Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157 results about "Kinetic inductance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

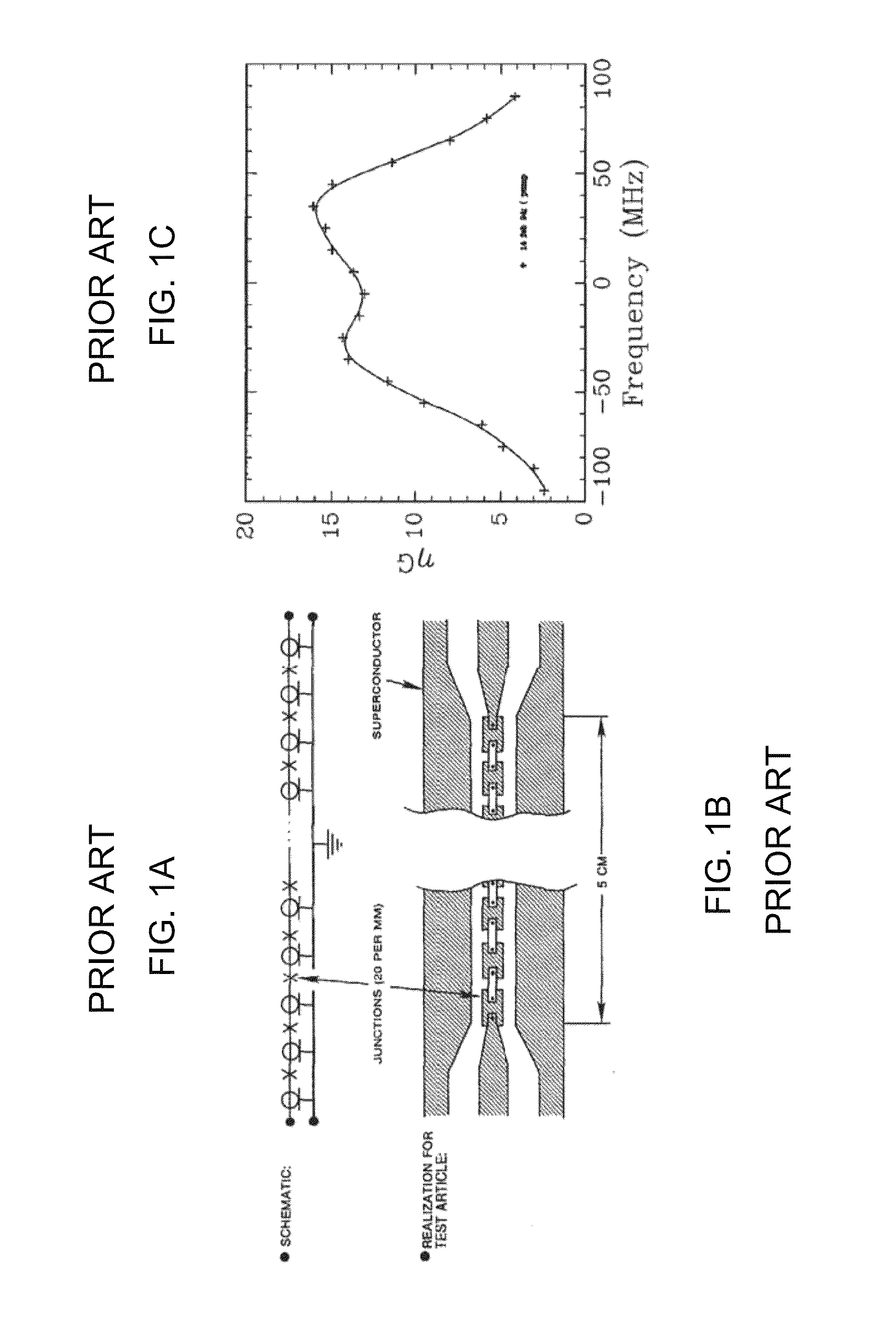

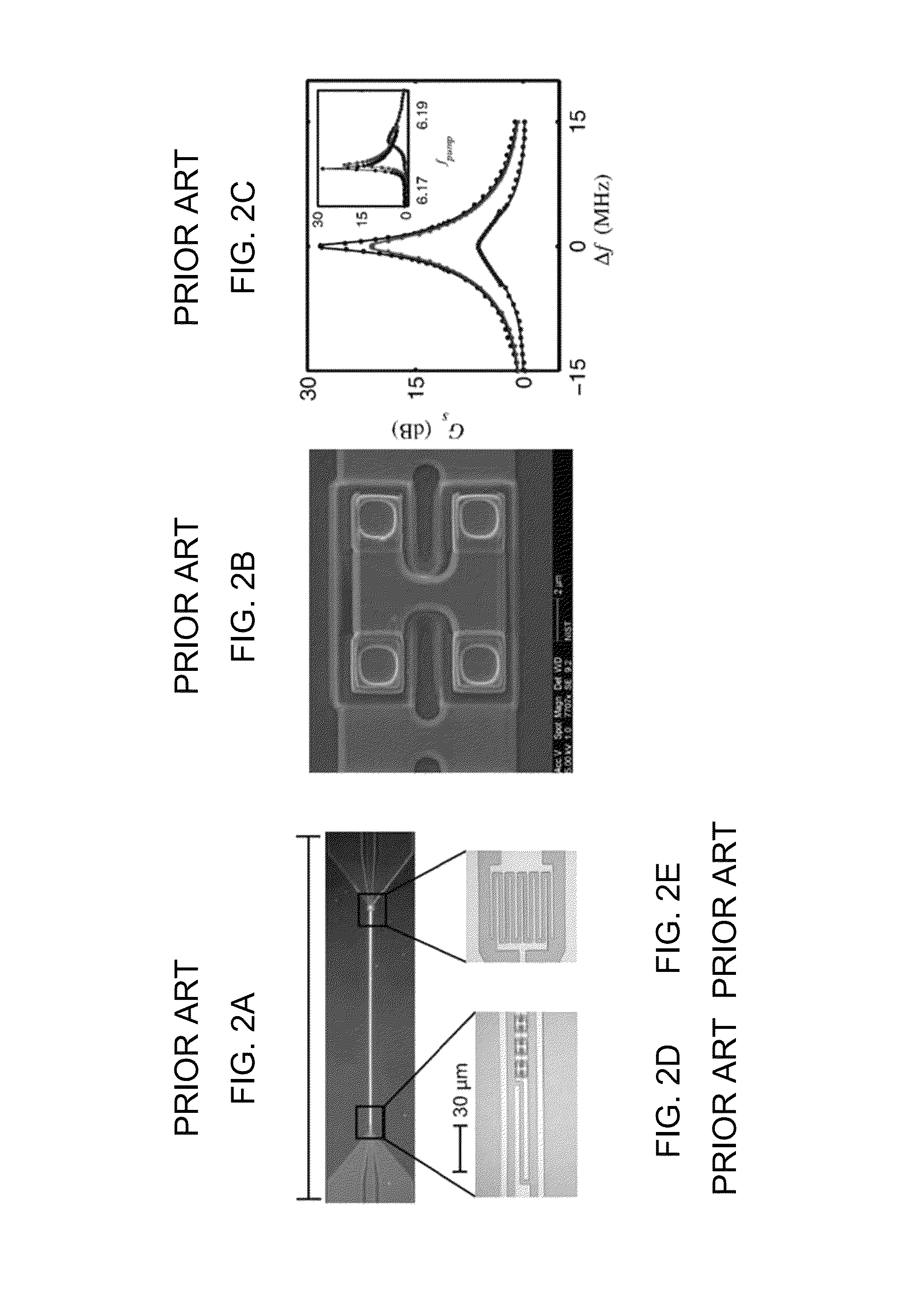

Kinetic inductance is the manifestation of the inertial mass of mobile charge carriers in alternating electric fields as an equivalent series inductance. Kinetic inductance is observed in high carrier mobility conductors (e.g. superconductors) and at very high frequencies.

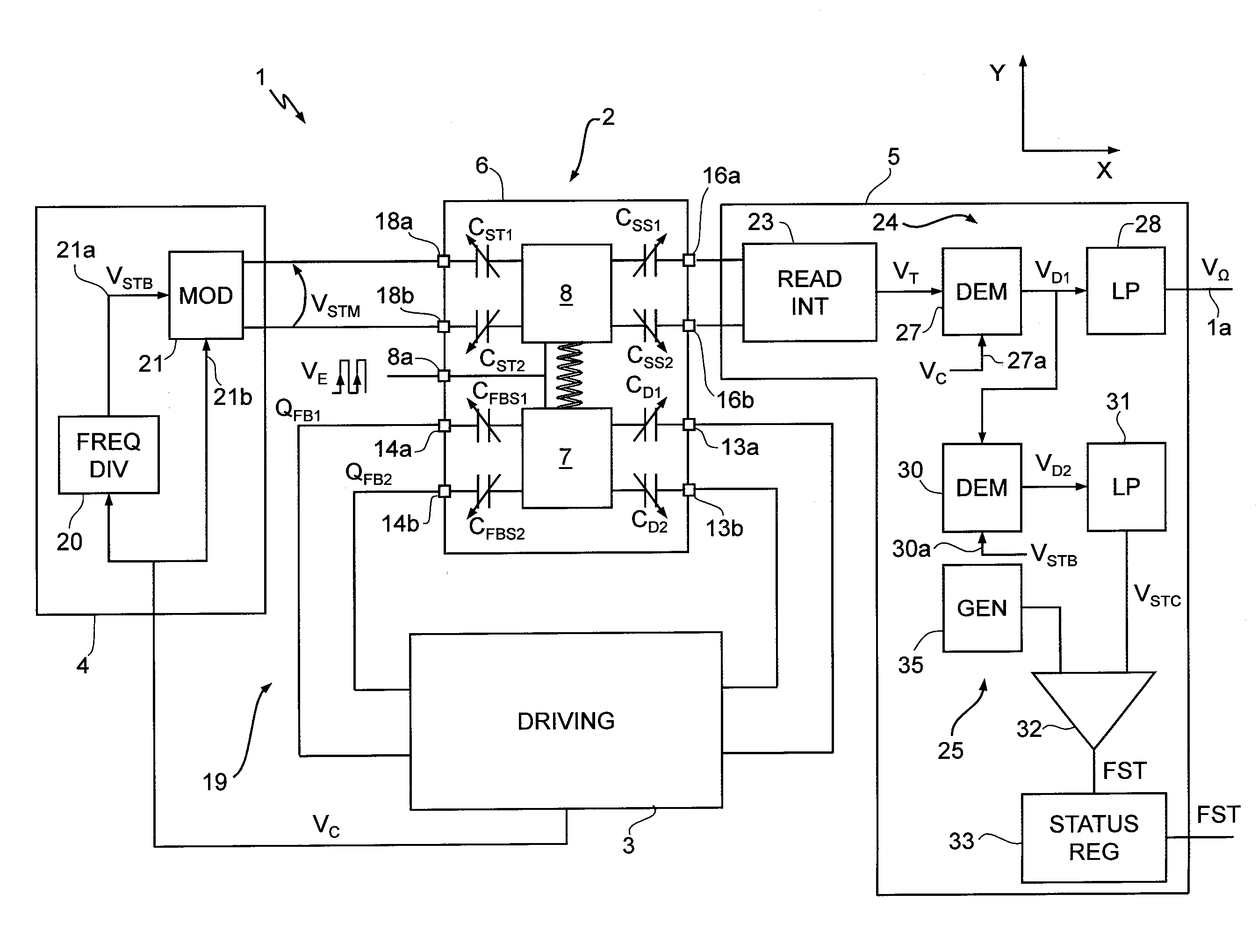

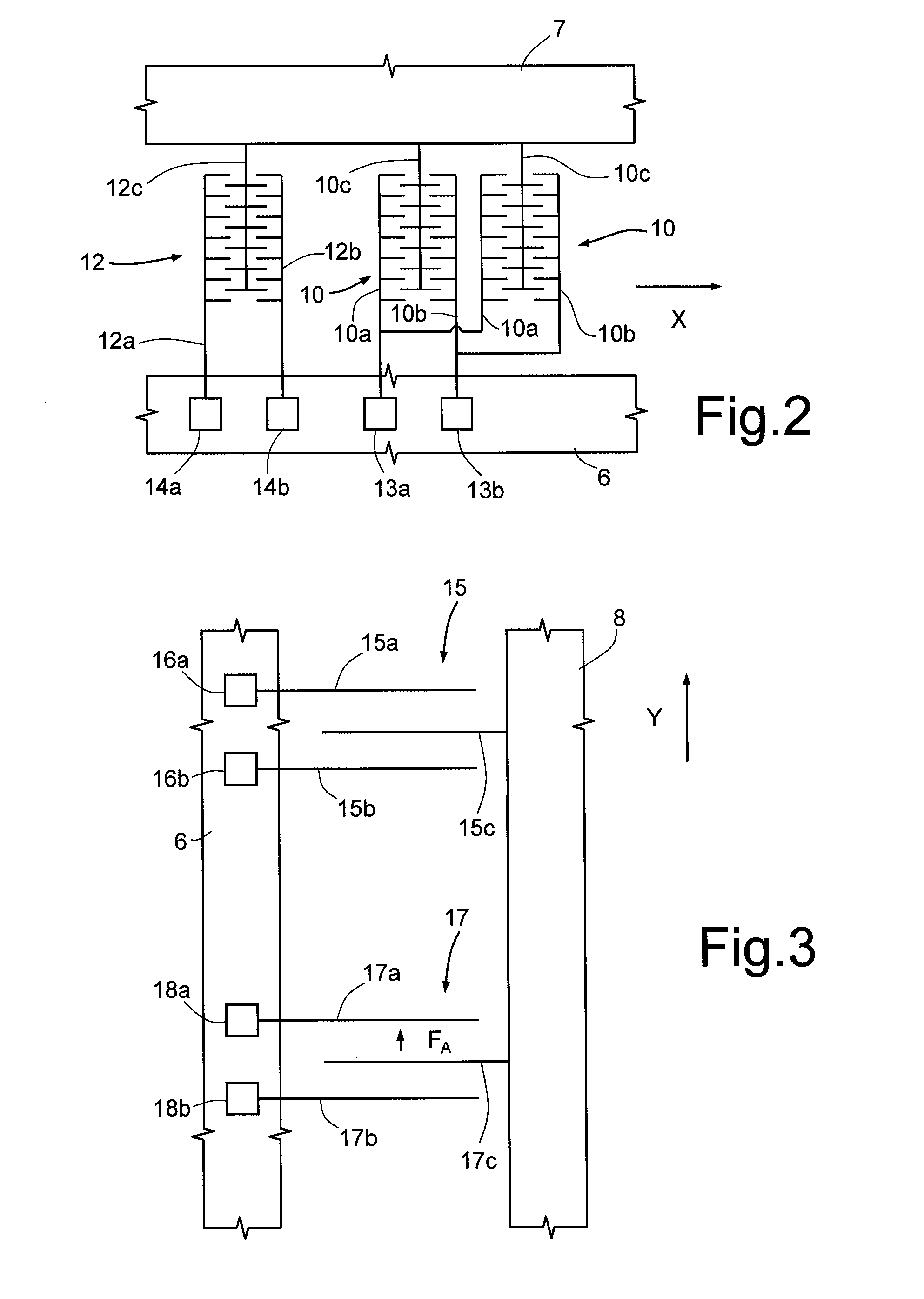

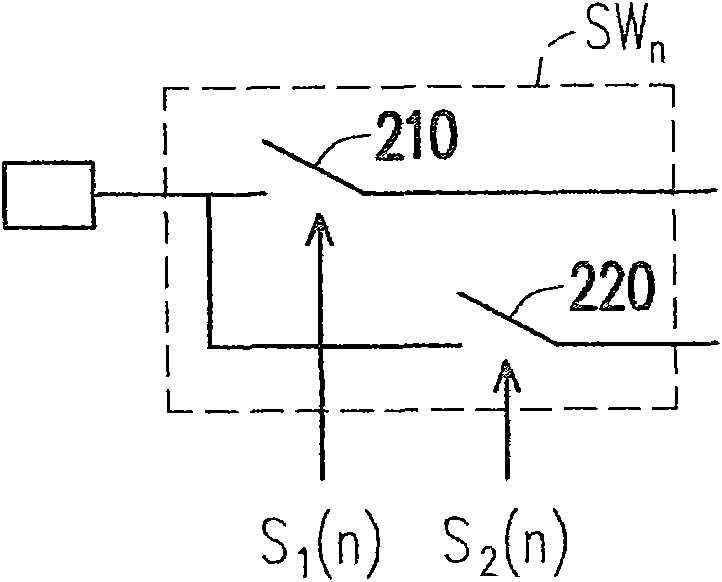

Microelectromechanical gyroscope with continuous self-test function, and method for controlling a microelectromechanical gyroscope

ActiveUS20110146402A1Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceFrequency spectrum

A microelectromechanical gyroscope includes a body and a sensing mass, which is movable with a degree of freedom in response to rotations of the body about an axis. A self-test actuator is capacitively coupled to the sensing mass for supplying a self-test signal. The capacitive coupling causes, in response to the self-test signal, electrostatic forces that are able to move the sensing mass in accordance with the degree of freedom at an actuation frequency. A sensing device detects transduction signals indicating displacements of the sensing mass in accordance with the degree of freedom. The sensing device is configured for discriminating, in the transduction signals, spectral components that are correlated to the actuation frequency and indicate the movement of the sensing mass as a result of the self-test signal.

