Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

186results about "Lubricant level maintainance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

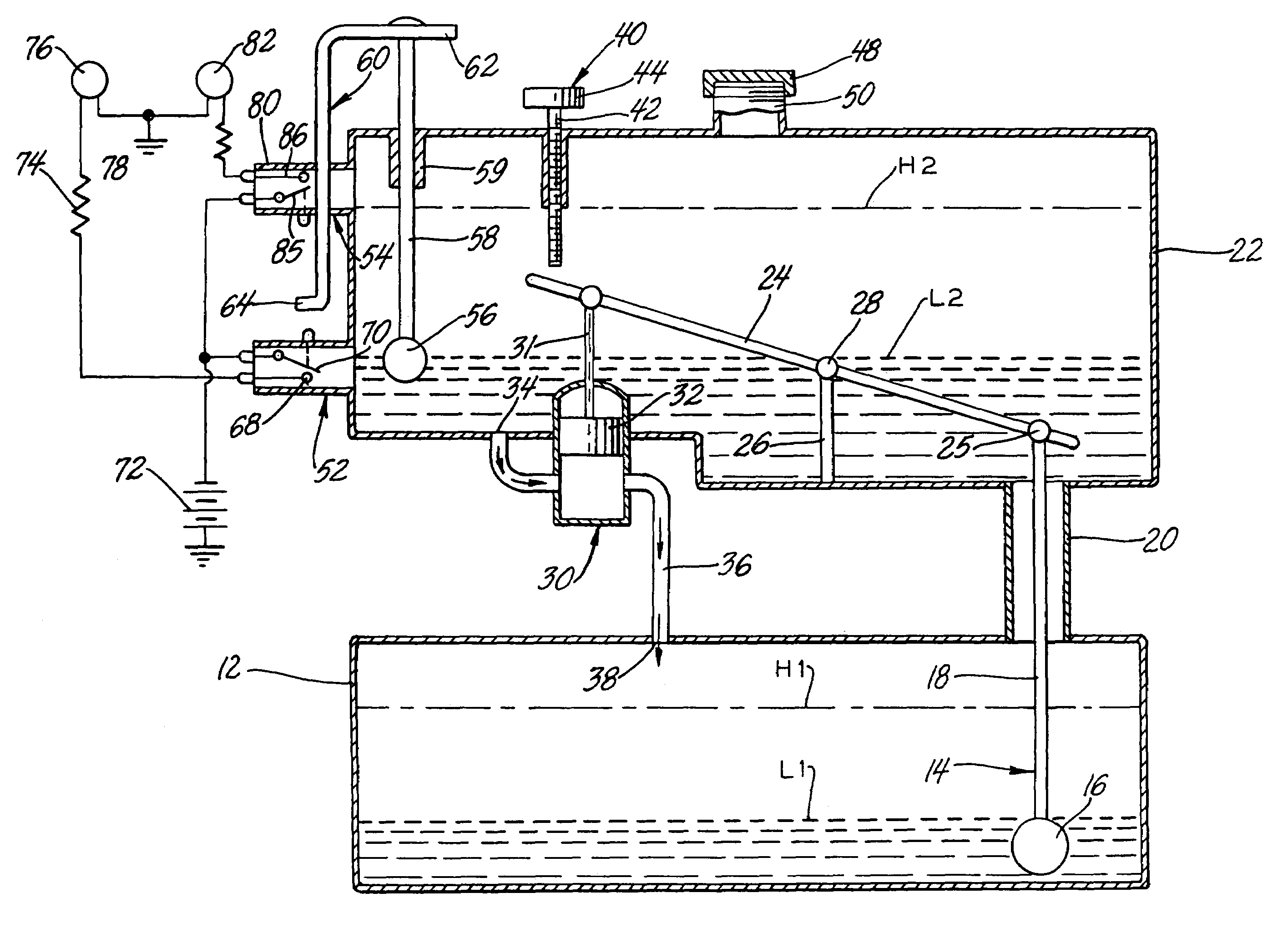

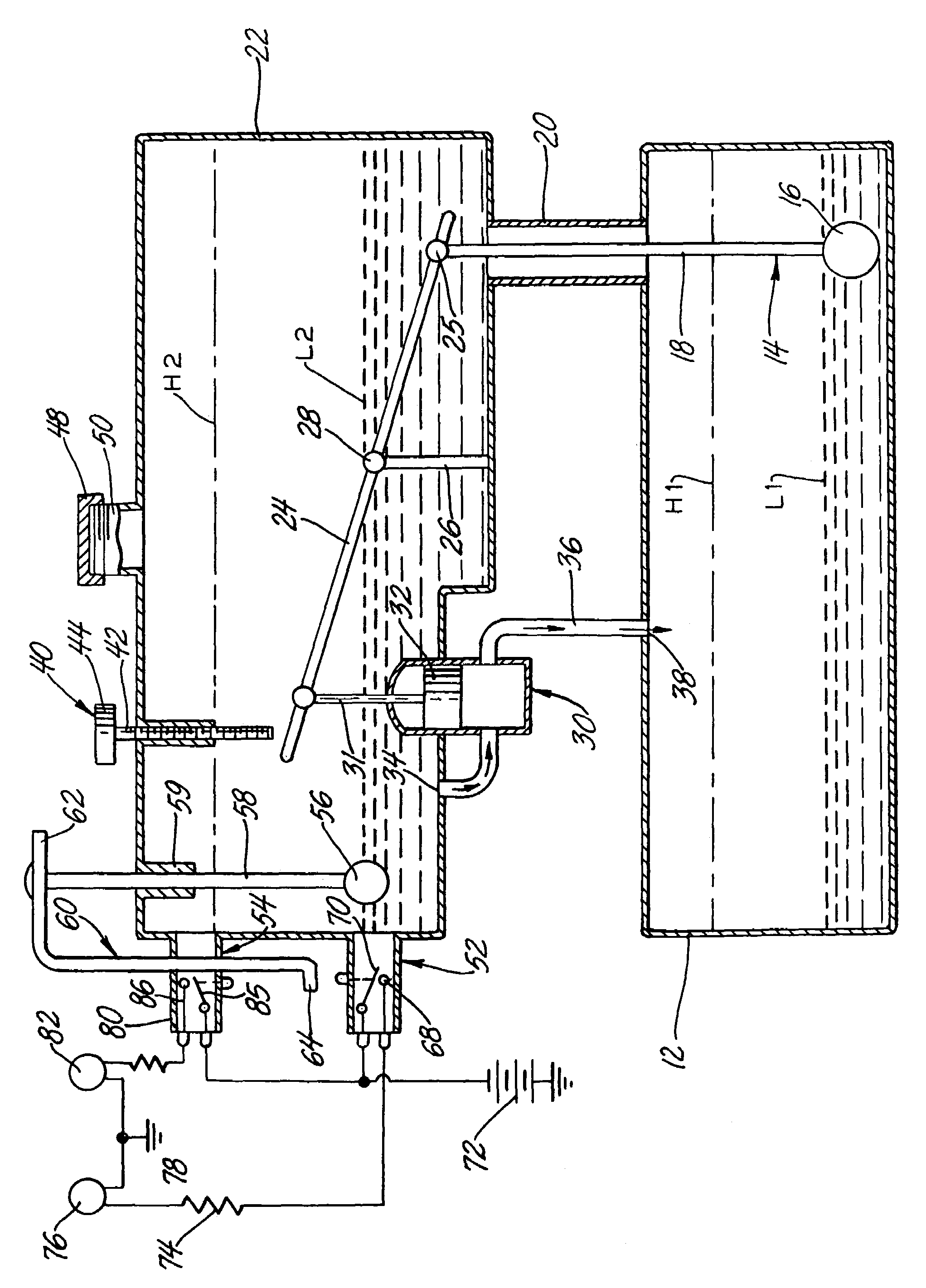

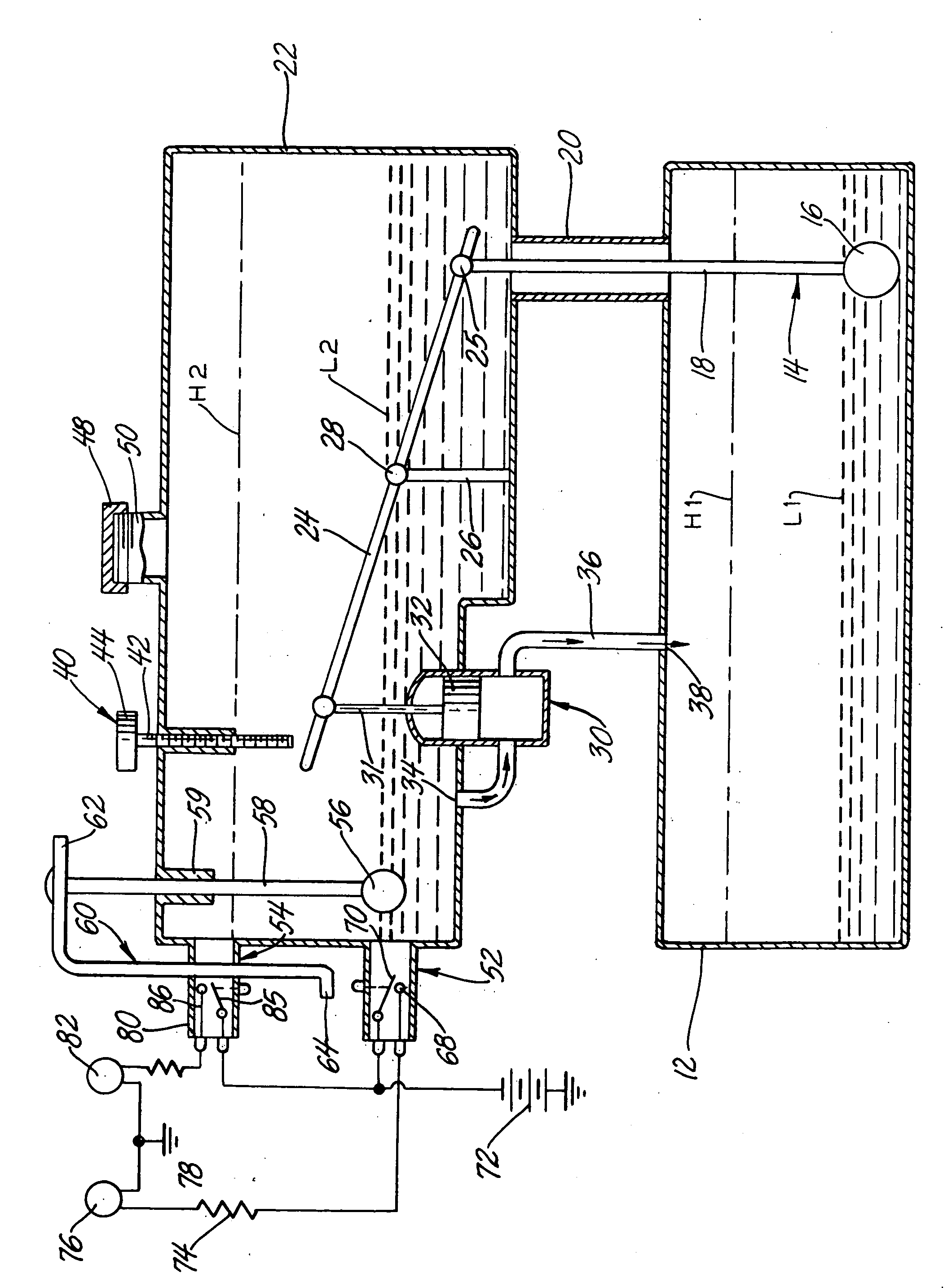

Apparatus and method for lubricant condition control and monitoring

InactiveUS7017712B1More and lessOvercome problemsEngine temperatureEngine pressureProcess engineeringKetone

A volumetric lubricant dispensing apparatus for delivering a precise volume of lubricant, such as oil, to a rotating machine element. The delivery mechanism includes a piston and cylinder assembly. A plurality of sensors are utilized to record operating conditions of the machine, element, environment, and lubricant. The apparatus is controlled either manually or with the aid of a controller unit such as a microprocessor. The output from each sensor is inputted into the microprocessor wherein an algorithm computes an responsive output. The responsive output is sent to the piston and cylinder assembly, which maintains an optimum lubricant condition within the reservoir wherein a rotating machine element located. Alternatively, for the purpose of qualitative control, the present invention may be described as a system intended for controlling lubricants, both mineral (natural) and synthetic based by measuring the condition characteristics of the lubricant. Some condition characteristics may include water or moisture content (the content could be any liquid, e.g., solvents like ketones are known to change condition characteristics like viscosity) and viscosity. Viscosity is related to temperature, therefore, temperature correlation to viscosity is helpful to provide relative indications for condition characteristics like lubricant flow.

Owner:TRICO CORP

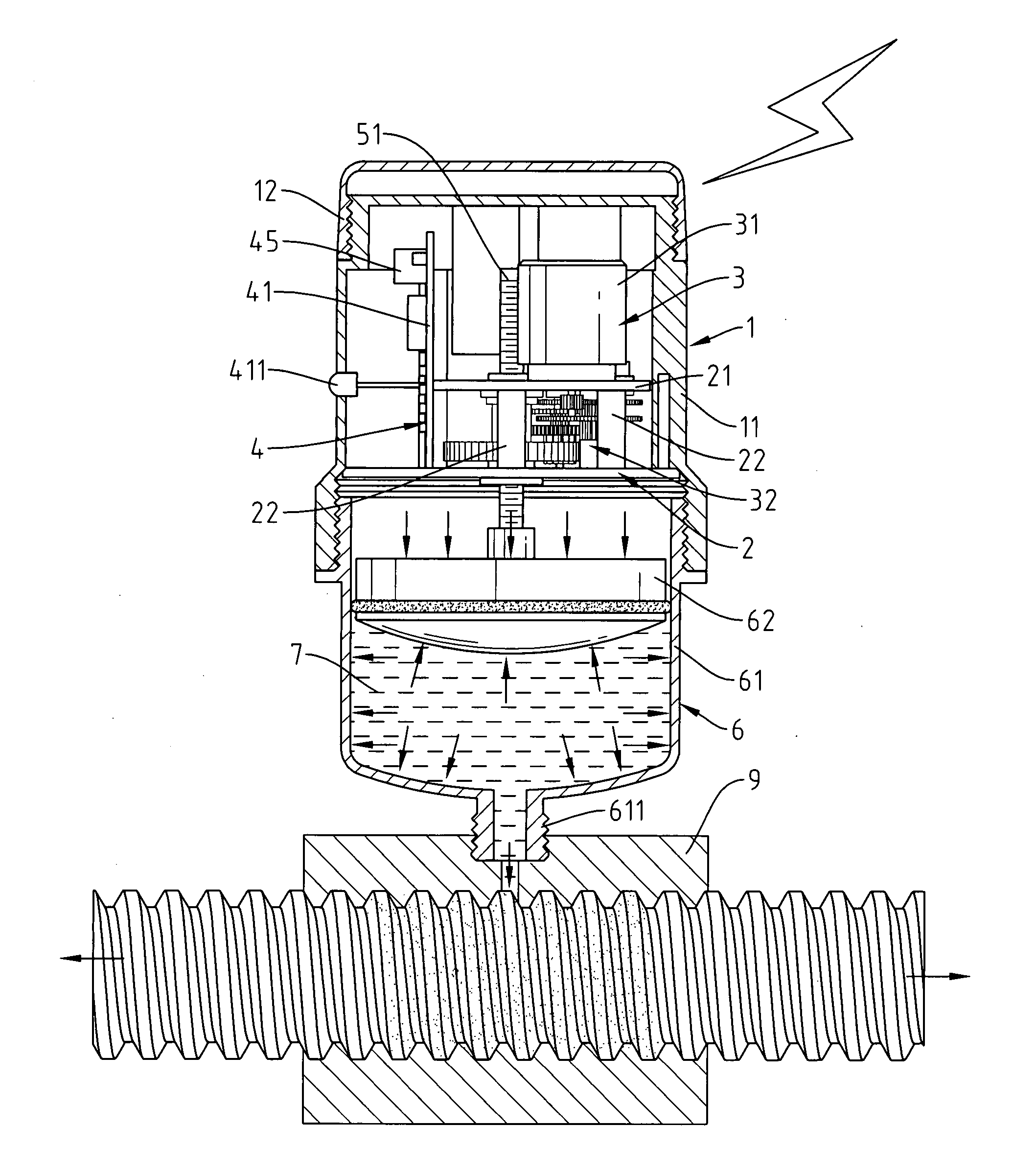

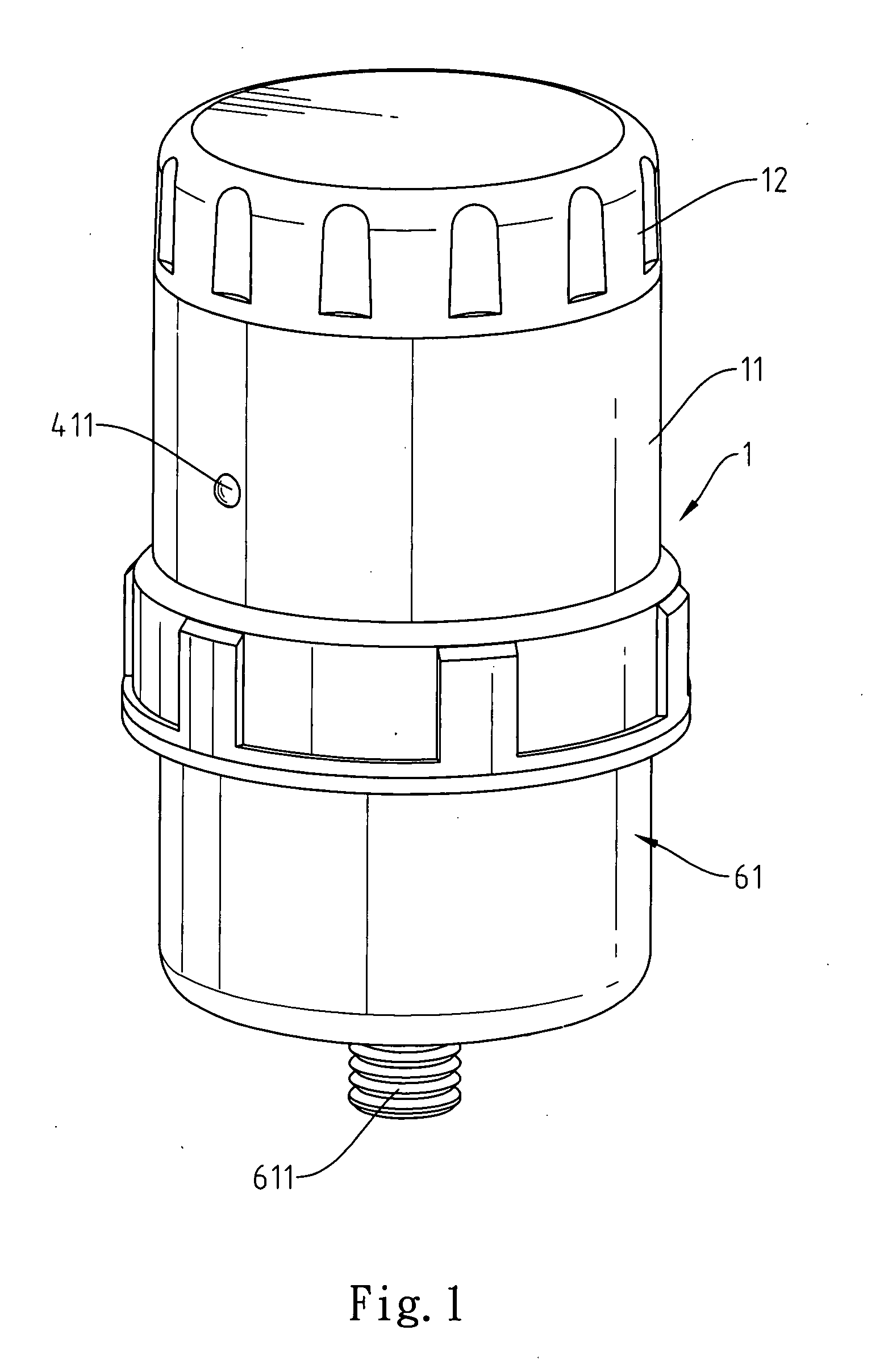

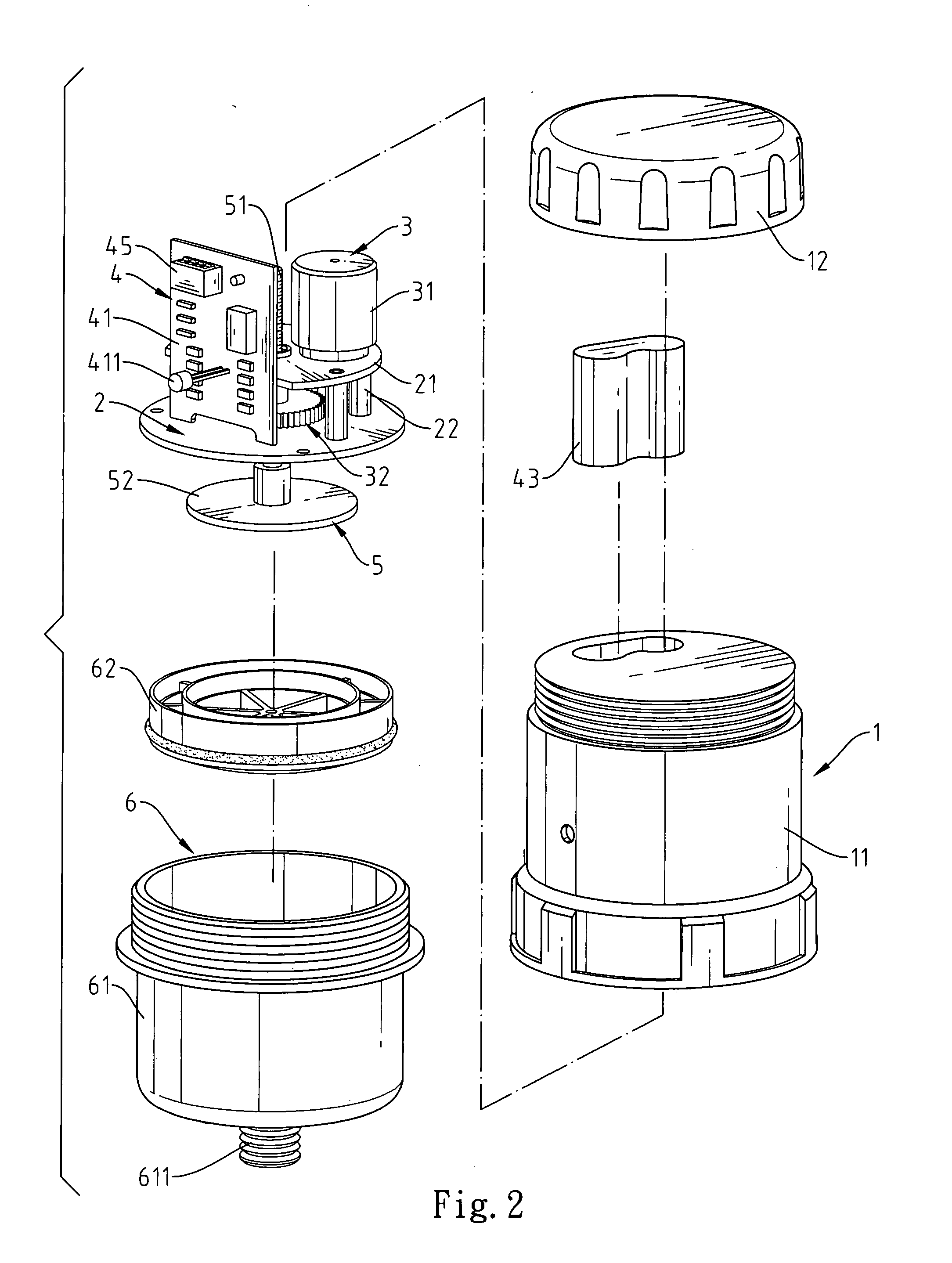

Automatic grease dispensing monitoring and alarm system

InactiveUS20110253481A1Step is necessaryPrecision lubricationSignal processingEngine rpmEngineeringLubrication

An automatic grease dispensing monitoring and alarm system using a control unit in each automatic grease dispenser to provide message to a center monitoring control and alarm system wirelessly, achieving wireless remote lubrication control, abnormality alarm, and auto grease-dispensing functions. Each automatic grease dispenser comprises a driving mechanism for driving a piston to dispense the lubricating grease, a microprocessor-based control unit for the setting of the lubricating cycle and for checking the grease dispensing amount subject to the detection of the rate of turn of the driving mechanism through a sensor and a black and white reflective plate.

Owner:LIN SHIH KUEI

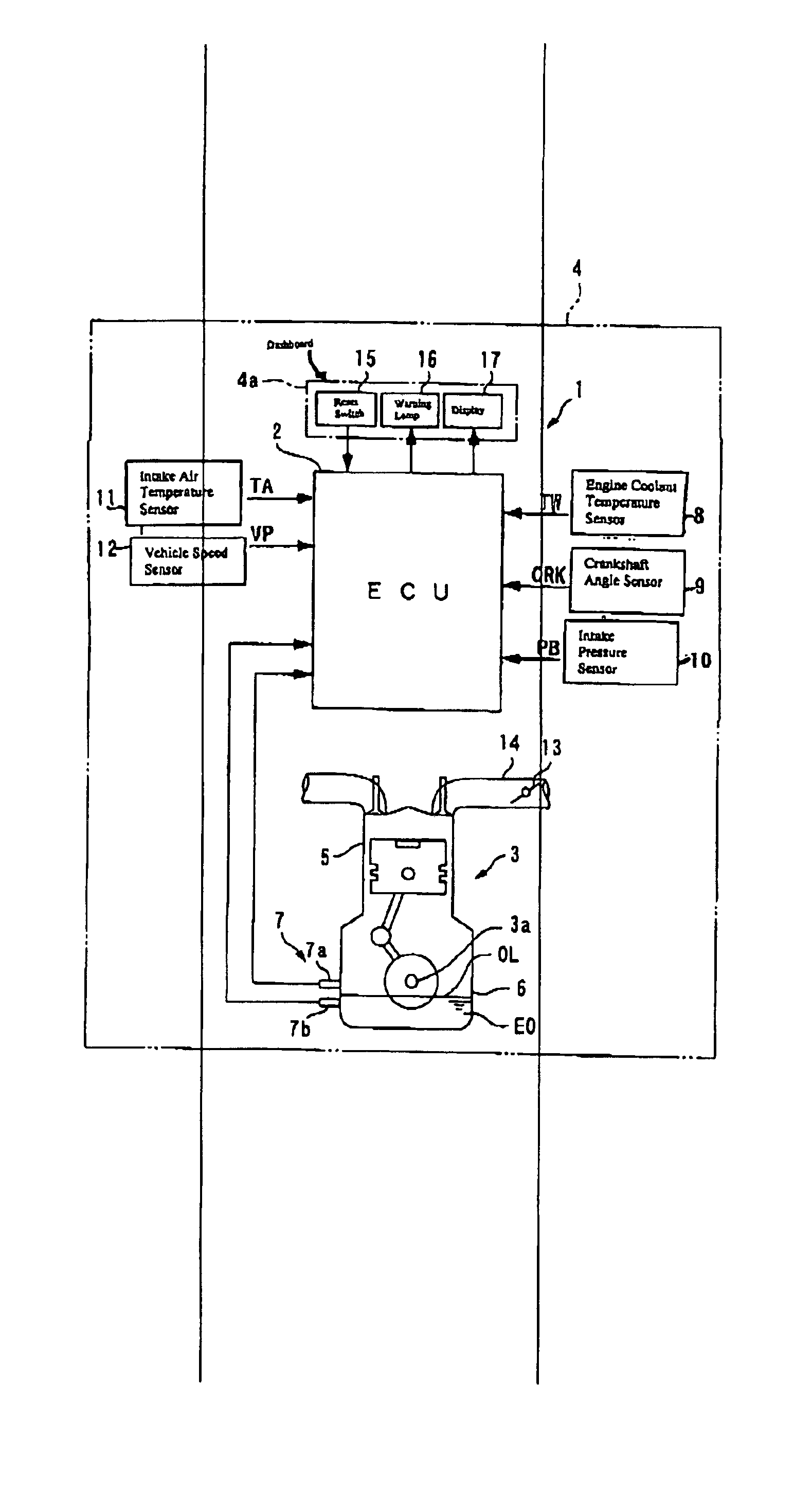

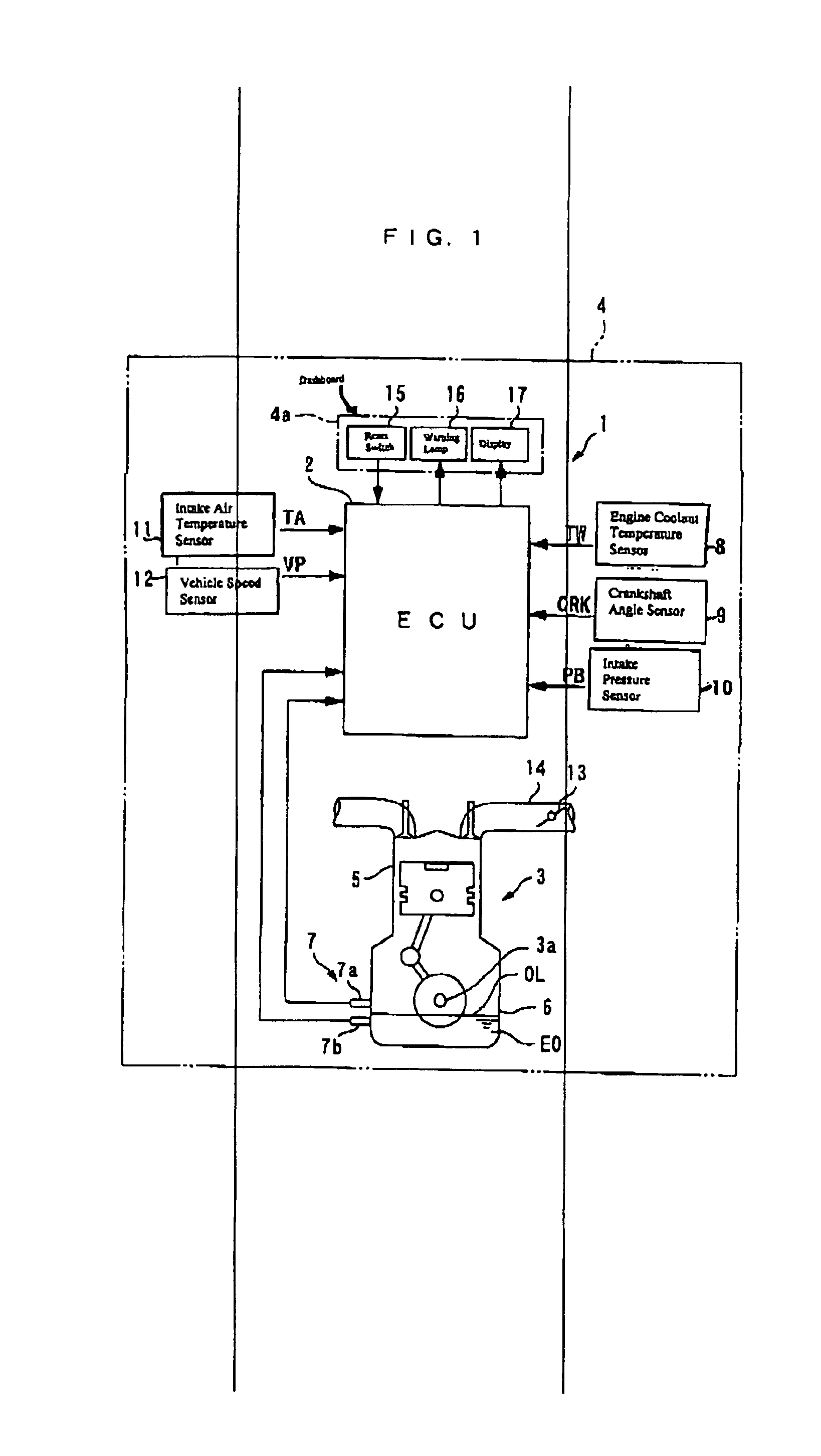

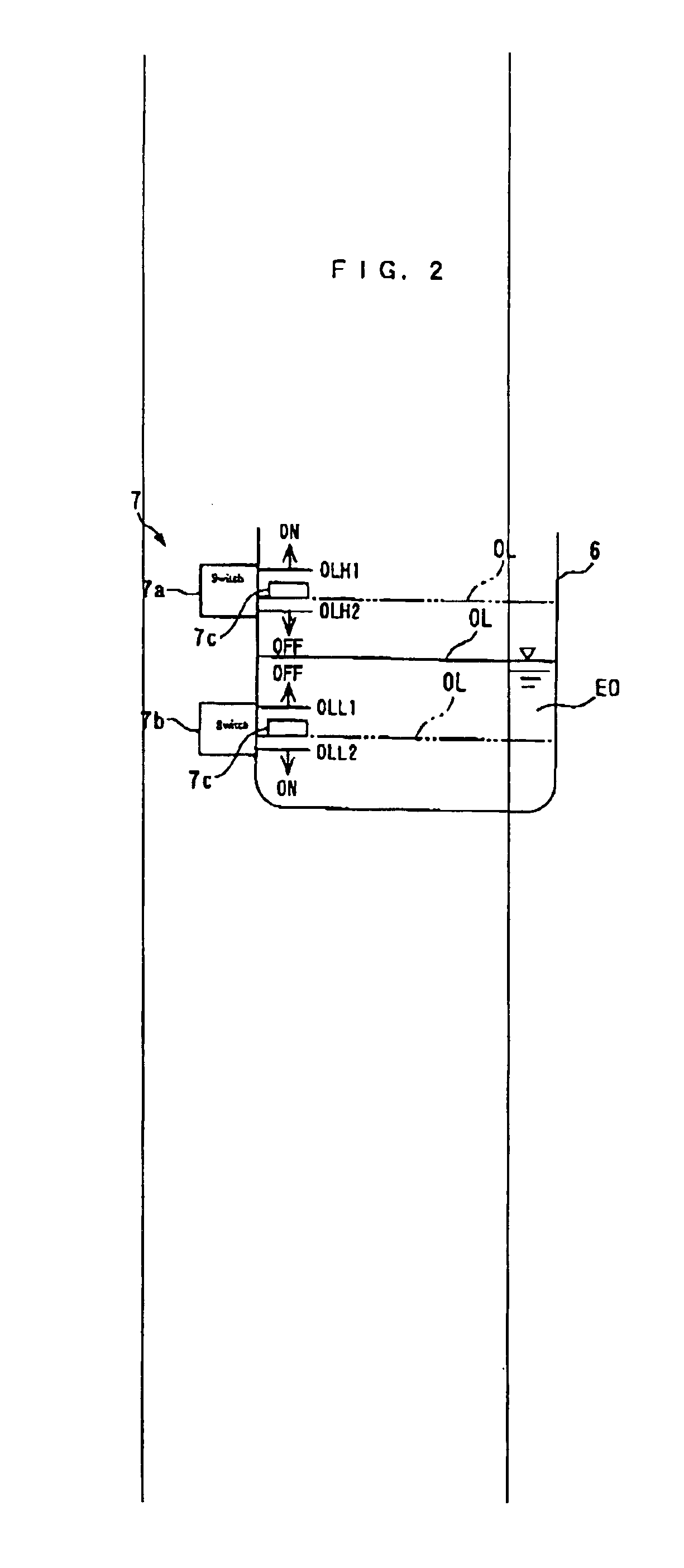

Engine oil, degradation-determining system and method, and engine control unit

There is provided an engine oil degradation-determining system which is capable of accurately detecting whether or not engine oil has been replenished, to thereby enhance accuracy of determination as to a degradation level of engine oil in use, at a low cost. A crankshaft angle sensor detects the engine rotational speed of an internal combustion engine. An ECU calculates a cumulative revolution number indicative of a degradation level of engine oil. An oil level sensor detects an oil level of the engine oil. When the detected oil level, which was equal to or lower than a predetermined lower limit level before stoppage of the engine, is equal to or higher than a predetermined higher limit level after start operation following the stoppage, the calculated cumulative revolution number is corrected in the direction of indicating a lower degradation level.

