Thrust bearing for a gyratory crusher and method of supporting a vertical shaft in such a crusher

A technology of gyratory crushers and thrust bearings, applied in the direction of rotating bearings, bearings, shafts and bearings, etc., can solve problems such as high cost, limited capacity of cone crushers, wear of horizontal support plates, etc., and achieve cost reduction and reduction Small power loss and reduced mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

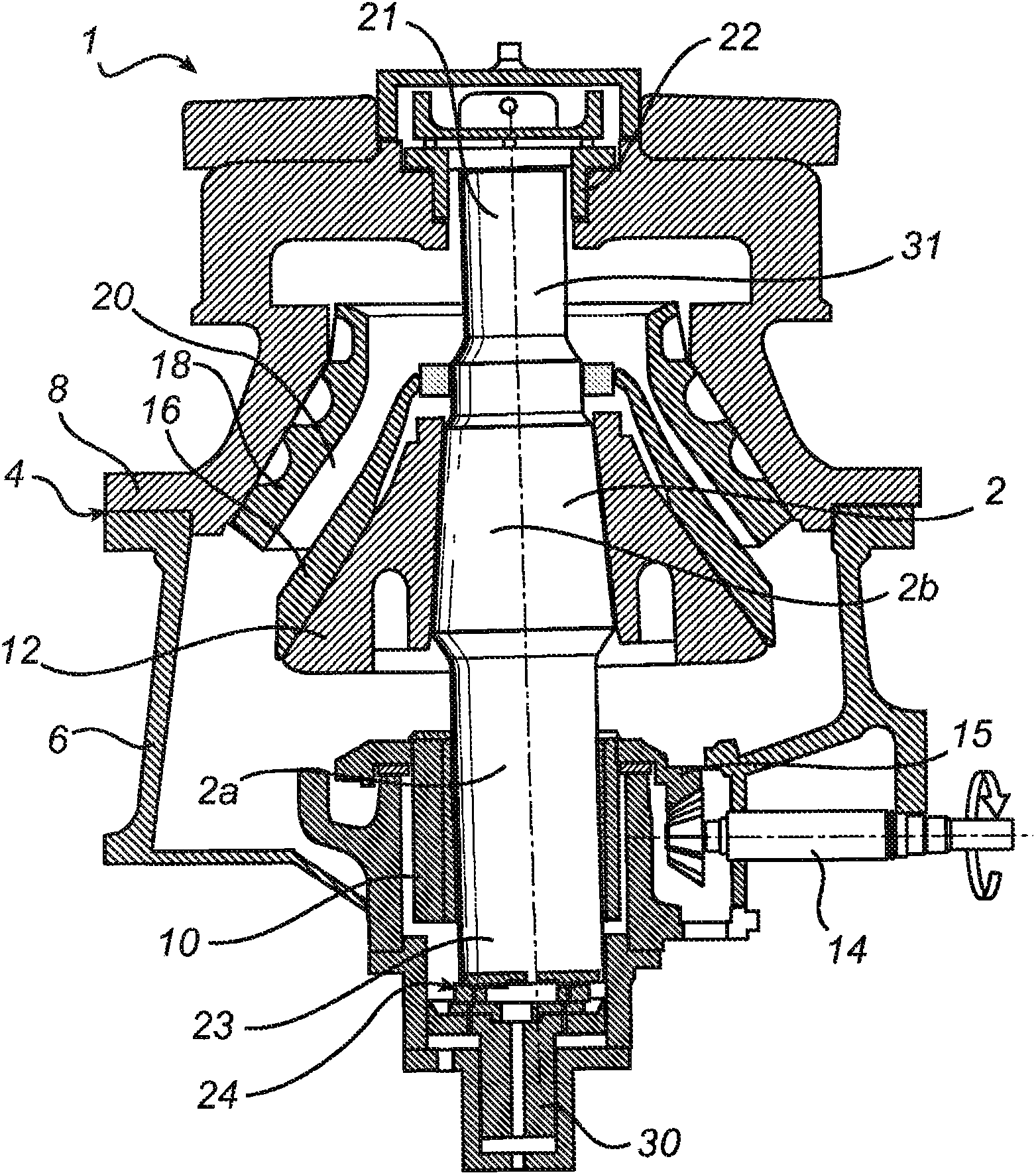

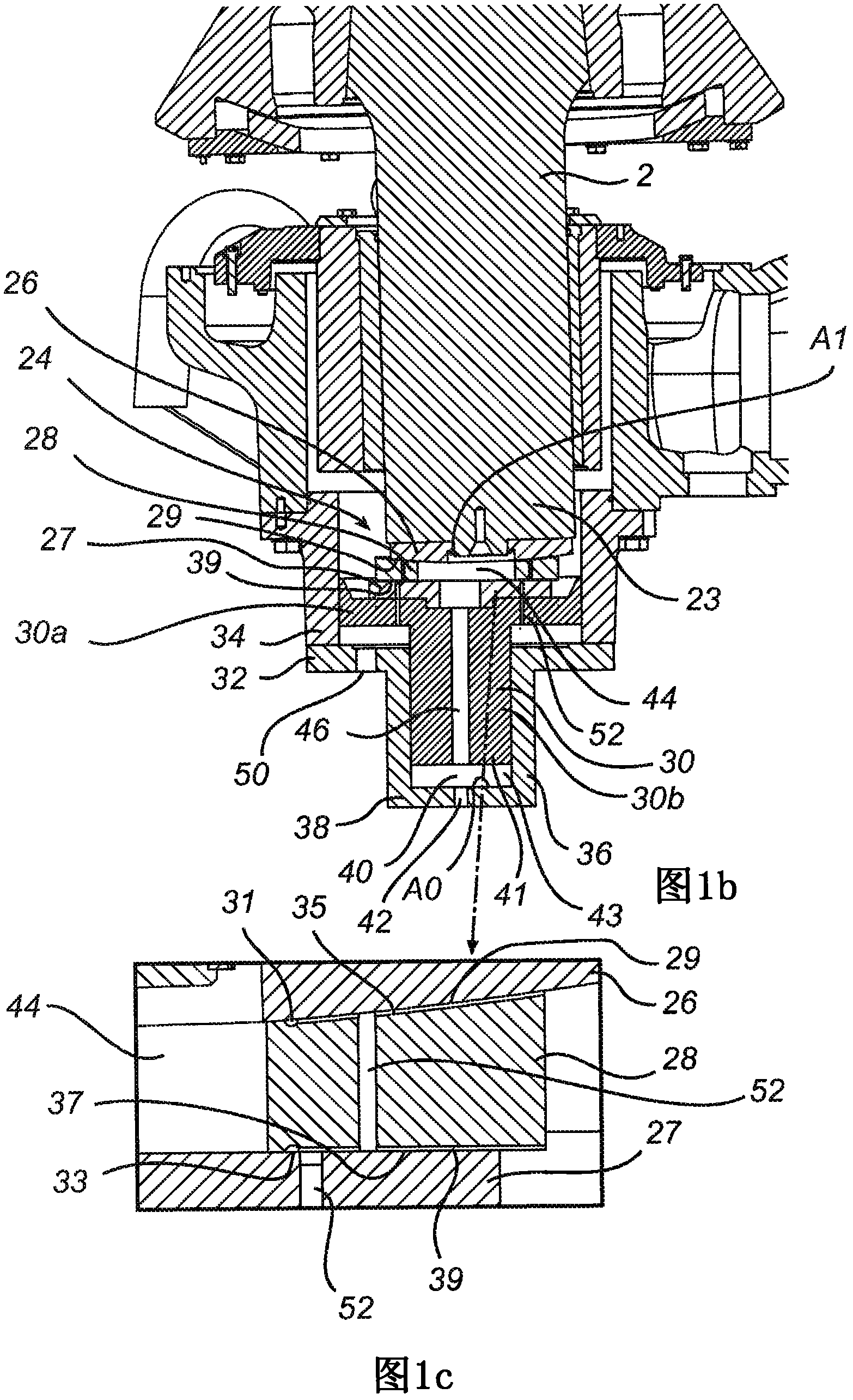