Owner:STMICROELECTRONICS SRL

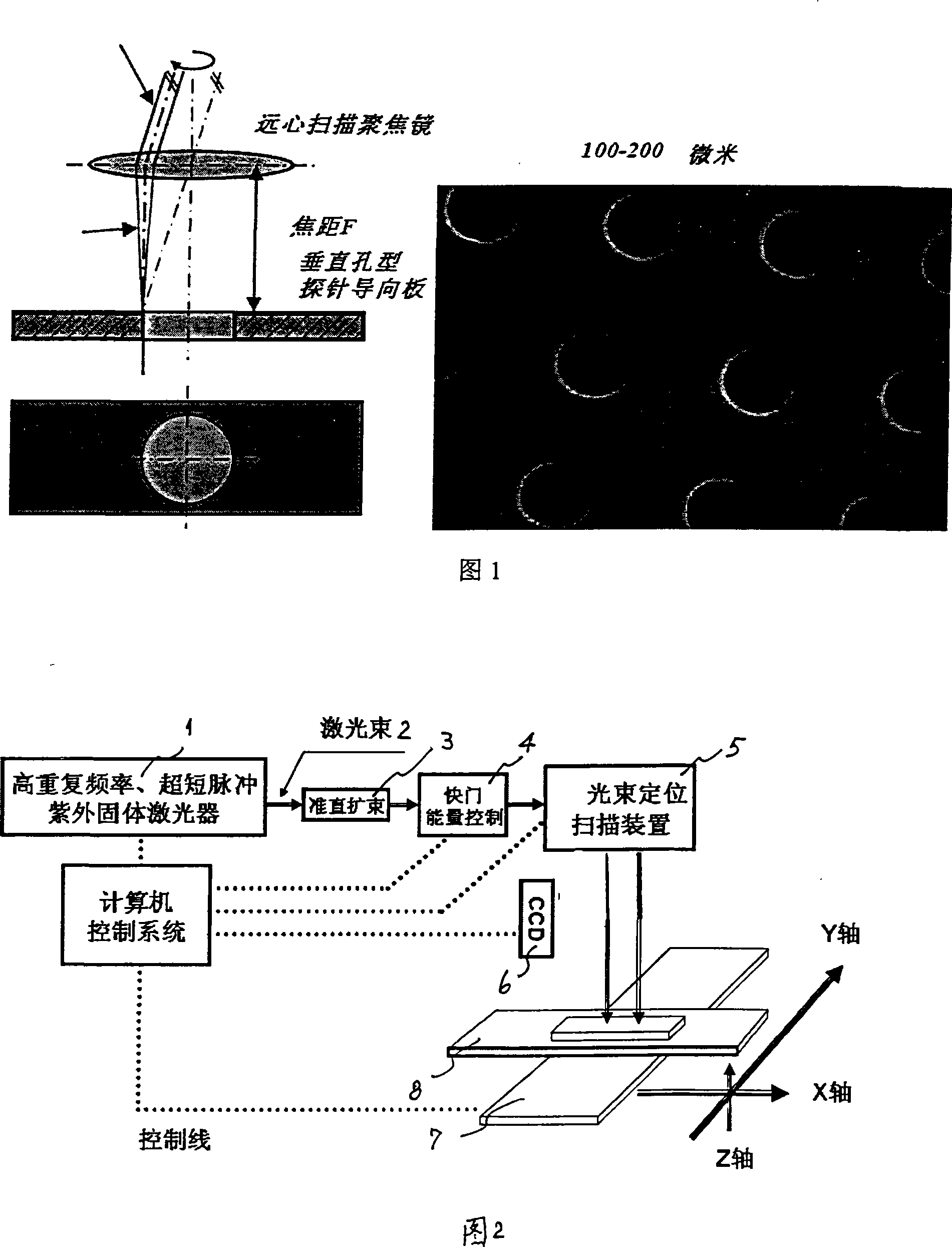

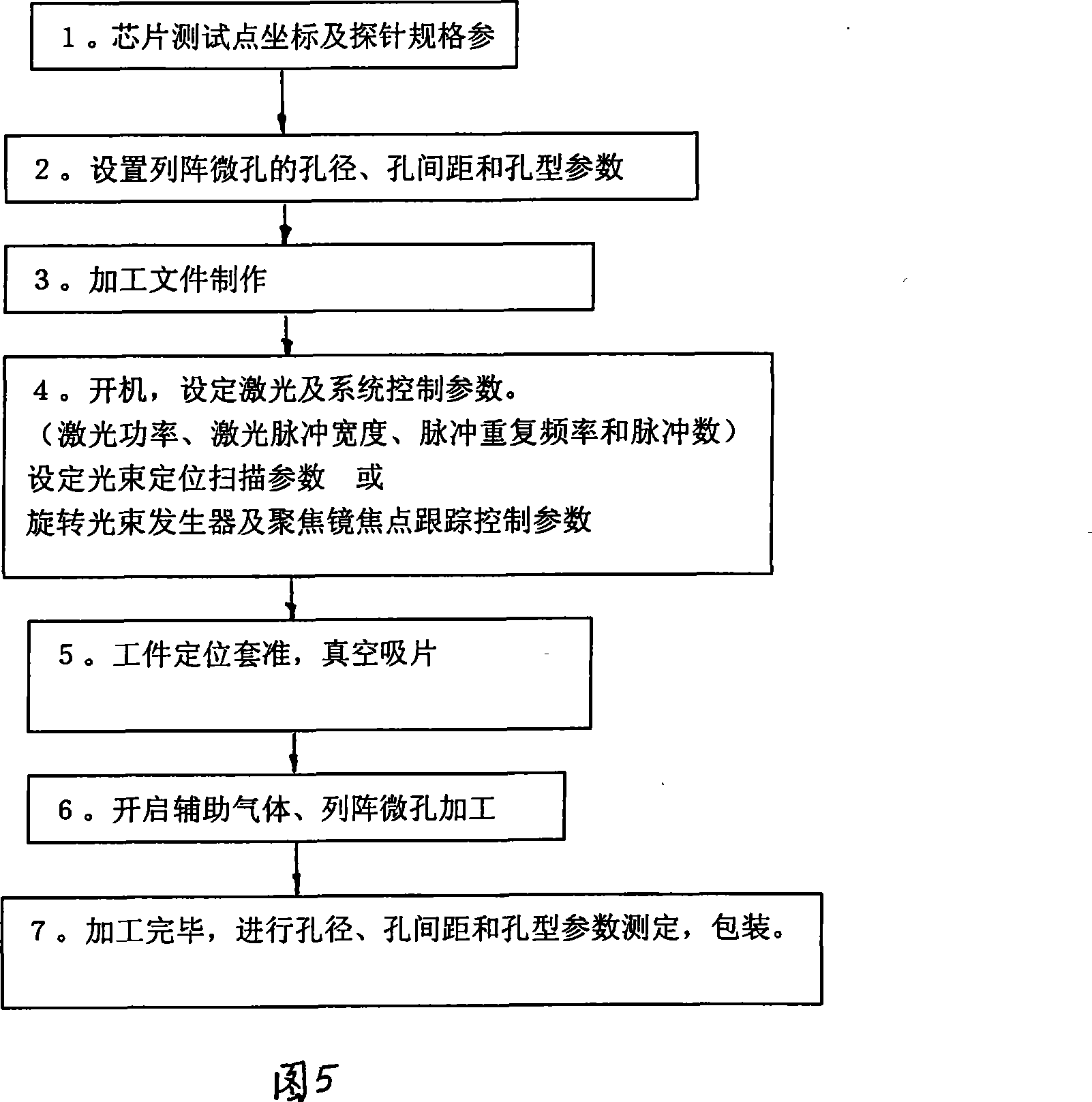

Laser array micro-pore forming device and method

The invention discloses laser-array pore molding devices and a method. The steps of the invention includes that, firstly, pore diameter, pore distance and caliber parameter of a pore plate are set, and a processing file is produced, secondly, laser power, pulse width, pulse repetition frequency and pulse count are set, thirdly, the parameter of light beam location scanning is set, fourthly, work-pieces are located, a visual system is located, and vacuum negative pressure absorbs a probe guide plate, fifthly, pressure and flow capacity of opening assistant gas are set, the processing is started, finally, the pore diameter, the pore distance and the caliber parameter are measured after the finishing of the processing. The laser-array pore molding devices include an ultraviolet solid laser with high repetition rate and ultrashort pulse, a laser beam generator, a collimation beam-expanding device, a shutter, a light beam location scanning device, a CCD visual location system, an XYZ displacement working platform, and a vacuum negative pressure absorbing-sheet frame. The invention has the advantages that the disadvantages of low efficiency, easy damage of a 'punch', changeable pore diameter and the like which exit in the present mechanical punching manner are overcome, dynamic digital hologram is directly pressed on the surface of the material of noble metal commemorative coins, thereby ensuring the esthetics of the commemorative coins.

Owner:SHANGHAI INST OF LASER TECH

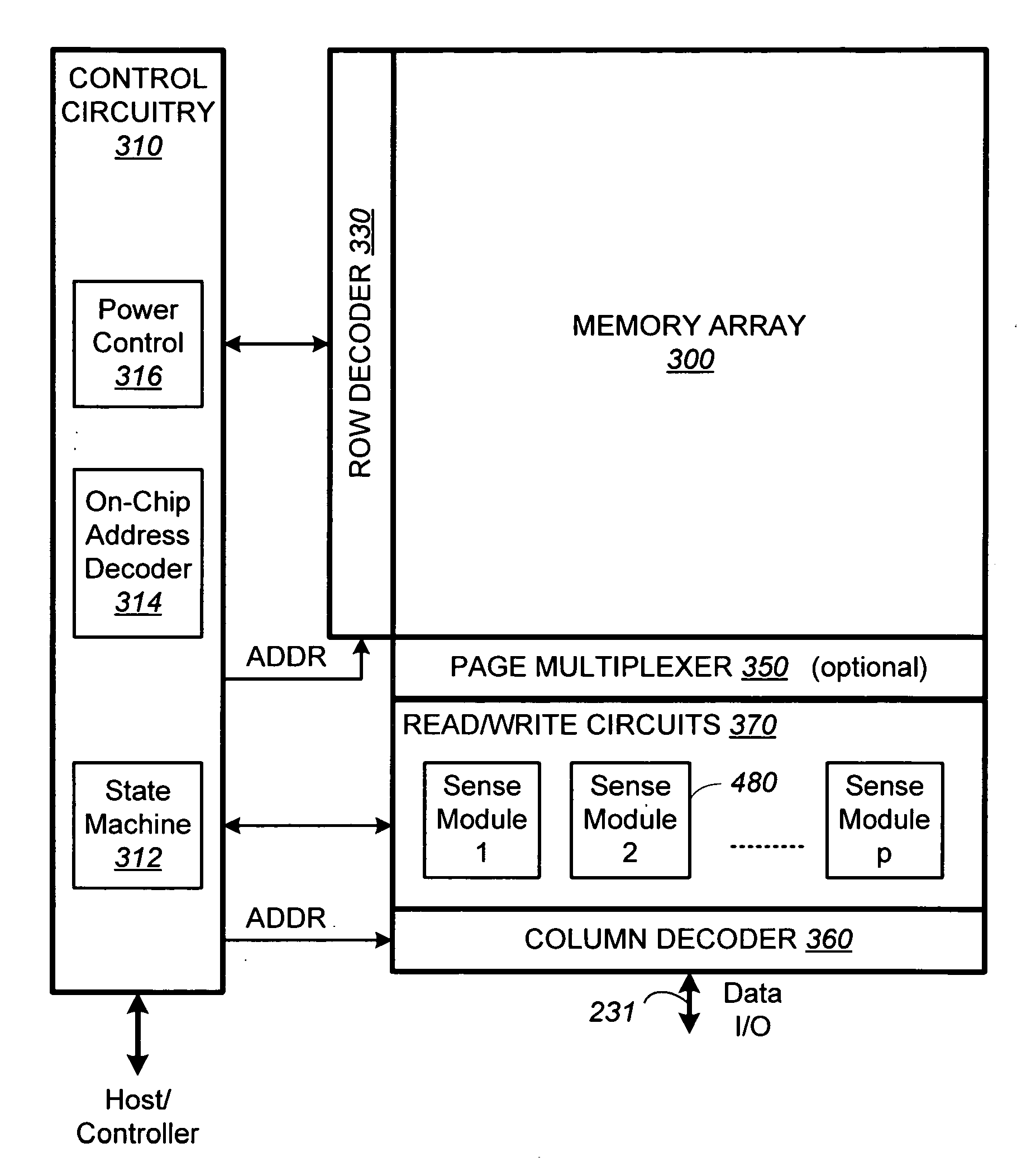

Method for power-saving multi-pass sensing in non-volatile memory

ActiveUS20070153604A1Shorten the overall cycleSave powerRead-only memoriesDigital storageBit lineCoupling

Power-saving techniques are employed in sensing a group of non-volatile memory cells in parallel. In one aspect, coupling of the memory cells to their bit lines are delayed during a precharge operation in order to reduced the cells' currents working against the precharge. In another aspect, a power-consuming precharge period is minimized by preemptively starting the sensing in a multi-pass sensing operation. High current cells not detected as a result of the premature sensing will still be able to be detected in a subsequent pass.