Owner:HONDA MOTOR CO LTD

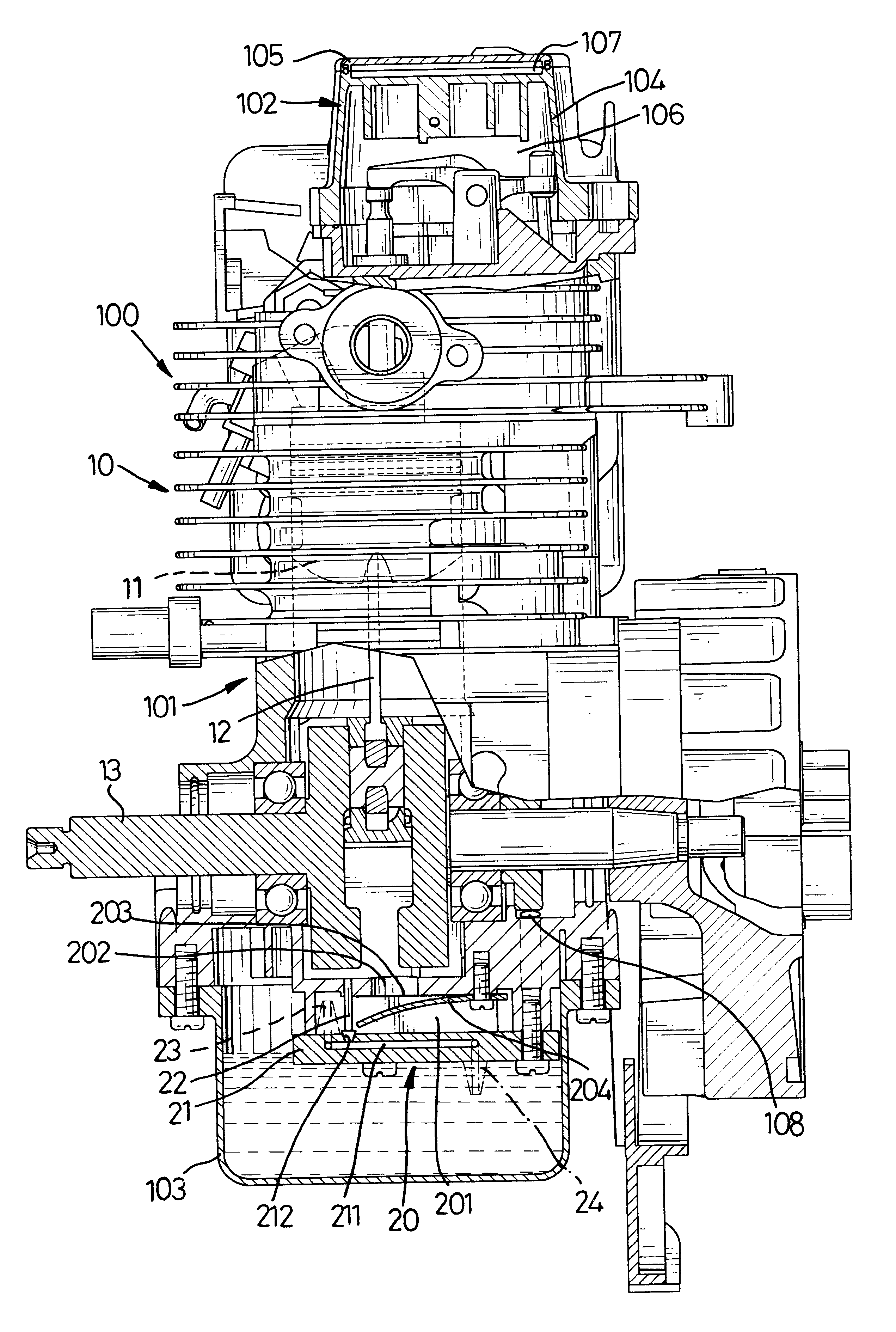

Four-stroke engine with an oil spray generating assembly for lubrication

InactiveUS6769391B1Lubrication of auxillariesLubricant conduit arrangementsFour-stroke engineEngineering

A four-stroke internal combustion engine includes a crankcase with a bottom, an oil pan and an oil spray generating assembly. The oil spray generating assembly having a closed sidewall, a valve, a bottom cap and nozzles is attached to the bottom of the crankcase and is enclosed by the oil pan. The closed sidewall is formed at the bottom of the crankcase to define a mist chamber enclosed by the bottom cap. The valve is mounted in the mist chamber with a valve port defined through the crankcase and a resilient valve flap corresponding to the valve port attached to the bottom of the crankcase. The nozzles are respectively mounted in the bottom cap out of the mist chamber inside the closed sidewall. The operation of the engine will produce an oil vapor for lubrication with the lubricating oil flowing out of the nozzles.

Owner:ECI ENGINE

Internal combustion engine

InactiveUS6786187B2Amount of oil in can optimizedSimple structureCrankshaftsLubrication of auxillariesFuel tankEngineering

An internal combustion engine capable of optimizing the amount of oil in the crank chamber with a simplified structure of lubrication system, in which a U-shaped oil reservoir is formed surrounding and adjacent to a crank chamber. At least one small hole is formed on a partition wall which separates the oil reservoir and the crank chamber from each other so that the crank chamber may always communicate with the oil reservoir through the small hole. Due to a flow resistance in the small hole, a pressure Po in the oil reservoir changes following a change of pressure Pc in the crank chamber with some delay, and where the pressure difference between the oil reservoir and the crank chamber caused by a delay in the change of the pressure Po in the oil reservoir, results in the introduction of the oil in the oil reservoir into the crank chamber. It further allows excessive oil in the crank chamber to be circulated back into the oil reservoir.

Owner:KIORITZ

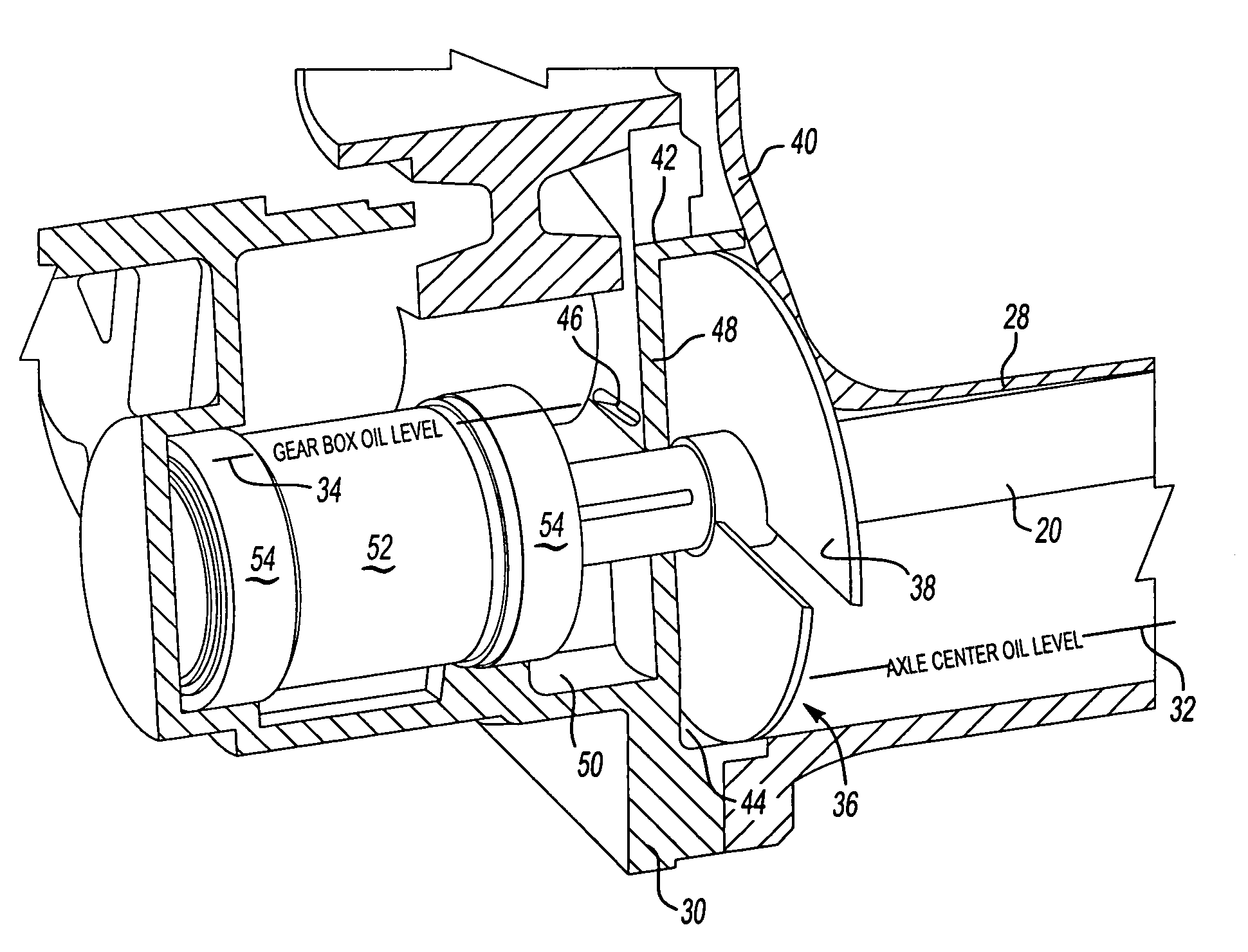

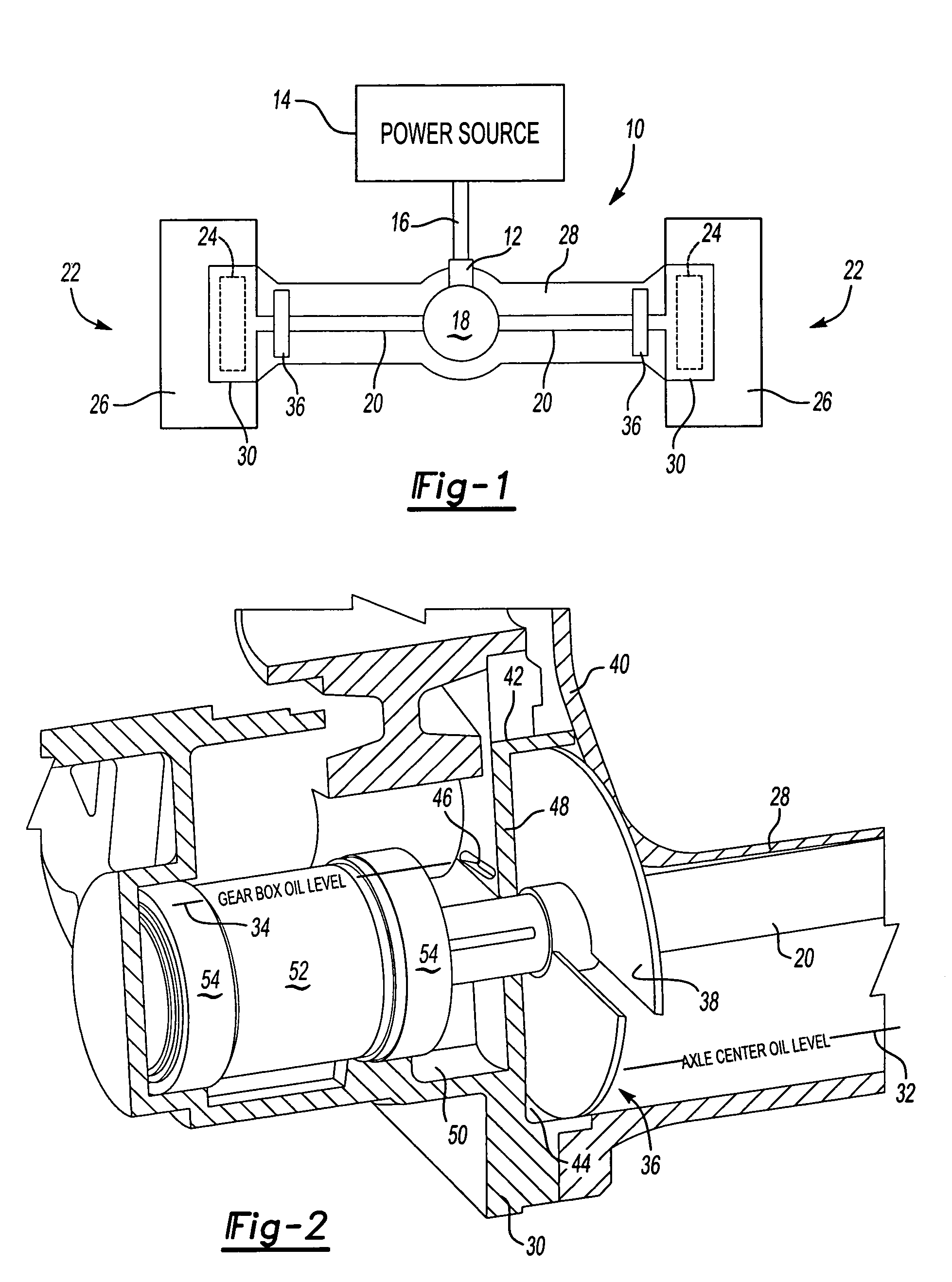

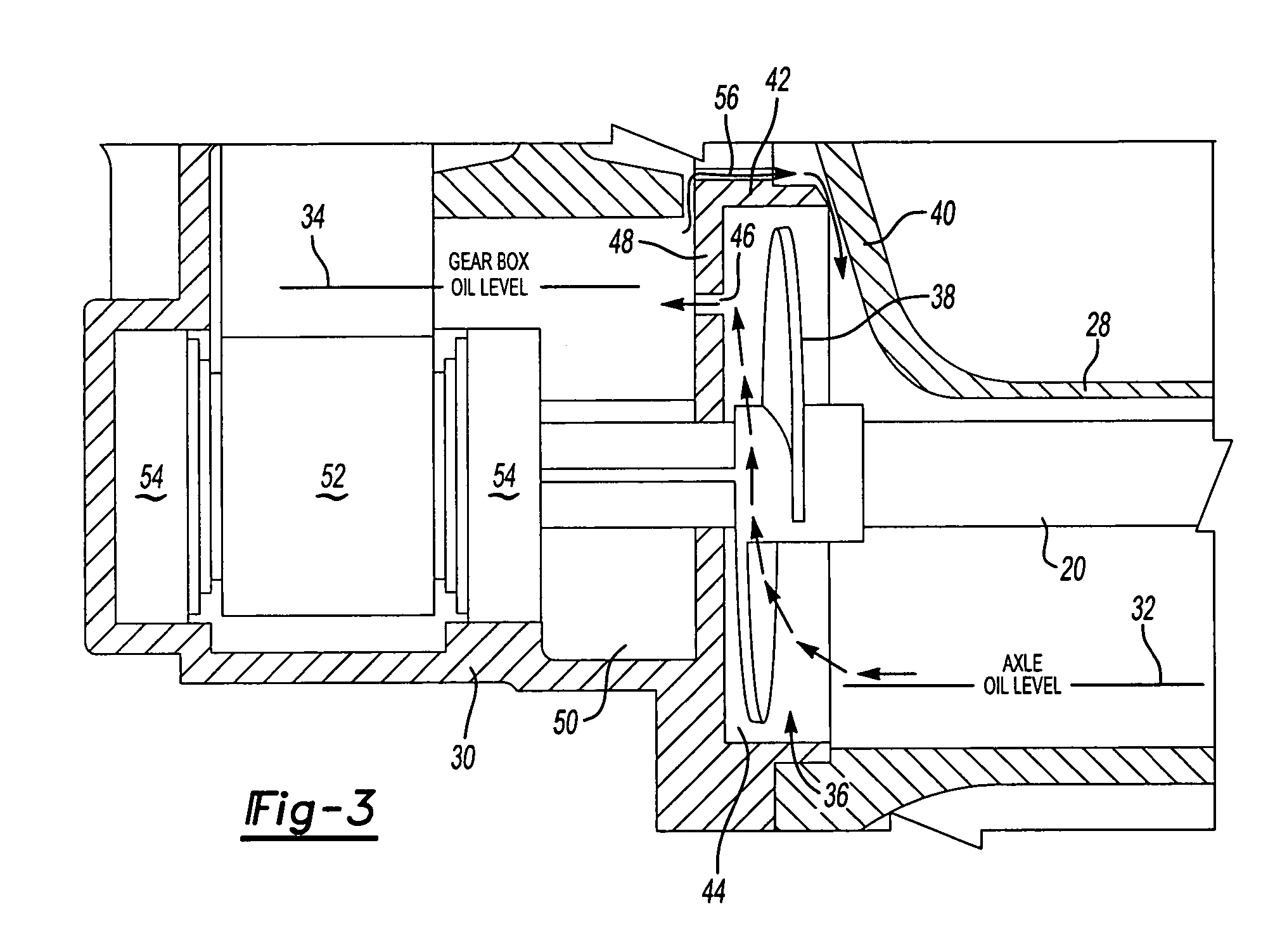

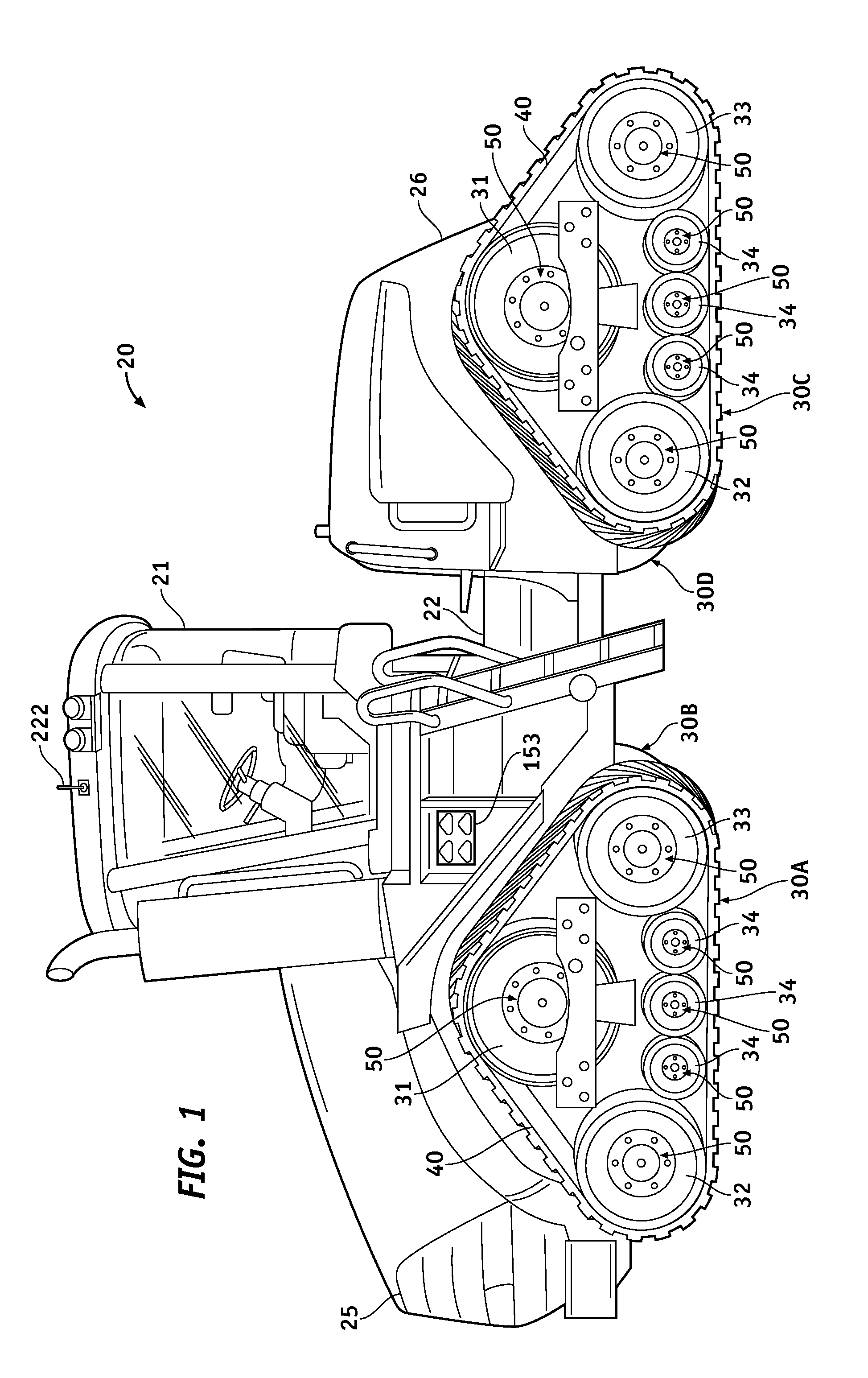

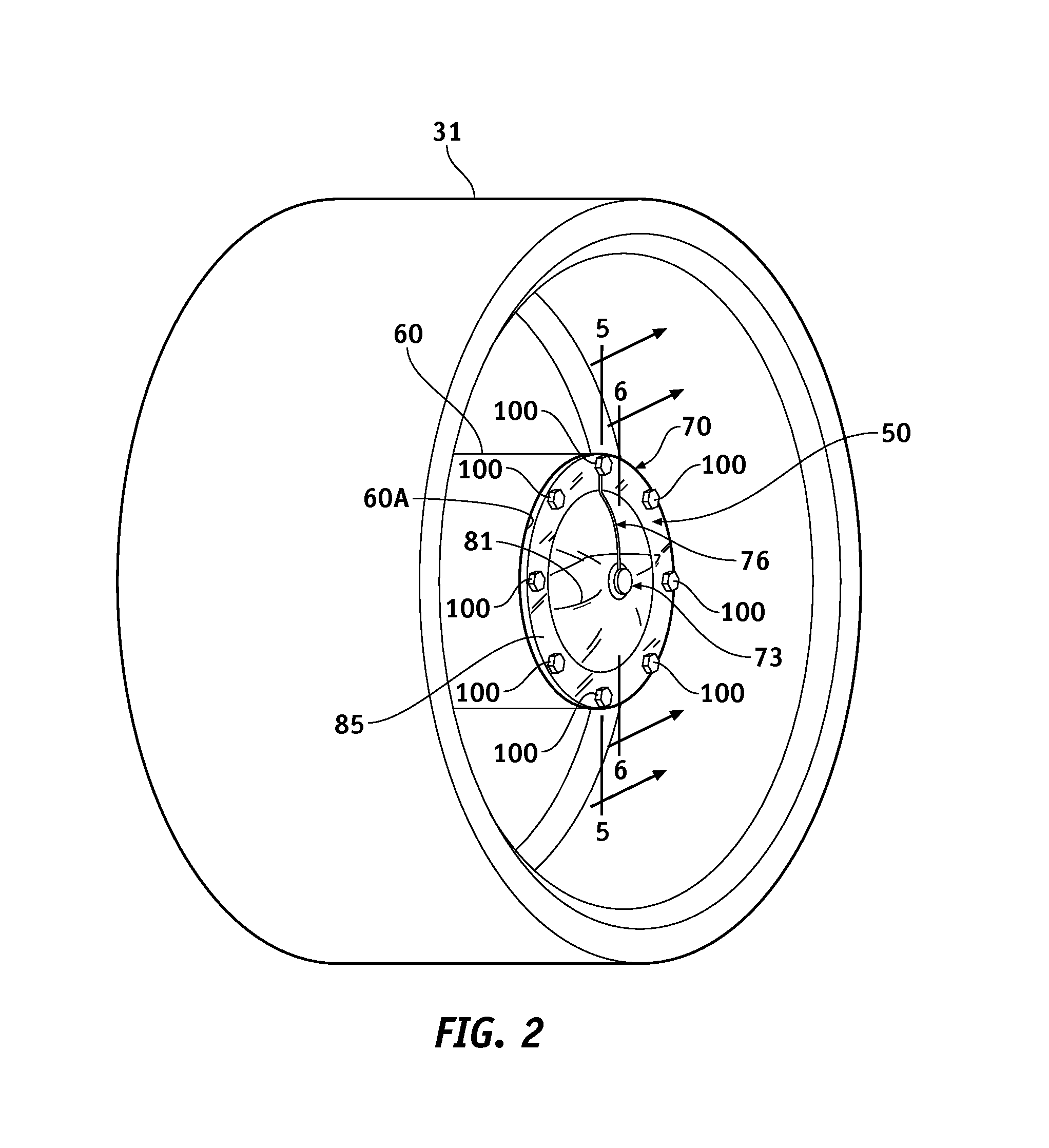

Dual level oil impeller for drive axle assembly

InactiveUS6991574B2Reduce the amount requiredFully lubricatedDrip or splash lubricationGear lubrication/coolingImpellerTransaxle

Owner:ARVINMERITOR TECH

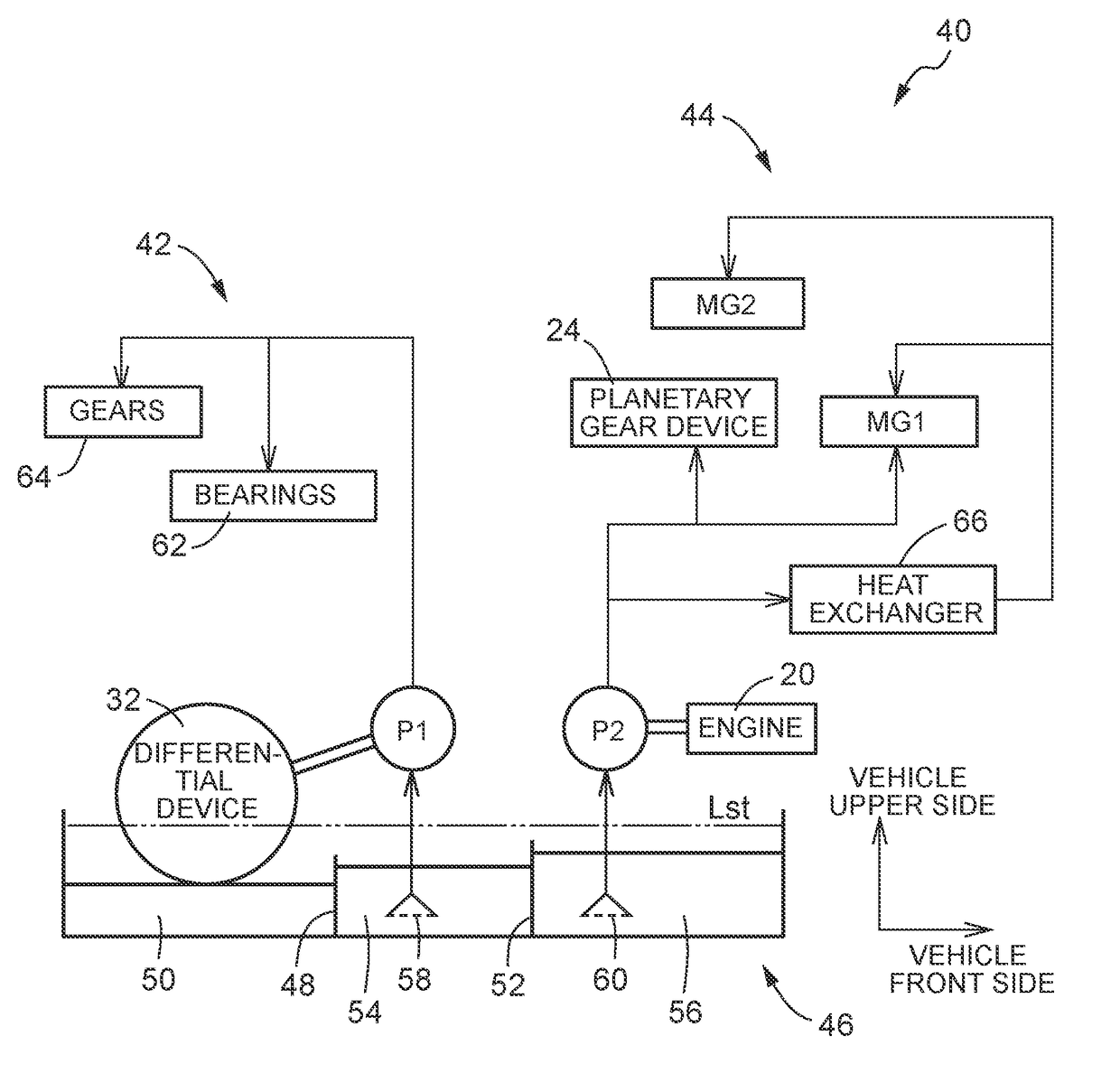

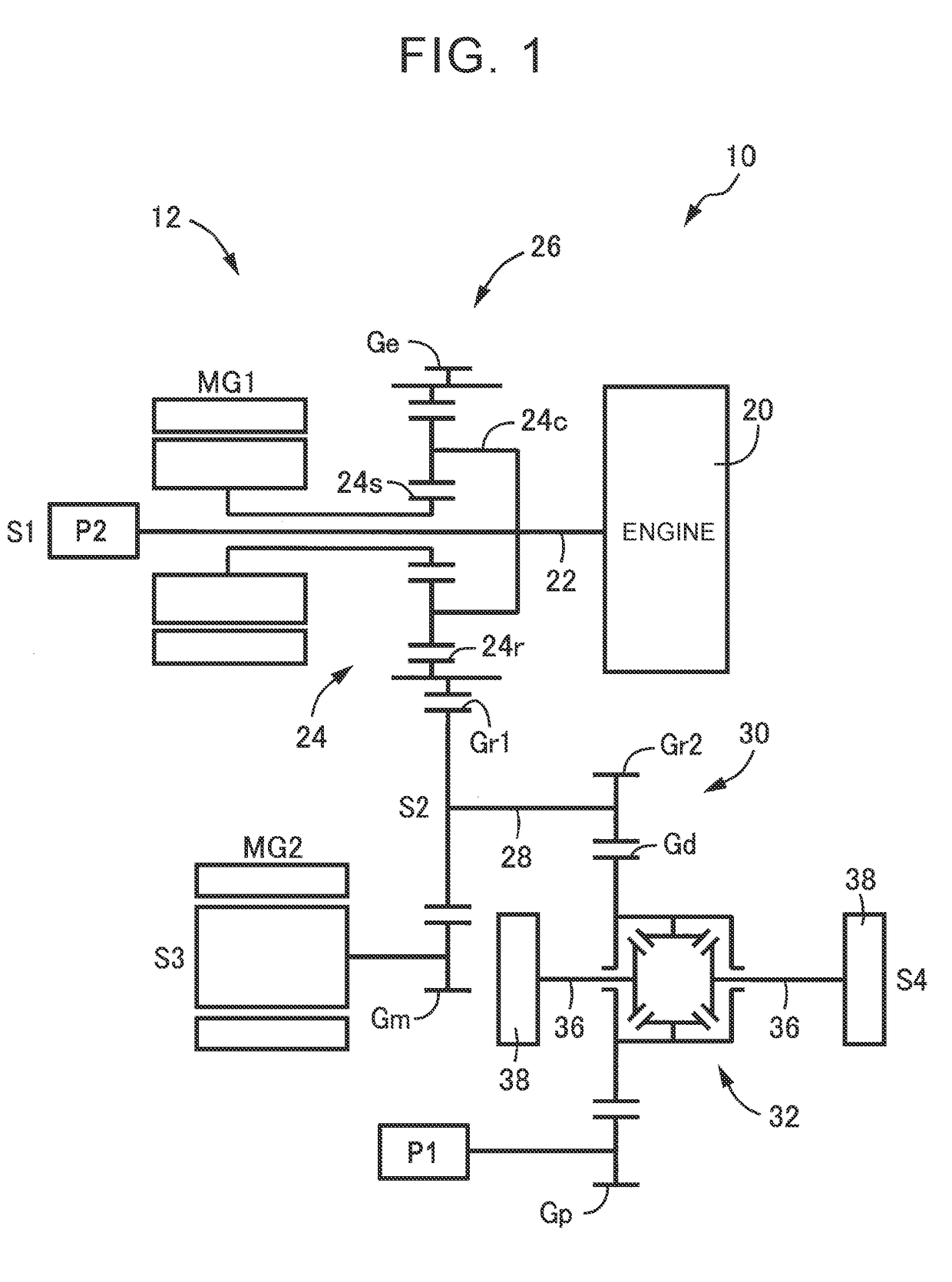

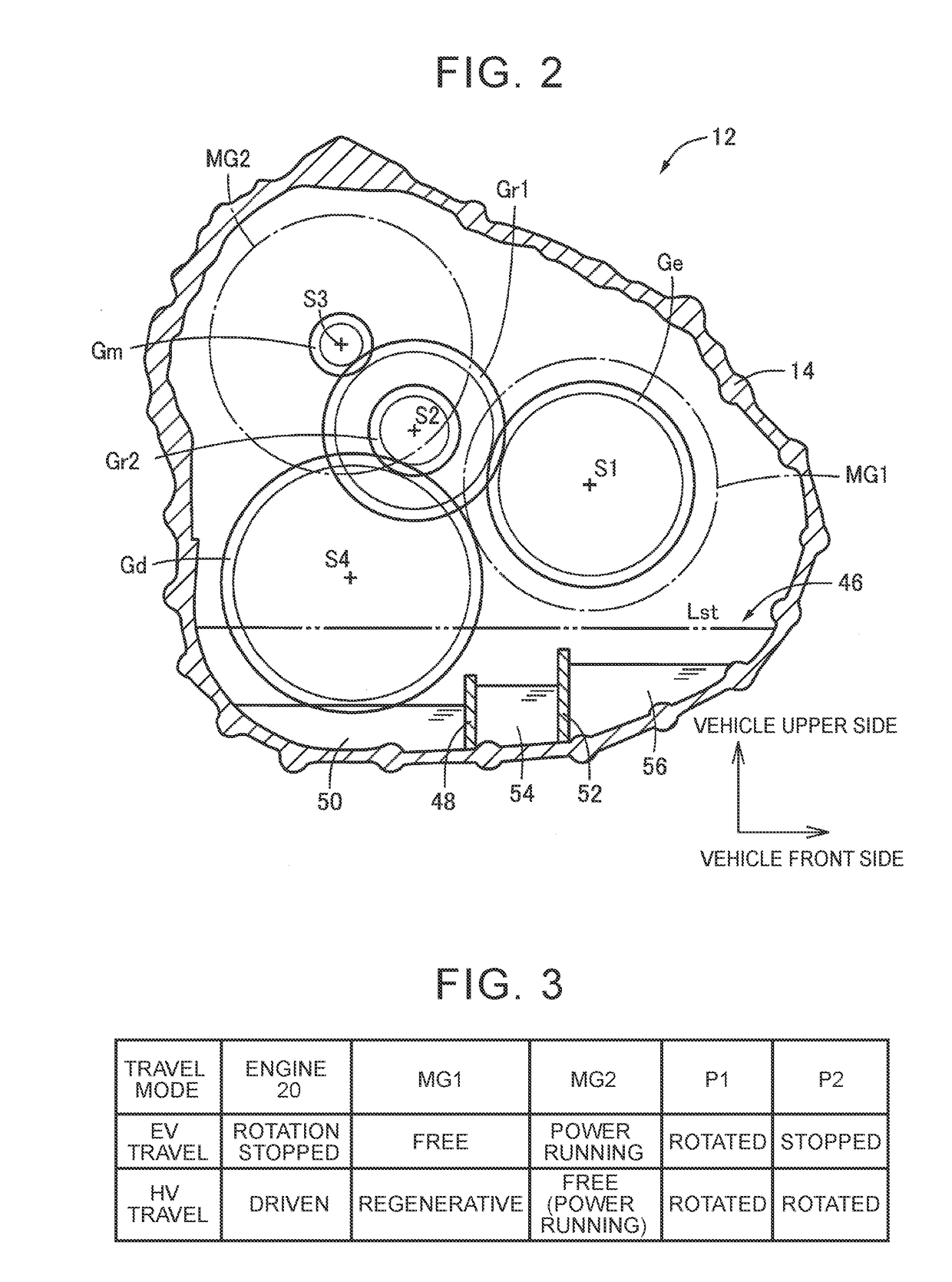

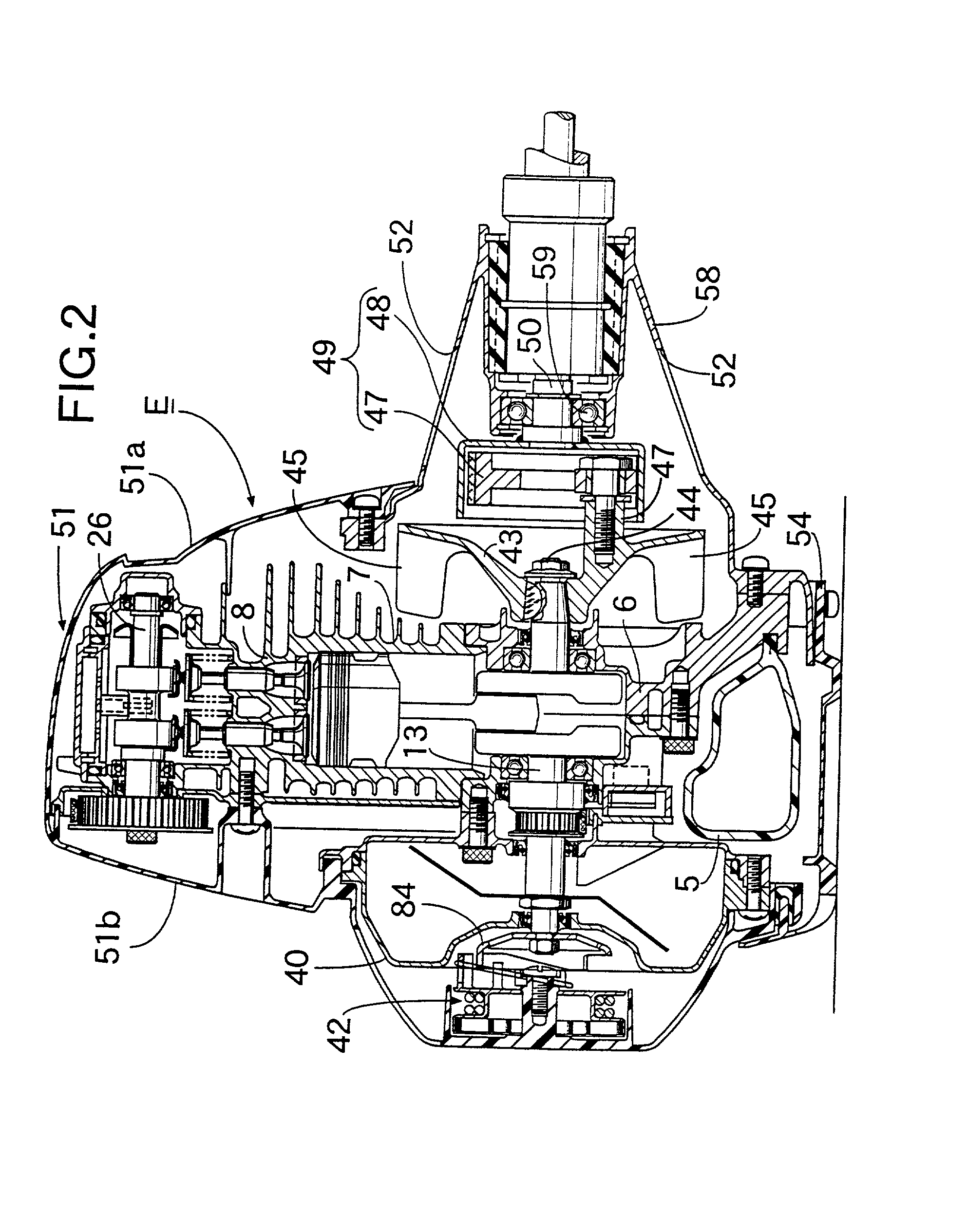

Lubricating Device of Power Transmission Device for Vehicle

ActiveUS20170219085A1Lower oil levelReduce energy lossGas pressure propulsion mountingGear lubrication/coolingPower transmissionOil storage

During the travel of a vehicle, the oil level of lubricating oil is lowered due to the suction by at least a first oil pump and the scraping-up by the rotation of a differential ring gear and so on. In particular, until the oil level becomes equal to or lower than an upper end of a first partition wall, the oil level is lowered due to both the suction by the first oil pump and the scraping-up by the rotation of the differential ring gear and so on, and therefore, a region, that is immersed in the lubricating oil, of the differential device rapidly becomes smaller. Since a suction port of the first oil pump is disposed in a second oil storage portion, the oil level in the second oil storage portion during the travel of the vehicle can be adjusted independently of that in a first oil storage portion.

