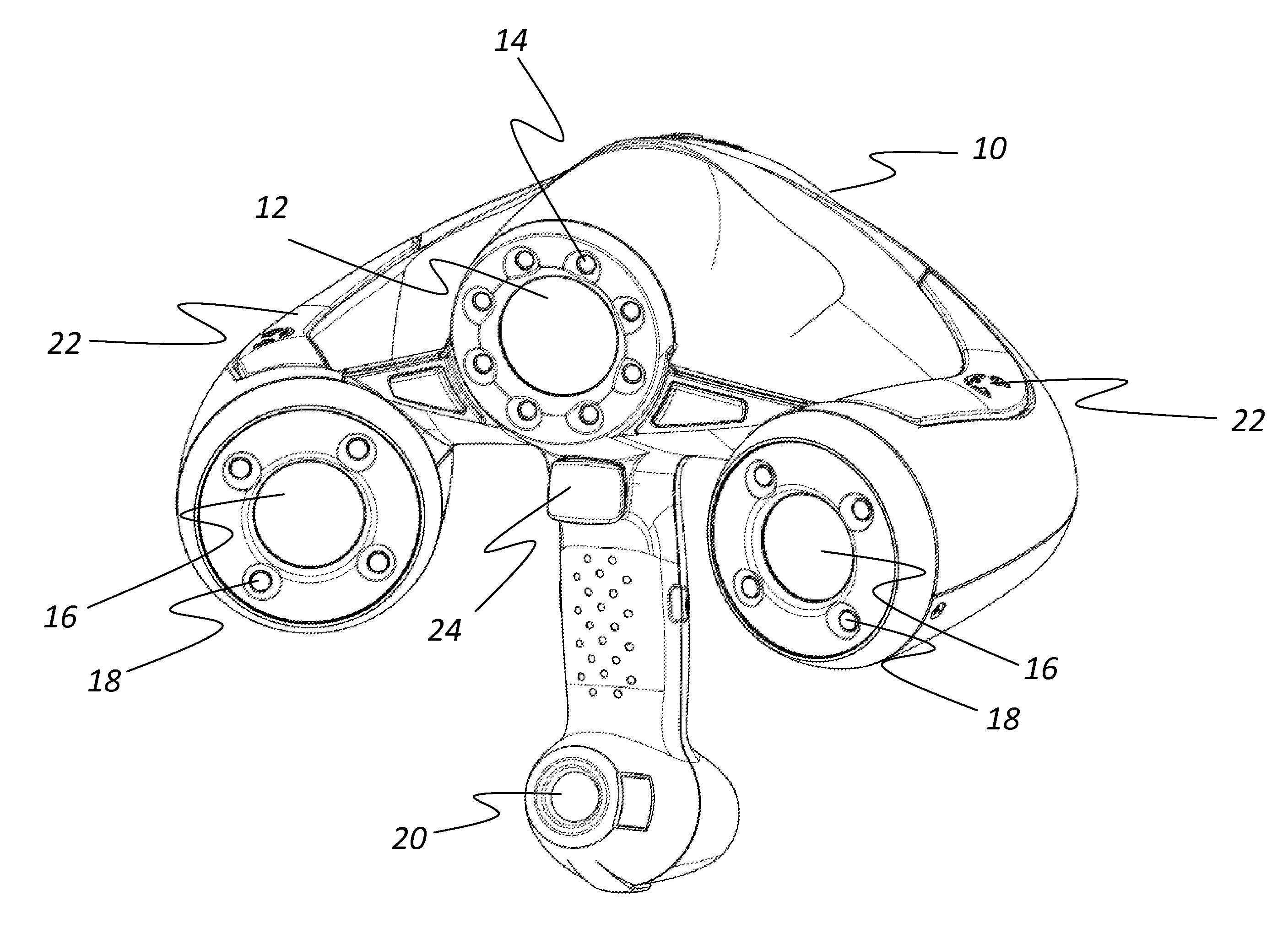

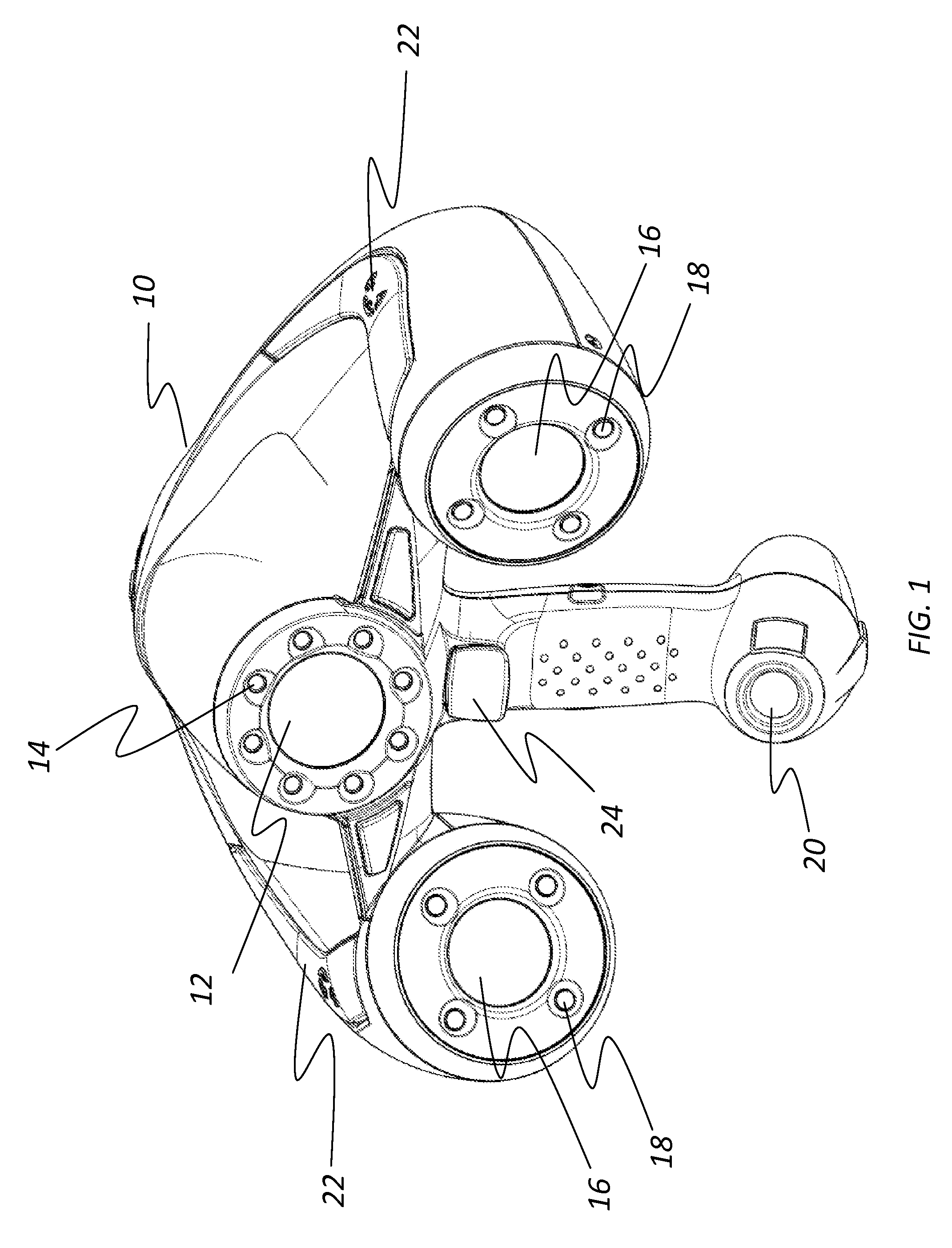

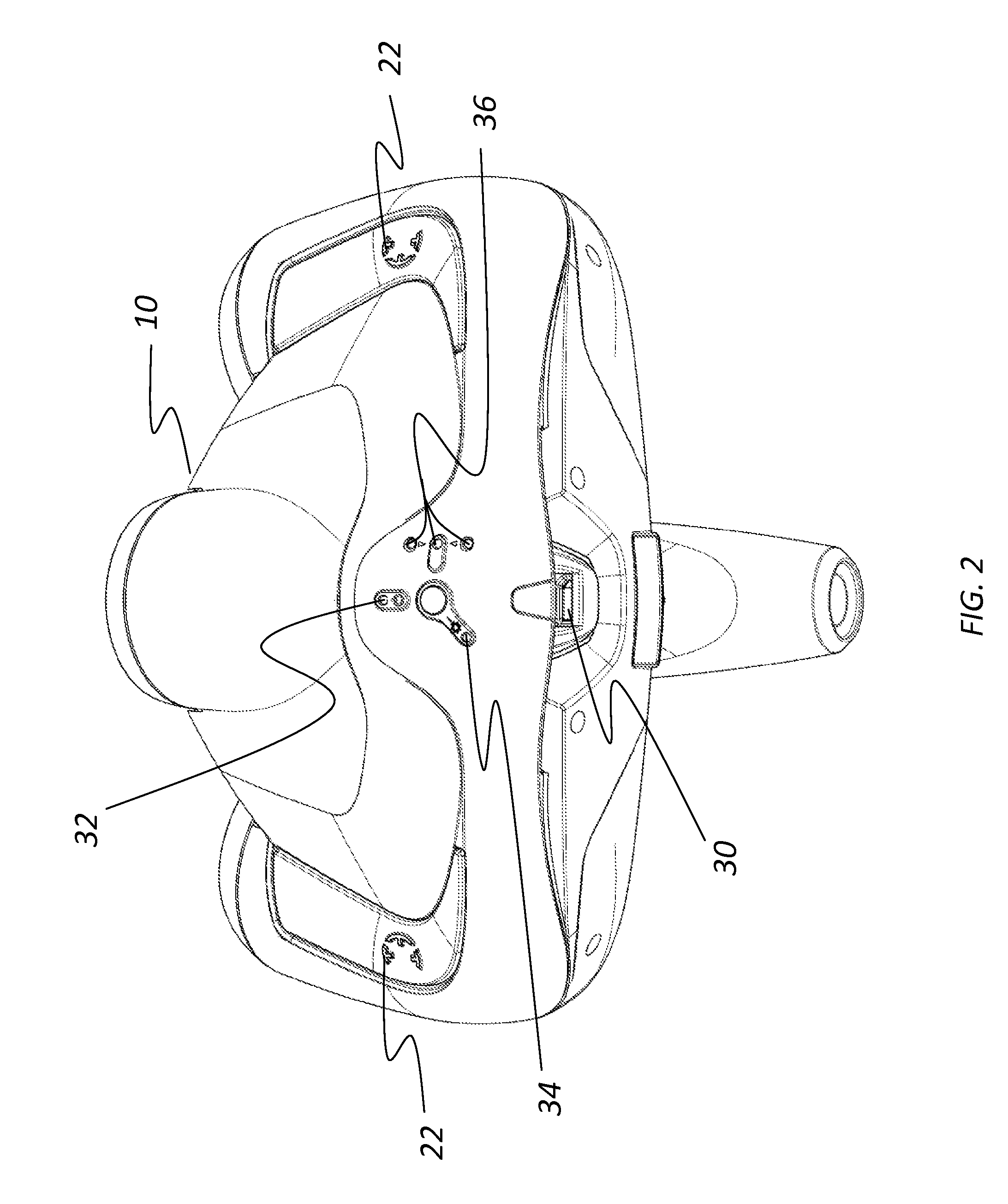

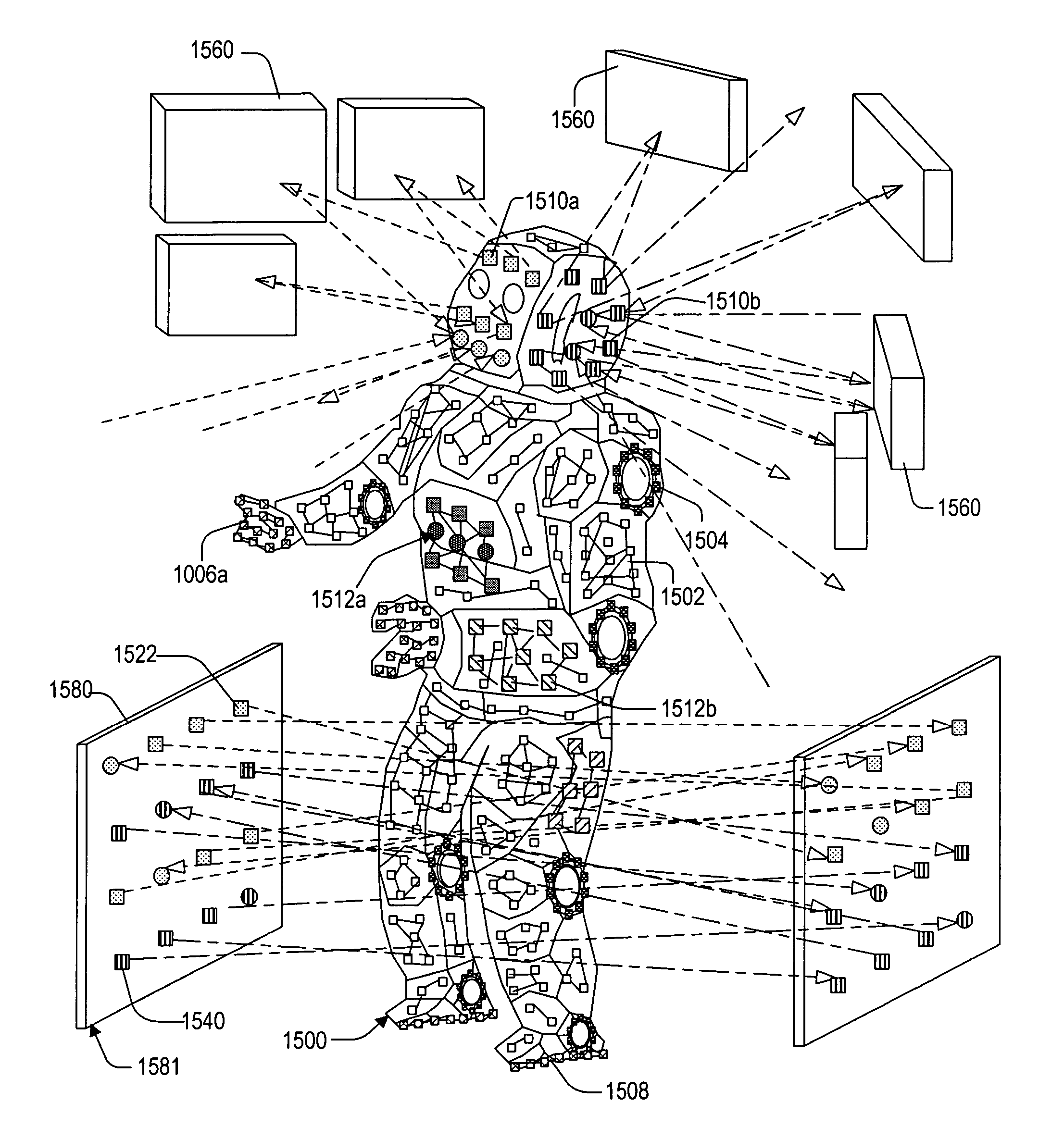

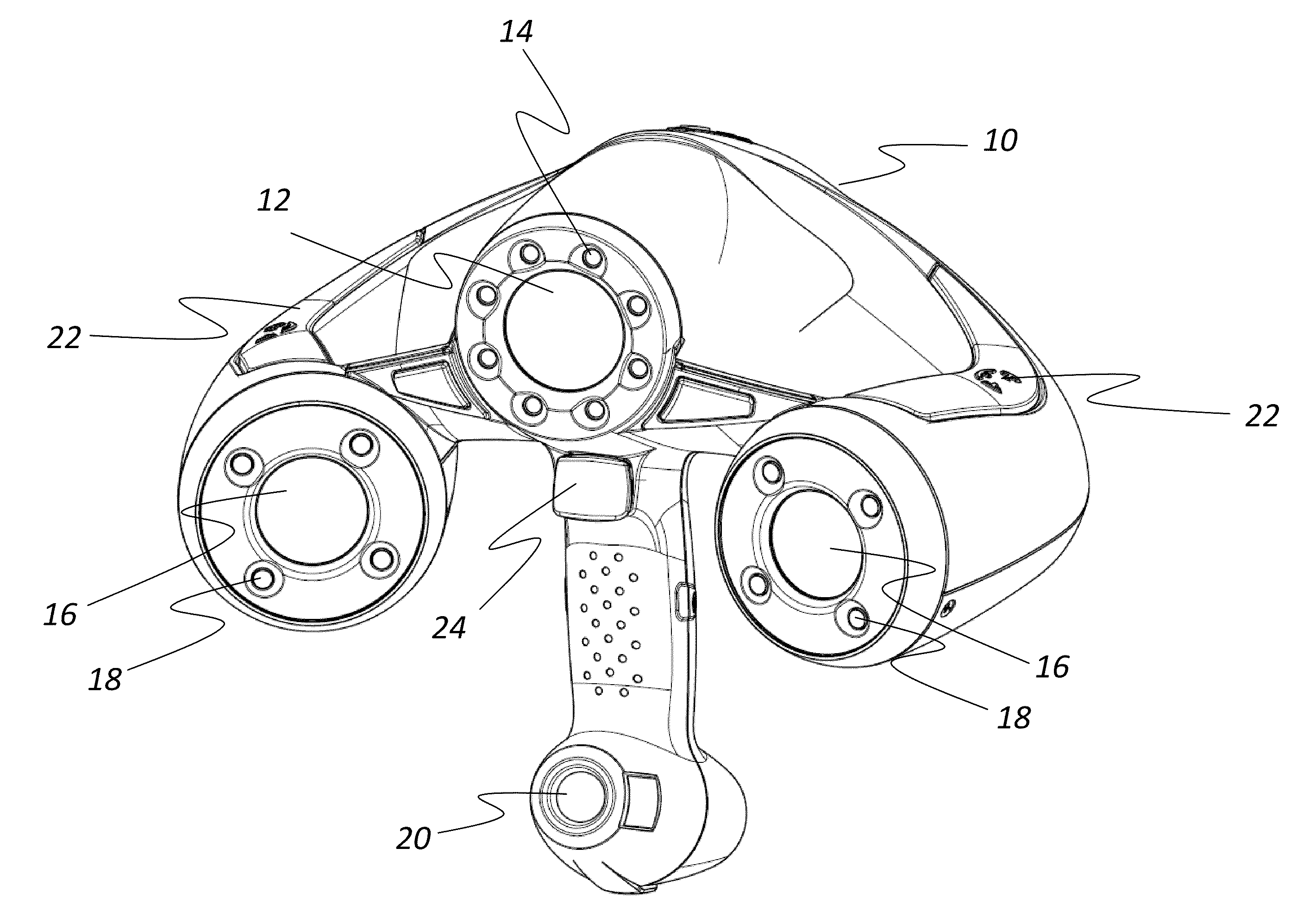

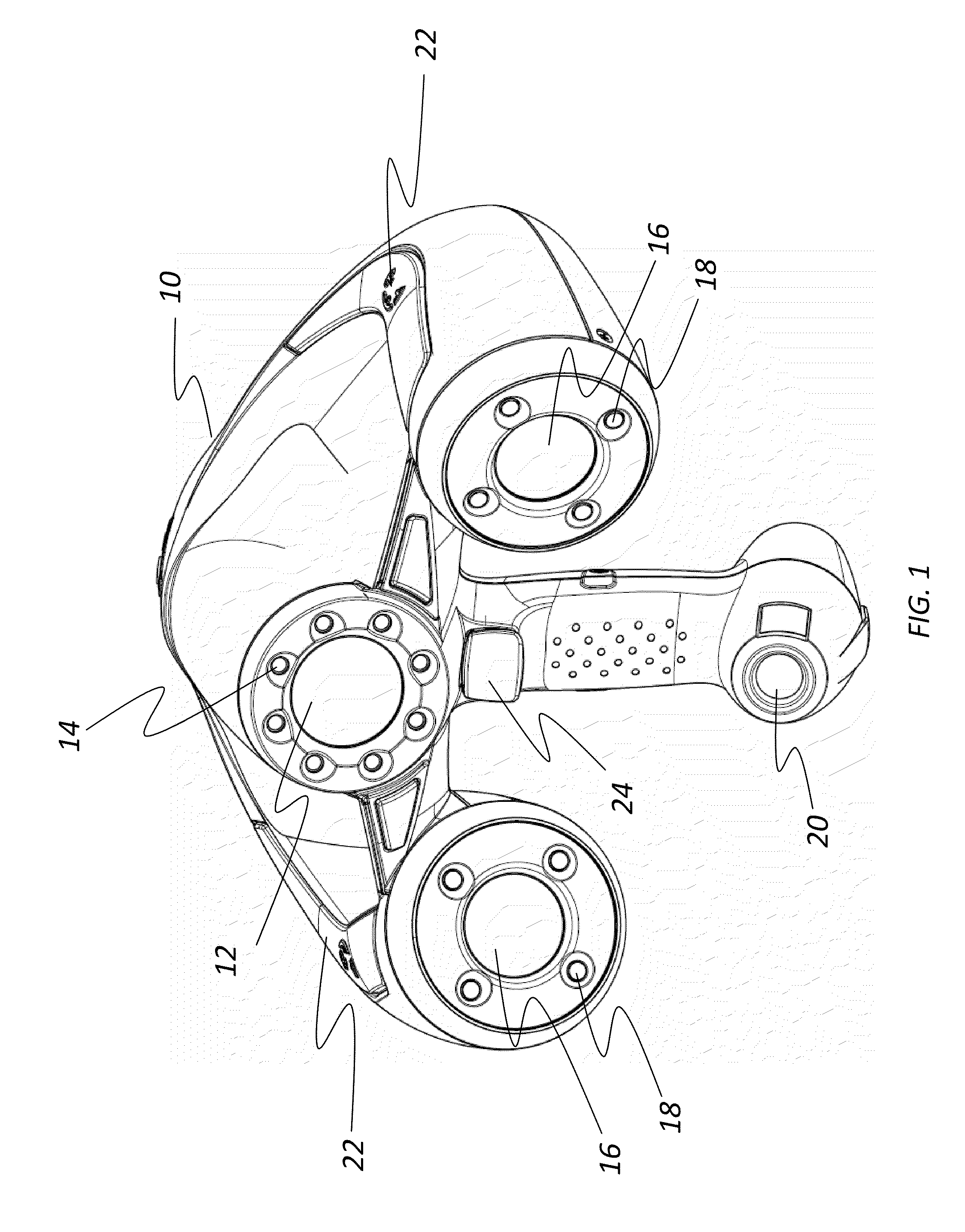

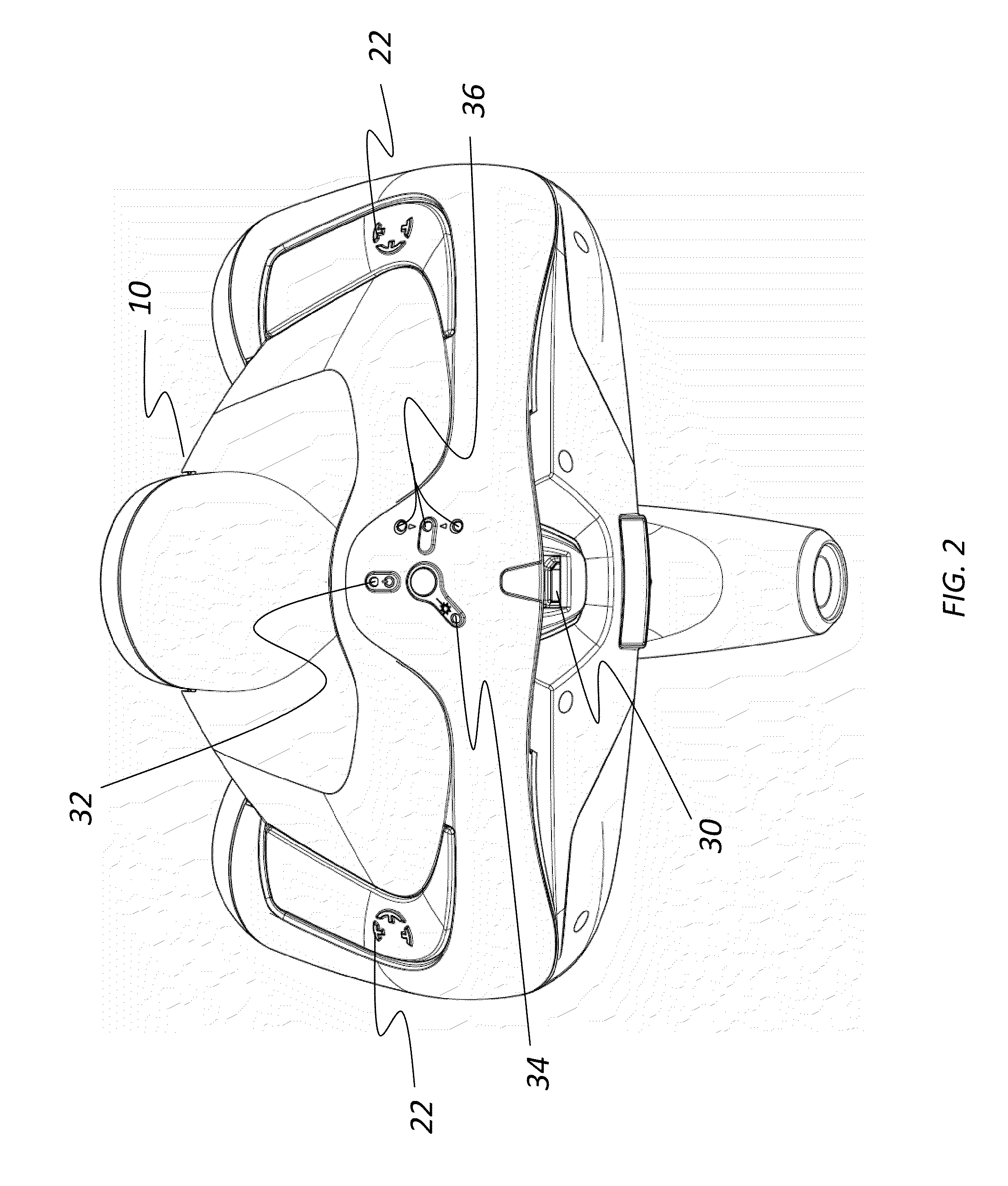

Hand-held self-referenced apparatus for three-dimensional scanning

ActiveUS20100134598A1Improve accuracyAccurate modelingCharacter and pattern recognitionSensing record carriersHand held3d scanning

A method and hand-held scanning apparatus for three-dimensional scanning of an object is described. The hand-held self-referenced scanning apparatus has a light source for illuminating retro-reflective markers, the retro-reflective markers being provided at fixed positions on or around the object, a photogrammetric high-resolution camera, a