Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about "Hydrostatic bearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air bearing for use as a seal

ActiveUS8753014B2Improve sealingReliable surfaceEngine sealsGas cushion bearingsAir bearingPressure difference

In order to effect a seal; a porous material which comprises one side of two opposing surfaces is used to restrict and evenly distribute externally pressurized gas, liquid, steam, etc. between the two surfaces, exerting a force which is opposite the forces from pressure differences or springs trying to close the two faces together and so may create a non contact seal that is more stable and reliable than hydrodynamic seals currently in use.

Owner:NEW WAY MACHINE COMPONENTS

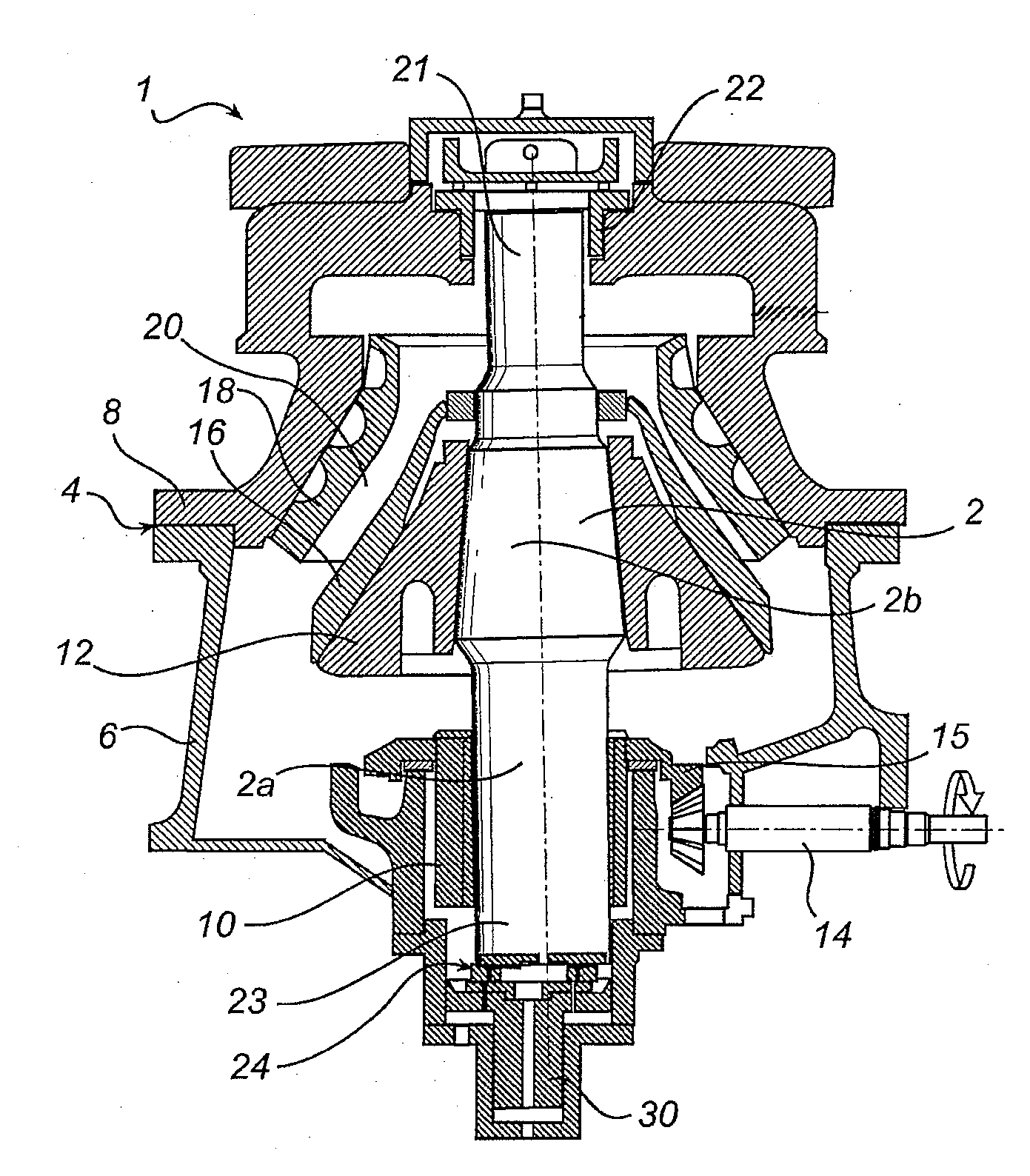

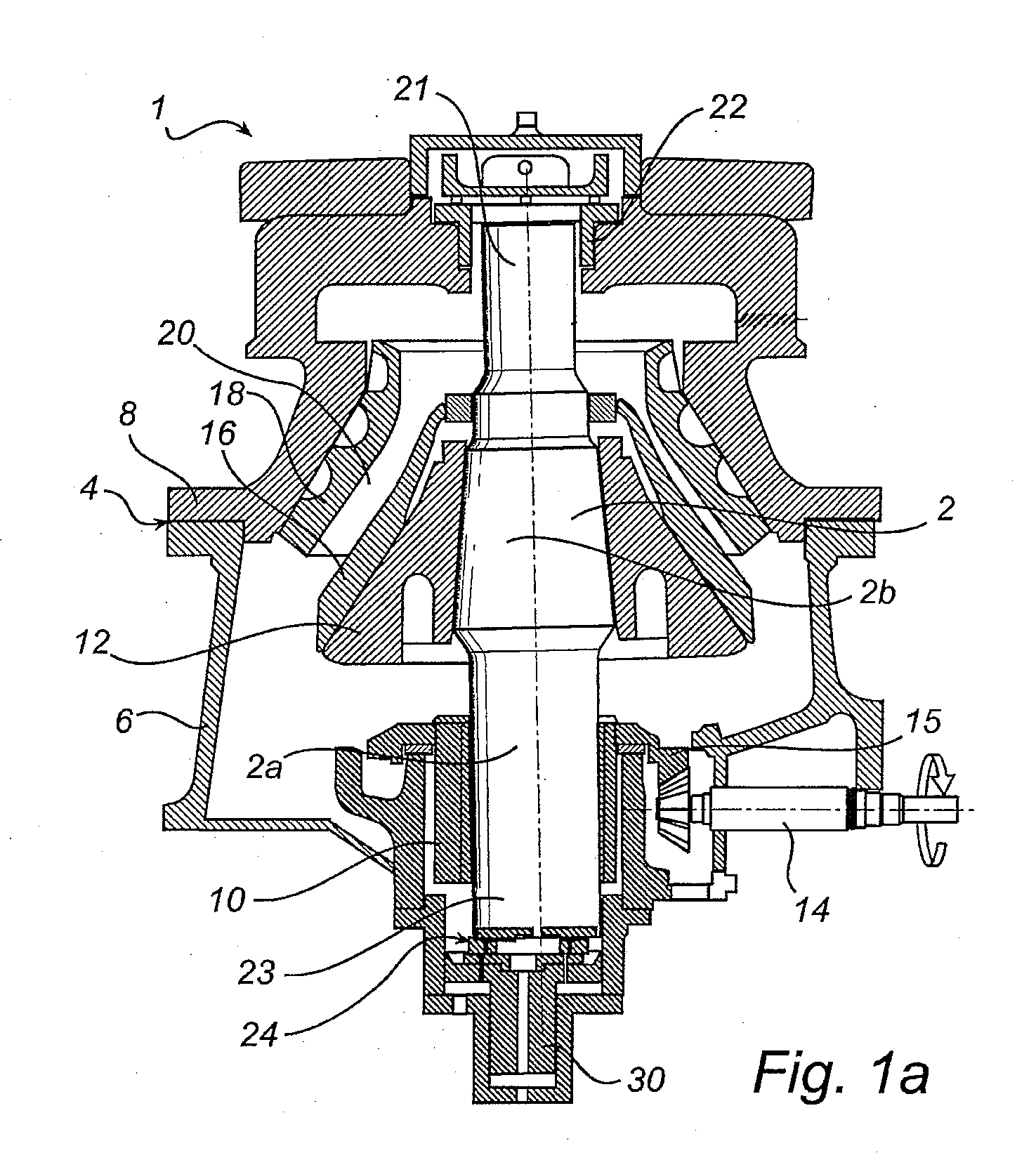

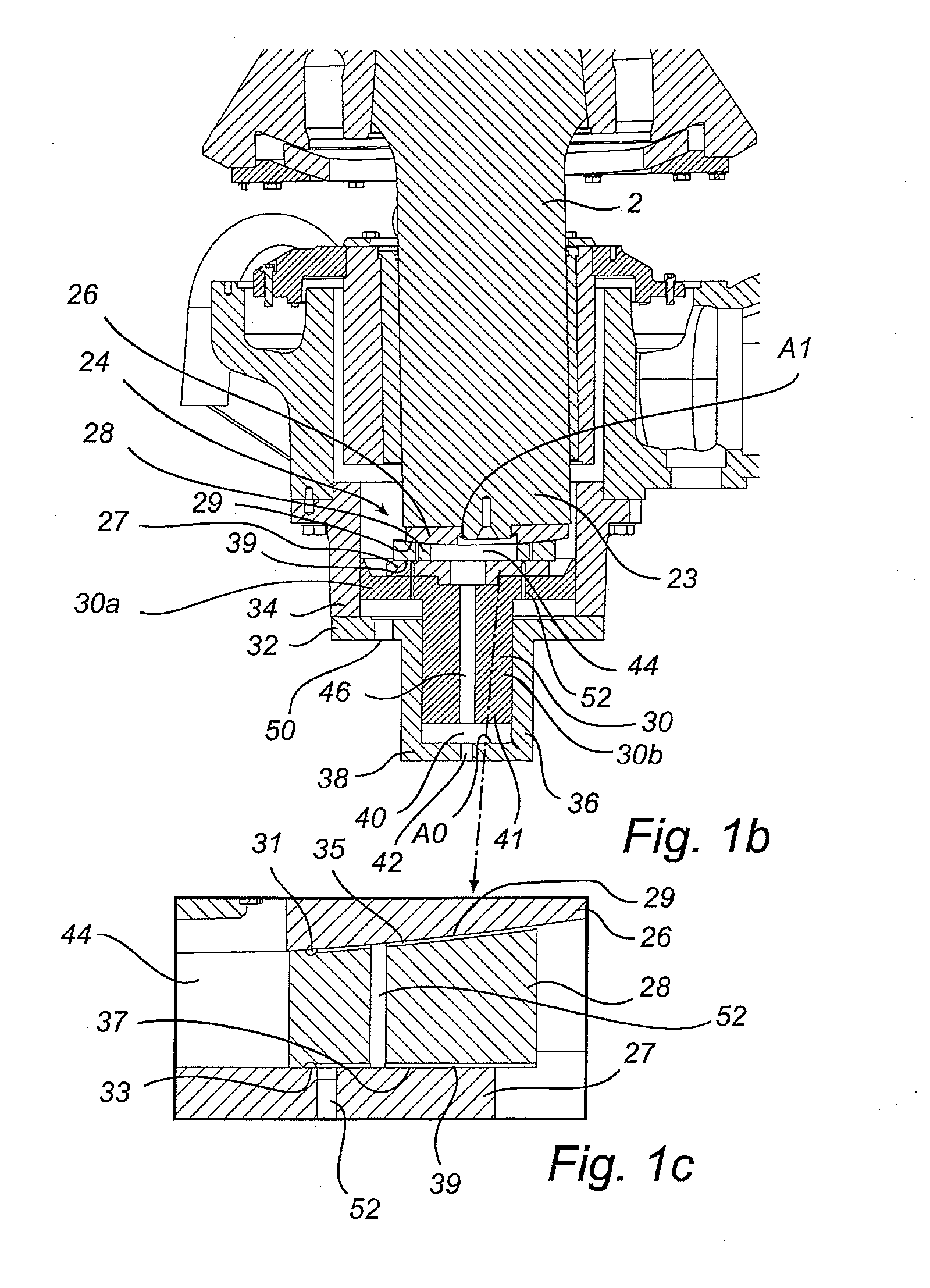

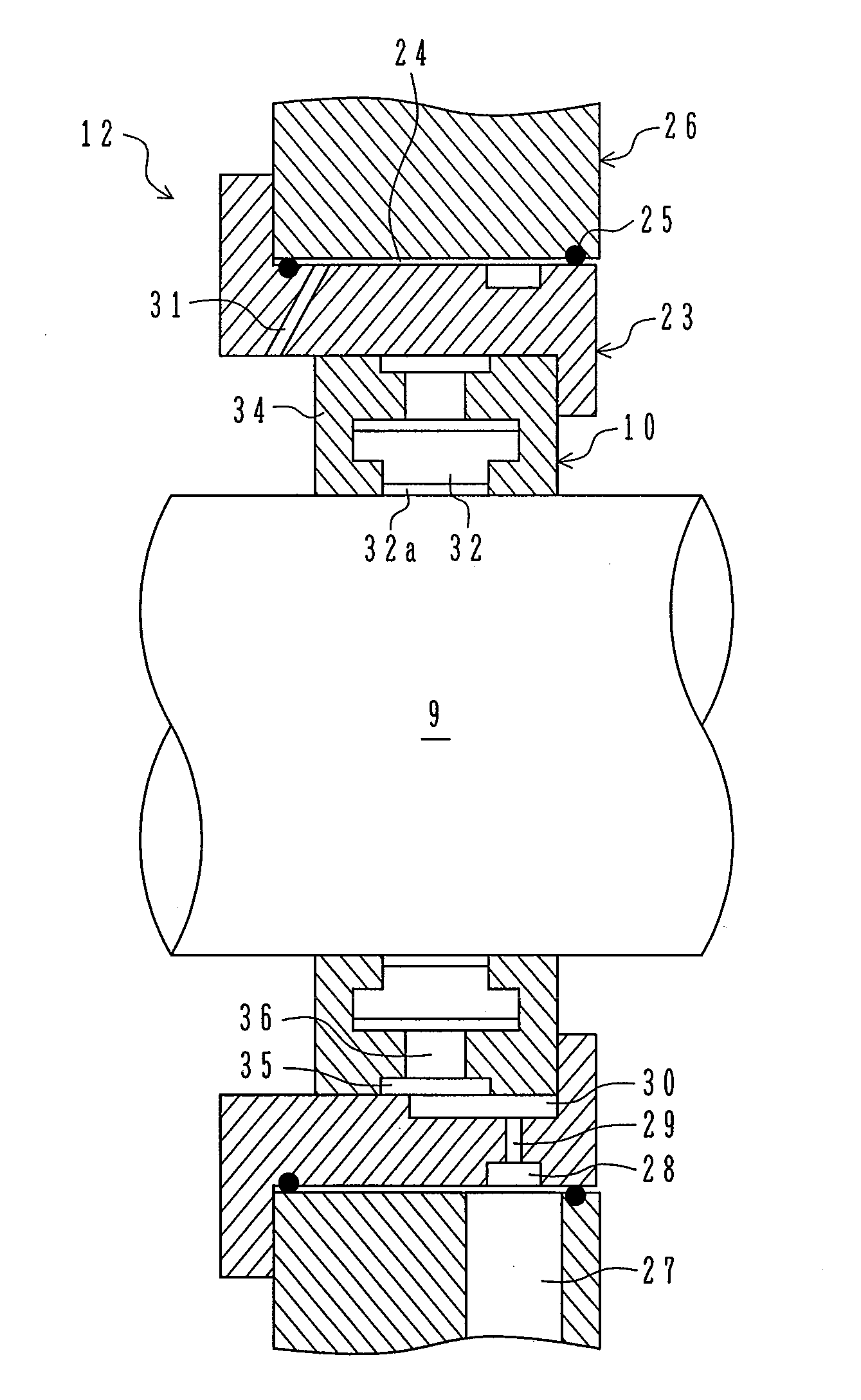

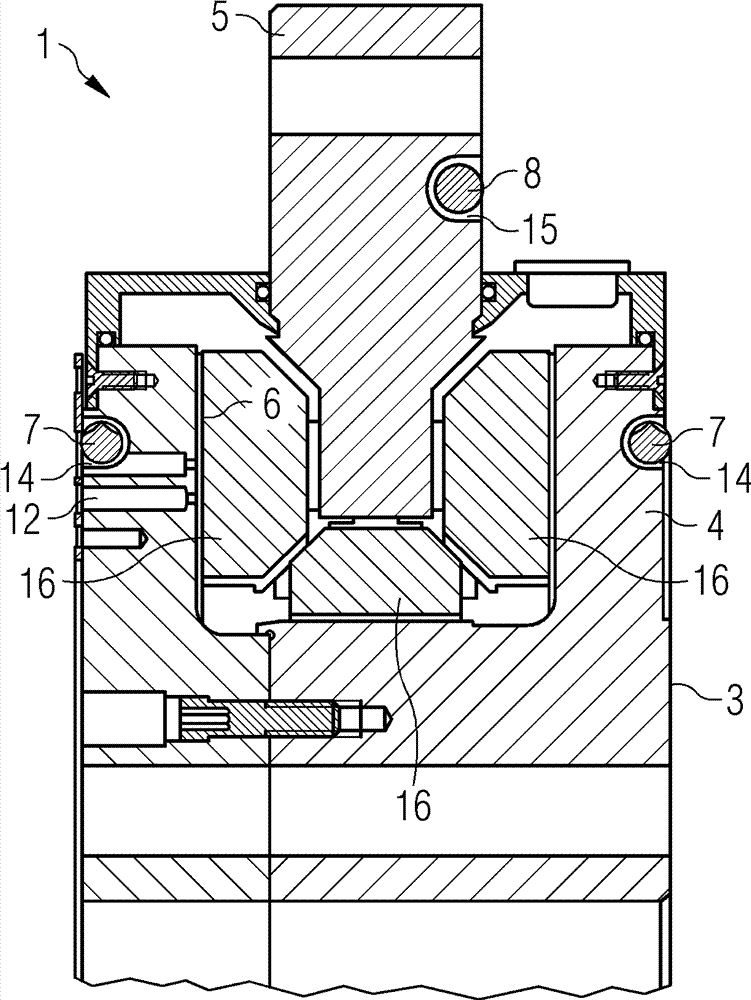

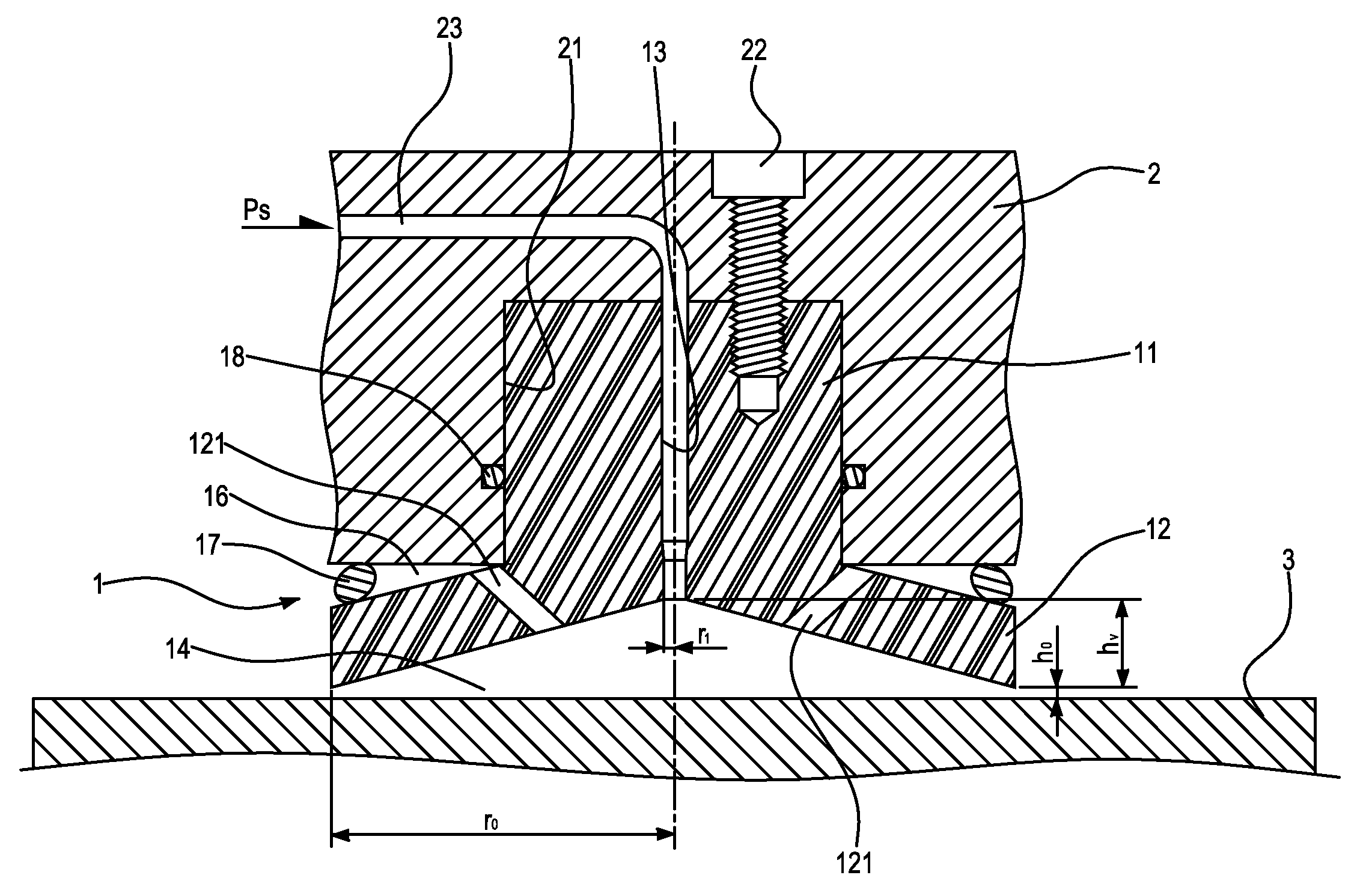

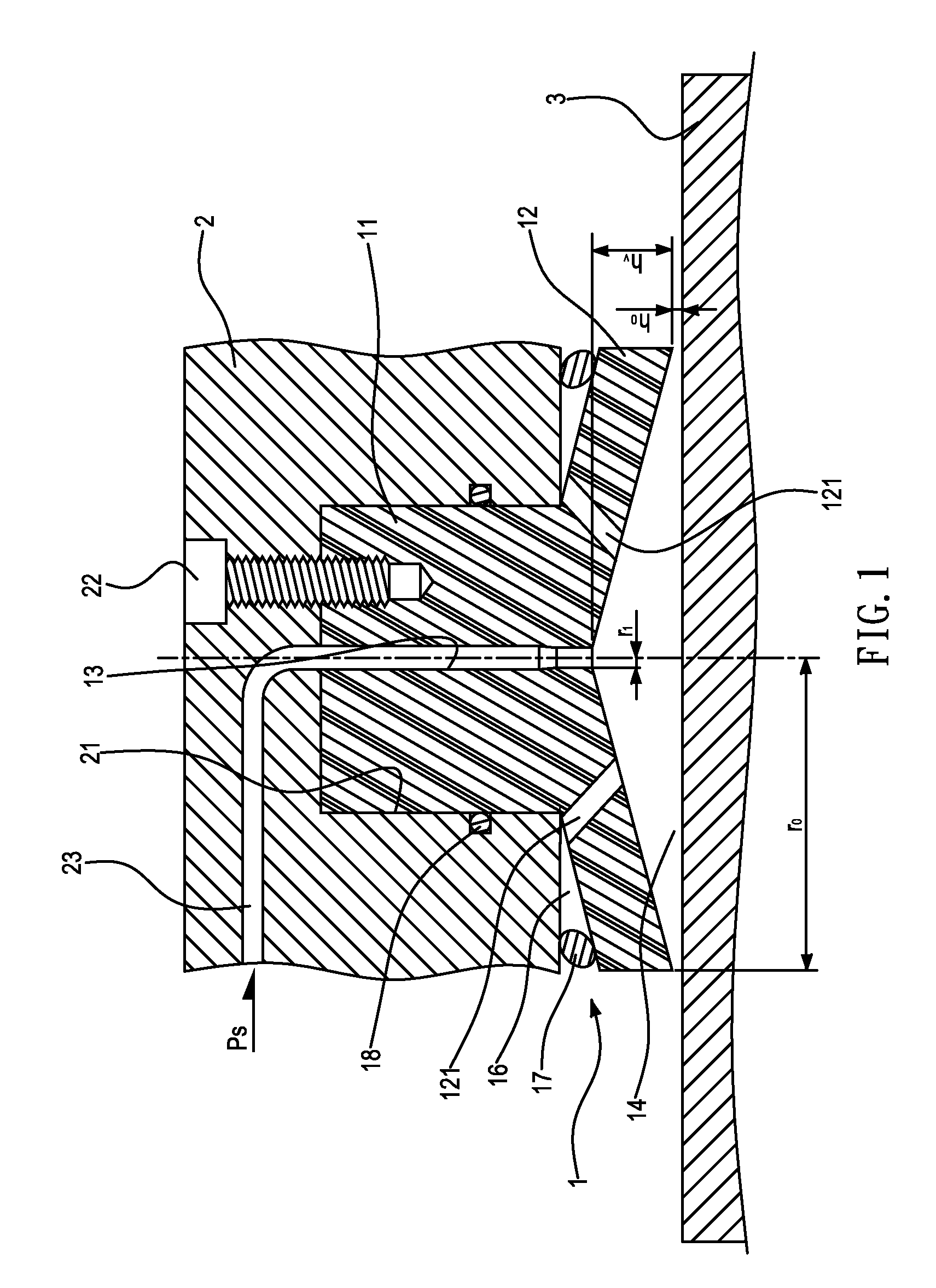

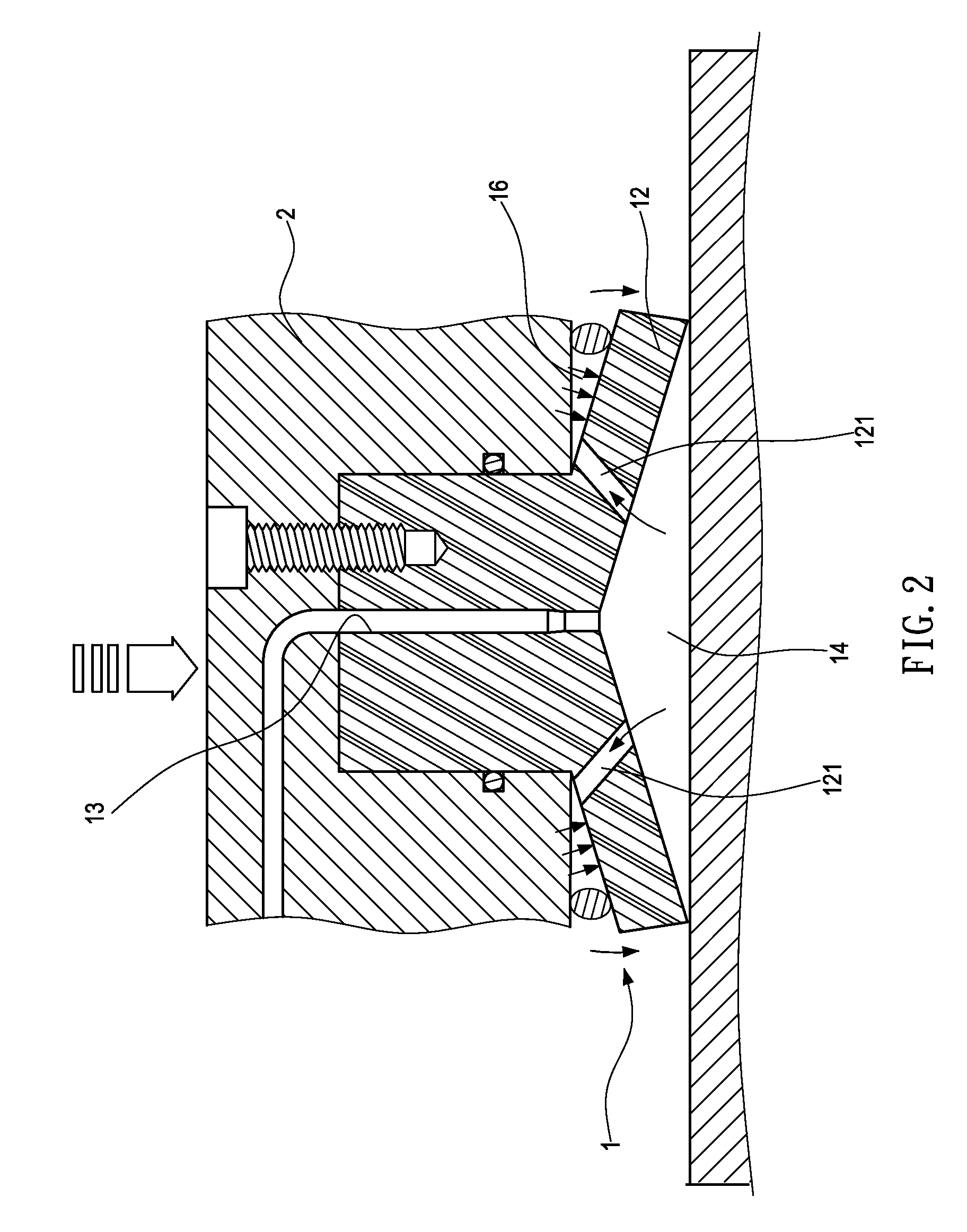

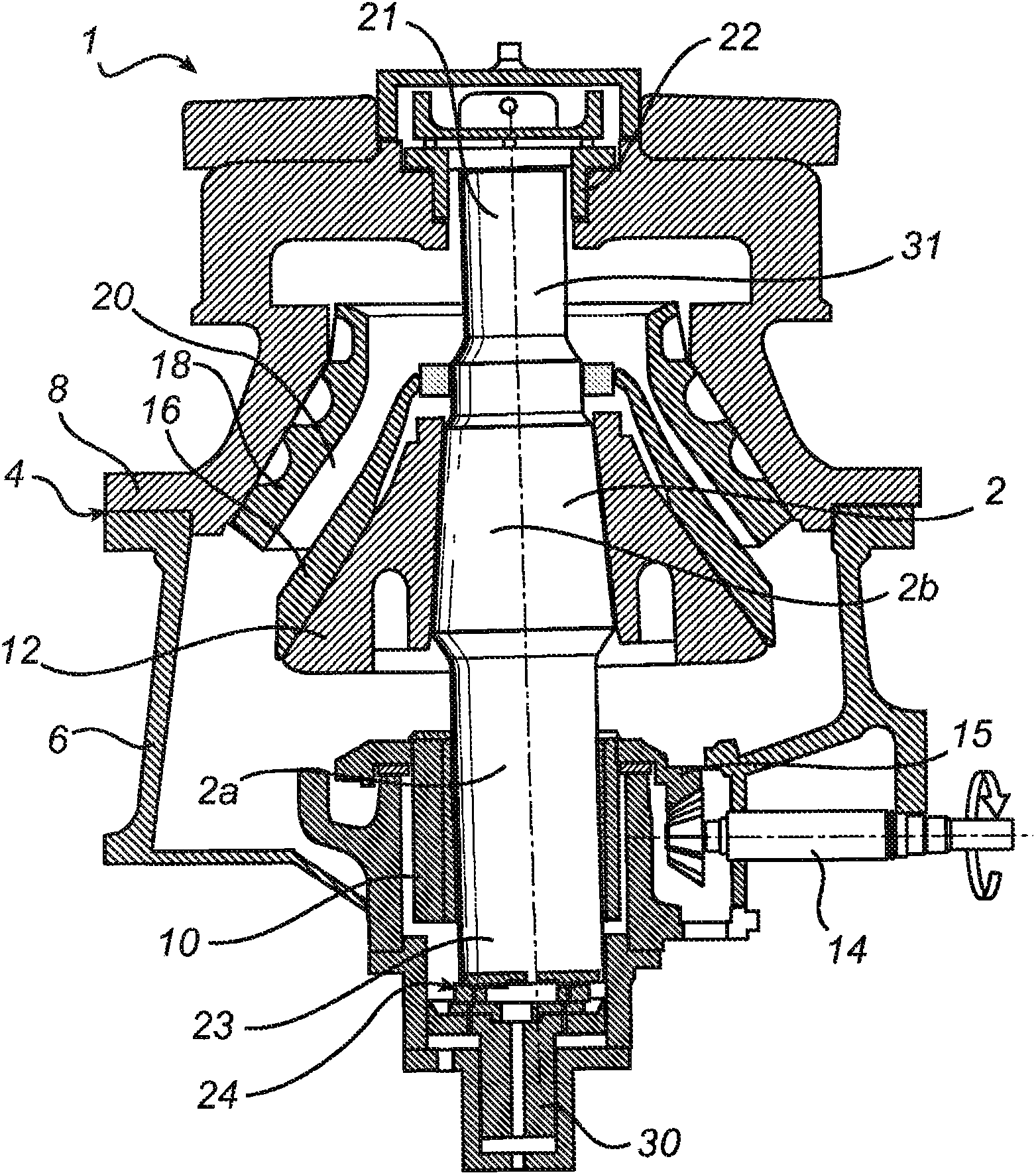

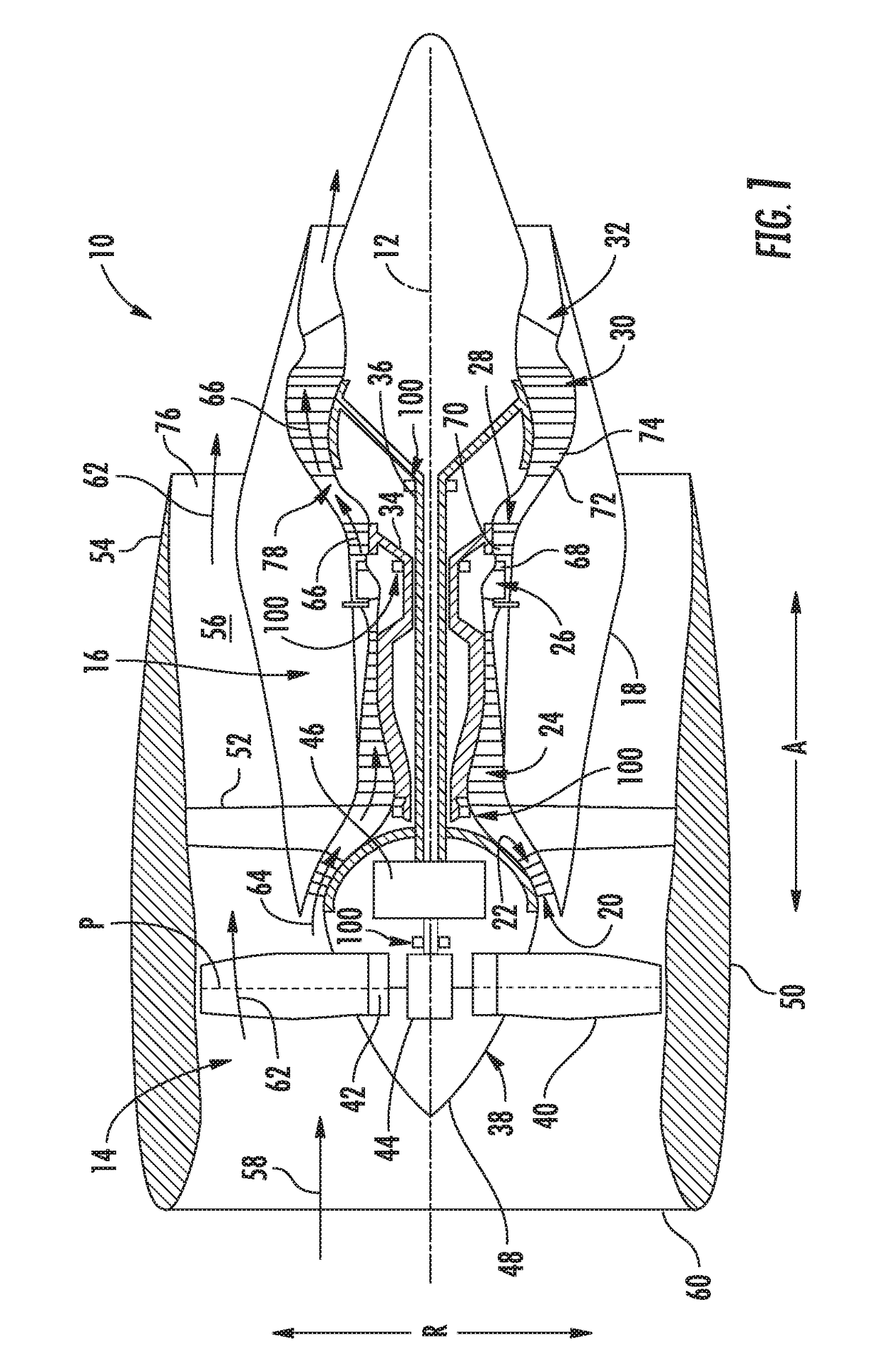

Thrust bearing for a gyratory crusher and method of supporting a vertical shaft in such a crusher

InactiveUS20100155512A1Reduce maintenance costsReduce mechanical wearSliding contact bearingsHydrostatic bearingsThrust bearingEngineering

A gyratory crusher includes a crushing head on which a first crushing shell is mounted, and a frame on which a second crushing shell is mounted. The crusher has a thrust bearing which is made up of horizontal bearing plates and which is located between a vertical shaft and a piston arranged vertically below the vertical shaft. The crusher further has a first space, which is adapted to receive a variable amount of pressurized liquid, the first space being defined by the piston and a piston housing formed in the frame, and a second space which is adapted to receive, by way of a duct, pressurized liquid from the first space, the second space being located between the vertical shaft and the piston and at least partly accommodated in an opening in at least one of the bearing plates. The first space and the second space are adapted, by the liquid, to transmit forces from the crushing head to the piston housing, in order that the load on the thrust bearing is relieved.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