Owner:SANDISK TECH LLC

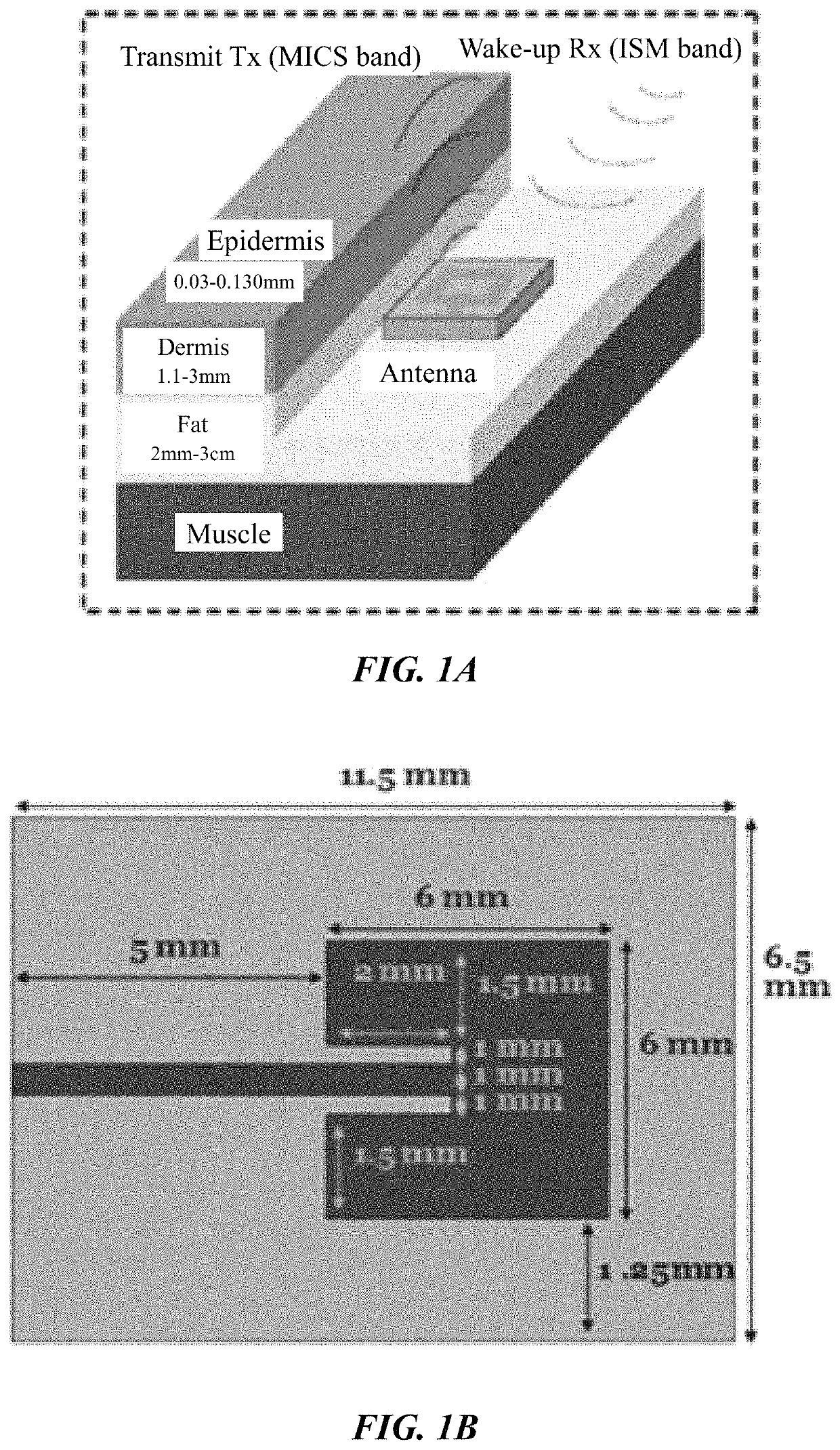

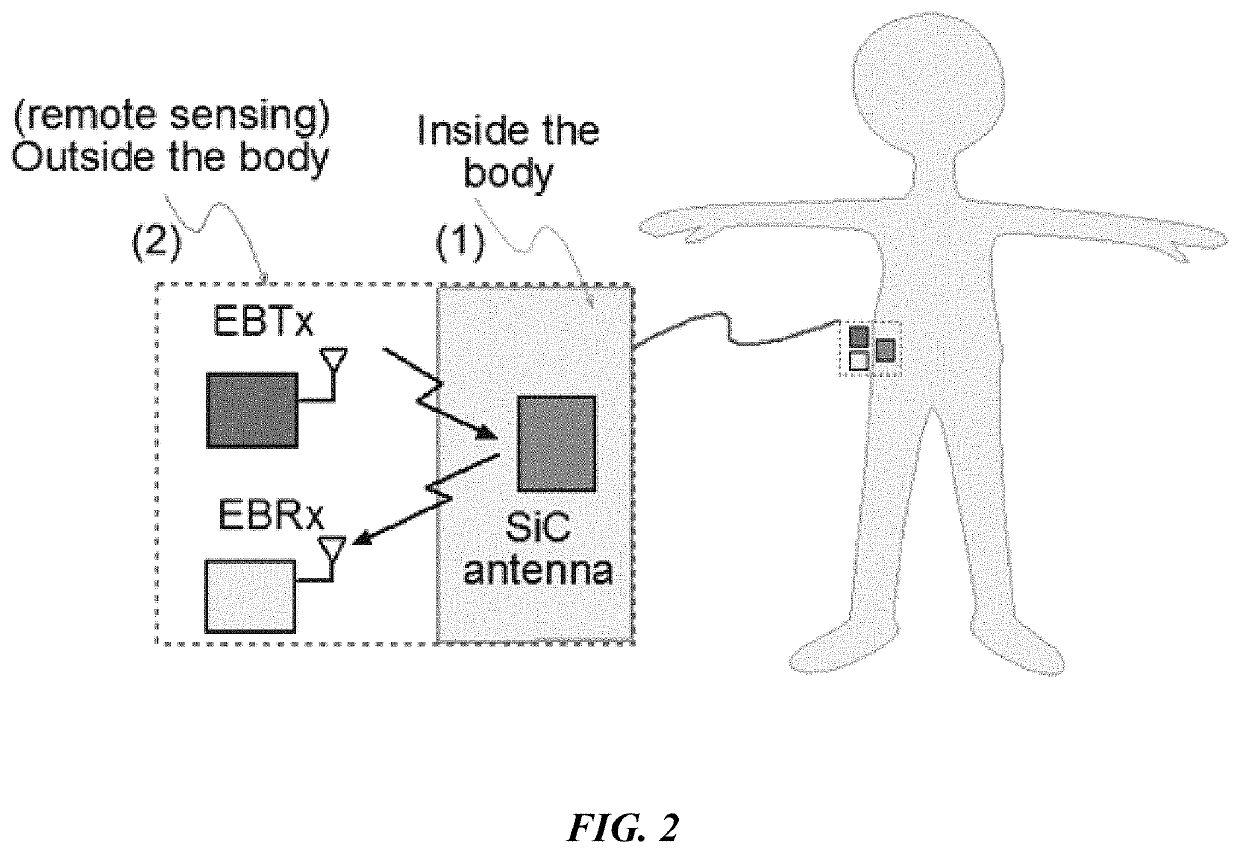

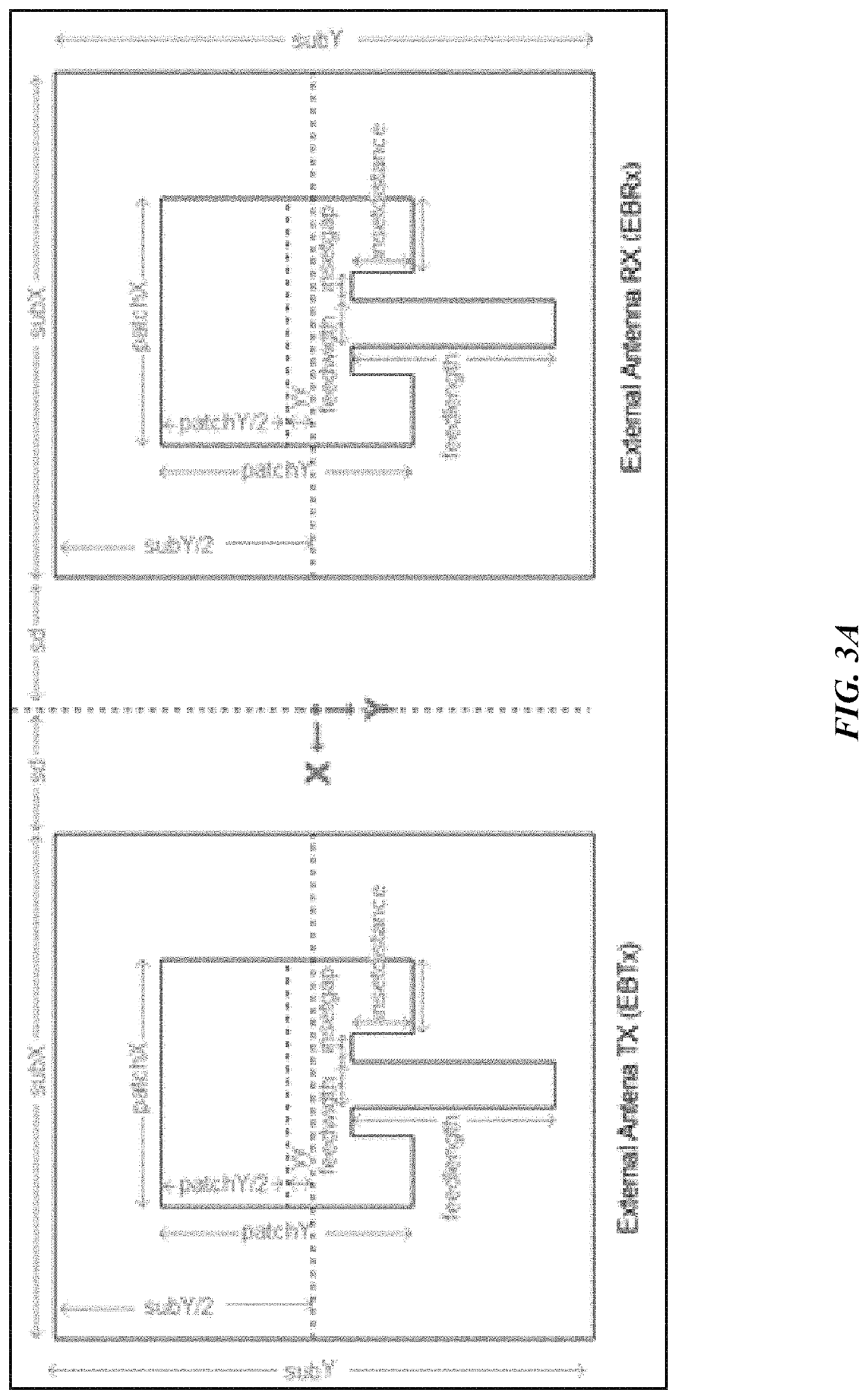

Continuous glucose monitoring based on remote sensing of variations of parameters of a SiC implanted antenna

A passive sensing continuous glucose monitoring system and method of use thereof. The system includes a passive antenna formed of biocompatible silicon carbide (SiC), modeled to a desired frequency, which is permanently implanted subcutaneously. The system further includes an external-to-the-body transmitting antenna to detect changes in the blood glucose level by sending a radio signal at the frequency of the implanted passive antenna into the body. This signal is received and reflected by the passive antenna, and the reflected signal is then received at an external-to-the-body receiving antenna. Changes in the glucose level lead to modifications in the signal and can be used to determine the blood glucose level externally.

Owner:UNIV OF SOUTH FLORIDA

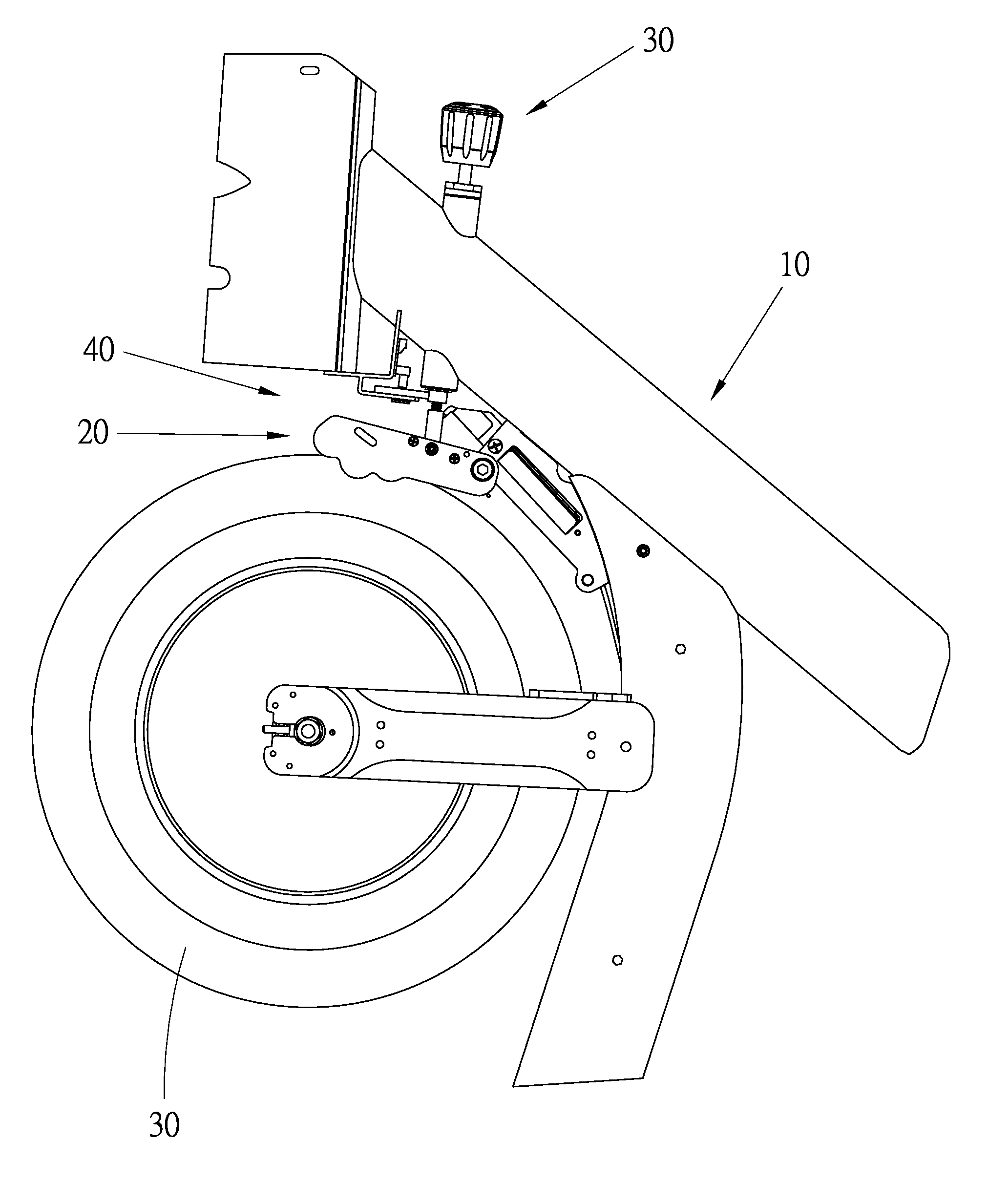

Spinning bike equipped with a sensor device

InactiveUS20160310785A1Provide resistanceFrictional force resistorsMovement coordination devicesElectrical resistance and conductanceGear wheel

A spinning bike includes a frame, a flywheel connected to the frame, a magnetic resistance device for providing magnetic resistance against the flywheel, an adjustment assembly for moving the magnetic resistance device relative to the flywheel, and a sensor device for measuring the magnetic resistance. The adjustment assembly includes a rod extending throughout a tube. The tube is secured to the frame and includes a stop at an end and a cover at another end. The rod includes a pinion and a thread. The thread and a portion of the pinion extend beyond the stop of the tube. The sensor device includes an axle connected to a variable resistor and a gear. The gear is engaged with the portion of the pinion that extends out of the tube. The electric resistance of the variable resistor is changeable by rotating the axle and translated into the value of the magnetic resistance.

Owner:DK CITY CORP

Microelectromechanical gyroscope with continuous self-test function

ActiveUS8459093B2Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceFrequency spectrum

A microelectromechanical gyroscope includes a body and a sensing mass, which is movable with a degree of freedom in response to rotations of the body about an axis. A self-test actuator is capacitively coupled to the sensing mass for supplying a self-test signal. The capacitive coupling causes, in response to the self-test signal, electrostatic forces that are able to move the sensing mass in accordance with the degree of freedom at an actuation frequency. A sensing device detects transduction signals indicating displacements of the sensing mass in accordance with the degree of freedom. The sensing device is configured for discriminating, in the transduction signals, spectral components that are correlated to the actuation frequency and indicate the movement of the sensing mass as a result of the self-test signal.

Owner:STMICROELECTRONICS SRL

Three Dimensional Air Flow Sensors for Data Center Cooling

Techniques for airflow analysis are provided. In one aspect, a mobile sensing device is provided. The mobile sensing device includes an airflow sensing system having a plurality of airflow sensing units arranged in a grid. Each airflow sensing unit includes a first air passage that contains at least one first airflow sensor; a second air passage perpendicular to the first air passage, wherein the second air passage contains at least one second airflow sensor; and a third air passage perpendicular to the first air passage and the second air passage, wherein the third air passage contains at least one third airflow sensor.

Owner:GLOBALFOUNDRIES US INC

Brake device

An object of the present invention is to provide a brake device in which brake feeling can be improved. In response to depression of a brake pedal 6, an electric brake 5 mounted on the rear side starts to generate a braking force at the time of stroke h1 before a fluid pressure brake 4 mounted on the front side starts to generate a braking force when the stroke reaches stroke h2. In the conventional art, the braking force on the rear side is set according to the fluid pressure on the front side, and braking can be controlled only by the response of the fluid pressure. In the conventional art, an invalid stroke is long, and when the stroke enters a braking force zone where a braking force is generated according to a pedal stroke, the braking force suddenly increases relative to an advance of the stroke (rigid impression), whereby the driver often feels discomfort and pedal feeling is deteriorated. On the other hand, in the present invention, the rear side can generate a braking force prior to the front side, whereby it is possible to reduce rigid feeling, and therefore improve pedal feeling.

Owner:HITACHI ASTEMO LTD

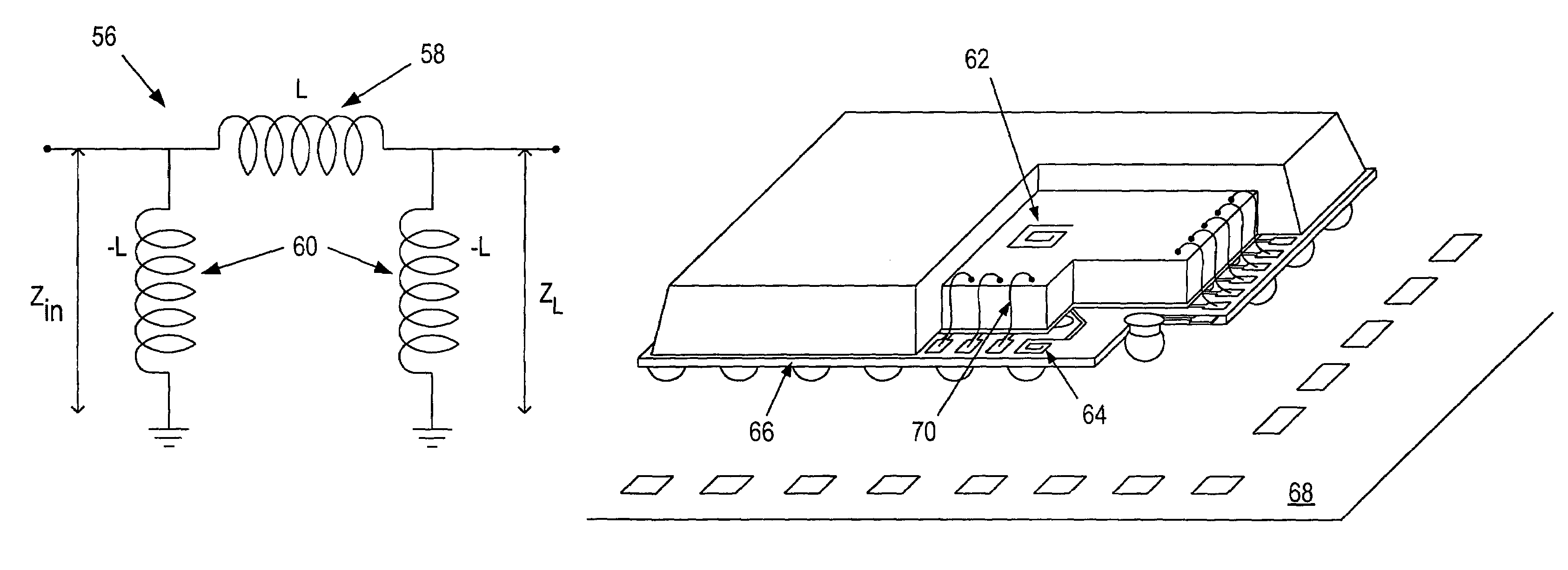

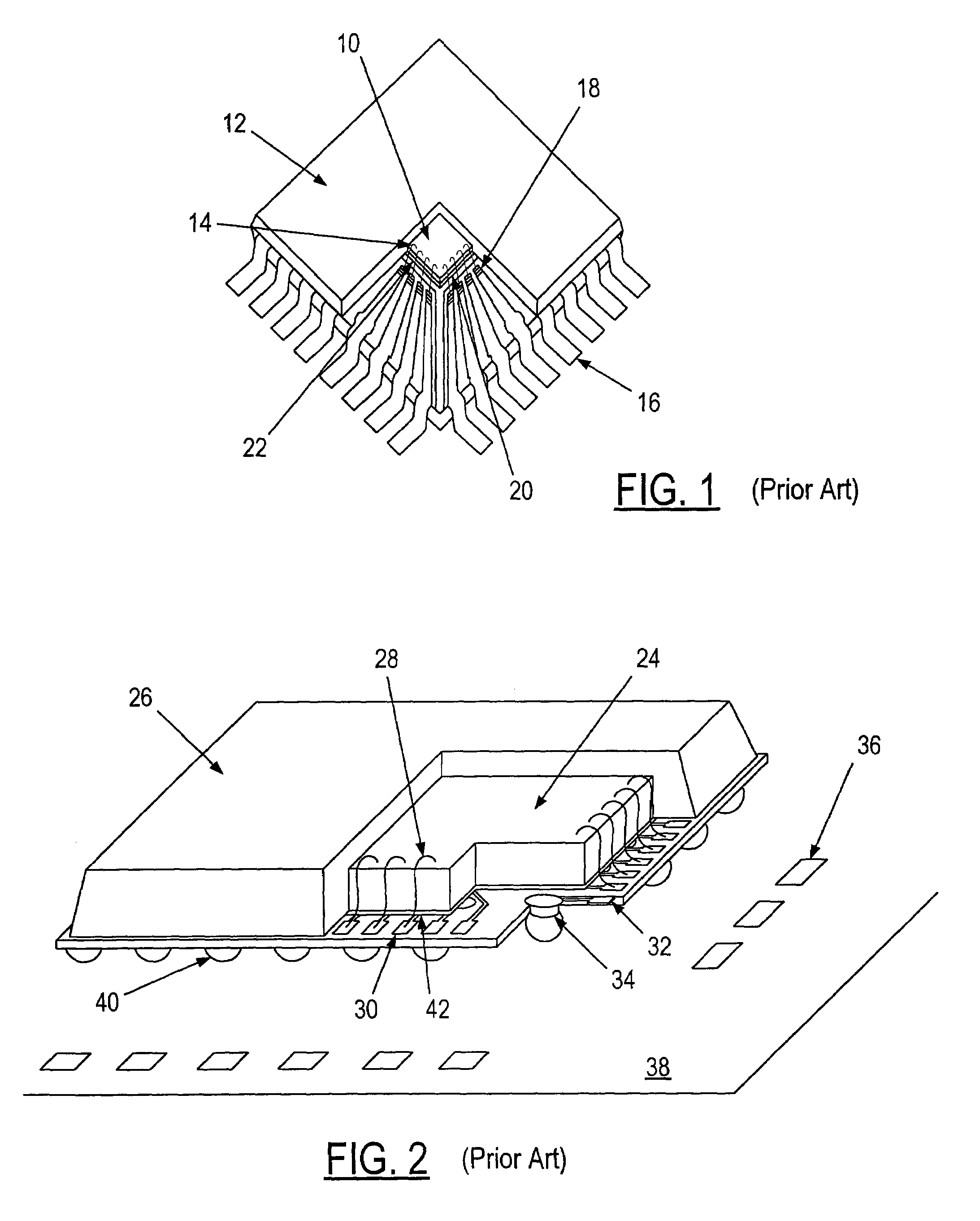

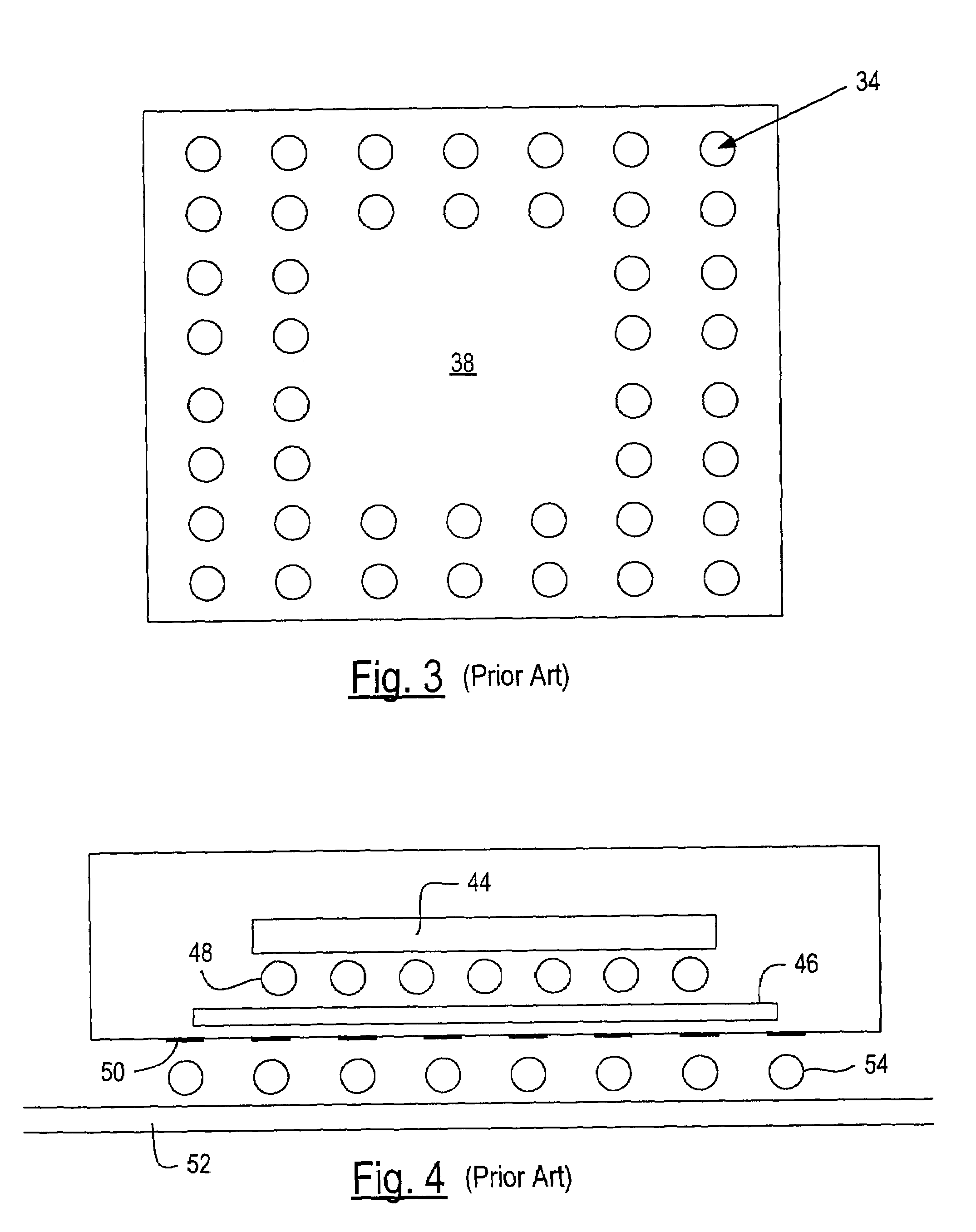

Integrated circuit incorporating wire bond inductance

InactiveUS7342300B2Semiconductor/solid-state device detailsSolid-state devicesLead bondingComputer module

The invention relates to the field of electronics, more particularly to the wire bonds incorporated into an integrated circuit package such as a quad flat pack, a ball grid array or hybrid style module. The present invention takes the normally undesirable wire bond inductance and uses it in an operational circuit where positive inductance is required. The circuit in which the wire bond inductance is used is located primarily in the integrated circuit die housed in the integrated circuit package, but may also include off-die components. In one example, a wire bond is used as the required series inductance in a discrete circuit impedance inverter which consists of two shunt-to-ground negative inductances and one series positive inductance. One of the negative inductances is located on-die, while the other is located off-die.