pattern projector for providing a projected pattern on a surface of the object; at least a pair of basic cameras, the basic camera cooperating with light sources, the projected pattern and at least a portion of the retro-reflective markers being apparent on the 2D images, a frame for holding all components in position within the hand-held apparatus, the frame having a handle, the frame allowing support and free movement of the scanning apparatus by a user.

Owner:CREAFORM INC

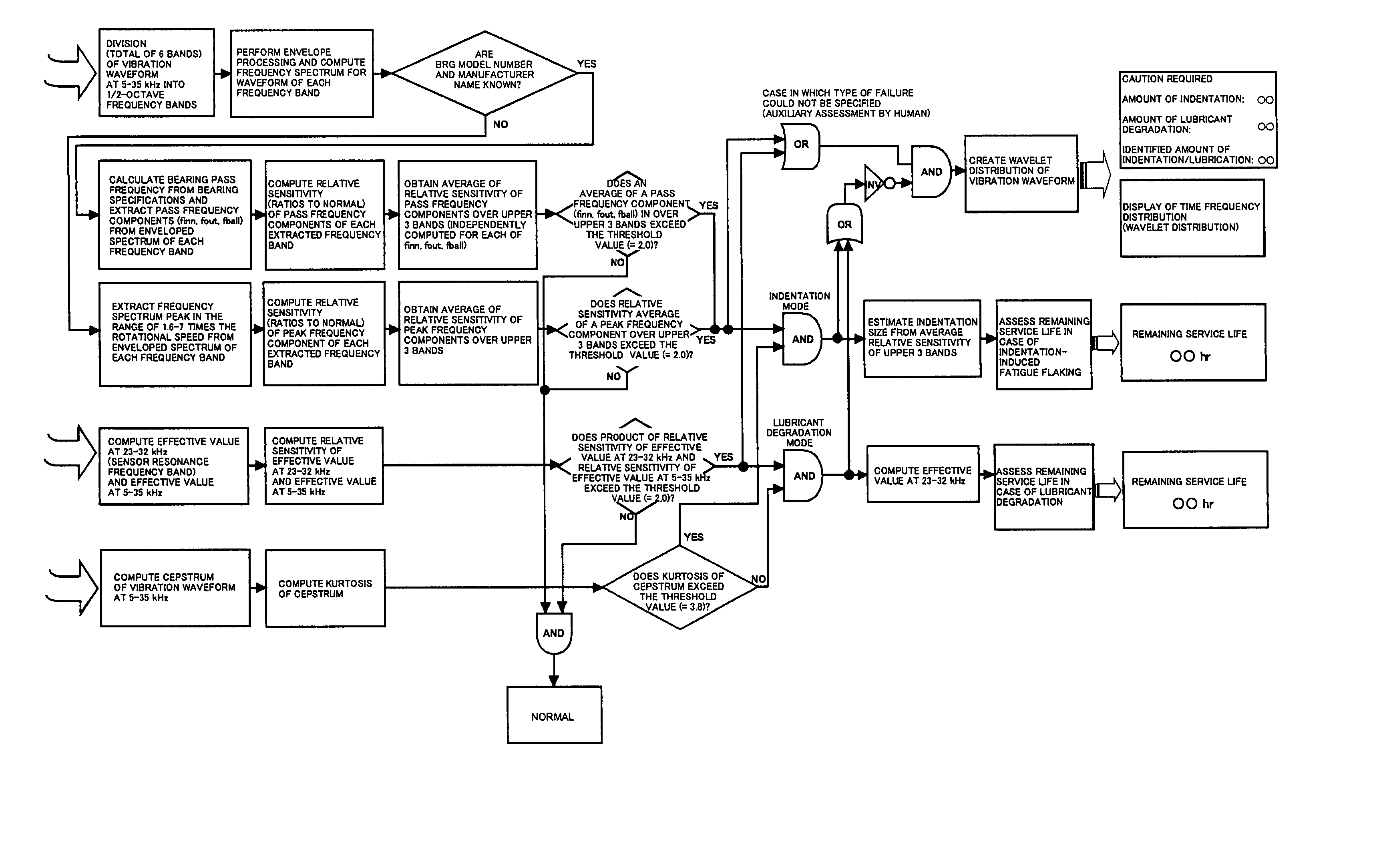

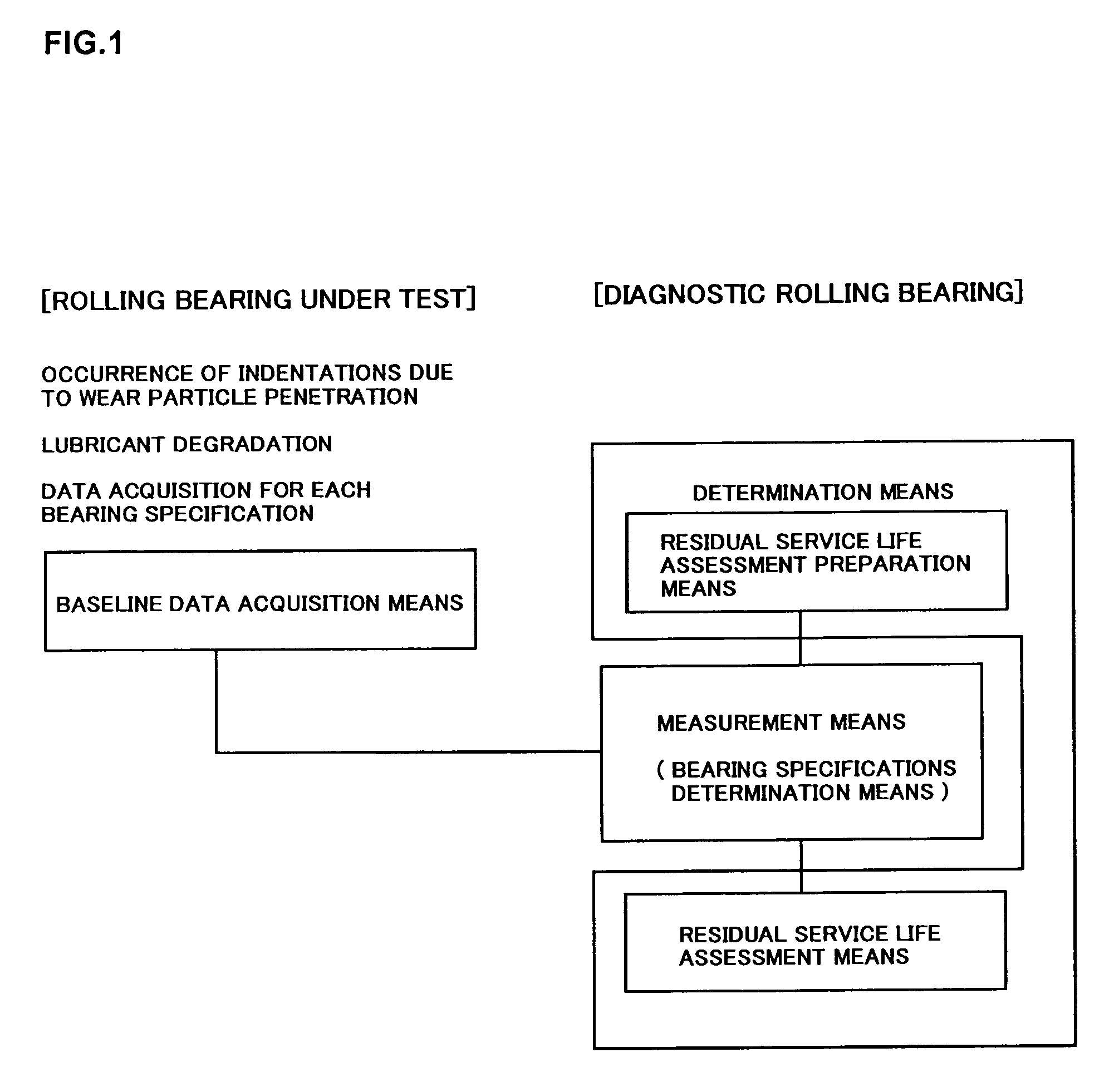

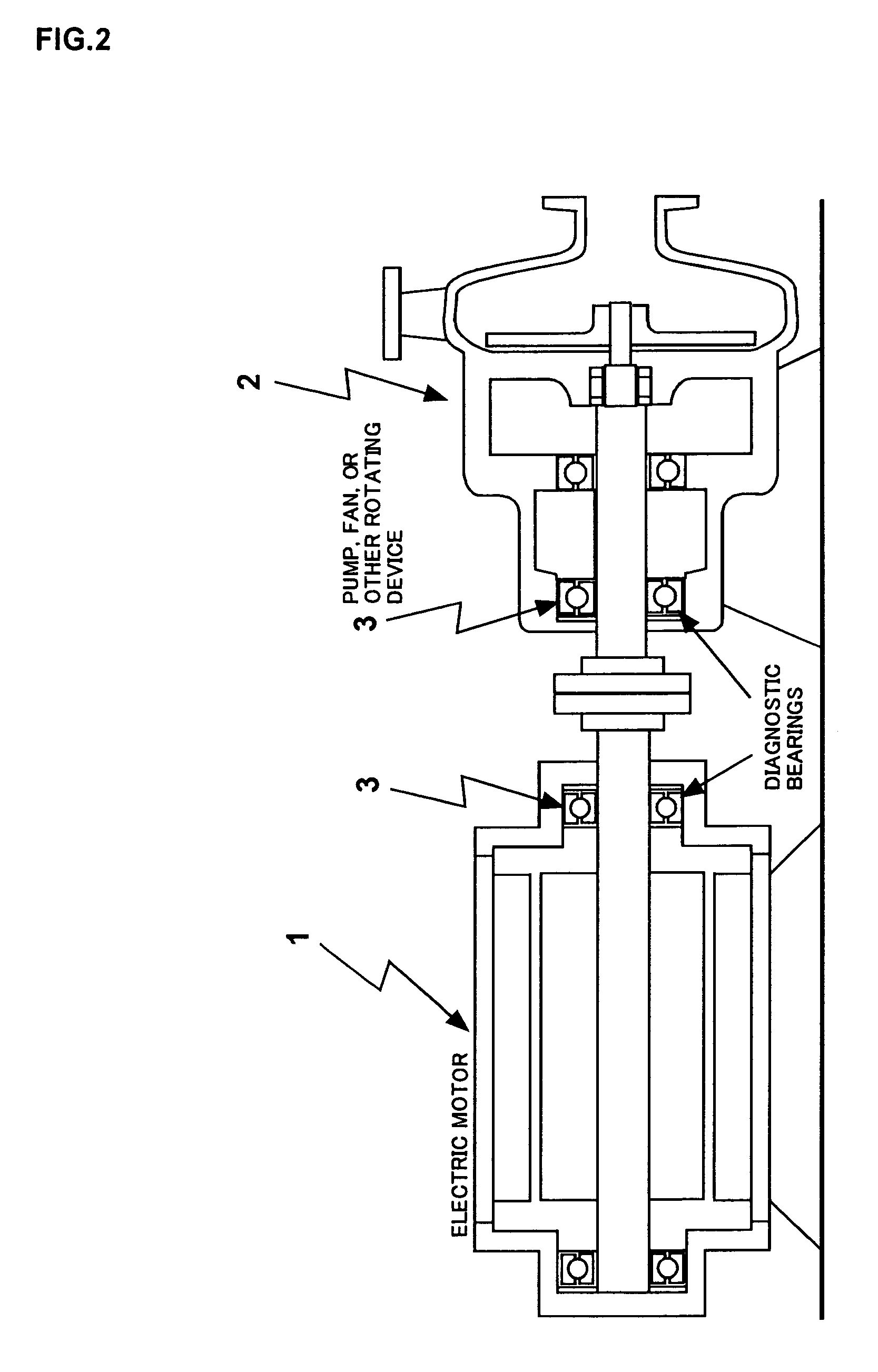

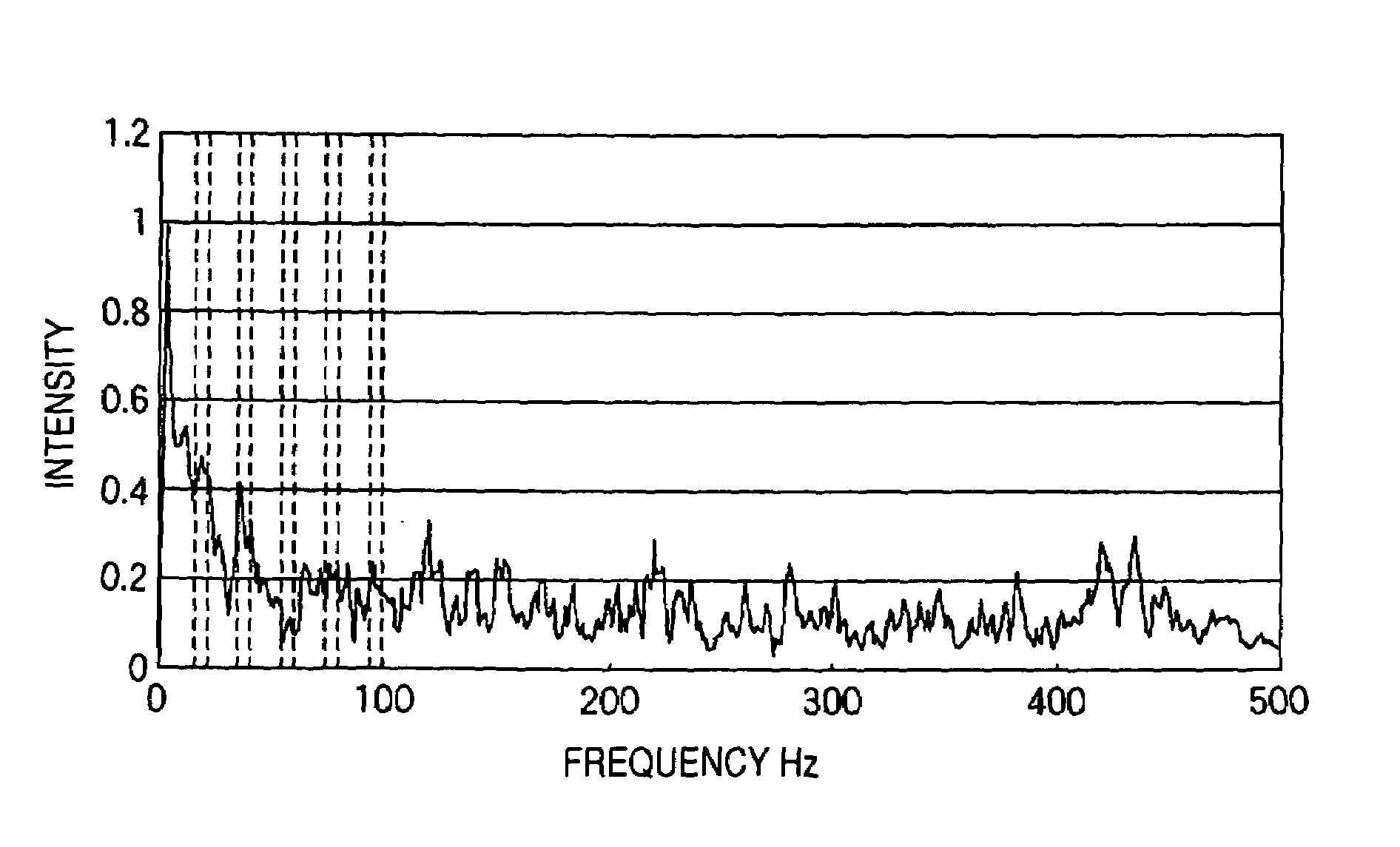

Method And Device For Assessing Residual Service Life Of Rolling Bearing

InactiveUS20070277613A1Improve accuracyVibration measurement in solidsMachine part testingBaseline dataAccelerometer