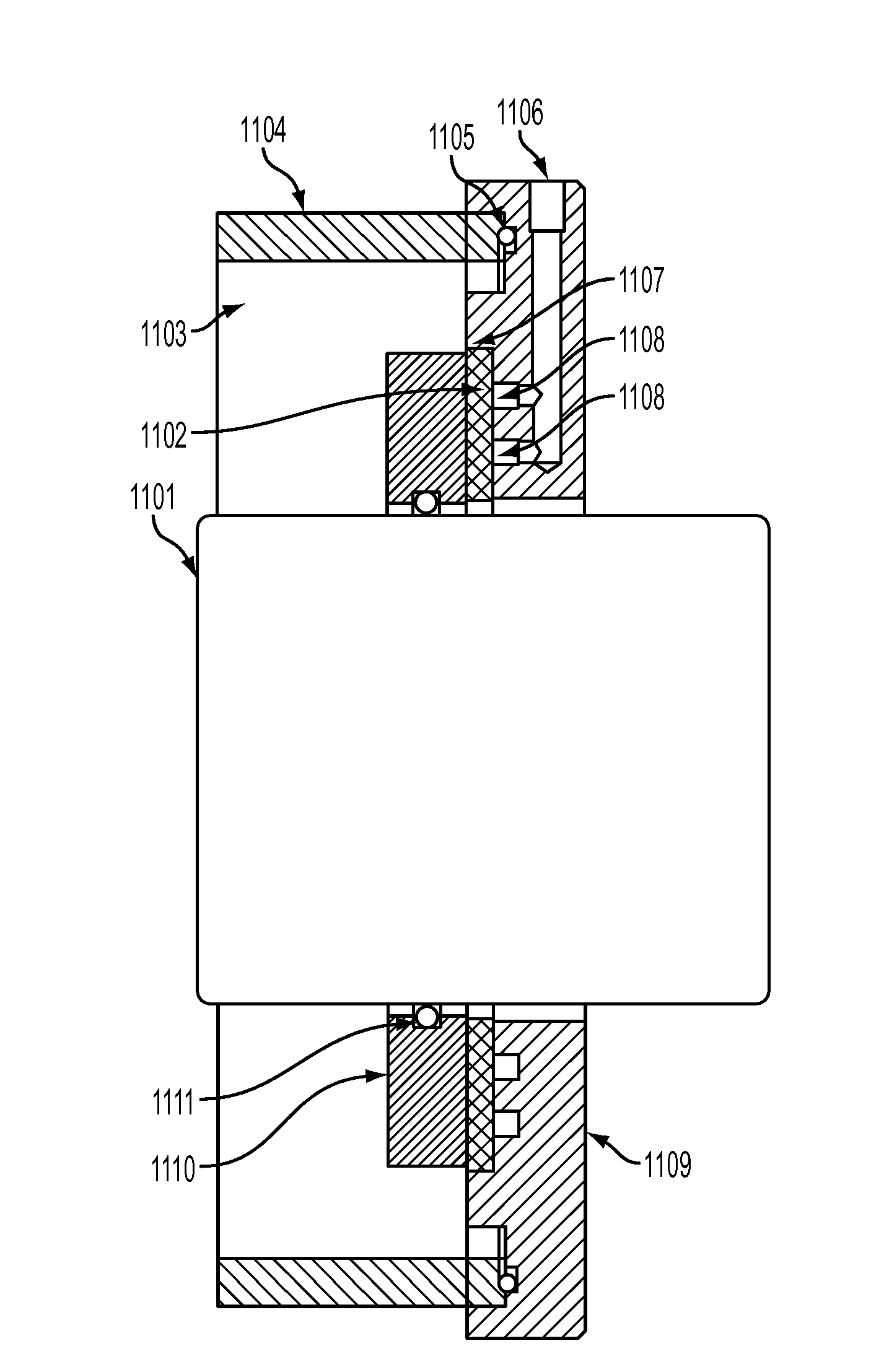

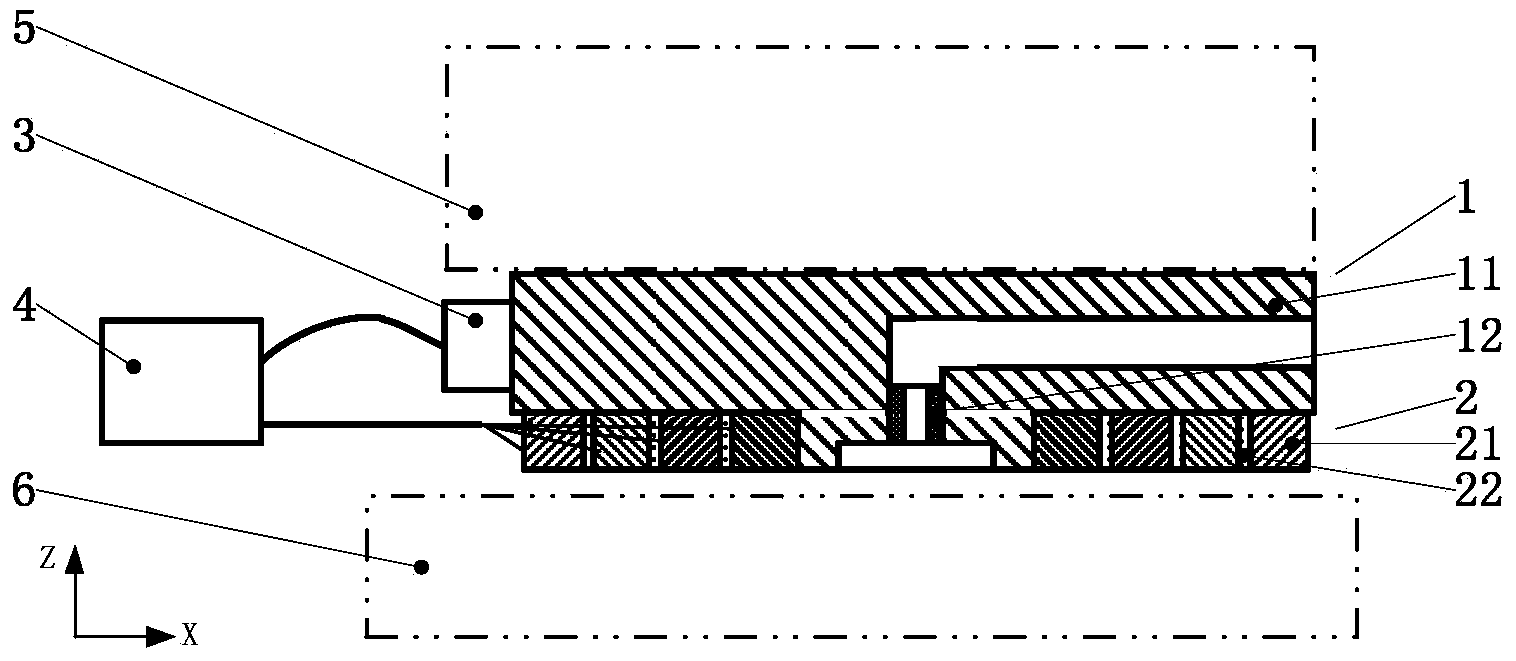

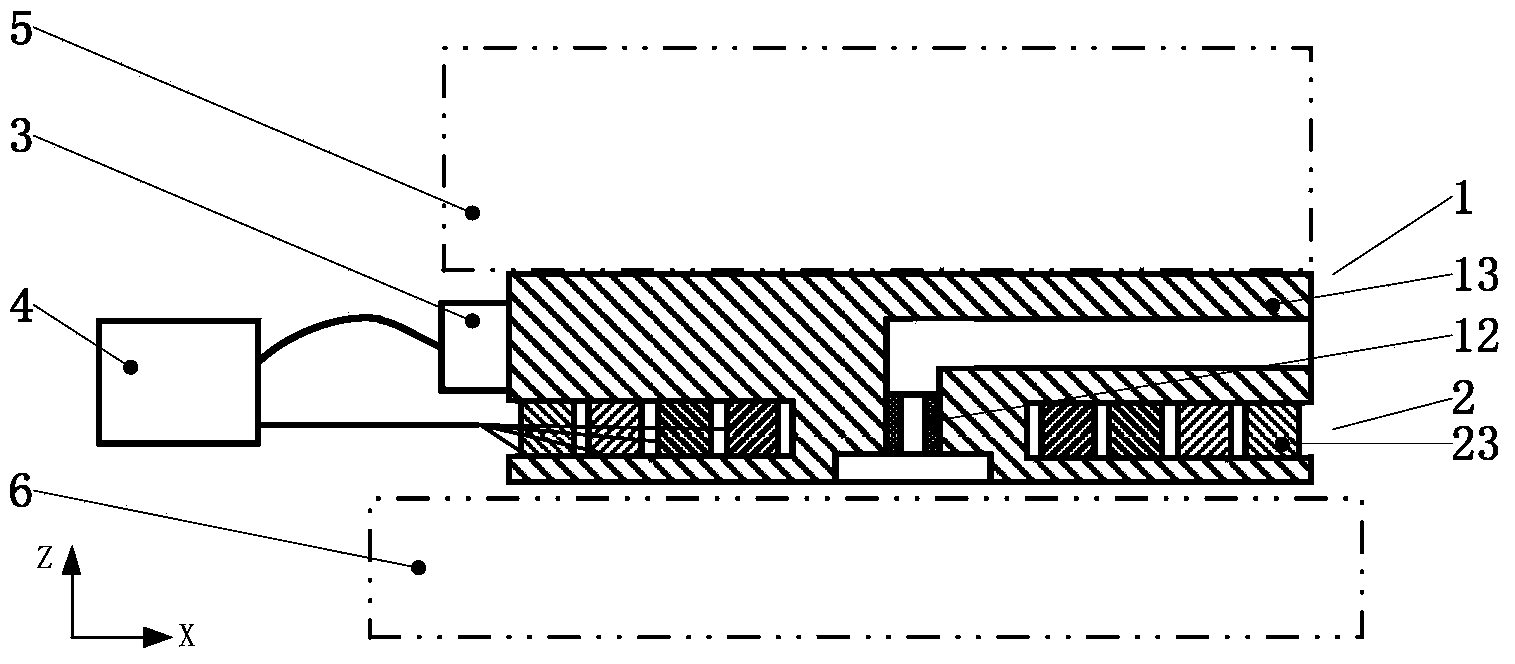

Active air-floatation support device

ActiveCN103836070AImprove dynamic stiffnessImprove dynamic stiffness characteristicsLinear bearingsGas cushion bearingsDynamic stiffnessControl signal

The invention discloses an active air-floatation support device which comprises an air-floatation support body, an air-film active adjustment unit, a support body detecting unit and a drive control unit, wherein the support body detecting unit measures the state of air-floatation support, the drive control unit generates a control signal according to a detection signal to drive and control the air-film active adjustment unit to generate an active role so as to dynamically adjust the air film form of an air-floatation support surface, thereby dynamically adjusting the pressure distribution of air film gaps of the air-floatation support device, and improving the dynamic stiffness characteristic of air-floatation support. According to the active air-floatation support device, the dynamic stiffness characteristic of air-floatation support can be significantly increased, and the purpose of stabilizing air-floatation support is achieved. In addition, the active air-floatation support device also has the characteristics of compact structure, convenience in control and high precision, thus being especially suitable for occasions of ultra-precision machining or with high-speed spindles with a high requirement on support dynamic stiffness.

