Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

514 results about "Transit line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

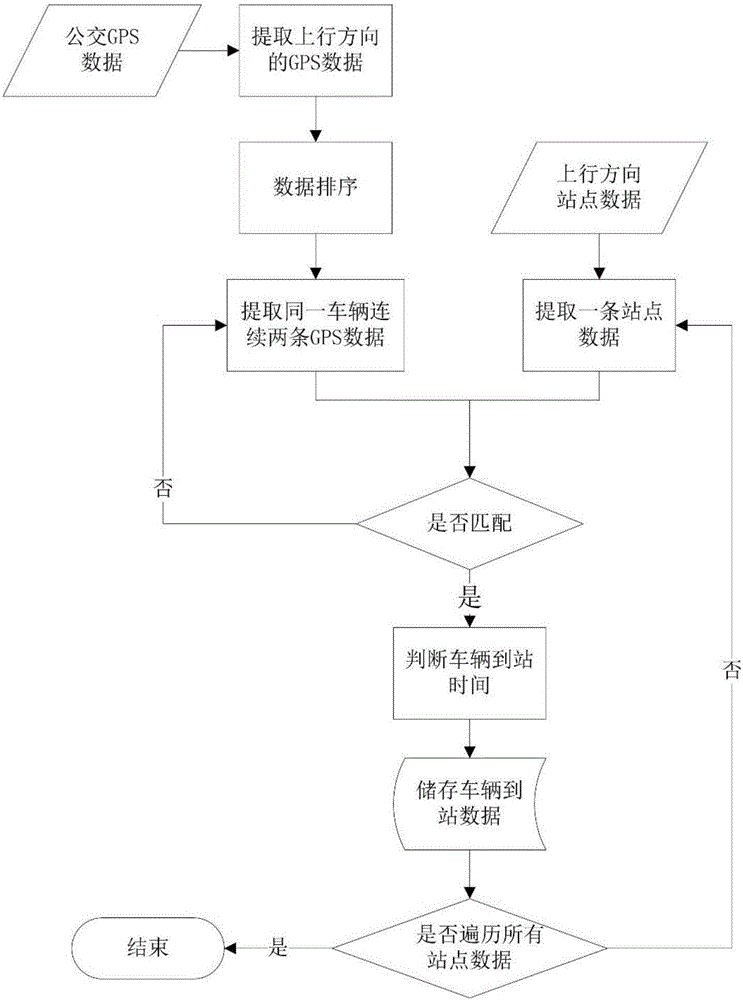

Bus arriving time prediction method and system based on floating data of the bus

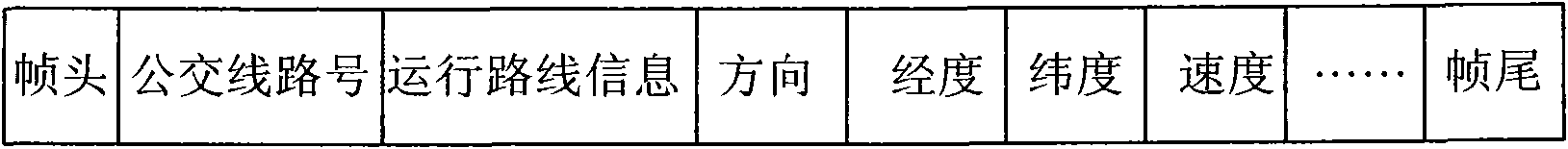

InactiveCN101388143ARelatively small errorSimple methodBeacon systems using radio wavesDetection of traffic movementArrival timeEngineering

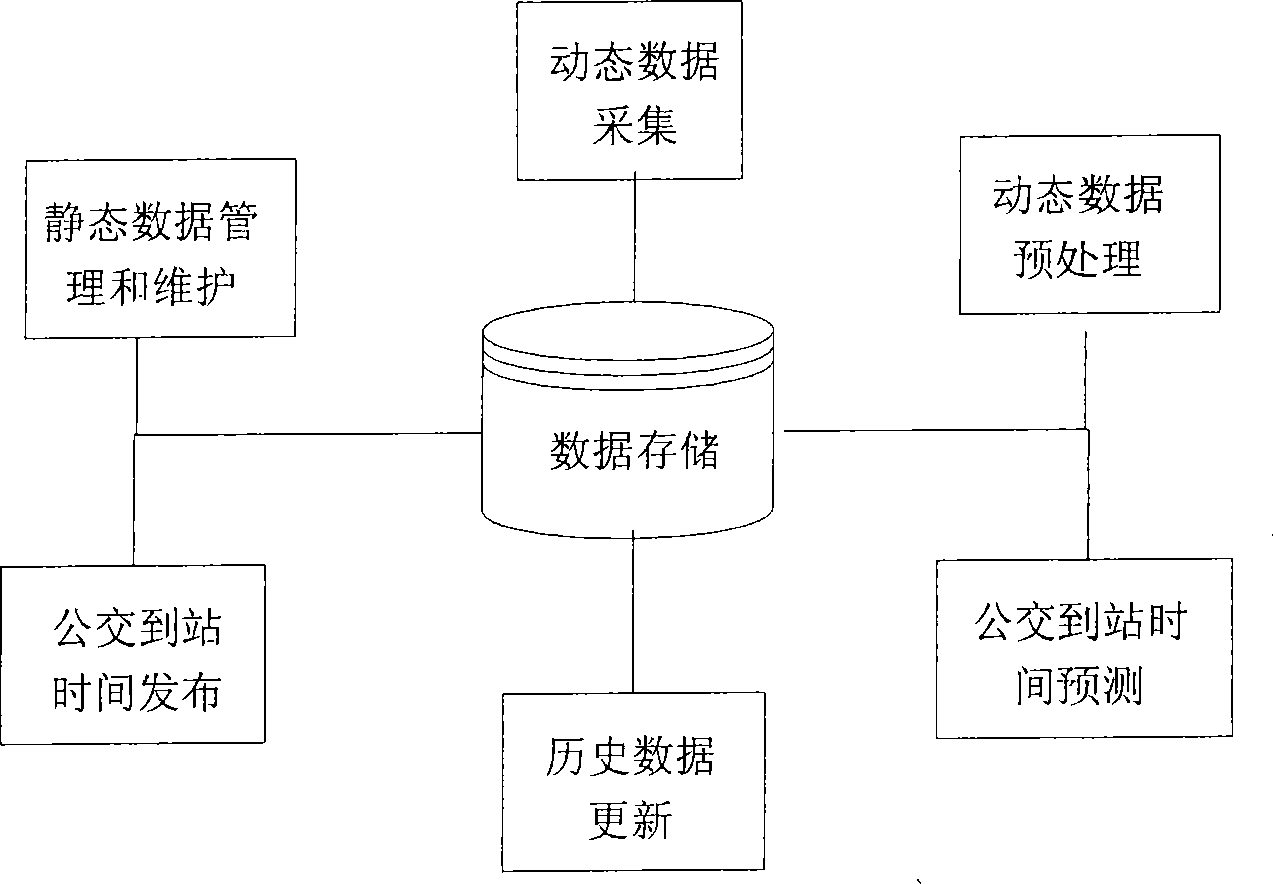

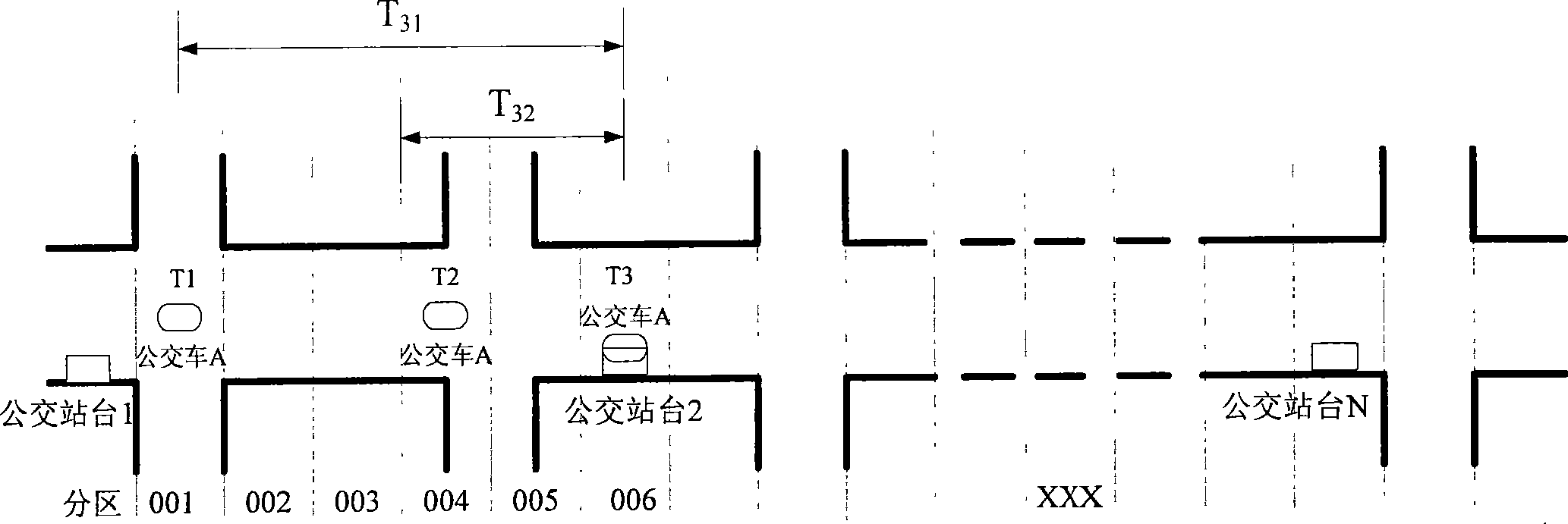

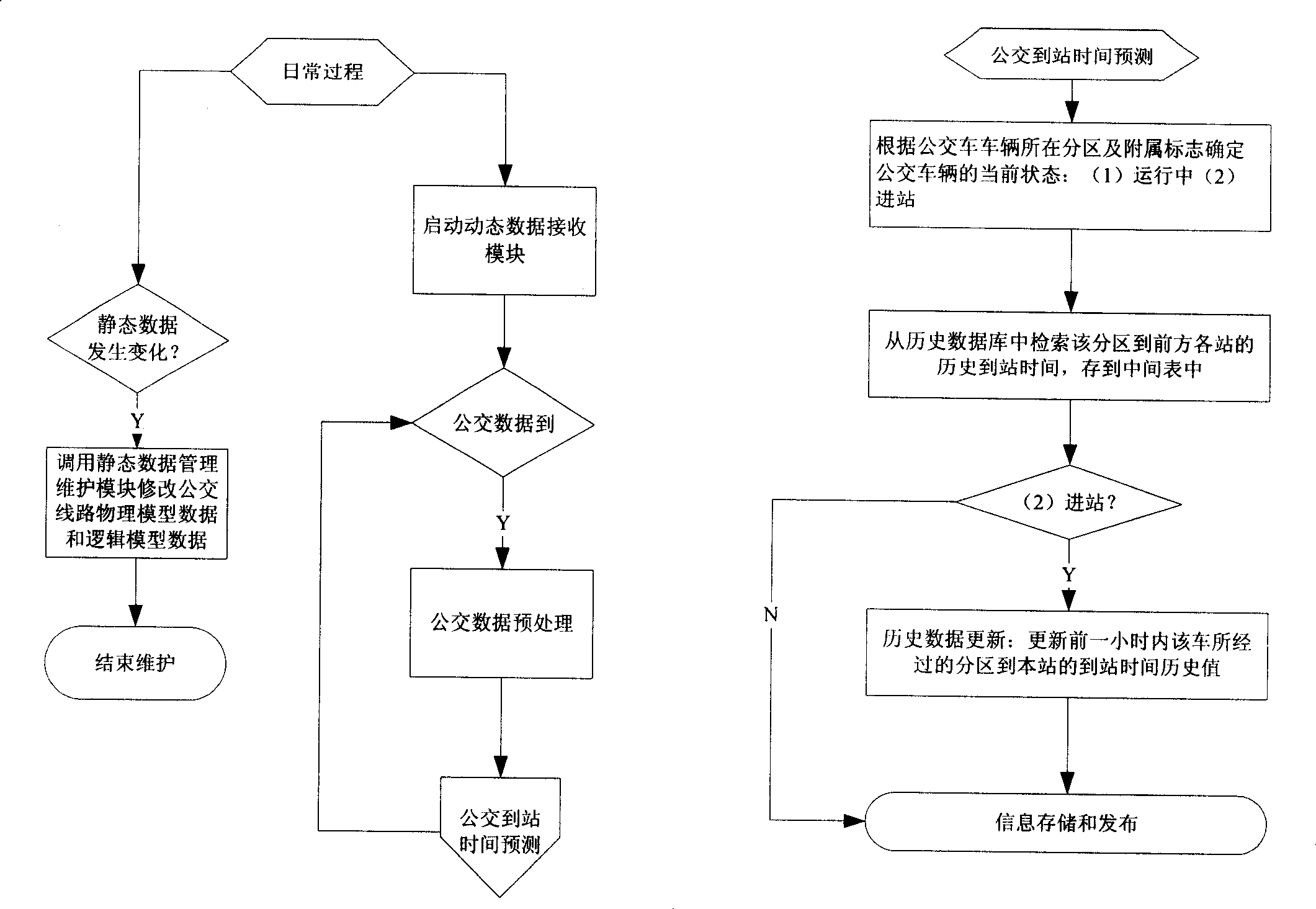

The invention relates to a bus arrival time prediction technique based on bus GPS data, which comprises sending out from the existing bus GPS data, making full use of auxiliary information such as pulling in, door opening and the like of a bus GPS apparatus, adopting a space dividing method to divide zones for bus lines, accounting the history arrival time of partitioned areas to each station in front according to the actual arrival time of a bus, and leading the bus arrival time to continuously do self-adapting update as the accumulation of history data, and meanwhile, predicating the bus arrival time by means of road traffic status which is calculated by GPS information of a taxi or road traffic status calculated by other systems, and improving the predicating accuracy.

Owner:TONGJI UNIV

Public transport bus exact stop method based on standard line matching

InactiveCN101334288AInstruments for road network navigationBeacon systems using radio wavesHigh densityHardware modules

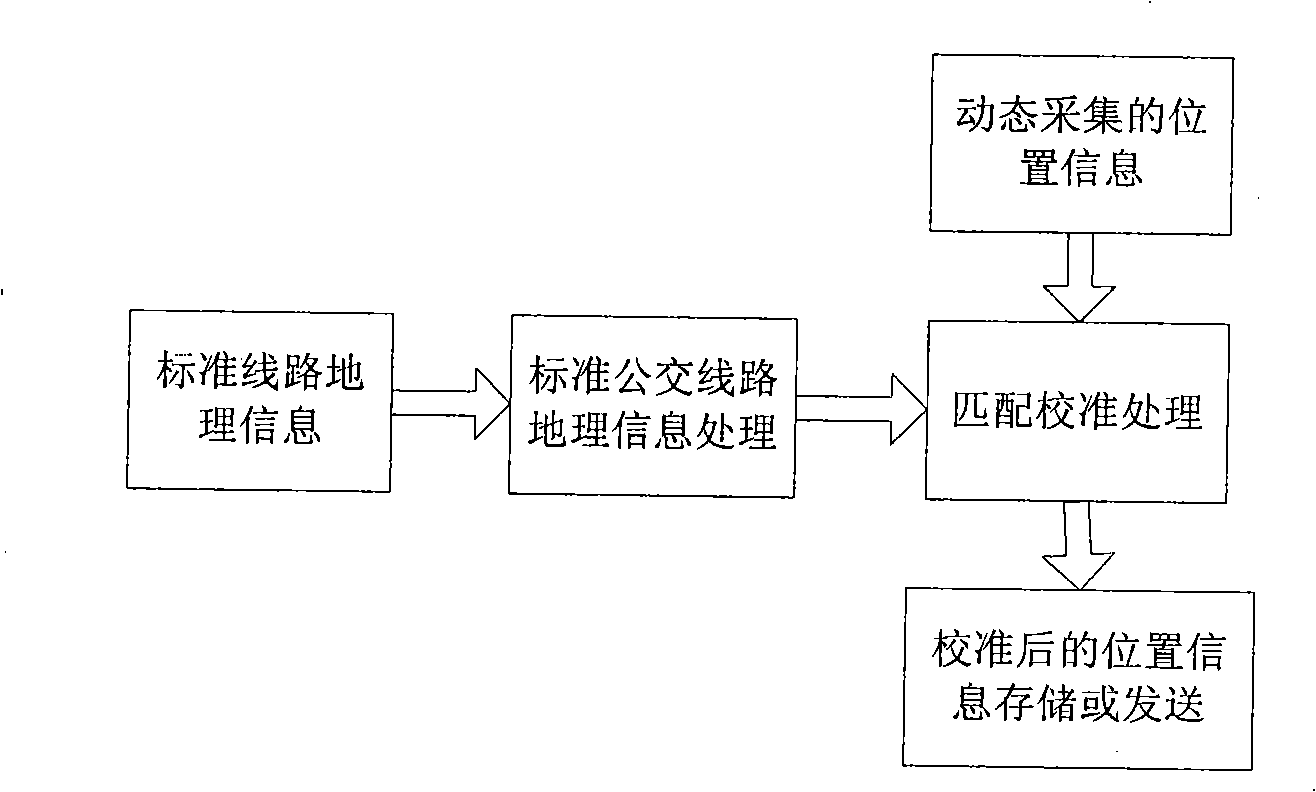

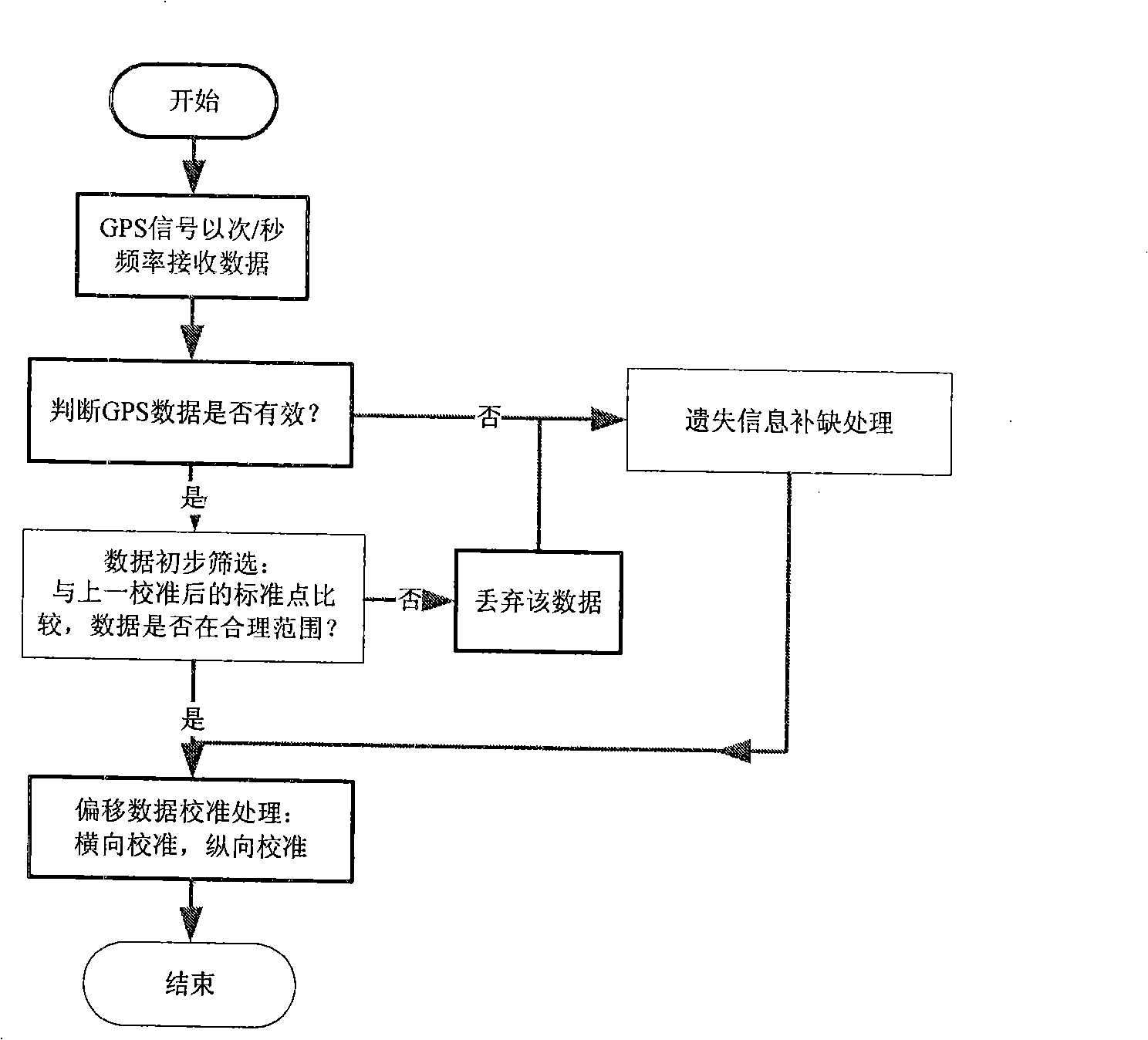

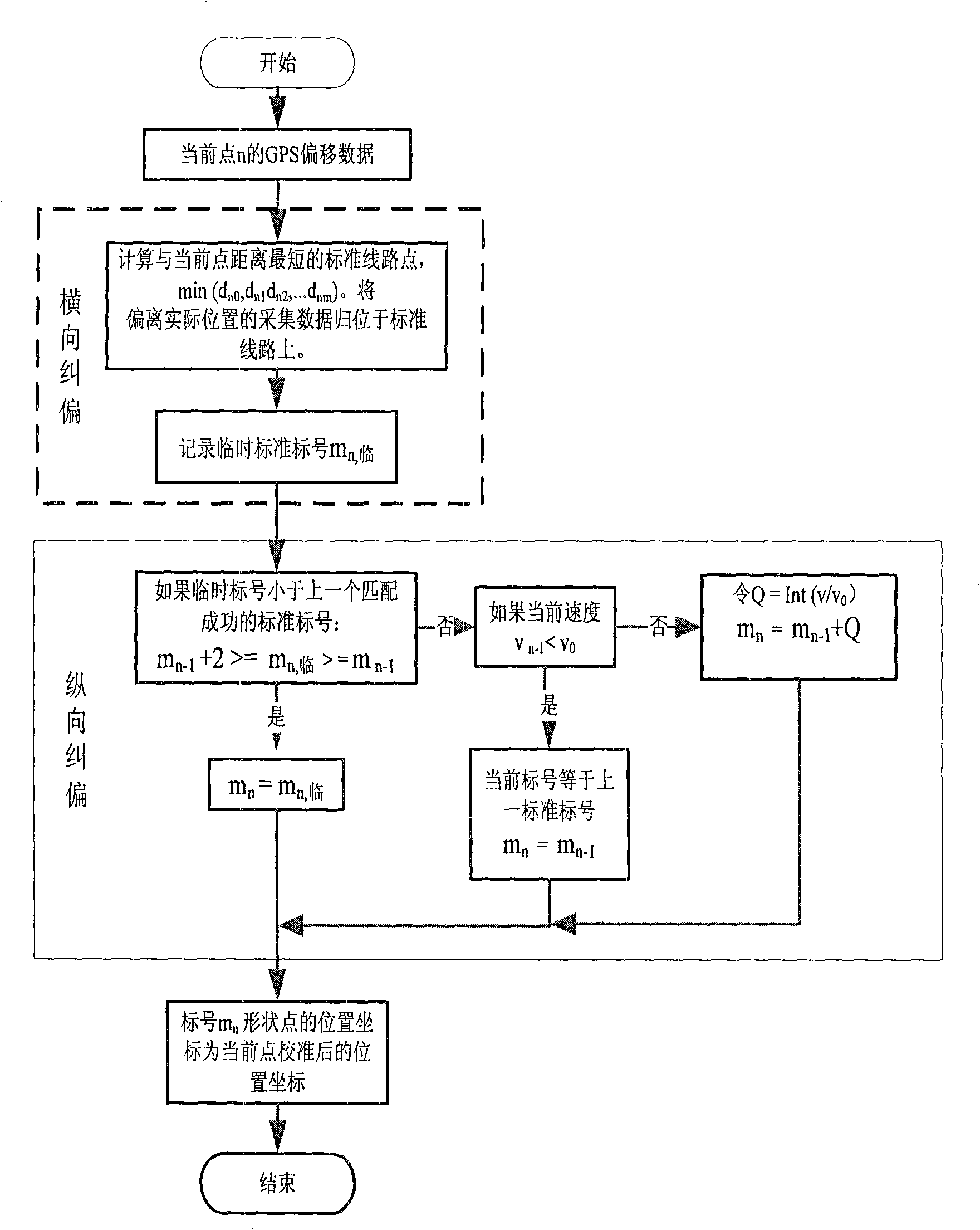

The invention discloses an accurate public traffic positioning method based on standard line matching, which pertains to the filed of dynamic public traffic information collection and is applied to dynamic information release and dynamic scheduling. The traditional method adopts the method of difference, inertial navigation or adding road test equipment to improve the positioning precision, and the equipment cost is increased due to the adding of additional hardware modules. According to the deviation or loss rule of the urban public traffic vehicle-bone GPS collected data, by being combined with the public traffic operation characters and on the basis of not increasing the equipment cost, the invention effectively improves the accuracy of the GPS positioning by being matched with the GIS public traffic line map data with the shape points of high density. The method firstly generates the GIS public traffic line map data with the shape points of high density and accurate stop positions so that the map data is taken as a reference to be used as the foundation for correcting the deviation and filling up the lost data, and matches the real-time collected data with the map data to obtain the precise position information, thus meeting the requirement of public traffic positioning. The method can also be applied to the problem of correcting other positioning information with fixed lines.