Owner:TOYOTA JIDOSHA KK

Oil pan structure for internal combustion engine

InactiveUS6568509B1Reduce aerationPerformance deteriorationCasingsOilsumpsSurface levelInternal combustion engine

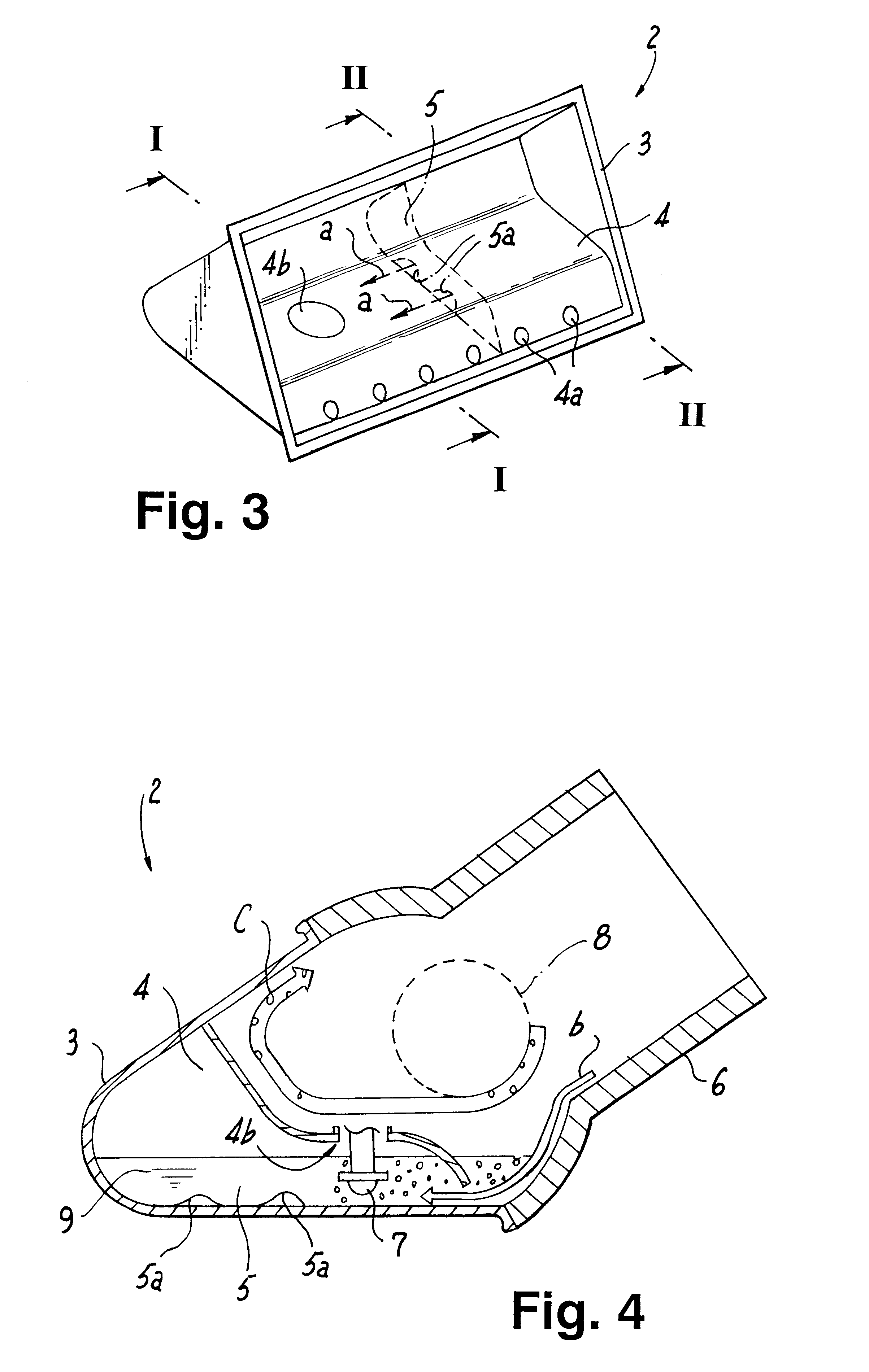

An oil pan (2) fixed on an engine mounted on a vehicle with an inclination angle has a first baffle plate (4), a portion of which is horizontally disposed, in the inside of the oil pan, a second baffle plate (5) disposed vertically between the first baffle plate (4) and the bottom of the oil pan (2) such that said second baffle plate (5) partitions the space into two compartments, and an oil passageway between the two compartments. Since the oil passage way reduces mixed air bubbles in the oil when the oil flows through the passageway, either compartment has less mixed air bubbles such that the oil surface levels in the two compartments may be equalized and that the aeration may be reduced.

Owner:SUZUKI MOTOR CORP

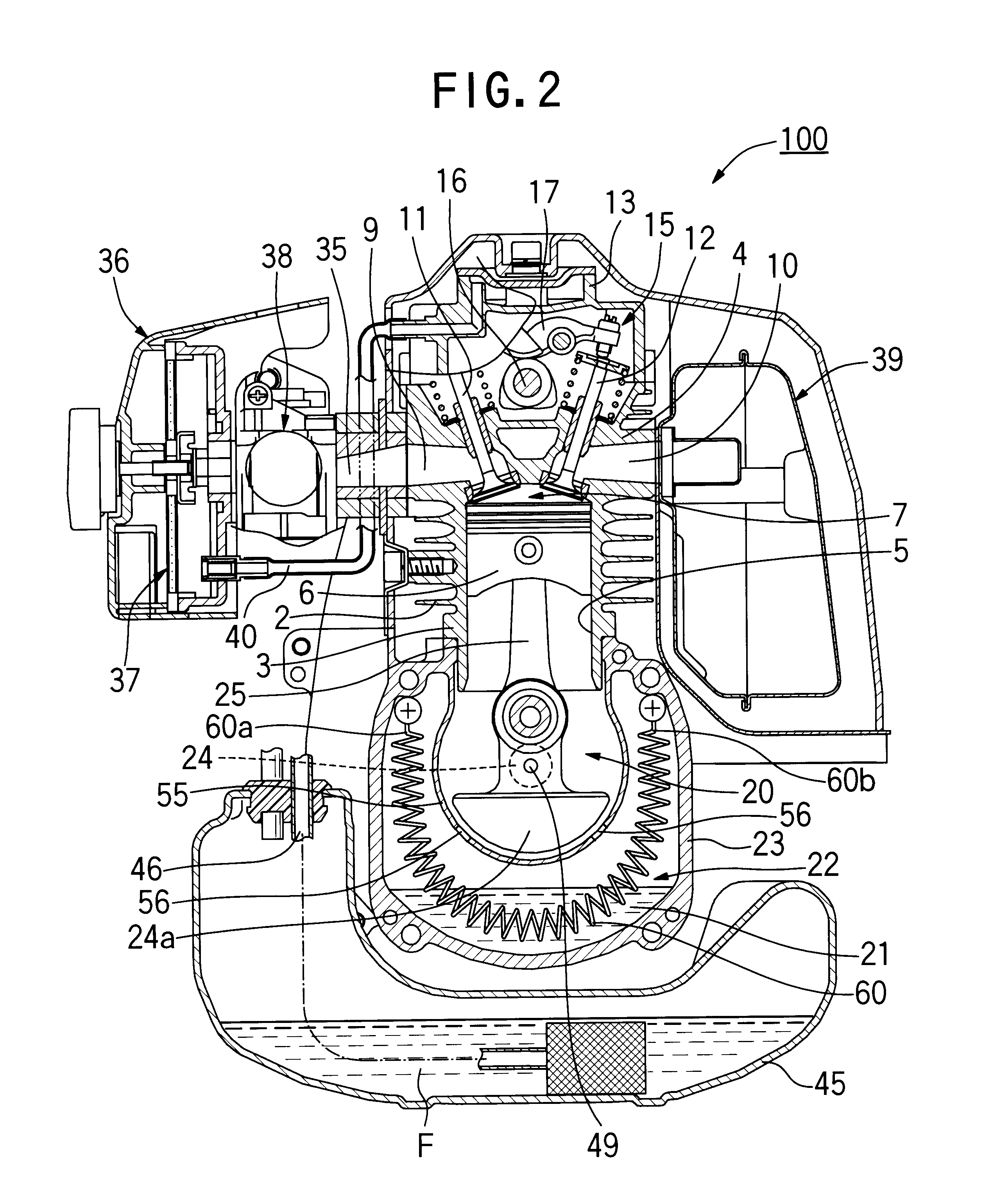

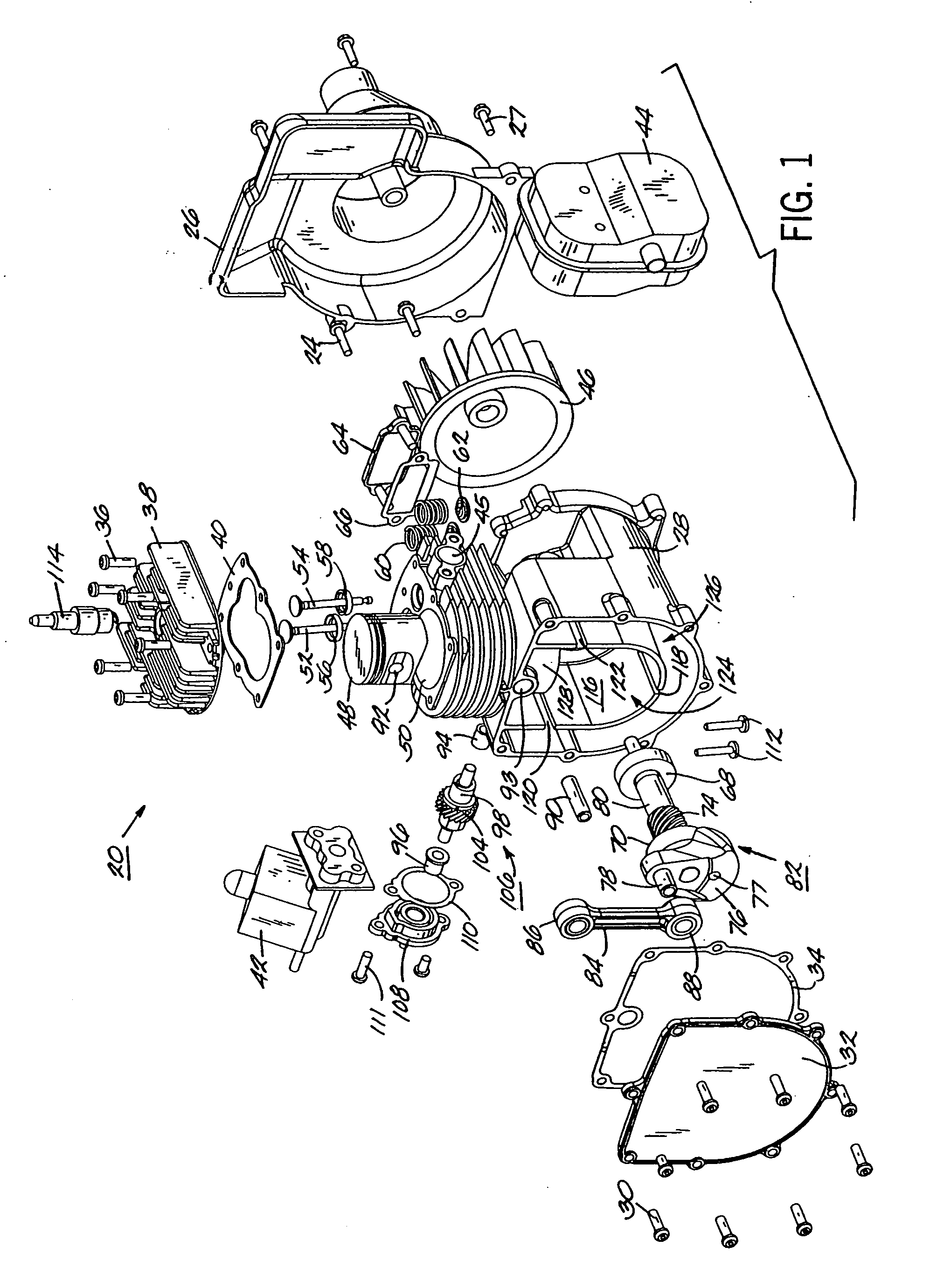

Four-stroke internal combustion engine

InactiveUS20050279318A1Emission reductionReduce manufacturing costLubrication of auxillariesLubricant conduit arrangementsEngineeringPower tool

A four-stroke internal combustion engine is provided that is capable of use in many power tools, including those power tools subjected to tippable applications. The engine includes an oil reservoir and a crank chamber separated by a divider. The divider includes a slot that allows lubricant to move from the oil reservoir into the crank chamber and from the crank chamber into the oil reservoir in response to pressure fluctuations of the engine. The engine can include an insert positioned within the slot to at least partially restrict the slot thereby modifying the lubricant communication between the crank chamber and the oil reservoir through the slot. The insert can be wedge-shaped and at least partially define a passage such that when the insert is positioned within the slot the transfer of lubricant between the crank chamber and the oil reservoir occurs through the passage.

Owner:BRIGGS & STRATTON

Electronic oil level detection and replacement system

An oil level monitoring and replenishment system for use with an internal combustion engine having an oil sump. The system as a sensor which continuously measures the sump level in the reservoir for holding a quantity of oil to be used in replenishment of the sump. A sensor monitors the oil level in the sump and causes replenishment from the reservoir when needed. The reservoir has warning circuit interactive with a reservoir sensor to signal from the reservoir has reached a lower level of oil and requires the filling. The sensor also provides means to signal when the reservoir has been filled to the desired level to prevent overfilling.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Electronic oil level detection and replacement system

an oil level monitoring and replenishment system for use with an internal combustion engine having an oil sump. The system as a sensor which continuously measures the sump level in the reservoir for holding a quantity of oil to be used in replenishment of the sump. A sensor monitors the oil level in the sump and causes replenishment from the reservoir when needed. The reservoir has warning circuit interactive with a reservoir sensor to signal from the reservoir has reached a lower level of oil and requires the filling. The sensor also provides means to signal when the reservoir has been filled to the desired level to prevent overfilling.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Oil suction system

ActiveUS8292036B2Easy constructionAvoid drawingGearboxesGear lubrication/coolingEngineeringLiquid surfaces

In an oil suction system for drawing up oil stored in an oil reservoir through a strainer, the oil reservoir is constructed such that, when the liquid surface of the oil is inclined due to movement of the stored oil, the level of the liquid surface close to the suction port varies in accordance with a plurality of directions of inclination of the liquid surface, and the level of the liquid surface close to the suction port is lower in a particular direction as one of the directions of inclination of the liquid surface than those in the other directions of inclination, and an inflow resistance portion is provided at a lowered liquid-level side of the suction port on which the liquid level is lowered when the oil surface is inclined in the particular direction, for increasing the resistance to flow of the oil from the lowered liquid-level side toward the suction port, to be larger than the resistance to flow of the oil from a raised liquid-level side of the suction port on which the liquid level is raised due to inclination in the particular direction, toward the suction port.

Owner:TOYOTA JIDOSHA KK

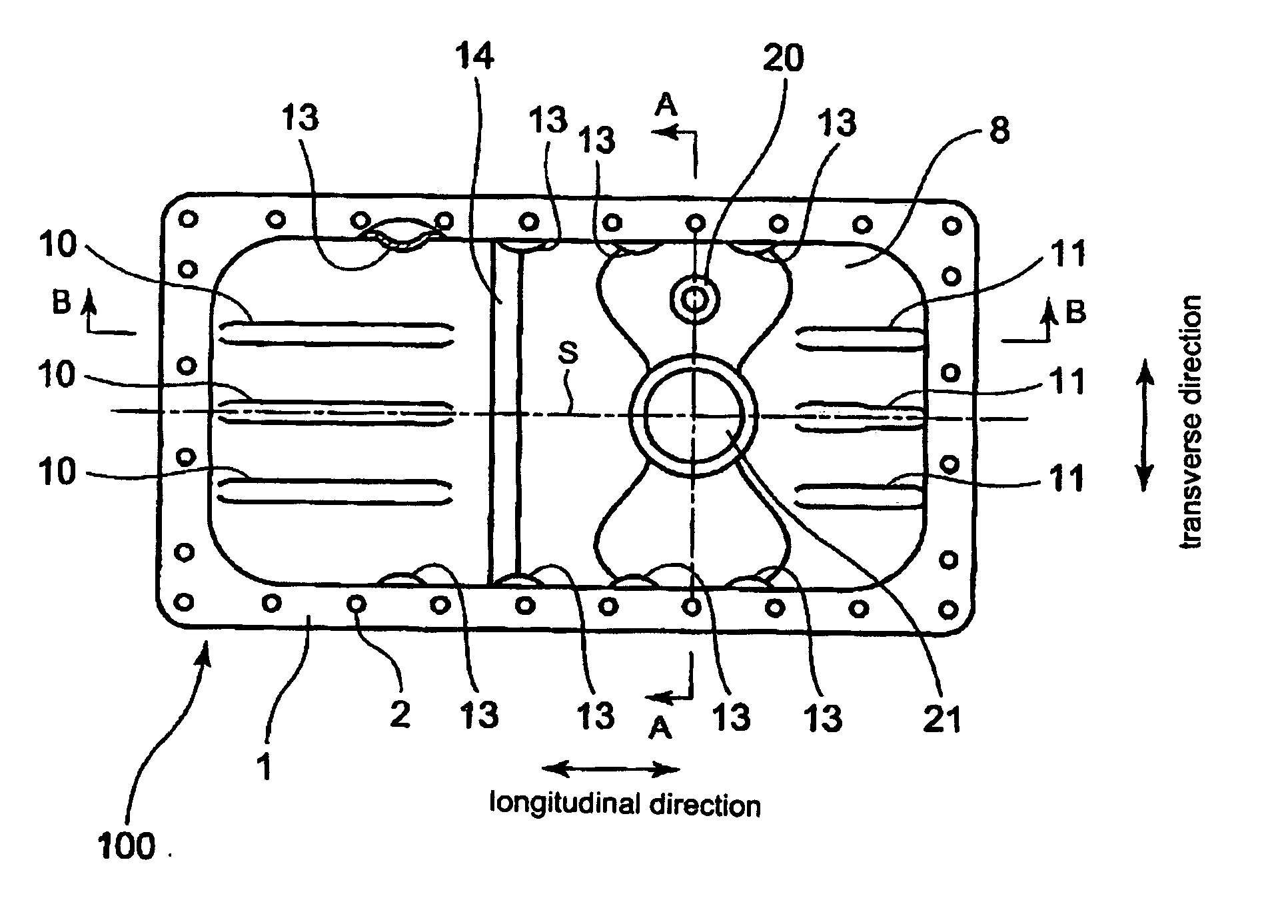

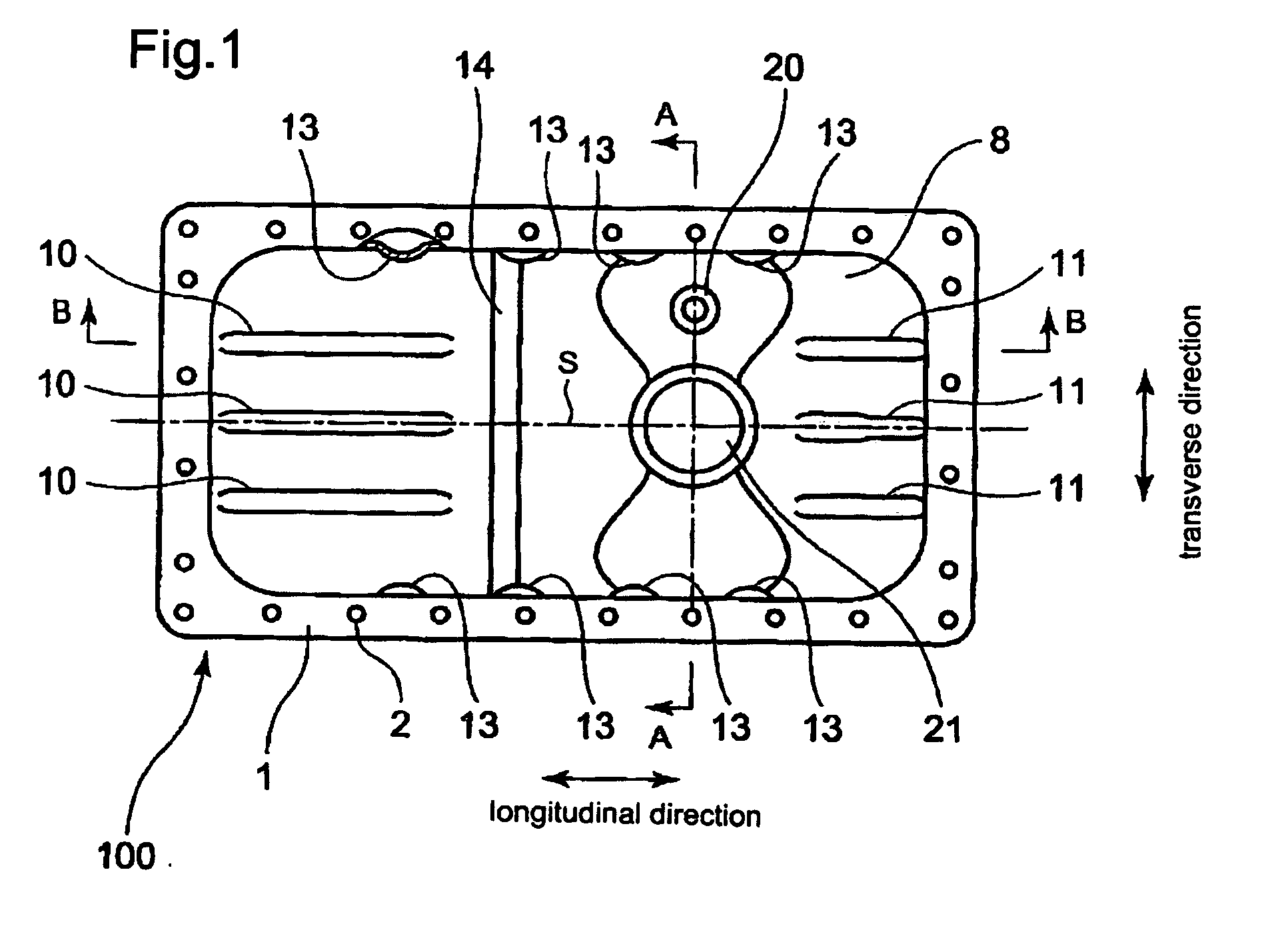

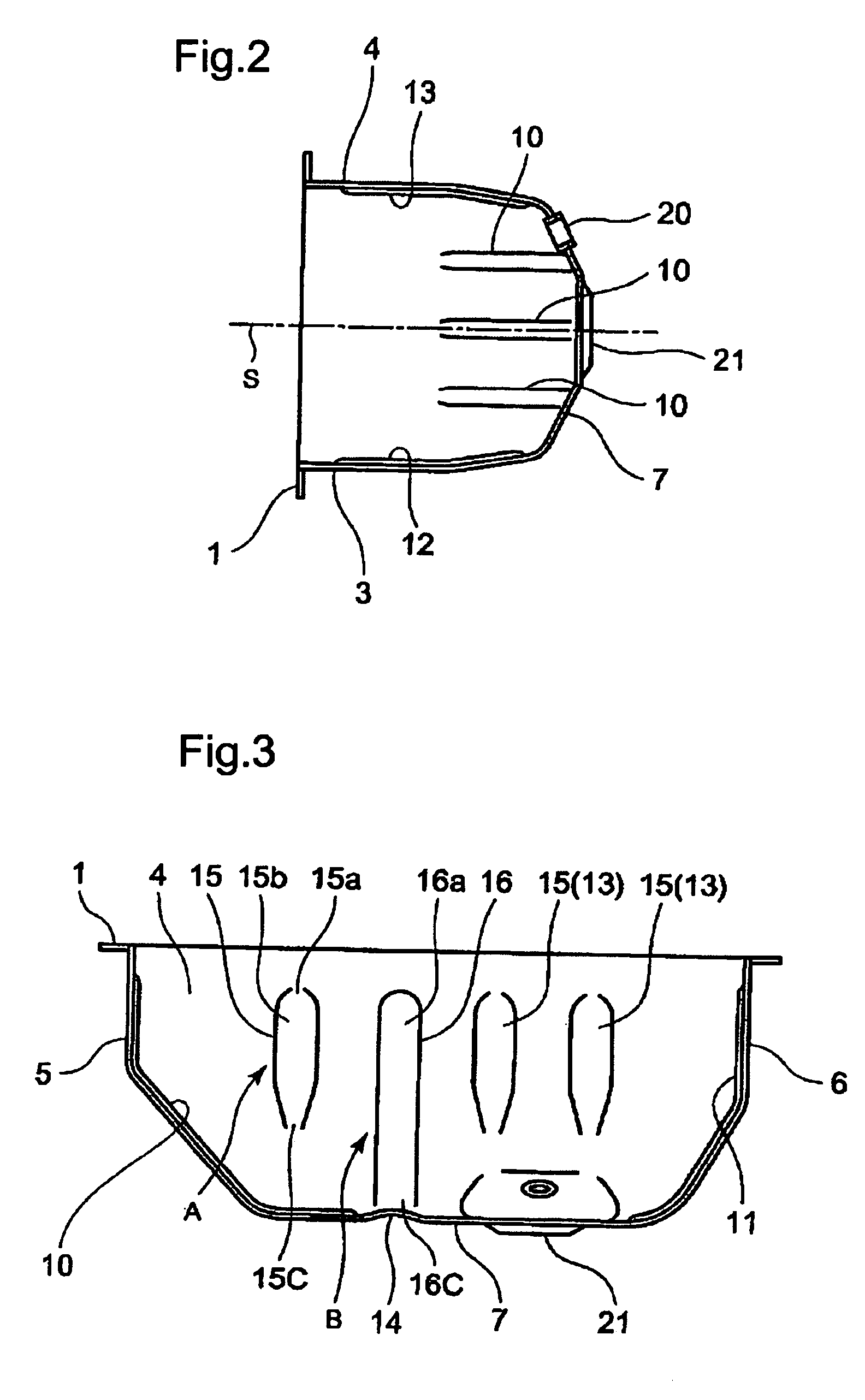

Oil pan structure and an engine therewith

ActiveUS20090145395A1Raise the natural frequencyImprove rigidityCasingsOilsumpsEngineeringNatural frequency

An oil pan structure includes a plurality of reinforcement beads of several kinds. An engine utilizes the oil pan, whereby the strength and vibration-rigidity (rigidity against vibration) of the oil pan and the engine are sufficiently enhanced so that a natural frequency of the oil pan and the engine therewith becomes adjustable through a selection as to the numbers, locations, and sizes of the beads.