Owner:HUAZHONG UNIV OF SCI & TECH

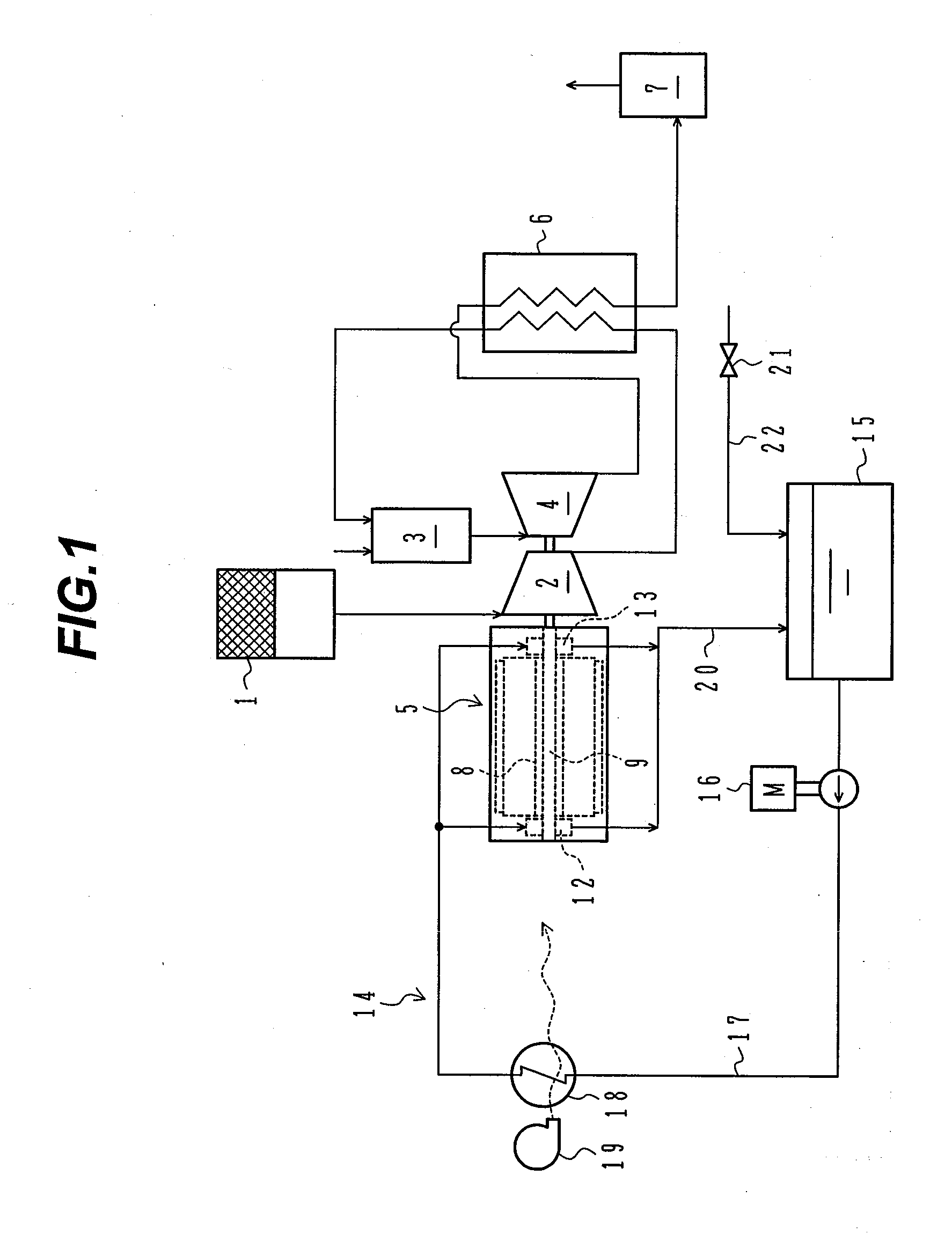

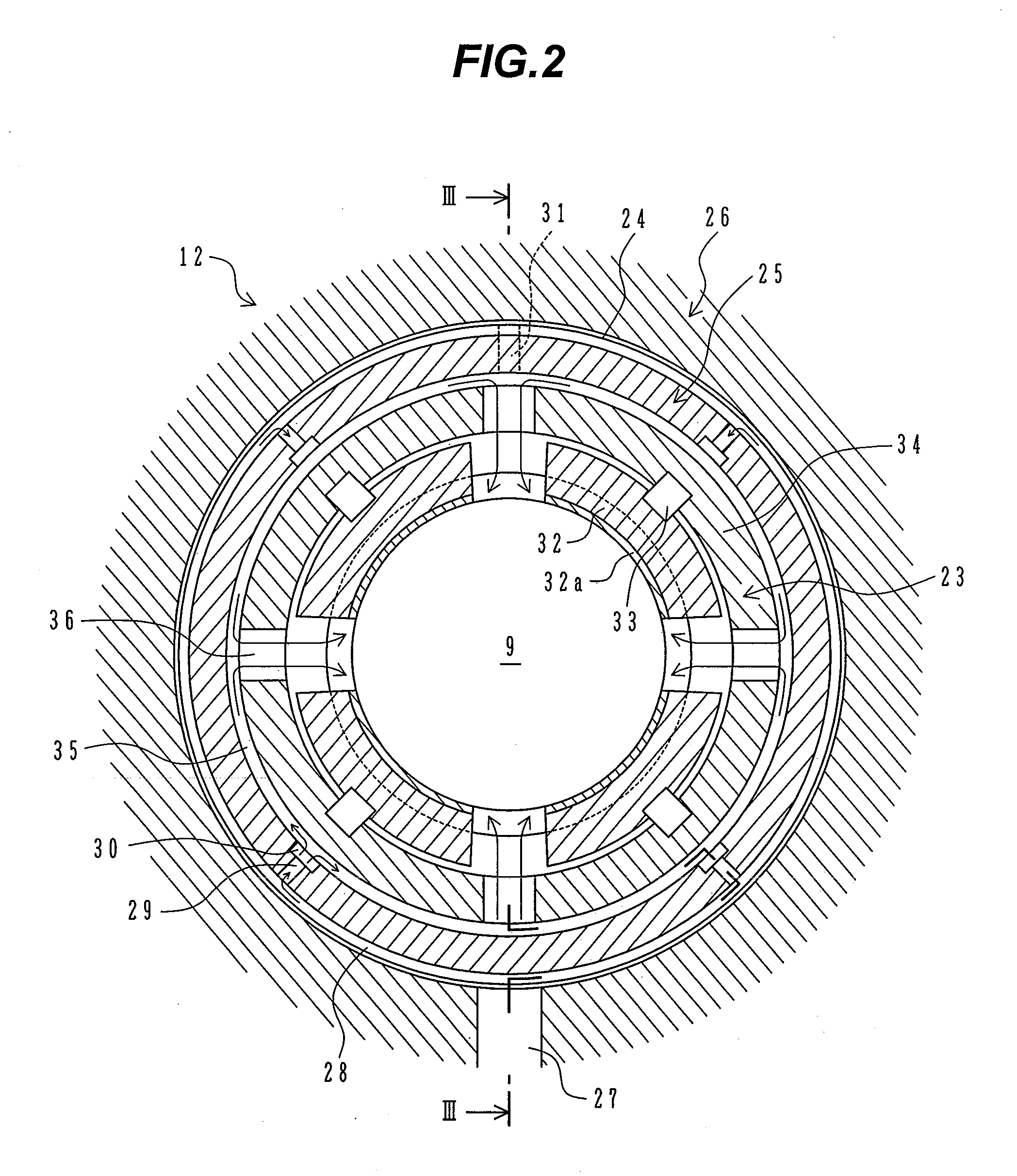

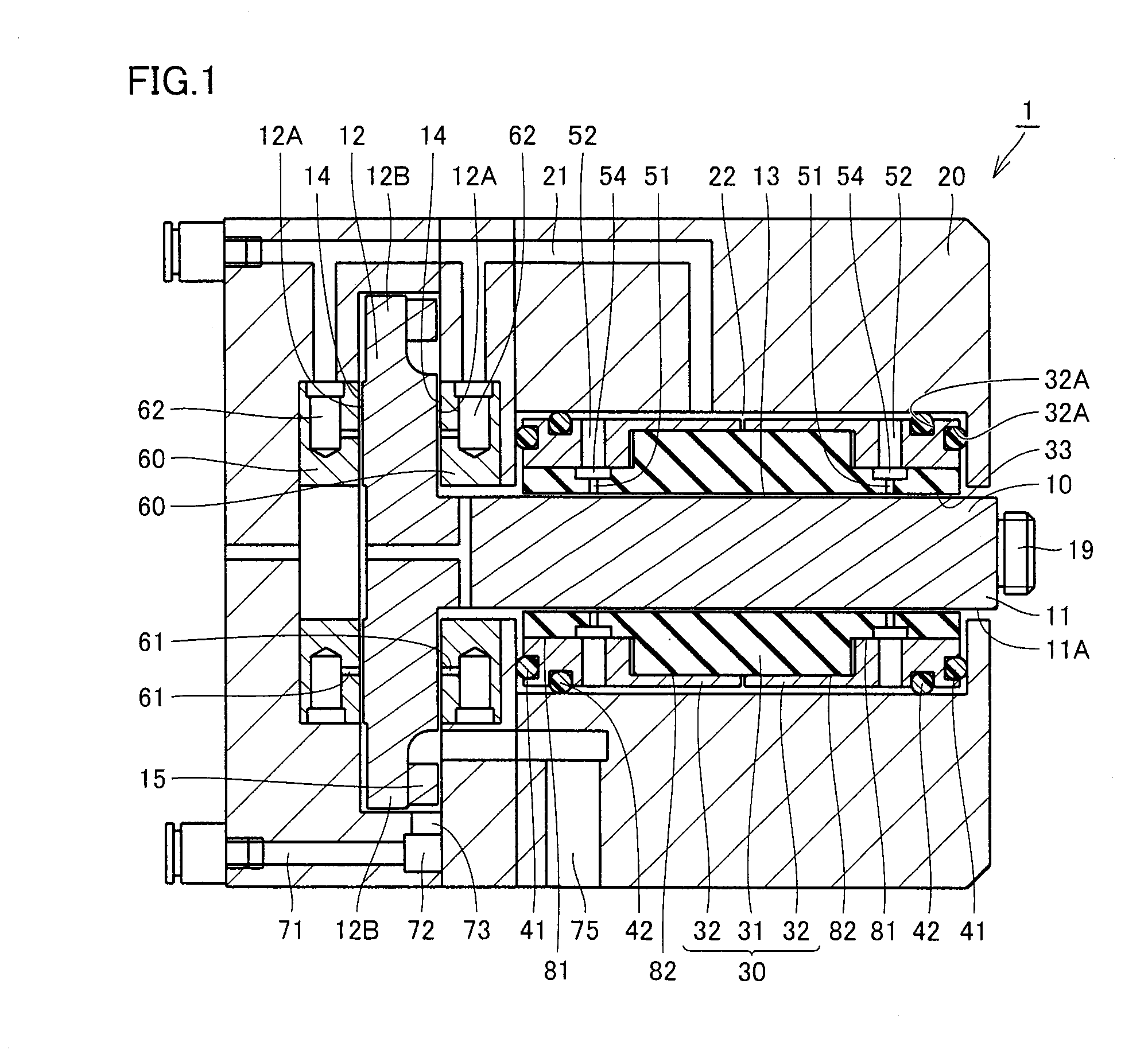

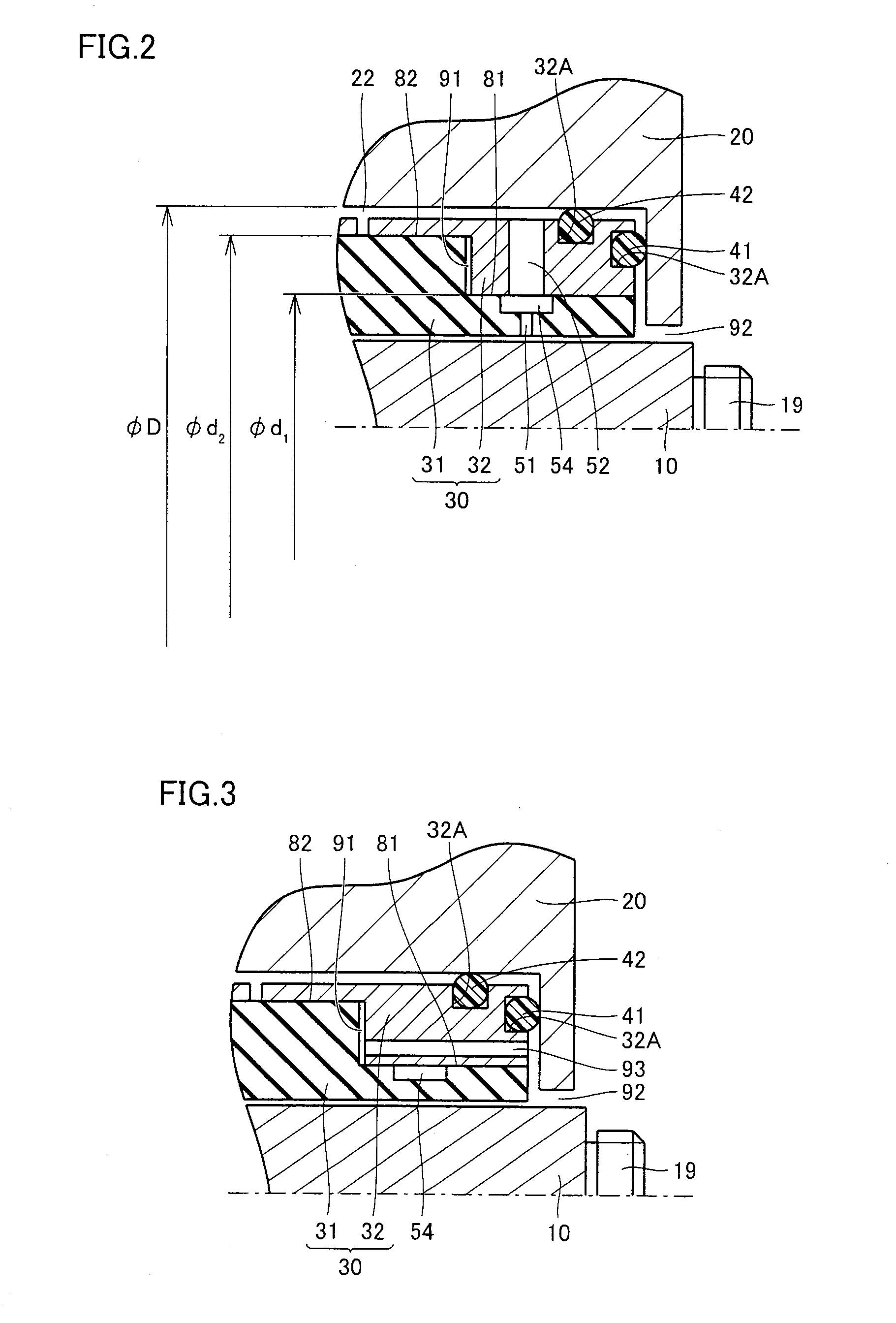

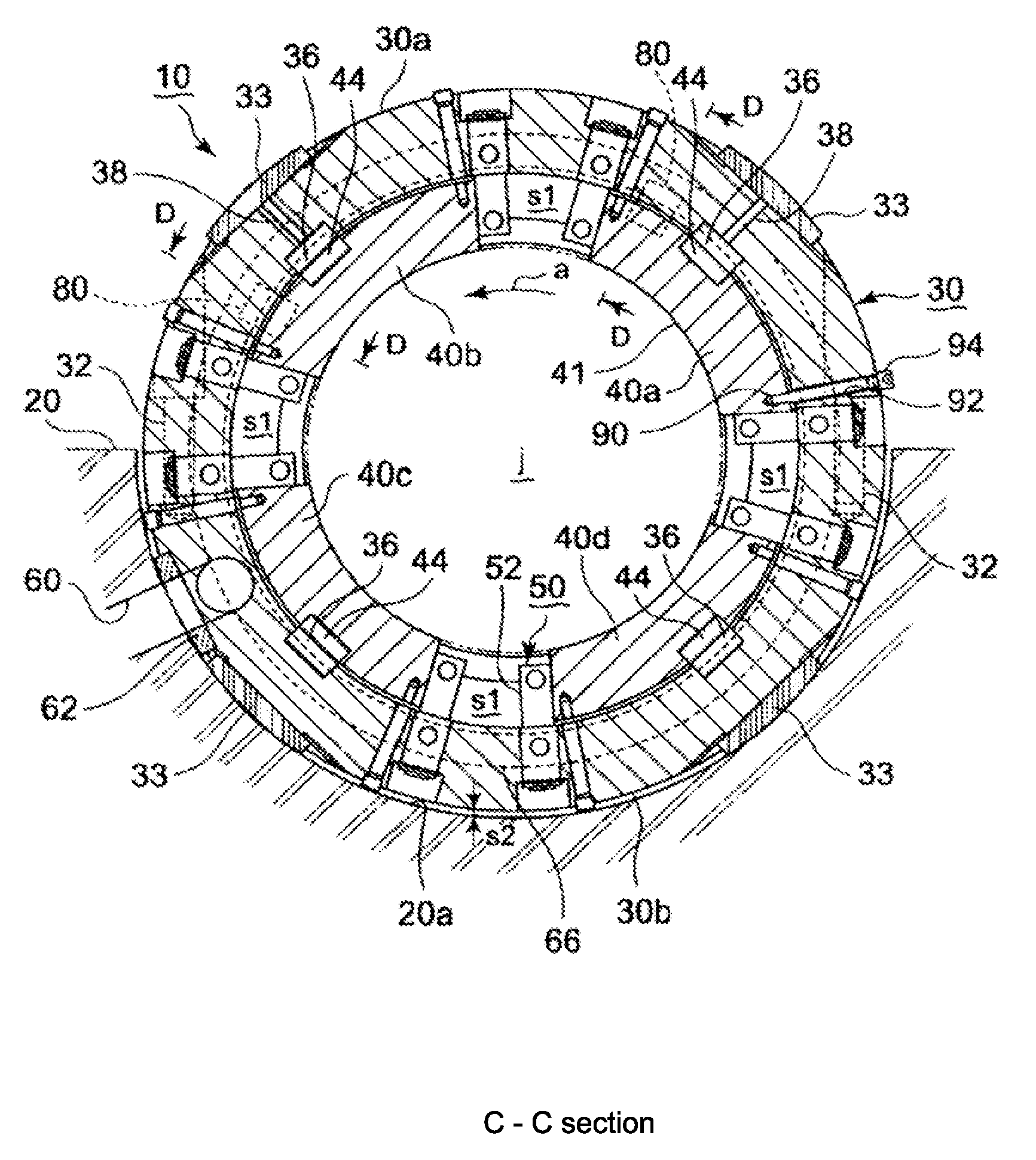

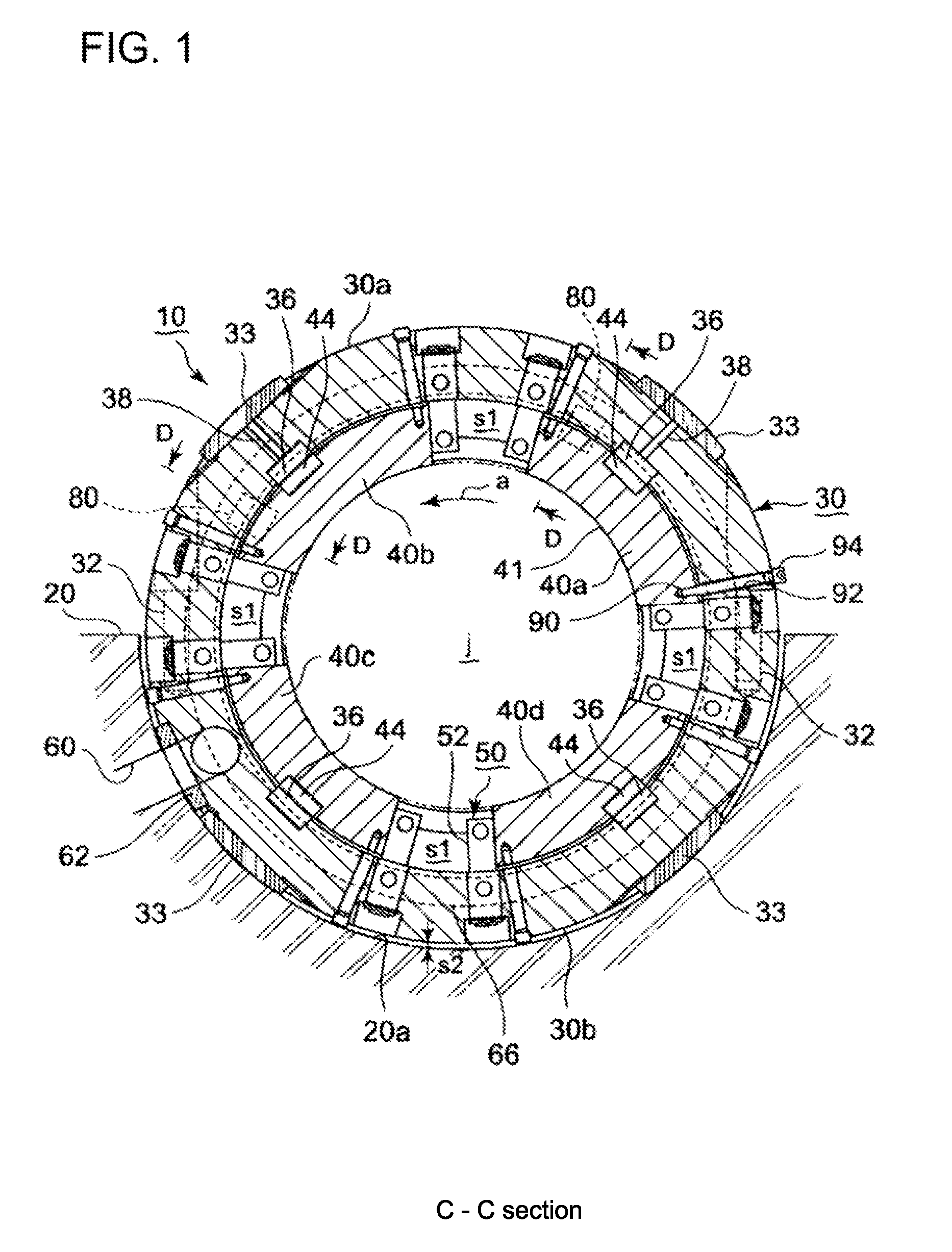

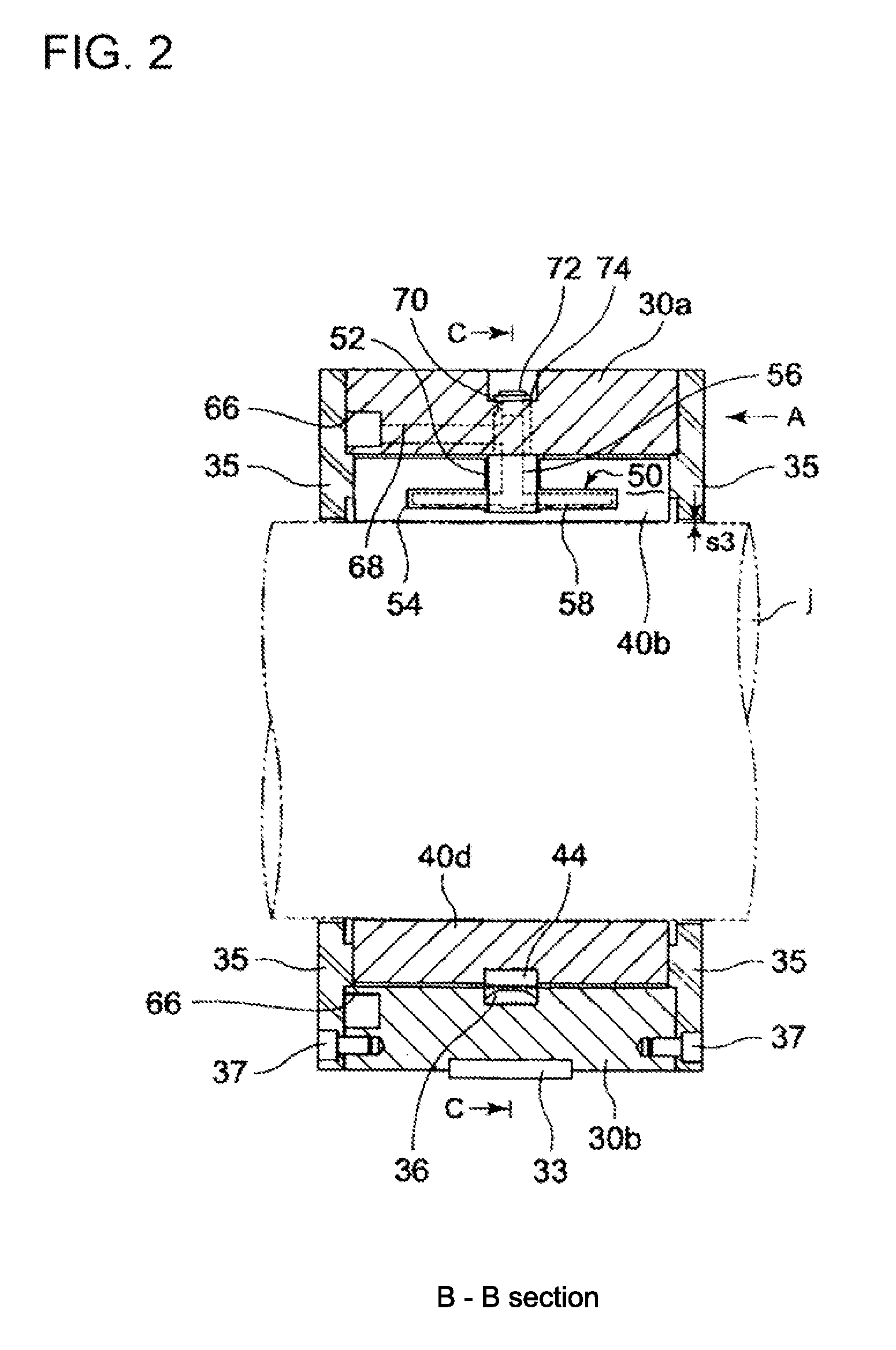

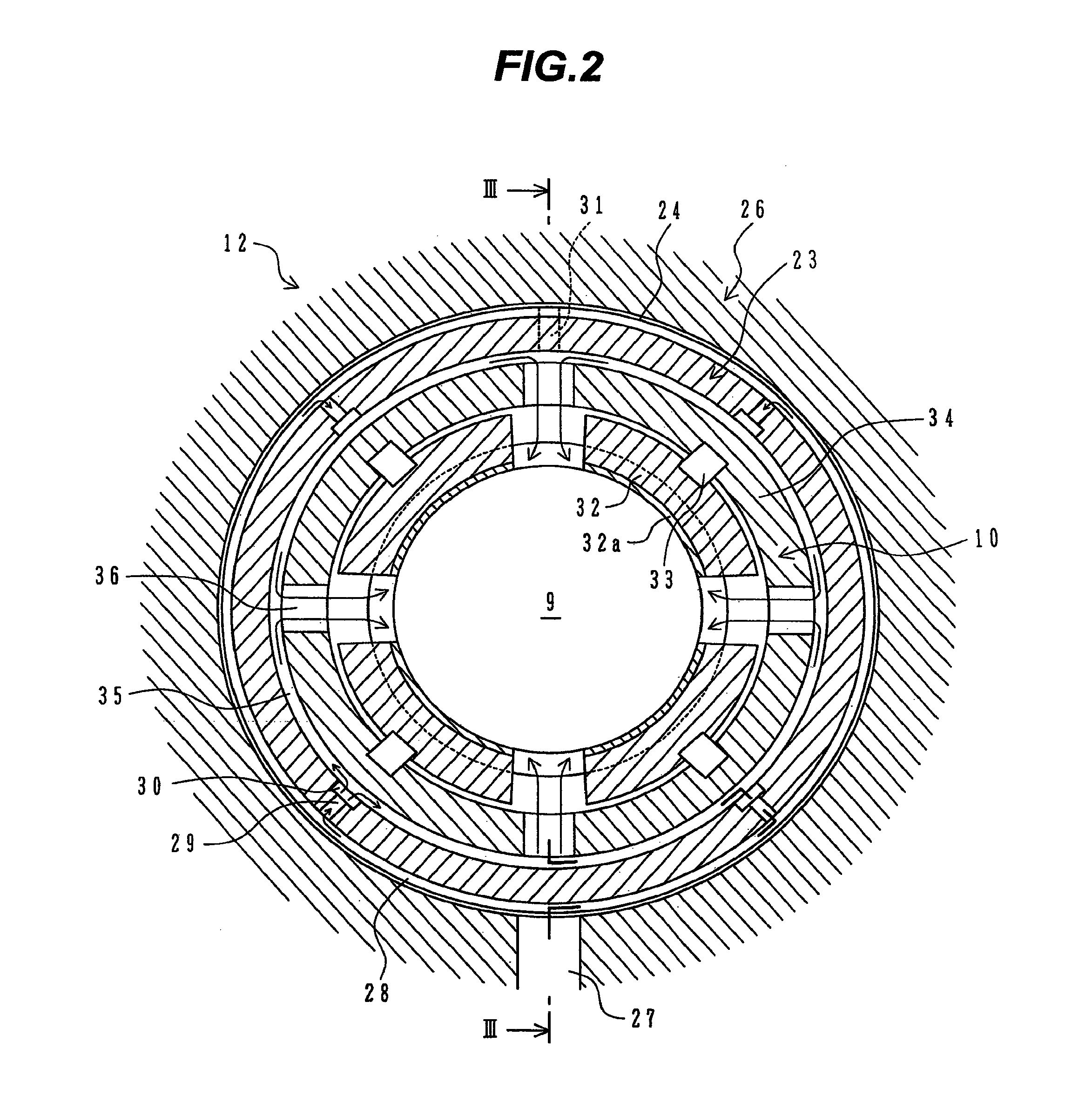

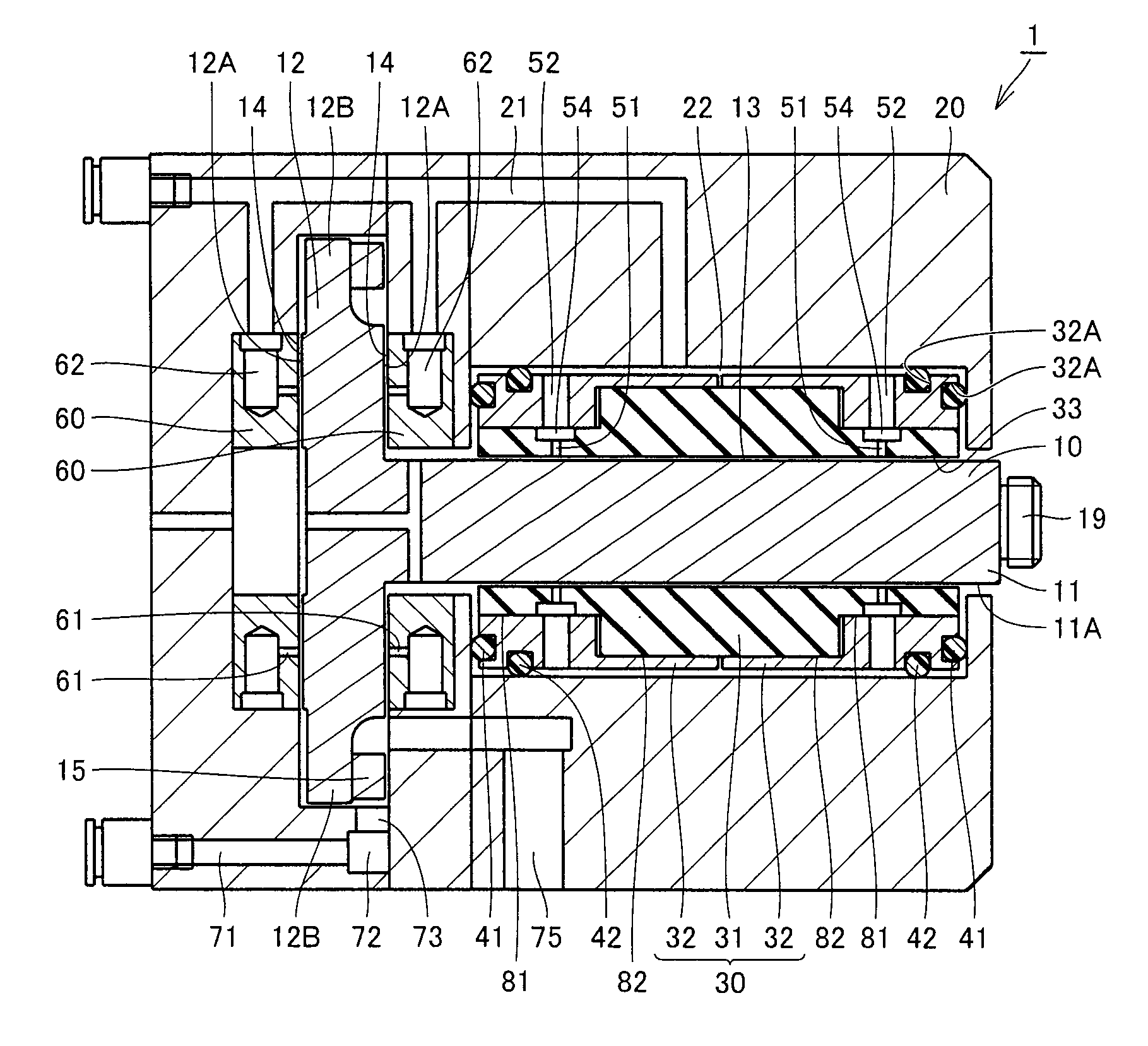

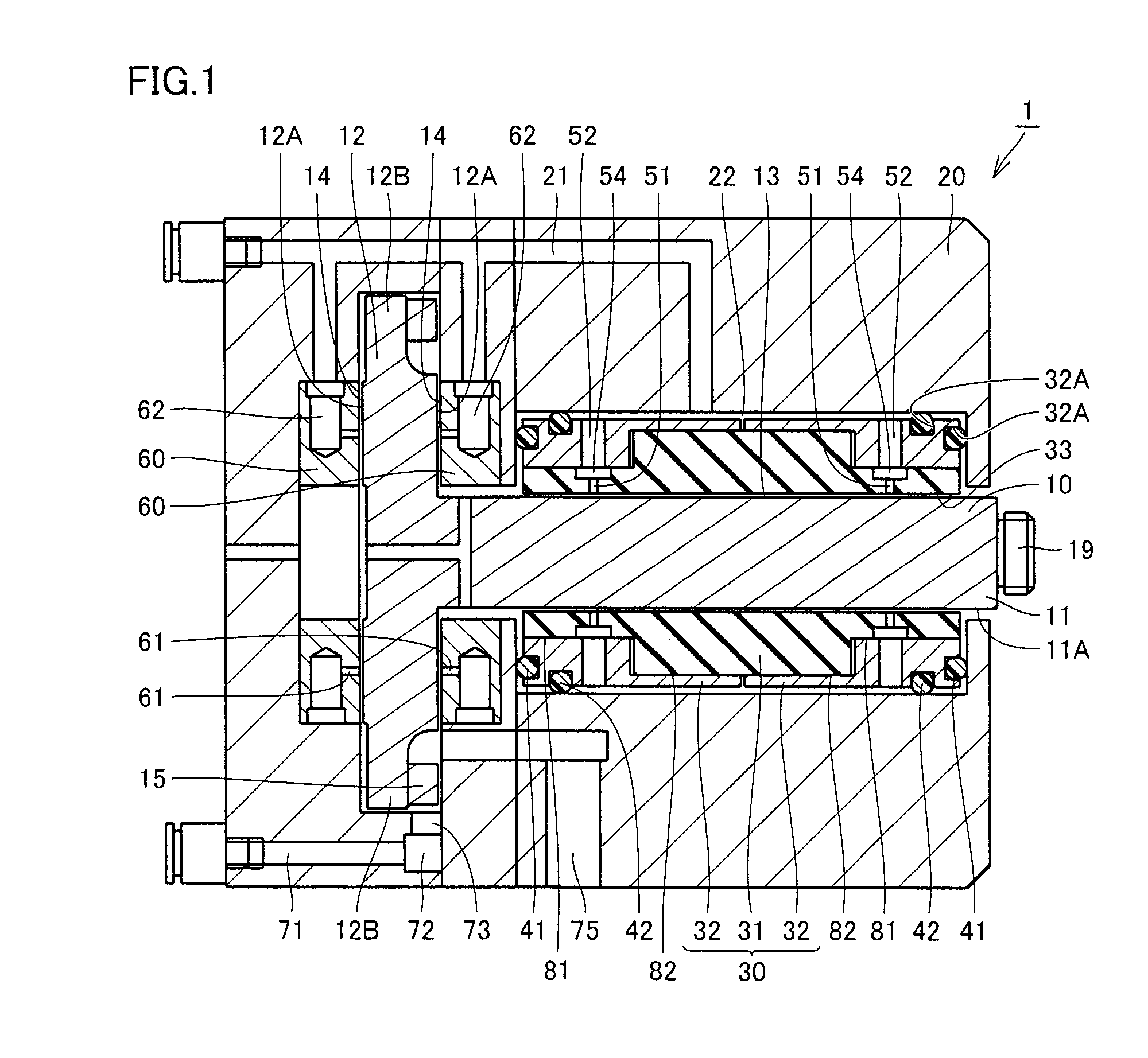

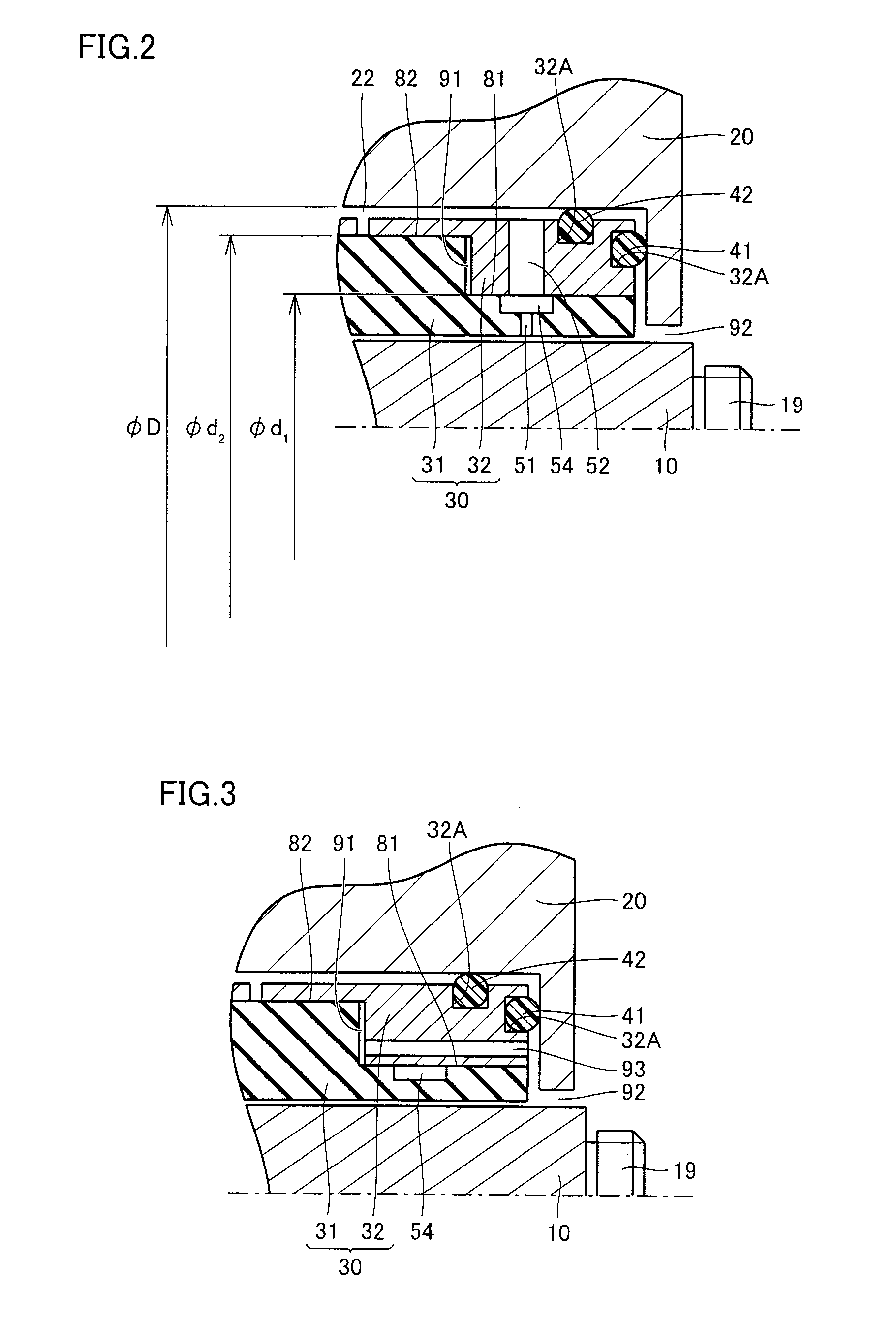

Bearing device of gas turbine power generation equipment and gas turbine power generation equipment

A bearing device of a gas turbine power generation equipment provides damping vibration of a shaft and lubricates and cools the bearing main body.The bearing devices have sleeves provided on the outer circumference sides of the bearing main bodies and bearing housings holding the respective sleeves via O-rings while each forming an annular clearance passage between each of the outer circumferences of the sleeves and a corresponding one of the bearing housings. The bearing housing has a feed-water hole communicating with the clearance passage and adapted to feed water thereto. The sleeve has a lead water hole communicating with the clearance passage and is adapted to lead water to the bearing main body, and a discharge hole which communicates with the clearance passage and is adapted to discharge water therefrom.

Owner:HITACHI LTD

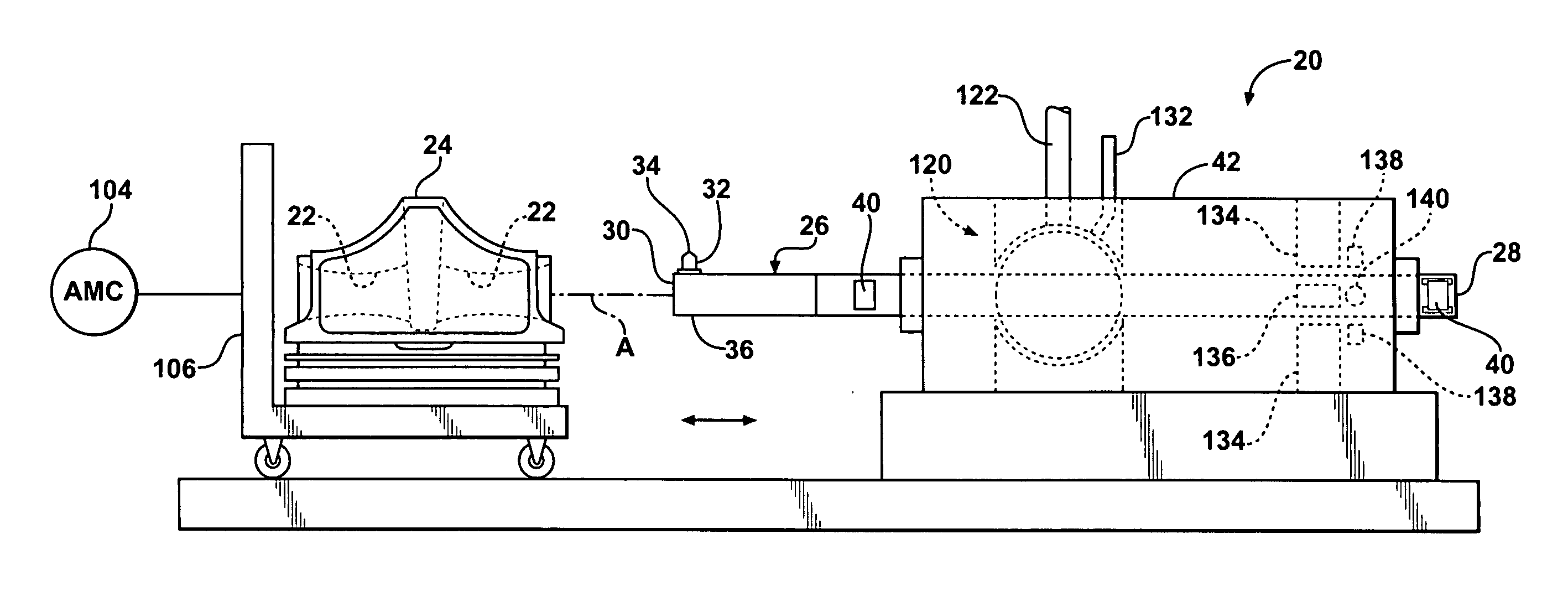

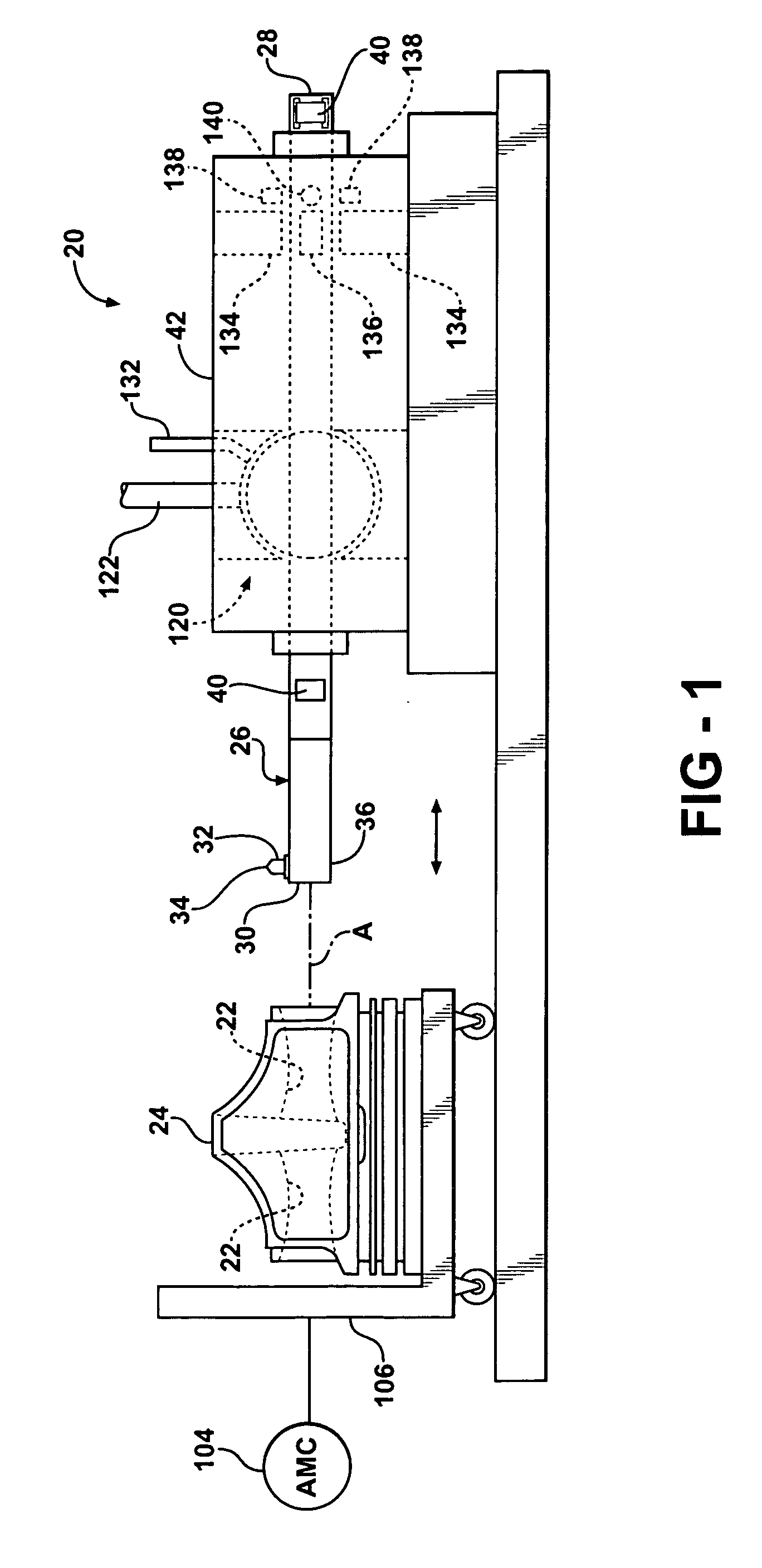

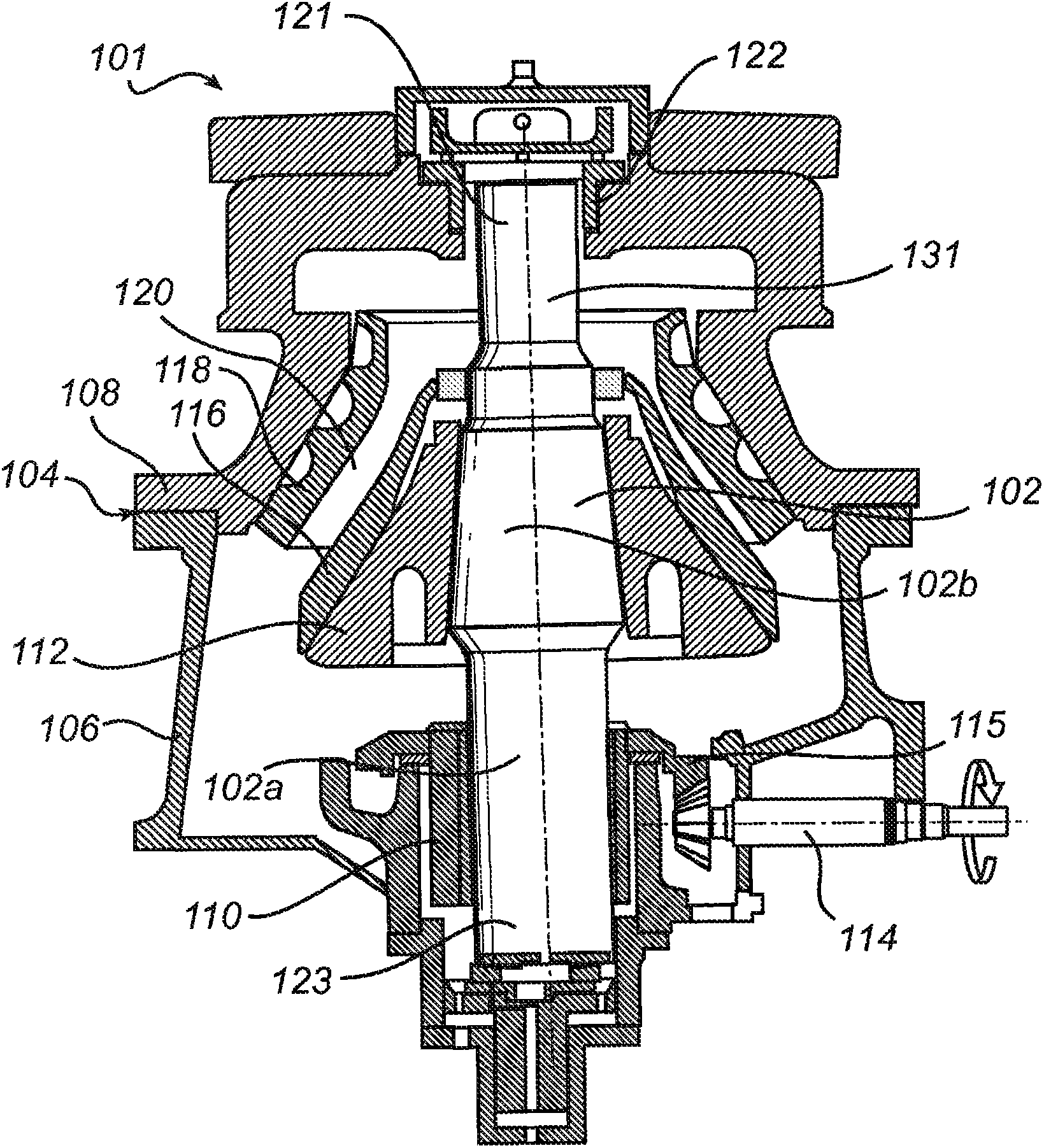

Hybrid orbiting spindle for shaping non-circular holes

InactiveUS20060219066A1Improve performanceCost advantageLathesTurning machine accessoriesAir bearingControl manner

A machine tool assembly includes a high speed rotating spindle for forming extremely precise surface contours on a work piece. The spindle is supported on a spherical air bearing about its center of gravity. The spindle can be rotated through an air turbine drive system incorporated into the spherical air bearing to eliminate any undesirable moments about an axis perpendicular to the long spindle axis. The spindle is adjustable in pitch and yaw directions through the influence of X-Y actuators. The X-Y actuation system is preferably electromagnetic and provides a non-contact method of displacing the spindle shaft in a controlled manner at any speed.

Owner:FEDERAL MOGUL WORLD WIDE LLC

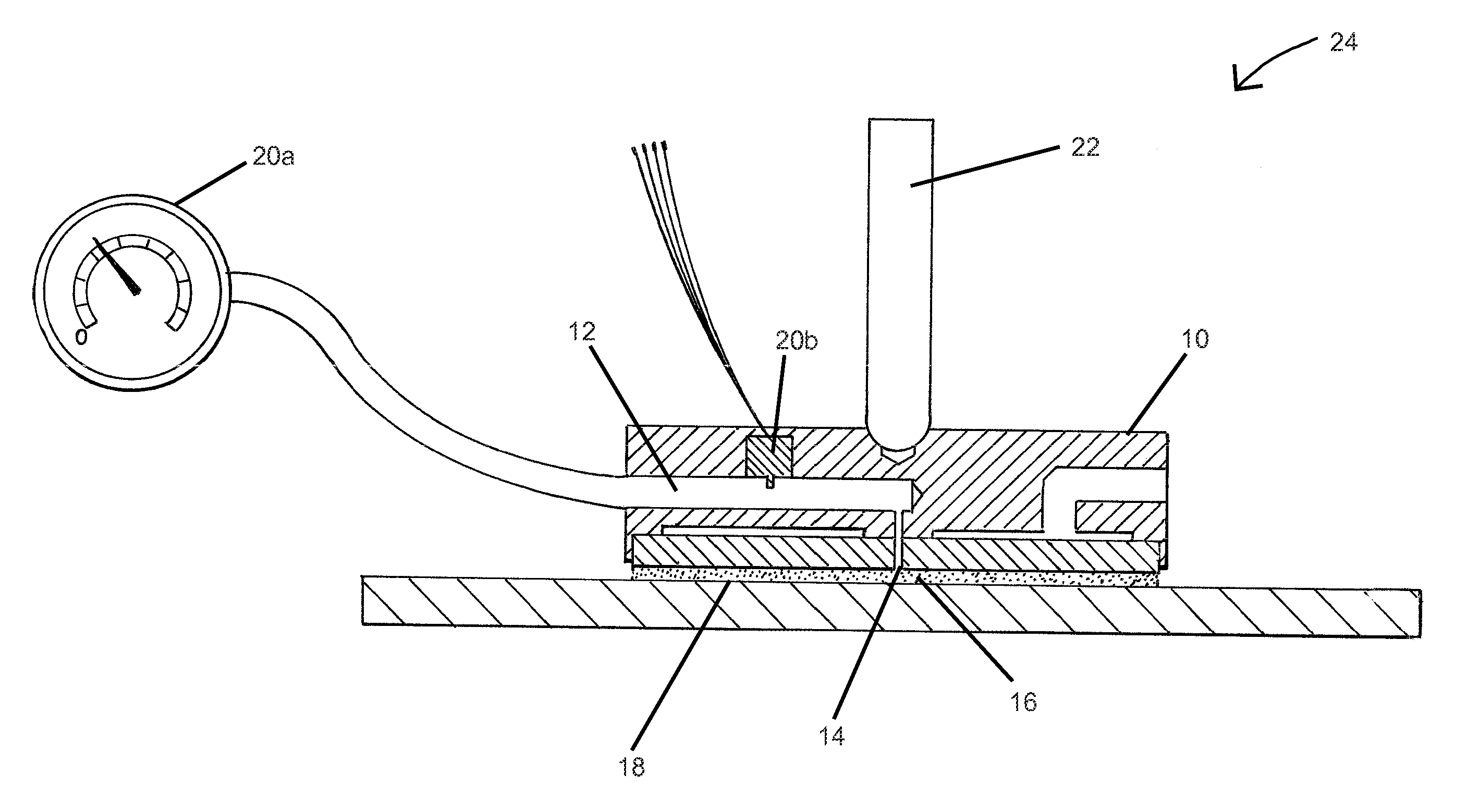

Air bearing for use as seal

ActiveUS20130188895A1Easy to adjustReduce wareEngine sealsGas cushion bearingsAir bearingEngineering

In order to effect a seal; a porous material which comprises one side of two opposing surfaces is used to restrict and evenly distribute externally pressurized gas, liquid, steam, etc. between the two surfaces, exerting a force which is opposite the forces from pressure differences or springs trying to close the two faces together and so may create a non contact seal that is more stable and reliable than hydrodynamic seals currently in use.