Owner:ZARBANA DIGITAL FUND

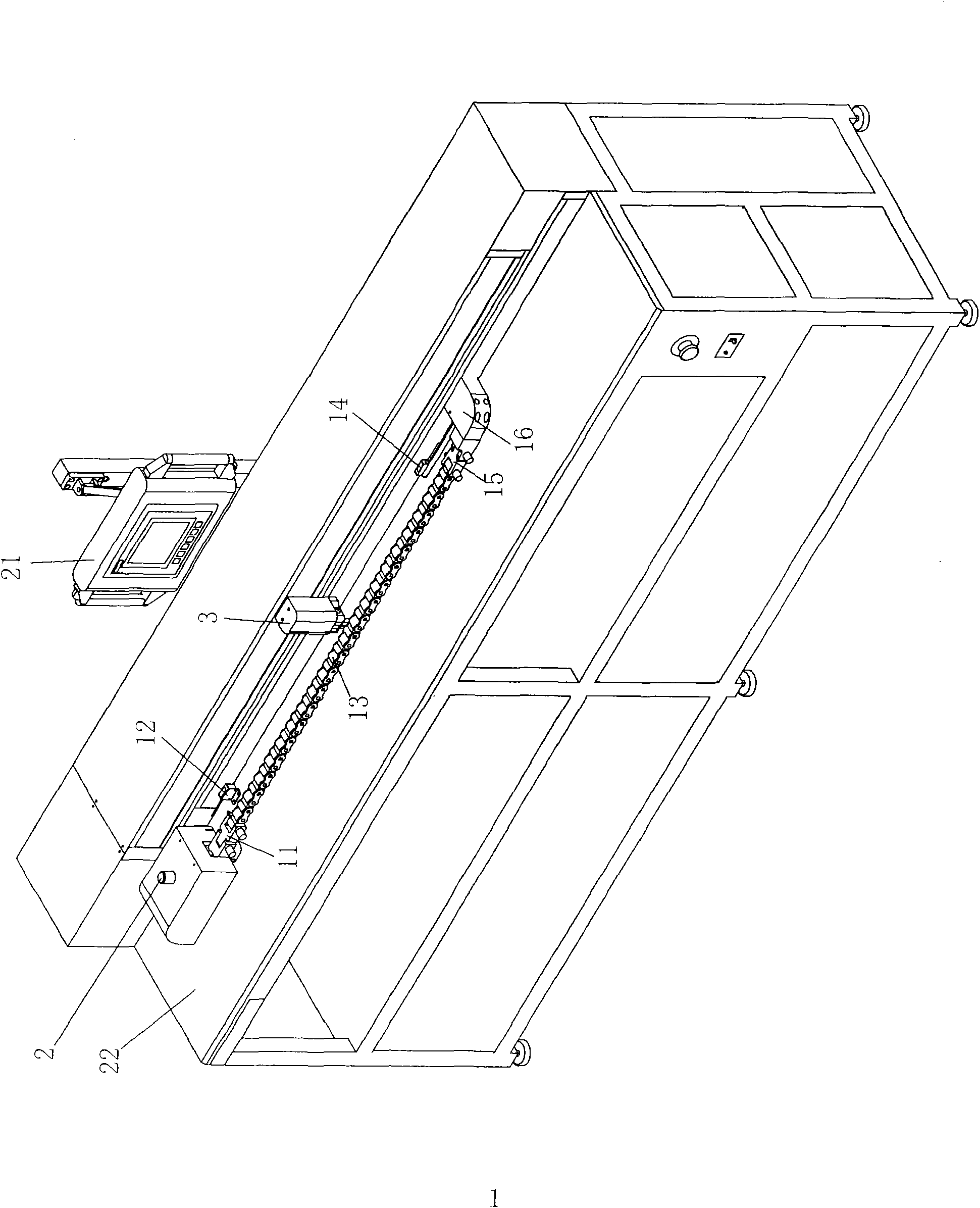

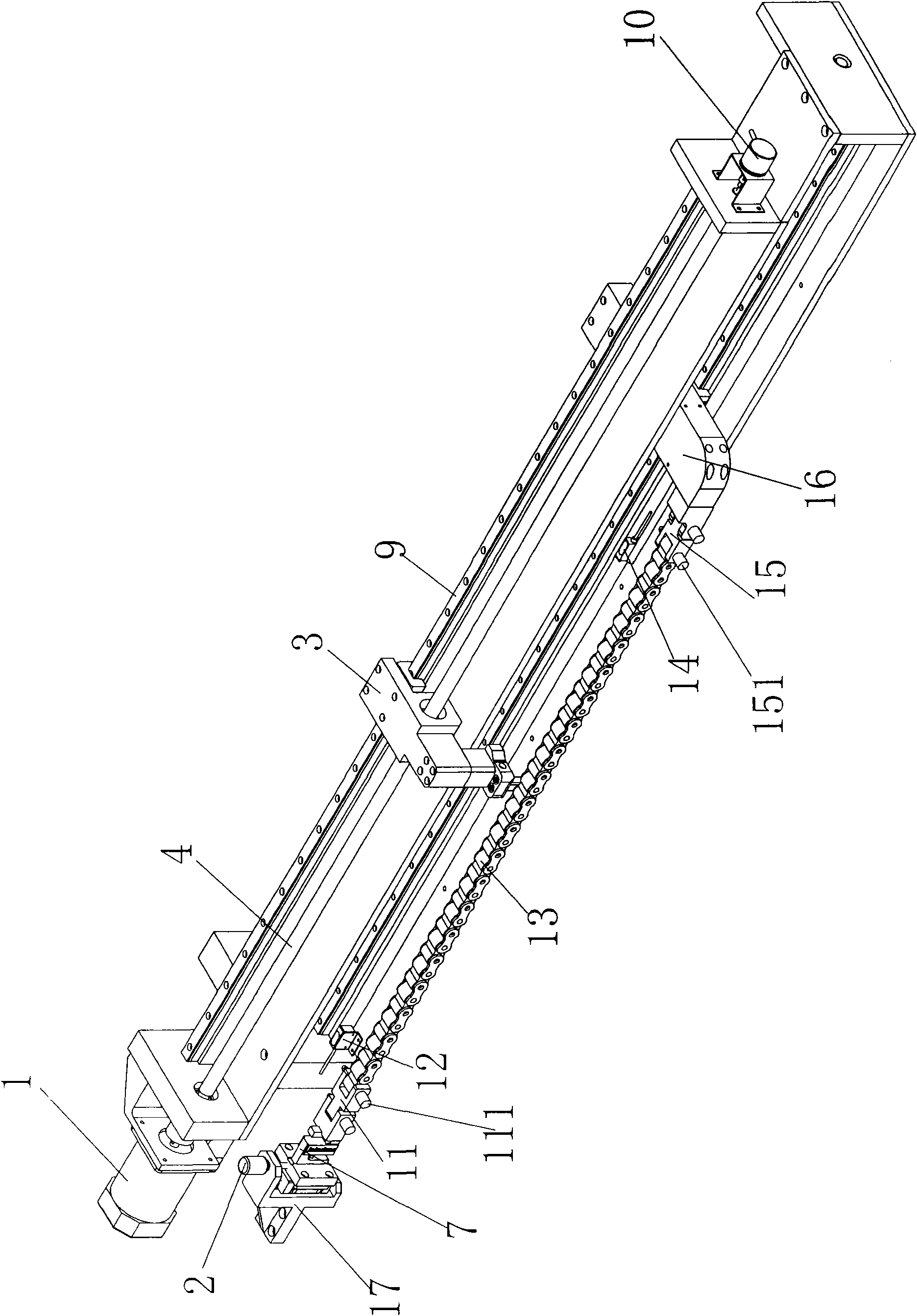

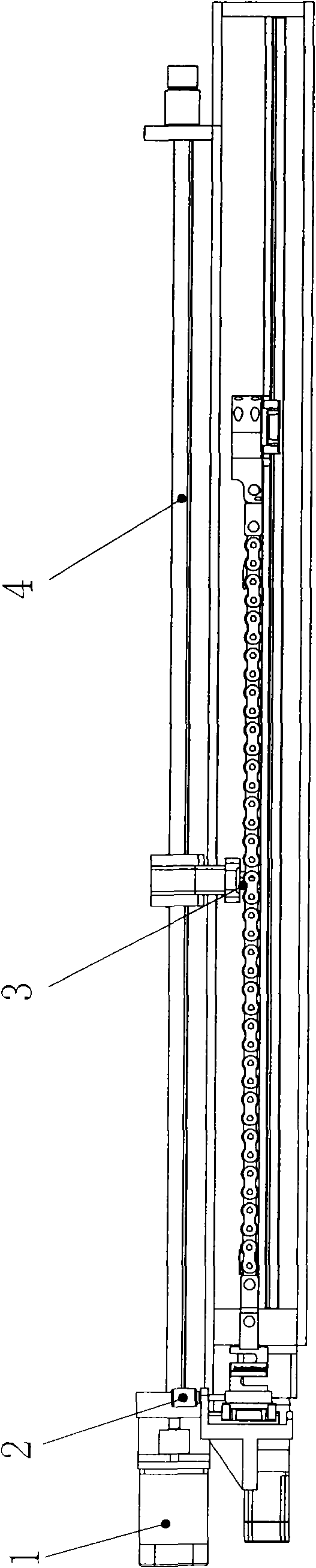

Chain length measuring instrument

InactiveCN101598532APrecise and reliable controlAutomatically display preset controlsUsing optical meansMetal chainsData displayMotor drive

The invention relates to a chain length measuring instrument, comprising a chain tension mechanism and a chain length measuring mechanism. The chain tension mechanism comprises a servo motor, wherein the servo motor drives a lead screw B to rotate to drive a movable gripper seat to move on a liner guide rail B and a liner guide rail C straight so as to tension the chain. The chain length measuring mechanism comprises a sensing head and an encoder, wherein the motor drives a lead screw A to rotate to drive a sensing head to move on a liner guide rail A straight so as to measure the chain length. The invention has the advantages that the tension force can be preset by a control panel, and the servo motor tensions the chain, therefore, the control is accurate and reliable. The motor drives the sensing head to measure the chain length, the encoder counts the number and transfers the number to the control panel so as to automatically display the chain length. Therefore, the invention has the advantages of high accuracy, default control and automatic data display, convenient reading, high efficiency, and the like.

Owner:GOTECH TESTING MACHINES DONGGUAN

Dispersion-engineered traveling wave kinetic inductance parametric amplifier

Owner:CALIFORNIA INST OF TECH

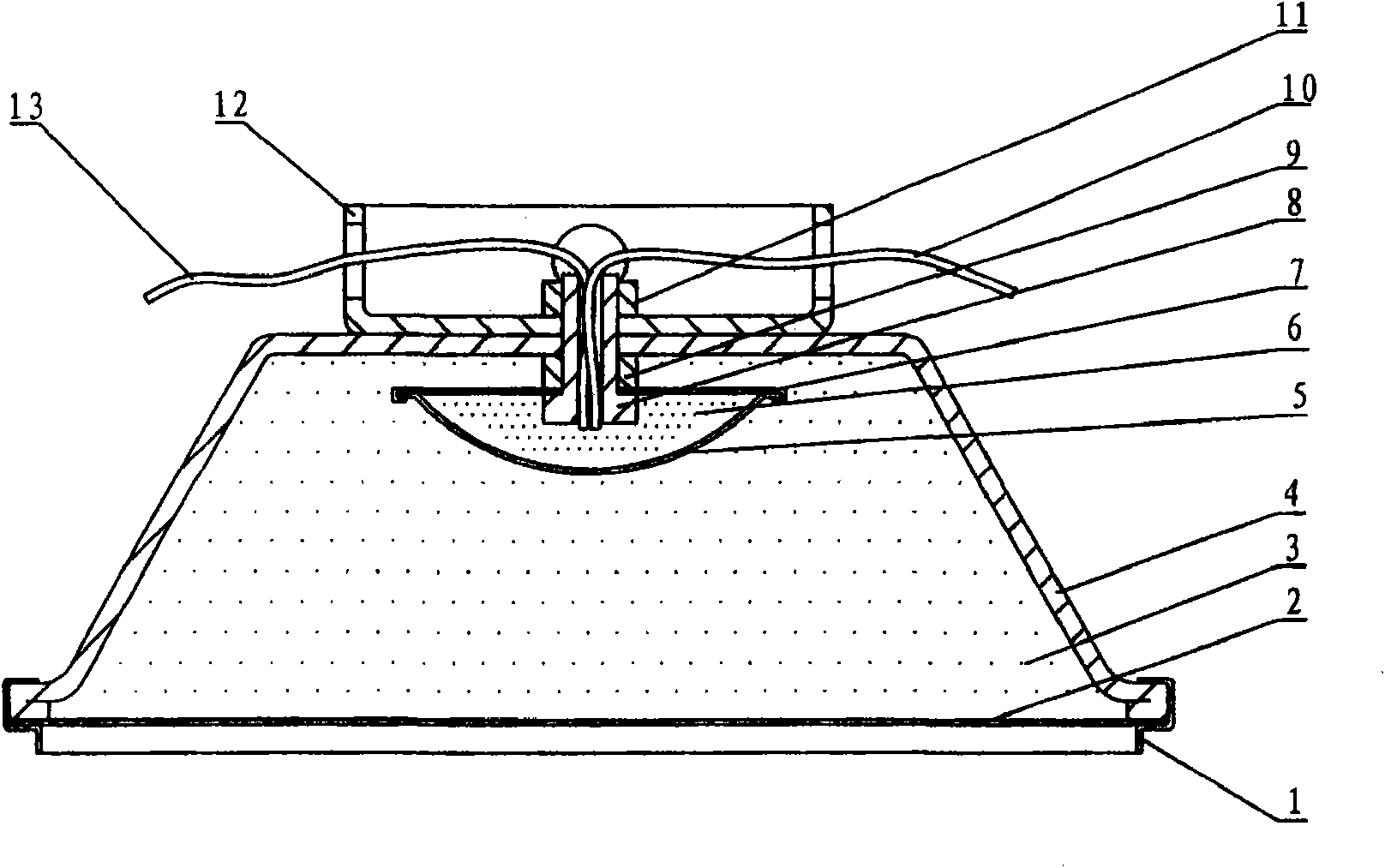

Vivid water bloom sprinkler

The invention discloses a vivid water bloom sprinkler. An electric generator, a control circuit board and at least one electromagnetic valve are arranged in the seal area of the vivid water bloom sprinkler, wherein the electric generator and the electromagnetic valve are respectively electrically connected with the control circuit board; a water inlet passage, at least one normal water outlet passage and at least one rhythm water outlet passage are arranged in the water passage of the vivid water bloom sprinkler, and the electromagnetic valve is arranged between one water inlet passage and one rhythm water outlet passage. Controlled by the control circuit board, the vivid water bloom sprinkler can adjust water currents along with the music rhythm, thereby enabling a user to enjoy the simulated vivid scenery.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