Owner:MITSUBISHI HEAVY IND LTD

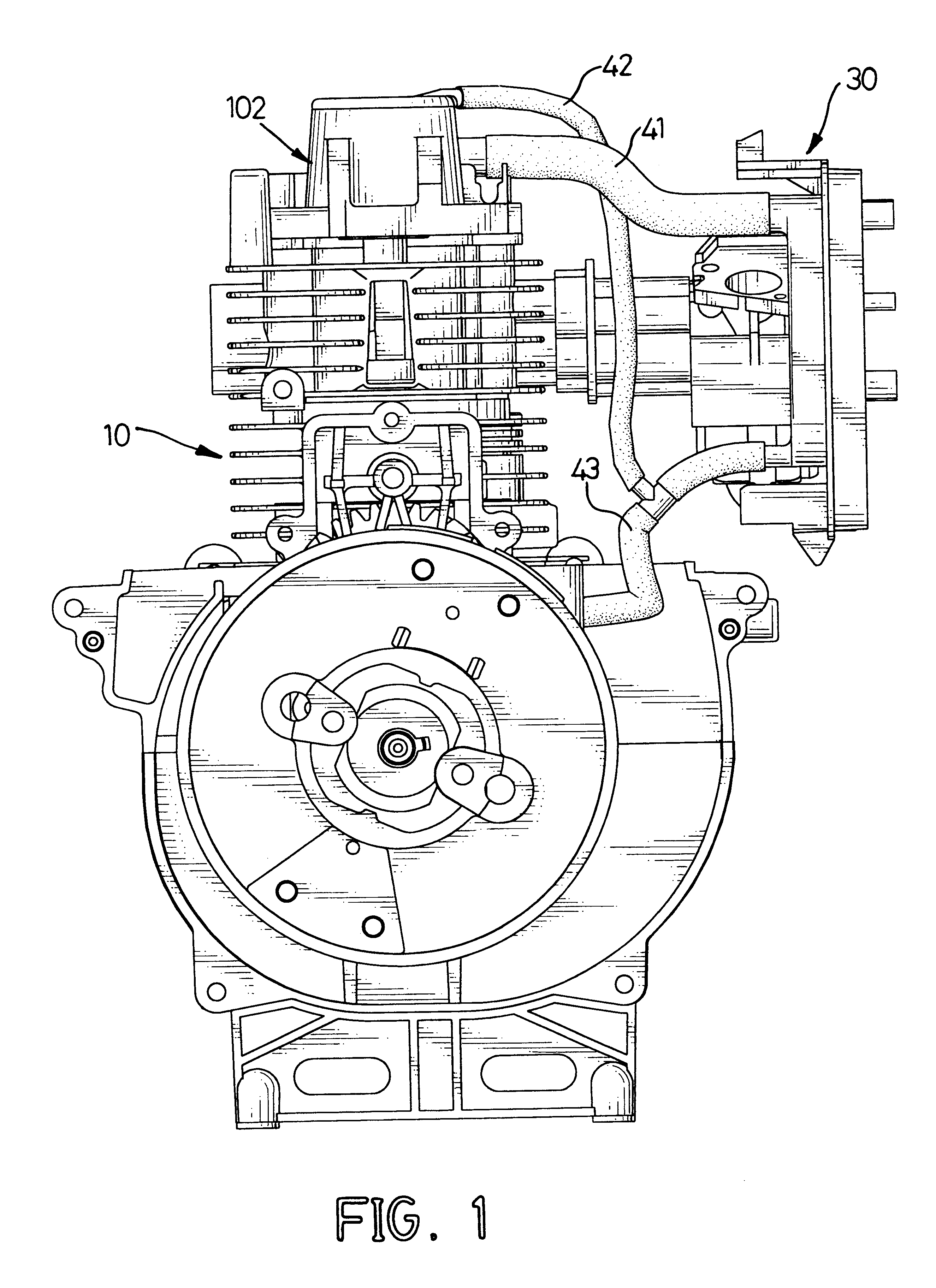

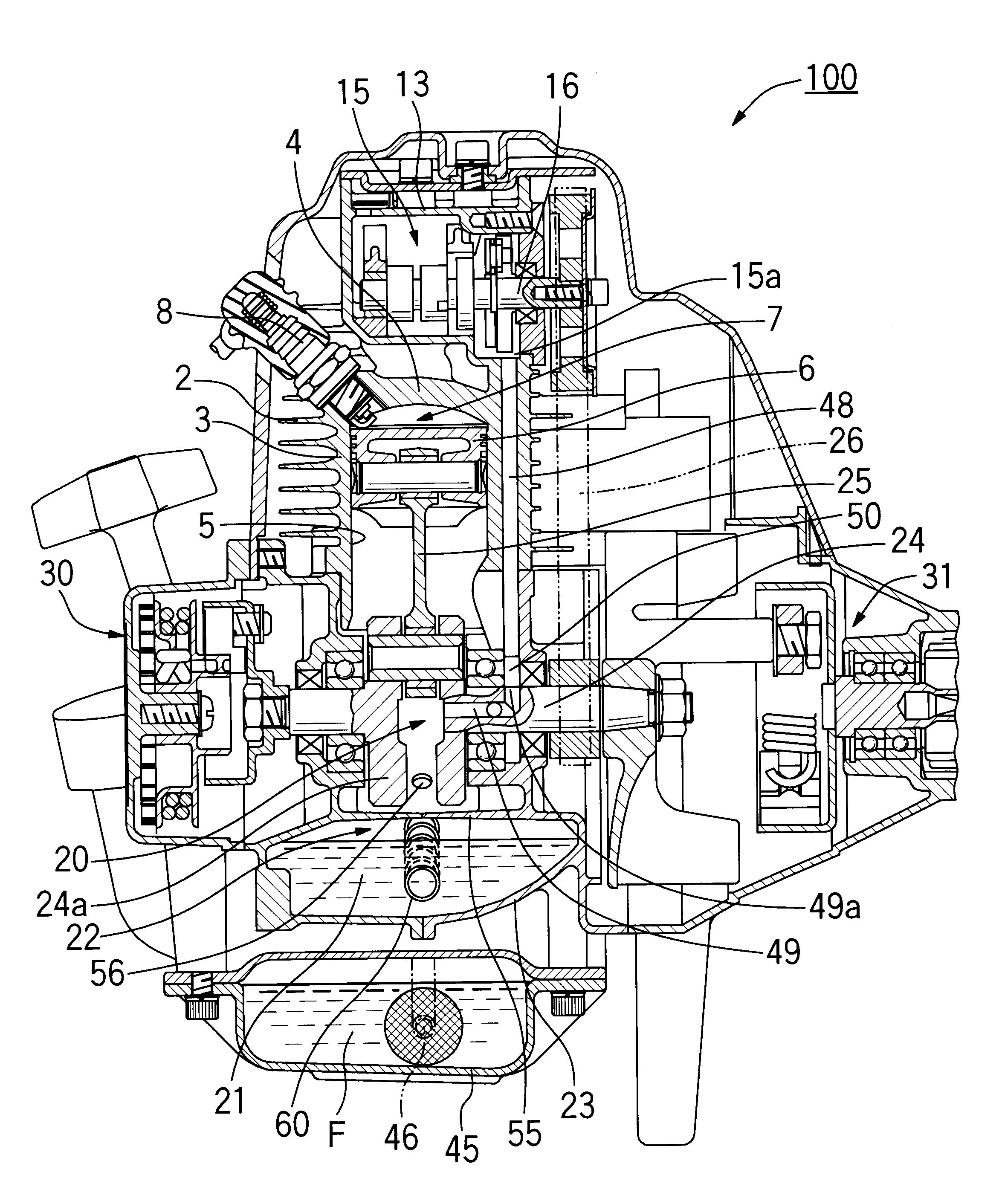

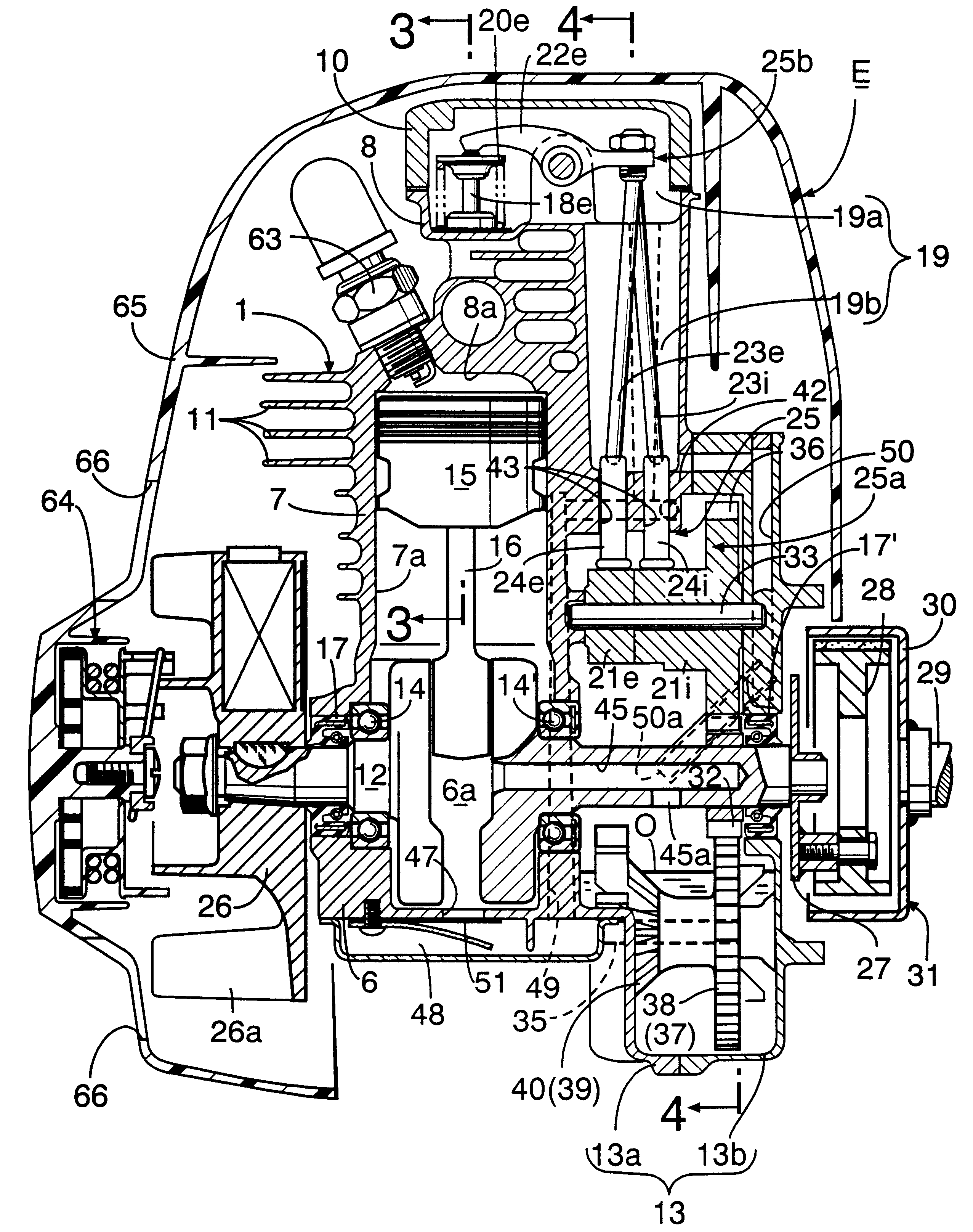

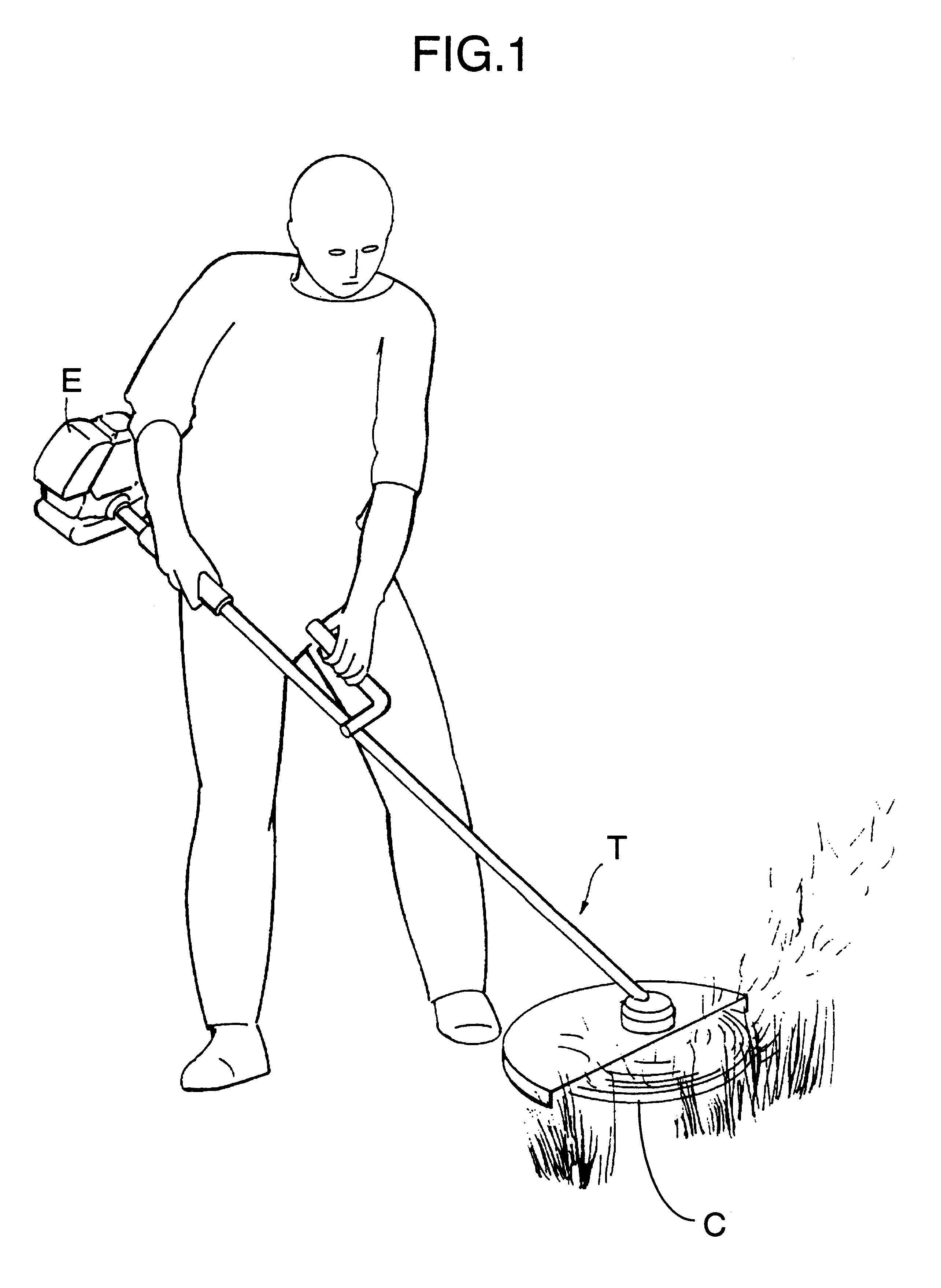

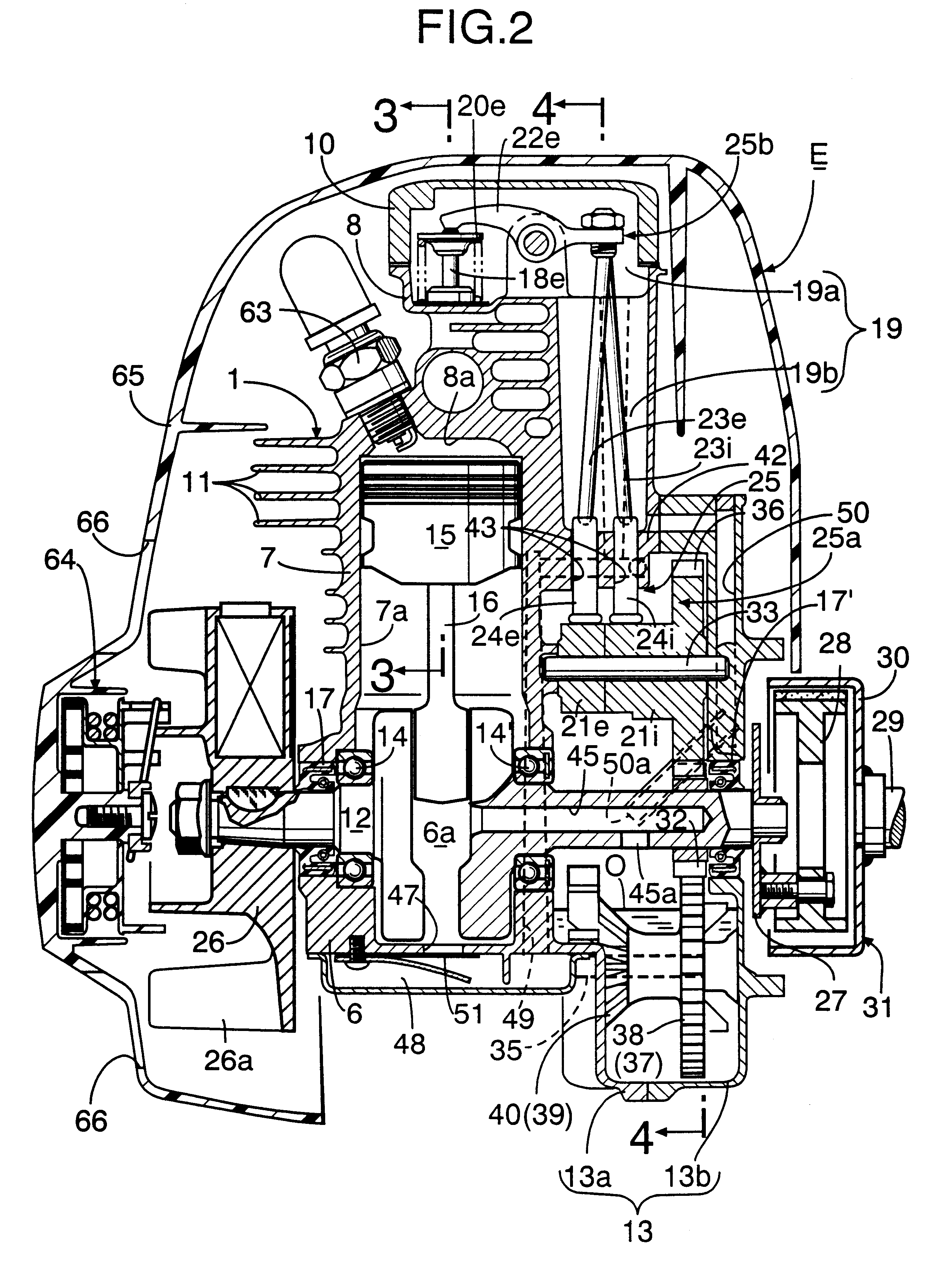

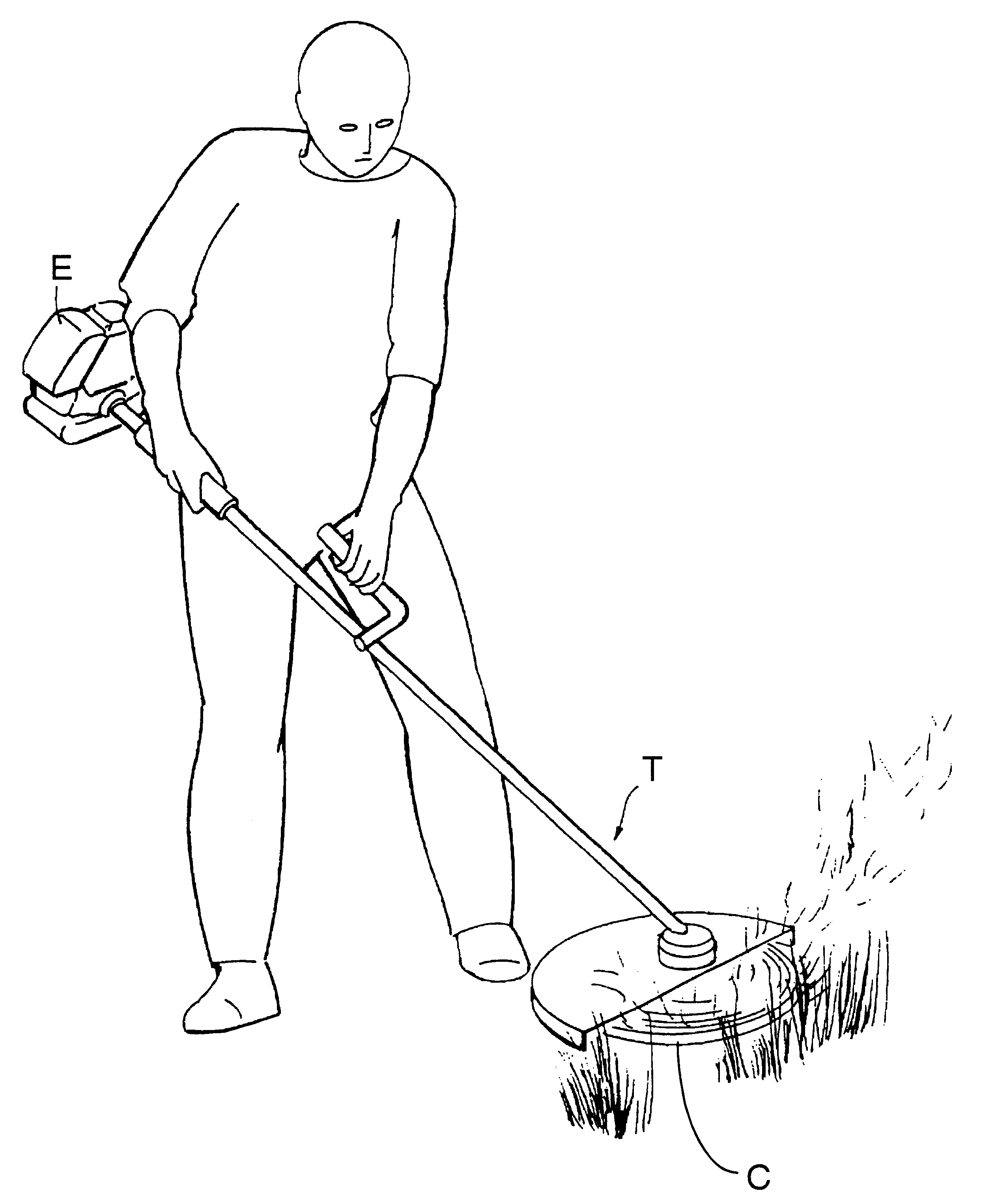

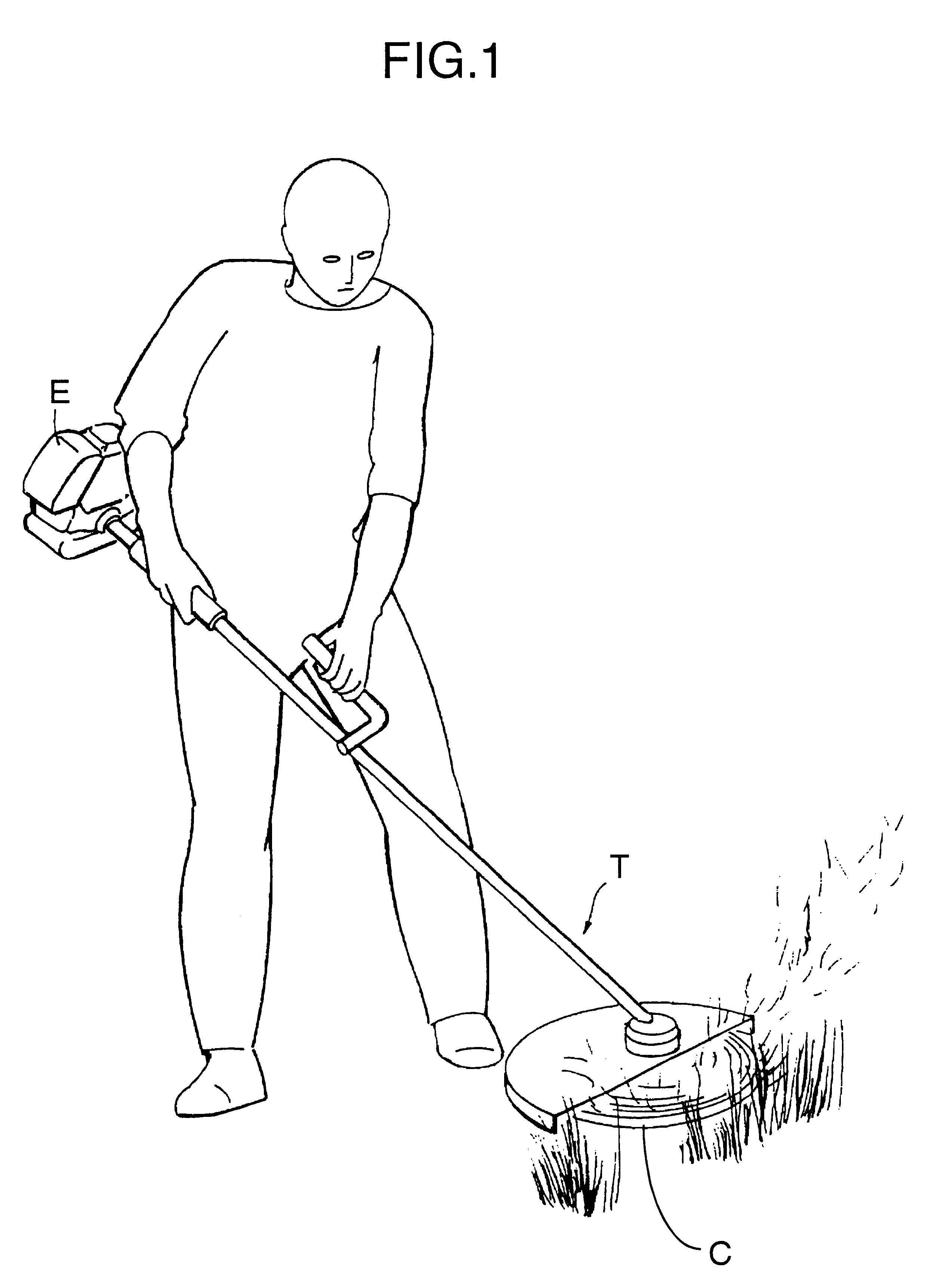

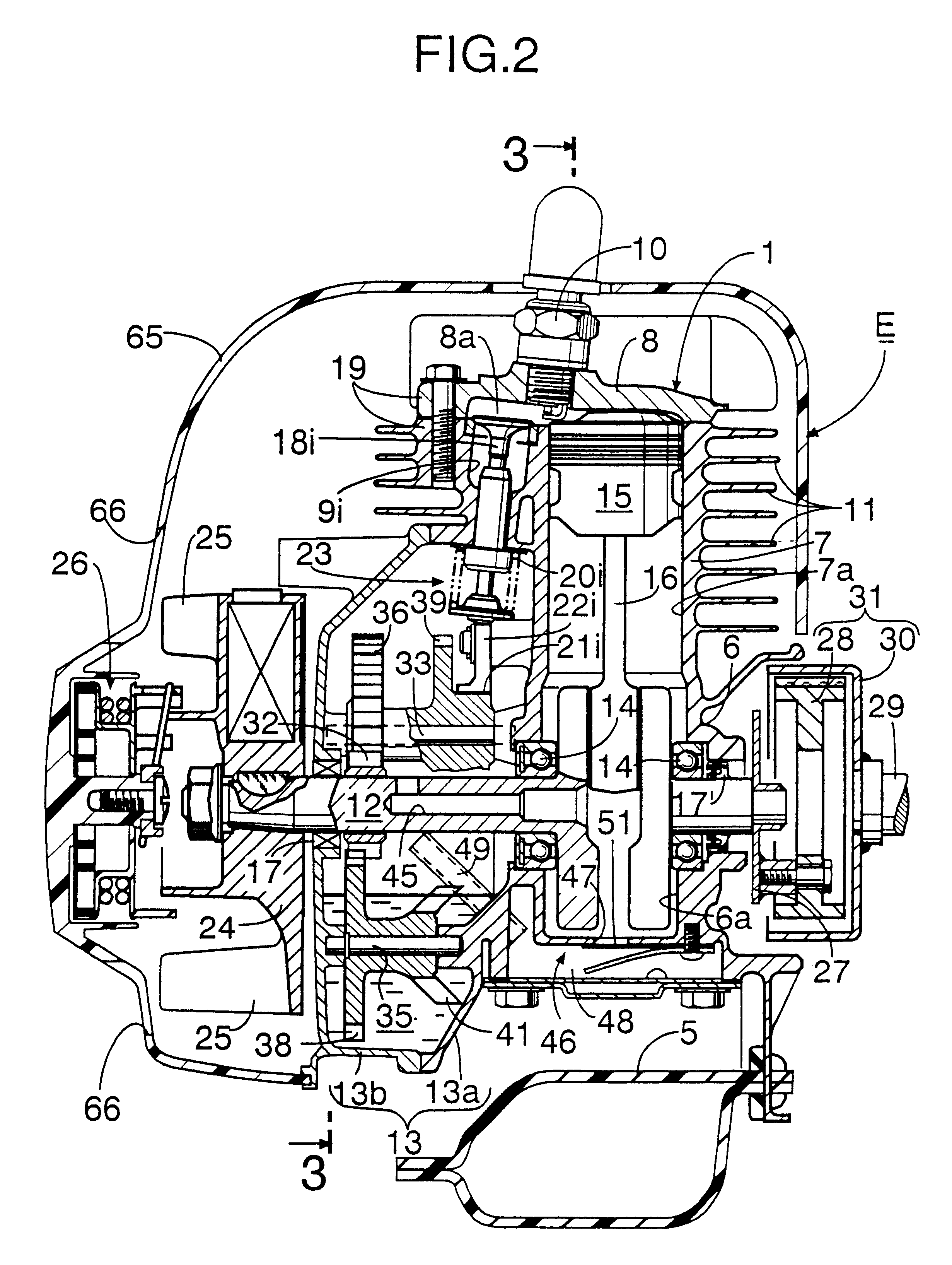

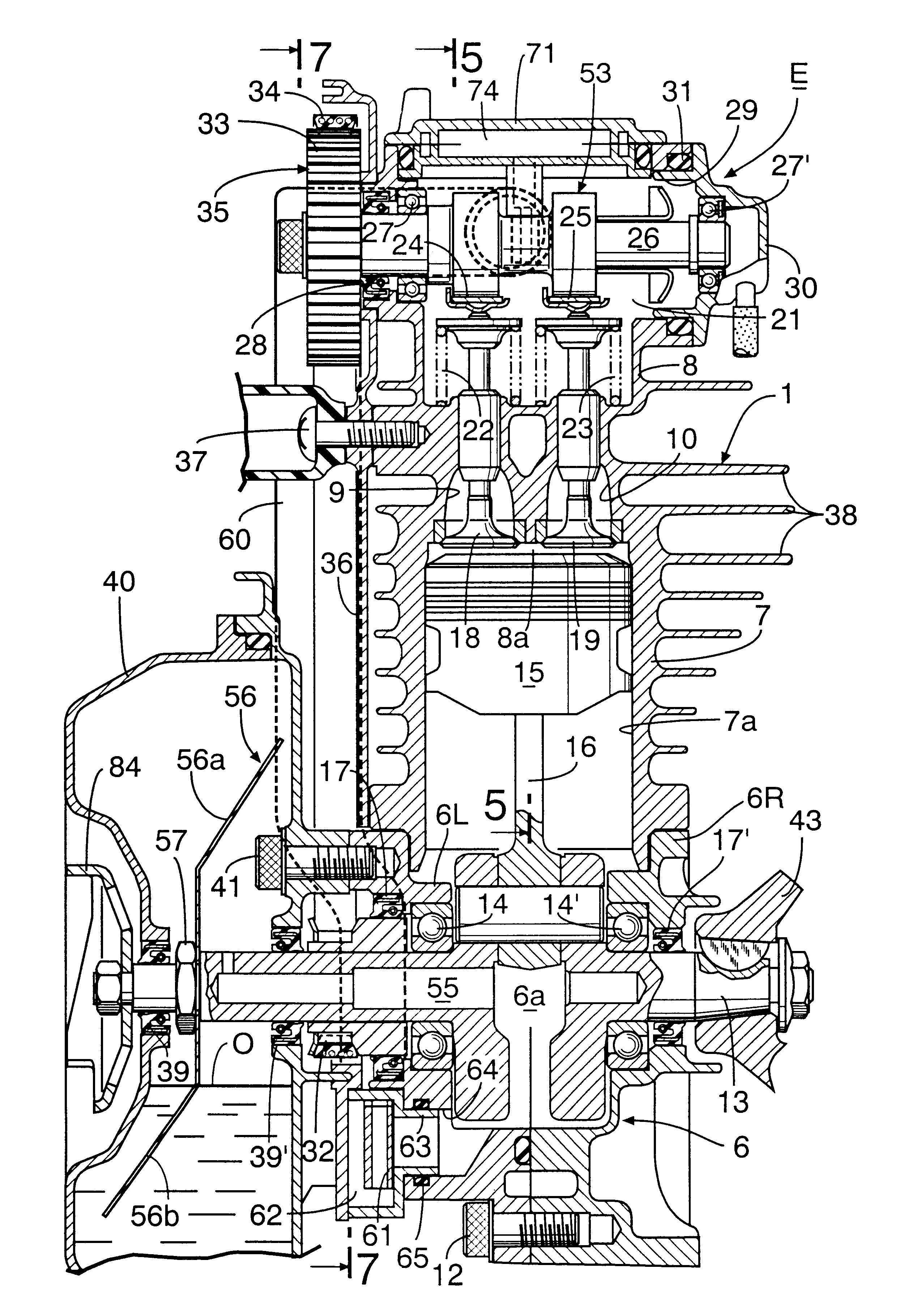

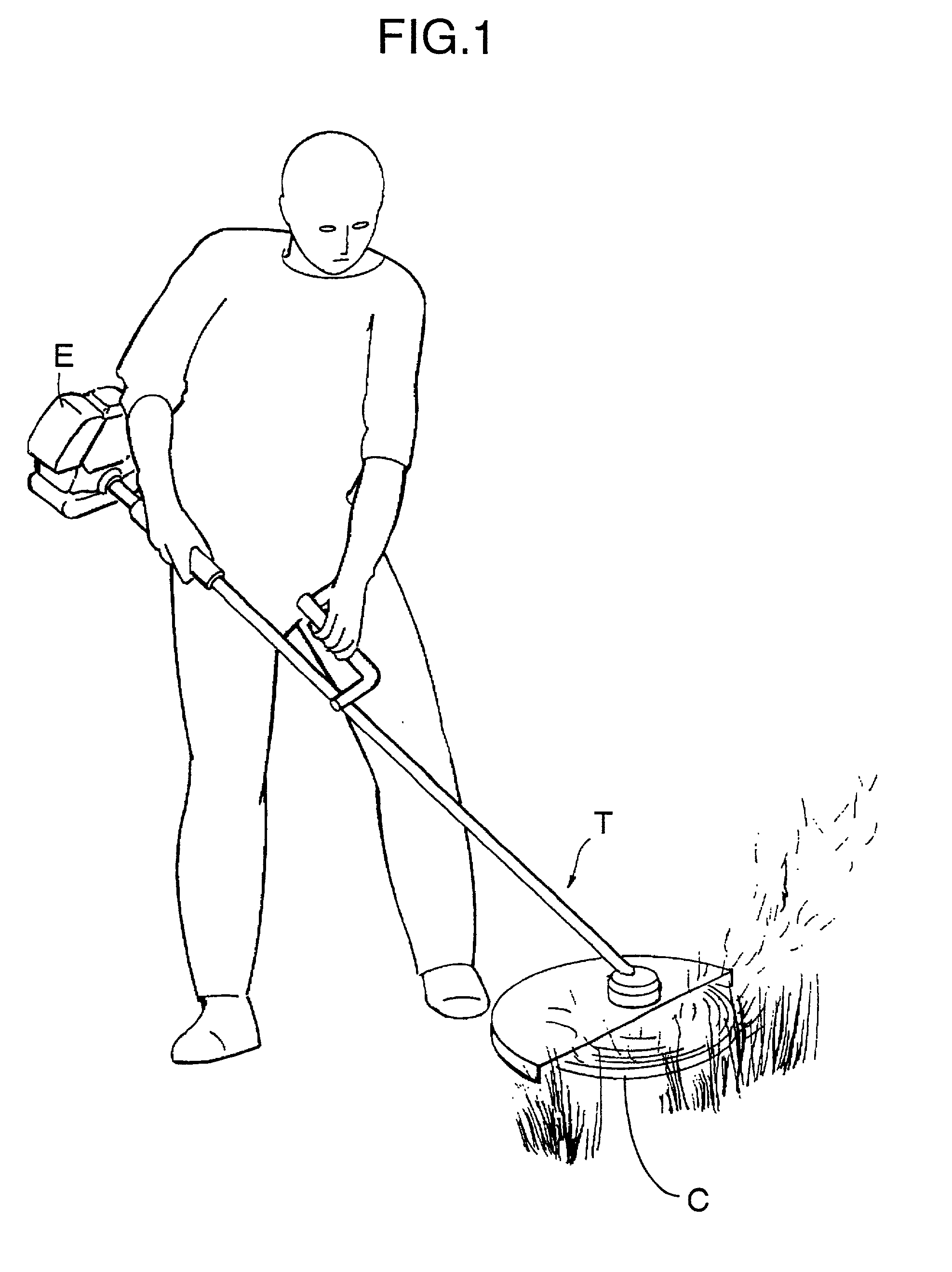

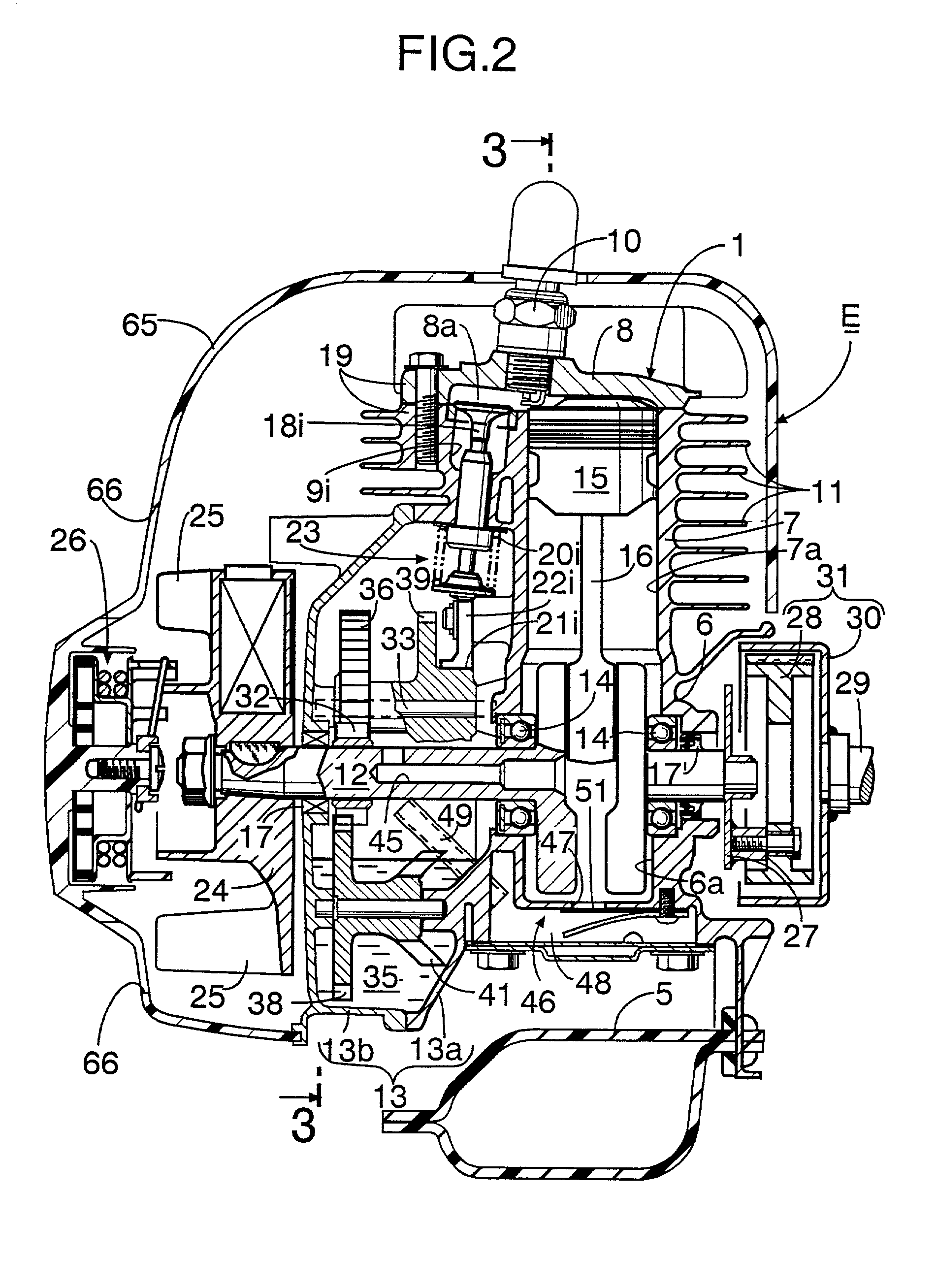

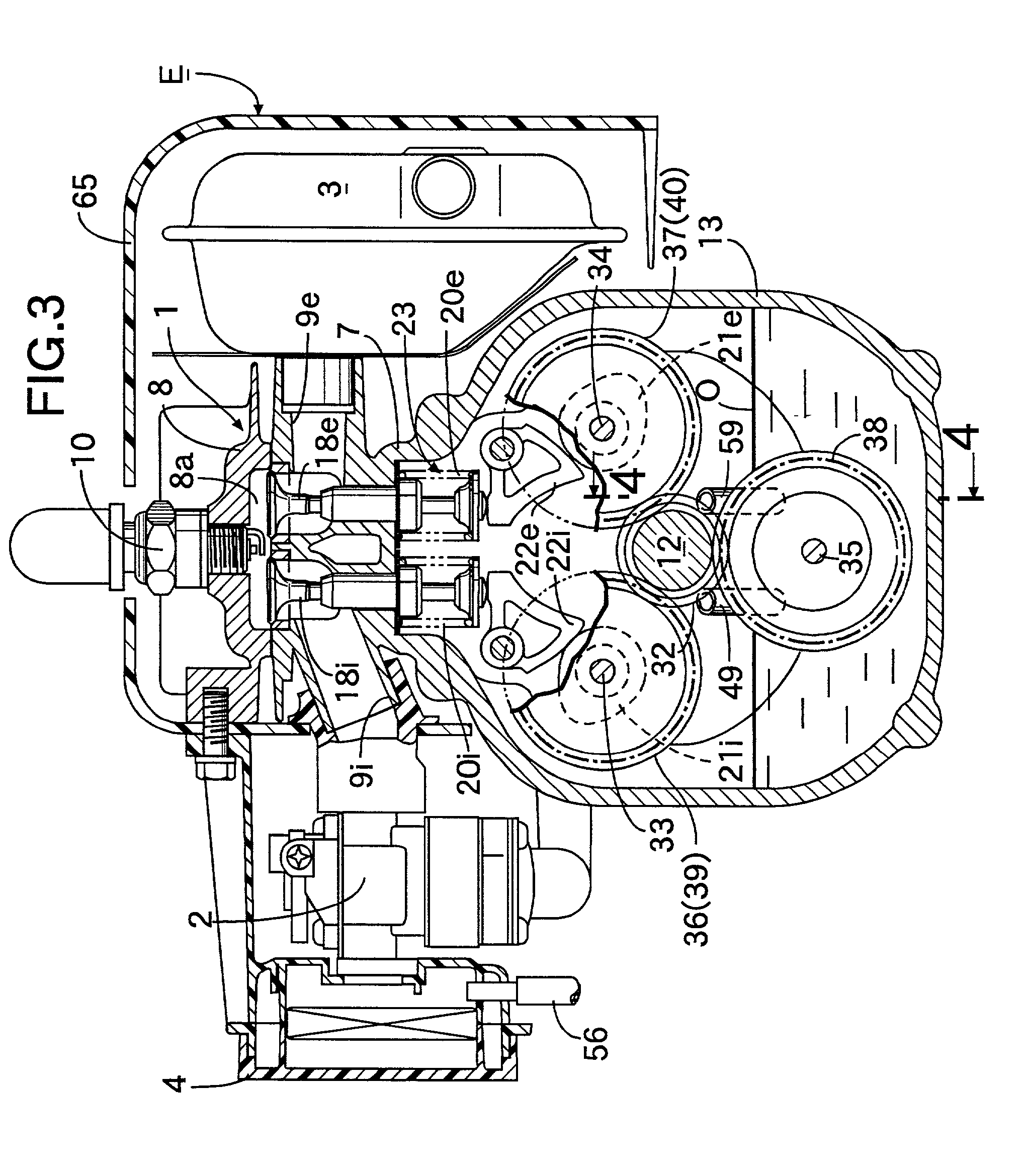

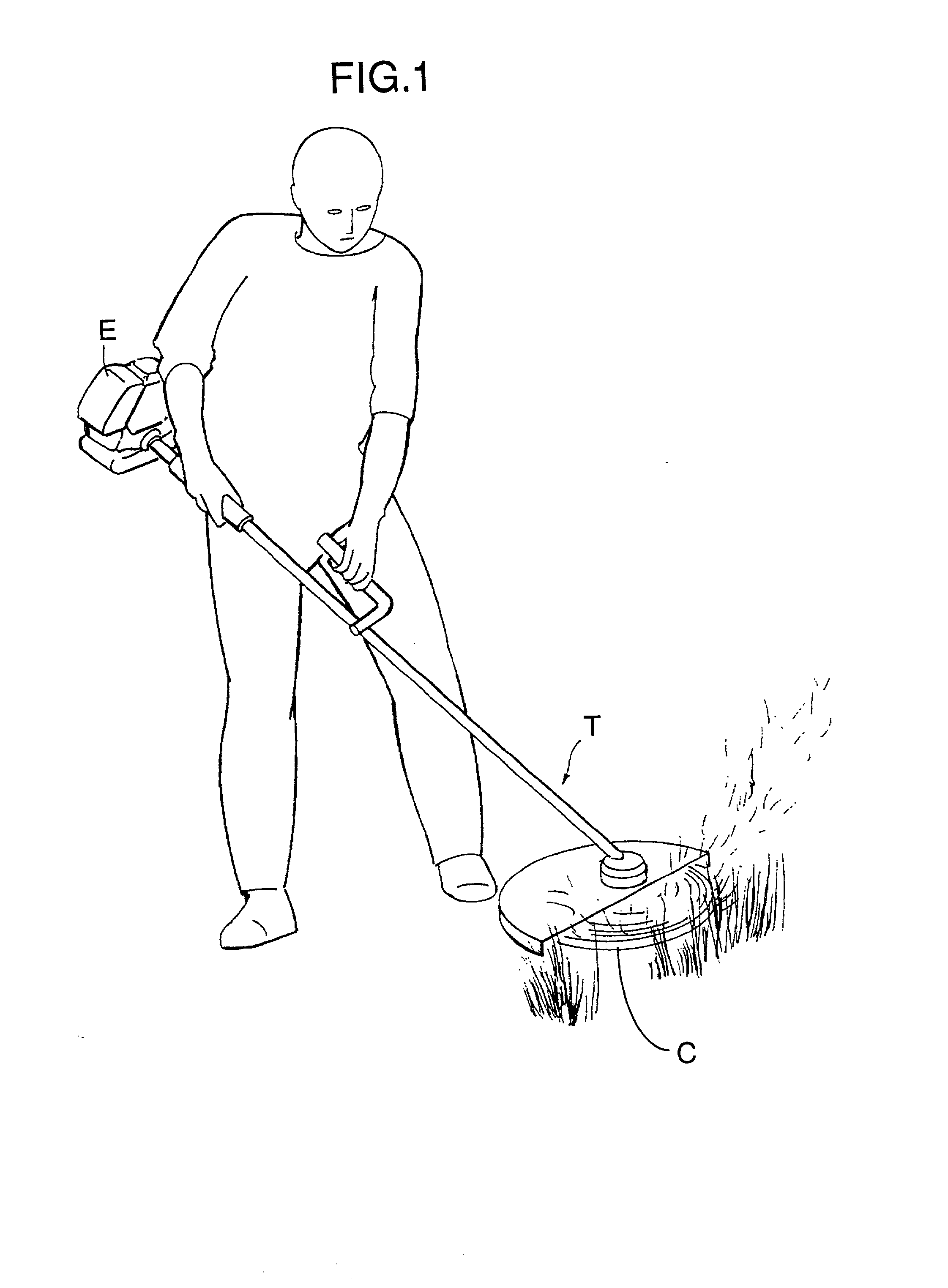

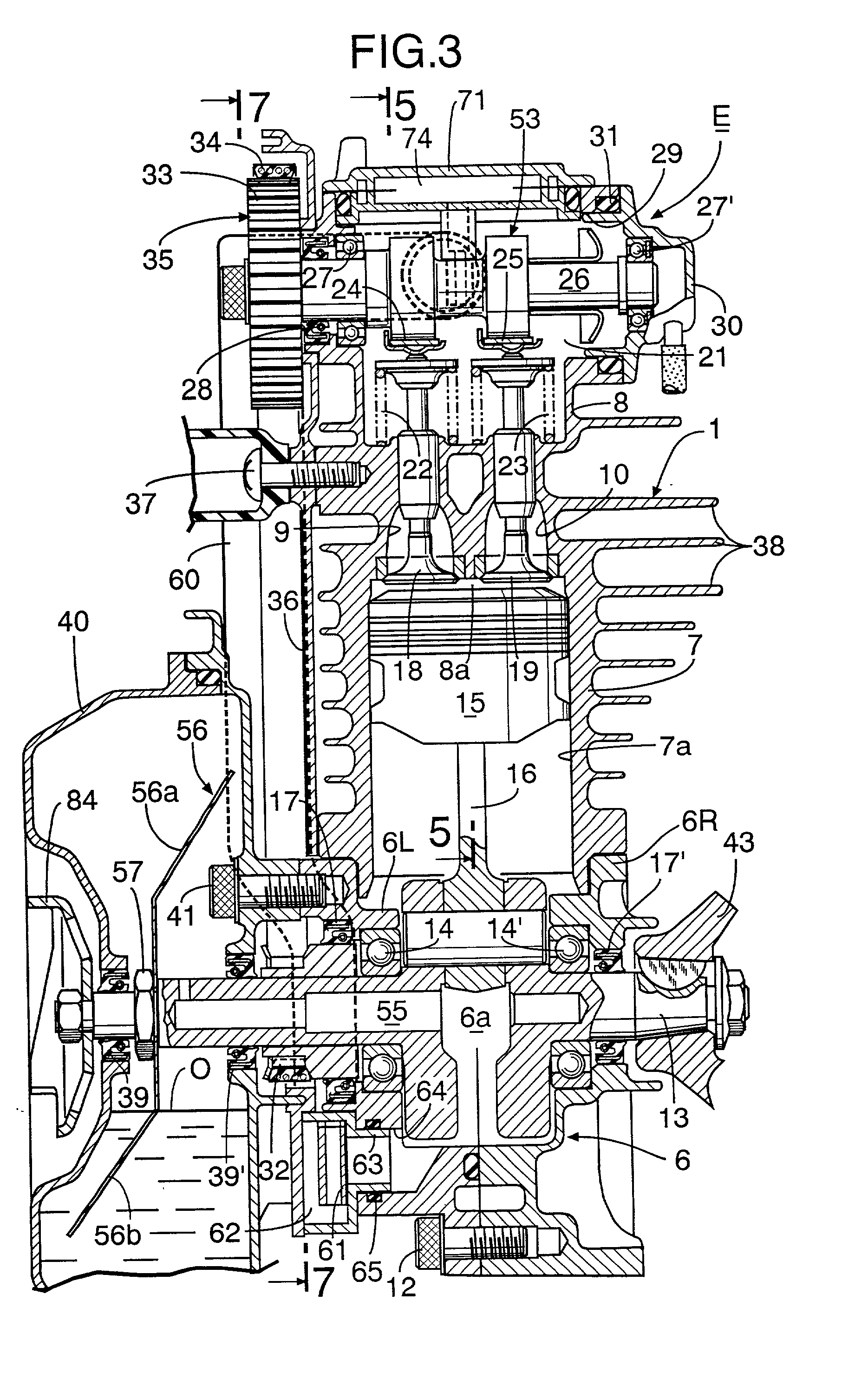

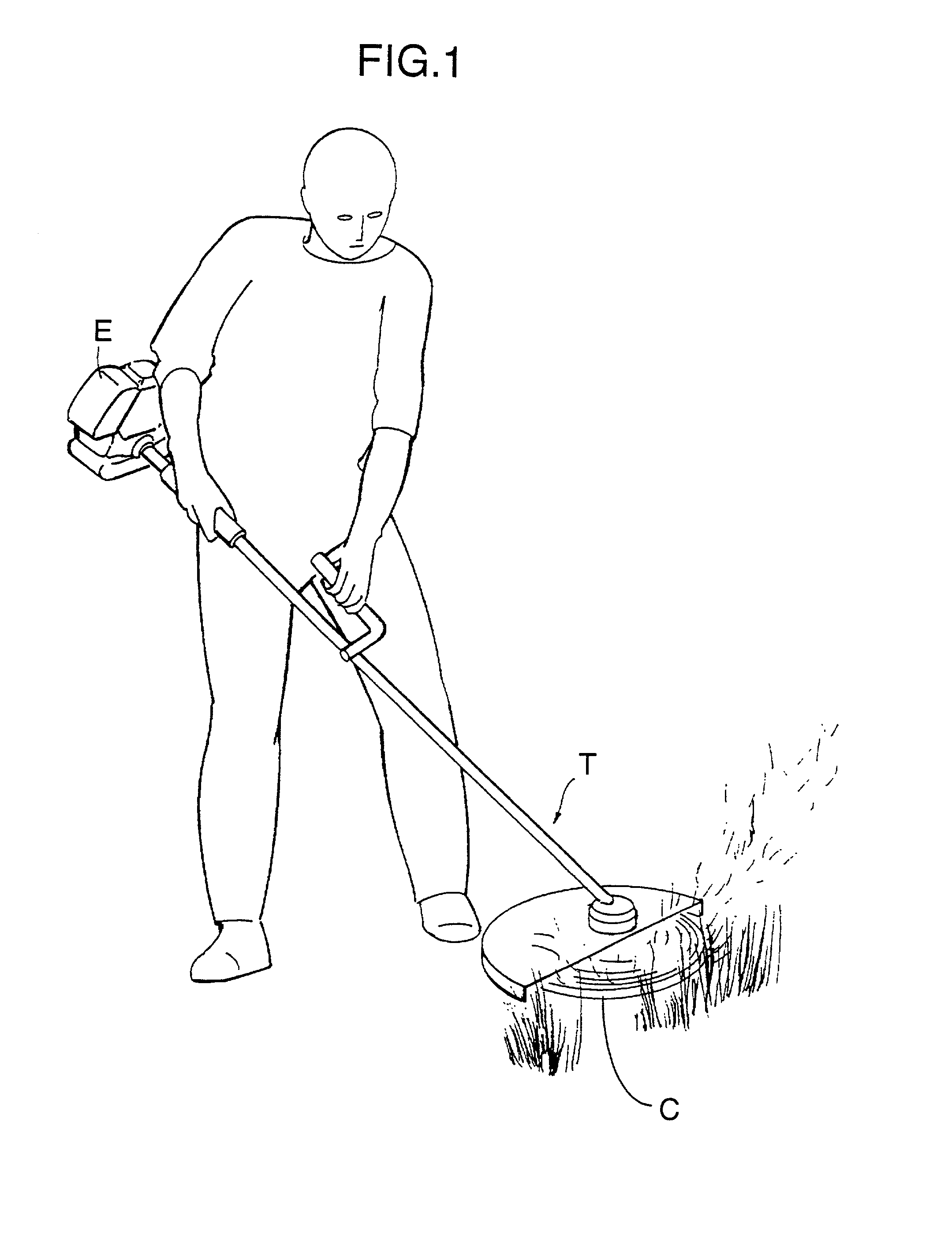

Handheld type four-cycle engine

InactiveUS6510829B2Reduce the overall heightMore compactLubrication of auxillariesDrip or splash lubricationReciprocating motionCylinder head

In a handheld type OHV engine, an oil tank is provided so as to be connected to one side wall running the length of a crankcase and a cylinder block, the oil tank houses oil mist generation means to and a rotational movement section of a valve operation mechanism, and the oil mist generated in the oil tank is supplied from a crank chamber to a valve operation chamber of a cylinder head housing a reciprocating movement section of the valve operation mechanism, and is returned to the oil tank by utilizing the pressure pulsations of the crank chamber and a one-way valve. It is thus possible to lubricate the inside of the crank chamber and the valve operation mechanism reliably regardless of the operational position of the handheld type OHV engine while reducing the overall height of the engine.

Owner:HONDA MOTOR CO LTD

Handheld type four-cycle engine

InactiveUS6422194B2Small sizeReduce weightLubrication of auxillariesDrip or splash lubricationExhaust valveFuel tank

With regard to a handheld type four-cycle engine including, in a side wall of a cylinder block, an intake valve, an exhaust valve and a valve operation mechanism operable in association with a crankshaft so as to open and close the above-mentioned valves and, an oil tank is formed in one side wall of the cylinder block, and the oil tank houses the valve operation mechanism and oil mist generation means for generating an oil mist from stored oil. It is thus possible to reliably lubricate the valve operation mechanism regardless of the operational position of the engine while allowing the size and weight of the engine main body to be reduced.

Owner:HONDA MOTOR CO LTD

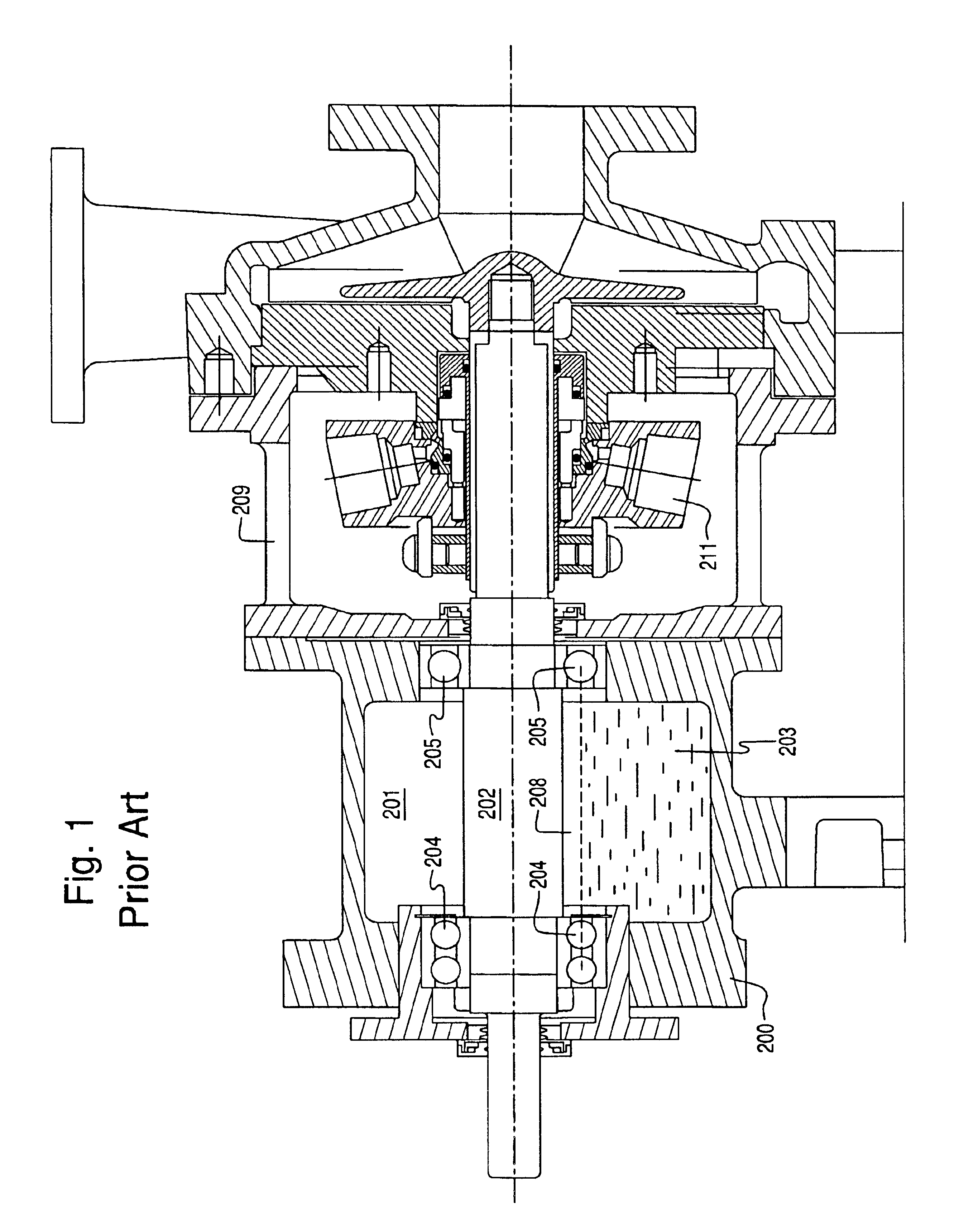

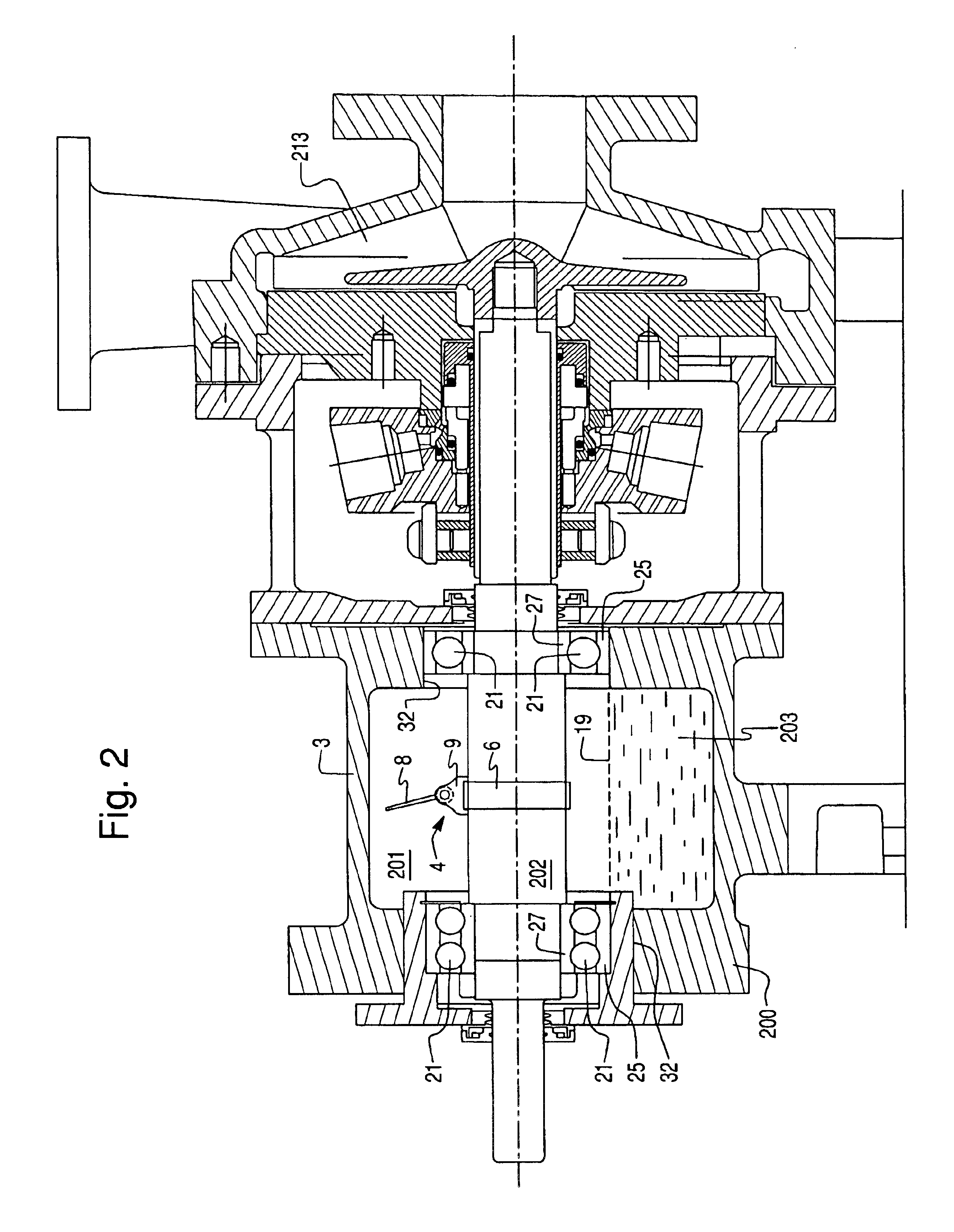

Total fluid exchange system for automatic transmissions

InactiveUSRE36650E1Easy to useQuick connectionCrankshaftsLiquid fillingAutomatic transmissionCoupling