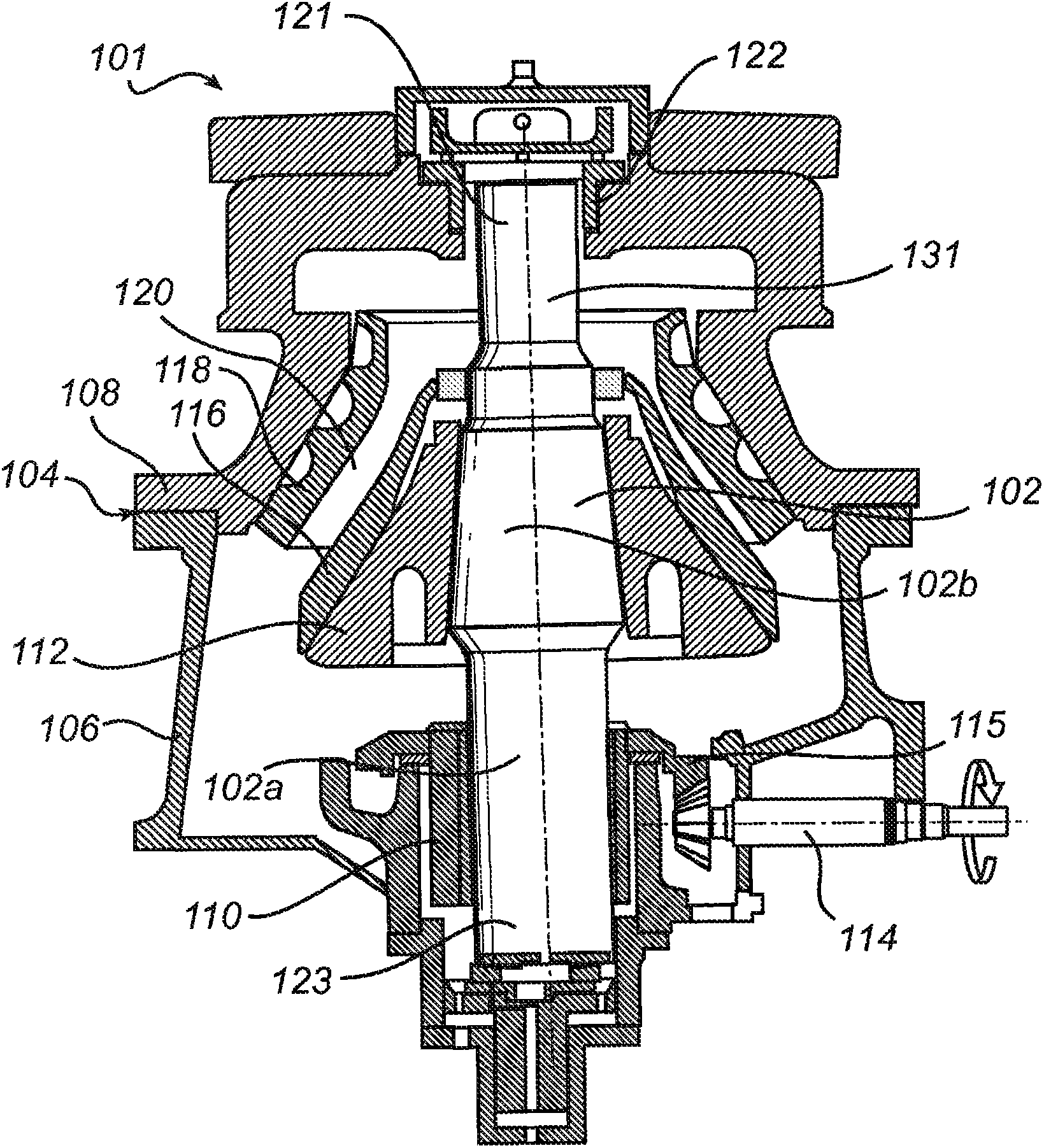

[0029] Figure 1a A gyratory crusher 1 according to a first embodiment is schematically shown. The gyratory crusher 1 has a vertical shaft 2 and a frame 4 comprising a frame bottom 6 and a frame top 8 . An eccentric in the form of an eccentric 10 is rotatably arranged around the lower part 2 a of the shaft 22 . The crushing head 12 is fixedly mounted on the upper part 2b of the shaft 2 . A drive shaft 14 is arranged to rotate the eccentric 10 via a motor (not shown) and a ring gear 15 mounted on the eccentric 10 . The vertical shaft 2 is supported at its upper end 21 in an upper cover bearing 22 in the frame top 8 . When the shaft 14 is driven to rotate the eccentric 10 during operation of the crusher 1, the shaft 2 and the crushing head 12 mounted thereon will perform a swivel movement.

[0030] The first crushing shell 16 is fixedly mounted on the crushing head 12 . The second crushing shell 18 is fixedly mounted on the frame top 8 . A crushing gap 20 is formed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com