Degradation of the lubricant due to contamination of the lubricant with wear particles or moisture, which greatly affects the service life of rolling bearings, can be detected in a cost-effective manner through the use of a resonance frequency band signal or high-frequency signal of an accelerometer, and the service life of a rolling bearing can be estimated with high precision at an early stage on the basis of the detected state of the wear particles and lubricant. Provided is a method comprising baseline data acquisition means for obtaining vibration signals by using an accelerometer 4 and using a testing device to acquire resonance frequency band signals detectable at the highest sensitivity, for each specification such as model number, manufacturer name, and other specifications for a rolling bearing 3 as pertains to the relationship between the state of wear particle penetration in a rolling bearing 3 and the vibration / bearing service life, and to lubricant degradation and vibration / bearing service life; measurement means whereby an accelerometer 4 is used to obtain vibration signals for the rolling bearing 3 whose remaining service life is being assessed and which resides on a fan, a pump, or another rotating device 1, 2, for the purpose of measuring resonance frequency band signals detectable at the highest sensitivity; and determination means for estimating the state of wear particle penetration and the state of lubricant degradation of the diagnostic rolling bearing 3, and computing the remaining service life of the diagnostic rolling bearing 3 by using measurement values obtained by the measurement means, determination results of the bearing specification determination means, and data obtained by the baseline data acquisition means.

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

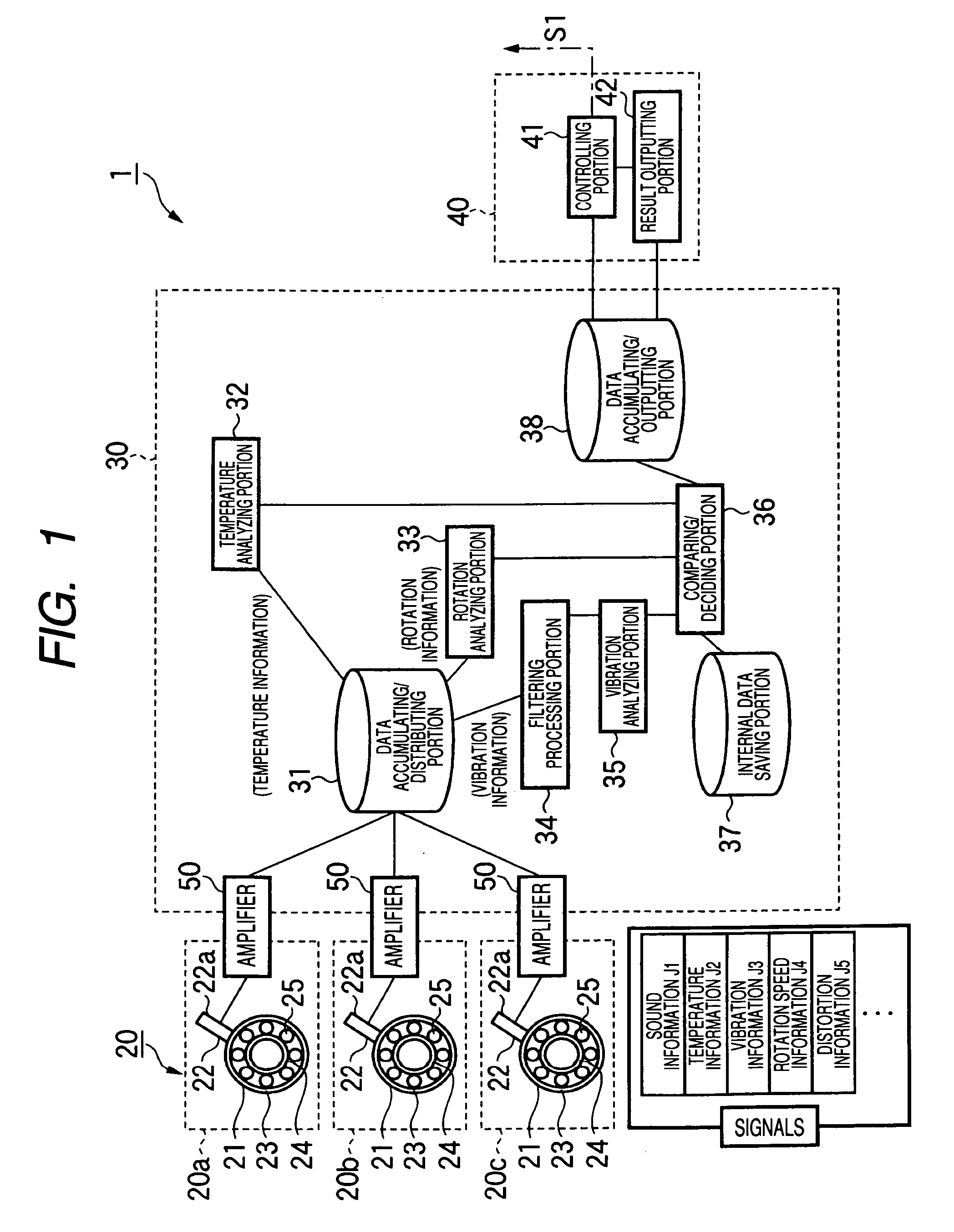

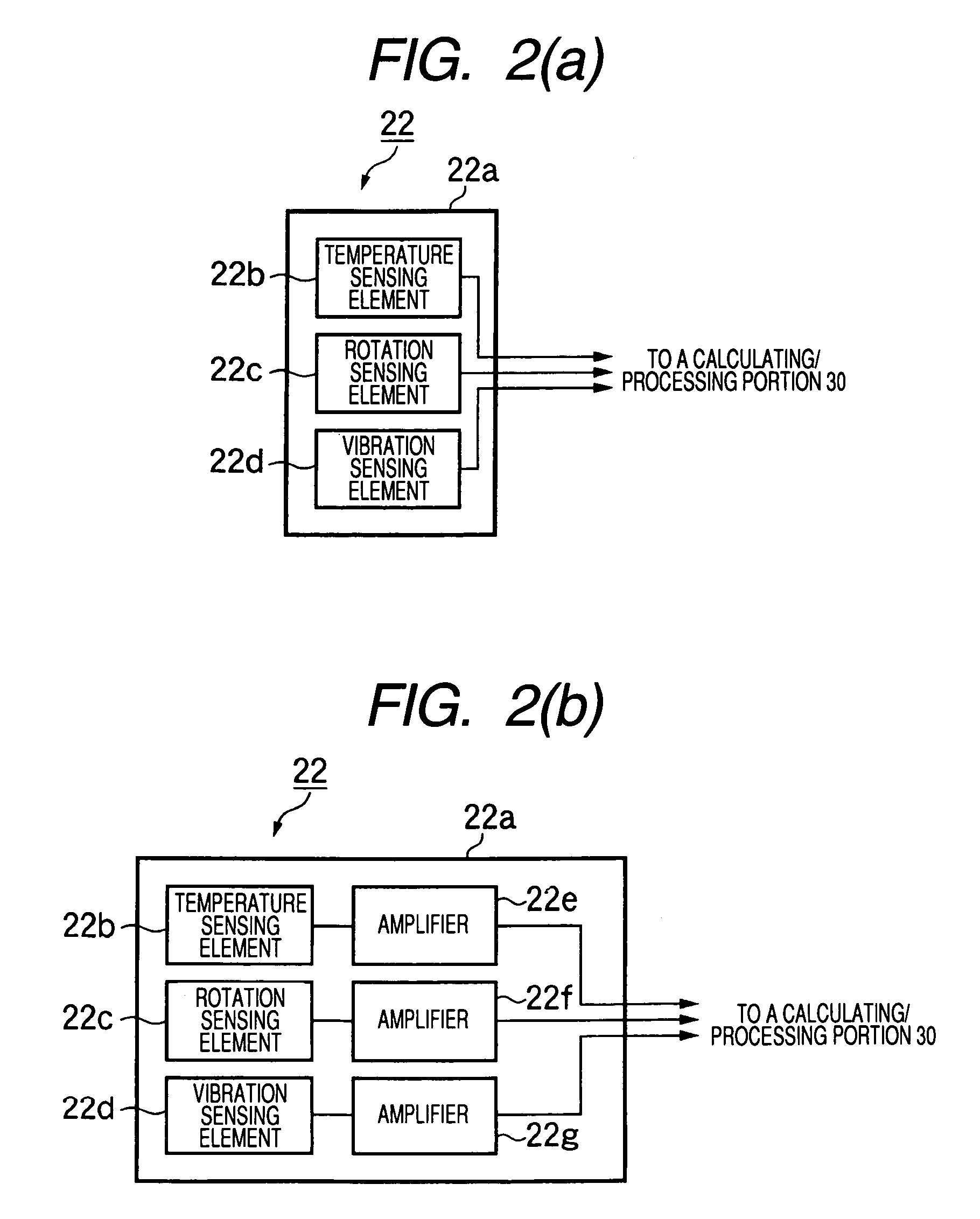

Method and device for monitoring status of mechanical equipment and abnormality diagnosing device

An abnormality diagnosis system for diagnosing a presence or absence of an abnormality of a bearing unit for a railway vehicle axle, comprises a sensing / processing portion for outputting a signal generated from the bearing unit as an electric signal, a calculating / processing portion for making an abnormality diagnosis of the bearing unit based on an output of the sensing / processing portion, a result outputting portion for outputting a decision result of the calculating / processing portion, and a controlling / processing portion for feeding back a control signal to a control system of the railway vehicle based on the decision result.

Owner:NSK LTD

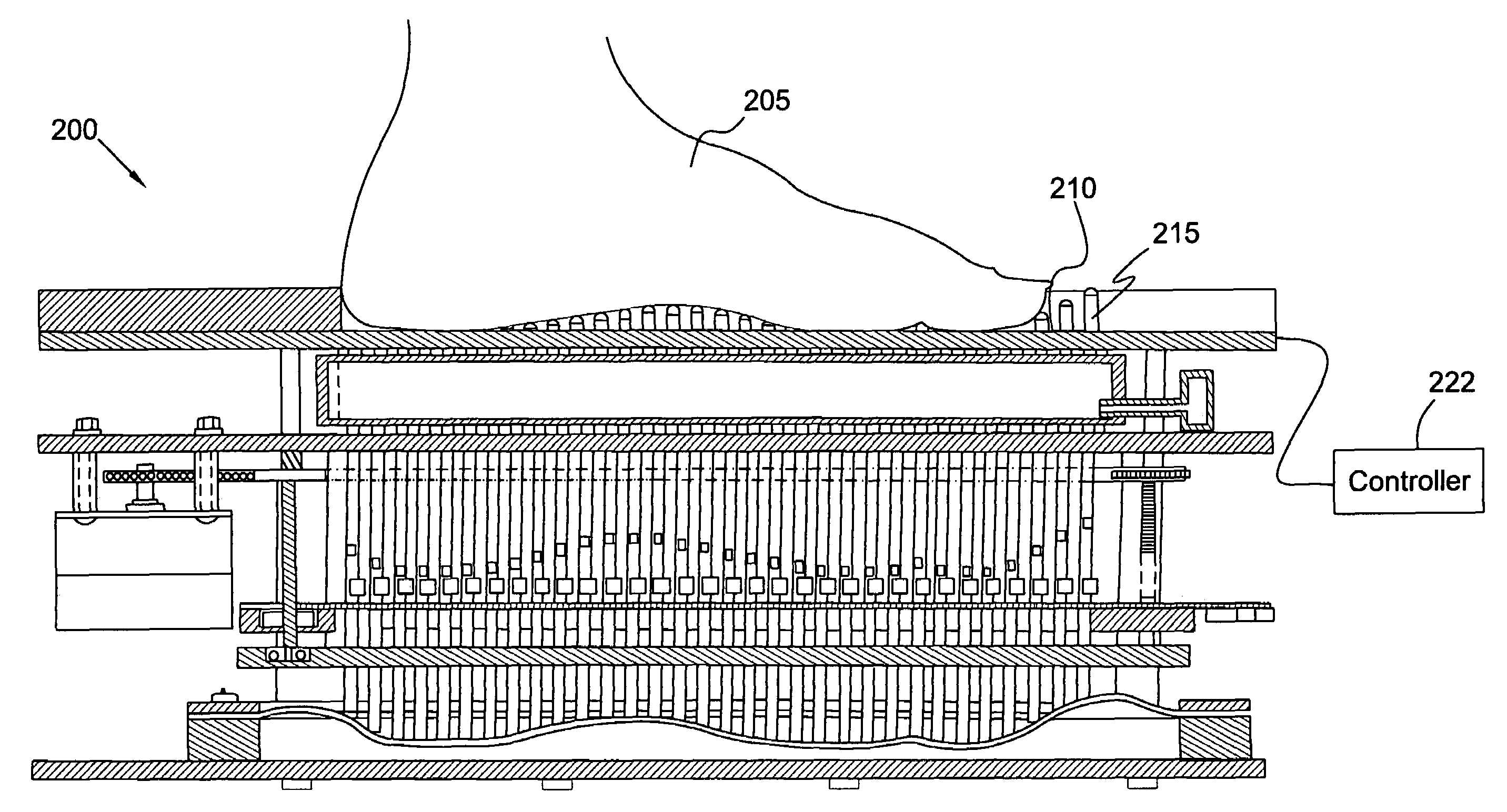

Method for determining relative mobility or regions of an object

ActiveUS7617068B2Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsPhysical medicine and rehabilitation