A system for providing total fluid exchange for an automatic transmission which interconnects with the transmission's opened cooling circuit to deliver new, fresh fluid to the transmission while simultaneously extracting the spent, used fluid. The system provides a means of quick and random interconnection to an opened cooling circuit and means of identifying and aligning direction of flow in such cooling circuit. The system can accurately calibrate and regulate the rate that fresh fluid will flow into the transmission to be the same as that at which the used fluid is extracted, both of which are regulated to flow at the same rate that fluid normally circulates at in the cooling circuit when it is closed under similar operating conditions. Quick coupling devices are used for ease and speed of interconnection of the system into operative position, for quick removal of the system and for reconnection of the opened cooling circuit for ease of repeat, periodic servicing by the system as a regular maintenance procedure.

Owner:VIKEN JAMES P

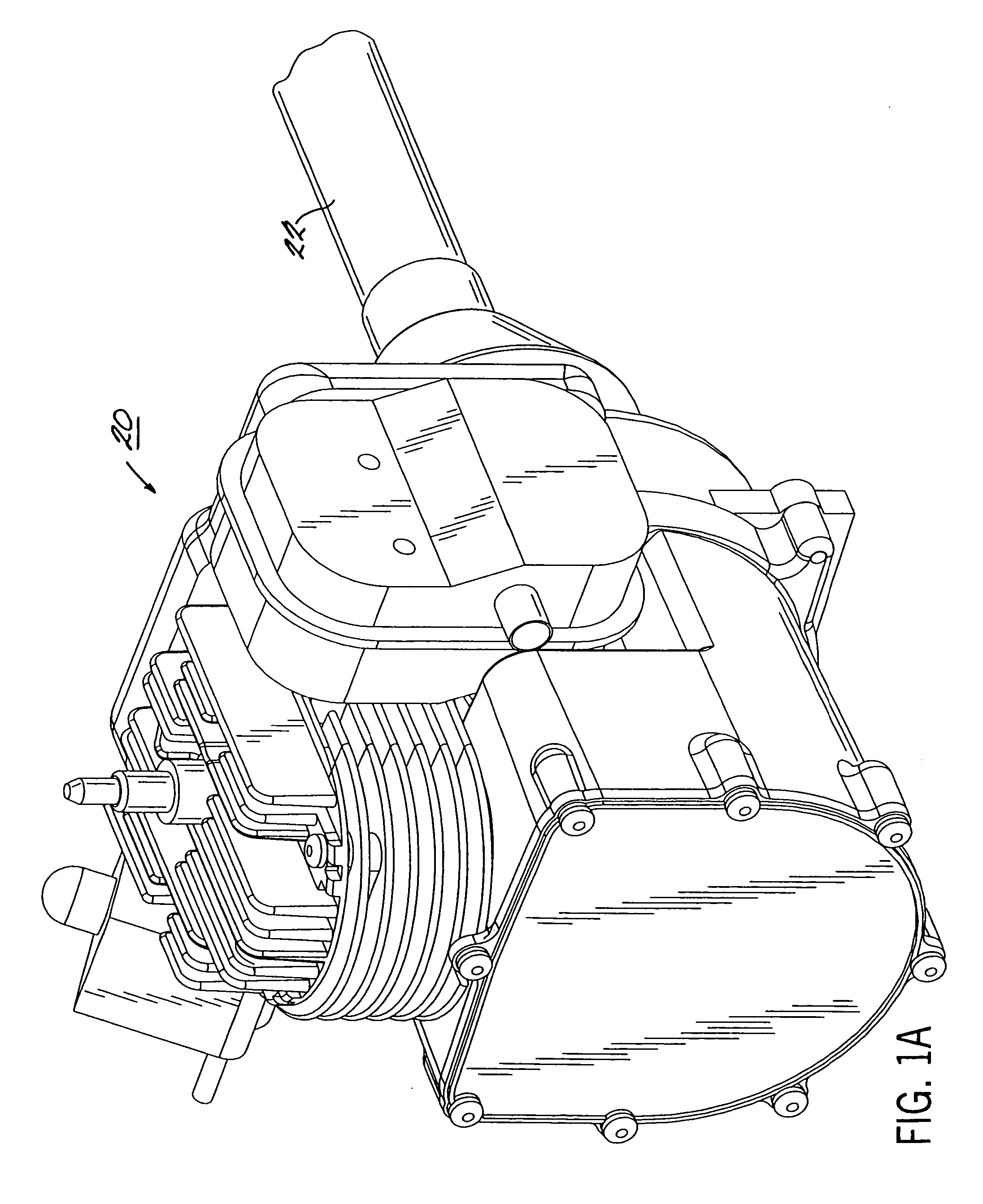

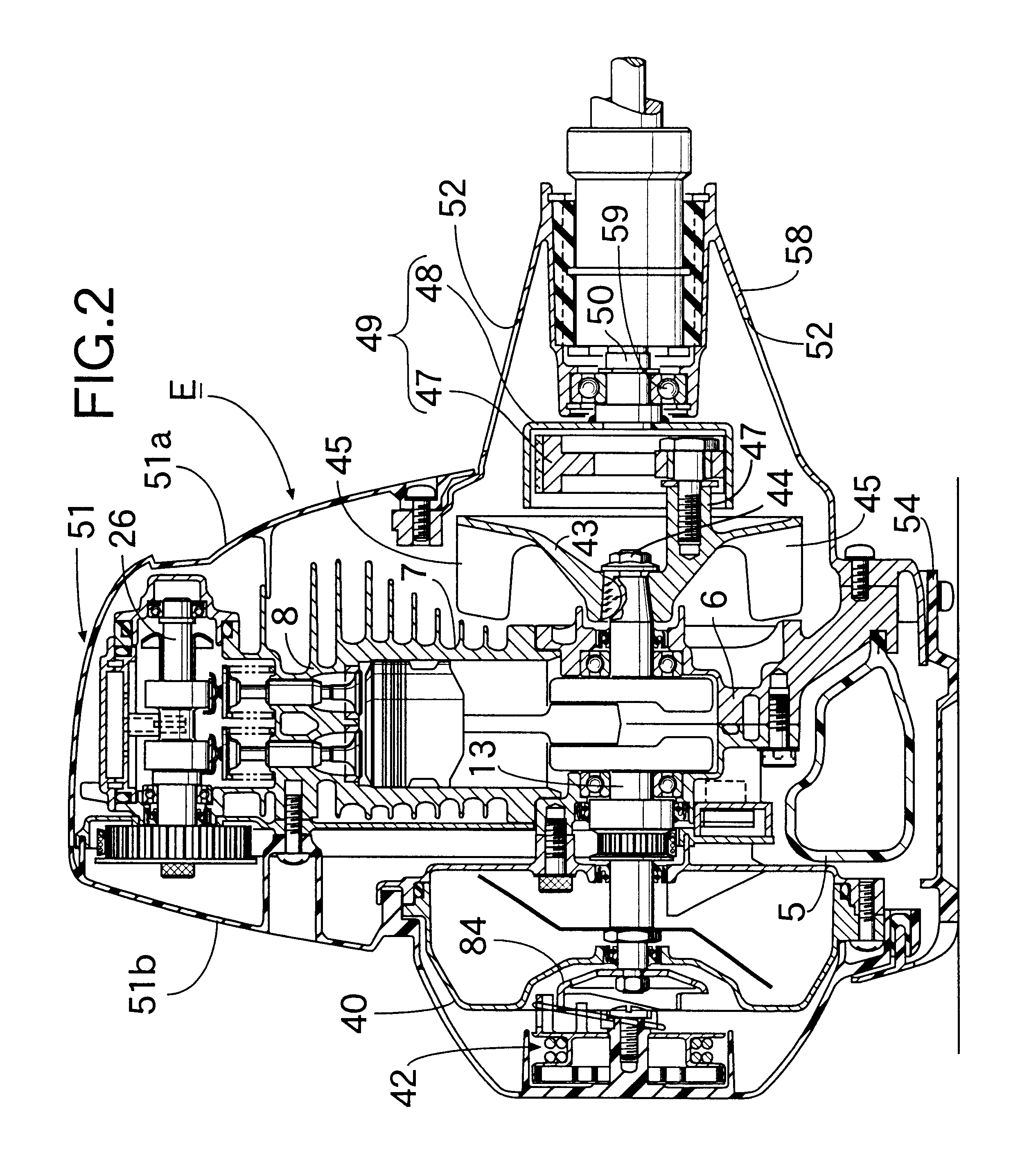

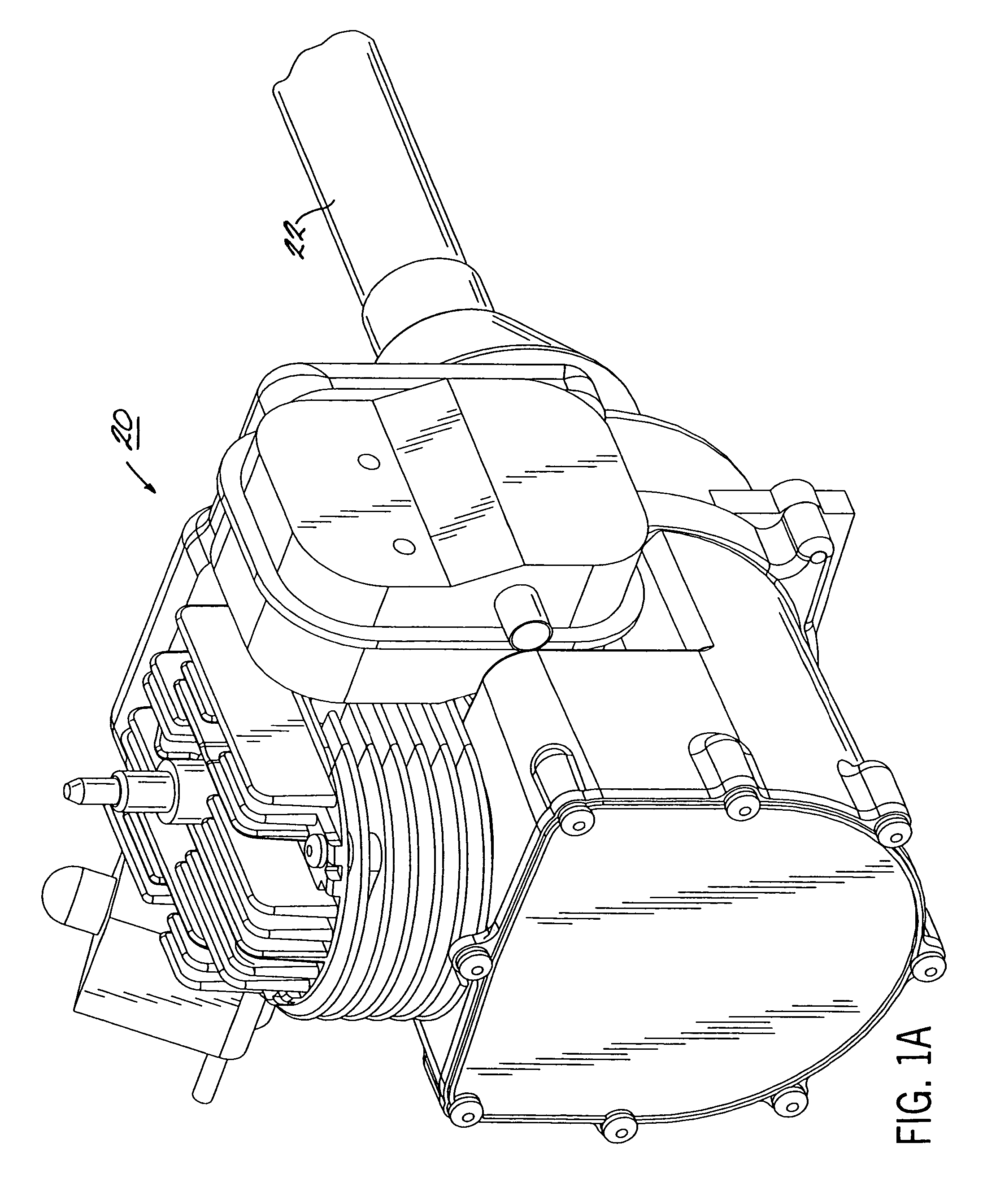

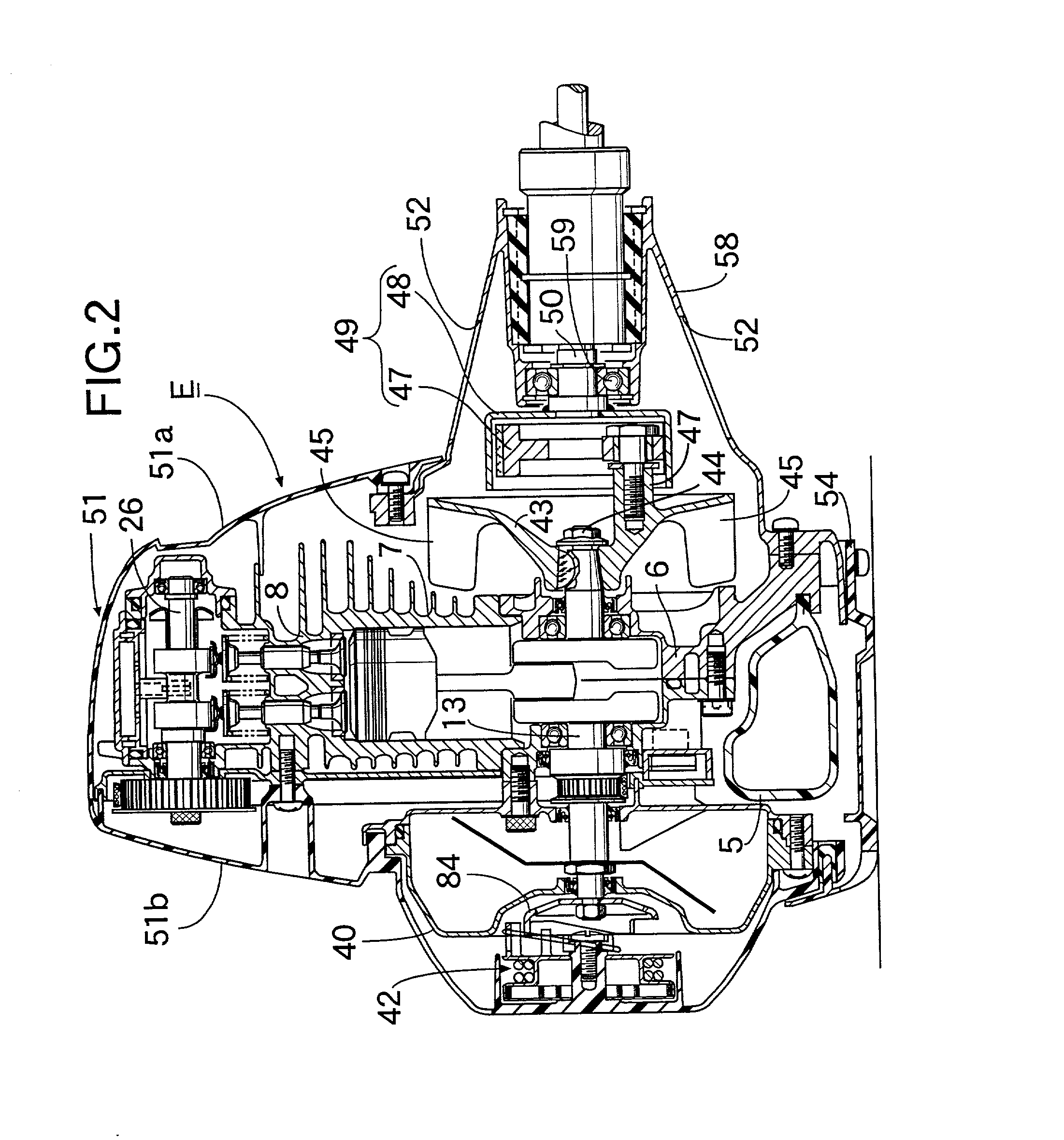

Handheld type four-cycle engine

InactiveUS6508224B2Easy to operateGood weight balanceCasingsLubrication of auxillariesExhaust valveCylinder head

In a handheld type four-cycle engine, a valve operation mechanism includes a camshaft rotatably supported in a cylinder head so as to open and close an intake valve and an exhaust valve and a timing transmission placed on one side outside an engine main body and providing association between a crankshaft and the camshaft, and a centrifugal clutch for power output is mounted on the crankshaft on the opposite side outside the engine main body. The timing transmission and the centrifugal clutch being positioned at the two ends of the crankshaft improves the weight balance, the centre of gravity of the engine can be made as close to the central part of the crankshaft as possible, which, together with the reduced weight, can enhance the operability of the engine.

Owner:HONDA MOTOR CO LTD

Pump lubrication system including an external reservoir

InactiveUS6913438B2Extended service lifeLower oil temperatureLubricant conduit arrangementsEngine cooling apparatusEngineeringLubrication

A circulating lubrication system for a centrifugal pump, or other rotating equipment utilizing an oil sump, is disclosed. The lubrication system includes an external reservoir located distant from the main lubrication chamber, so that lubricating fluid from the main misting chamber is forced out of the main chamber, cooled and cleaned (i.e. filtered) in the external reservoir, and thereafter fed back into the main lubricating chamber. In such a manner, the lubrication system maintains substantially clean, cool, and moisture free lubricating fluid in the main misting chamber and reduces the required downtime of the device. Thus, the life span of the device is lengthened while at the same time production is increased.