Owner:BEIJING UNIV OF TECH

Station-based urban public traffic network optimized configuration method

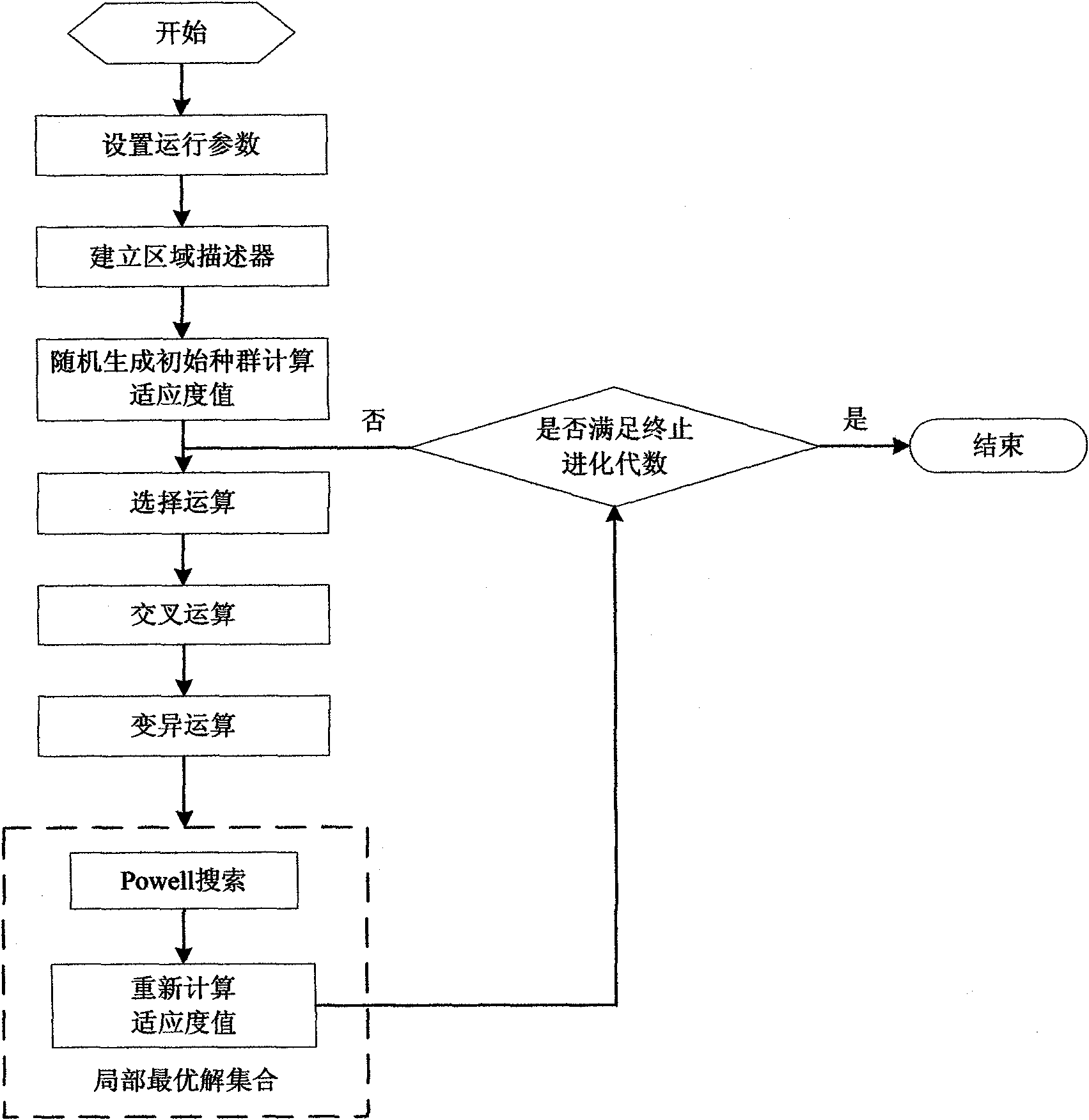

InactiveCN101807222AImprove configuration efficiencyHigh fitness valueRoad vehicles traffic controlSpecial data processing applicationsTraffic networkGenetic algorithm

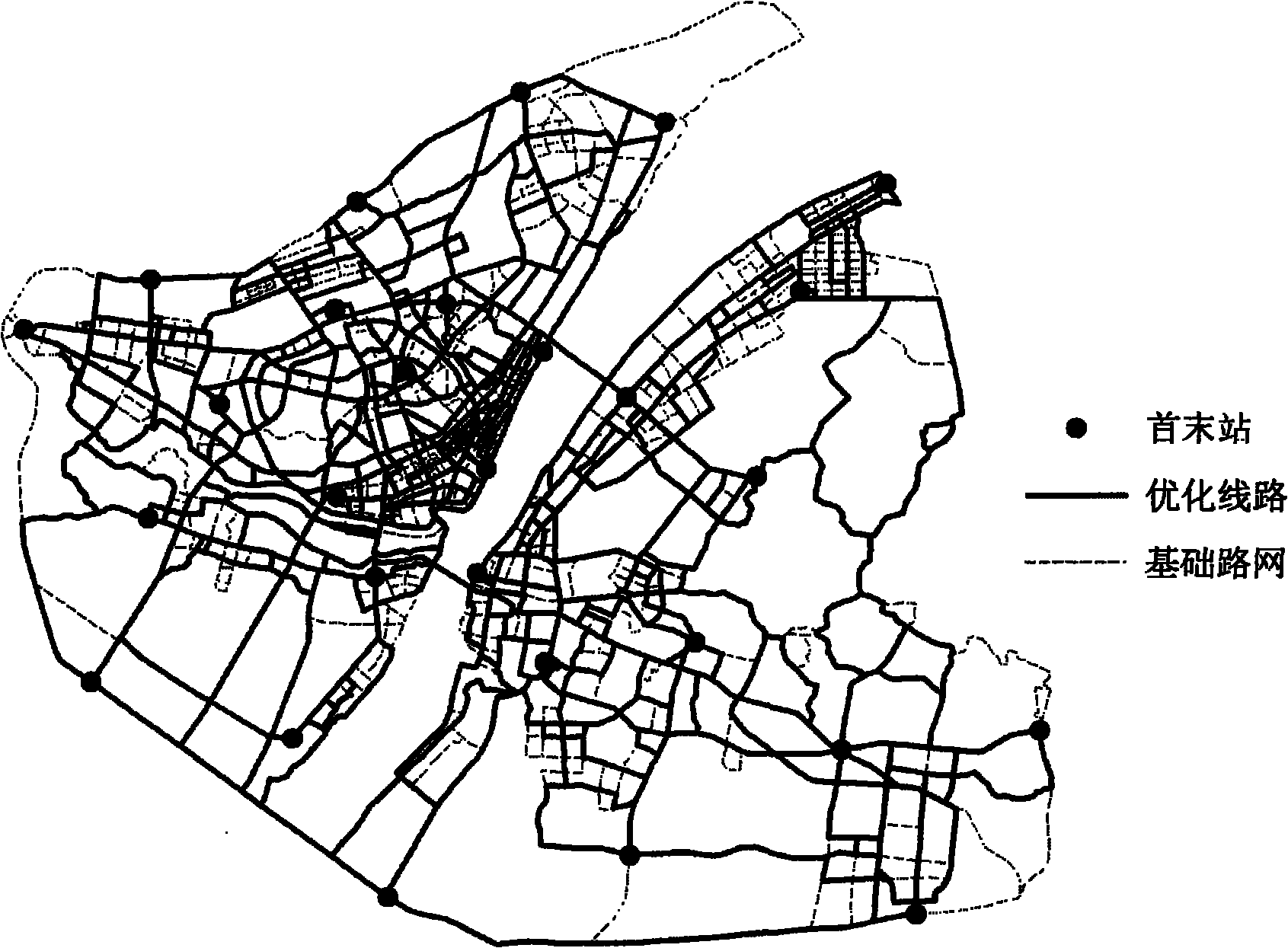

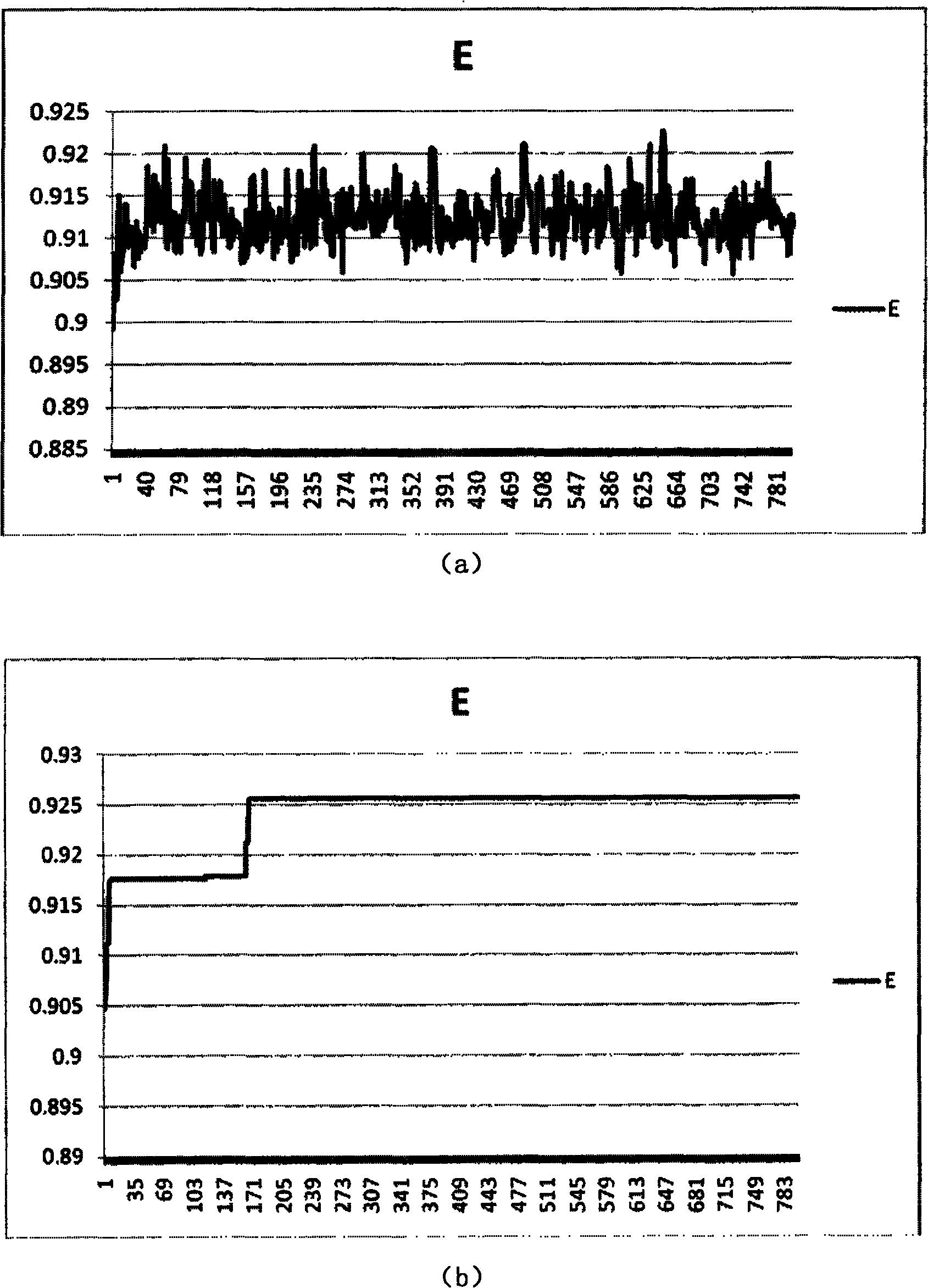

The invention discloses a station-based urban public traffic network optimized configuration method, which comprises the following steps of: optimized layout of bus stops under the constraint condition; calculation of trip generation of the bus stops; generation of candidate routes based on bus stop generation and route constraint condition; and genetic algorithm-based bus route optimization and index evaluation thereof. The station-based urban public traffic network optimized configuration method can search new routes based on the conventional routes, particularly realizes conventional public traffic network optimized layout in the presence of rapid transit. The station-based urban public traffic network optimized configuration method can directly evaluate the generation of the bus stops based on urban land utilization and population distribution, and also can directly utilize the generation and origin and destination data acquired by field transit survey. The system can be used for spatial distribution optimization of conventional metropolitan public traffic networks, and the efficiency for public traffic network regulation and layout is improved.

Owner:WUHAN UNIV

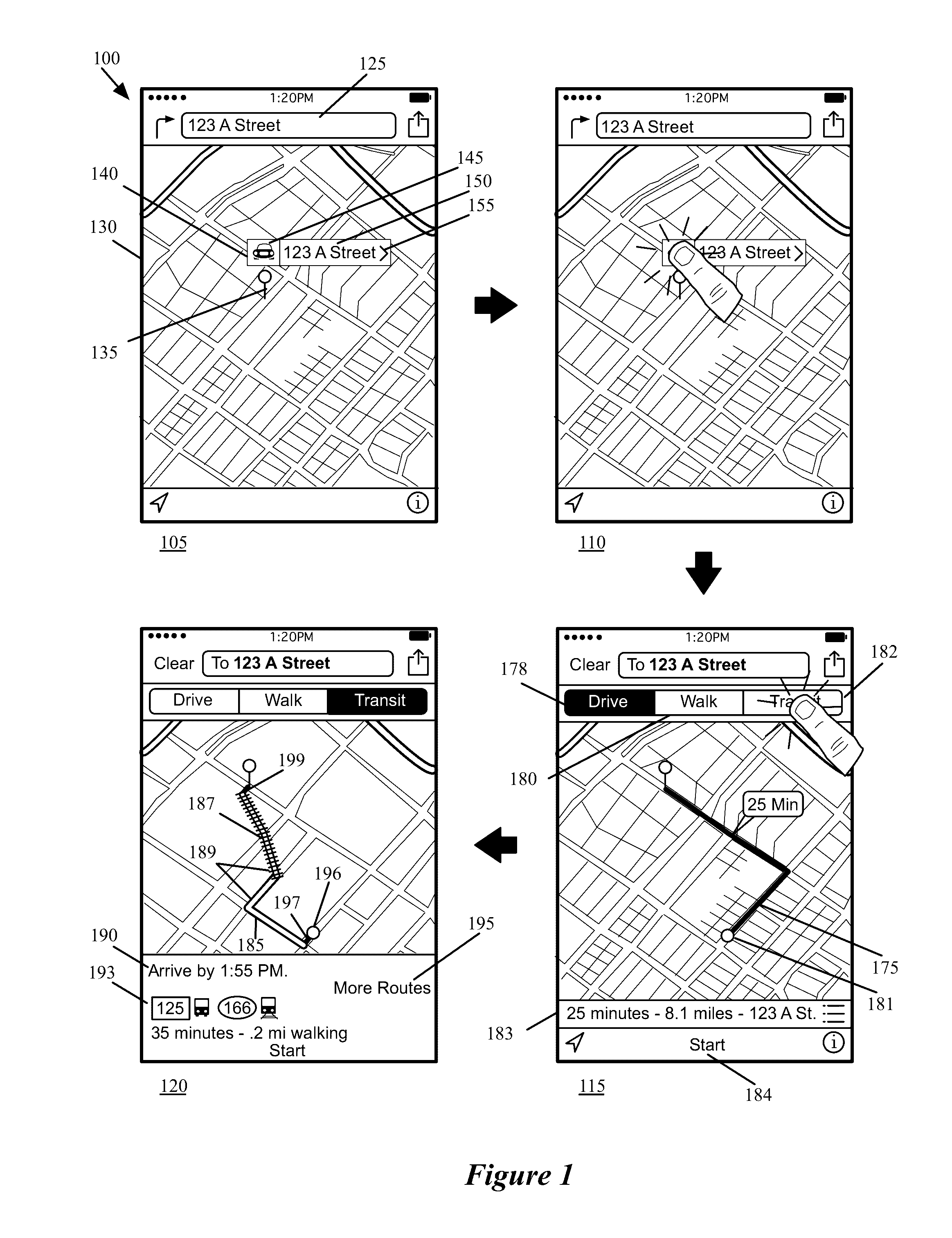

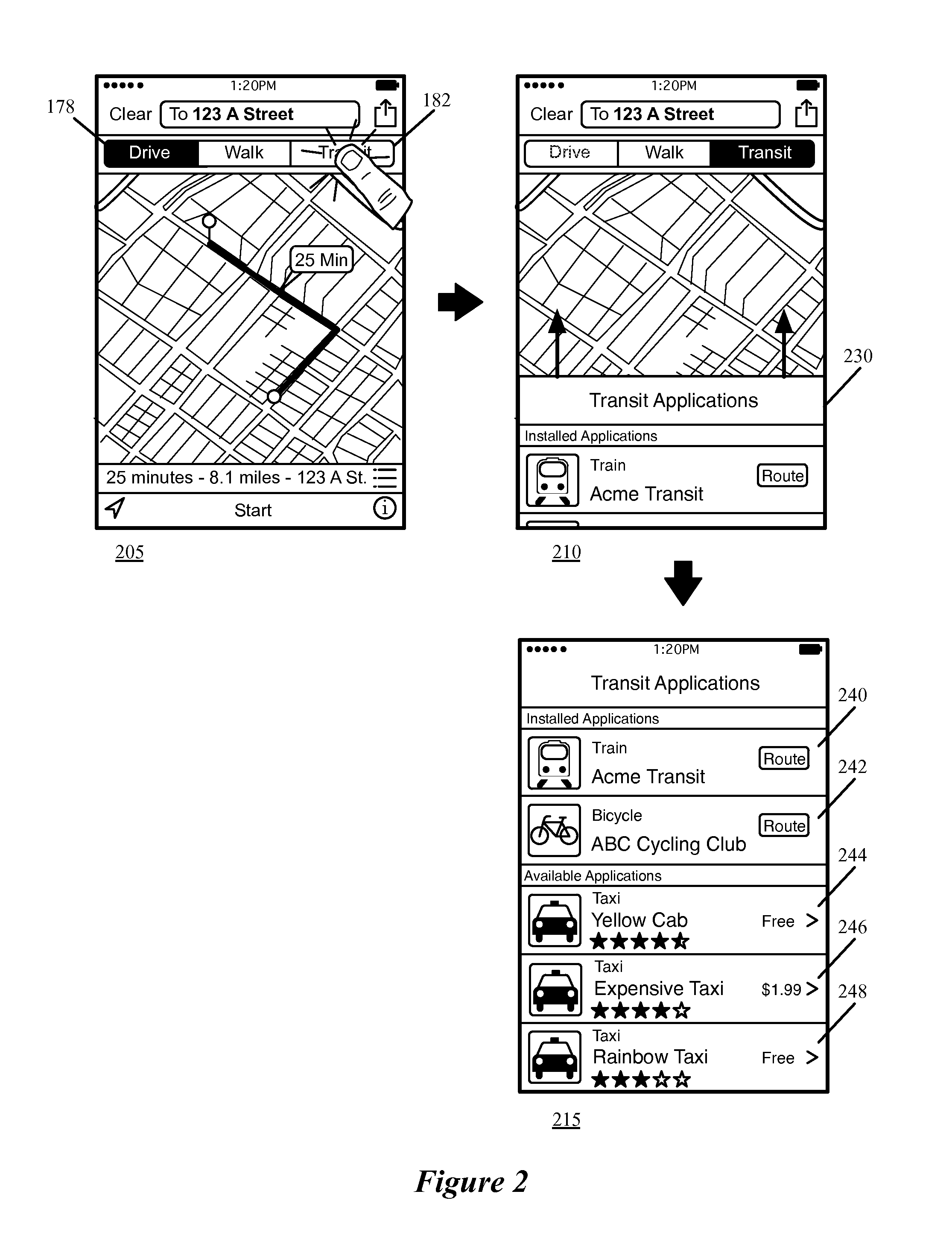

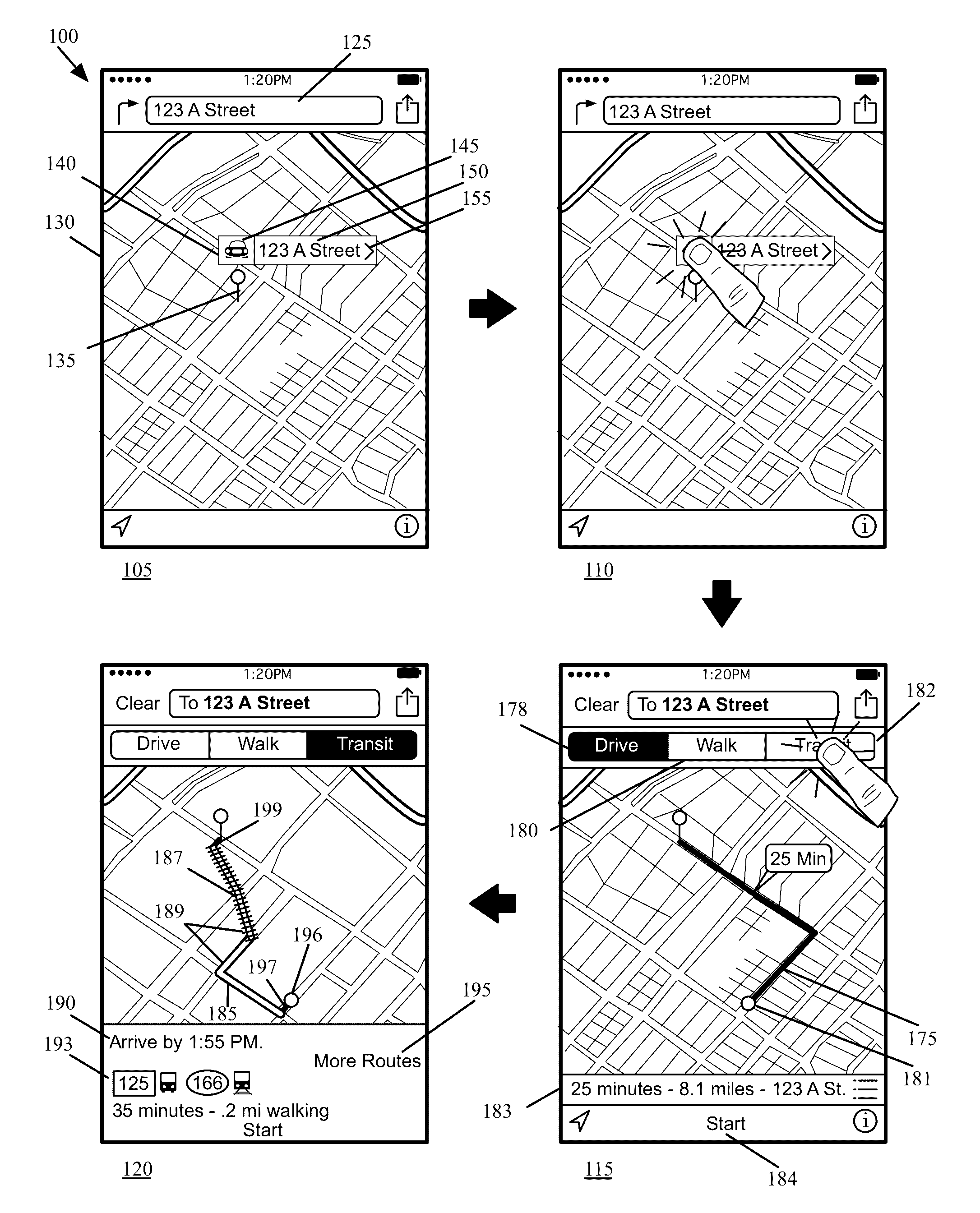

Map application with transit navigation mode

ActiveUS20160358471A1Accurate detectionInstruments for road network navigationNavigational calculation instrumentsGraphicsGraphical user interface

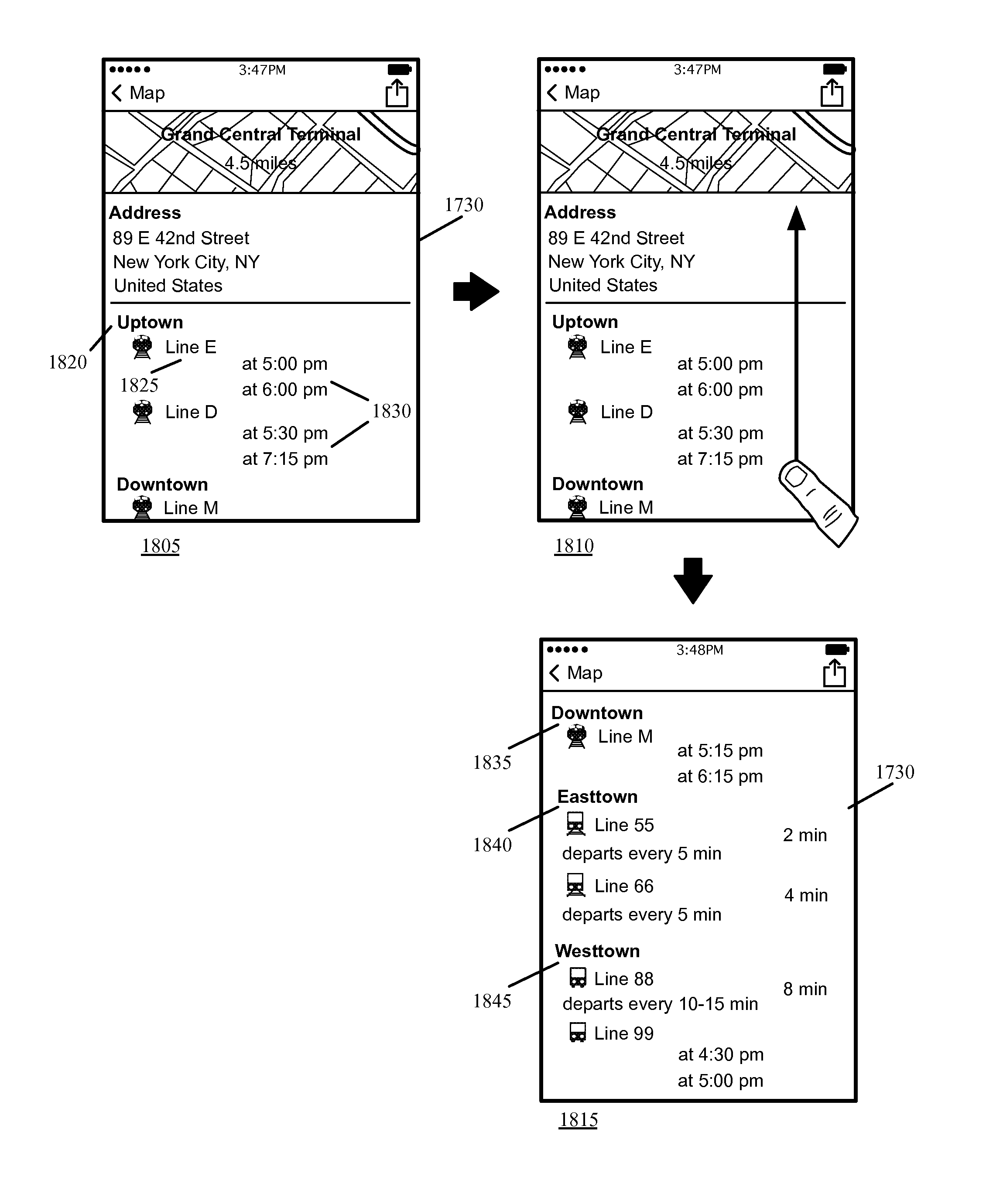

Some embodiments provide a map application that displays a selectable user interface (UI) item for a transit station, a representation of which, is displayed over a presentation of a portion of a map of an area. Upon selection of the UI item, the map application of some embodiments provides a graphical user interface (GUI) that includes a first set of information about the transit station, and a second set of information about departure schedules of several different transit lines from the transit station.