Owner:AMFIT INCORPORATED

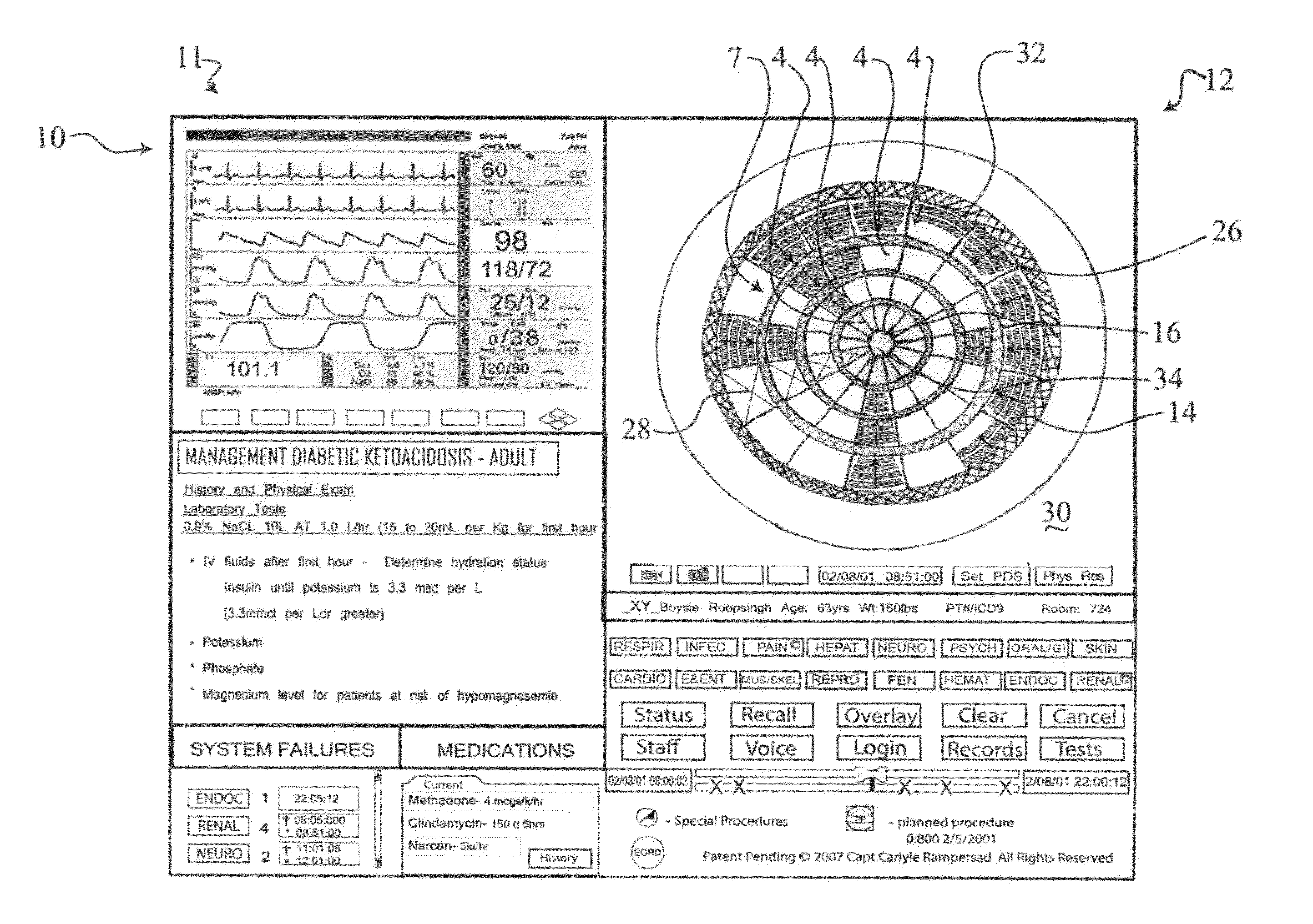

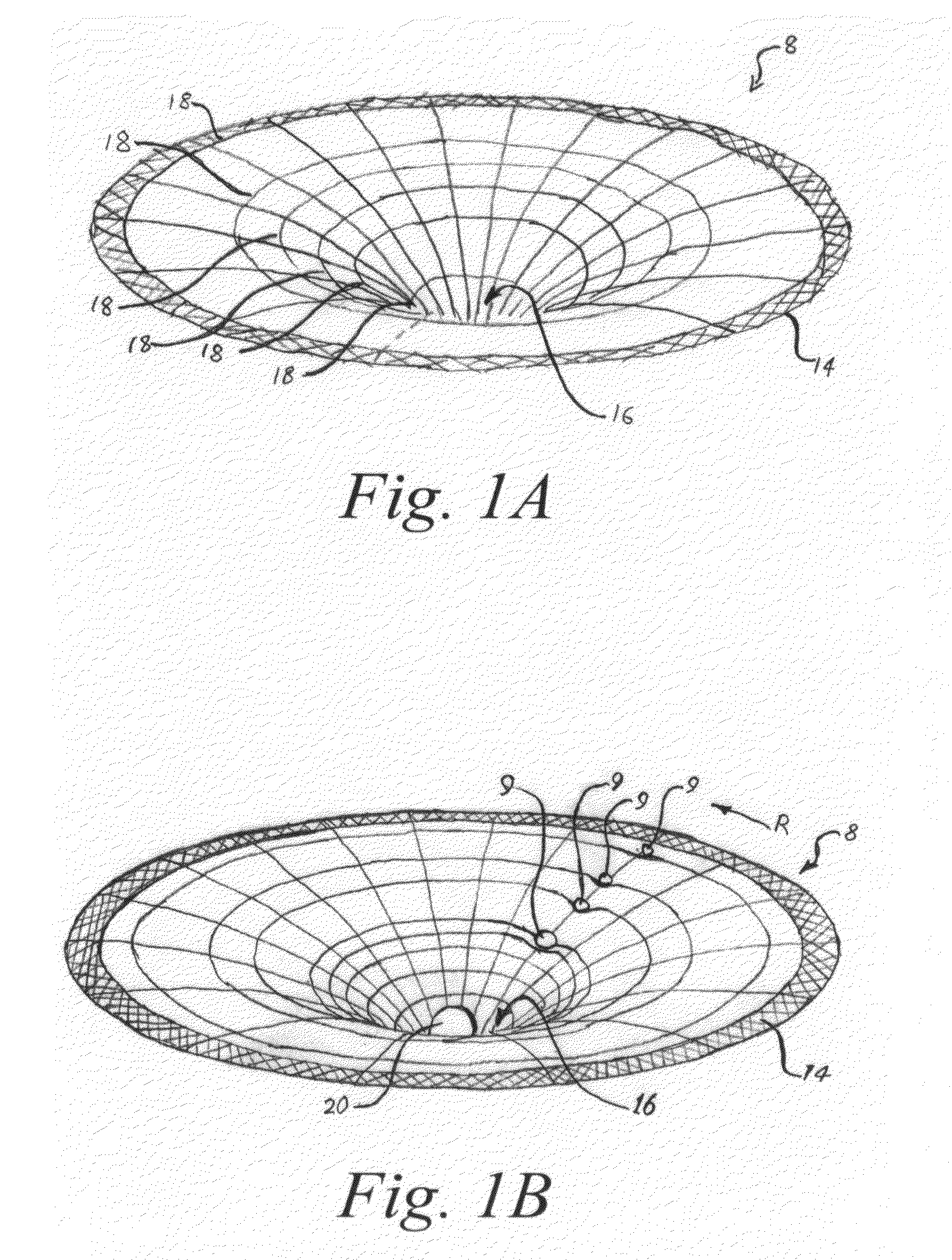

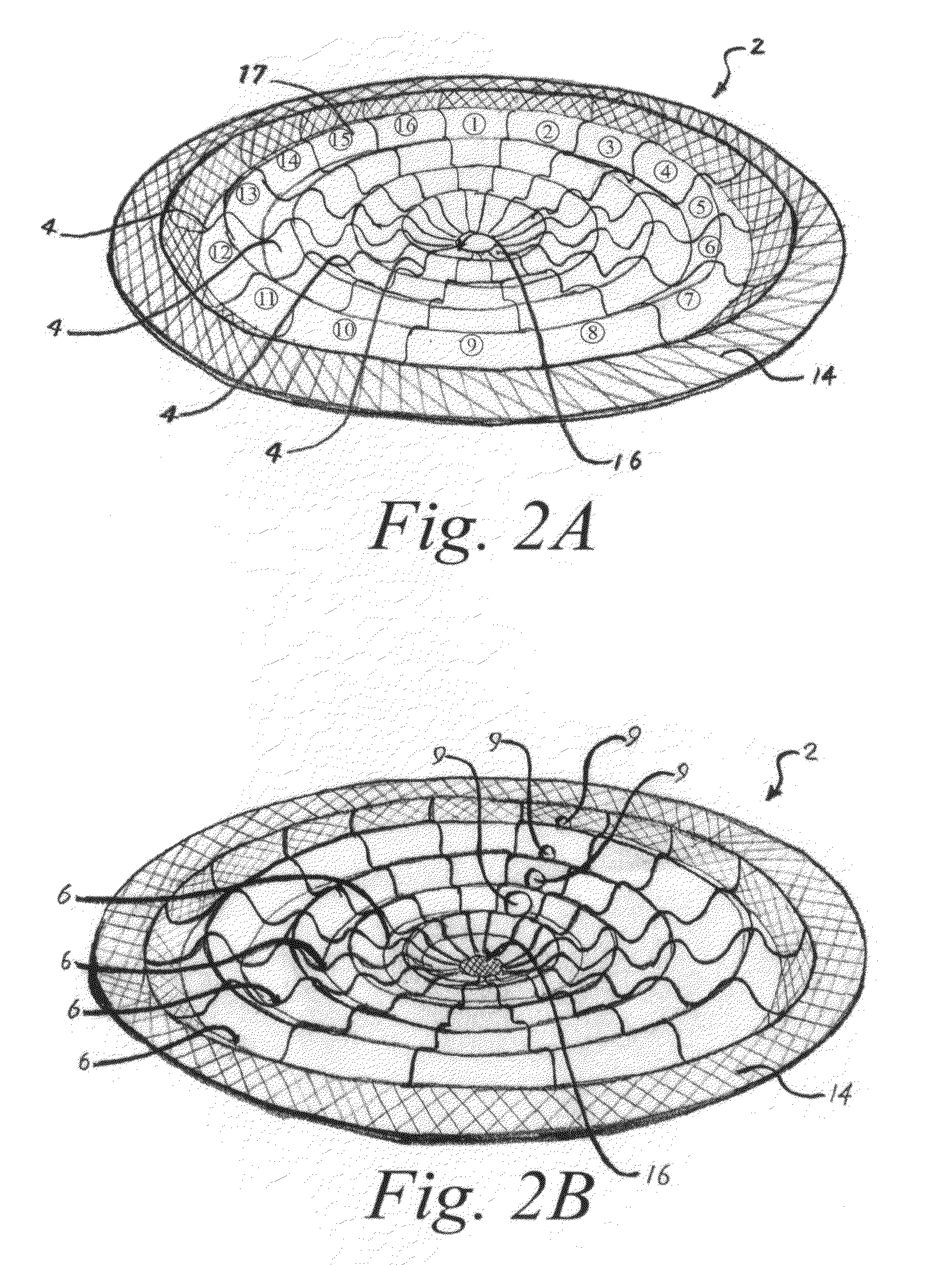

Totally integrated intelligent dynamic systems display

An apparatus for graphically displaying analytical data, comprising a generic model to graphically represent a complex set of physical characteristics potentially leading to catastrophic failure of a physical system. A central region represents failure of the physical system; a series of concentric ridges represents level of function. Wedge shaped regions upon the ridges represent predetermined subsystems of the physical system. An icon is displayed with changes in the icon proportional to time, and any one or more of color, position, shape, and rotation of the icon representing prescribed analysis of the physical characteristics. Mappings correlate predetermined characteristics of the system with failure of the physical system, levels of functioning represented by the ridges, subsystems represented by the wedge shaped regions, and / or analysis of the physical characteristics represented in the icon. A sensor interface receives measurements, and a graphics generator prepares a presentation of the model.

Owner:OJARALI SYST LLP

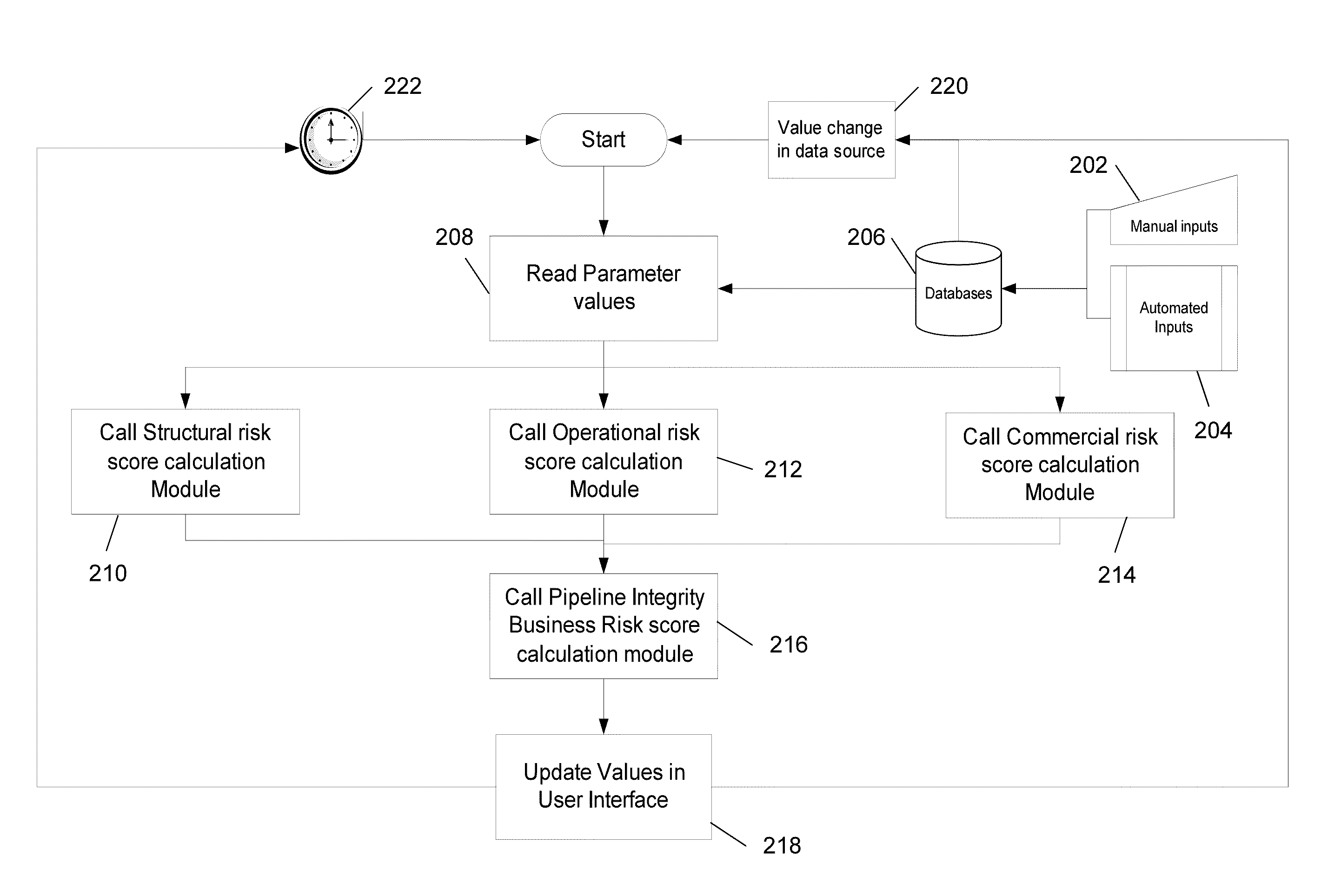

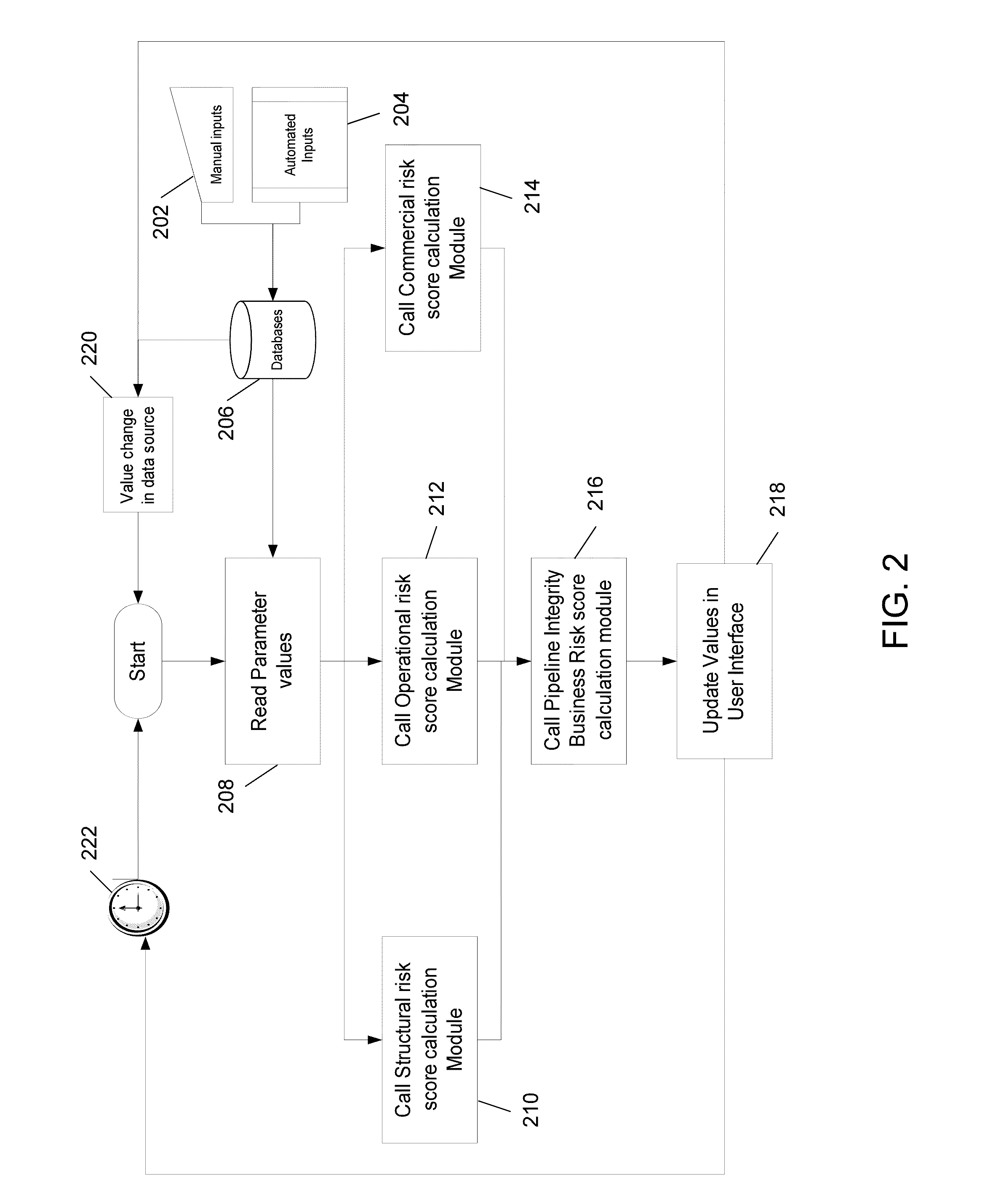

System and method for calculating a comprehensive pipeline integrity business risk score

ActiveUS20110137704A1Level indicatorsTesting/calibration of speed/acceleration/shock measurement devicesEngineeringWeight factor

A method and system for calculating pipeline integrity business risk score for a pipeline network is provided. The method includes a step of first calculating a structural risk score, an operational risk score and a commercial risk score for each pipeline segment in a pipeline network. The method further includes calculating pipeline integrity business risk score for each pipeline segment. The structural risk score, operational risk score, commercial risk score and pipeline integrity business risk score for each pipeline segment is rolled-up to calculate the respective risk scores of a pipeline network. The rolled-up risk scores are calculated by computing weight factors for each pipeline segment, relative risk scores weight of each pipeline segment and relative risk scores contribution of each pipeline segment. The system of the invention comprises executable files, dynamic linked libraries and risk score computing modules configured to display the risk scores using a dashboard.

Owner:INFOSYS LTD

Methods of networking interrogation devices for structural conditions

InactiveUS7668665B2Vibration measurement in solidsSpecial data processing applicationsDirected graphUndirected graph

Owner:ADVANCED STRUCTURE MONITORING

Guided wave pipeline inspection system with enhanced focusing capability

InactiveUS7751989B2Economical to useMinimized data collectionError preventionFrequency-division multiplex detailsMultiplexingTime delays