Owner:NEW WAY MACHINE COMPONENTS

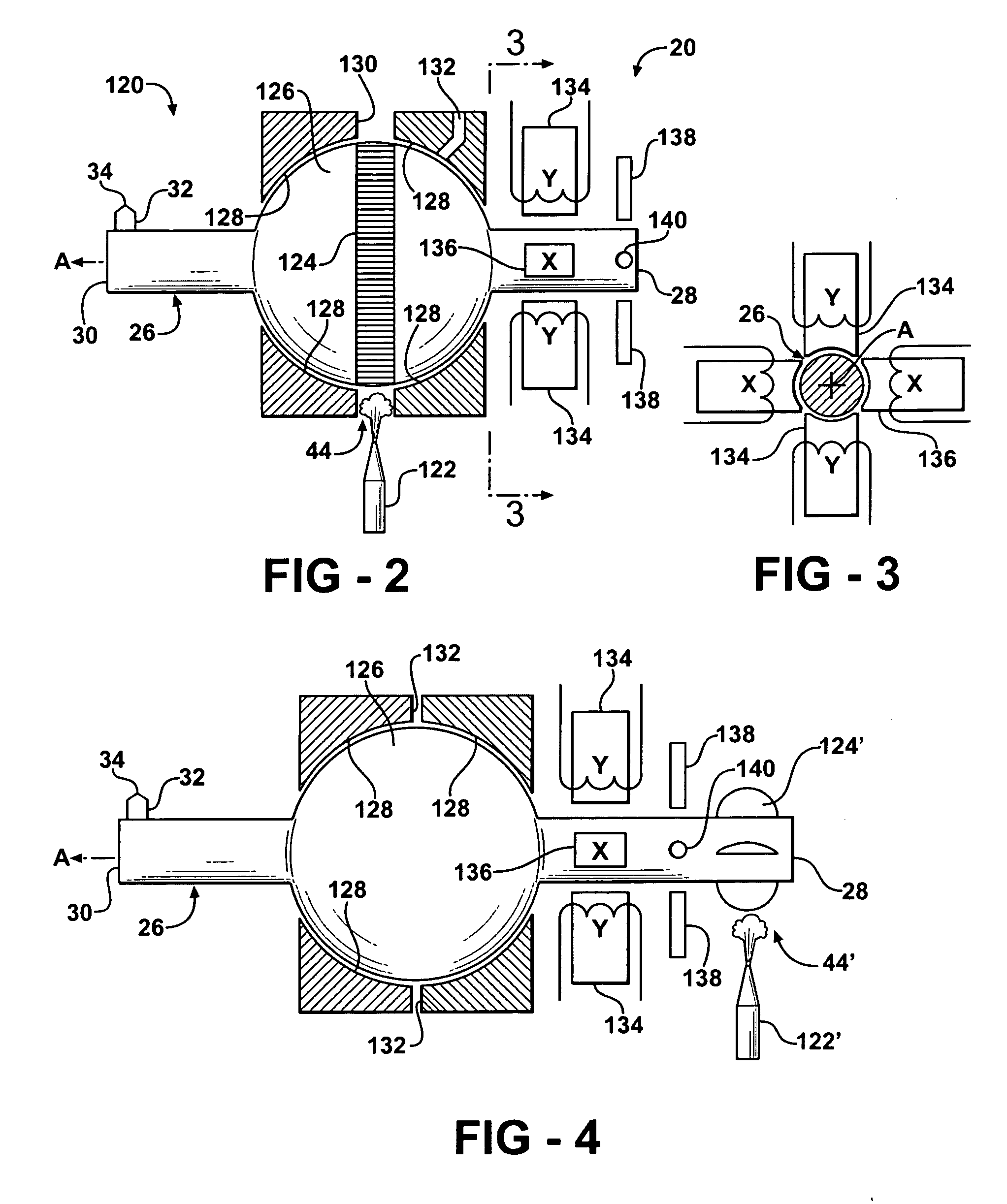

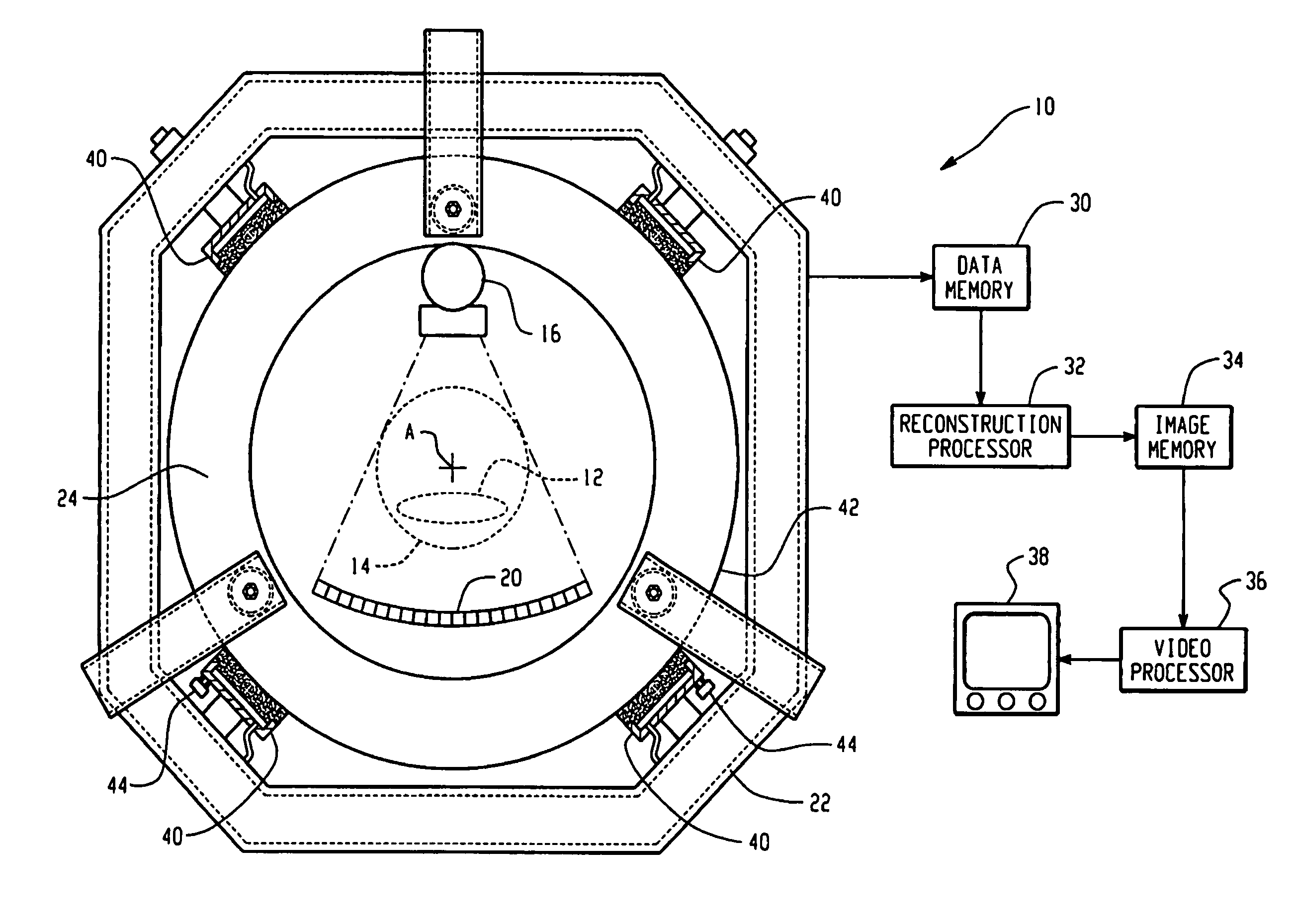

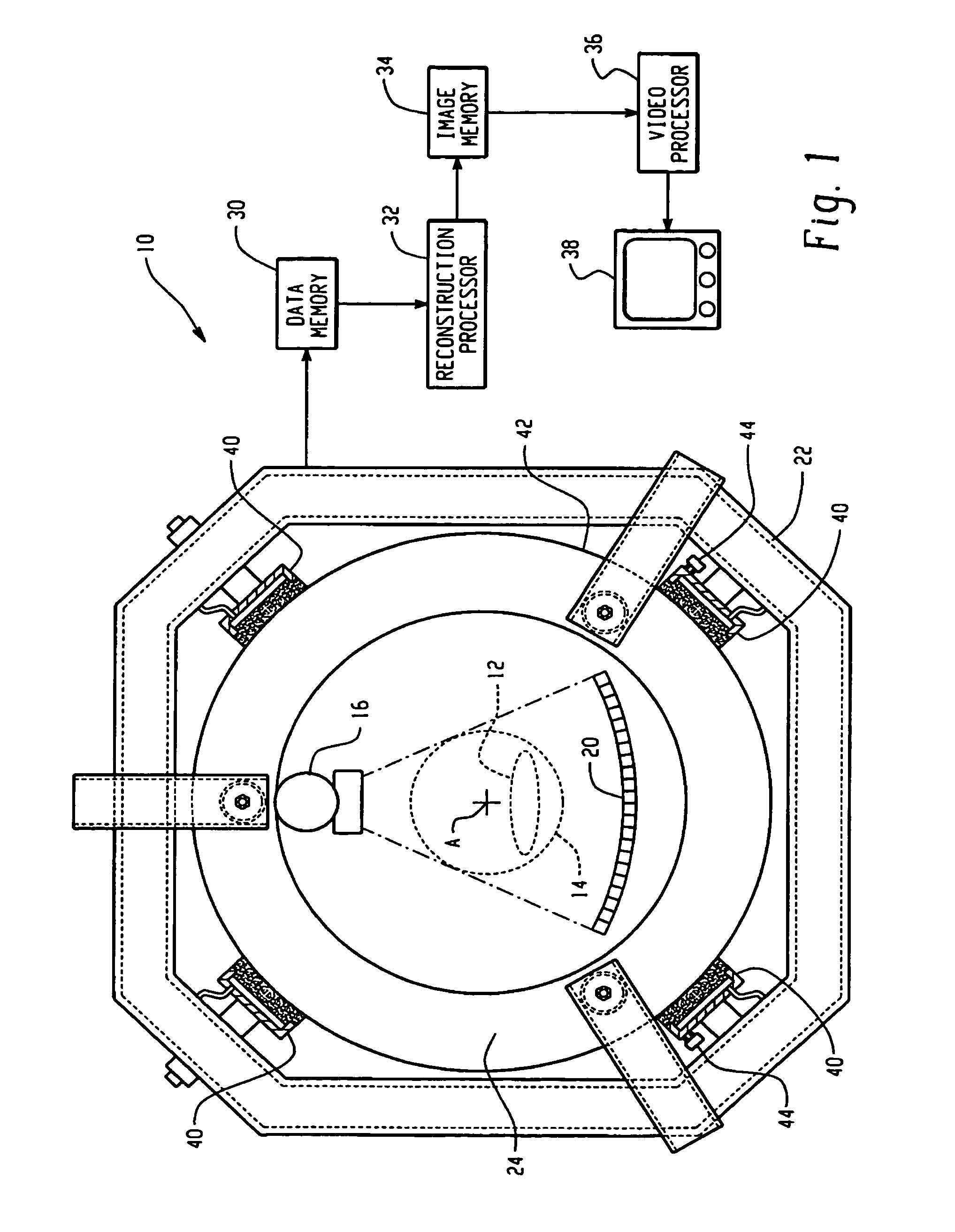

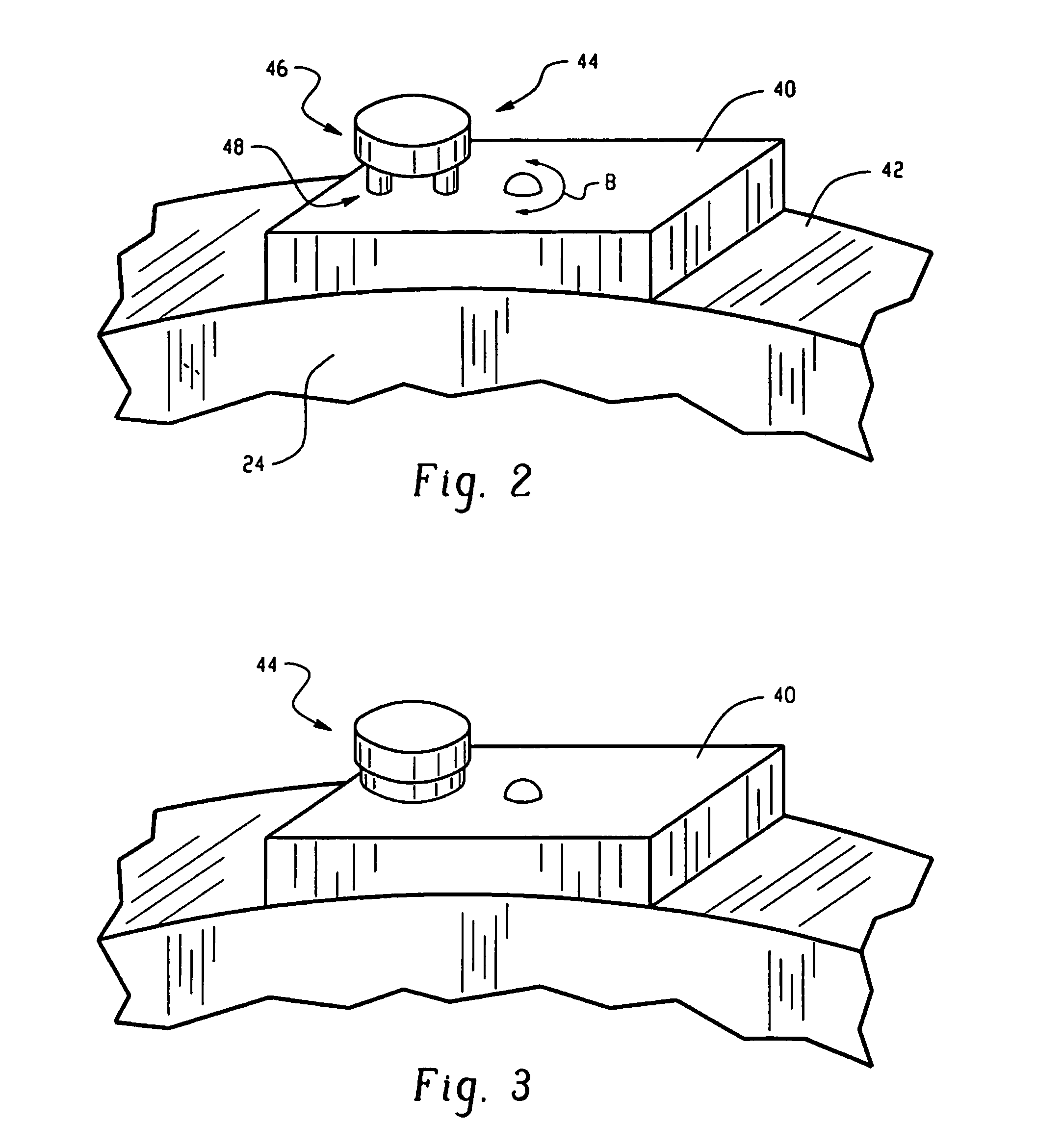

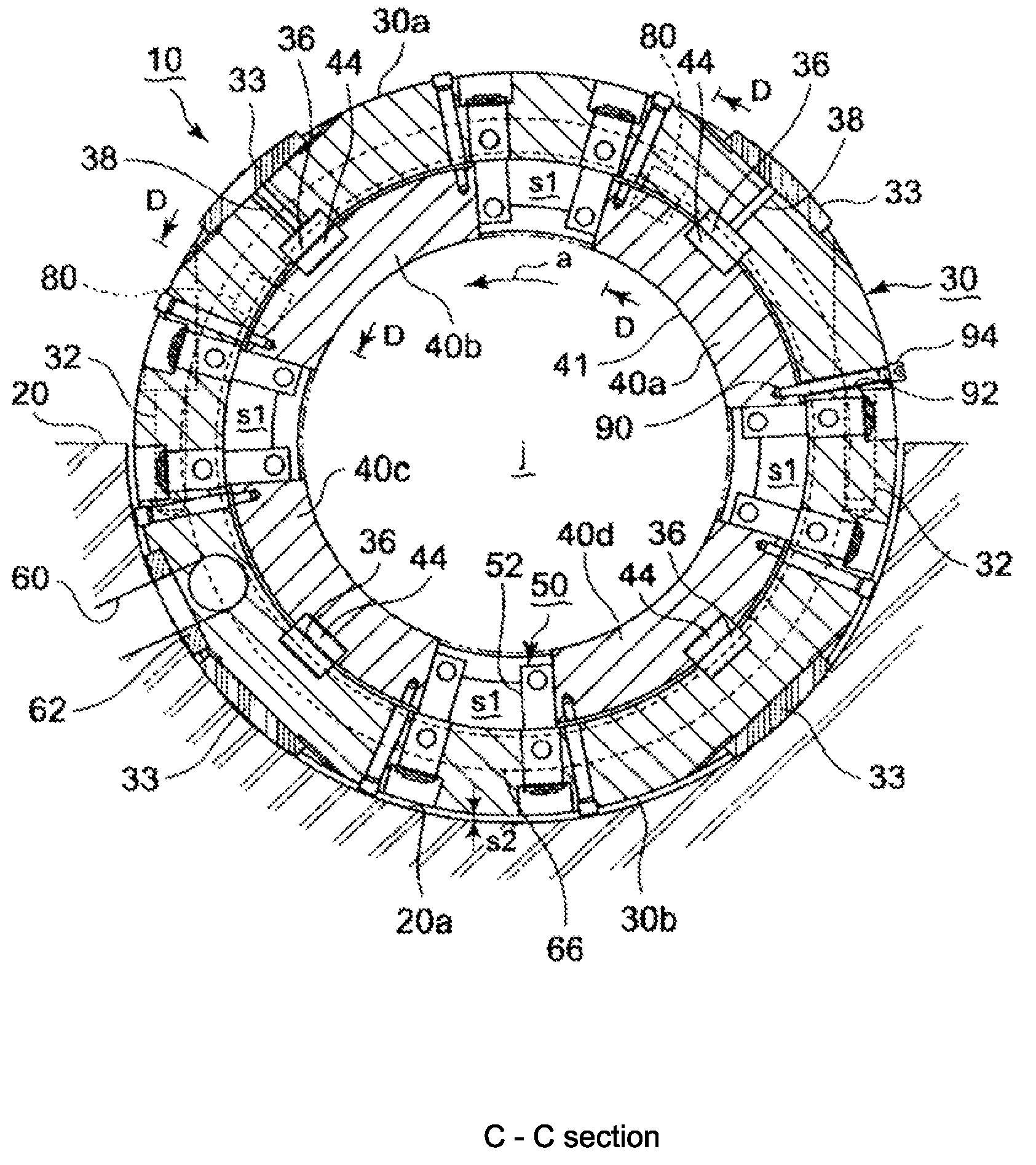

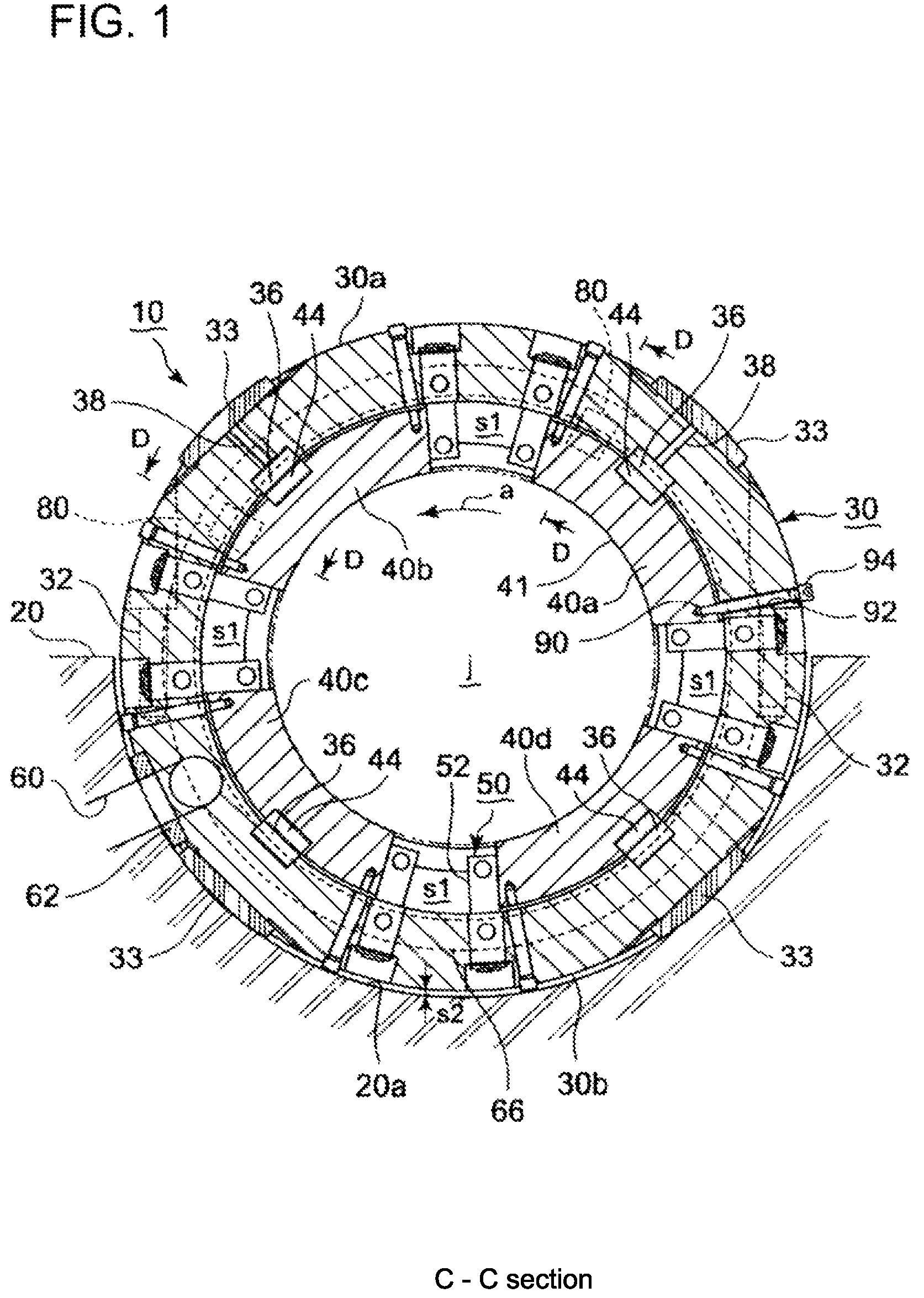

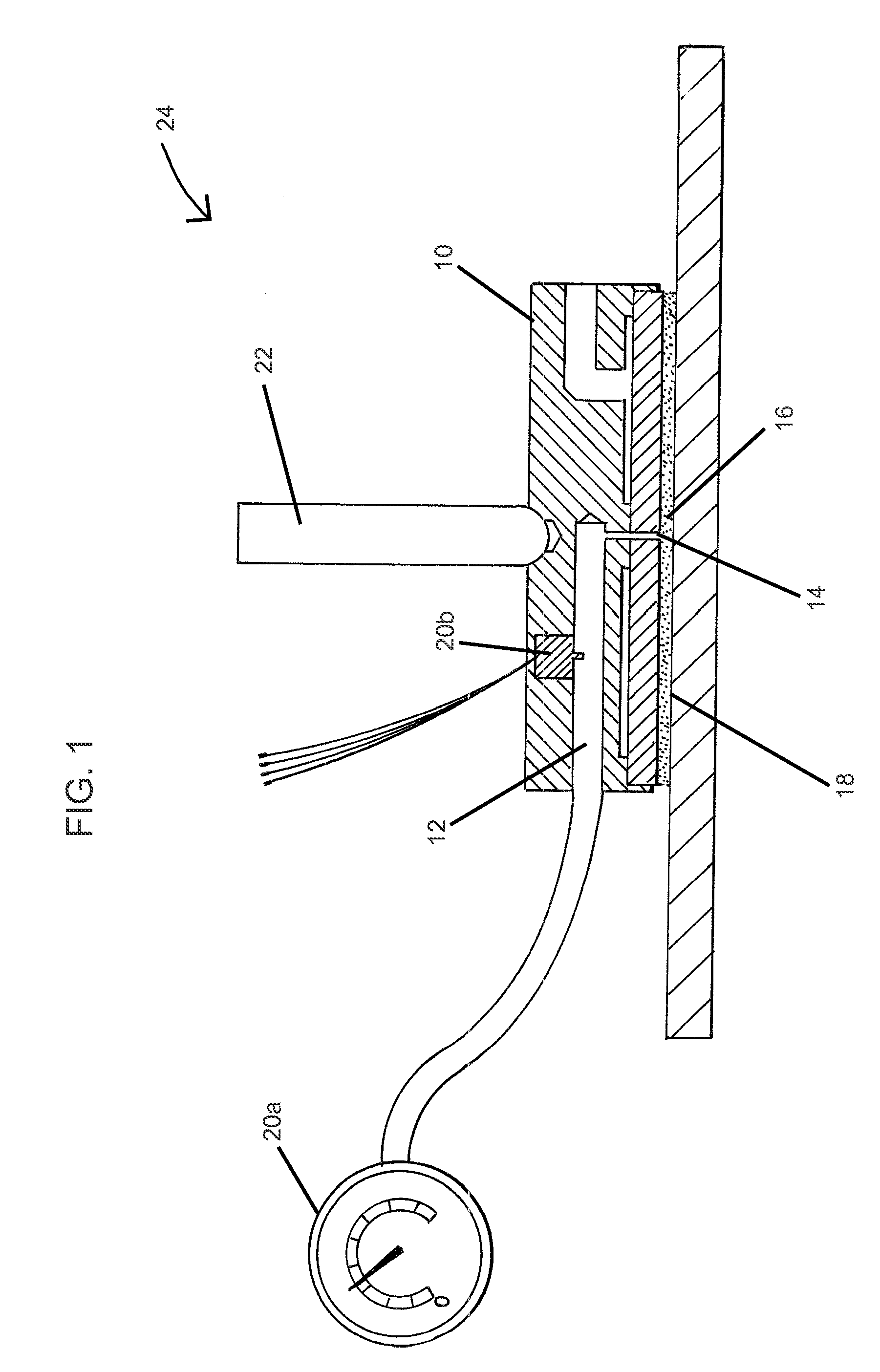

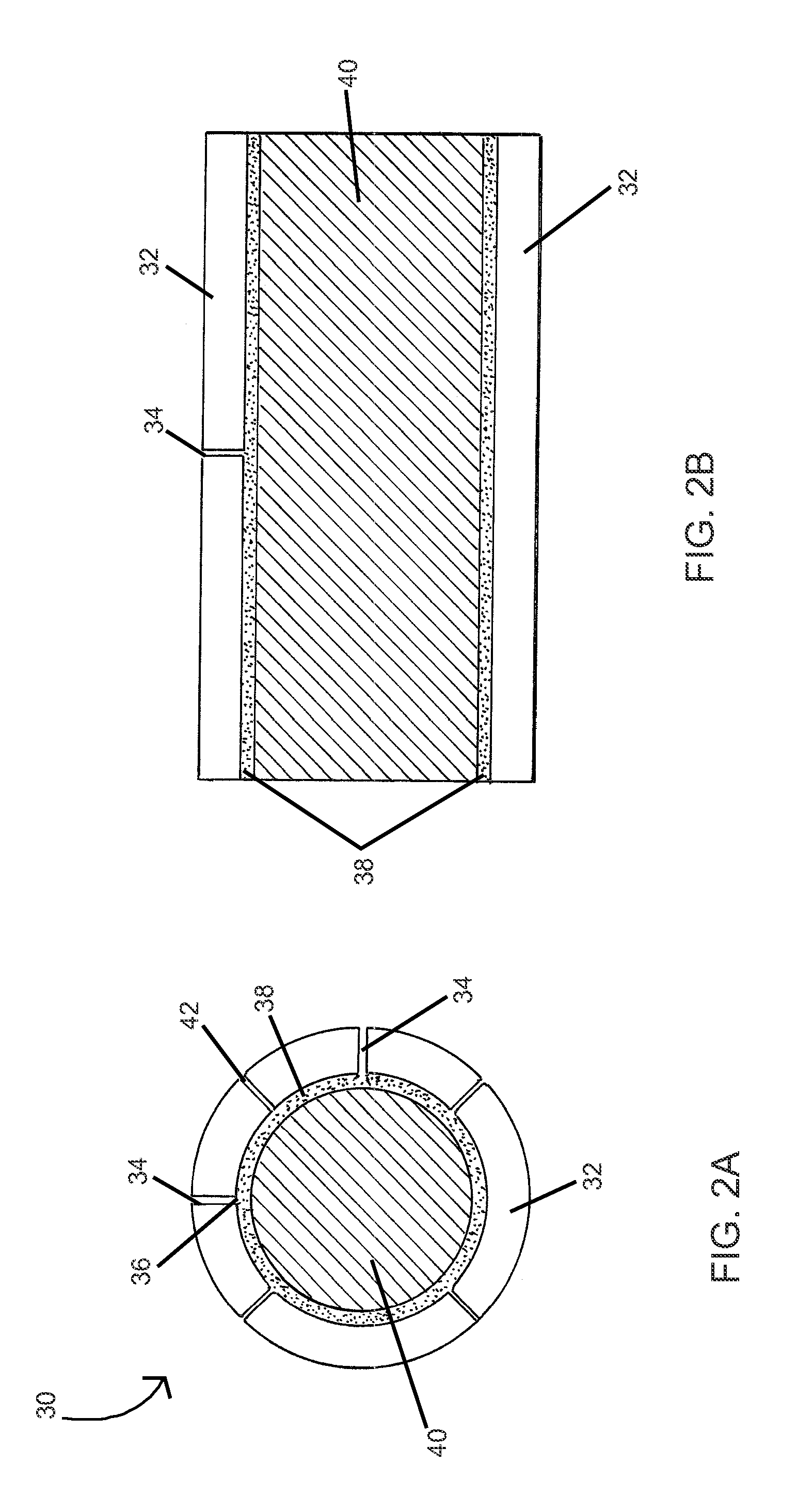

Mechanical damper for air pad instability

InactiveUS7023952B2Reduce wearReduce noiseMaterial analysis using wave/particle radiationRadiation/particle handlingAir bearingInstability

In a diagnostic imaging apparatus, a stationary gantry (24) and a rotating gantry (22) are interfaced by a plurality of air bearing elements (40). Lower air bearing elements bear the weight of the rotating gantry (22) which induce air hammering phenomena at a characteristic vibration frequency. To counteract the air hammering, a damping assembly (44) is mounted to at least one lower bearing element (40). The damping assembly (44) includes a damping mass (46) and an elastomeric connector (48) that are tuned to a frequency near the air hammer frequency to absorb the vibrational energy and damp the air hammer vibrations.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

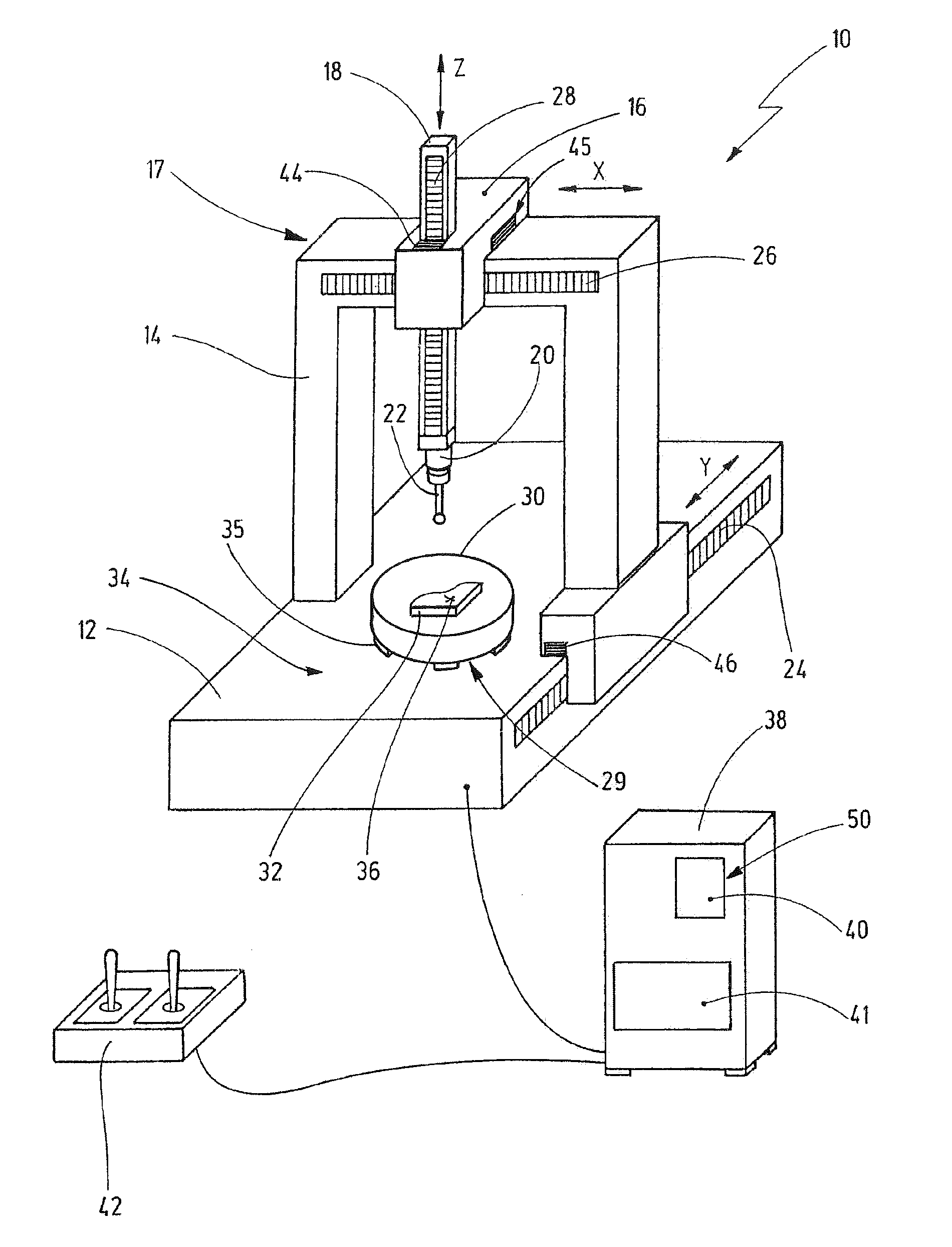

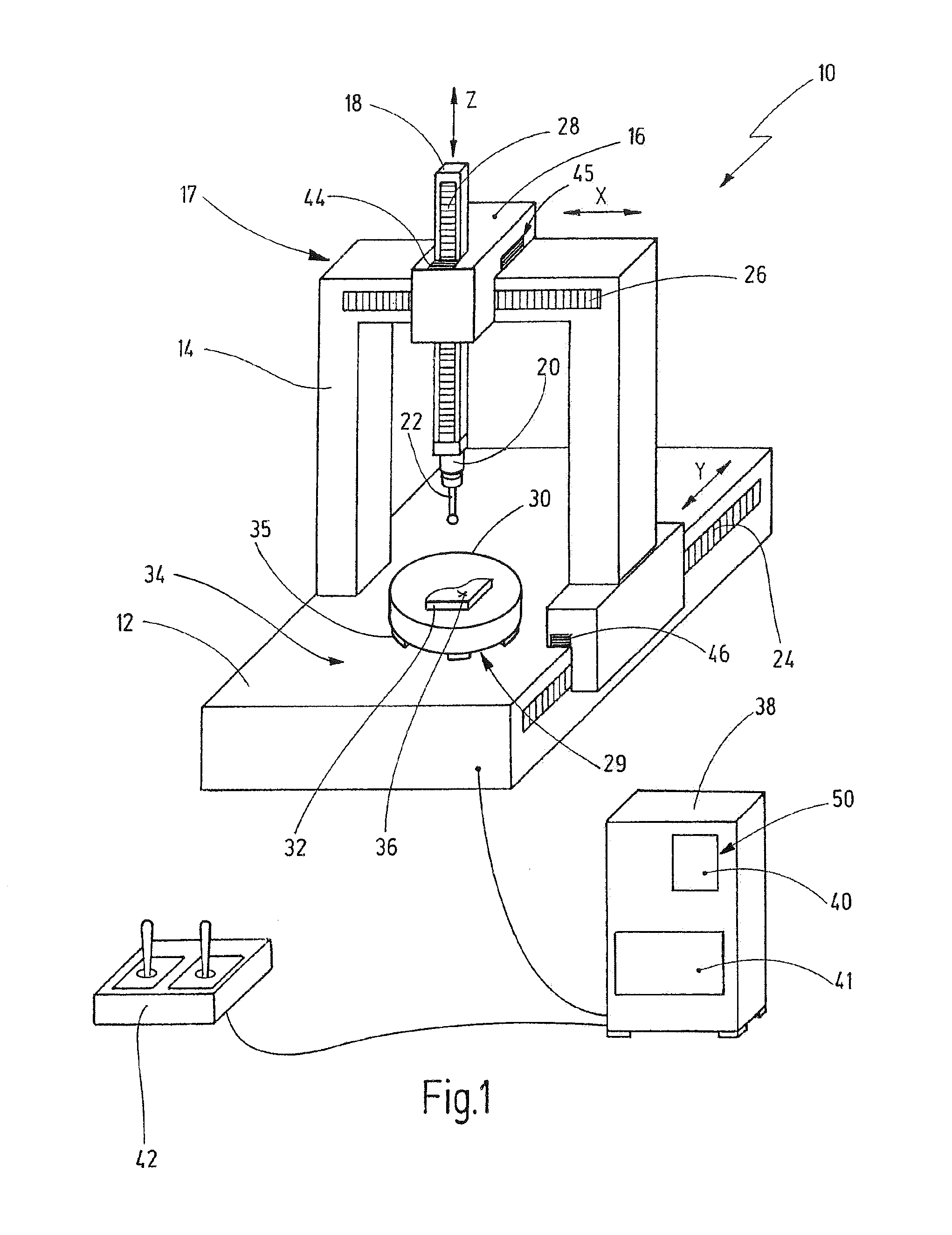

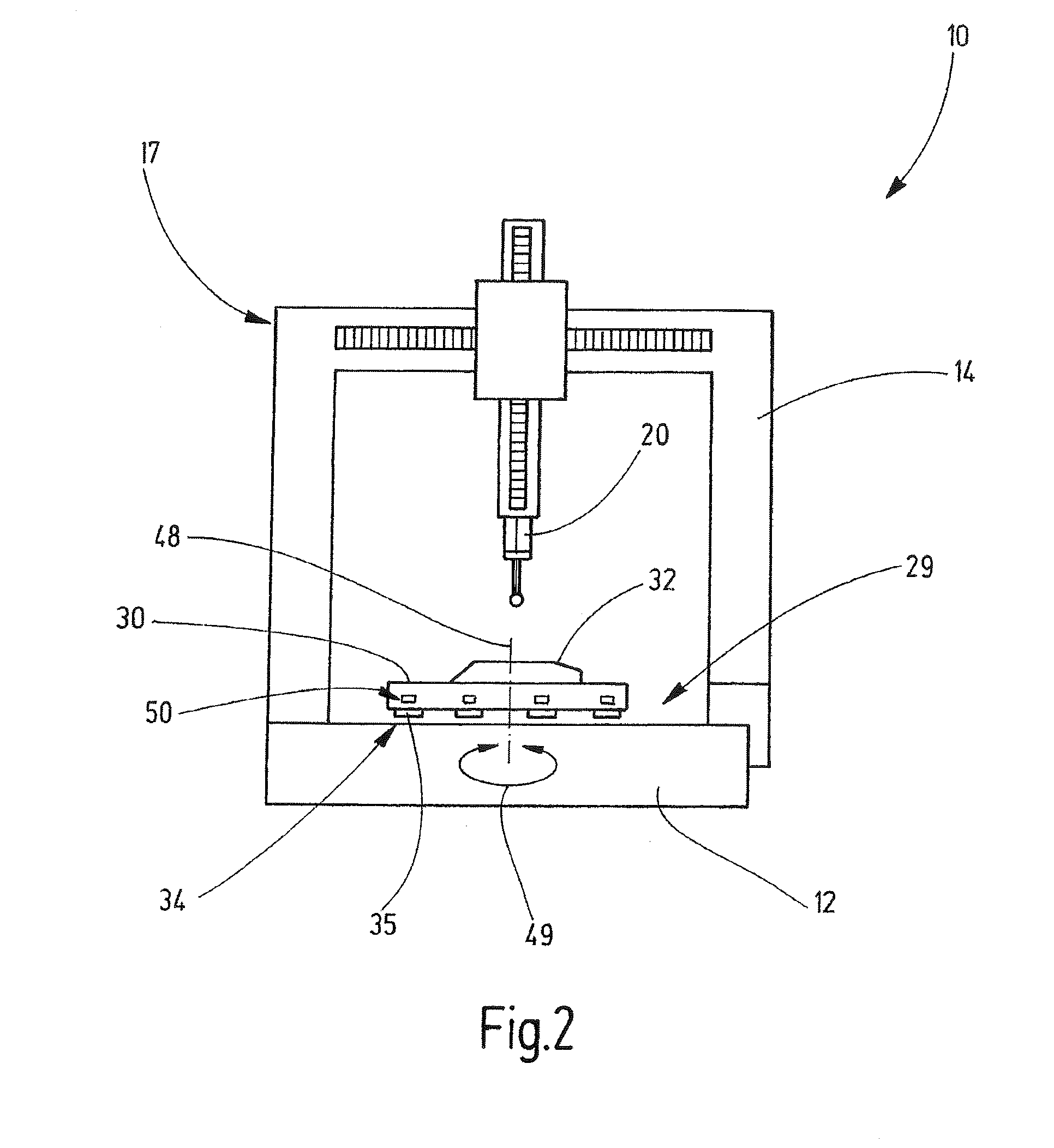

Method for determining a correction value for the monitoring of a fluid bearing and machine having at least one fluid bearing

ActiveUS20140317942A1Improve accuracyImproved monitoring of a fluid bearingShaftsHydrostatic bearingsEngineeringCoordinate-measuring machine

A method for ascertaining a correction value for monitoring a fluid bearing of a coordinate measuring machine or other machine tool. Also disclosed is a coordinate measuring machine having at least one fluid bearing. The machine further includes a first element and a second element which are supported against each other by means of at least one fluid bearing. In addition, a control device is provided for controlling the machine. A quantity representing a pressure in the at least one fluid bearing is ascertained as a function of a position and / or orientation of the first element relative to the second element. A correction value for a pressure in the at least one fluid bearing is determined for the position and / or orientation of the first element relative to the second element. The correction value is then stored in the control device, and subsequently used for machining or measuring a workpiece.

Owner:CARL ZEISS IND MESSTECHN GMBH

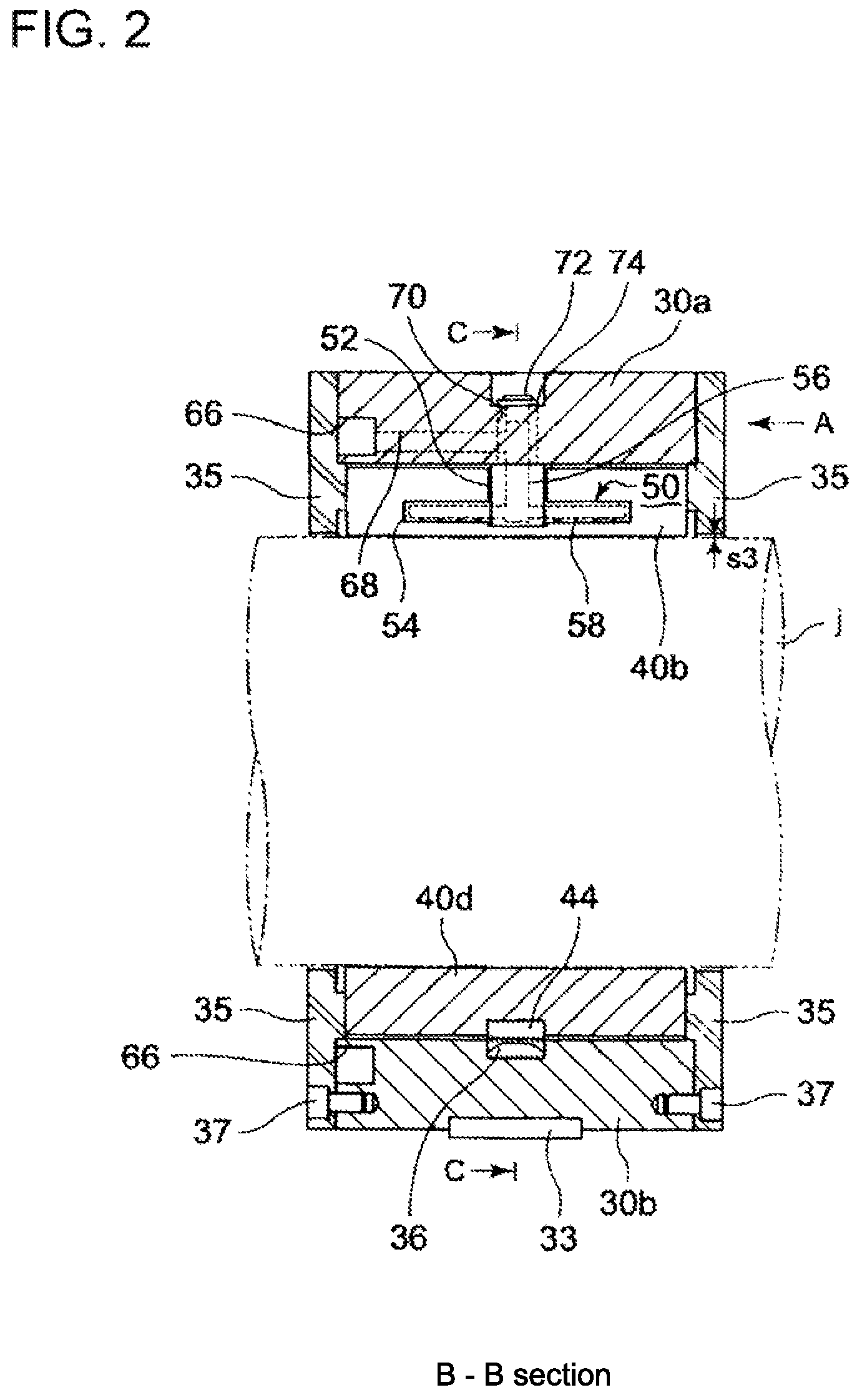

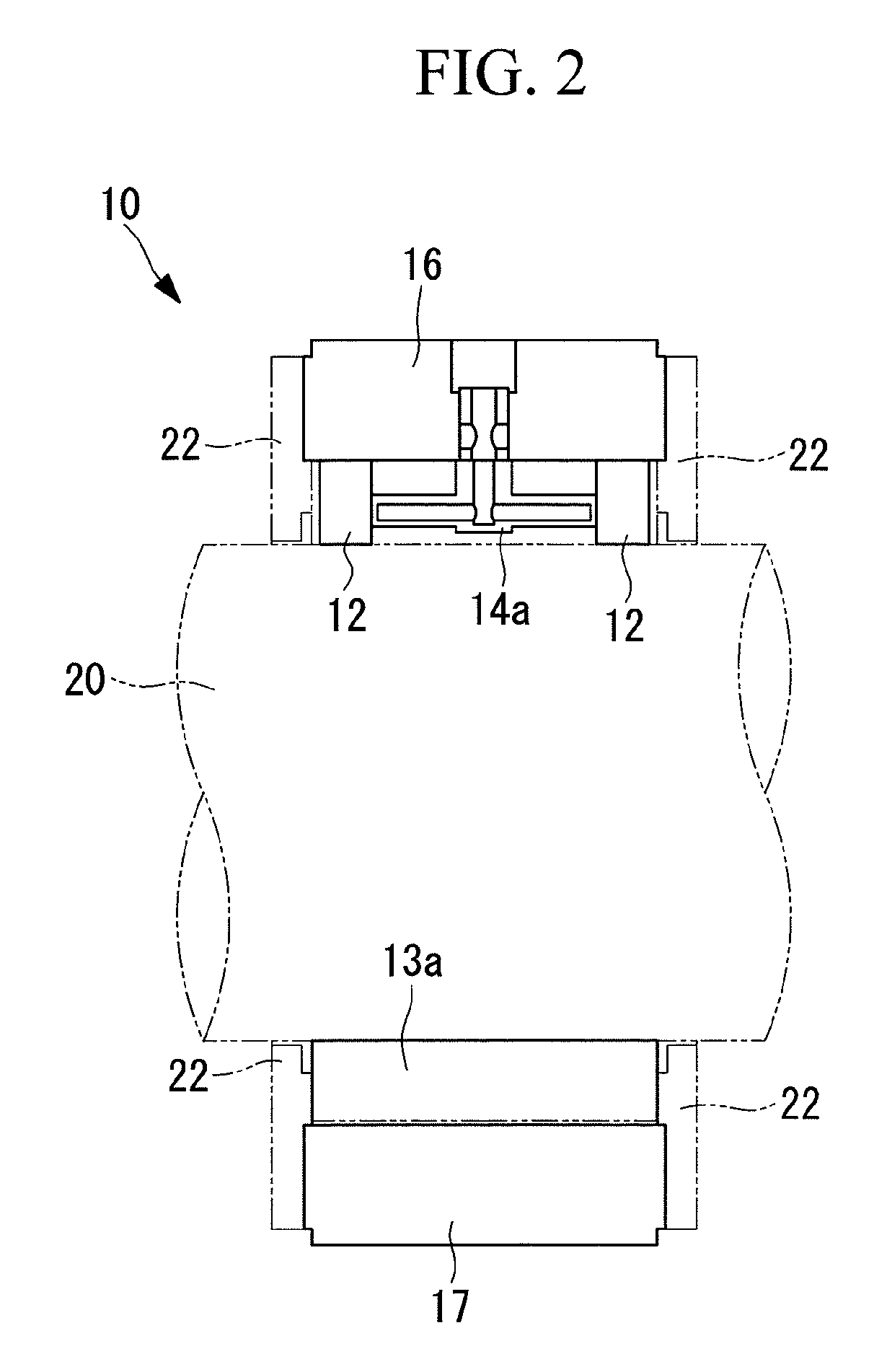

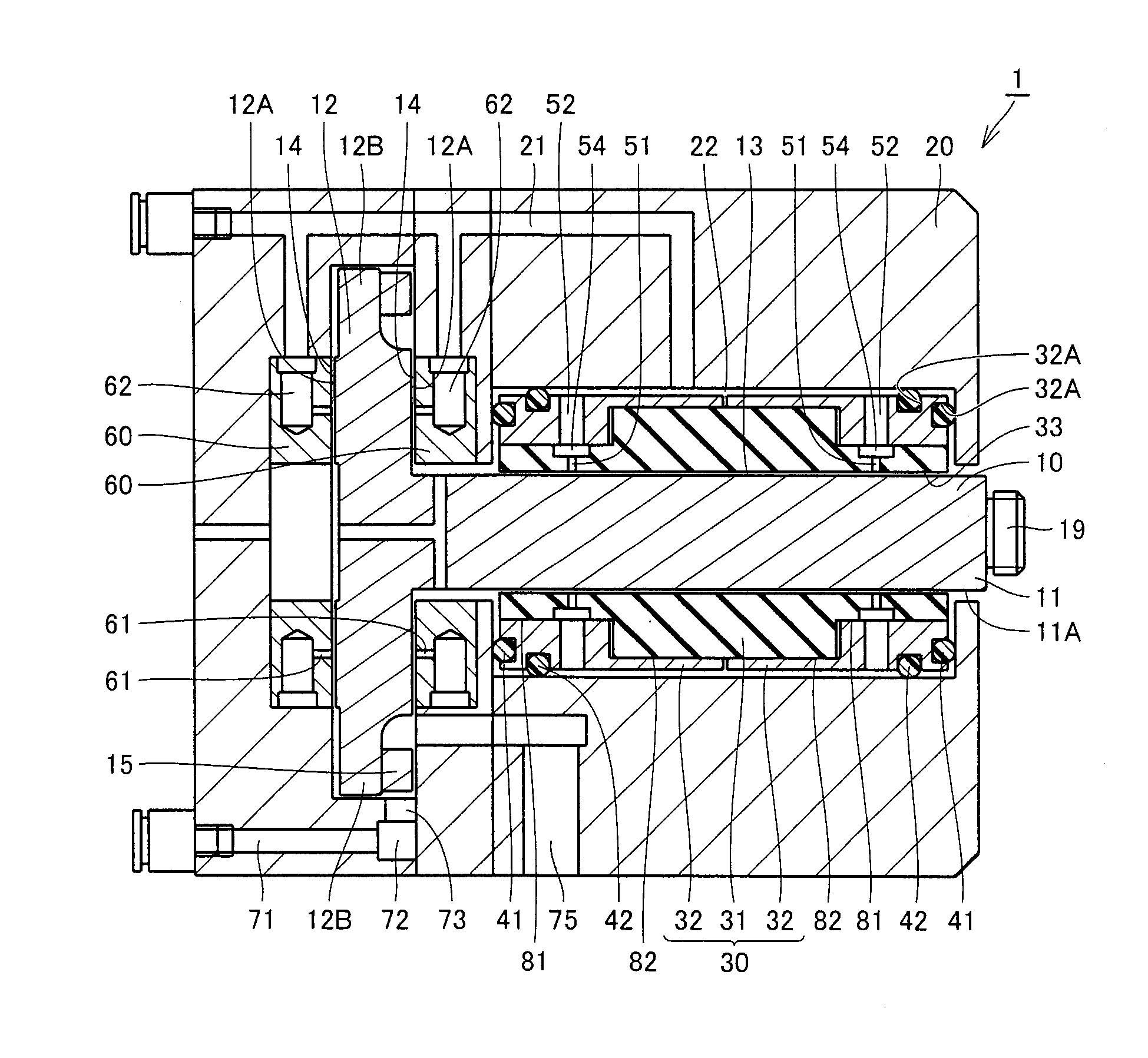

Rotation shaft supporting structure with journal bearing and assembling method of the bearing