Owner:ENVIRONAMICS +1

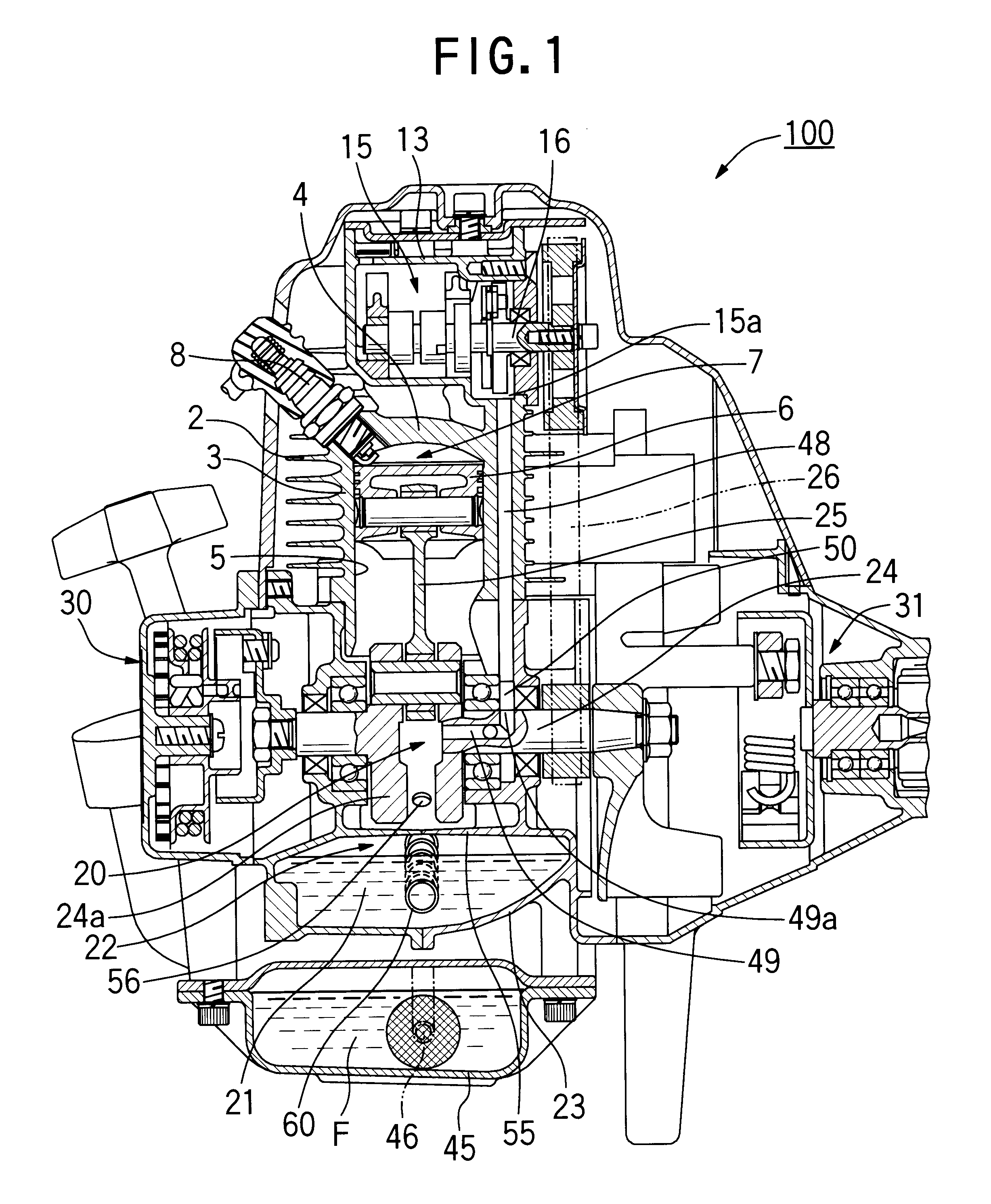

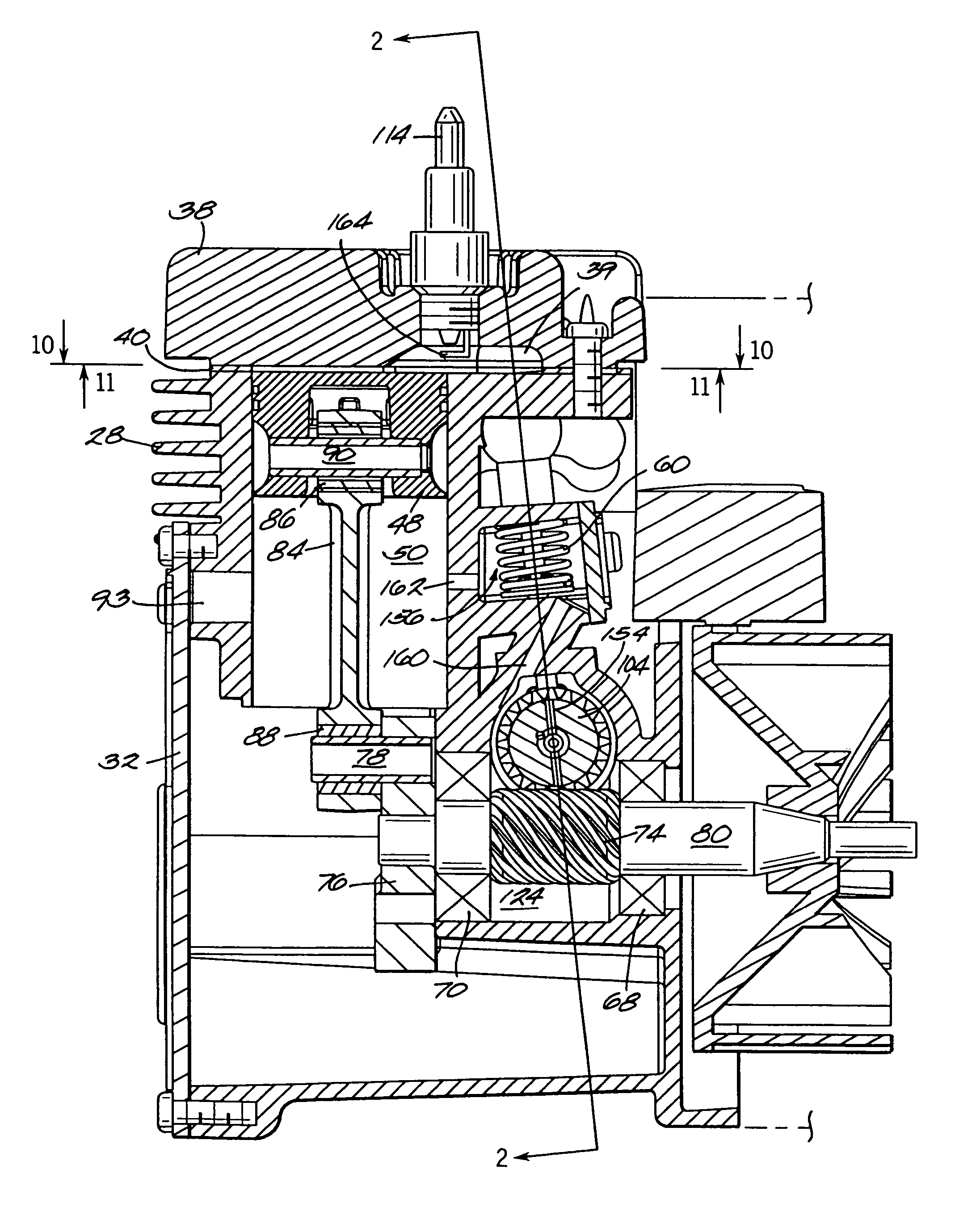

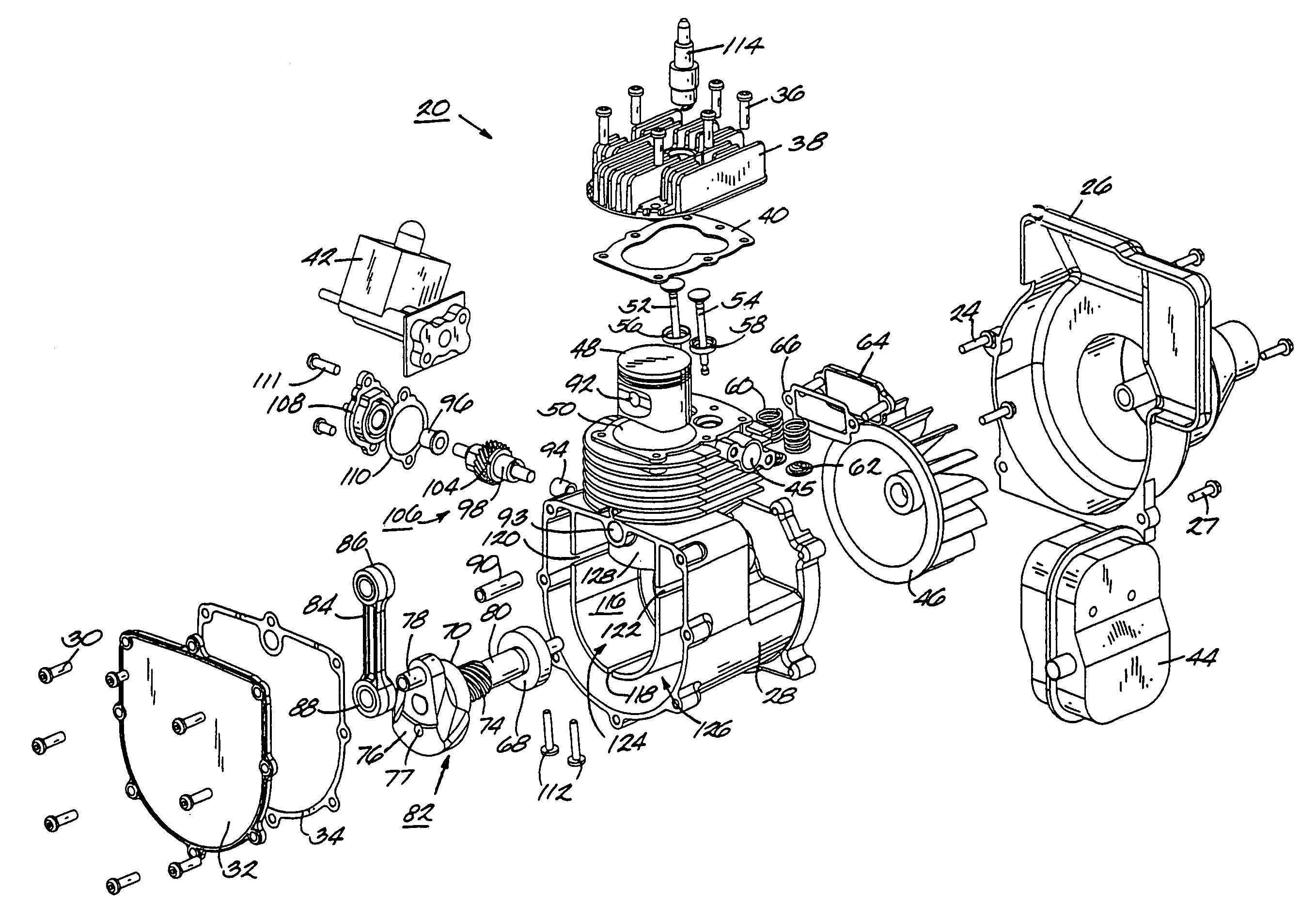

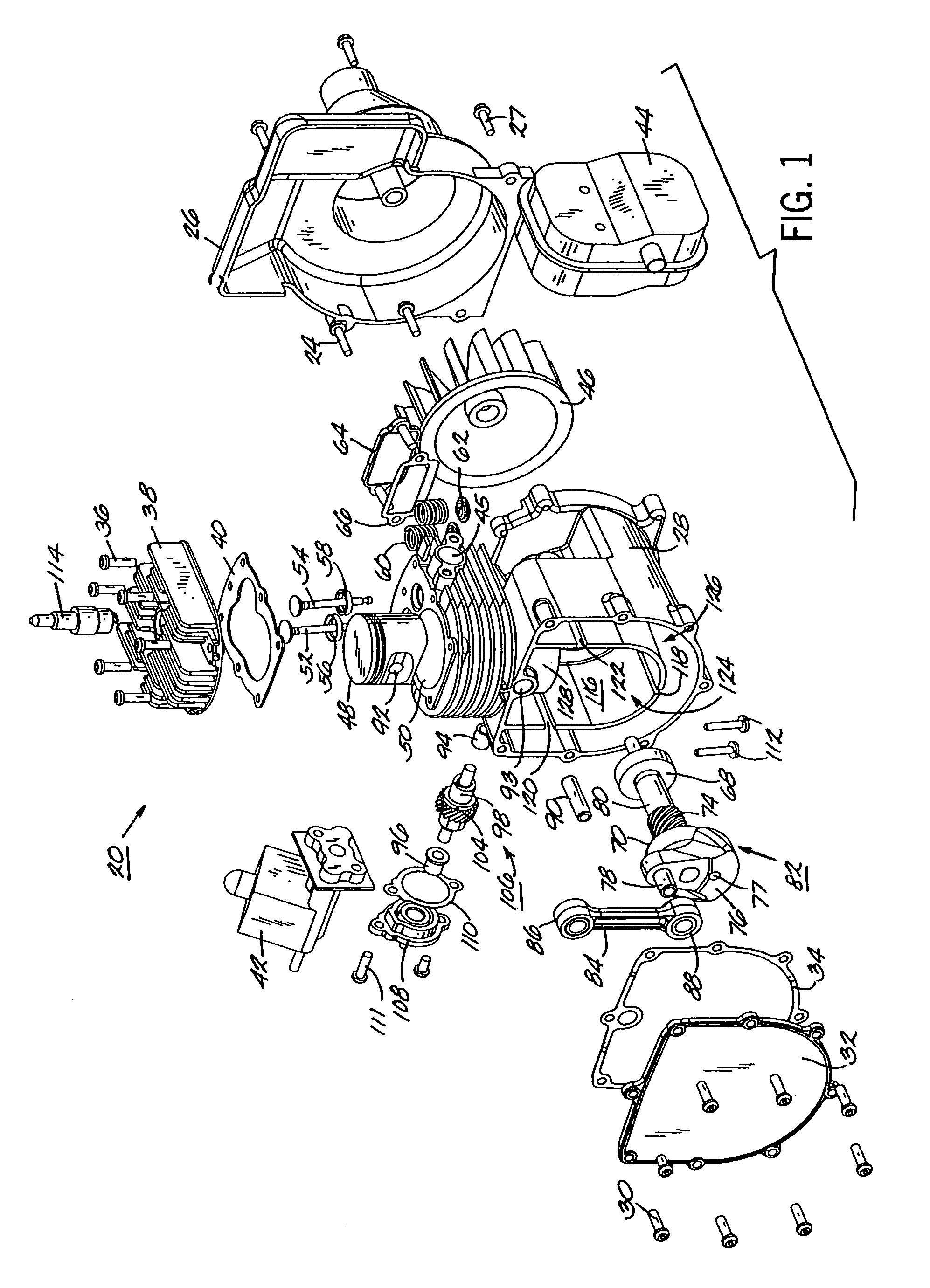

Four-stroke internal combustion engine

InactiveUS7134418B2Emission reductionReduce manufacturing costLubrication of auxillariesLubricant conduit arrangementsEngineeringPower tool

A four-stroke internal combustion engine is provided that is capable of use in many power tools, including those power tools subjected to tippable applications. The engine includes an oil reservoir and a crank chamber separated by a divider. The divider includes a slot that allows lubricant to move from the oil reservoir into the crank chamber and from the crank chamber into the oil reservoir in response to pressure fluctuations of the engine. The engine can include an insert positioned within the slot to at least partially restrict the slot thereby modifying the lubricant communication between the crank chamber and the oil reservoir through the slot. The insert can be wedge-shaped and at least partially define a passage such that when the insert is positioned within the slot the transfer of lubricant between the crank chamber and the oil reservoir occurs through the passage.

Owner:BRIGGS & STRATTON

Handheld type four-cycle engine

InactiveUS20010047788A1Small sizeReduce weightLubrication of auxillariesDrip or splash lubricationExhaust valveInlet valve

With regard to a handheld type four-cycle engine including, in a side wall of a cylinder block, an intake valve, an exhaust valve and a valve operation mechanism operable in association with a crankshaft so as to open and close the above-mentioned valves and, an oil tank is formed in one side wall of the cylinder block, and the oil tank houses the valve operation mechanism and oil mist generation means for generating an oil mist from stored oil. It is thus possible to reliably lubricate the valve operation mechanism regardless of the operational position of the engine while allowing the size and weight of the engine main body to be reduced.

Owner:HONDA MOTOR CO LTD

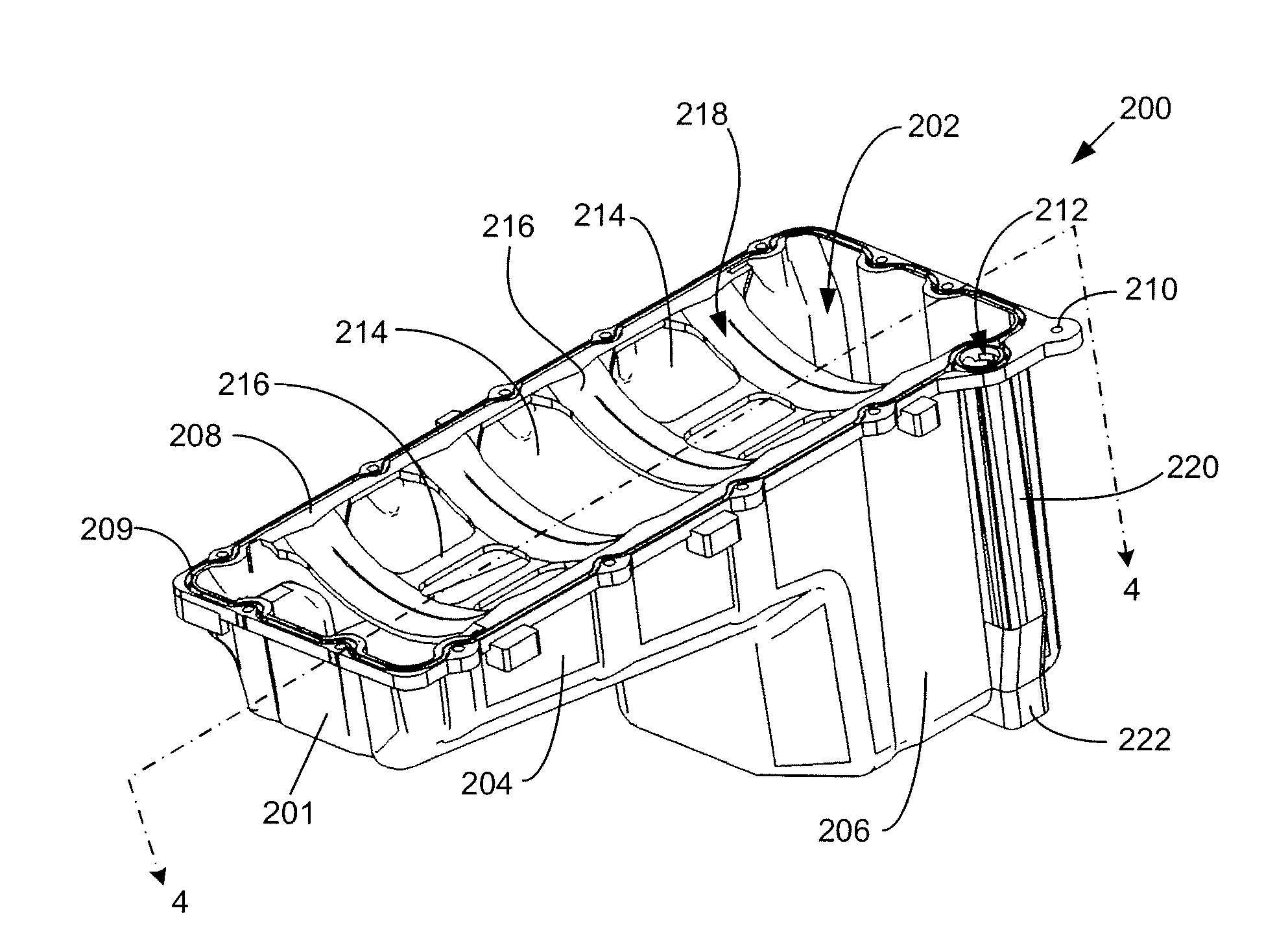

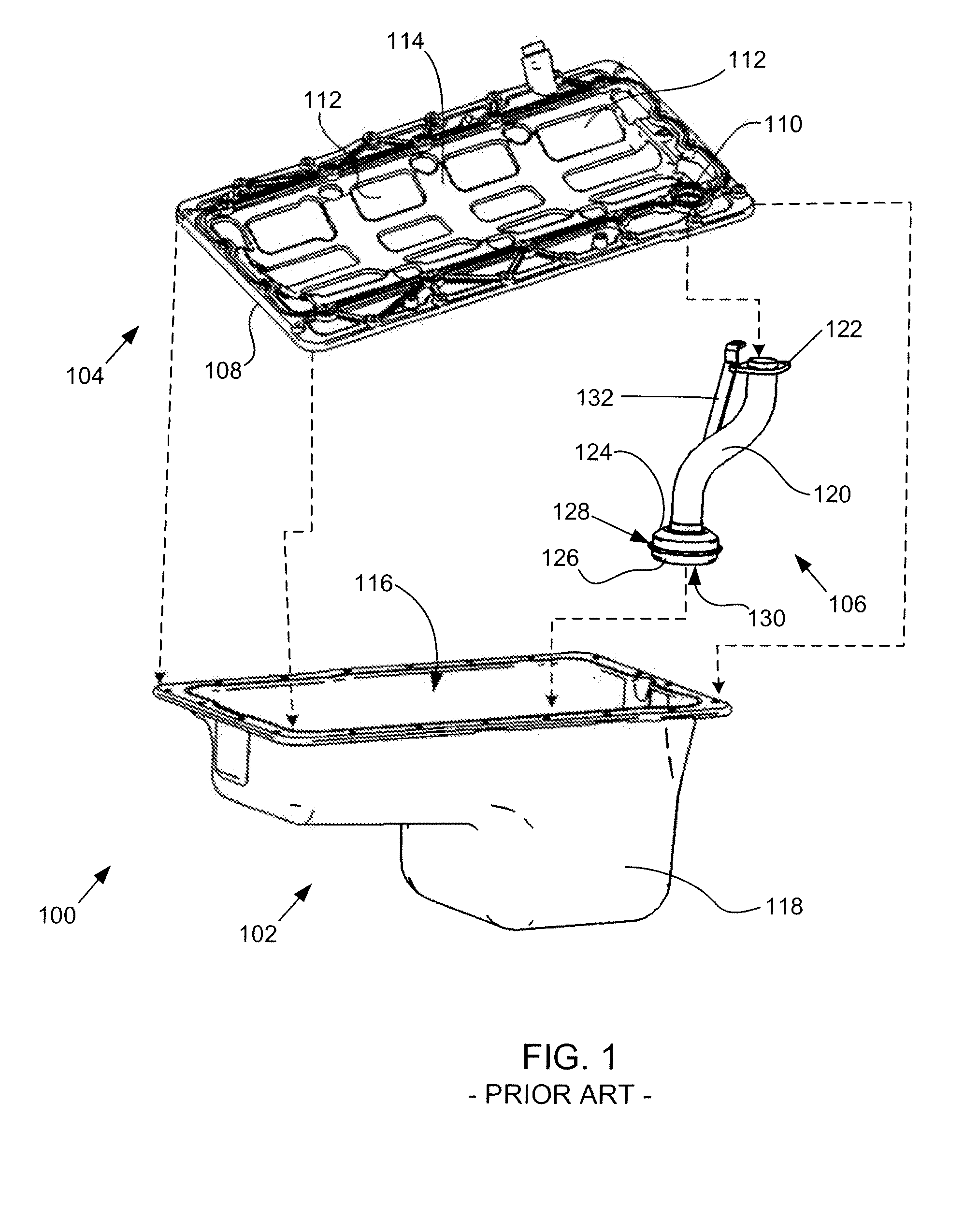

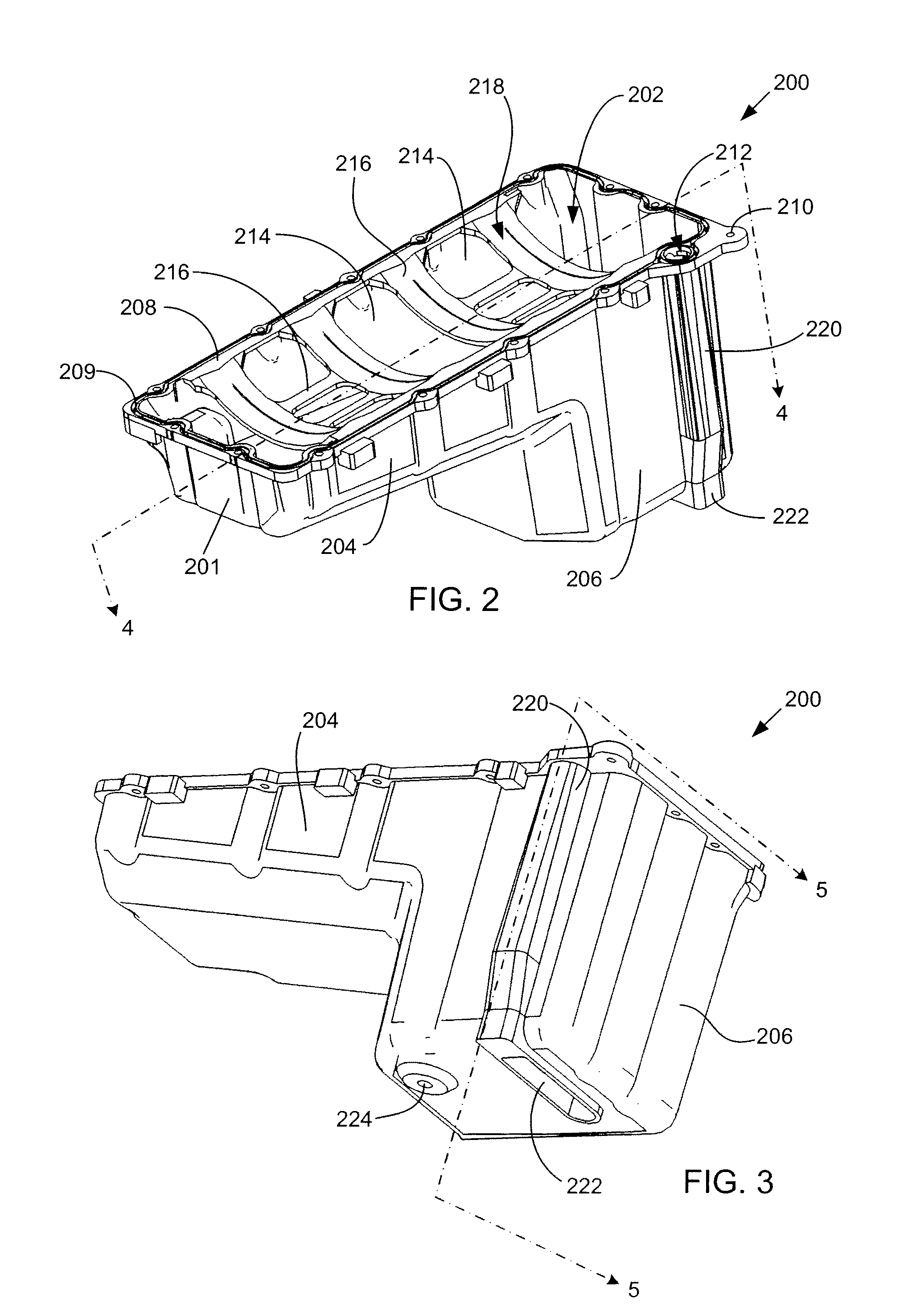

Oil Pan

An oil pan (200) for an internal combustion engine includes a body (201) that defines a reservoir cavity (202). A collector cavity (222) is defined by at least one wall of the body (201) and is in fluid communication with the reservoir cavity (202). An oil supply passage (220) is defined by at least one wall of the body (201) and is in fluid communication with the collector cavity (222).

