Chain length measuring instrument

A length measuring instrument and chain technology, which is applied in the direction of metal chains, instruments, measuring devices, etc., can solve the problems of complex mechanisms, affecting measurement accuracy, and low efficiency, and achieve the effects of accurate and reliable control, high measurement accuracy, and convenient reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

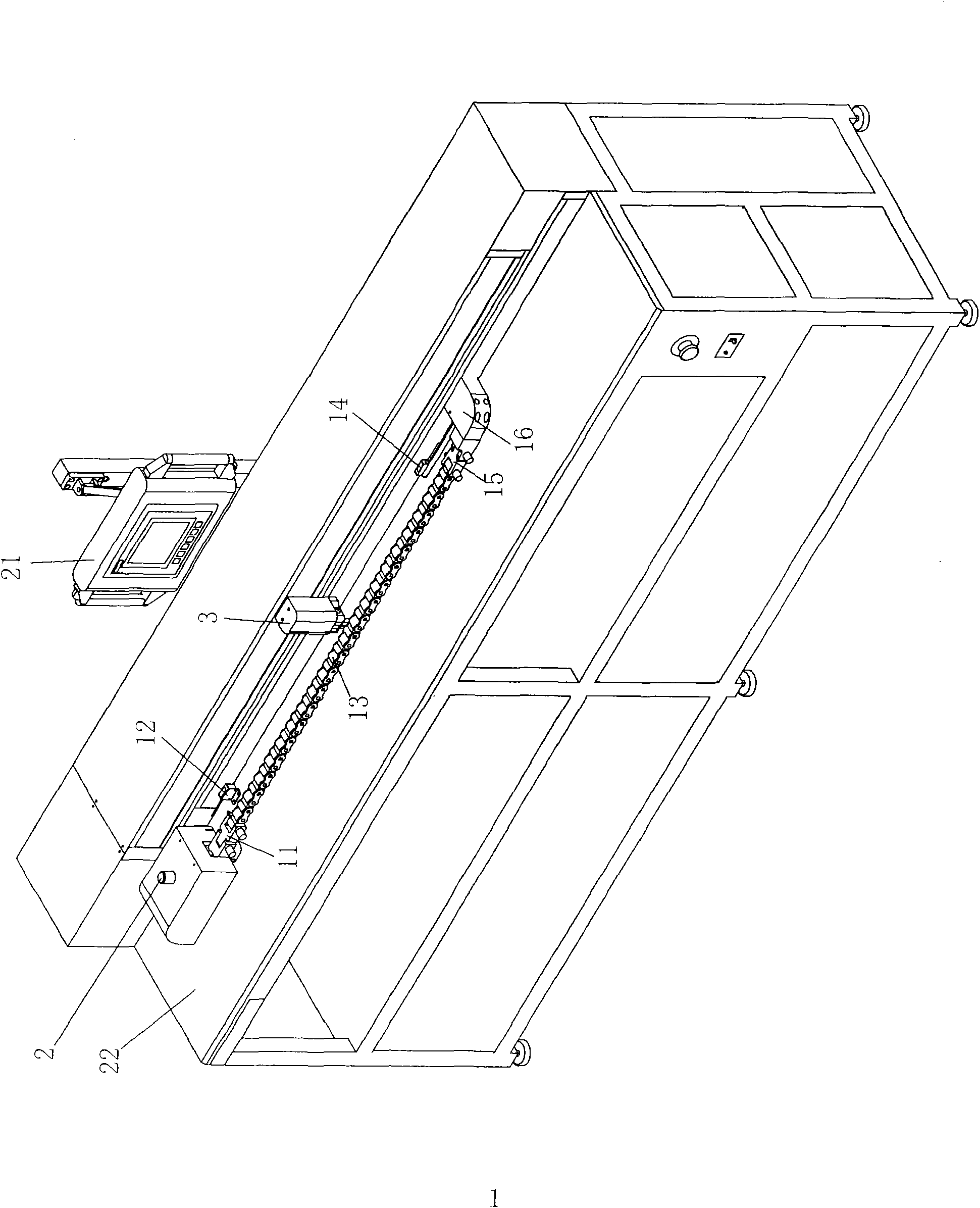

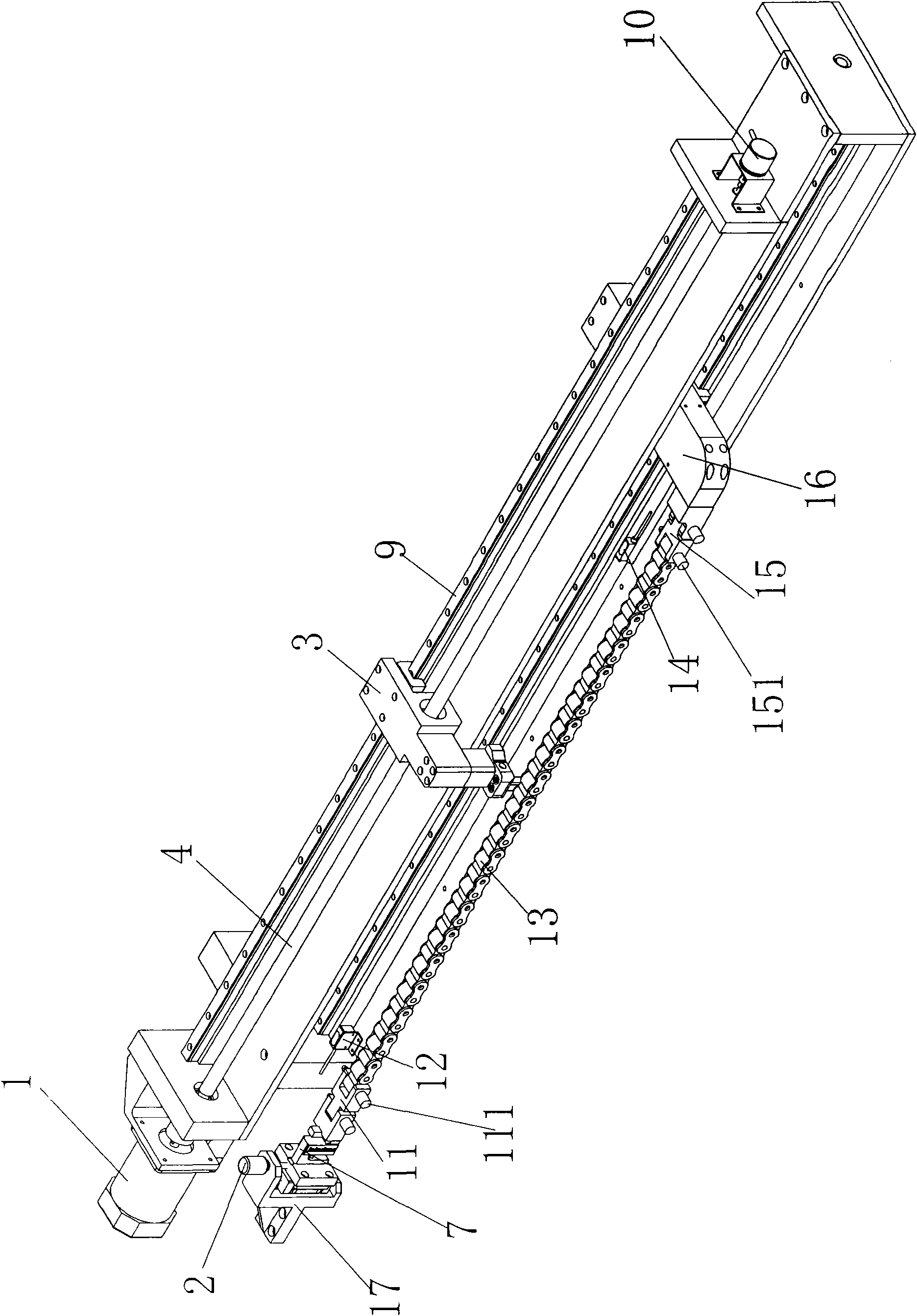

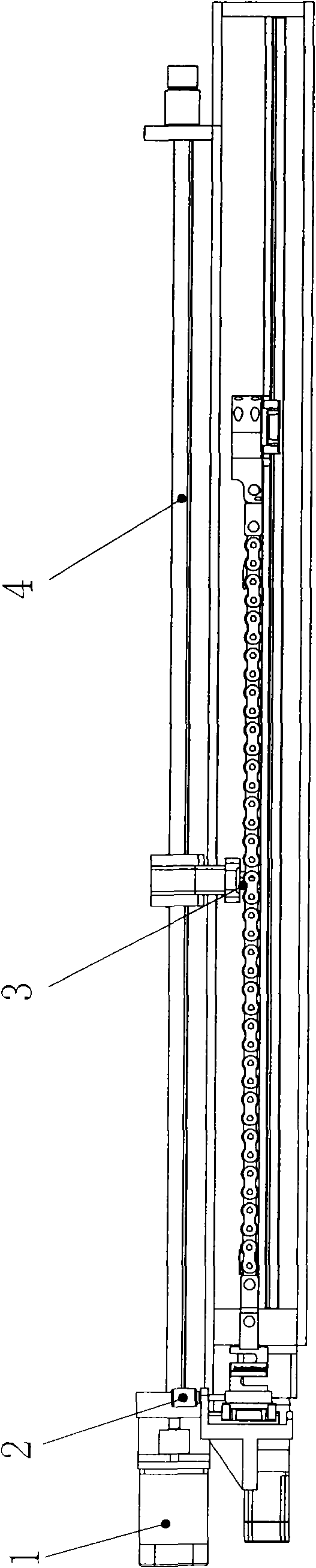

[0015] see Figure 1 to Figure 5 , a chain length measuring instrument, including a frame and a chain tensioning mechanism, also includes a chain length measuring mechanism, which includes a sensing head 3, a left photoelectric sensor 12, a right photoelectric sensor 4, and a left positioning pin 111 , right positioning pin 151, encoder 10, and motor 1, lead screw A4, linear guide rail A9 installed on the frame, the two ends of lead screw A4 are respectively connected with the output shaft of motor 1 and the input shaft of encoder 10, and the wire The screw nut on the rod A4 is connected with the sensor head 3, and the motor 1 can drive the screw A4 to rotate and drive the sensor head 3 to move linearly on the linear guide rail A9, and the left photoelectric sensor 12 and the right photoelectric sensor 14 are placed on the machine table 22 and adjacent to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com