Owner:FUKUOKA BROADCASTING CORPORATION

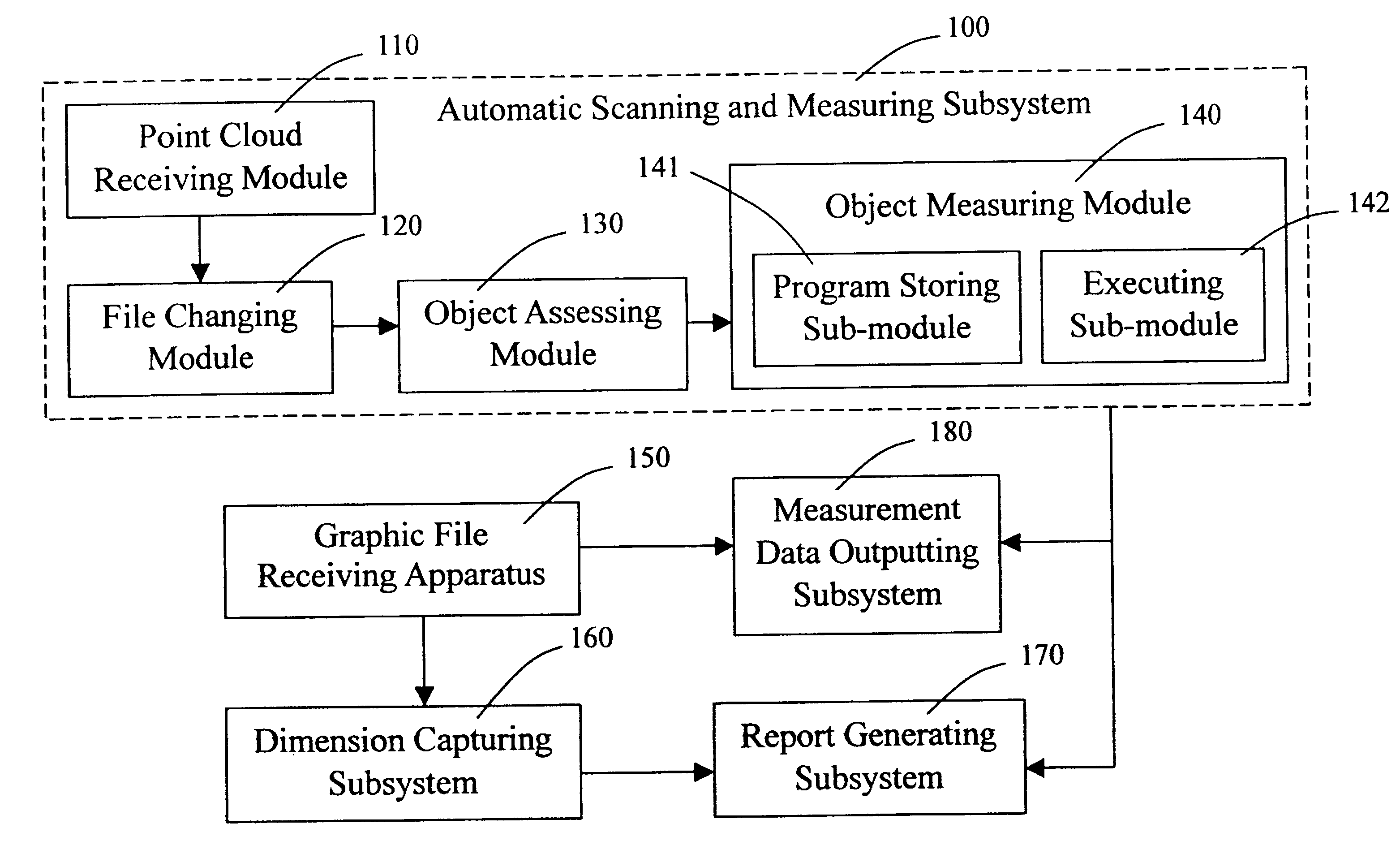

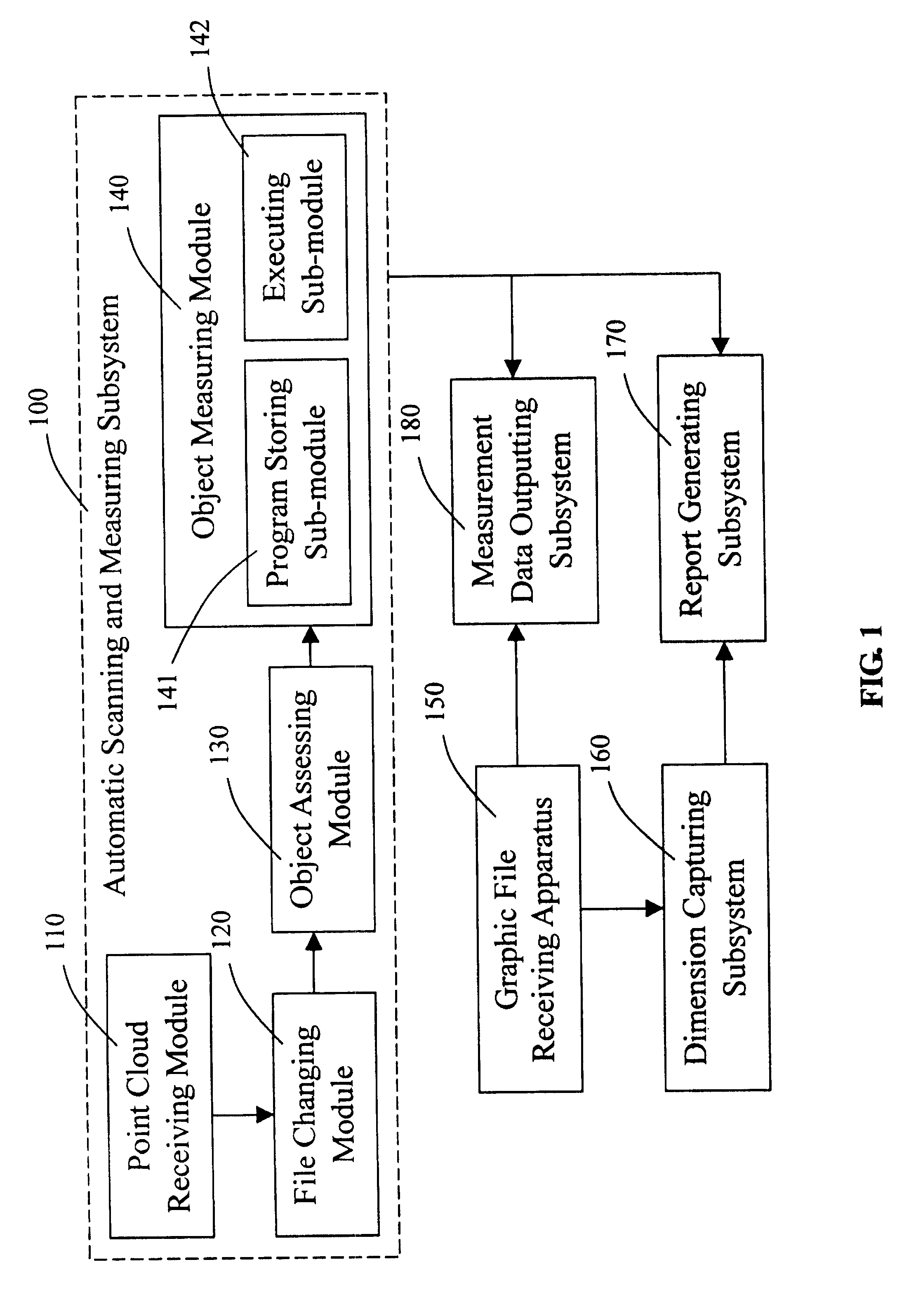

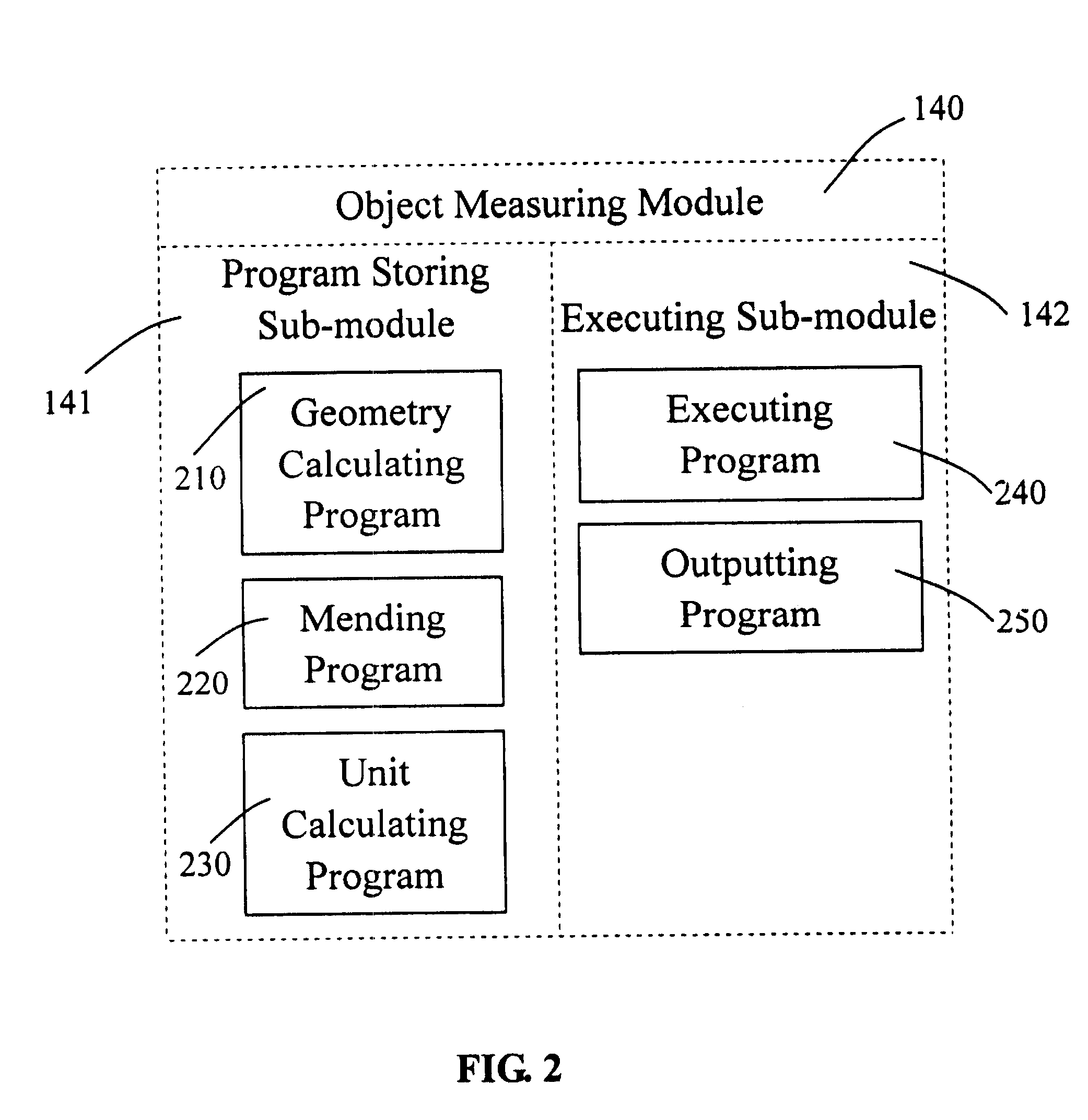

System and method for analyzing and processing data on an object

A system and method for analyzing and processing data on an object. The system includes: an automatic scanning and measuring subsystem (100) for obtaining point cloud data on the object by scanning the object, and generating measurement data on the object by processing the point cloud data; a graphic file receiving apparatus (150) for receiving a graphic file of the object; a dimension capturing subsystem (160) for retrieving design dimensions from the graphic file; a report generating subsystem (170) for generating a dimension report by combining the measurement data and the design dimensions; and a measurement data outputting subsystem (180) for outputting the measurement data to the graphic file.

Owner:HON HAI PRECISION IND CO LTD

Application of abnormal event detection technology to fluidized catalytic cracking unit

ActiveUS7567887B2PropellersSpecial data processing applicationsPrincipal component analysisCorrelation analysis

Owner:EXXON RES & ENG CO

Hand-held self-referenced apparatus for three-dimensional scanning

ActiveUS8082120B2Improve accuracyAccurate modelingCharacter and pattern recognitionSensing record carriersHand heldFixed position

A method and hand-held scanning apparatus for three-dimensional scanning of an object is described. The hand-held self-referenced scanning apparatus has a light source for illuminating retro-reflective markers, the retro-reflective markers being provided at fixed positions on or around the object, a photogrammetric high-resolution camera, a pattern projector for providing a projected pattern on a surface of the object; at least a pair of basic cameras, the basic camera cooperating with light sources, the projected pattern and at least a portion of the retro-reflective markers being apparent on the 2D images, a frame for holding all components in position within the hand-held apparatus, the frame having a handle, the frame allowing support and free movement of the scanning apparatus by a user.

Owner:CREAFORM INC

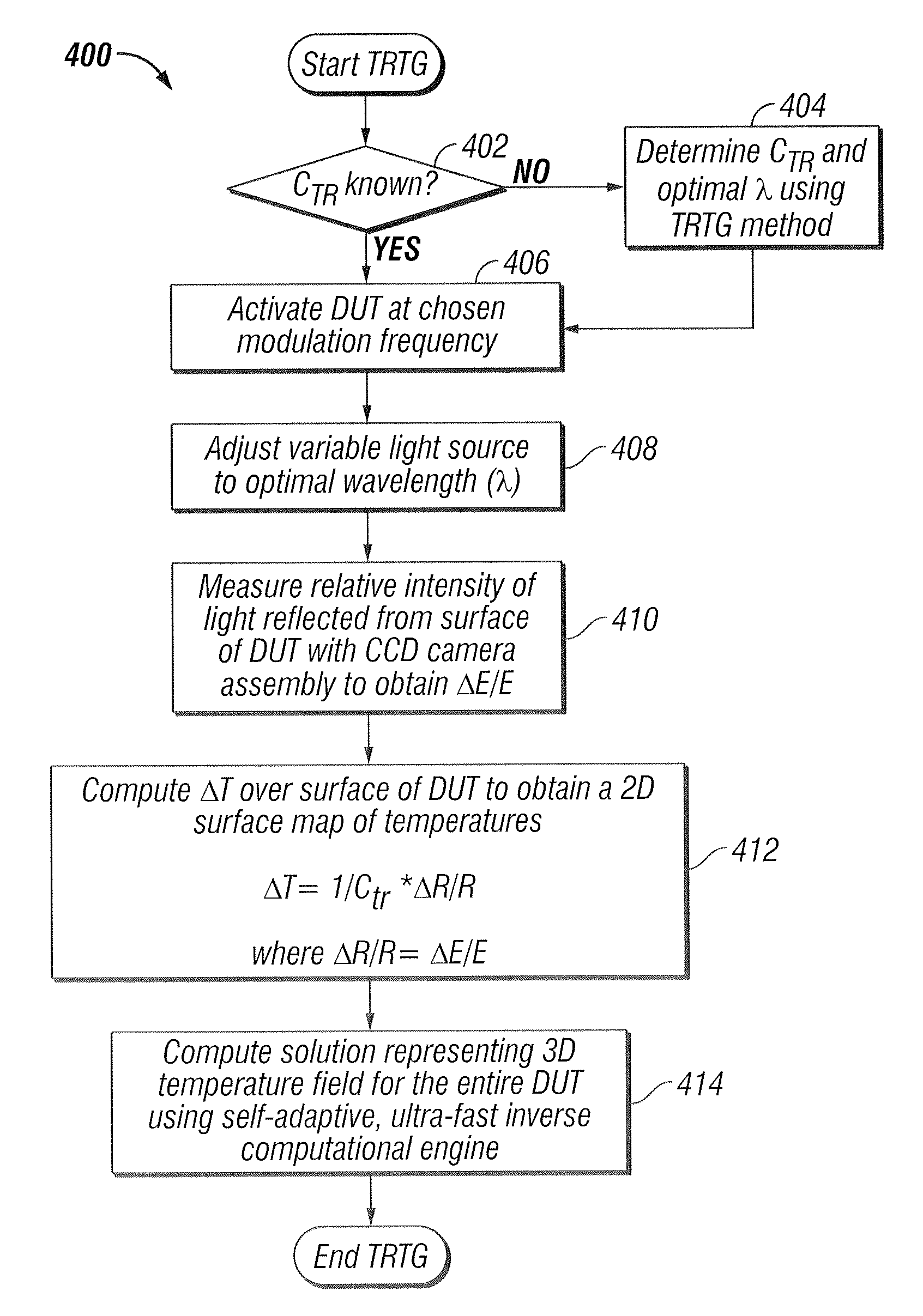

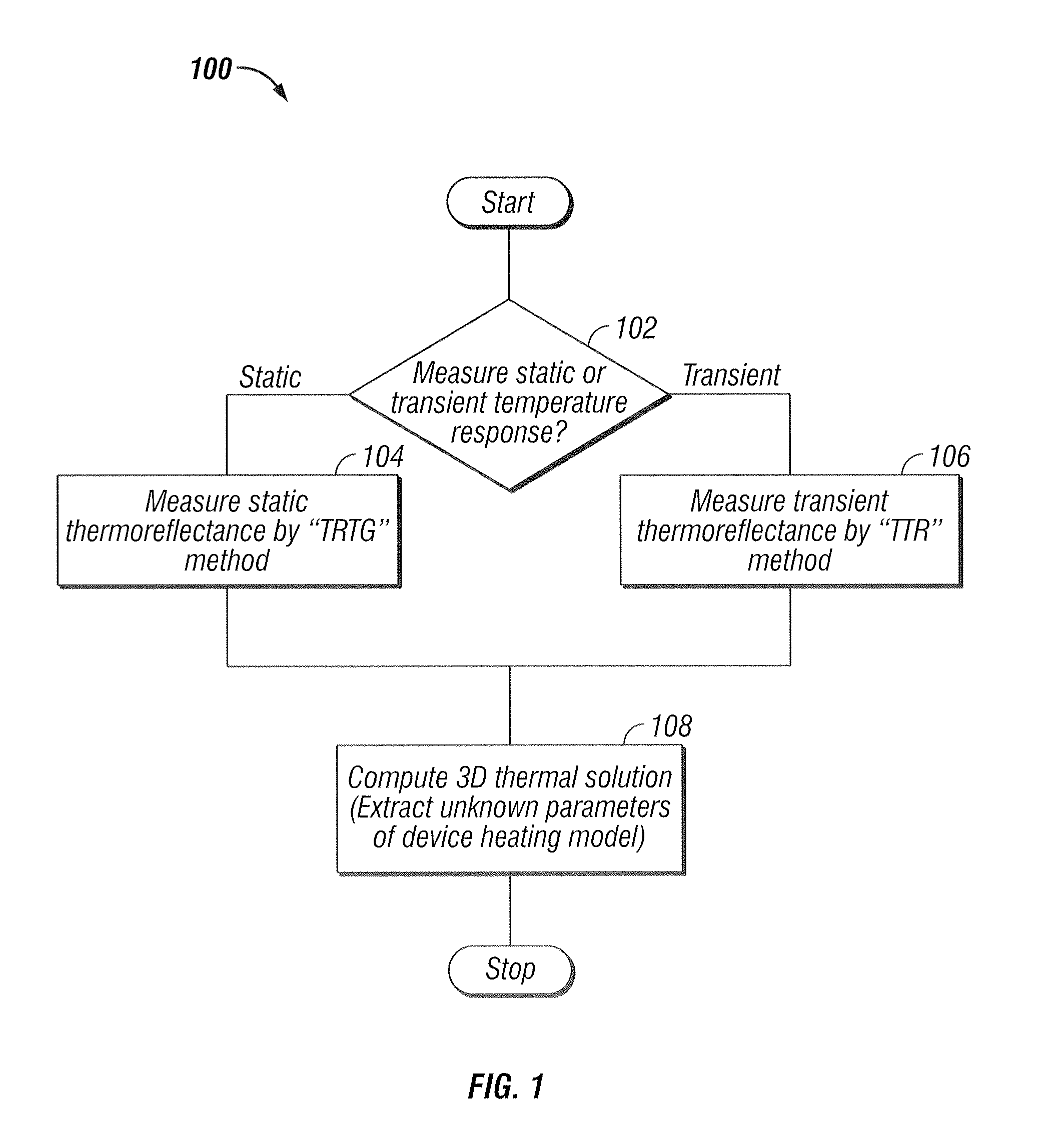

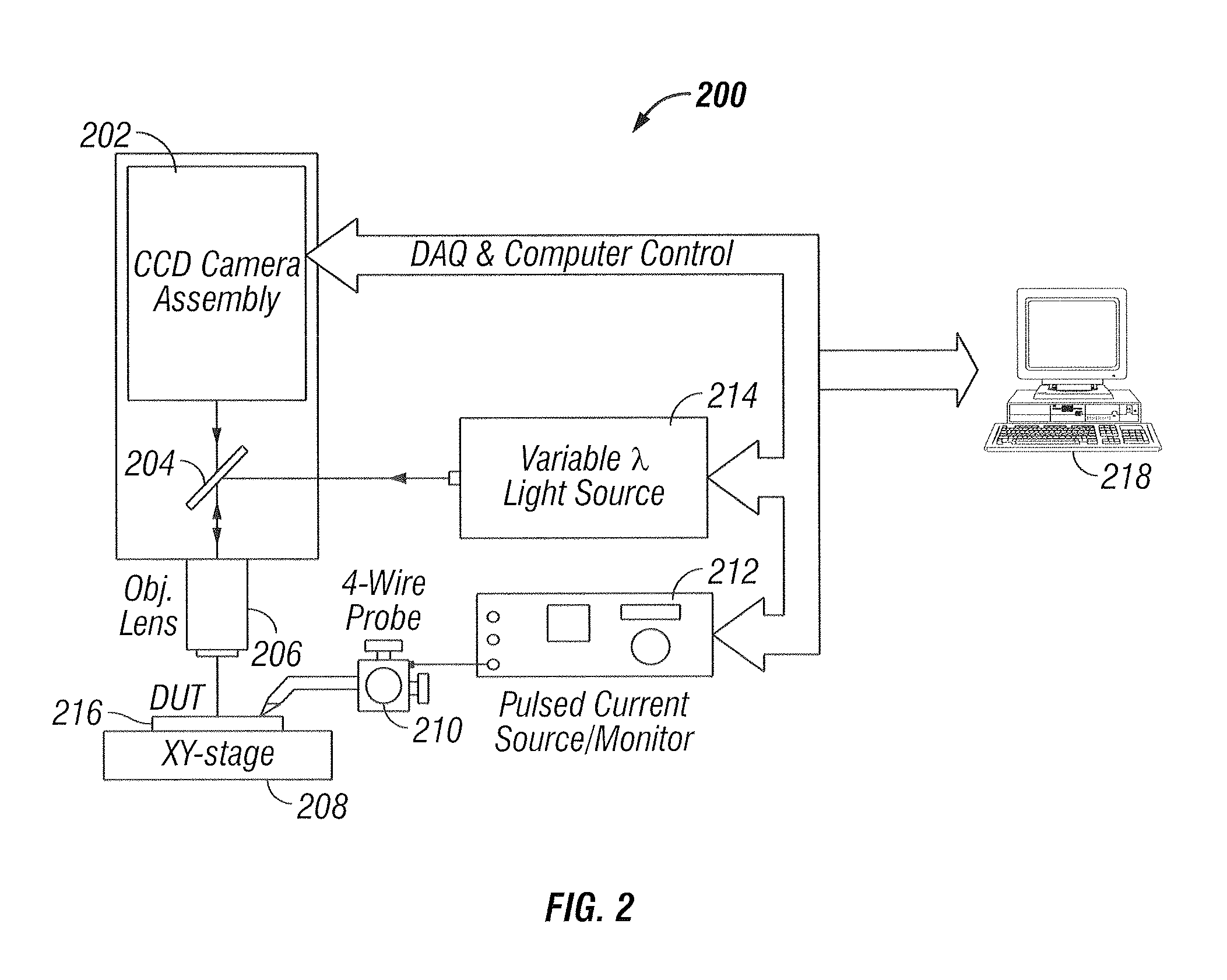

Thermography measurement system for conducting thermal characterization of integrated circuits

ActiveUS20080082288A1High spatialHigh temporal accuracyCounting objects with random distributionSpecial data processing applicationsLight energyPhotodetector

A system and method to fully characterize the thermal behavior of complex 3D submicron electronic devices. The system replaces and / or supplements laser-based surface temperature scanning with a CCD camera-based approach. A CCD camera records multiple points of light energy reflected from an integrated circuit to obtain a static temperature measurement. The system is used to non-invasively measure with submicron resolution the 2D surface temperature field of an activated device. A CW laser illuminates a single point on the surface of an active device and a photodetector records the reflected light energy to obtain a transient temperature measurement. The measured 2D temperature field is used as input for an ultra-fast inverse computational solution to fully characterize the thermal behavior of the complex 3D device. The system extracts geometric features of a known device, assessing the system's ability to combine measured results and computations to fully characterize complex 3D electronic devices.