Owner:APPLE INC

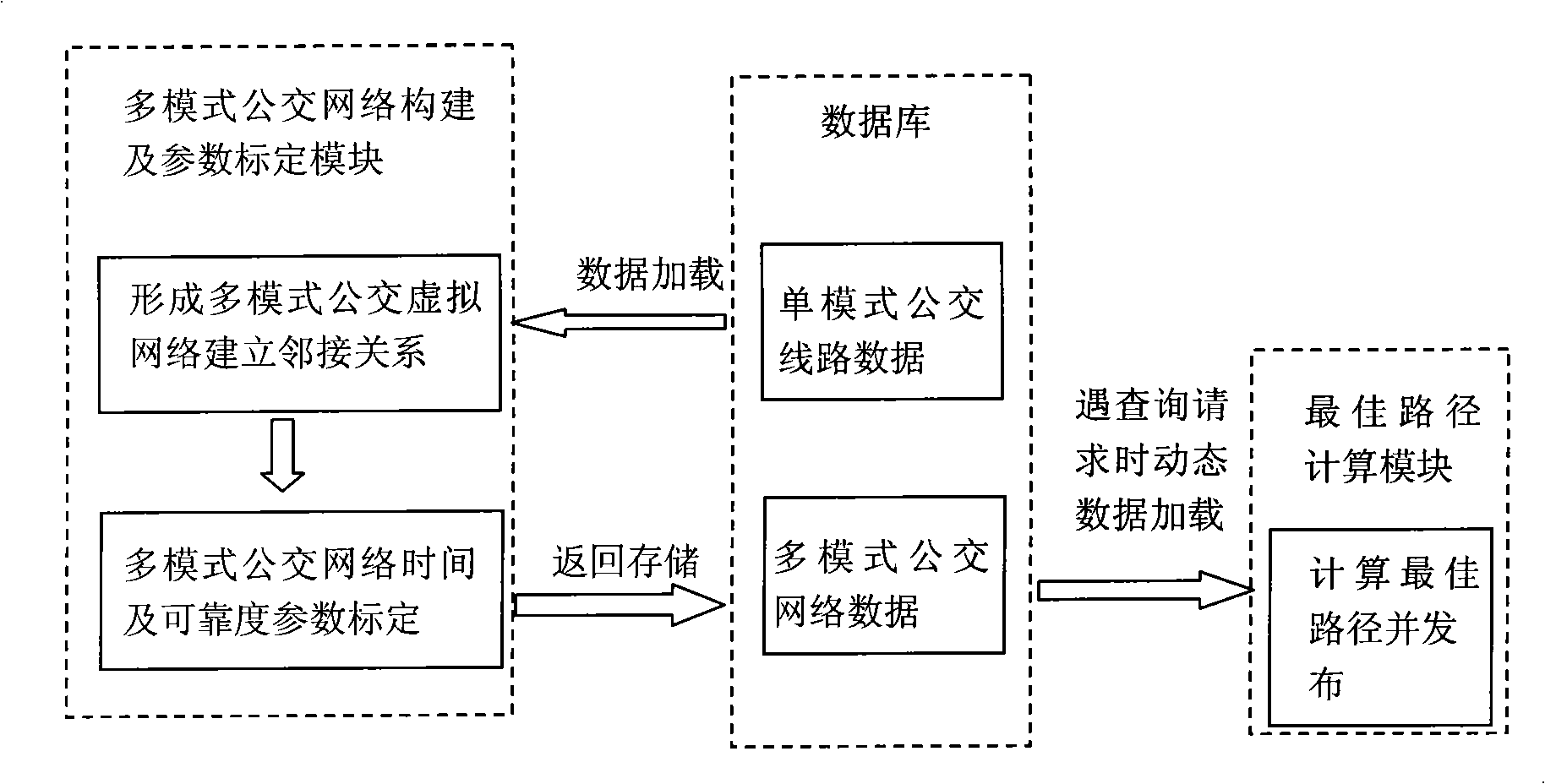

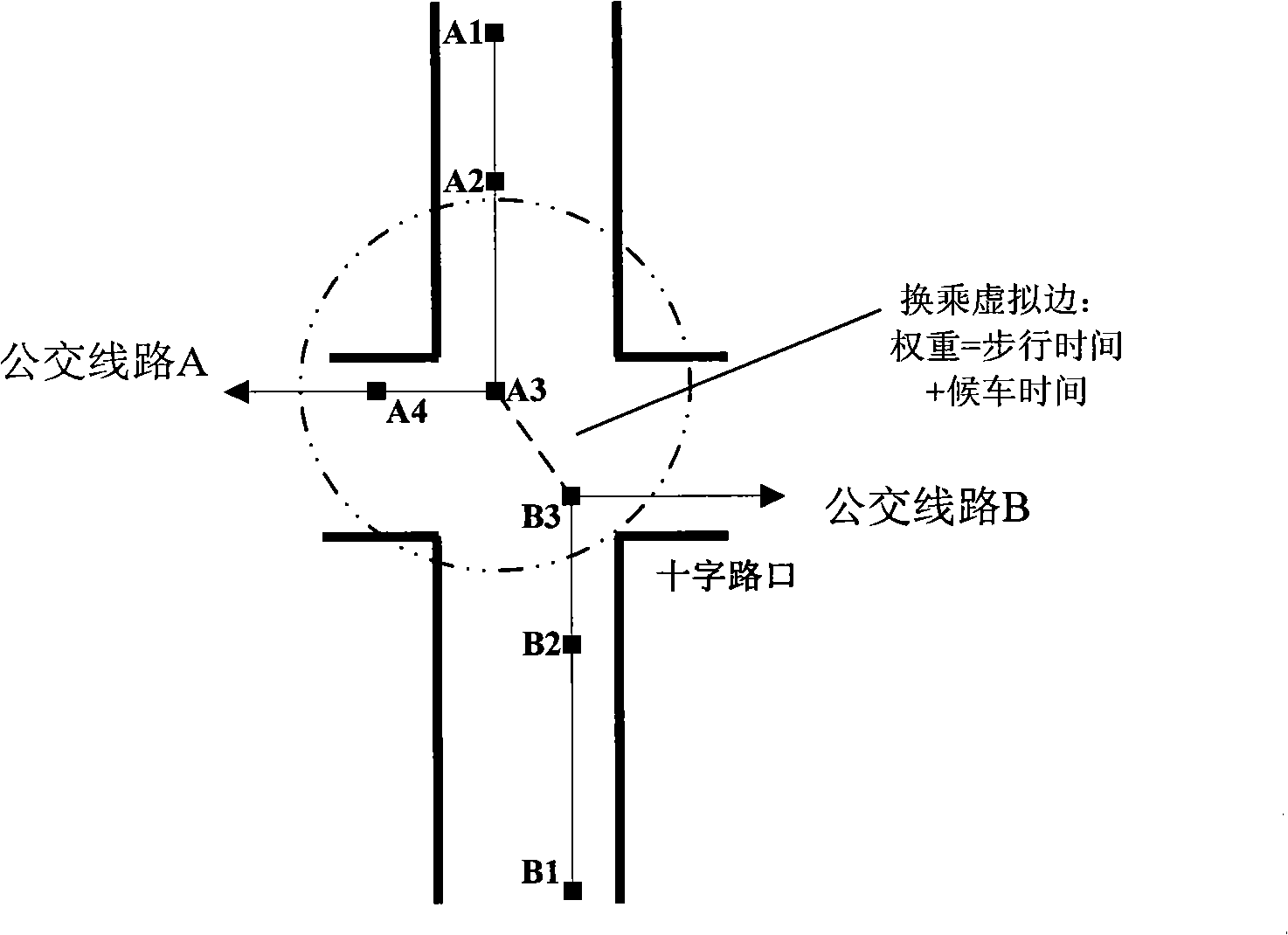

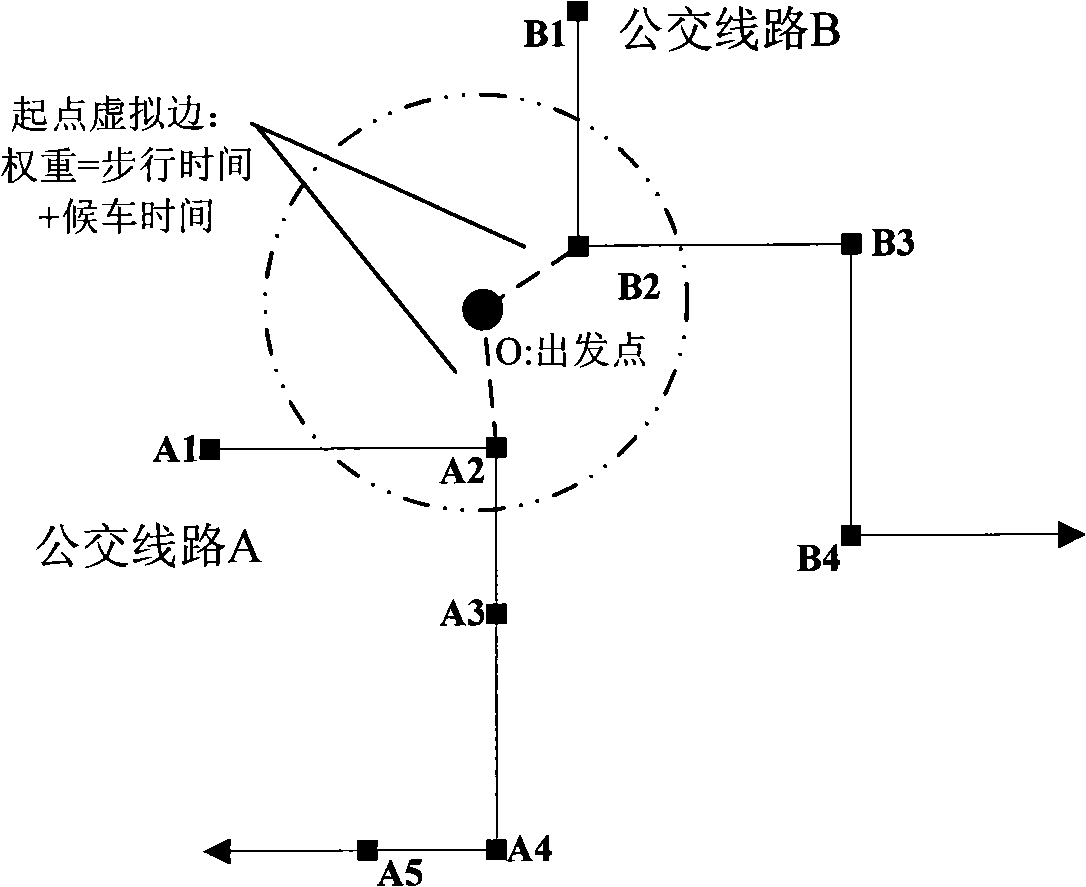

Multi-mode optimal path selection method for public transport

InactiveCN101308555AImprove accuracyRich release contentForecastingSpecial data processing applicationsBus laneTime information

A multi-mode public transport travel route optimization method belongs to the public transport travel information release field and is specifically used for optimum line inquiry in public transport traveling. The invention takes each line of the public transport travel chain as edges to establish a multi-mode public transport line network which allows transfer, through constituting a multi-level network adjacent relationship which comprises different public transport modes, such as metro, light rail, bus lane and ground bus, and enabling double-empowerment of the average travel time and the time reliability to each edge; in the absence of real-time information conditions, the relatively short traffic time and the smaller delay risk are taken as the double targets for route optimization to achieve rapid search of the reliable route which can effectively reduce the delay risk within the range permitted by the traveling time, through the heuristic avoidance from the routes and transfer points prone to delay in the route optimization process. Based on the method, a touch-screen information system or internet is taken as a platform to build a multi-mode public transport route inquiring system and carry out the route and transfer information inquiry and release.

Owner:BEIJING UNIV OF TECH

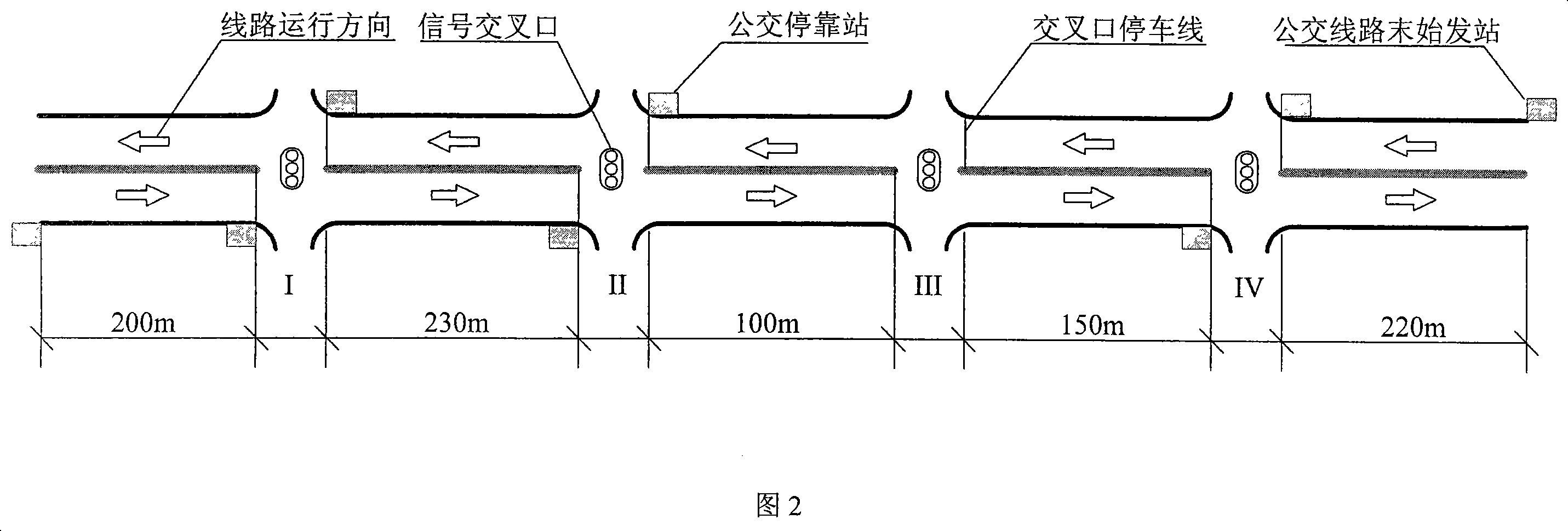

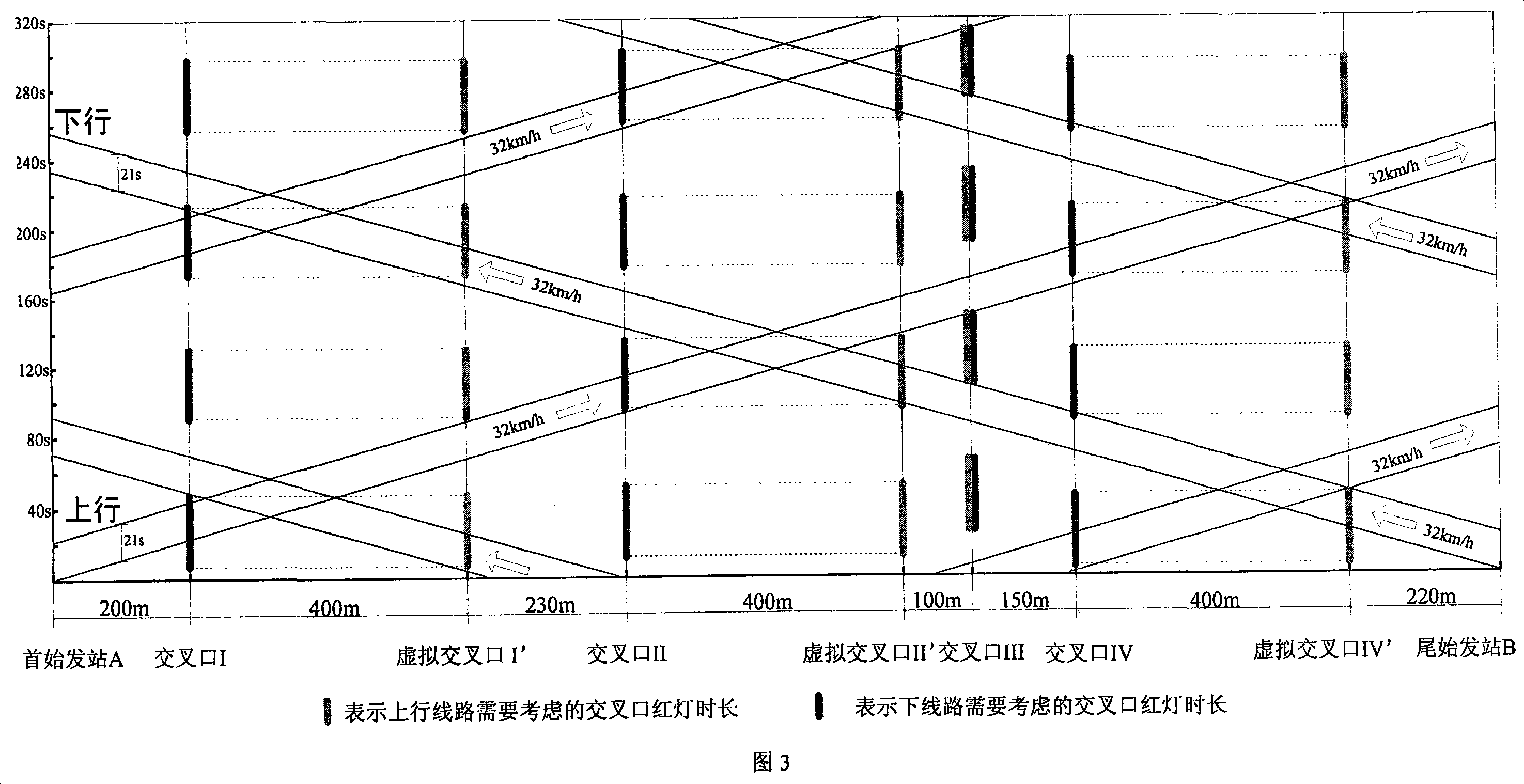

Signal coordinating control method of one-road one-line straightgoing type public transport system

InactiveCN101159097AReduce delaysFew influencing factorsControlling traffic signalsCritical signalTransit time

Owner:SOUTHEAST UNIV

Operation coordination optimizing method of common public transit connecting with urban rail transit and system thereof

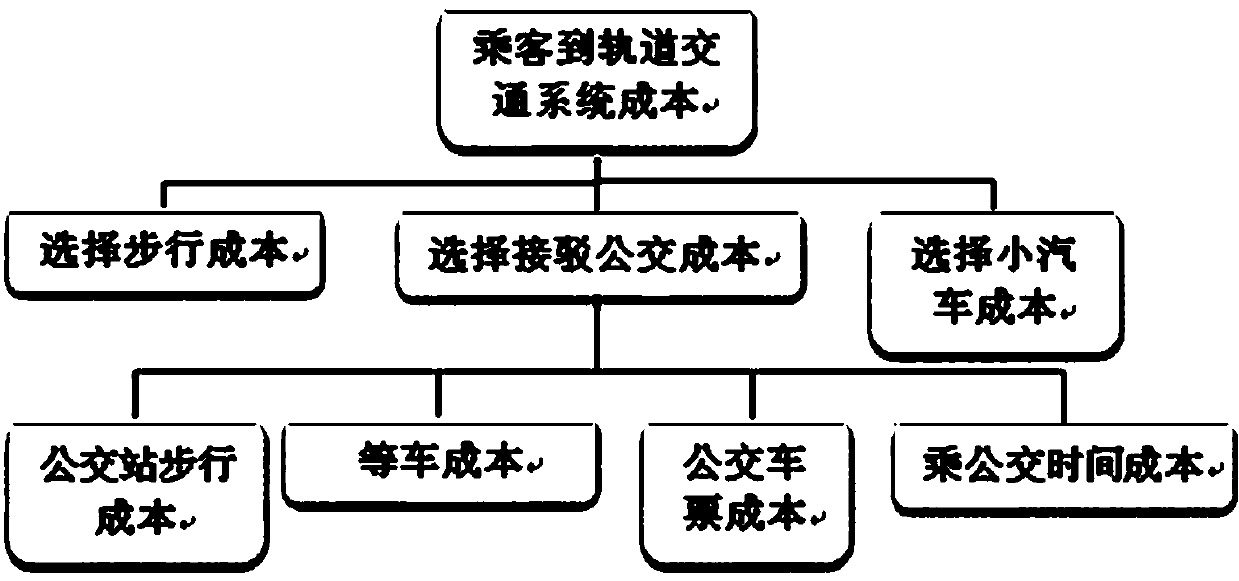

ActiveCN101630440AImprove scienceImprove effectivenessControlling traffic signalsDetection of traffic movementTransit networkCost analysis

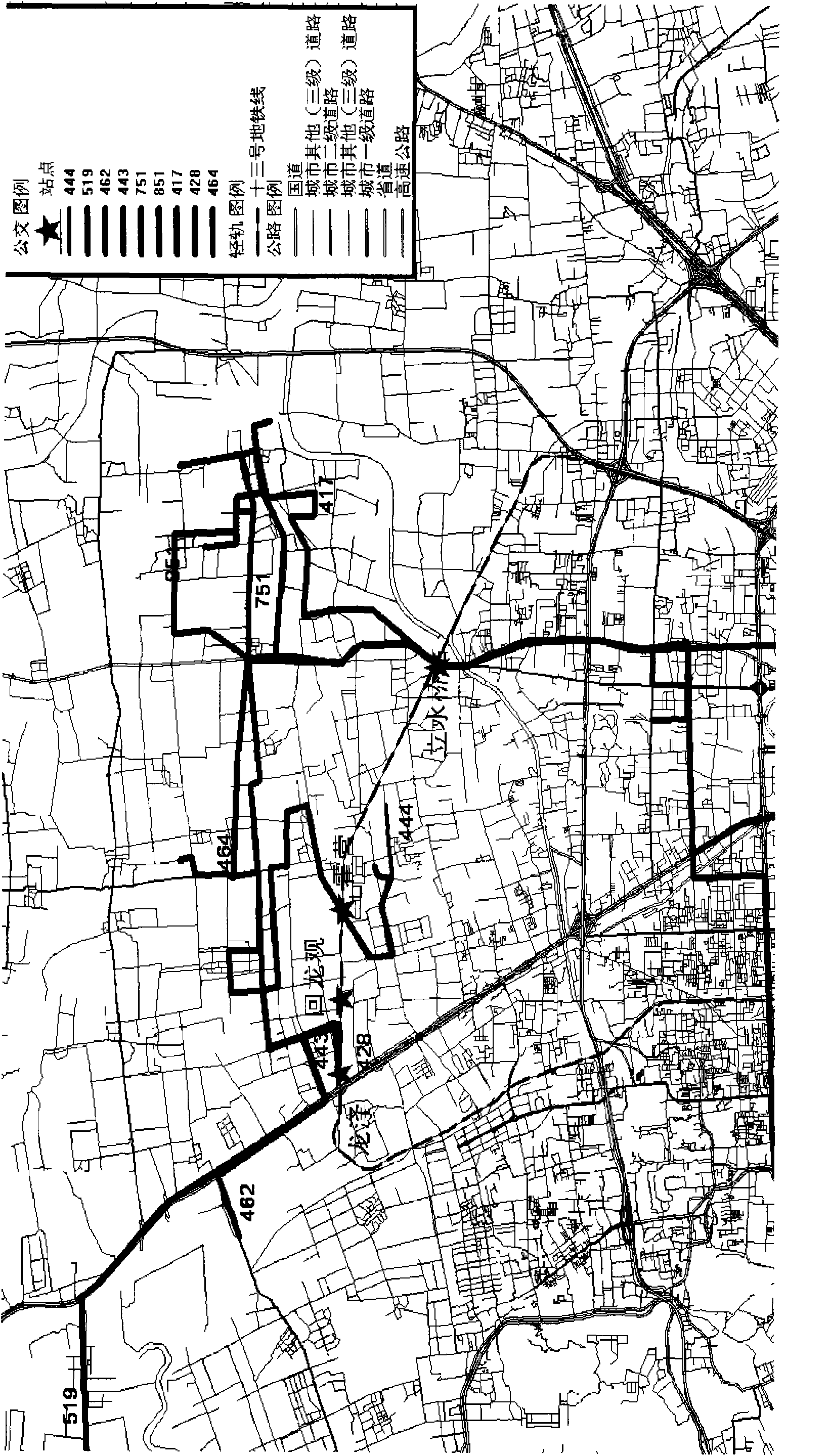

The invention provides an operation coordination optimizing method of common public transit connecting with urban rail transit and a system thereof. By counting with mathematical statistics, coordination transfer rate and passenger transfer cost under each transfer mode are obtained, a multivariable operation coordination optimizing mode which aims at the least mass cost of the transit system total cost which comprises operator cost and passenger travel cost is built, and an algorithm with a genetic algorithm based on Powell is optimized. The system comprises a GIS map reading and transit line identification procedure module, a transit system data inputting procedure module, a transit system cost analyzing procedure module and a transit system optimization processing procedure module. The invention solves the problem of the operation coordination of the urban rail transit and the common public transit, so as to improve the scientificity and the effectiveness of transit network operation. Simultaneously, the system has simple input and increases the convenience of operation coordination work.