ActiveUS8366323B2Easy constructionReduce manufacturing costShaftsBearing componentsRotational axisHigh pressure

Owner:MITSUBISHI HEAVY IND LTD

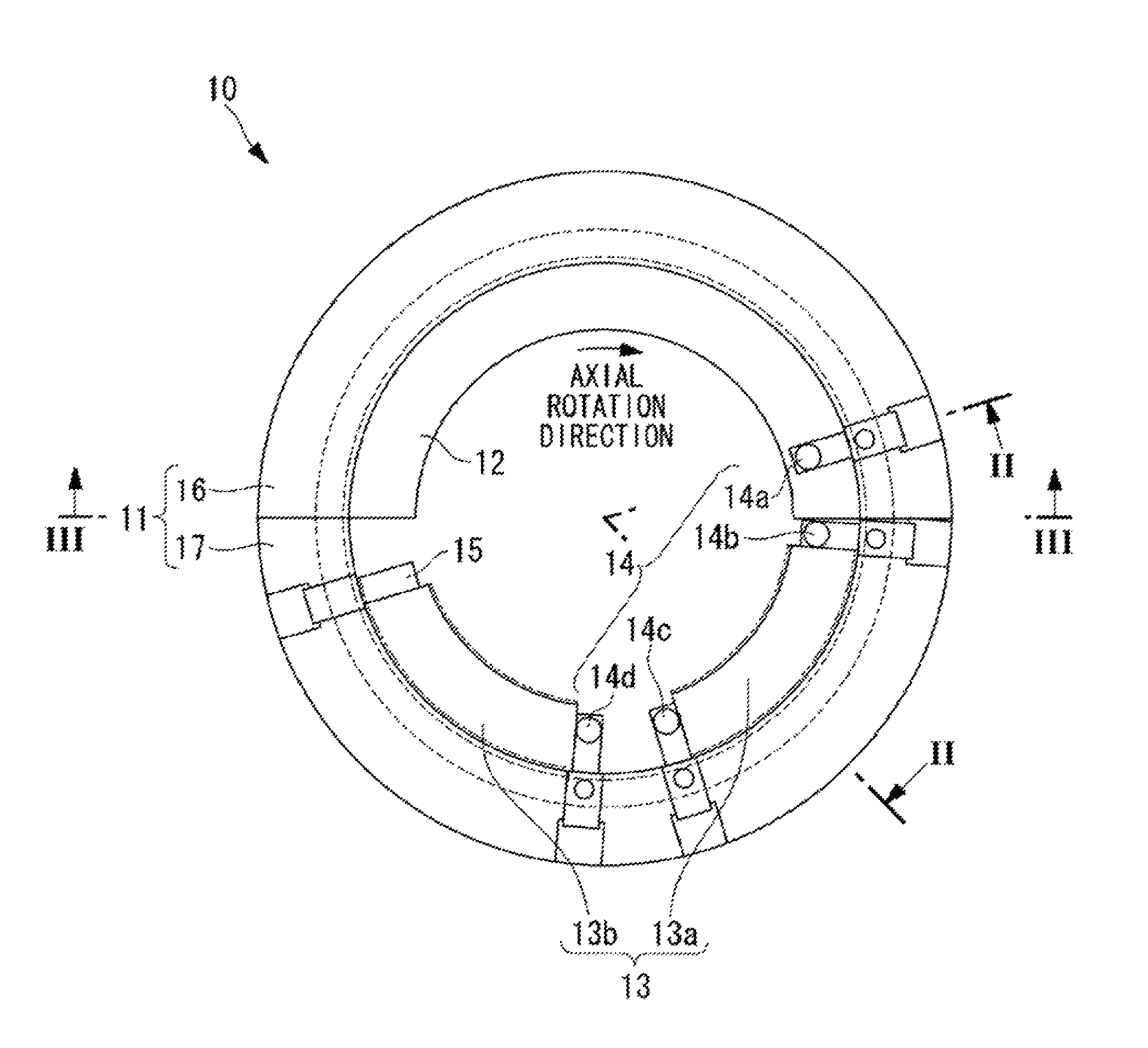

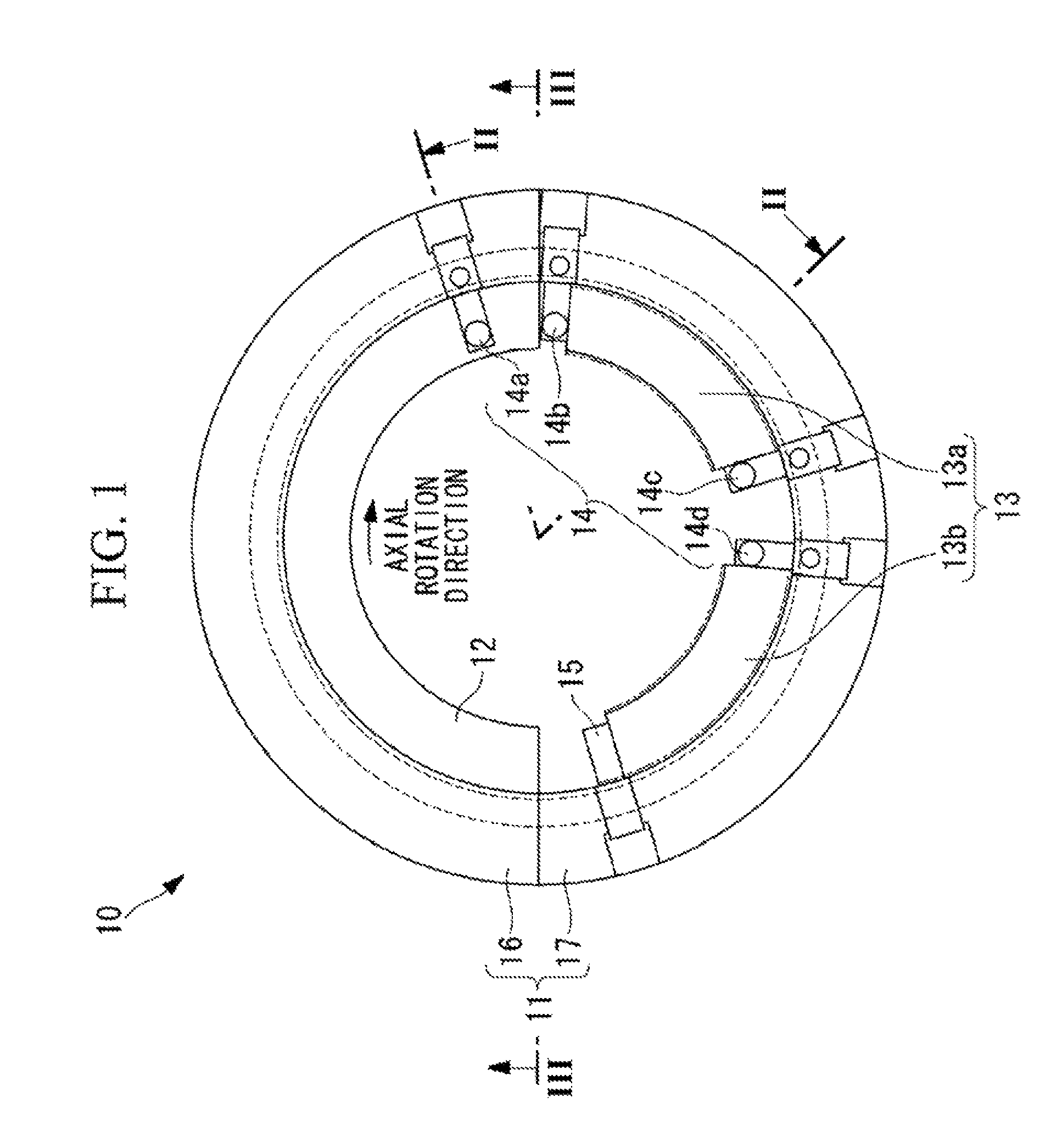

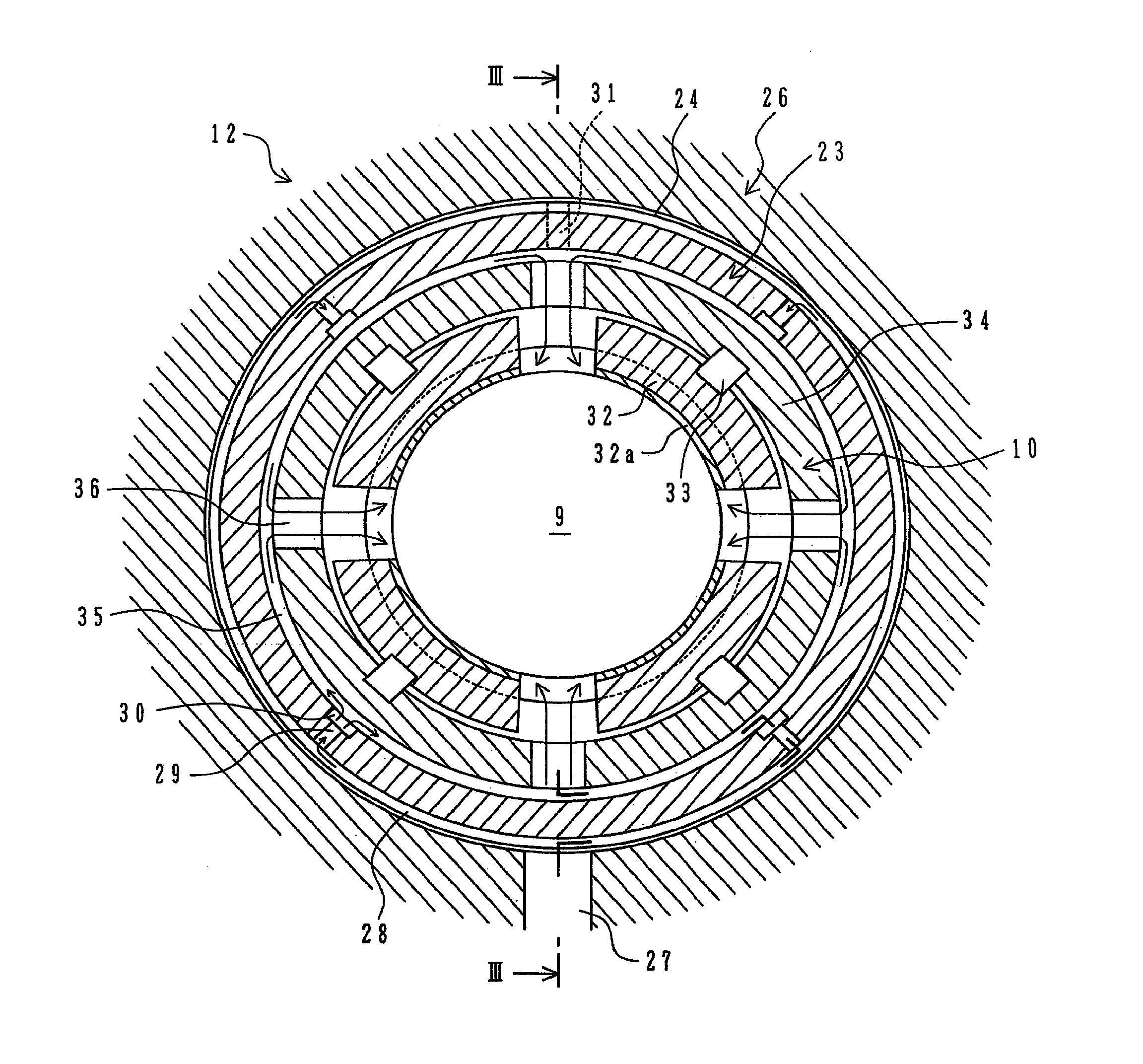

Journal bearing

ActiveUS8123409B2Reduce the amount requiredReduce the churning lossCrankshaftsCrossheadsEngineeringNozzle

Owner:MITSUBISHI HEAVY IND LTD

Journal bearing

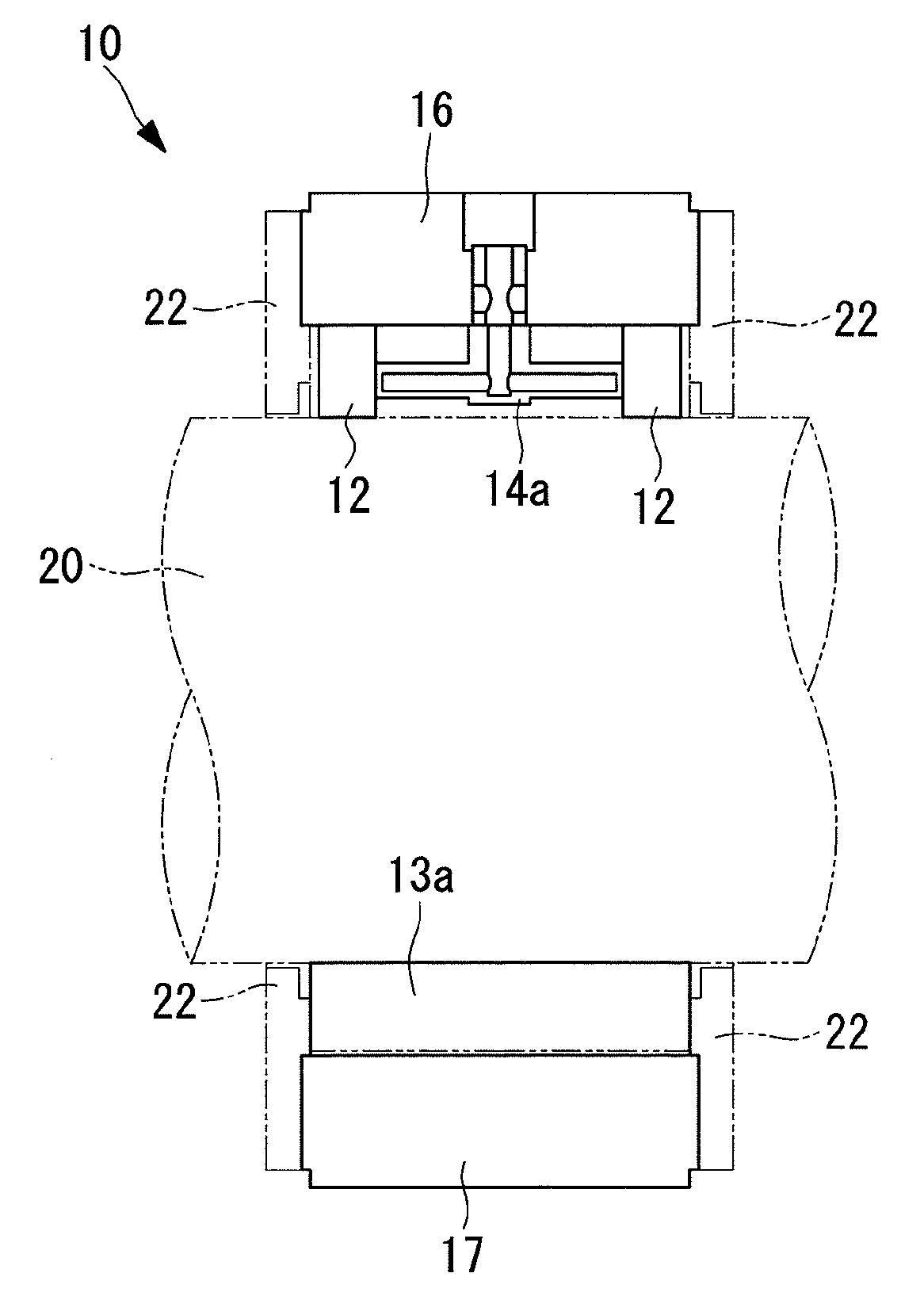

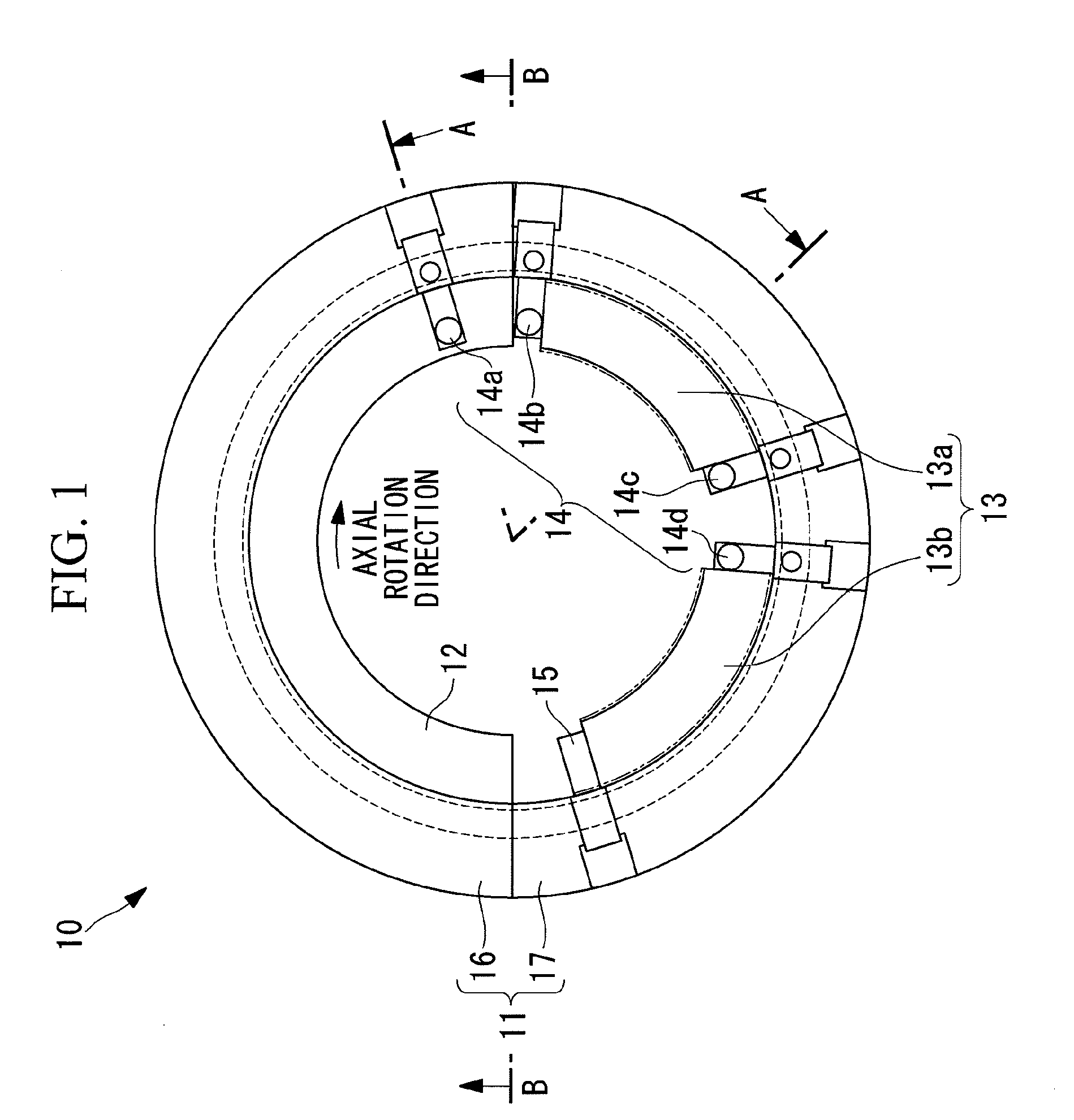

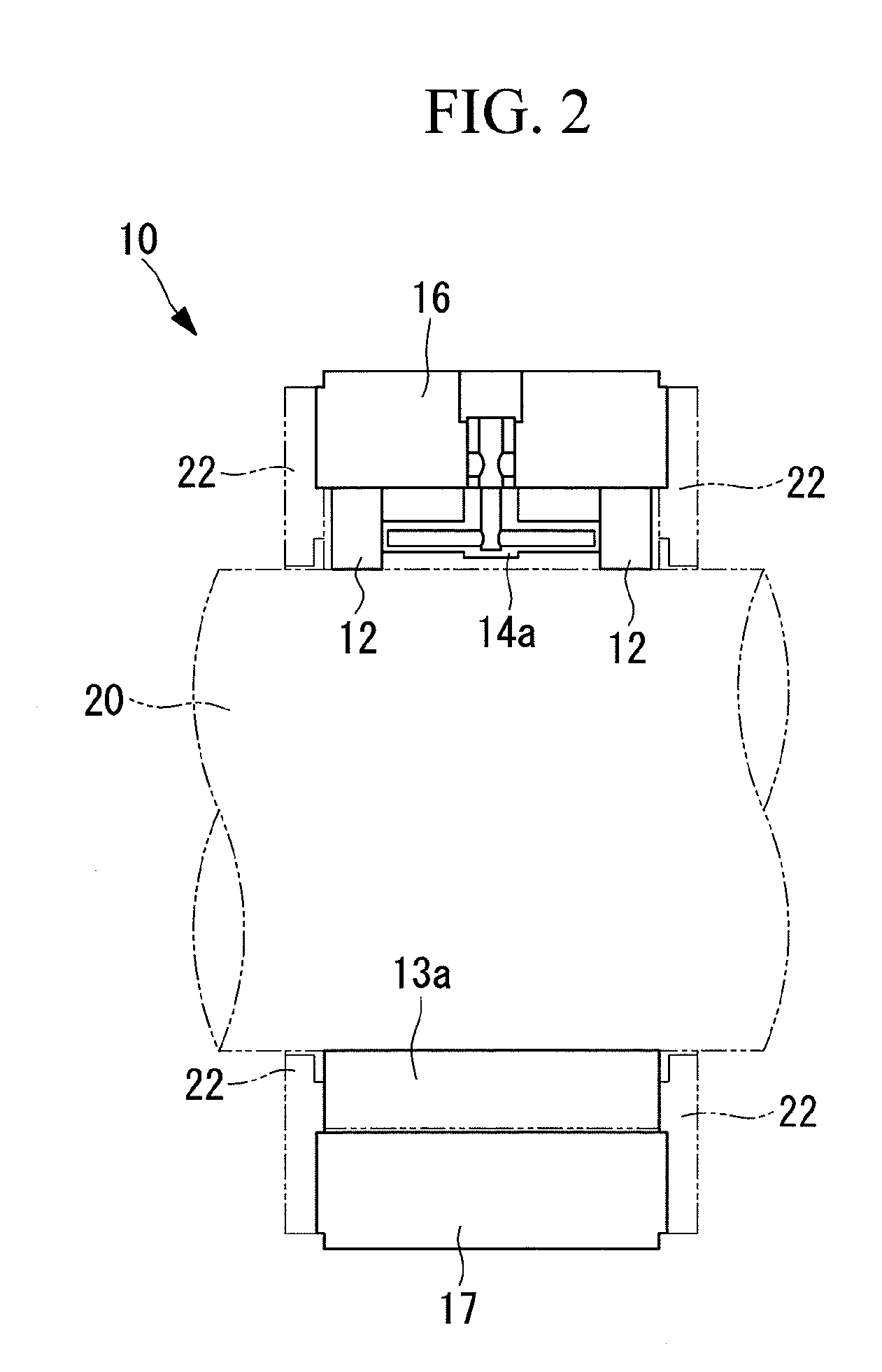

ActiveUS20100220944A1Reduce the amount requiredLower oil temperatureCrankshaftsCrossheadsRotational axisAxial rotation

To reduce the amount of lubricating oil released (supplied) between the outer circumferential surface of a rotation shaft and the inner circumferential surfaces of pads, so as to reduce the churning loss, and to reduce the bearing loss. The journal bearing comprises: a plurality of pads arranged radially inside a lower half-carrier ring at intervals, for receiving load from the rotation shaft; and a plurality of pad stops respectively arranged at the circumferentially opposite ends of the respective pads, for restraining circumferential movements of the respective pads, wherein, among these pad stops, the pad stops other than the pad stop located in the most forward position in the axial rotation direction of the rotation shaft have functions as oiling nozzles for releasing lubricating oil between the outer circumferential surface of the rotation shaft and the inner circumferential surfaces of the pads.

Owner:MITSUBISHI HEAVY IND LTD

Gas bearing spindle

A gas bearing spindle includes a rotation shaft, a sleeve, and a housing. The sleeve includes a bearing portion formed of a nonmetallic sintered body; and a retaining ring formed of a metal. Further, the retaining ring and the bearing portion are in contact with each other at a first fit surface that is a boundary surface between the outer circumferential surface of the bearing portion and the inner circumferential surface of the retaining ring, as well as at a second fit surface that is a boundary surface between the outer circumferential surface of the bearing portion and the inner circumferential surface of the retaining ring, is distant further away from the sleeve through hole relative to the first fit surface, and is formed adjacent to a center of the sleeve through hole in a direction in which the sleeve through hole extends, when viewed from the first fit surface.

Owner:NTN CORP

Rotation shaft supporting structure with journal bearing and assembling method of the bearing

ActiveUS20100177999A1Improve the lubrication effectAvoid it happening againShaftsBearing componentsRotational axisEngineering

Owner:MITSUBISHI HEAVY IND LTD

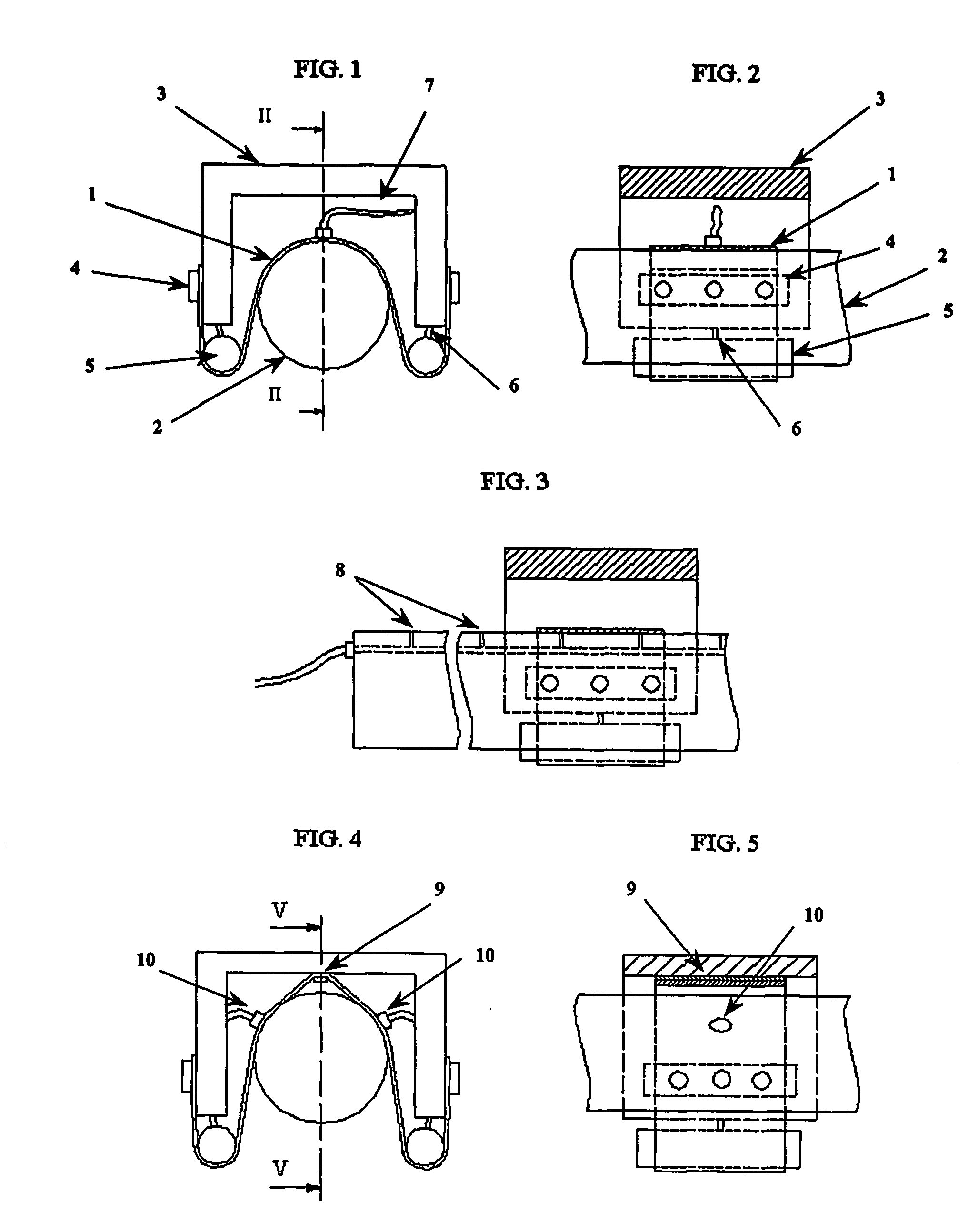

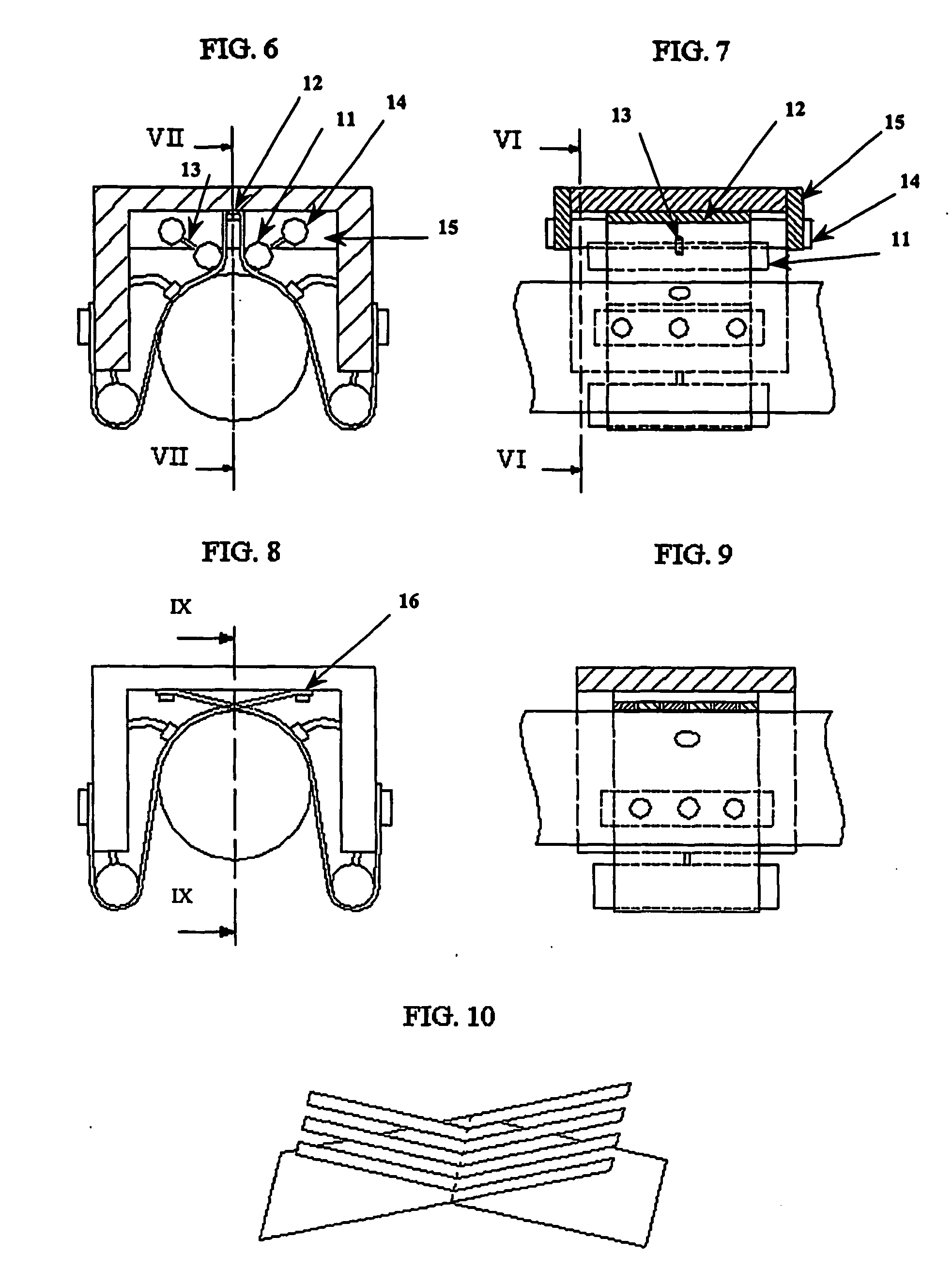

Novel foil bearing

The present invention relates to a new kind of foil bearing. The present invention relates to a bearing comprising a flexible foil with a self-aligning mechanism. The present invention furthermore relates to a foil bearing enabling a linear and / or rotary movement along / around an axis (i.e. a shaft). The present invention also relates to a foil gas / air bearing with a self-aligning mechanism. The present invention furthermore relates to the use of said foil bearing in machines, more specifically in precision and / or high-speed machines and in high-speed precision spindles.