Owner:RAAD PETER E

Vibration sensor and method for monitoring the condition of rotating components and bearings

ActiveUS20050155429A1Easy to operateReliable of stateVibration measurement in solidsMachine part testingSignal conditioningA d converter

A vibration sensor (1) for monitoring the state of rotating components or bearings, includes a housing (2), a sensor element (3), evaluation electronics (4), and at least one interface (5, 6). With the vibration sensor (1), reliable monitoring of the state of rotating components and bearings can be done easily and economically, and in addition the vibration sensor can be easily operated. The evaluation electronics (4) has an analog-to-digital converter (7), and a signal conditioning means (8) having a plurality of signals, which have been acquired by the sensor element (3), and which are converted into a state value using signal analysis and a diagnosis algorithm.

Owner:I FOR T

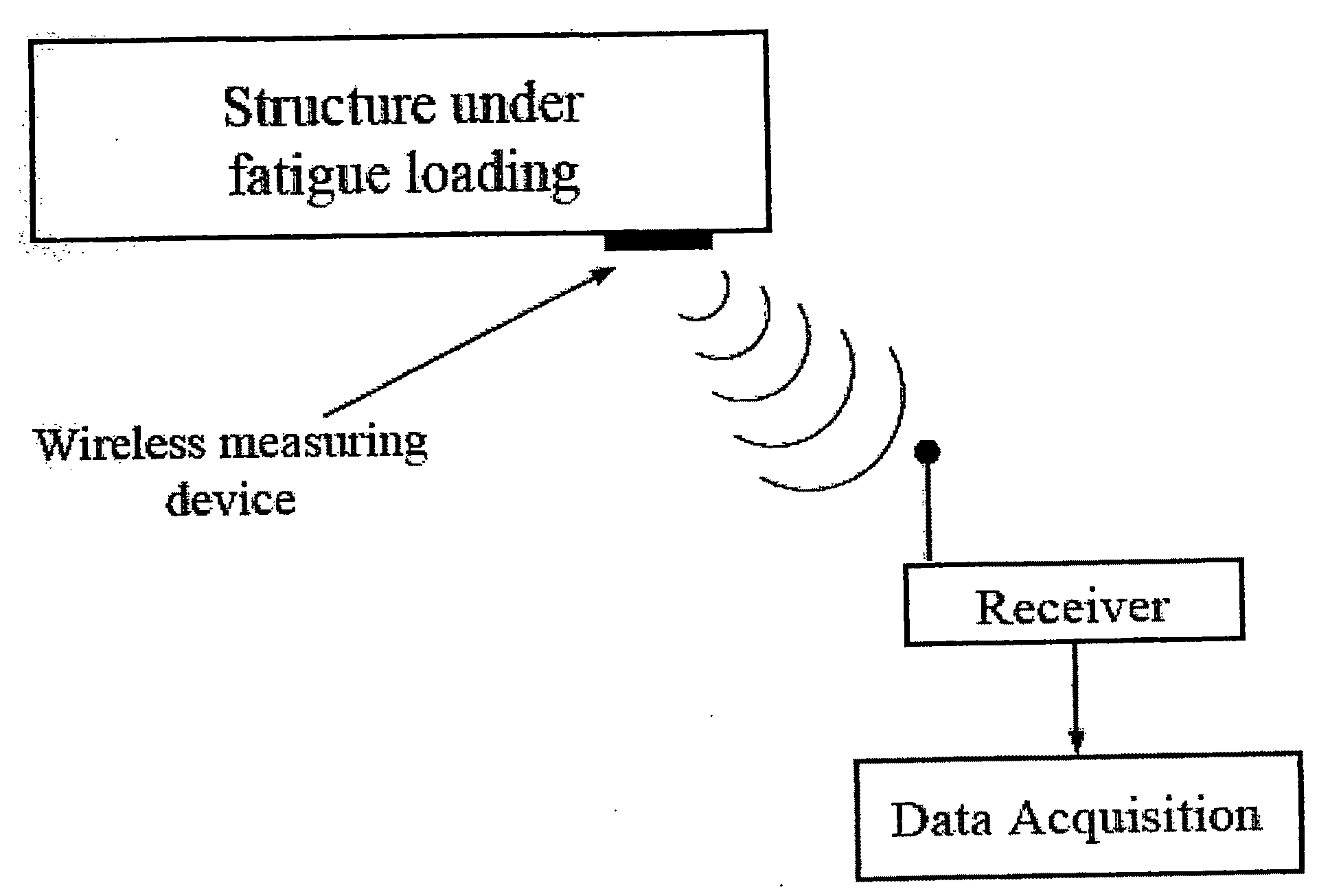

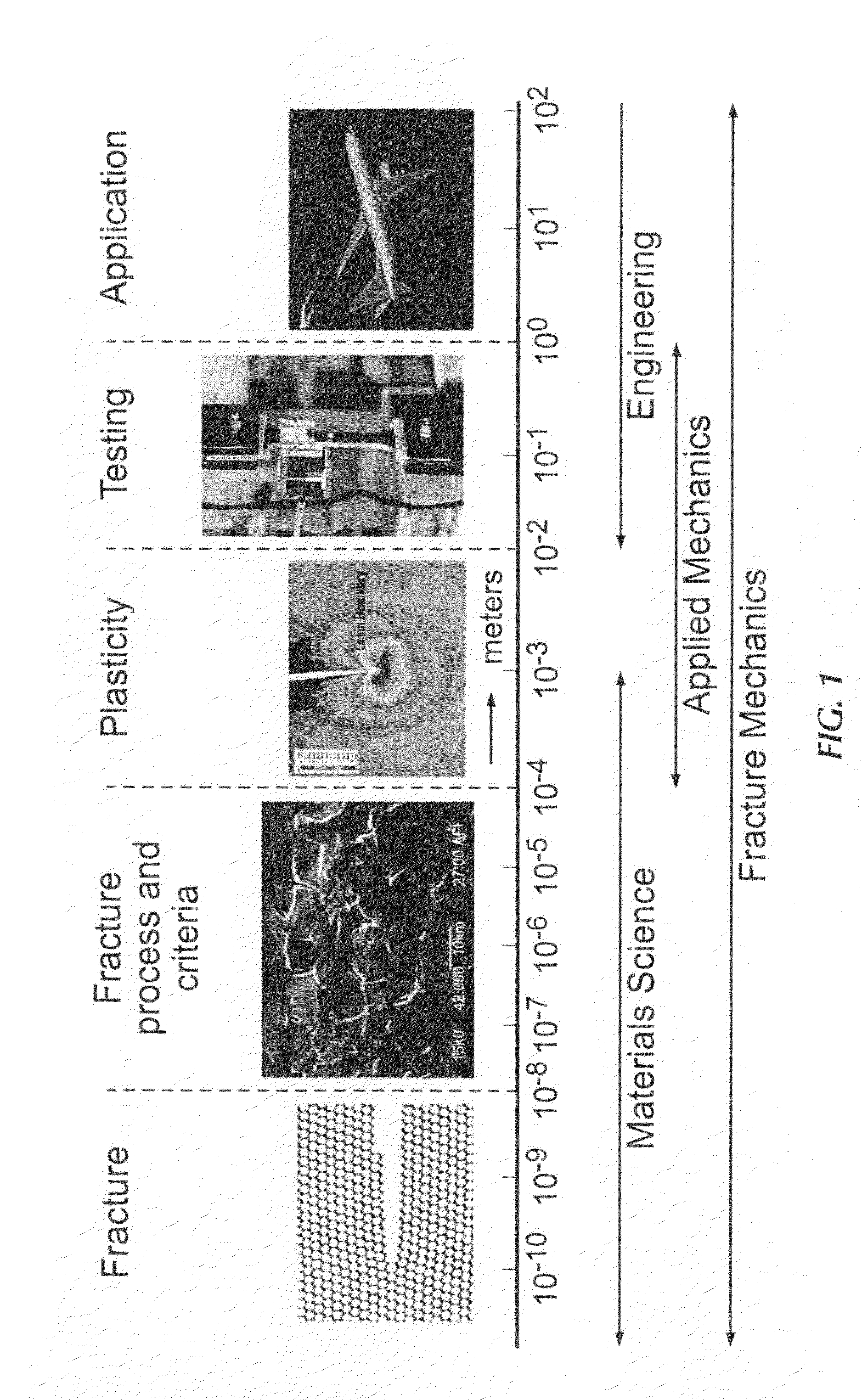

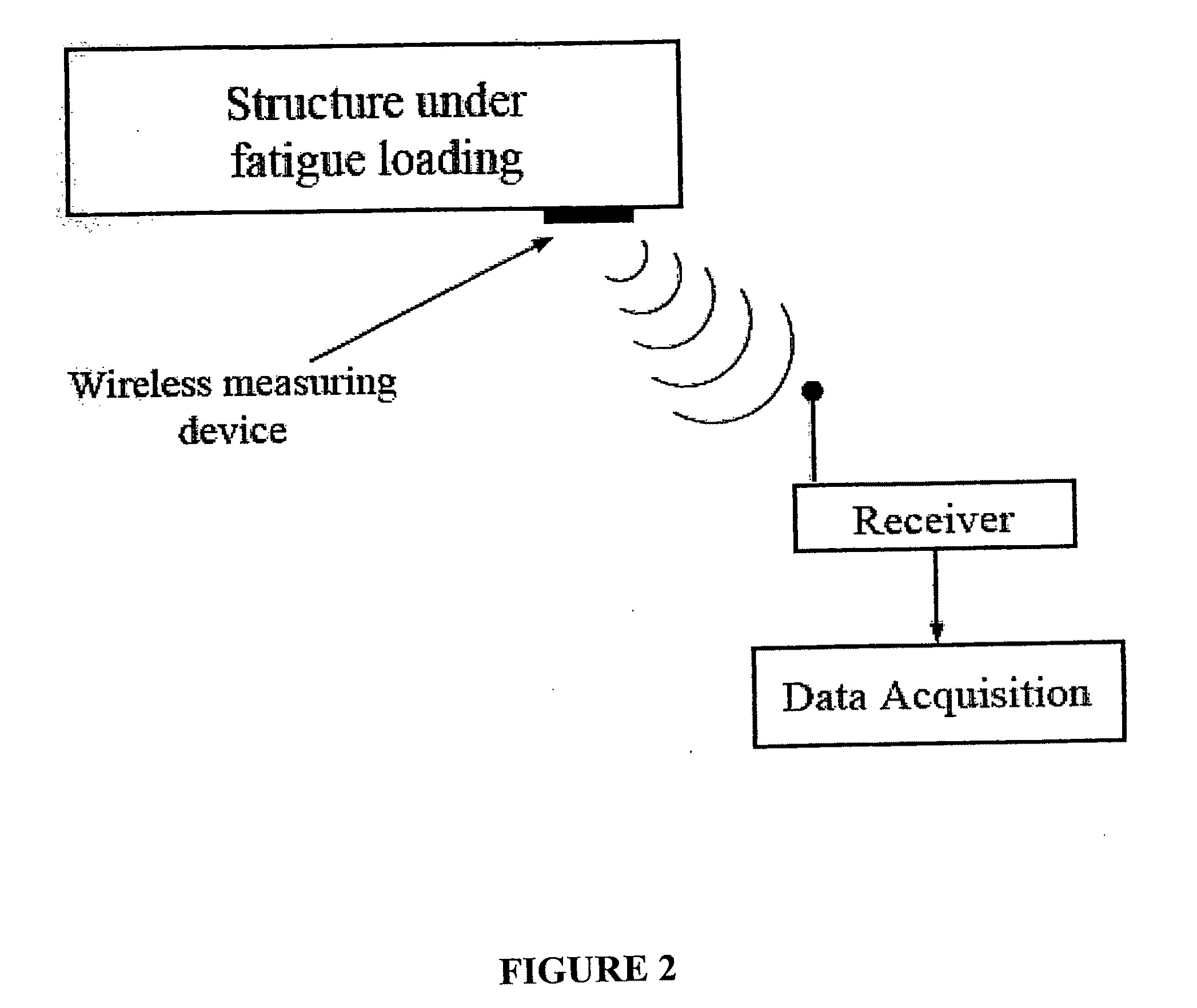

Rapid determination of fatigue failure based on temperature evolution

InactiveUS20090048788A1Efficient use ofAvoid catastrophic failureMeasurement gaugesAmplifier modifications to reduce noise influenceEngineeringUsage analysis

A method and apparatus are disclosed for predicting the service life of a metallic structure subjected to cyclic loading. Such structures experience fatigue, which can lead to failure after a number of loading cycles. The disclosed invention allows for an accurate prediction of the number of cycles to failure for a metallic structure by observing the slope of the rise in surface temperature of the structure after the cyclic loading has begun. The method of this invention provides early and accurate predictions of service life and does not require destructive testing. The method and apparatus of the present invention may be installed on working equipment, thus providing service life predictions for materials in real world use. The invention uses an empirically derived relationship that was confirmed using analytical relationships and material properties. The derived formula uses two constants that may be determined empirically using a disclosed process. The constants also may be estimated mathematically. The apparatus may include a wireless temperature sensor mounted on the metallic structure of interest and a data analysis unit to perform the needed calculations.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

System and method for detecting anamolies in wind turbines

A device and method for use in detecting anomalies in wind turbines is provided. The method includes monitoring data acquired by at least one sensor in a first wind turbine, wherein the data is calculated to produce a value for a predetermined amount of time, monitoring data acquired by at least one sensor in a grouping of wind turbines similar to the first wind turbine, wherein the monitored data corresponds to the monitored data of the first wind turbine and is combined for a predetermined amount of time, and comparing the monitored data of the first wind turbine with the monitored data of the grouping of wind turbines. The method also includes generating a sensor error if the monitored data of the first wind turbine deviates more than a predetermined amount from the monitored data of the grouping of wind turbines, and displaying the results of the comparison of the monitored data.

Owner:GENERAL ELECTRIC CO

Apparatus and methods for measuring the pin diameter of a crankshaft at the place of grinding

InactiveUS6931749B2The process is simple and fastWide measurement rangeGrinding machine componentsFeeding apparatusNumerical controlDisplay device

An apparatus for checking diametral dimensions of crankpins and main journals in the course of grinding is provided. The apparatus includes a head with a Vee-shaped reference device and an axially movable feeler that contacts the surface of the pin to be checked, and an articulated support device, coupled to the grinding wheel slide that carries the head and enables it to keep contact with the surface of the pin during possible orbital rotations. A transducer in the head cooperates with the feeler for detecting its displacements and transmits signals to a processing and display device in turn connected with the computer numerical control of the grinding machine. The processing and display device processes the transducer signals with compensation values or coefficients stored in a memory unit for obtaining measuring signals output by the head that vary in a linear way in a wide range and for compensating errors due to temperature variations.

Owner:MARPOSS SPA

Vibration sensor and method for monitoring the condition of rotating components and bearings

InactiveUS7231303B2Reliable of stateEasy to operateVibration measurement in solidsMachine part testingSignal conditioningEngineering

A vibration sensor (1) for monitoring the state of rotating components or bearings, includes a housing (2), a sensor element (3), evaluation electronics (4), and at least one interface (5, 6). With the vibration sensor (1), reliable monitoring of the state of rotating components and bearings can be done easily and economically, and in addition the vibration sensor can be easily operated. The evaluation electronics (4) has an analog-to-digital converter (7), and a signal conditioning device (8) having a plurality of signals, which have been acquired by the sensor element (3), and which are converted into a state value using signal analysis and a diagnosis algorithm.