Owner:BEIJING JIAOTONG UNIV

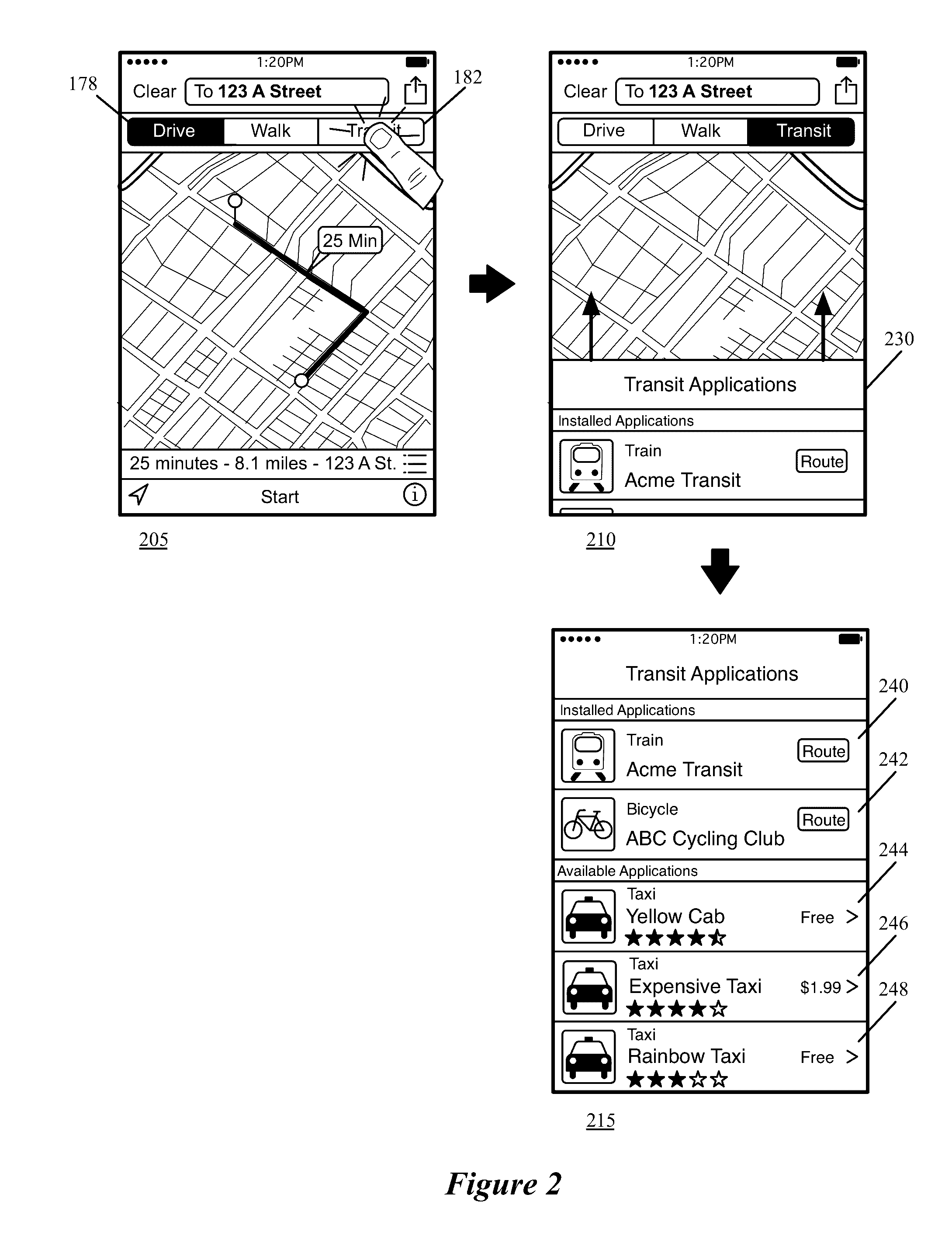

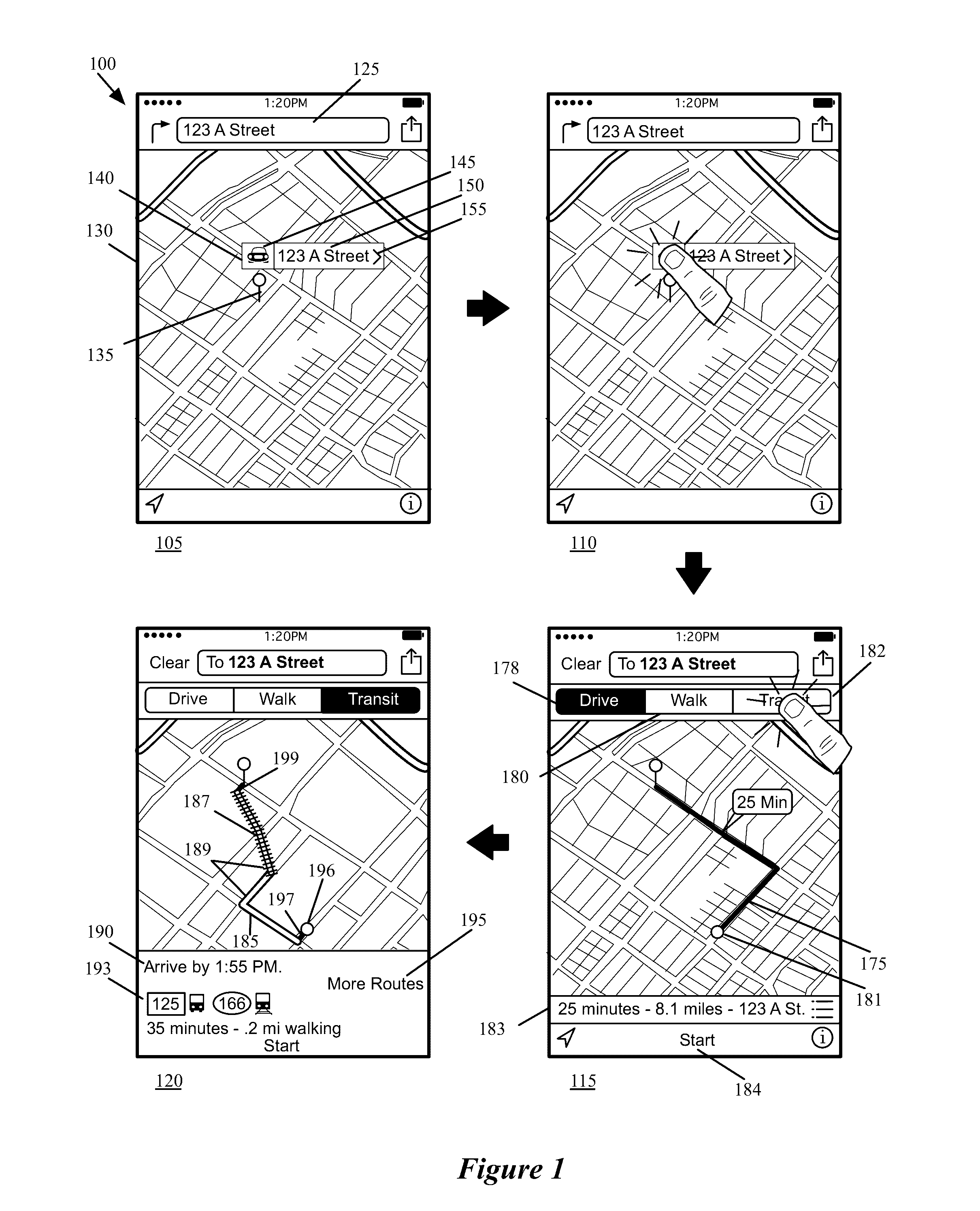

Map application with transit navigation mode

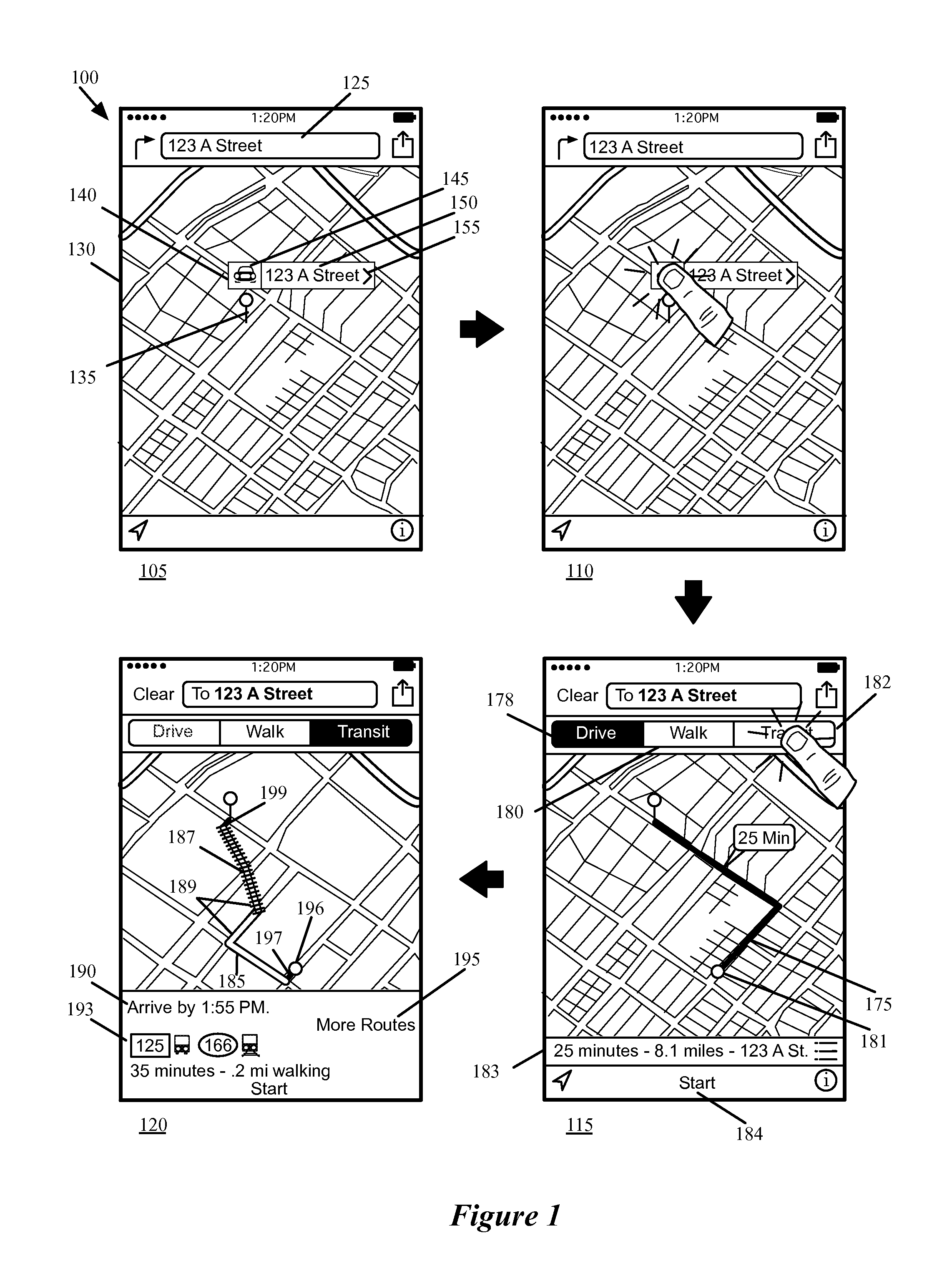

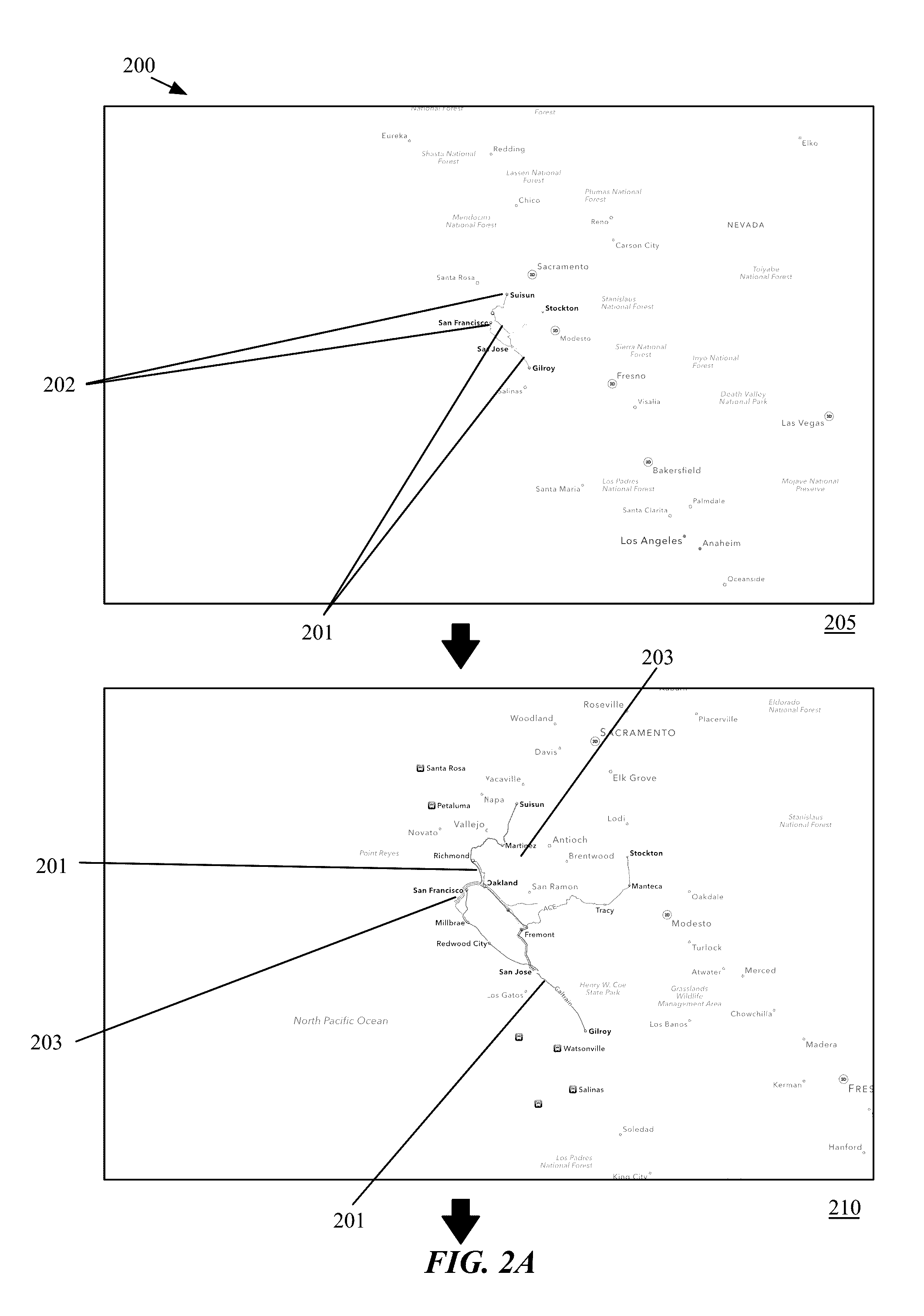

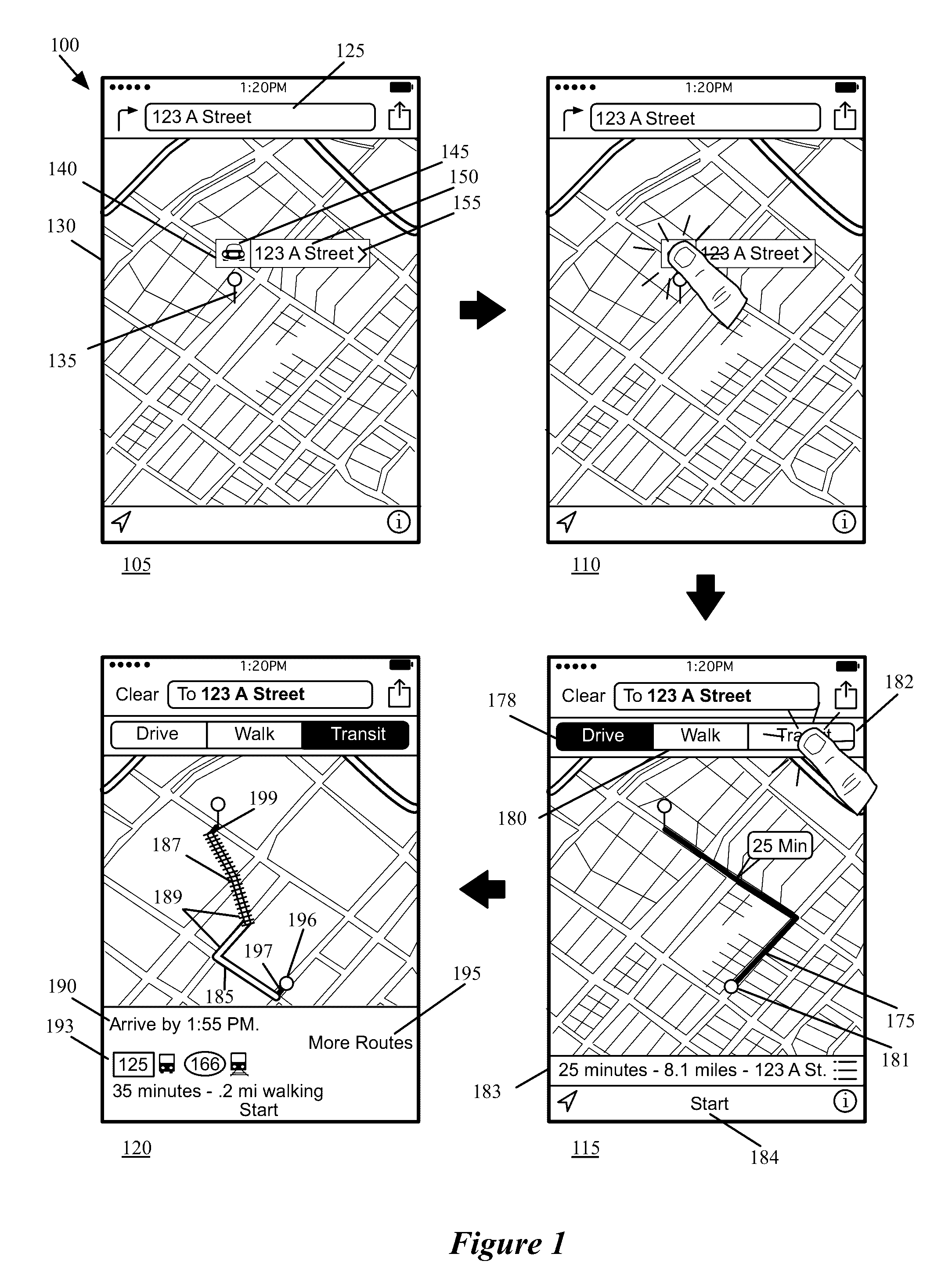

InactiveUS20160356603A1Accurate detectionInstruments for road network navigationNavigational calculation instrumentsComputer scienceMarine navigation

Some embodiments provide a map application that receives a starting location and a destination location. The application then identifies several different transit routes from the starting location to the destination location based on a set of transit preferences. Each transit route includes a set of transit legs each of which is serviced by a different transit line. In some embodiments, the application ranks the identified transit routes based on a set of criteria, and displays a representation of a highest ranked transit route over a portion of a map presentation along with a set of information about the displayed transit route.

Owner:APPLE INC

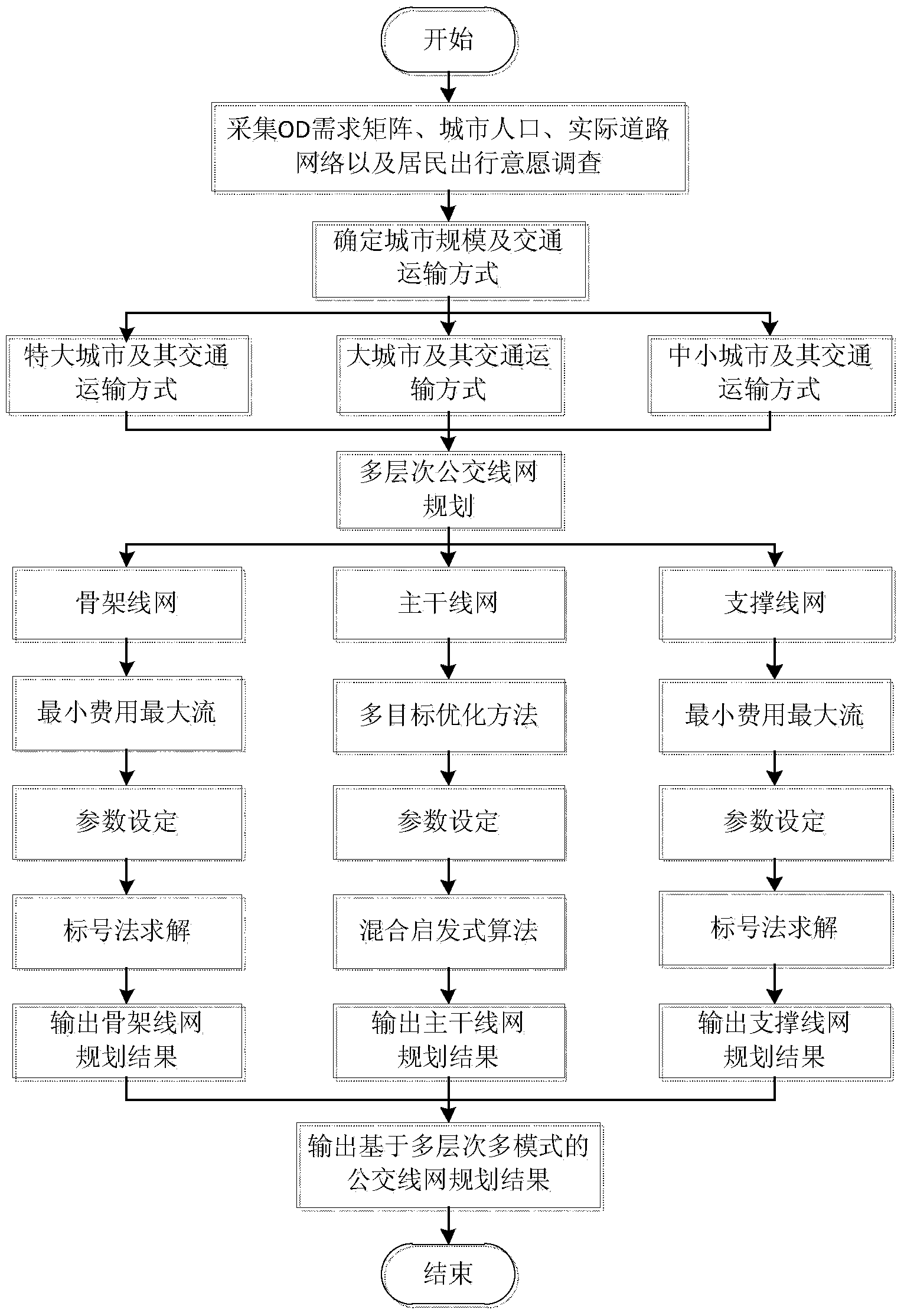

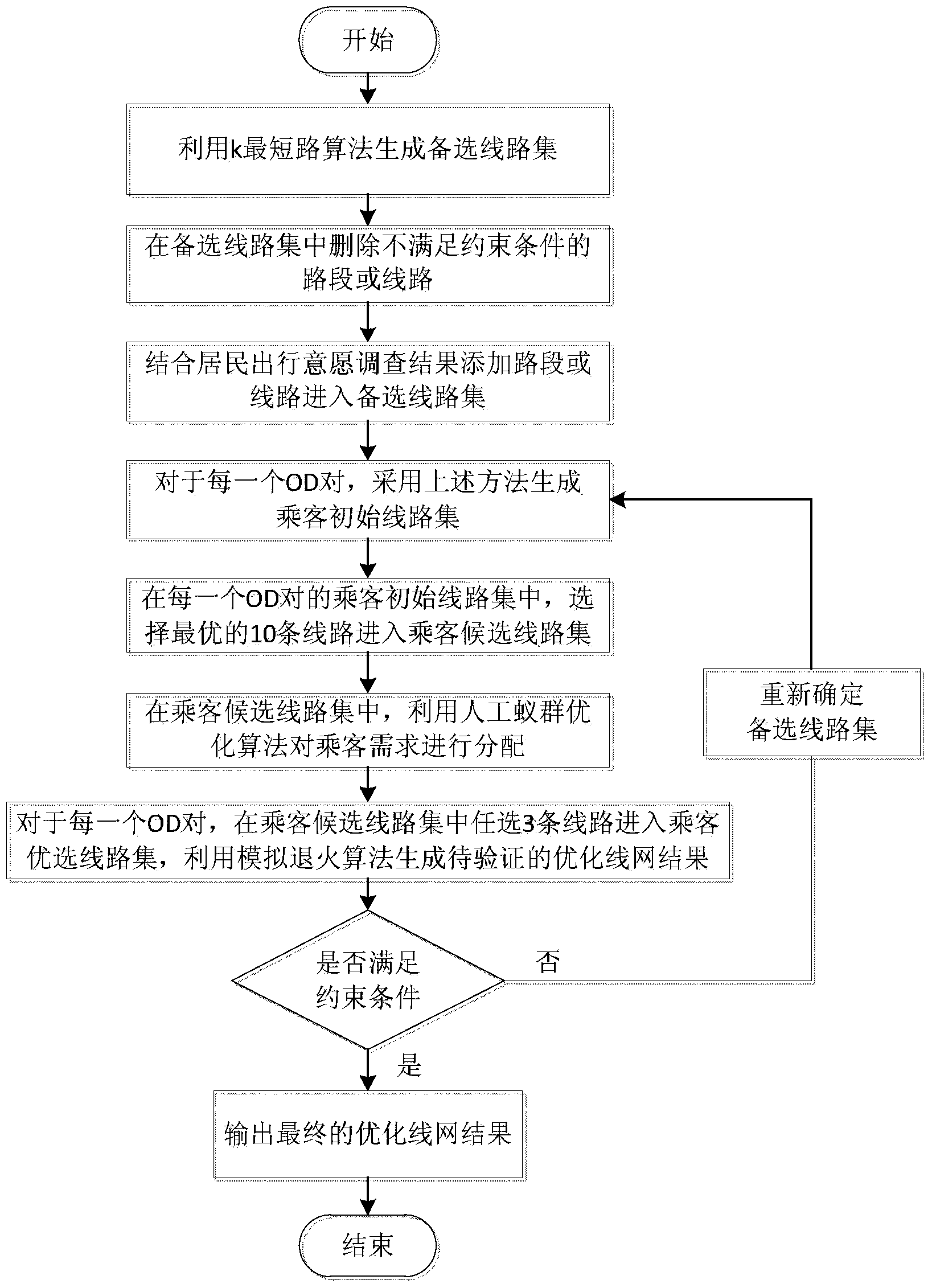

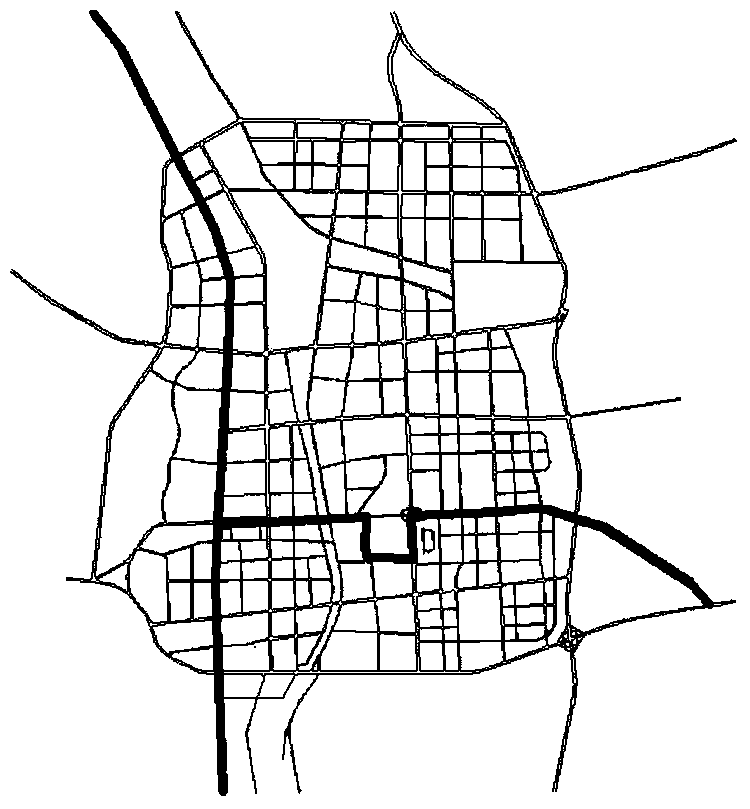

Public transit network planning method based on multiple levels and multiple modes

ActiveCN104318758AImprove fitImprove performanceRoad vehicles traffic controlForecastingTransit networkMode of transport

The invention discloses a public transit network planning method based on multiple levels and multiple modes. The public transit network planning method comprises the following steps that basic data are collected, communication and transportation modes are determined according to the city size, and influence factors needed by public transit network planning are analyzed; a public transit network planning model is built, and relevant parameters are set; the public transit network planning model is solved; a planning result is output. The public transit network planning method can better adapt to passenger flow features and setting features of different public transit networks, thereby being better in effect; the public transit network planning method is superior to existing methods on the evaluation index aspects of the nonstop passenger flow volume, the passenger demand ratio, the total travel time and the like.

Owner:SOUTHEAST UNIV

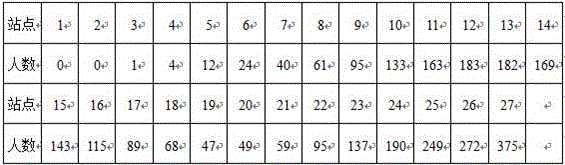

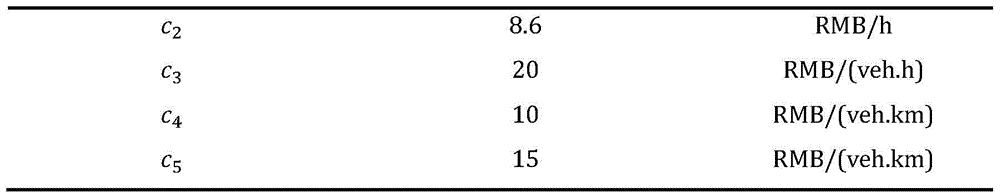

Big data based bus route time table collaborative optimization method

ActiveCN106448233AFully consider the possibility of travelThe results are scientifically accurateRoad vehicles traffic controlForecastingIntegrated circuitOperational costs

The invention relates to a big data based bus route time table collaborative optimization method, and belongs to the technical field of urban bus operation management. Bus GPS (global positioning system) data, bus IC (integrated circuit) card data and route station data are fused and processed into a bus time table to provide actual operation based data support, and a bus time table optimization model considering rail transit transfer is provided. The model takes departure intervals at each time period as decision variables, takes minimum total system cost as an objective function, and comprehensively considers waiting time cost of non-transfer passengers, waiting time cost of transfer passengers and operating cost of bus operating enterprises. Passenger flow data are obtained through multi-source data fusion, a lot of manpower is saved, and accuracy in data is improved. By the consideration of routine bus system and rail transit transfer, reasonability in bus time table preparation is improved. A data model is set up to optimize the bus time table, waiting time cost of passengers and enterprise operating cost are both taken into consideration, and coordination in passenger and enterprise profits is realized.

Owner:DALIAN UNIV OF TECH

Transit navigation

ActiveUS20160356613A1Accurate detectionInstruments for road network navigationNavigational calculation instrumentsComputer scienceMarine navigation

Some embodiments provide a map application that identifies a transit route that includes one or more transit legs between a starting location and a destination location. In response to a request to start navigating the identified transit route, the map application of some embodiments provides a first display area for displaying a set of navigation instructions, each of which describes a transit maneuver that is associated with a transit leg of the transit route. The map application also provides a second display area for displaying a map region presentation associated with the navigation instruction that is displayed in the first display area.