Owner:K U LEUVEN RES & DEV

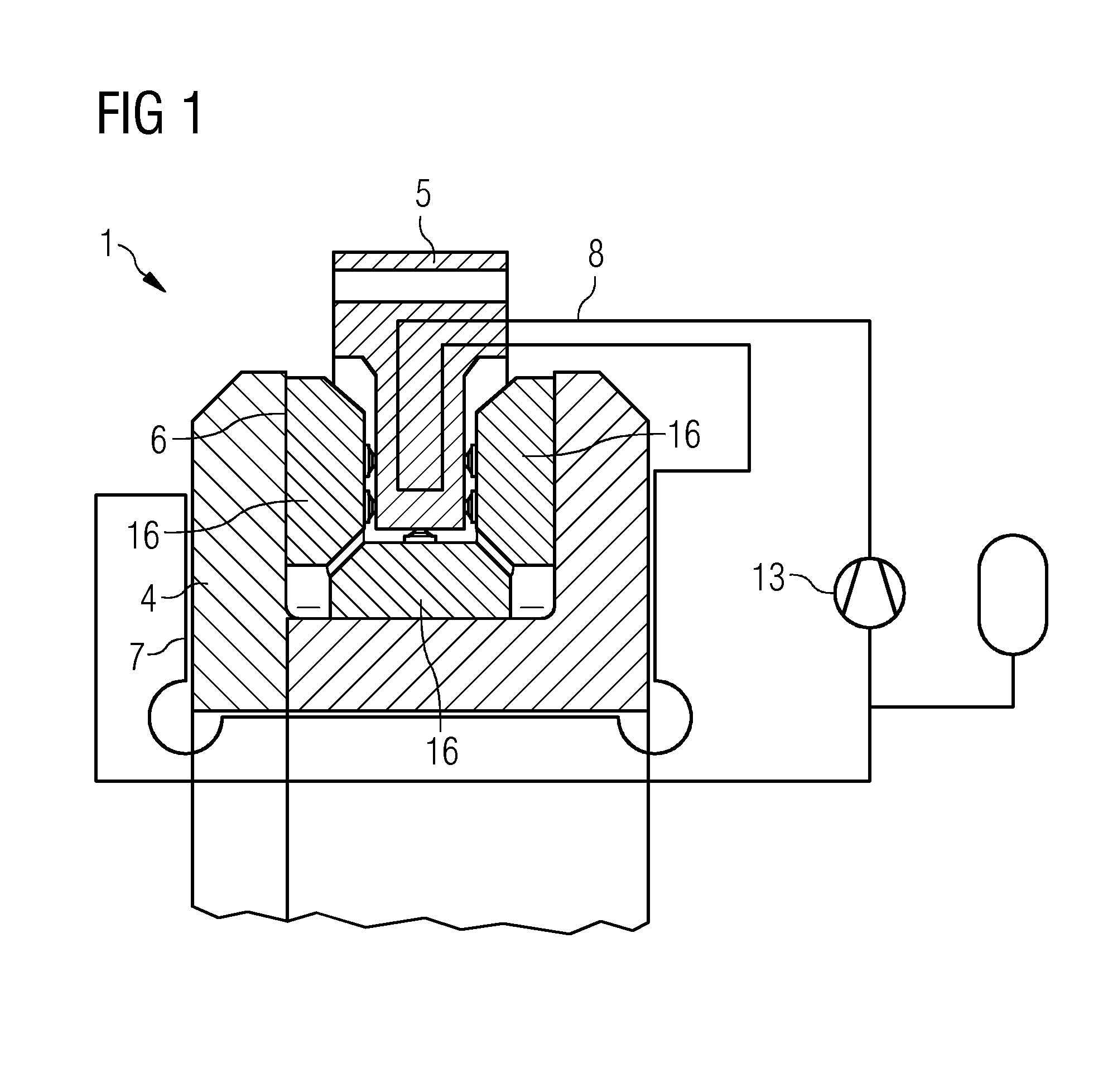

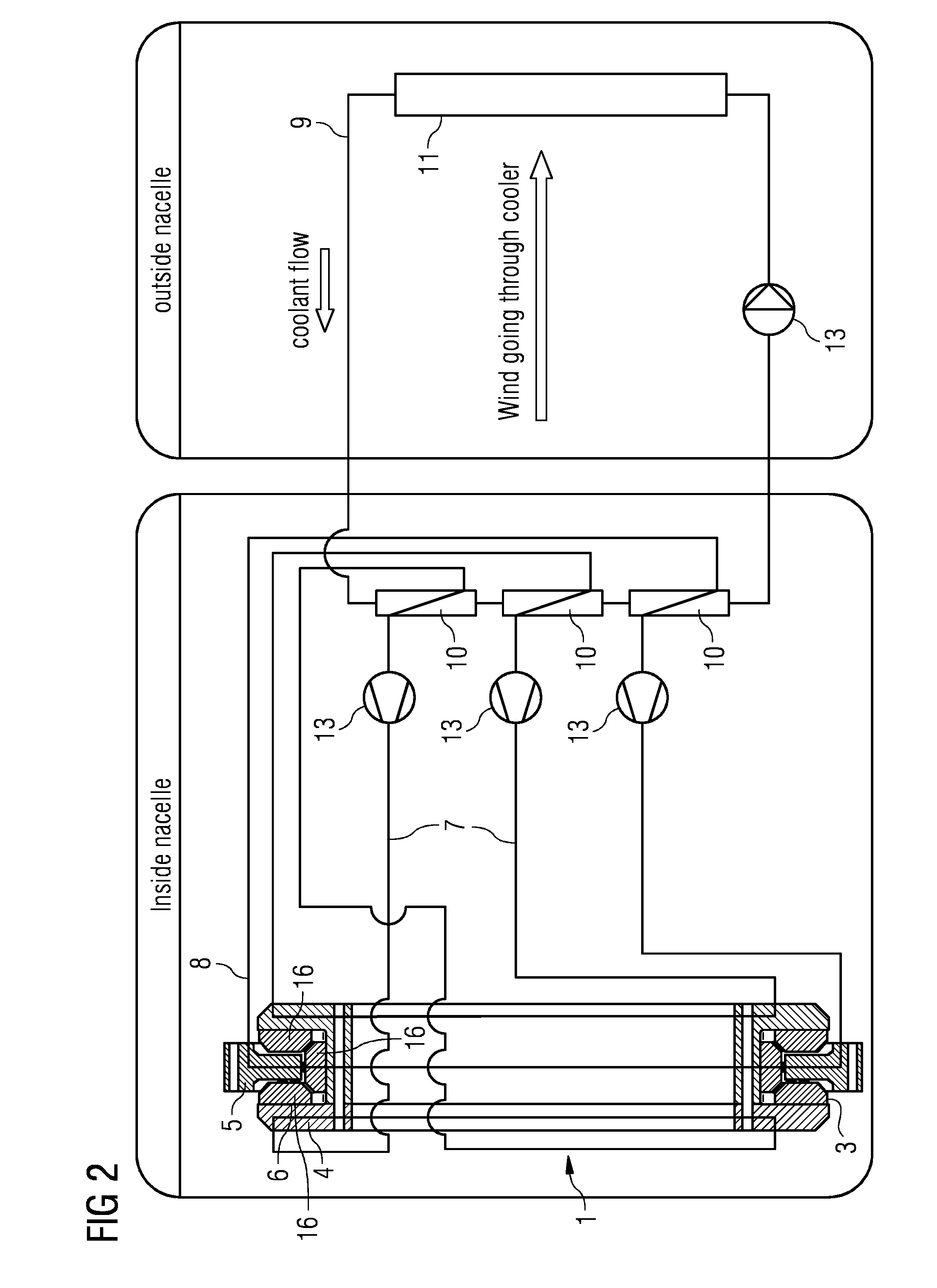

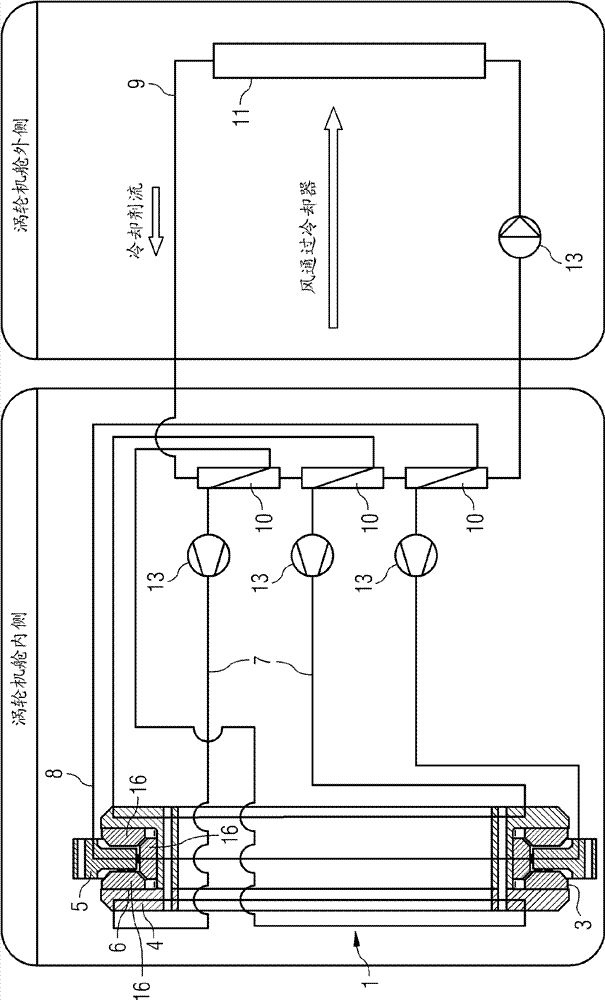

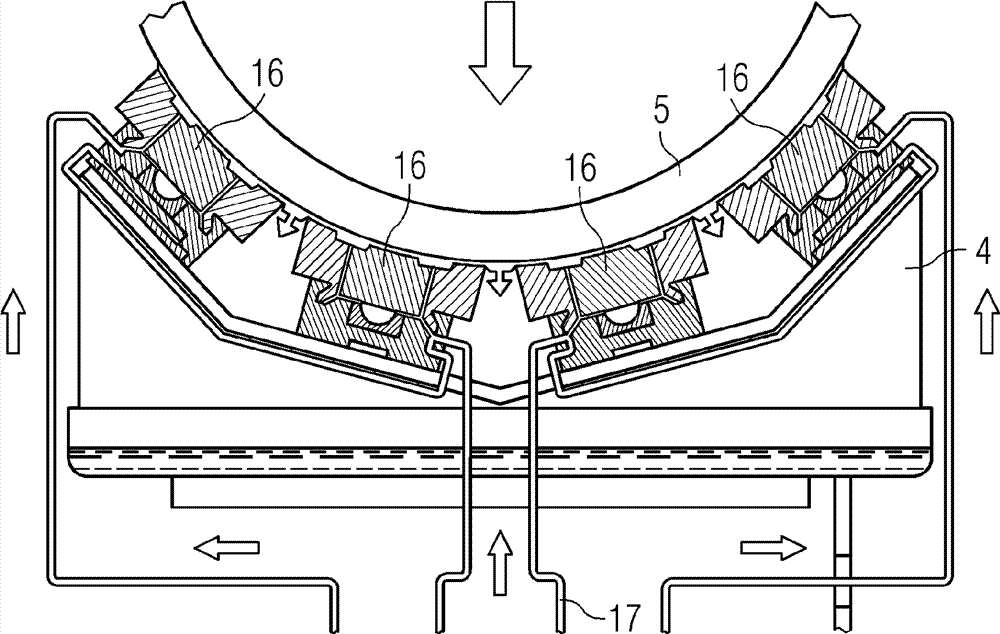

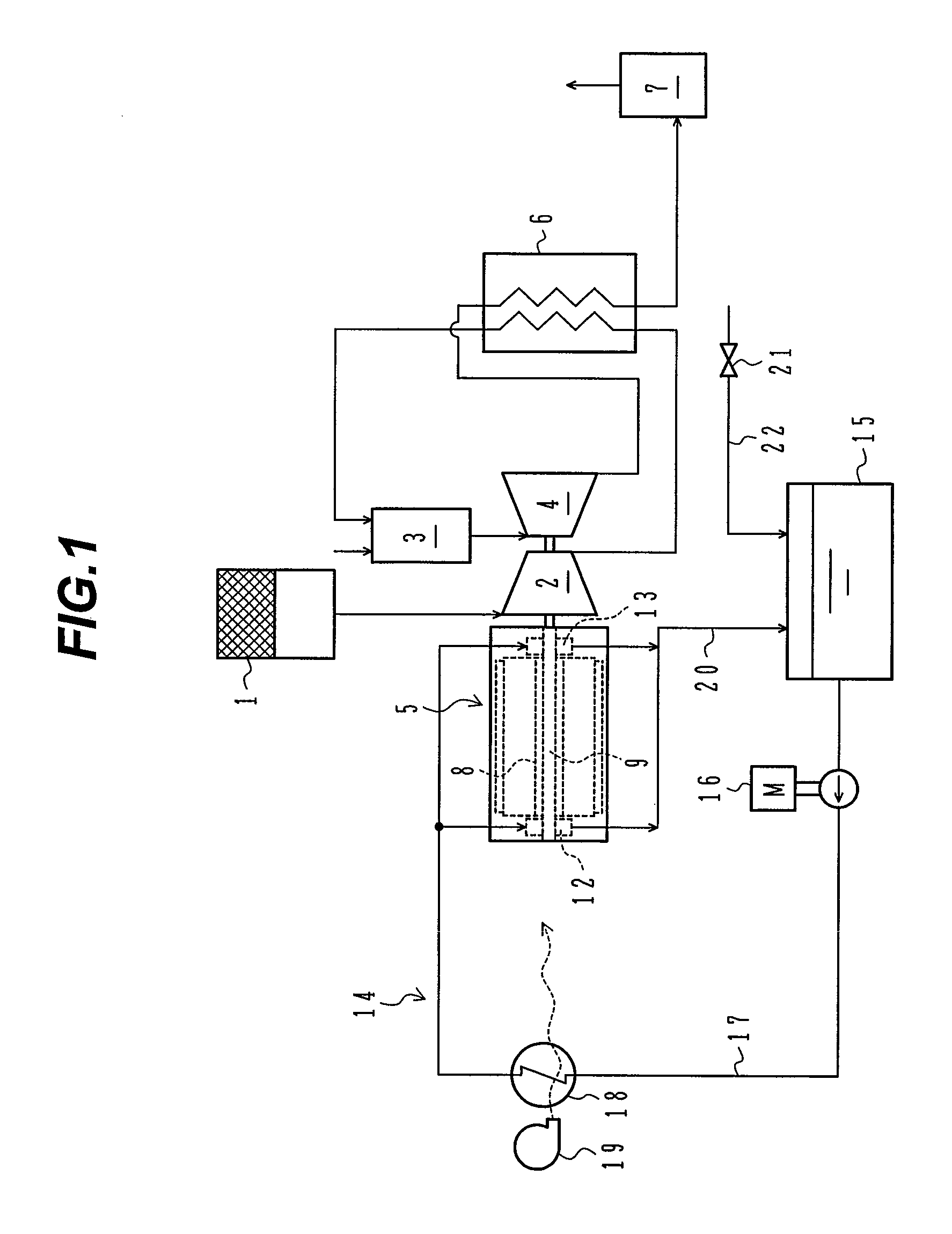

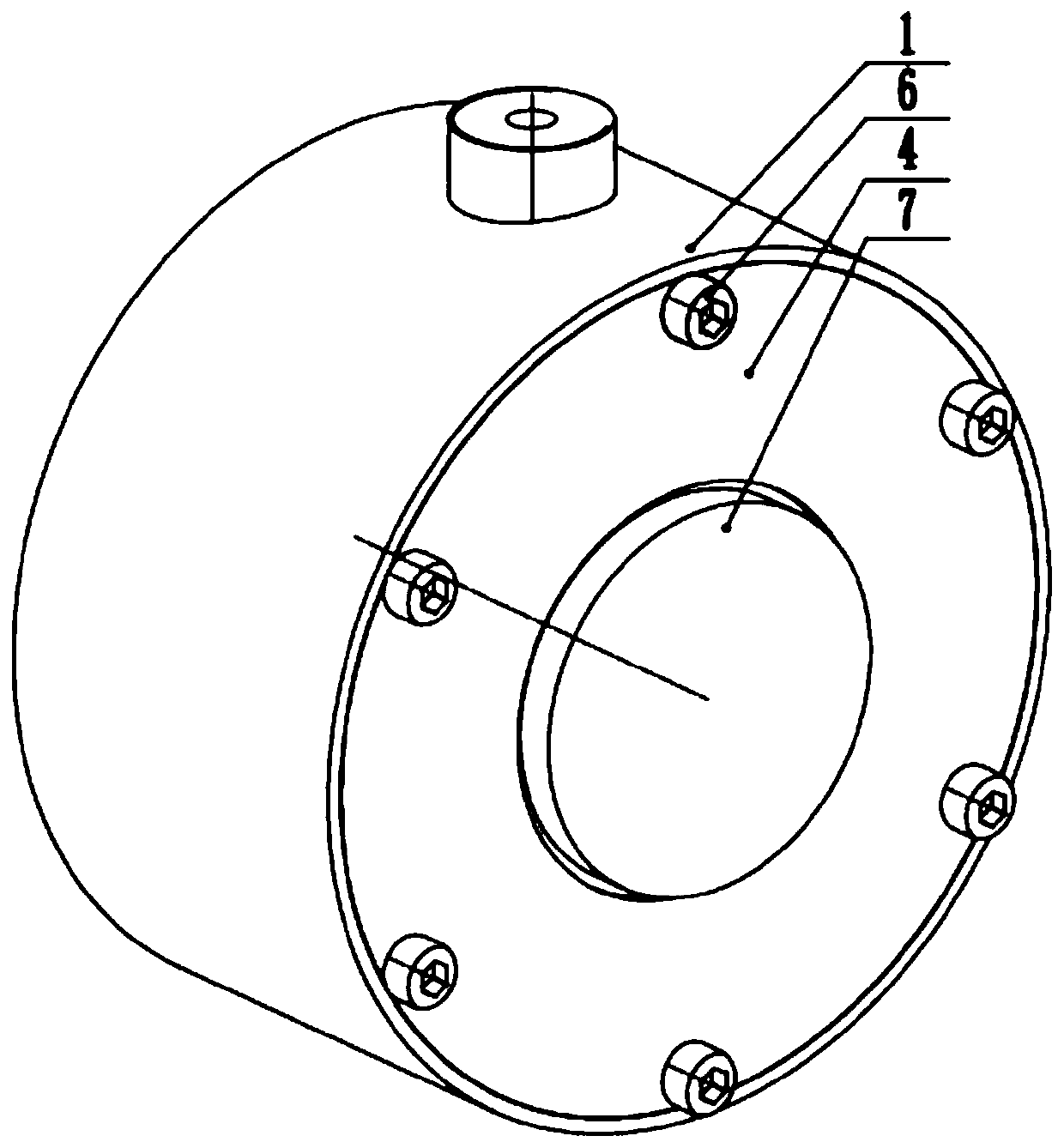

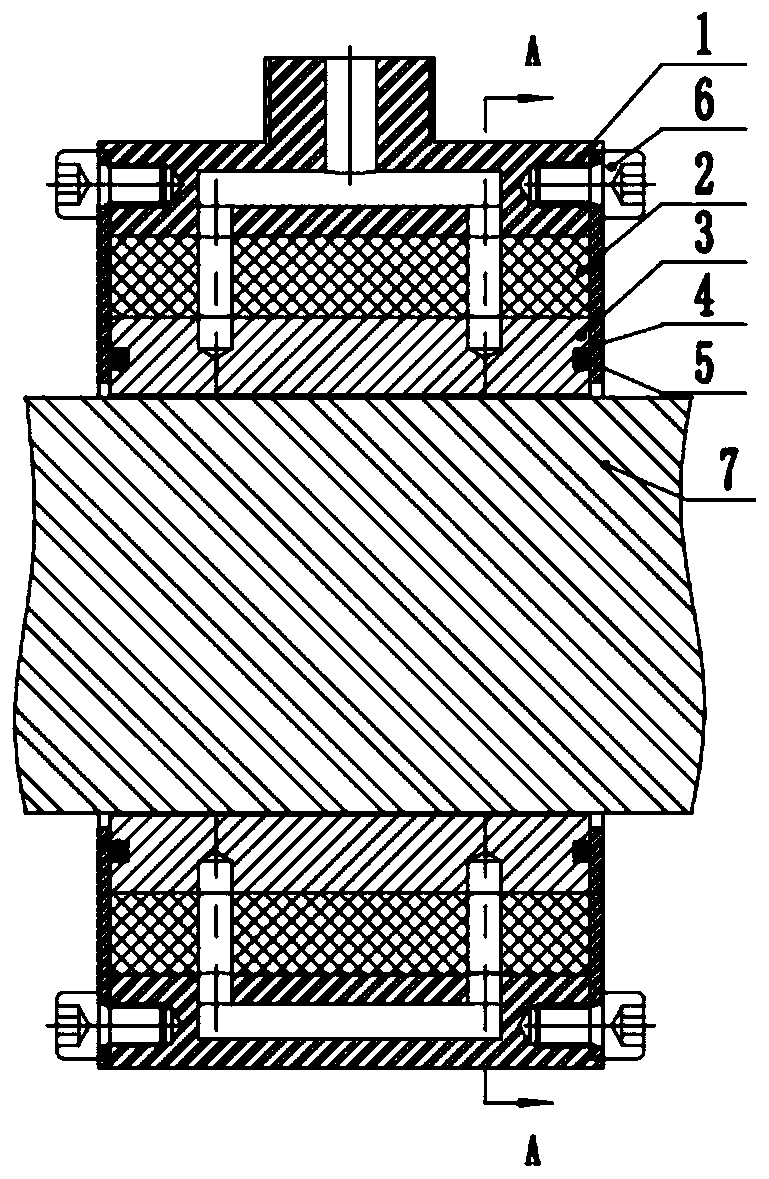

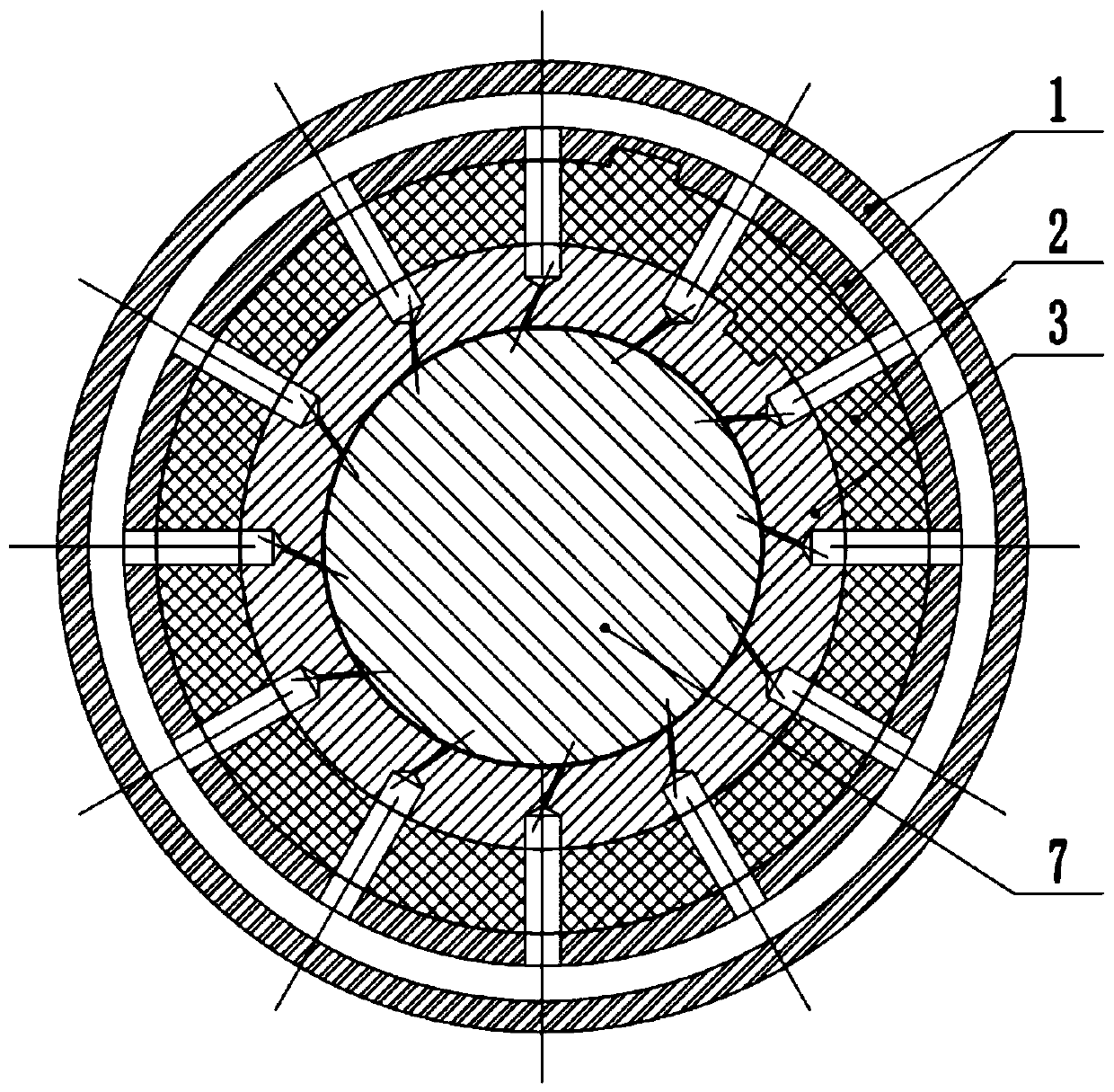

Arrangement to control the clearance of a sliding bearing

An arrangement to control the clearance of a sliding bearing is disclosed. A sliding bearing arrangement, of a direct driven wind turbine, comprises a bearing. The bearing comprises a first bearing shell and a second bearing shell, whereby the first bearing shell and the second bearing shell are arranged rotatable in respect to each other. A certain predetermined clearance is present between the first bearing shell and the second bearing shell, while the bearing is in rotation. A first circuit comprises a first fluid, while the first circuit is in thermal contact with the first bearing shell. A second circuit comprises a second fluid, while the second circuit is in thermal contact with the second bearing shell. The first circuit and the second circuit are coupled in a way that a difference in the temperature between the first bearing shell and the second bearing shell is compensated via the first and the second fluid, thus the clearance is kept within a predetermined range.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

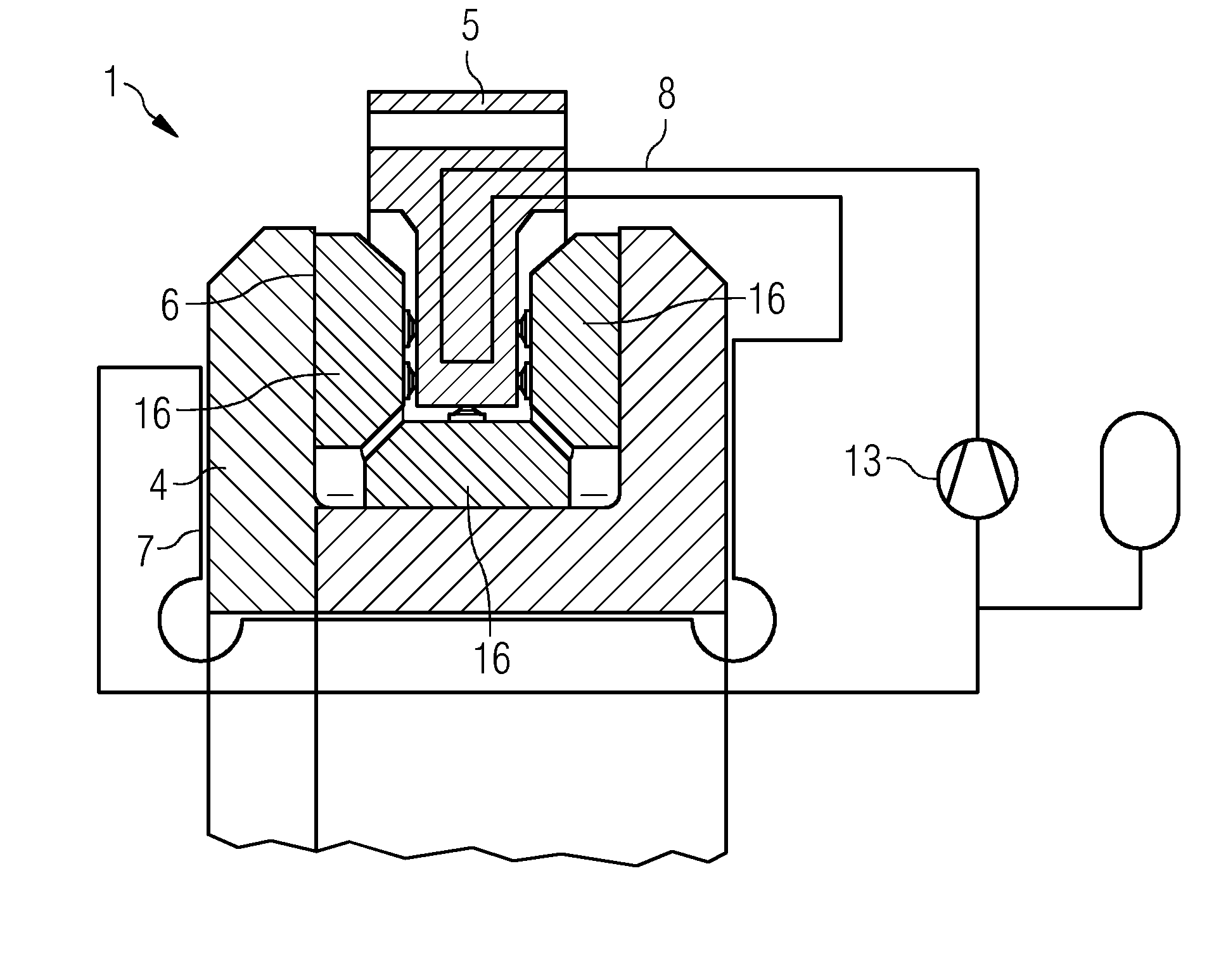

Arrangement controlling clearance of sliding bearing

A sliding bearing arrangement 1, of a direct driven wind turbine 2, comprises a bearing 3 having a first bearing shell 4 and a second bearing shell 5, rotatable with respect to each other. A predetermined clearance 6 is present between the first bearing shell 4 and the second bearing shell 5, while the bearing 3 is in rotation. A first circuit 7 comprising a first fluid is in thermal contact with the first bearing shell 4. A second circuit 8 comprising a second fluid is in thermal contact with the second bearing shell 5. The first circuit 7 and the second circuit 8 are coupled in a way that a difference in the temperature between the first bearing shell 4 and the second bearing shell 5 is compensated via the first and the second fluid, thus the clearance 6 is kept within a predetermined range.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Thrust bearing for a gyratory crusher and method of supporting a vertical shaft in such a crusher

InactiveUS7922109B2Low costConsumes less energySliding contact bearingsHydrostatic bearingsThrust bearingCrusher

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Gap Sensing Method For Fluid Film Bearings

A method for adjusting a fluid gap in fluid film bearings comprising the steps of applying a load to the bearing, measuring fluid pressure of the fluid film, determining the fluid gap using a known relationship between the bearing load applied versus gap and corresponding fluid pressure and adjusting the gap to a desired width using the known relationship between the bearing load applied versus gap and corresponding fluid pressure. Predetermined measurements of film gage pressure, supply gage pressure and gap distance can be used to determine the ratio of absolute film pressure to absolute input pressure which, in turn, can be used to determine a formula for calculating unknown gap distances.

Owner:SPECIALTY COMPONENTS

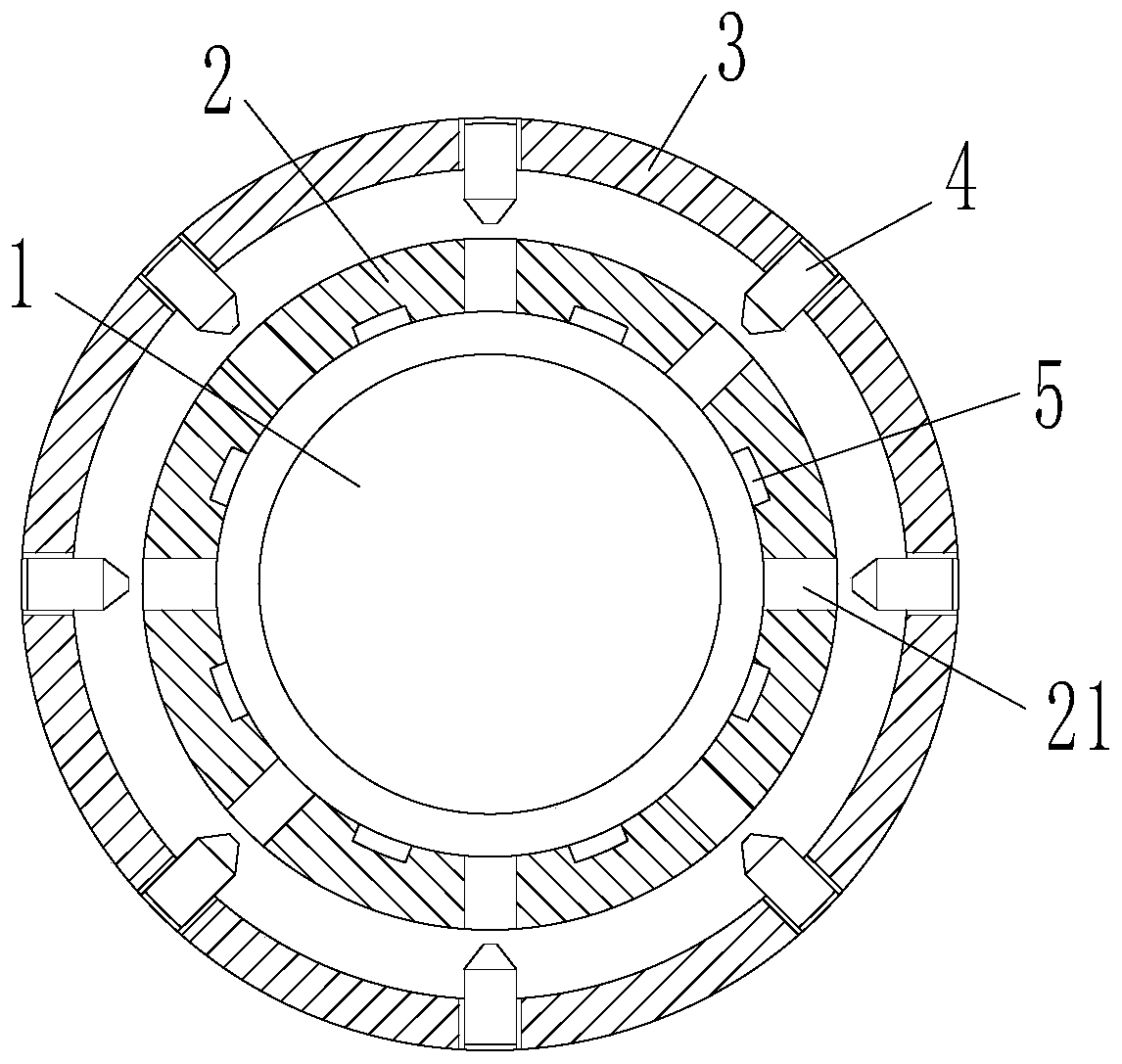

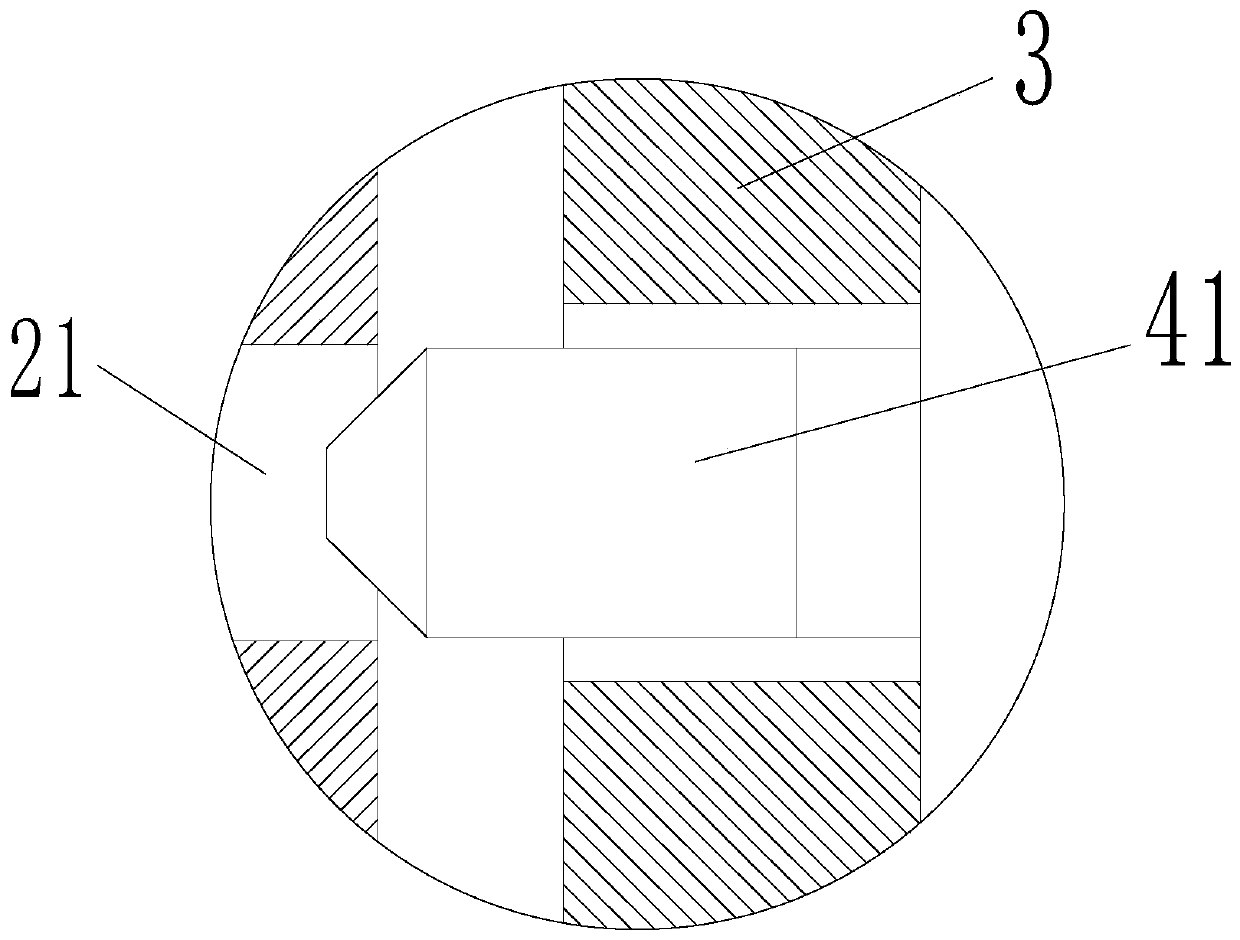

Gas film pressure vector control device for aerostatic bearing

PendingCN110030266AControllable outlet pressureRealize vector controlHydrostatic bearingsControl vectorEngineering

The invention provides a gas film pressure vector control device for an aerostatic bearing. The control device comprises a main shaft and a bearing, wherein the bearing is arranged outside the main shaft, an air film is formed in a gap area between the main shaft and the bearing, and throttling holes are uniformly distributed in the bearing; an air chamber coat sleeves outside the bearing, a closed area formed between the air chamber coat and the bearing is the air chamber, and the throttling holes communicate the air film and the air chamber; a flow control valve is arranged on the wall surface of the air chamber coat opposite to the throttling holes in a penetrating mode, the flow control valve is coaxially arranged with the throttling holes, and the valve element of the flow control valve is used for adjusting the opening degree of the throttling holes; an air inlet hole penetrates through the wall surface of the air chamber coat and is externally connected with an air inlet pipe; awireless pressure sensor is arranged in a groove formed in the inner wall of the bearing, the shape, close to one side of the main shaft, of the wireless pressure sensor is consistent with the shapeof the inner wall surface of the bearing, and namely the wireless pressure sensor and the gas film flow field do not interfere with each other; the flow control valve is connected with a wire collecting terminal through a wire harness; the control device is connected with the wire collecting terminal through an anti-interference bus; and the vector control of the gas film pressure of the aerostatic bearing can be realized.