Owner:I FOR T

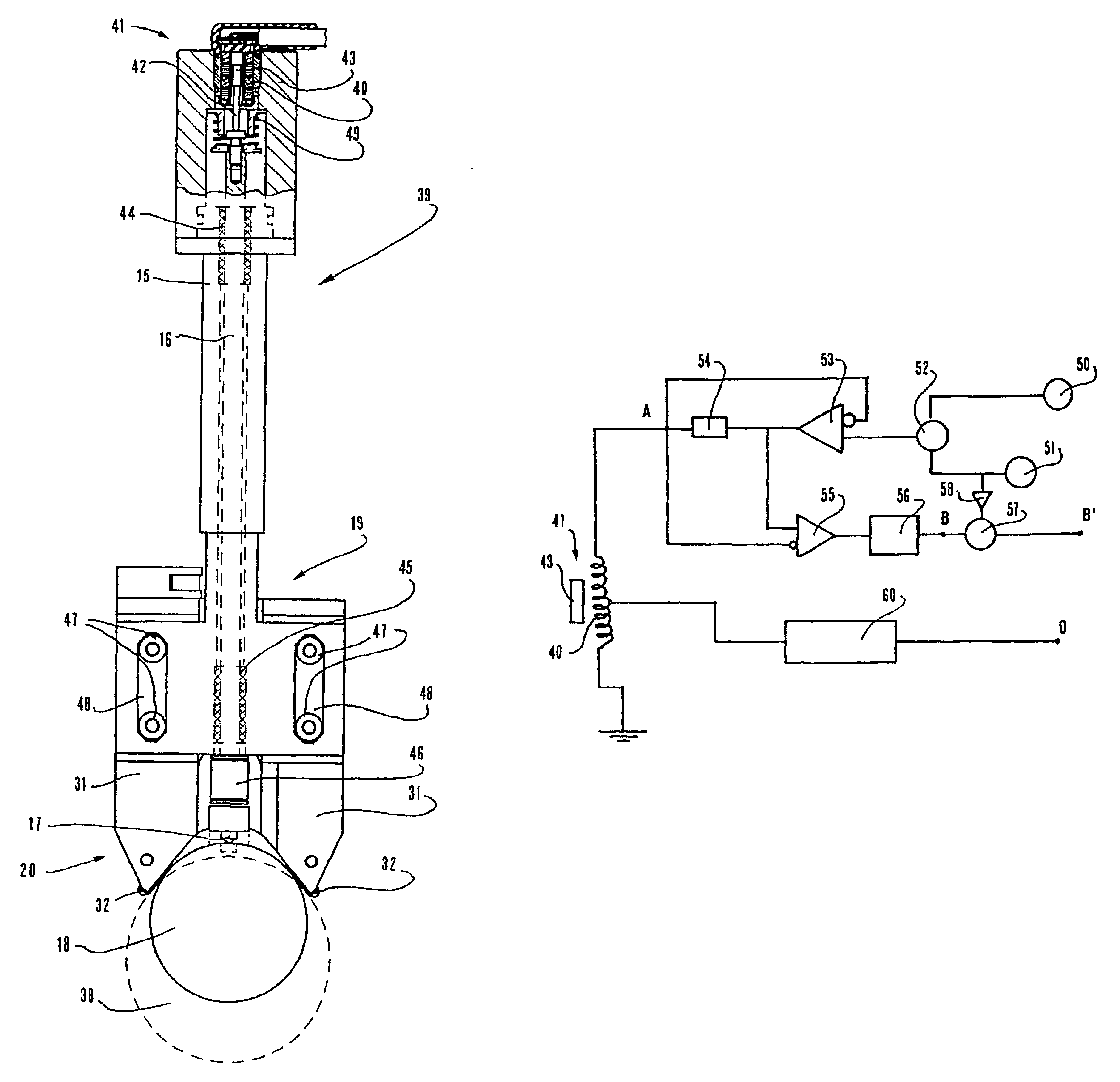

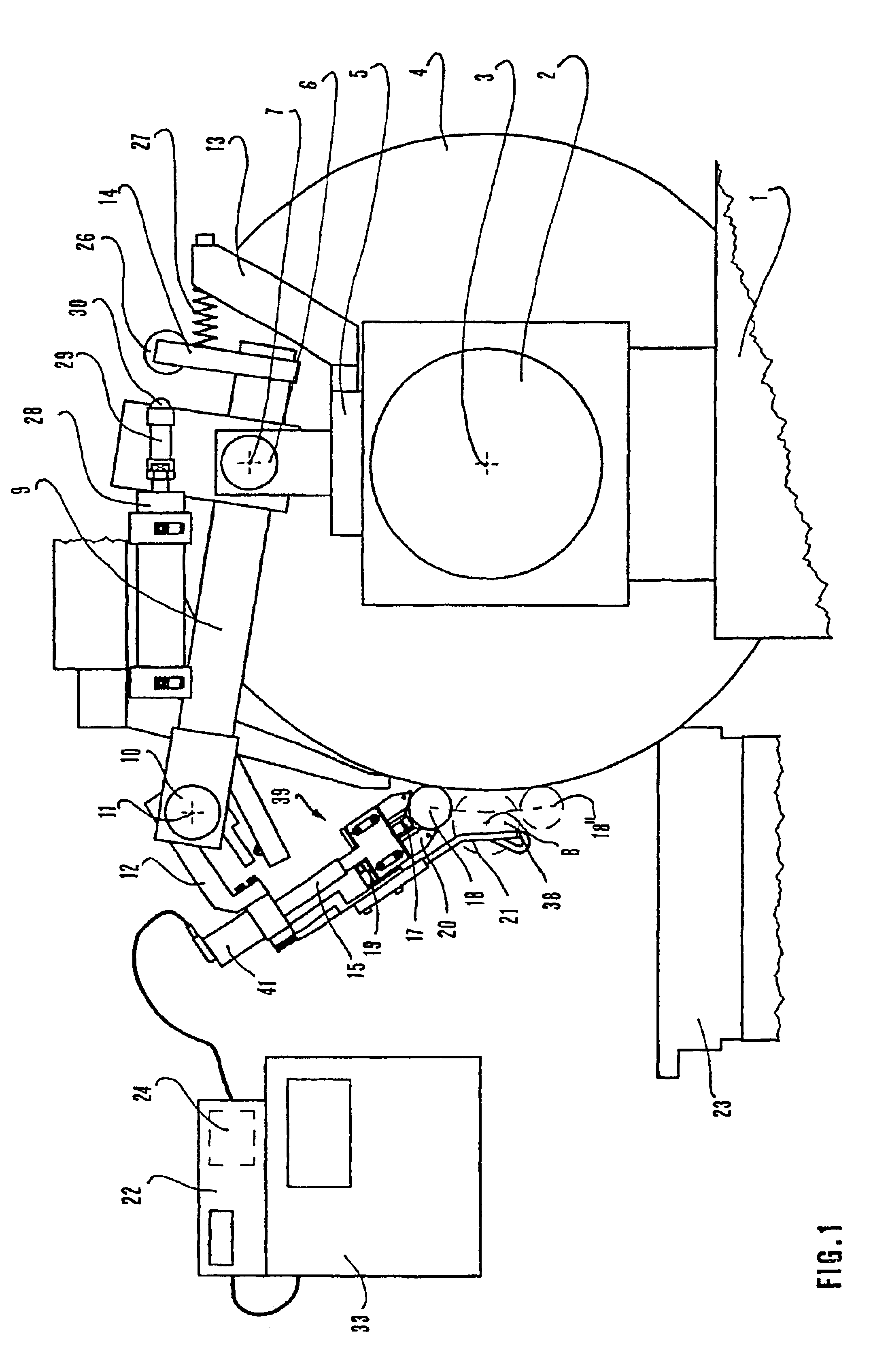

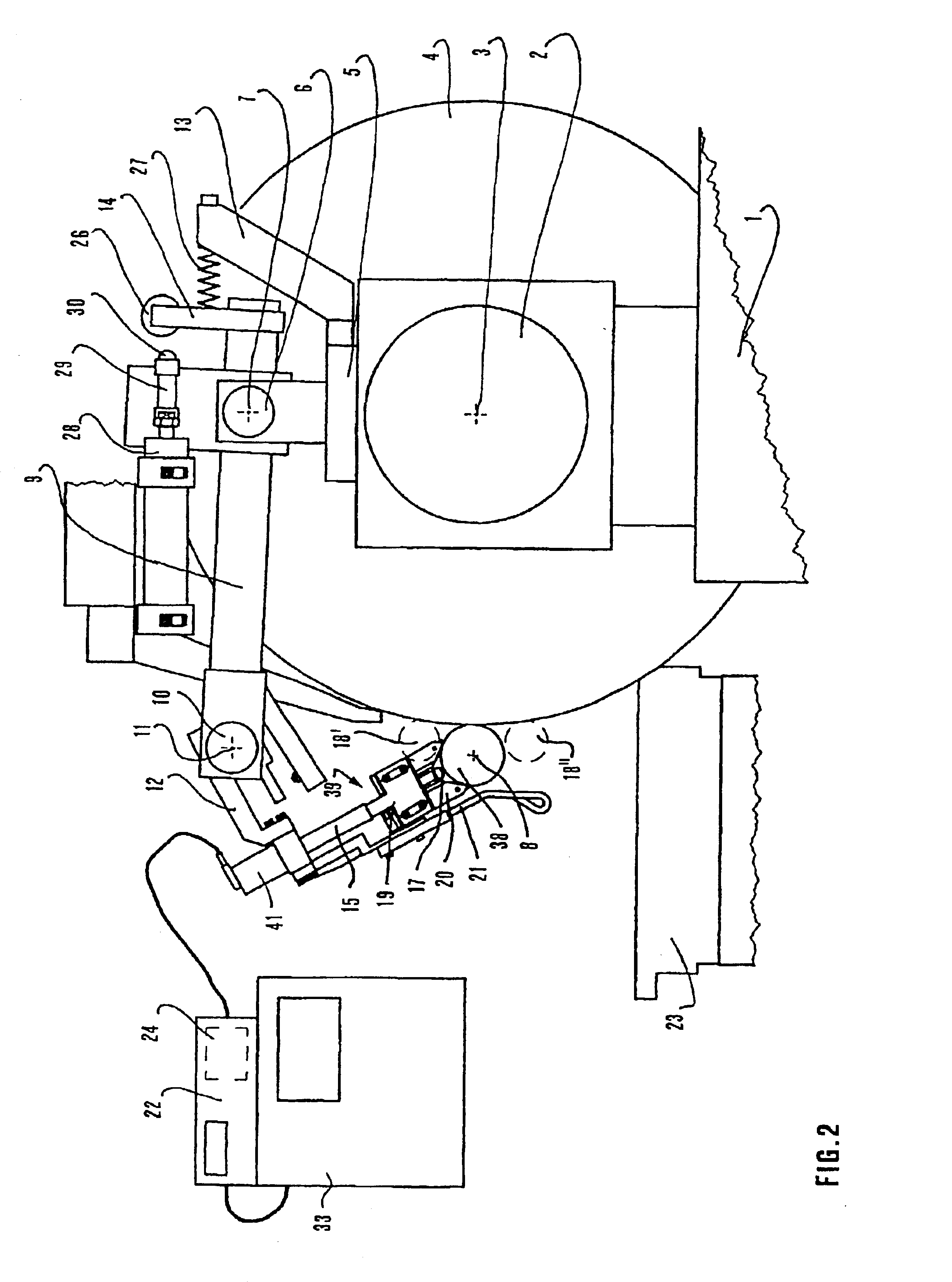

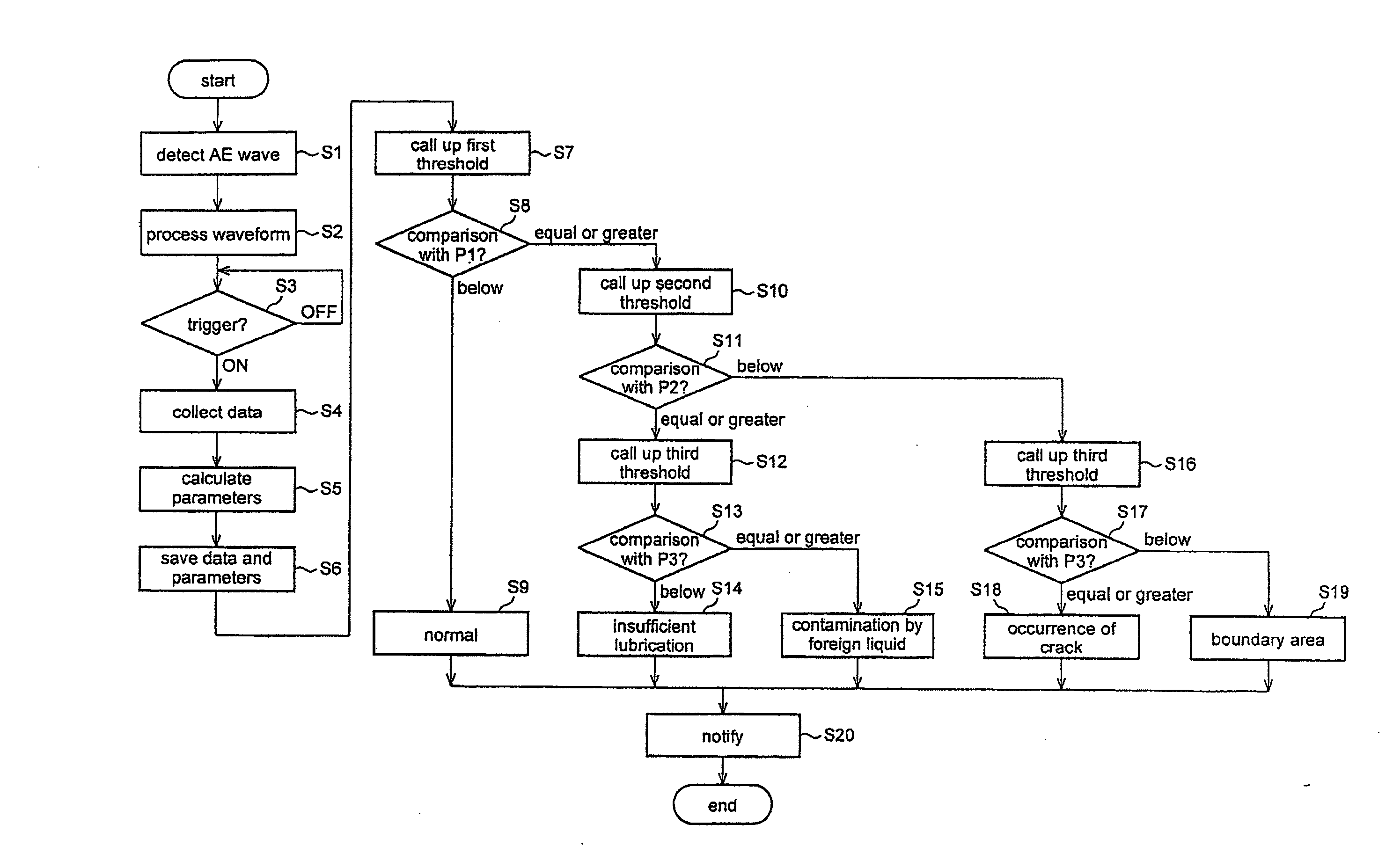

Condition Detection Apparatus, Condition Detection Method, Condition Detection Program, Information Recording Medium Therefor, and Condition Display Apparatus, Condition Display Method, Condition Display Program, Information Recording Medium Therefor

ActiveUS20080065354A1Extended service lifeImprove maintainabilityVibration measurement in solidsRotary bearingsMaintainabilityPrediction system

A condition detection apparatus comprising an AE sensor 1 that detects AE waves, which elastically-occur when a plurality of balls included in an LM system self-rotate and revolve within a circulation section at the same time, and generates detection signals Sae, and a signal processing unit 4 that generates a first parameter indicating an intensity of the AE waves based on the generated detection signals Sae, generates based on the detection signals Sae a second parameter by weighting only detection signals Sae temporally-continuously detected among the detection signals Sae, generates based on the detection signals Sae a third parameter by weighting only detection signals Sae temporally-discontinuously detected in correspondence with the movement of the balls among the detection signals Sae, and judges contents of an operational condition of the LM system using any one of the first, second or third parameter, is provided to enable prognosis of occurrences of failures in the LM system, to improve maintainability for a user of the LM system, and to contribute to the prolonging of the operation life of the LM system as well as performance assurance and quality improvement of apparatuses or devices incorporated with the LM system.

Owner:THK CO LTD

Totally Integrated Intelligent Dynamic Systems Display

ActiveUS20090046096A1Avoid catastrophic failureVehicle testingRegistering/indicating working of vehiclesGraphicsPhysical system

An apparatus for graphically displaying analytical data, comprising a generic model to graphically represent a complex set of physical characteristics potentially leading to catastrophic failure of a physical system. A central region represents failure of the physical system; a series of concentric ridges represents level of function. Wedge shaped regions upon the ridges represent predetermined subsystems of the physical system. An icon is displayed with changes in the icon proportional to time, and any one or more of color, position, shape, and rotation of the icon representing prescribed analysis of the physical characteristics. Mappings correlate predetermined characteristics of the system with failure of the physical system, levels of functioning represented by the ridges, subsystems represented by the wedge shaped regions, and / or analysis of the physical characteristics represented in the icon. A sensor interface receives measurements, and a graphics generator prepares a presentation of the model.