Owner:APPLE INC

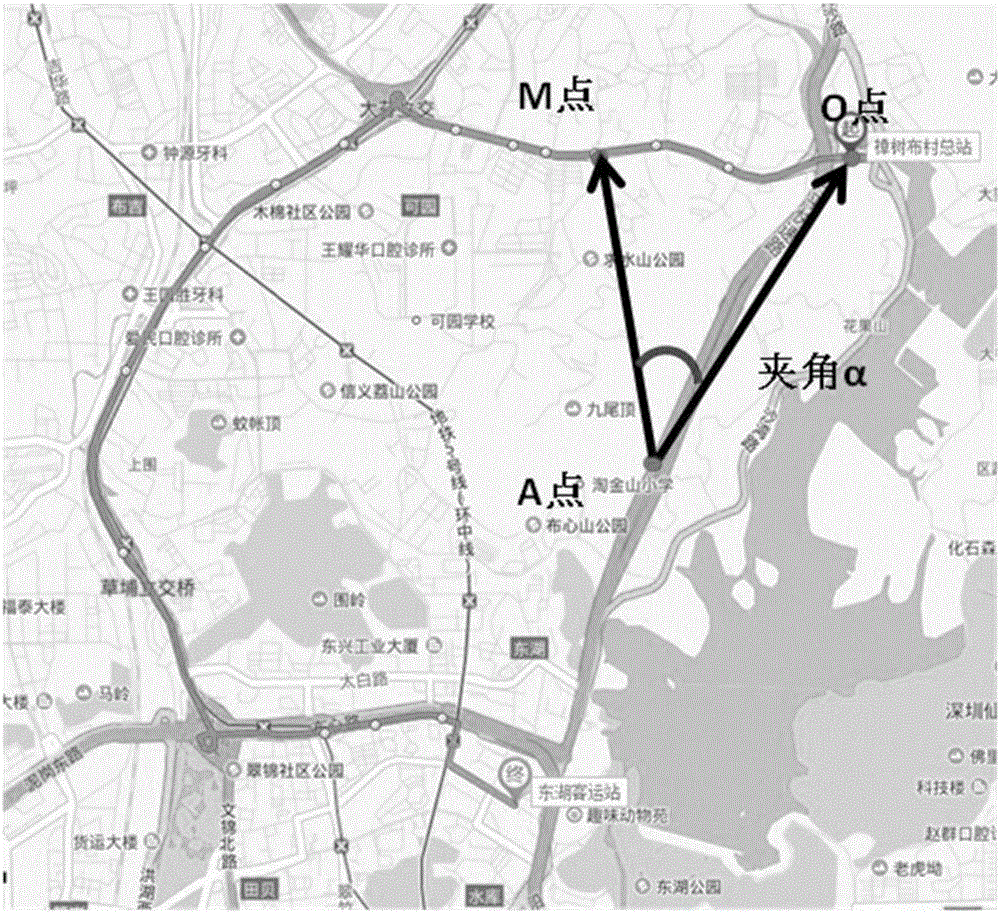

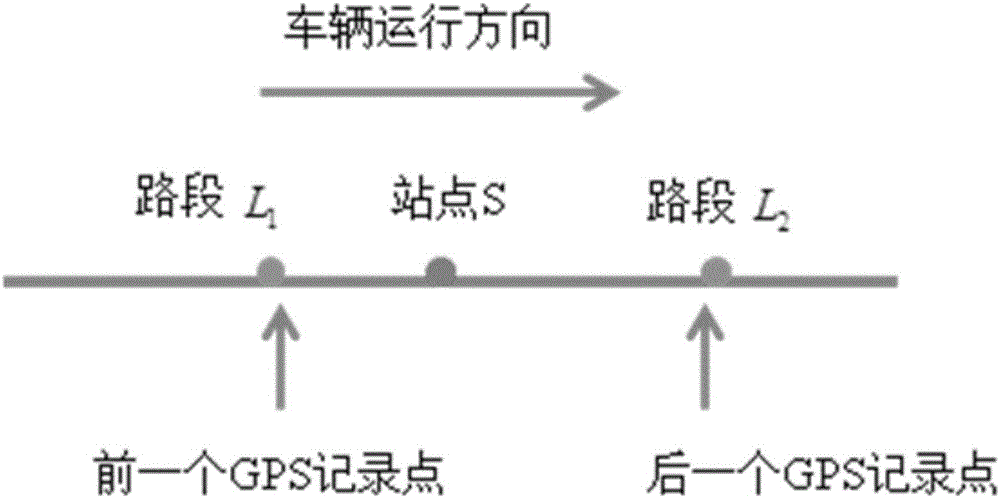

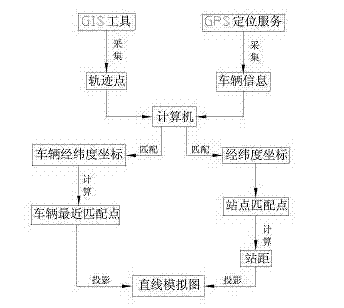

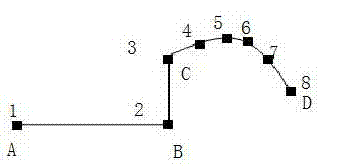

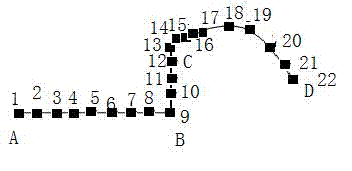

Method for drawing display of bus on straight line simulated diagram by applying tracing points

ActiveCN102903260AAccurately reflectCause interferenceRoad vehicles traffic controlSimulationGeographic information system

The invention discloses a method for drawing display of a bus on a straight line simulated diagram by applying tracing points and relates to the field of public transport line scheduling. Actual bus line advancing route tracing point information is acquired by a GIS (Geographic Information System) operation tool and is matched with longitude and latitude coordinates for calculation, then stations are projected onto the straight line simulated diagram, the position information of an operating bus transponded in real time by a GPS (Global Position System) positioning service is received by a computer, and after the position information of the operating bus is matched with the actual longitudes and latitudes of the tracing points drawn on the straight line simulated diagram for calculation, a bus mark is displayed on the straight line simulated diagram. The method disclosed by the invention has the advantages that the proportion of station spacing and bus spacing can be visually displayed; the position information of the bus can be actually reflected; when station reporting of the bus is abnormal, or continuous station reporting is caused by the manual intervention of a driver, the actual bus information can not be disturbed; and a tracing point auxiliary insertion method is adopted to solve the problem that station matching and a bus driving track are anamorphic on the straight line simulated diagram due to the over-small acquisition amount of the tracing points.

Owner:HUALU ZHIDA TECH

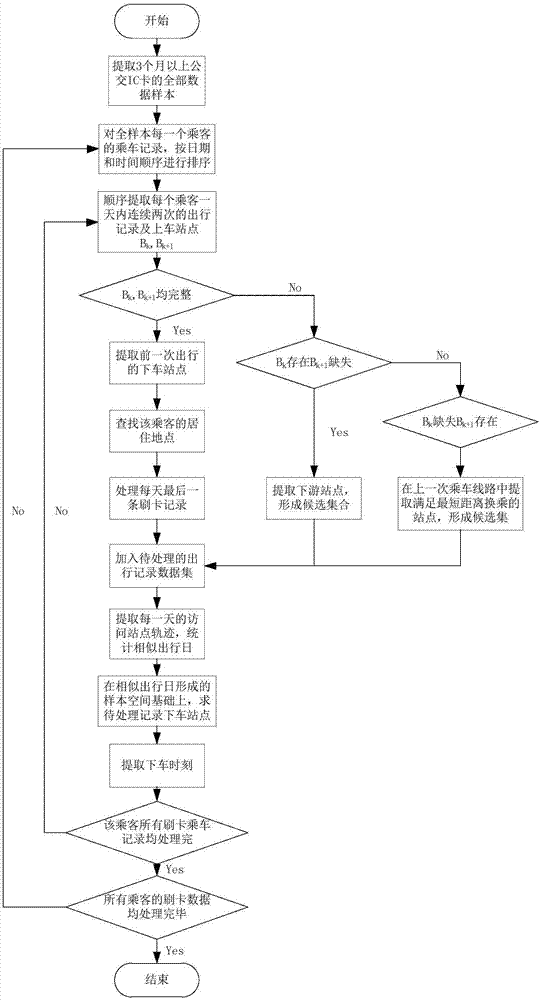

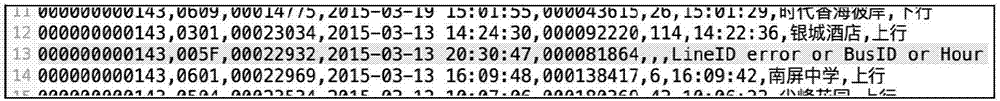

Method for extracting public transport passenger trip space-time tracks

ActiveCN106874432AAvoid the pitfalls of overriding individual featuresRespond effectively to distractionsData processing applicationsSpecial data processing applicationsTransit networkSimulation

The invention discloses a method for extracting public transport passenger trip space-time tracks. Data resources of full-sample passenger bus-taking records and bus running records are fused; based on the continuous trip chain method, starting from similarity analysis of everyday bus station tracks of each passenger, similar trip days are extracted; a statistical sample space is constructed to mine passenger activity rules; by means of the Bayesian estimation method, getting-off stations of one-ticket bus passenger card-swiping bus-taking records are extracted more reasonably and accurately, and trip tracks of the passengers are reduced from missing information. According to the method, implicit passenger individual activity rules in full-sample card-swiping data can be fully utilized for reasonably deducing the card-swiping getting-off stations of the passengers, and follow-up public transit network section flow statistics and data mining are promoted.

Owner:SOUTH CHINA UNIV OF TECH

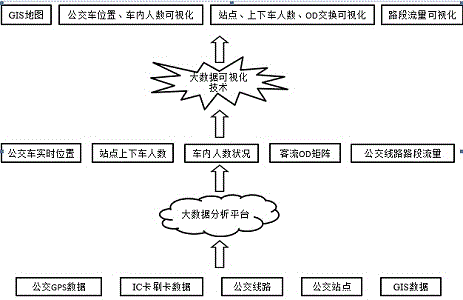

Visual bus big data analysis system

InactiveCN106844624AEasy to handleHandle exceptions quicklyData processing applicationsRelational databasesTraffic capacityThe Internet

The invention discloses a visual bus big data analysis system and belongs to the field of traffic big data application. The visual bus big data analysis system is characterized in that vehicle GPS data and IC card swiping data collected by bus GPS devices and card swiping devices and data related to bus lines and bus stops are transmitted to a big data analysis platform in real time, technologies such as cloud computing, big data analysis, internet and visualization are fully utilized to visualize real-time bus positions and in-bus passenger number states, and the system sends out warning information if buses deviate in position or passenger numbers in the buses exceed a specific threshold value; the numbers of passengers who get on or off the buses at the bus stops, passenger flow OD matrixes among bus stops and bus line link traffic flows are displayed through visual interfaces according to a great number of data analysis results. The visual bus big data analysis system is capable of showing real-time bus operation states and passenger flow states among the bus stops and of every bus line precisely.

Owner:BEIJING YAXIN LANTAO TECH CO LTD

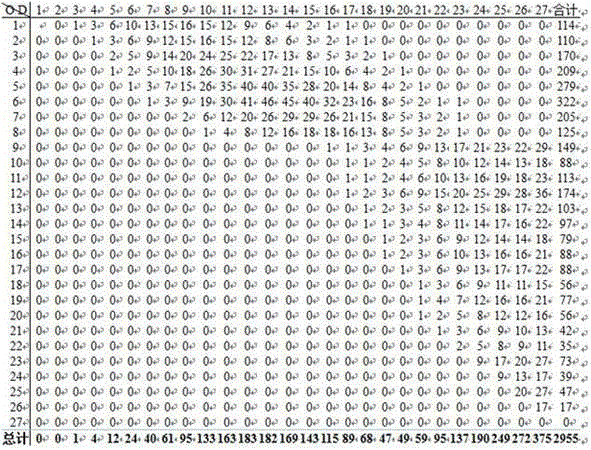

Urban railway transit timetable optimizing technology application framework

ActiveCN104200286AReflecting the spatio-temporal distribution of attractivenessImprove operational efficiencyForecastingEngineeringShort terms

The invention discloses an urban railway transit timetable optimizing technology application framework. The urban railway transit timetable optimizing technology application framework comprises a passenger flow data extraction and preprocessing module 1, an interstation passenger flow distributive-law extraction module 2, a platform passenger arrival rate extraction module 3, a dispatch model establishment and analysis module 4 and an optimization result output and verification module 5. The module 1 is in charge of extracting available passenger transaction information from original passenger flow data for use in follow-up links; the module 2 and the module 3 are in charge of extracting passenger-flow characteristic parameters significant to later modeling; the module 4 serves as the core of the framework and is capable of establishing a dispatch optimization model and solving on the basis of the passenger-flow characteristic parameters; the module 5 is mainly used for converting optimization results into corresponding train timetables. The urban railway transit timetable optimizing technology application framework is used for optimizing and adjusting current departure timetables of urban railway transit lines, and can be combined with the short-term passenger flow forecasting technology for providing technique support for working out a train optional dispatch plan within a given future period.

Owner:SOUTHEAST UNIV

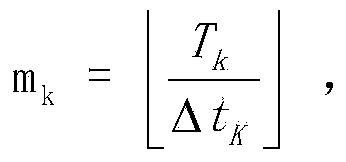

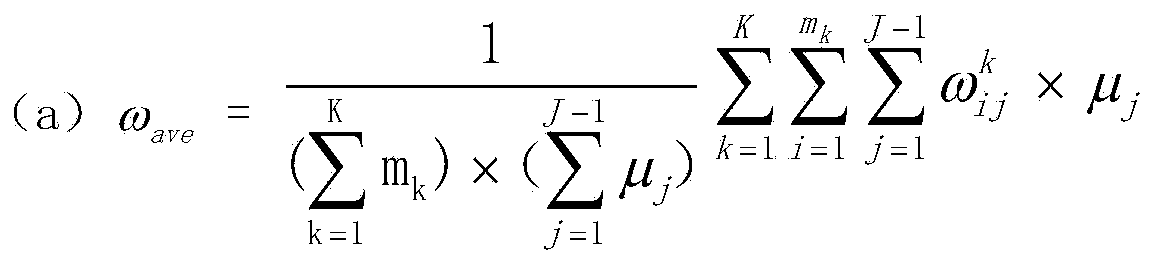

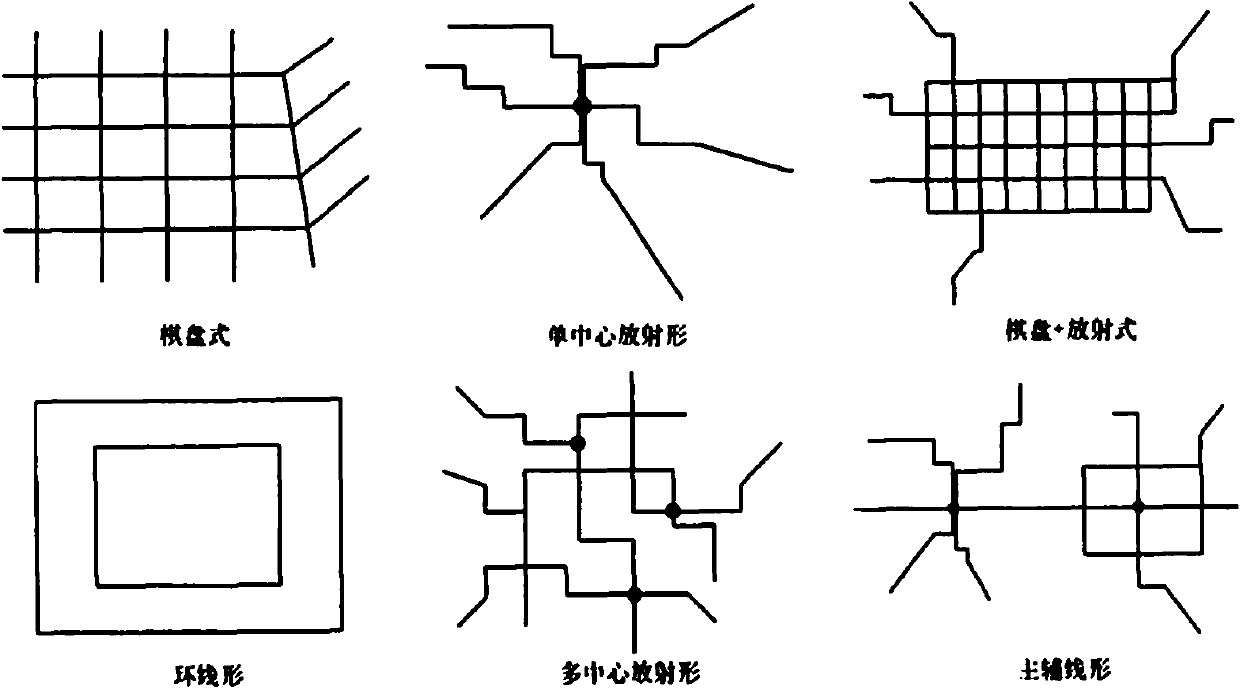

Rail transit connection public transit network optimizing system

The invention discloses a rail transit connection public transit network optimizing system, which comprises a data acquisition module, a data processing module and a result output module, and is characterized in that the data processing module is used for optimizing comprehensive parameters such as connection public transit network trends, station positions and departure frequency within a coverage area of rail transit target stations. According to the rail transit connection public transit network optimizing system, the problem of global optimization of a public transportation connection net under the conditions of a combined type road network and multimodal competitiveness is solved, and the total cost including operation cost and rail transit connection cost is minimized.

Owner:NINGBO UNIV

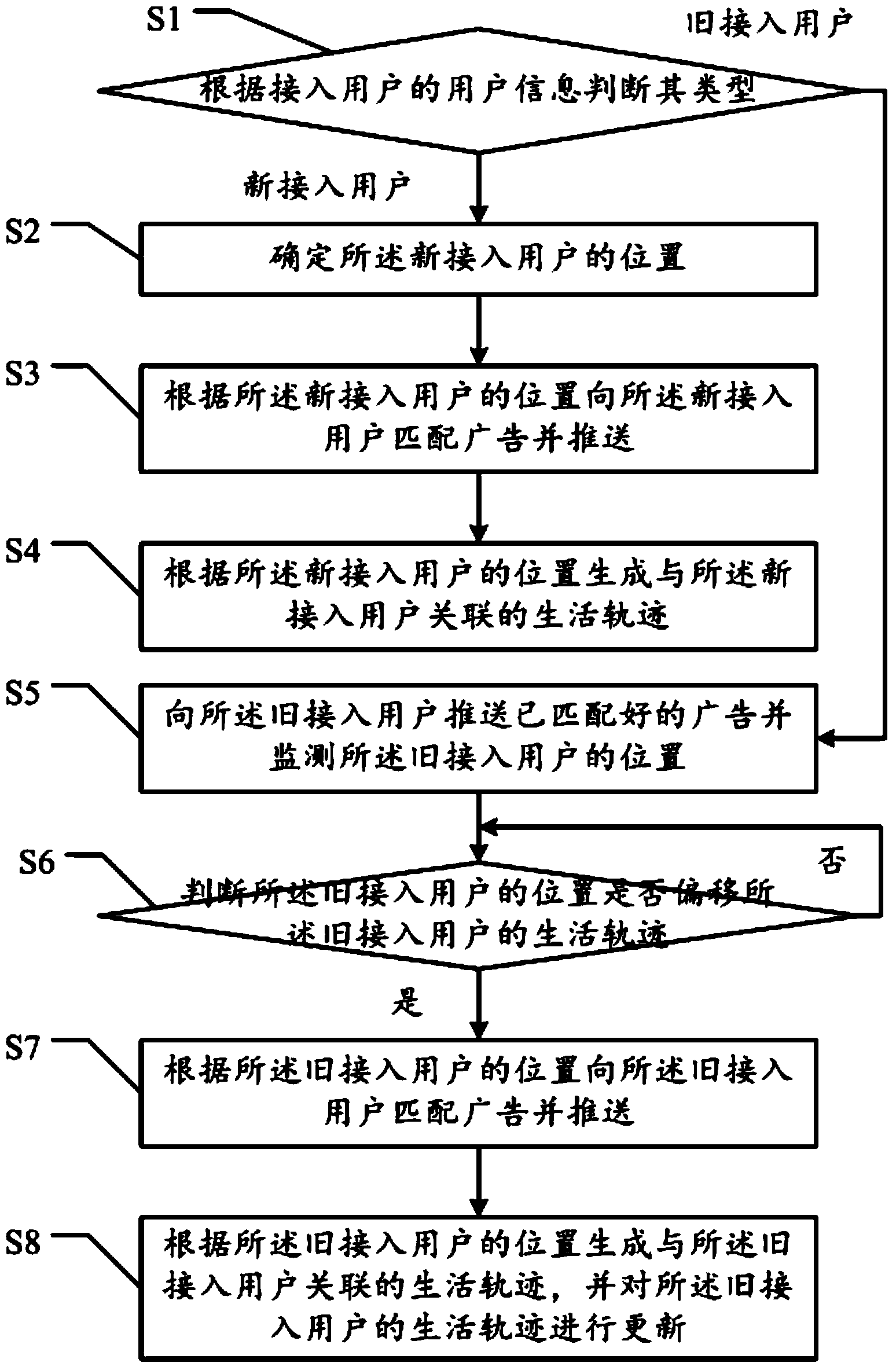

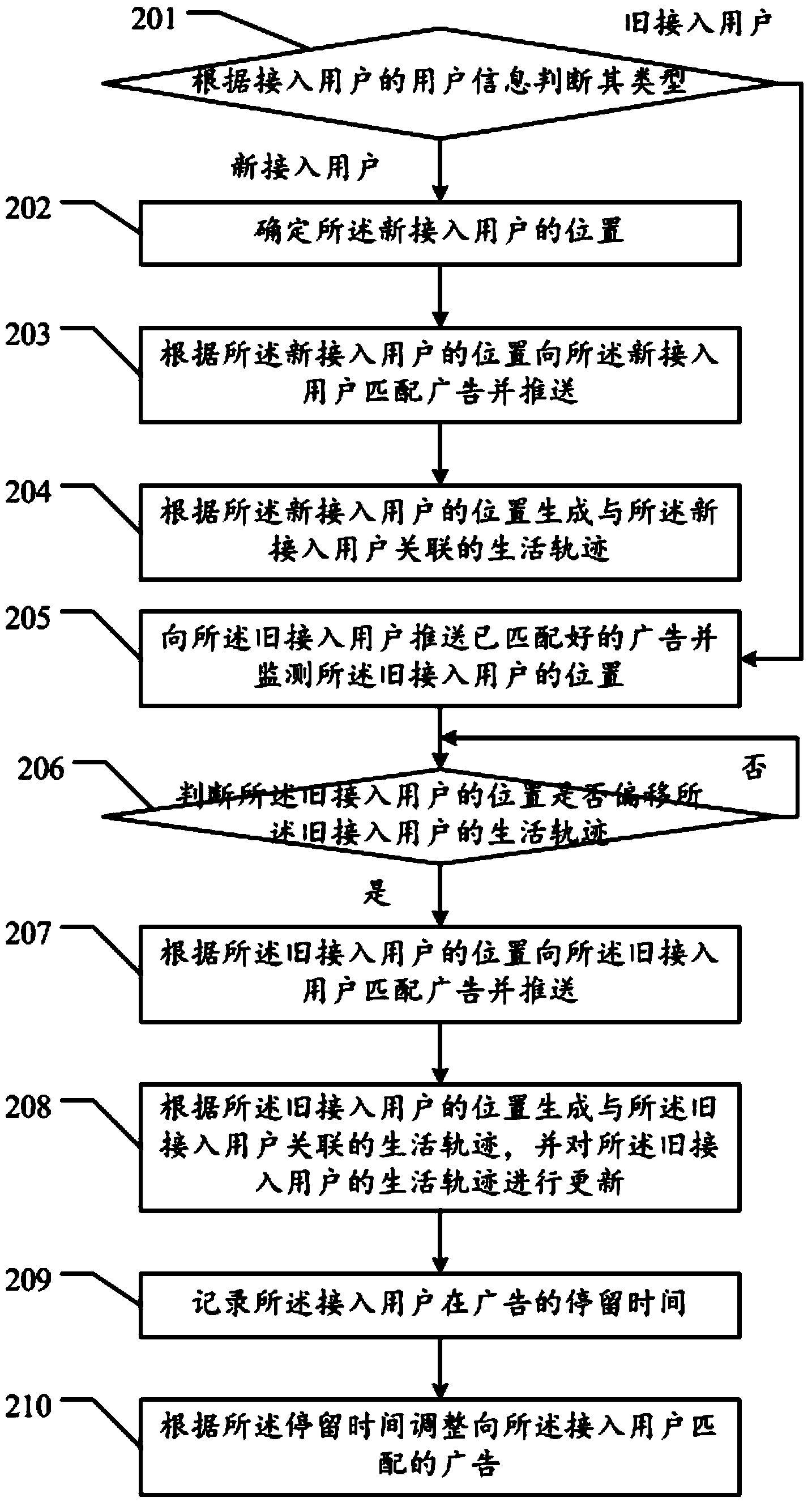

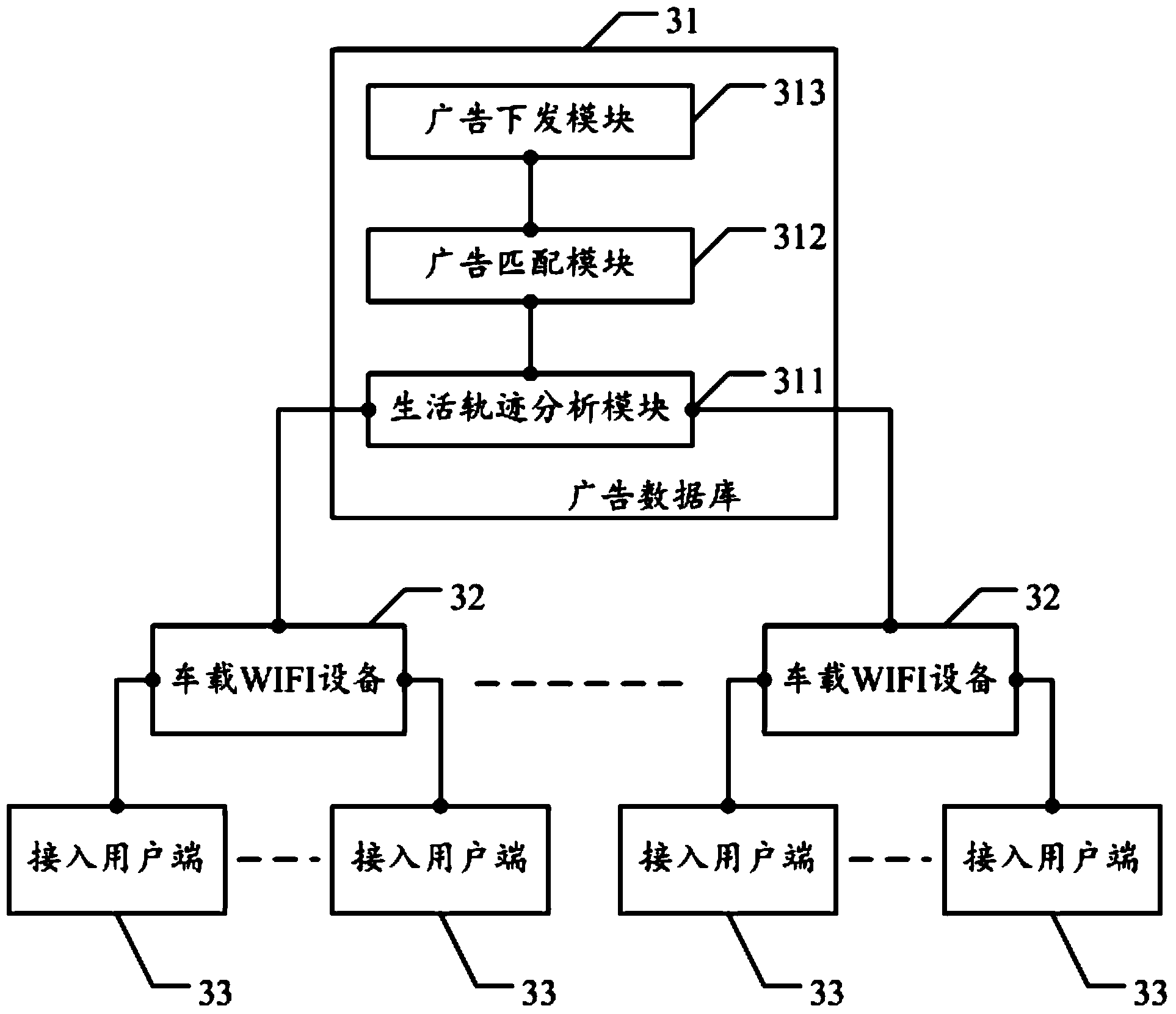

Advertisement putting method and system based on analysis of user life tracks

InactiveCN103745389AImprove user experienceImprove relevanceMarketingSpecial data processing applicationsUsage experienceAd serving

The invention discloses an advertisement putting method and a system based on analysis of user life tracks; the advertisement putting of vehicle-mounted WIFI equipment is enabled to become more precise and intelligent according to the life track and bus route matching advertisement mode through acquiring the user life tracks; advertisements with high relevancy can be provided to users, so that the usage experience of the users is improved. The advertisement putting system based on the analysis of the user life tracks comprises an advertisement database, the vehicle-mounted WIFI equipment and an access user terminal, wherein the advertisement database is used for analyzing the life tracks from the vehicle-mounted WIFI equipment, implementing the advertisement matching and issuing the matched advertisements to the vehicle-mounted WIFI equipment; when the access user terminal is accessed, the vehicle-mounted WIFI equipment calls or generates the life tracks according to the type of the access user terminal, and issues the advertisements from the advertisement database to the access user terminal; the access user terminal is connected with the vehicle-mounted WIFI equipment through WIFI, and is used for receiving the advertisements from the vehicle-mounted WIFI equipment.