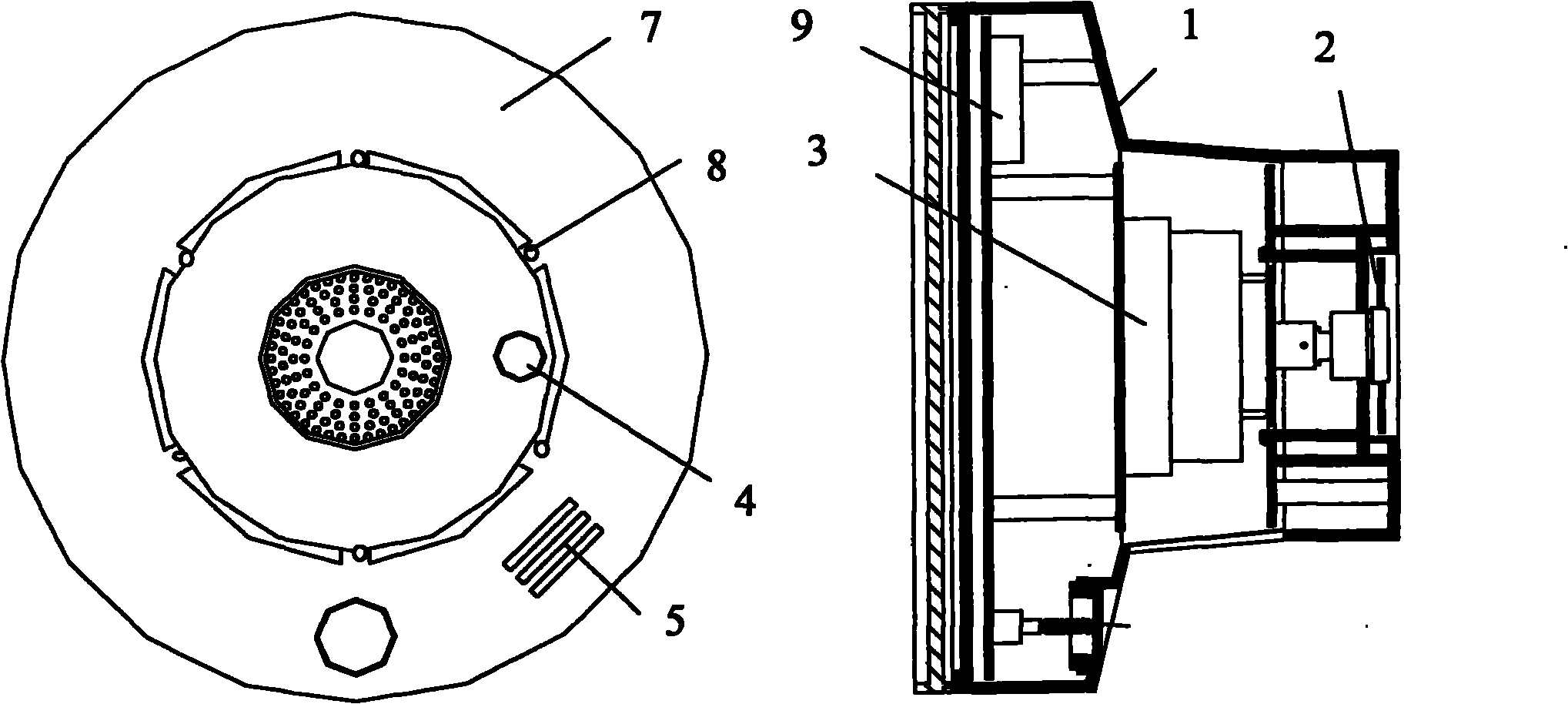

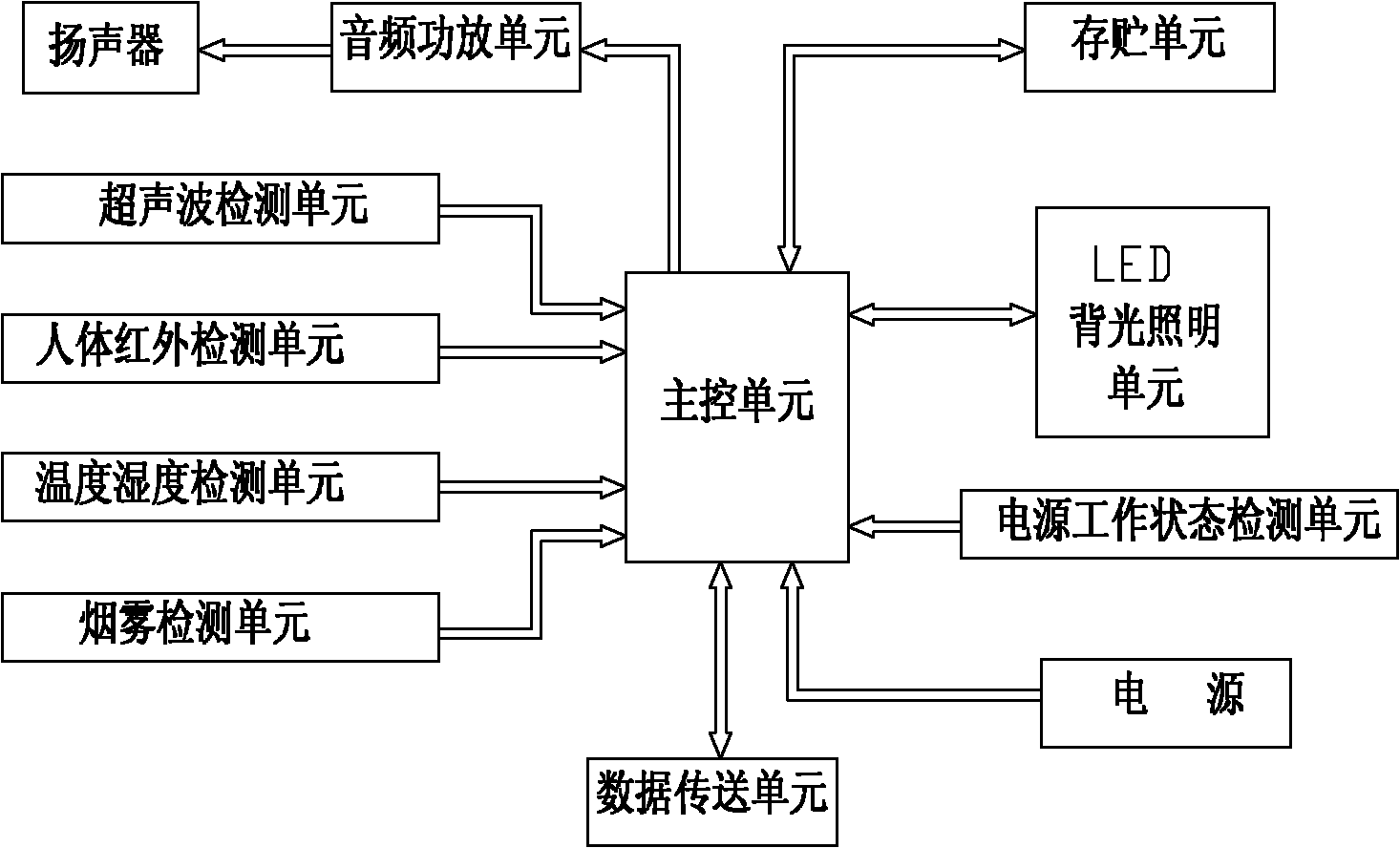

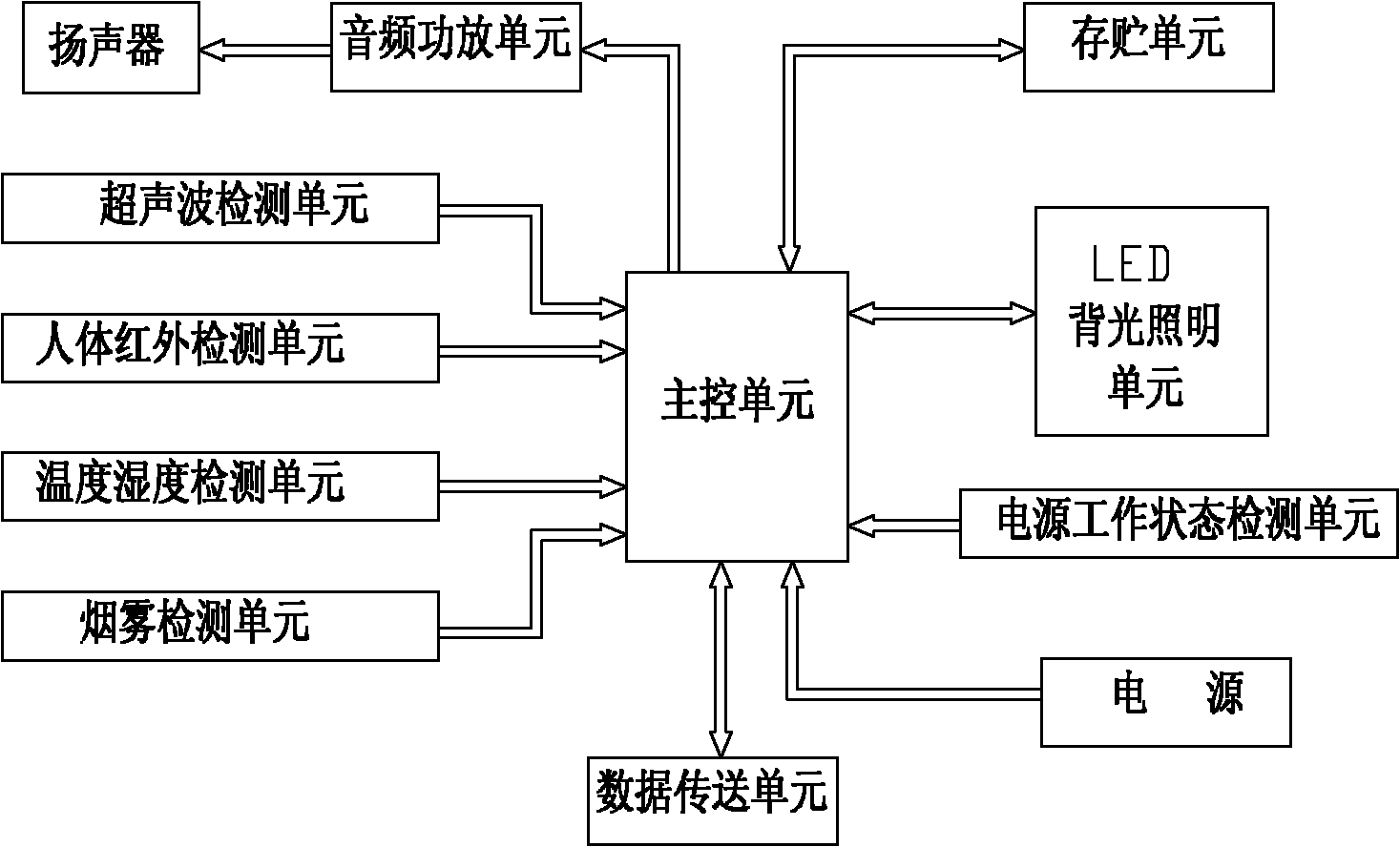

Point-type complex fire detector based on mechanical type temperature sensing element and alarm method thereof

InactiveCN101783056AImprove alarm reliabilitySave electricityThermometers using material expansion/contactionFire alarmsFire detectorEngineering

The invention relates to a point-type complex fire detector based on a mechanical type temperature sensing element and an alarm method thereof. The detector comprises a shell, a mechanical type temperature-sensing sensor, a smoke-sensing sensor, a gas sensor or a flame sensor, an indicating lamp, an alarm, a control device and a power supply. The point-type complex fire detector based on a mechanical type temperature sensing element starts the smoke-sensing sensor, the flame sensor, the gas sensor and an electronic type temperature sensor by utilizing the passive action of the mechanical type temperature sensing element, thereby saving power and greatly improving the alarm reliability of the temperature sensing or smoke sensing or flame or gas fire detector under the condition of single use; and the invention can accurately and reliably finish all functions of detection, alarm, control and extinguishment of a small fire automatic extinguishing system particularly without utilizing alarm control of a fire alarm control host machine in a place without a power supply or with difficult power supply connection. The alarm method is simple and convenient.

Owner:XIAN BOKANG ELECTRONICS

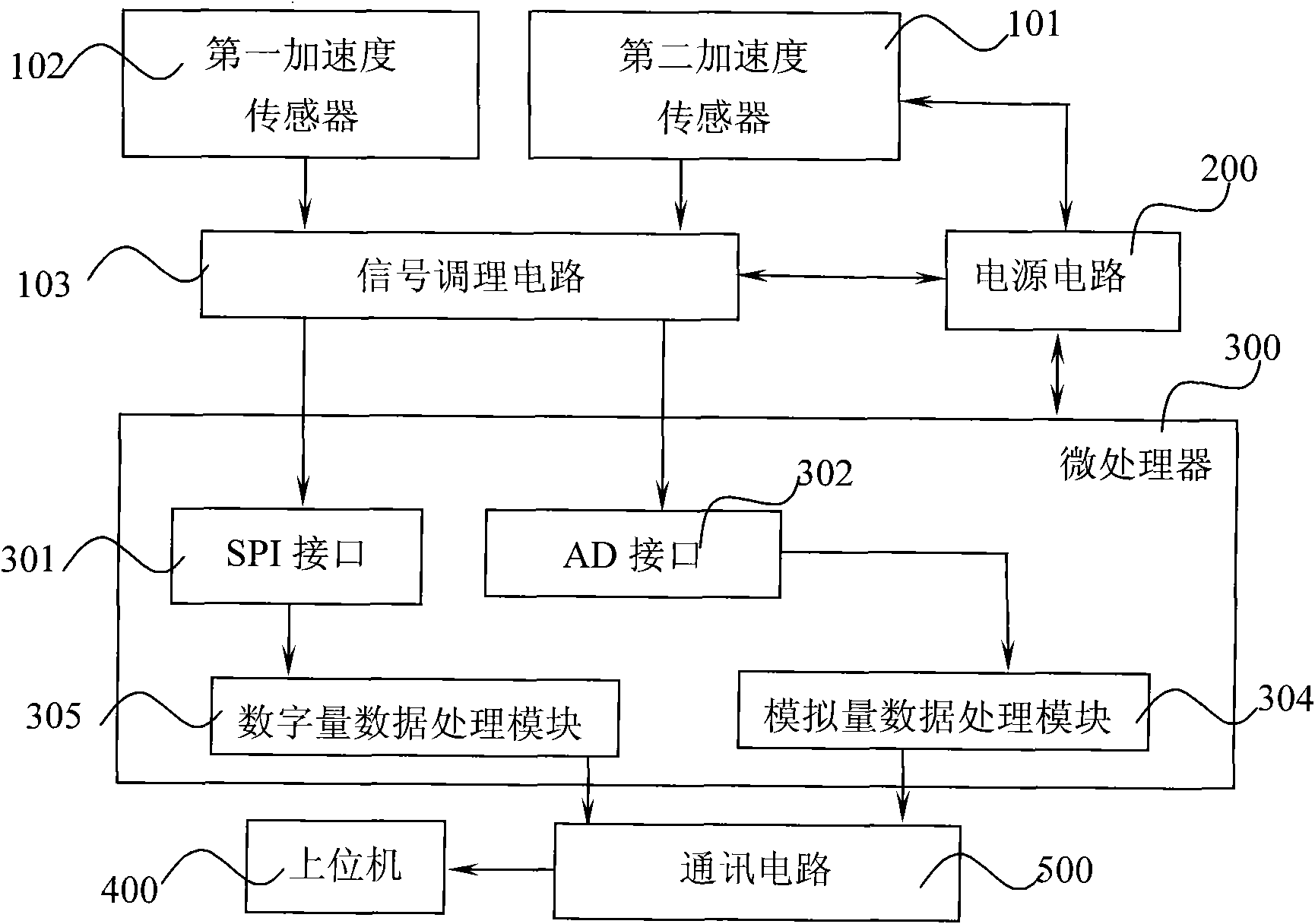

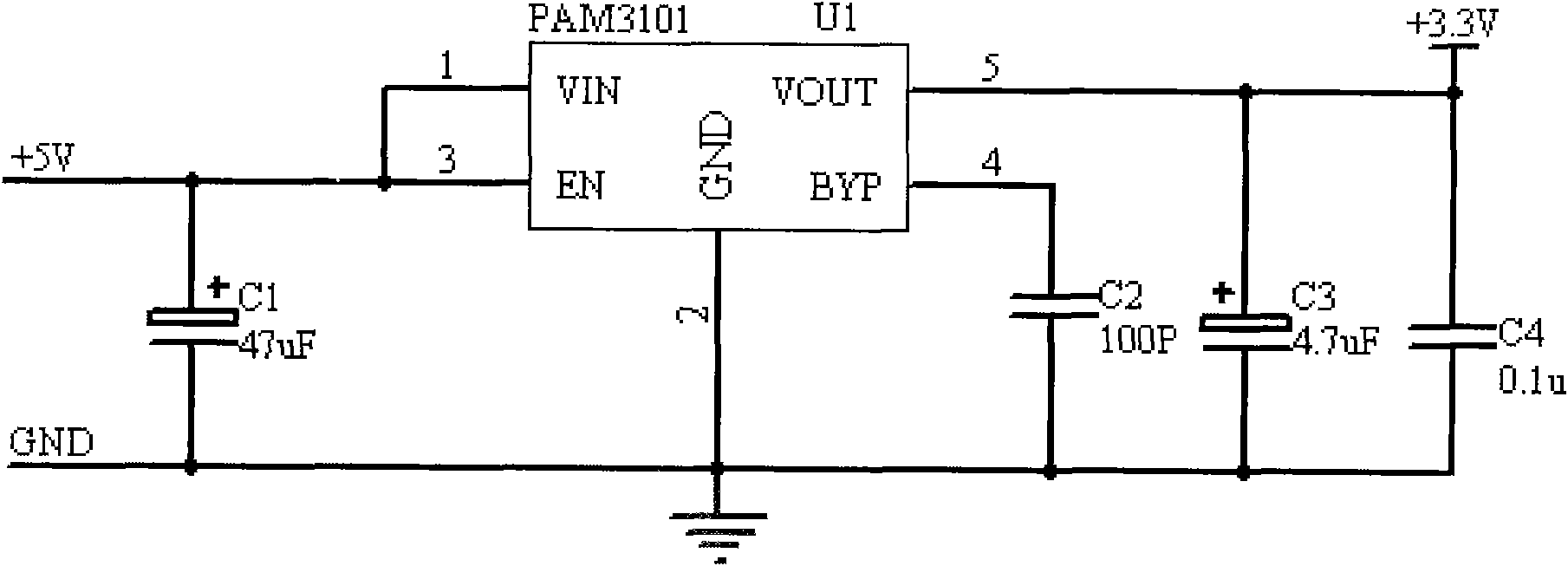

Dynamic inclination detecting device for automotive dynamic driving simulator and method thereof

InactiveCN101813453AAvoid difficultiesAvoid complex mathematical calculationsUsing electrical meansMicrocontrollerSignal on

The invention discloses a dynamic inclination detecting device for an automotive dynamic driving simulator, which comprises two acceleration transducers, a signal conditioning circuit, a microcontroller, a data processing module, a communication circuit and an upper computer. The invention discloses a detecting method using the dynamic inclination detecting device, which is characterized in that probes of the two transducers are arranged on a detected object and a movement carrier of the detected object in the same posture respectively, and the arranging positions are as close as possible so that the two transducers are approximately positioned in one rigid body. Meanwhile, three-dimensional acceleration signals on the detected object and the carrier are extracted; data fusion and processing are performed on the two groups of signals to remove common-mode signals of common vibration, rotational inertia, posture change and the like; and the different-mode signals of the taper angle change of the relative movement carrier of the detected object are reserved so as to acquire the angle variable of the relative carrier of the detected object. The device and the method are used for detecting the angle or the taper in the dynamic carrier, and expand the application range of the acceleration transducers.