Owner:OJARALI SYST LLP

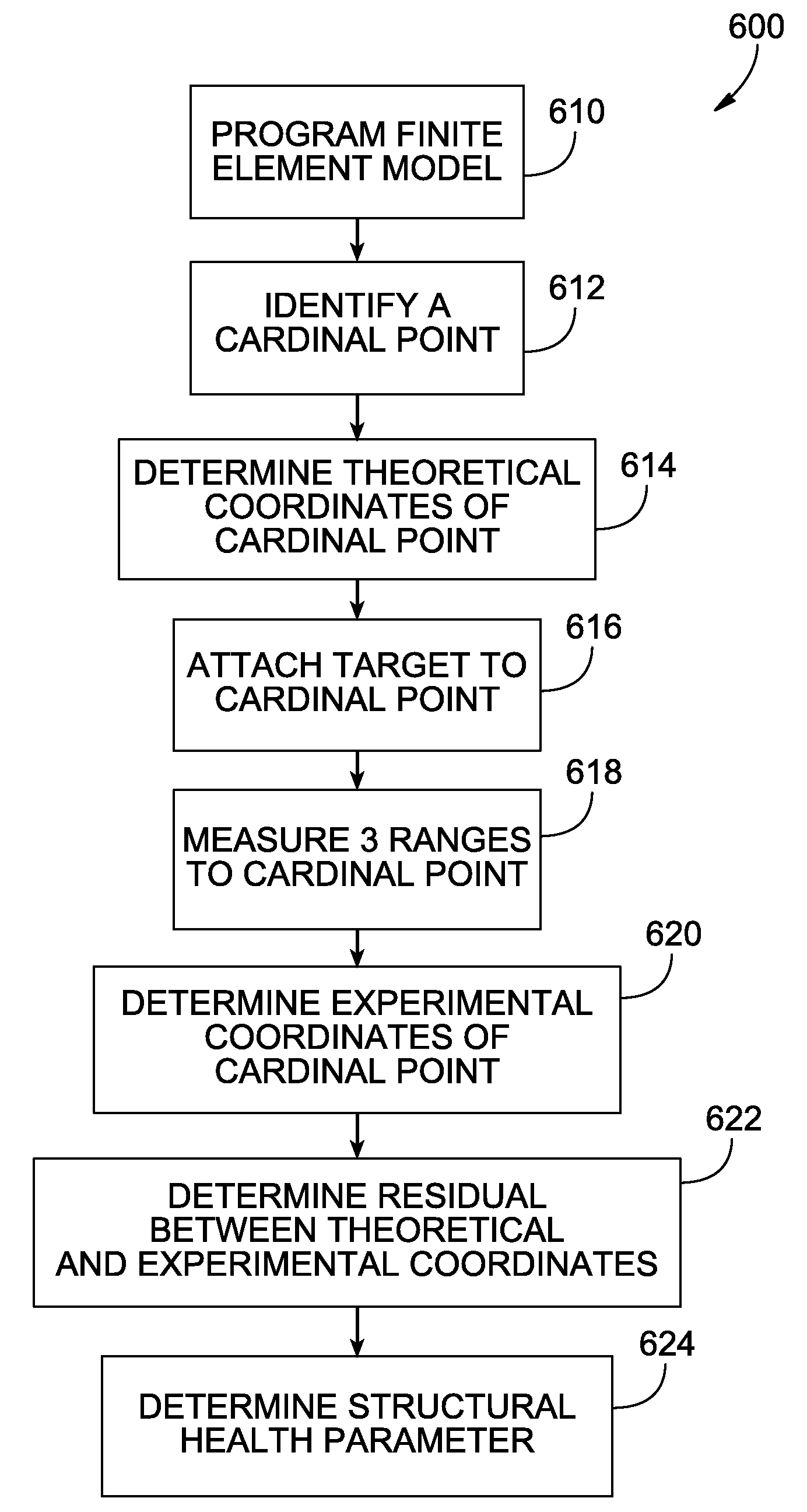

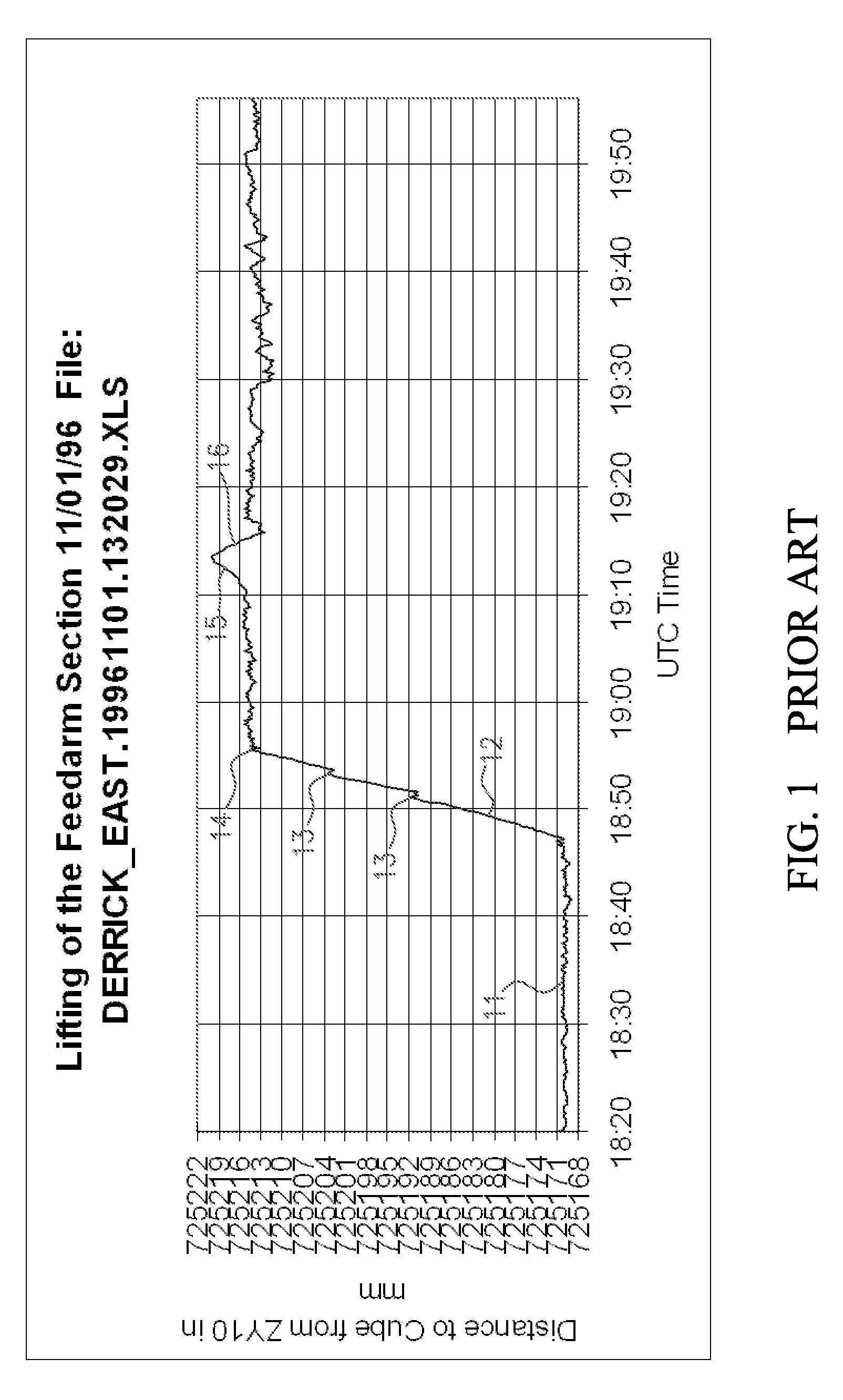

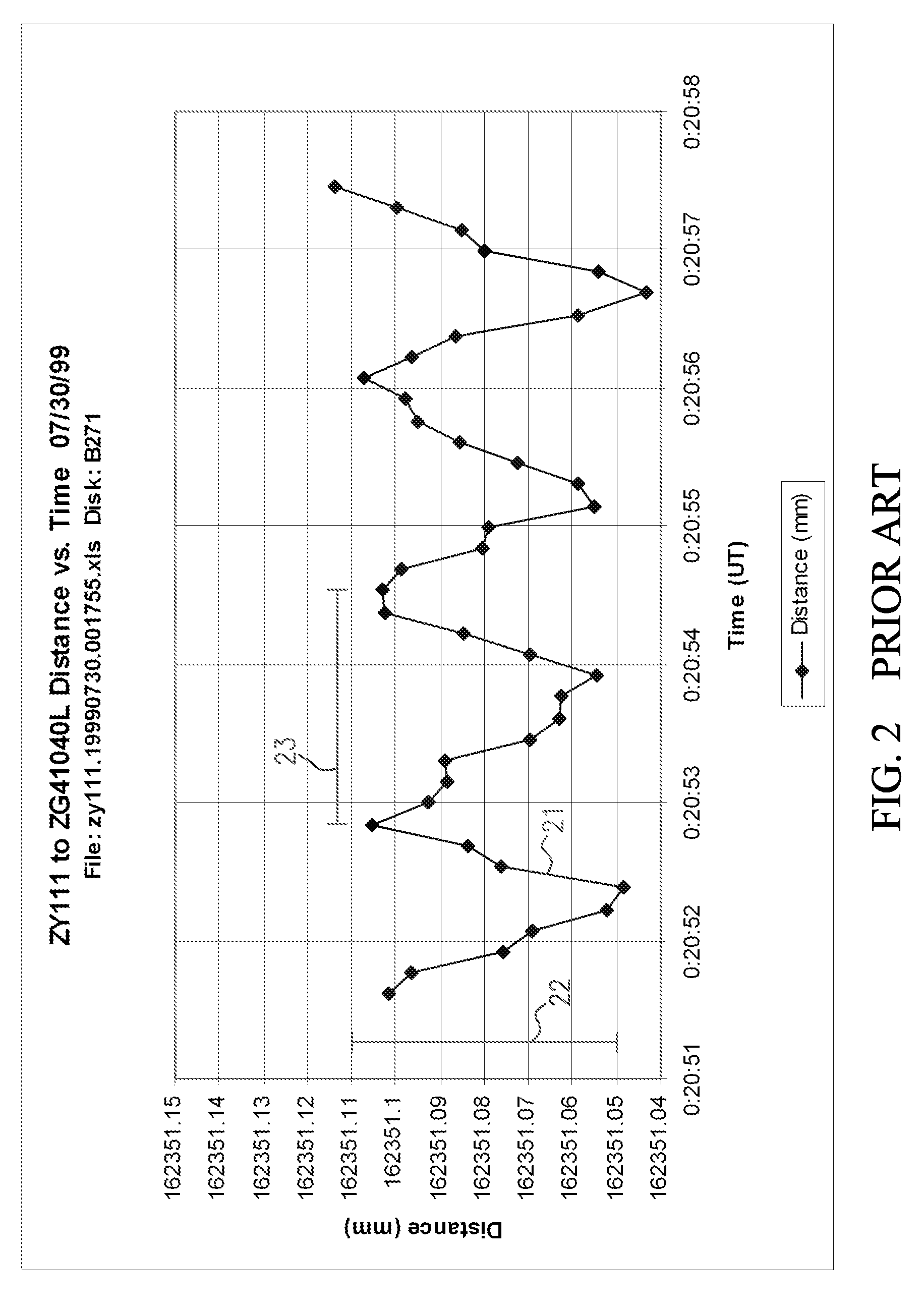

Methods for modeling the structural health of a civil structure based on electronic distance measurements

Methods are disclosed wherein the structural health of a civil structure, such as, but not limited to, a bridge or the like is measured by electronic distance measurement (EDM) from a plurality of stable locations to a plurality of cardinal points on the structure in a methodical manner. By measuring the coordinates of the cardinal points, the dynamic and long-term static behavior of the structure provide an indication of the health of the structure. Analysis includes: comparison to a Finite Element Model (FEM); comparison to historical data; and modeling based on linearity, hysteresis, symmetry, creep, damping coefficient, and harmonic analysis.

Owner:SOLLIDAY LAURA P +1

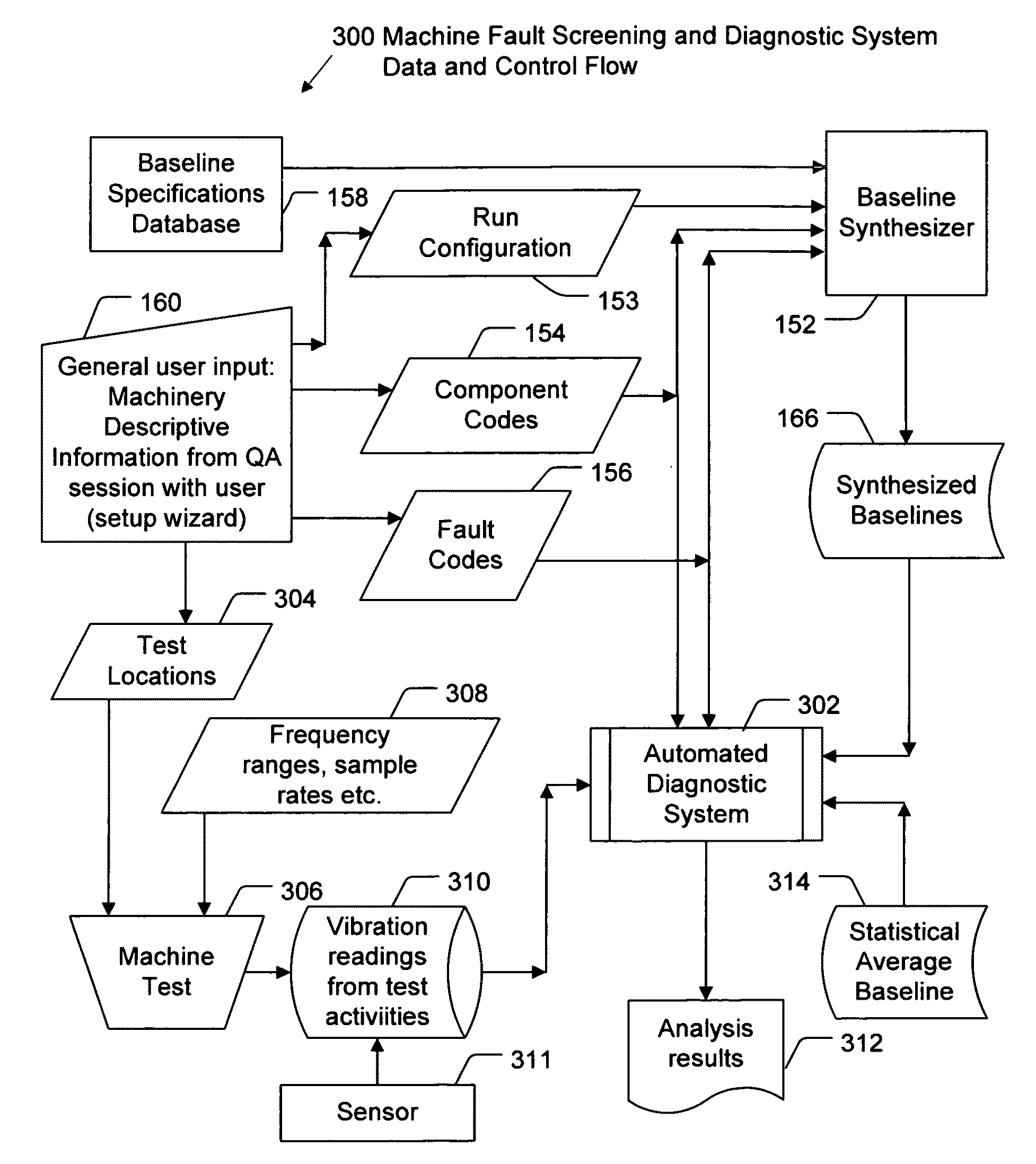

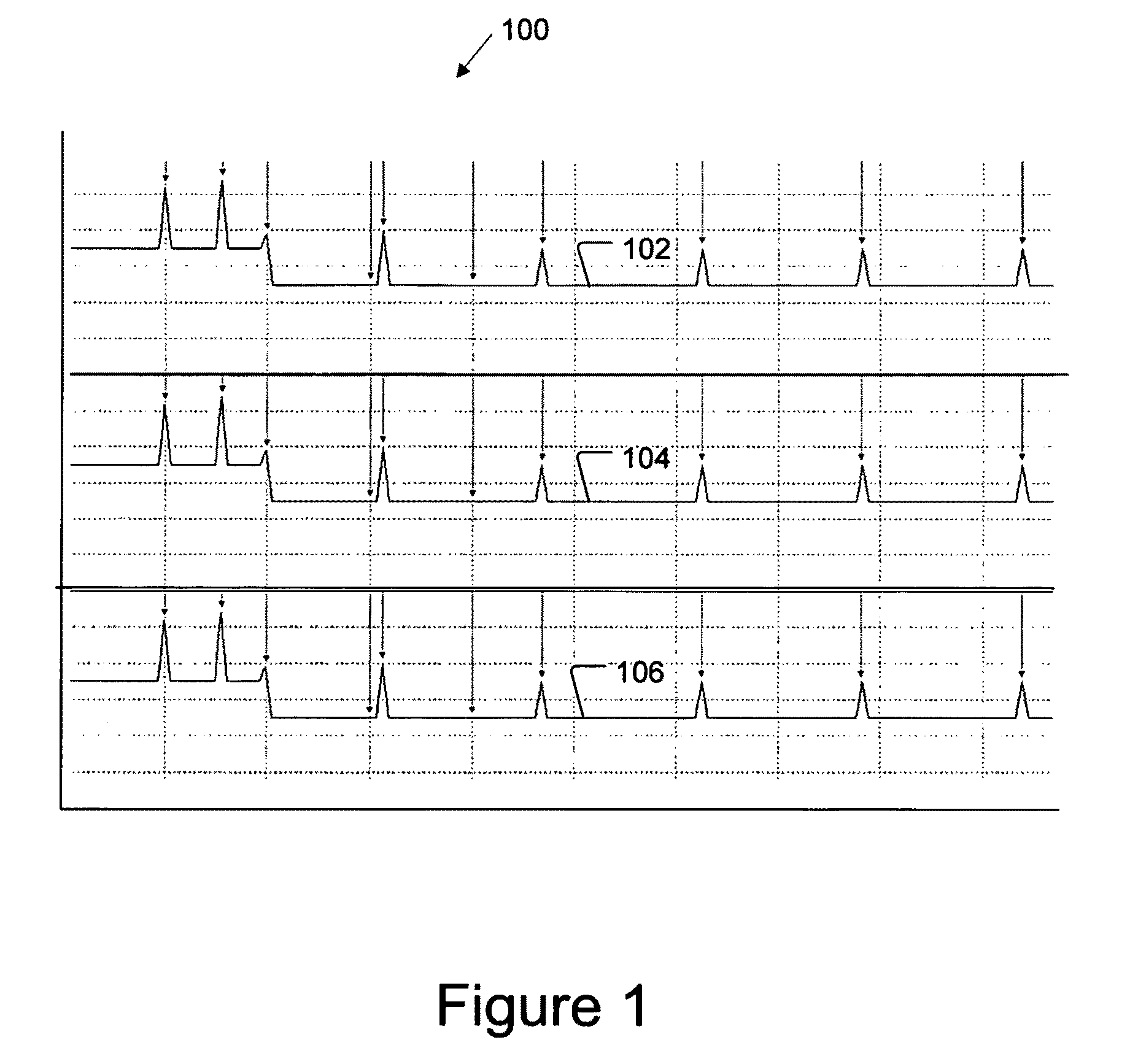

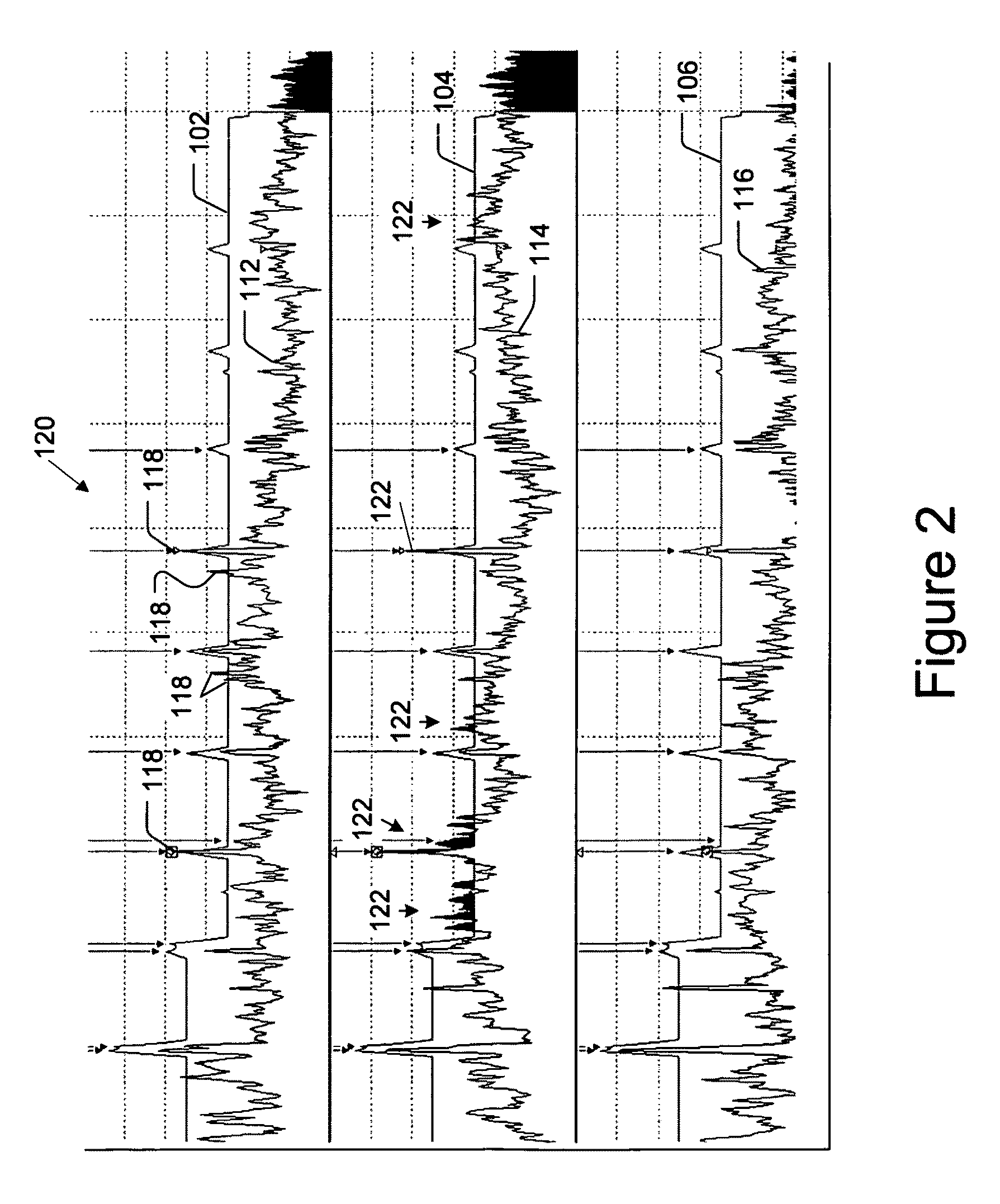

Machine vibration baseline synthesizer

ActiveUS20090292505A1Vibration measurement in solidsMachine part testingVibration amplitudeForce frequency

Machine vibration baselines are synthesized without averaging historical vibration data. Instead machinery configuration information is used, including data about the machine train, the machine's rotating components, and the machine speeds. For each component being considered, a plurality of parameters is identified for deriving baseline portions. The parameters for one component are used to identify baseline vibration amplitude floor values, vibration amplitudes at frequencies corresponding to various harmonics of a rotational speed, and vibration amplitudes corresponding to forcing frequencies and their harmonics / sidebands. Parameters for other components also may be used to identify amplitudes at harmonic frequencies and forcing frequencies.

Owner:SYMPHONYAI IND PLANT PERFORMANCE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com