Owner:SHANLING ON LINE NETWORK TECH BEIJING

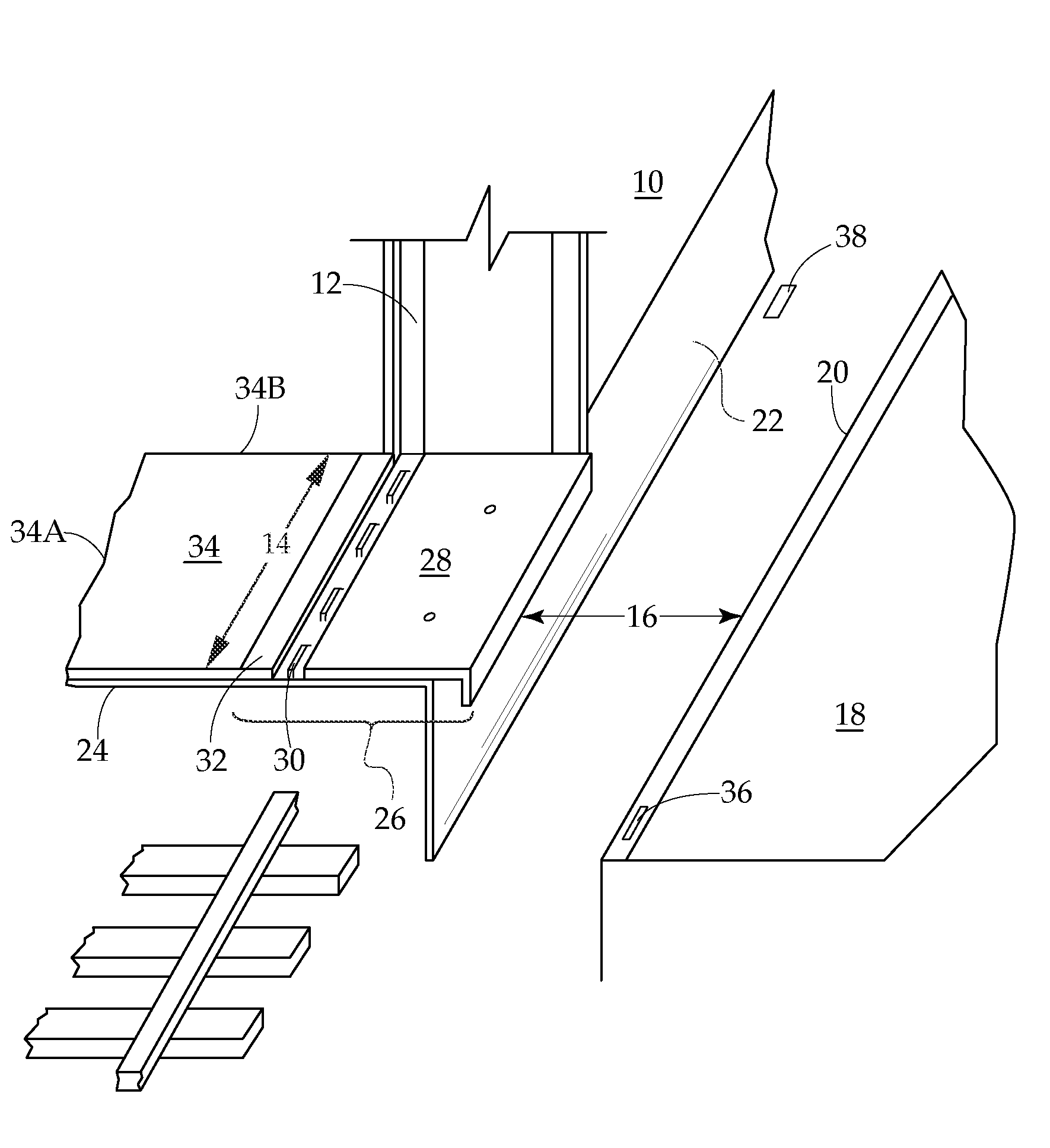

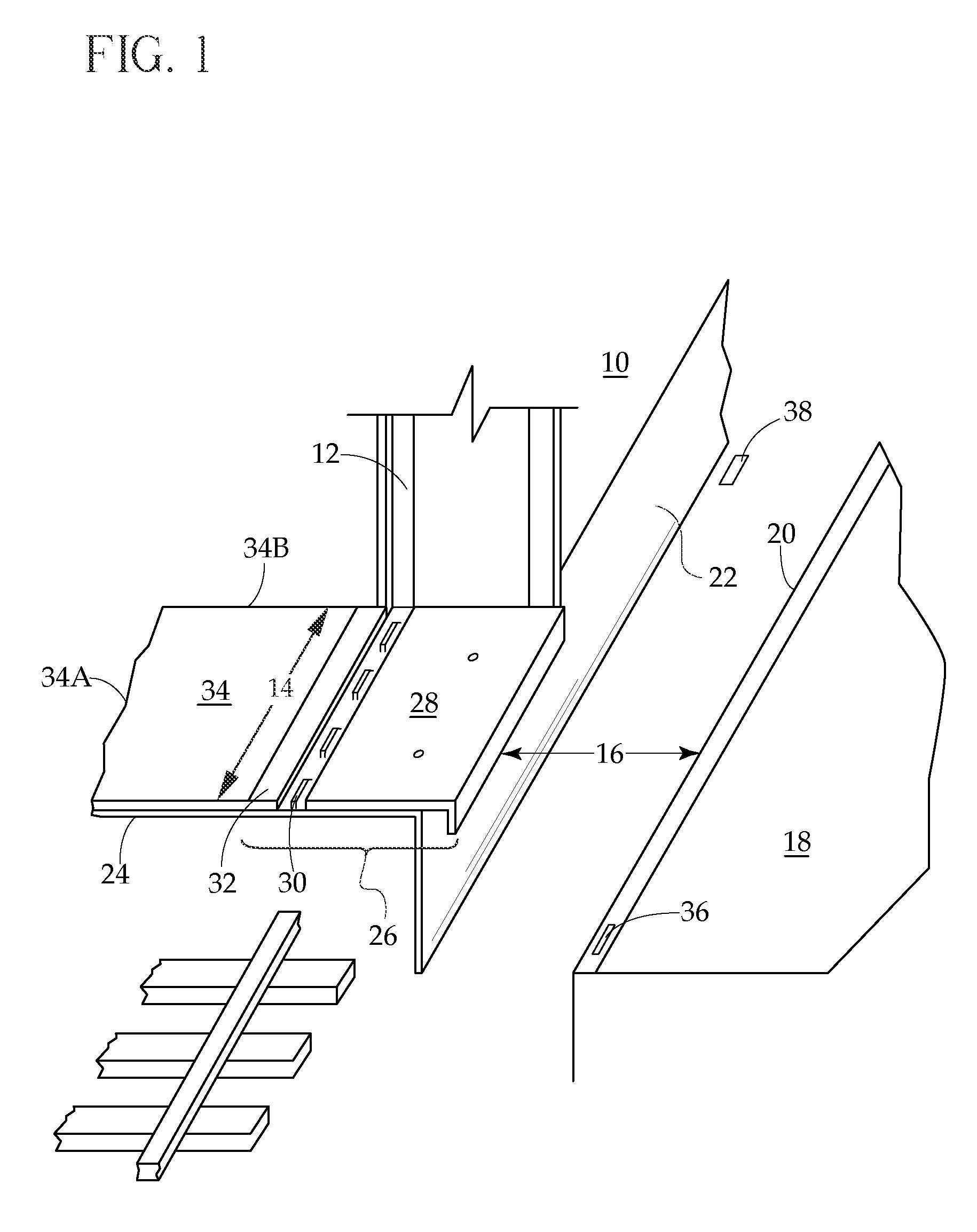

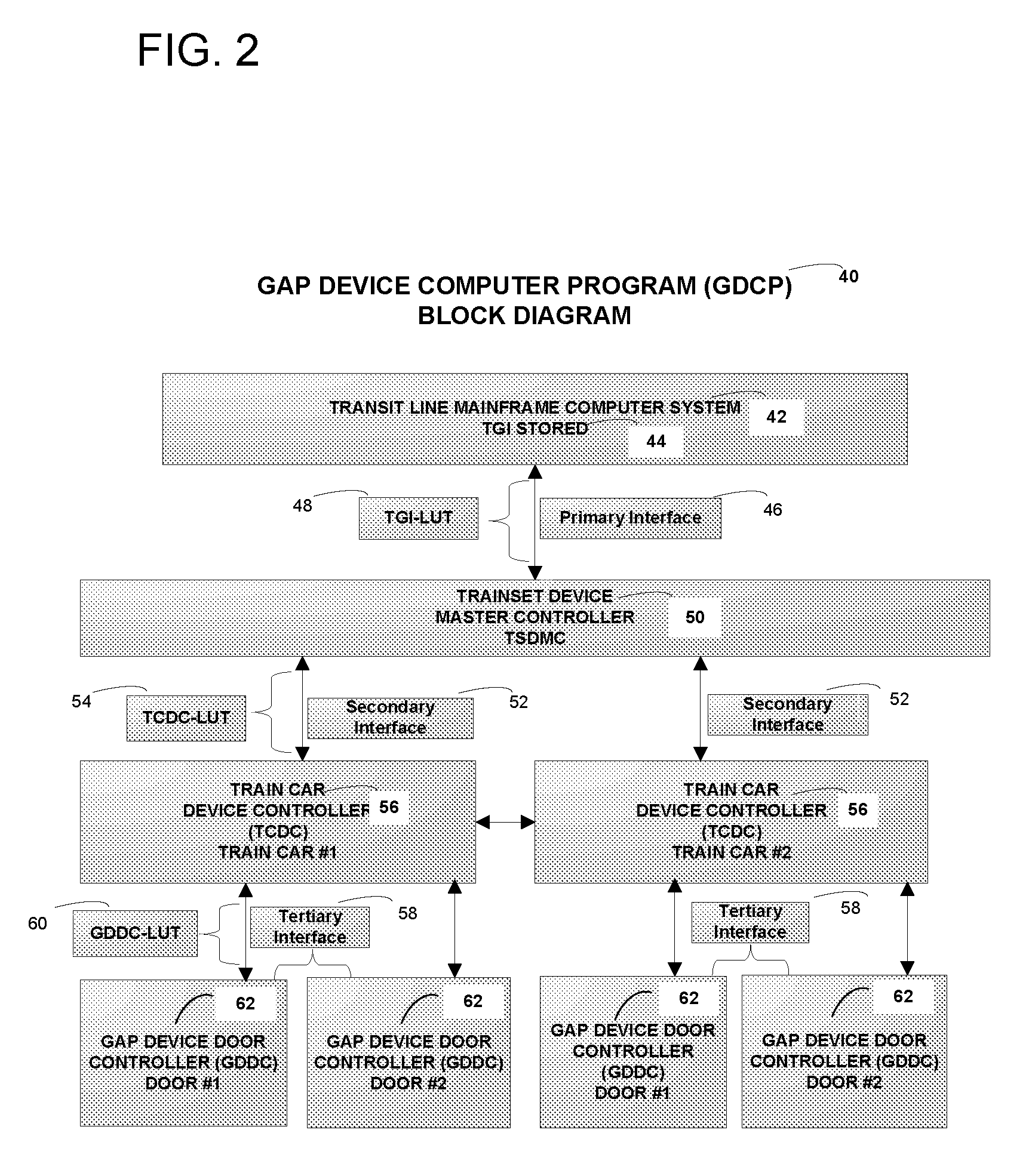

Train-to-platform gap mitigator

ActiveUS20080276832A1Gap minimizationEasy to trainRefuge islandsRailway stationSingle plateTransit line

An improved gap filler in the form of a single plate or a plurality of plates attached to the train car exterior or emanating from below train car vestibule floor which permits transit line system operator to utilize one device to obtain any desired gap minimization at every train car door in a trainset relative to its corresponding platform edge at all stations on its transit line regardless of platform and / or track configuration while simultaneously adhering to its gap clearance standards pertaining to safe passage of any train within its fleet through any station.

Owner:CHISENA MICHAEL P

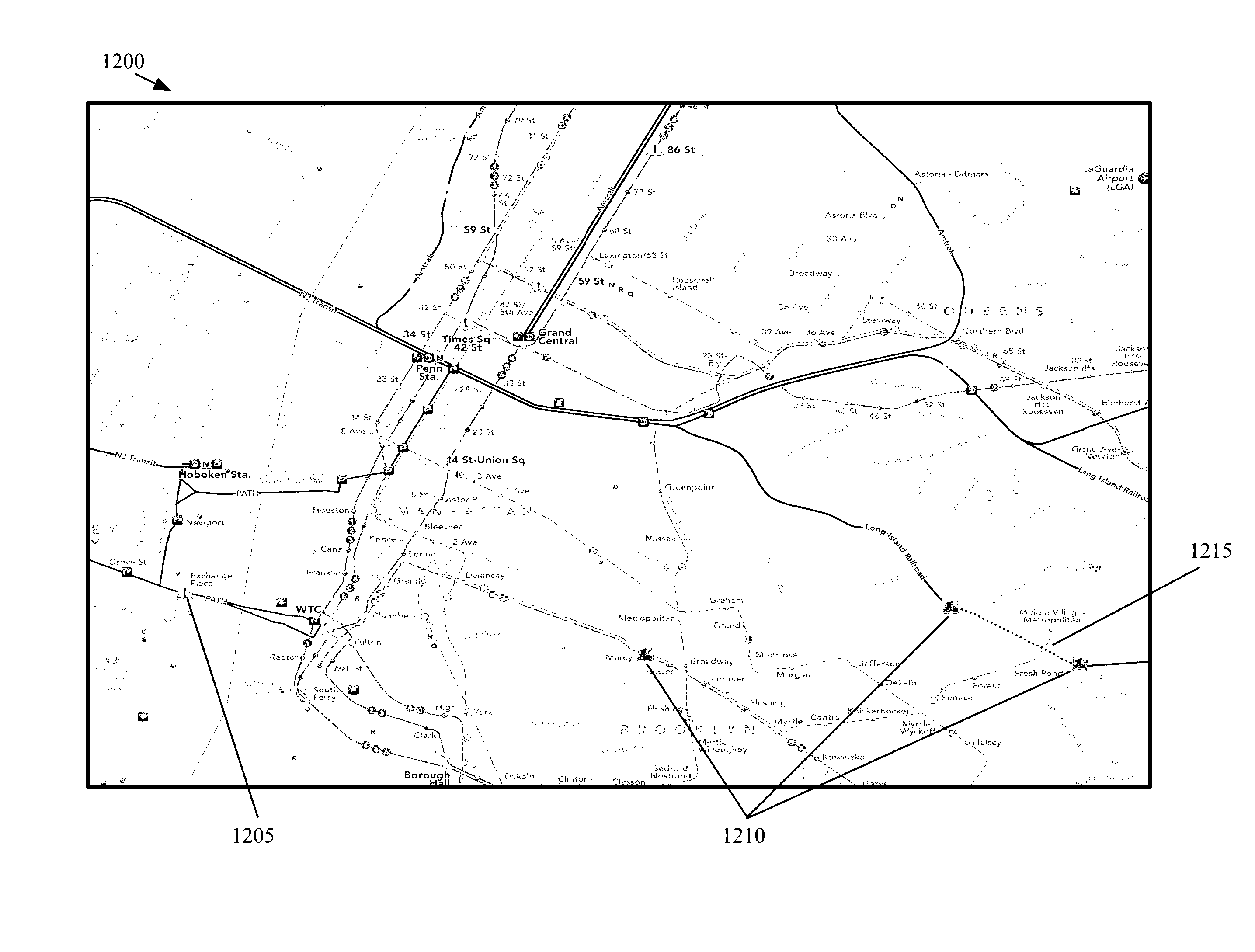

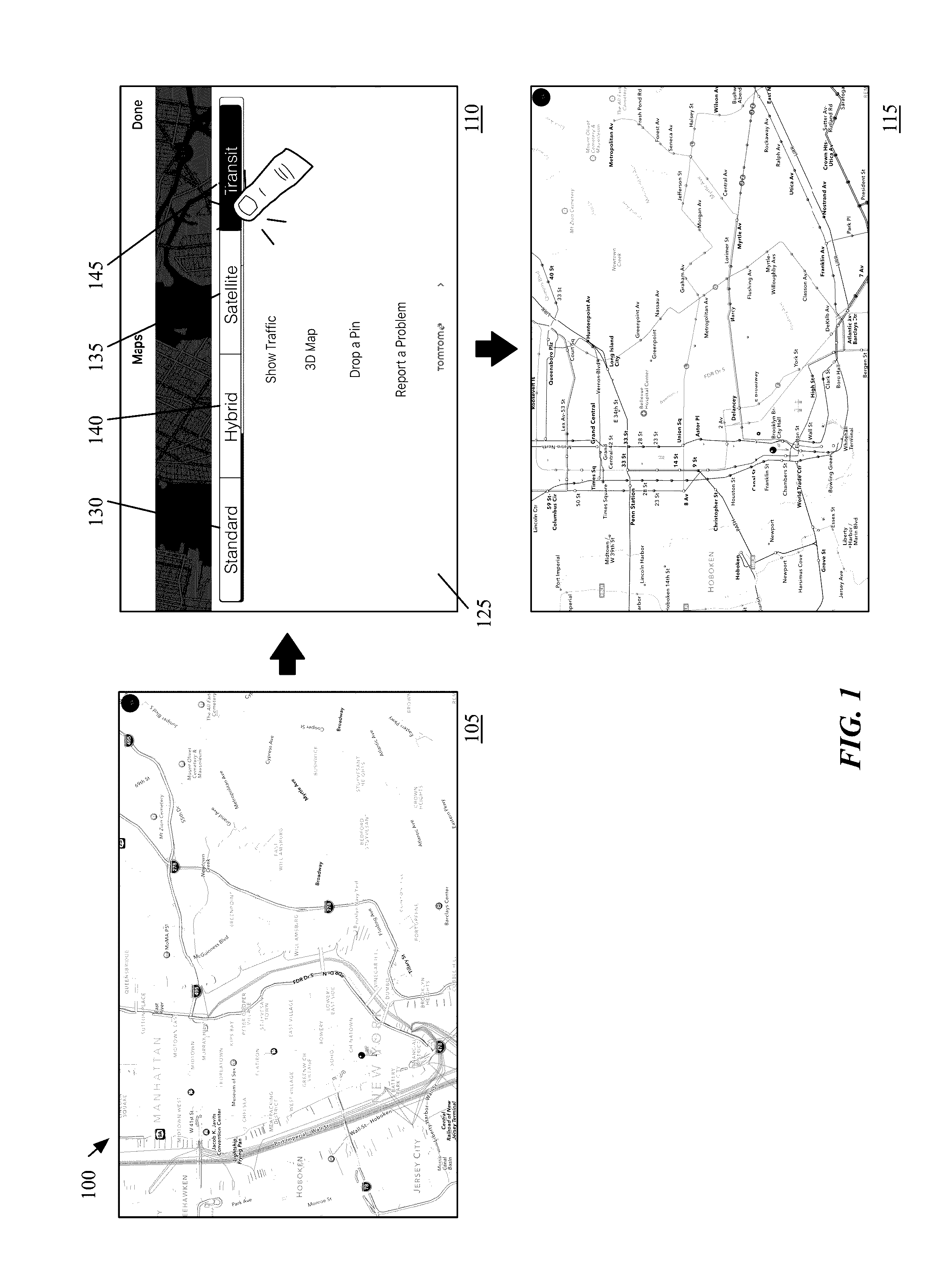

Mapping Application with Transit Mode

ActiveUS20160356625A1Instruments for road network navigationTexturing/coloringTransfer modeTransit line

Some embodiments provide a mapping application that displays a transit map including a group of transit lines. The mapping application receives a request to display a transit route in the transit map. The mapping application also, in response to the received request, displays the transit route by modifying portions of transit lines along the route to emphasize the portions of the transit lines while modifying other transit lines not along the route to de-emphasize the transit lines not along the route.