Owner:MILITARY TRANSPORTATION UNIV PLA

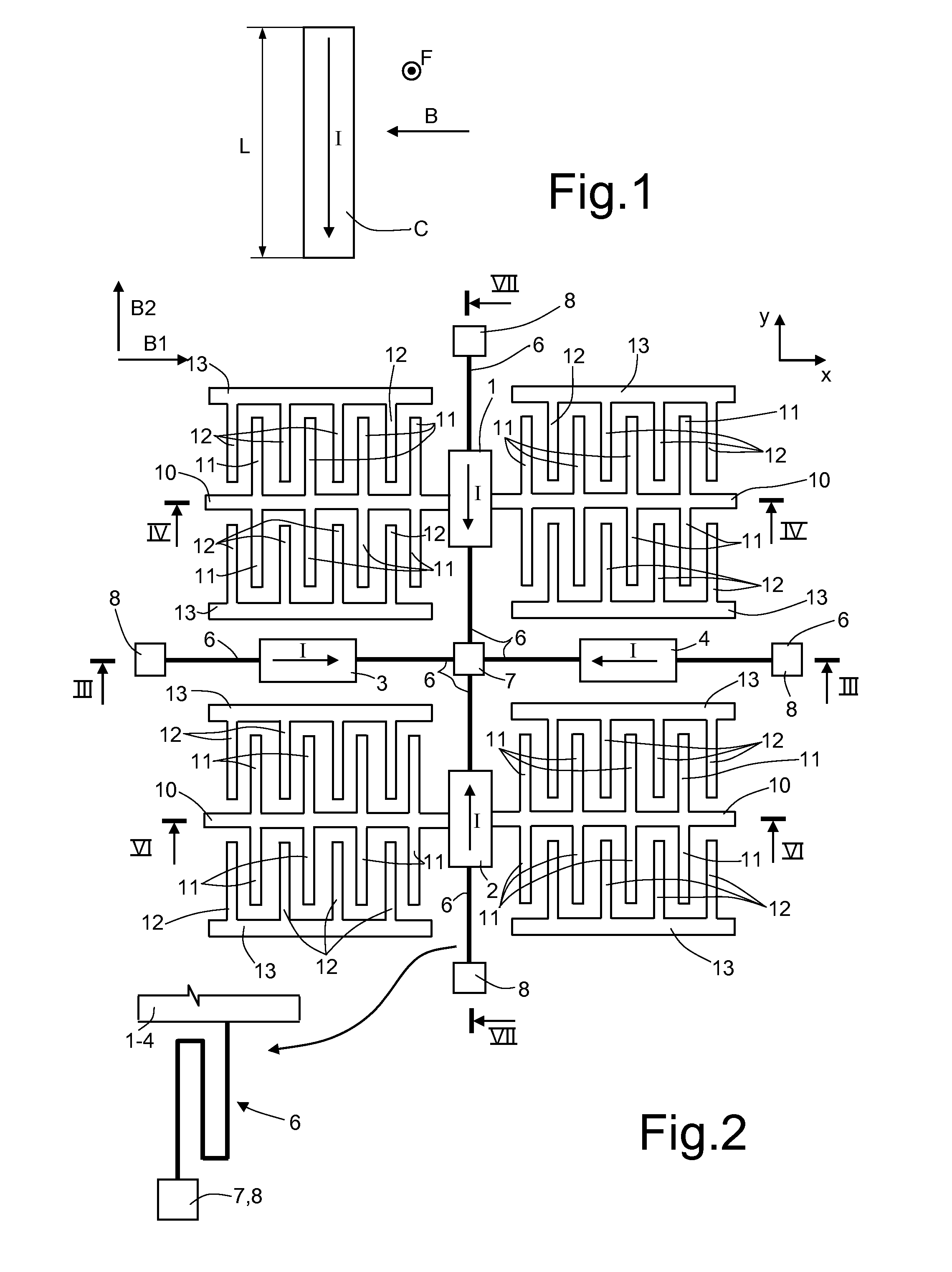

Integrated triaxial magnetometer of semiconductor material manufactured in MEMS technology

ActiveUS20110140693A1Low costSmall dimensionMagnetic field measurement using permanent magnetsMagnetic sensor geometrical arrangementsSemiconductor materialsClassical mechanics

Two suspended masses are configured so as to be flowed by respective currents flowing in the magnetometer plane in mutually transversal directions and are capacitively coupled to lower electrodes. Mobile sensing electrodes are carried by the first suspended mass and are capacitively coupled to respective fixed sensing electrodes. The first suspended mass is configured so as to be mobile in a direction transversal to the plane in presence of a magnetic field having a component in a first horizontal direction. The second suspended mass is configured so as to be mobile in a direction transversal to the plane in presence of a magnetic field having a component in a second horizontal direction, and the first suspended mass is configured so as to be mobile in a direction parallel to the plane and transversal to the current flowing in the first suspended mass in presence of a magnetic field having a component in a vertical direction.

Owner:STMICROELECTRONICS SRL

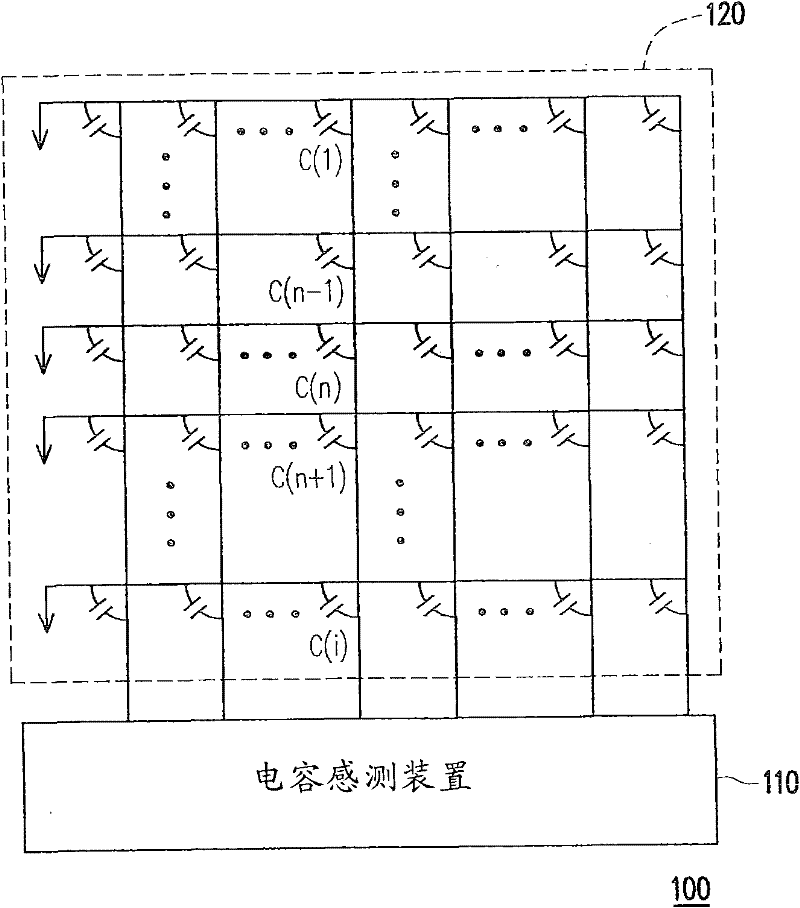

Touch sensing system, capacitance sensing device and capacitance sensing method

InactiveCN102163109AAdjustable measurement reference valueAccurate measurementInput/output processes for data processingCapacitanceTouch Senses

The invention relates to a touch sensing system, a capacitance sensing device and a capacitance sensing method. The touch sensing system comprises a touch input interface and at least one capacitance sensing device. The capacitance sensing device comprises a plurality of switching units and a differential sensing circuit. Each switching unit is connected with a corresponding sensing capacitor. The to-be-measured input end of the differential sensing circuit receives a to-be-measured capacitance value provided by at least one of the sensing capacitors, and the reference input end of the differential sensing circuit receives a reference capacitance value provided by at least one of the sensing capacitors. The differential sensing circuit compares the to-be-measured capacitance value with the reference capacitance value to output a first difference corresponding to the to-be-measured capacitance value and the reference capacitance value at the output end of the differential sensing circuit. According to the technical scheme provided by the invention, the measurement efficiency can be promoted by adjusting the measurement reference value of the to-be-measured capacitor.

Owner:NOVATEK MICROELECTRONICS CORP

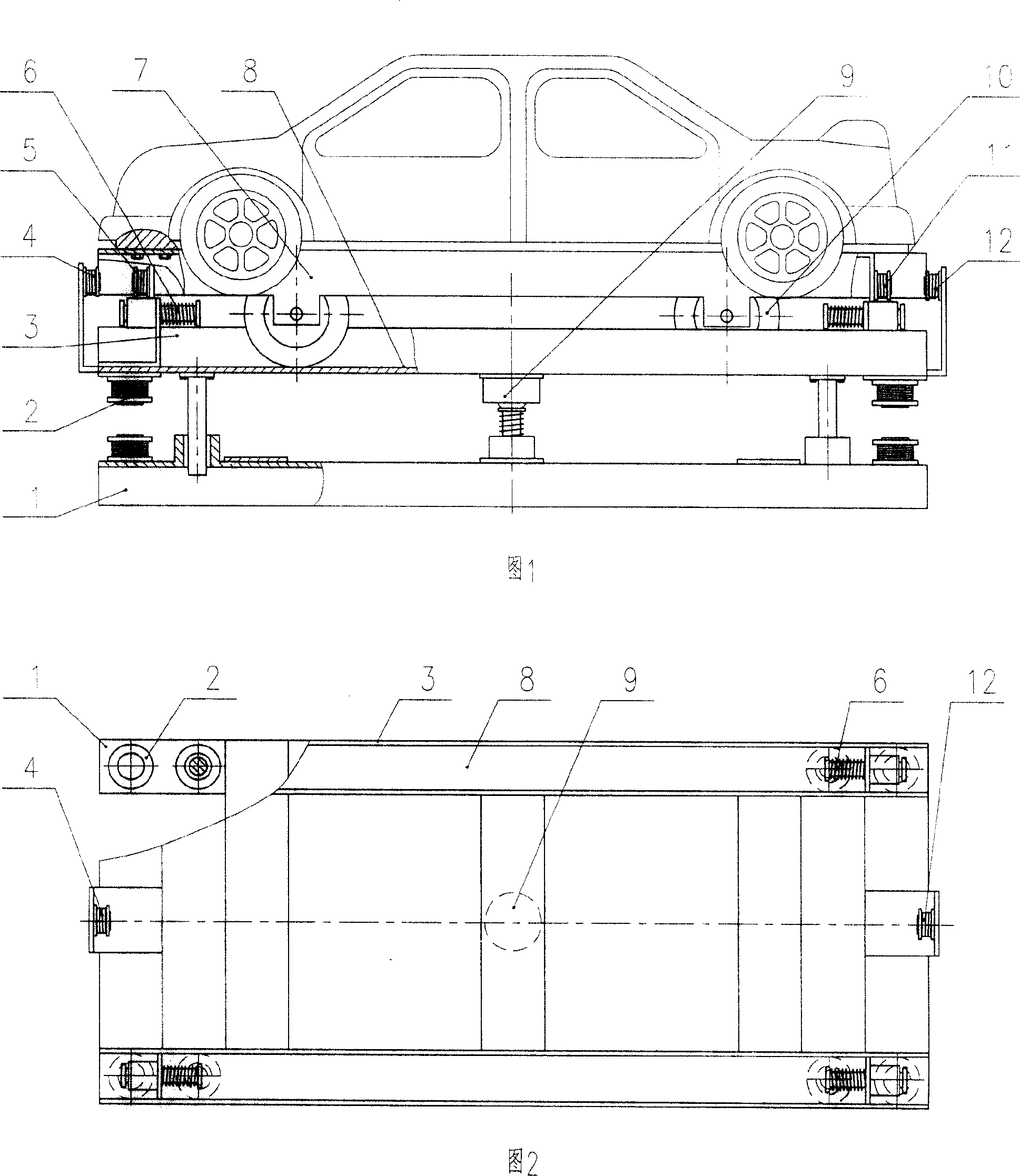

Magnetic suspension balanced autokinetic effect platform for simulating driving motor vehicle

InactiveCN101004864AOvercome hydraulicOvercoming various disadvantages of the dynamic platform of the pneumatic power deviceCosmonautic condition simulationsSimulatorsEngineeringMotorized vehicle

A magnetic suspension platform used for simulating motor vehicle driving is prepared for fixture-connecting four support points of middle support and bottom support separately with four pairs of magnetic suspension devices being rejected to each other, slide-connecting top and middle supports by roll bearings, setting electromagnetic irons on front and back of middle and top supports for making speed be up and down and fixture-connecting four elastic space baffles on middle support.

Owner:李椒良

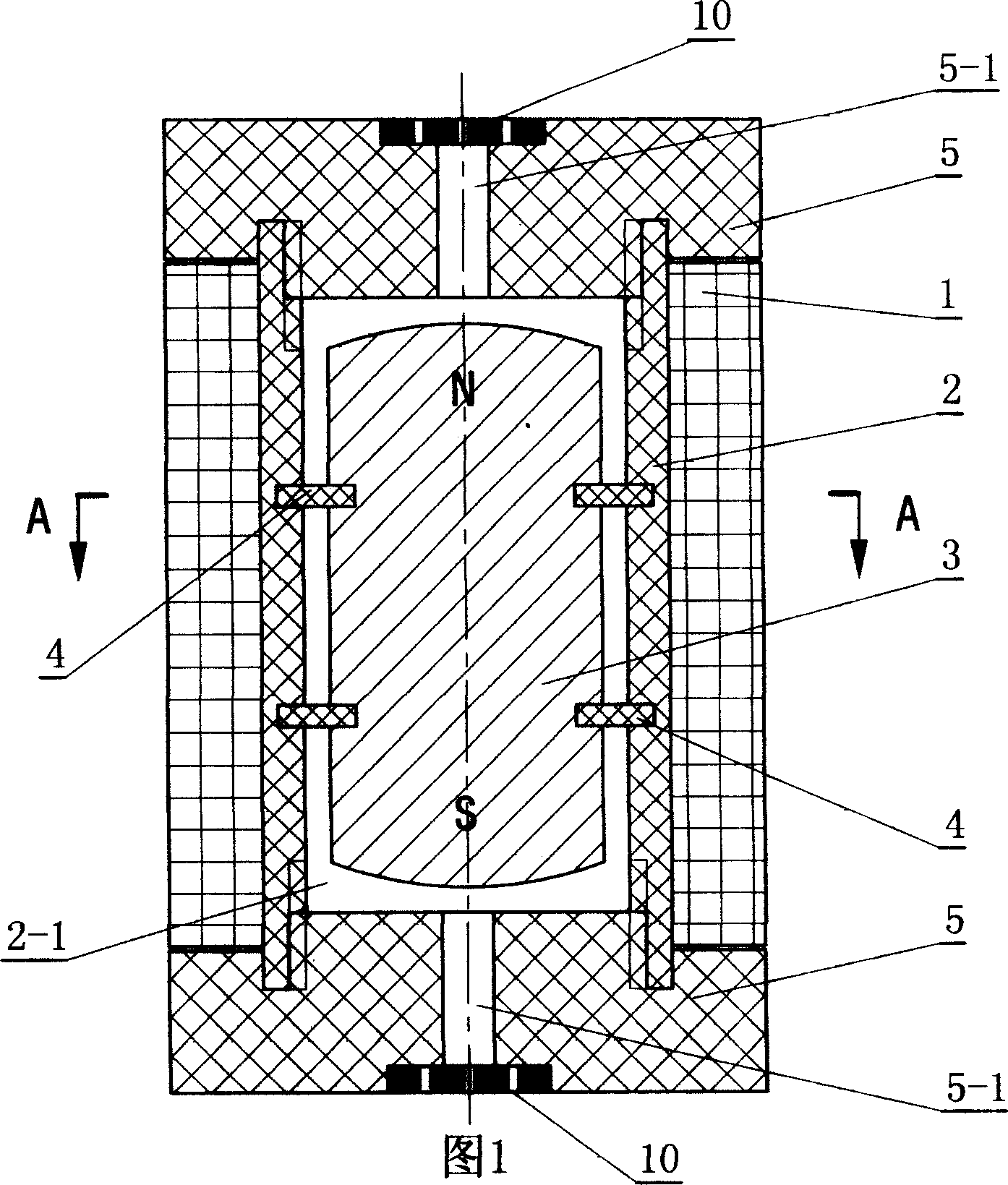

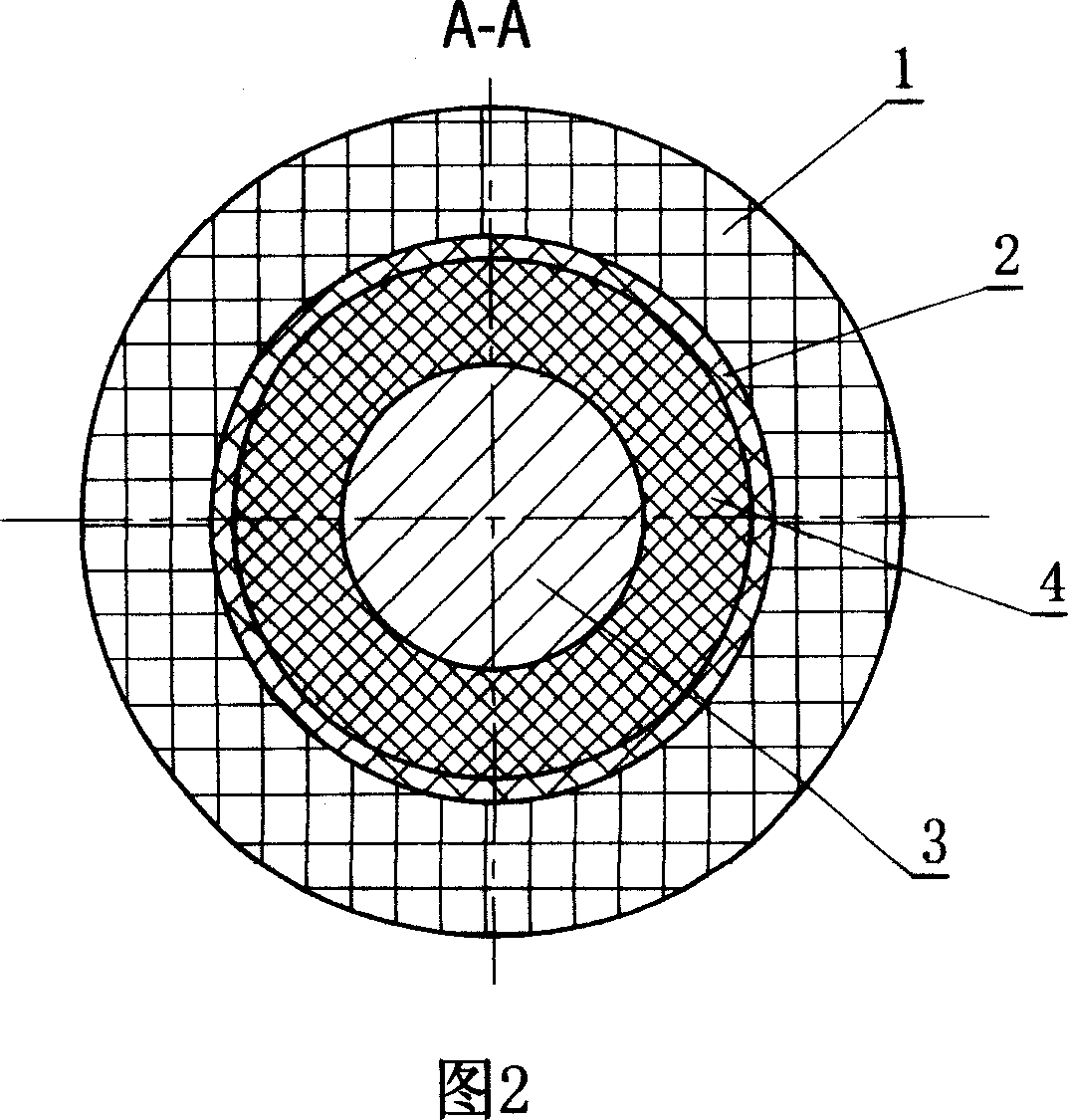

Artificial vibrator

InactiveCN101051774ARealistic vibrationSo as not to damageMechanical energy handlingReciprocating motionEngineering

Being applicable to apparatus in video game, simulated training, motion effect cinema, and the simulated vibrator includes shell, winding, and magnetic hammer. The shell supports winding. The magnetic hammer is installed in cavity of the shell. Through elastic piece, the magnetic hammer is connected to the shell body flexibly. End plates are installed on two ends of the shell body. When doing reciprocal motion, the magnetic hammer contacts end plates or vibration transmission pieces. Advantages are: directivity of vibration, high simulation capability, and obvious collision effect, vivid effect. When multiple simulated vibrators are utilized together can simulate most of vibration situation in reality.