Owner:ZHEJIANG UNIV OF TECH

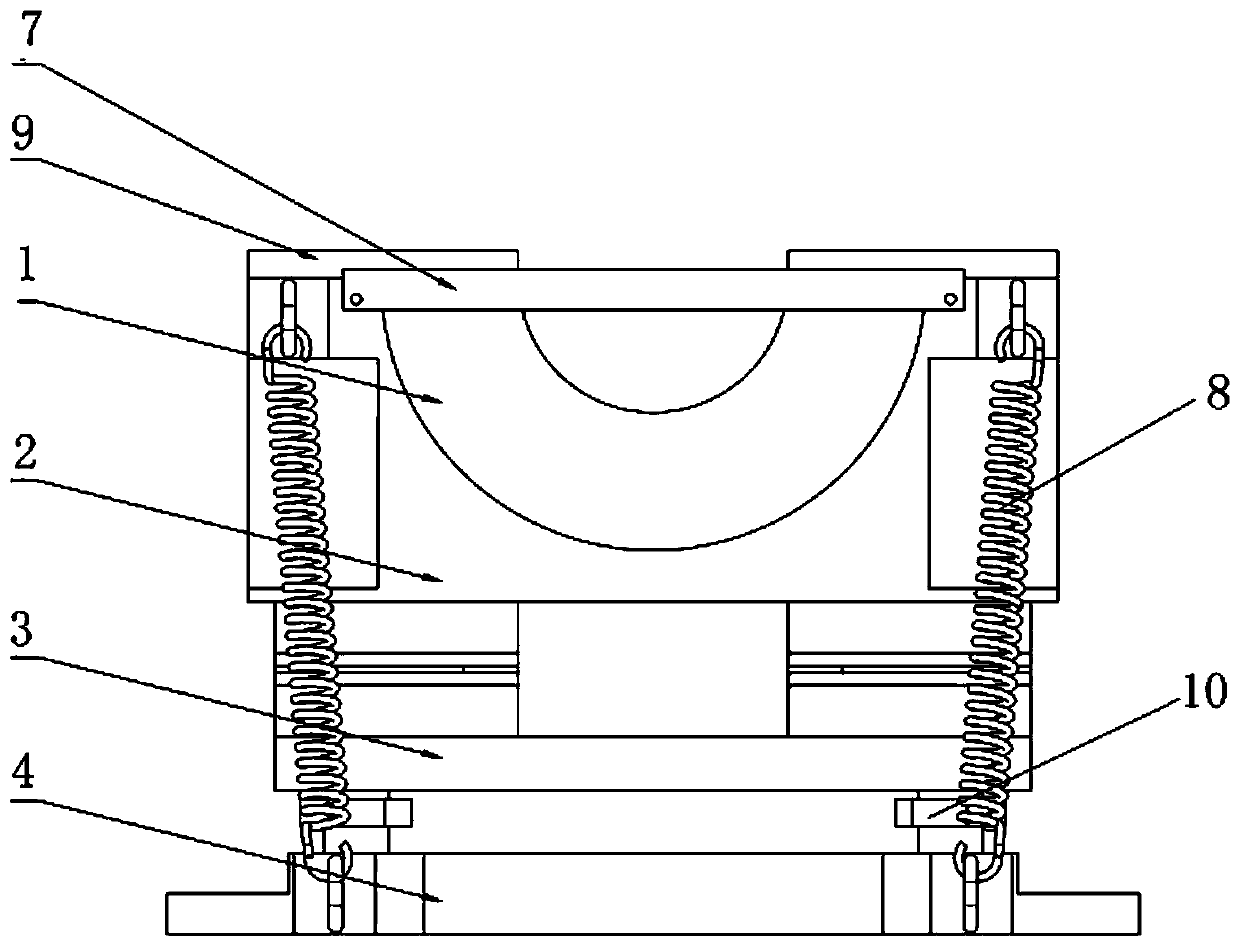

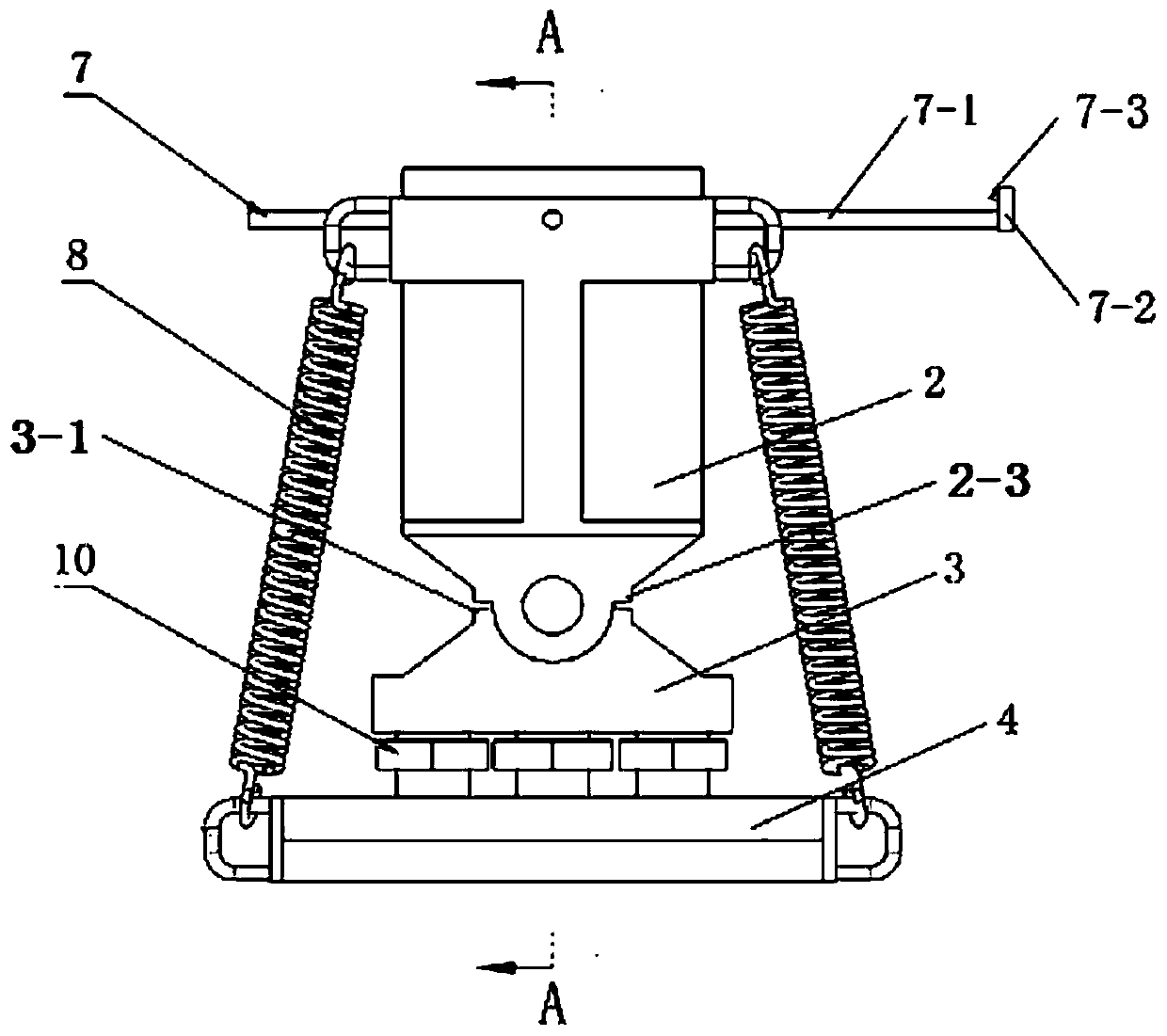

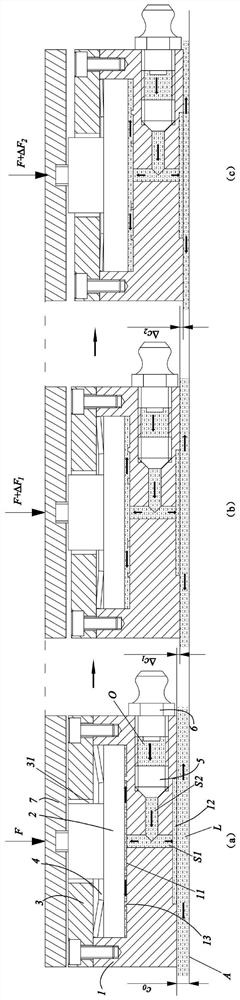

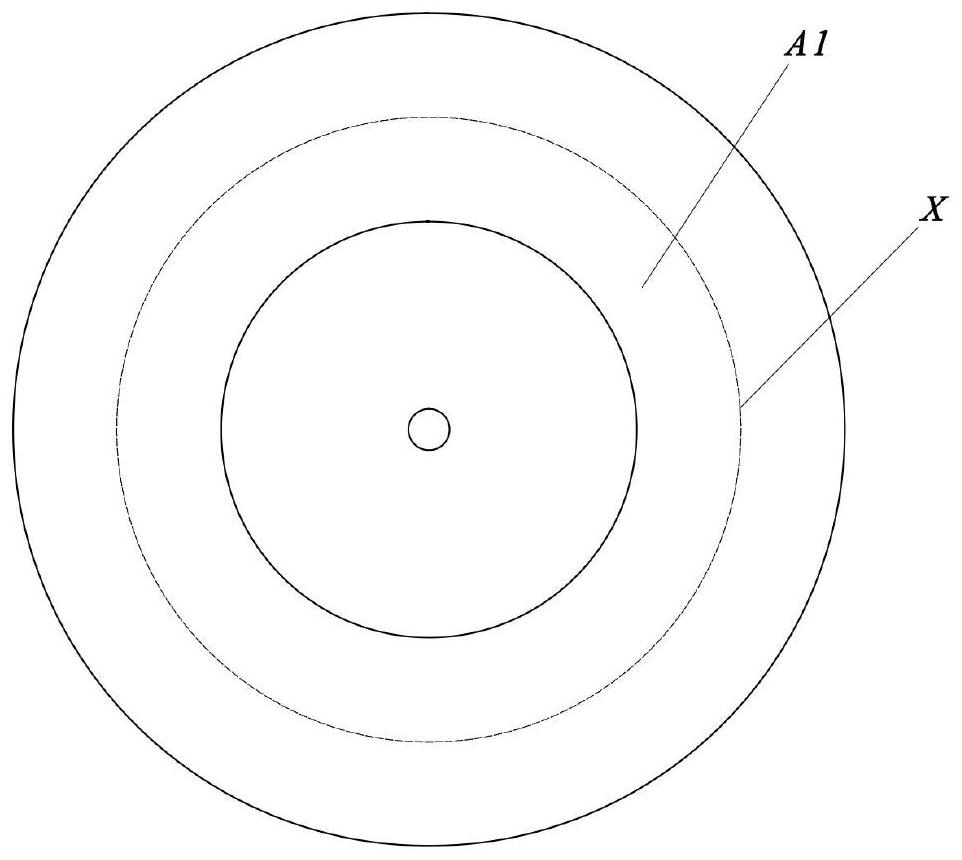

Split type static pressure gas bearing device with adjustable swing angle and for rotor static balance

ActiveCN110094424AAvoid wear and tearPlay a supporting roleGas cushion bearingsShaftsInlet channelRolling-element bearing

The invention discloses a split type static pressure gas bearing device with an adjustable swing angle and for rotor static balance, and belongs to the field of rotor static balance detection. The split type static pressure gas bearing device with the adjustable swing angle and for rotor static balance is used for solving the problems that an existing rotor static balance device uses a rolling bearing as a support, due to the fact that the frictional resistance is high, rolling balls can be worn after the rolling bearing is used for a long time, the rotor measurement accuracy is reduced, and most of existing static pressure gas bearings are integrally manufactured and cannot be applied to the existing rotor static balance device. The split type static pressure gas bearing device with the adjustable swing angle and for rotor static balance comprises a bearing pedestal, an upper supporting base, a lower supporting base, a base and a gas inlet channel. A first semi-cylindrical face whichis inwards concave is processed on the bearing pedestal, and multiple gas holes are formed in the first semi-cylindrical face. The bearing pedestal is fixed to the upper supporting base, a sealed gascavity is formed between the bearing pedestal and the upper supporting base, the multiple gas holes communicate with the sealed gas cavity, and the sealed gas cavity is connected with an external gassupply device through the gas inlet channel. The upper supporting base and the lower supporting base are hinged so that the axis of the semi-cylindrical face can swing by a certain angle in the vertical direction. The lower supporting base and the base are connected together. The split type static pressure gas bearing device with the adjustable swing angle and for rotor static balance is suitablefor rotor static balance detection.

Owner:HARBIN INST OF TECH

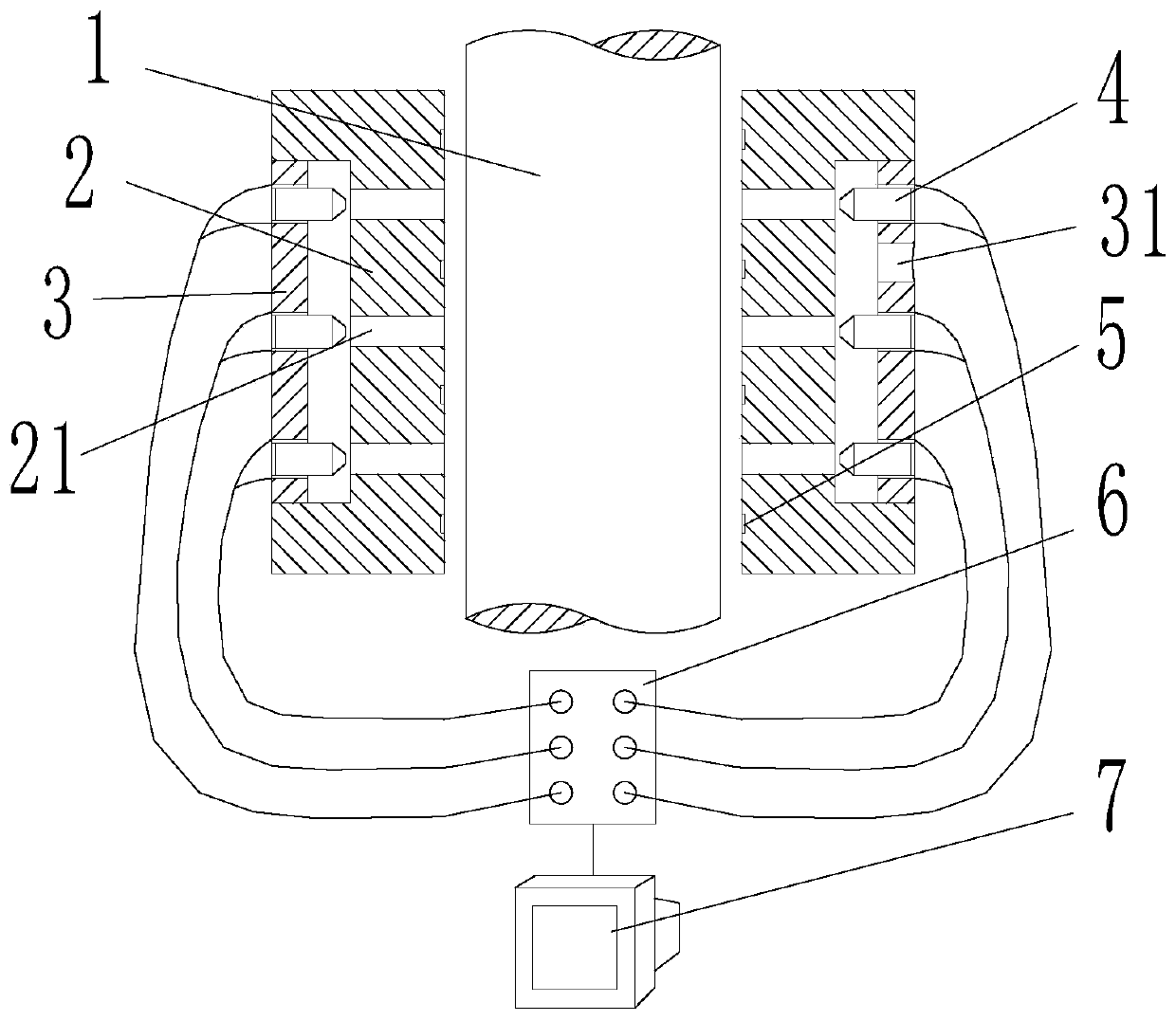

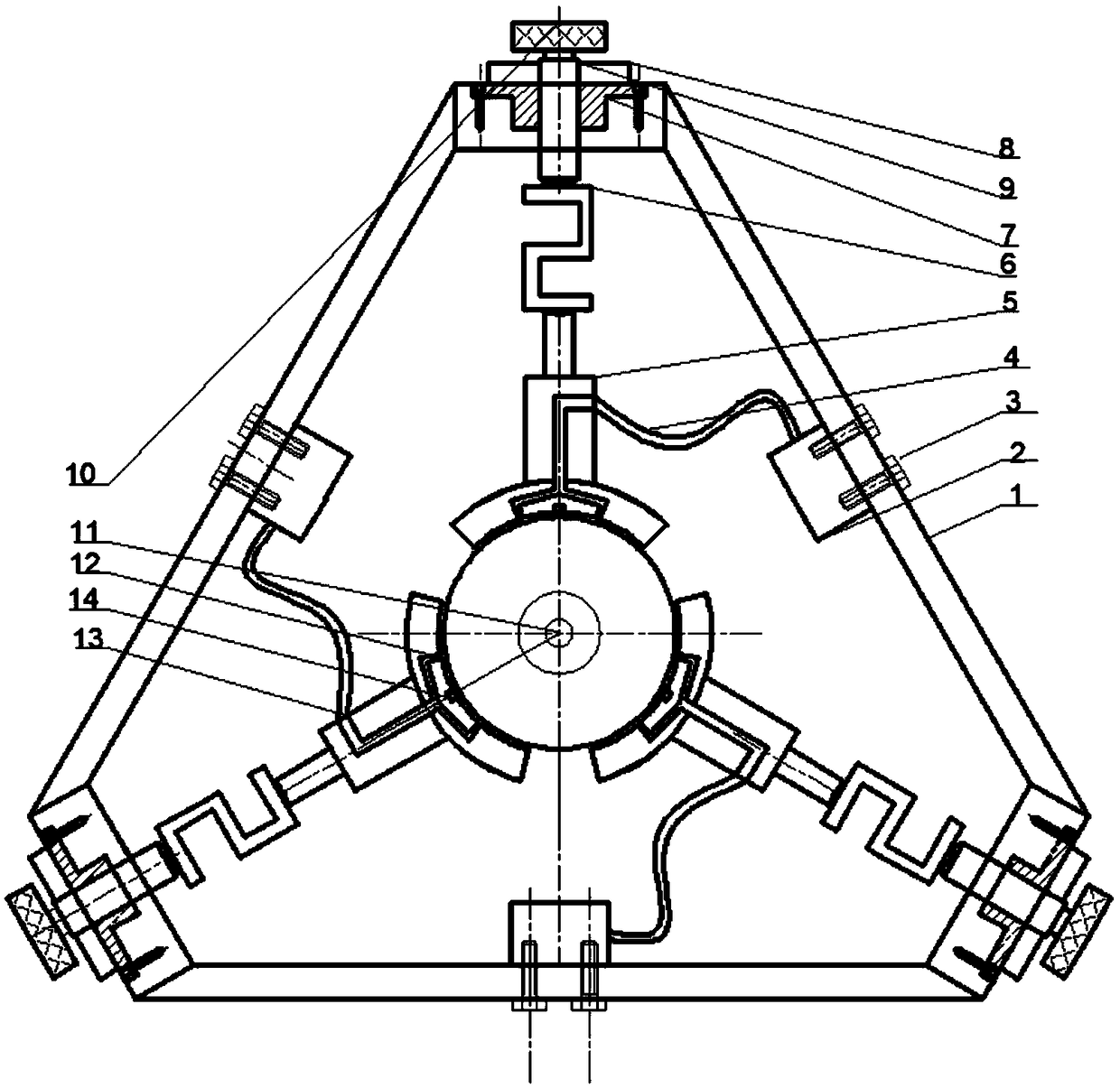

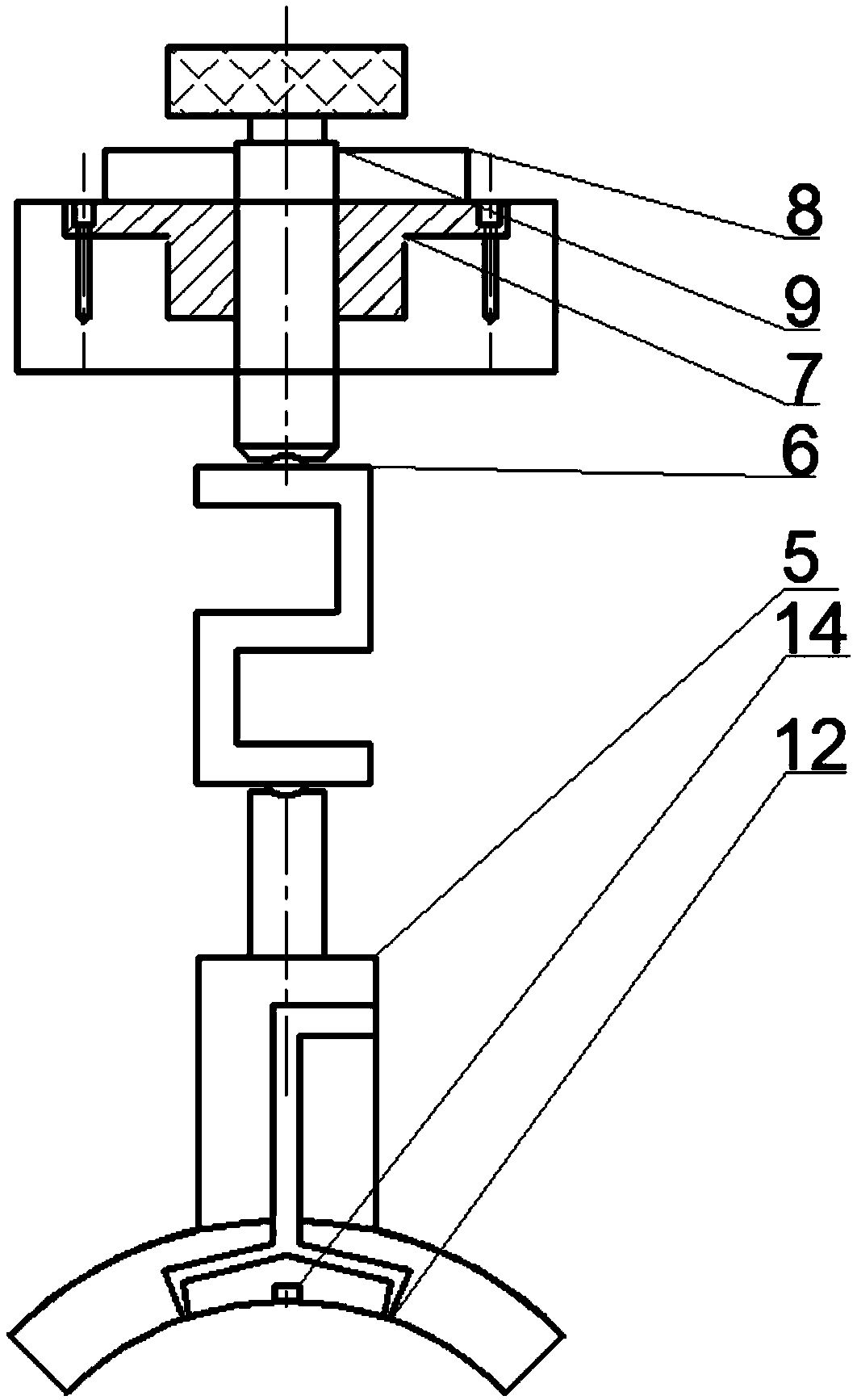

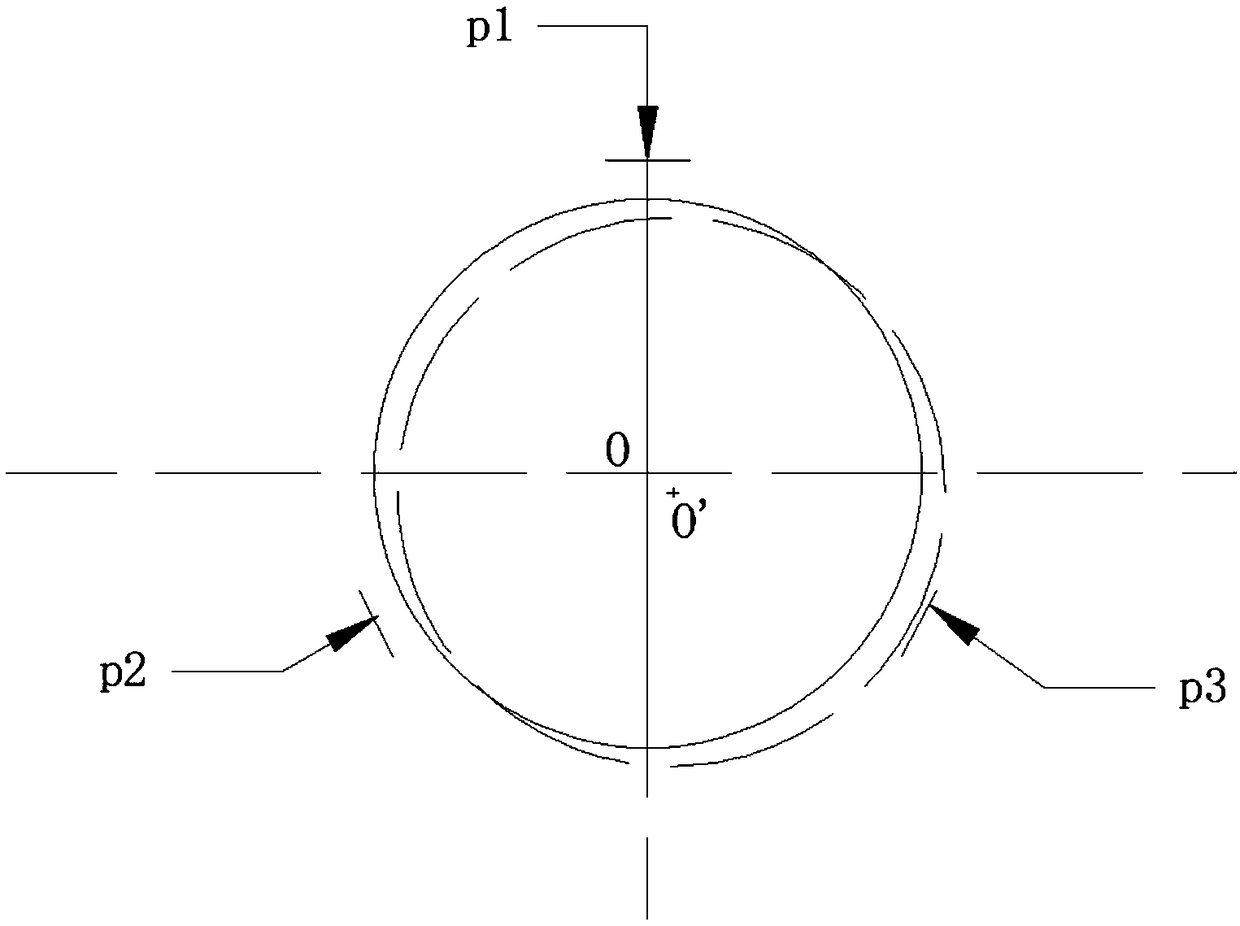

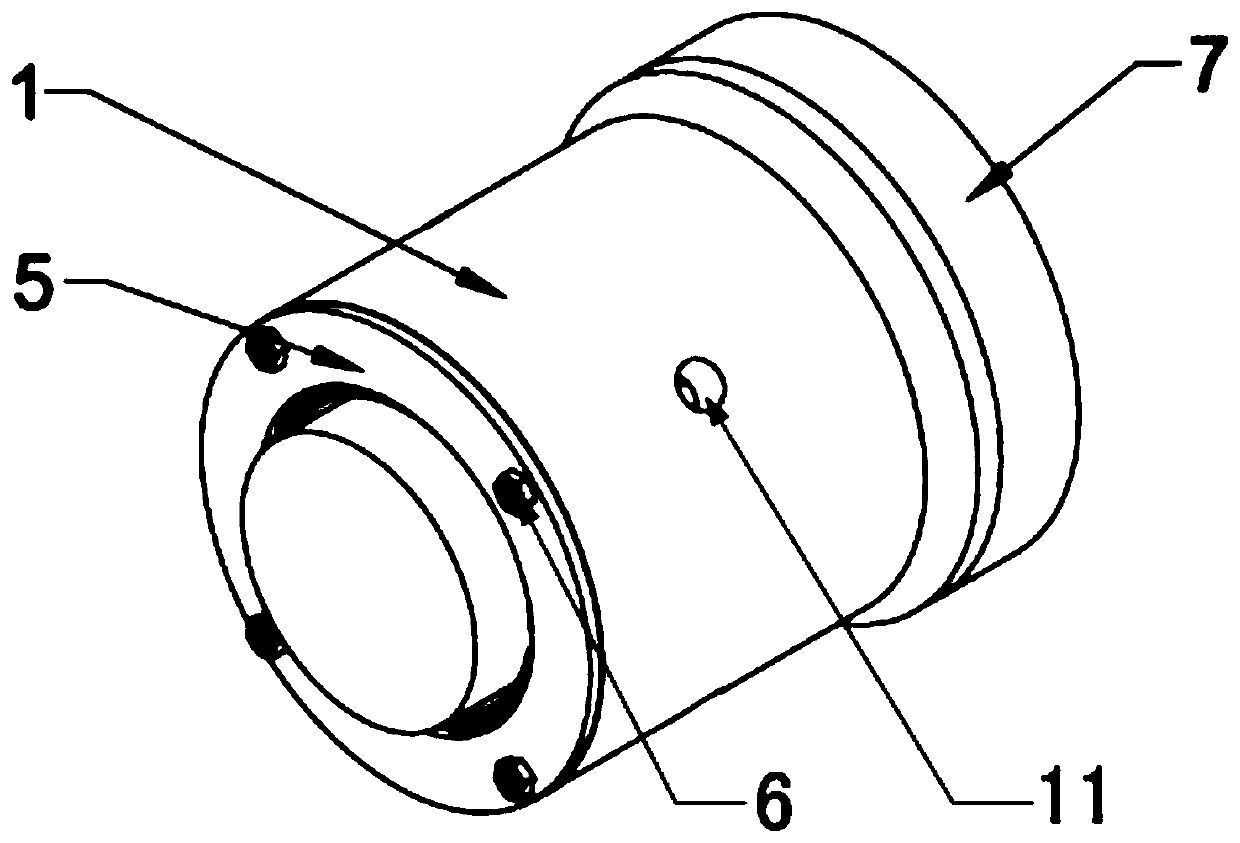

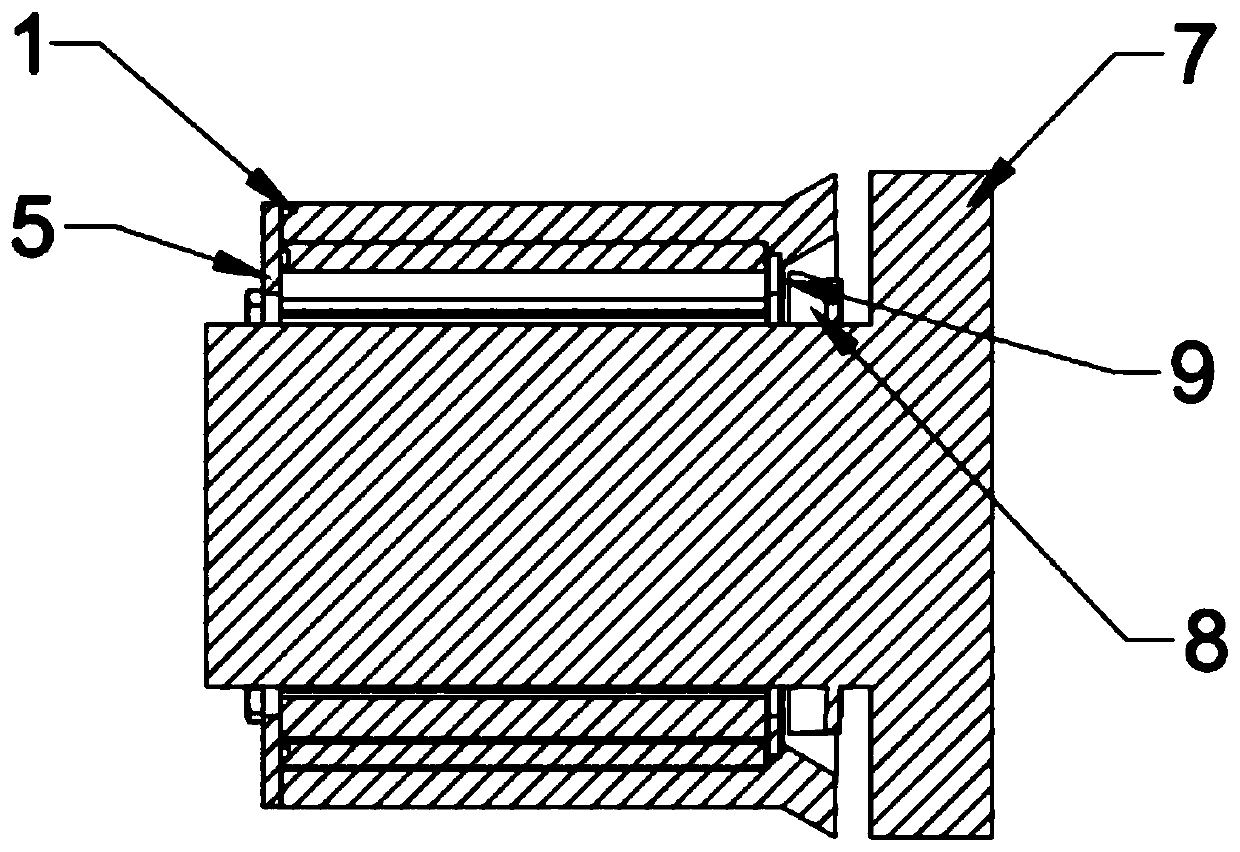

Air flotation main shaft bearing compensation device and method

PendingCN109488689ADoes not affect rotational movementUniform Compensation Bearing CapacityHydrostatic bearingsControl valvesMachining

The invention discloses an air flotation main shaft bearing compensation device and method. Bearing compensation is conducted on rotation errors of existing air flotation bearings through weights or springs, and real-time detection and bearing compensation cannot be achieved. When an air flotation main shaft generates rotation errors, a control valve adjusts the output gas pressure under the control of a controller, bearing compensation is conducted on the side, with a thin air film, of the air flotation main shaft, and adjustment of the controller is not stopped until displacement sensors ofthree air flotation support assemblies detect that the radial clearances between the air flotation support inner ends of the three air flotation support assemblies and the air flotation main shaft arethe same. The air flotation main shaft returns to the air floatation support centering position of the three air flotation support assemblies, and air flotation main shaft bearing compensation is achieved. By means of the air flotation main shaft bearing compensation device and method, real-time compensation of bearing force is achieved, and a pressure sensor displays air flotation support bearing force; and the radial clearances between the air flotation support inner ends and the air flotation main shaft are adjustable, and therefore the device can better adapt to different rotating speedsand machining of different parts.