Owner:APPLE INC

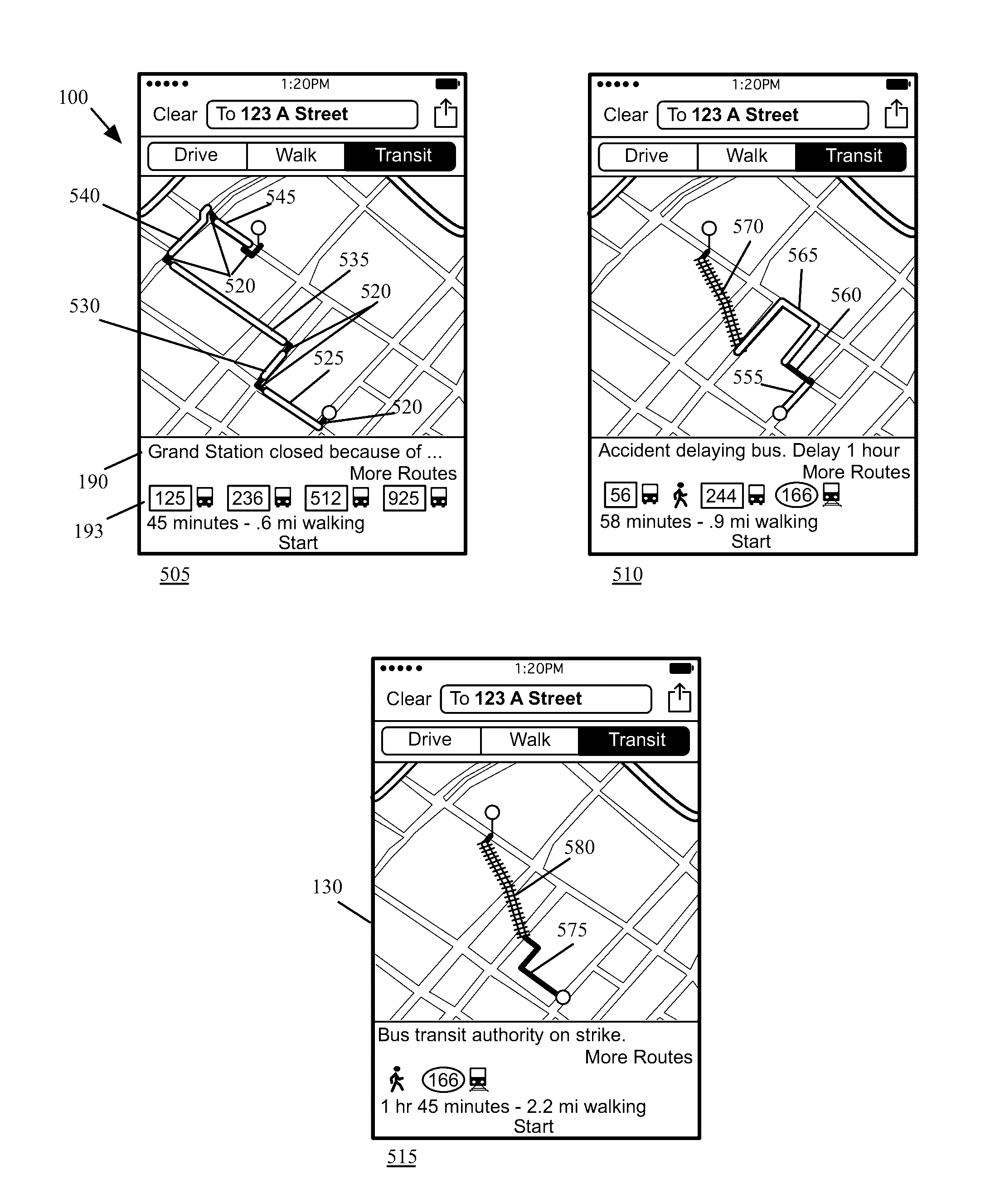

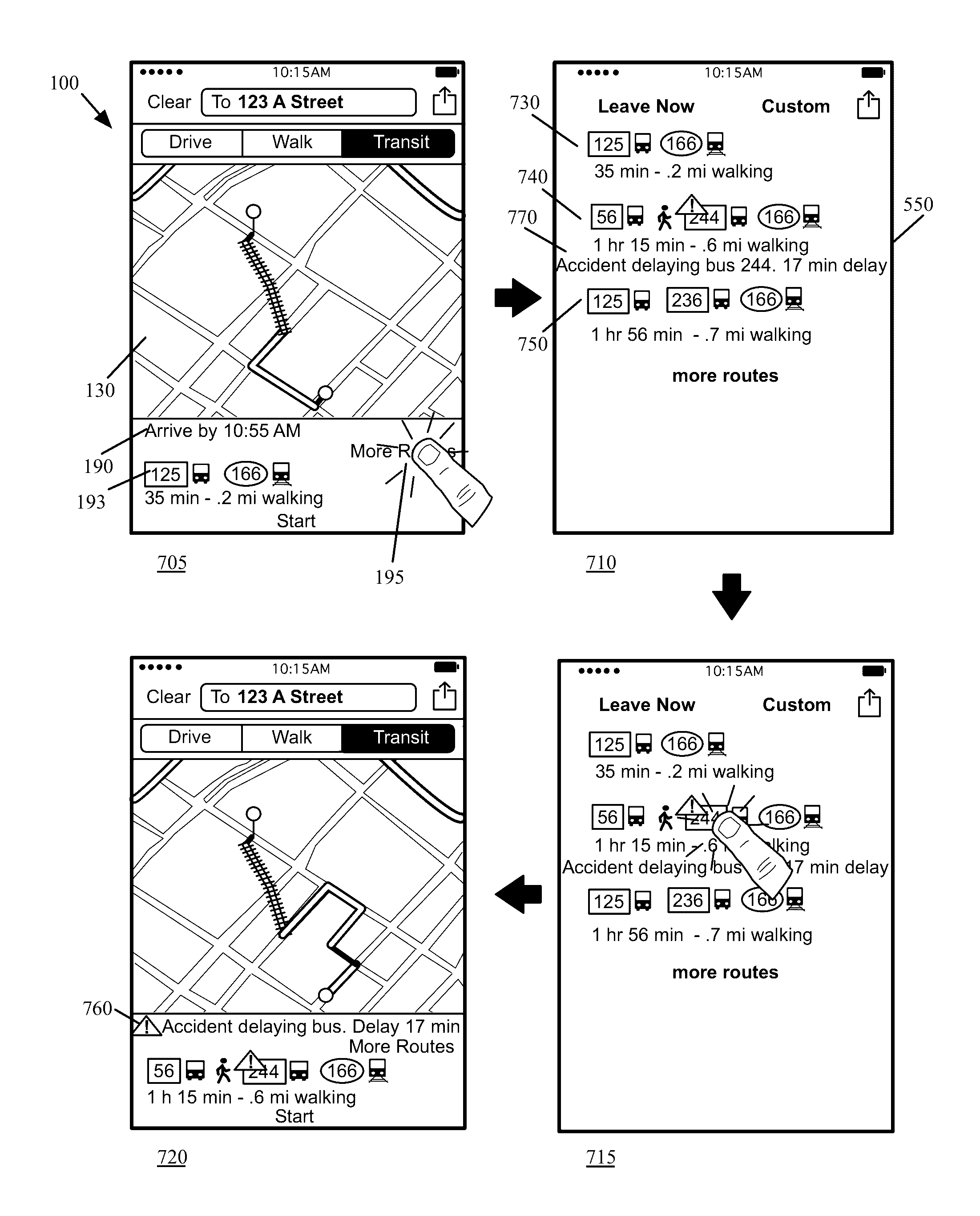

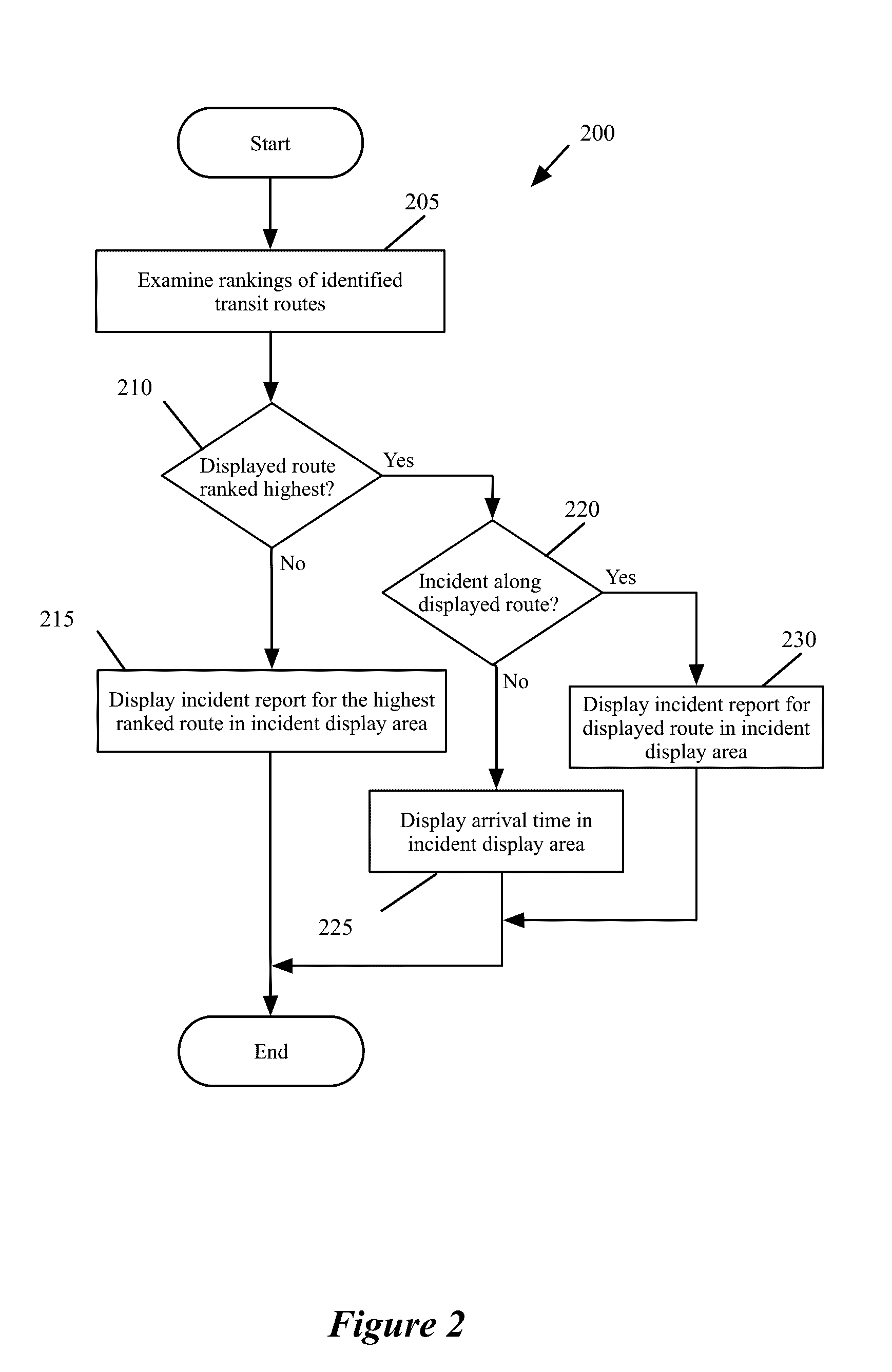

Transit Incidents

ActiveUS20160356617A1Instruments for road network navigationRoad vehicles traffic controlComputer scienceTransit line

Some embodiments provide a map application that identifies several different transit routes from a starting location to a destination location. Each identified transit route includes one or more transit legs that are serviced by different transit vehicles of different transit lines. The map application also identifies a set of incidents that are associated with one or more transit legs of one or more of the identified transit routes. The map application of some embodiments then ranks the transit routes based on a set of criteria and the identified set of incidents. The map application displays, in a display area, a representation of a highest ranked transit route over a portion of a map presentation.

Owner:APPLE INC

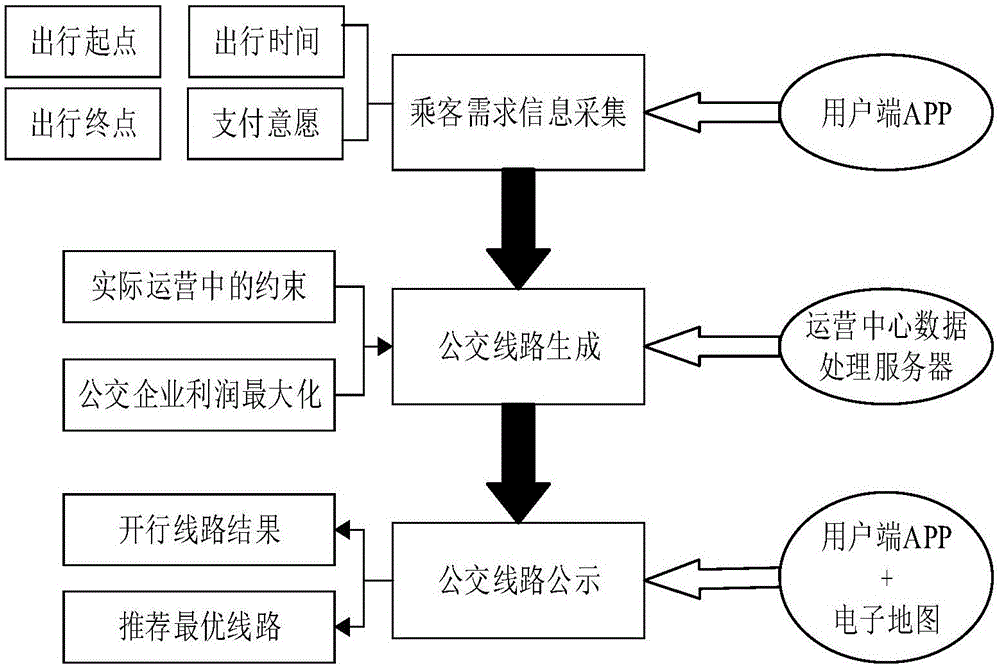

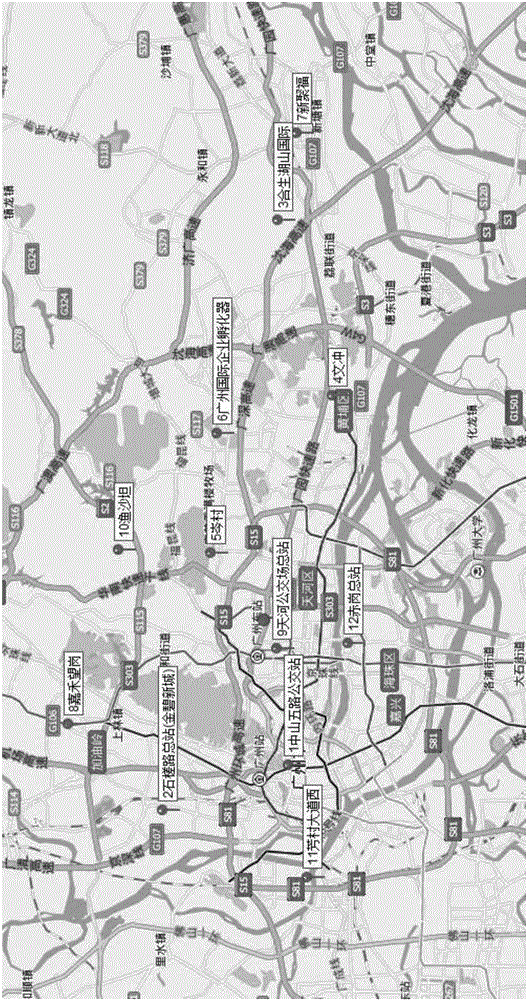

Appointment-data-based automatic route arranging system and method for customized bus

The invention provides an appointment-data-based automatic route arranging system and method for a customized bus. The system comprises a passenger demand information acquisition module for collecting passenger demand information, a bus route generating module for analyzing and processing the passenger information and providing a precise bus customized route, and a bus route displaying module for displaying a bus route arrangement result publicly and pushing a route prompting message. The passenger demand information acquisition module includes a user terminal APP; the bus route generating module includes a data processing server; and the bus route displaying module includes the user terminal APP and an electronic map. The user terminals included by the passenger demand information acquisition module and the bus route displaying module are the same one. According to the invention, a drafting mode based on route setting by companies and bus taking selection by passengers is changed and an appointment-data-based precise route setting method is provided. Therefore, an occupancy rate of a customized bus is improved well, the bus transport wasting is reduced, and profits of bus companies are increased.

Owner:SOUTH CHINA UNIV OF TECH

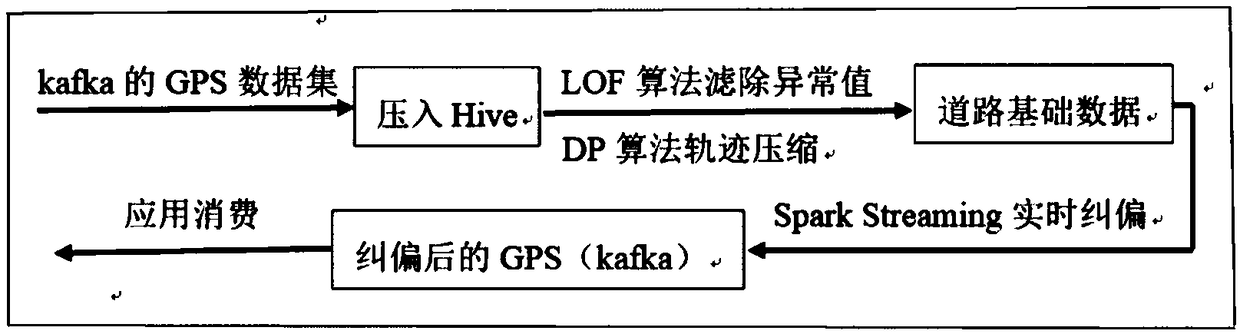

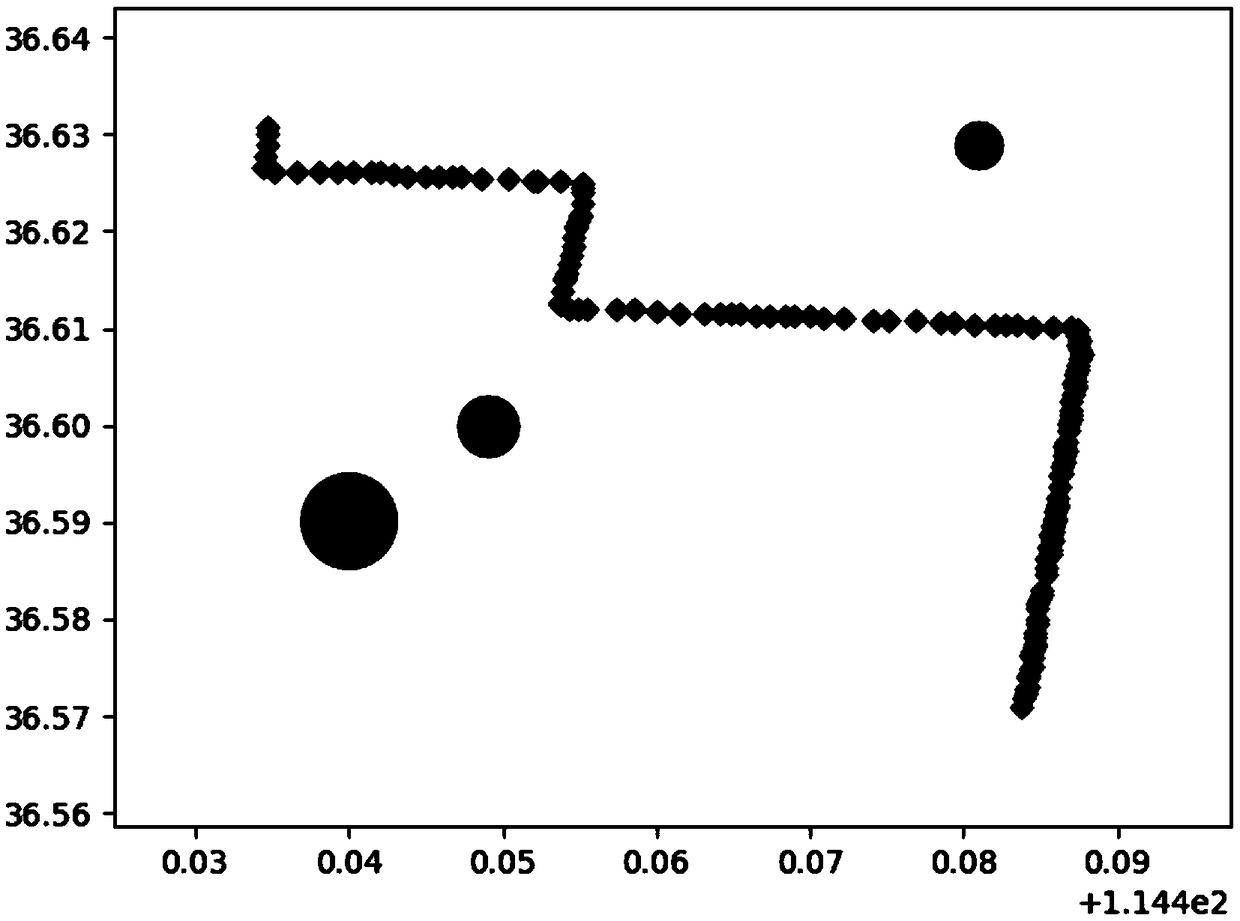

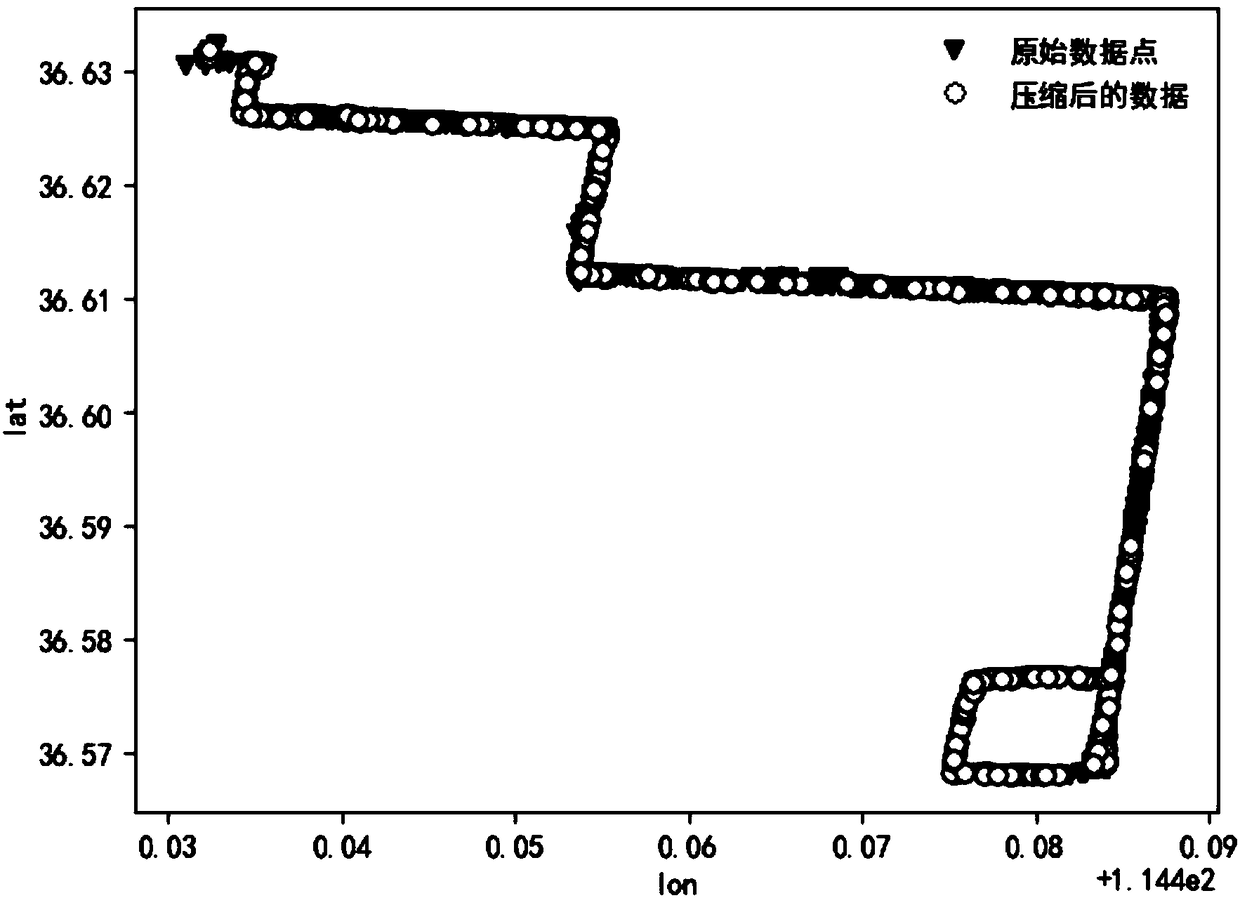

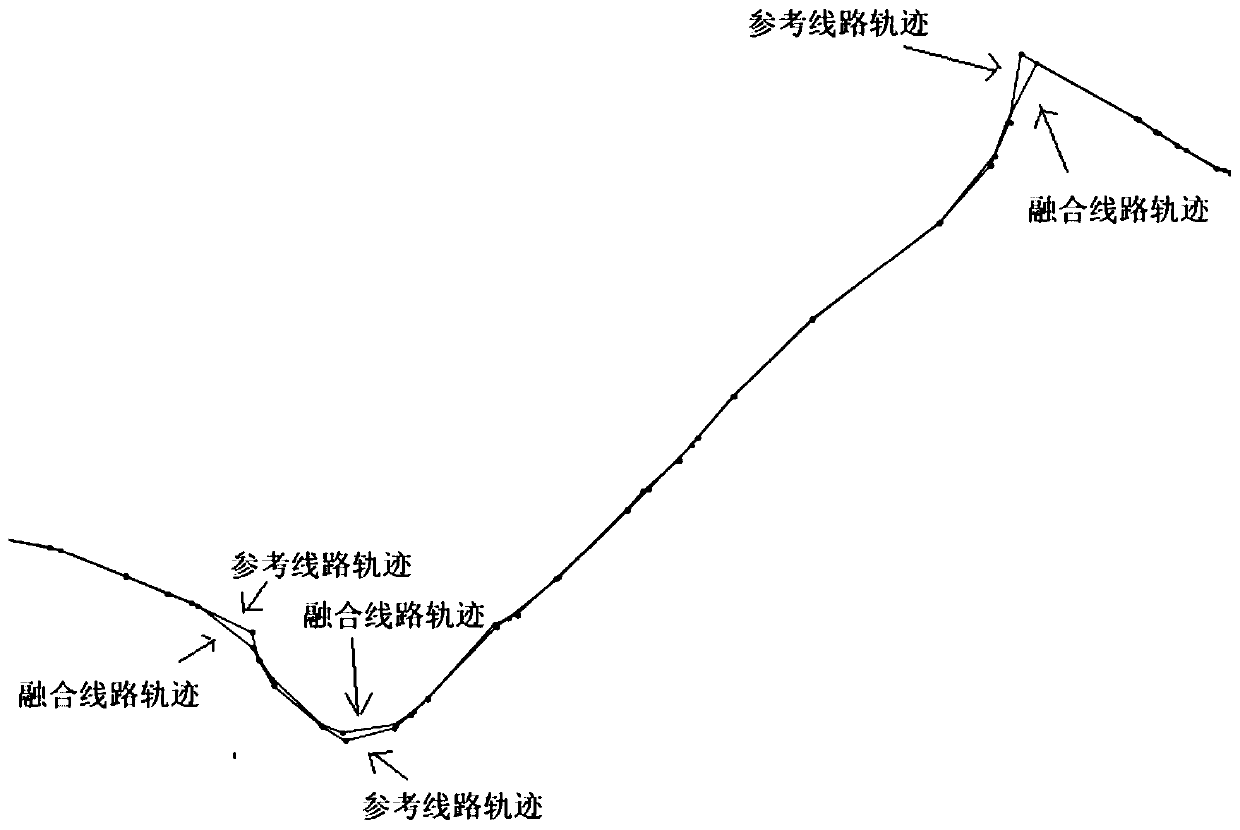

Bus GPS correction method based on abnormal point elimination and trajectory compression algorithm

ActiveCN108802776AAccurate positioning referenceDetection of traffic movementSatellite radio beaconingMap LocationFiltration

The invention discloses a bus GPS correction method based on abnormal point elimination and a trajectory compression algorithm. The method comprises the following steps: step 1, acquiring historical GPS data of a specified bus route; step 2, performing filtration treatment on the acquired historical GPS data of the specified bus route by applying a local abnormal factor algorithm; step 3, simulating GPS trajectory data of the specified bus route; and step 4, based on the GPS coordinate point information of the specified bus route, performing trajectory correction on the real-time GPS data acquired from message-oriented middleware by utilizing the GPS trajectory data of the specified bus route, and taking the coordinate value of the midpoint of two coordinate points closest to the real-timeGPS point on the GPS trajectory of the specified bus route as a correction point of a bus GPS location drift point. The method provided by the invention can improve the accuracy of the GPS route point of a specific vehicle shift on a map location.

Owner:SHENZHEN EMPEROR TECH

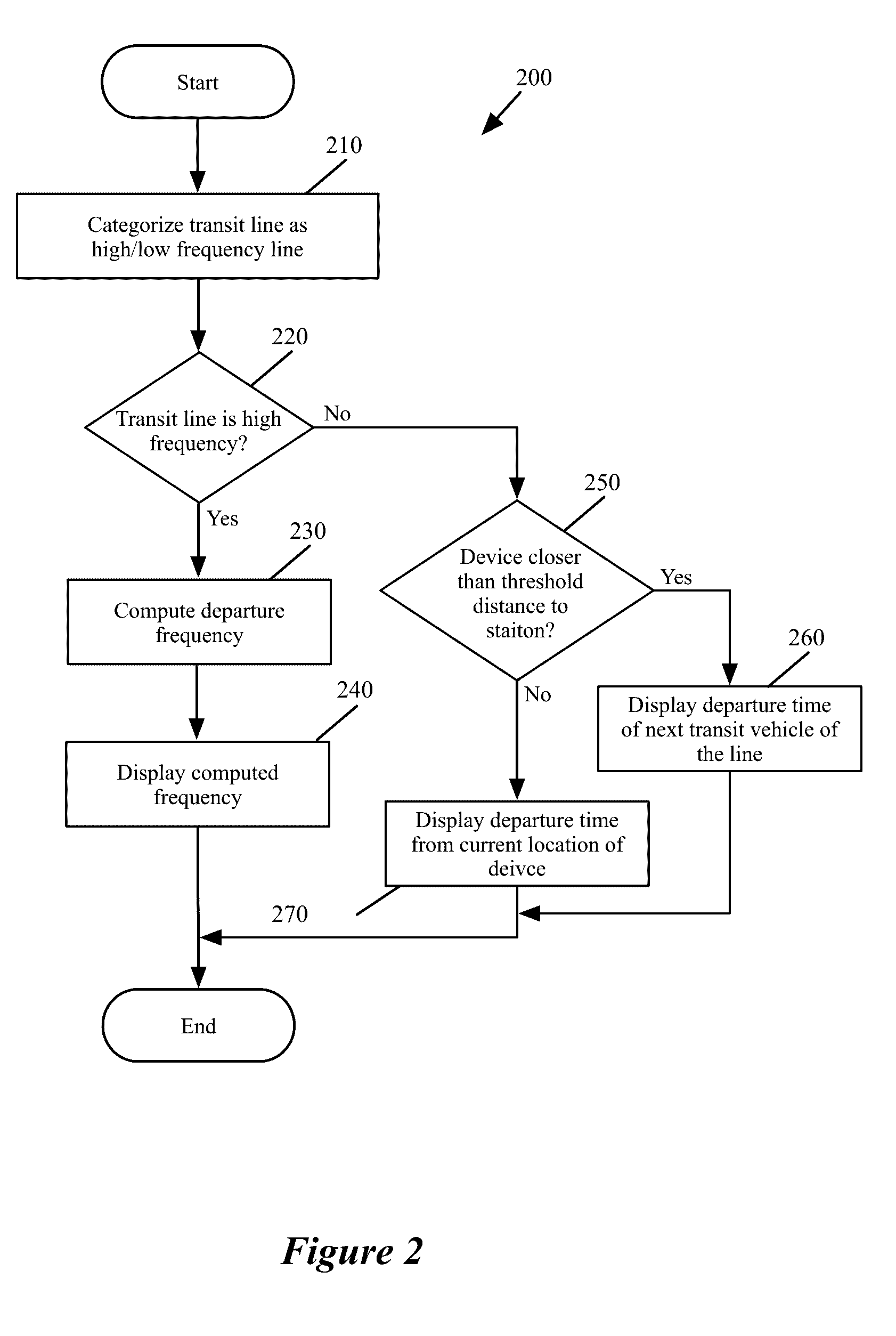

Frequency Based Transit Trip Characterizations

ActiveUS20160358470A1Instruments for road network navigationNavigational calculation instrumentsWalking distanceComputer science

Some embodiments provide a map application that identifies a transit route between a starting location and a destination location. The transit route, in some embodiments, comprises a set of transit legs that each is serviced by transit vehicles of a transit line and a set of walking distances. The map application of some embodiments generates a frequency of departures for transit vehicles of each transit line in the set of transit lines from a first transit station of the transit leg that is serviced by the transit line. The map application of some such embodiments further generates a frequency of departures for the entire transit route.