Owner:吴志恒

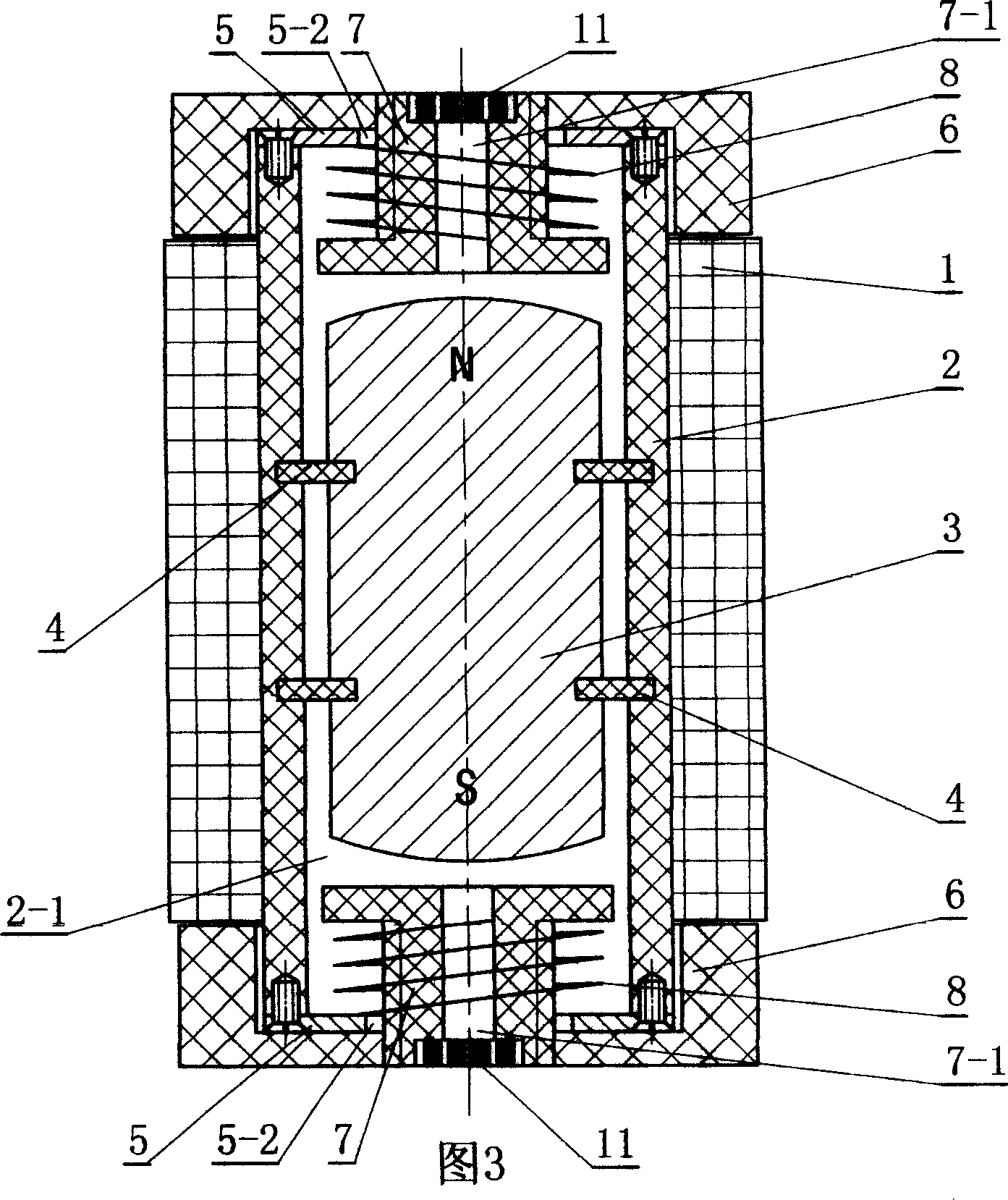

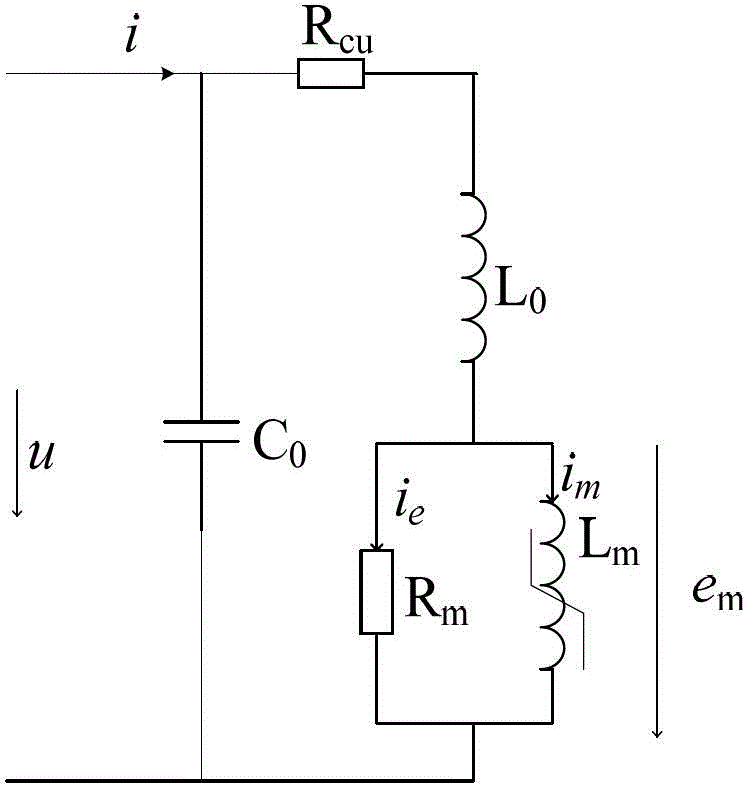

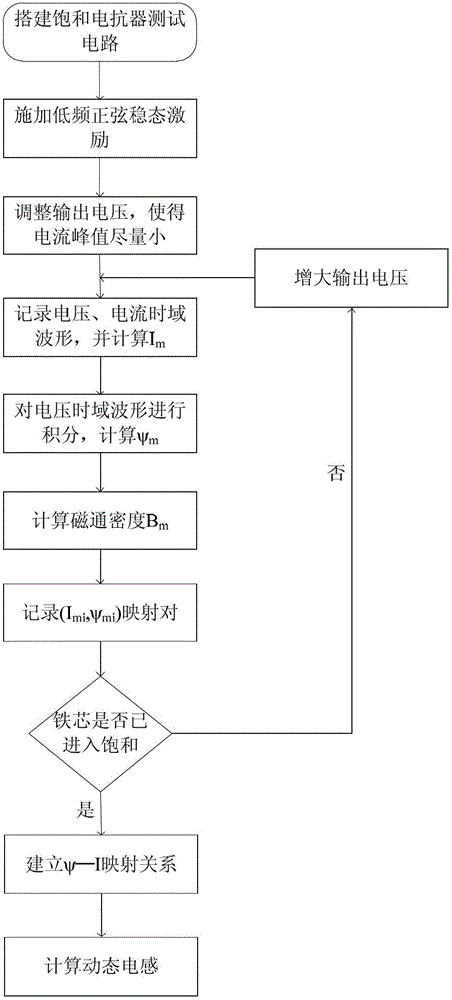

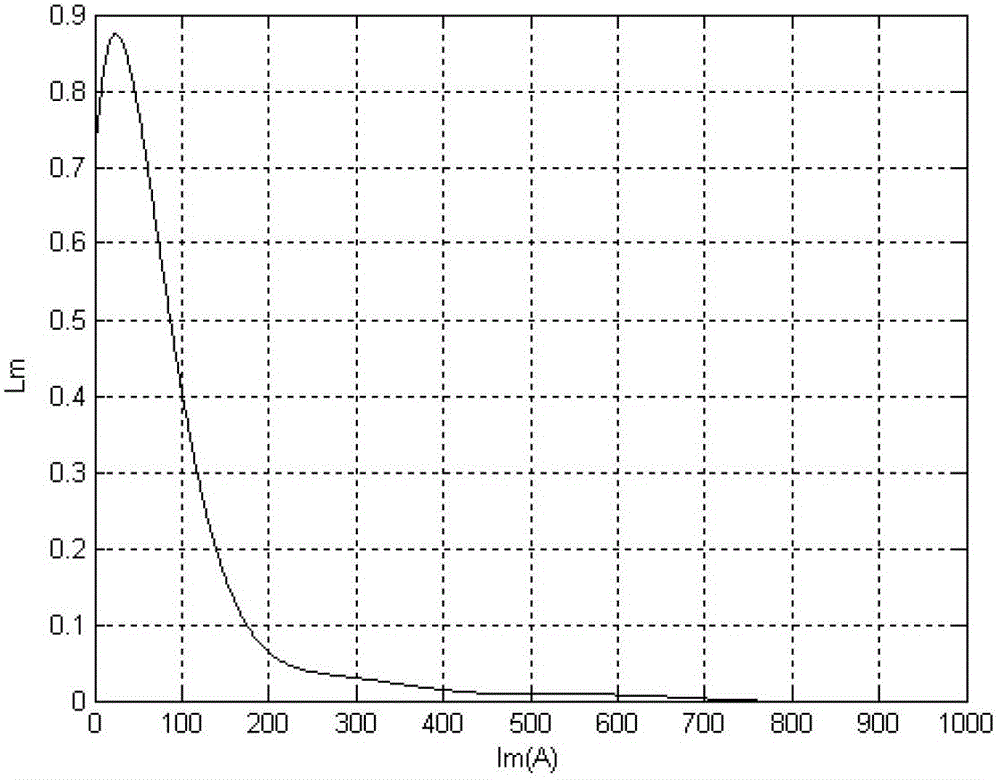

Testing method for dynamic inductance of saturable reactor of direct-current converter valve

ActiveCN102749526AReduce computational complexityReduce numerical errorResistance/reactance/impedenceComputation complexityHypothesis

The invention relates to a testing method for dynamic inductance, and in particular relates to the testing method for the dynamic inductance of a saturable reactor of a direct-current converter valve. The testing method comprises the following steps of: A. setting up a testing circuit of the saturable reactor; B. testing the voltage of a dynamic inductance end of an iron core of the saturable reactor; C. applying low frequency sinusoidal steady state excitation to the saturable reactor; D. testing the electric current of a dynamic inductance branch of the iron core; E. determining the electromagnetic parameter of the dynamic inductance of the iron core; and F. determining the dynamic inductance of the iron core. According to the testing method, the circuit characteristic measurement for determining the dynamic inductance of the iron core is converted into a electromagnetic field parameter through strict test and calculation on the basis of the dynamic inductance definition, thereby reducing the computational complexity and numerical errors; the physical property of the dynamic inductance is expressed by adopting the parameter of the port of the saturable reactor through a reasonable physical hypothesis, thereby avoiding the direct measurement on the parameters of the two ends of the dynamic inductance and greatly reducing the test complexity; and equipment needed for tests is simple and frequently-used; and the test process is easy to operate.

Owner:STATE GRID CORP OF CHINA +2

Power transmission line live work equipotential entering simulation training system and method

InactiveCN108711329AEliminate psychological barriersImprove training efficiencyCosmonautic condition simulationsEducational modelsViewpointsDisplay device

The invention provides a power transmission line live work equipotential entering simulation training system and method, and relates to a simulation training system and method. The safety in the training process is inadequate at present. The system comprises a master control computer, an operation handle, virtual reality head-mounted display equipment and a dynamic seat. The dynamic seat is provided with an operation control box, a servo controller and a motor. Vibration and swinging of the seat and the outdoor effect of entering the equipotential process are realized by the motor. The head-mounted display equipment is provided with a motion sensing positioner and a stereoscopic displayer. The motion sensing positioner performs information exchange with the master control computer and is used for positioning the location of the trainee in the virtual environment and performing viewpoint switching. The stereoscopic displayer performs information interaction with the master control computer through a data transmission line. According to the technical scheme, theoretical and operation training can be performed for the power operator so that the training efficiency is high and the safety is great.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +2

LED lighting bar

The invention provides a LED glow stick, which comprises a transparent stick shell with a LED string and a power supply. The LED string is coupled with a control circuit which comprises a memory for memorizing the array of characters and graphics needed to be shown. A central processing unit which is coupled with the memory can take out the array of characters and graphics needed to be shown form the memory, and can output to the LED string line by line or row by row; so, at a certain moment, the LED string only shows one line or one row of the array of characters and graphics needed to be shown. The LED glow stick is manually operated, thereby responding to the manual swing and rotation of the LED glow stick and completely show the array of characters and graphics needed to be shown. The invention has the beneficial effects that a single line LED can show the glow charters; no motor is used in the method; the single line LED can be shown during naturally moving; the shown characters and graphics are rich and dynamic and so on.

Owner:刘建军 +1

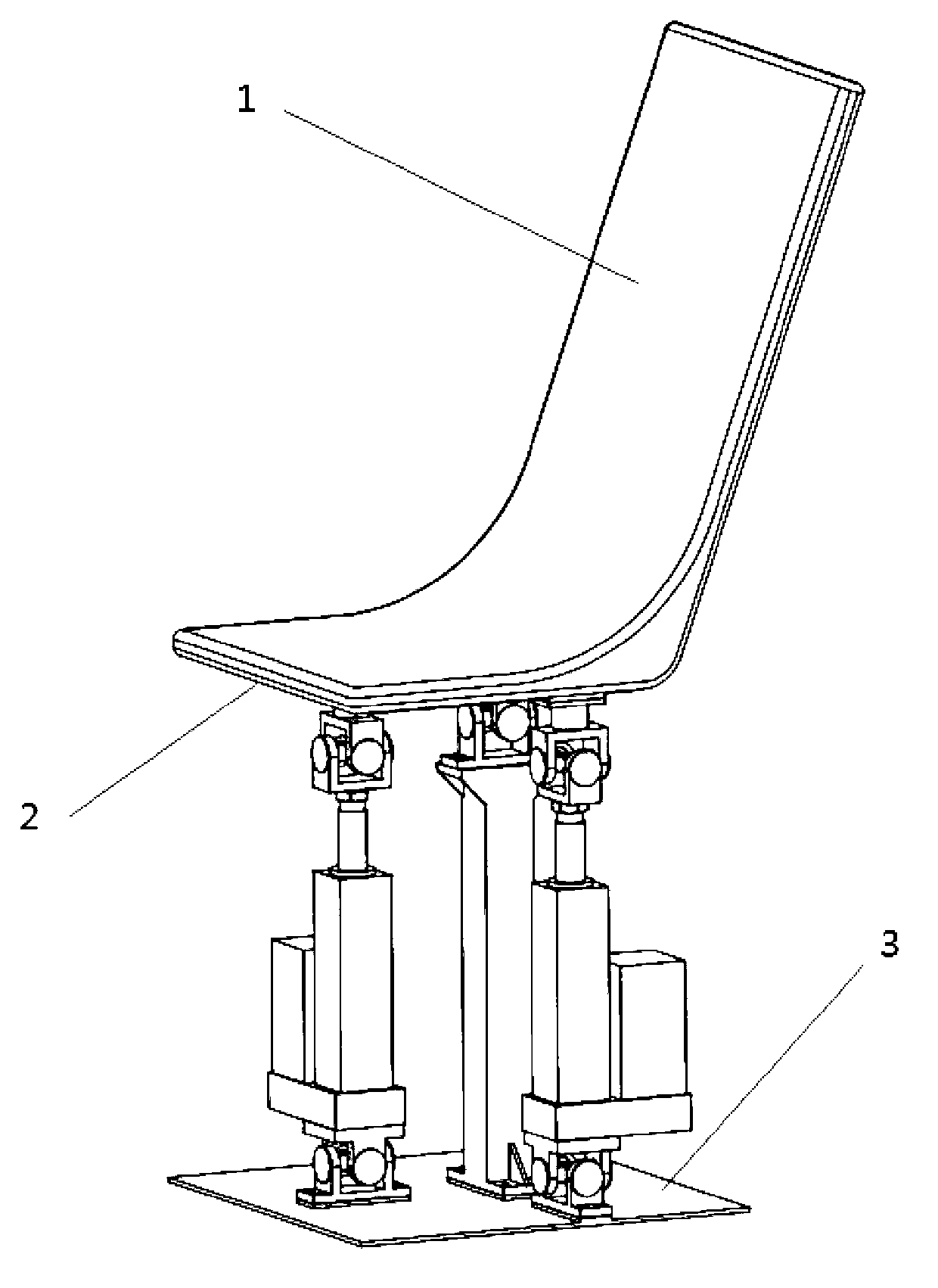

Six-DOF (degree of freedom) carrier dynamic simulator

InactiveCN102346978AHeavy loadHigh movement precisionCosmonautic condition simulationsSimulatorsClosed loopEngineering

The invention discloses a six-DOF (degree of freedom) carrier dynamic simulator. The dynamic simulator is composed of a real-time simulation computer and a movement control computer, a servo channel driver, a six-DOF electromechanical movement platform; each servo channel comprises a servo driver and an electromechanical actuator, the servo driver comprises a servo main loop frequency conversion power amplifying circuit module and a control loop circuit module, the electromechanical actuator is used for connecting a serve motor, a synchronous belt transmission box, a ball screw pair and a rotary encoder together. The six-DOF carrier dynamic simulator has the advantages that the modular structure is simple and compact, convenient for mounting, and simple in maintenance, the electromechanical cylinder improves the platform movement precision, a control scheme of a movement control card controls the position of each servo electromechanical cylinder, and greatly improves the precision and a limiting switch is built in to guarantee the ultimate safety; the full-digitalized closed loop servo control is used for guaranteeing the smooth transition of the movement and high simulation and reducing the dynamic drifting and distortion, the efficiency of the system is as high as 85%, and the application range of the simulator is wide.

Owner:LIM TEC BEIJING TRANSMISSION EQUIP

Electric dynamic seat

InactiveCN103126362AEliminate stuck phenomenonFlexible and stable movementAmusementsCinema apparatusUniversal jointEngineering

The invention discloses an electric dynamic seat which is applied to entertainment places such as 4D cinemas. The dynamic seat comprises a seat, a seat connecting plate, a support mechanism and two lifting mechanisms, wherein the supporting mechanism and the two lifting mechanisms are connected between the seat and the seat connecting plate, the lower end of the supporting mechanism is fixed on the seat through bolts, the upper end of the support mechanism is connected with the seat connecting plate through universal joints, the lifting mechanism is composed of two universal joints and an electric cylinder, the lower ends of the lifting mechanisms are connected with the seat through the universal joints, the upper ends of the lifting mechanisms are connected with the seat connecting plate through a rotating assembly, and accordingly the phenomenon that the two lifting mechanisms are clamped when moving is avoided. A long hole is formed on the seat connecting plate, wherein different types of seats can be installed, and gravity of seats can be adjusted in a front and back mode according to requirements. The electric dynamic seat is driven by a servo electric cylinder, is coordinated with a rotating assembly and universal joints, can achieve two freedom degree rotating in a plane, has the advantages of being flexible in moving, low in noise and adjustable in gravity, is combined with three-dimensional film effect, and can bring real immersion enjoyment to audiences.