Owner:HANGZHOU DIANZI UNIV

Self-compensating hydrostatic planar bearing device and method thereof

Owner:IND TECH RES INST

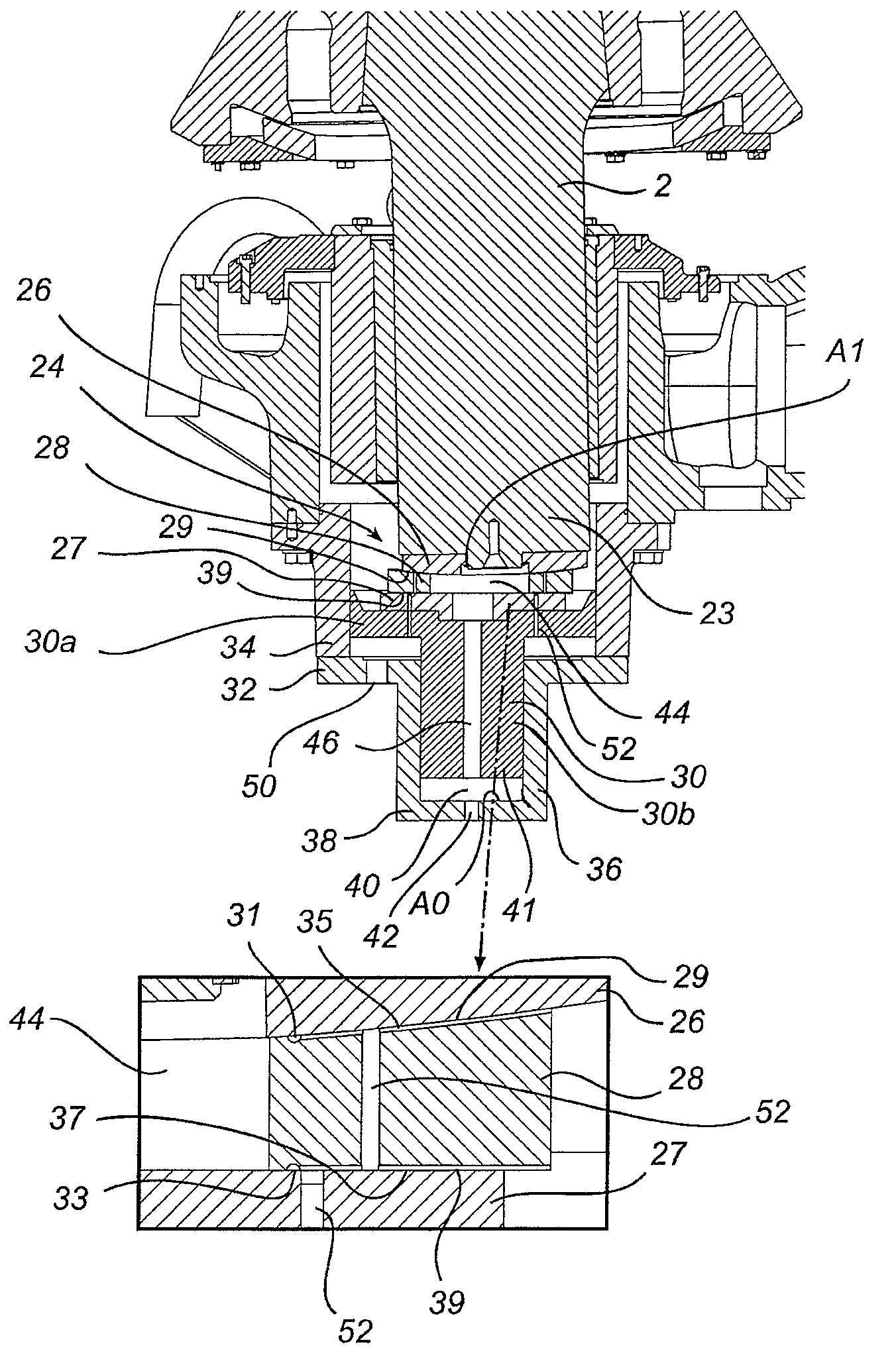

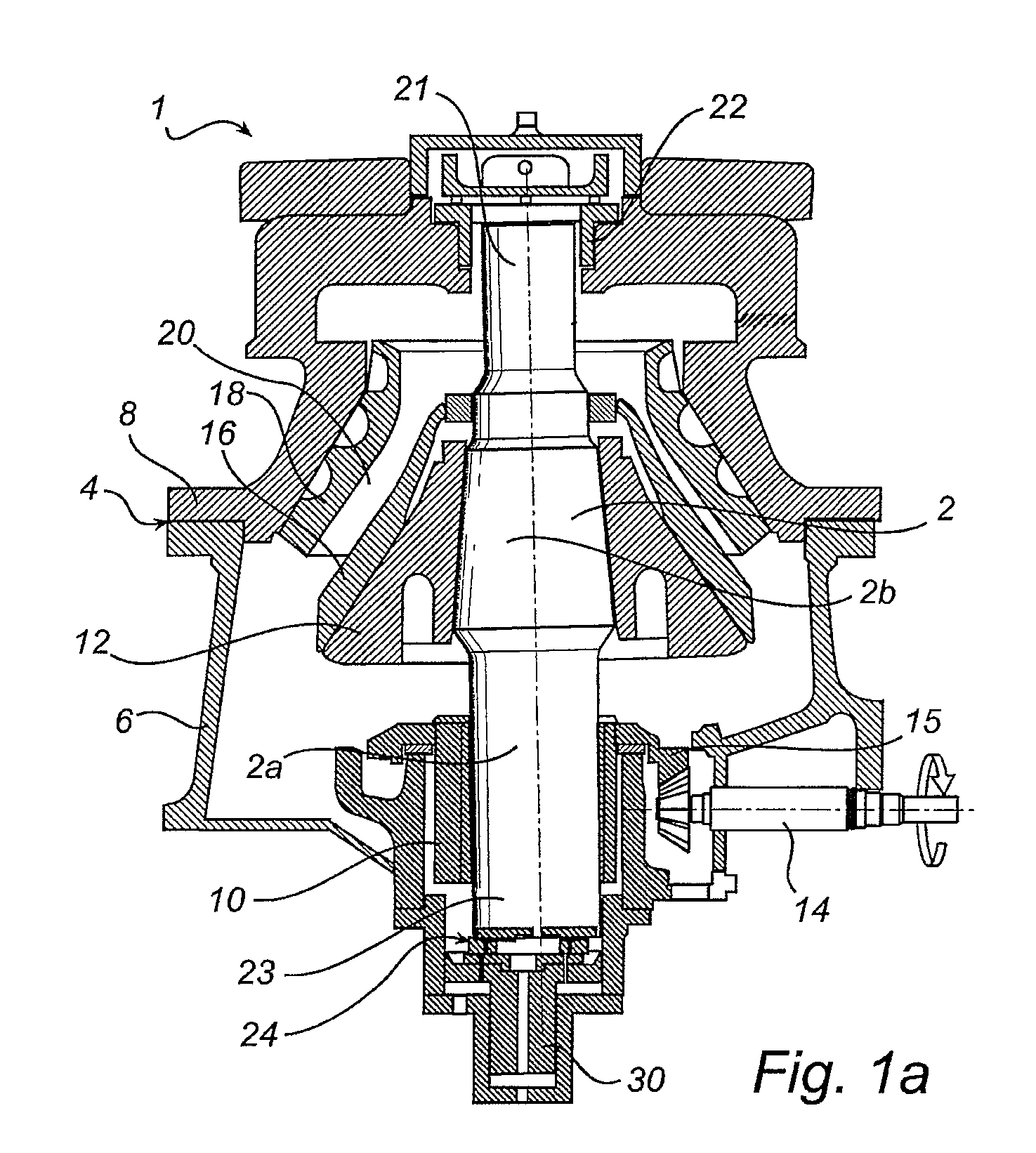

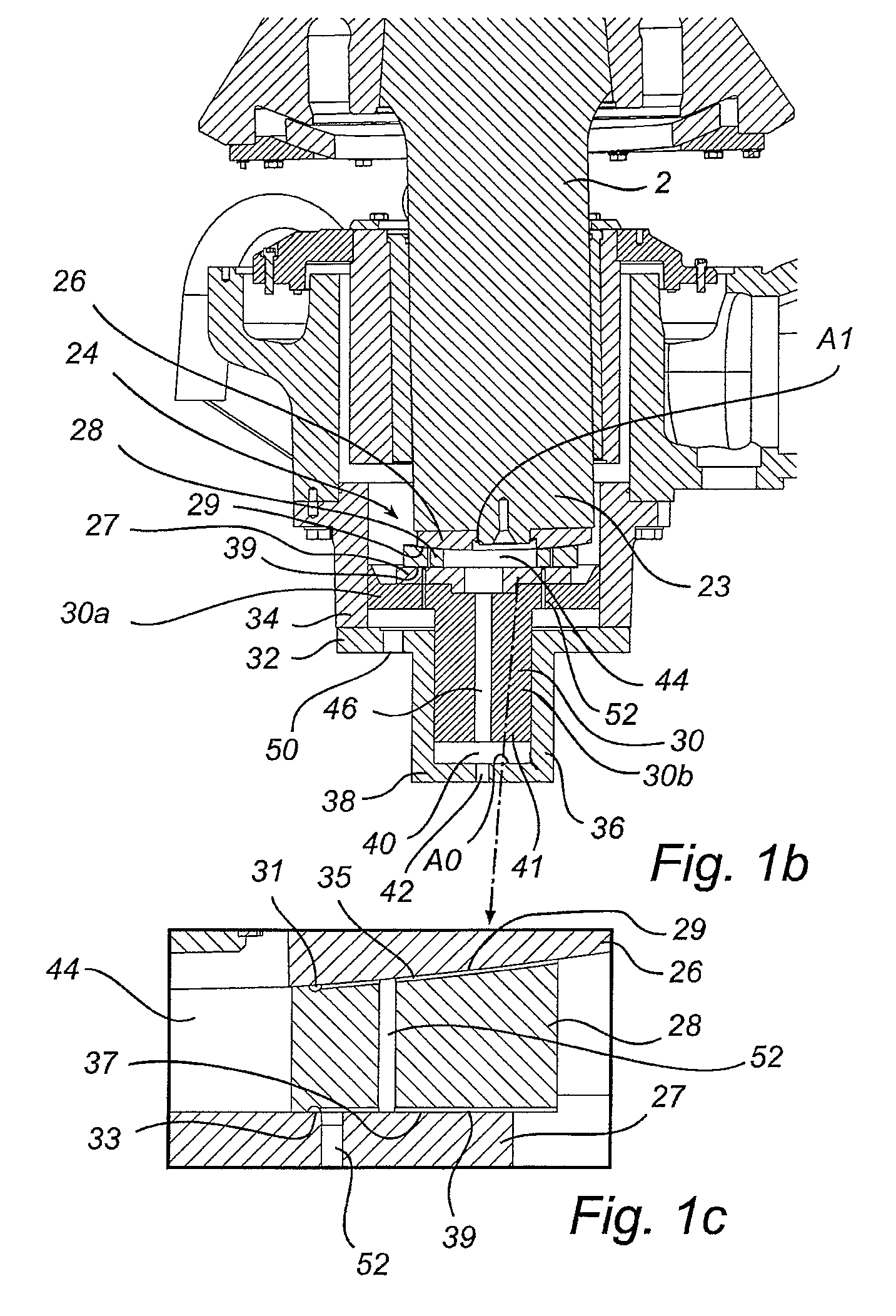

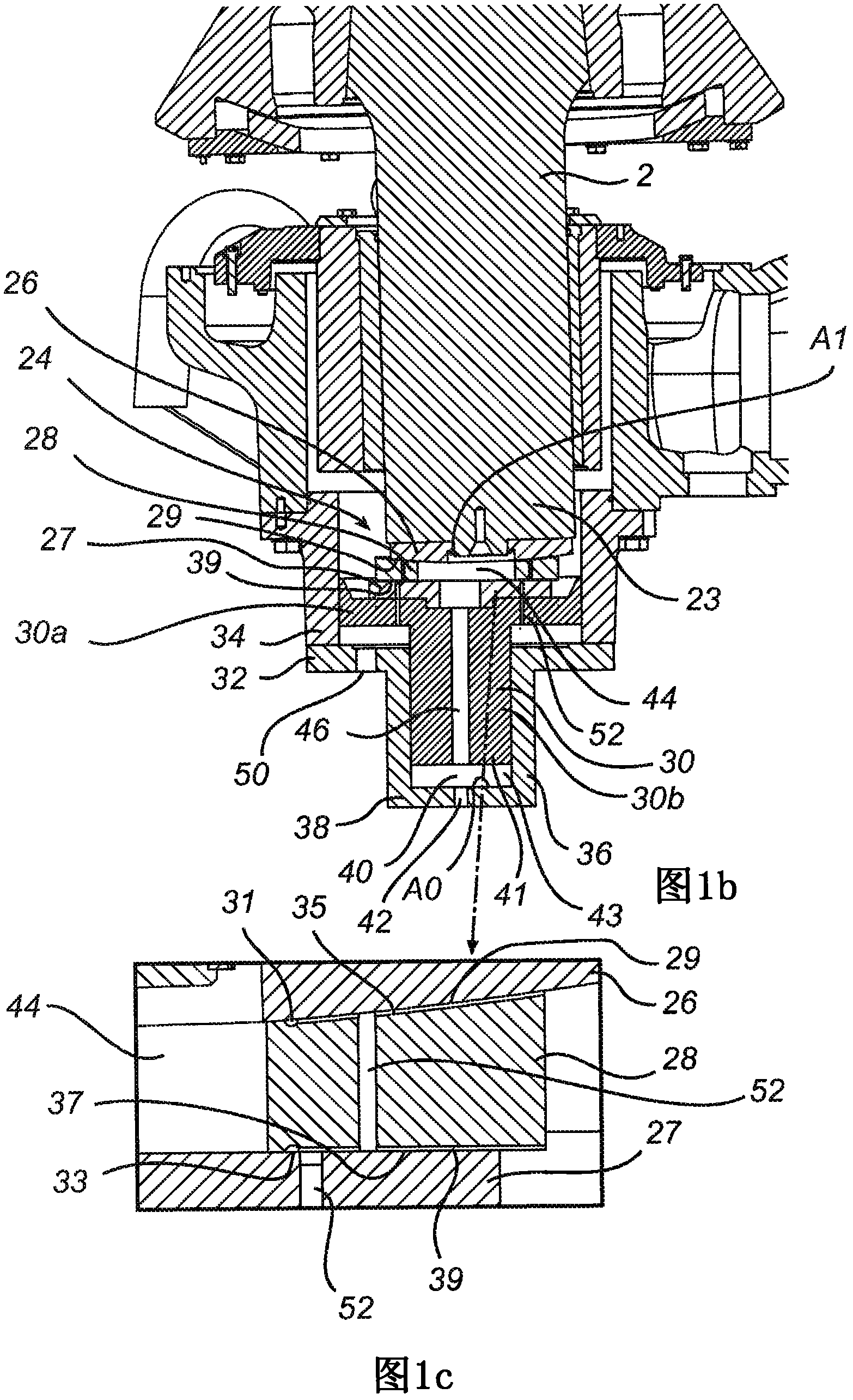

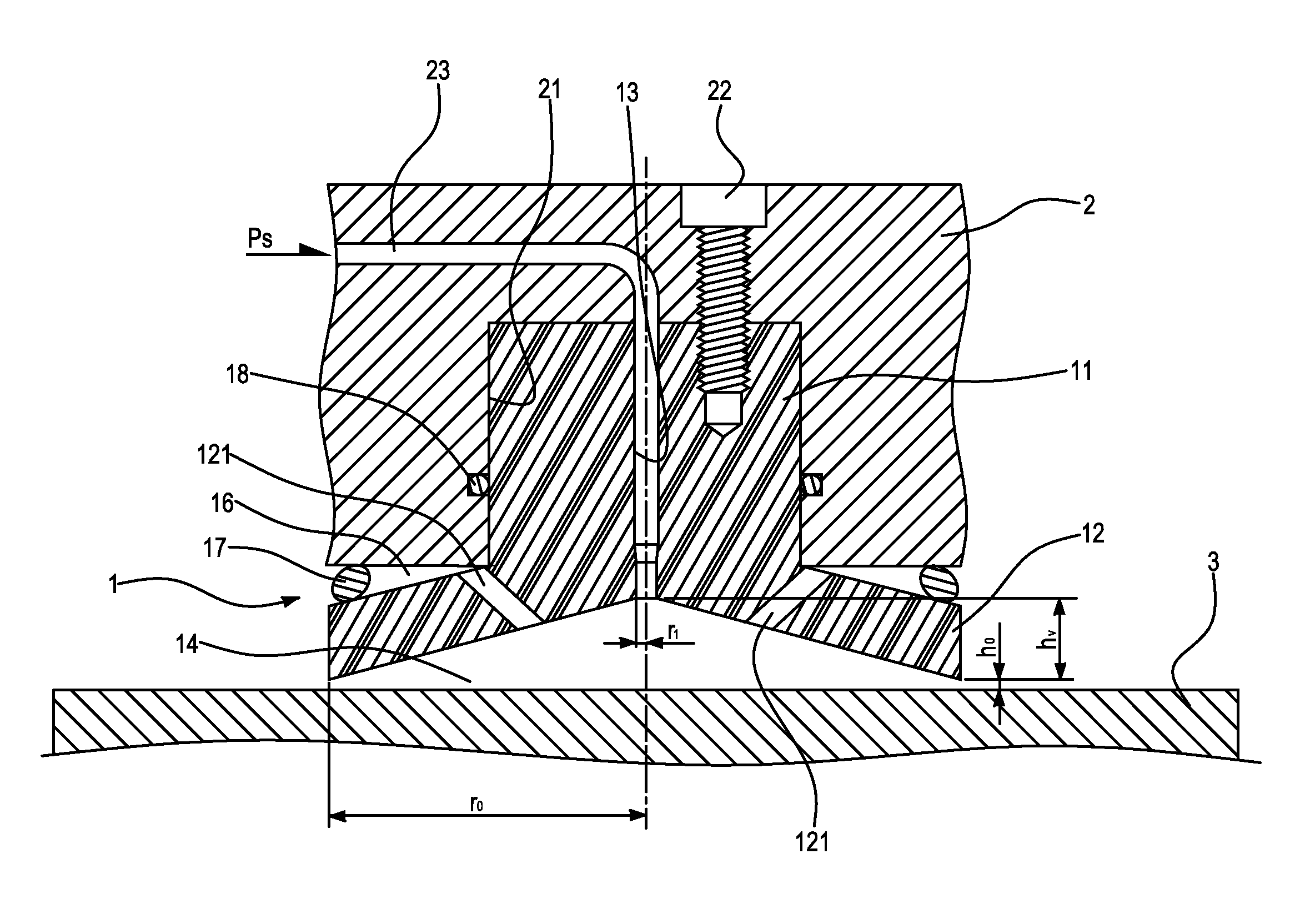

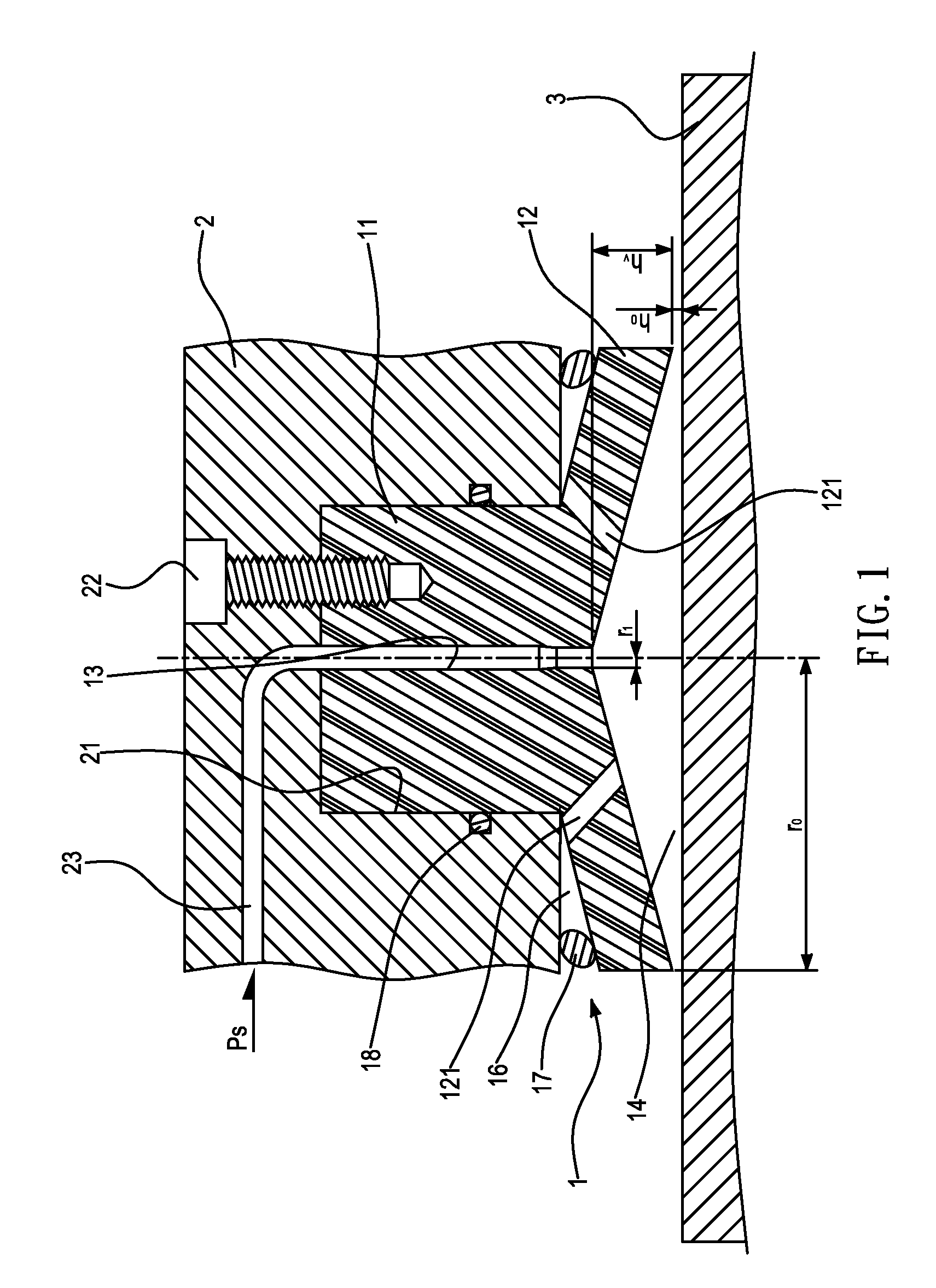

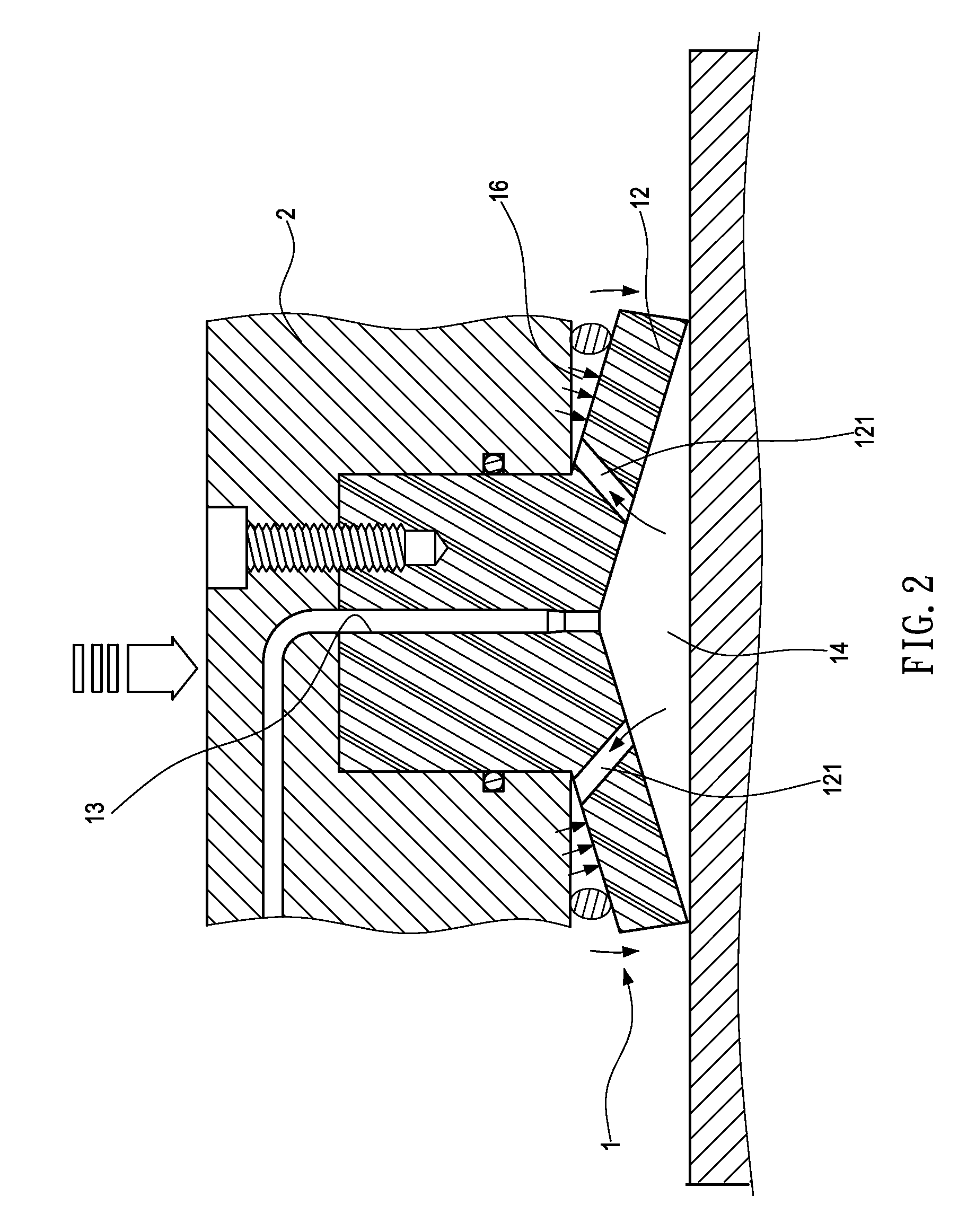

Thrust bearing for a gyratory crusher and method of supporting a vertical shaft in such a crusher

InactiveCN102256708ALow costReduce loadSliding contact bearingsHydrostatic bearingsThrust bearingCrusher

A gyratory crusher comprises a crushing head on which a first crushing shell is mounted, and a frame on which a second crushing shell is mounted. The crusher has a trust bearing (24) which is made up of horizontal bearing plates (26, 27, 28) and which is located between a vertical shaft (2) and a pis-ton (30) arranged vertically below the same. The crusher further has a first space (40), which is adapted to receive a variable amount of pressurized liquid, which first space (40) is defined by the piston (30) and a piston housing (32) formed in the frame, and a second space (44) which is adapted to receive, by way of a duct (46), pressurized liquid from the first space (40), which second space (44) is located between the vertical shaft (2) and the piston (30) and at least partly accommodated in an opening in at least one of said bearing plates (26, 27, 28). The first space (40) and the second space (44) are adapted by means of the liquid to transmit forces from the crushing head to the piston housing (32), in order that the load on the trust bearing (24) is relieved.

Owner:SANDVIK INTPROP AB

Bearing device of gas turbine power generation equipment and gas turbine power generation equipment

Owner:HITACHI LTD

Static pressure type radial gas bearing structure

ActiveCN111577765AEffective adjustment of stiffnessAdjust stiffnessGas cushion bearingsHydrostatic bearingsMetal rubberStructural engineering

The invention discloses a static pressure type radial gas bearing structure. The static pressure type radial gas bearing structure mainly consists of components such as a fixing bearing seat, metal rubber, bearing bushes and bearing bush baffles, wherein the fixing bearing seat adopts a circular ring design, and achieves a fixing effect on the bearing bushes and the metal rubber; and an annular high-pressure gas cavity is formed inside the fixing bearing seat, anti-rotation grooves extend on the inner surface in the axial direction, and the bearing bush baffles are fixedly arranged at the endsurfaces of the two ends. Each bearing bush is processed and manufactured by carbon-graphite alloy materials, anti-rotation grooves are formed in the outer surface in the axial direction, and annulargrooves are designed at the end surfaces of the two ends of the bearing bush and are used for installing a meal sealing ring. The meal sealing ring is arranged between the bearing seat and the bearingbushes, and is provided with position limiting bulges corresponding to the anti-rotation grooves of the fixing bearing seat and the bearing bushes. The bearing bush baffles are arranged at the fixingbearing seat, form a sealing surface by cooperating with the end surfaces of the two ends of the bearing bushes, and are used for sealing of high-pressure gas supply of a bearing.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

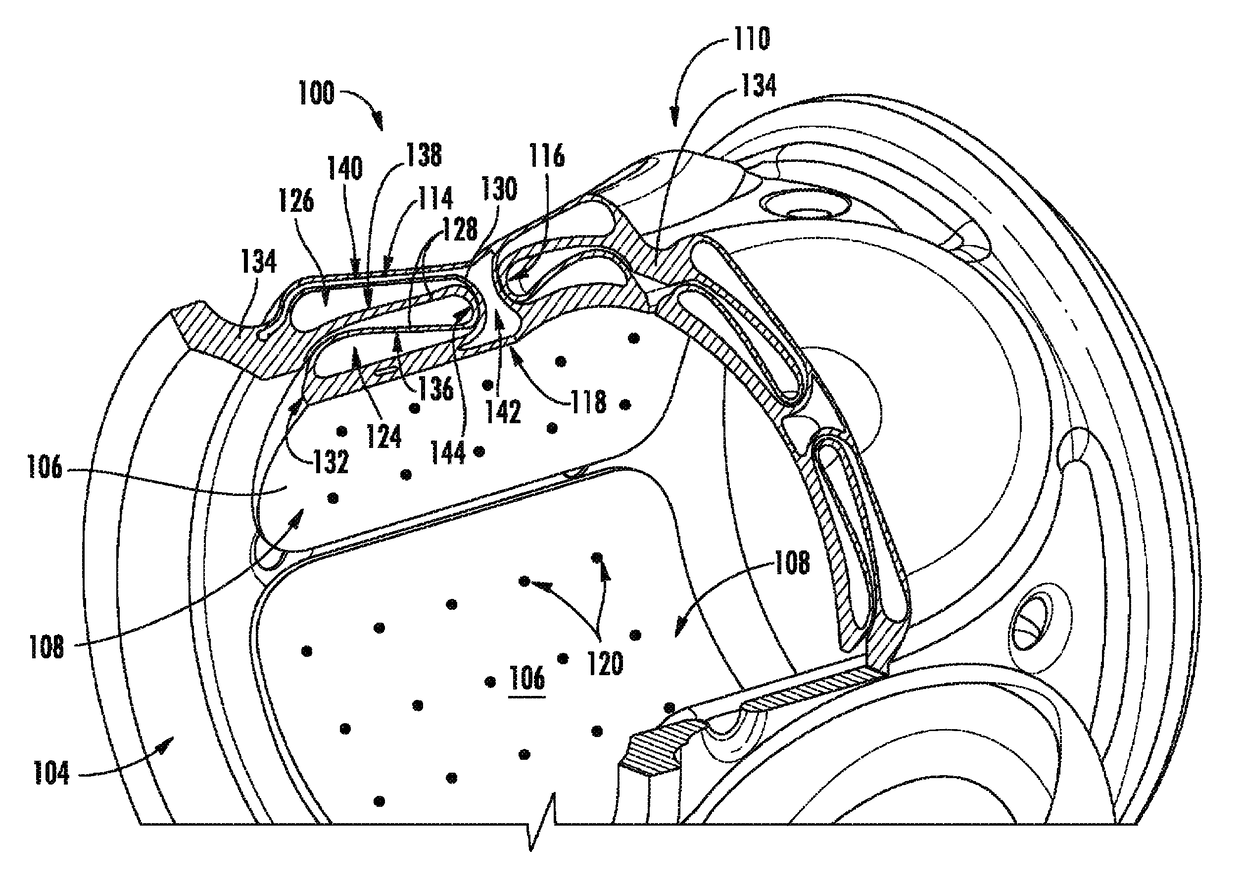

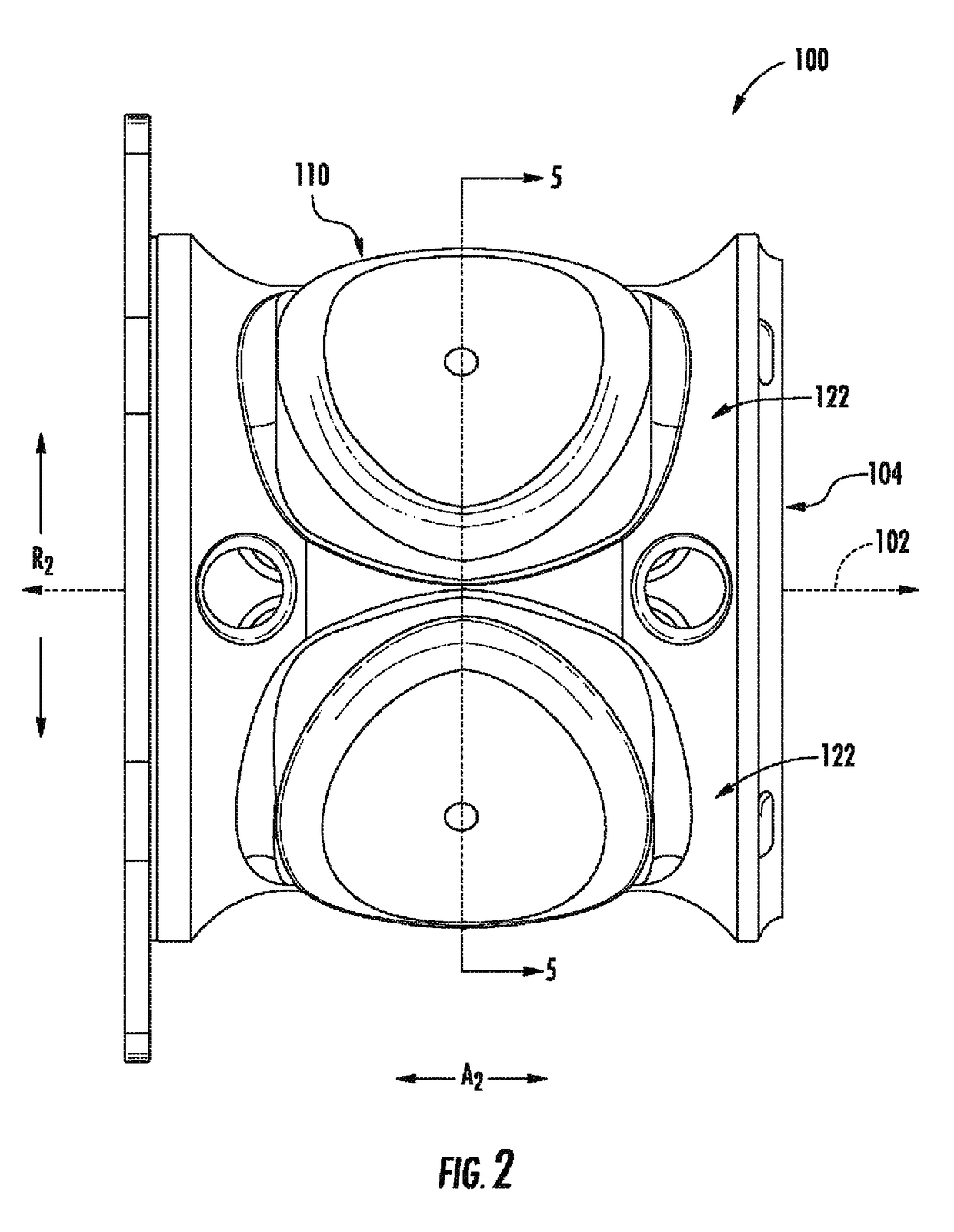

Gas distribution labyrinth for bearing pad

The present disclosure is directed to a bearing assembly for a gas turbine engine. The bearing assembly includes a bearing housing and a bearing pad for supporting a rotary component of the gas turbine engine. The bearing pad includes at least one gas inlet and a plurality of gas outlets configured on an inner surface thereof. The gas inlet is in fluid communication with the plurality of gas outlets via a gas distribution labyrinth. Further, the gas distribution labyrinth includes a plurality of passageways configured to evenly distribute pressurized gas entering the gas inlet to an interface between the inner surface of the bearing pad and an outer diameter of the rotary component.

Owner:GENERAL ELECTRIC CO

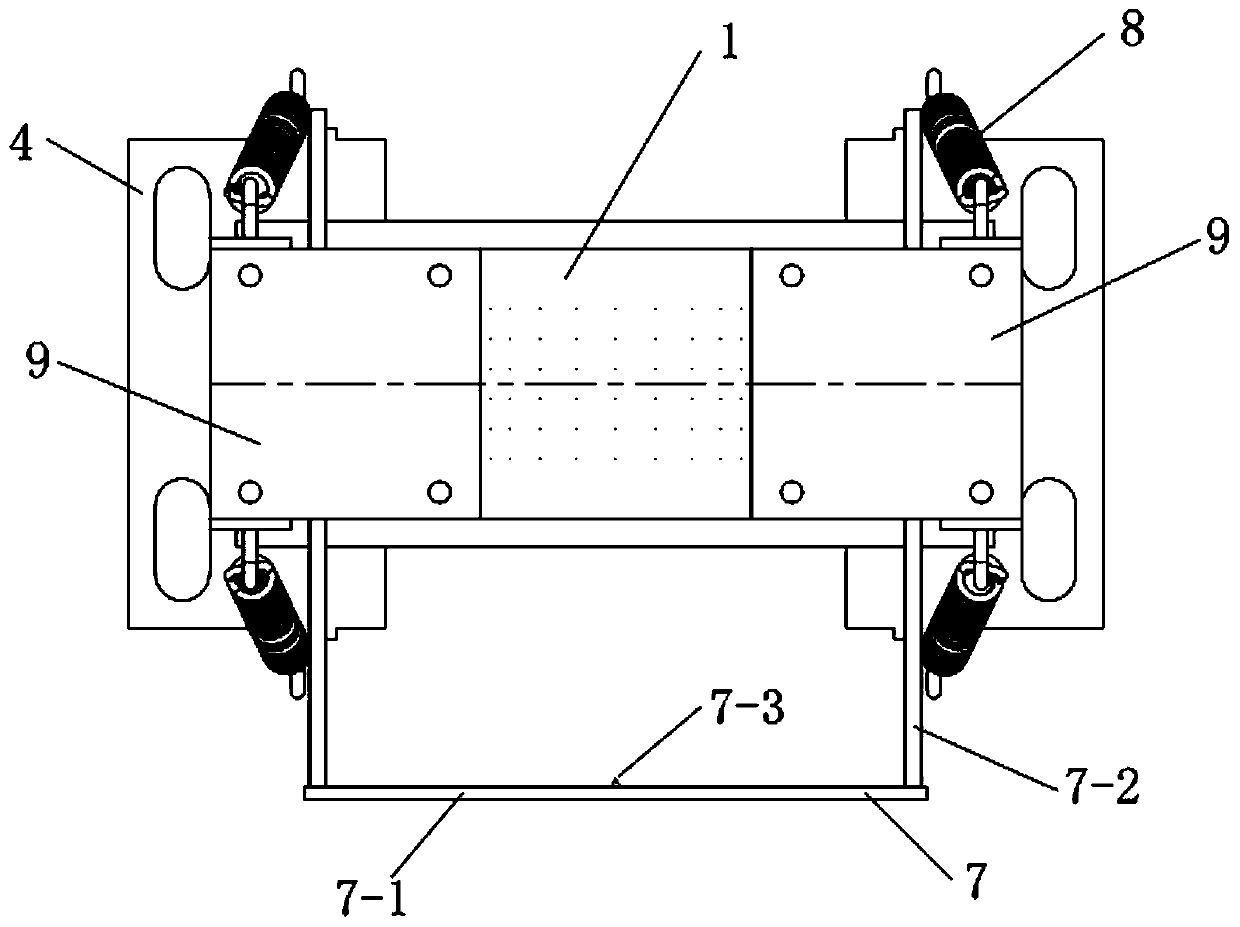

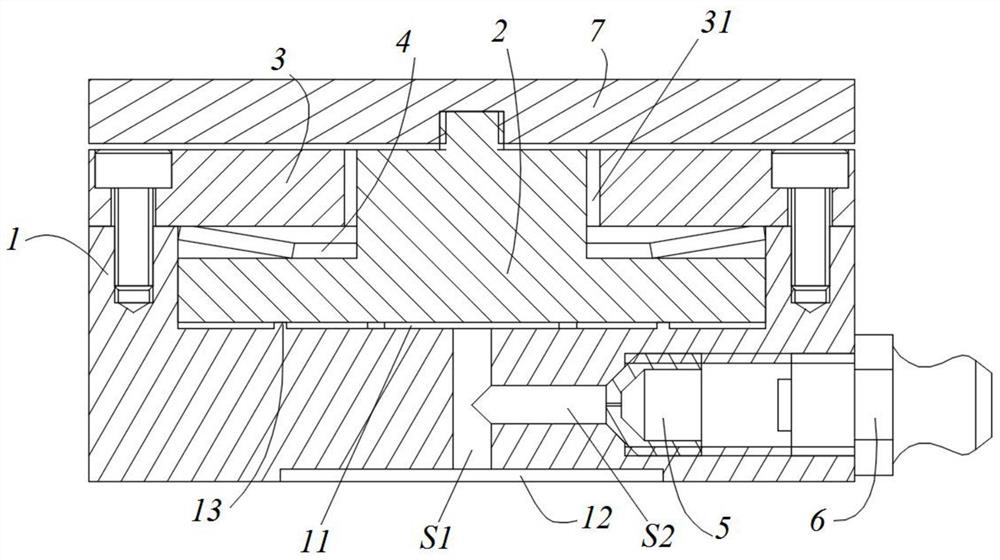

Hydrostatic bearing and hydrostatic guide rail assembly

The invention discloses a hydrostatic bearing and a hydrostatic guide rail assembly. The hydrostatic bearing comprises a supporting block, a cover plate, a bearing piston, a bearing disc, an elastic element and a throttler, wherein an auxiliary cavity is formed in the upper portion of the supporting block, a main cavity is formed in the lower portion of the supporting block, and the auxiliary cavity communicates with the main cavity; the cover plate covers the supporting block and is provided with an open hole communicating with the auxiliary cavity; the bearing piston is contained in the auxiliary cavity; the bearing disc is connected with the top of the bearing piston extending out of the open hole and used for bearing external loads; the elastic element is arranged in the auxiliary cavity, one end of the elastic element abuts against the bearing piston, and the other end of the elastic element abuts against the bottom face of the cover plate; and the throttler is installed in the supporting block, an outlet of the throttler communicates with a first channel through a second channel, and an inlet of the throttler communicates with external oil supply equipment. According to the hydrostatic bearing and the hydrostatic guide rail assembly, small hole throttling is combined with a piston type displacement self-compensation structure, so that when the bearing force borne by the hydrostatic bearing changes, rapid response can be achieved, the hydrostatic bearing can return to the original position within a short time, and then quasi-infinite rigidity is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Elastic foil sheet gas bearing and elastic foil sheet gas bearing friction pair

InactiveCN110030269AAir supply pressure adjustablePrecise control of stiffnessShaftsRotary machine partsSystem stabilityEngineering

The invention provides an elastic foil sheet gas bearing and an elastic foil sheet gas bearing friction pair. The elastic foil sheet gas bearing comprises a bearing block, arch foil and a porous lining sleeved with the part between the bearing block and the arch foil. The bearing block is provided with a plurality of gas supply holes evenly arranged in the circumferential direction, and the gas supply pressure of the gas supply holes can be adjusted. The porous lining is provided with a plurality of pressure equalizing holes communicating with the gas supply holes and the arch foil. High-pressure gas in the gas supply holes directly acts on the arch foil through the pressure equalizing holes. During work, high-pressure gas inflation is conducted from the gas supply holes of the bearing block, the high-pressure gas directly acts on the arch foil through the pressure equalizing holes of the porous lining, and additional rigidity and damping are provided for the arch foil. Meanwhile, thevibration situation of a rotor system is analyzed according to the feedback result of the gas supply pressure of the gas supply holes, the gas supply pressure of various gas supply holes is adaptivelyadjusted, accordingly accurate regulation and control over the arch foil rigidity and damping can be achieved, the flexibility of the arch foil is good under the light load condition, the arch foil is not crushed under the heavy load condition, and stability of the rotor system is guaranteed.

Owner:SHANGHAI HYDROGEN PROPULSION TECH CO LTD

Self-compensating hydrostatic planar bearing device and the method thereof

A self-compensating hydrostatic planar bearing device comprises: a flow restrictor, disposed on a slide-table, having a flexible supporting unit extendedly formed on an end thereof; a first chamber, formed on another end of the flow restrictor opposite to that of the flexible supporting unit for communicating with a pipe disposed penetrating through the flow restrictor; and a second chamber, formed between the supporting unit and the slide-table for communicating with the first chamber through a communication hole. Operationally, when the load is changing, the pressure to the first chamber will be changing accordingly while the pressure change will be transferred to the second chamber through the communication hole for causing the flexible supporting unit to deform and thereby further causing the volume of the first chamber to change so that the pressure of the first chamber is consequently changed therewith and thus accomplishes a self-compensating process of the bearing's stiffness.

Owner:IND TECH RES INST

Gas bearing spindle

Owner:NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com