Owner:APPLE INC

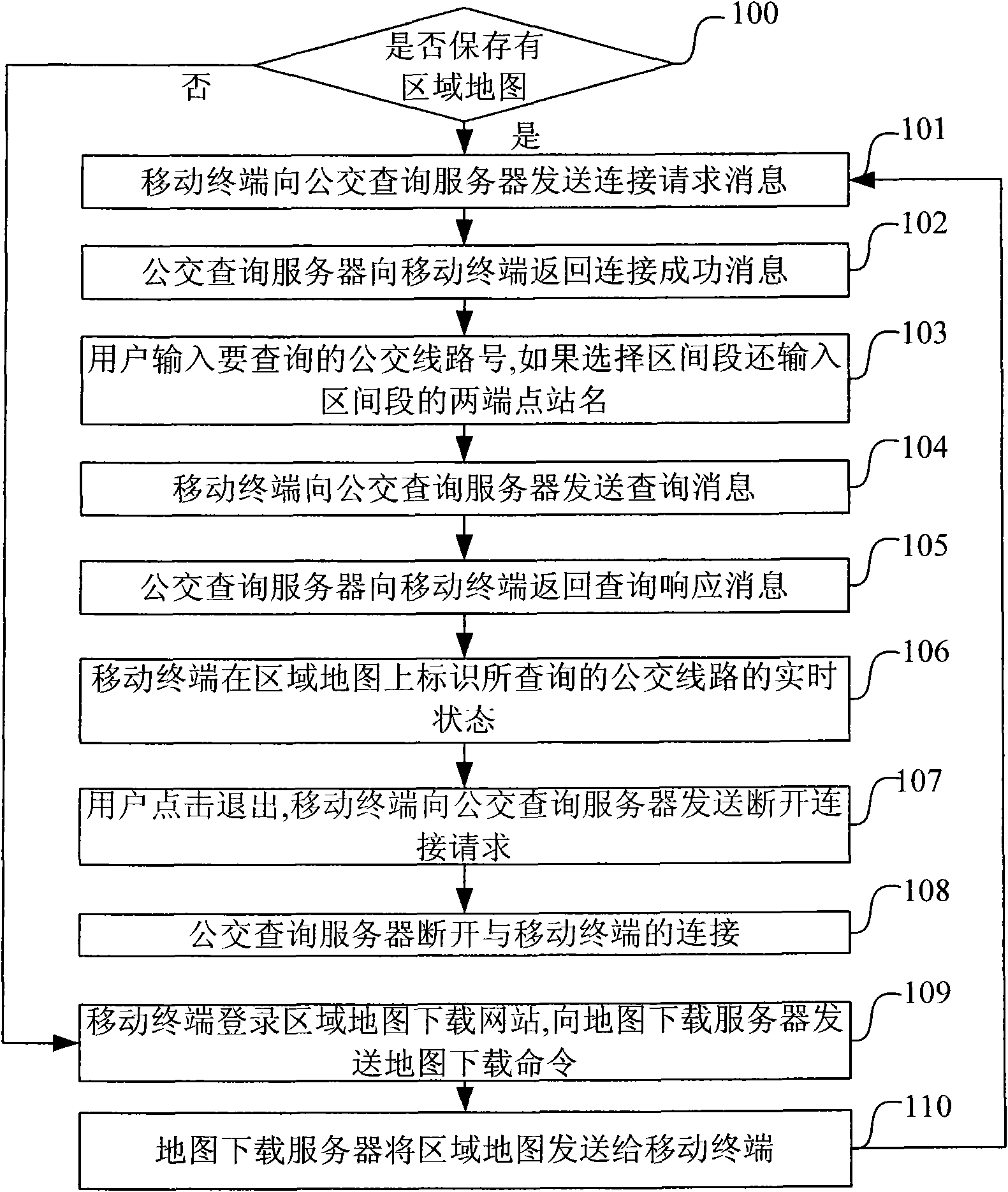

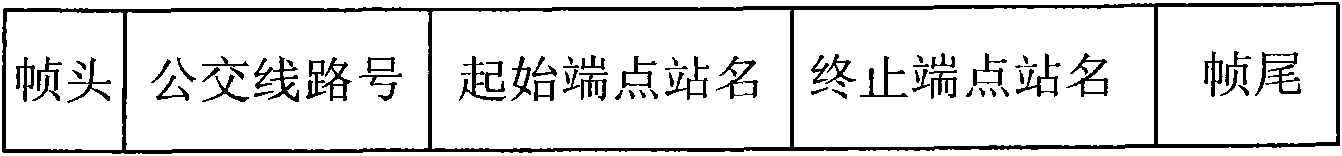

Method, system and mobile terminal for realizing public bus inquiry service

InactiveCN101577057ARelieve operating pressureConvenient travelRoad vehicles traffic controlSpecial data processing applicationsEmbedded systemTransit line

The invention discloses a method for realizing public bus inquiry service, comprising the steps that: a mobile terminal sends a bus route number which is input by a user for inquiry to a public bus inquiry server; after receiving the bus route number to be inquired, the public bus inquiry server sends to the mobile terminal monitored coordinates information of buses that run on a bus route; the mobile terminal marks the locations of the buses that are in the process of running on the inquired bus route in accordance with the received coordinates information on a regional map. With the help of the method of the invention, the user can clearly obtain the running state of the buses to be taken, can consider using other transportation means in case that the distance between the bus that the user waits for and a bus stop where the user stands is long, and meanwhile, can wait for the next bus when knowing that the coming bus is quite crowded and the next bus will come in a very short time, thus greatly reducing operating pressure of public bus and bring remarkable convenience for people to go out.

Owner:ZTE CORP

Public-transit-network layout optimization method

InactiveCN104134105AImprove satisfactionGood scheduling serviceForecastingTransit networkTraffic capacity

The invention discloses a public-transit-network layout optimization method. The method comprises the following steps that key indexes determining backgrounds ksi<1> of travelers are obtained; parameter indexes determining the public transit operation service level eta<2> are obtained; key control indexes determining the tolerance eta<1> of the travelers are set; key indexes S<x> influencing the travelers to judge the public transit service satisfaction degree are determined; control indexes E<BX> influencing public transit operation benefits are determined; the traffic capacity C of a public transit network of a city is worked out; an optimal object model of the layout of the public transit network is established; a layout scheme of the public transit network of the city is determined; whether the layout scheme of the public transit network meets the requirements of the optimal object model or not is judged, wherein if yes, the layout scheme of the public transit network is output, and if not, measurement and calculation in the last step are conducted, and the layout scheme of the public transit network is further optimized. By means of the public-transit-network layout optimization method, contradictions between public transit service differences pursued by different types of travelers and the public transit operation benefits can be balanced, the public transit service satisfaction degree can be increased, and the degree of loyalty of the travelers to the public transit service can be increased.

Owner:SOUTHEAST UNIV

Customized bus line design method based on a two-stage heuristic algorithm

The invention discloses a customized bus line design method based on a two-stage heuristic algorithm, comprising the steps of obtaining the customized bus line demand, constructing a customized bus line design model with a time window, designing the customized bus line scheme based on the two-stage heuristic algorithm and solving the model. The method considers the problem of multi-regional customized bus route design, constructs a customized bus route design model and outputs a route scheme on the basis of considering the passenger travel cost and the customized bus operation cost, which provides a reference for the actual planning and operation of the customized bus. Compared with the research of the prior customized bus route design problem, the invention considers the passenger demandin time and space, and designs a two-stage heuristic algorithm, the output of the algorithm includes the information such as the station through which the route passes, the arrival time of the vehicleat each station, the operation time and the like. The results obtained by the invention can provide a theoretical method for actually customizing the planning of the bus line and the compilation of the timetable.

Owner:BEIHANG UNIV

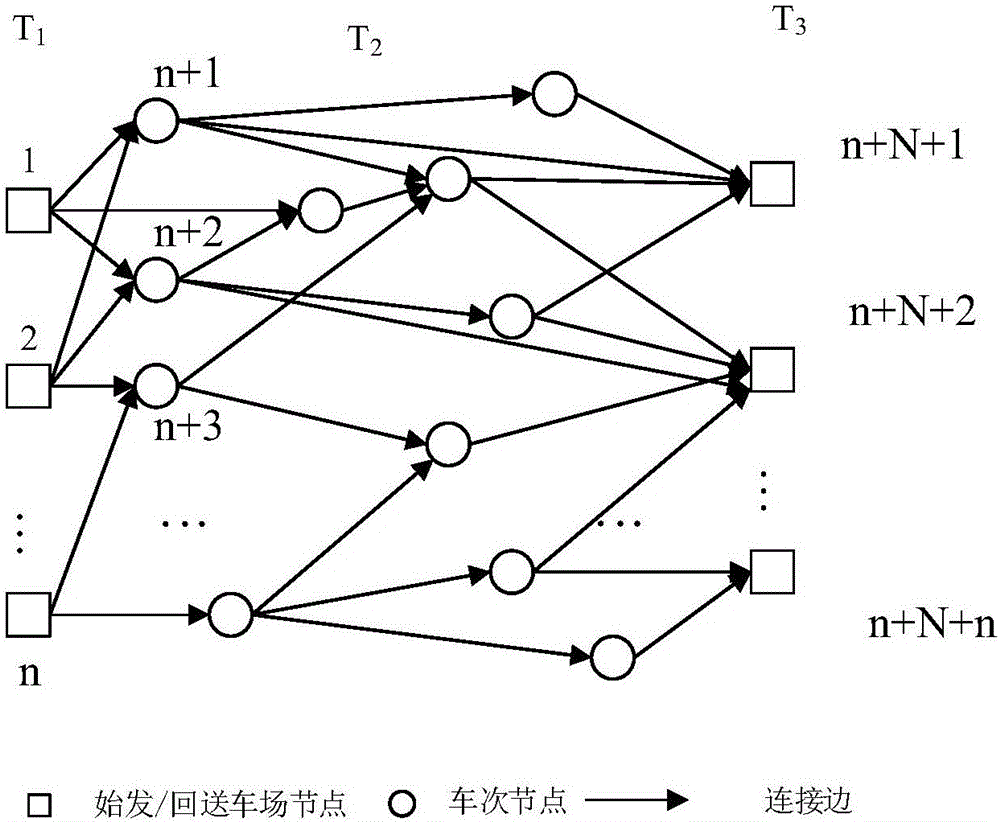

Urban rail line passenger flow peak prediction method based on linear programming

ActiveCN105095994AReduce the difficulty of solvingImprove accuracyForecastingTransit networkSimulation

The invention discloses an urban rail line passenger flow peak prediction method based on linear programming, and the method comprises the following steps: 1), representing a starting station and an ending station of one travel through OD, and enabling an urban mass transit train working diagram and passenger flow distribution to be projected to a single passenger flow-operation graph network through the OD parameters of passenger flow, thereby converting a passenger transportation peak value of an urban mass transit network into a multi-source multi-commodity network max-flow solution; 2), obtaining the number of passengers in one rail transportation of one train based on the passenger flow-operation graph network obtained at step 1), and obtaining the peak value of the whole urban mass transit line through summation. The method provided by the invention simplifies the travel process of urban mass transit passengers into the passenger flow-operation graph network through network conversion, and improves the calculation efficiency. Meanwhile, the method avoids the prediction of the behaviors of passengers, employs the time of trains expected by the passengers to achieve the division of a travel time window, and improves the objectivity.

Owner:SOUTHWEST JIAOTONG UNIV

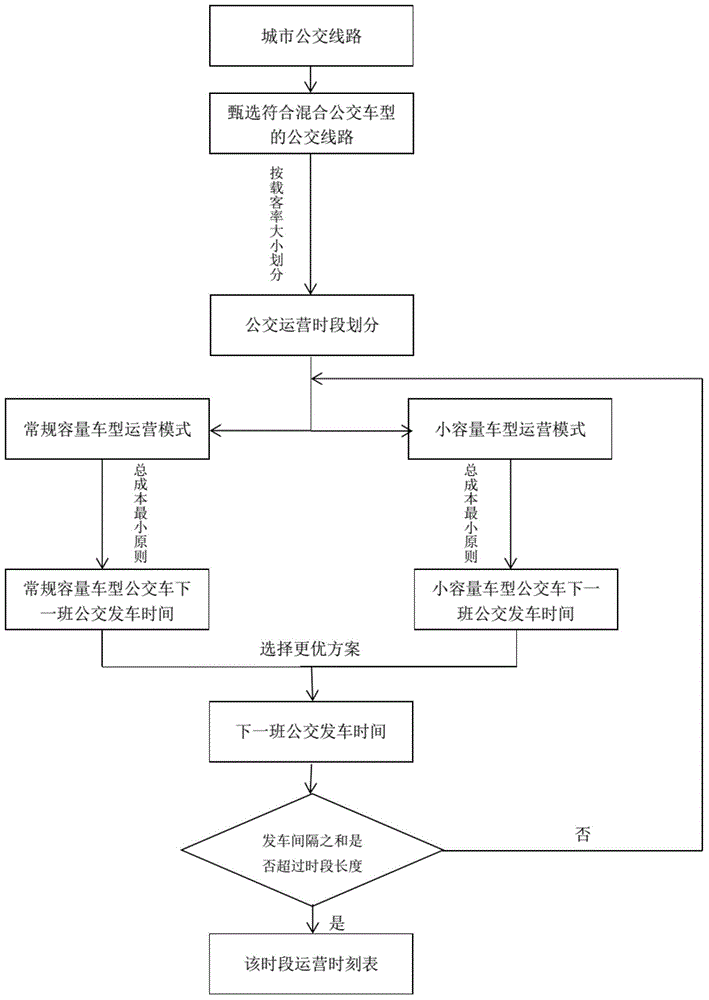

Mixed bus type-based bus operation time control system and method

InactiveCN104835315AEffective selectionImprove utilization efficiencyRoad vehicles traffic controlOperational costsControl system

A mixed bus type-based bus operation time control system and method. Bus routes are classified, and the city bus routes are divided into a part with significant difference and a part with non-significant difference according to the difference of passenger flow in peak and low-ebb periods, so that whether a mixed bus type bus operation mode needs to be adopted is determined; categories of buses of the mixed bus type bus operation mode include buses of a conventional-capacity bus type with M seats and buses of a small-capacity bus type with N seats; bus scheduling work is to determine the car type of a regular bus of each time and departure interval time; based on getting-on and getting-off data of passengers of each station and related data of bus operation cost and the like, an optimal departure interval of the buses of the conventional-capacity bus type of the shift and an optimal departure interval of the buses of the small-capacity car type are calculated; costs of the bus operation modes of the two bus types at the optimal departure intervals are compared, and the regular bus with the lowest cost is selected and executed; and the abovementioned steps are repeated till a time period is over.

Owner:SHANGHAI JIAO TONG UNIV

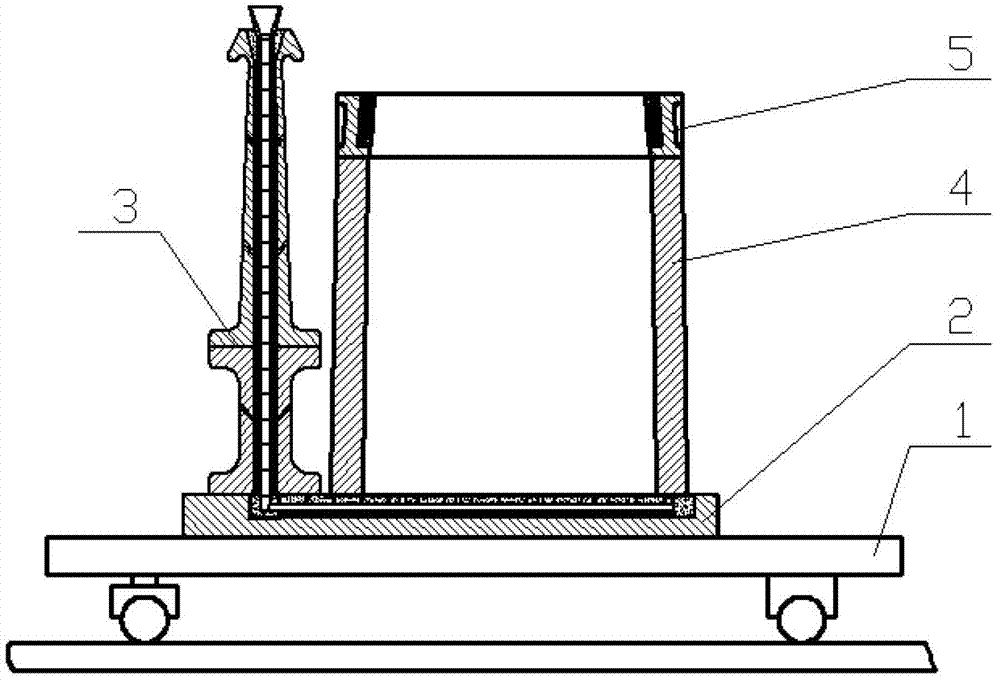

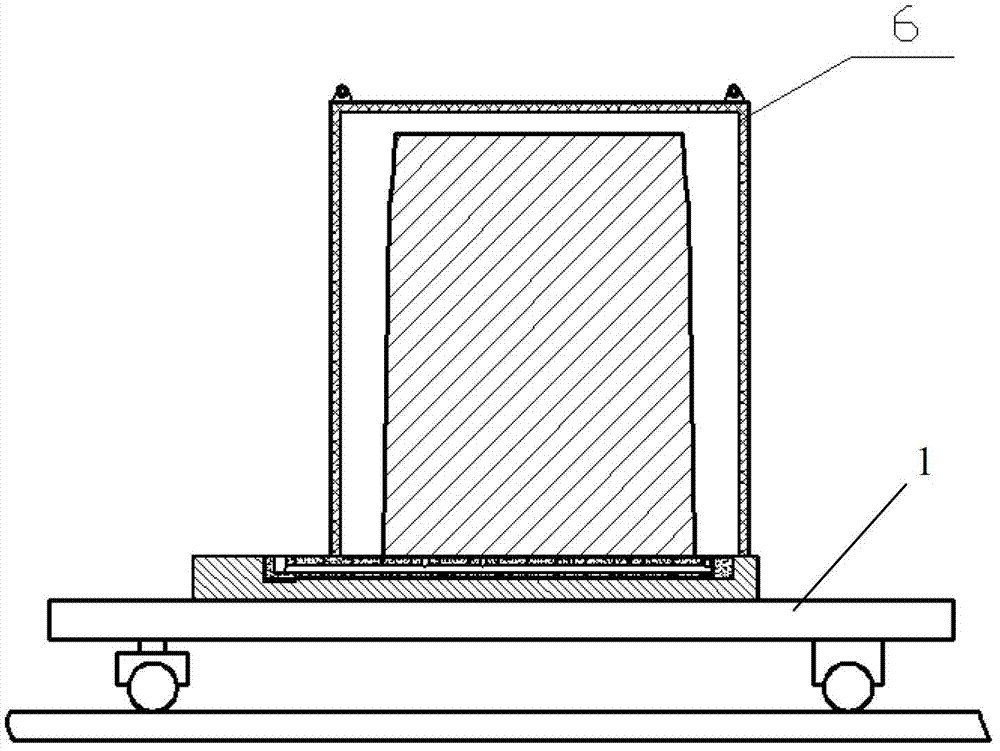

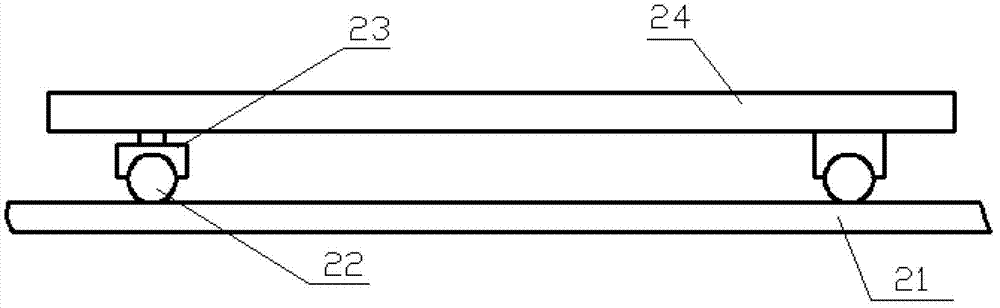

Tooling for efficiently manufacturing wide thick plate blank for wide thick plate rolling machine and manufacture method thereof

The invention relates to the field of the manufacture of a wide thick plate blank for a wide thick plate rolling machine, in particular to a tooling for efficiently manufacturing the wide thick plate blank for the wide thick plate rolling machine and an efficient manufacture method of the wide thick plate blank, aiming at the problems such as cavity shrinking, loosing and cracking and the like of the plate blank and the low manufacture efficiency. The manufacture tooling is provided with a pouring system, an ingot mould, an insulated feeder, a pouring trolley, an automatic control pouring transit line, a heat preservation cover and a burial pit. Before pouring, the ingot mould, the pouring system and a chassis are assembled on the pouring trolley, and the insulated feeder is preheated. The pouring is carried out slowly; after pouring, high-temperature demolding is carried out, and the temperature of a steel ingot is kept by the heat preservation cover; and then the steel ingot is carried away by the trolley, and is hoisted into the burial pit to be slowly cooled. Finally, a flash groove is cut out of the wide thick plate, so that the flashes and strains can be removed, and the wide thick plate is put into a thermal treatment furnace to be annealed. The tooling and the method are applicable to the production of the thick plate blanks with thickness of 350-1200mm and weight of 20-70 tons.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

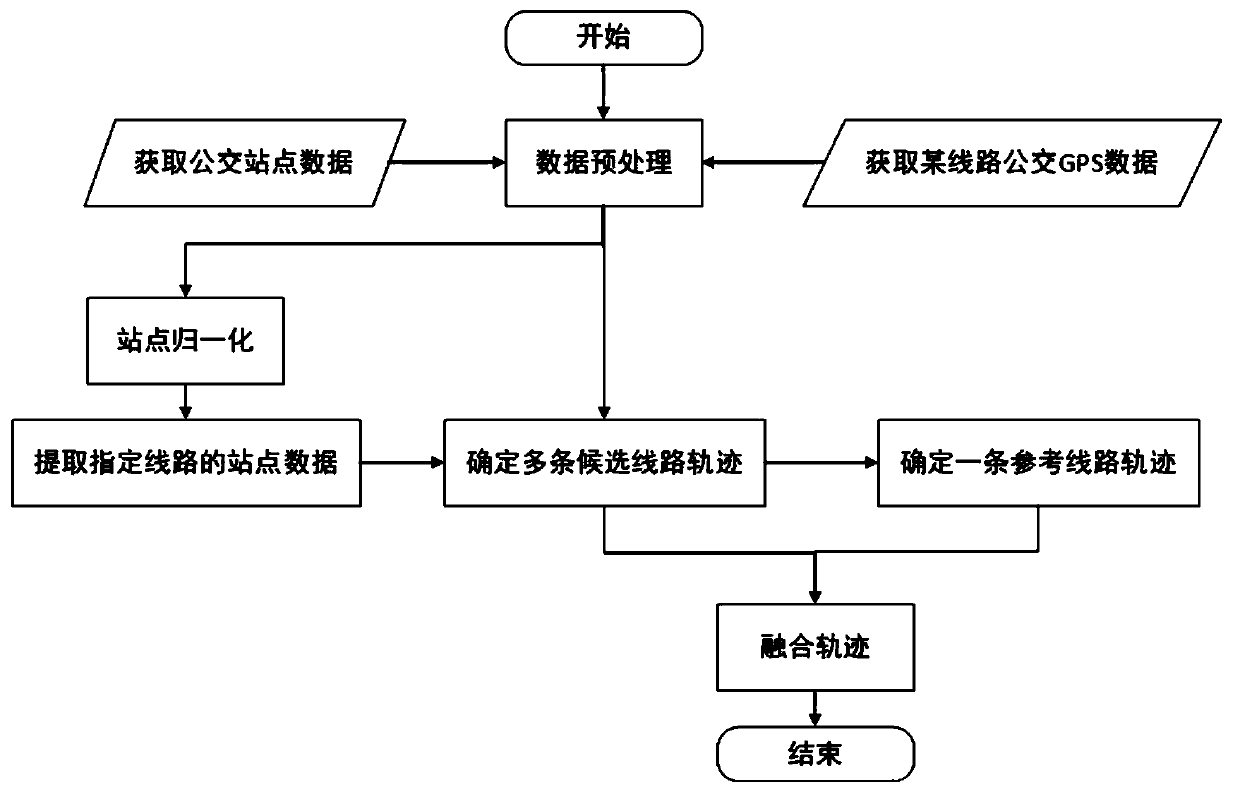

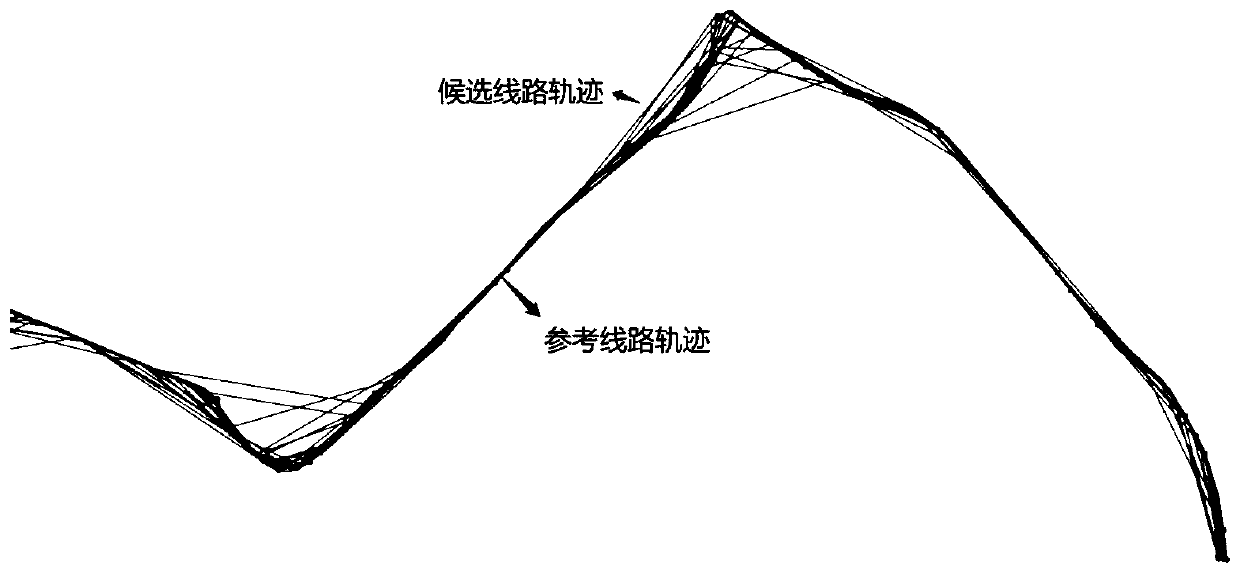

Method for extracting bus route track based on bus GPS data and station information

ActiveCN111210612AAvoid the problem of GPS point offsetAvoid offsetRoad vehicles traffic controlCharacter and pattern recognitionCluster algorithmEngineering

The invention discloses a method for extracting a bus route track based on bus GPS data and station information, and the method comprises the following steps: obtaining station data of all bus routesof a certain city, and carrying out the preprocessing of the station data; performing normalization processing on the station data, analyzing station longitude and latitude of all stations, and if more than two station longitudes and latitudes exist, clustering the station longitudes and latitudes by adopting an improved kmeans clustering algorithm to obtain new station longitudes and latitudes. The method has the advantages that the bus route track is obtained by combining the station information and the bus GPS historical data, and the bus route track with the obvious deviation trend is effectively prevented from being obtained.

Owner:ZHEJIANG SUPCON INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com