Owner:大连爱智控制系统有限公司

Method and device for playing dynamic electronic album

ActiveCN101751901ACharacter and pattern recognitionCathode-ray tube indicatorsComputer graphics (images)Focal position

The invention discloses a method and a device for playing a dynamic electronic album. The device comprises a rendering unit, a face recognizing unit, a focal point judging unit and a central control unit, wherein the focal point judging unit is used for making a judgment according to a set strategy based on a recognition judgment result of the face recognizing unit and determining a figure focal point position in a current digital photo. In the method and the device for playing the dynamic electronic album provided by the invention, the focal point judging unit is used for judging the figure focal point position in the current digital photo according to the set strategy based on a face existence signal and outputs the figure focal point position to the central control unit; and the central control unit dynamically adjusts zooming and translating centers of the digital photo according to the figure focal position, sends the adjusted digital photo to the rendering unit for rendering, and outputs and displays a rendering result. The device can display the digital photo taking a figure as a main visual focal point emphatically so as to provide convenience for users.

Owner:深圳康佳控股集团有限公司

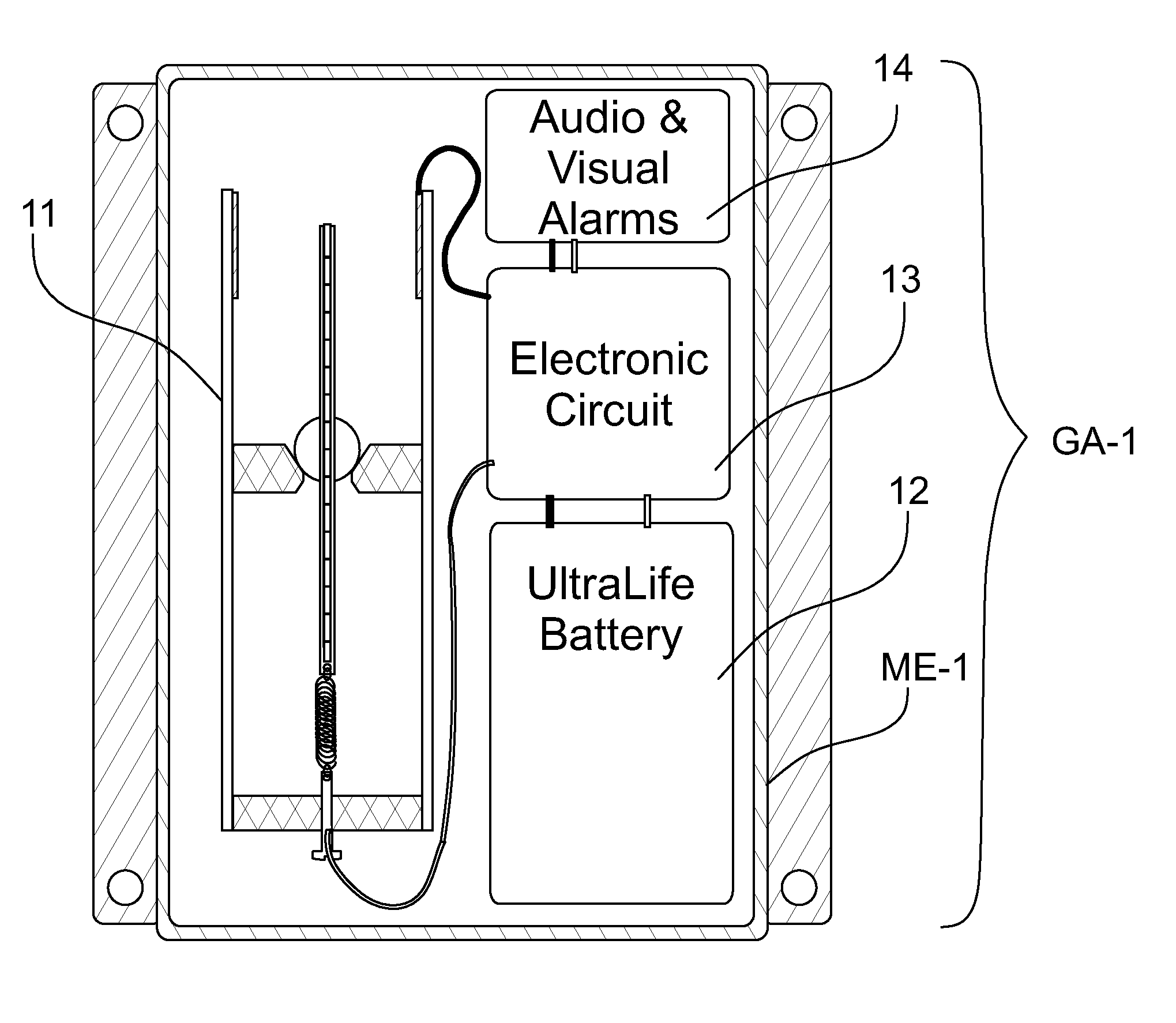

Magnetic field strength threshold alarm

A magnetic field strength threshold alarm that includes sensing means responsive to a magnetic field and actuating in response to field strength above a predetermined threshold, the sensing means being configured to be operational and able to actuate without consumption of energy; and alarm means for outputting an alarm responsive to the sensing means actuation, the alarm means being configured not to consume energy prior to actuation of the sensing means and only consuming energy subsequent to actuation of the sensing means. So, energy is not consumed by the alarm means prior to actuation. The alarm may be considered to include energy storage means for providing electrical energy, wherein the sensing means, the alarm means and energy storage means being operatively connected such that the electrical energy from the energy storage means is provided only when the sensing means is actuated.

Owner:KOPP DEV

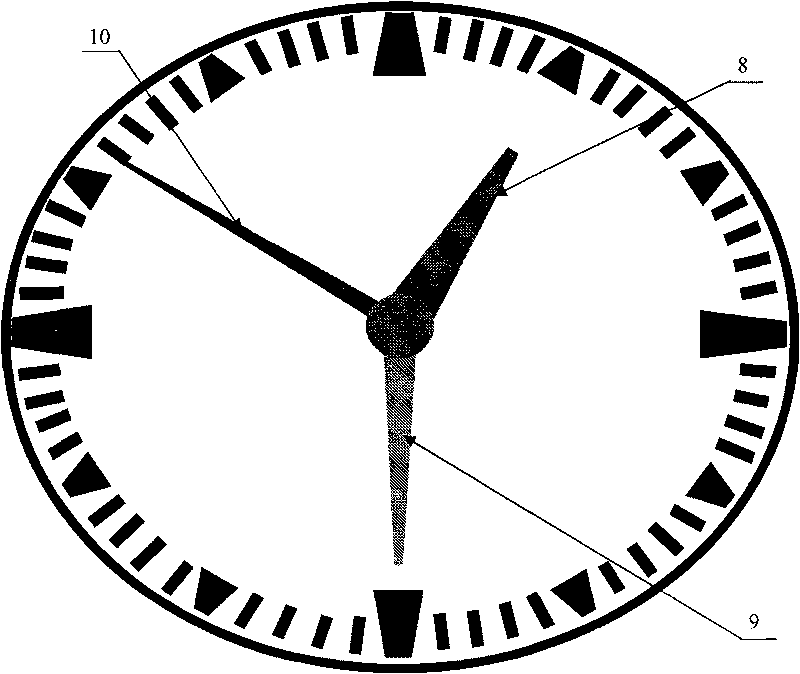

Intelligent electronic clock with laser beam indicators

InactiveCN101718967ASolution to short lifeNo errorVisual indicationsTime-pieces with integrated devicesLaser technologyClock tower

The invention discloses an intelligent electronic clock with laser beam indicators, belonging to an all-electronic timer. The invention aims at improving travel-time accuracy of the traditional clock and prolonging the service life of the traditional clock. By using an intelligent test technology and a laser technology, the intelligent electronic clock with laser beam indicators simulates traditional indicator by using laser beams to replace a traditional mechanical travel-time mechanism. The electronic clock consists of a time base signal generating device, a standard time calibration device, a travel-time control device, a laser emitting device, a clock dial, a voice time device and a power supply device which are sequentially connected with each other. The intelligent electronic clock with laser beam indicators has the laser beams with three colors of red, green and blue to simulate time hand, minute hand and second hand, and the indicators are in a radial shape inwards or outwards with bright and clear indication, smooth running like running water and powerful rhythm. Therefore, the clock is suitable for homes, schools, enterprises and public institutions as well as public occasions, and particularly suitable for clock towers, and has wide market prospect.

Owner:CHONGQING UNIV

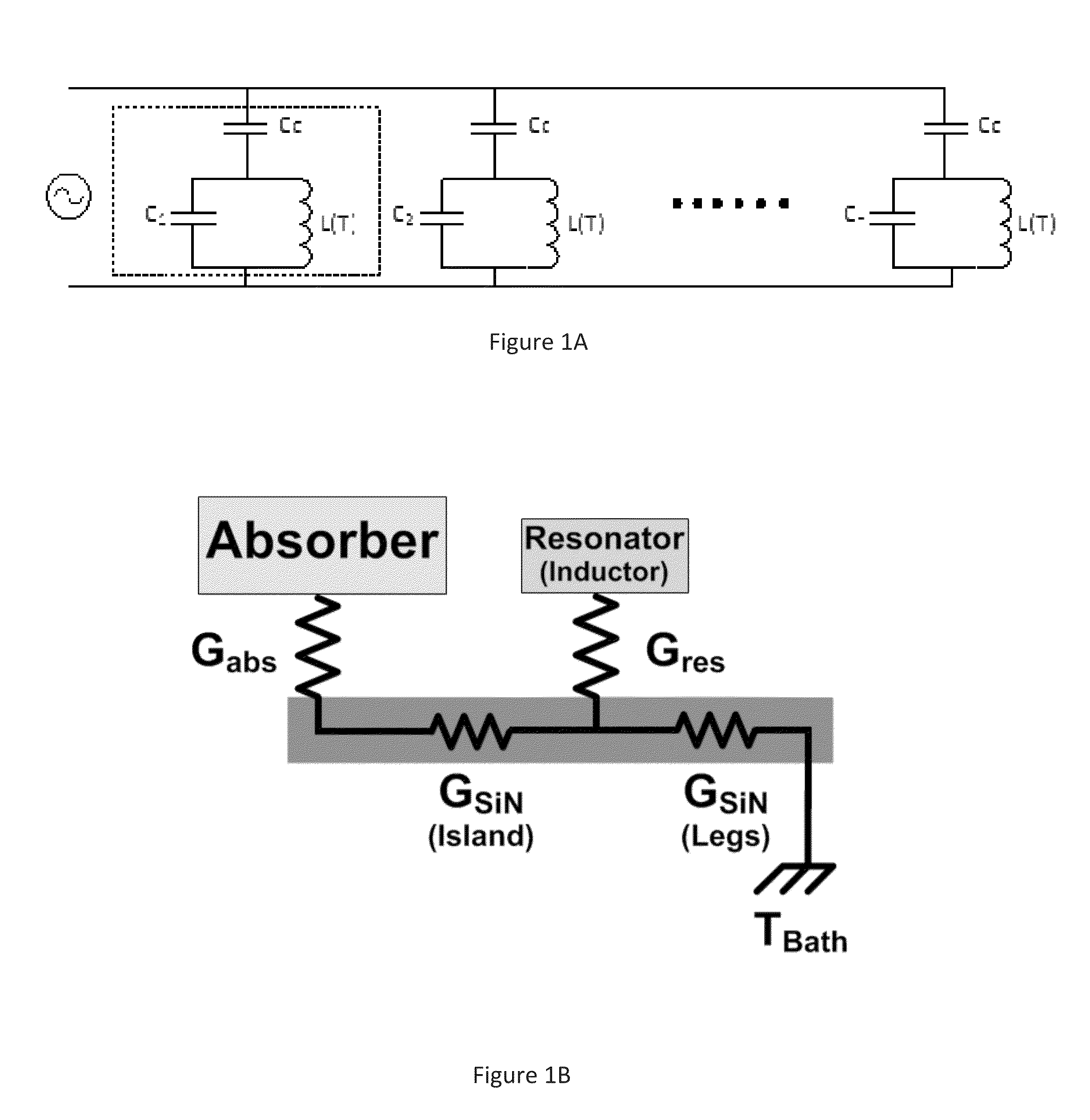

Thermal kinetic inductance detector

ActiveUS20150293236A1Solid-state devicesMaterial analysis by optical meansKinetic inductanceResonator

A microcalorimeter for radiation detection that uses superconducting kinetic inductance resonators as the thermometers. The detector is frequency-multiplexed which enables detector systems with a large number of pixels.

Owner:UCHICAGO ARGONNE LLC

A dynamic advertising light box system and its dynamic advertising light box

InactiveCN102280081AMonitor working status in timeExtended service lifeAdvertisingImage resolutionAnimation

The invention discloses a dynamic advertising light box system and a light box. The dynamic advertisement light box system includes a monitoring center and several dynamic advertisement light boxes. The dynamic advertising light box includes: a box frame, a canvas; an LED backlight unit including several LED lights; a storage unit storing animation files; calling animation files to generate driving signals to drive each LED light to work, thereby providing dynamic lighting for the canvas The main control unit; the power supply module for the advertising light box. The dynamic advertising light box system adopting the technical solution of the present invention not only has low cost, stable operation, environmental protection and energy saving, can achieve high resolution, but also can produce dynamic effects, thereby attracting the attention of the public more. Not only can the animation files of the dynamic advertising light boxes be updated conveniently, but also the working status of each dynamic advertising light box can be monitored in time, thereby facilitating maintenance and repair, and improving the service life of the dynamic advertising light boxes.

Owner:SHENZHEN AOTO LIGHTING

Dynamic seat control method and control system for household entertainment

InactiveCN106647420AQuick buildSimple control methodProgramme control in sequence/logic controllersMovement controlKinetic inductance

The invention specifically relates to a dynamic seat control method and control system for household entertainment. The method comprises the following steps: when a user is detected on a dynamic seat, a dynamic seat starting instruction and a dynamic game or dynamic movie and television starting instruction are orderly obtained, movement data corresponding to game plots and movie and television plots are obtained at an interval of preset time, the movement data is parsed, and a movement control instruction is generated for controlling the dynamic seat to realize movements corresponding to the game plots or the movie and television plots. Via the dynamic seat control method disclosed in the invention, the movement data corresponding to a game plot or a movie and television plot can be obtained after the user is detected on the dynamic seat, and the dynamic seat is controlled to realize movement changes corresponding to the game plot or the movie and television plot. The method and system are simple and low in cost, the system can be quickly built via direct use of household equipment such as a computer, sound equipment and the like; the method and system are suitable for household application.

Owner:MOTUS TECHNOLOGIES INC

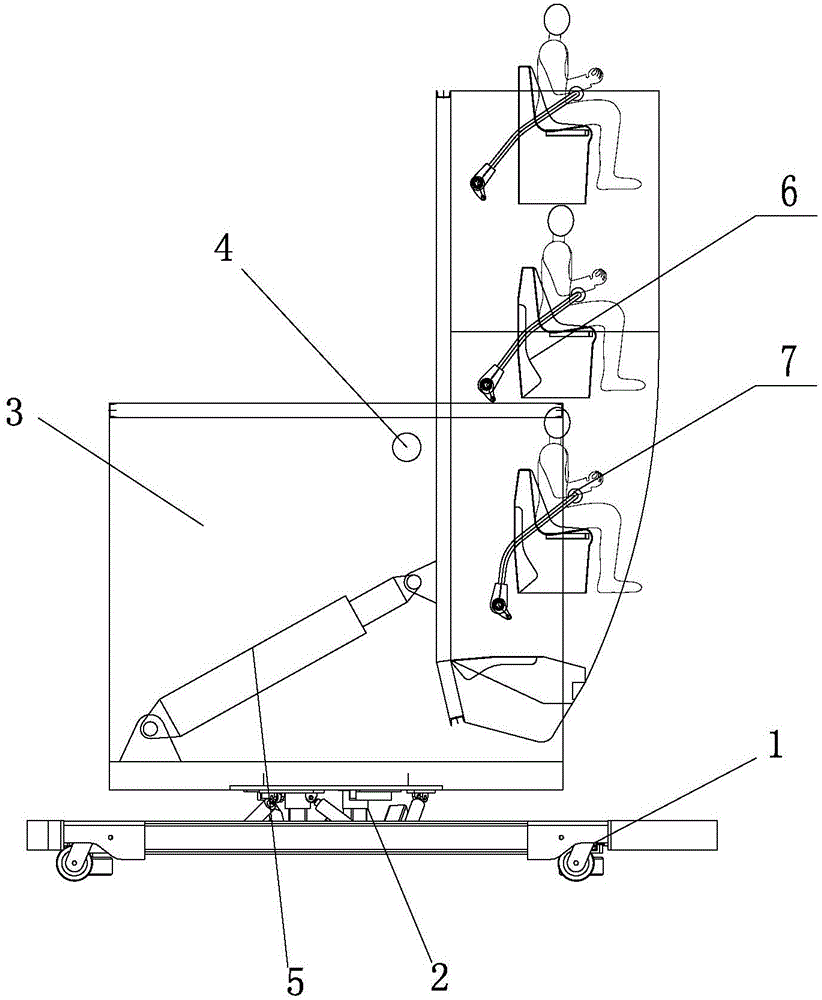

Multi-dimension flying movement-sense simulation riding device capable of travelling

The invention discloses a multi-dimension flying movement-sense simulation riding device capable of travelling. The multi-dimension flying sensation simulation riding device capable of travelling comprises a self-travelling device, a multi-freedom-degree movement-sense platform, a linkage frame structure, a movement-sense base cabin rotating shaft, a movement-sense base cabin rotation driving device, a movement-sense base cabin, a seat rotating device and a safety pressure lever. The self-travelling device can travel along a track. The multi-freedom-degree movement-sense platform is installed above the self-travelling device, and the upper part can be driven to perform multi-freedom-degree movement as required. The linkage frame structure is installed above the multi-freedom-degree movement-sense platform and used for being connected with the movement-sense base cabin rotating shaft, the movement-sense base cabin rotation driving device, the movement-sense base cabin and the seat rotating device. According to the riding device, by means of rotation of the movement-sense base cabin and the seat rotating device, a passenger can have various kinds of vehicle-riding movement-sense experience, the flying experience that the two feet rise high into the air can also be simulated, and therefore the multi-freedom-degree movement-sense platform and the self-travelling device can be matched better, multiple experience of different scenes, different actions and multiple freedom degrees can be achieved through combination of video playing content, and curiosity sense and shocking power of performance are improved.

Owner:DALIAN WANDA GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com