Owner:INT ENGINE INTPROP CO LLC

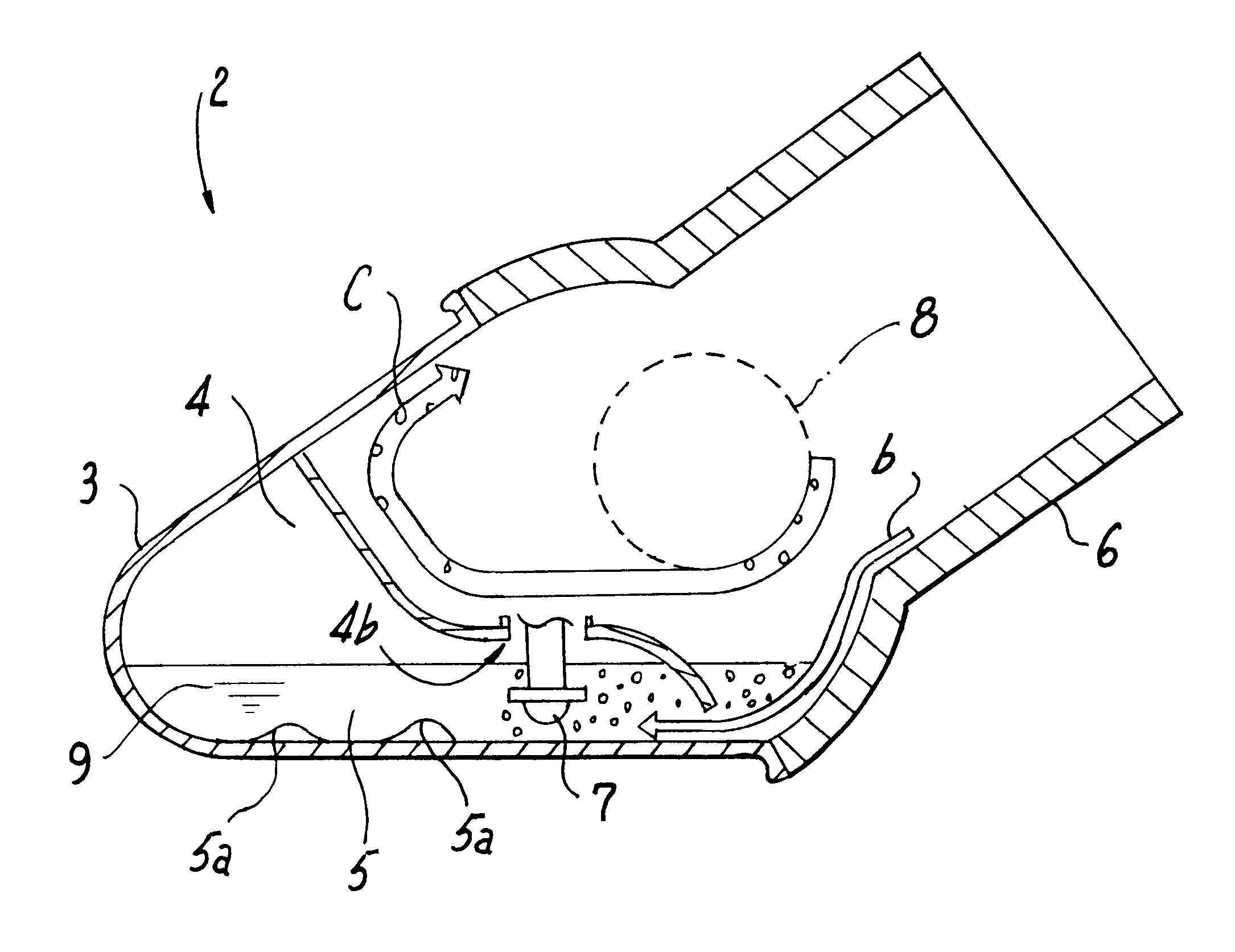

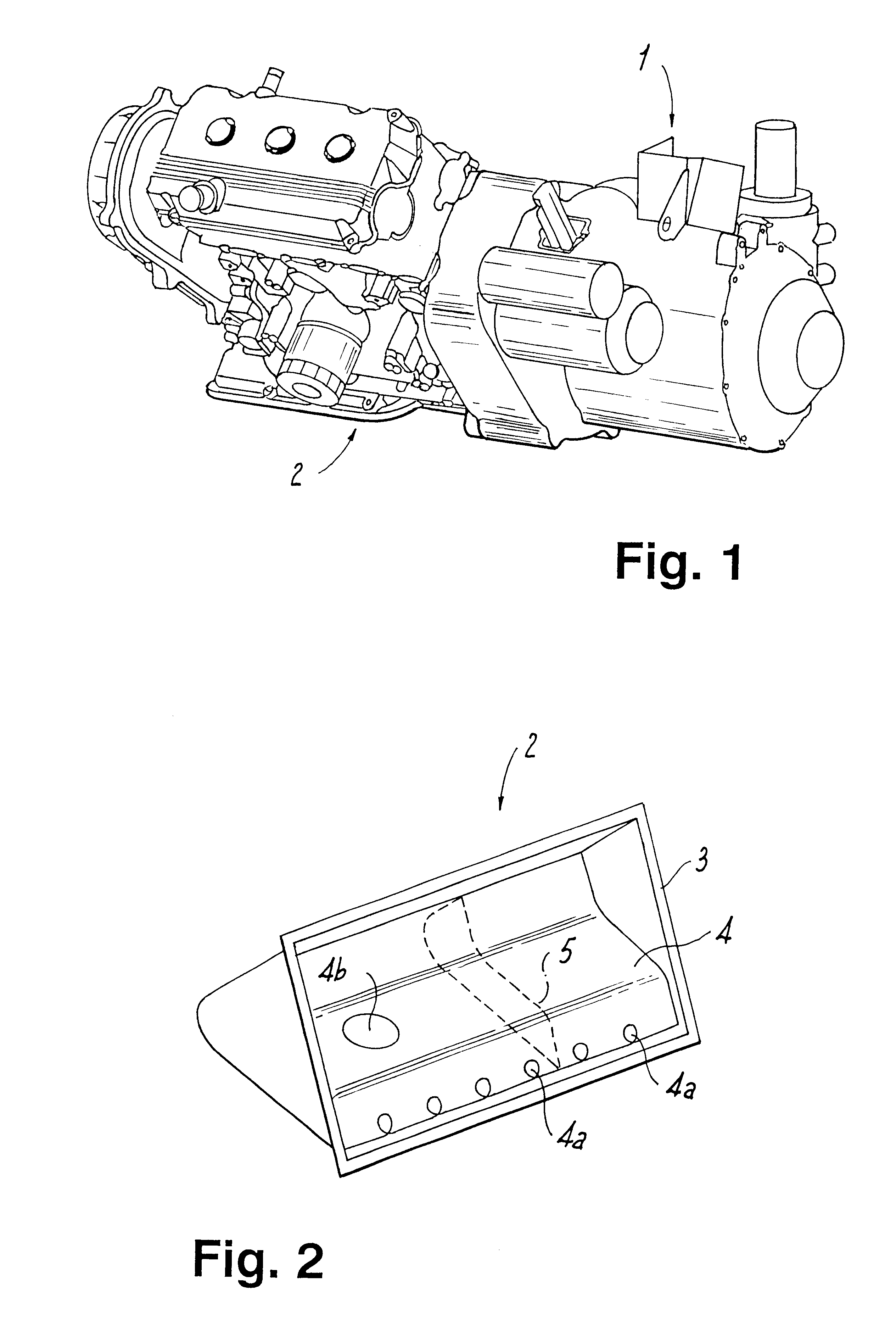

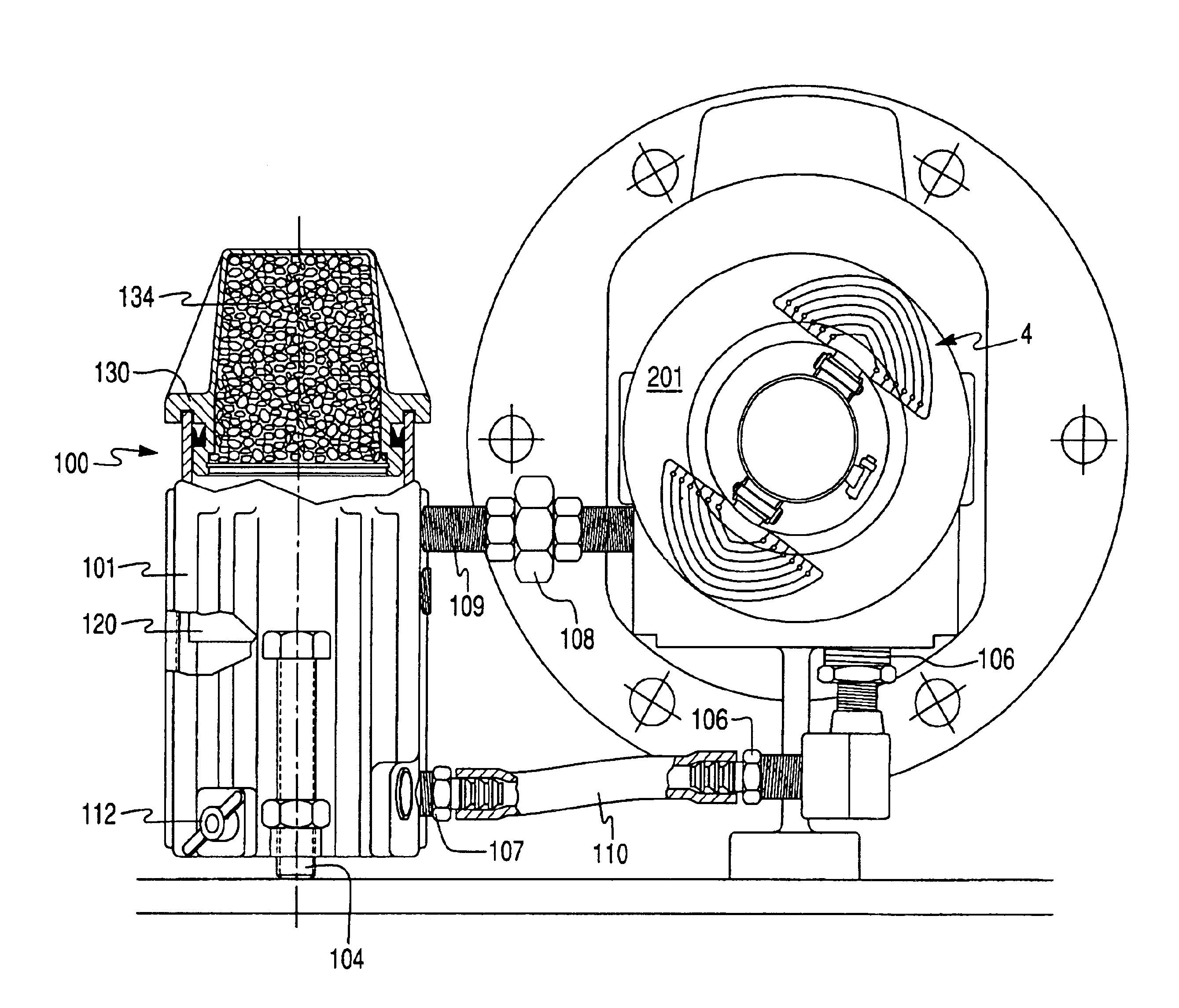

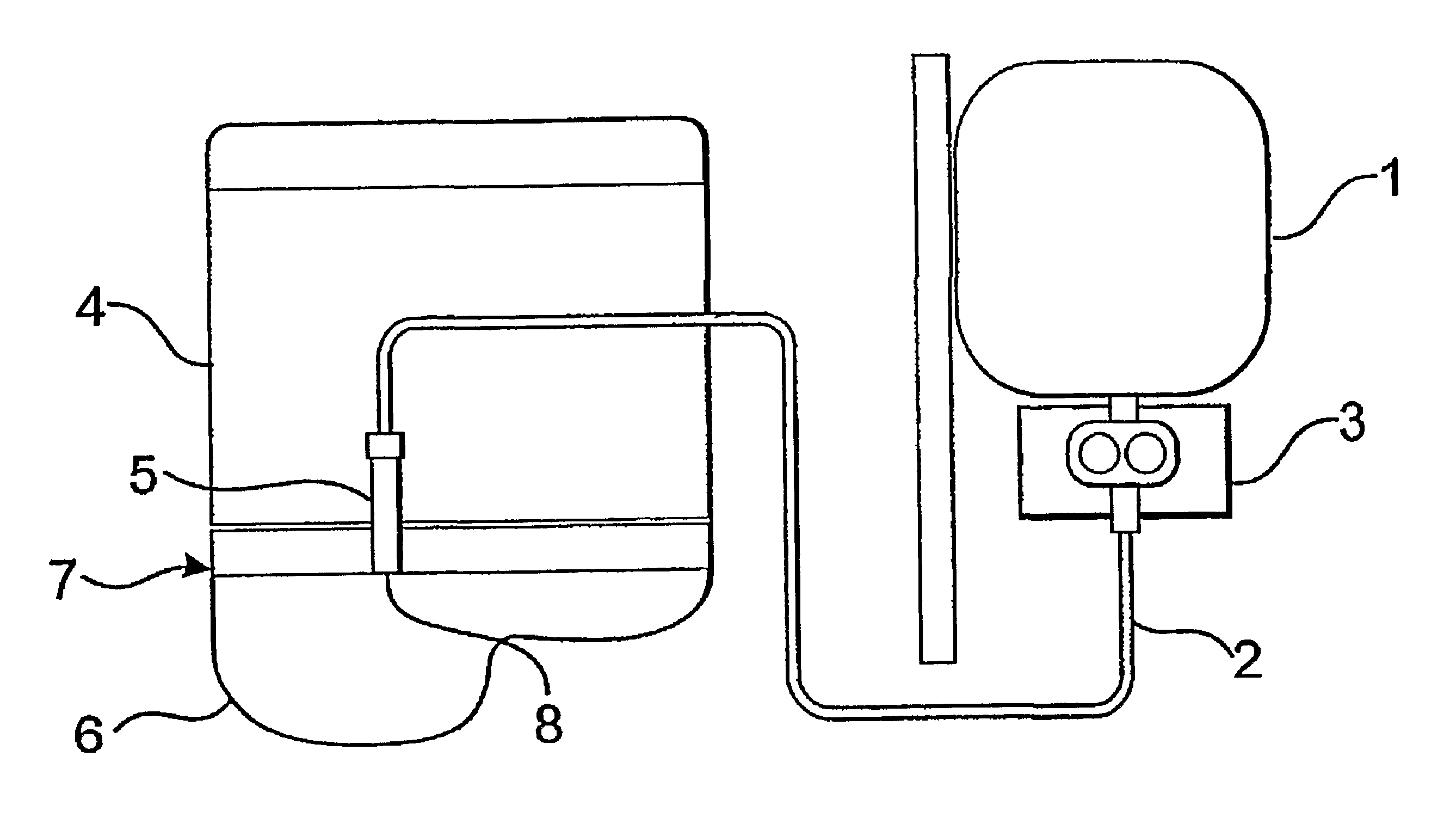

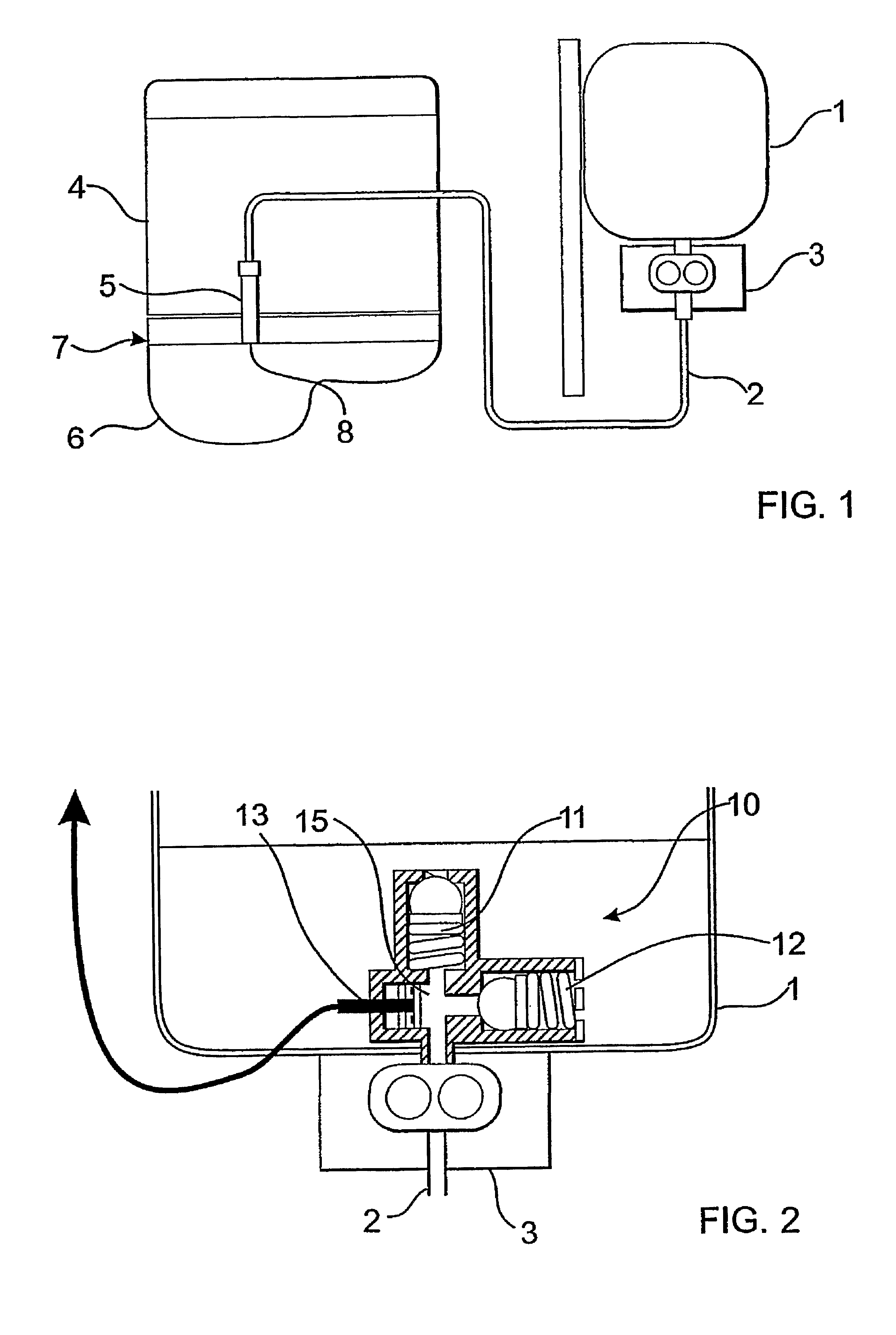

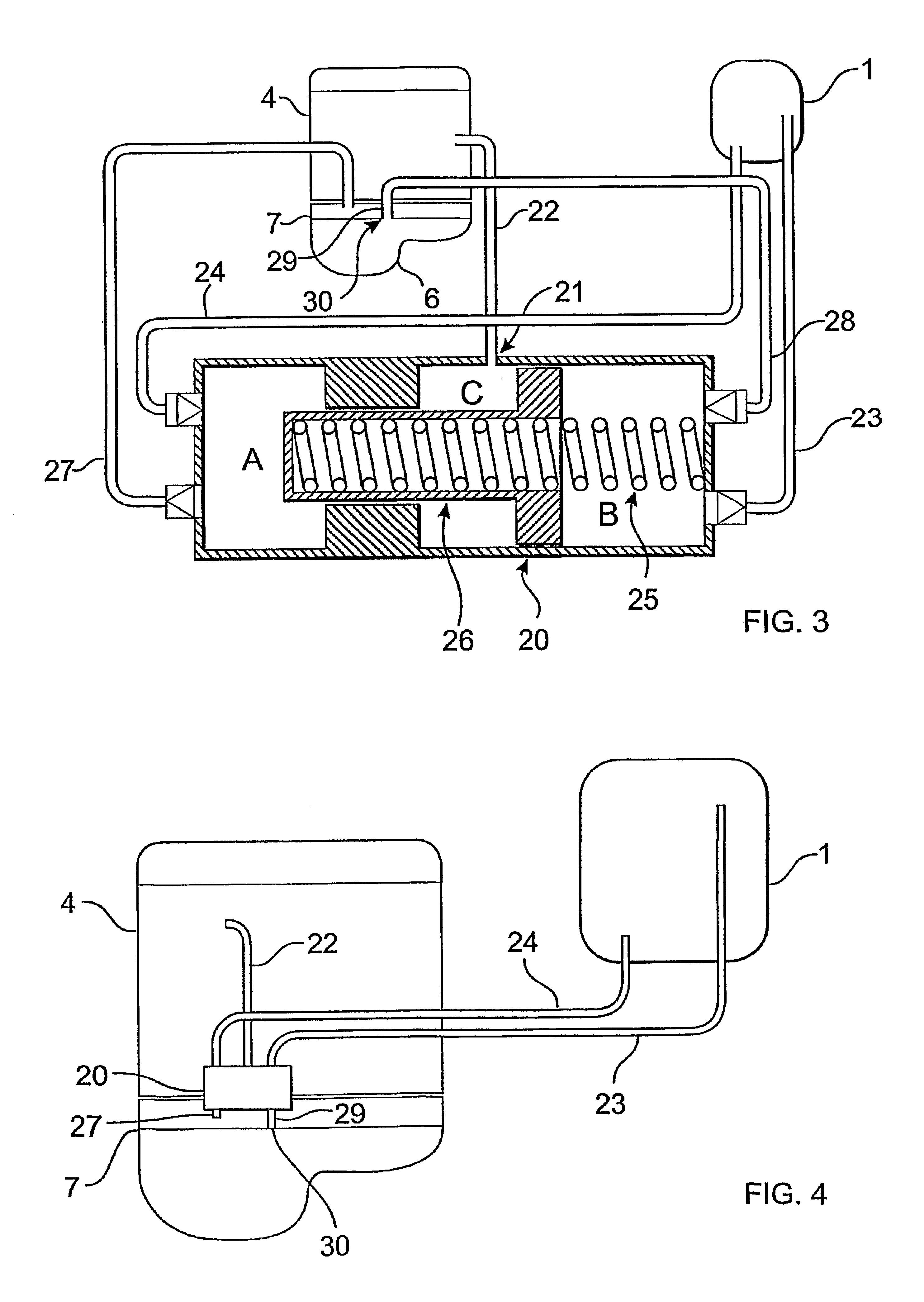

Apparatus for controlling a lubrication fluid level

InactiveUS6928976B2Quantity minimizationLong changeLubrication of auxillariesLubricant conduit arrangementsEngineeringInternal combustion engine

System and a method for automatically topping up an internal combustion engine (4) with lubricant. A lubricant container that includes a (1), a pipe (2) which connects the container to the internal combustion engine (4), a level pipe (5) which defines the oil level in a sump (6) and an apparatus (3) for transferring lubricant. The apparatus (3) for transferring lubricant makes it possible to transfer lubricant both from the container (1) to the internal combustion engine (4) and from the internal combustion engine (4) to the container (1).

Owner:VOLVO LASTVAGNAR AB

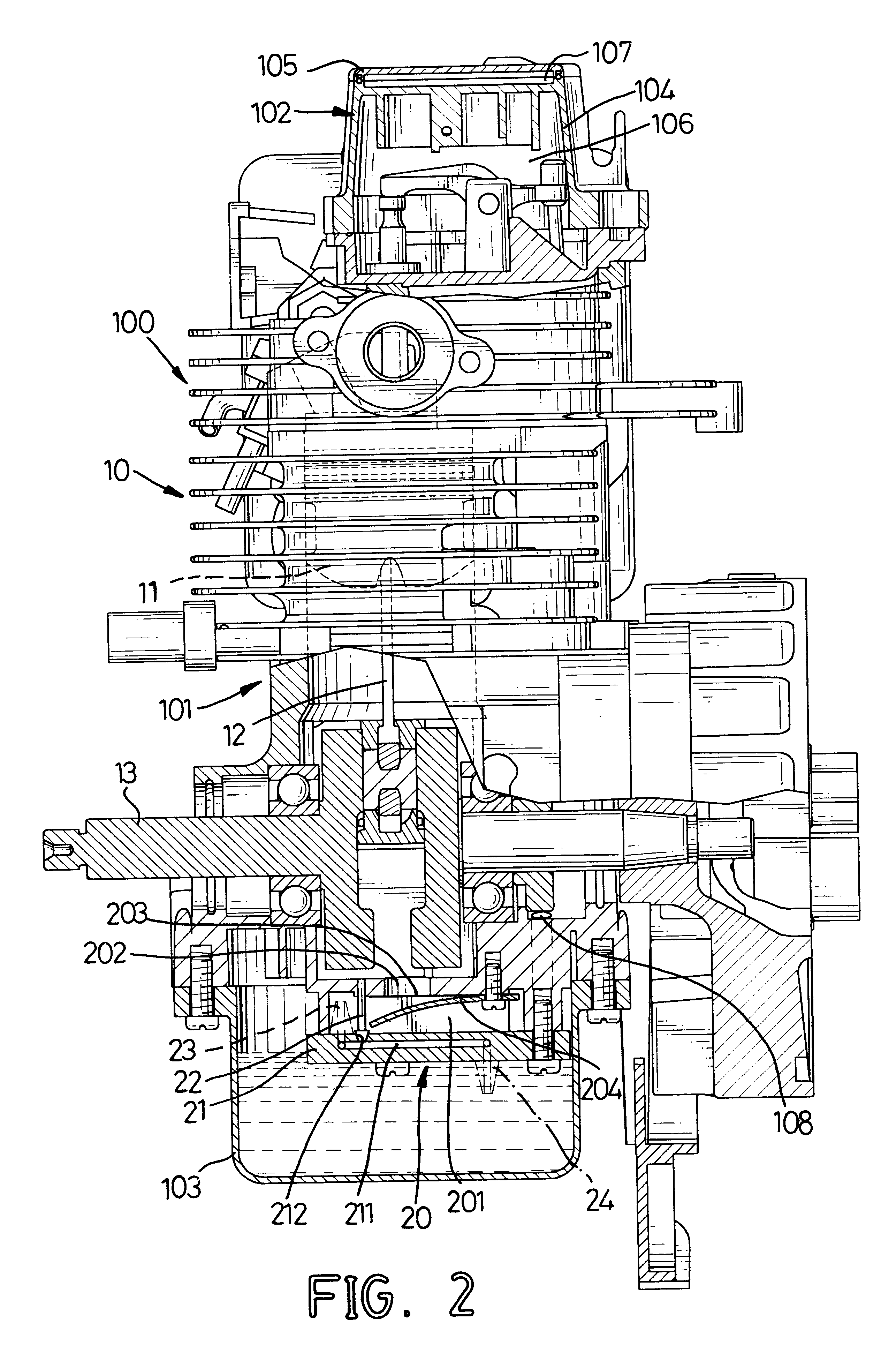

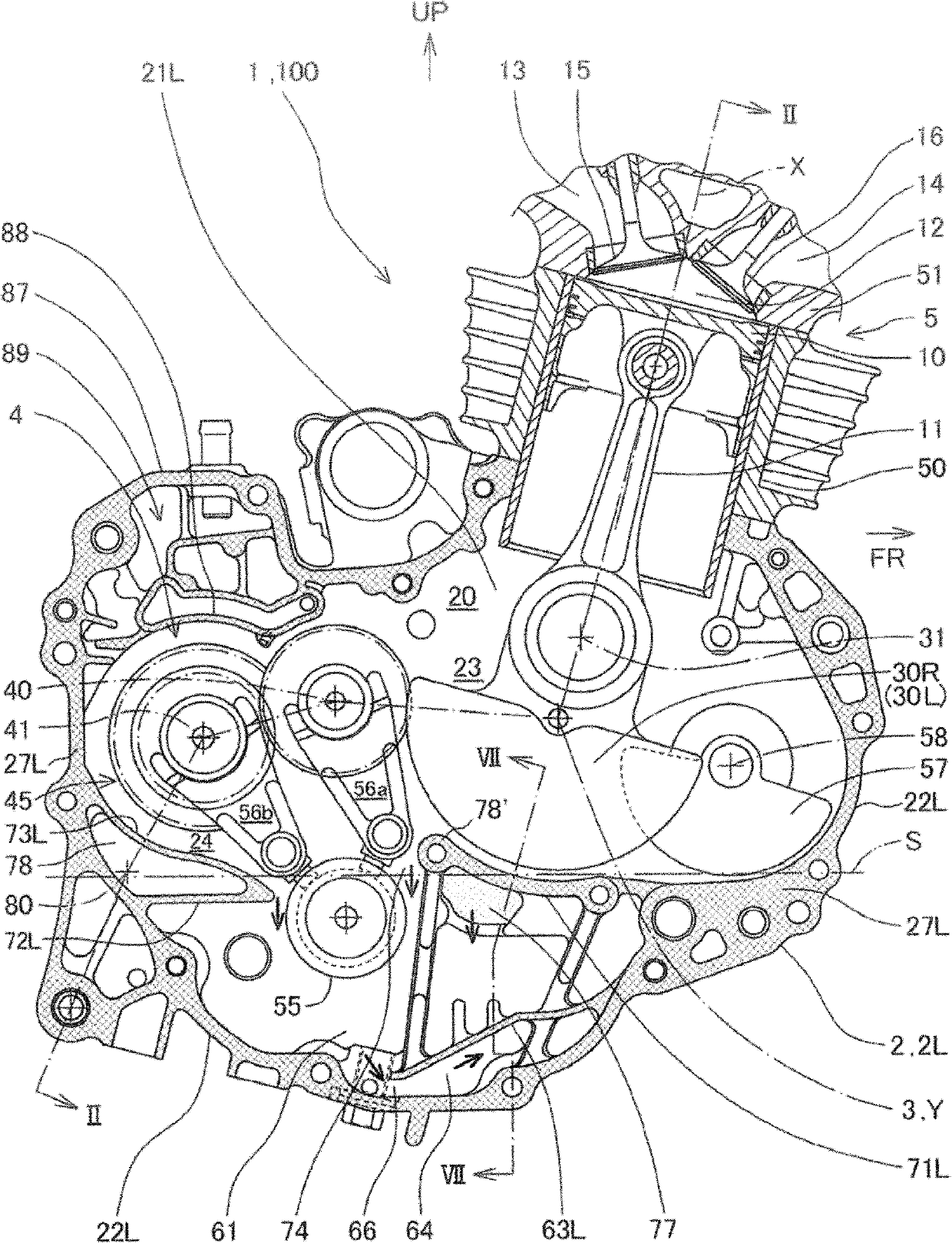

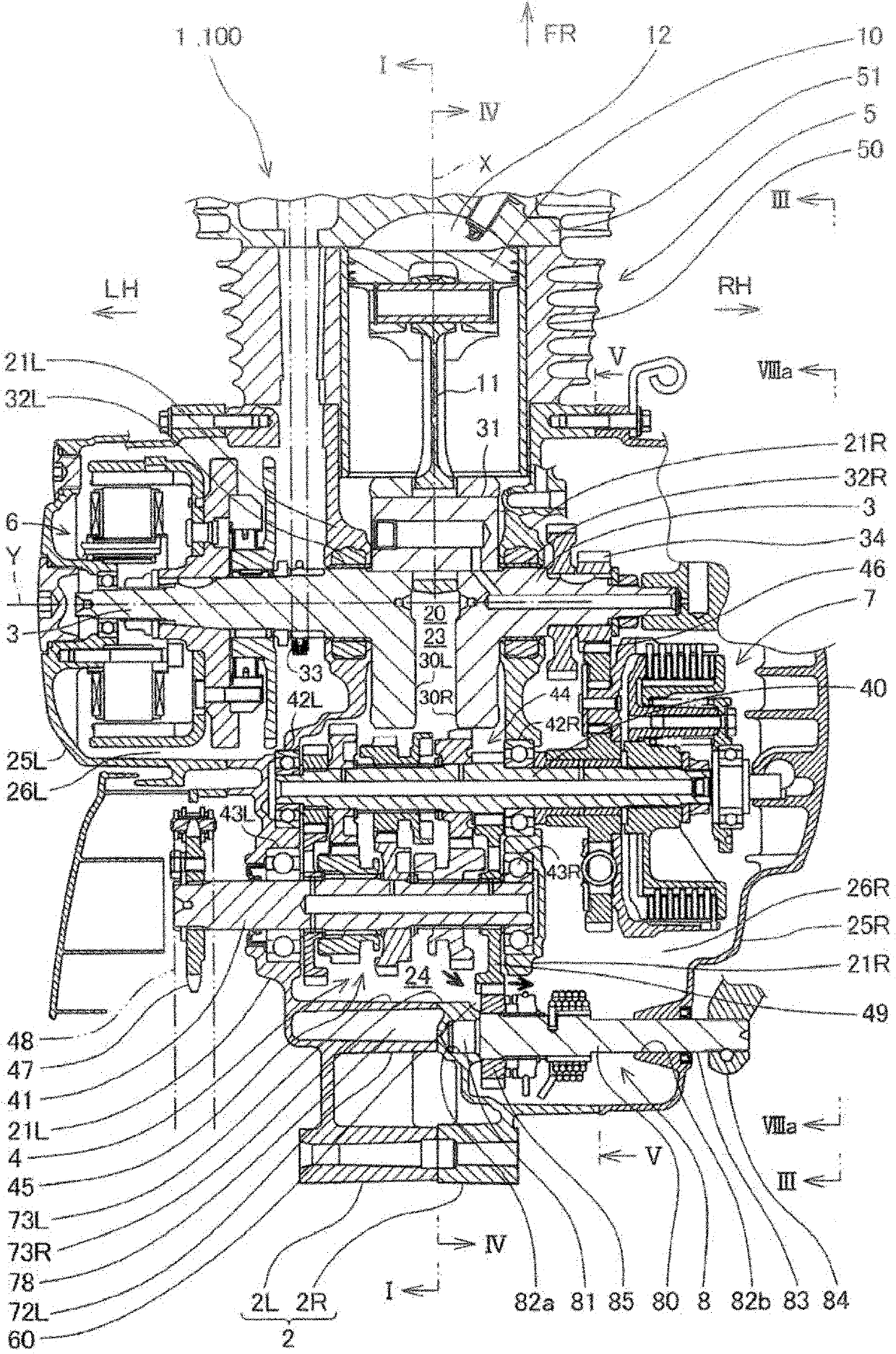

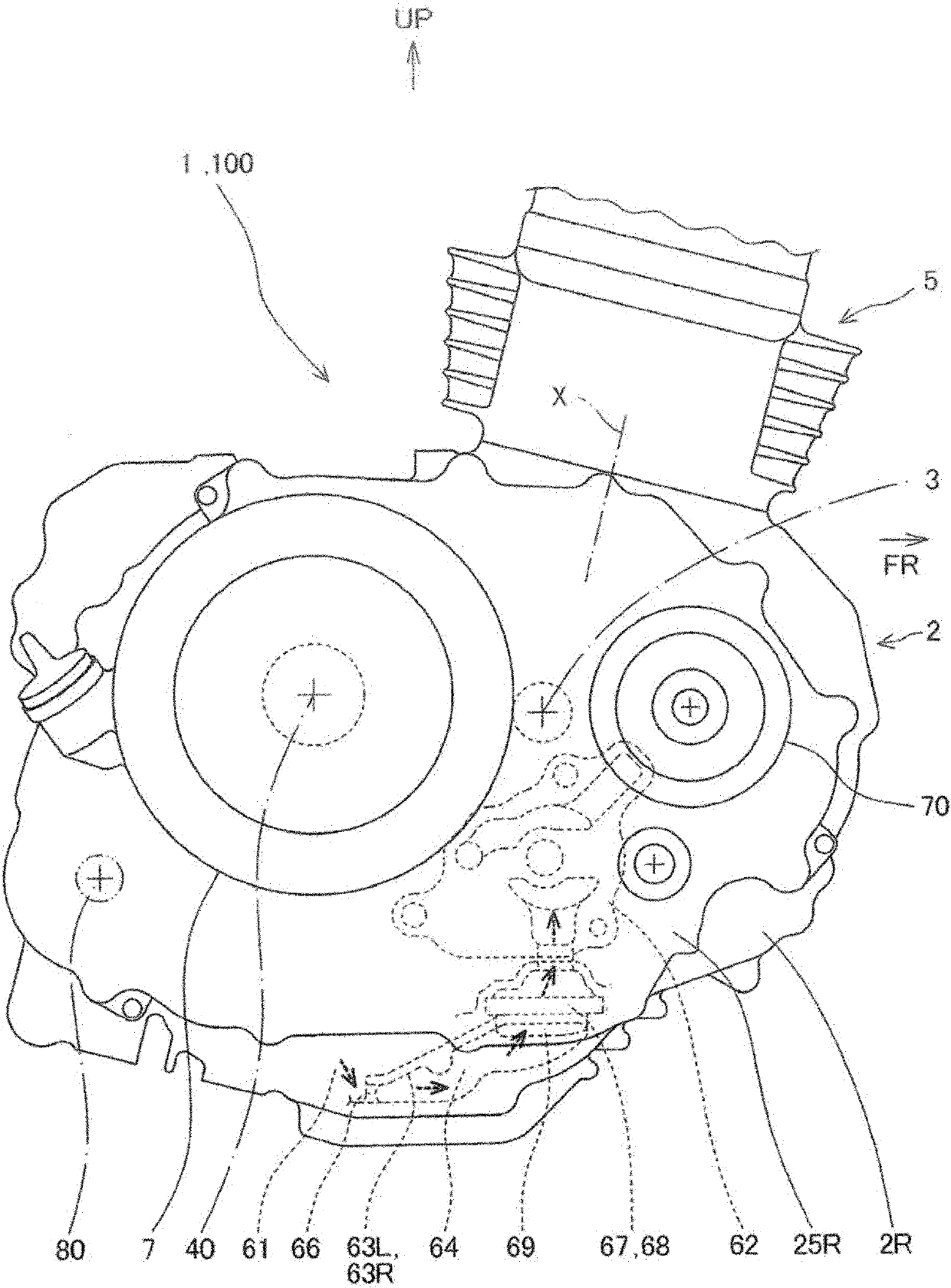

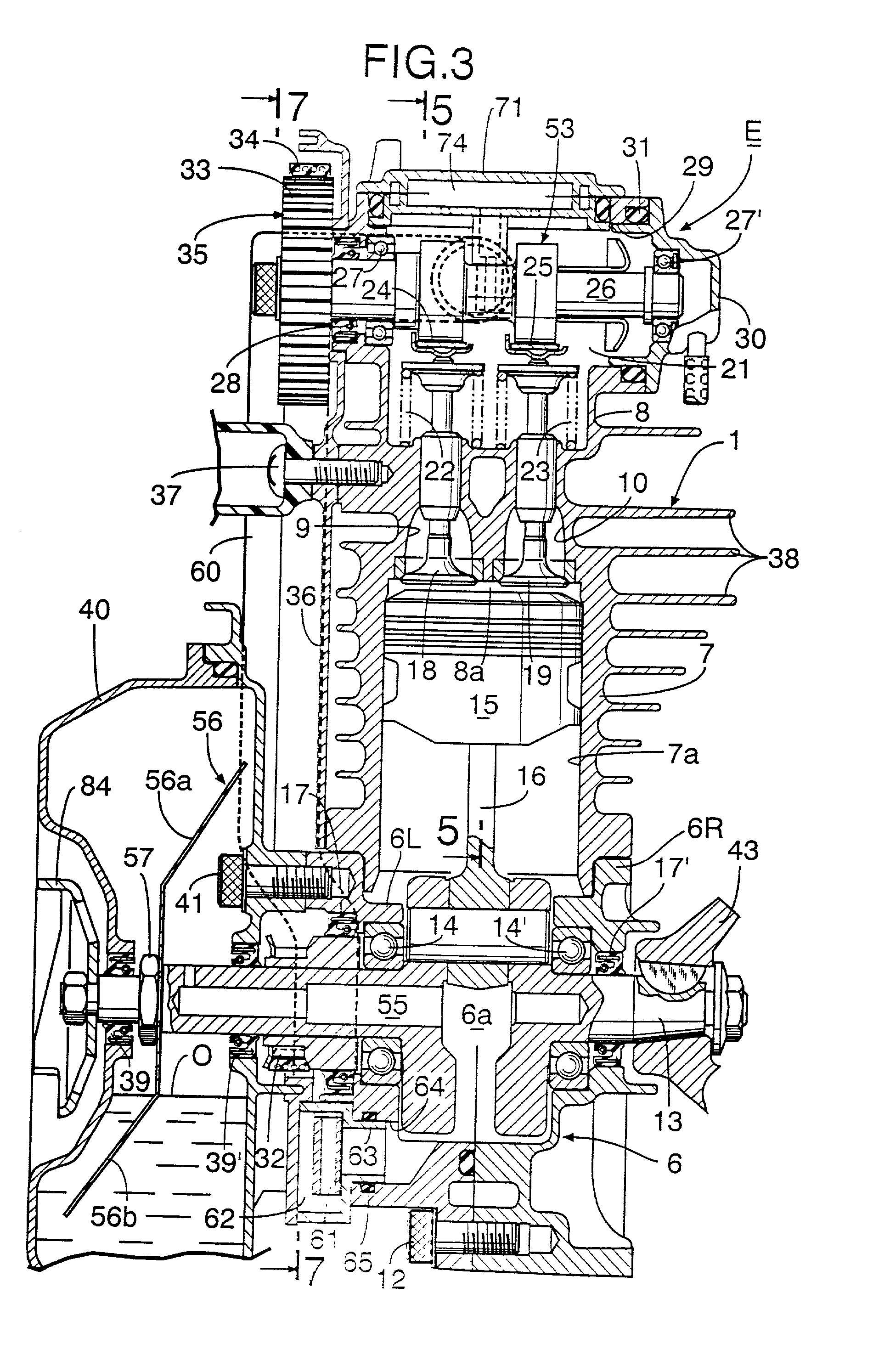

Crankcase structure

The invention provides a crankcase structure, which inhibits the change and descending of oil level in the bottom of the casing due to the inclination of an internal combustion engine and enables the oil to rapidly return for preventing the exposure of an oil-sucking opening and preventing an oil pump from generating cavitation. In a supporting crankshaft (3) and a speed changer (4) and a crankcase (2) of an internal combustion engine (1) having an oil sump (61) at the bottom, an oil-sucking opening (66) which sucks the oil in the oil sump (61) through an oil pump (62) is disposed at the bottom of the oil sump (61). The crankcase (2) comprises an oil return port (74) which enables the oil of a lubricating crankshaft (3) or the speed changer (4) to return to the oil sump (61), separating walls (71L, 71R) for separating the crankshaft (3) and the oil sump (61) or separating walls (72L, 72R) for separating the speed changer (4) and the oil sump (61), and oil discharging parts (78, 78') which are connected to the separating walls and are at least partially disposed at the upper part of the oil surface when the internal combustion engine storing proper amount of oil stops.

Owner:HONDA MOTOR CO LTD

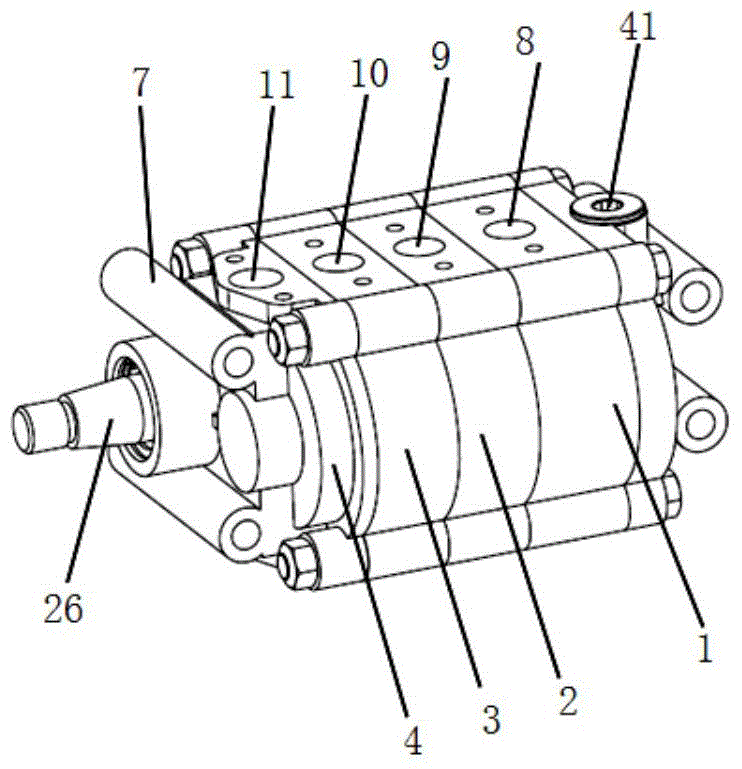

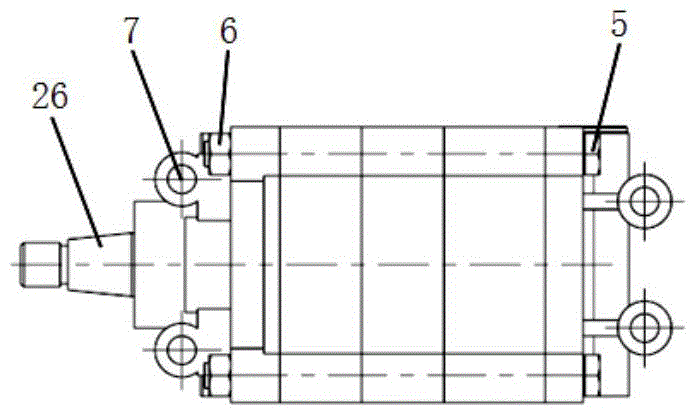

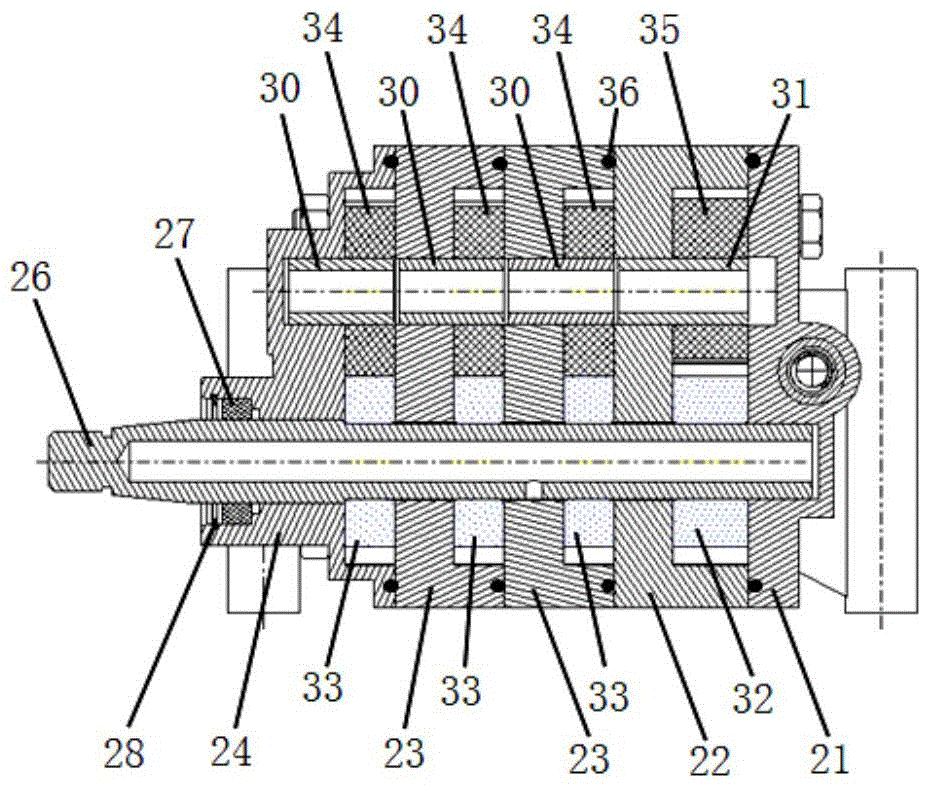

Engine oil pump and engine lubrication system thereof

InactiveCN104405469ALower the altitudeOptimize layoutRotary/oscillating piston combinationsMachines/enginesDrive shaftPulp and paper industry

The invention discloses an engine oil pump and an engine lubrication system thereof. The engine oil pump comprises a main pump and an auxiliary pump; the main pump and the auxiliary pump are of a sectional structure; the main pump and the auxiliary pump share one driving shaft; the main pump and the auxiliary pump are respectively provided with independent oil inlet and oil outlet. The engine lubrication system comprises an oil pan and an engine lubrication passage, and also comprises an oil collecting container; the oil inlet of the auxiliary pump is communicated with the oil pan, and the oil outlet of the auxiliary pump is communicated with the oil collecting container; the oil inlet of the main pump is communicated with the oil collecting container, and the oil outlet of the main pump is communicated with the engine lubrication passage. When an engine is inclined at a large angle, engine oil in the engine can be cycled continuously and normally participates in lubricating work.

Owner:CHERY AUTOMOBILE CO LTD

Handheld type four-cycle engine

InactiveUS20010029910A1Easy to operateGood weight balanceLubrication of auxillariesCoolant flow controlExhaust valveCylinder head

In a handheld type four-cycle engine, a valve operation mechanism includes a camshaft rotatably supported in a cylinder head so as to open and close an intake valve and an exhaust valve and a timing transmission placed on one side outside an engine main body and providing association between a crankshaft and the camshaft, and a centrifugal clutch for power output is mounted on the crankshaft on the opposite side outside the engine main body. The timing transmission and the centrifugal clutch being positioned at the two ends of the crankshaft improves the weight balance, the center of gravity of the engine can be made as close to the central part of the crankshaft as possible, which, together with the reduced weight, can enhance the operability of the engine.

Owner:HONDA MOTOR CO LTD

Handheld type four-cycle engine

InactiveUS20010029921A1Reduce weightPrevent the lubricating oil from becoming overheatedLubrication of auxillariesAir coolingCylinder headHand held

In a handheld type four-cycle engine, the lubricating system includes an oil tank placed outside an engine main body, a through hole providing communication between the oil tank and a crank chamber, an oil feed pipe placed outside the engine main body and providing communication between the crank chamber and a valve operation chamber of a cylinder head, an oil return pipe placed outside the engine main body and providing communication between the valve operation chamber and the oil tank, and a one-way valve for transferring oil from the crank chamber to the valve operation chamber side via the oil feed pipe. The side walls of the engine main body can thus be made thinner and the weight of the engine main body can therefore be reduced regardless of the presence of the oil feed pipe and the oil return pipe.

Owner:HONDA MOTOR CO LTD

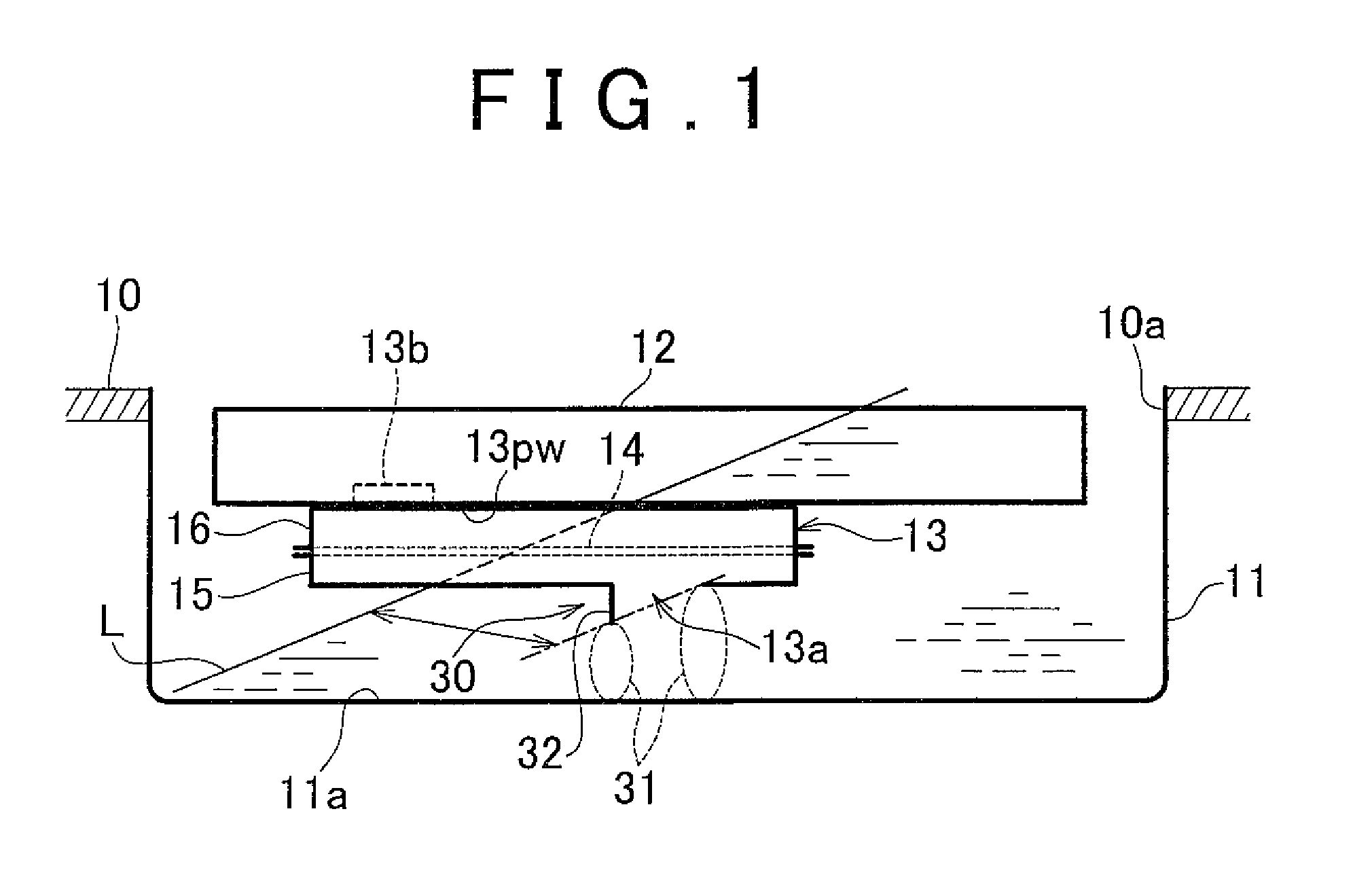

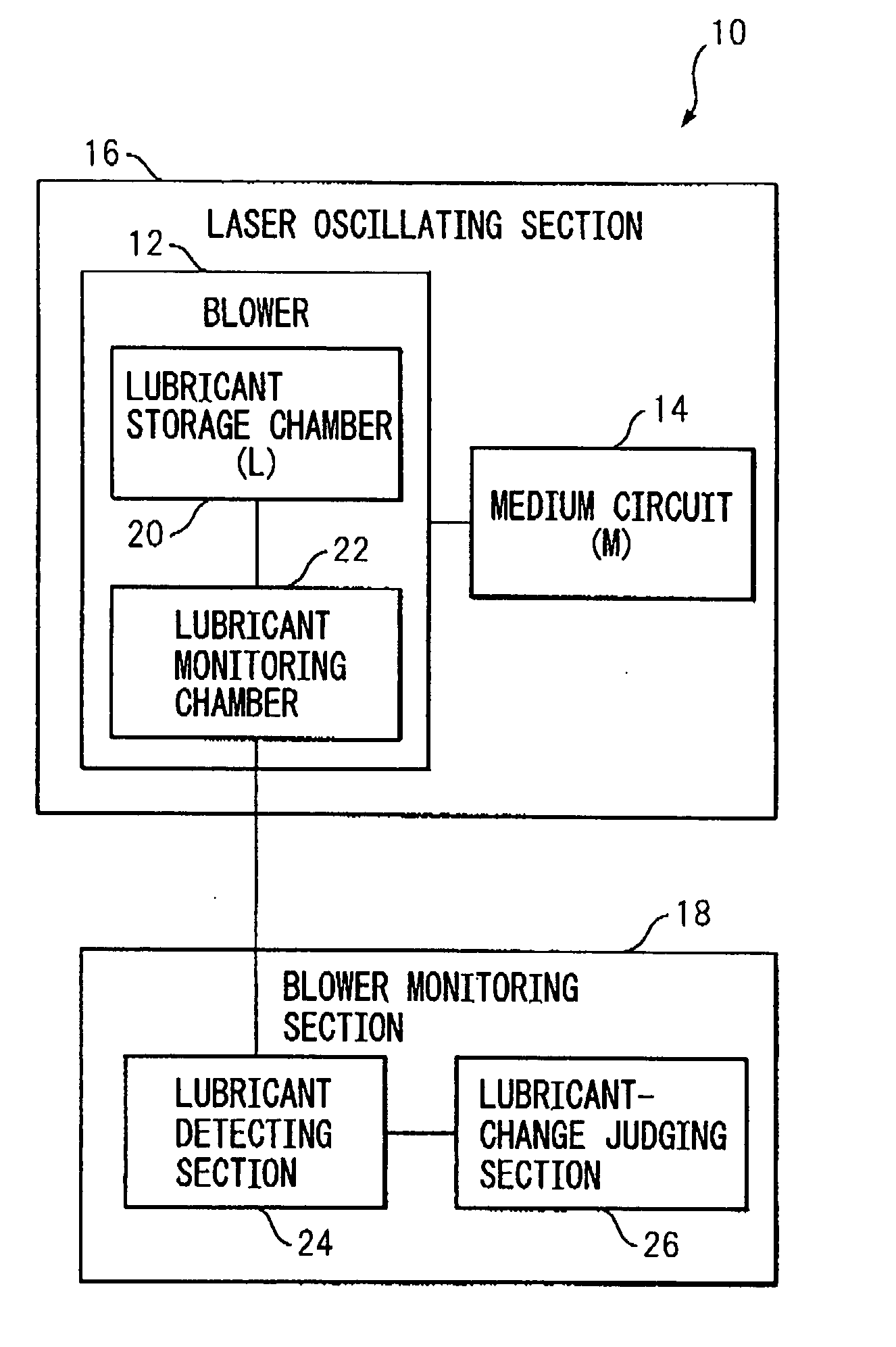

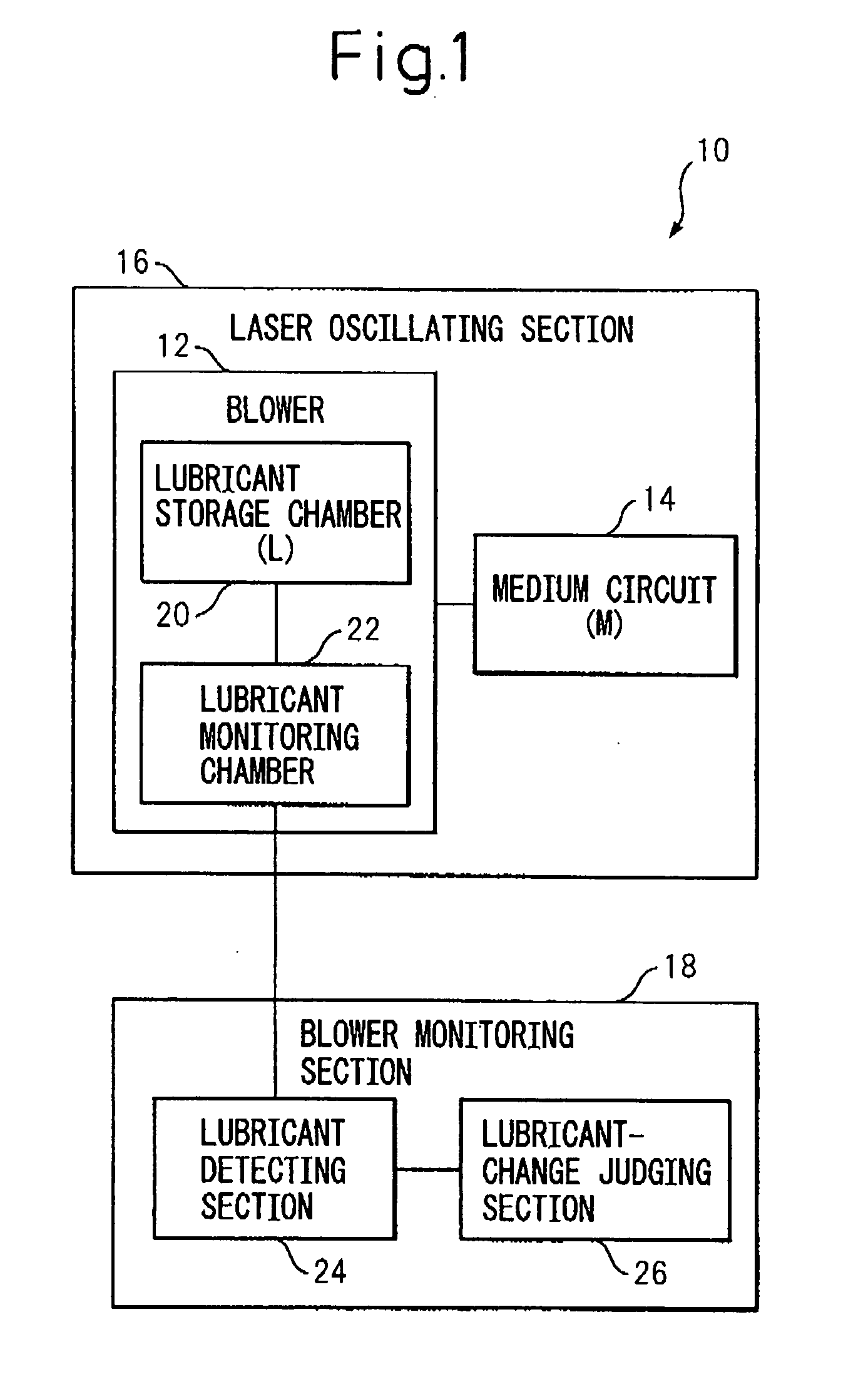

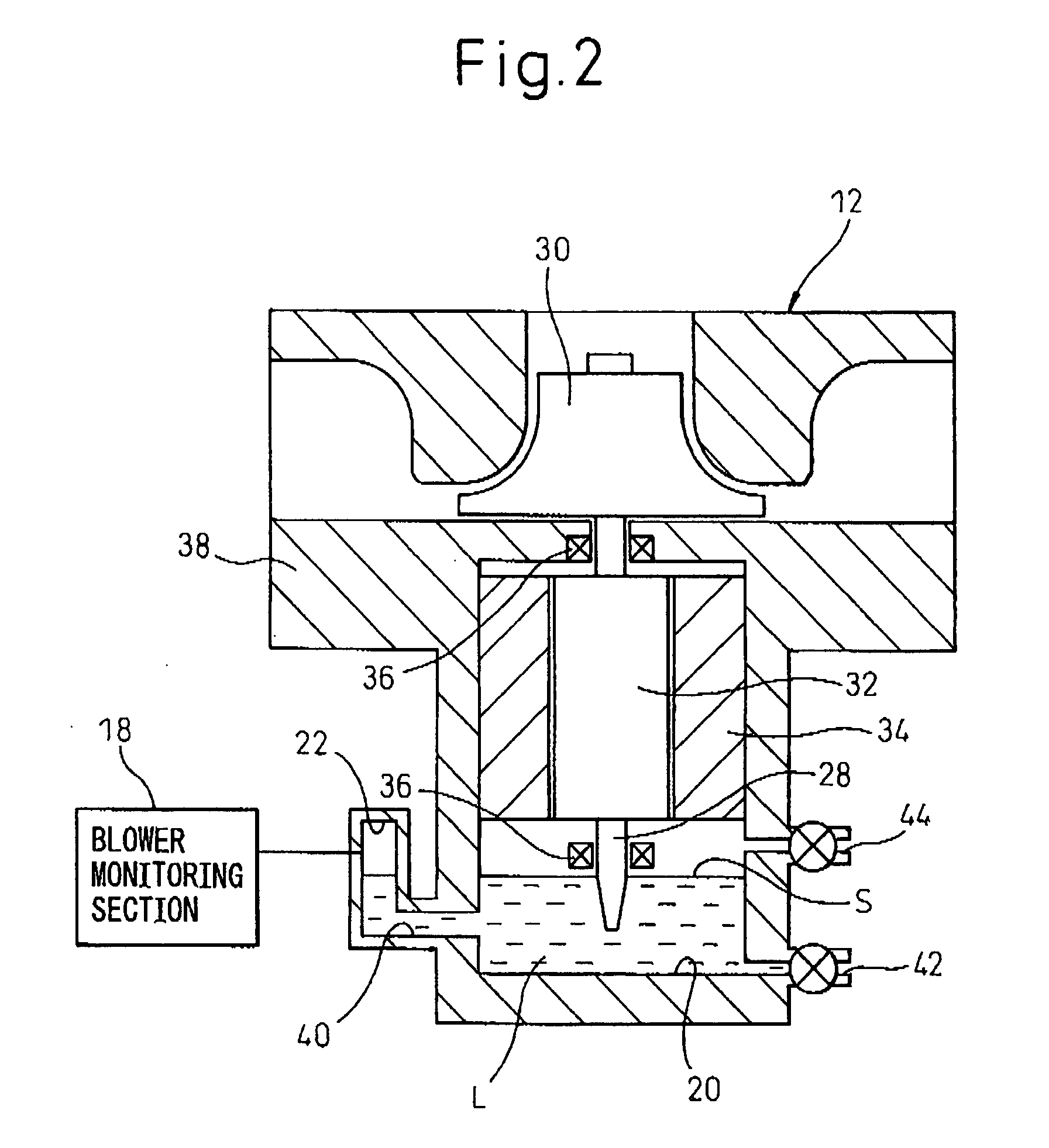

Gas laser apparatus, and method and device for monitoring blower

InactiveUS20080056325A1Reduce the burden onEliminate riskActive medium materialPump controlInternal pressureGas laser device

A gas laser apparatus including a laser oscillating section including a blower forcibly circulating a medium gas in a medium circuit, and a blower monitoring section monitoring a maintenance state of the blower. The blower includes a lubricant storage chamber storing a lubricant, and a lubricant monitoring chamber connected to the lubricant storage chamber to ensure fluidic communication therebetween at a position lower than an oil level of a lubricant having a predetermined appropriate volume and stored in the lubricant storage chamber. The blower monitoring section includes a lubricant detecting section detecting that a lubricant stored in the lubricant storage chamber of the blower flows into the lubricant monitoring chamber and at least a part of the lubricant is present in the lubricant monitoring chamber, as a result of internal-pressure change in the lubricant storage chamber, and a lubricant-change judging section monitoring whether the lubricant detecting section detects a presence of the lubricant in the lubricant monitoring chamber, before the laser oscillating section is activated, and judging that, when the lubricant detecting section does not detect the presence, the lubricant stored in the lubricant storage chamber is in a state immediately after a lubricant change.

Owner:FANUC LTD

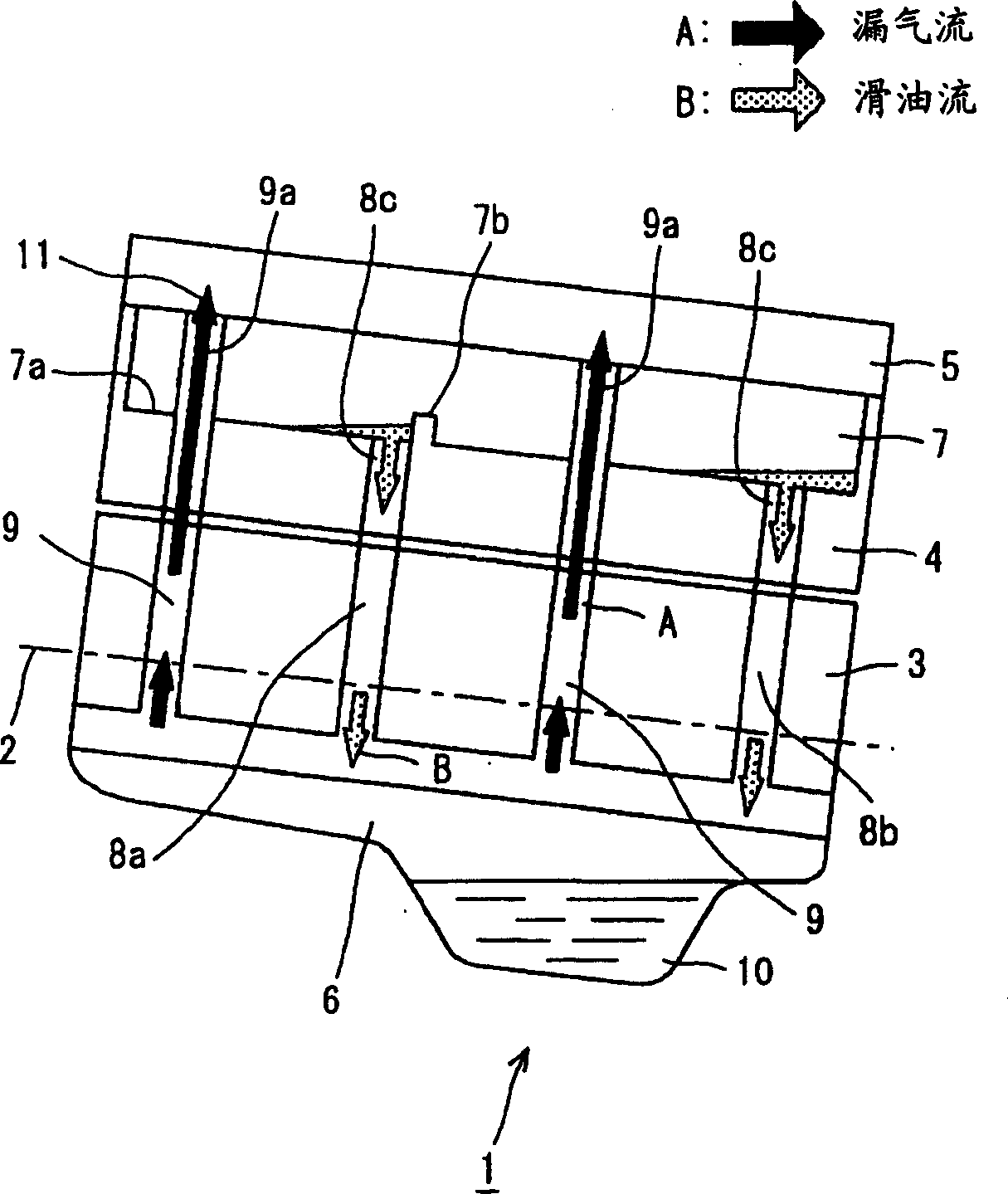

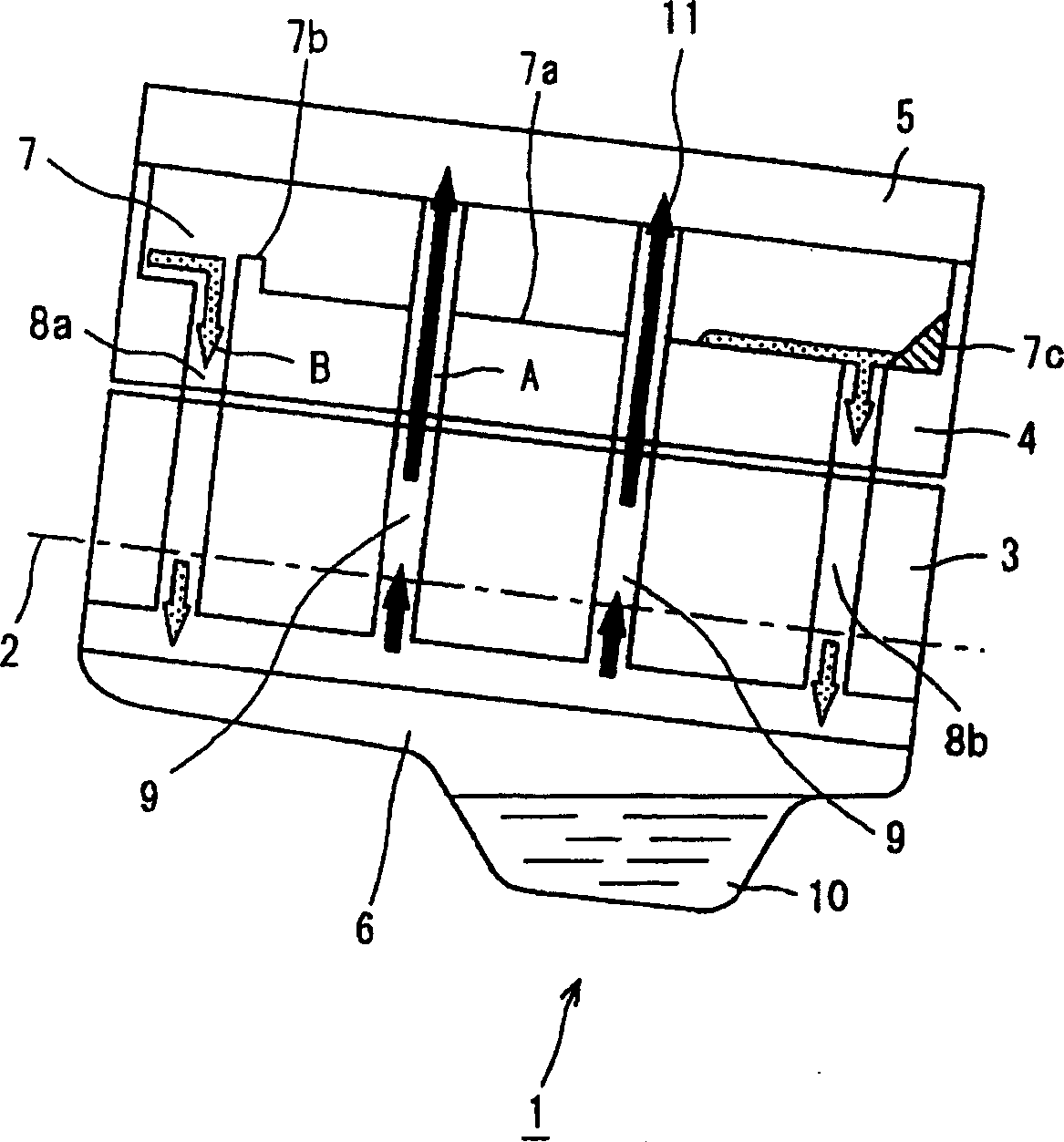

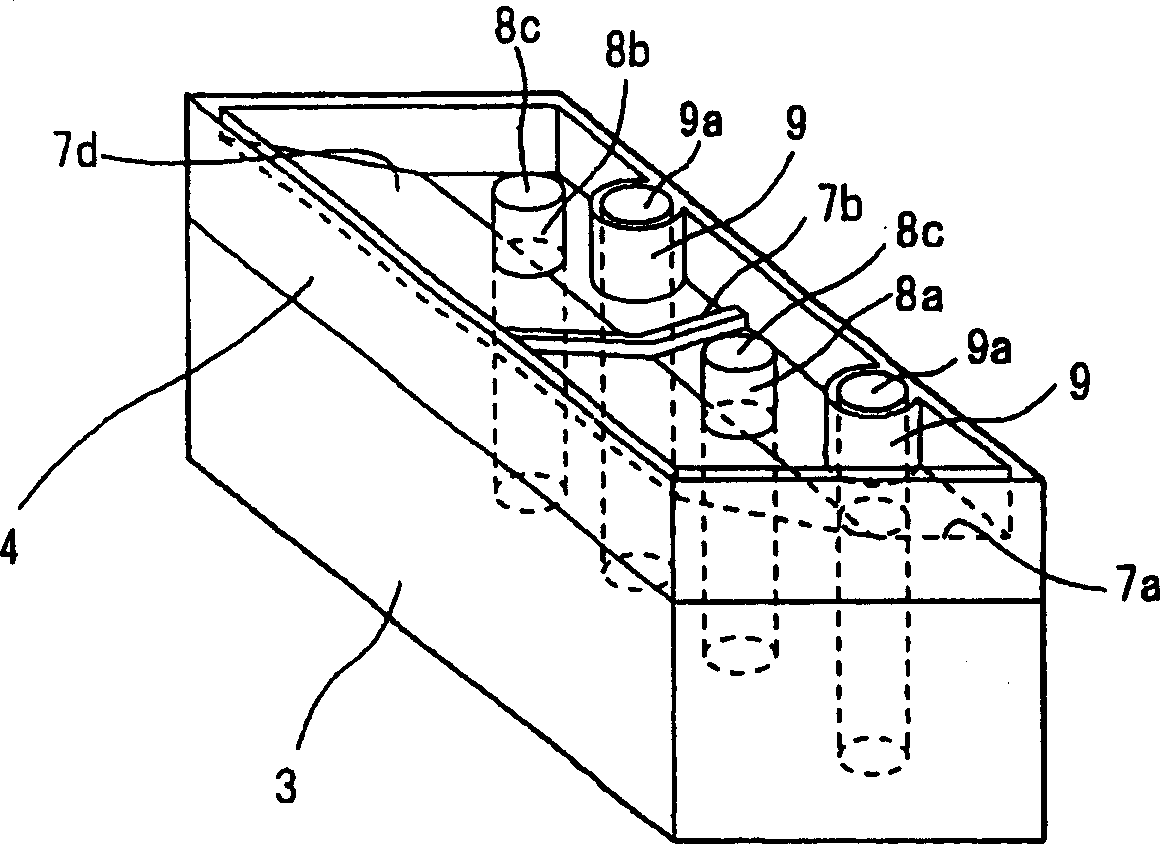

Cylinder cap structure

To provide a cylinder head structure smoothening the flow of oil and blowby gas which are deteriorated at the time of making an engine for a vehicle into a direct-injection multiple valve type. In the engine 1 for the vehicle mounted being inclined in a direction of a crankshaft 2, a weir is provided in an inclined lower side of an oil recovery passage 8a other than an inclined lower end in a lower surface 7a of a locker chamber in a cylinder head 4. An inclined surface 7c is provided in the inclined lower side of an oil recovery passage 8b positioned in a lowermost part, or an inclined surface 7d is provided in one side with no oil recovery passage 8 toward the oil recovery passage. An upper part 9a of a hole of a blowby gas passage 9 is formed to be higher than the lower surface 7a of the locker chamber. (C)2005,JPO&NCIPI.

Owner:MITSUBISHI MOTORS CORP

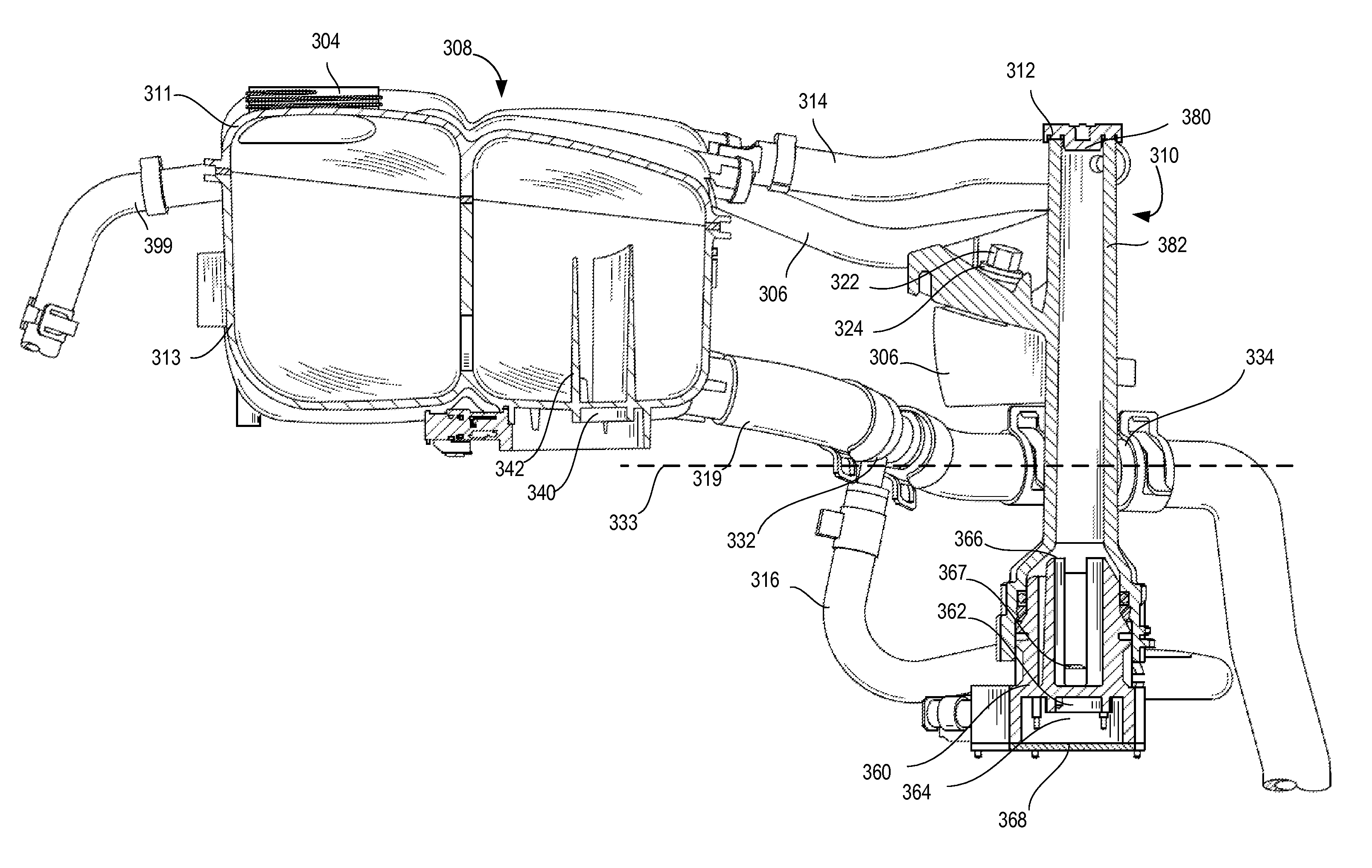

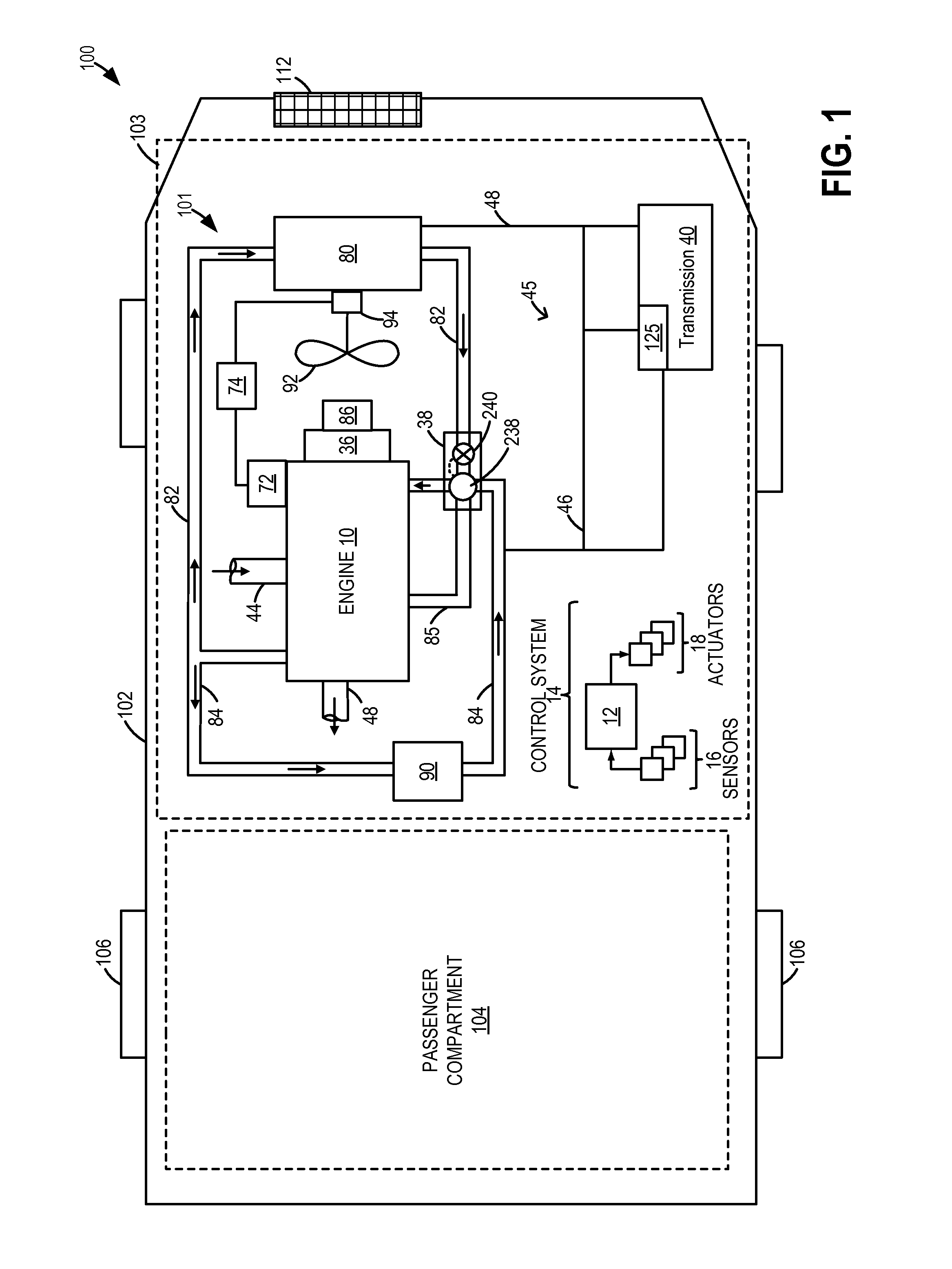

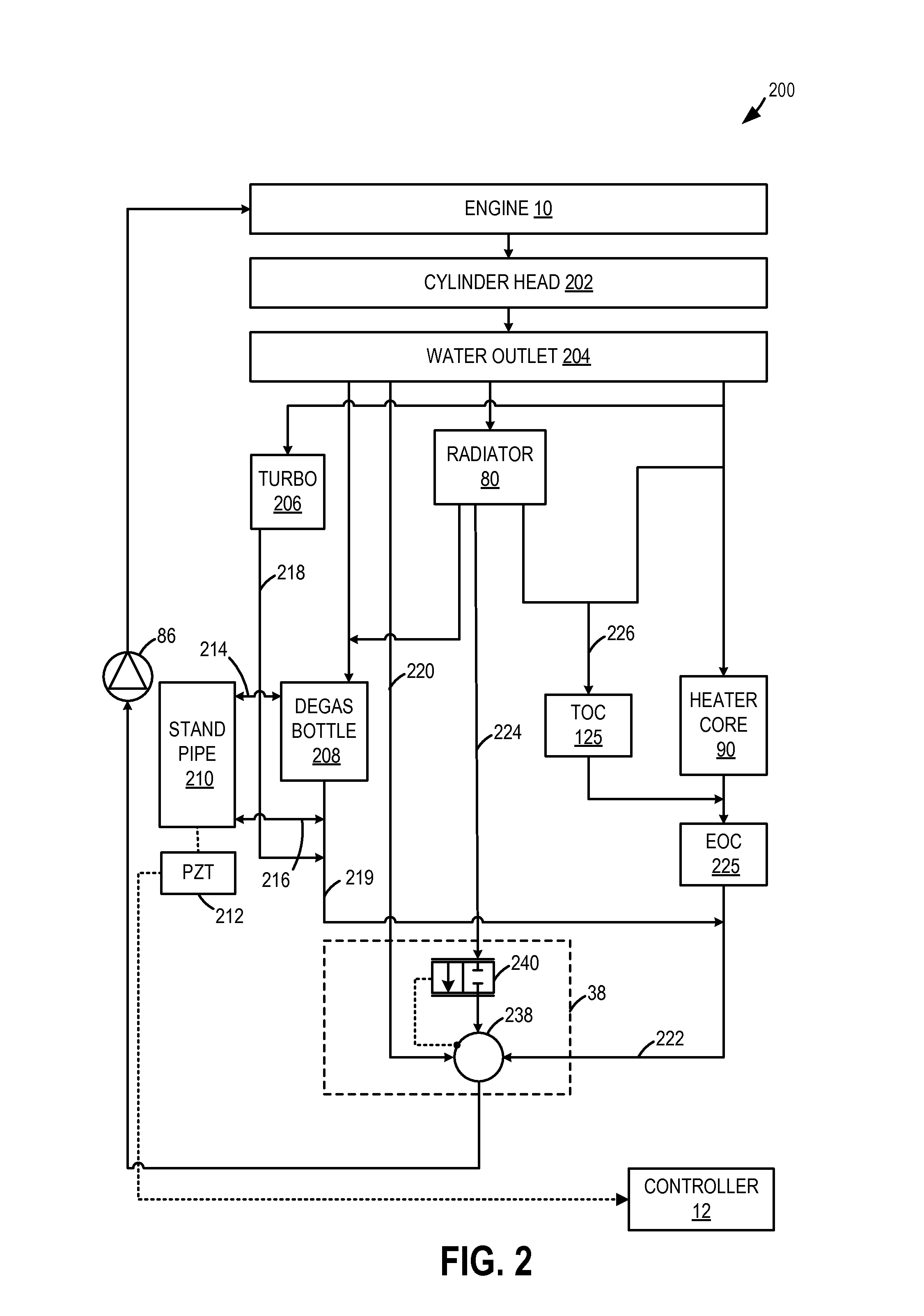

Method and system for engine cooling system control

ActiveUS9458759B2Maintain efficiencyIncrease powerMaterial analysis using sonic/ultrasonic/infrasonic wavesCoolant flow controlHarmonicHigher order harmonics

Owner:FORD GLOBAL TECH LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com